Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

231 results about "Nozzle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A nozzle is a device designed to control the direction or characteristics of a fluid flow (especially to increase velocity) as it exits (or enters) an enclosed chamber or pipe. A nozzle is often a pipe or tube of varying cross sectional area, and it can be used to direct or modify the flow of a fluid (liquid or gas). Nozzles are frequently used to control the rate of flow, speed, direction, mass, shape, and/or the pressure of the stream that emerges from them. In a nozzle, the velocity of fluid increases at the expense of its pressure energy.

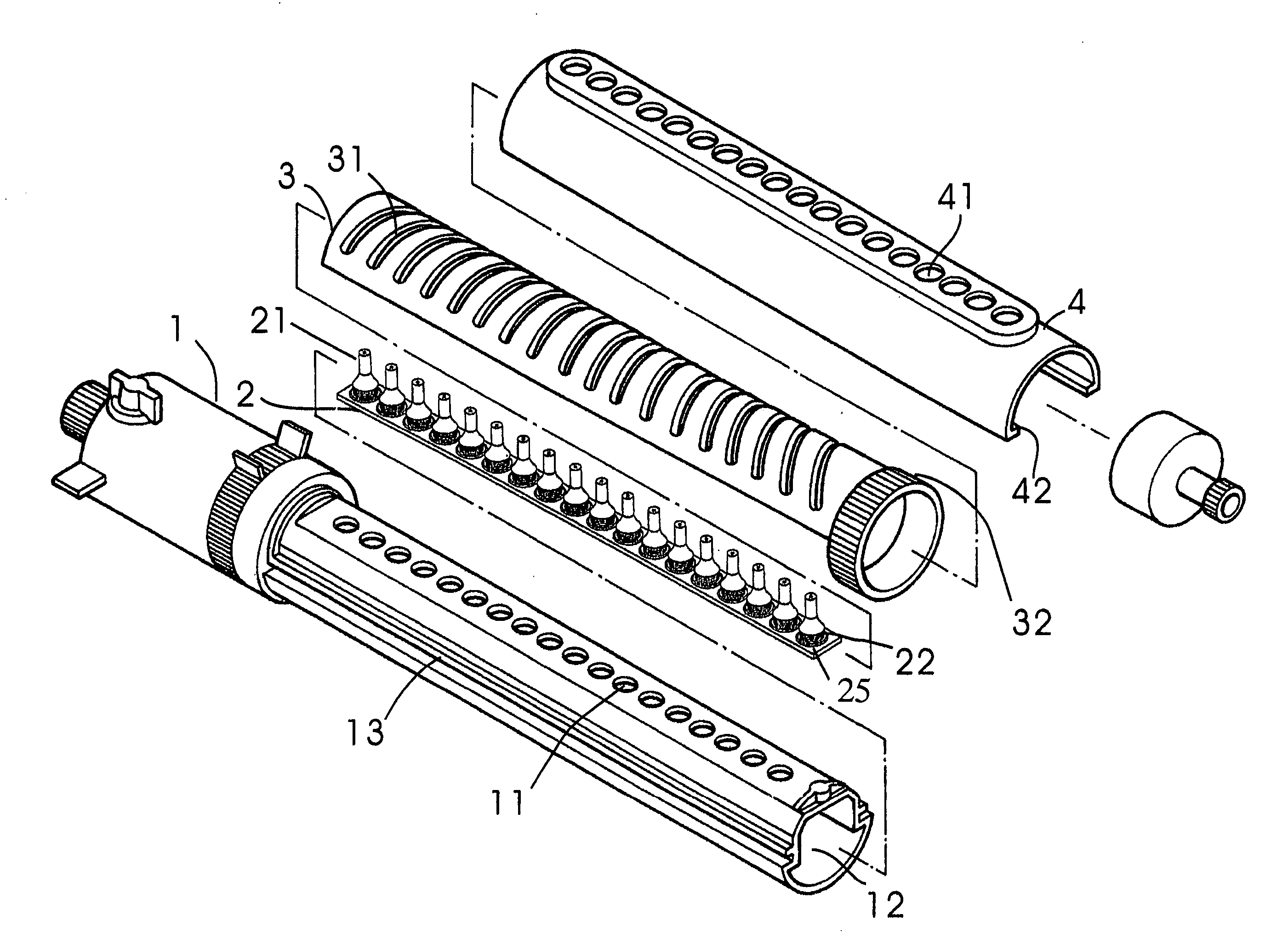

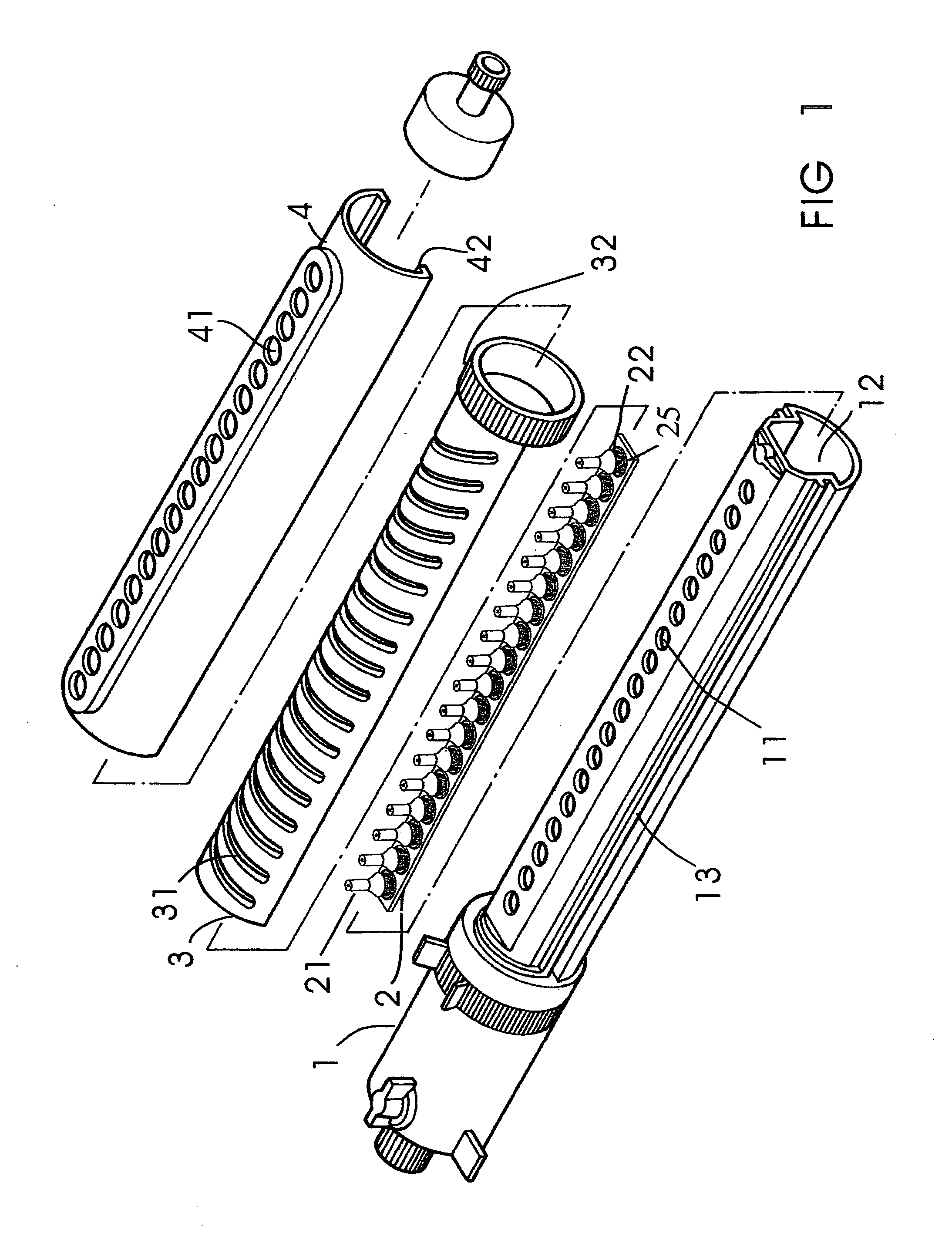

Spray head

InactiveUS7040554B2Eliminate the problemEasy to disassembleLiquid surface applicatorsDust removalLiquid productCoupling

Owner:ASEPT INT

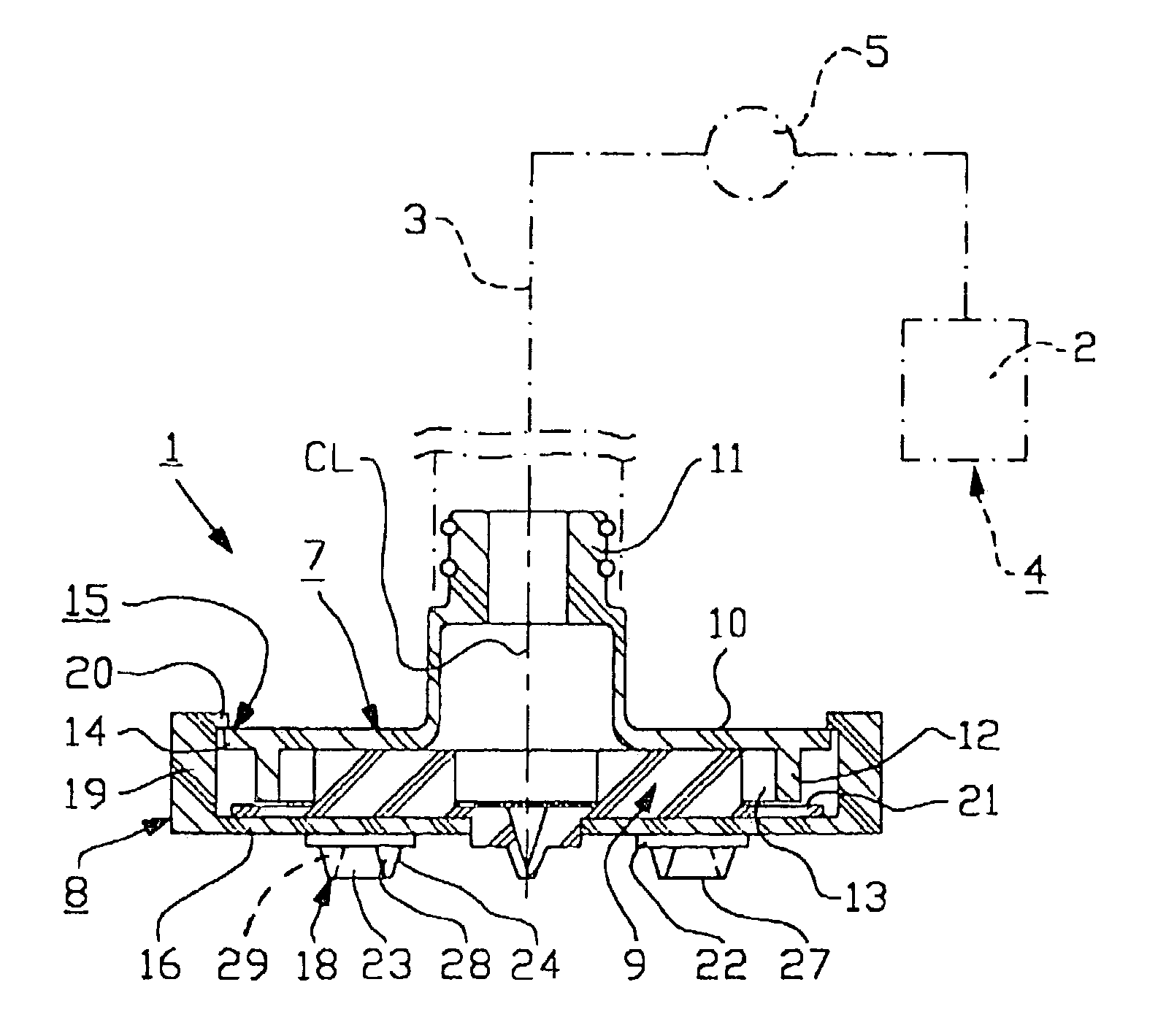

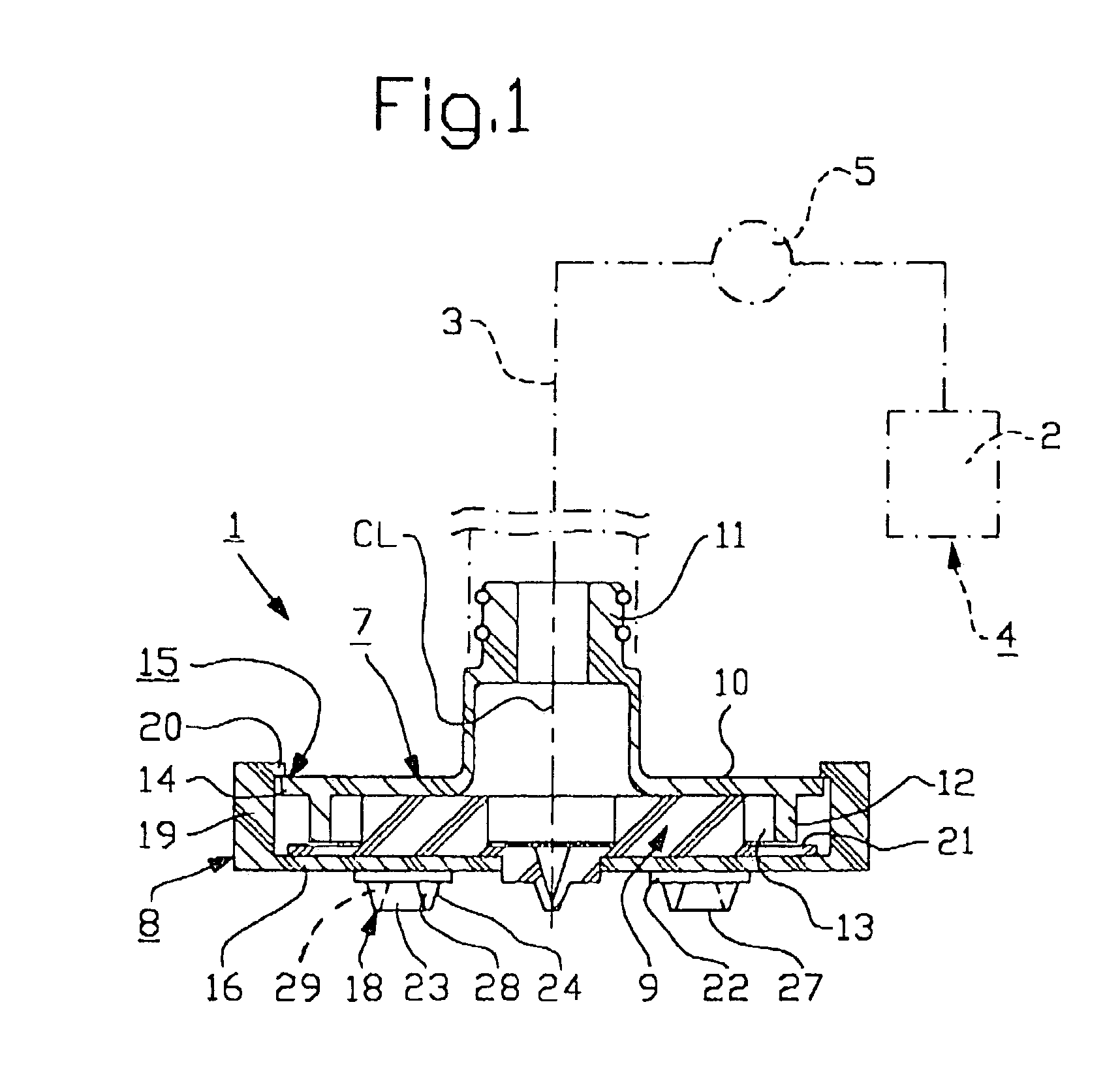

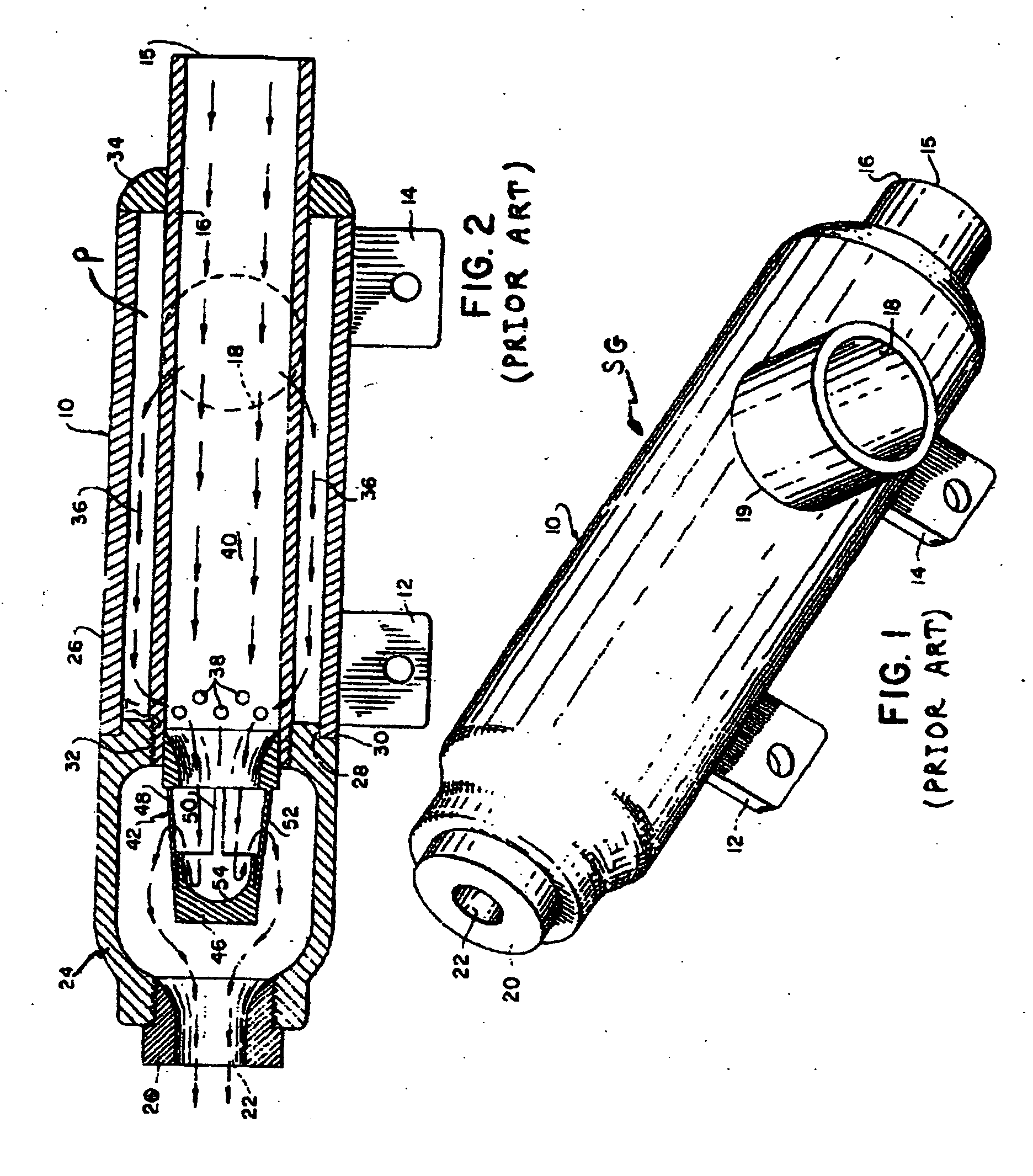

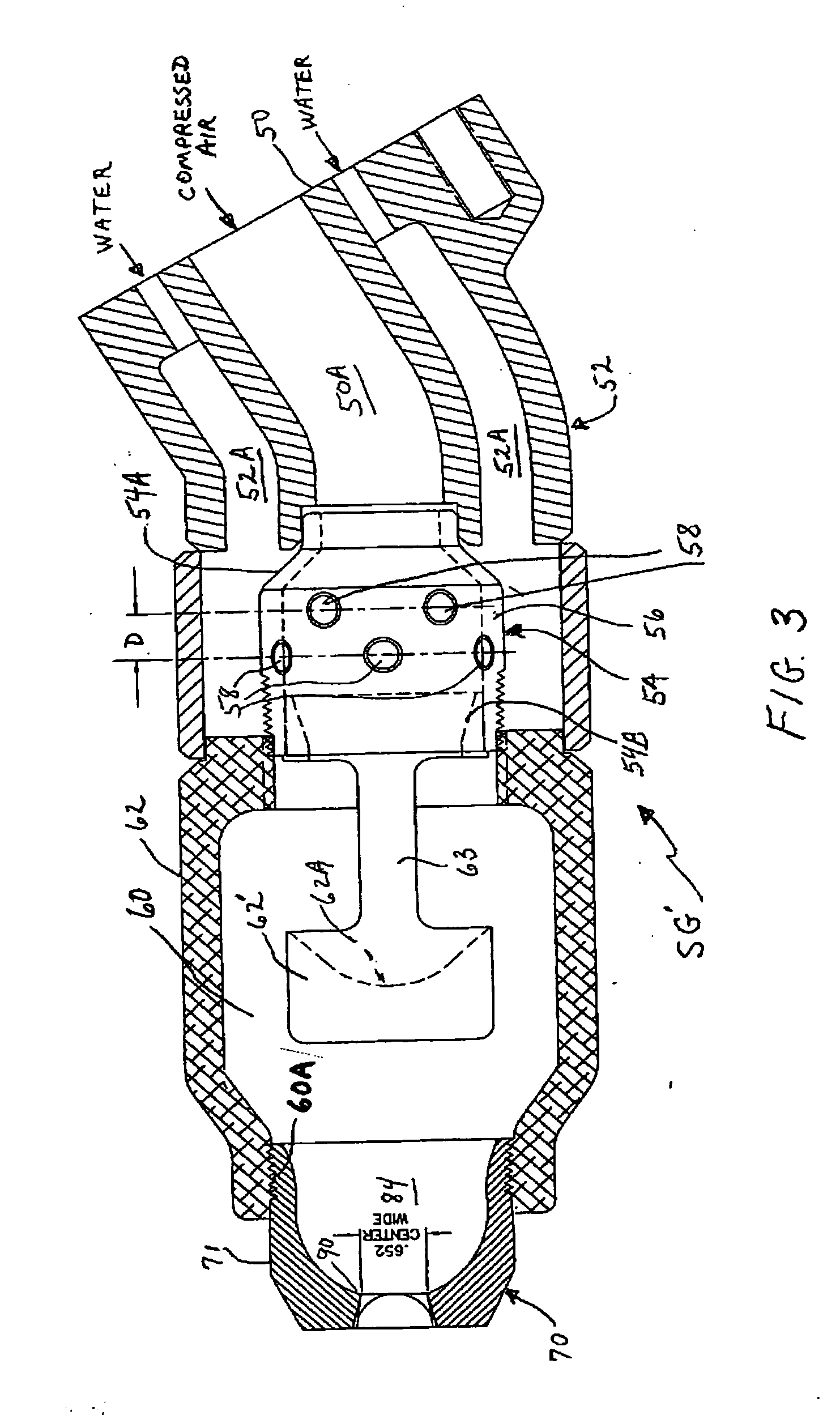

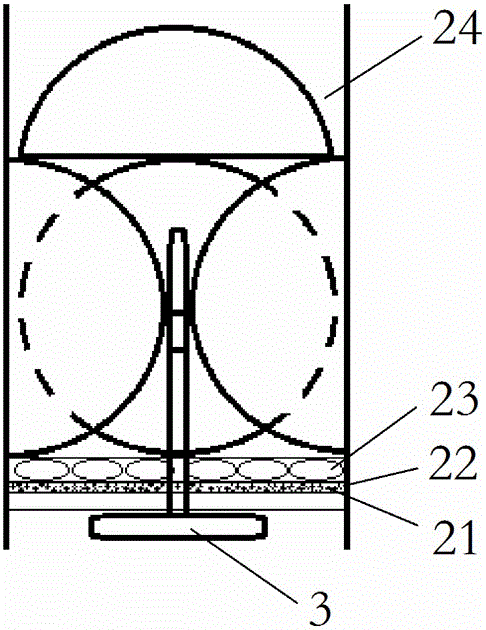

Snow-gun

ActiveUS20060071091A1Improve efficiencyRecreational ice productionSpray nozzlesWater featureWater particle

Owner:RATNIK IND

Sprinkler having movable nozzles

Owner:YUAN MEI CORP

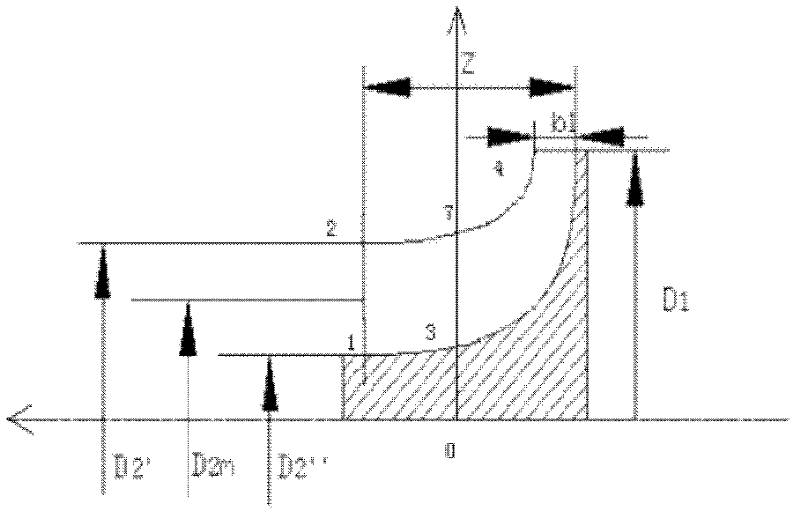

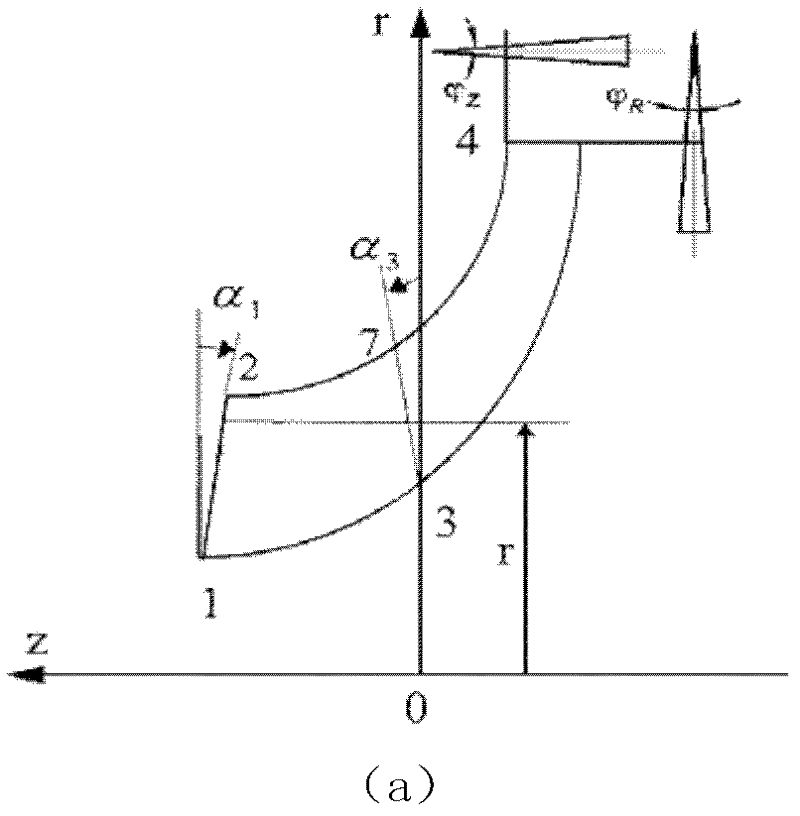

Optimization design method of radial-flow-type hydraulic turbine

ActiveCN102608914ASmall amount of calculationHigh precisionAdaptive controlImpellerMultivariable optimization

Owner:开山(西安)透平机械有限公司

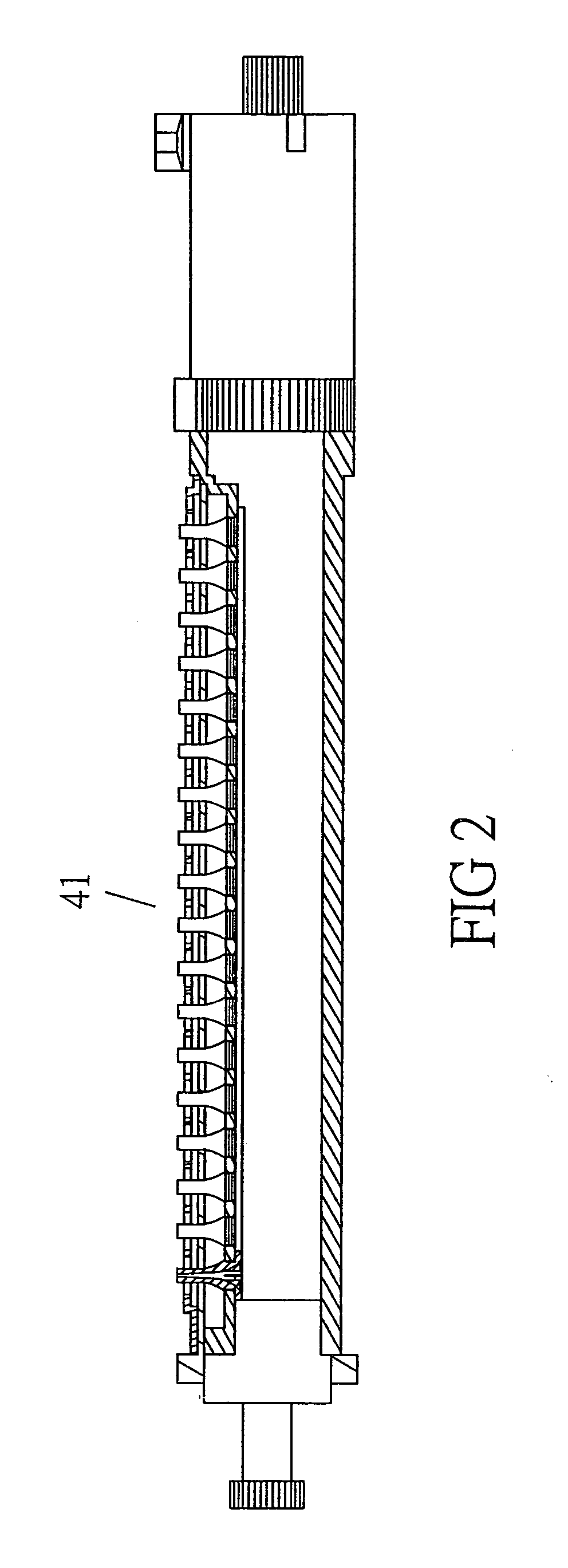

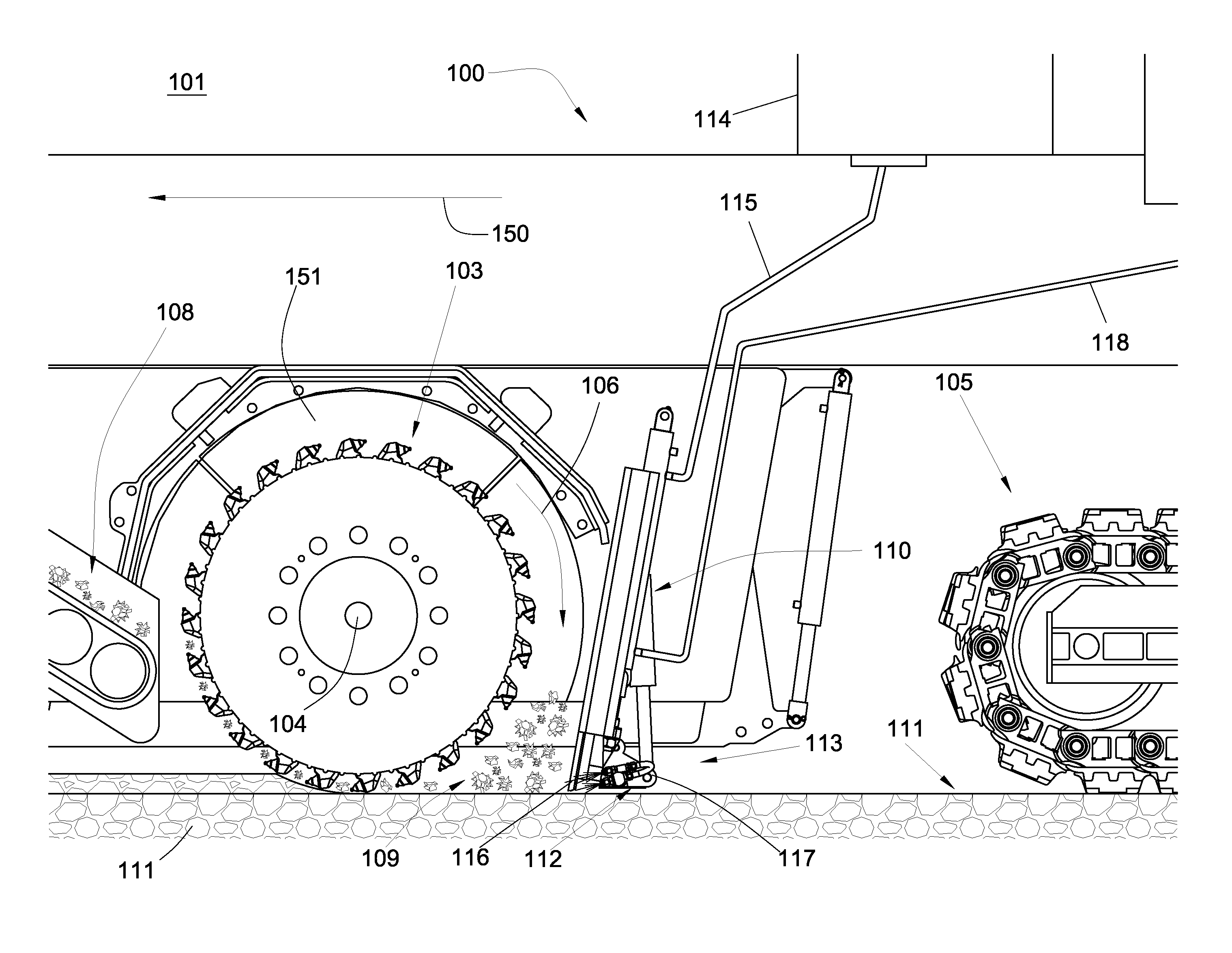

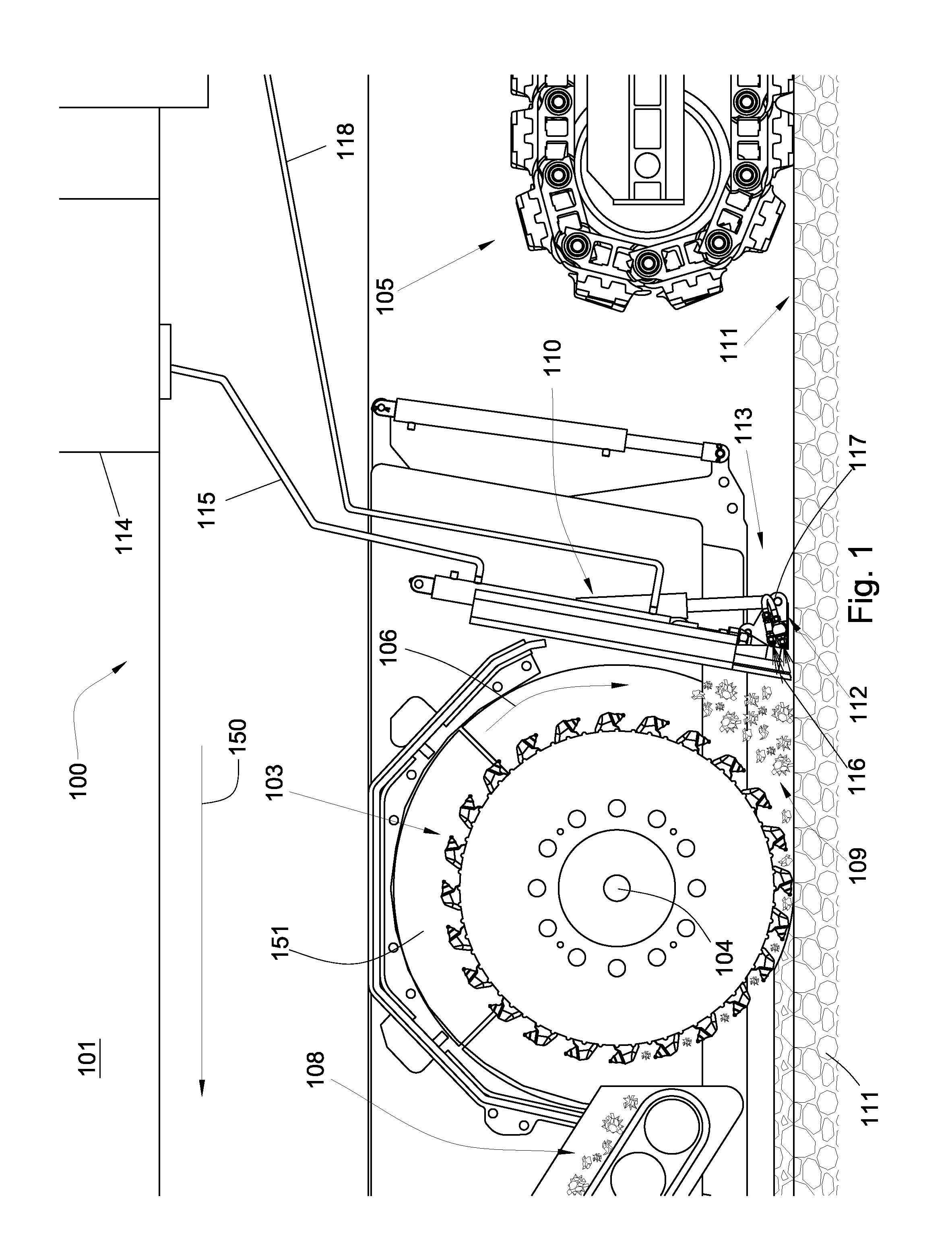

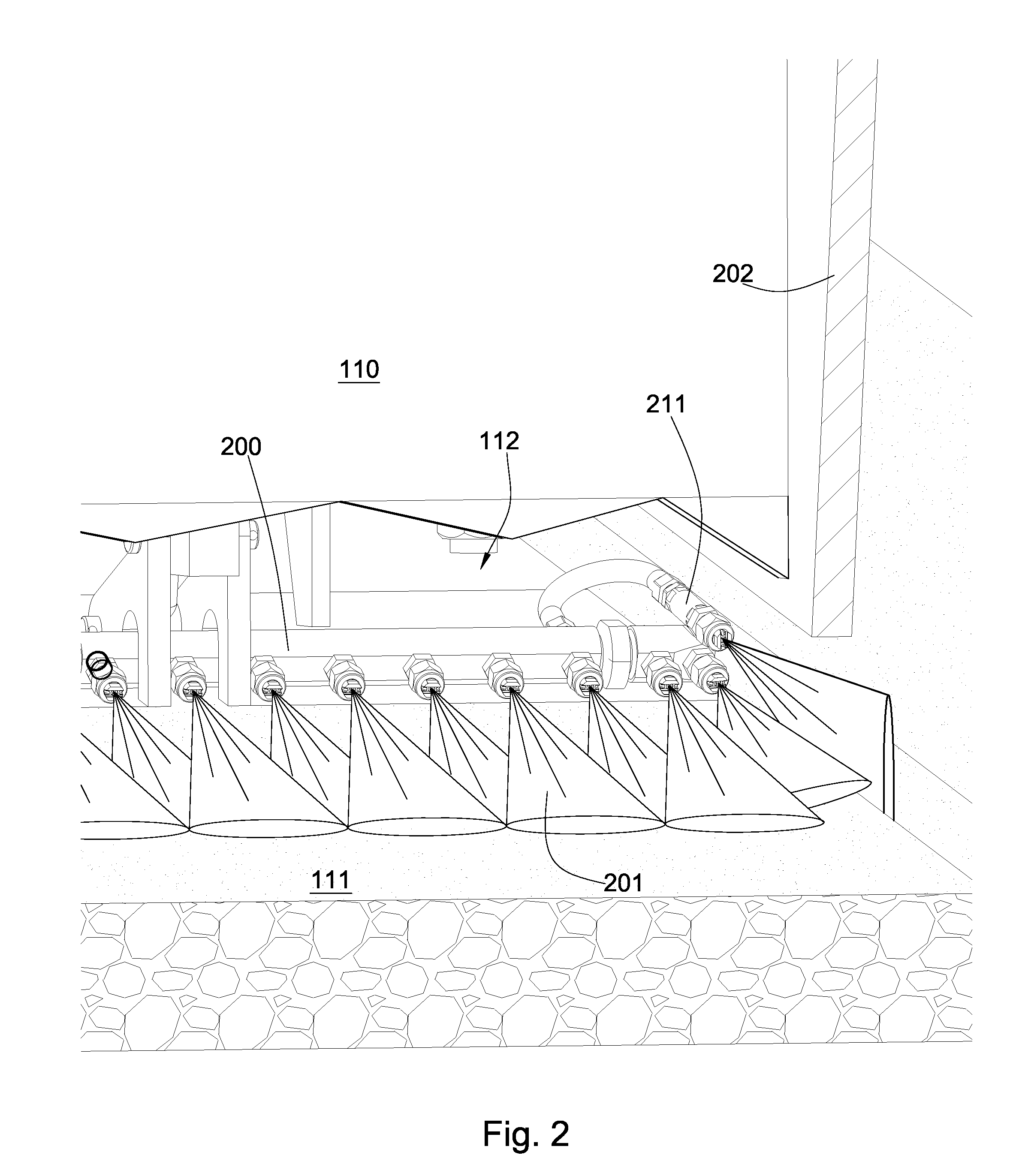

Nozzles Incorporated into a Milling Machine

Owner:NOVATEK IP

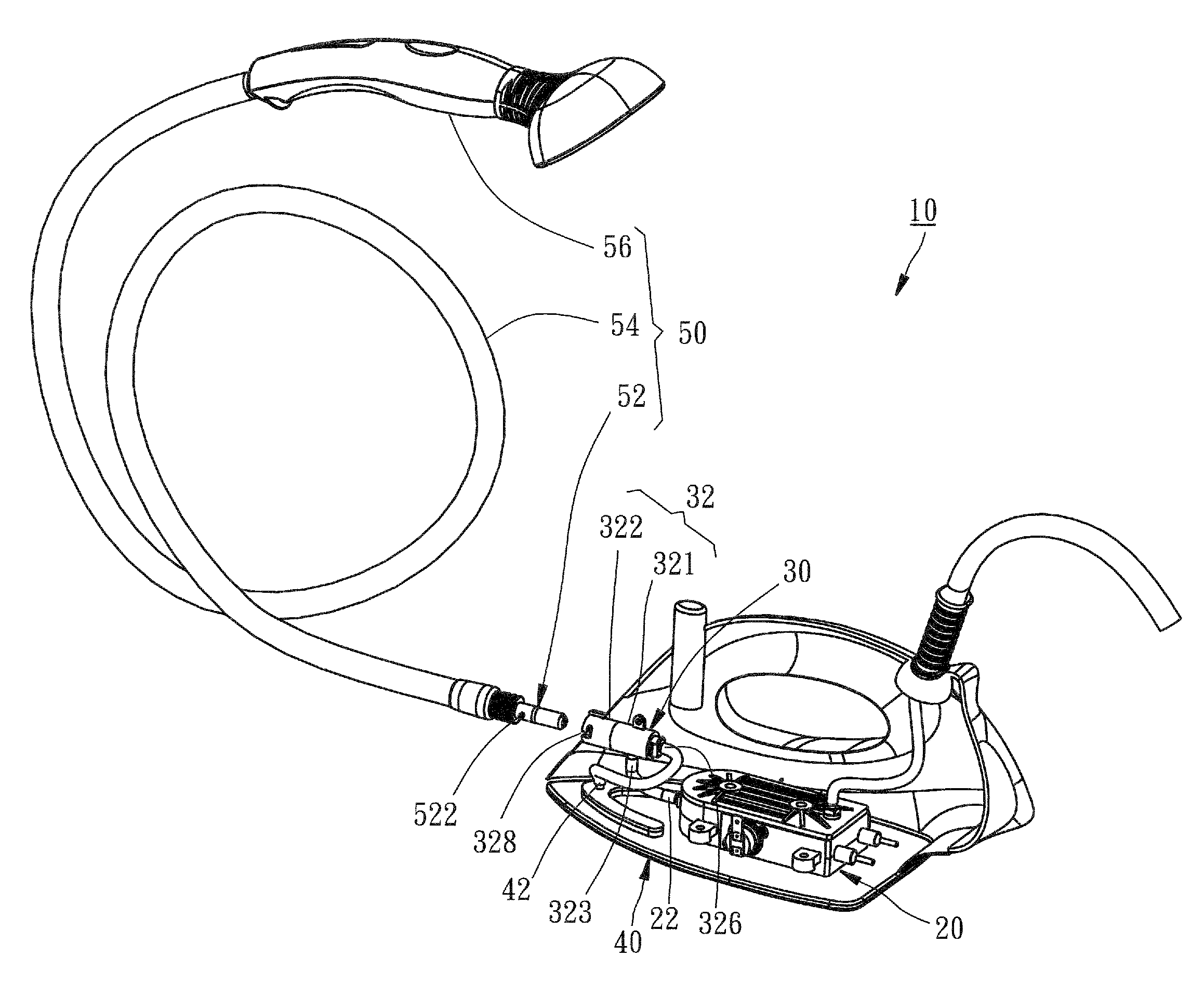

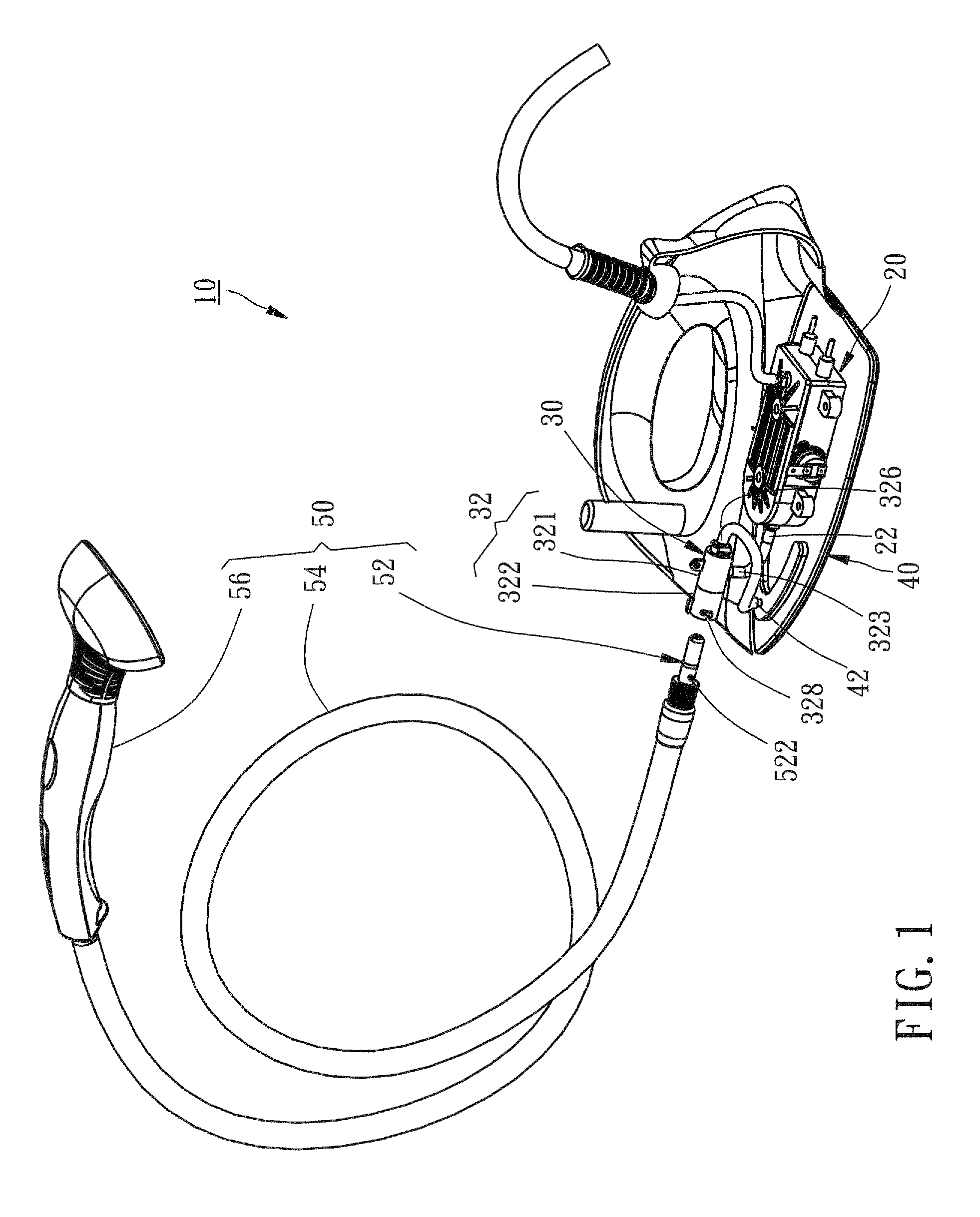

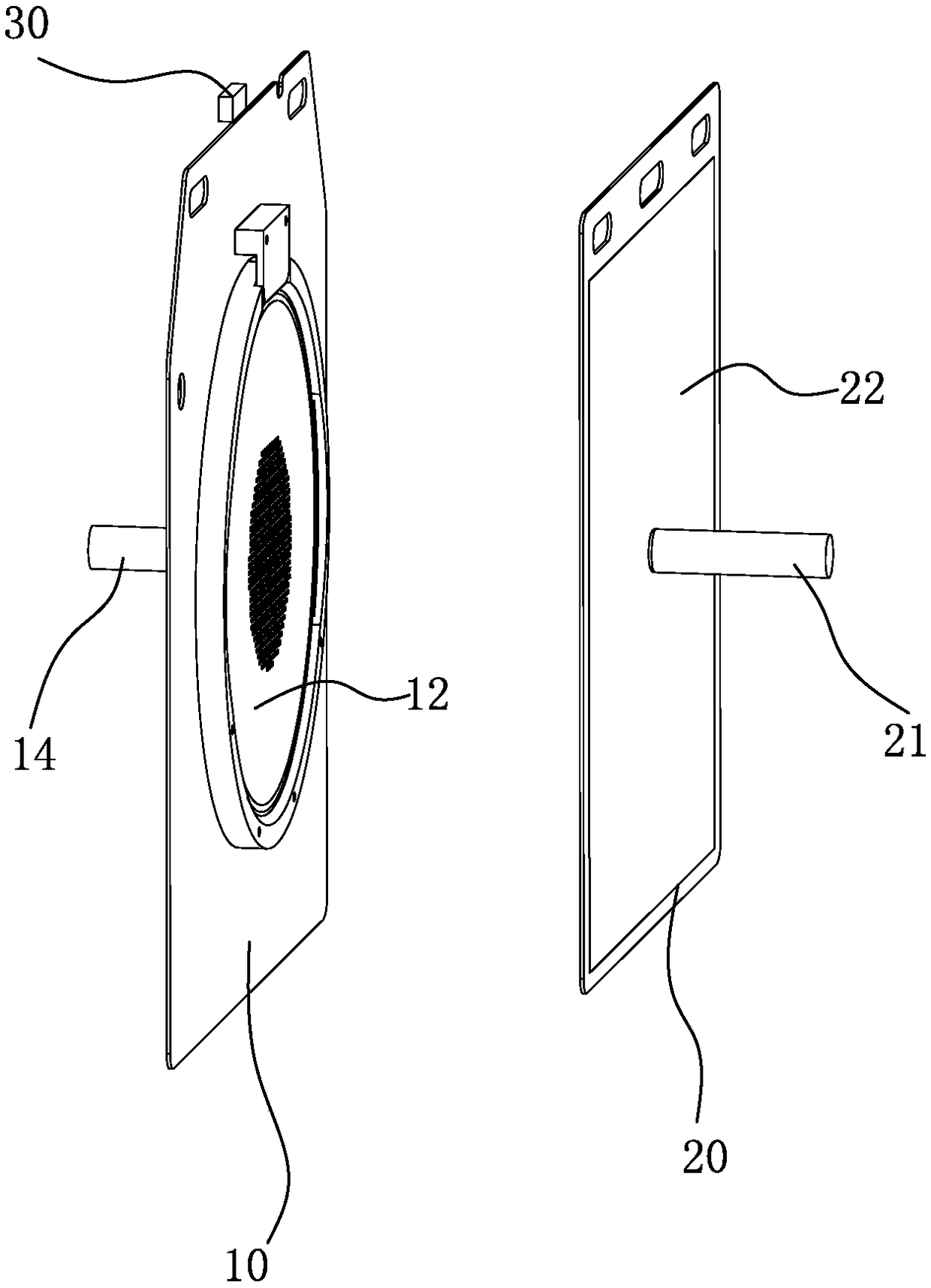

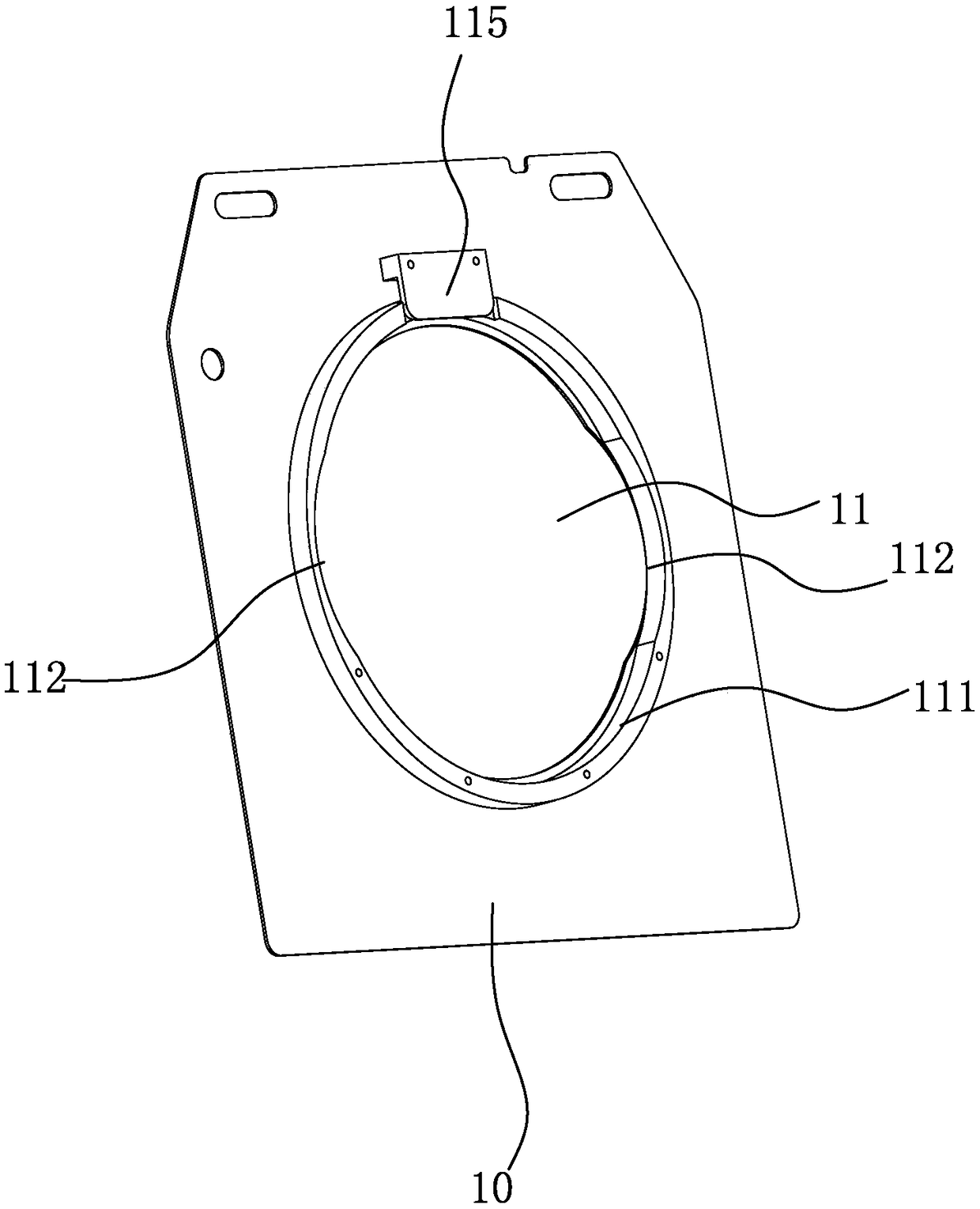

Electric steam iron

Owner:CHEN HSI FU +1

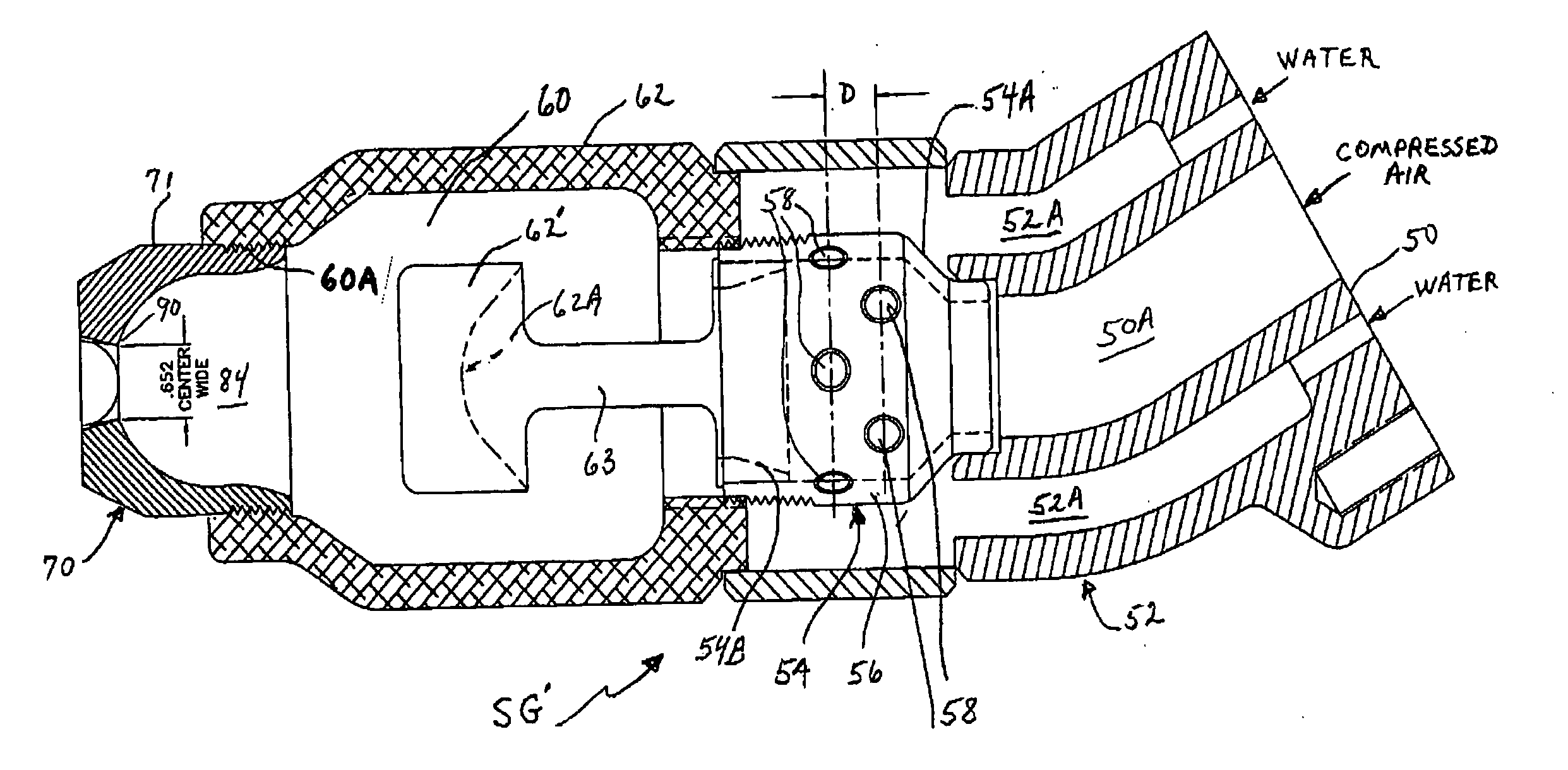

Special fixture for processing inclined conical nozzle steam passage and method thereof

InactiveCN101670527AGuaranteed accuracyImprove operational efficiencyPrecision positioning equipmentPositioning apparatusMilling cutterDrill bit

A special fixture for processing an inclined conical nozzle steam passage and a method thereof relate to a fixture for processing the inclined conical nozzle steam passage and a method thereof. The invention solves the problem that at present, no special fixture for processing the inclined conical nozzle steam passage exists, and when a tapered hole of the nozzle steam passage is processed, a drilling bit is difficult to be centered. An indexing plate of the special fixture is provided with twenty indexing through holes along the periphery direction; the center of a stepped through hole and the center of the indexing through holes are on one periphery; a spotting spindle is mounted on the indexing plate in a plug-in manner; the processing method is as follows: using a milling cutter with diameter of 13mm to feed from a P point so as to process a plane C which is vertical to the central line of the tapered hole to be processed; and stopping feeding when the milling cutter mills to a Q point, wherein the center of a hole pitch circle having diameter of 13mm and milled by the milling cutter is the core-bit of the drilling bit. The special fixture solves the problem that at present, nospecial fixture for processing the inclined conical nozzle steam passage exists; and the inclined conical hole of the nozzle stream passage processed by the method has high position accuracy.

Owner:HARBIN TURBINE

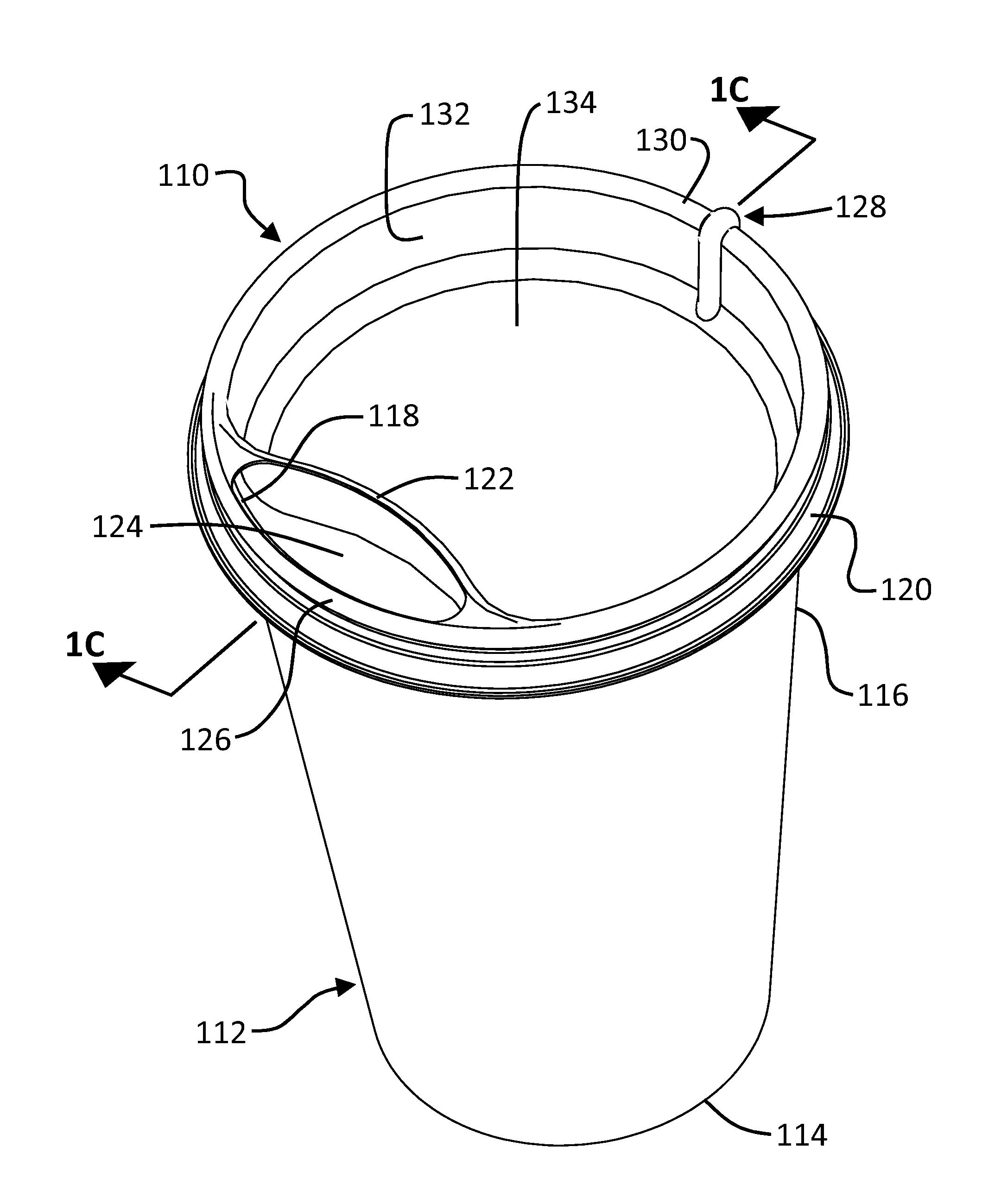

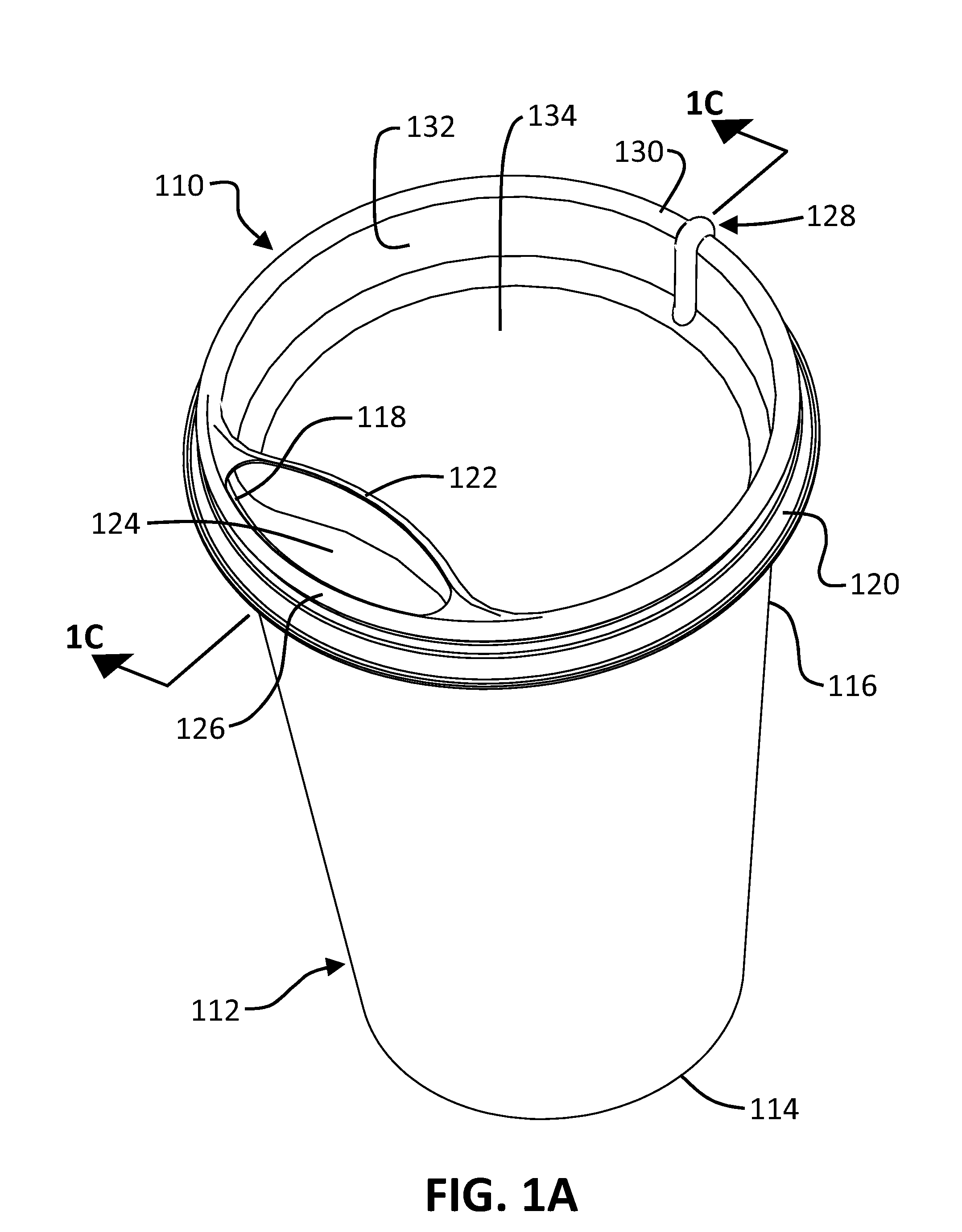

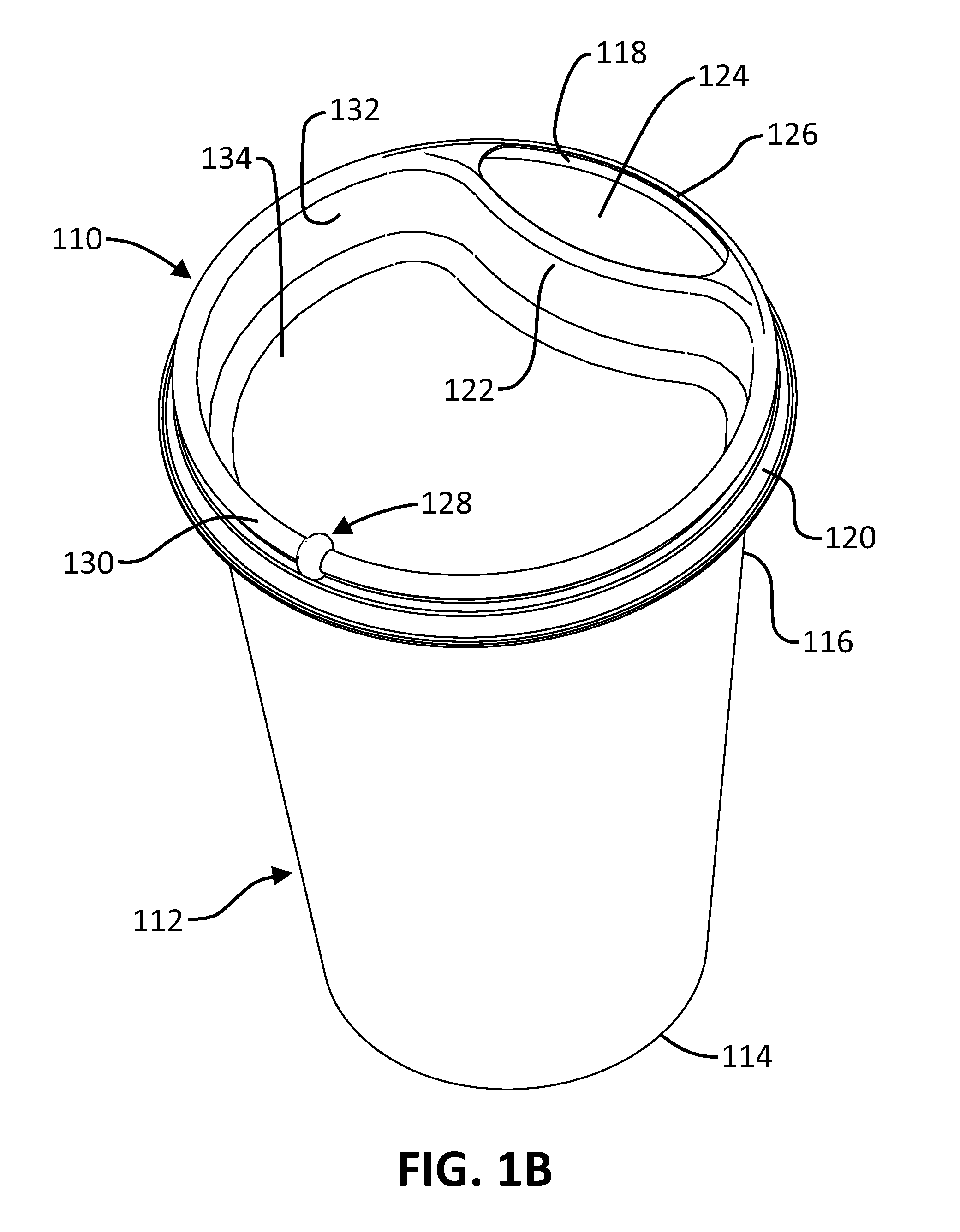

Rapid-flow and smooth-spouted container lid

Owner:POWELL WADE ANTOINE

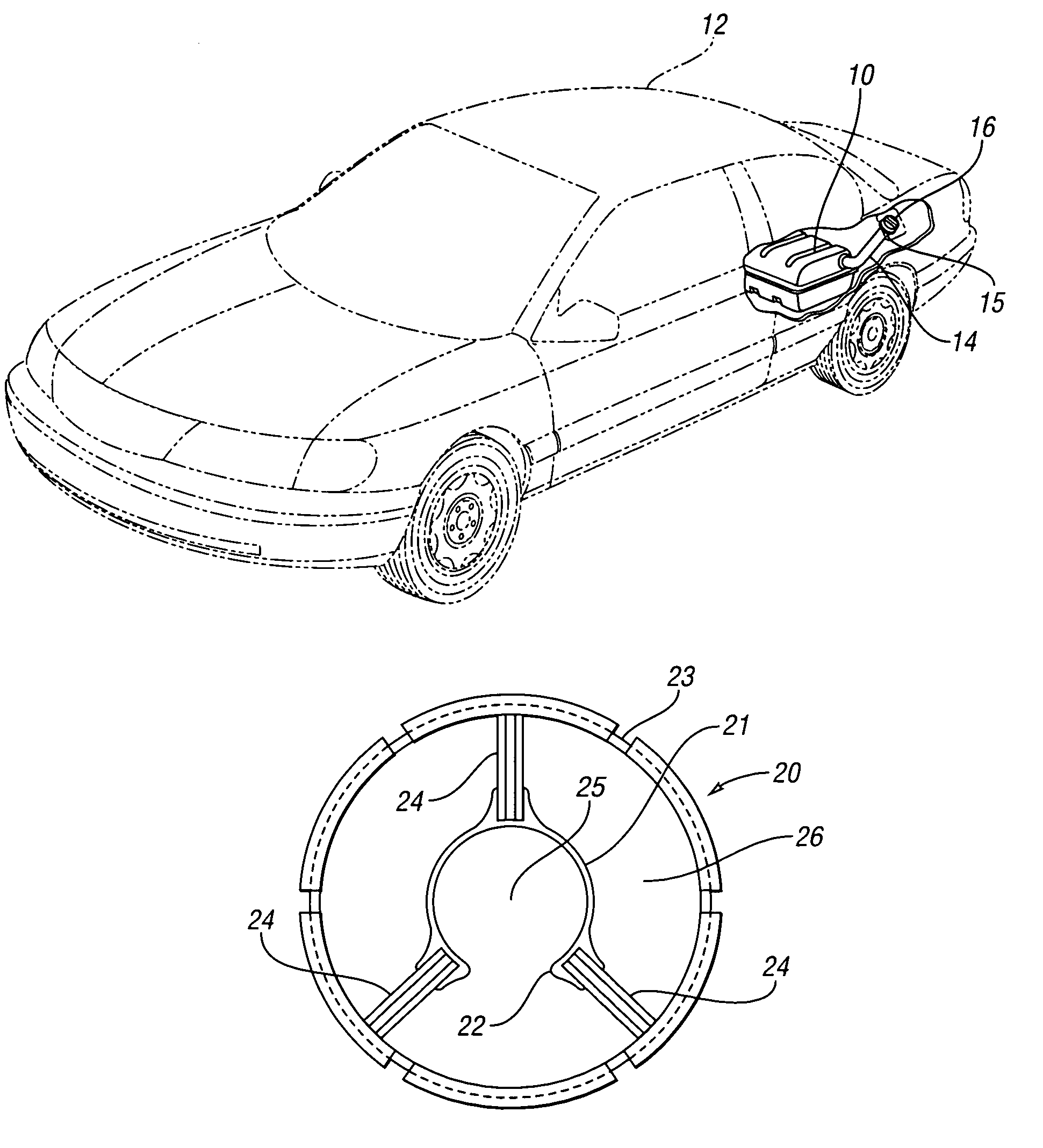

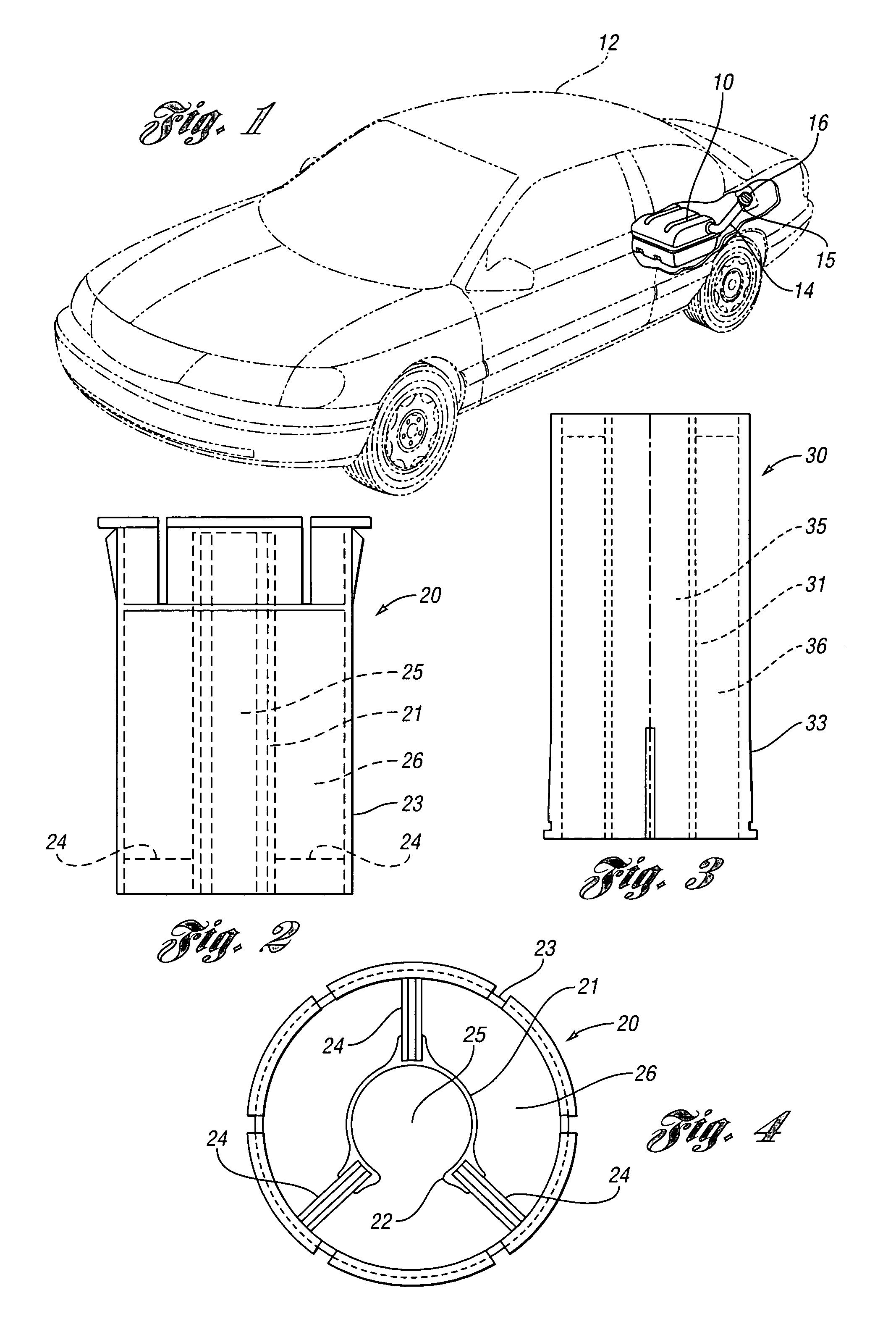

Misfueling prevention device

InactiveUS6966349B1Simple and reliable processEasy to operateSolid materialClosures to prevent refillingFuel tankEngineering

Owner:LADUKE INNOVATIONS

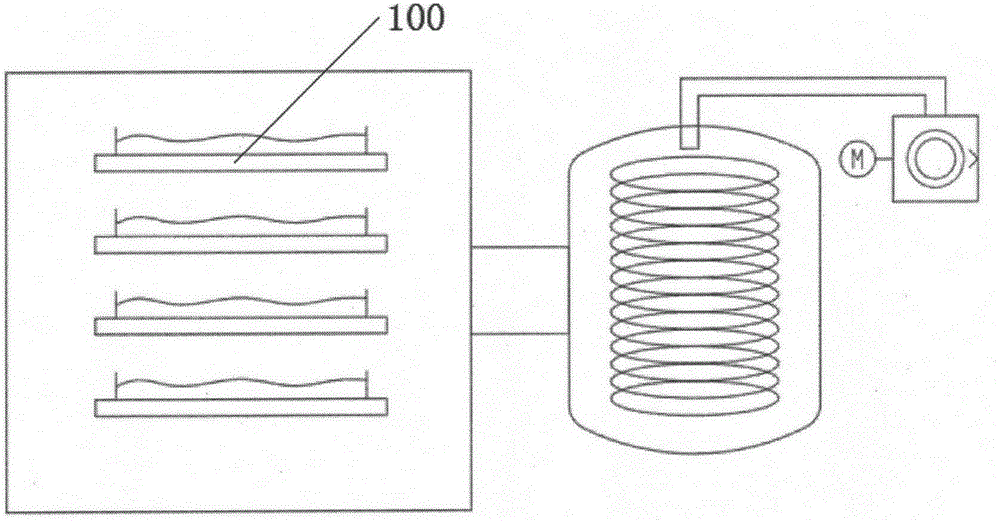

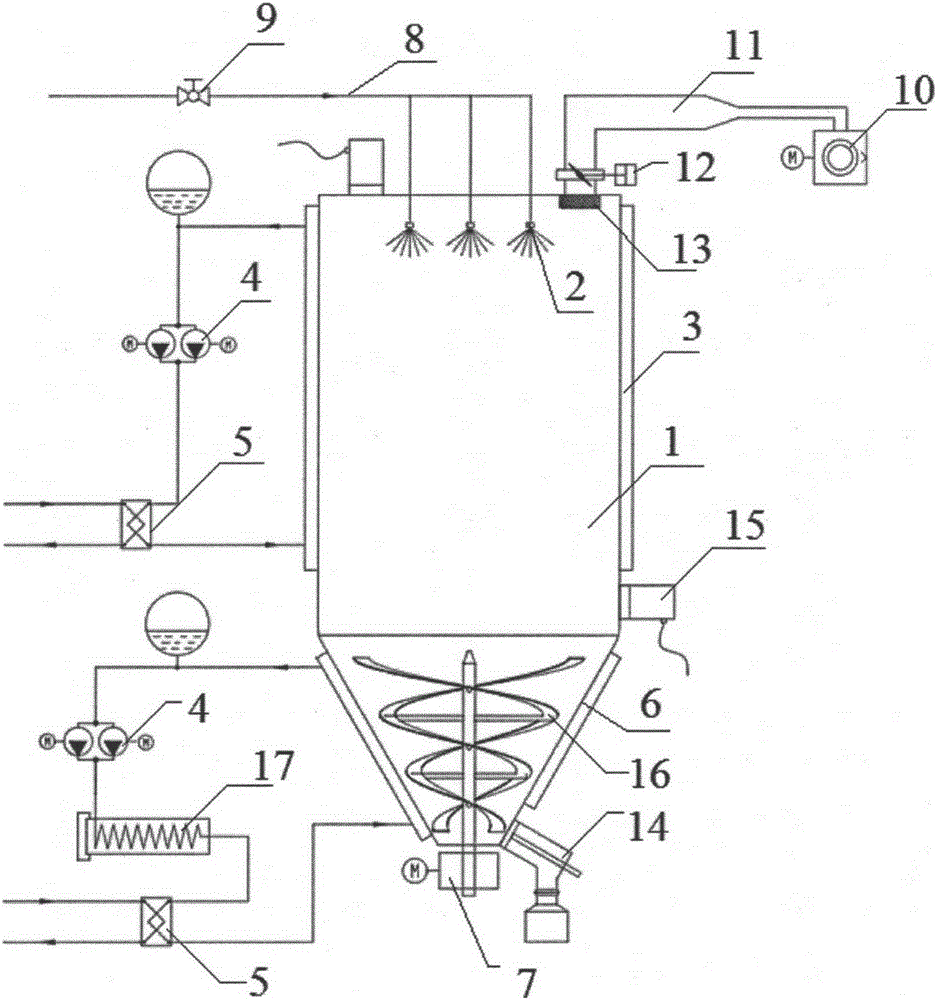

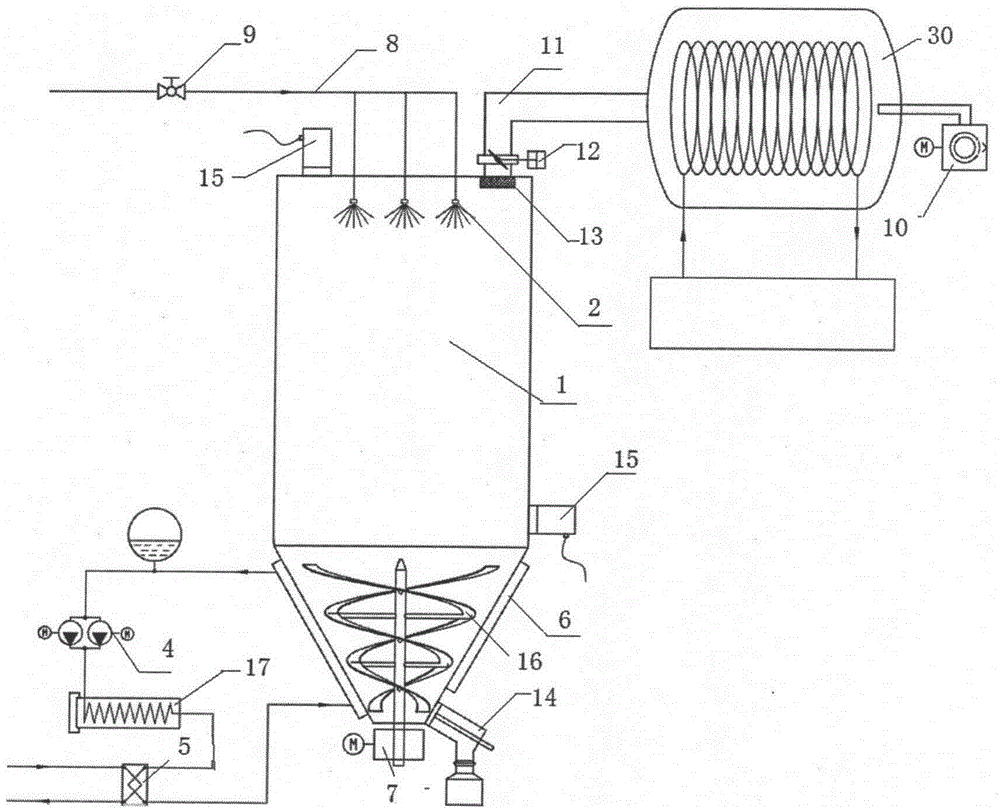

Vacuum spray freeze-drying device and method

Owner:SHANGHAI TOFFLON SCI & TECH CO LTD

Asphalt mixture regenerating heating stirring roller

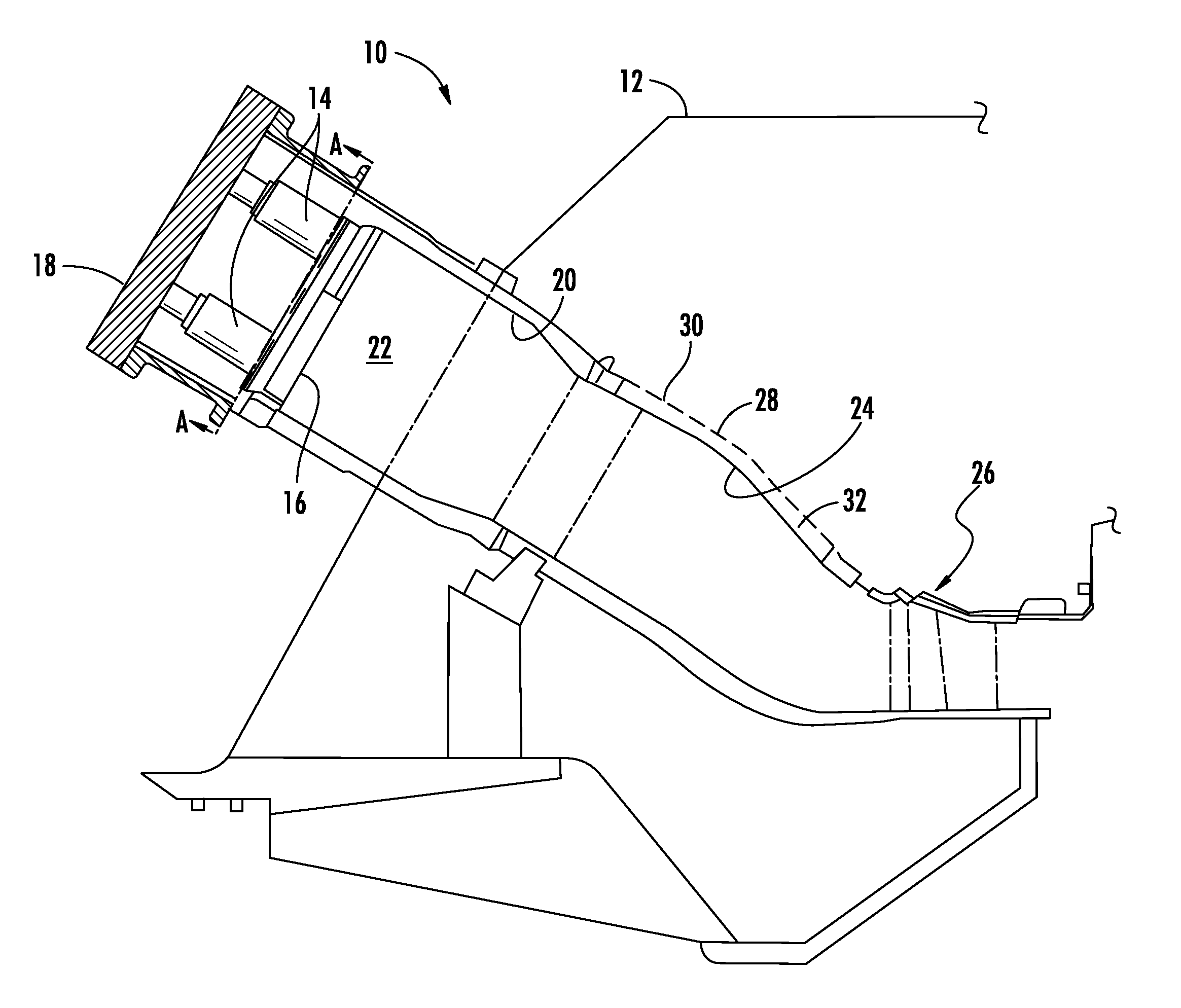

The invention discloses an asphalt mixture regenerative heating rod and mixing roller, and belongs to the concrete stirring technical field. The invention has a tilted roller supporting frame, a rolling ring, a roller and a roller driving device, wherein, the rolling ring is sleeved on the roller and supported by a rolling wheel arranged on the roller supporting frame, a burner is arranged at the lower end of the roller, a material outlet is arranged on the roller at the lower part of the burner, a material inlet is arranged at the other end of the roller, and a smoke outlet is arranged on the roller; wherein, an inner screening tube is sleeved inside the roller positioned at the material inlet end, and the inner screening tube is connected with the roller, the outer peripheral wall of the inner screening tube is composed of a screening mesh, a circular filtering mesh is sealed at the end part on the inner side of the inner screening tube, the material inlet is communicated with the inner screening tube, and an asphalt nozzle is arranged inside the roller positioned below the burner at the outlet end. The invention has compact and rational structure and high heat exchange efficiency, does not require secondary breakup of the waste asphalt mixture, can directly heat the block shape waste asphalt mixture for recycling; and the regenerated asphalt mixture can be directly utilized.

Owner:HENAN ROADY ROAD MACHINERY

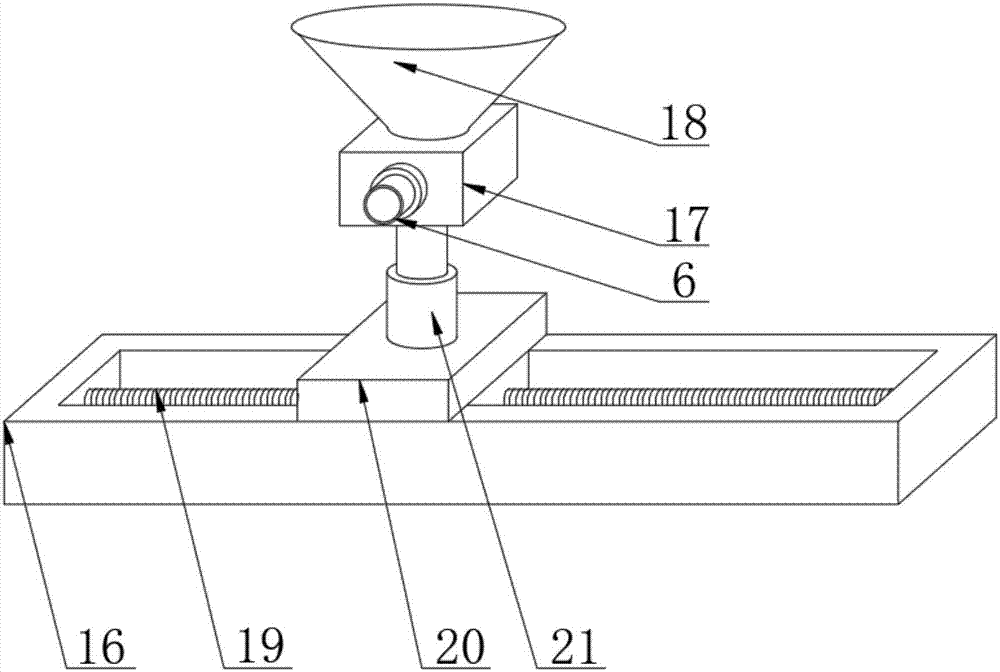

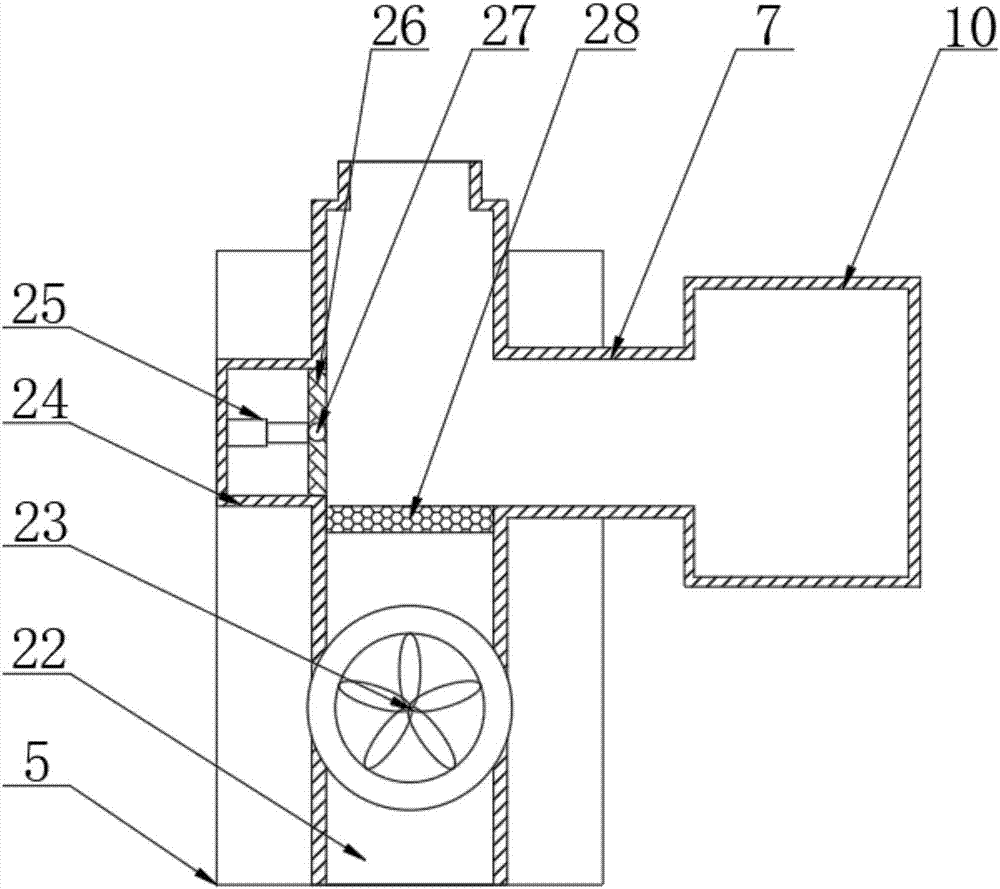

Rapid molding method based on electrorheological fluid, and apparatus thereof

A rapid molding method based on an electrorheological fluid, and an apparatus thereof are provided. The electrorheological fluid is jetted to a deposition base station with electric field, the electrorheological fluid is rapidly cured through utilizing an electrorheological effect, and the electrorheological fluid deposits on the deposition base station layer by layer to construct a three dimensional entity; a liquid storage container, a driving pump and a nozzle are sequentially communicated through a pipeline to form an electrorheological fluid conveying path; two control lines are set by a computer, a first control line controls the flow of the driving pump, and a second control line controls the three dimension movement of the nozzle through a servo mechanism; and electrodes which comprise an anode and a cathode closely adhere to two sides of a model to be deposited on the deposition base station to provide the electric field required by the curing of the electrorheological fluid. The apparatus which utilizes the electrorheological effect of the electrorheological fluid and utilizes the electric field to replace a temperature control module and a constant temperature environment in traditional fusion jet rapid molding has the advantages of simple structure, substantial reduction of the cost and energy, and realization of micromation; and the method and the apparatus can be applied to fields of prosthesis models, industrial design, mechanical manufacturing, three dimensional scene display, entertainment and art, and the like.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

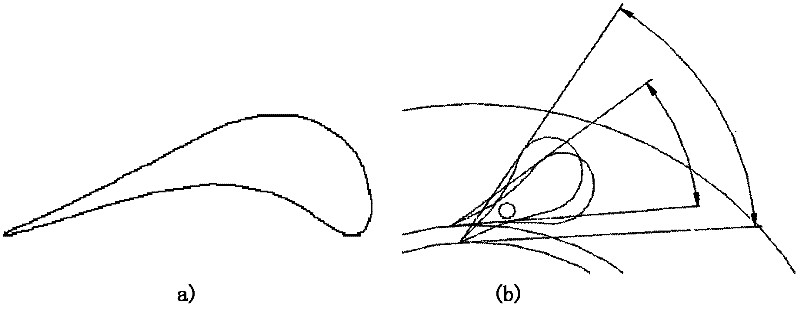

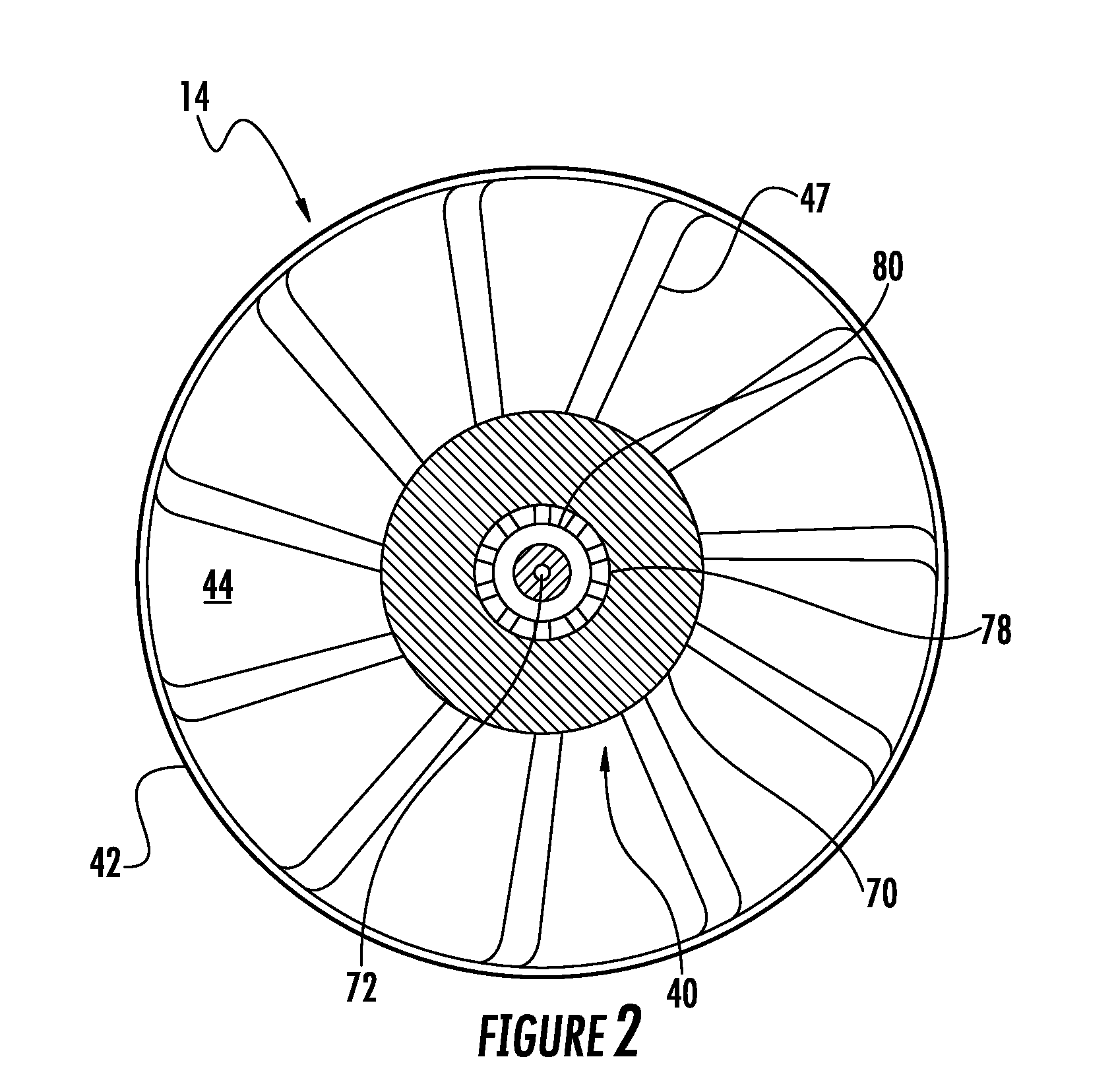

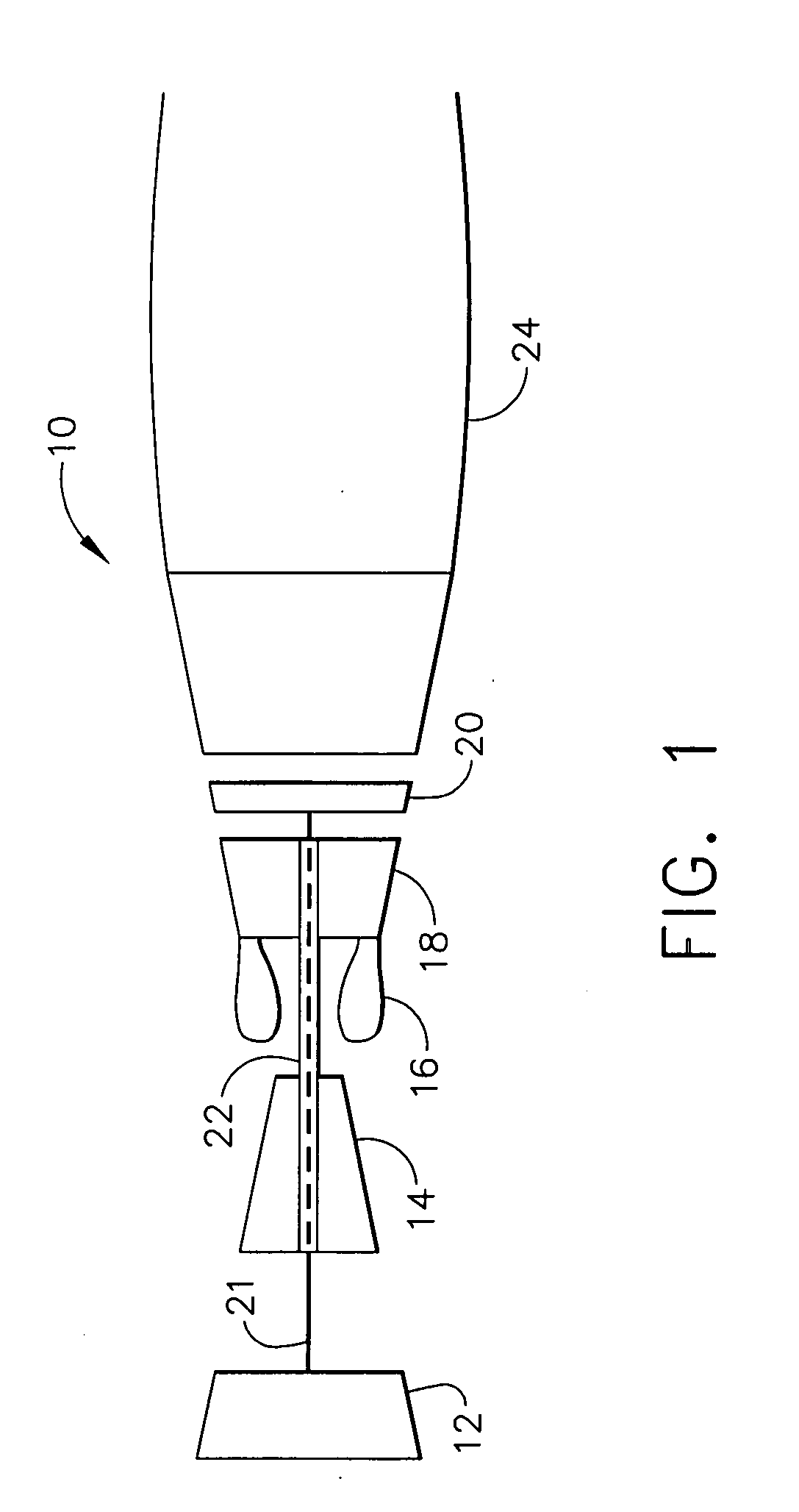

Blowing pollinator and method for using same to carry out blowing pollination

The invention relates to the field of cross breeding, in particular to a blowing pollinator and a method for using the same to carry out blowing pollination. The blowing pollinator comprises a fan and an air guide; the air outlet of the fan is connected with the air guide, and the air outlet end of the air guide is connected with two air nozzles; each air nozzle is an adjustable air nozzle, and can adjust the angle between the jetted airflow and the horizontal plane; each air nozzle is perpendicular to the air outlet end of the air guide, i.e., the flowing direction is changed by 90 degrees after the airflow enters the air nozzle via the air guide; the two air nozzles respectively face up at the left and the right of the air outlet end of the air guide; and the fan is connected with a storage battery for supplying power and a flow velocity regulator for regulating the velocity of the airflow. The blowing pollinator and the blowing pollination method provided by the invention can utilize the airflow to directly blow the mature pollen of male parents into the air over a male parent area, the pollen then spontaneously falls to finish the pollination process, and thereby the setting rate of the cross breeding can be remarkably increased.

Owner:SICHUAN CHUANLONG TRACTORS MFG CO LTD

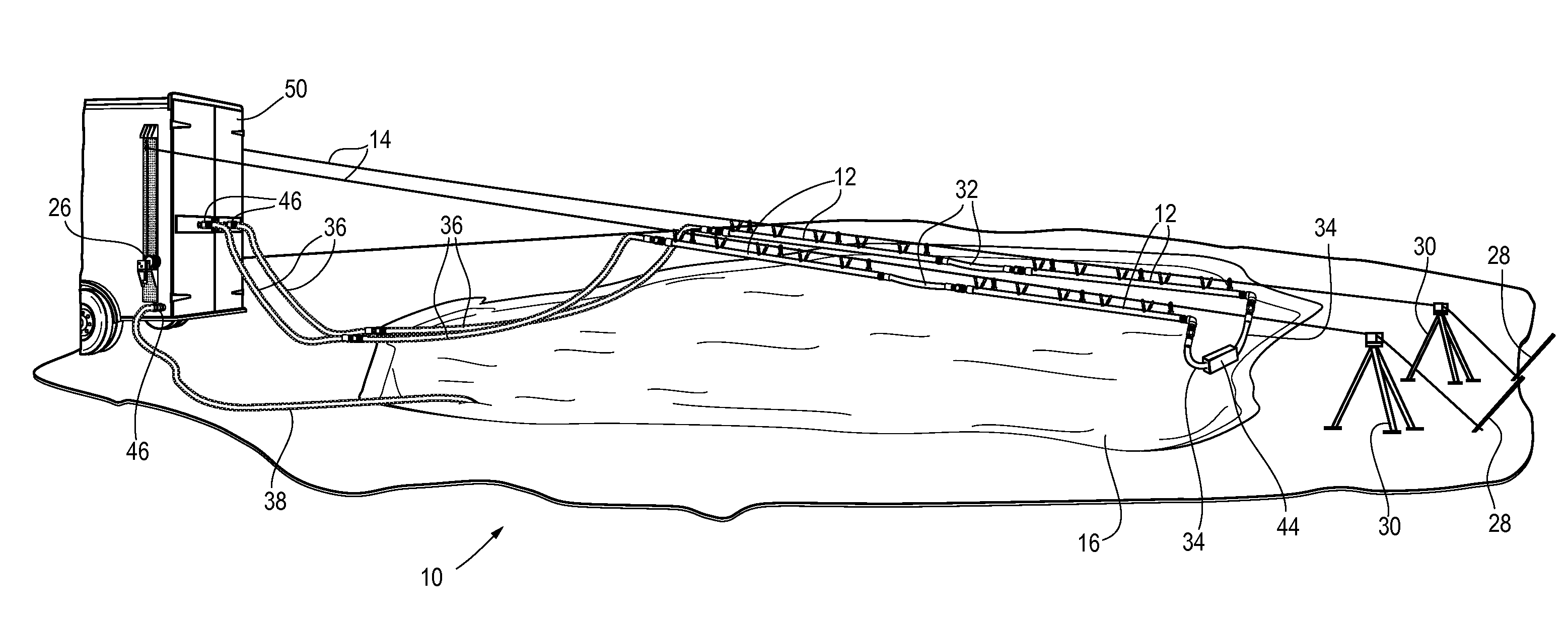

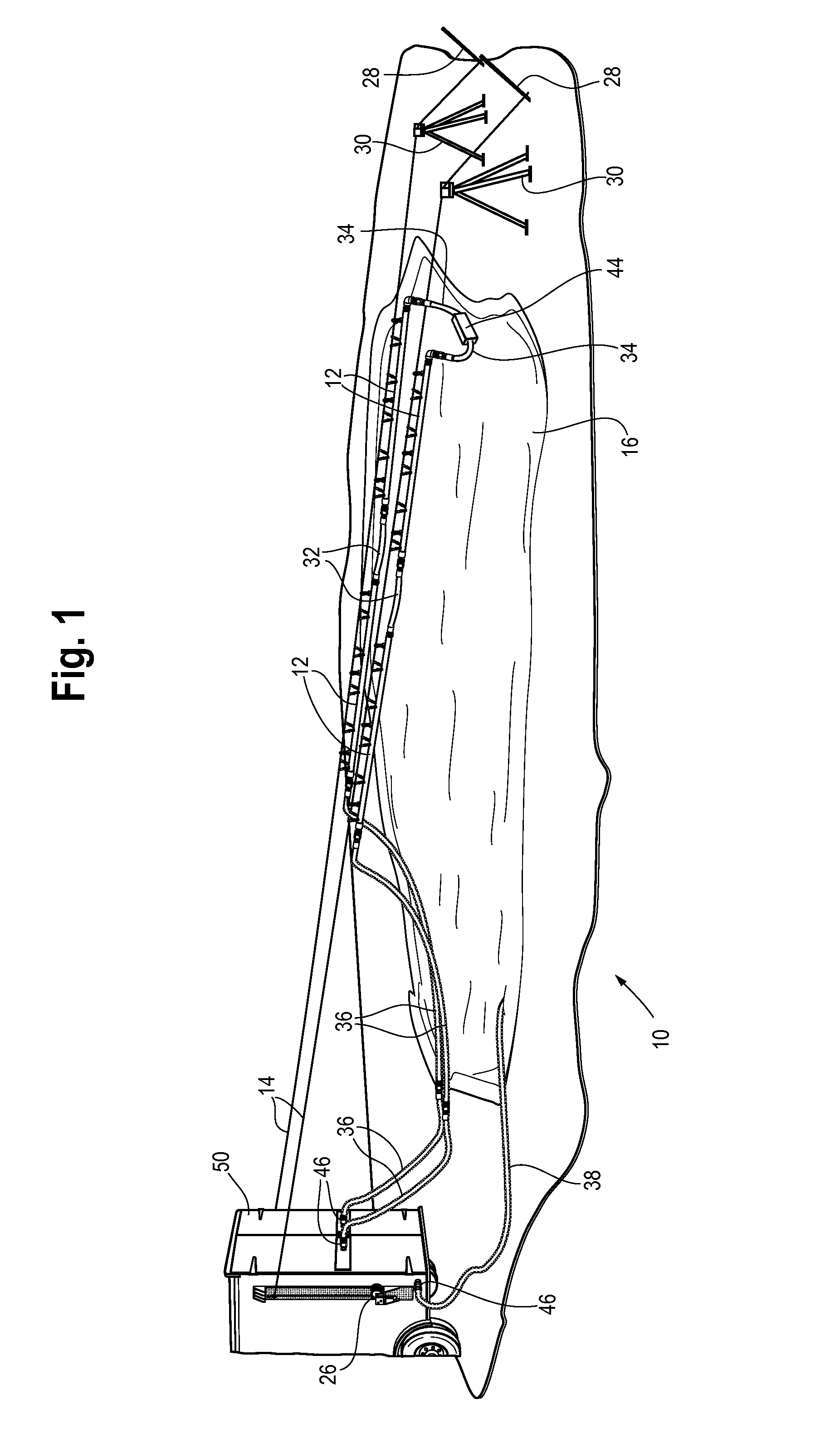

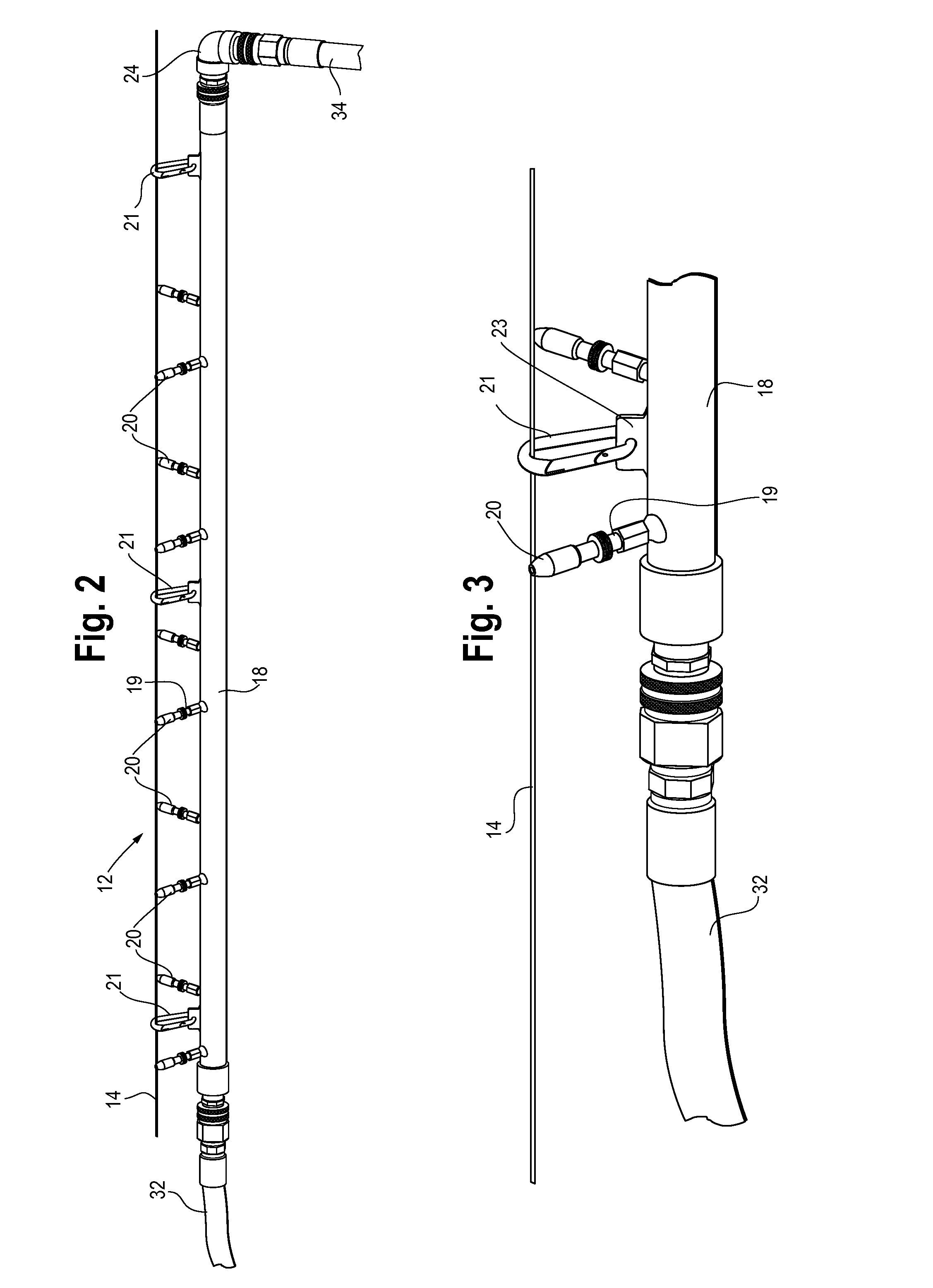

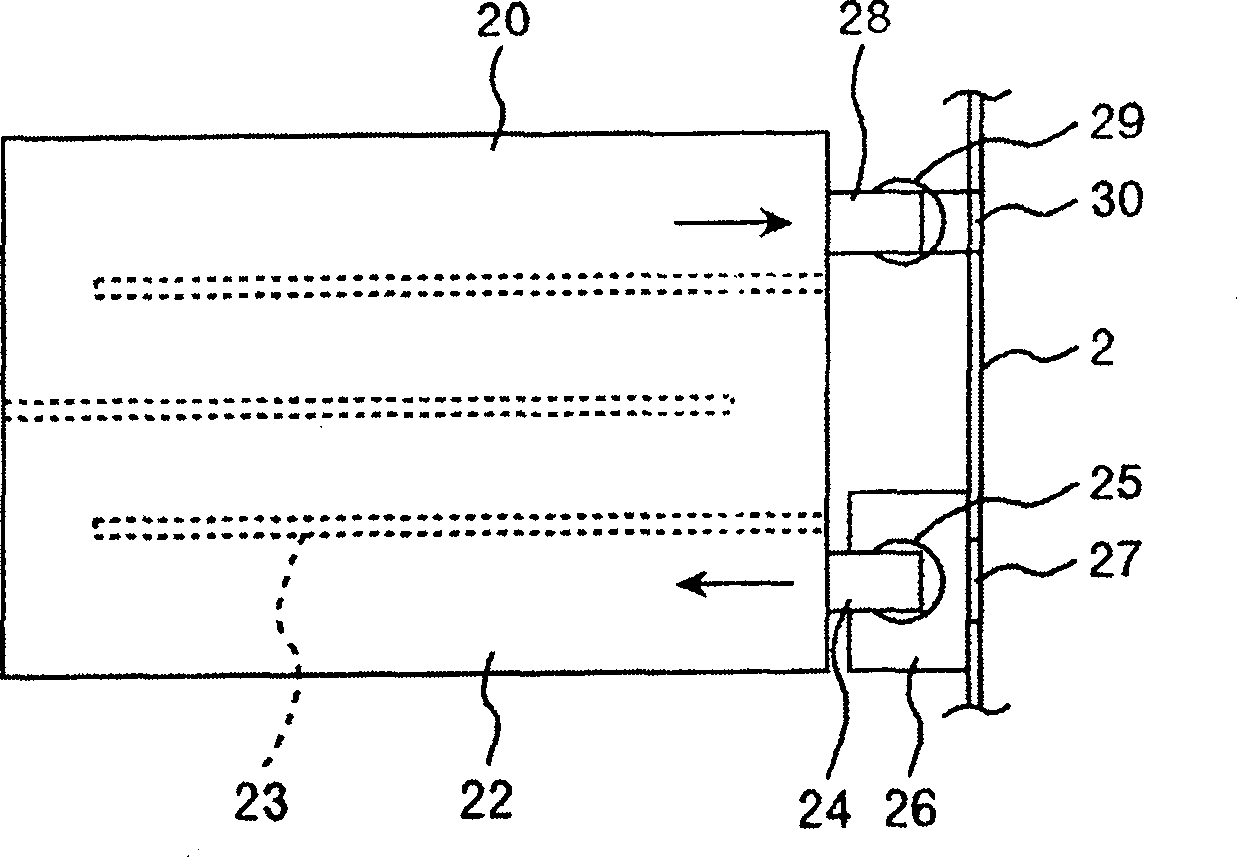

Water evaporation system using nozzles attached to a suspended cable

Owner:EVAPORITE SYST

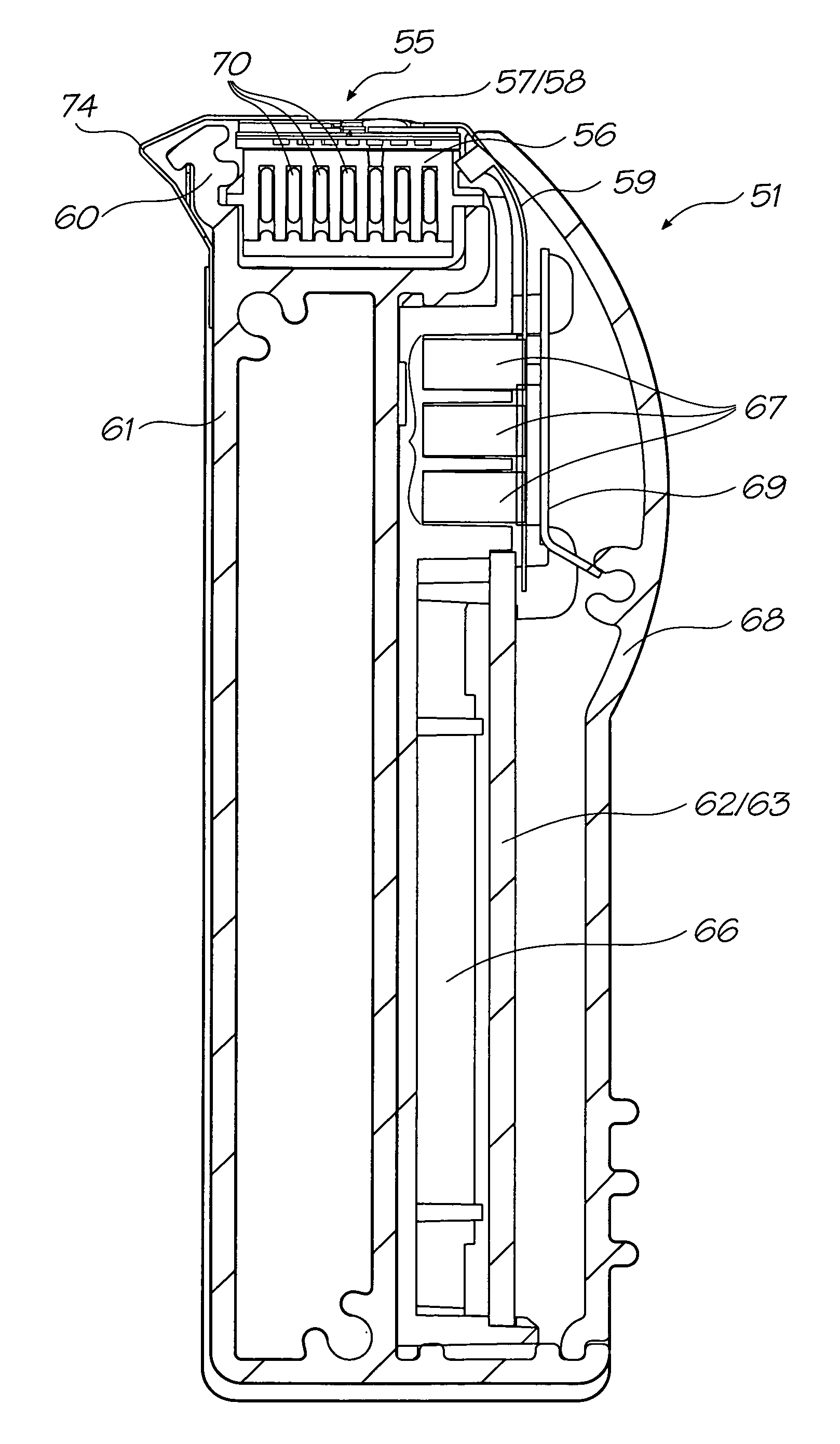

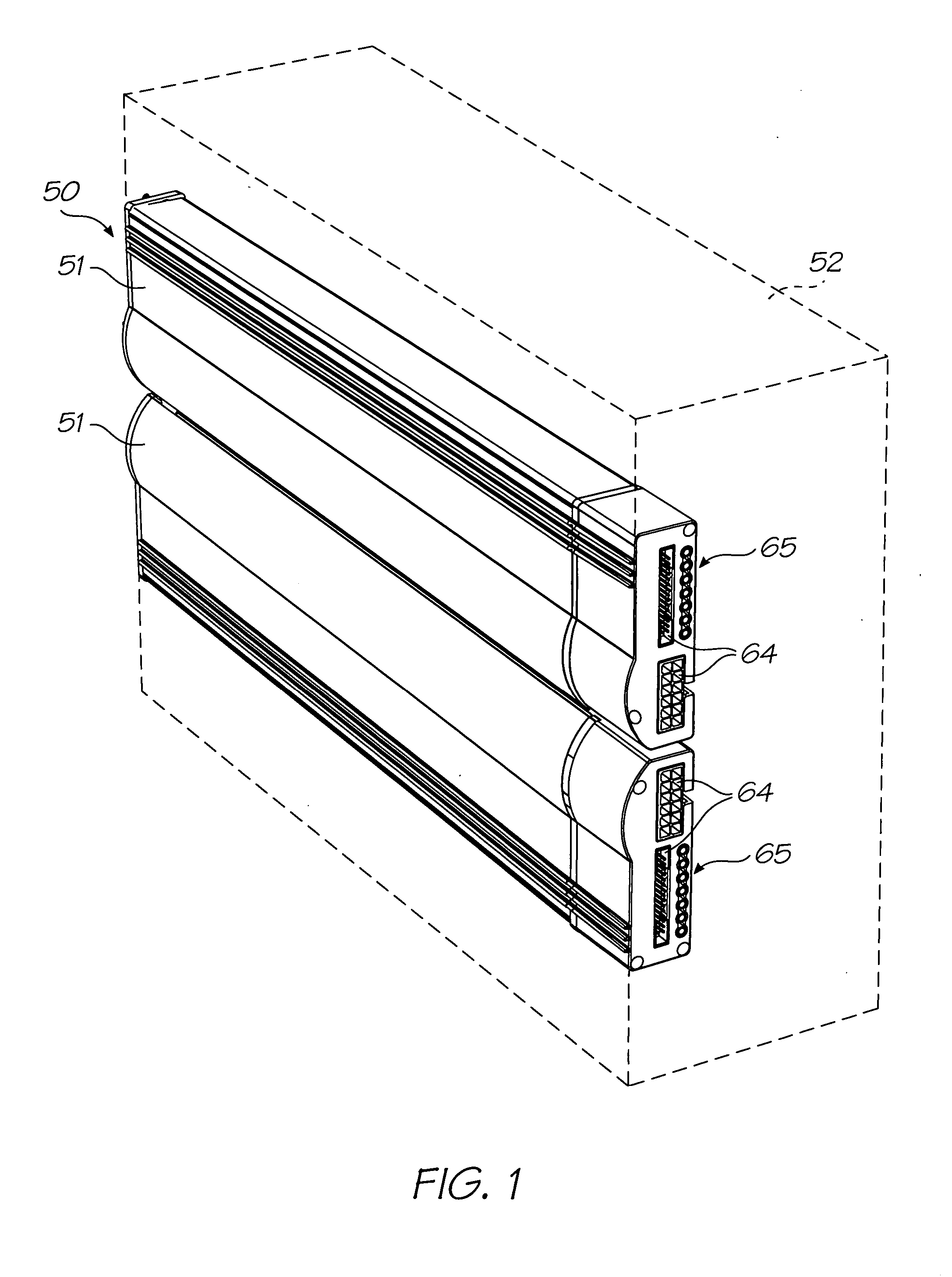

Inkjet printer with interposing printhead capping mechanism

Owner:MEMJET TECH LTD +1

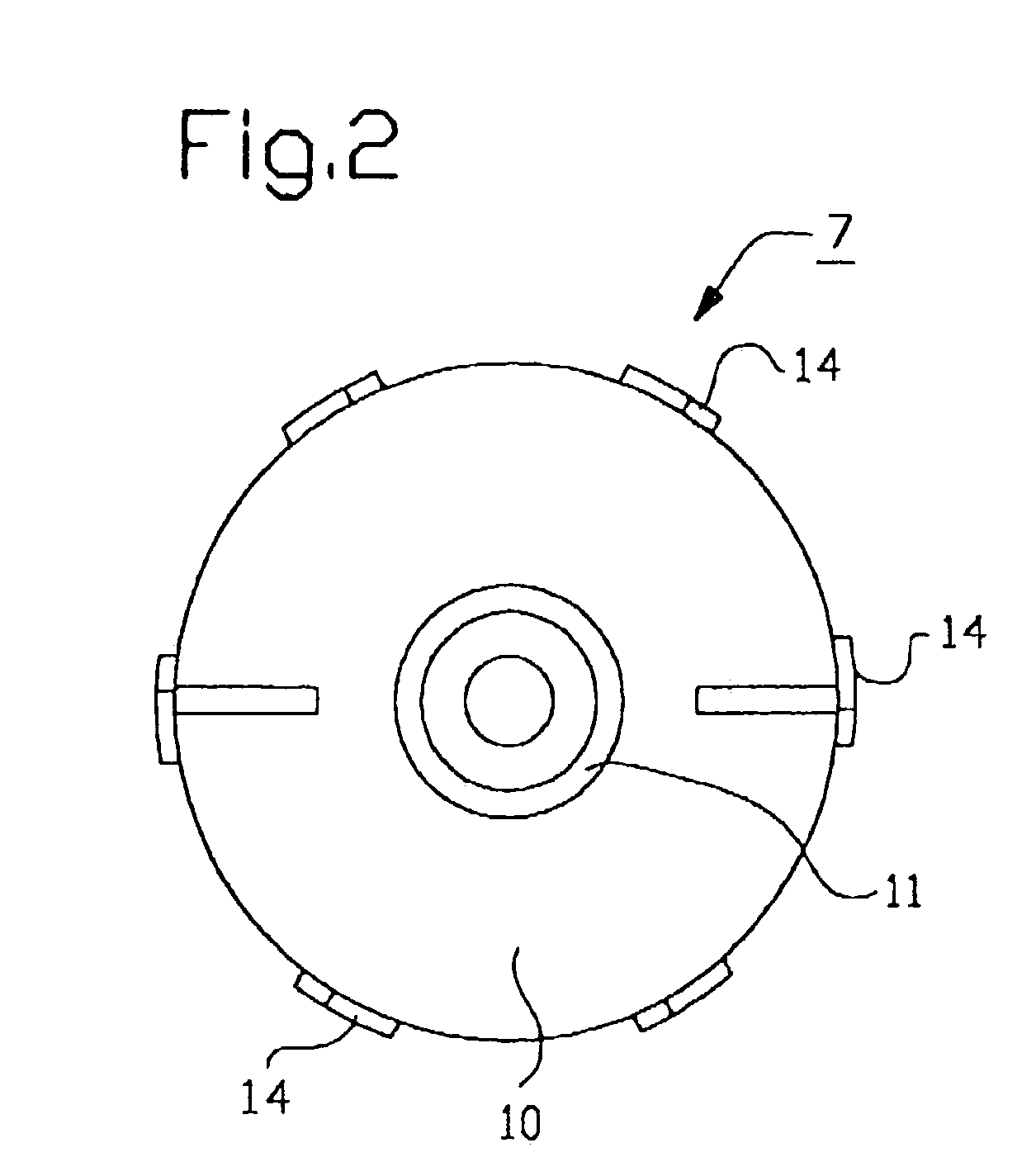

Combustor nozzle and method for supplying fuel to a combustor

Owner:GENERAL ELECTRIC CO

Apparatus and method used for analyzing effects of shot blast materials

InactiveCN103411840AMaterial strength using single impulsive forceClassical mechanicsImpact velocity

The invention discloses an apparatus and a method used for analyzing effects of shot blast materials. The apparatus comprises a peening machine, a support for plates, a displacement sensor, a laser velocity sensor, a controller and an X-ray emitter; the nozzle of the peening machine is vertical to the plane of a plate; the laser velocity sensor is used for measuring the velocity of the shot blast materials; and the displacement sensor is used for recording the displacement of the shot blast materials; and the X-ray emitter is used for measuring the plate residual stress caused by the impact of the shot blast materials. The apparatus and method are capable of measuring the change of the impact velocity of the shot blast materials on the plate and the plate residual stress, so that the apparatus and the method are capable of analyzing influences of different shot blast parameters on the effects of the shot blast materials.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

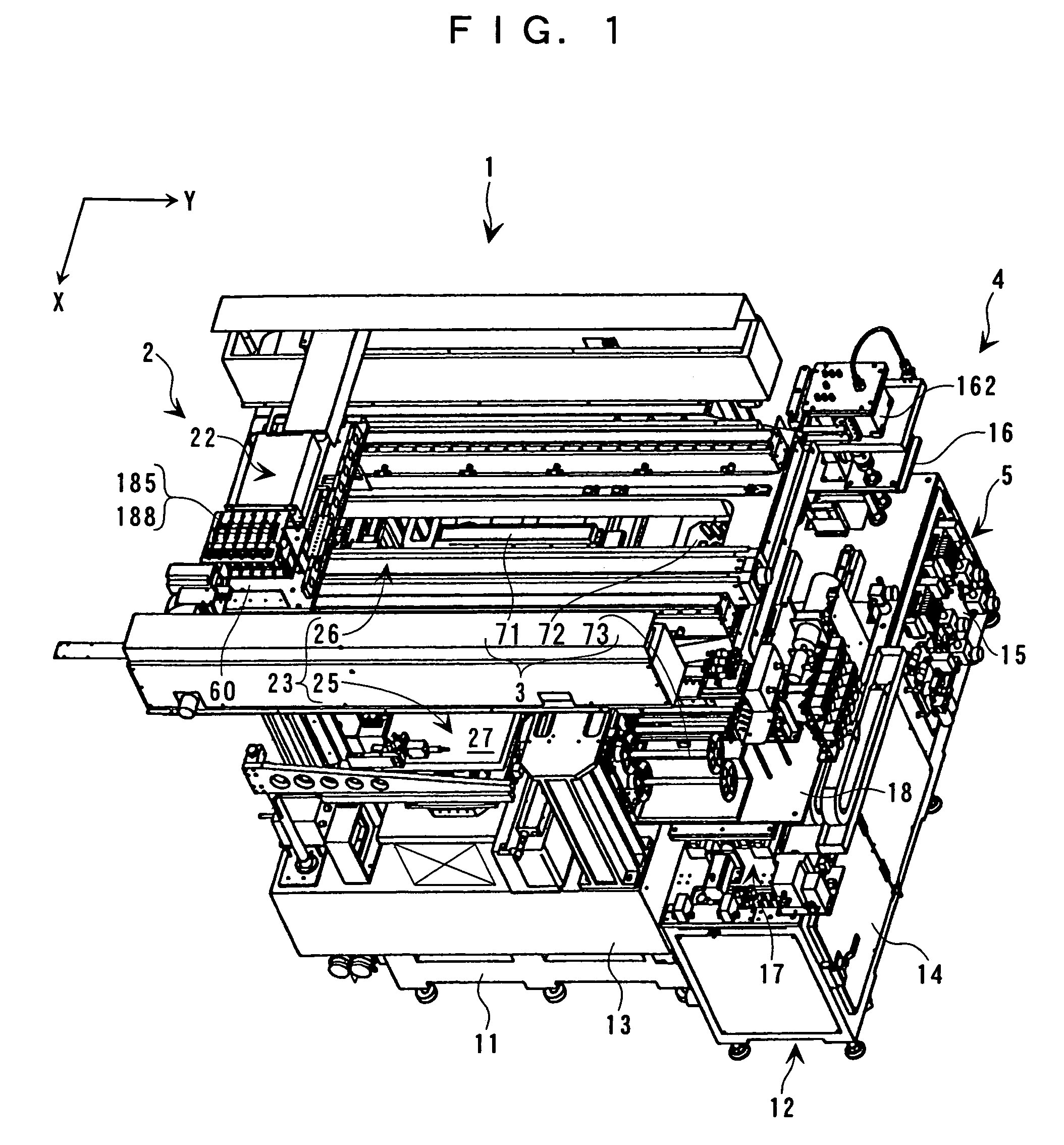

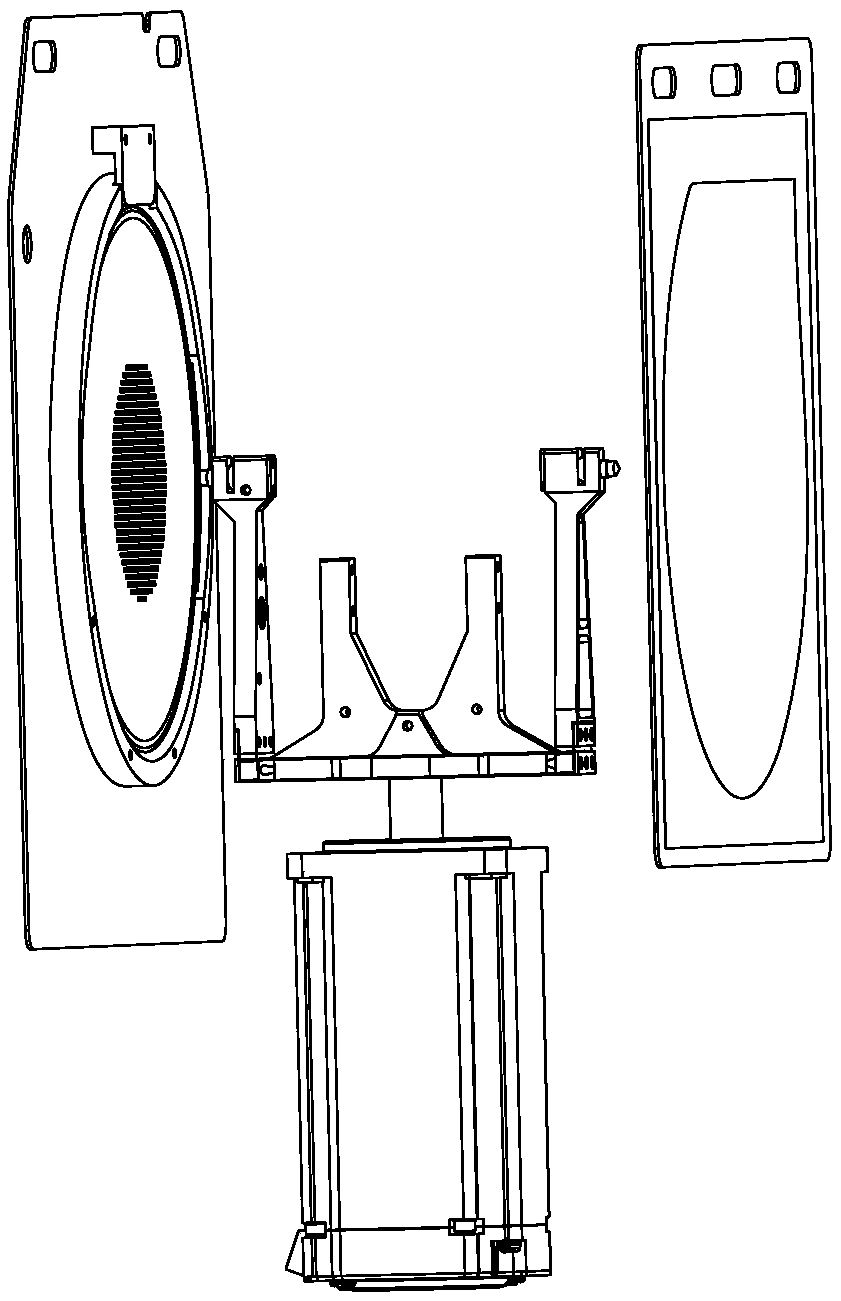

A chip sorting mechanism and a chip sorting method thereof

PendingCN109065482AAvoid scratchesNot easy to dropSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringElectrical and Electronics engineering

Owner:SHENZHEN HI TEST SEMICON EQUIP

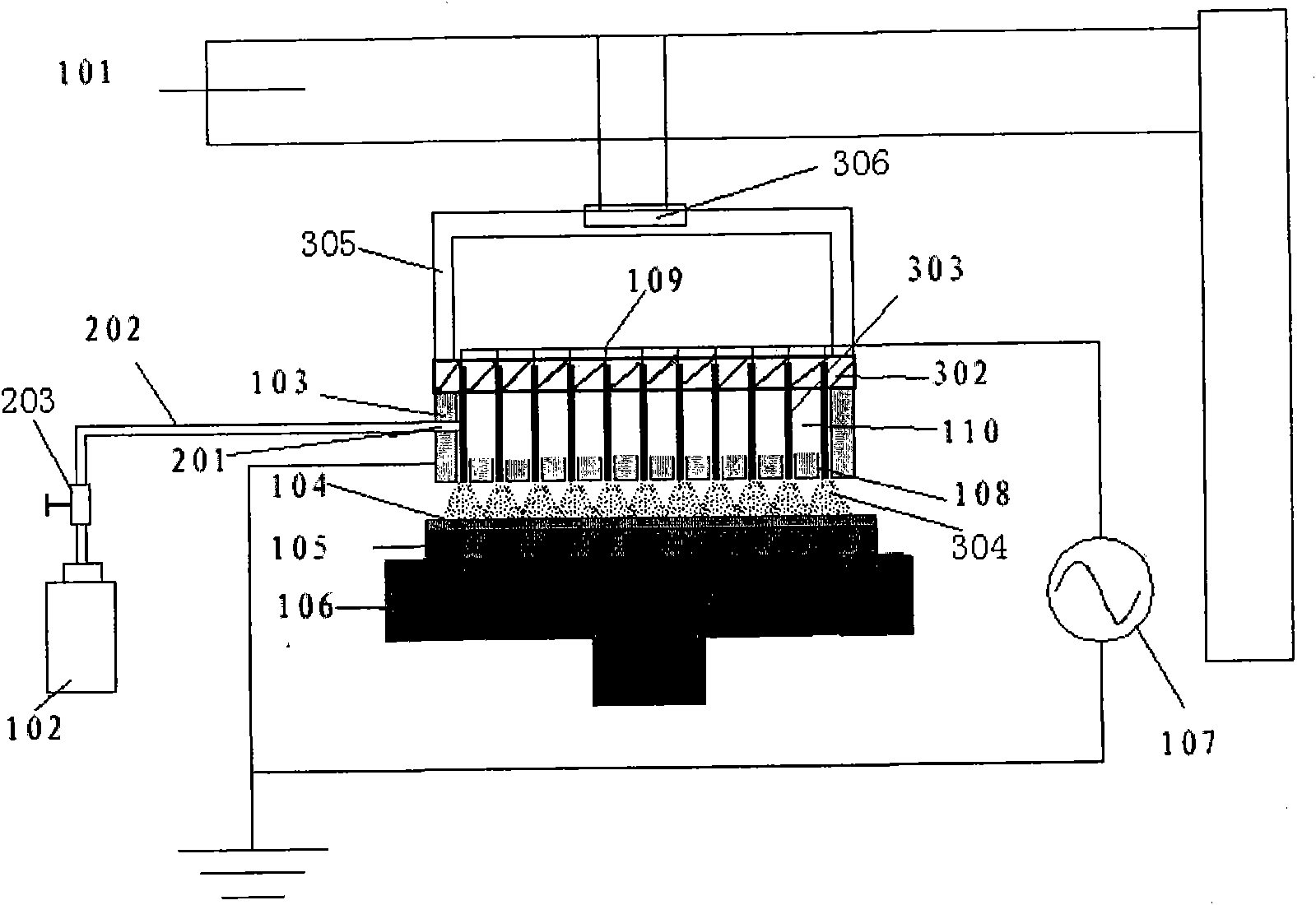

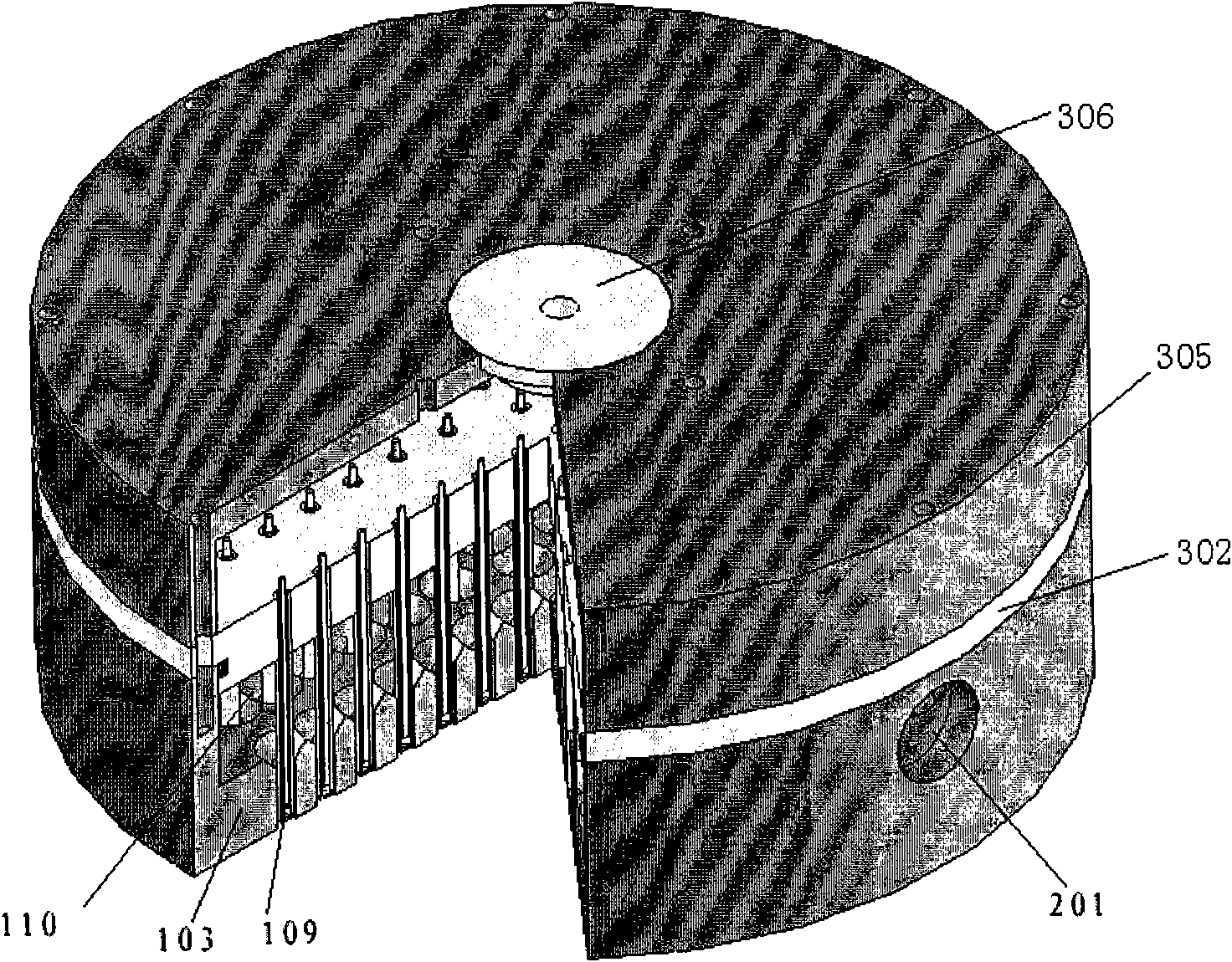

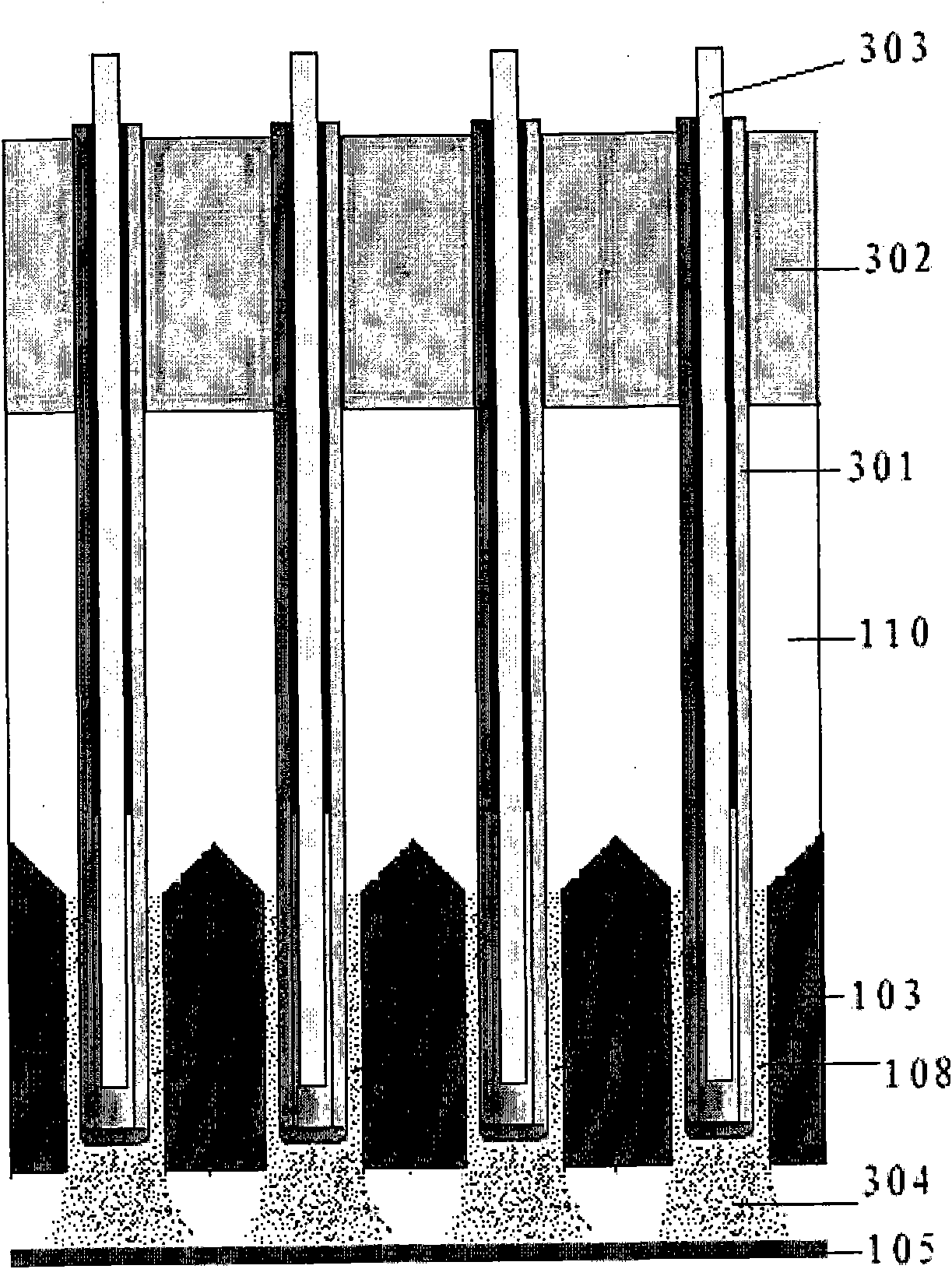

Cleaning system for honeycomb-shaped plasma free radicals

InactiveCN102310063AUniform and stable dischargeIncrease productivityPhotosensitive material processingCleaning using gasesPlasma generatorHoneycomb

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

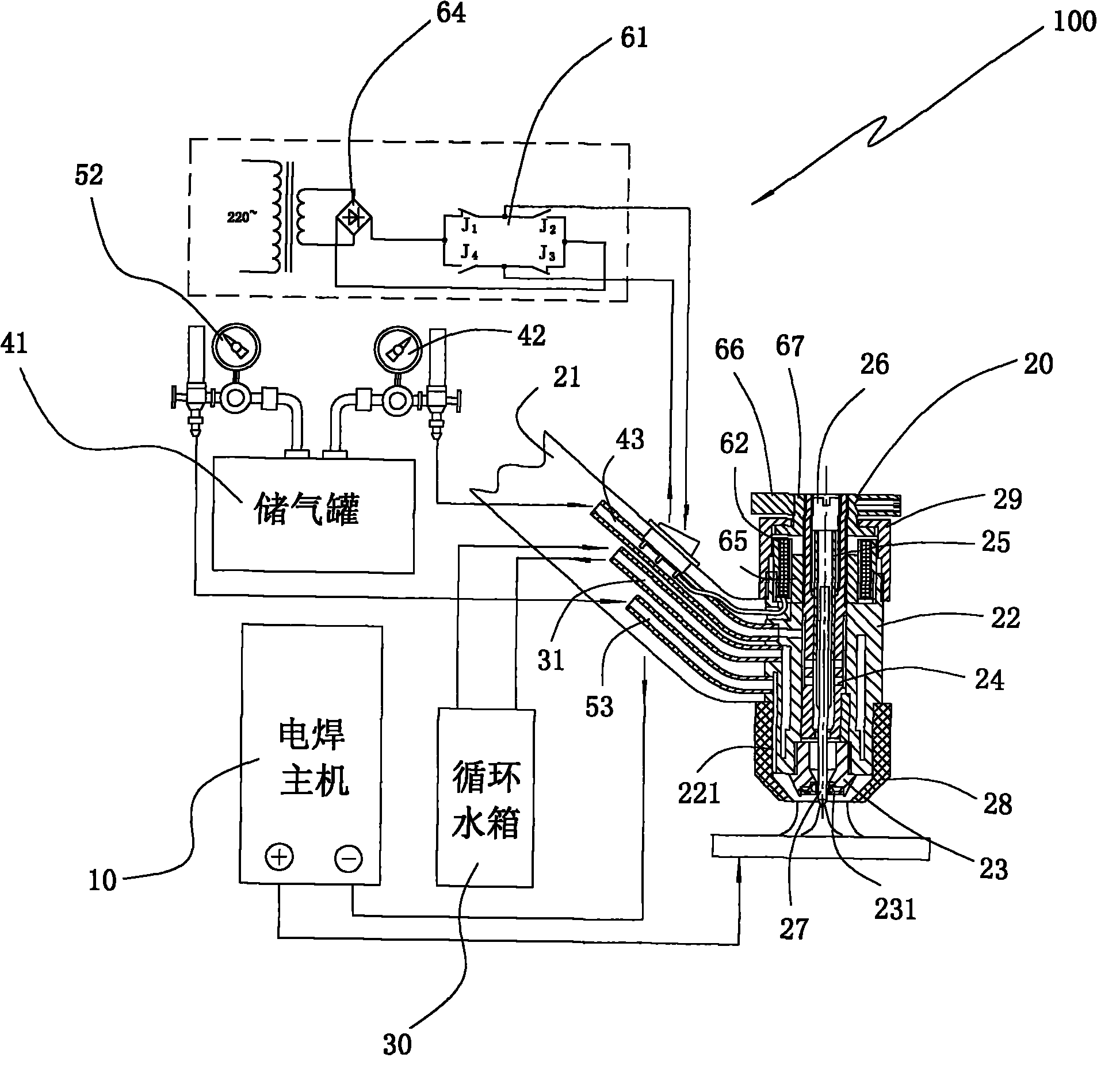

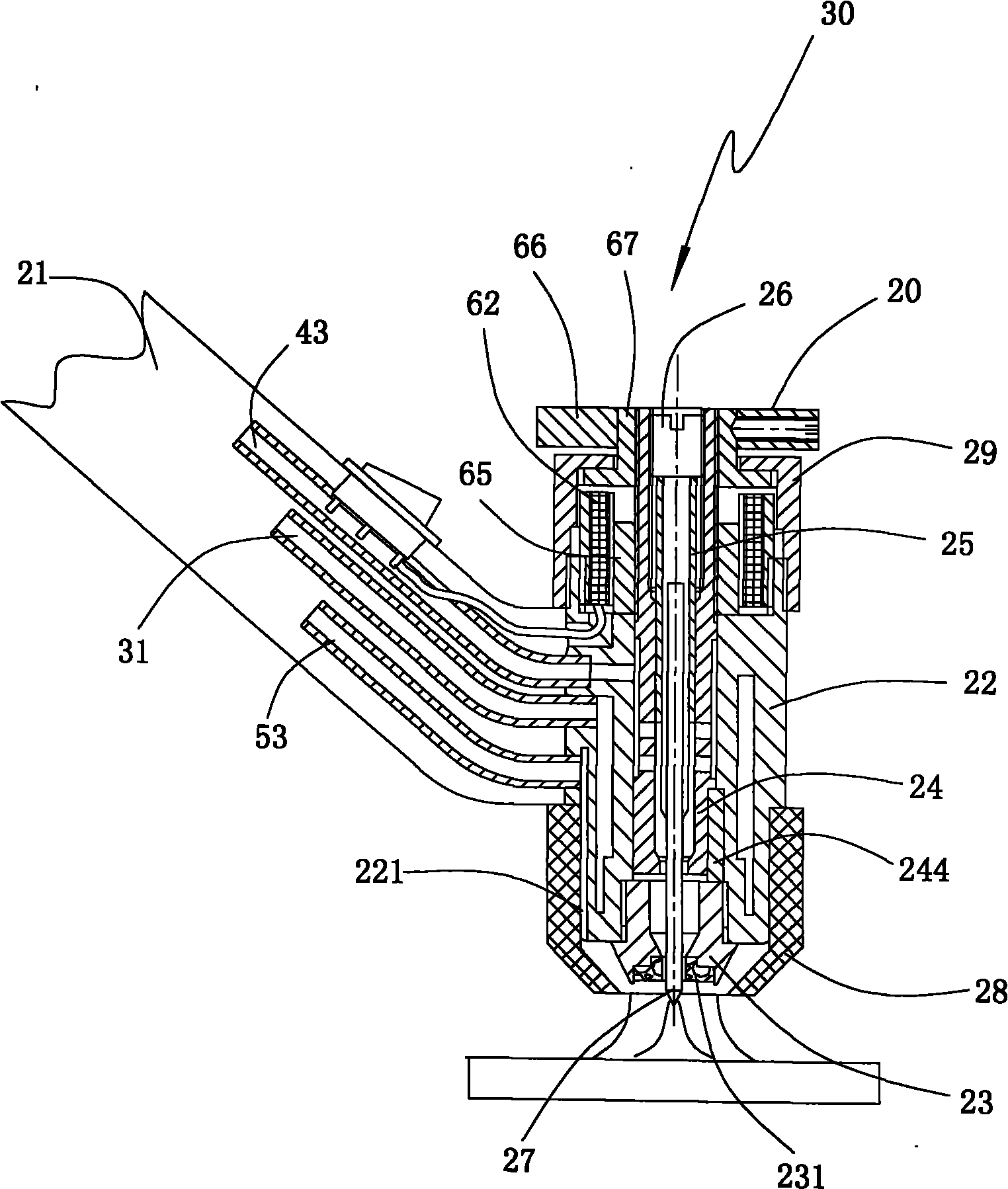

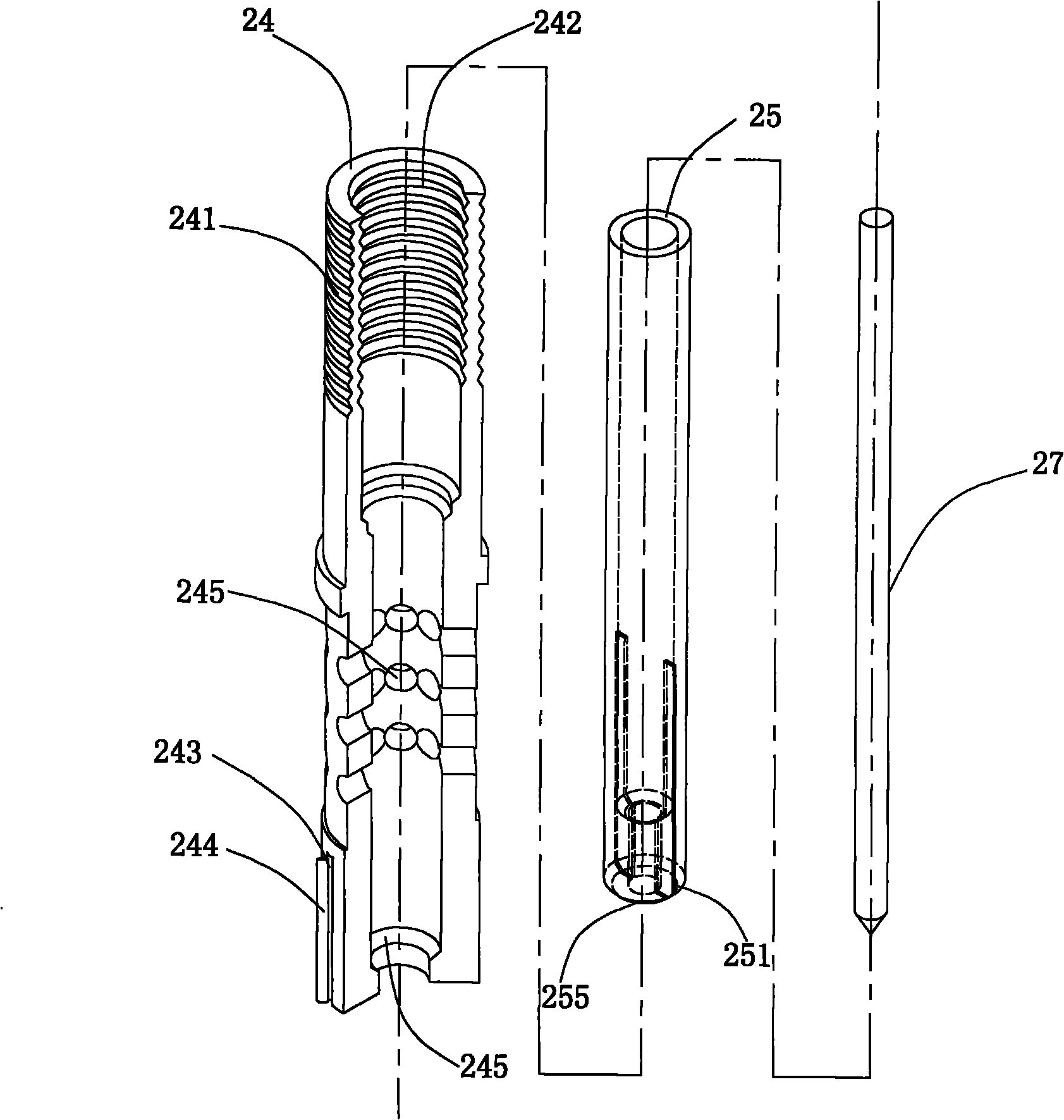

Inverter electric welding machine device with adjustable electric arc

InactiveCN101823176AImprove stabilityImprove practicalityElectrode vibration holdersShielding gasCompression screw

Owner:上海新亚电焊机有限公司

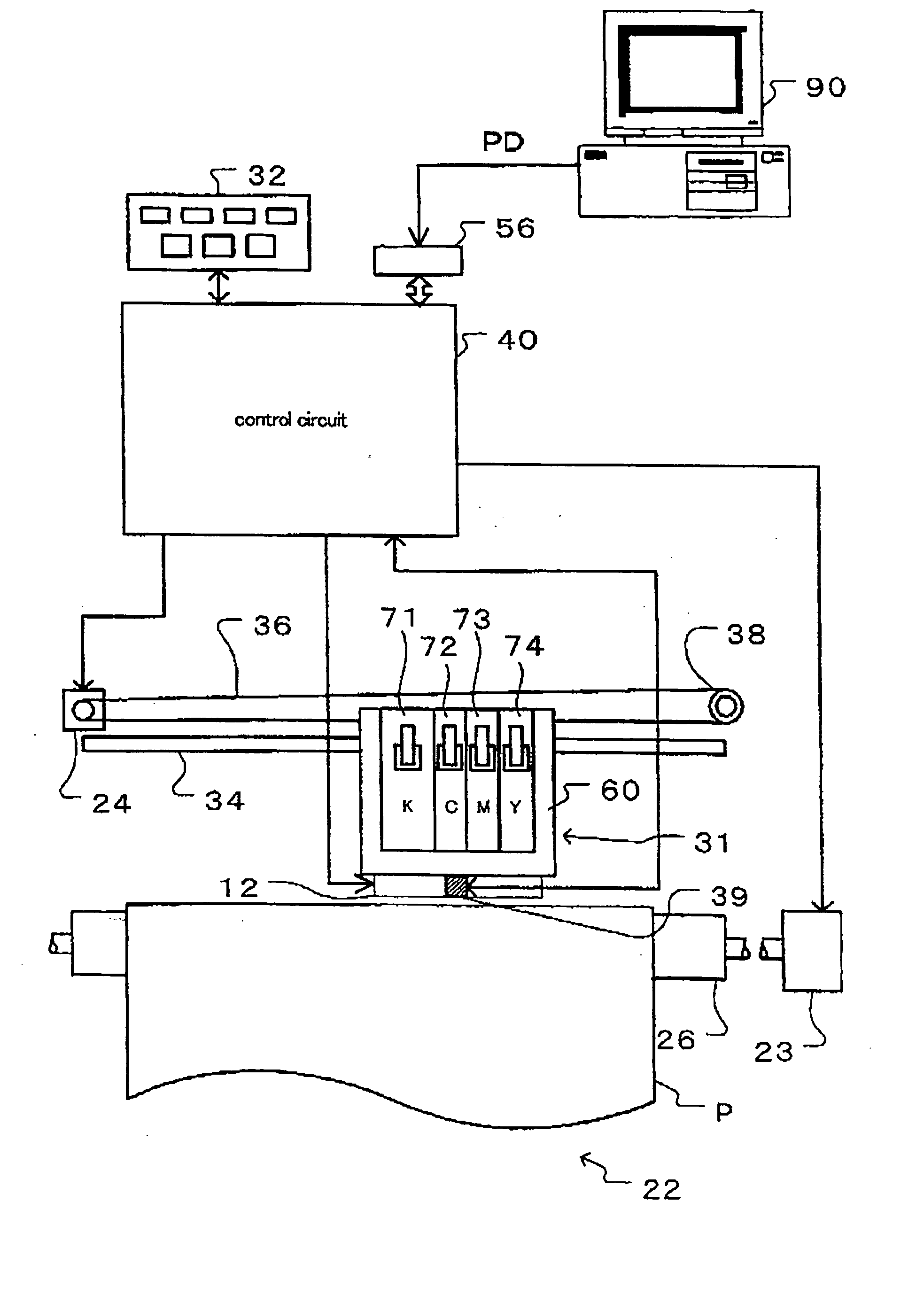

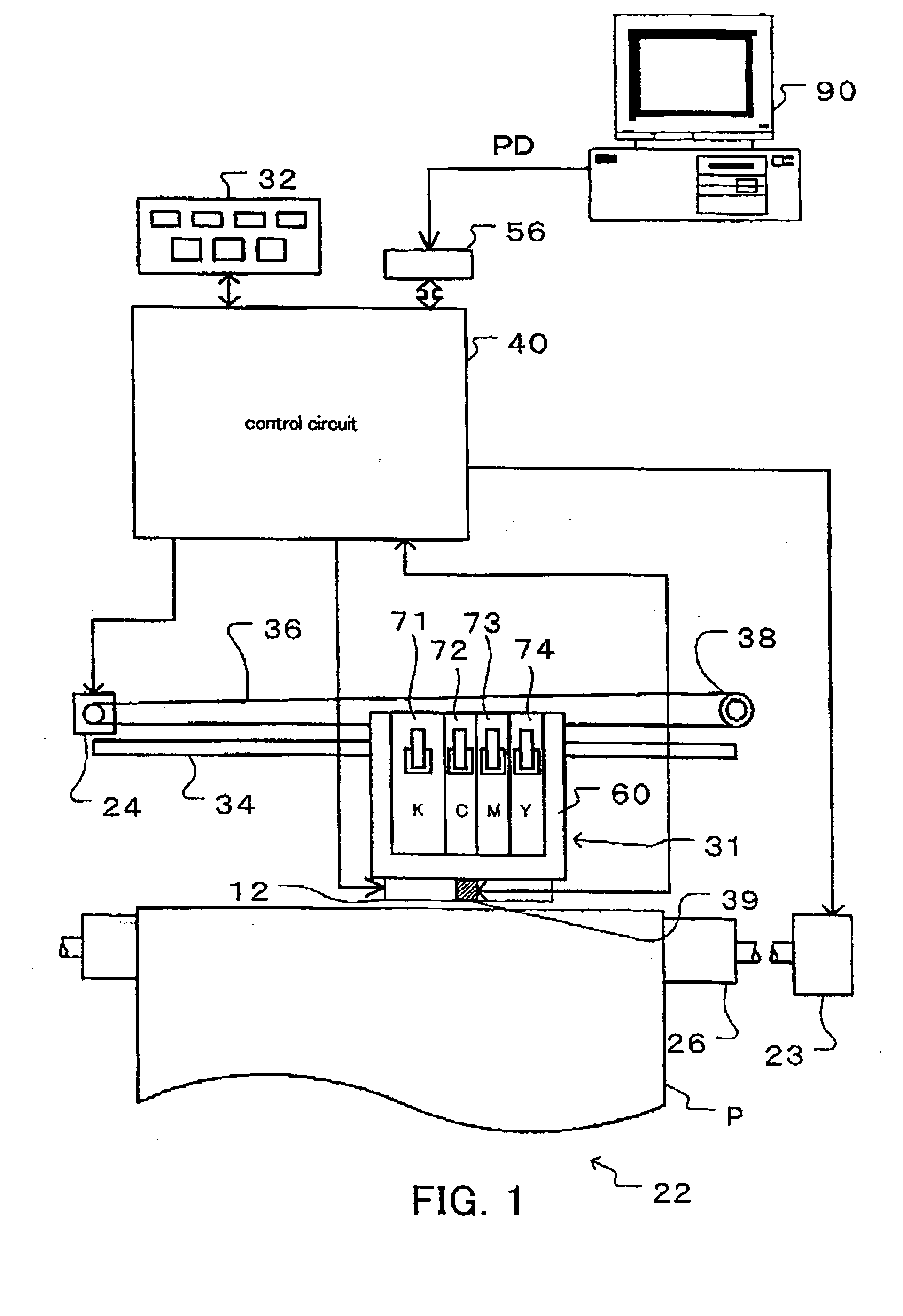

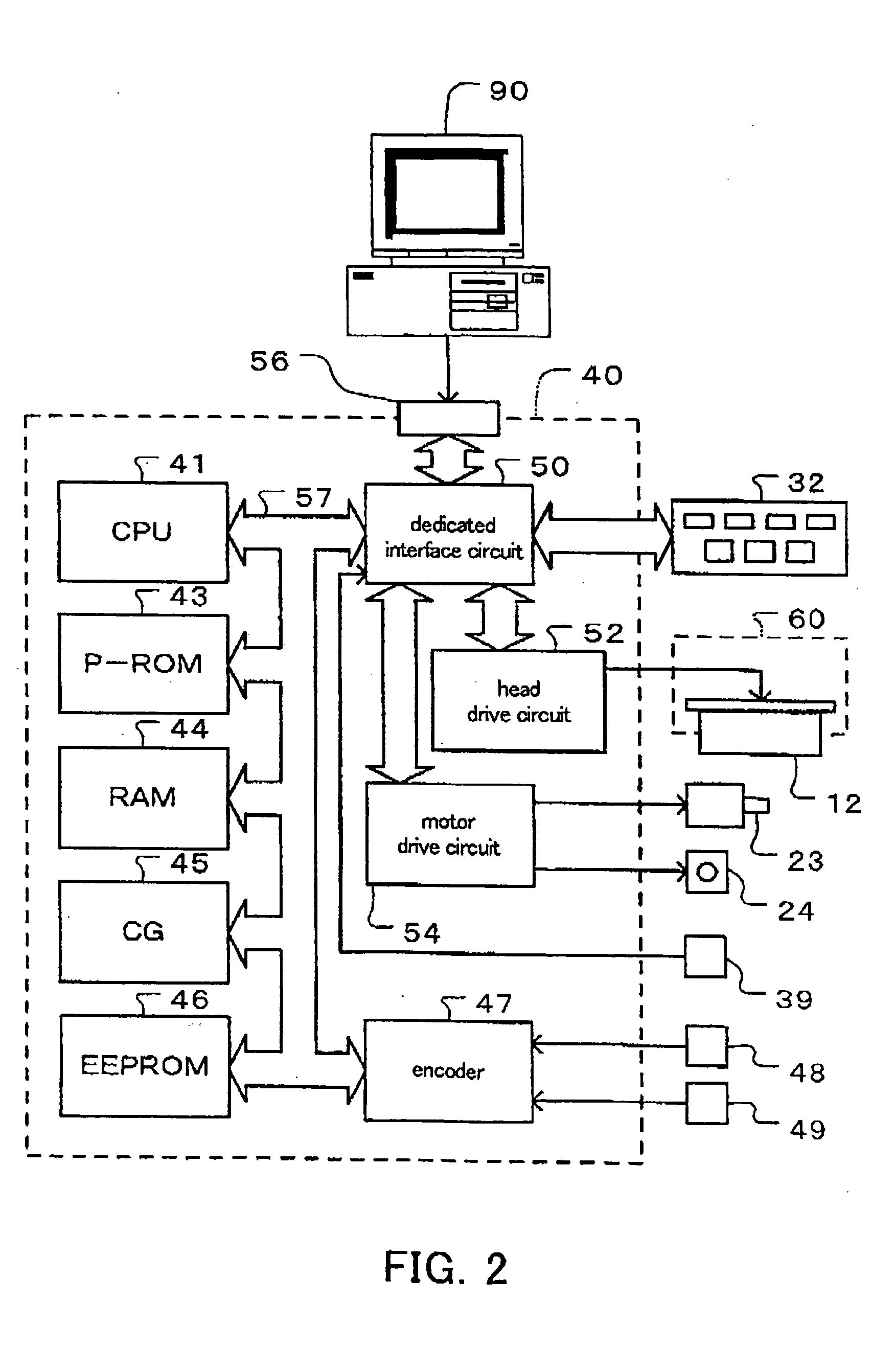

Printing method, printing apparatus, and storage medium

Owner:SEIKO EPSON CORP

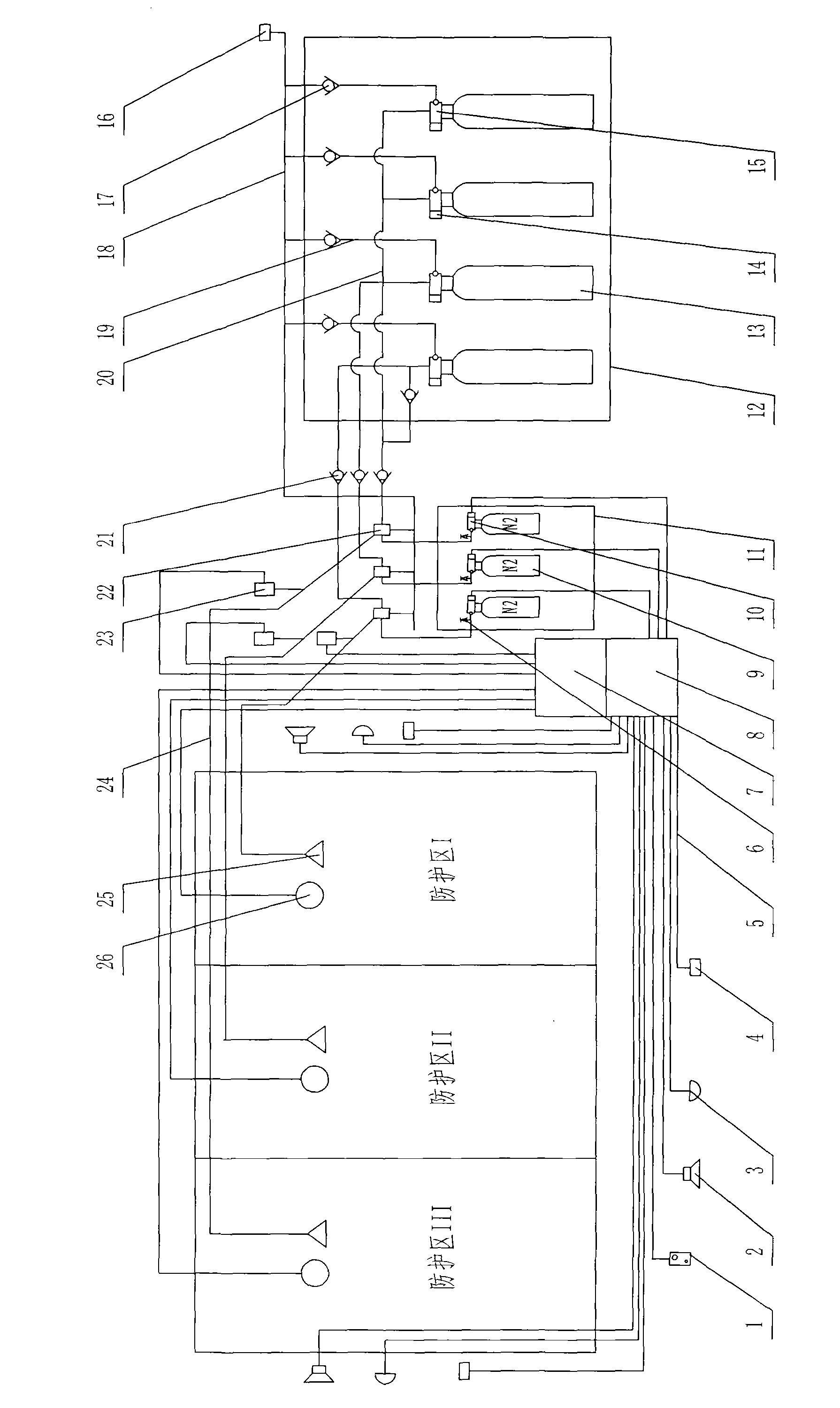

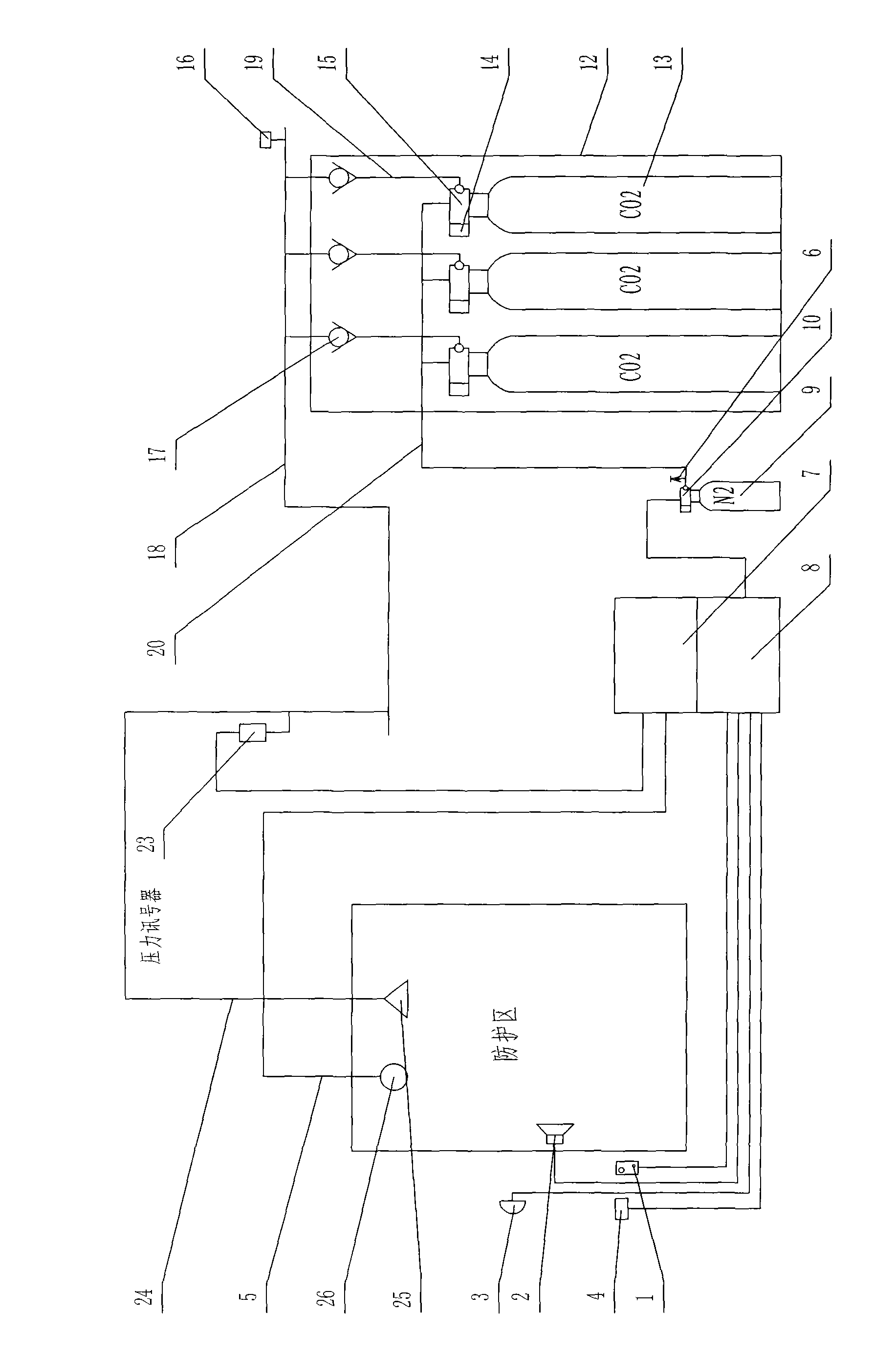

Automatic carbon dioxide fire extinguishing system

InactiveCN103656922AImprove performanceEasy to clean up after a disasterFire rescueFire detectorUnit system

Owner:徐连宽

Spinning dust collecting device for spinner

ActiveCN107354546AImprove adsorption capacityThe downward movement of the adsorption cover is beneficial to adjust the adsorption and facilitateAuxillary apparatusCleaning using liquidsEngineeringElectric control

Owner:南通德和布业有限公司

Dinnerware cleaning machine

InactiveCN1846595ASimple structureRealize water savingTableware washing/rinsing machine detailsThermal conductivityWaste management

Owner:HITACHI HOME & LIFE SOLUTIONS INC

Glaze spraying device for mosaic tile manufacturing

ActiveCN106313288ASuitable temperatureGood glazing effectCeramic shaping apparatusViscosityMaterials science

Owner:肇庆市宏润陶瓷有限公司

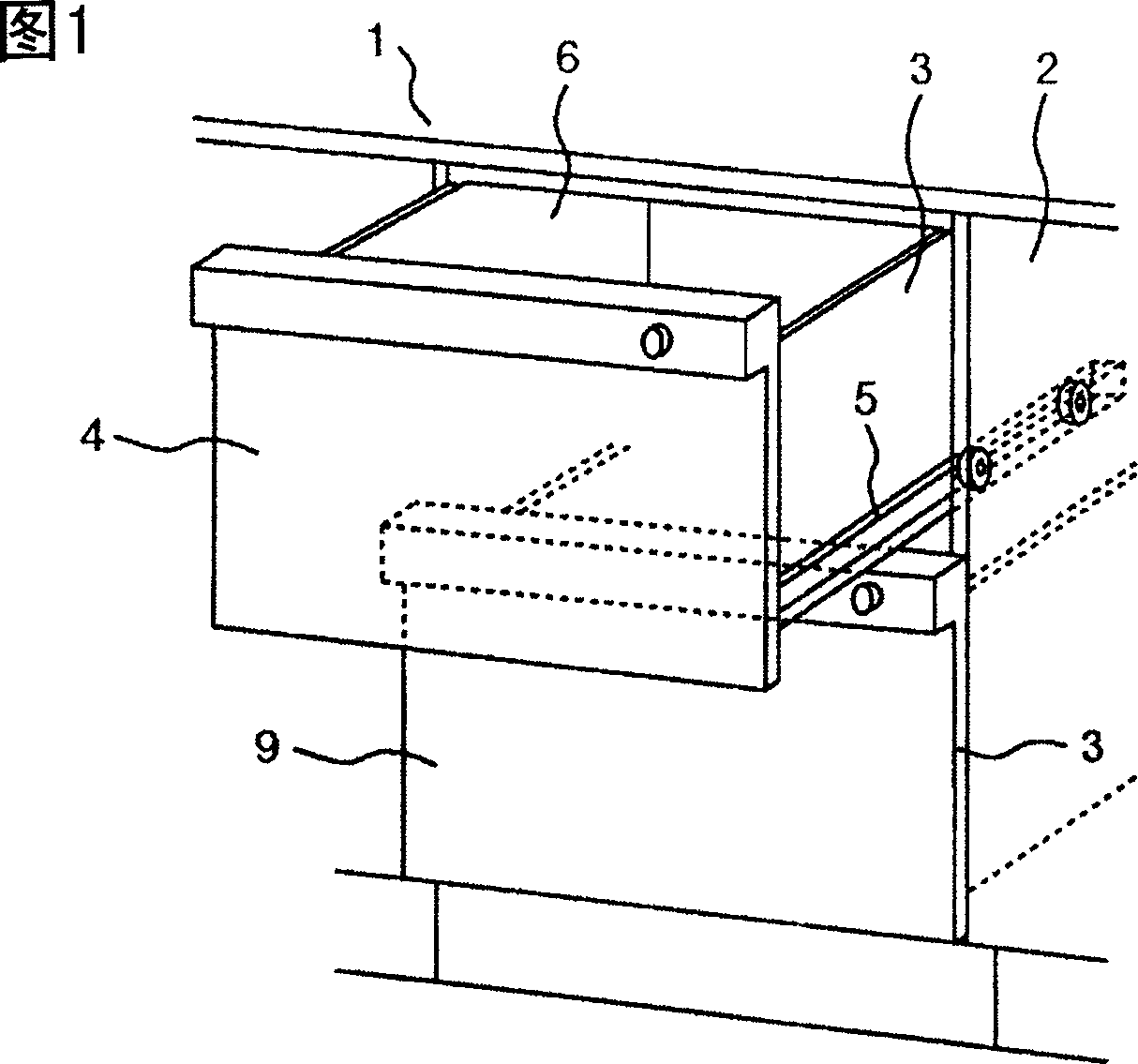

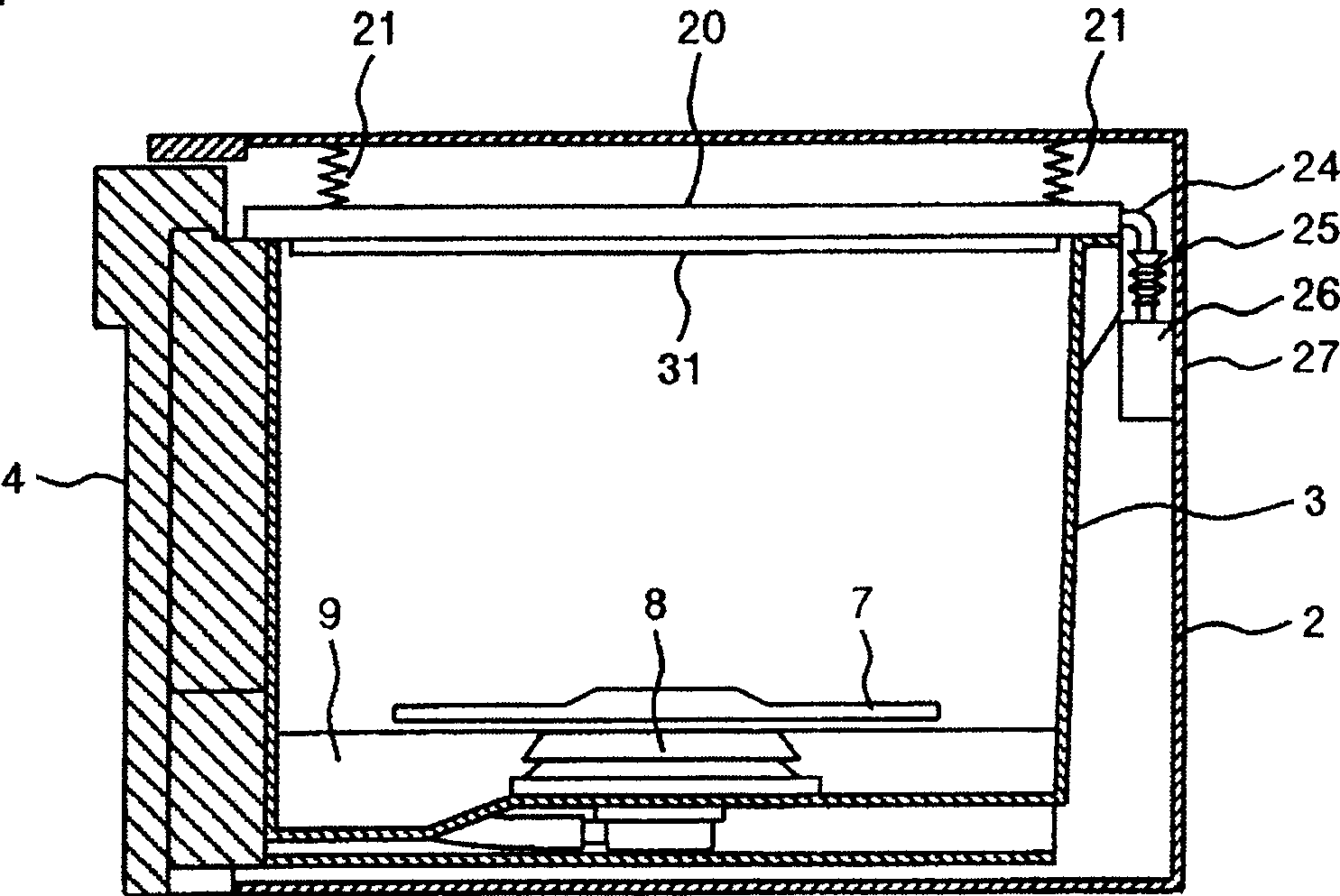

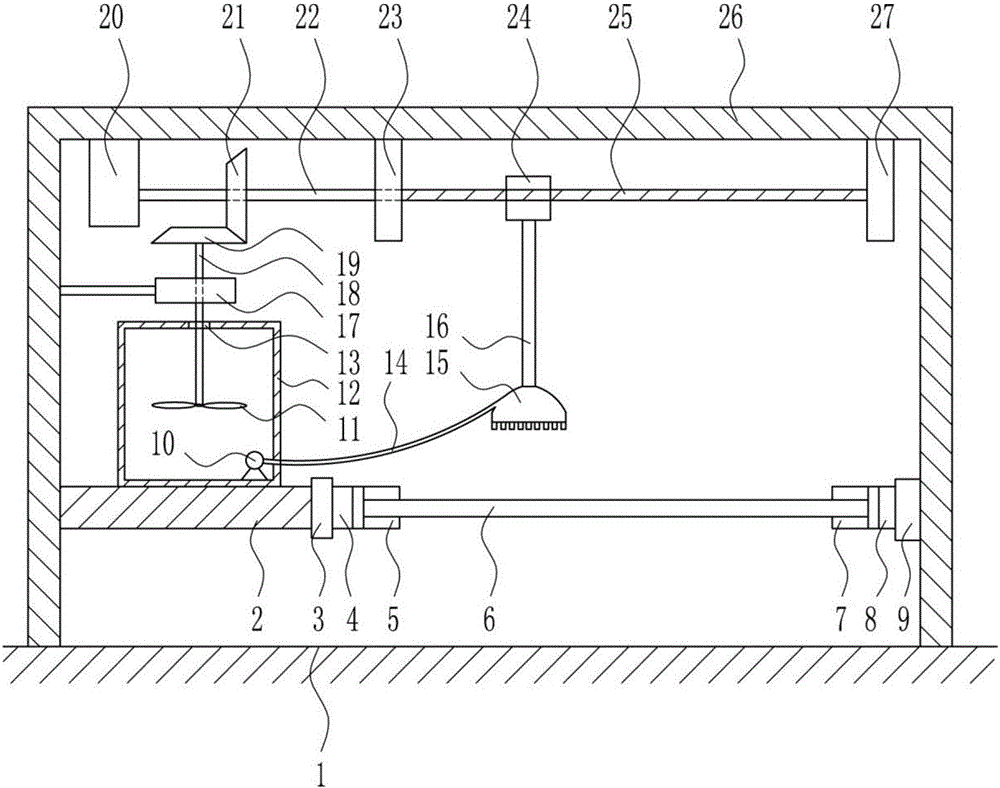

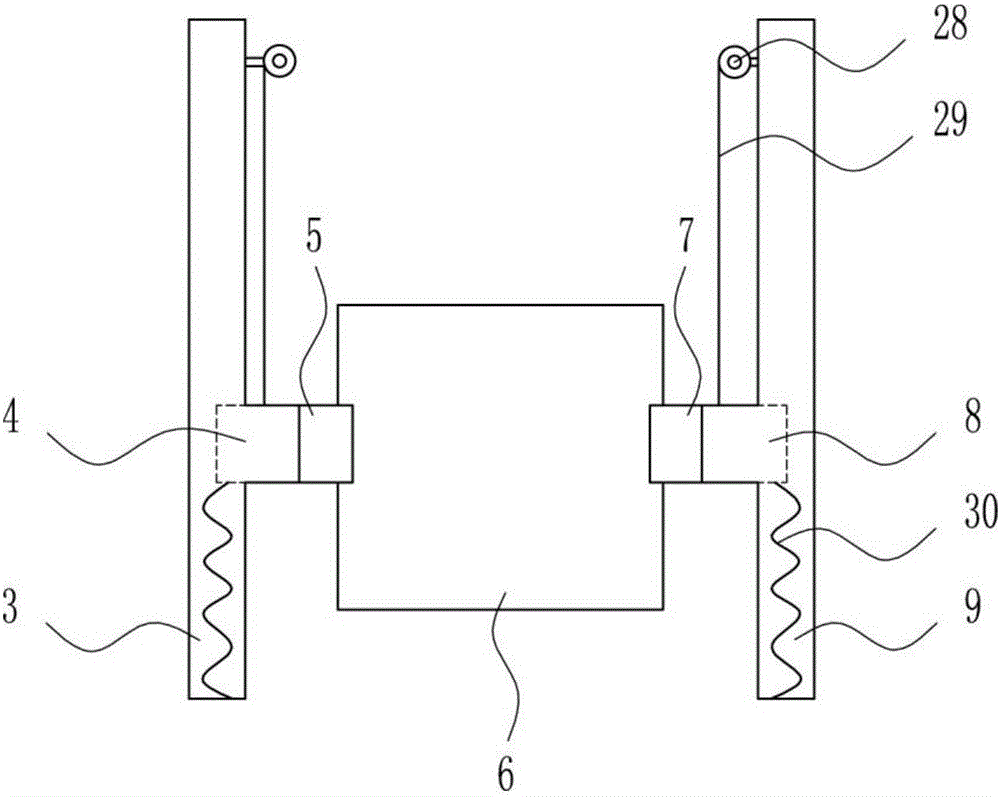

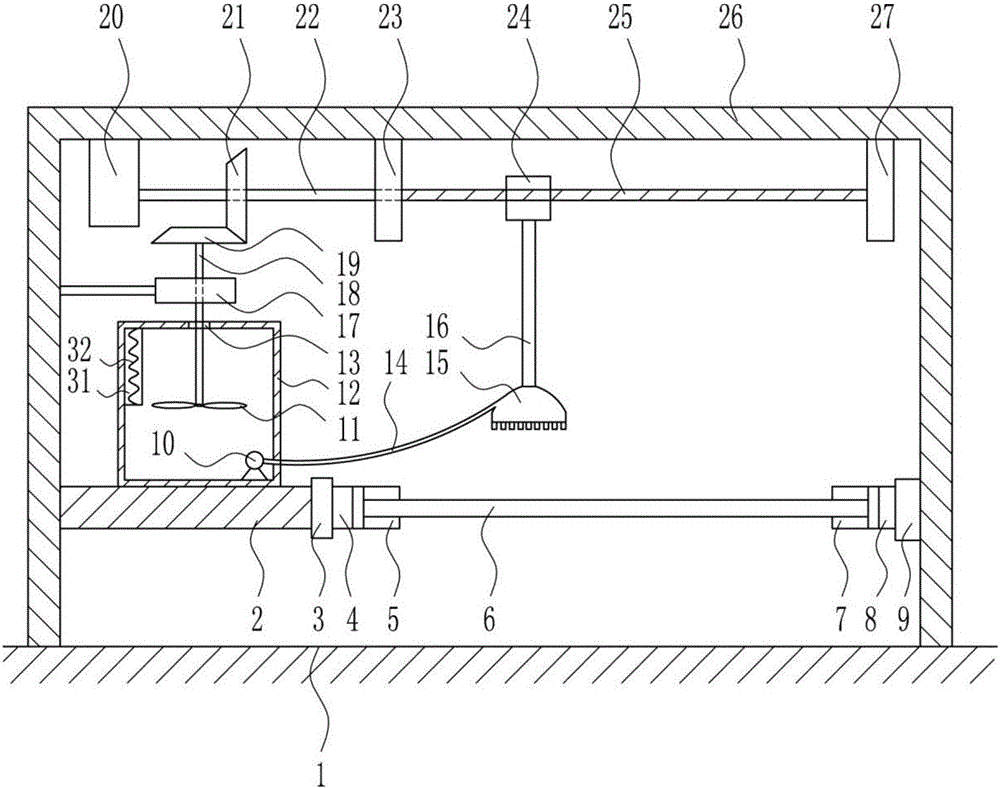

Automatic guide type spray irrigating machine and spray irrigating method for greenhouse

InactiveCN105794600ALess investmentLower investment priceWatering devicesCultivating equipmentsVehicle frameGreenhouse

The invention discloses an automatic guide type spray irrigating machine and a spray irrigating method for a greenhouse. The spray irrigating machine comprises a differential steering chassis, a micro control system, a water supply system and a storage battery, wherein the differential steering chassis includes a vehicle frame, a left driving system, a right driving system and omnidirectional wheels, power is supplied to the left driving system and the right driving system through the storage battery to drive the spray irrigating machine to travel. As the differential steering chassis is employed, the spray irrigating machine can travel and steer automatically along with a guide line under the control of the micro control system, without needing manual removal or special rail-based transfer; and during the travelling, water in a water tank is pumped by a water pump and is sprayed through a nozzle to realize spray irrigation; a master controller is configured to calculate amount of deviation of the spray irrigating machine from the guide line during the travelling process and give a control command to control revolving speeds of a left electric motor and a right electric motor, so as to enable the spray irrigating machine to travel along the guide line all the time. The spray irrigating machine disclosed by the invention has the advantages that the labor intensity is reduced, the cost for greenhouse construction and spray irrigating machine investment is lowered, the running distance of a single spray irrigating machine is not limited, the spray irrigating area for the greenhouse is large, the structure is simple, the automation degree is high and the practicality is strong.

Owner:CHINA UNIV OF MINING & TECH

Cold burden laying method and casting starting technology of sizing nozzle open type continuous casting billets

Owner:玉溪新兴钢铁有限公司

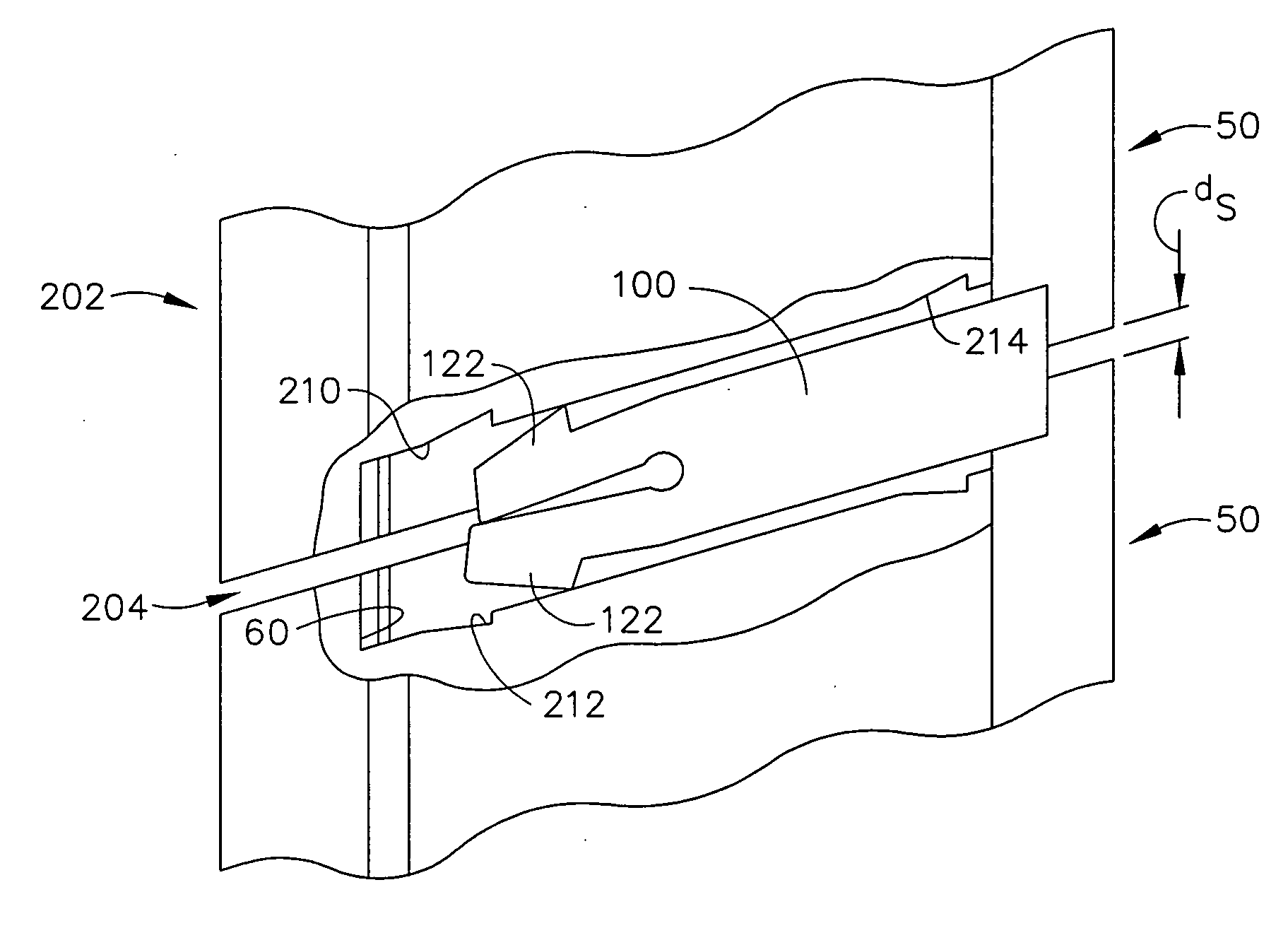

Methods and apparatus for assembling gas turbine engine stator assemblies

Owner:GENERAL ELECTRIC CO

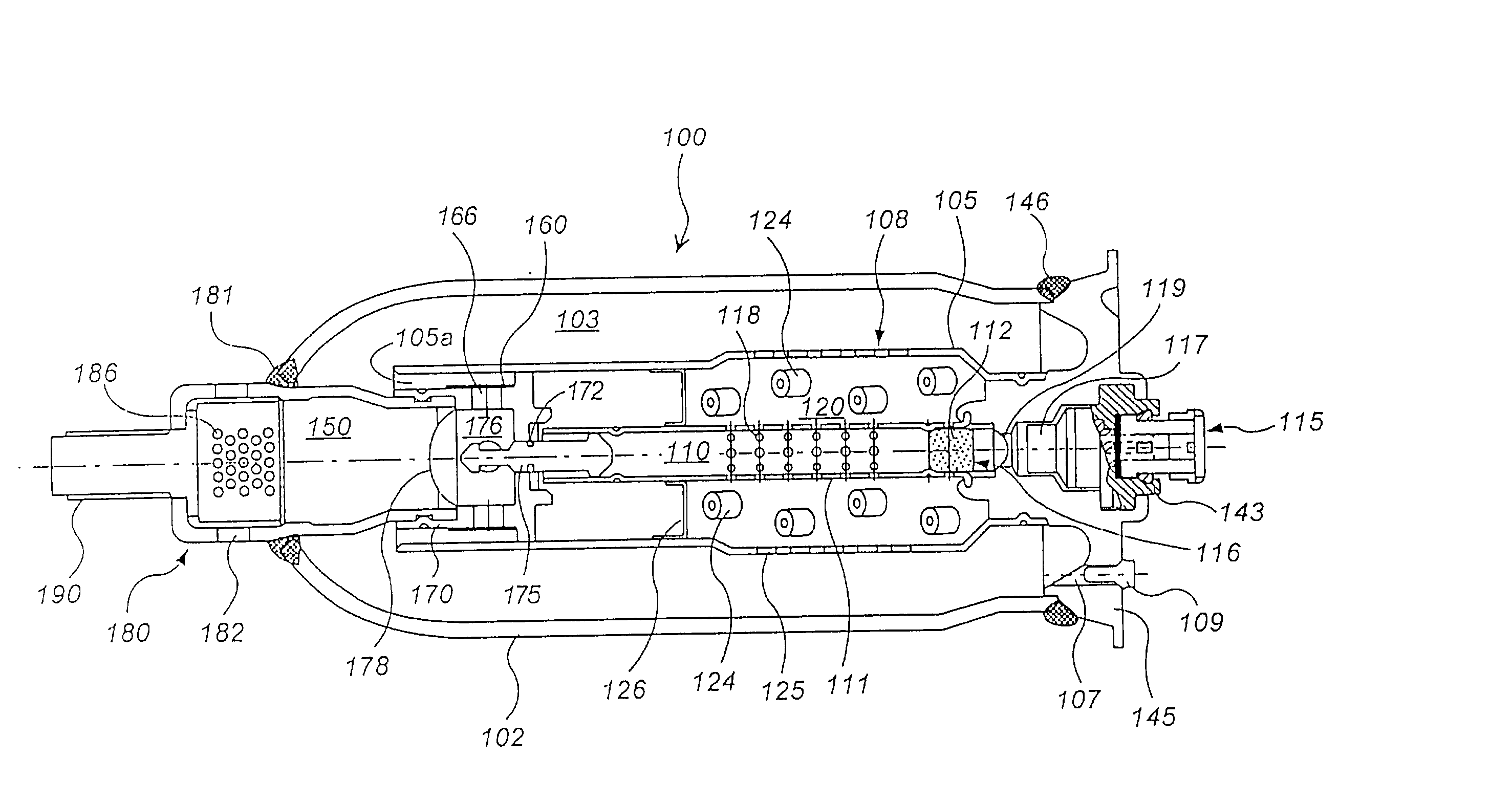

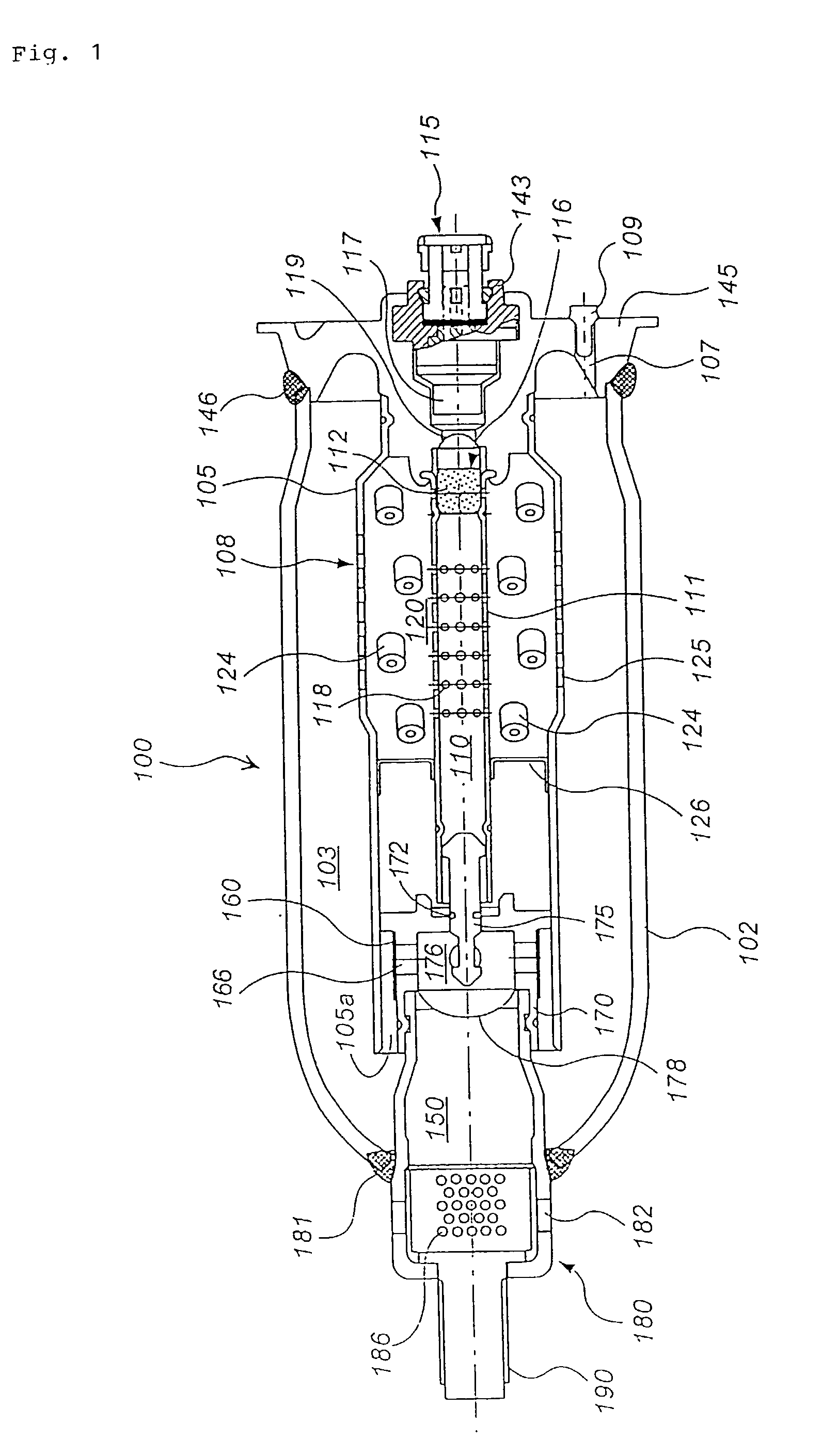

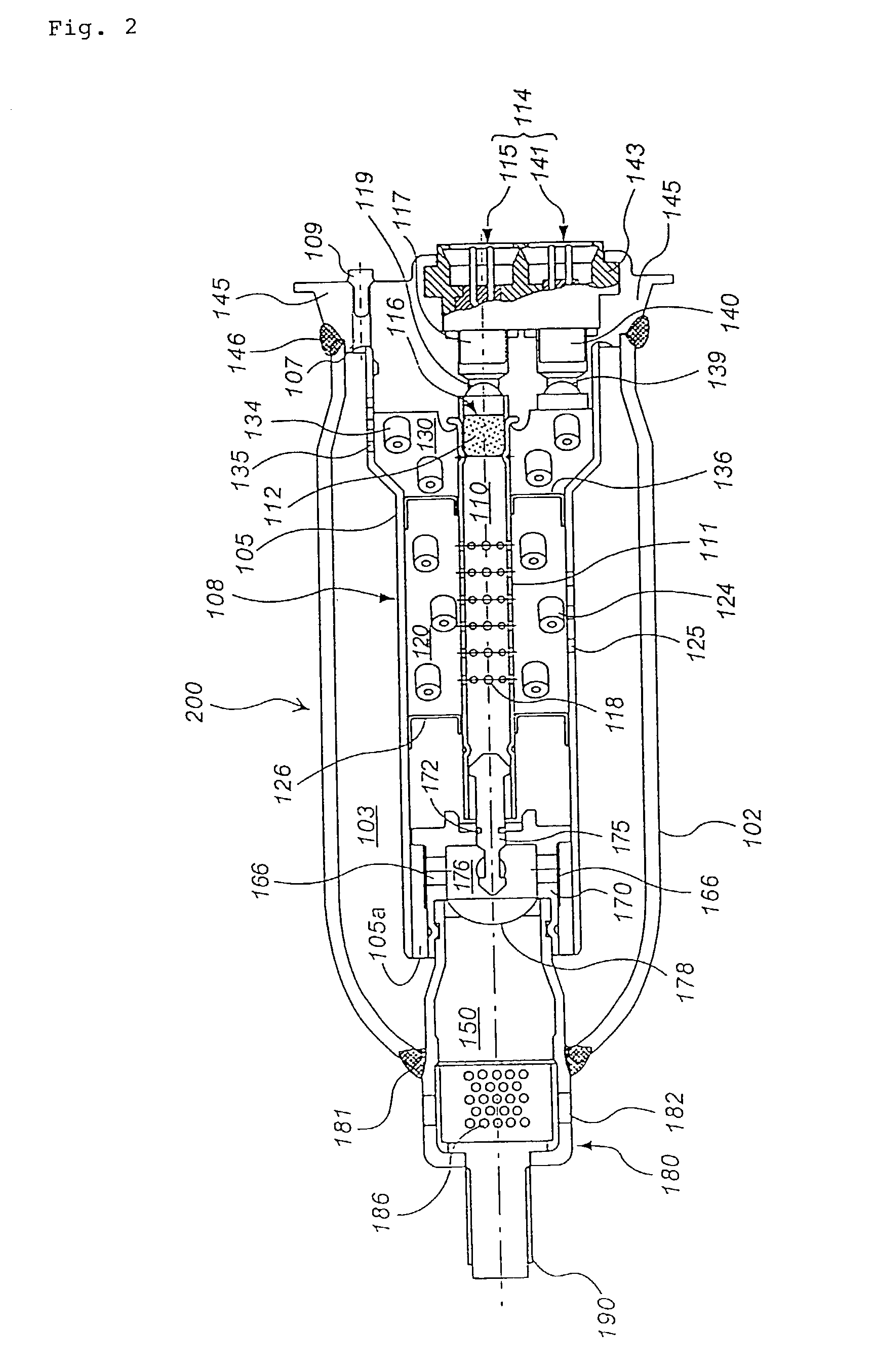

Hybrid inflator

InactiveUS20020190510A1Pedestrian/occupant safety arrangementGas generation devicesInternal pressureNozzle

Owner:DAICEL CHEM IND LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap