Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

88results about "Grinding drives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

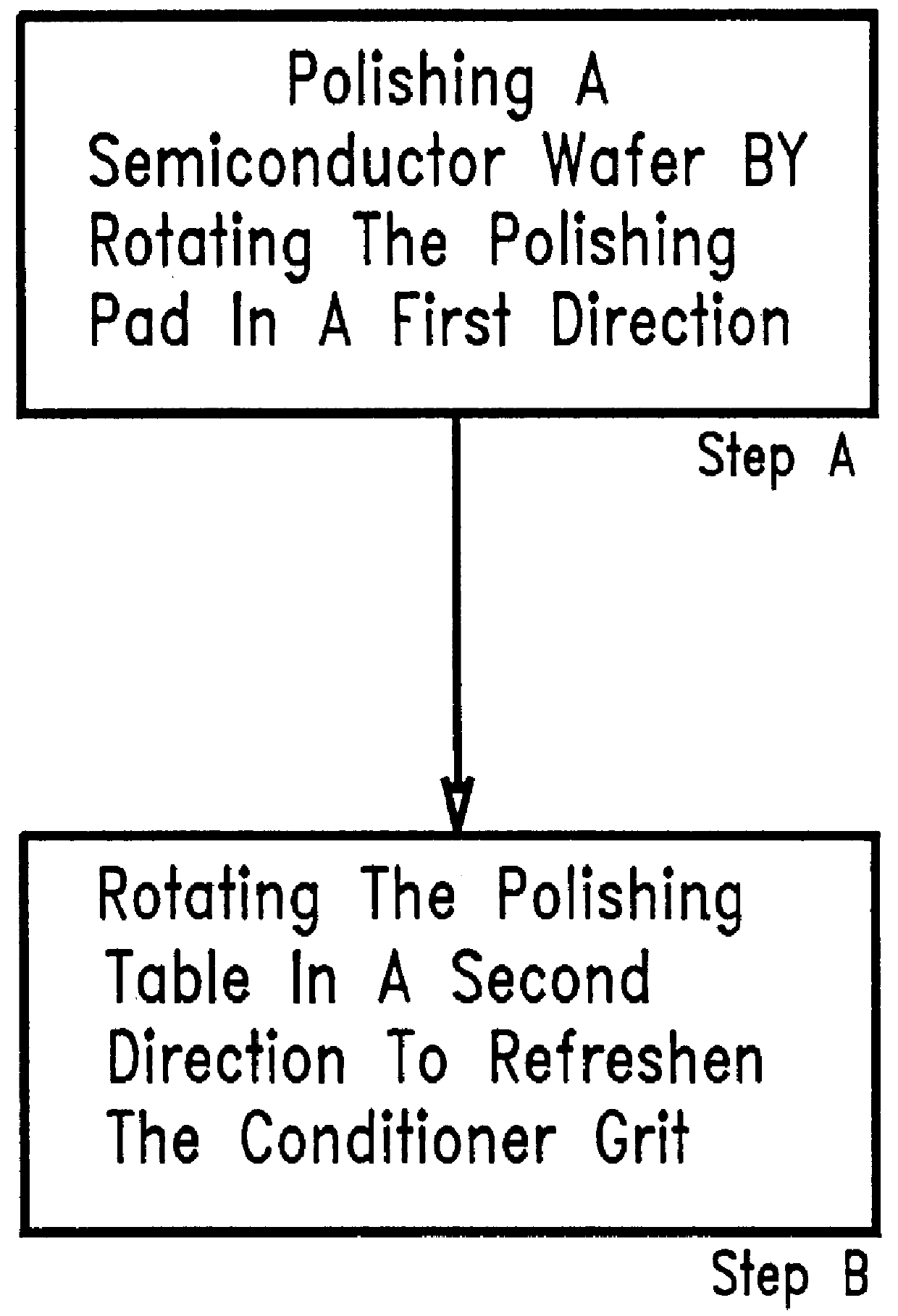

In-situ pad conditioning process for CMP

InactiveUS6022266AGood conditioning effectGrinding drivesBelt grinding machinesSlurryImproved method

Owner:GOOGLE LLC

Die polishing device with dust collector

Owner:芜湖凝鑫机械有限公司

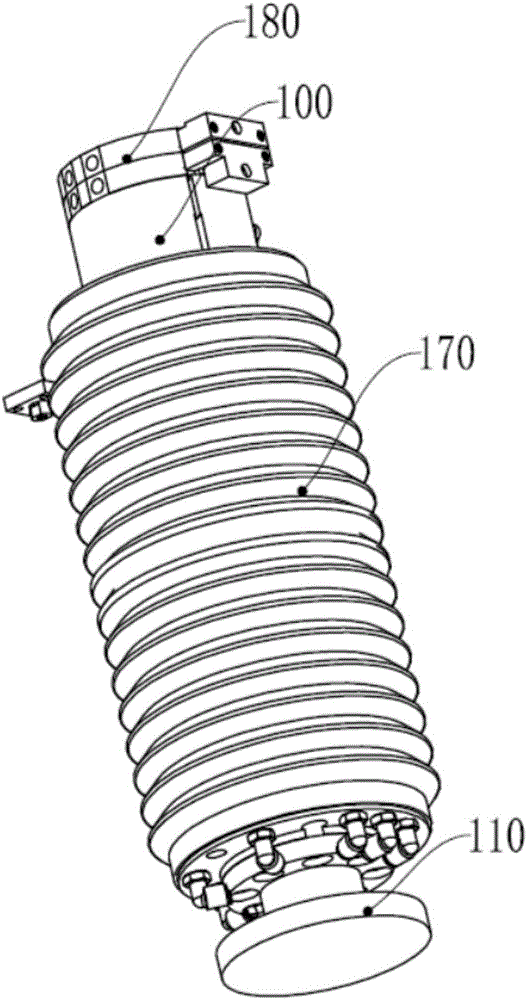

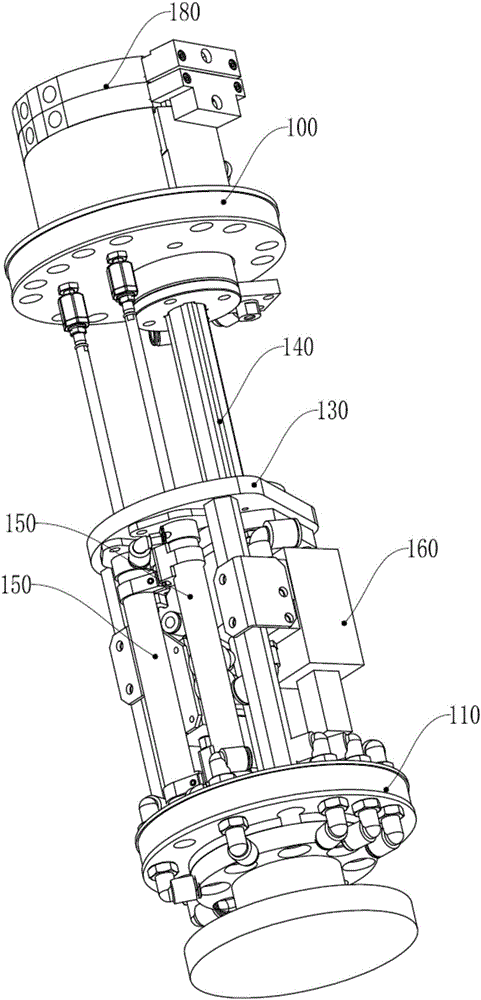

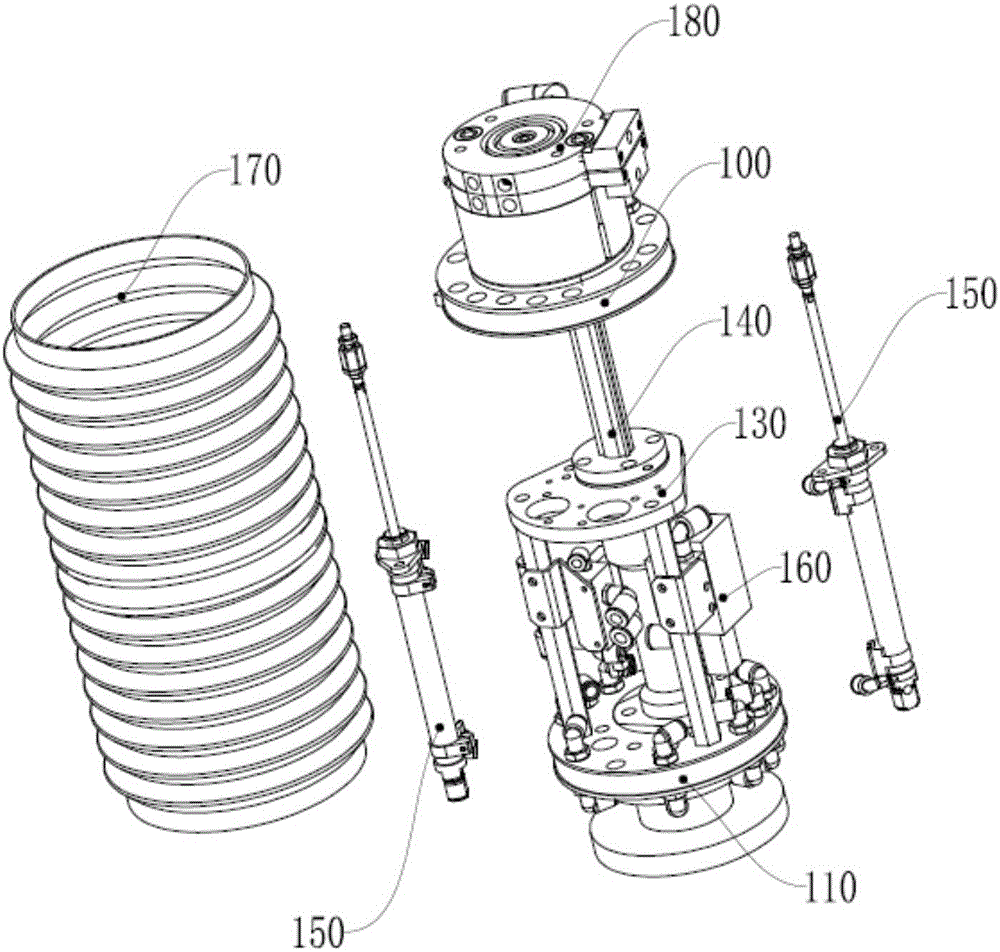

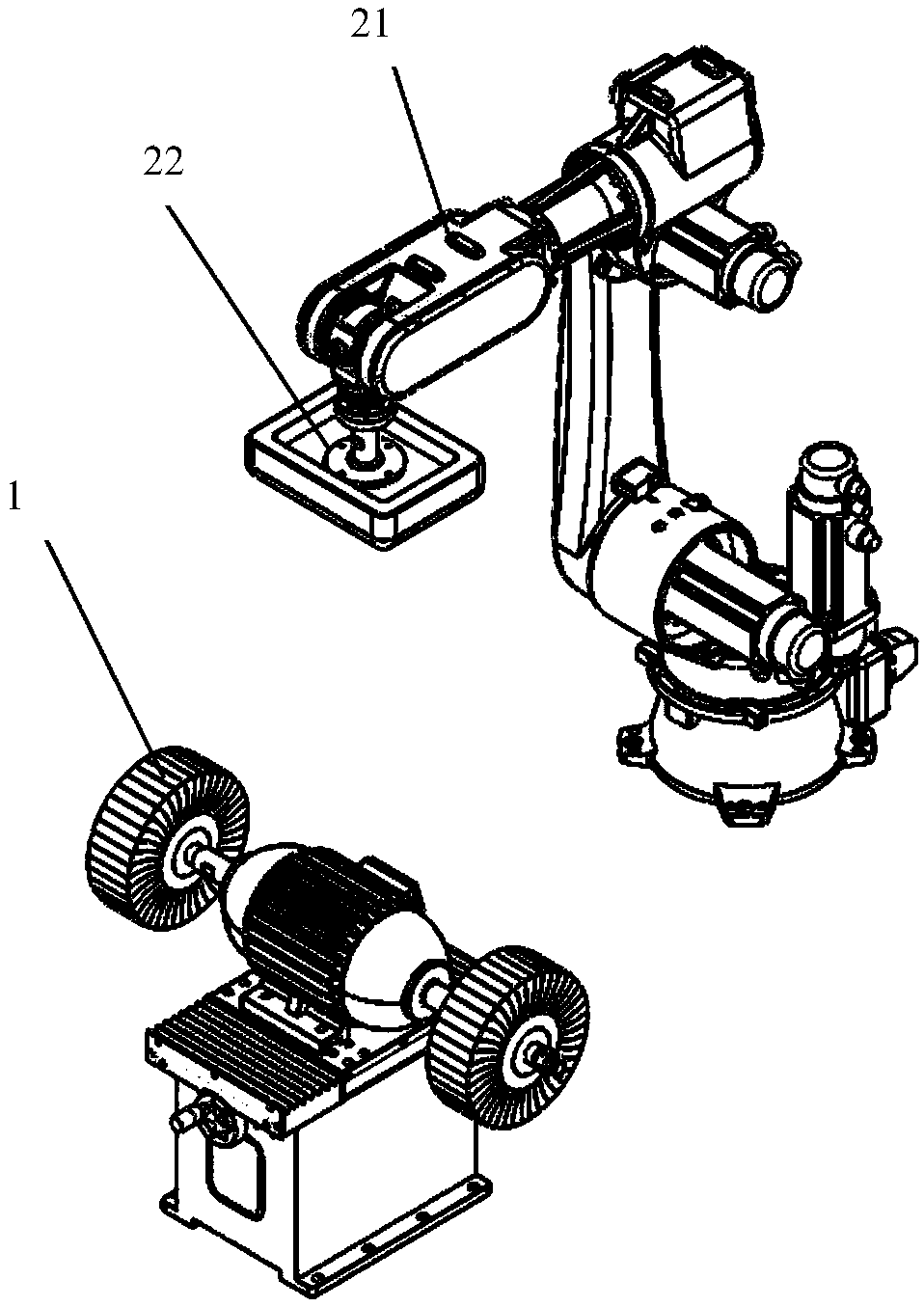

Force-controlled polishing device and polishing robot applying force-controlled polishing device

Owner:GUANGDONG LXD ROBOTICS CO LTD

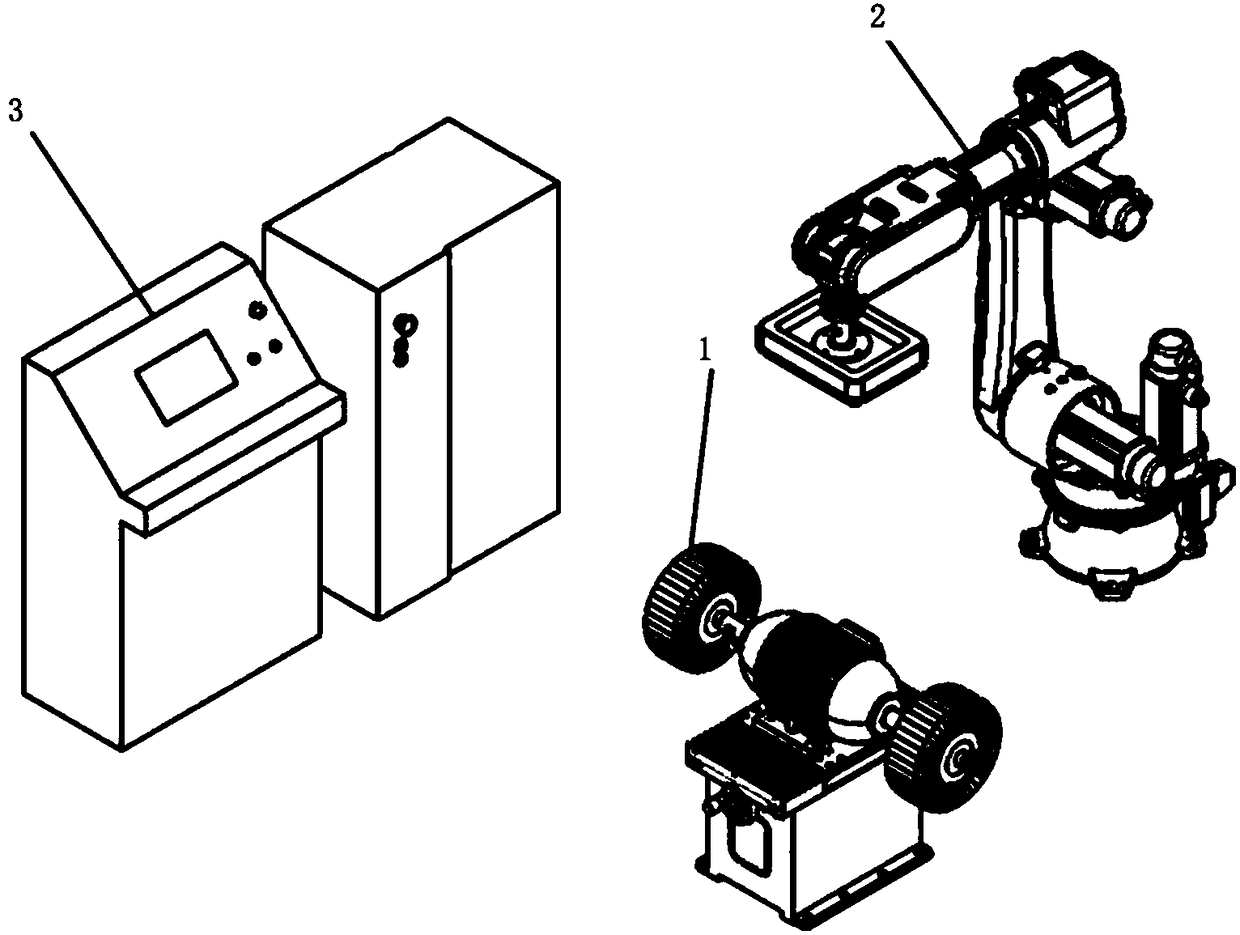

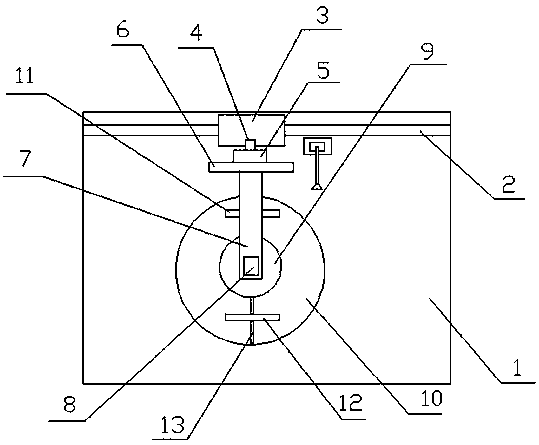

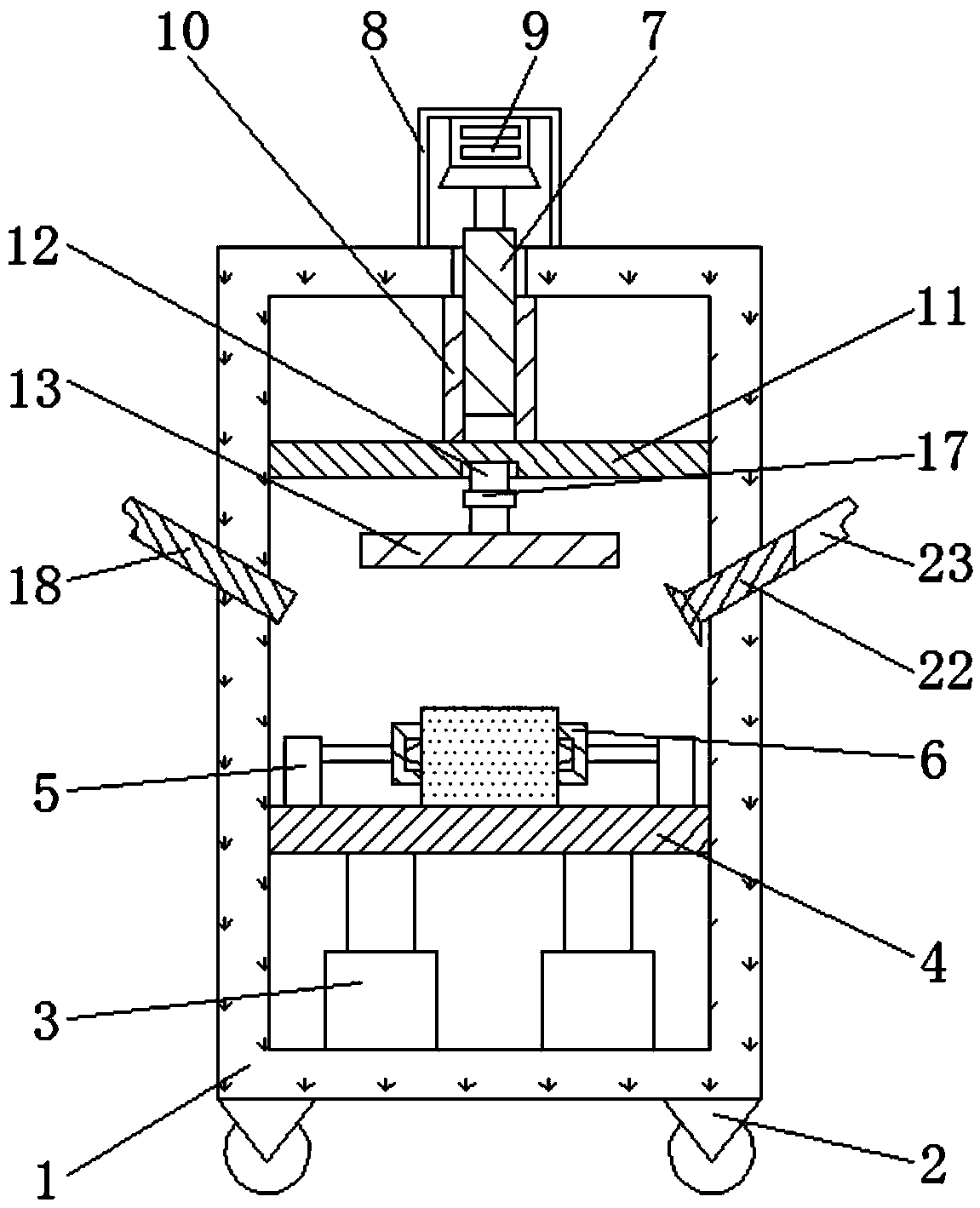

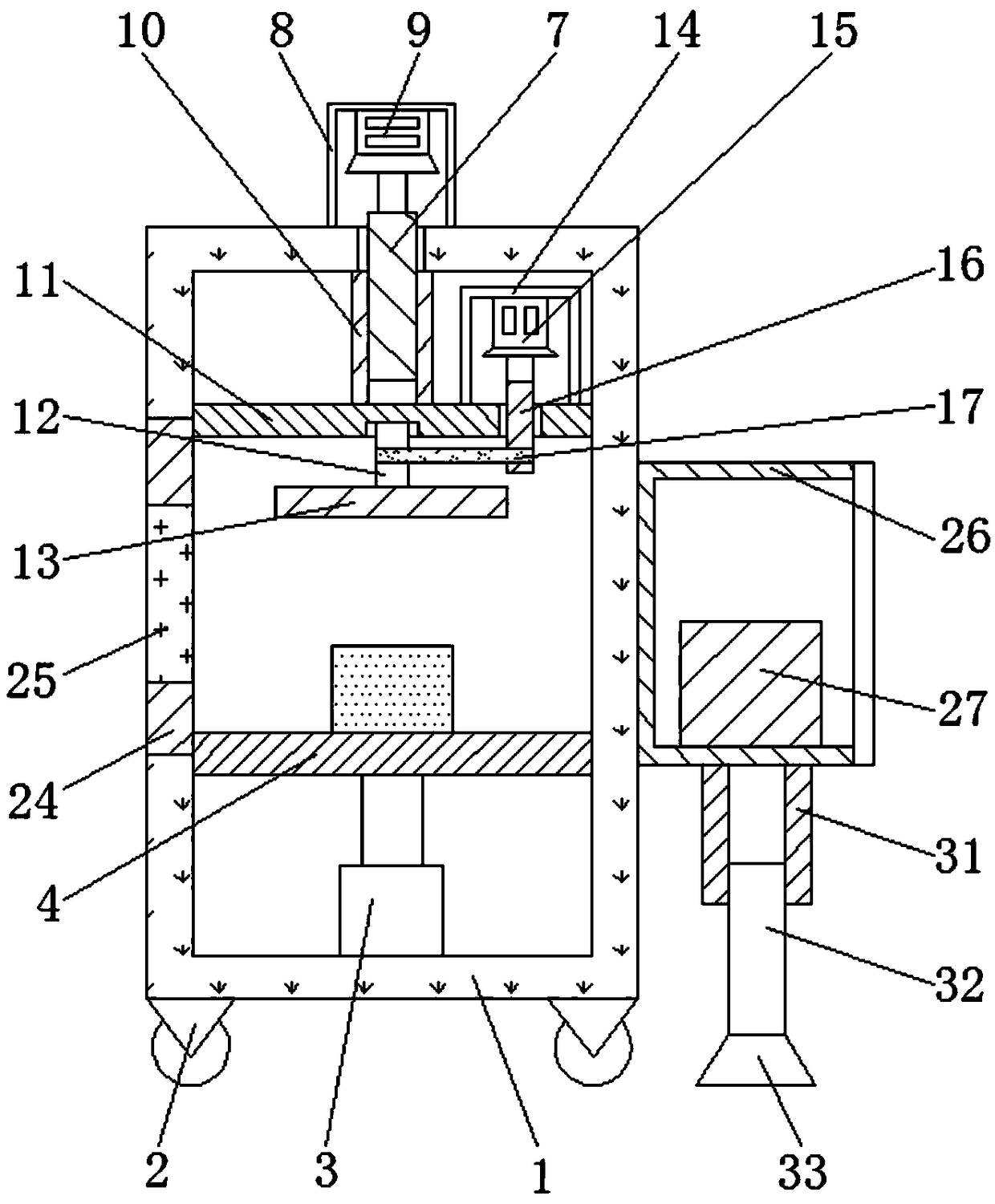

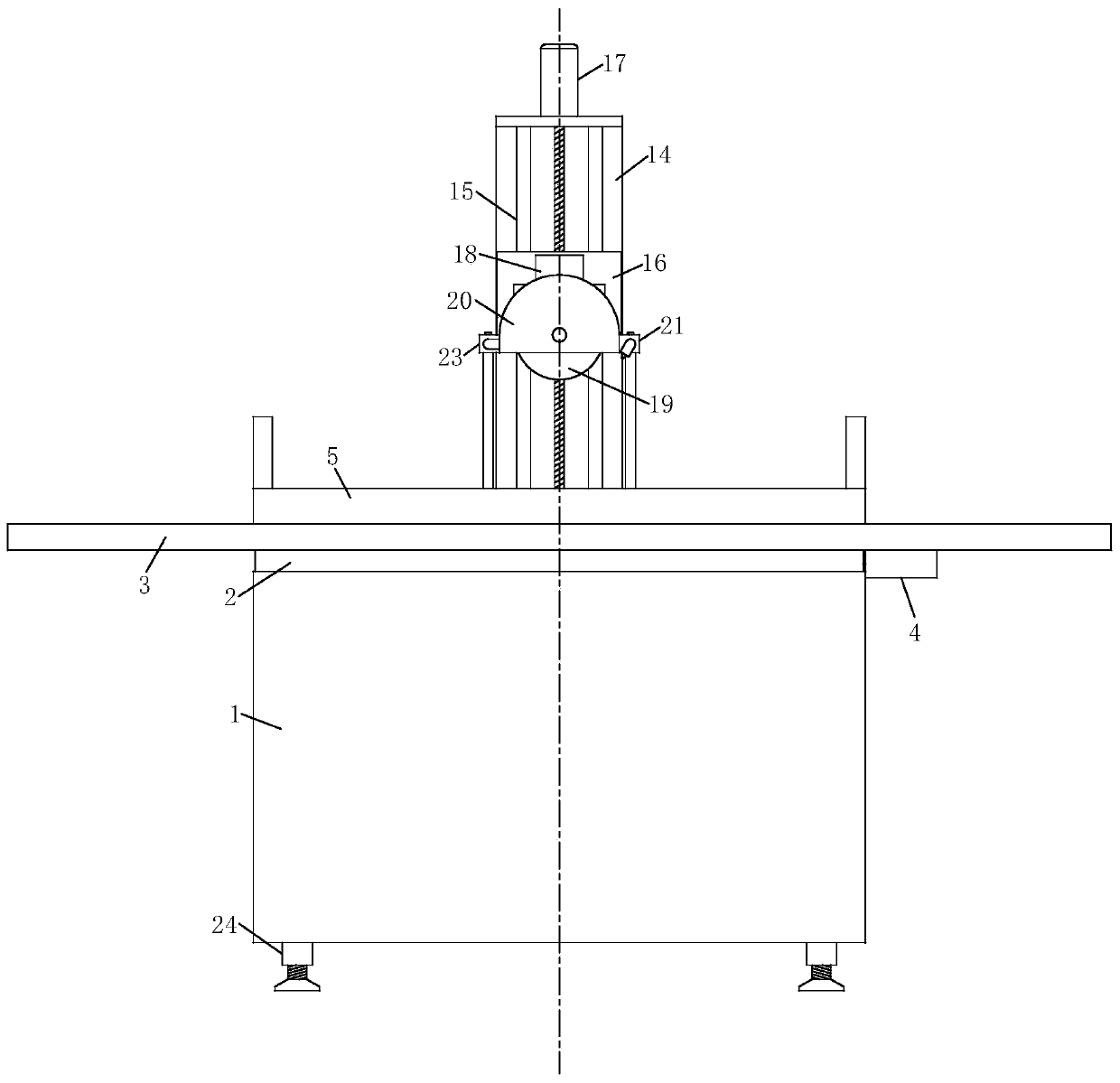

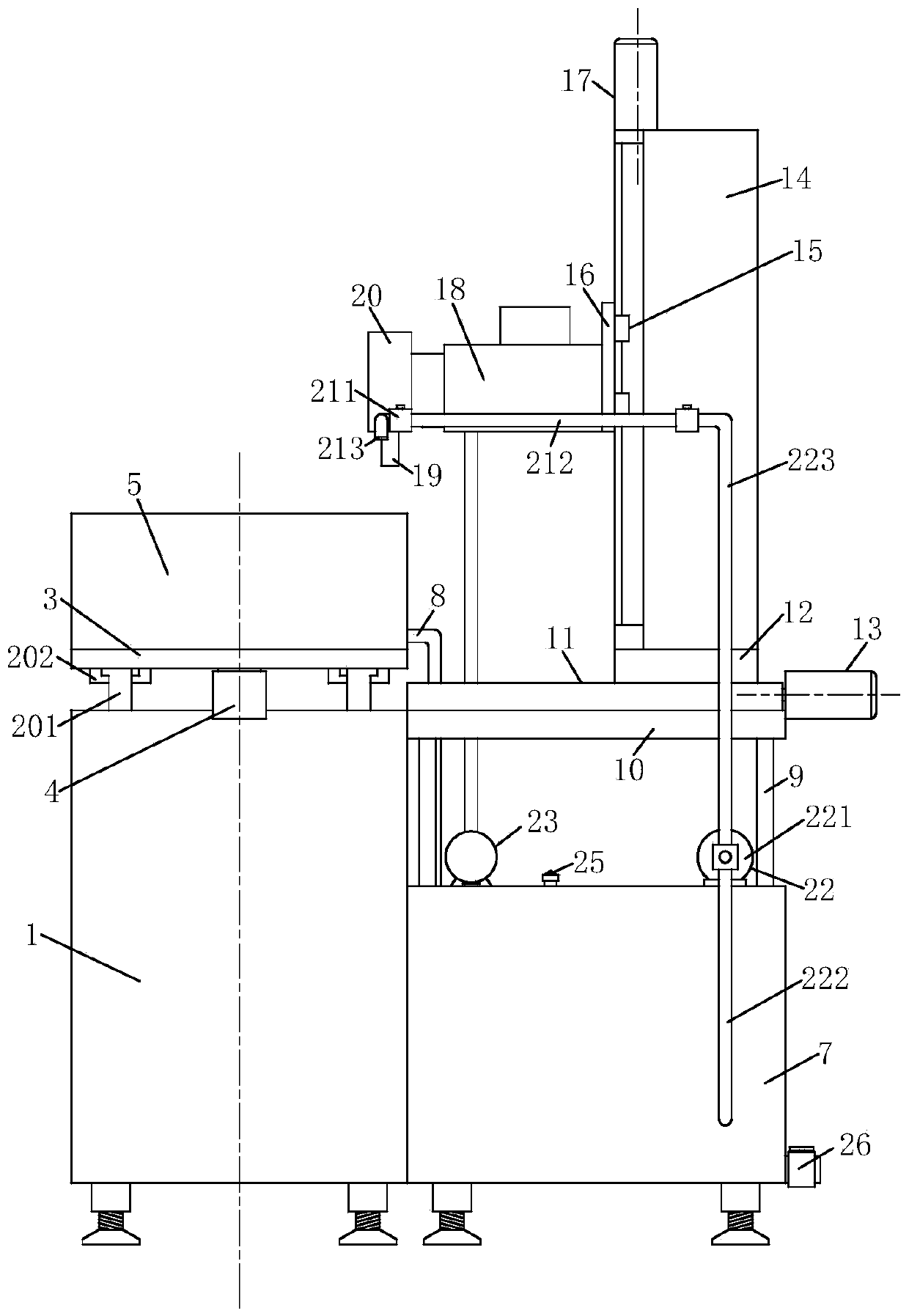

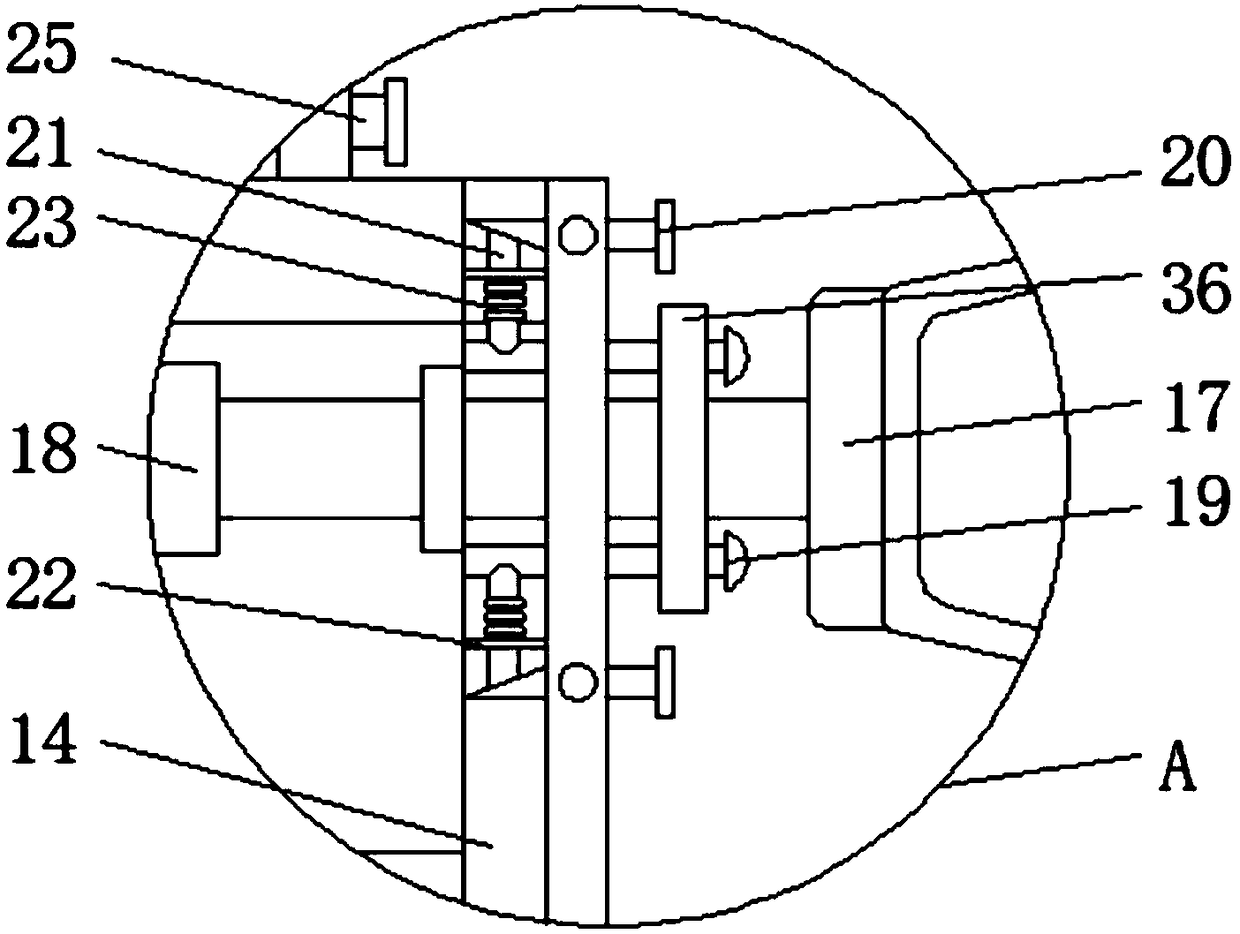

Pressure-controllable industrial robot grinding and polishing system and grinding and polishing method

PendingCN108296962AImprove grinding and polishing effectImprove production efficiency and product qualityPolishing machinesGrinding drivesPulp and paper industryIndustrial robot

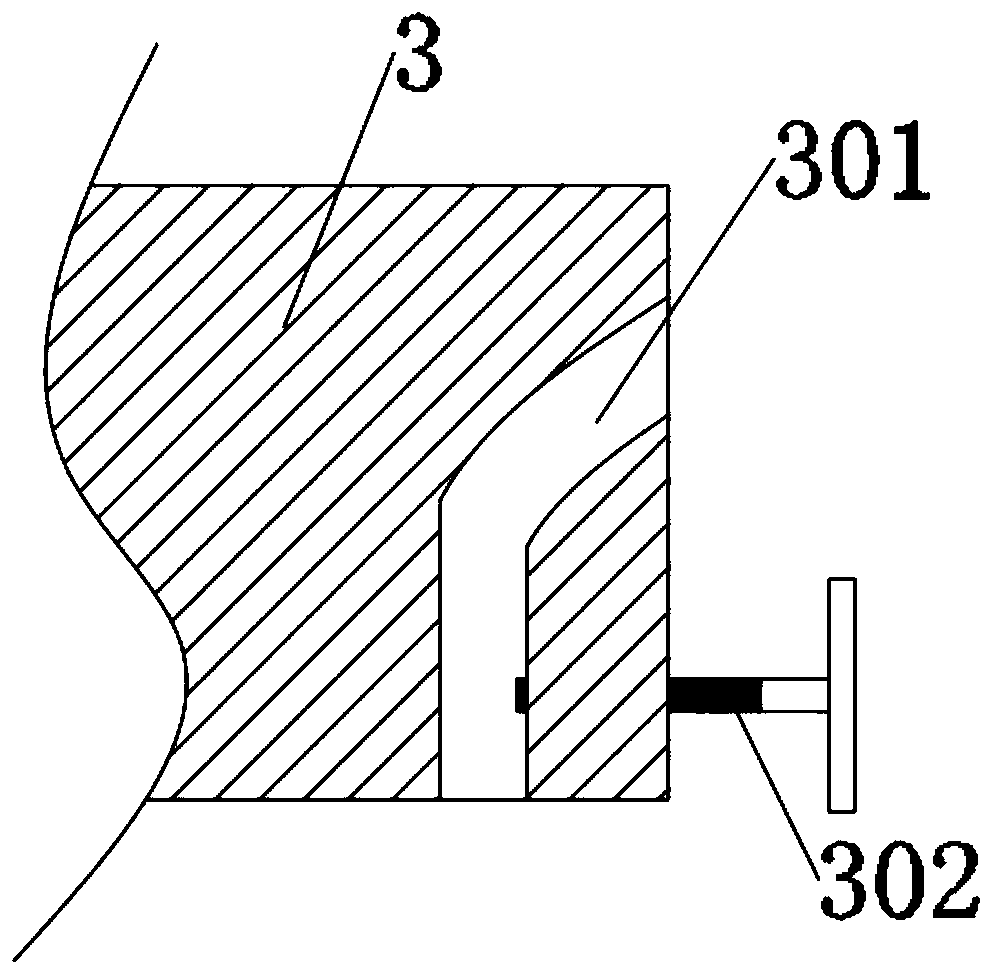

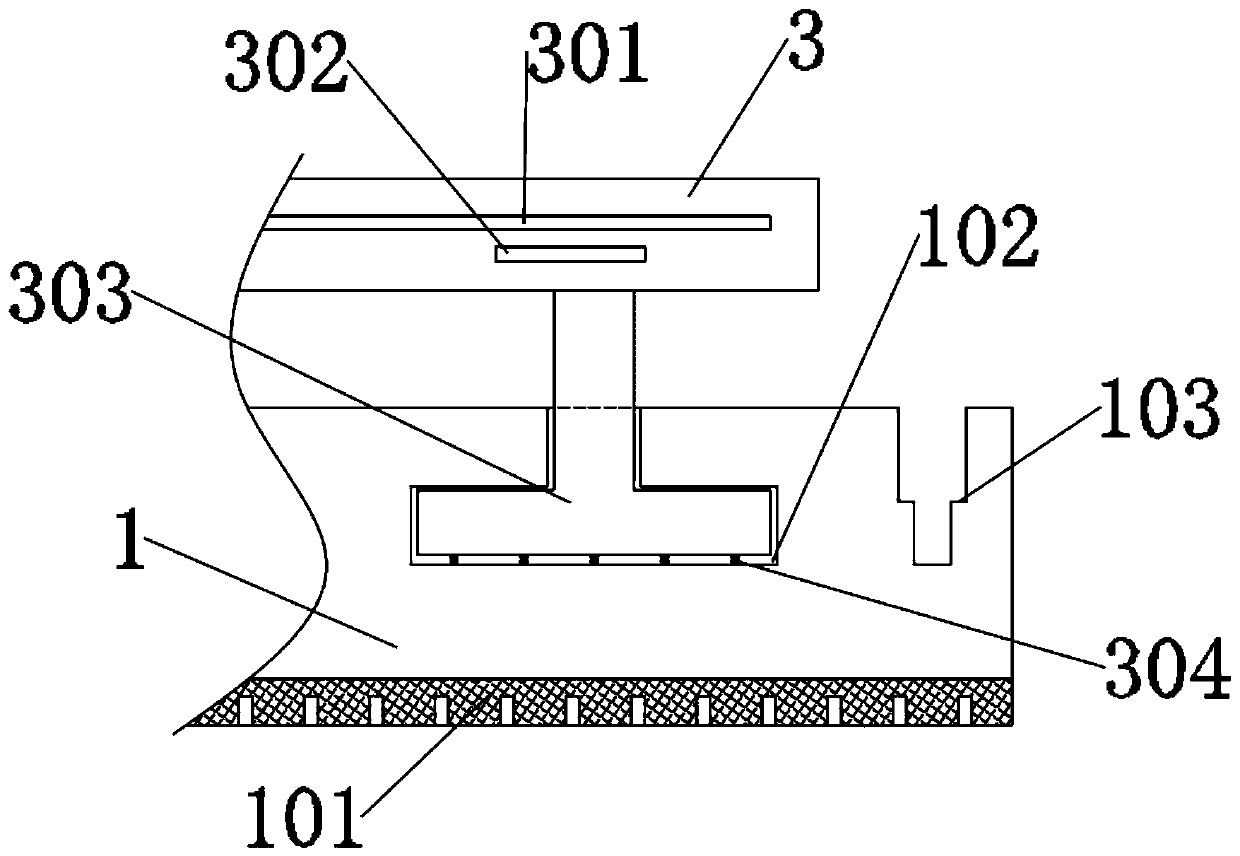

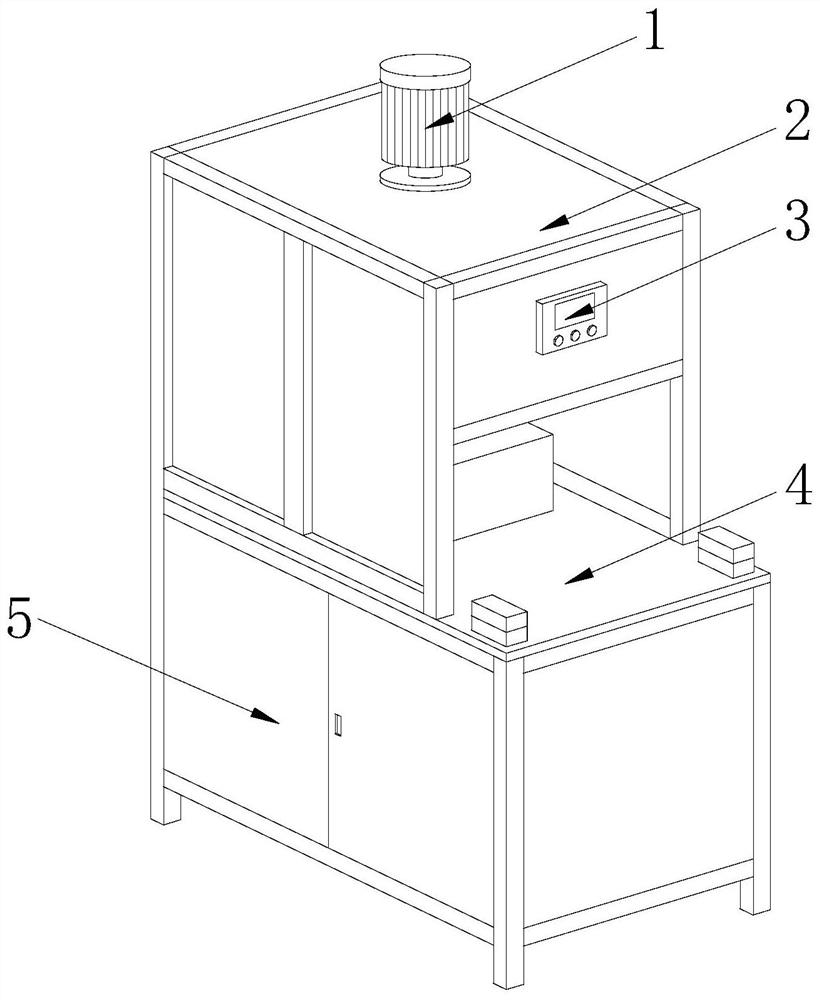

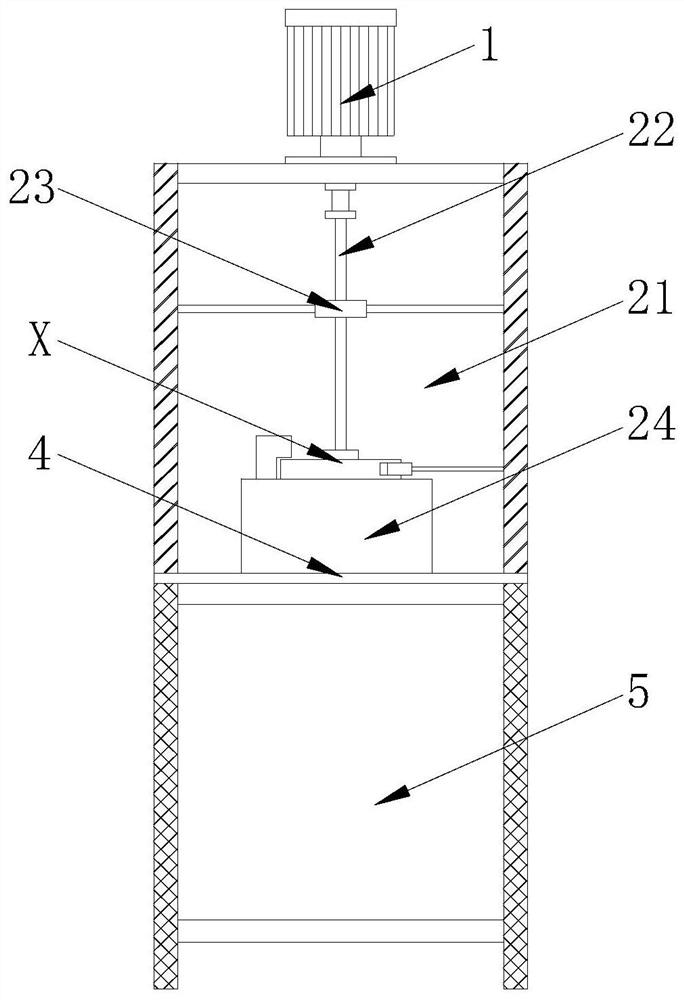

The invention provides a pressure-controllable industrial robot grinding and polishing system. The pressure-controllable industrial robot grinding and polishing system is characterized by comprising apolishing device, a feeding device and a controller, and the polishing device comprises a fixed base, a mounting seat, a polishing mechanism, first slide rails, a position adjusting mechanism and a cylinder. The cylinder is connected with the mounting seat, and the mounting seat is slidably connected with the first slide rails to realize that the cylinder pushes the mounting seat to move in the length direction of the first slide rails to drive the polishing mechanism to move. The cylinder is connected with the controller to enable the controller to control the cylinder to control grinding pressure between the polishing mechanism and a workpiece. The cylinder is disposed on the fixed base through the position adjusting mechanism. The pressure-controllable industrial robot grinding and polishing system can improve grinding and polishing effects and improve production efficiency and product quality. The invention further provides an industrial robot grinding and polishing method which is capable of realizing constant grinding pressure between the polishing mechanism and the workpiece, effectively improving the grinding and polishing effects and improving the production efficiency and the product quality.

Owner:FOSHAN INST OF INTELLIGENT EQUIP TECH +1

Plastic grinding and polishing machine

Owner:NANJING CONCORD FERTILIZER CHEM

Computer hardware developing grinding device having dust removal function

InactiveCN108942516AReduce labor intensitySave time at workGrinding drivesGrinding machinesUltimate tensile strengthComputer engineering

Owner:上海宴阳智能科技有限公司

High-efficiency glass polishing equipment

Owner:蚌埠承永玻璃制品有限公司

Workpiece grinding equipment

Owner:林红英

Ceramic tile surface polishing device

PendingCN112025523ATo achieve the function of high and low adjustmentTo achieve the effect of clampingGrinding wheel securing apparatusGrinding carriagesComposite materialCeramic tiles

Owner:凌亮

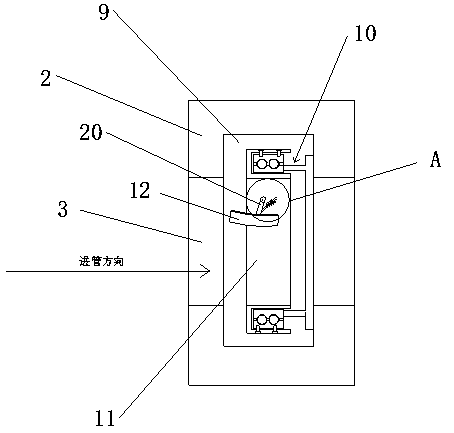

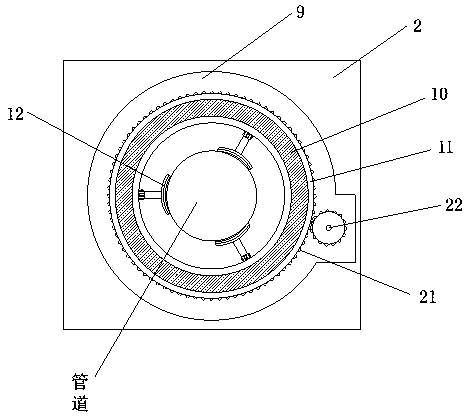

Displacement type environment-friendly floor grinding machine

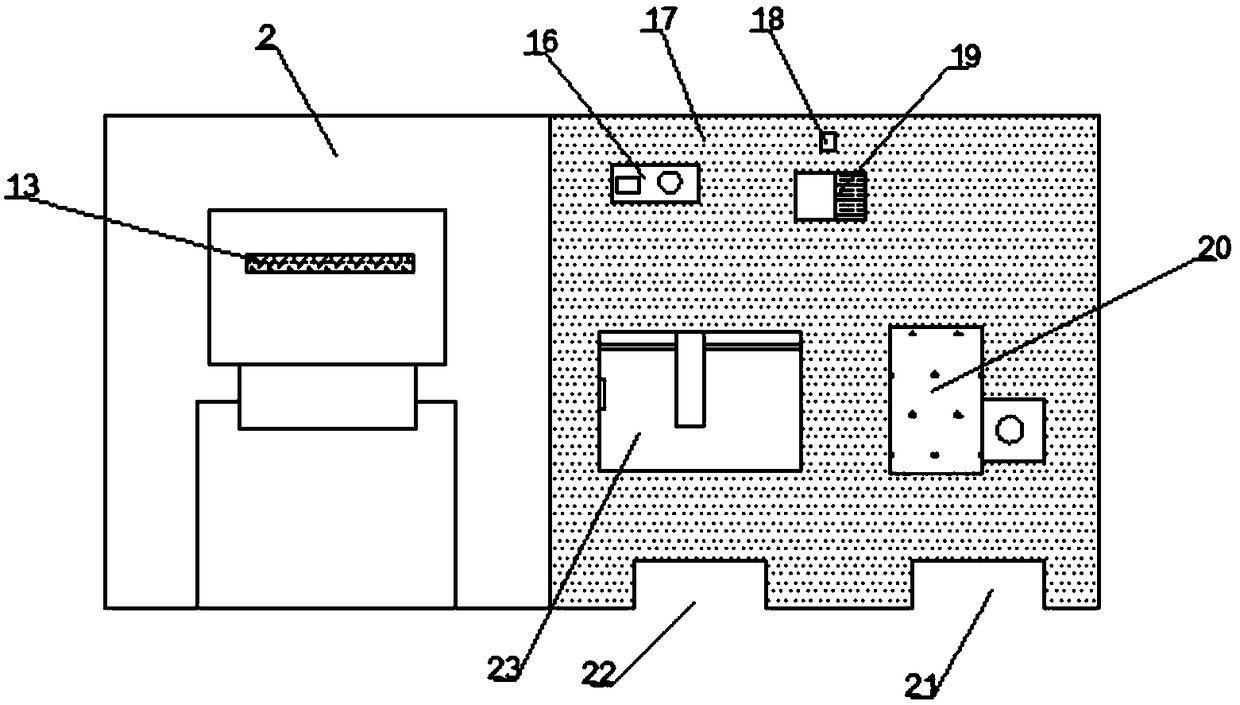

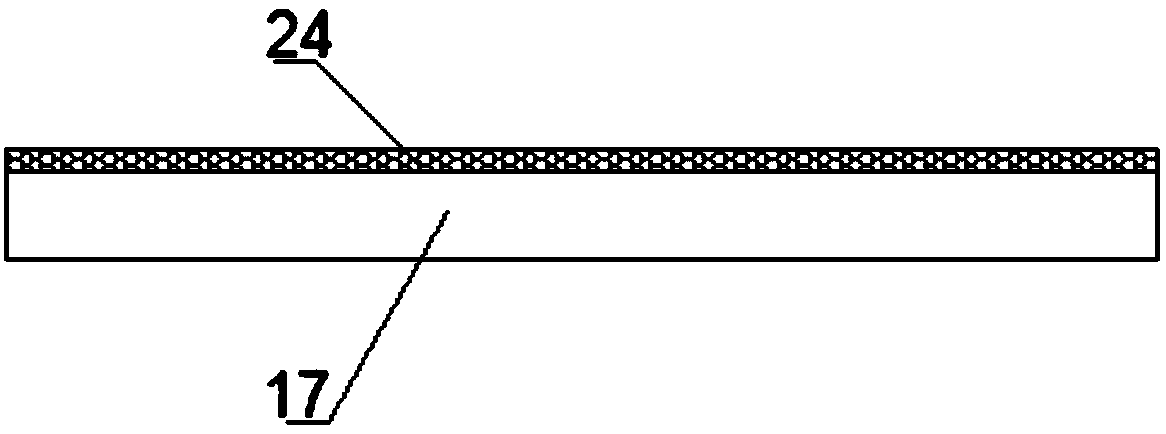

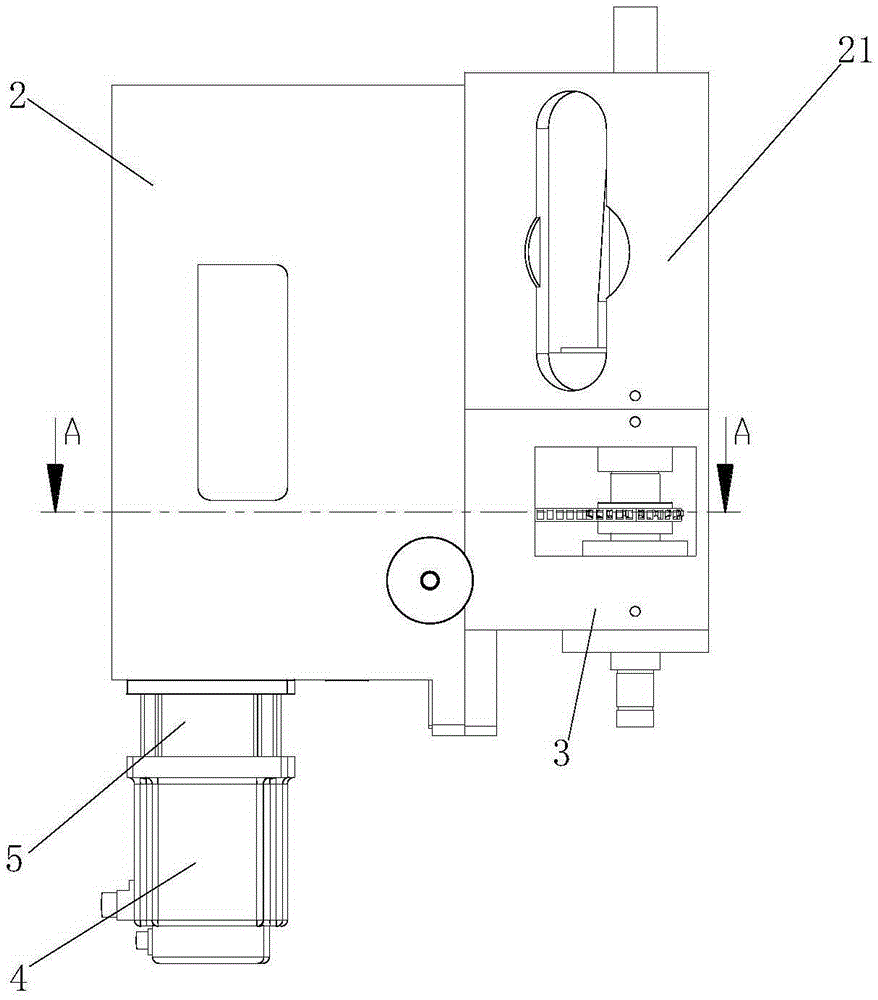

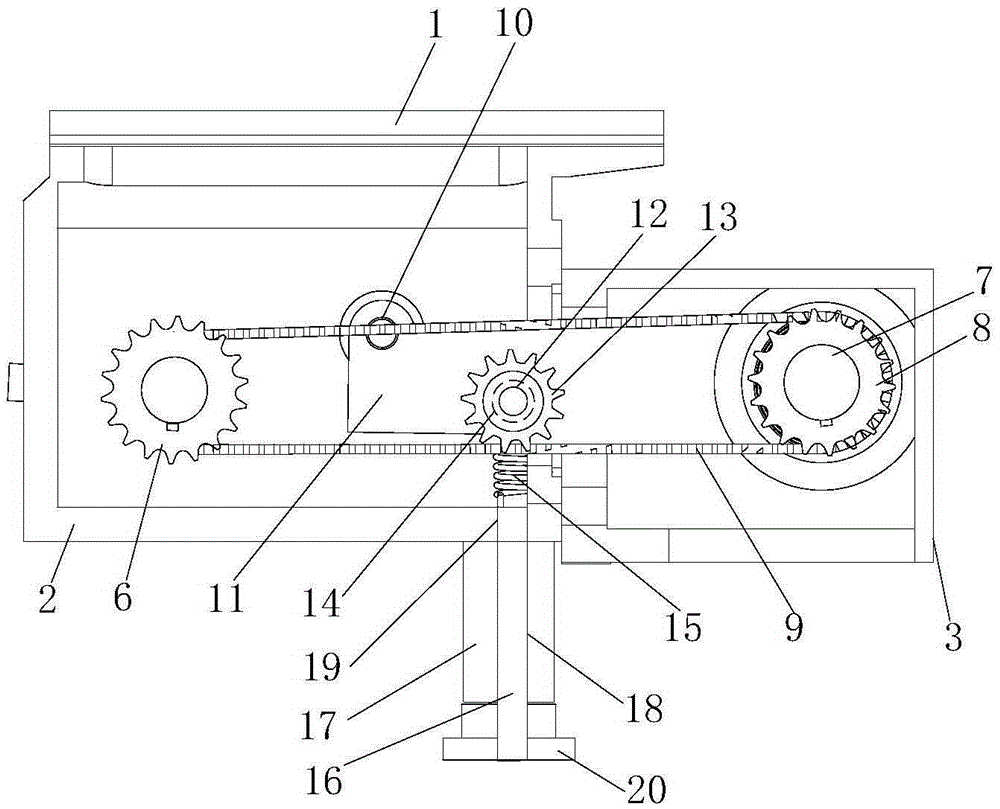

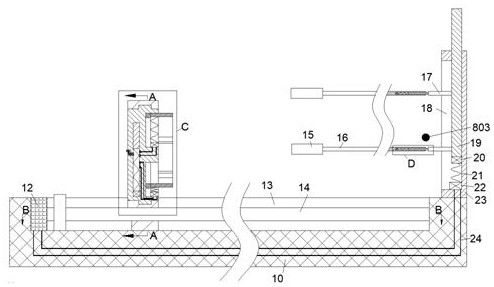

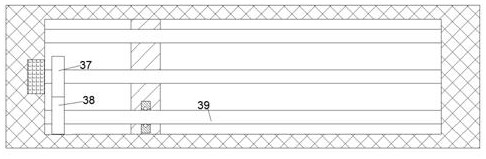

PendingCN108262656ASimple structureImprove transmission efficiencyGrinding drivesPlane surface grinding machinesEngineeringHigh pressure water

Owner:DALIAN SHUNTAI TECH

Automatic grinding machine

Owner:芜湖银海机械制造有限公司

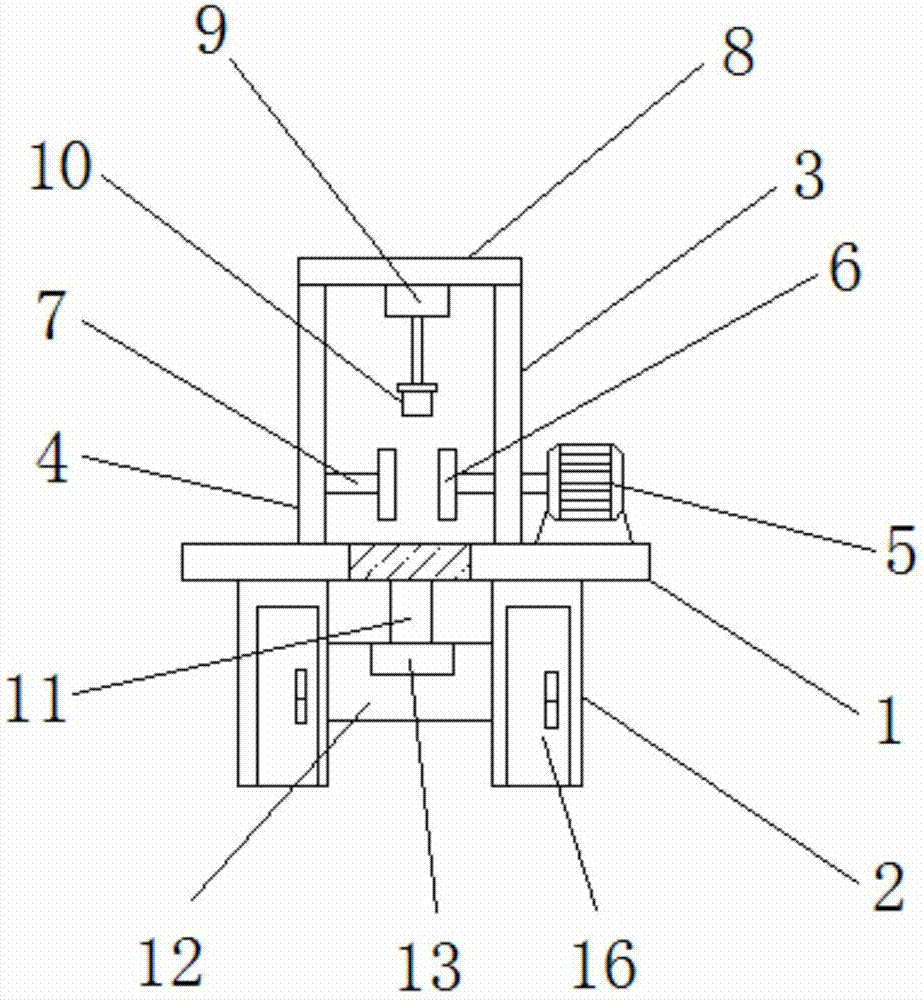

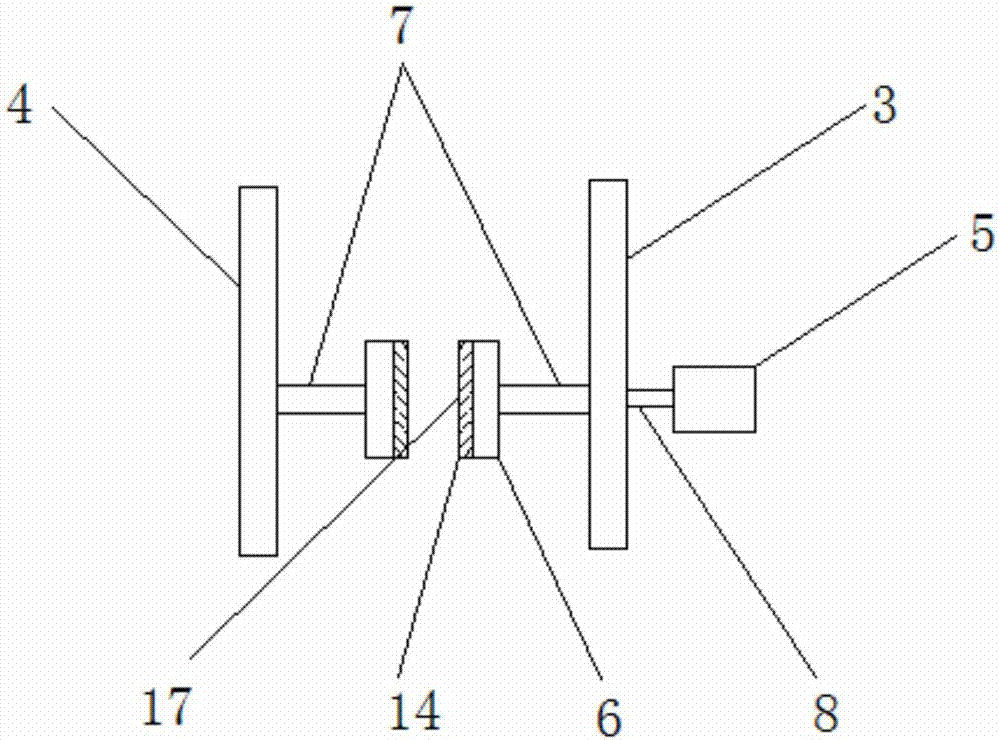

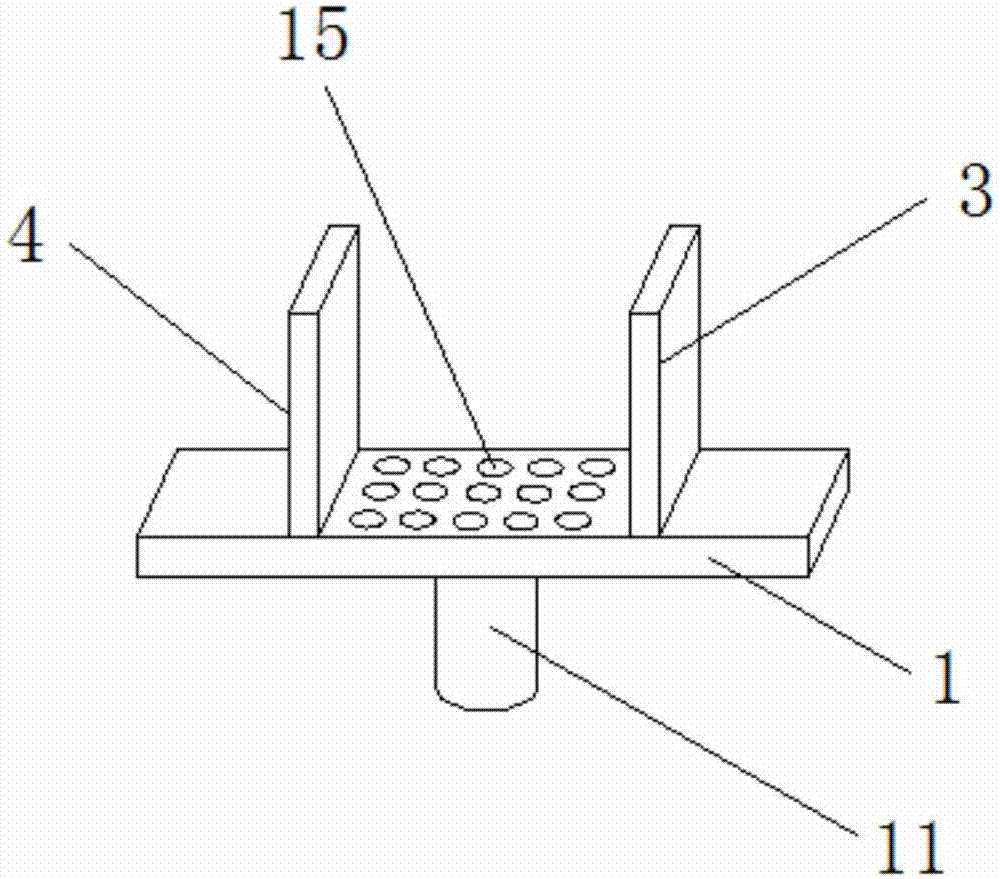

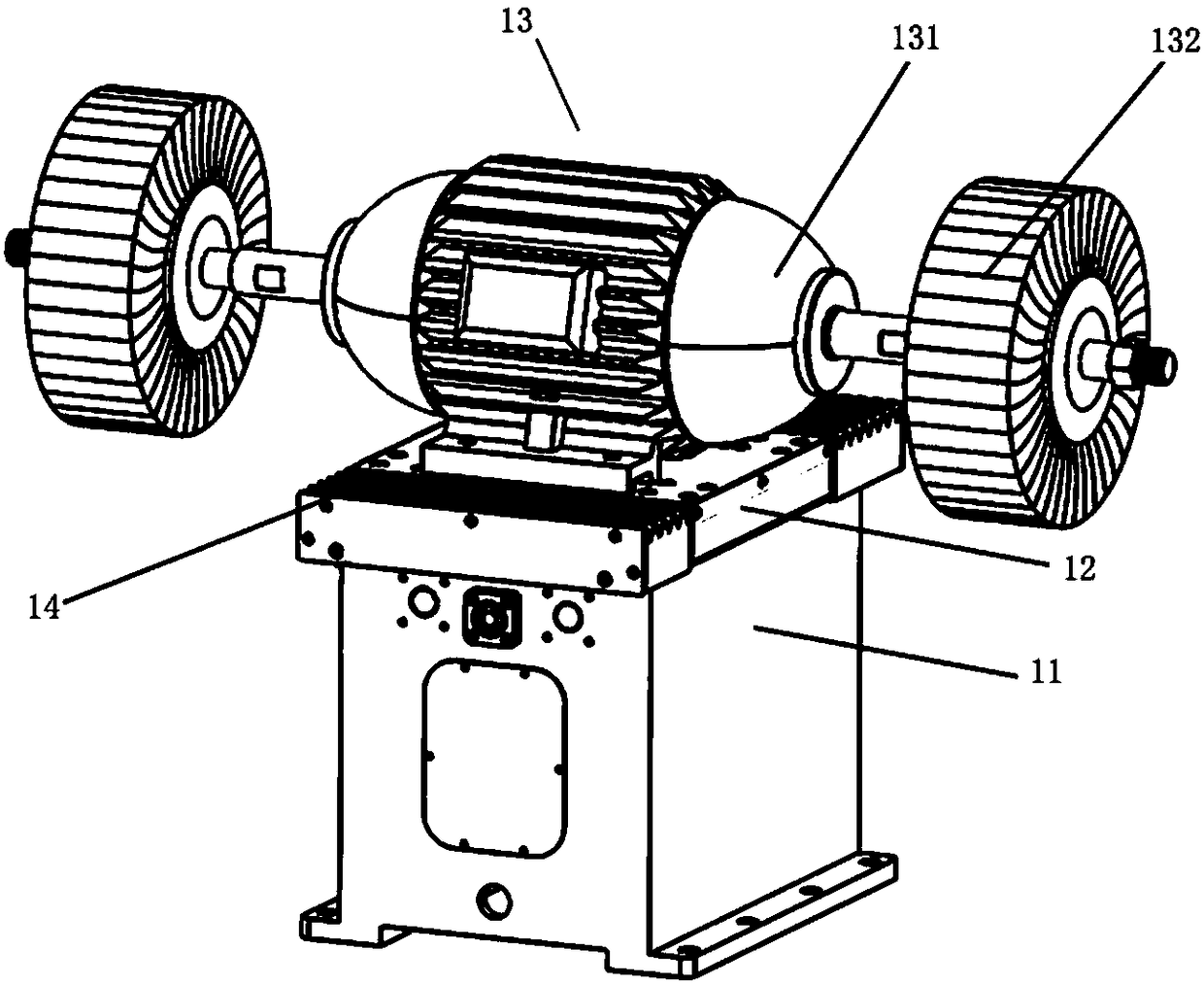

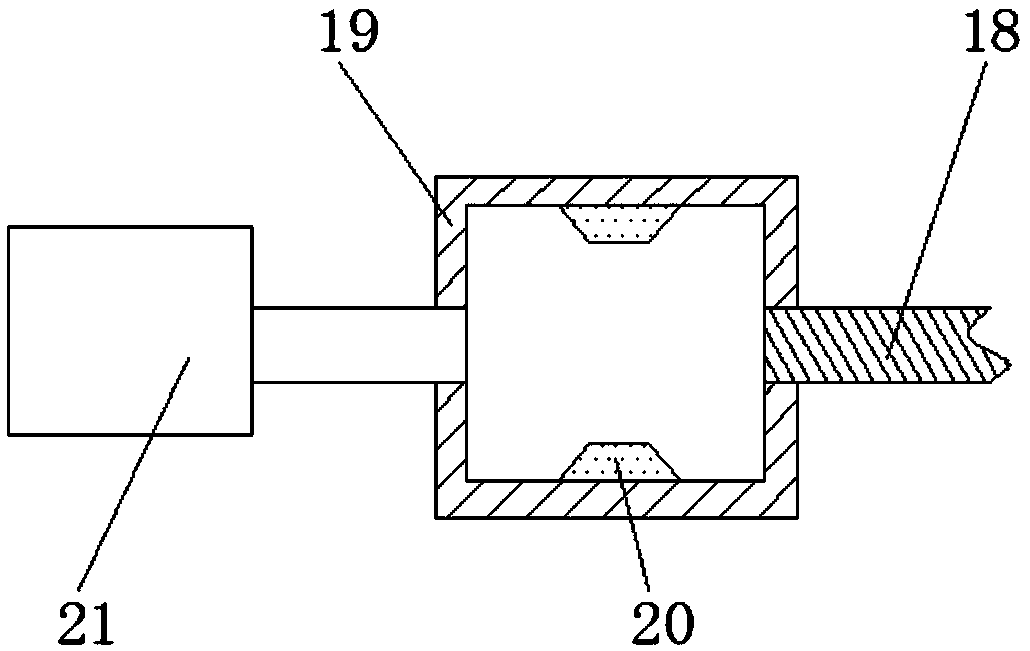

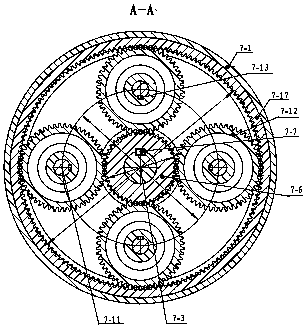

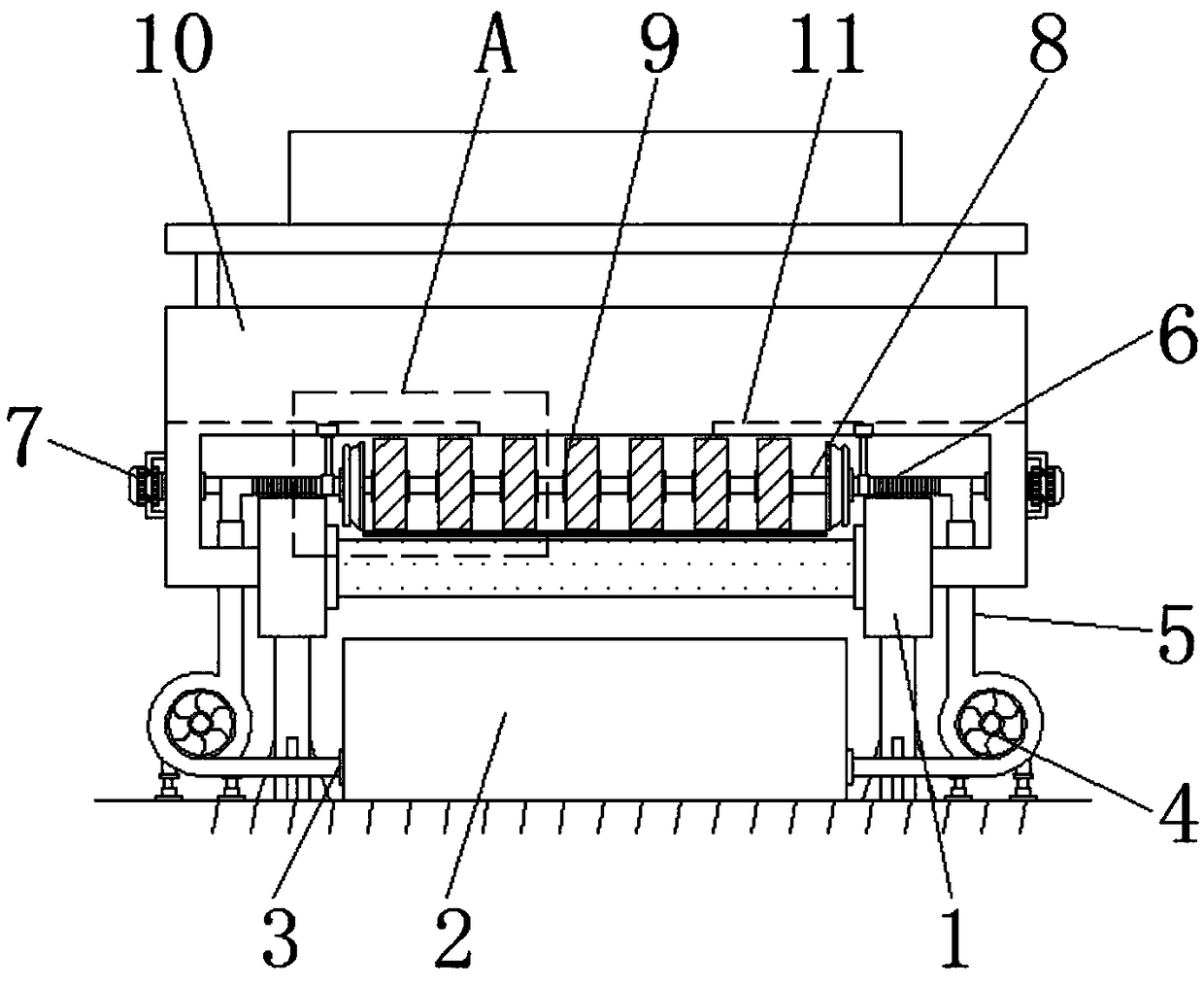

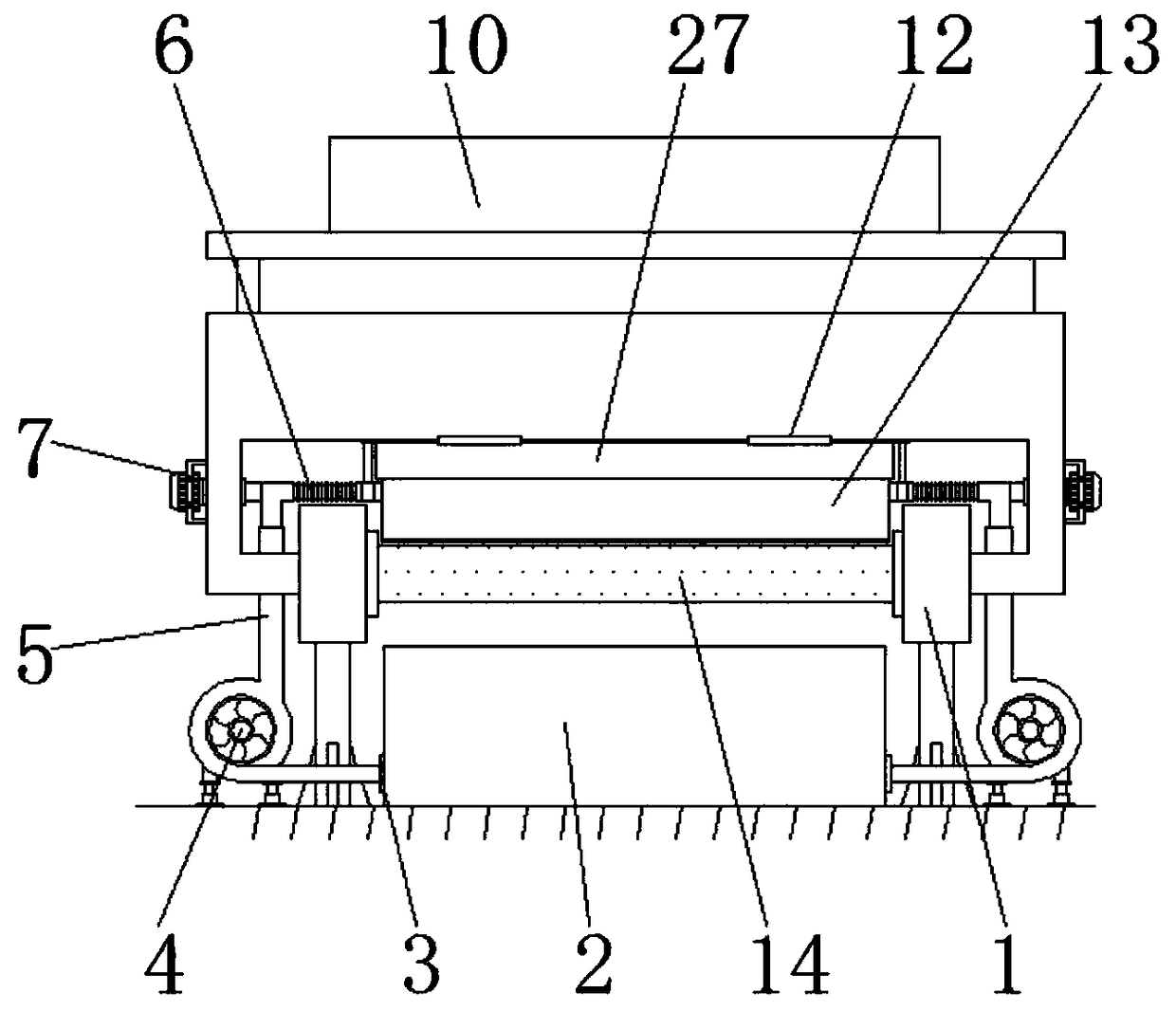

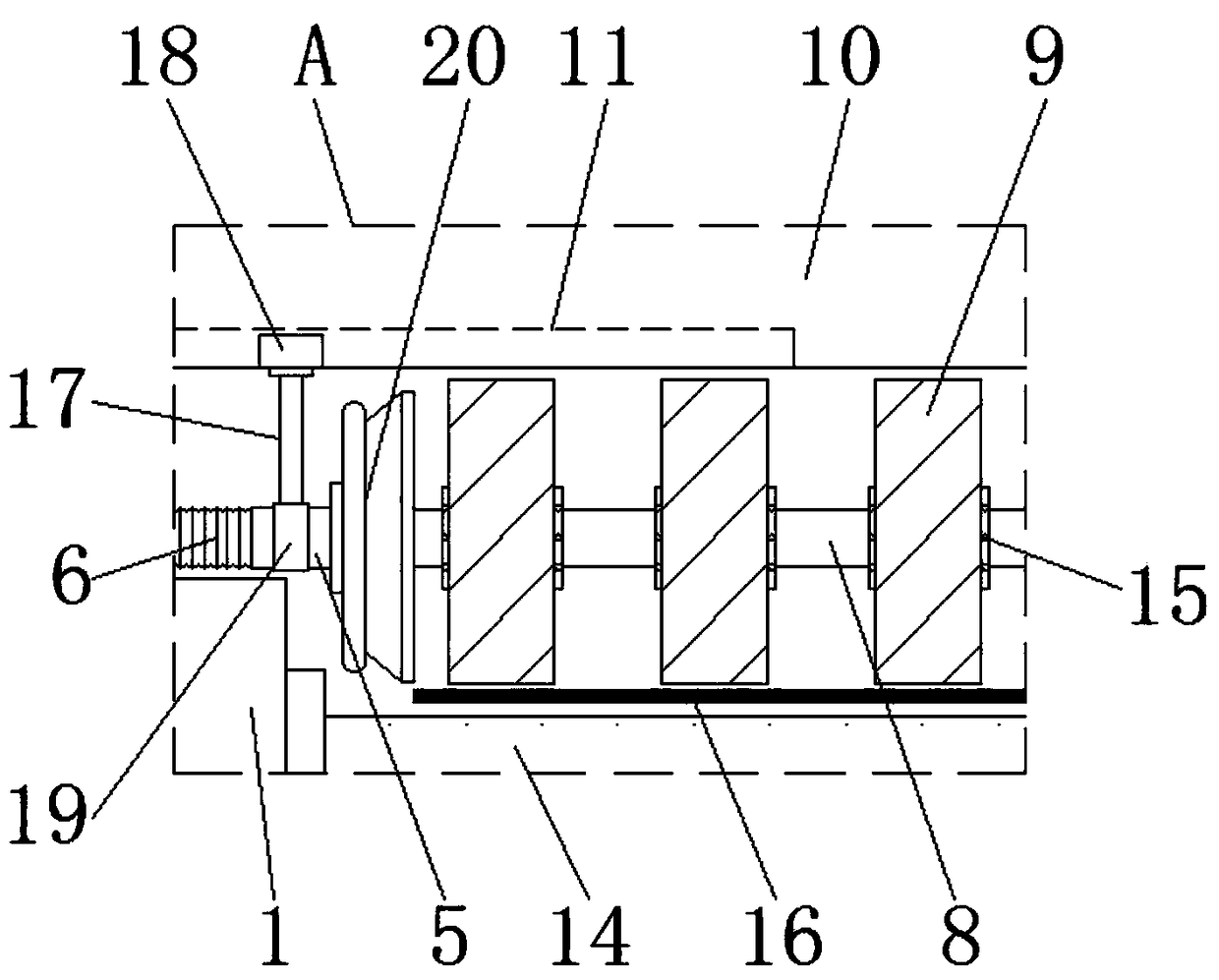

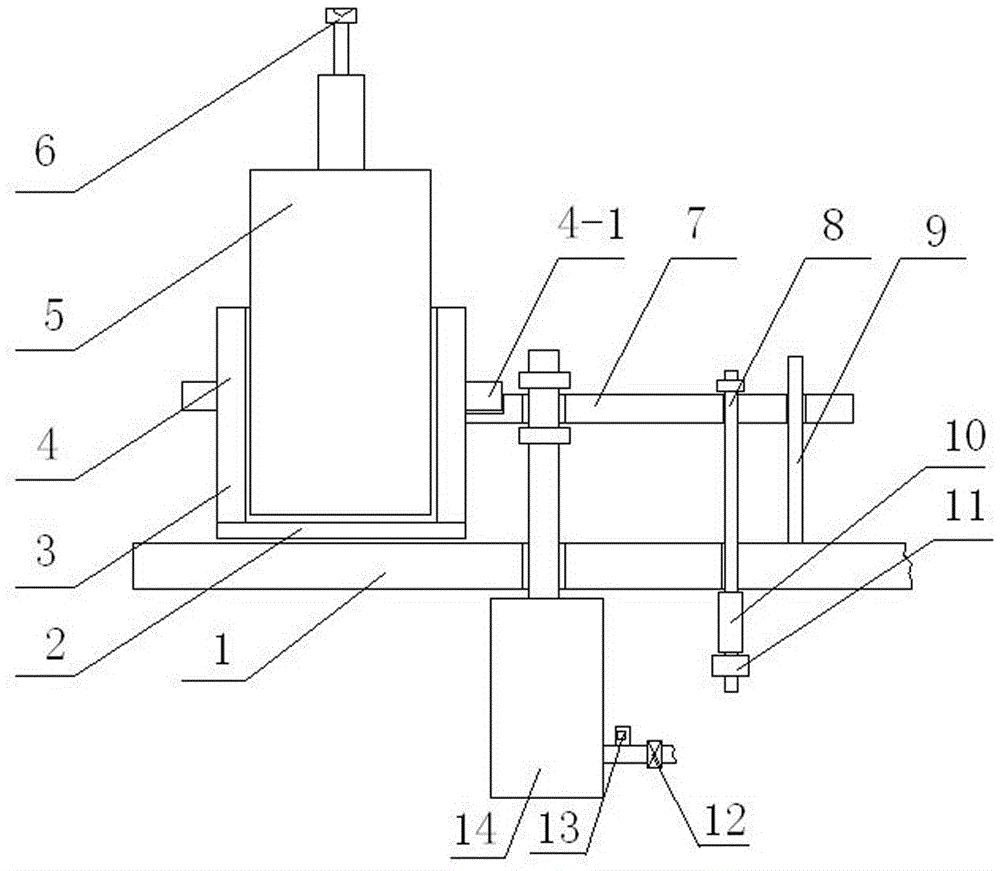

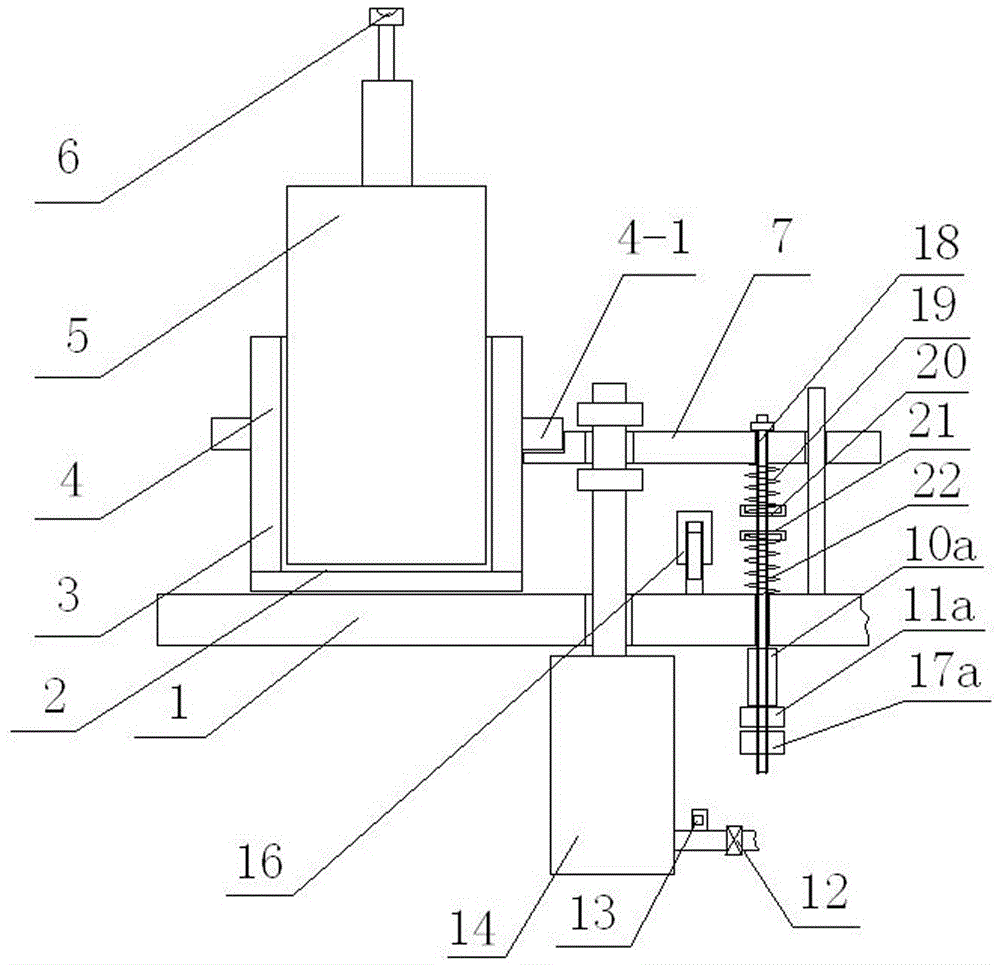

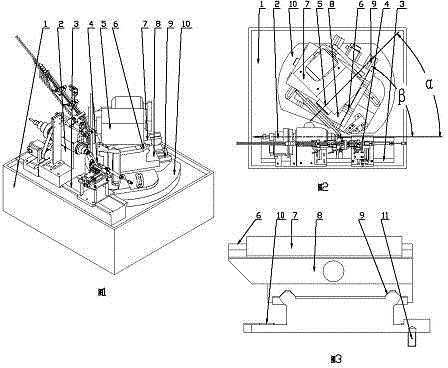

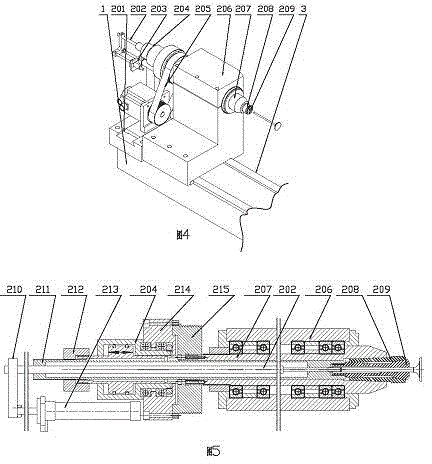

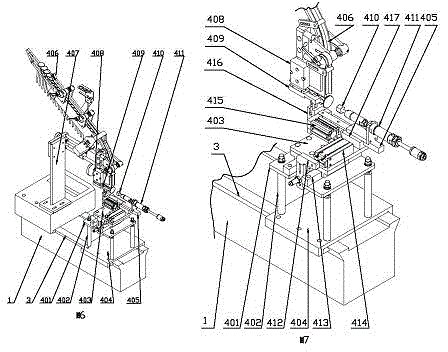

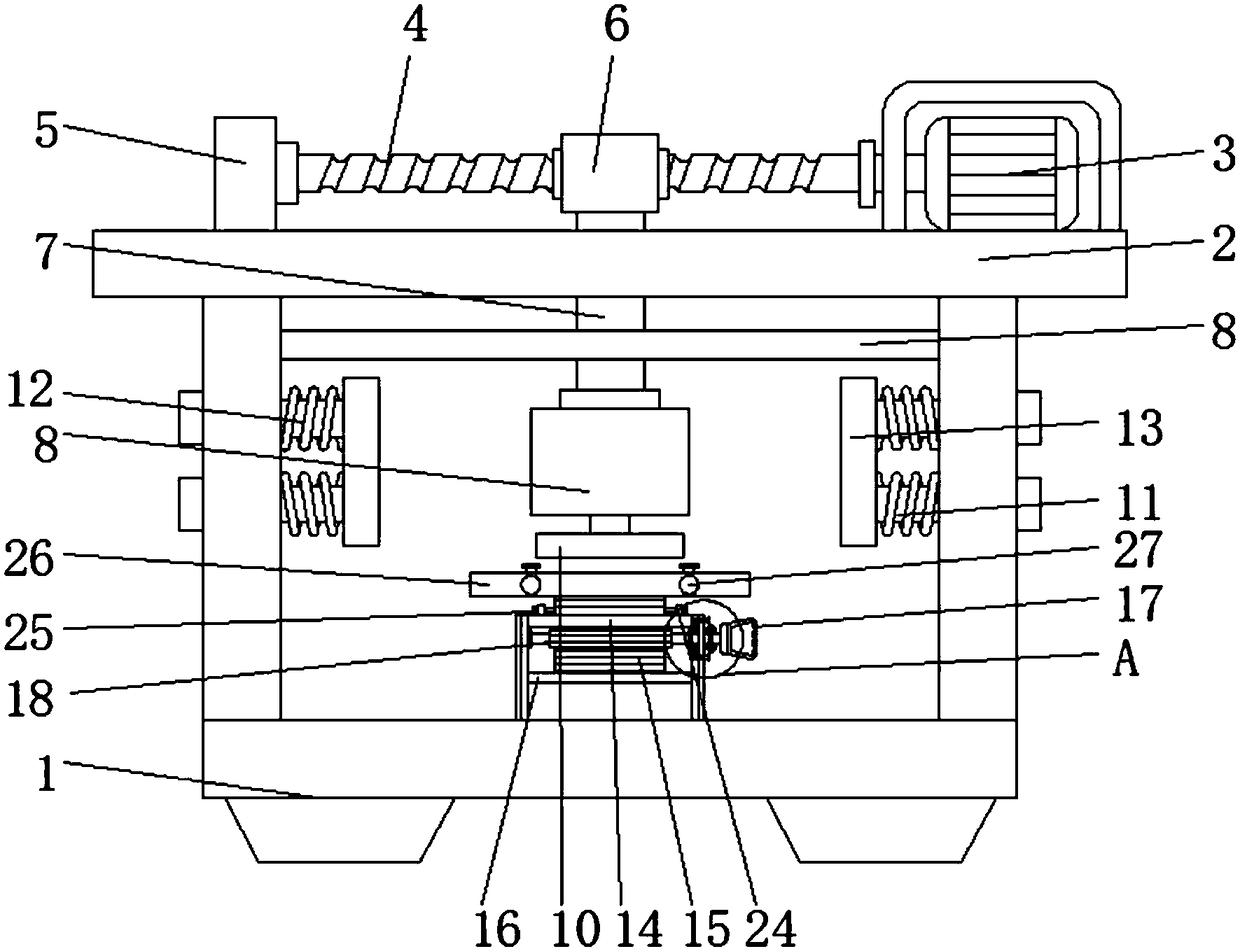

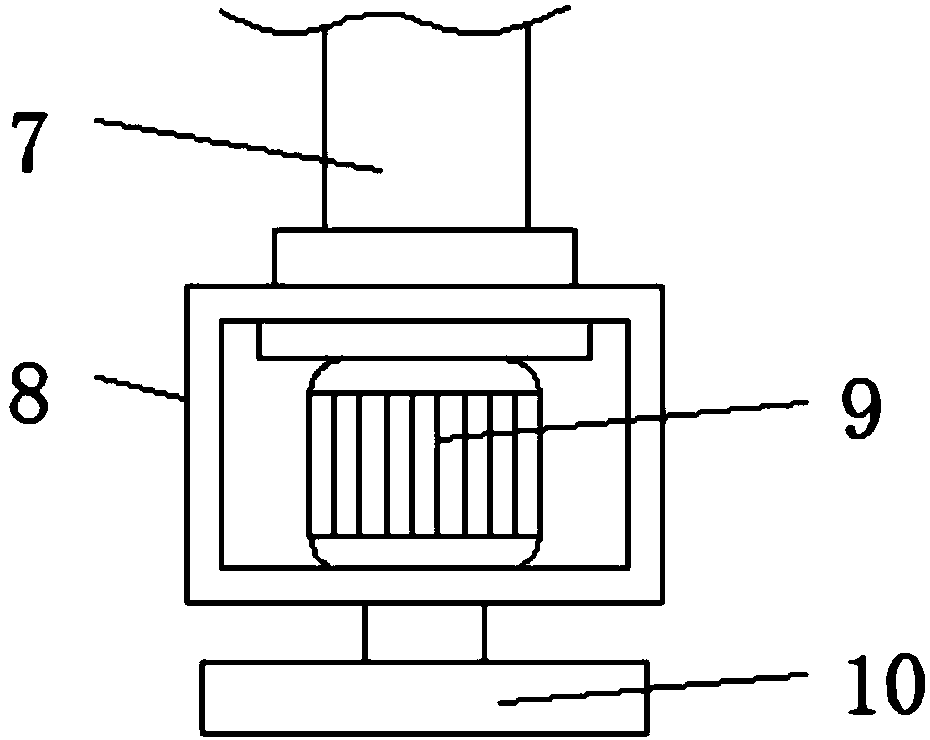

Efficient double-end-face grinding machine and control method thereof

ActiveCN106363475AHigh finish precisionHigh degree of automationGrinding carriagesGrinding drivesMotor driveControl system

The invention relates to an efficient double-end-face grinding machine and a control method thereof. The efficient double-end-face grinding machine comprises a machine body, tool feeding devices, a contact type measuring device and a feeder. Each tool feeding device comprises a spindle, a grinding wheel, a spindle motor and a tool feeding motor, wherein the spindle motor drives the spindle to drive the grinding wheel to rotate, and the tool feeding motor drives the spindle to move left and right. The contact type measuring device comprises a measuring head vertical-moving cylinder and a contact type measuring head, and the measuring head vertical-moving cylinder drives the contact type measuring head to move vertically. The feeder comprises a magnetic reciprocating workbench and a feeding motor. A five-axis control system is adopted by the efficient double-end-face grinding machine, automatic grinding, automatic compensation and automatic measuring of double end faces are achieved, coarse and fine machining and automatic measuring on the periphery of a mold core can be efficiently completed during one-time clamping of the ceramic mold core, production efficiency for the mold core is improved, and the precision and smoothness of the mold core are improved.

Owner:FOSHAN SHIWAN CERAMICS IND RES INST CO LTD

Steel plate machining rust removal device capable of collecting waste scraps conveniently

InactiveCN108687634AEasy to collectAvoid random flyingGrinding carriagesGrinding drivesFixed frameArchitectural engineering

Owner:芜湖良匠机械制造有限公司

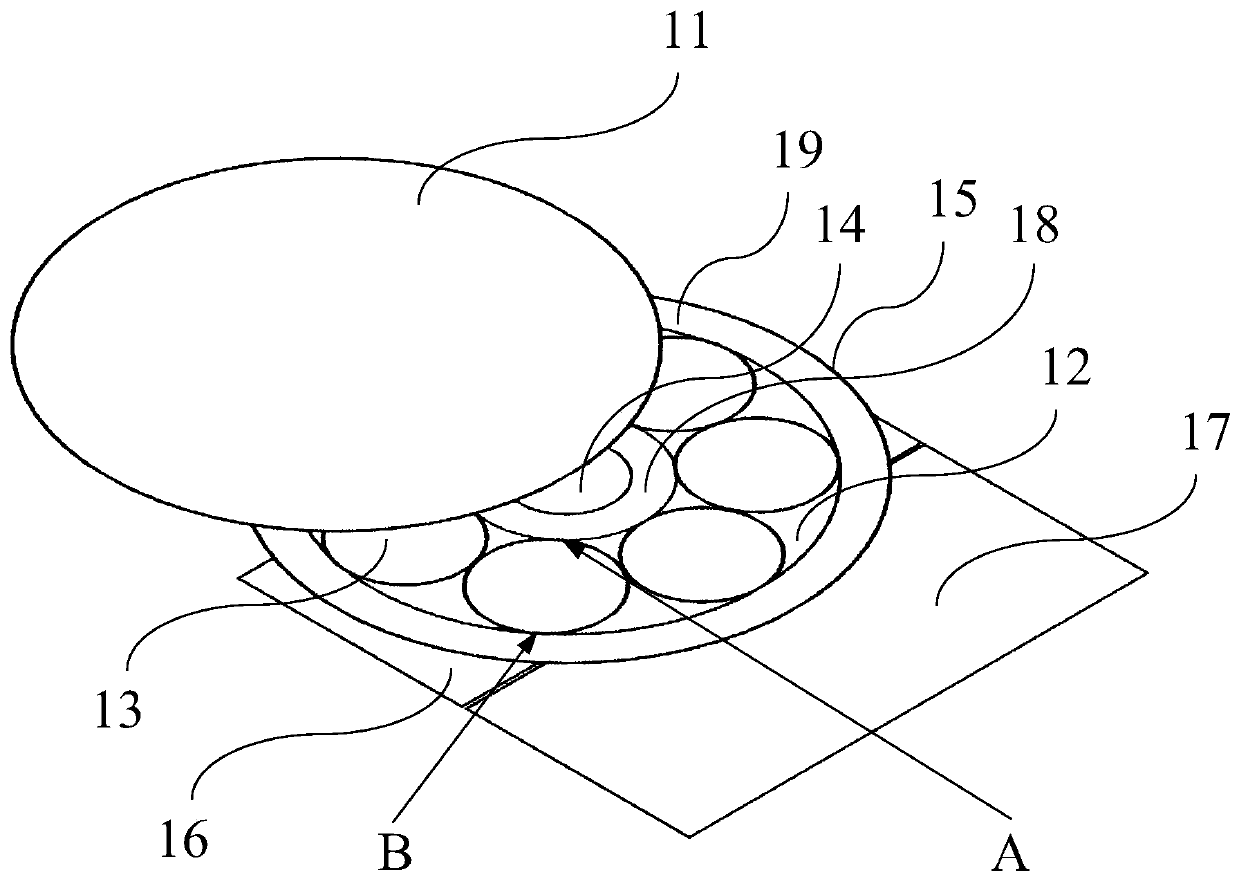

Machine for blasting abrasives

ActiveUS20120252327A1Simple structureSimple and novel structureRevolution surface grinding machinesGrinding drivesEngineeringAbrasive

The object of the present invention is to provide a machine for blasting abrasives that has a simple structure and that solves the problem of abrasives falling when the door for the gateway for the work is opened or closed. The machine for blasting abrasives comprises a chamber 11 for processing, a nozzle 13 that is provided within the chamber 11 for shooting the abrasives (shots) S onto the work W, and a jig 15 for holding the work W at a position facing the nozzle 13. A gateway 17 with a door 19 is formed in the ceiling 11a of the chamber 11. The size of the gateway 17 enables the work W to protrude from the chamber 11 by means of the jig 15 at a position corresponding to the jig 15 that is linearly moving up and down. The door 19 is provided within the chamber 11 so as to seal the gateway by linearly moving up and down and so as to create a vacant plane on the gateway for passing the work by horizontally moving.

Owner:SINTOKOGIO LTD

Automatic grinding device for short steel bars

InactiveCN109227288APrevent slidingPrevent rotationGrinding drivesGrinding feed controlArchitectural engineeringRebar

The invention discloses an automatic grinding device for short steel bars. The automatic grinding device comprises a base, wherein the left side of the upper portion of the base is provided with a positioning assembly, a sliding assembly is arranged under the positioning assembly, the positioning assembly is slidingly connected with the base through the sliding assembly, the right side of the upper portion of the base is provided with a grinding assembly, and the outer side of the base is provided with a central control module. The problem is solved that after steel bars are placed for a period of time, certain rust unavoidably exists on the surfaces, so steel bar grinding is needed, a worker needs to hole one end of each steel bar in the grinding process and then pull out the steel bar from the other end after the steel bar penetrates through the grinding device, the method needs manual control, unthorough surface grinding is possible if steel bar pulling is too quick, excessive grinding is also possible if the steel bar pulling is slower, the steel bar pulling is very strenuous, and large body burden is brought to the operator.

Owner:RUIXIONG METAL PROD (WUHU CO LTD

Multi-station surface grinding machine

InactiveCN108942452AEasy to move up and downHeight adjustableGrinding drivesGrinding work supportsHydraulic cylinderLED display

Owner:XIANGYANG TRADETOOL AUTOMOBILE PARTS

Chain transmission mechanism for grinding machine

Owner:芜湖中驰机器人科技有限公司

Friction rust removal device for inner wall and outer wall of steel pipe

Owner:浦江县旭星机械科技有限公司

Steel ball grinding device

Owner:山东菏益科技有限公司

Mechanical workpiece grinding equipment with splash-proof waste residue collecting structure

Owner:绍兴宏通机械有限公司

Burr cutting equipment for rubber processing

InactiveCN112060433AImprove sanding effectContact strength is normalEdge grinding machinesGrinding drivesElectric machineryStructural engineering

Owner:成都喃呓商贸有限公司

Full-automatic flat grinder

ActiveCN110640564AAchieve recyclingWork environment hygieneGrinding drivesGrinding work supportsEngineeringCooling fluid

Owner:江苏锋宝冶金设备有限公司

Steel pipe rust removal device

PendingCN108789101AAdjust effective lengthChange spacingGrinding carriagesGrinding drivesArchitectural engineeringDrive motor

Owner:HAIYAN HUITONG INTELLIGENT FURNITURE CO LTD

Plastic part processing mechanism

ActiveCN112873392ARealize moving forwardImprove adaptabilityGrinding drivesPlastic recyclingStructural engineeringMechanical engineering

The invention discloses a plastic part processing mechanism, and belongs to the field of rubber part processing. The plastic part processing mechanism comprises a bending frame, wherein the bending frame is fixedly provided with four ground feet, the ground feet are uniformly arranged at the bottom end of the bending frame, the lower part of the side wall of the bending frame is provided with a passing opening and a pushing opening, the side wall of the bending frame is provided with an inclined plate pushing frame, the upper end and the lower end of the inclined plate pushing frame are fixedly connected with the side wall of the bending frame through compression springs correspondingly, and a plane shaft seat is fixedly installed at the top end of the bending frame. The plastic part processing mechanism can realize automatic blanking of plastic parts.

Owner:SHANGRAO MEIYUDA OPTICAL INSTR CO LTD

Grinding machine special for conical surface of valve

ActiveCN104128863AGuaranteed structural spaceGrind evenlyGrinding carriagesRevolution surface grinding machinesEngineeringGrinding wheel

Owner:江苏吉斯特科技有限公司

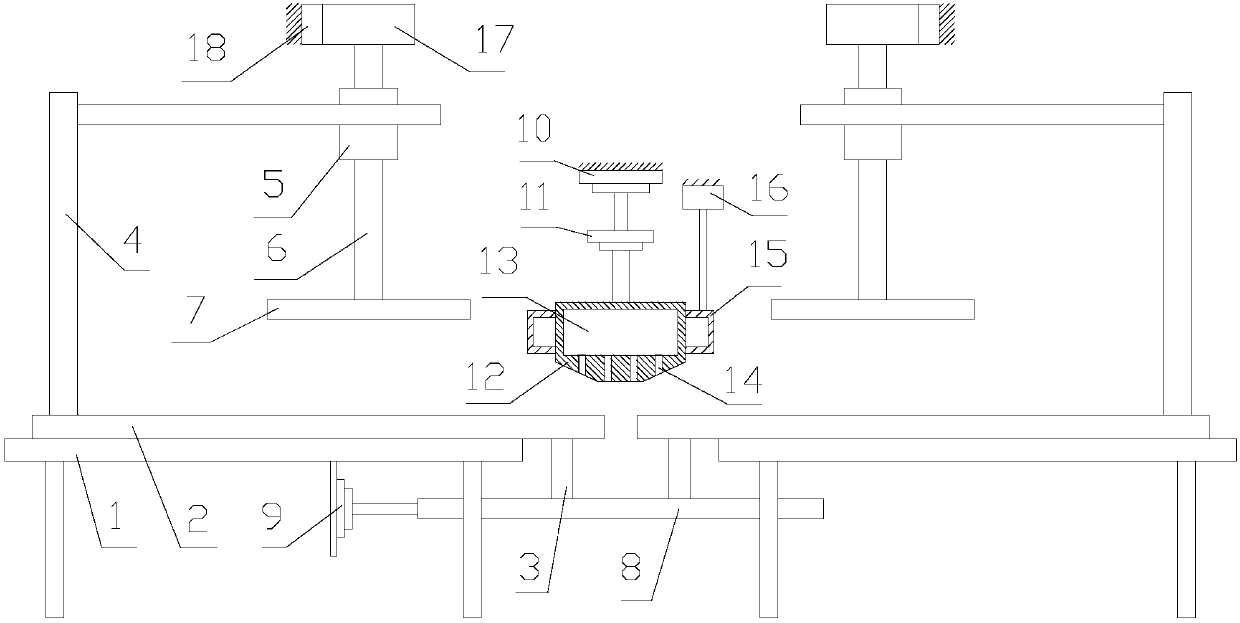

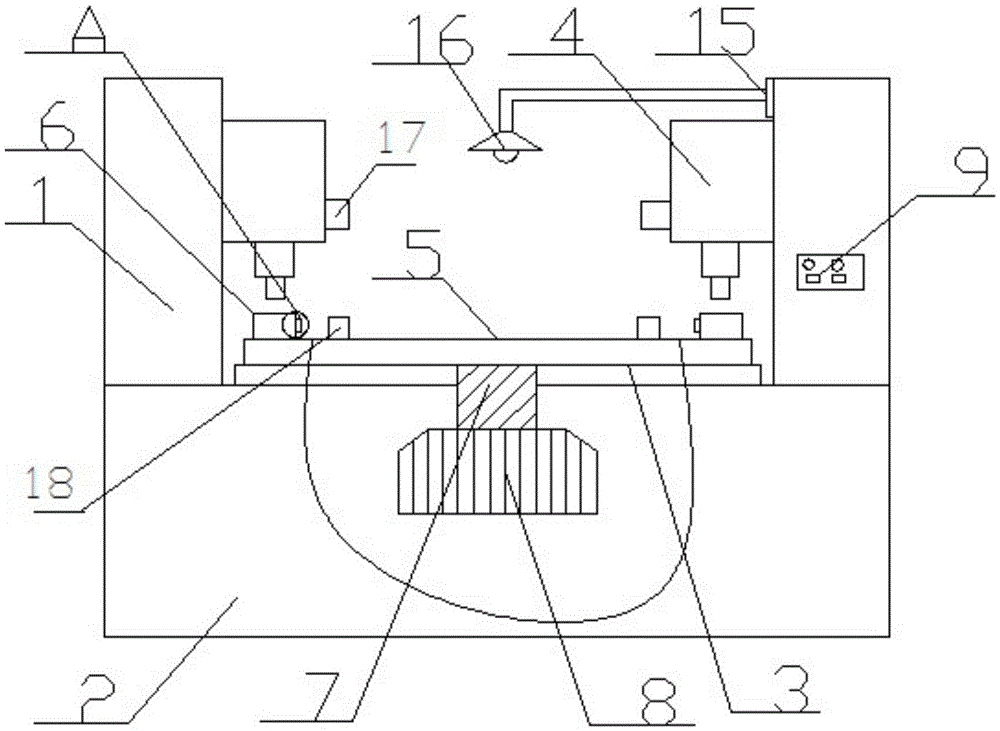

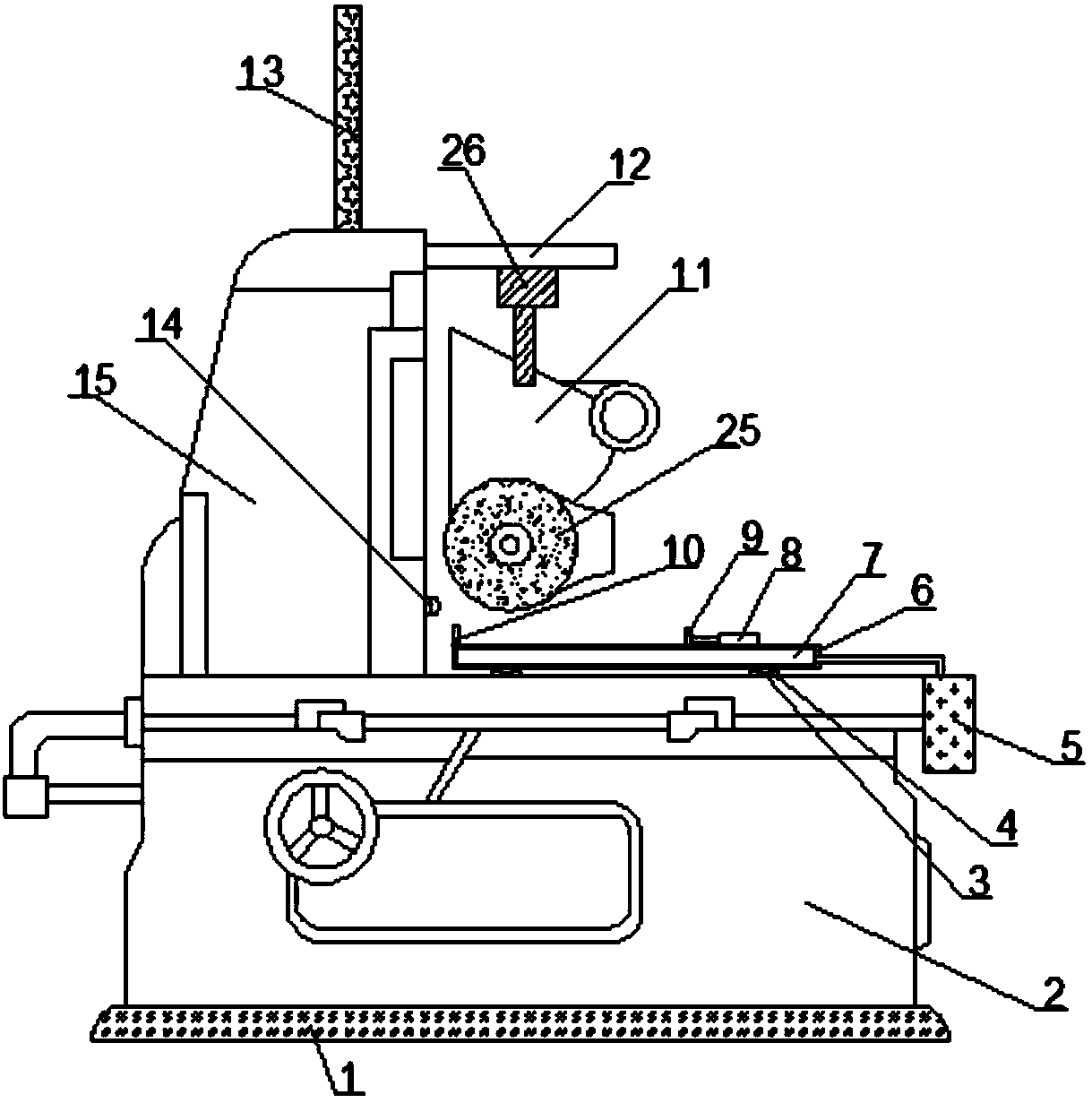

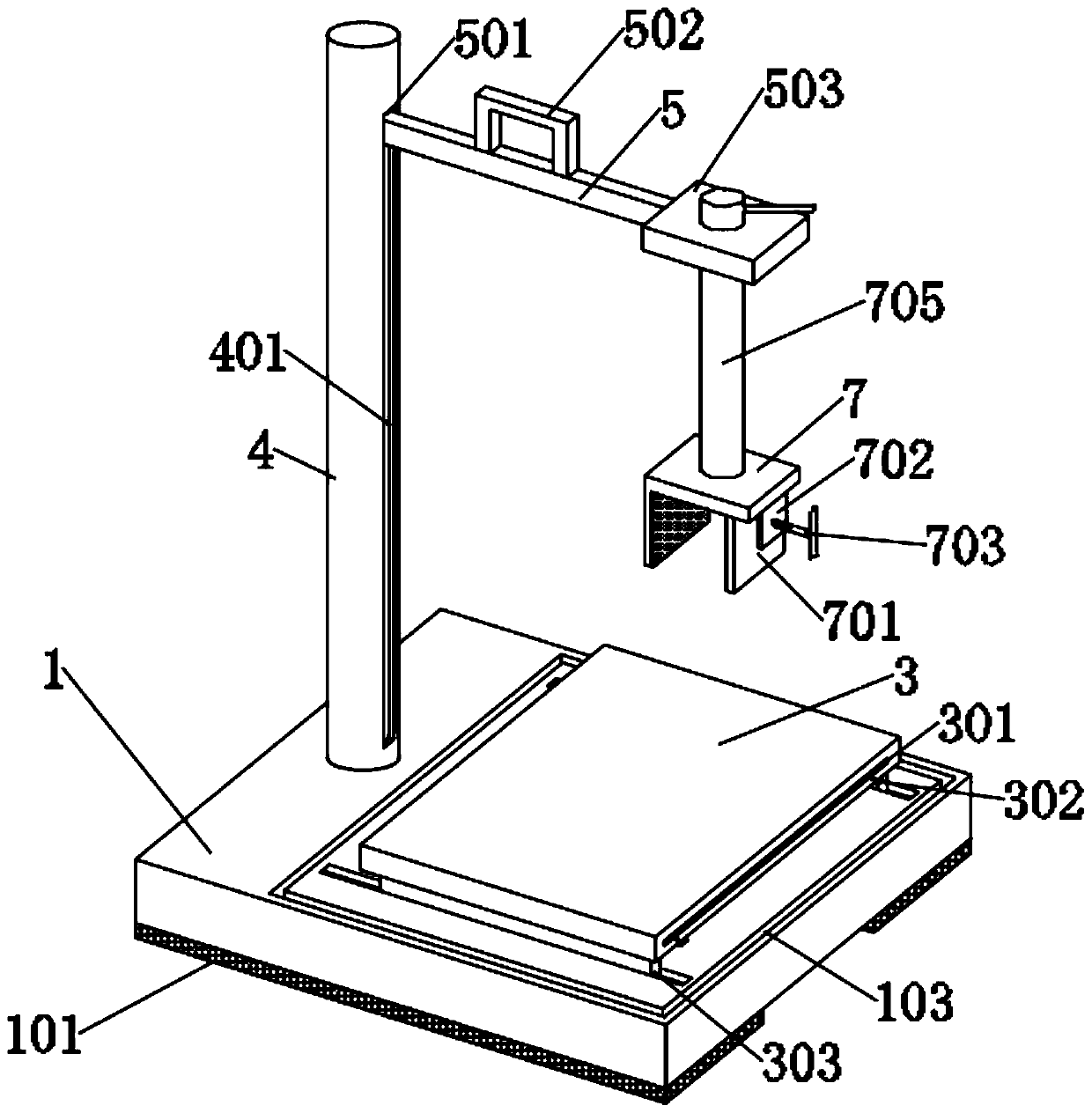

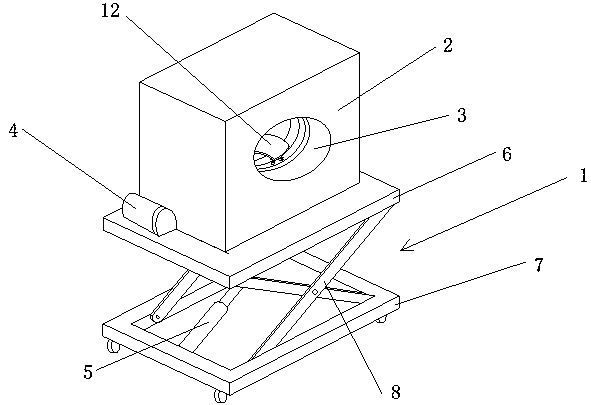

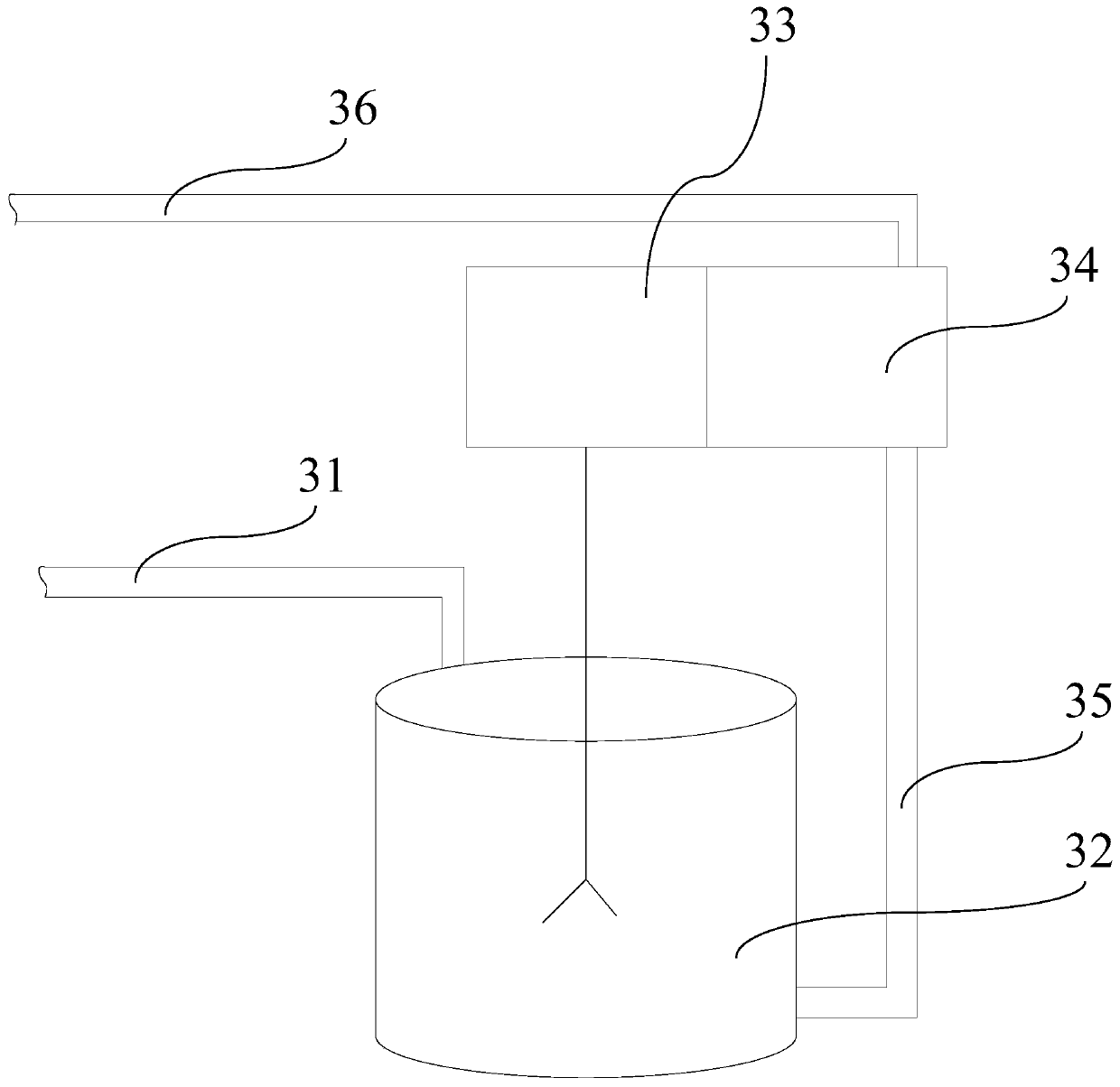

Potentiometer polishing equipment and polishing method

ActiveCN107984371ASmooth surface requires uniformityIngenious structurePolishing machinesGrinding drivesElectric machineEngineering

The invention relates to potentiometer polishing equipment, and relates to the technical field of grinding processing. The potentiometer polishing equipment mainly comprises a polishing wheel power mechanism, a rotating mechanism, a feeding mechanism and a straight-line motion part, wherein the straight-line motion part and the polishing wheel power mechanism are mounted on an equipment deck plate(52); the rotating mechanism and the feeding mechanism are mounted on the straight-line motion part; a servo motor B (28) of the straight-line motion part is used for driving the straight-line motionunit (31), so that the whole rotating mechanism and the whole feeding mechanism are in transverse motion; a potentiometer (1) is in longitudinal feeding by the feeding mechanism to compensate the abrasion of a polishing wheel (41); and the polishing wheel is driven by a motor (45); and the clamping of the potentiometer (1) is realized by the rotating mechanism through the control of a handle mechanism seat (12). The potentiometer polishing equipment disclosed by the invention is ingenious in structure and simple to operate; requirements that the polishing angle is adjustable, the rotating frequency is adjustable, the polishing length is adjustable and the accuracy is high can be met; polishing operation can be efficiently performed; and after the potentiometer is polished, the surfaces ofthe obtained potentiometer are smooth and uniform, and the resistivity of the surfaces is the same.

Owner:GUIYANG WANJIANG AVIATION ELECTROMECHANICAL

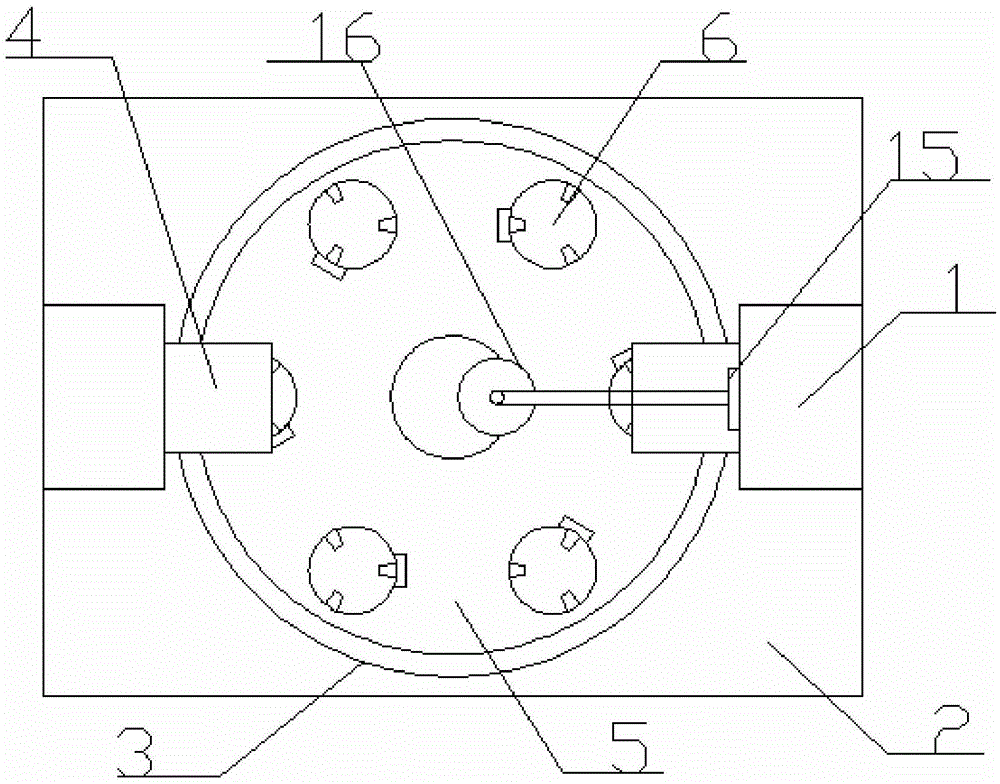

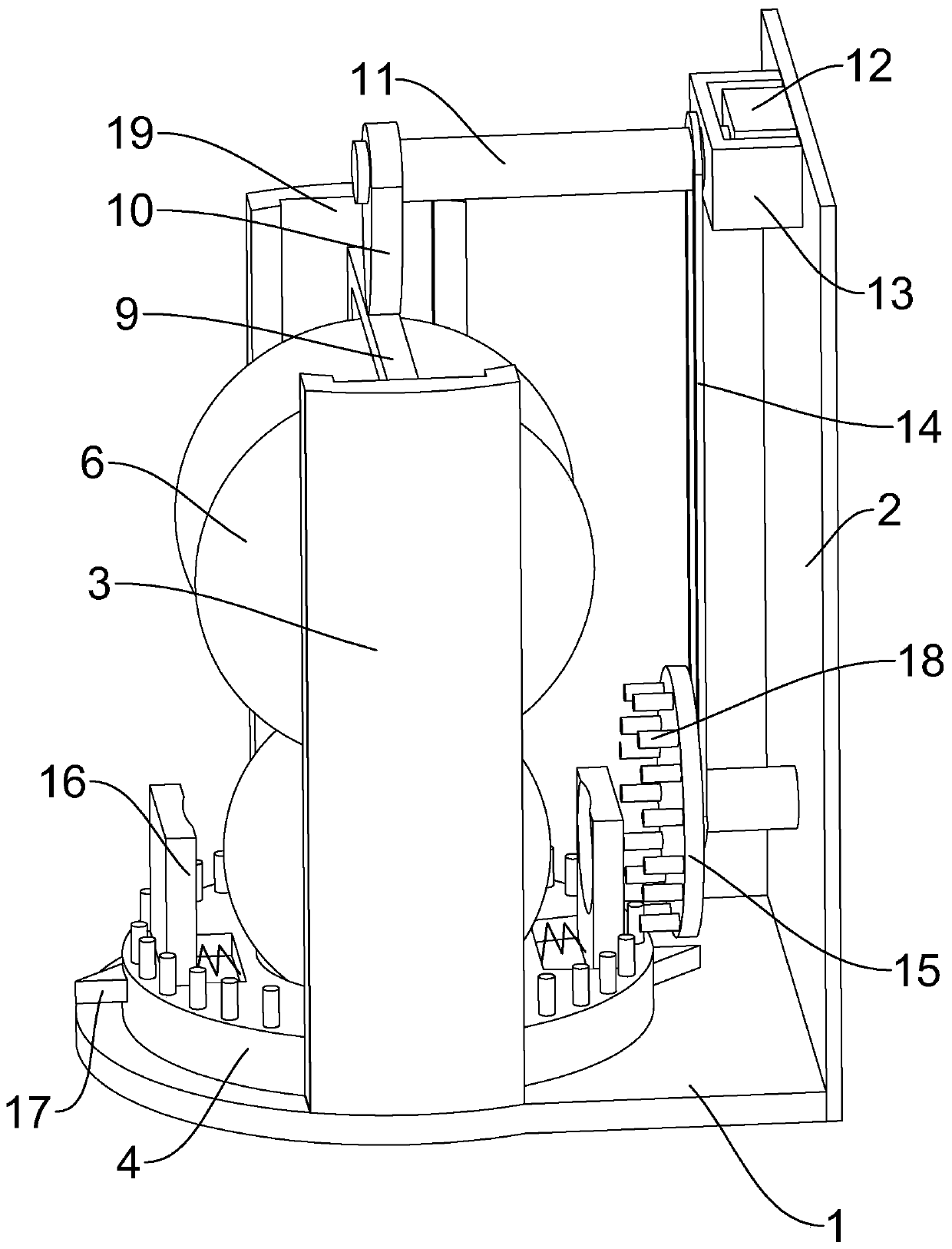

Two-sided grinding machine and two-sided grinding method

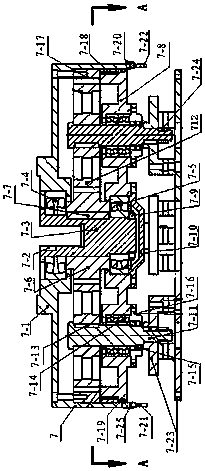

ActiveCN110640621AImprove machining accuracyImprove flatnessGrinding drivesLapping machinesGear driveGear wheel

Owner:HC SEMITEK ZHEJIANG CO LTD

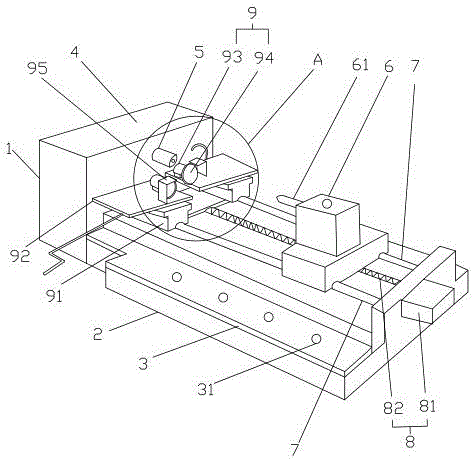

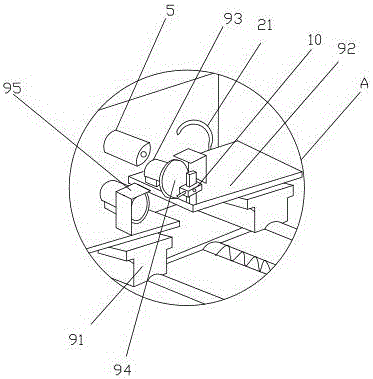

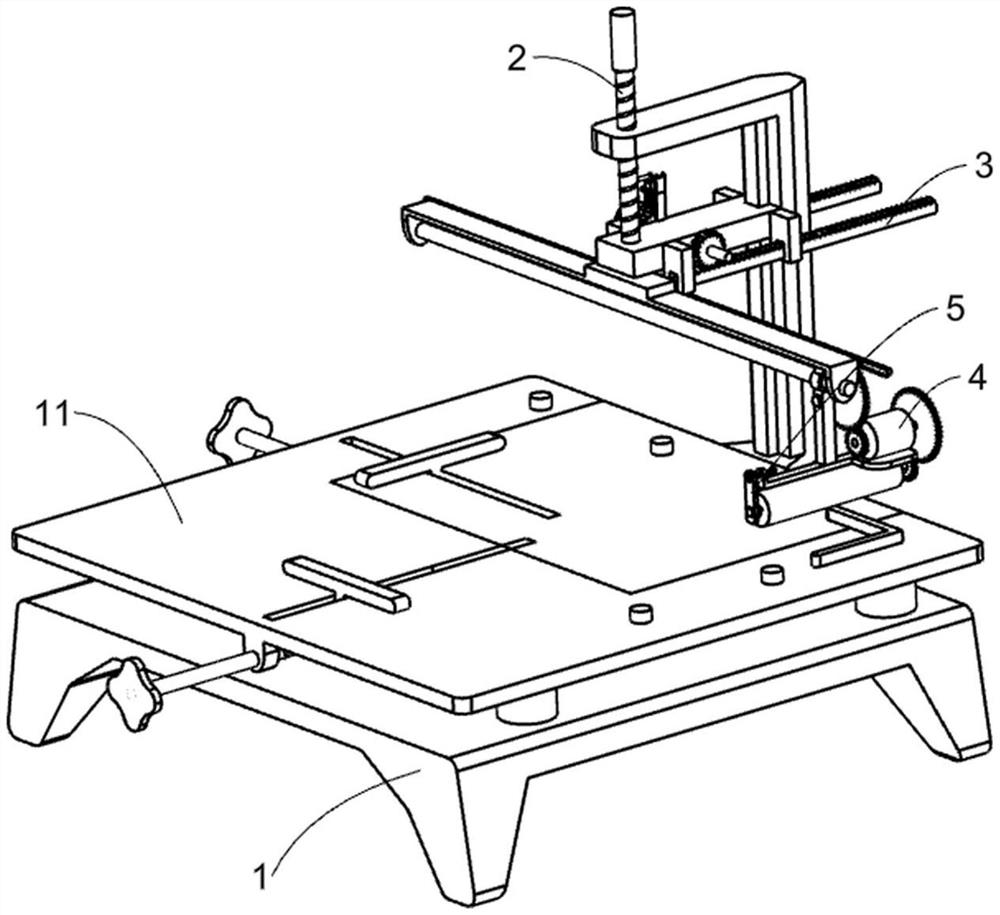

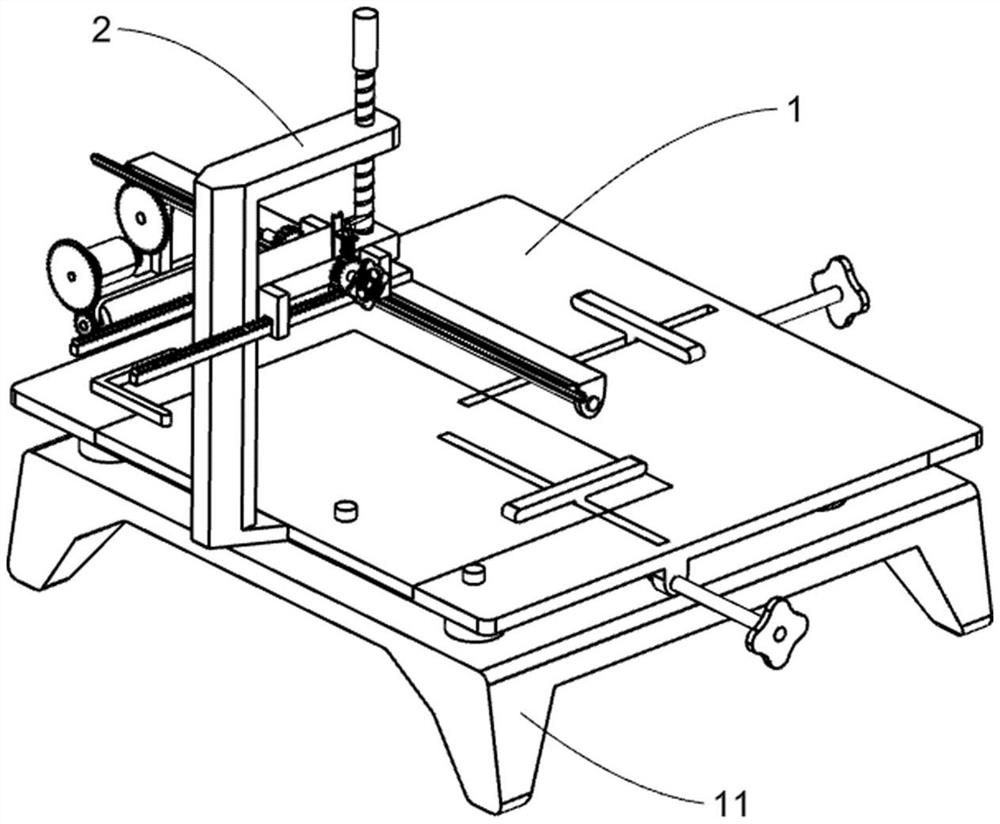

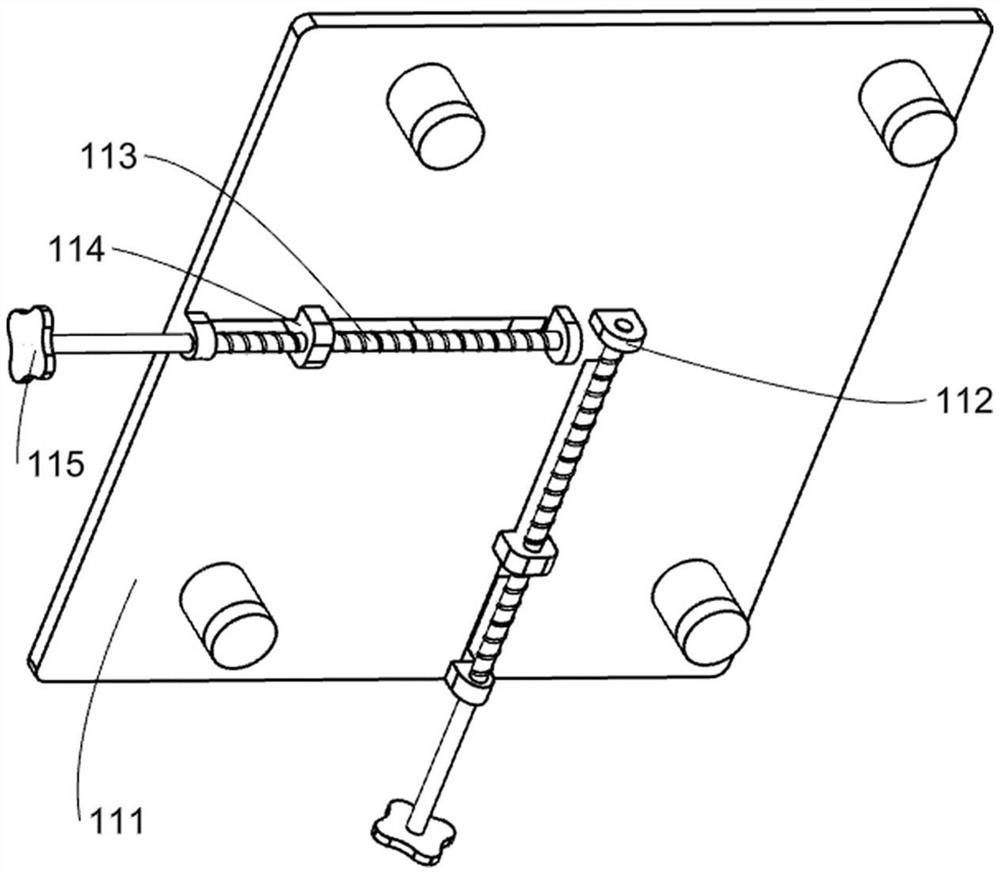

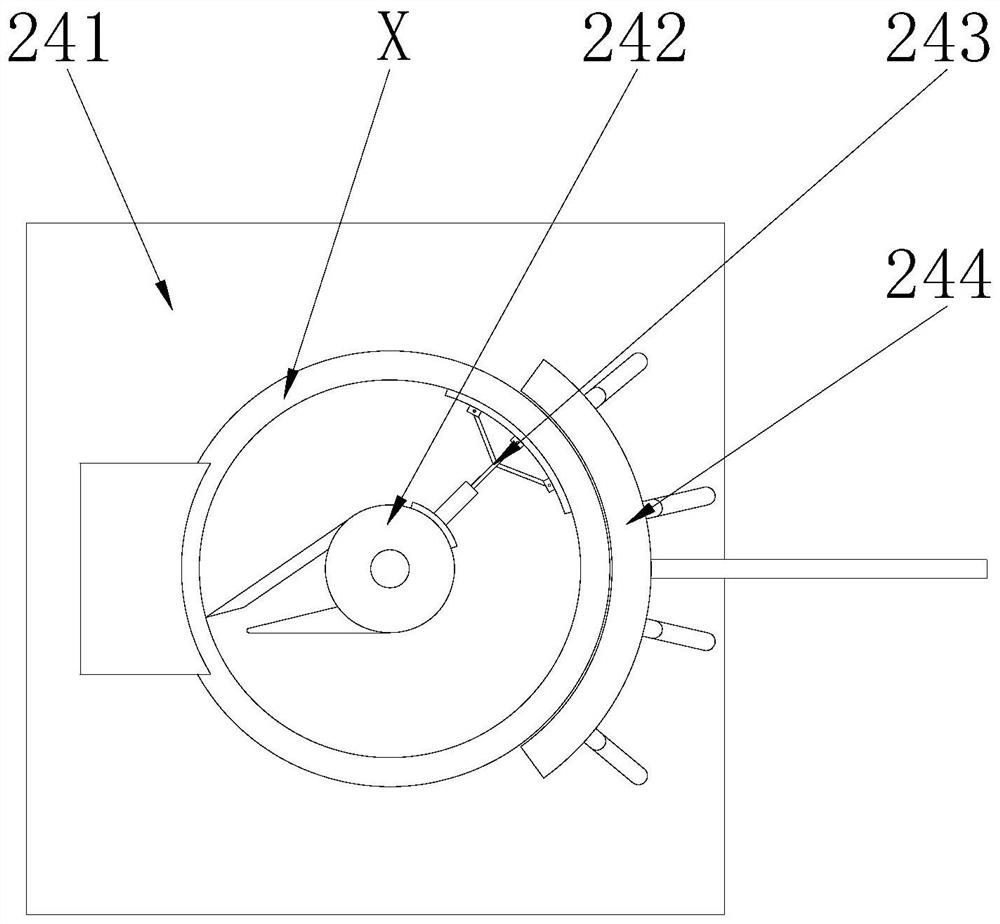

Multi-function grinding filing machine head and grinding filing machine

PendingCN109834542ABest orientation adjustmentAdapted to grinding tasksEdge grinding machinesGrinding drivesEngineeringMachine

The invention provides a multi-function grinding filing machine head and a grinding filing machine, and relates to the field of grinding equipment. The grinding problems that the grinding angle adjustment effect of an existing rotary support is not ideal and the existing rotary support is not suitable for longitudinal line welding inside and outside the cylinder are solved, the multi-function grinding filing machine head includes a machine seat, a power assembly, and a rotary support; the power assembly is provided with a grinding spindle for mounting and driving grinding tools, and the powerassembly is mounted on the machine seat; the machine seat is mounted on an inner ring of the rotary support, and the machine seat and the power assembly can rotate with rotation of the inner ring of the rotary support; and an axis of the grinding spindle is parallel to the rotary surface of the rotary support, and the grinding task of circumferential and longitudinal weld bead welding inside and outside a cylinder vessel can be adapted; and the multi-function grinding filing machine head of the grinding filing machine can adapt to the grinding task of circumferential and longitudinal weld beadwelding inside and outside of the cylinder vessel.

Owner:张敏

Hardware fitting polishing device

Owner:刘新娟

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap