Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

73results about "Grinding work supports" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

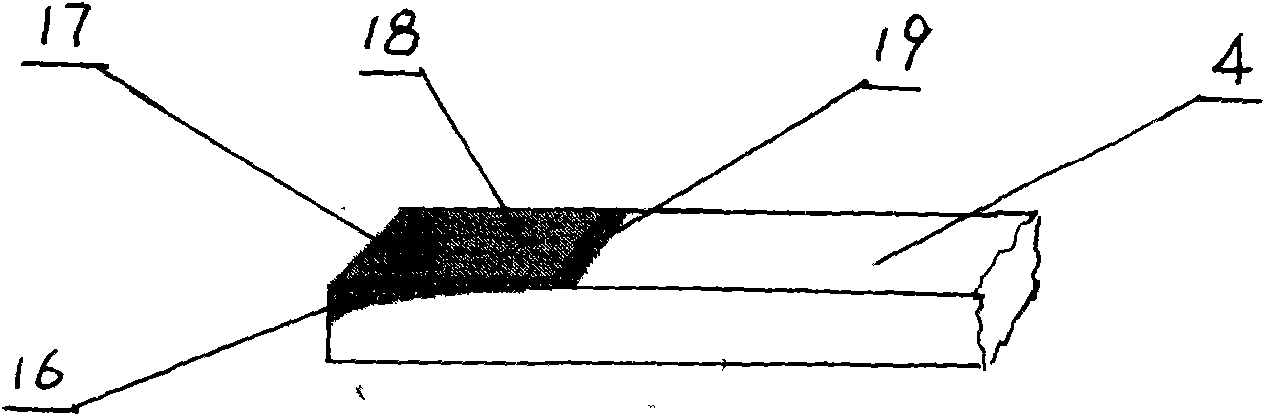

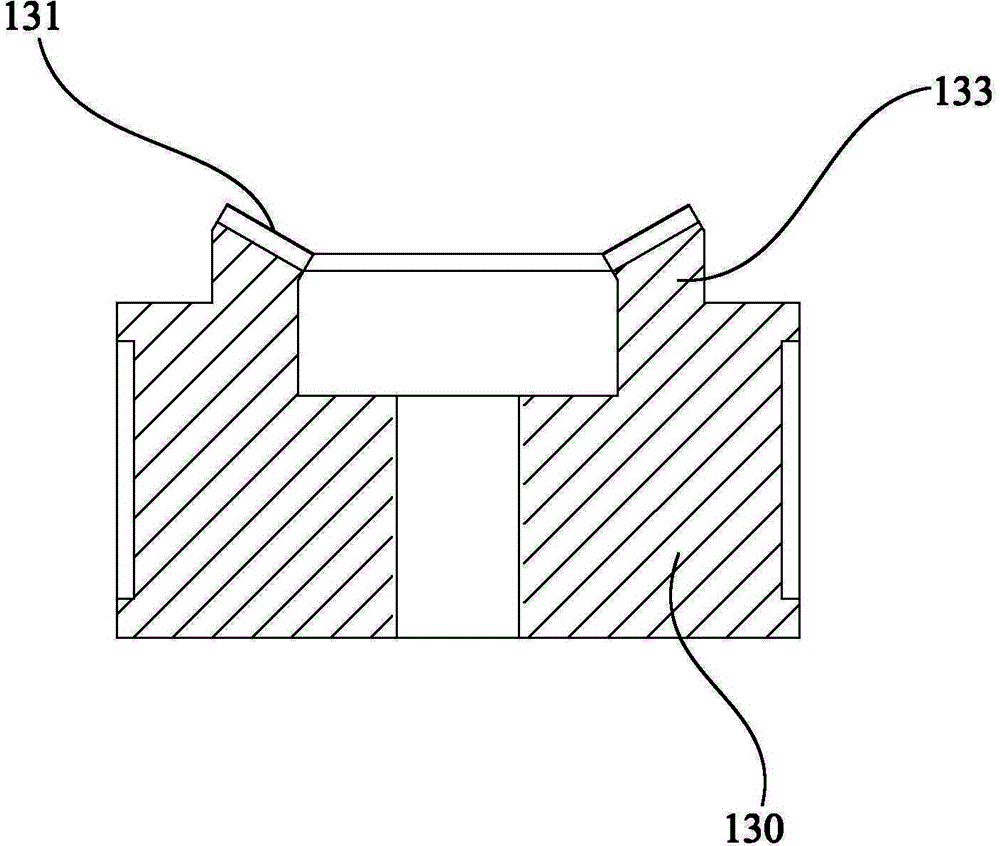

Precision grinding frock clamp, grinding method and product of coating scraper ceramic coating

InactiveCN102059594ALess investmentReduce manufacturing costOther manufacturing equipments/toolsDoctorsCeramic coatingSurface roughness

Owner:SHANDONG UNIV OF SCI & TECH

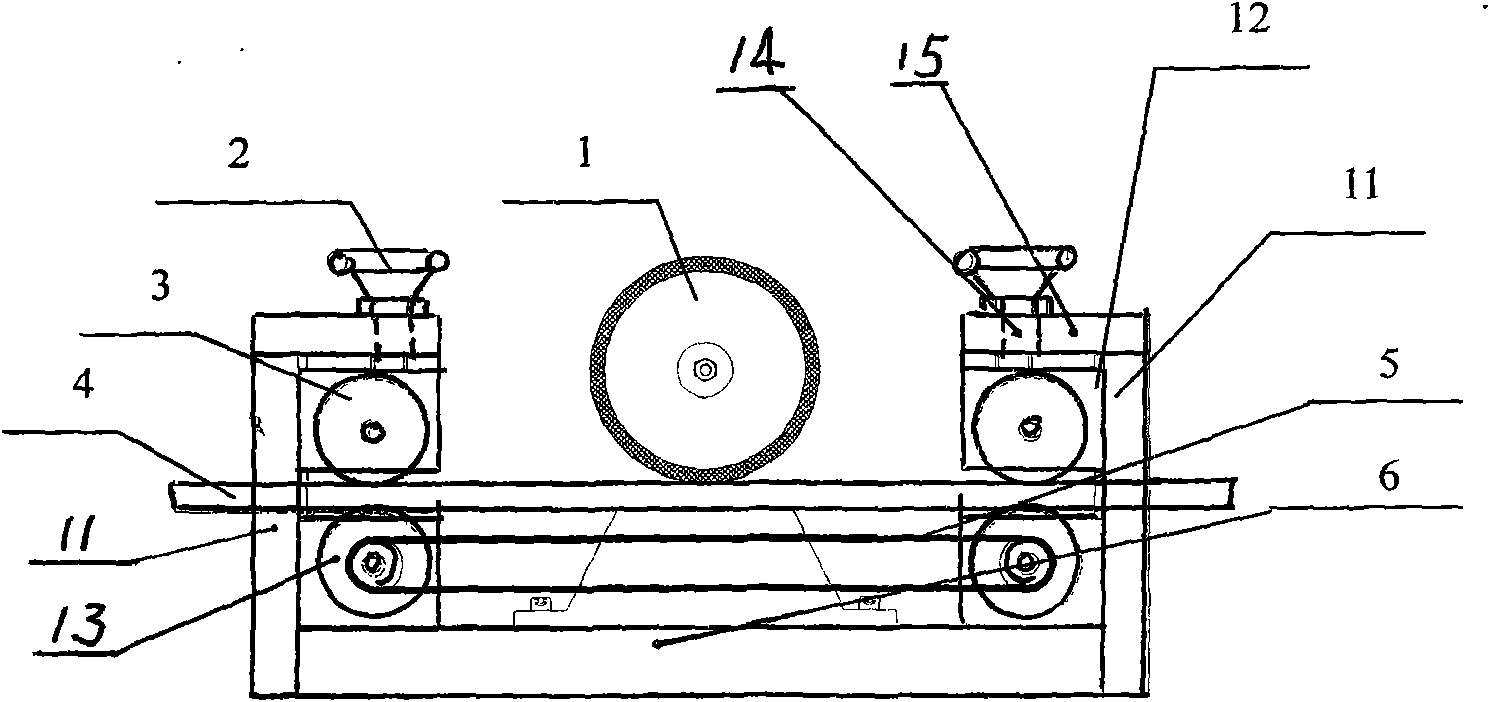

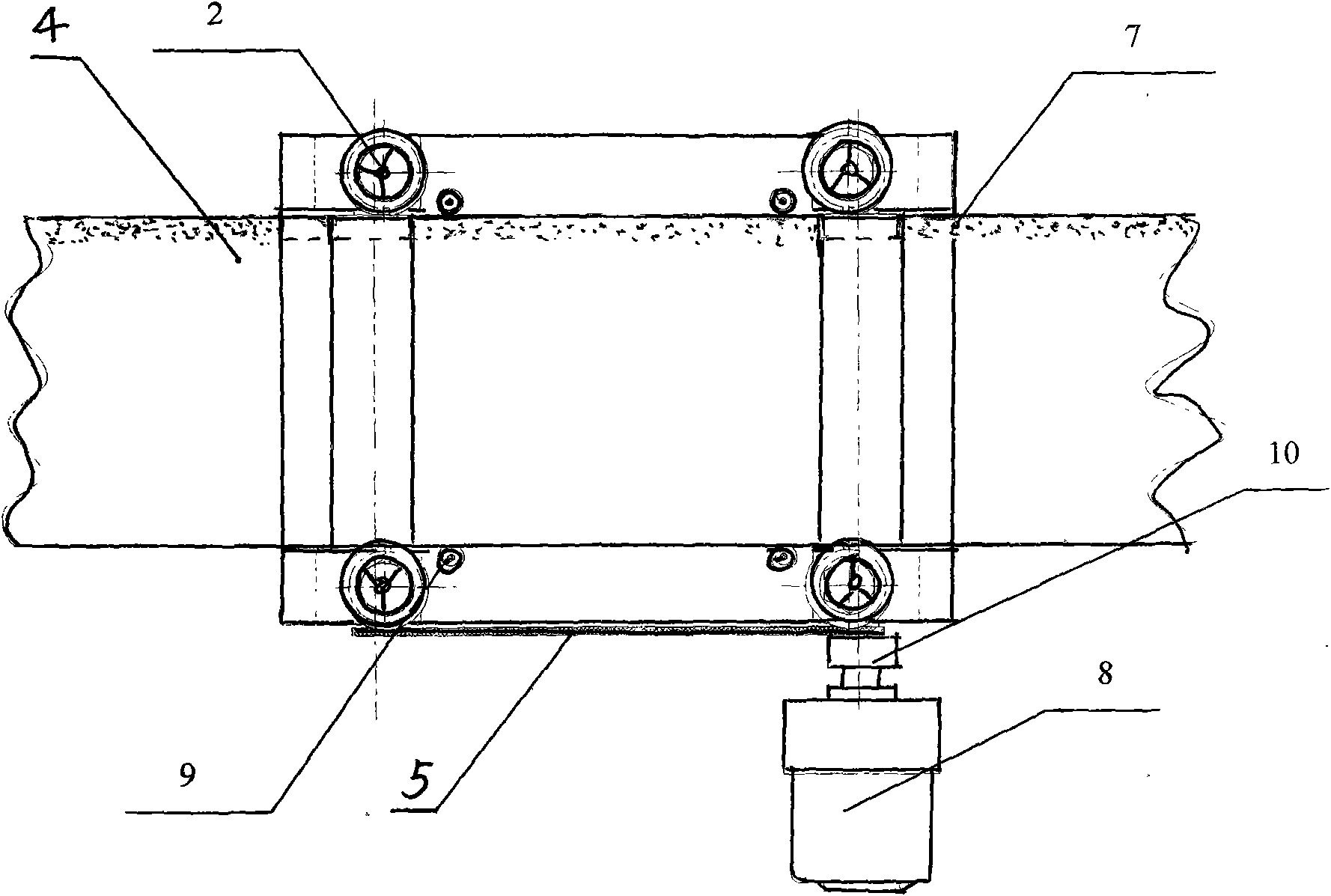

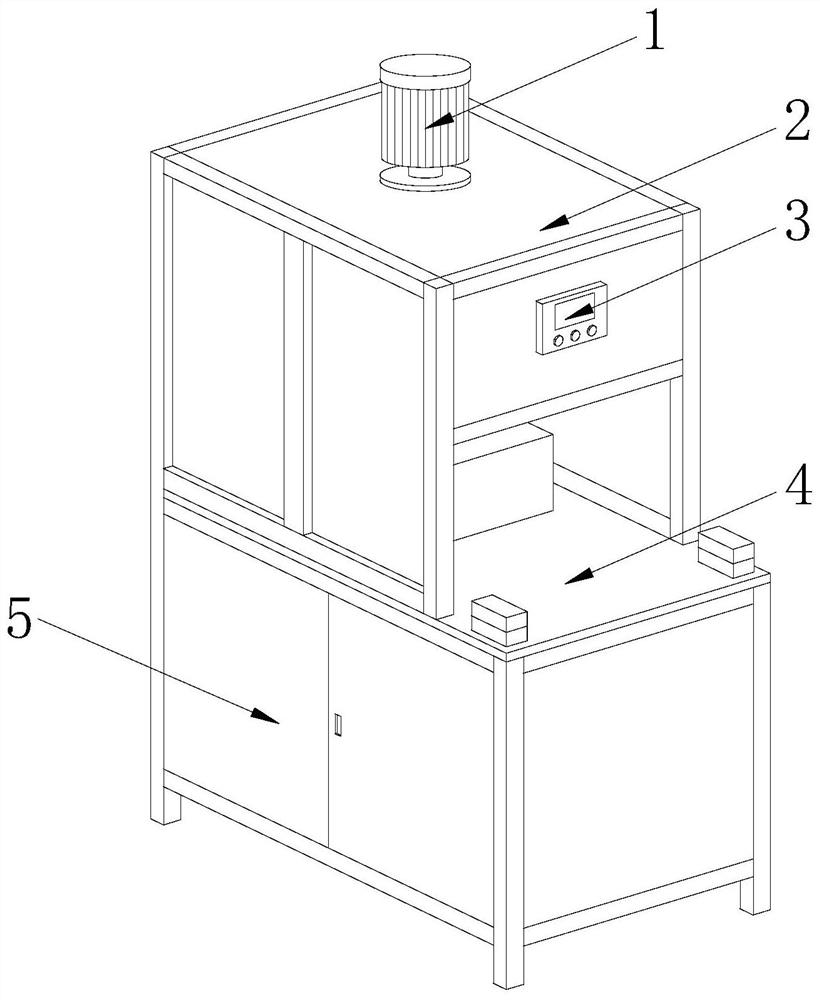

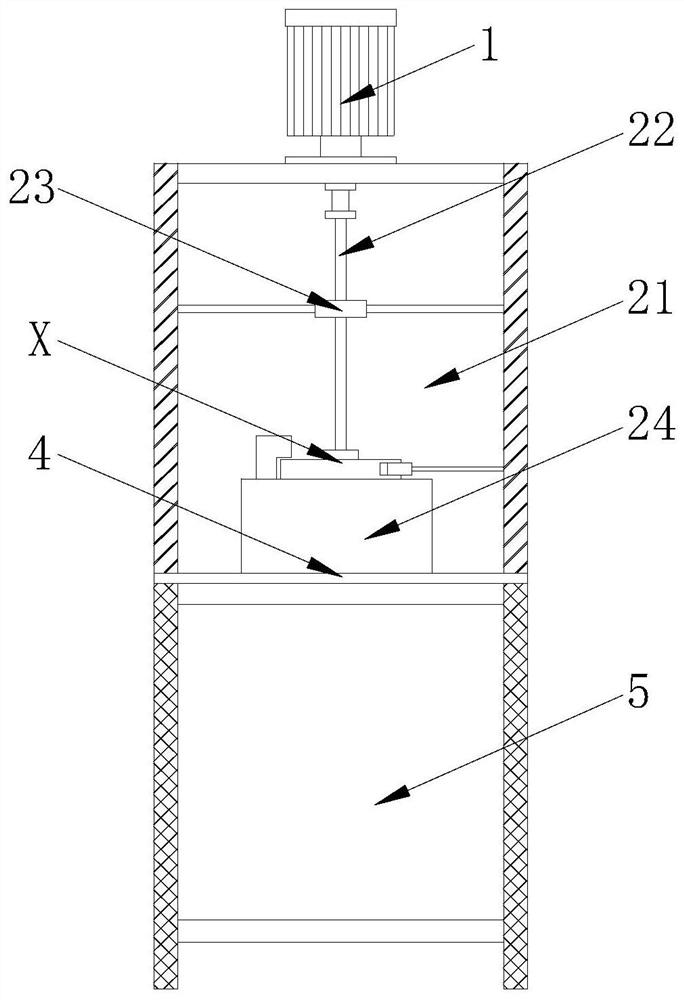

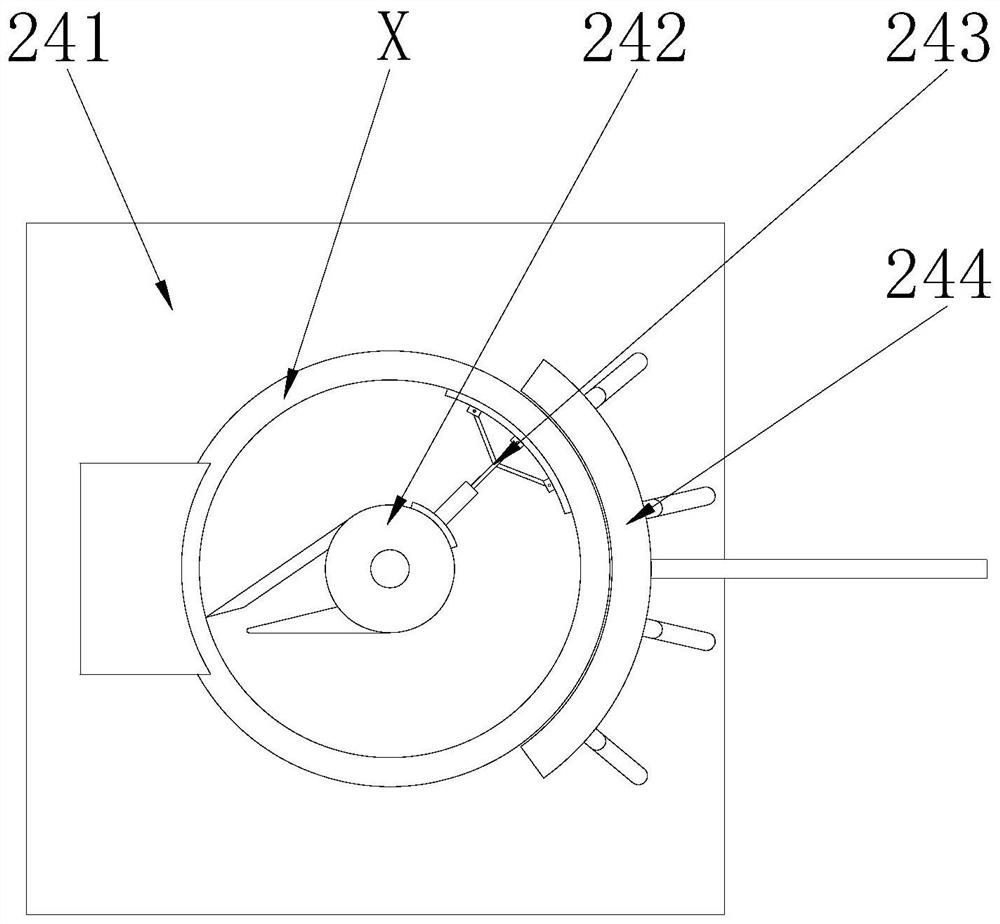

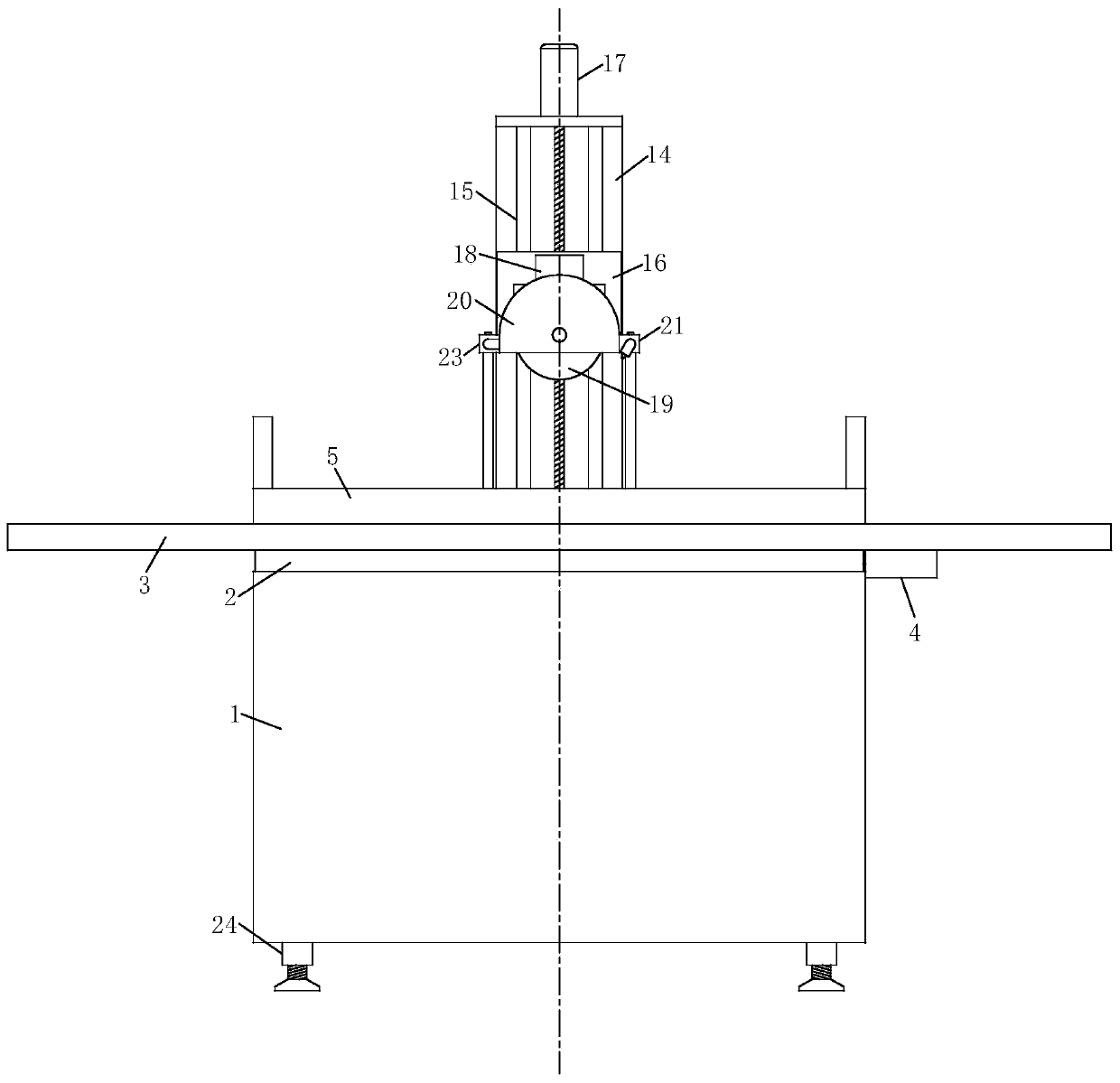

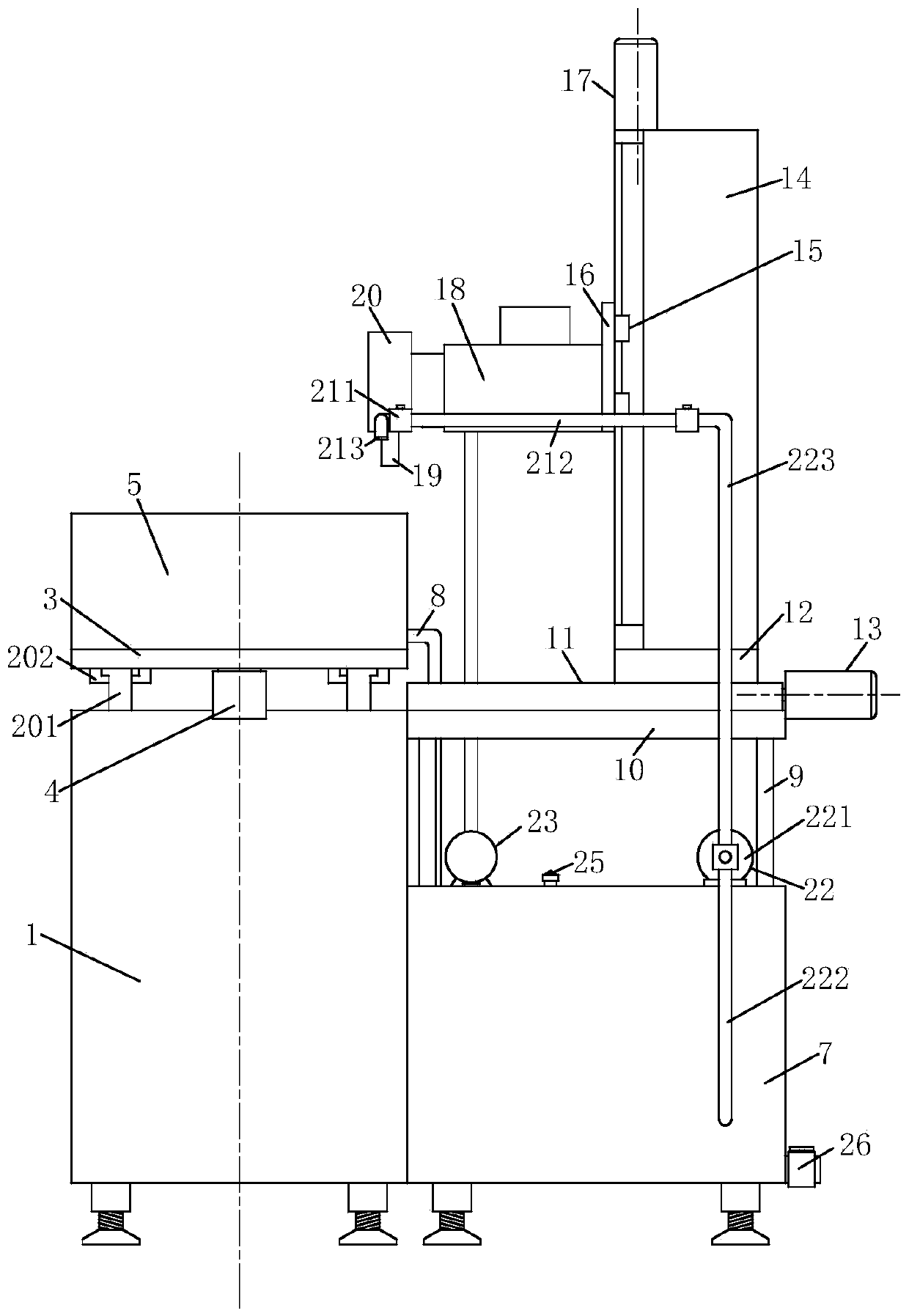

Glass edge grinding machine

InactiveCN106002530AImprove processing efficiencySmall footprintEdge grinding machinesGrinding carriagesMotor driveFeed drive

The invention provides a glass edge grinding machine. The glass edge grinding machine comprises a first double-edge grinding device and a second double-edge grinding device positioned below the first double-edge grinding device, wherein a transfer mechanism is arranged at an outlet end of the first double-edge grinding device; an inlet end of the second double-edge grinding device is positioned just below the outlet end of the first double-edge grinding device; the transfer mechanism comprises a rotating plate, a rotating motor, a transfer position-adjusting driving piece and a transfer feeding driving piece; the rotating plate receives glass from the outlet end of the first double-edge grinding device; the rotating motor drives the rotating plate to rotate at an angle of 180 degrees; the transfer position-adjusting driving piece drives the rotating plate to move at the outlet end of the first double-edge grinding device and the inlet end of the second double-edge grinding device; and the transfer feeding driving piece is used for pushing the glass on the rotating plate to enter the second double-edge grinding device when the rotating plate is positioned at the inlet end of the second double-edge grinding device. The machining efficiency is high.

Owner:HANGZHOU TUOCHUAN MASCH CO LTD

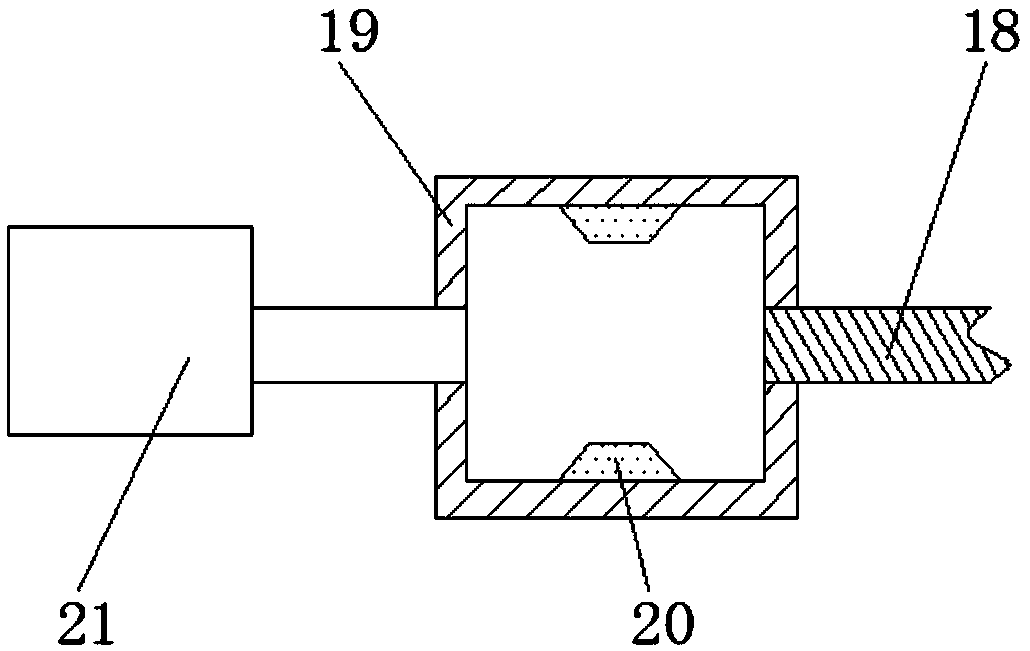

Die polishing device with dust collector

Owner:芜湖凝鑫机械有限公司

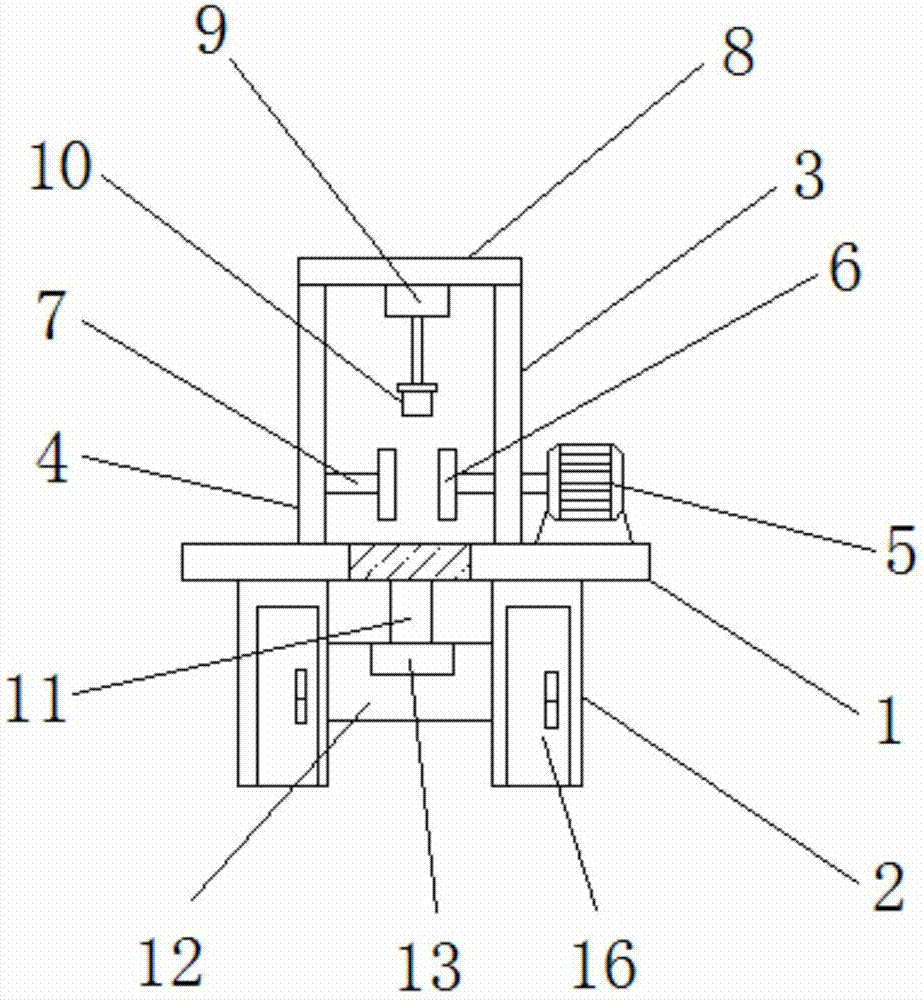

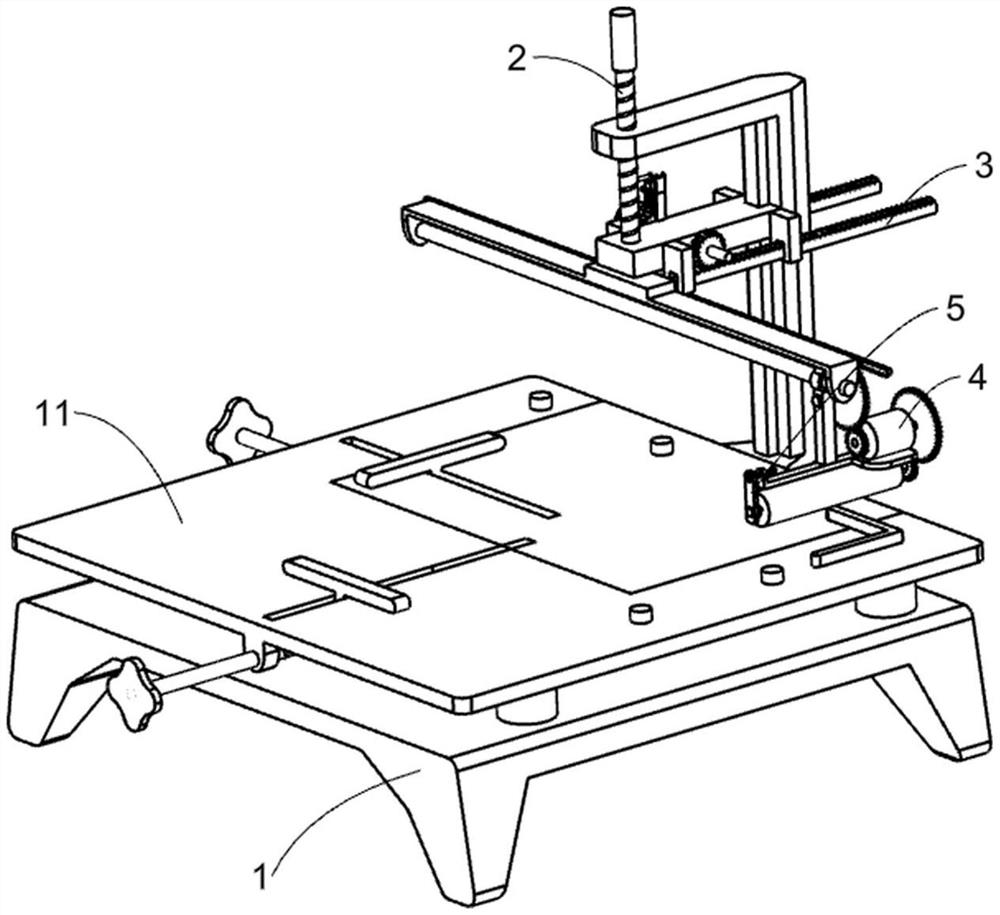

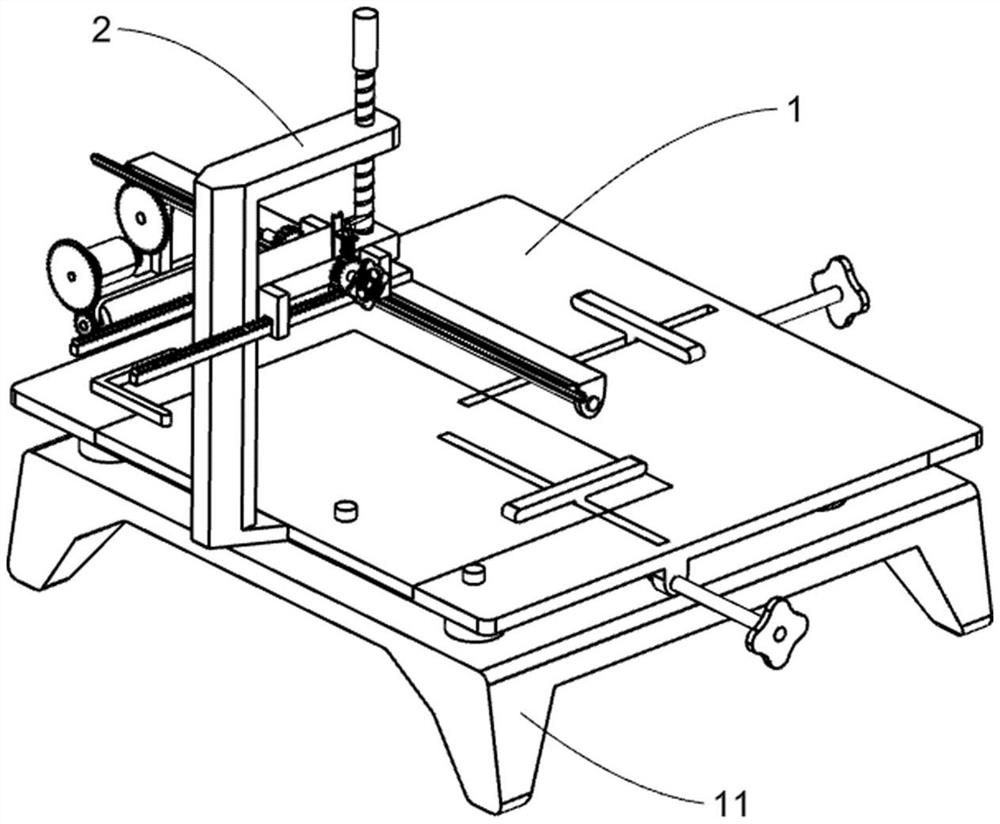

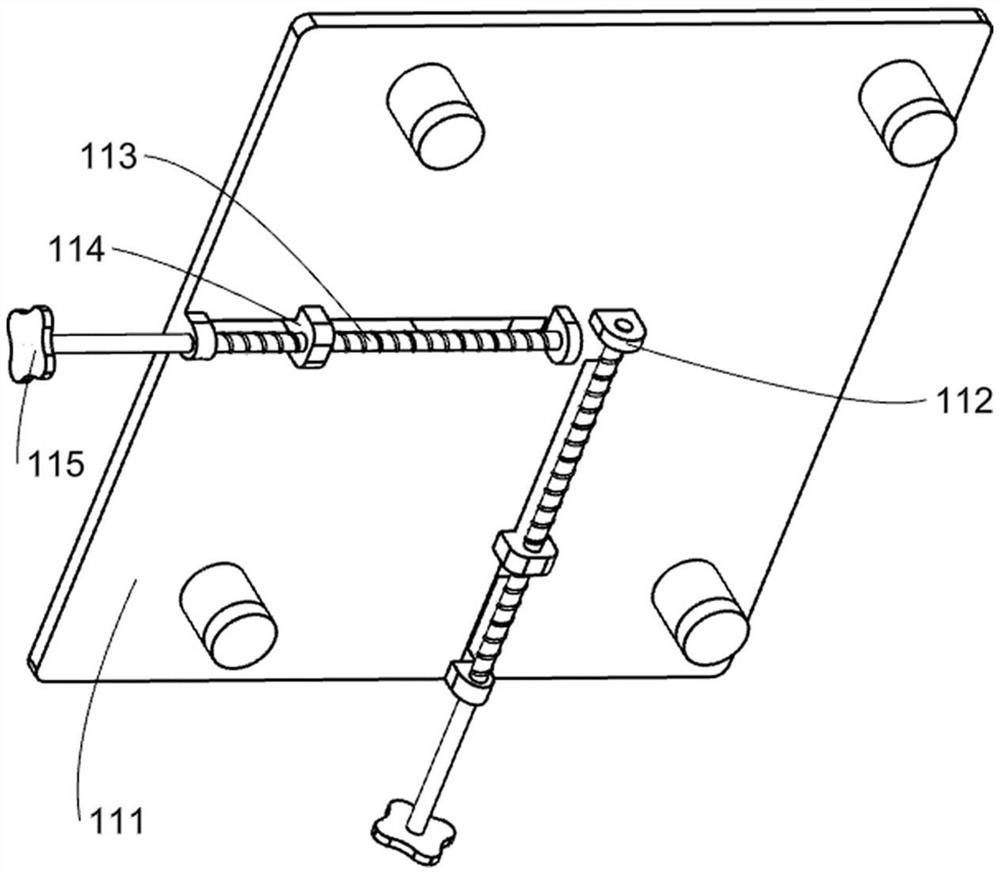

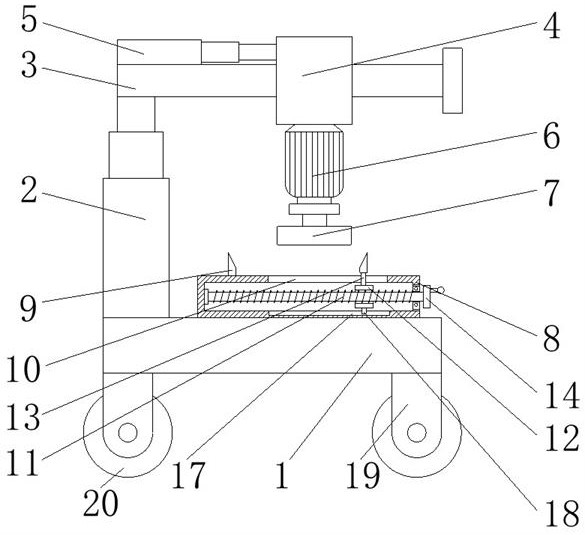

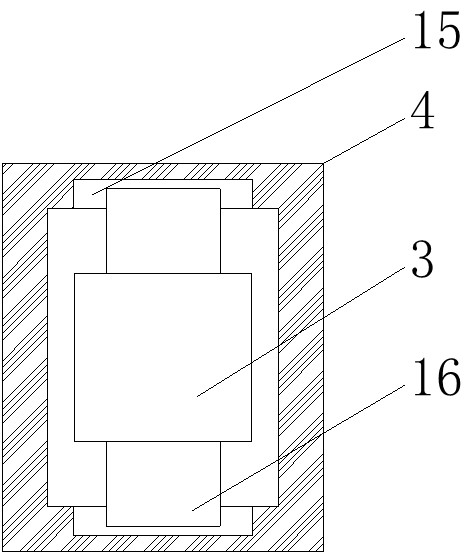

Electric grinding machine clamp

InactiveCN107471110AImprove operational efficiencyStable clampingGrinding work supportsDrive motorEngineering

The invention relates to the field of grinders, in particular to an electric grinder fixture. An electric grinder fixture, comprising a base, the base is provided with a fixed splint, a movable splint is slidably connected to the base, a threaded rod is connected to the movable splint, a support plate is arranged on the base, and the support plate rotates Connected with a rotating sleeve, the center of the rotating sleeve is provided with a through hole, the inner surface of the through hole is provided with an internal thread matching the external thread on the threaded rod, and the threaded rod passes through the through hole and is threadedly connected with the rotating sleeve , the end of the rotating sleeve away from the movable splint is provided with a driving device, the driving device includes a body on the base, a second bevel gear, a first bevel gear and a driving motor, the driving motor is connected with the first bevel gear, and the rotating sleeve The cylinder runs through the center of the second bevel gear and is fixedly connected with the second bevel gear. The fixed splint, the movable splint and the supporting plate are all arranged on the base in parallel. The invention has high operating efficiency, saves time and effort, and can hold the workpiece stably.

Owner:HUZHOU MINGHAO MASCH CO LTD

Automatic cutting, grinding and polishing machine for PCB

InactiveCN107378707AAccurate cutting positionImprove processing efficiencyGrinding feed controlGrinding machinesVertical planeWorkspace

The invention provides an automatic cutting, grinding and polishing machine for a PCB. The automatic cutting, grinding and polishing machine comprises a machine body, a working region, a clamping jaw, an action executing unit and a control panel, wherein the machine body is provided with a horizontal plane and a vertical plane which is perpendicular to the horizontal plane and is positioned at one side of the horizontal plane; the working region is arranged on the horizontal plane, and comprises a polishing disc, a grinding disc, a cutting disc and a laser aligning device; the action executing unit is arranged on the vertical plane, and the clamping jaw is connected with the action executing unit and is driven by the action executing unit to move in the vertical plane; and the control panel is arranged on the machine body and is positioned at one side of the working region. The automatic cutting, grinding and polishing machine for the PCB provided by the invention can realize advanced determining as well as automatic continuous cutting, grinding and polishing treatment of the PCB, is accurate in cutting position, is high in processing efficiency, is good in continuity, and sufficiently meets the needs, on product structure checking, of a laboratory of the PCB.

Owner:KUNSHAN HUANSHENG ELECTRONICS CO LTD

Computer hardware developing grinding device having dust removal function

InactiveCN108942516AReduce labor intensitySave time at workGrinding drivesGrinding machinesUltimate tensile strengthComputer engineering

Owner:上海宴阳智能科技有限公司

High-efficiency glass polishing equipment

Owner:蚌埠承永玻璃制品有限公司

Workpiece grinding equipment

Owner:林红英

Ceramic tile surface polishing device

PendingCN112025523ATo achieve the function of high and low adjustmentTo achieve the effect of clampingGrinding wheel securing apparatusGrinding carriagesComposite materialCeramic tiles

Owner:凌亮

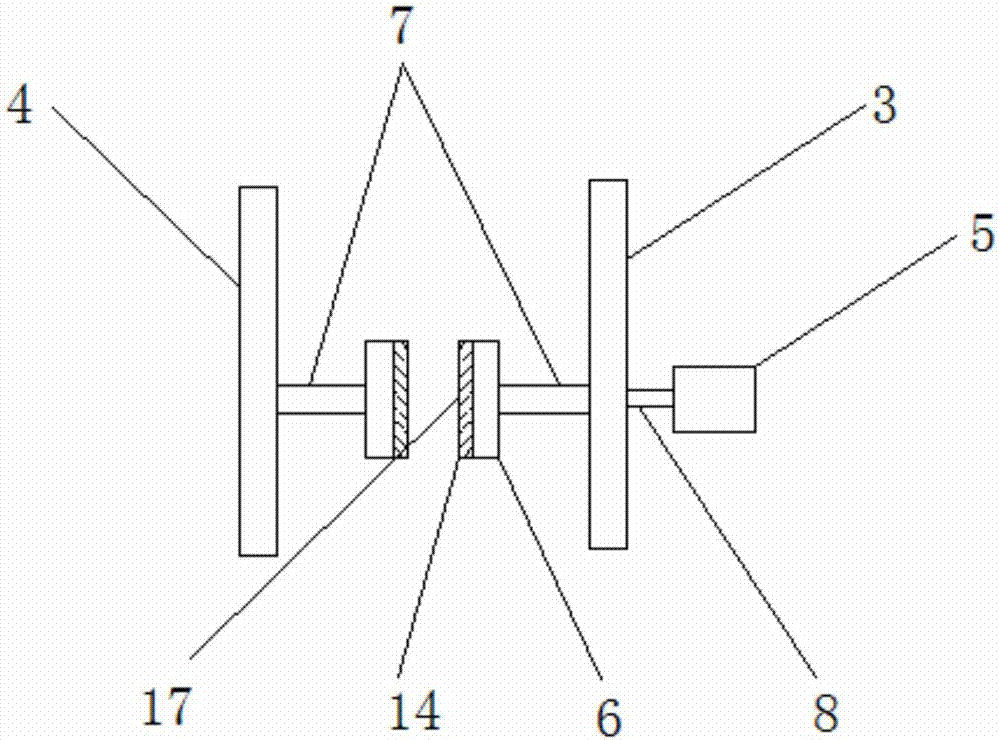

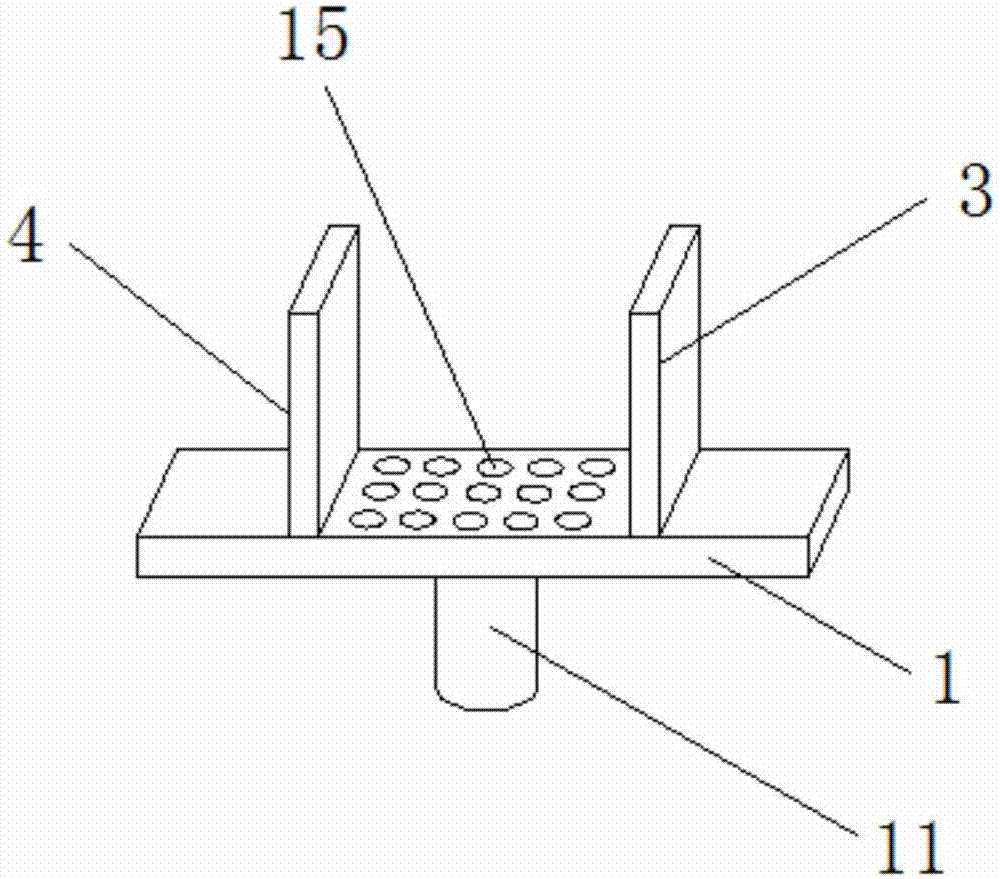

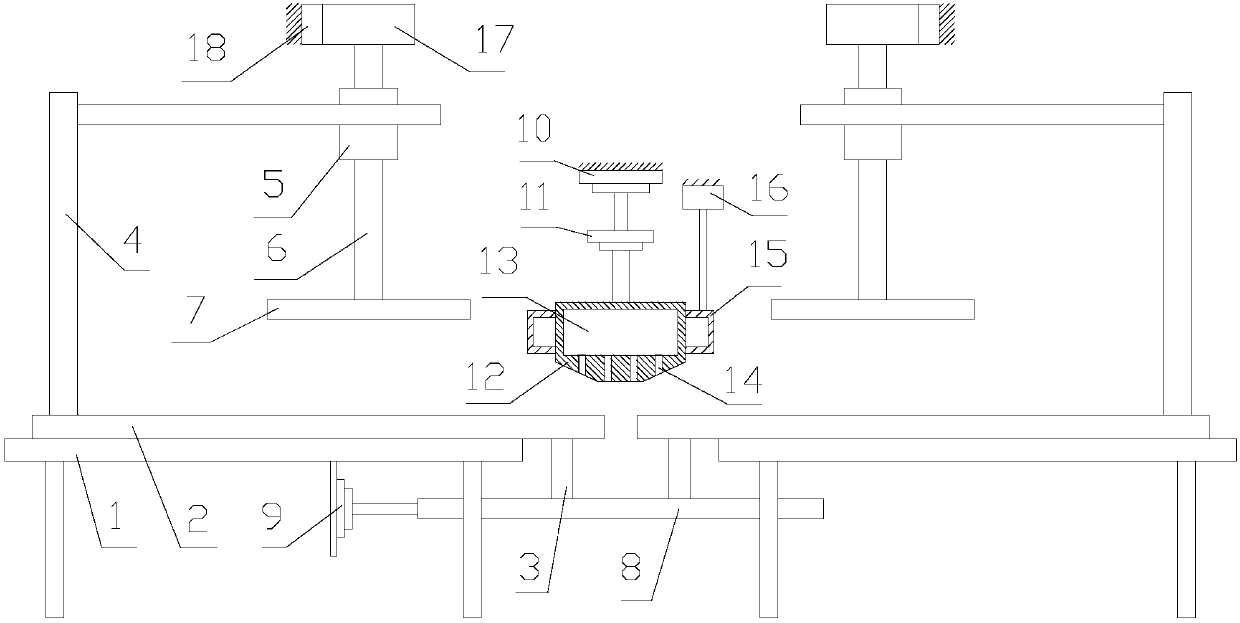

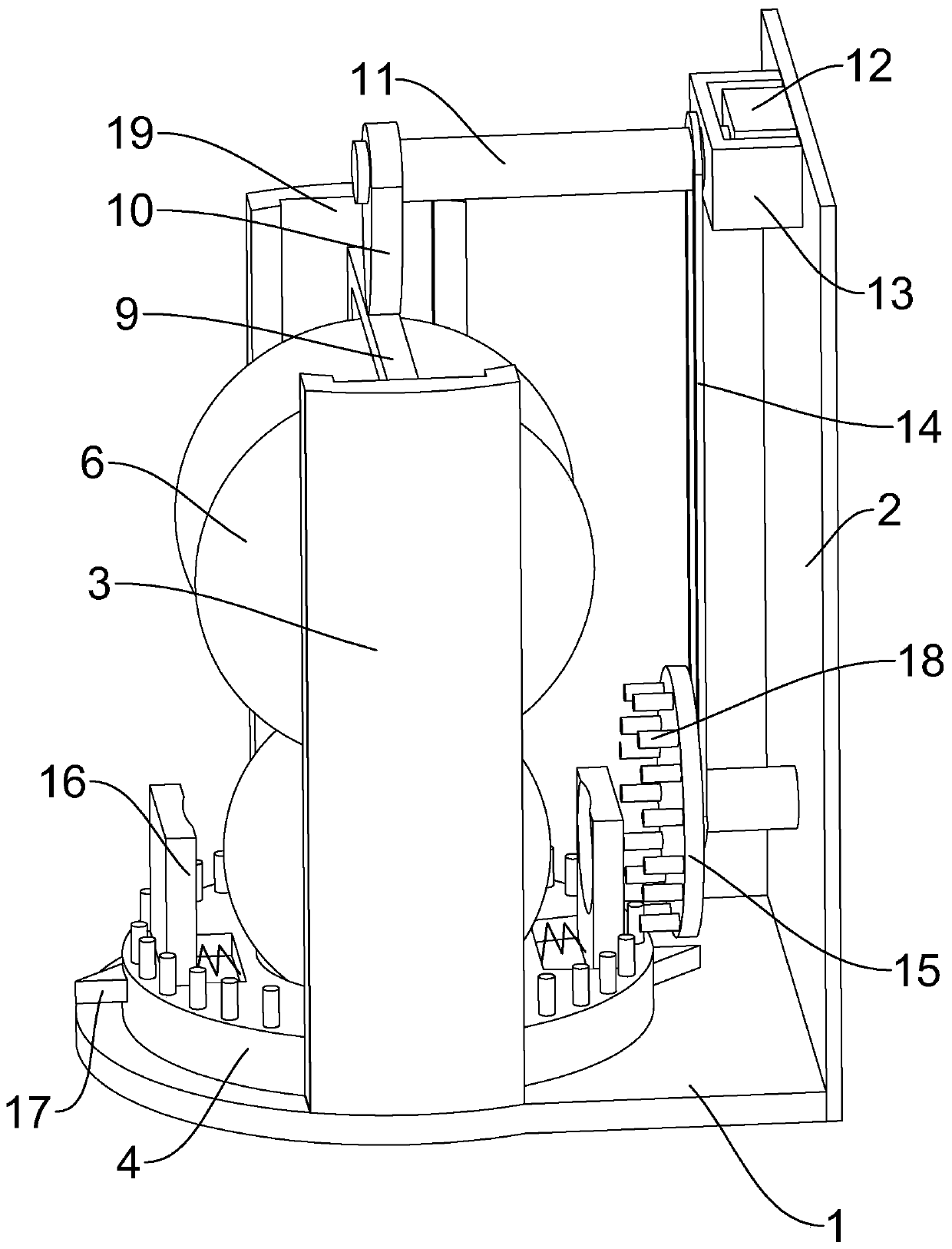

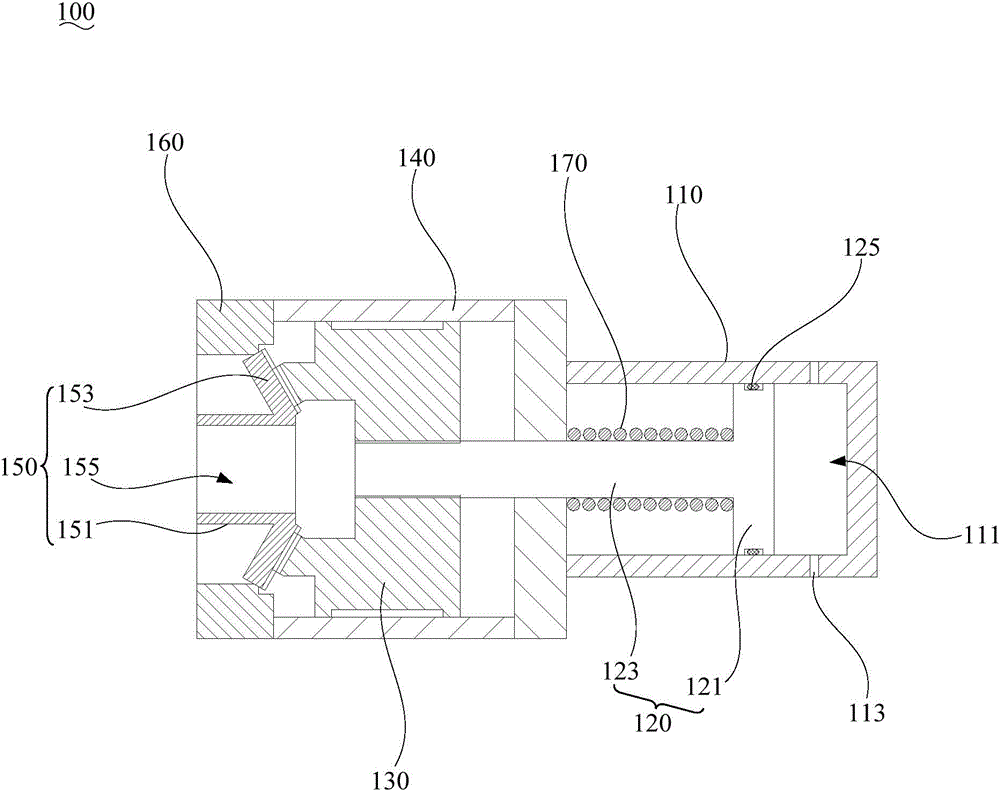

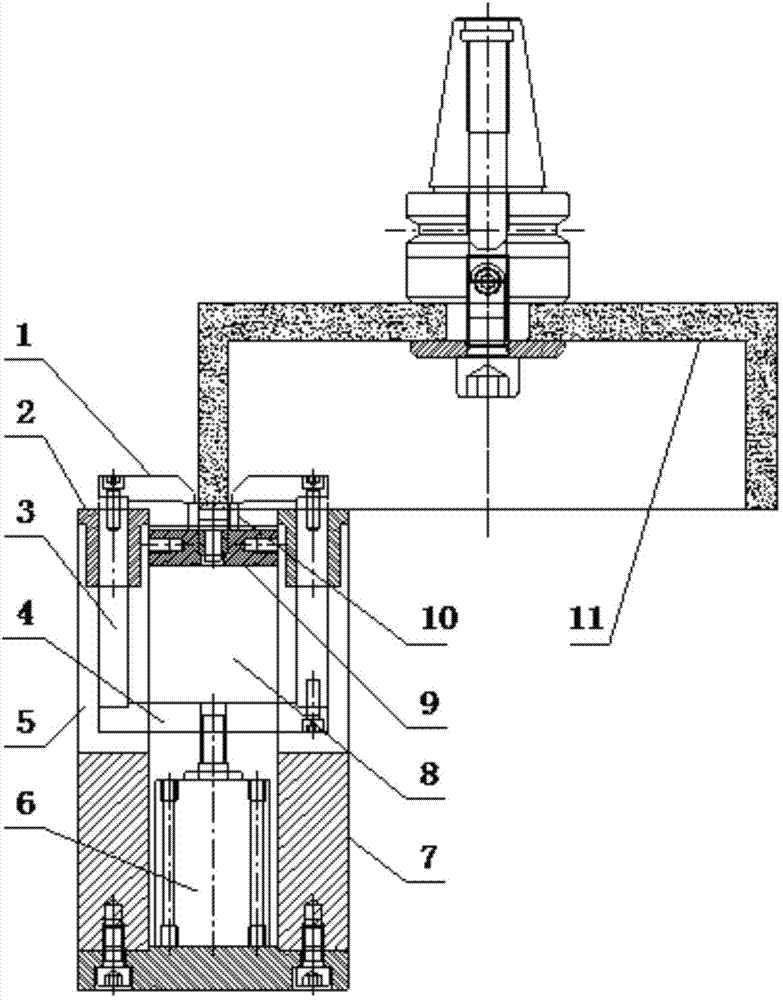

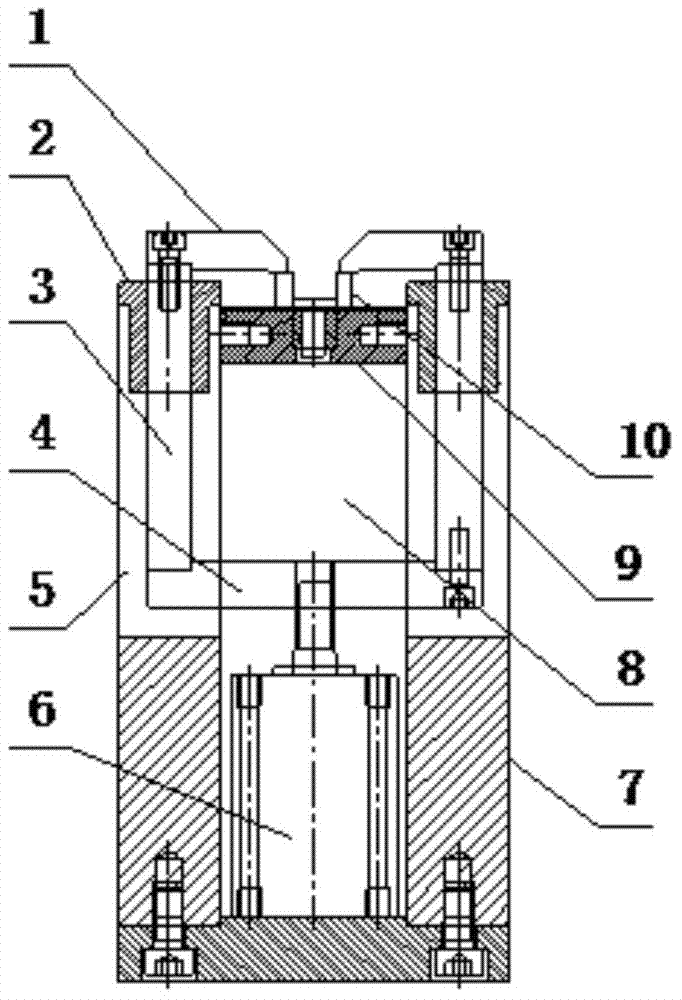

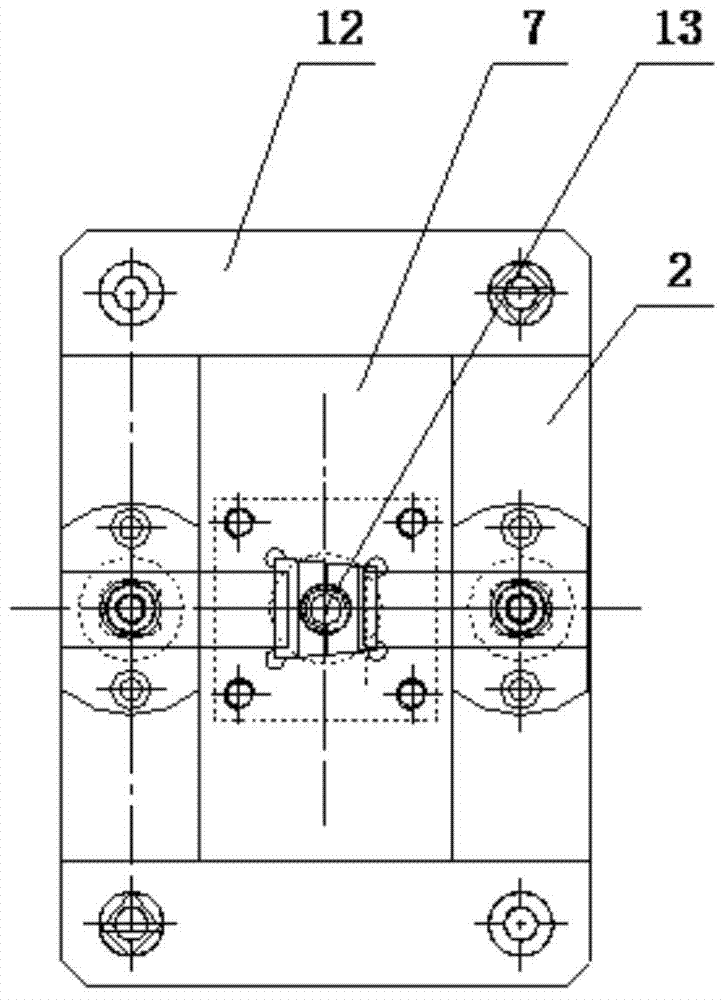

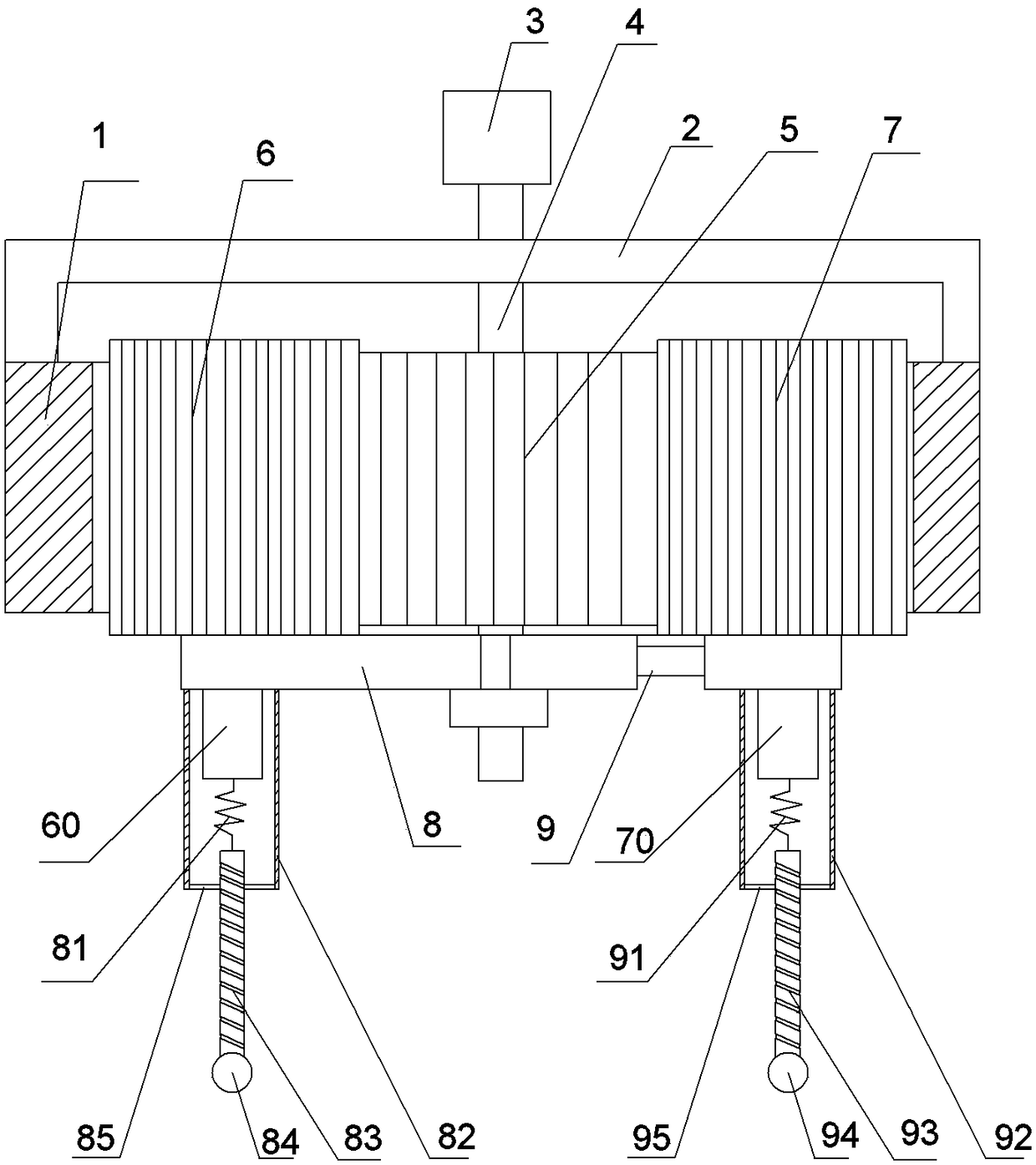

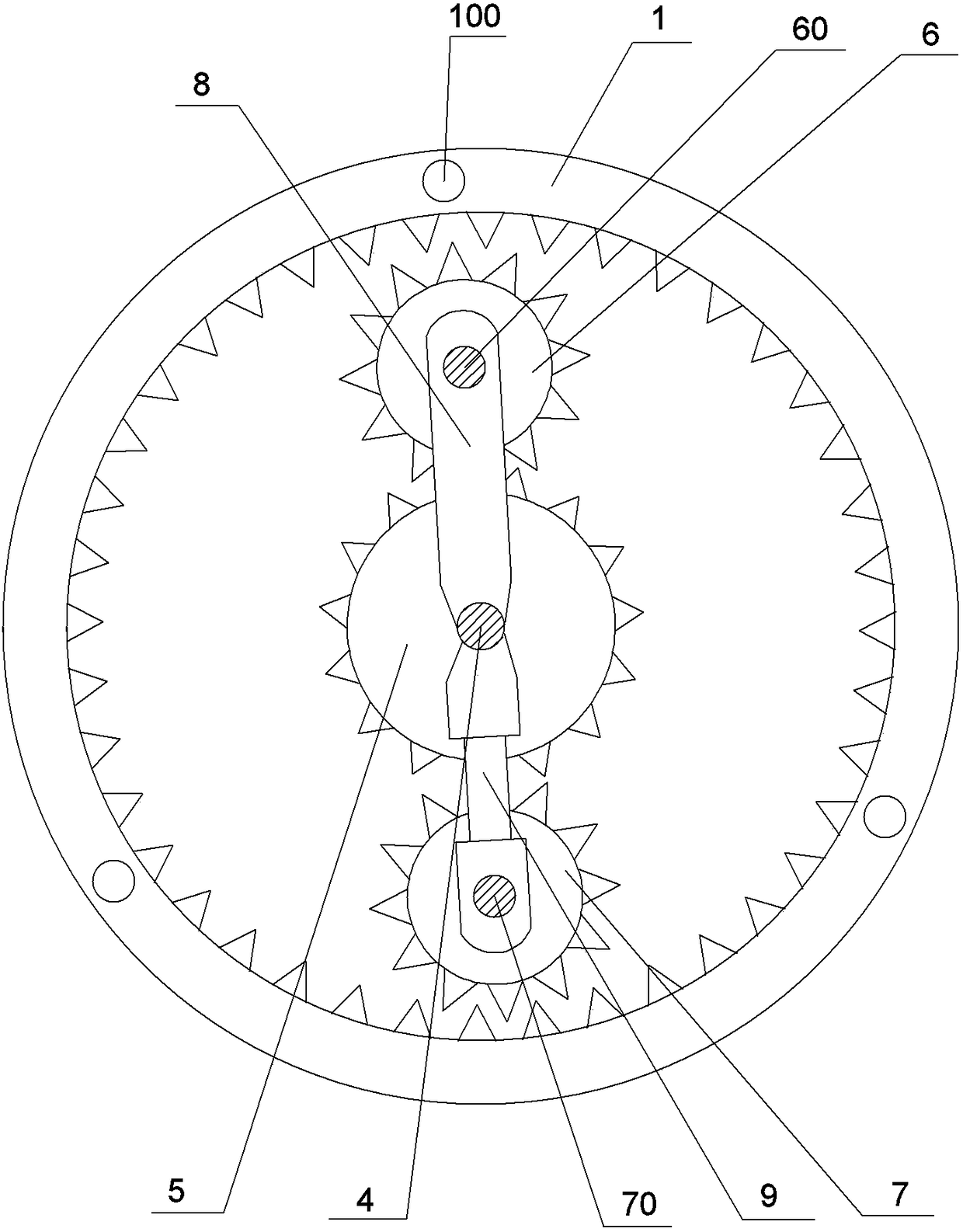

Efficient double-end-face grinding machine and control method thereof

ActiveCN106363475AHigh finish precisionHigh degree of automationGrinding carriagesGrinding drivesMotor driveControl system

The invention relates to an efficient double-end-face grinding machine and a control method thereof. The efficient double-end-face grinding machine comprises a machine body, tool feeding devices, a contact type measuring device and a feeder. Each tool feeding device comprises a spindle, a grinding wheel, a spindle motor and a tool feeding motor, wherein the spindle motor drives the spindle to drive the grinding wheel to rotate, and the tool feeding motor drives the spindle to move left and right. The contact type measuring device comprises a measuring head vertical-moving cylinder and a contact type measuring head, and the measuring head vertical-moving cylinder drives the contact type measuring head to move vertically. The feeder comprises a magnetic reciprocating workbench and a feeding motor. A five-axis control system is adopted by the efficient double-end-face grinding machine, automatic grinding, automatic compensation and automatic measuring of double end faces are achieved, coarse and fine machining and automatic measuring on the periphery of a mold core can be efficiently completed during one-time clamping of the ceramic mold core, production efficiency for the mold core is improved, and the precision and smoothness of the mold core are improved.

Owner:FOSHAN SHIWAN CERAMICS IND RES INST CO LTD

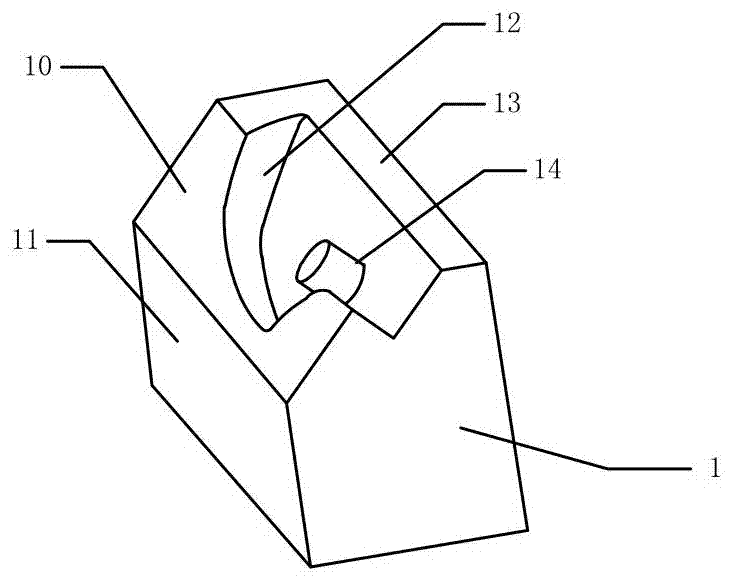

Machine for blasting abrasives

ActiveUS20120252327A1Simple structureSimple and novel structureRevolution surface grinding machinesGrinding drivesEngineeringAbrasive

The object of the present invention is to provide a machine for blasting abrasives that has a simple structure and that solves the problem of abrasives falling when the door for the gateway for the work is opened or closed. The machine for blasting abrasives comprises a chamber 11 for processing, a nozzle 13 that is provided within the chamber 11 for shooting the abrasives (shots) S onto the work W, and a jig 15 for holding the work W at a position facing the nozzle 13. A gateway 17 with a door 19 is formed in the ceiling 11a of the chamber 11. The size of the gateway 17 enables the work W to protrude from the chamber 11 by means of the jig 15 at a position corresponding to the jig 15 that is linearly moving up and down. The door 19 is provided within the chamber 11 so as to seal the gateway by linearly moving up and down and so as to create a vacant plane on the gateway for passing the work by horizontally moving.

Owner:SINTOKOGIO LTD

Tubular steel frame dust-removal device

InactiveCN107745319AGuaranteed derusting effectNo shakingGrinding carriagesGrinding machinesEngineeringSteel frame

Owner:四川大黄河建设工程有限公司

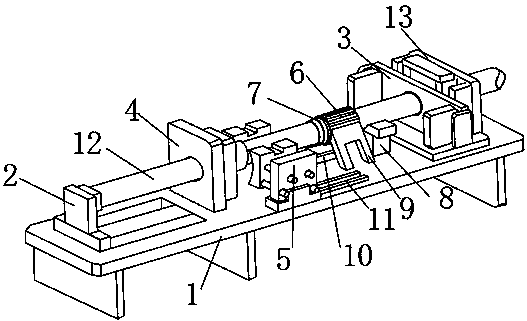

Automatic grinding device for short steel bars

InactiveCN109227288APrevent slidingPrevent rotationGrinding drivesGrinding feed controlArchitectural engineeringRebar

The invention discloses an automatic grinding device for short steel bars. The automatic grinding device comprises a base, wherein the left side of the upper portion of the base is provided with a positioning assembly, a sliding assembly is arranged under the positioning assembly, the positioning assembly is slidingly connected with the base through the sliding assembly, the right side of the upper portion of the base is provided with a grinding assembly, and the outer side of the base is provided with a central control module. The problem is solved that after steel bars are placed for a period of time, certain rust unavoidably exists on the surfaces, so steel bar grinding is needed, a worker needs to hole one end of each steel bar in the grinding process and then pull out the steel bar from the other end after the steel bar penetrates through the grinding device, the method needs manual control, unthorough surface grinding is possible if steel bar pulling is too quick, excessive grinding is also possible if the steel bar pulling is slower, the steel bar pulling is very strenuous, and large body burden is brought to the operator.

Owner:RUIXIONG METAL PROD (WUHU CO LTD

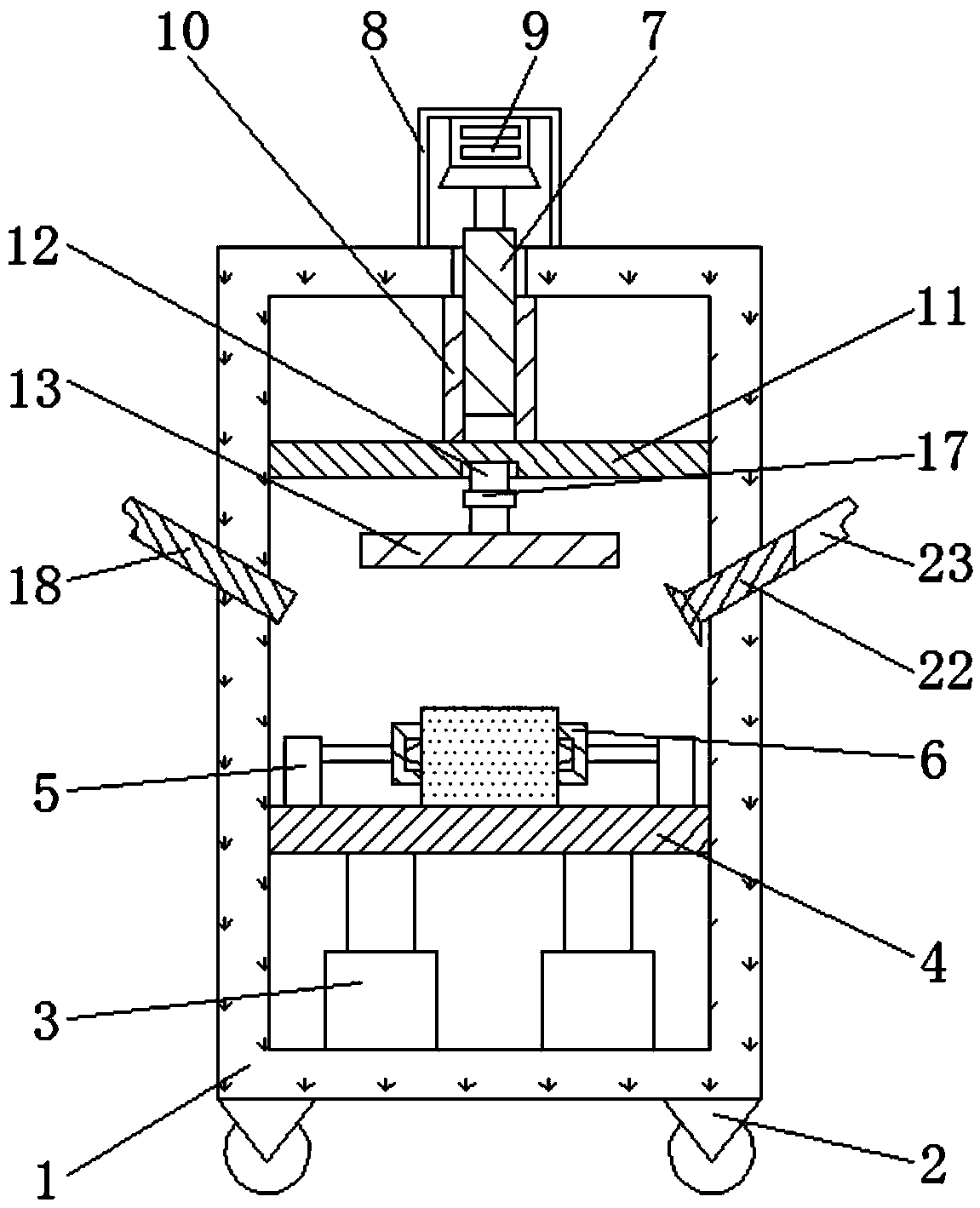

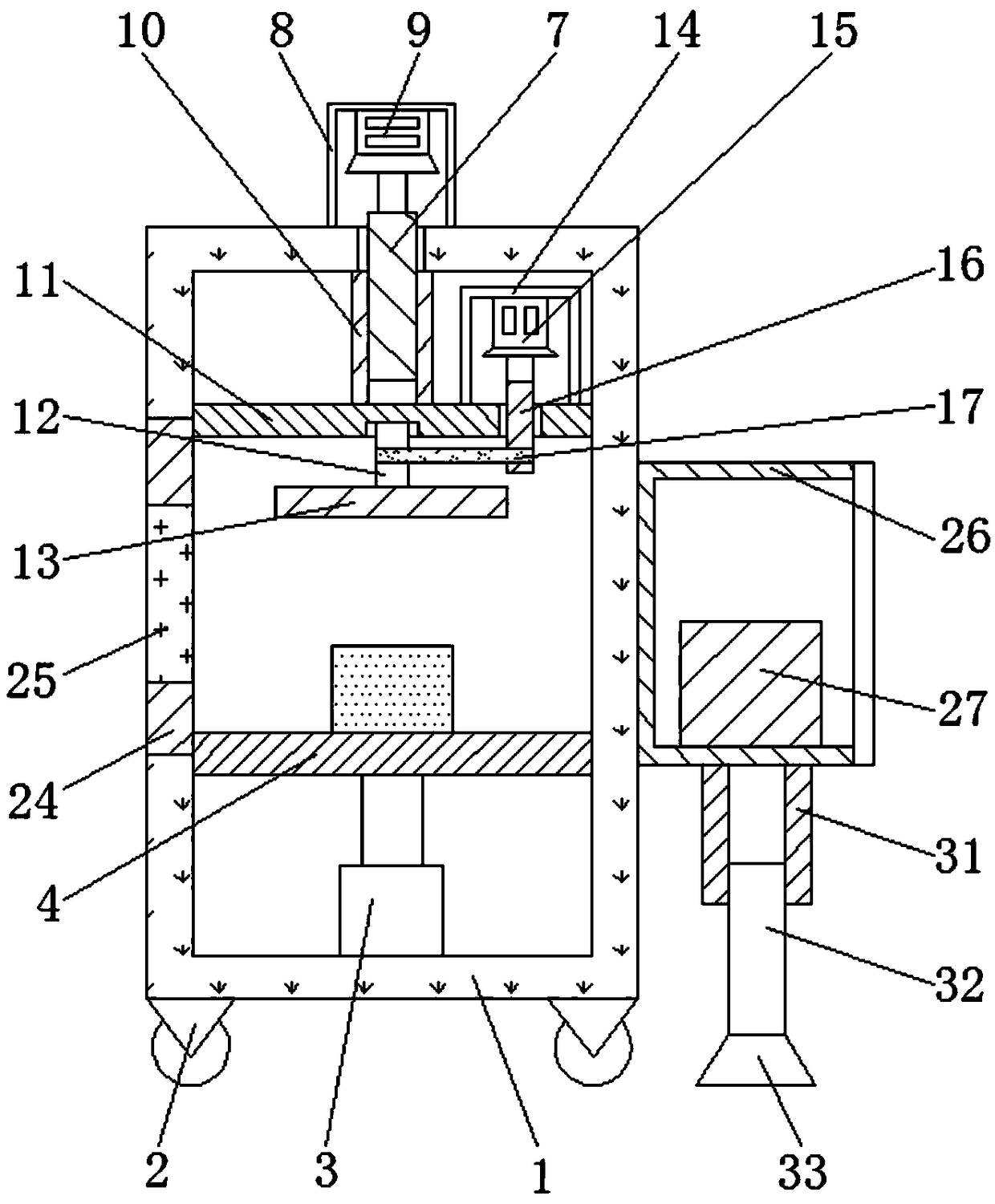

Multi-station surface grinding machine

InactiveCN108942452AEasy to move up and downHeight adjustableGrinding drivesGrinding work supportsHydraulic cylinderLED display

Owner:XIANGYANG TRADETOOL AUTOMOBILE PARTS

Steel ball grinding device

Owner:山东菏益科技有限公司

Burr cutting equipment for rubber processing

InactiveCN112060433AImprove sanding effectContact strength is normalEdge grinding machinesGrinding drivesElectric machineryStructural engineering

Owner:成都喃呓商贸有限公司

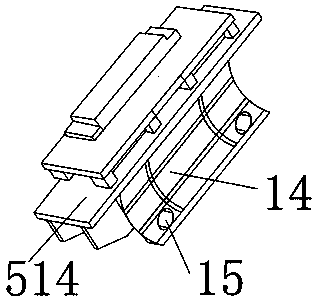

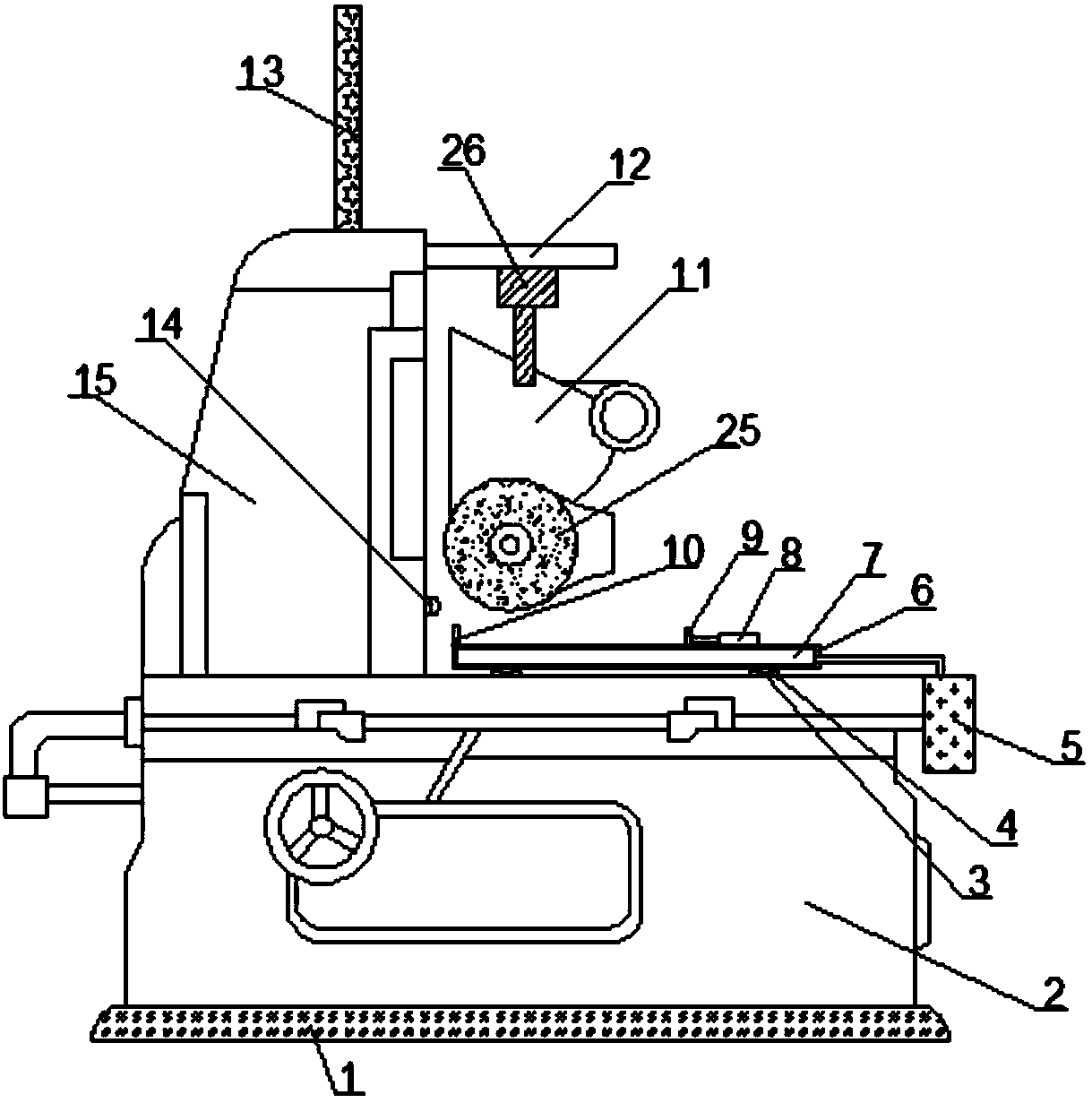

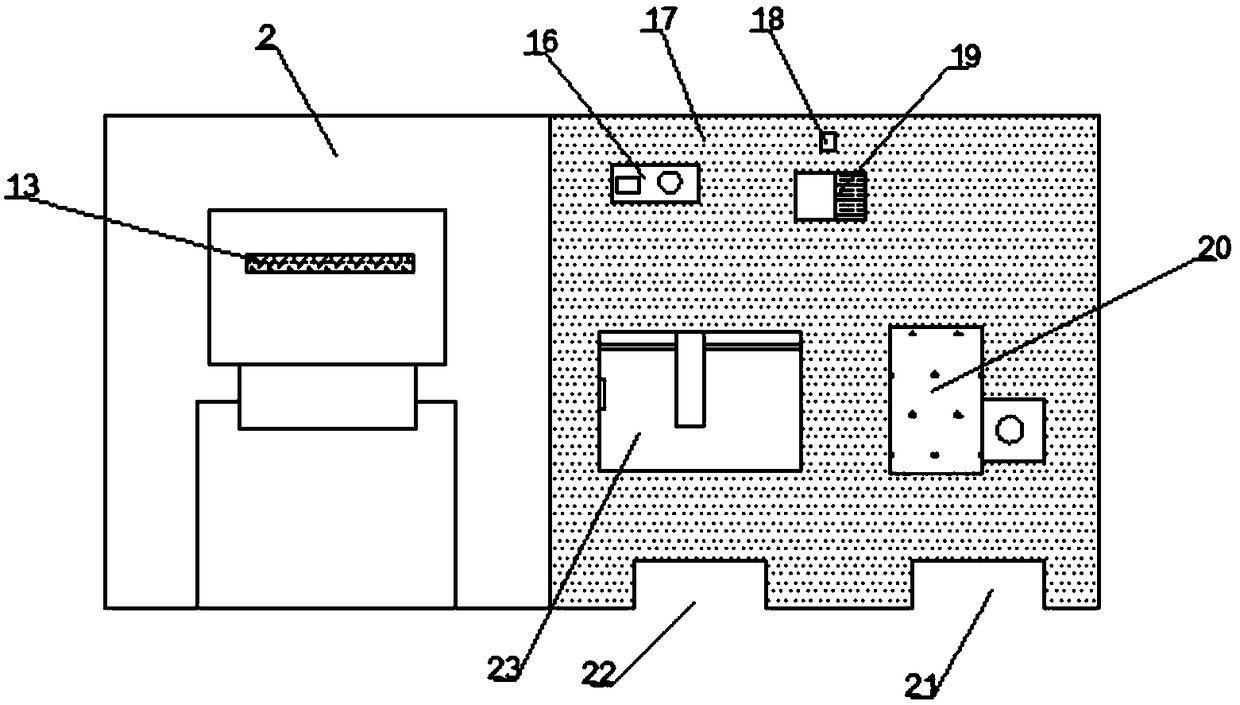

Full-automatic flat grinder

ActiveCN110640564AAchieve recyclingWork environment hygieneGrinding drivesGrinding work supportsEngineeringCooling fluid

Owner:江苏锋宝冶金设备有限公司

Lamp processing positioning fixture

Owner:SHENZHEN OCEANS KING LIGHTING ENG CO LTD +1

Machining tooling and machining method for ultra-large gas turbine blade

Owner:成都和鸿科技股份有限公司

Pneumatic precise arc-shaped groove machining fixture

InactiveCN103753273ARealize fixed clamping workEasy to operatePositioning apparatusGrinding work supportsHorizontal barMachining

Owner:TIANJIN BAOLAI PRECISION MACHINERY

Leather material location device for vertical type edge finishing machine

InactiveCN102490100APrecise positioningStable clampingEdge grinding machinesGrinding work supportsEngineeringMechanical engineering

Owner:SHENZHEN HOCHUEN TECH +1

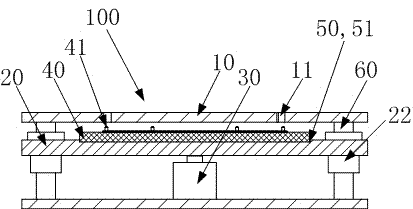

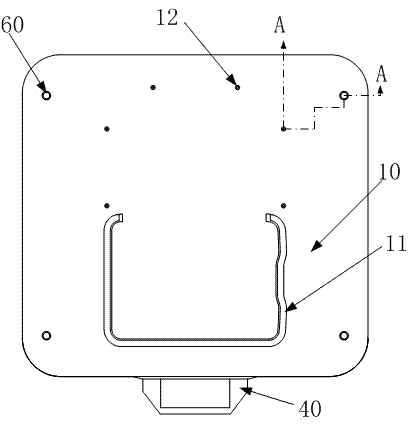

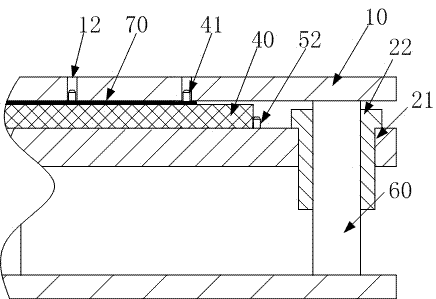

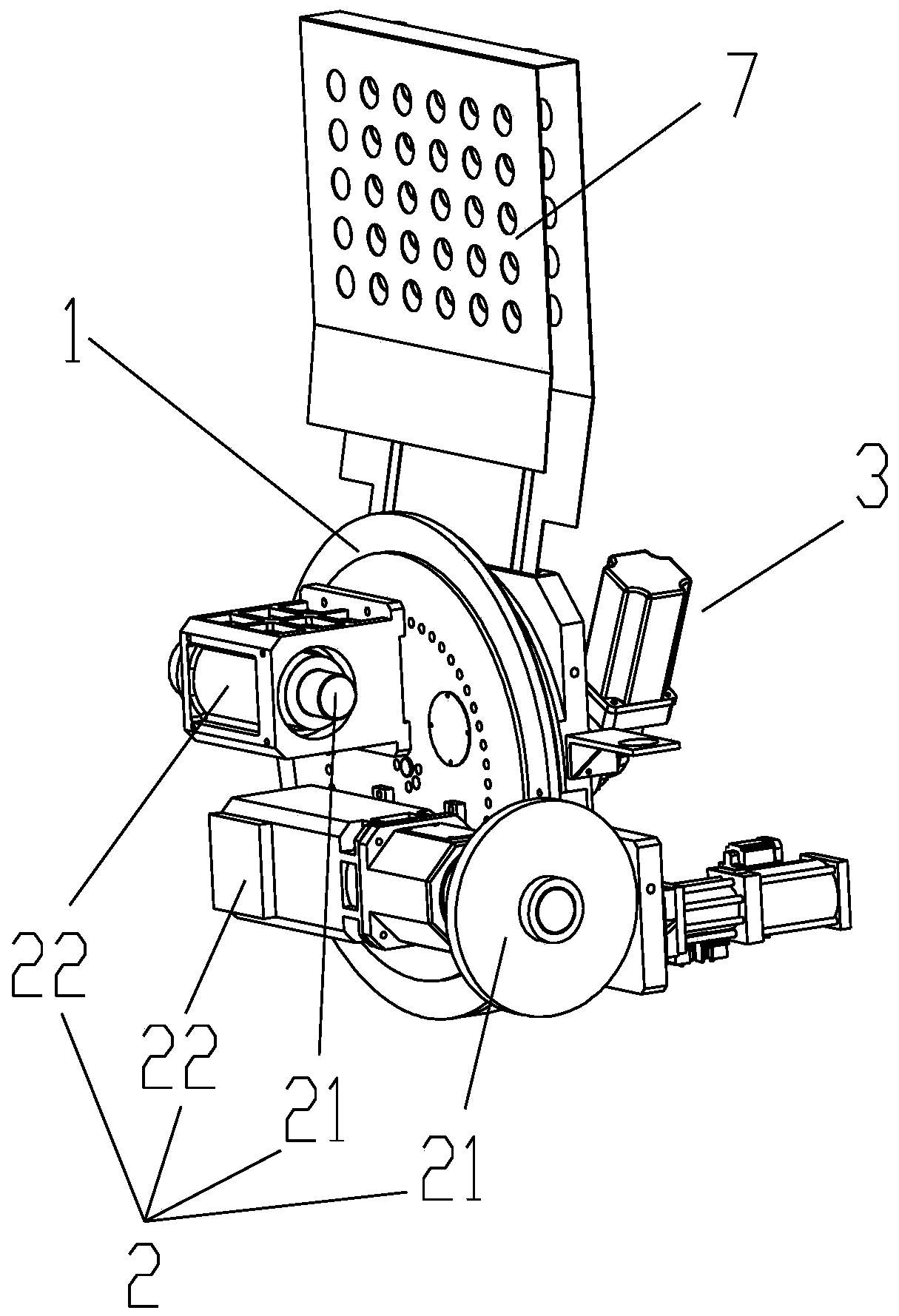

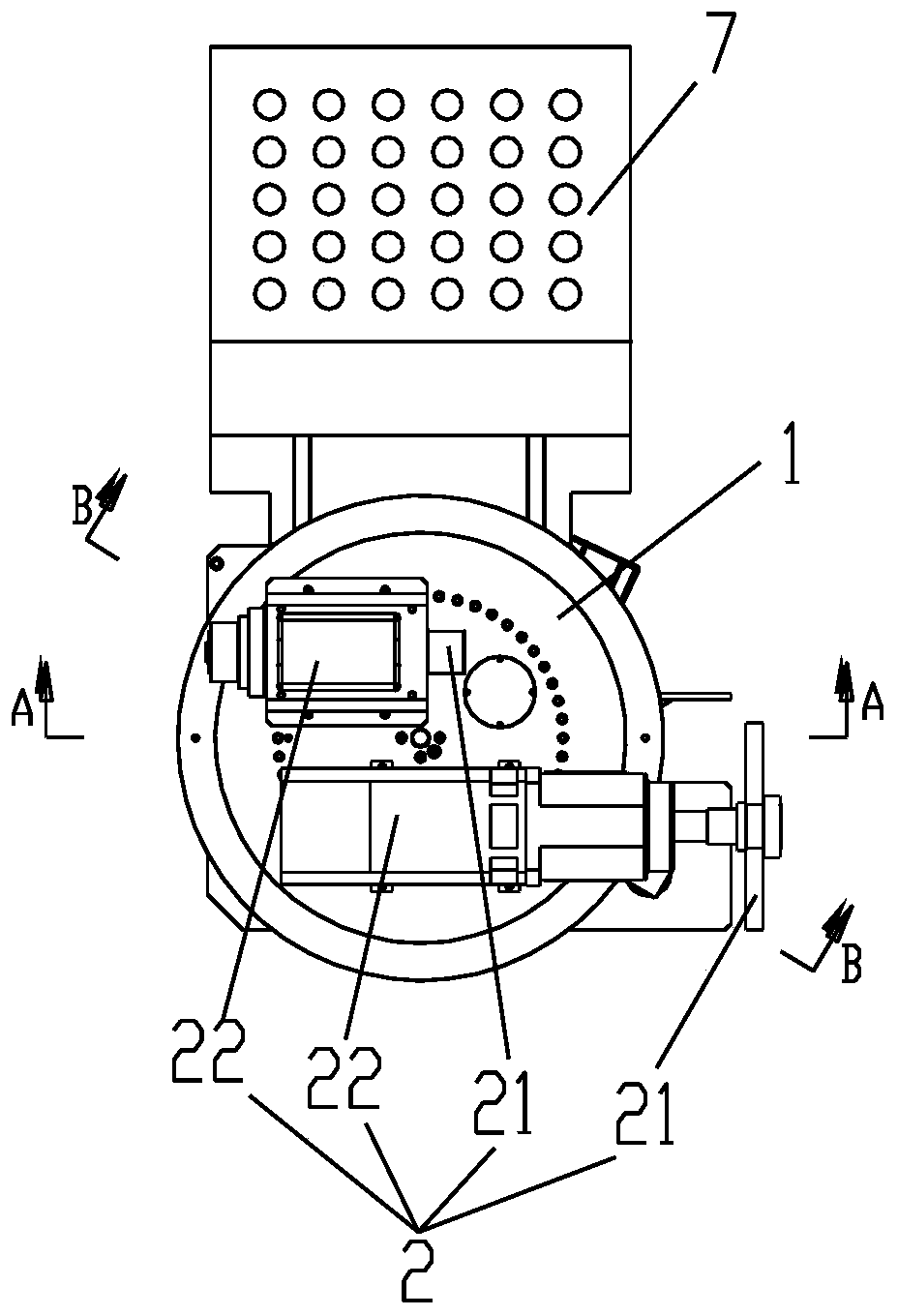

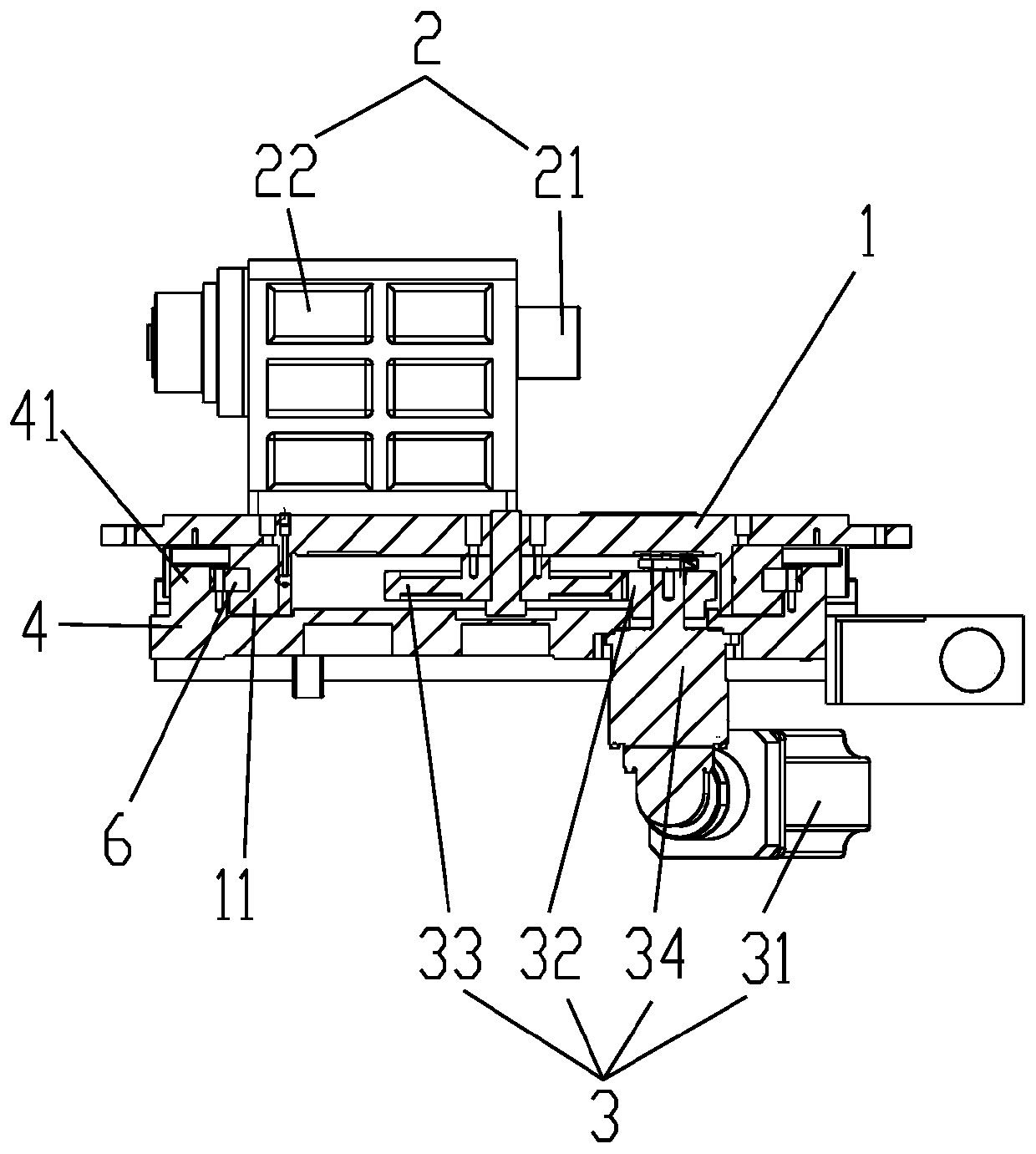

Potentiometer polishing equipment and polishing method

ActiveCN107984371ASmooth surface requires uniformityIngenious structurePolishing machinesGrinding drivesElectric machineEngineering

The invention relates to potentiometer polishing equipment, and relates to the technical field of grinding processing. The potentiometer polishing equipment mainly comprises a polishing wheel power mechanism, a rotating mechanism, a feeding mechanism and a straight-line motion part, wherein the straight-line motion part and the polishing wheel power mechanism are mounted on an equipment deck plate(52); the rotating mechanism and the feeding mechanism are mounted on the straight-line motion part; a servo motor B (28) of the straight-line motion part is used for driving the straight-line motionunit (31), so that the whole rotating mechanism and the whole feeding mechanism are in transverse motion; a potentiometer (1) is in longitudinal feeding by the feeding mechanism to compensate the abrasion of a polishing wheel (41); and the polishing wheel is driven by a motor (45); and the clamping of the potentiometer (1) is realized by the rotating mechanism through the control of a handle mechanism seat (12). The potentiometer polishing equipment disclosed by the invention is ingenious in structure and simple to operate; requirements that the polishing angle is adjustable, the rotating frequency is adjustable, the polishing length is adjustable and the accuracy is high can be met; polishing operation can be efficiently performed; and after the potentiometer is polished, the surfaces ofthe obtained potentiometer are smooth and uniform, and the resistivity of the surfaces is the same.

Owner:GUIYANG WANJIANG AVIATION ELECTROMECHANICAL

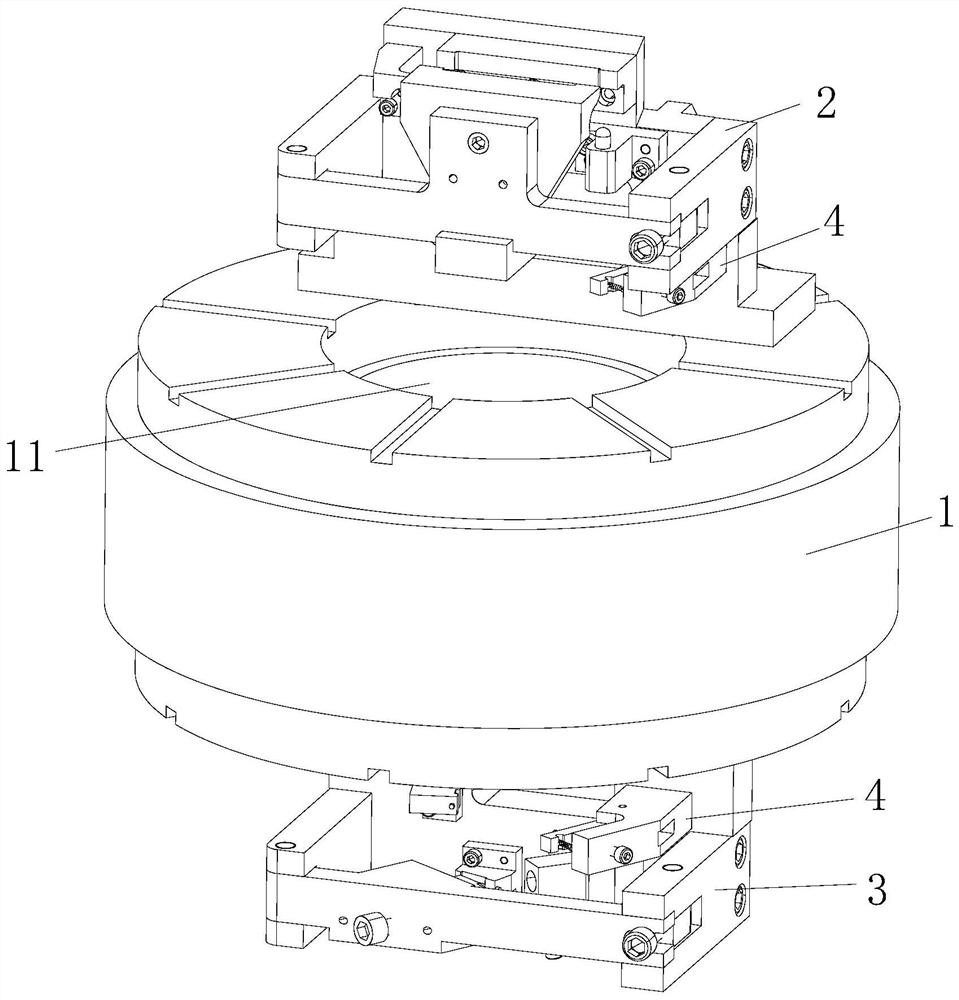

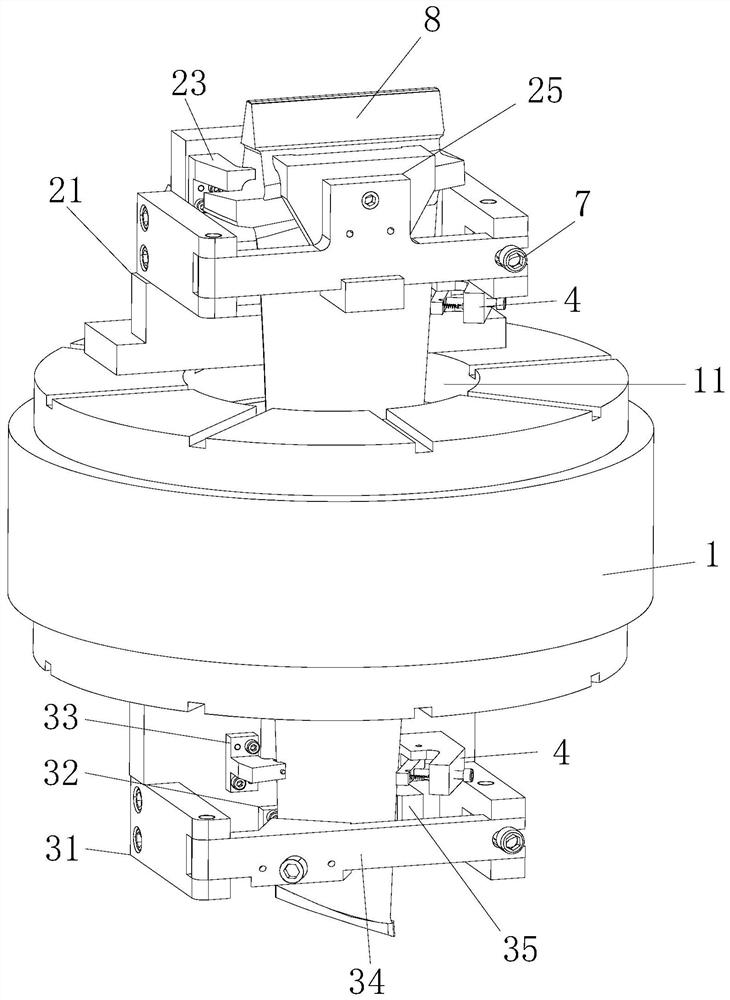

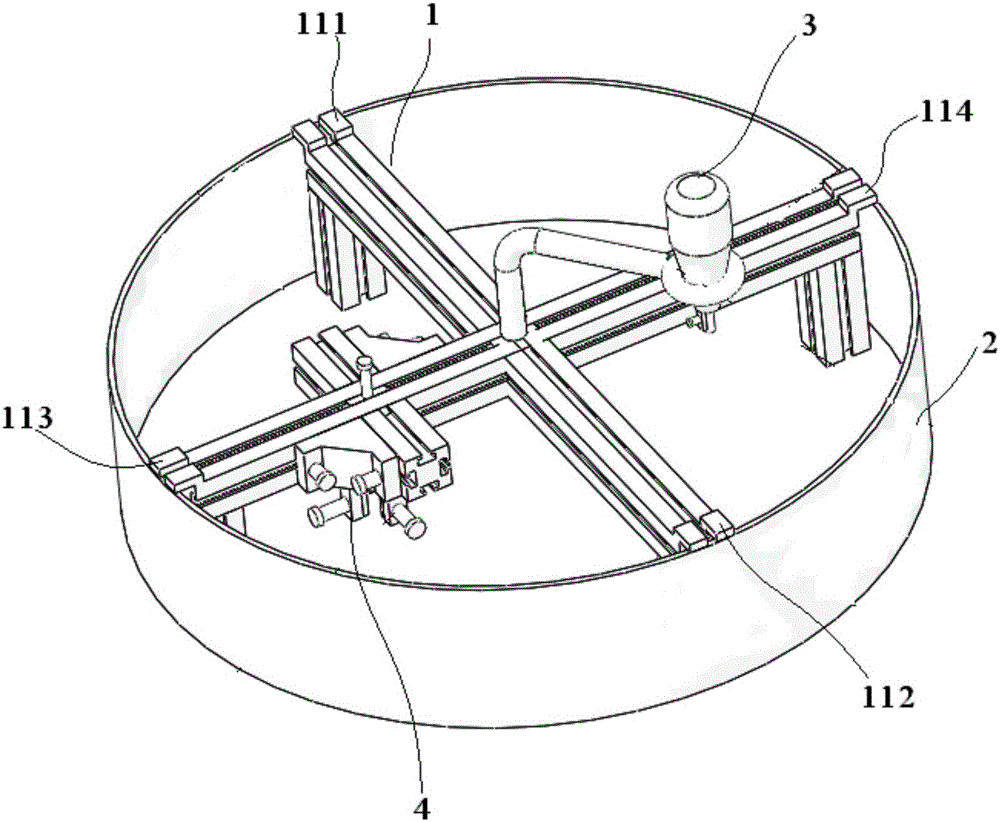

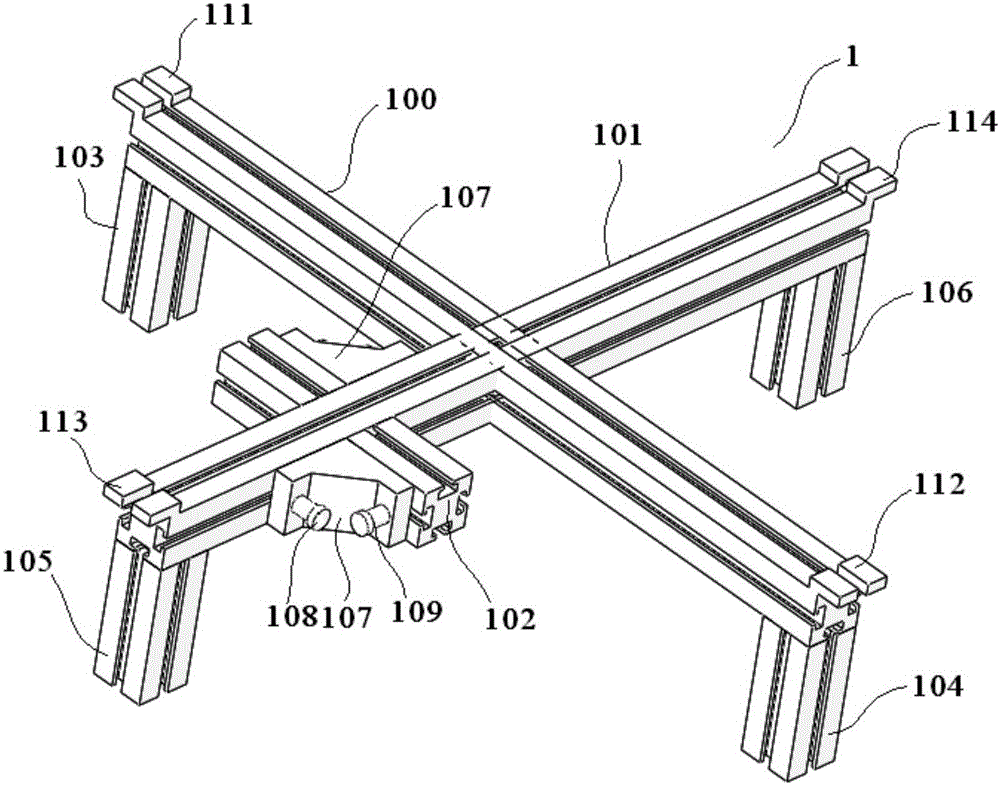

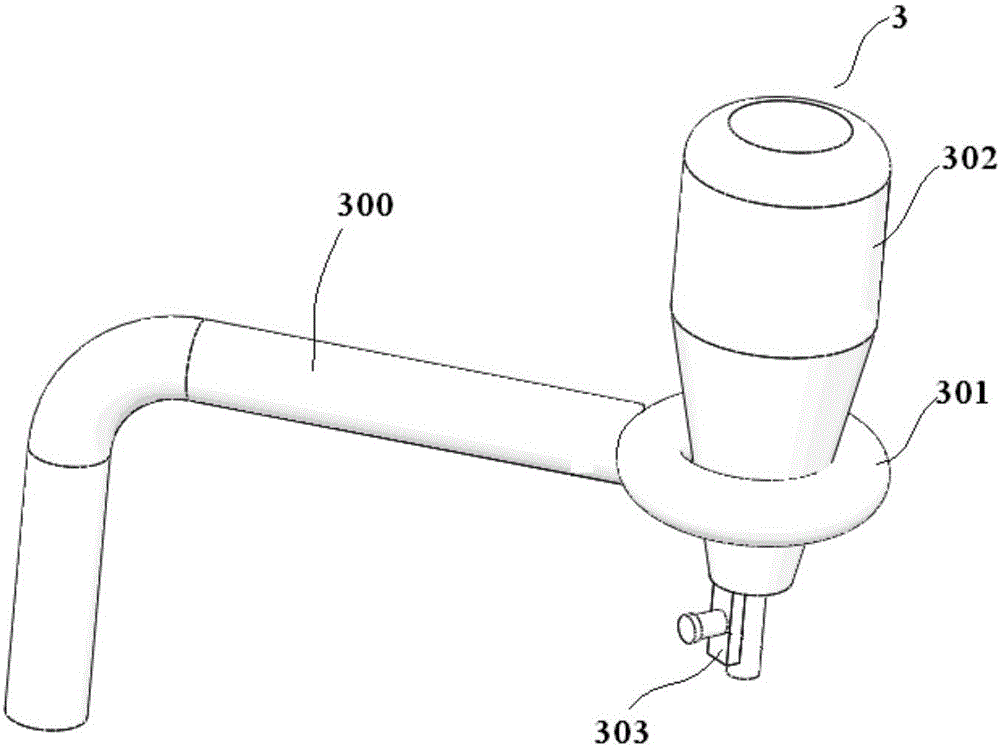

Positioning and aligning device for grinding blade tips of aero-engine compressor rotor

ActiveCN111604734AEliminate errorsGuaranteed accuracyRevolution surface grinding machinesGrinding work supportsEngineeringMechanical engineering

The invention discloses a positioning and aligning device for grinding blade tips of an aero-engine compressor rotor. The positioning and aligning device comprises a front end clamp and a rear end clamp, wherein the front end clamp comprises a columnar front end clamp body, a threaded hole matched with an outer thread of the engine compressor rotor is formed in one end of the front end clamp body,a first tip hole is formed in the other end of the front end clamp body, and a plurality of first fine adjustment devices are arranged on the cylindrical surface of the front end clamp body in the circumferential direction; and the rear end clamp comprises a columnar rear end clamp body, a bushing mounting hole is formed in one end of the rear end clamp body, the bushing mounting hole is internally provided with a grooved bushing in clearance fit with the peripheral wall of the spline end of the engine compressor rotor, a second tip hole is formed in the other end of the rear end clamp body,and a plurality of second fine adjustment devices are uniformly arranged on the cylindrical surface of the rear end clamp body in the circumferential direction. According to the positioning and aligning device, the influence of the eccentric load caused by the gravity of the rotor in the clamping process and the machining error of the outer diameter of a spline shaft can be eliminated, and the precision of rotor grinding is ensured.

Owner:CHINA HANGFA SOUTH IND CO LTD

Edging device for high-density fiber cement fireproof board

InactiveCN111660162AStable positionAvoid affecting the working environmentEdge grinding machinesGrinding drivesFiberThermodynamics

The invention belongs to the field of cement fireproof board processing equipment, and in particular is an edging device for a high-density fiber cement fireproof board. Aiming at the problem that manual handheld grinders are required for existing grinding operations, which is time-consuming and laborious, has low grinding efficiency, and is easy to produce large amounts of dust during the grinding to cause pollution of the surrounding environment, the following solution is proposed that the edging device comprises an operating table, wherein the top of the operating table is fixedly installedwith a raised platform, the top of the raised platform is fixedly installed with a placement board, the top of the placement board is placed with a fireproof board, two grooves are formed on the topof the placement board, clamping plates are slidably installed in both grooves, and the sides of the two clamping plates close to each other are in contact with two sides of the clamping plate respectively. The edging device has a reasonable structure and convenient operation. During the edging operation, the grinding head can be controlled automatically for grinding to save time and labor and have high grinding efficiency, and the dust generated can be processed while grinding without polluting the surrounding environment.

Owner:要虎岭

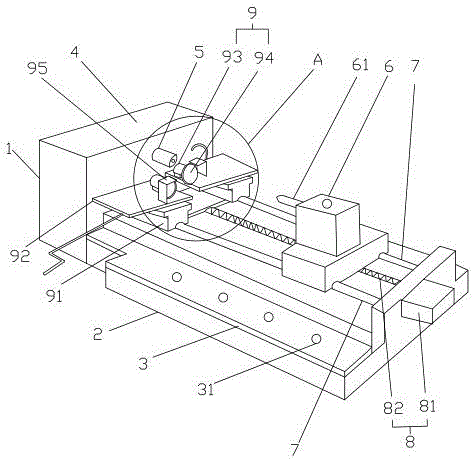

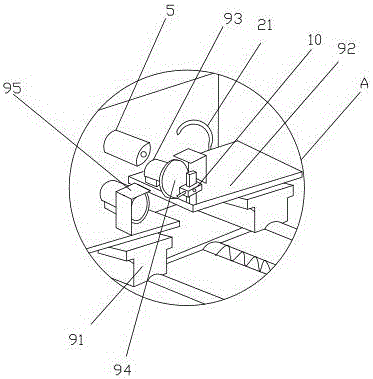

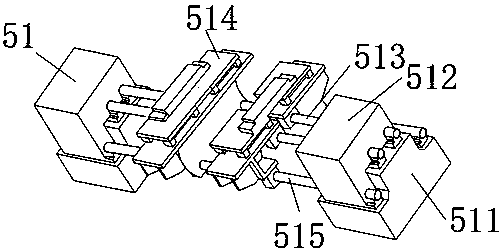

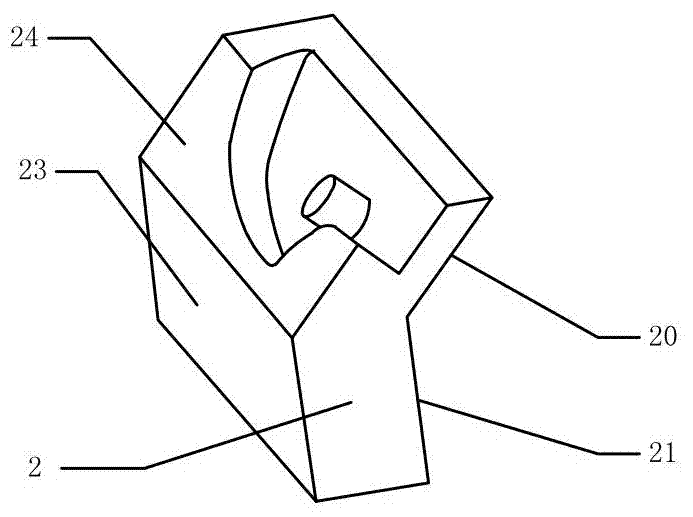

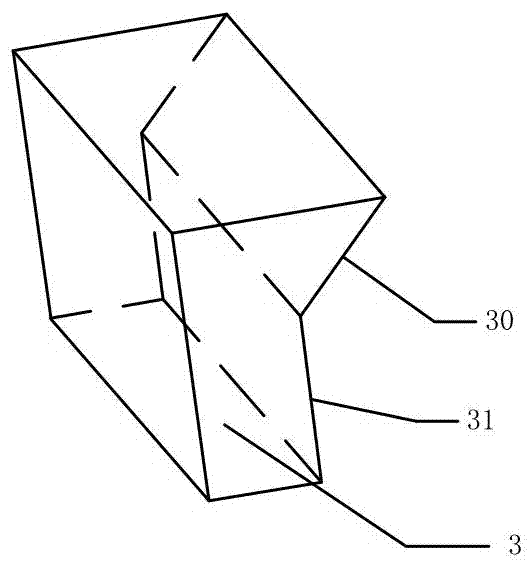

Workpiece machining mechanism, grinding device and grinding machine

PendingCN110103141AAvoid unsandable situationsImprove grinding efficiencyGrinding drivesGrinding machinesEngineeringMachining

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

L-shaped grinding mechanism for forklift part

InactiveCN106625119ARealize automatic grinding functionSimple and fast operationGrinding carriagesGrinding drivesHydraulic cylinderEngineering

The invention relates to an L-shaped grinding mechanism for a forklift part. The L-shaped grinding mechanism comprises a bottom plate, wherein the upper end surface of the bottom plate is welded with a fixed plate; a hydraulic cylinder is mounted on the fixed plate; a middle part fixing frame of the hydraulic cylinder is erected on a supporting column; the supporting column is mounted on the bottom plate; the supporting column achieves an effect of fixedly supporting the hydraulic cylinder; a push plate is mounted at the front end of the hydraulic cylinder through a screw; the push plate is tightly attached to a workpiece; the workpiece is mounted on the bottom plate; the hydraulic cylinder drives the push plate to move, and the push plate drives the workpiece to move on the bottom plate; two auxiliary lifting lugs are arranged on the upper end surface of the bottom plate; an auxiliary shaft is mounted between the two auxiliary lifting lugs through bearings; a longitudinal grinding wheel is mounted at the middle part of the auxiliary shaft; a driven gear is mounted at the right end of the auxiliary shaft; and the longitudinal grinding wheel is used for longitudinally grinding and derusting the workpiece. The L-shaped grinding mechanism can realize an automatic grinding function of an L-shaped forklift part, and has the advantages of simplicity and convenience for operation, short grinding time, good grinding effect, high working efficiency and the like.

Owner:YUEXI COUNTY HONGSHENG CASTING

Metallographical test piece polishing clamp

ActiveCN105710780AFlexible useAdjust the clamping situation in timePreparing sample for investigationGrinding work supportsStress conditionsTest sample

Owner:FENGYANG L S NET FORMING CO LTD

Compacting device for blade sharpening of scissor

PendingCN107253104AQuantity free adjustmentIncrease productivityOther manufacturing equipments/toolsGrinding work supportsStructural engineeringKnife blades

Owner:湖州泉欣五金科技有限公司

Notebook enclosure production device

InactiveCN108214214AShorten the timeEasy to processGrinding drivesGrinding machinesGear wheelDrive shaft

Owner:英力电子科技(重庆)有限公司

Polishing device for automobile part machining

PendingCN114523355APlay a fixed clamping effectHeight adjustableEdge grinding machinesGrinding drivesMotor vehicle partElectric machinery

Owner:WUXI AOYUTE NEW TECH DEV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap