Verification and optimization method of gearbox body design

A technology of gear box and optimization method, which is applied in the direction of design optimization/simulation, calculation, special data processing application, etc., can solve the problems of complex loading and deformation, verification and optimization, etc., and achieve reliable and stable strength and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with embodiment the specific embodiment of the present invention is described in further detail:

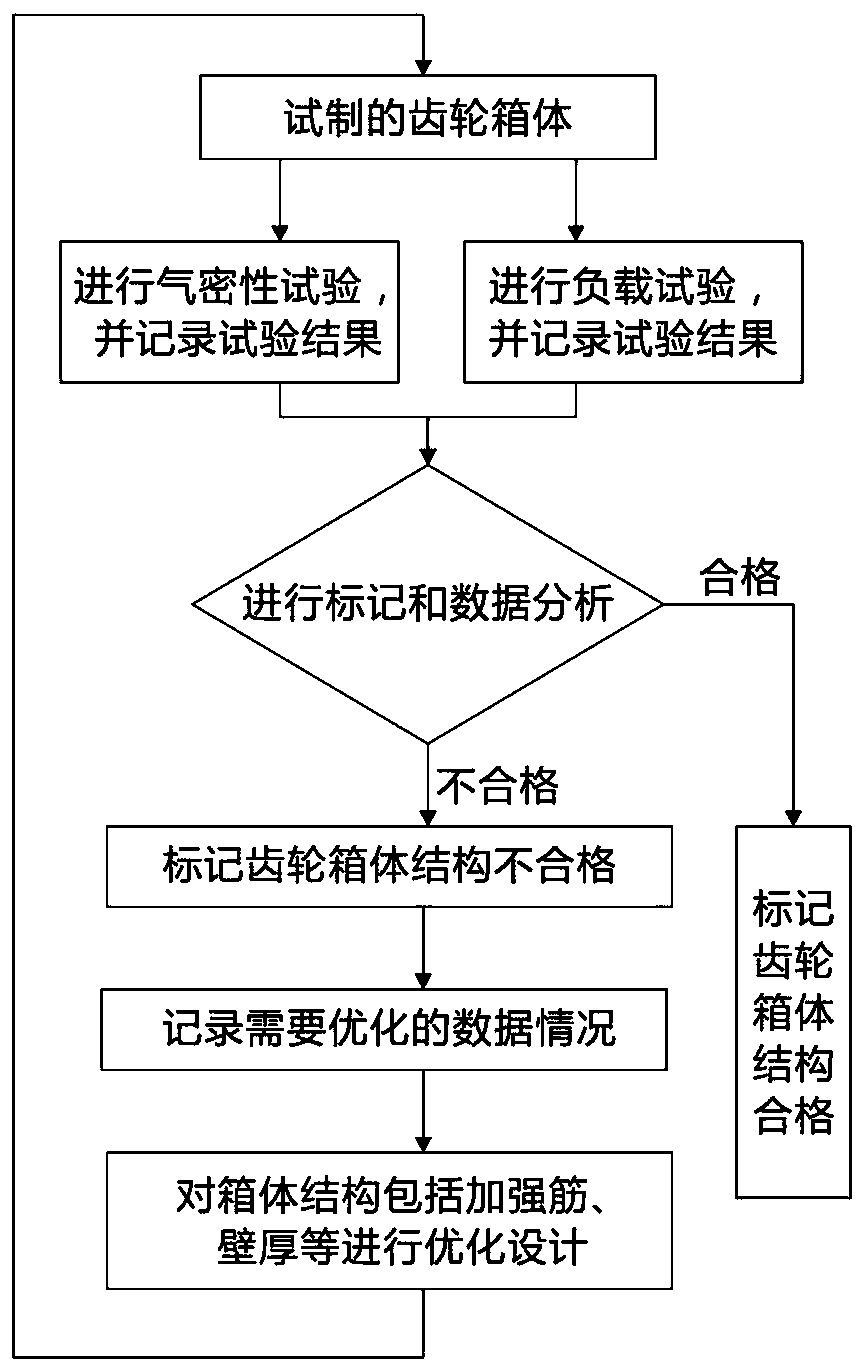

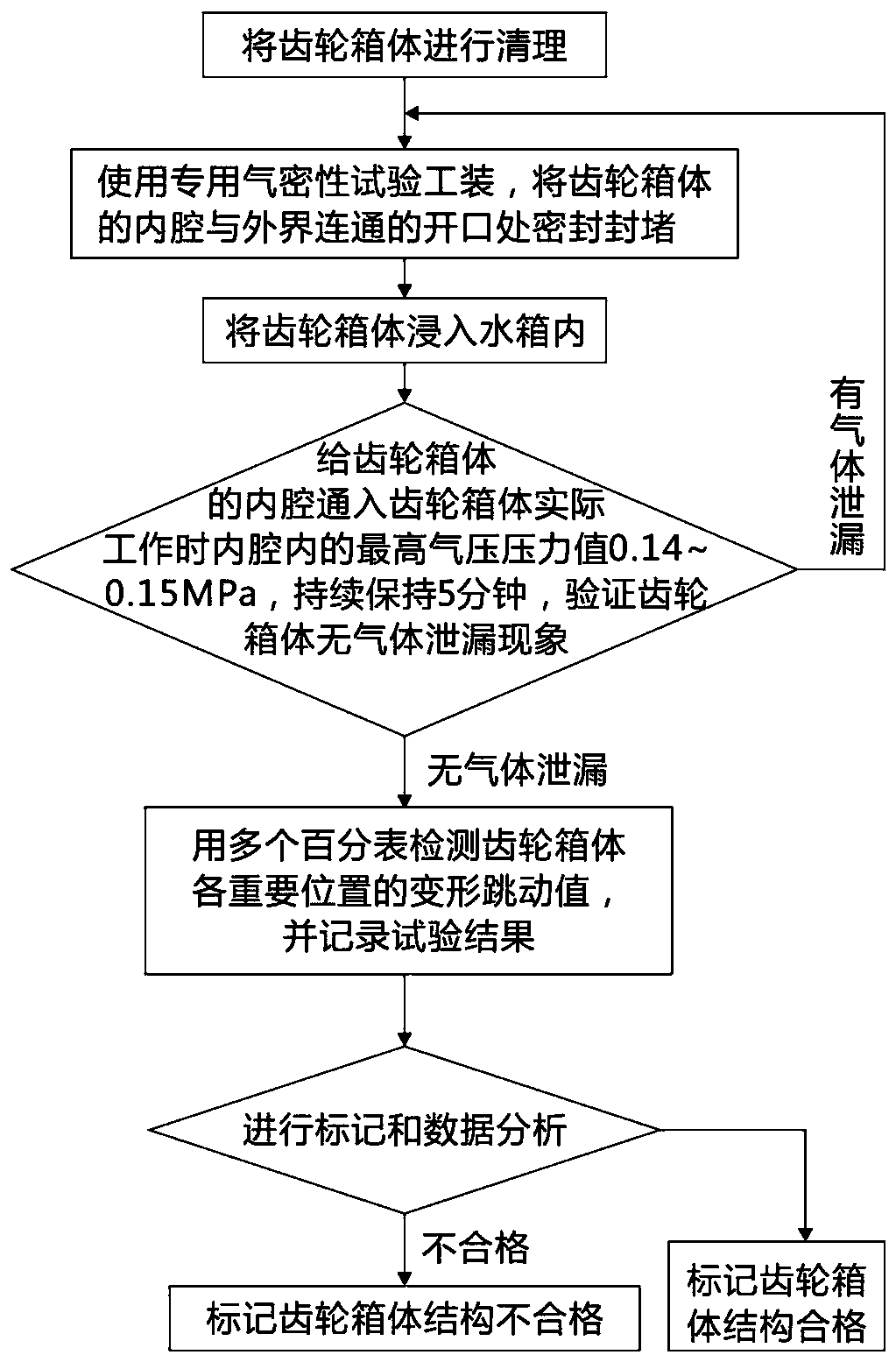

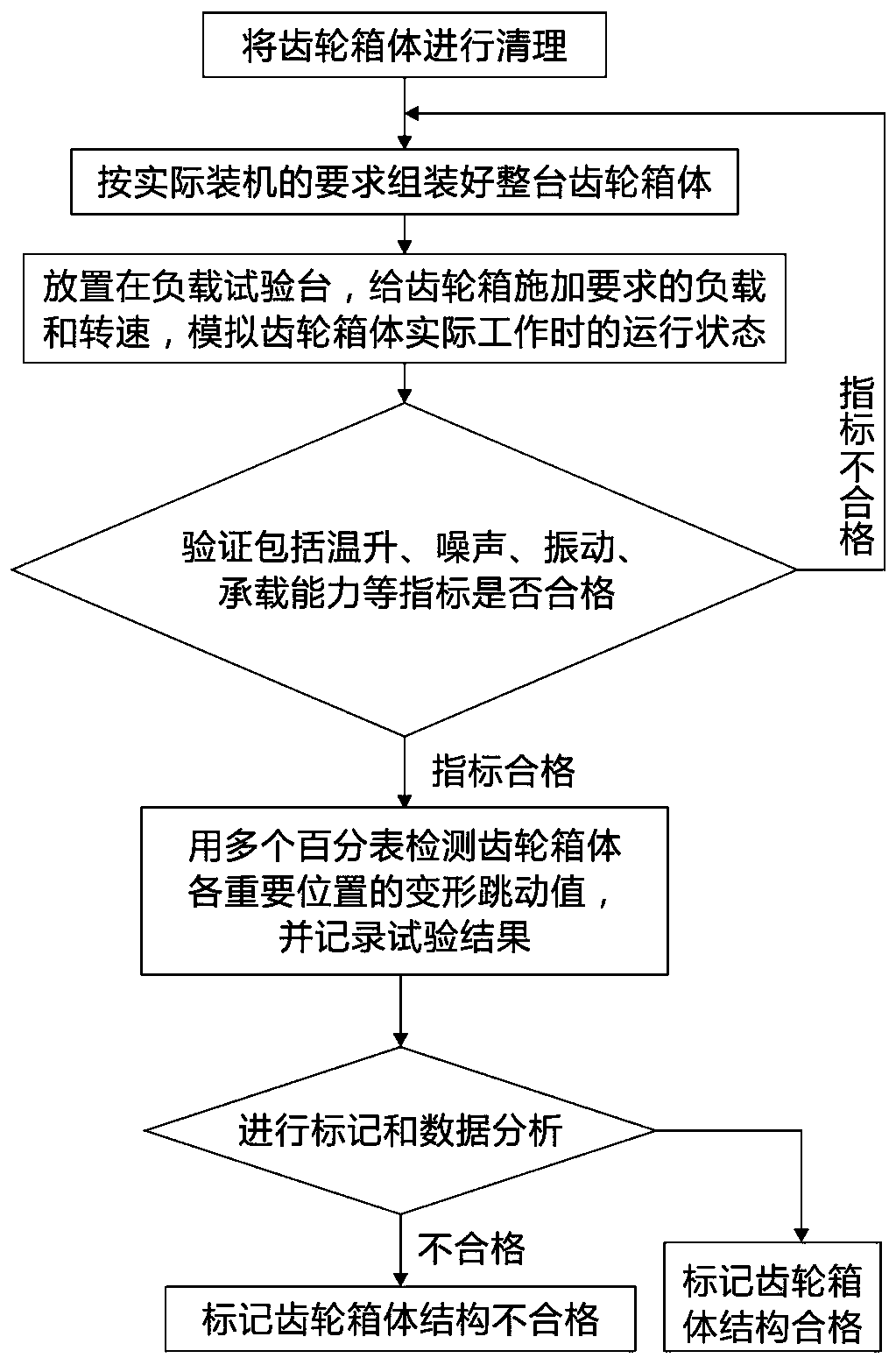

[0016] Such as figure 1 , figure 2 and image 3 As shown, a verification and optimization method for gearbox body design is implemented in the following steps:

[0017] 1. Clean the gear box body; make a special air tightness test tool with appropriate size and thickness with bakelite board, and make mounting holes for fixing the air pressure pipe and pressure gauge on it, and then use the special air tightness test tool to install the gear box Seal and block the opening where the inner cavity of the gear box communicates with the outside world, then immerse the gear box body in the water tank, and pass the inner cavity of the gear box body into the inner cavity of the gear box body. , keep it for 5 minutes to verify that there is no gas leakage in the gear box; if there is a gas leak, perform a seal check and re-seal; if there is no gas leak, the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap