Leather material location device for vertical type edge finishing machine

A technology of positioning device and edge grinding machine, which is applied to machine tools, grinding machines, grinding workpiece supports and other directions suitable for grinding workpiece edges, can solve the problems of high risk and difficult to control grinding accuracy, and avoid injury accidents, The effect of firm clamping and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Specific embodiments of the present invention are described with reference to the above drawings.

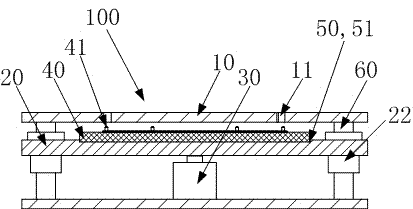

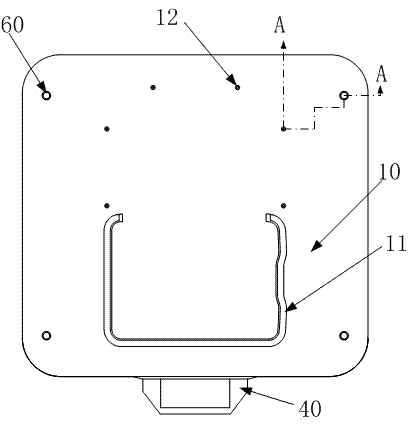

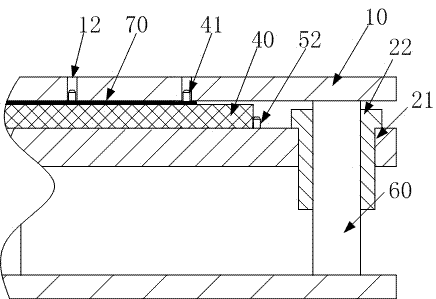

[0011] Depend on figure 1 with figure 2 It can be seen from the above that the leather positioning device of this vertical edger includes a clamp 100 arranged on the frame of the vertical edger for clamping the leather. The clamp 100 includes a fixed upper splint 10, and 10 below the lower clamping plate 20 and the lifting mechanism 30 that controls the lower clamping plate 20 to approach or move away from the upper clamping plate 10 . In the present invention, the clamping method is adopted to fix the leather material. Since the leather material is a soft material, it is easy to deform during the processing, which affects the quality of grinding. Using the clamping method to fix the leather material can keep the leather material The shape of the material during processing improves the processing quality. In addition, due to the strict requirements on the grinding depth

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap