Sensor for monitoring metal abrasive particles in oil liquid on line and application method for sensor

A technology of metal abrasive particles and sensors, which is applied in the direction of instruments and analytical materials, can solve the problems of high cost measurement sample points, etc., and achieve the effect of accurate and reliable monitoring results, good linearity and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments.

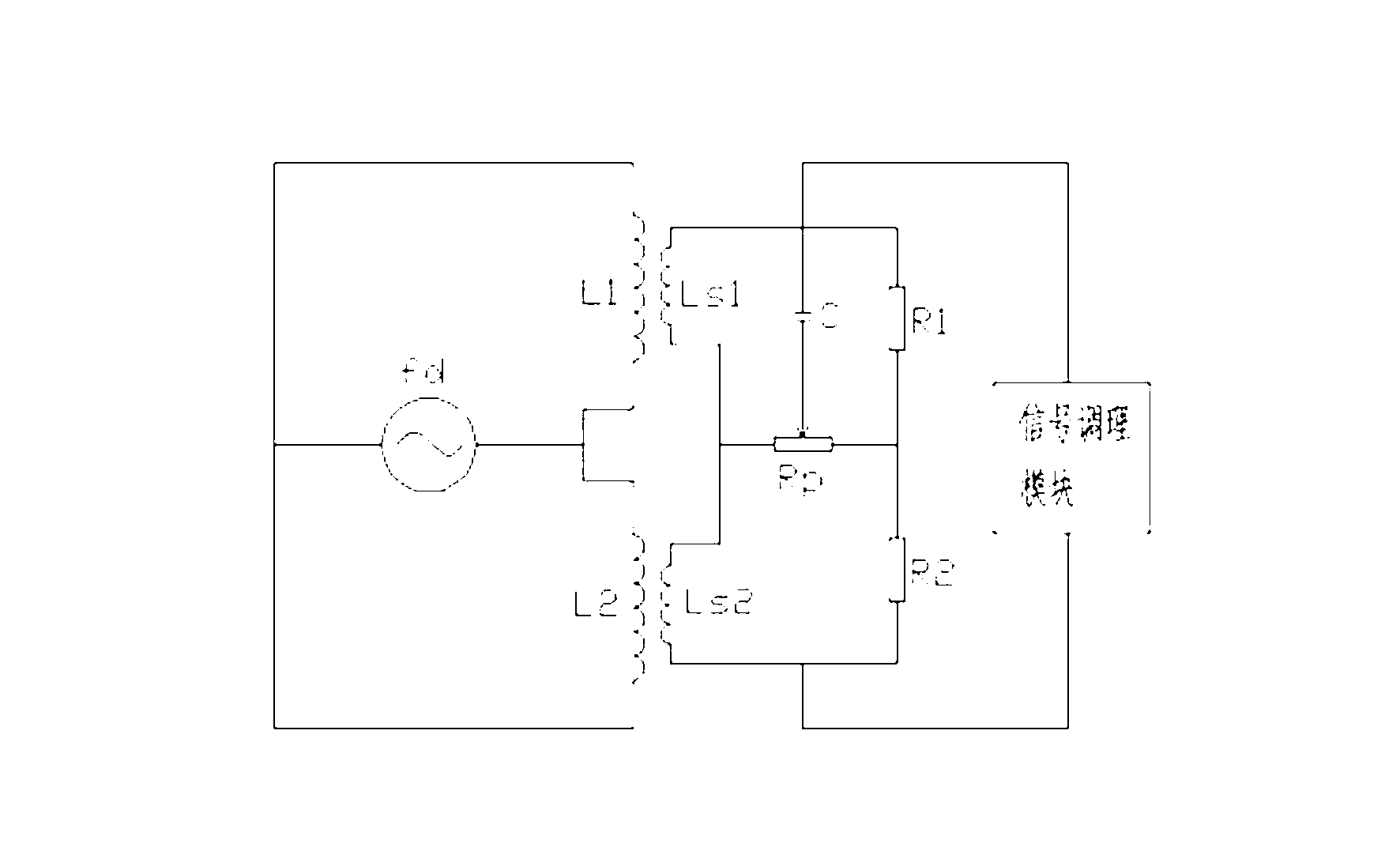

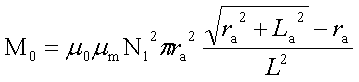

[0040] See figure 1 . The sensor for online monitoring of oil and metal abrasive particles is a mutual inductance sensor, including an excitation coil and an induction coil. An oil circuit that can pass through the oil is set in the center of the skeleton made of magnetically inert material, and a coaxial excitation coil and a coil are wound on the skeleton. Induction coil, the induction coil is located between the excitation coil and the frame, the axial length of the induction coil is 1 / 3 of the axial length of the excitation coil, and the axial midpoint of the induction coil and the excitation coil coincides, that is, in the axial direction, the induction coil The coil is in the middle of the excitation coil.

[0041] See figure 2 . The main steps of using the above sensors to monitor oil metal abrasive particles online

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap