Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about "Printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

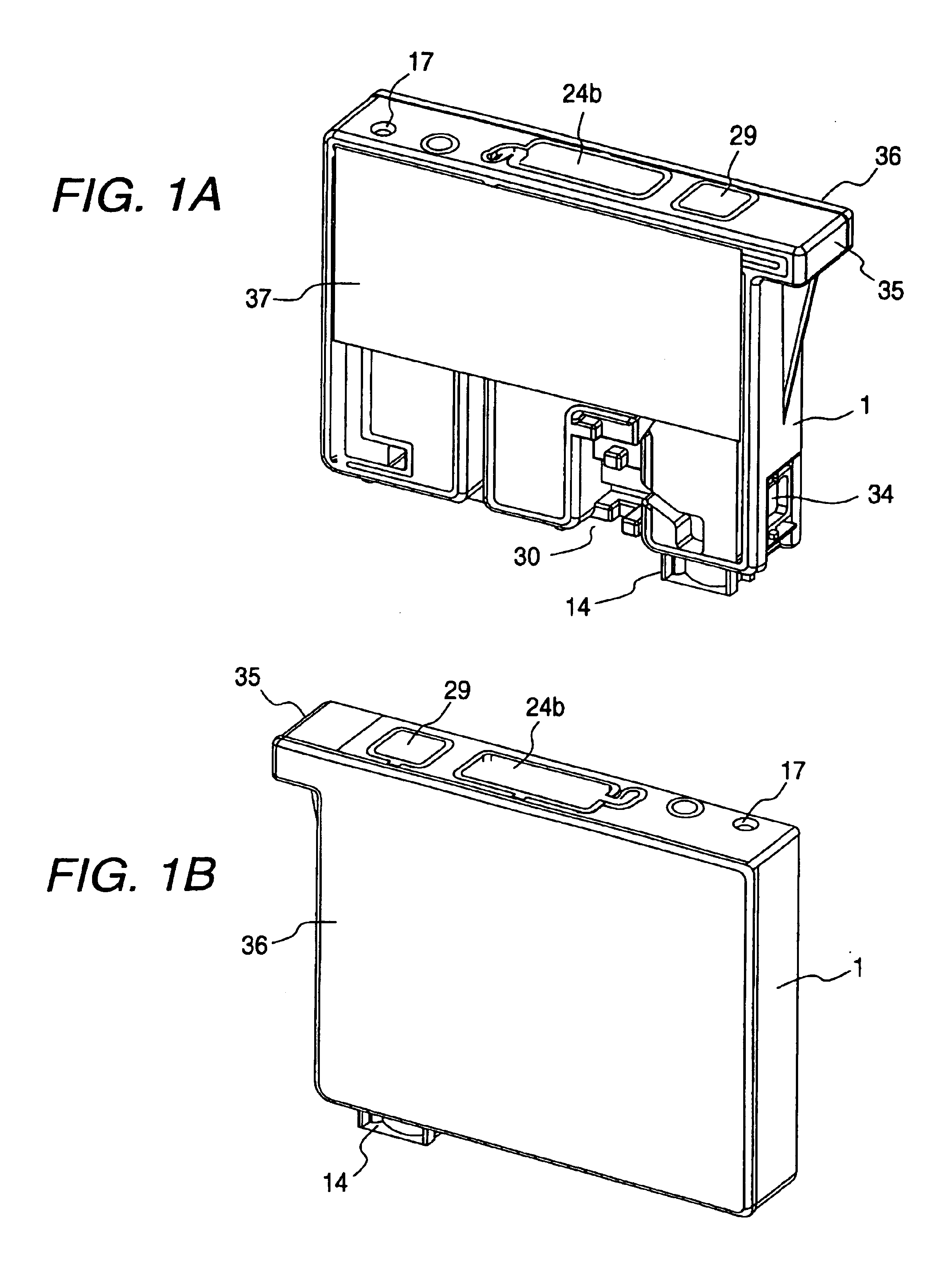

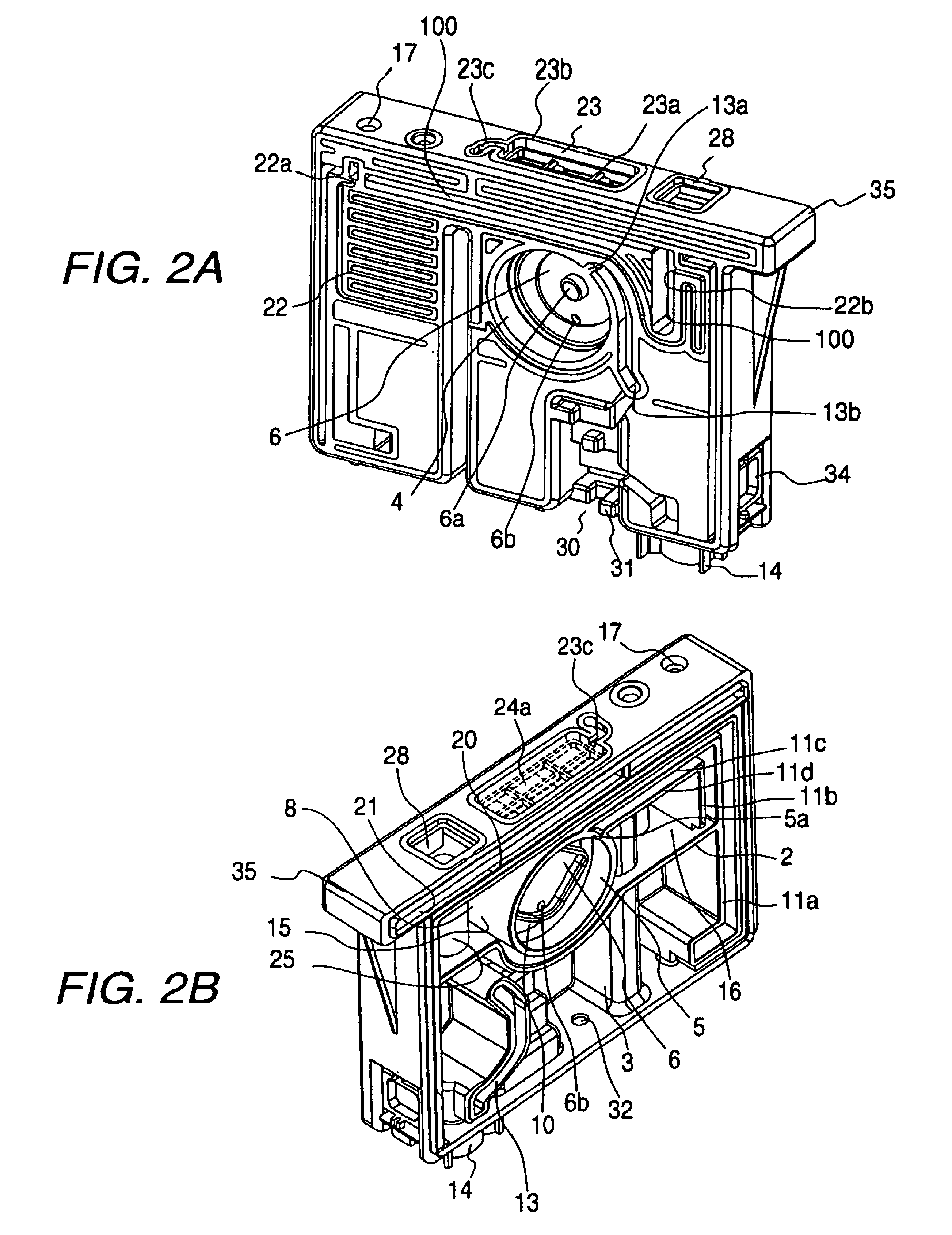

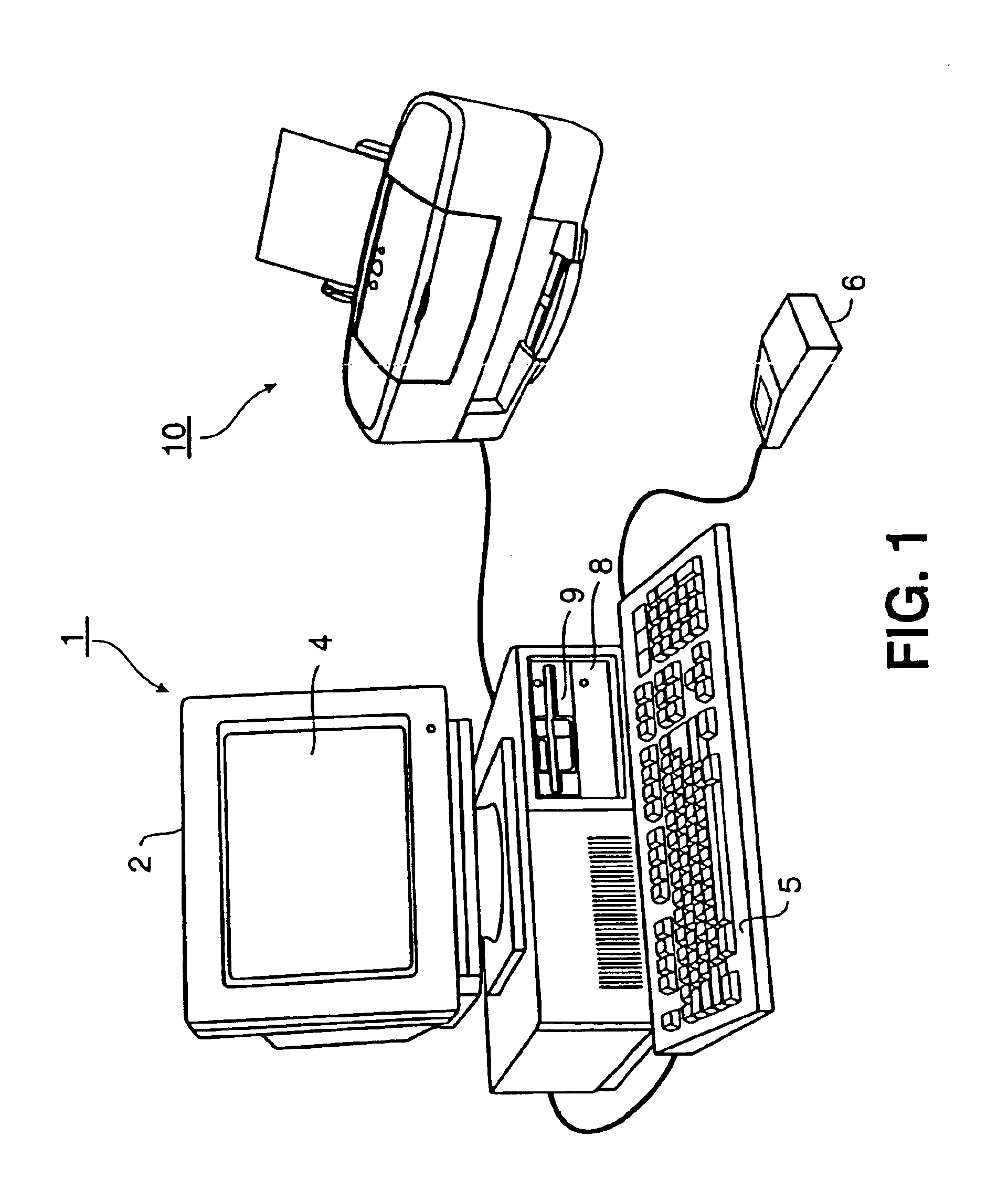

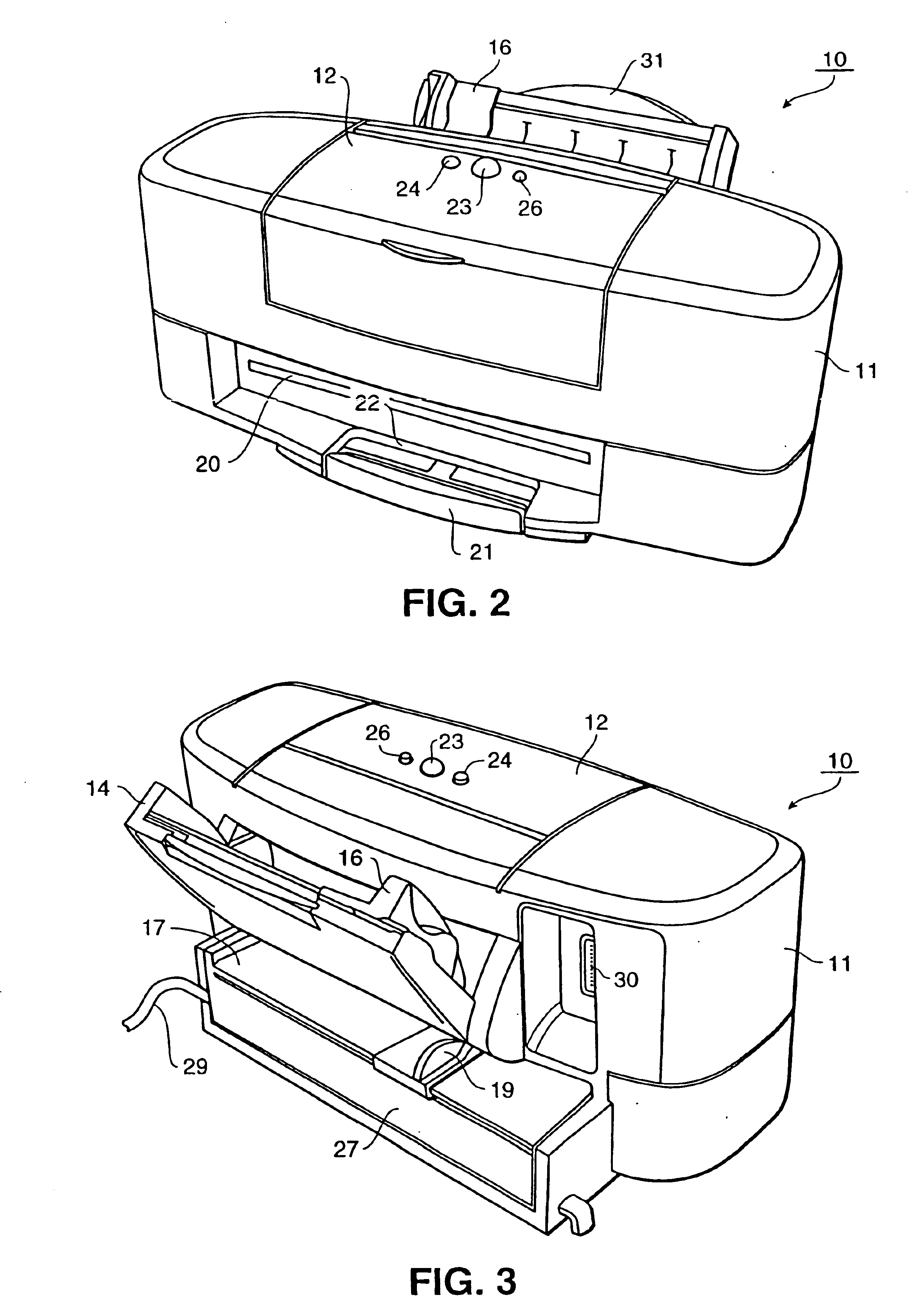

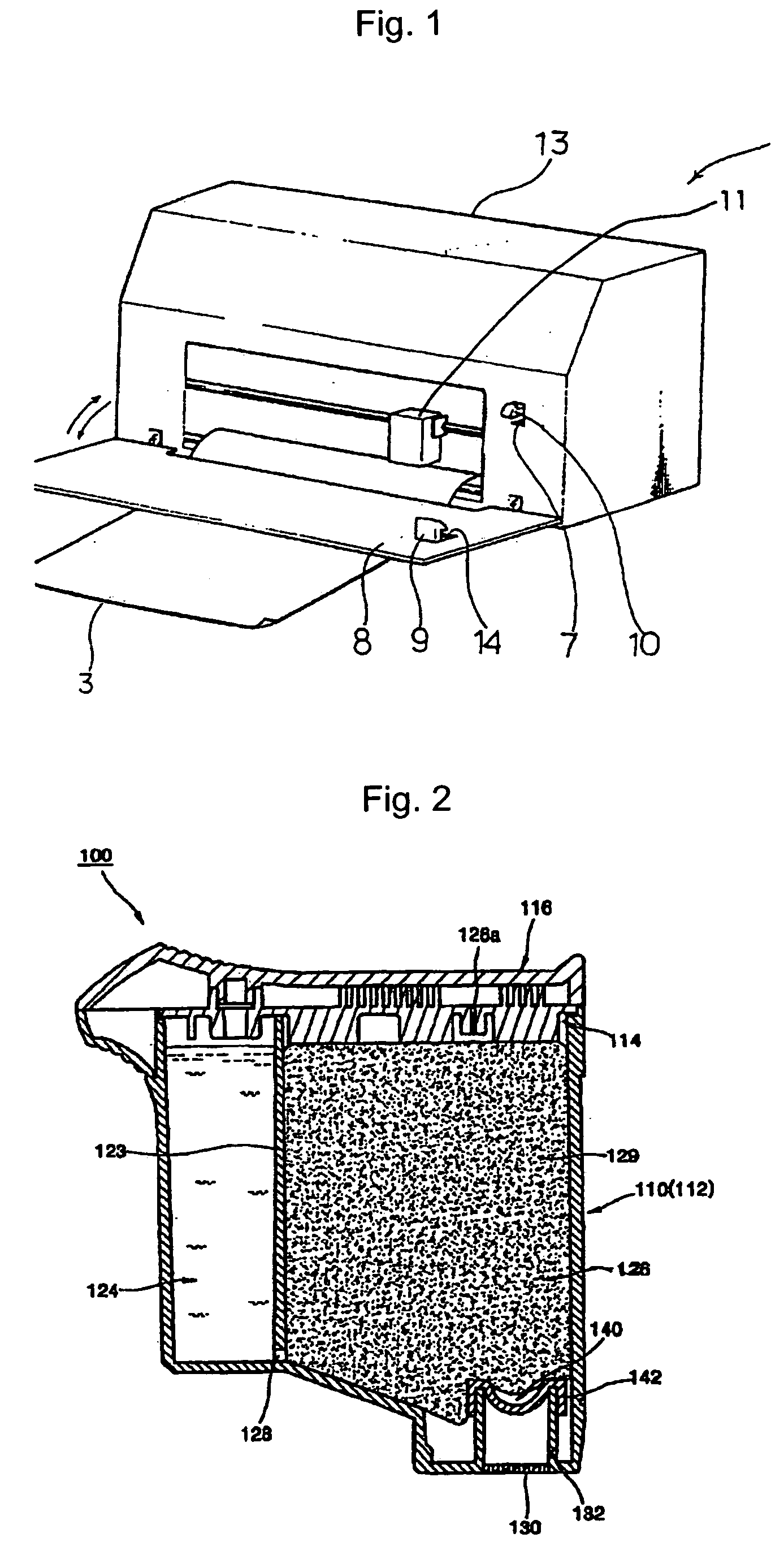

Ink cartridge for ink jet recording device

Owner:SEIKO EPSON CORP

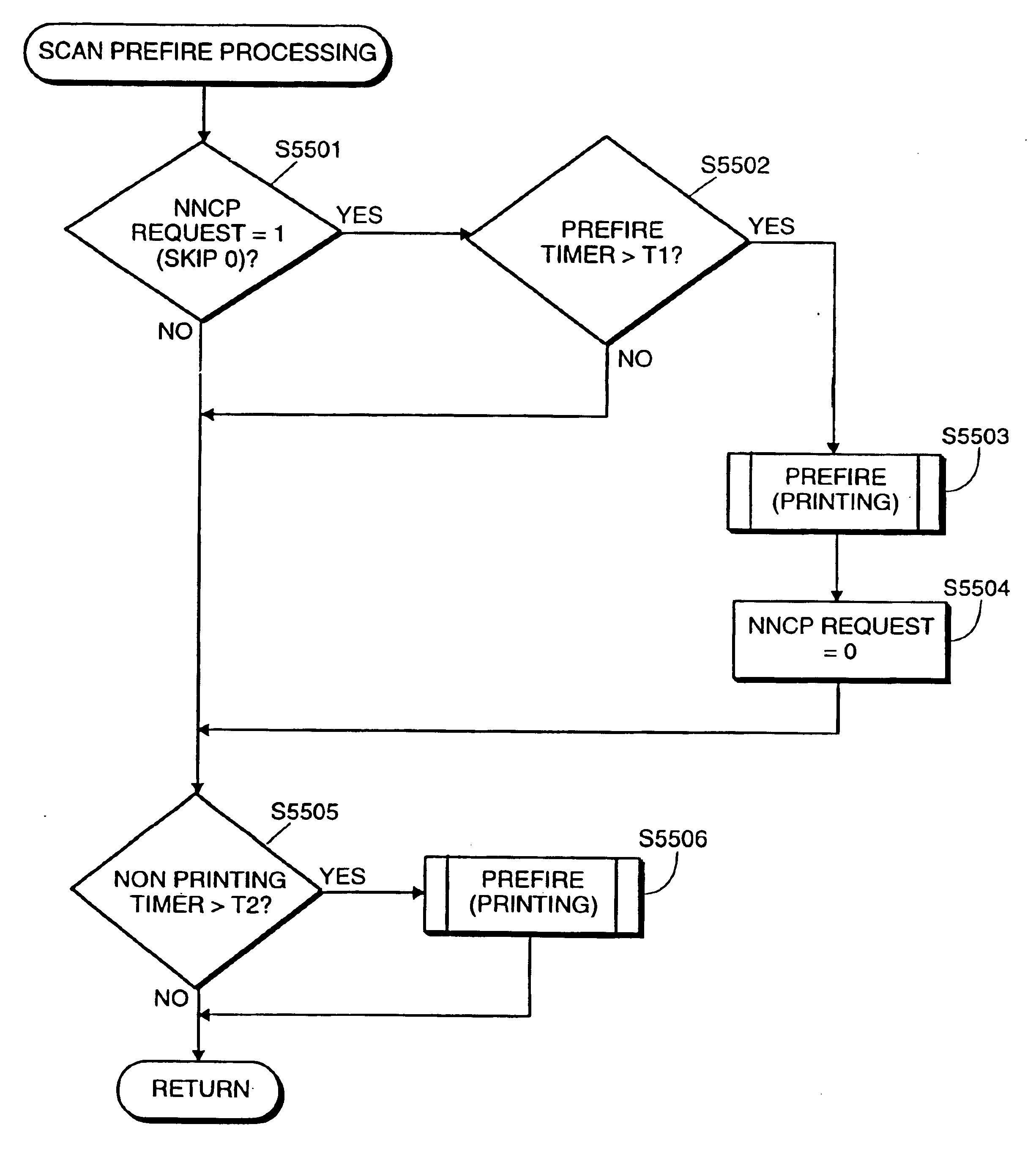

Control of ink jet nozzle prefiring

Owner:CANON KK

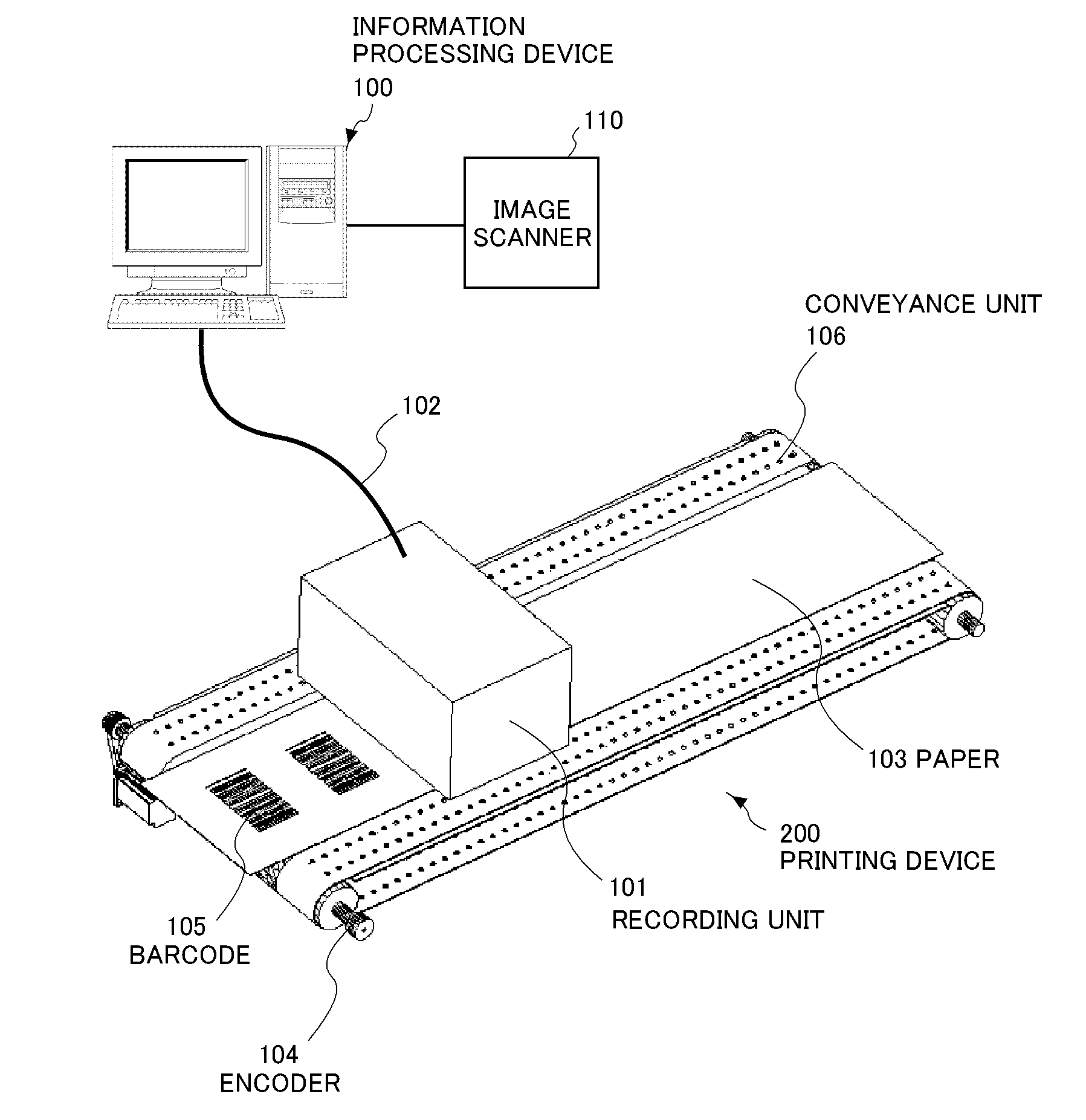

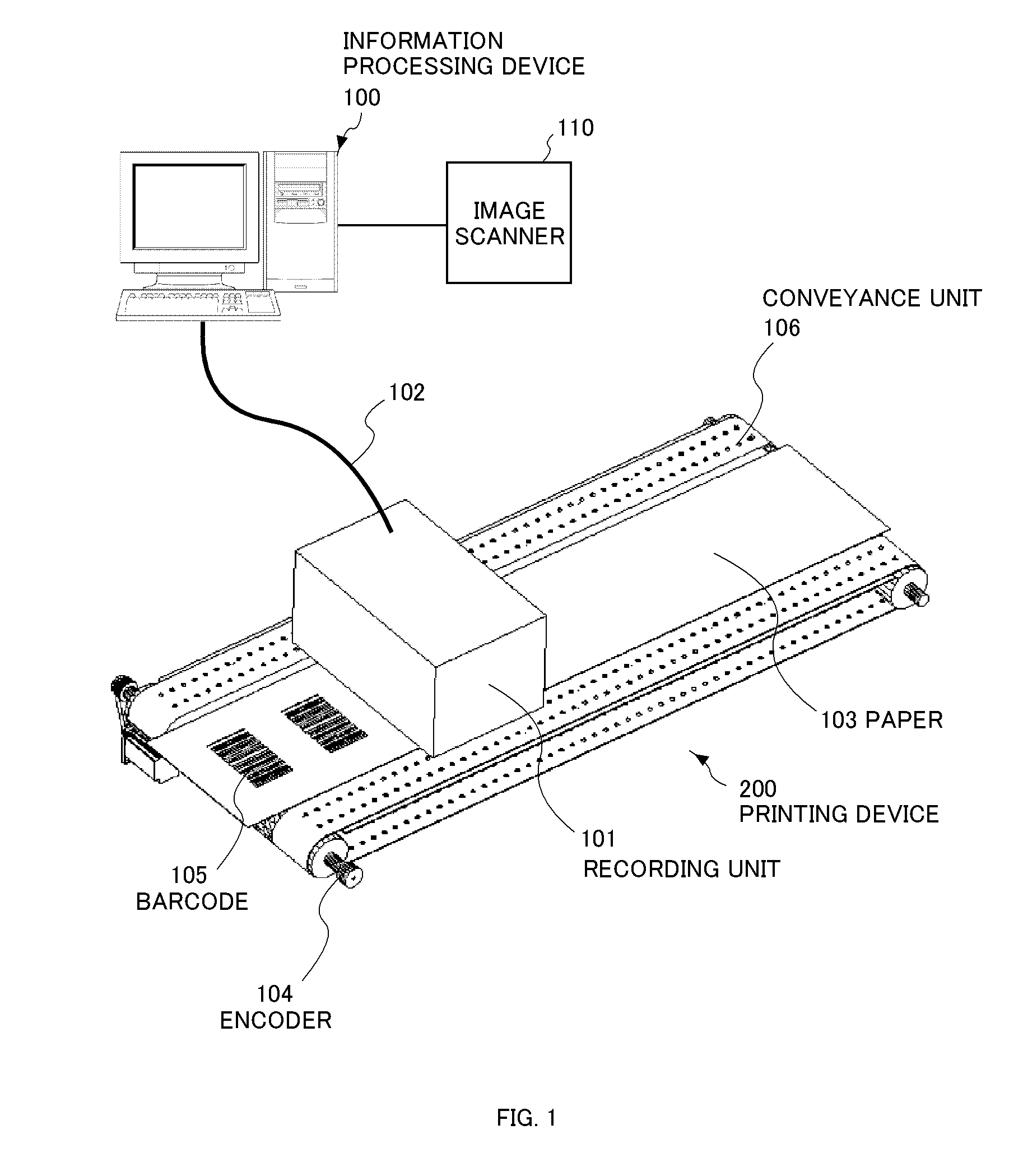

Barcode generation system, barcode generation program, printing device, and test chart

InactiveUS20090072035A1Minimum usage amountPrintingRecord carriers used with machinesBarcodeImaging data

Owner:COPYER

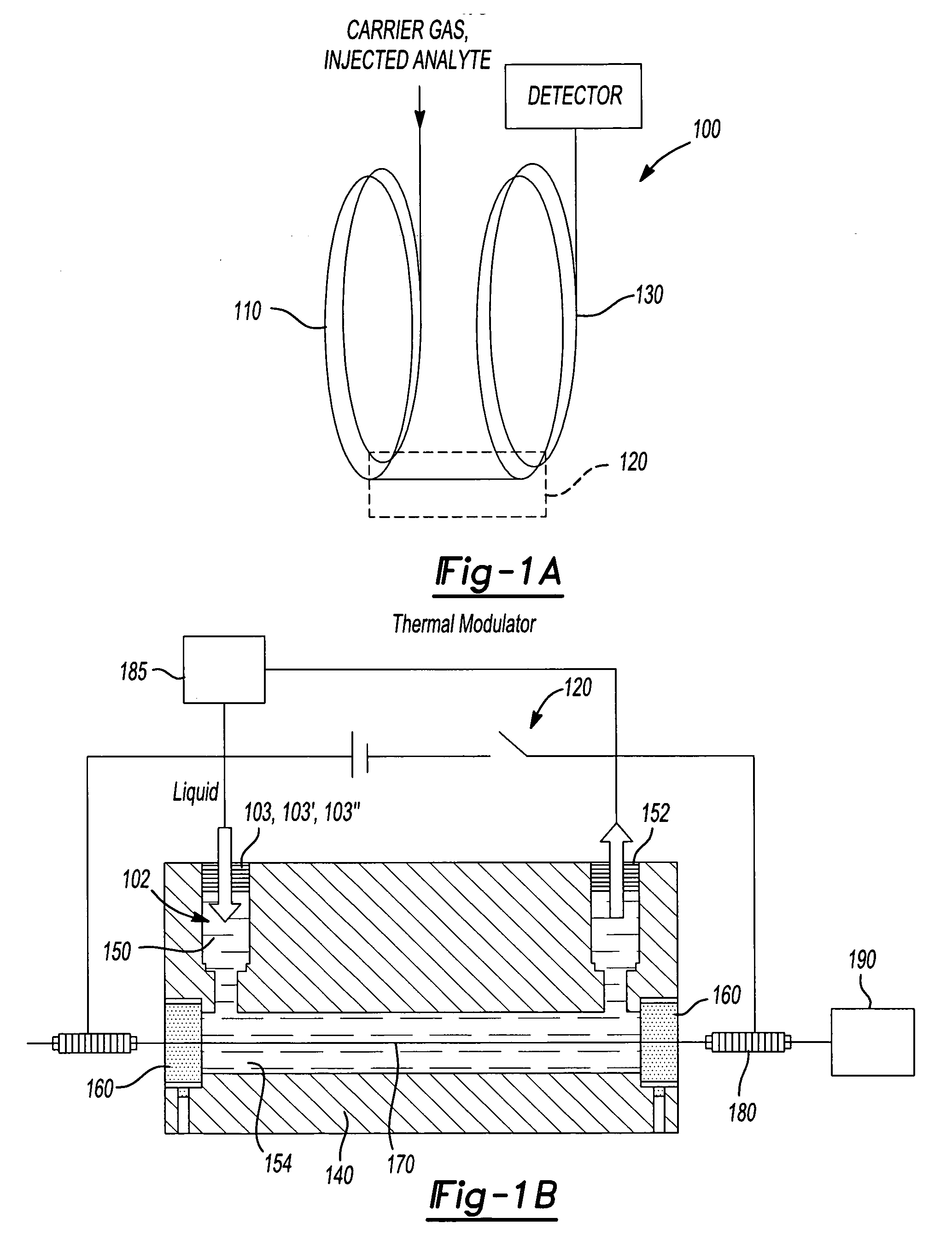

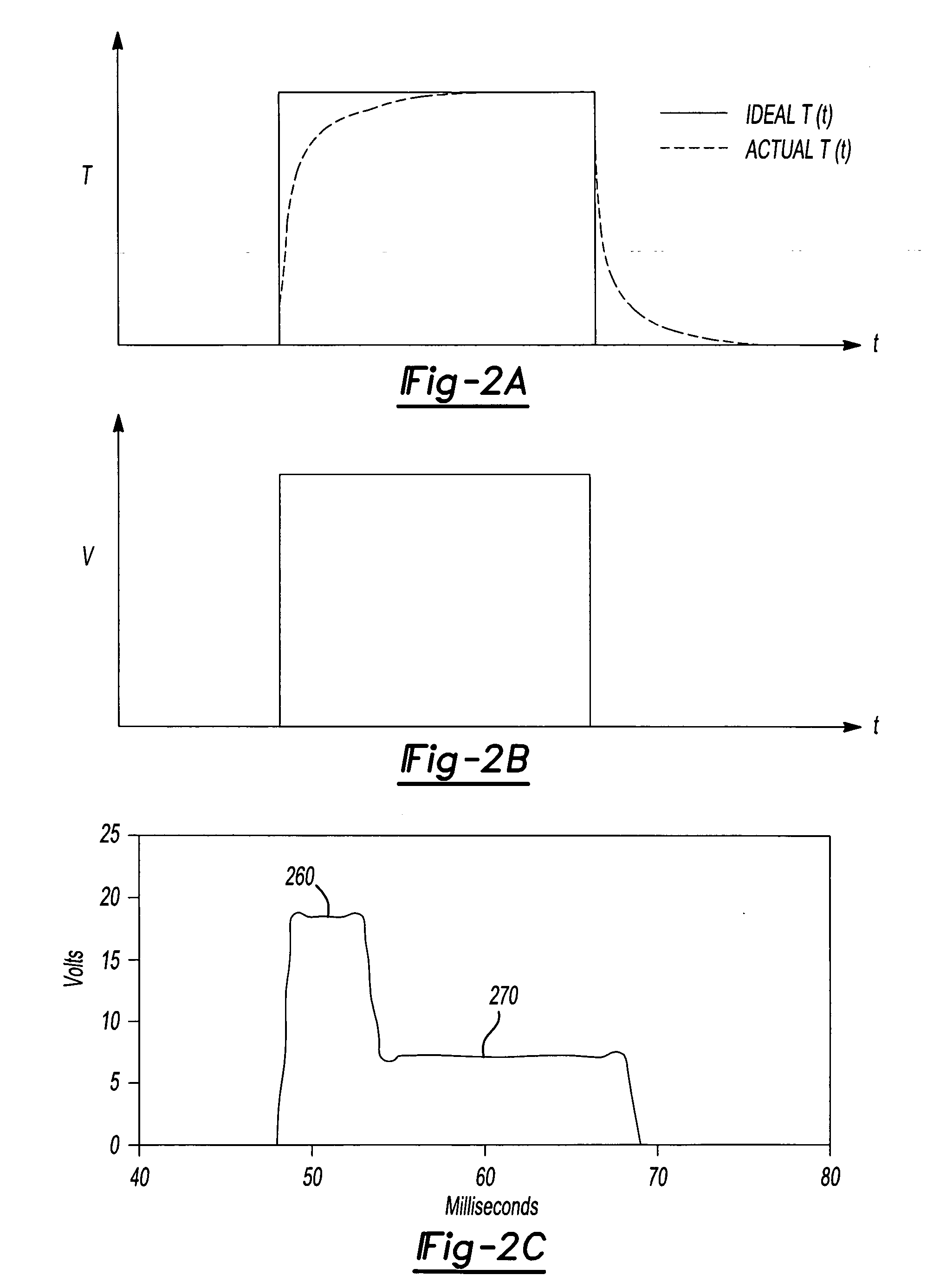

Thermal modulation for gas chromatography

Owner:THE RGT OF THE UNIV OF MICHIGAN

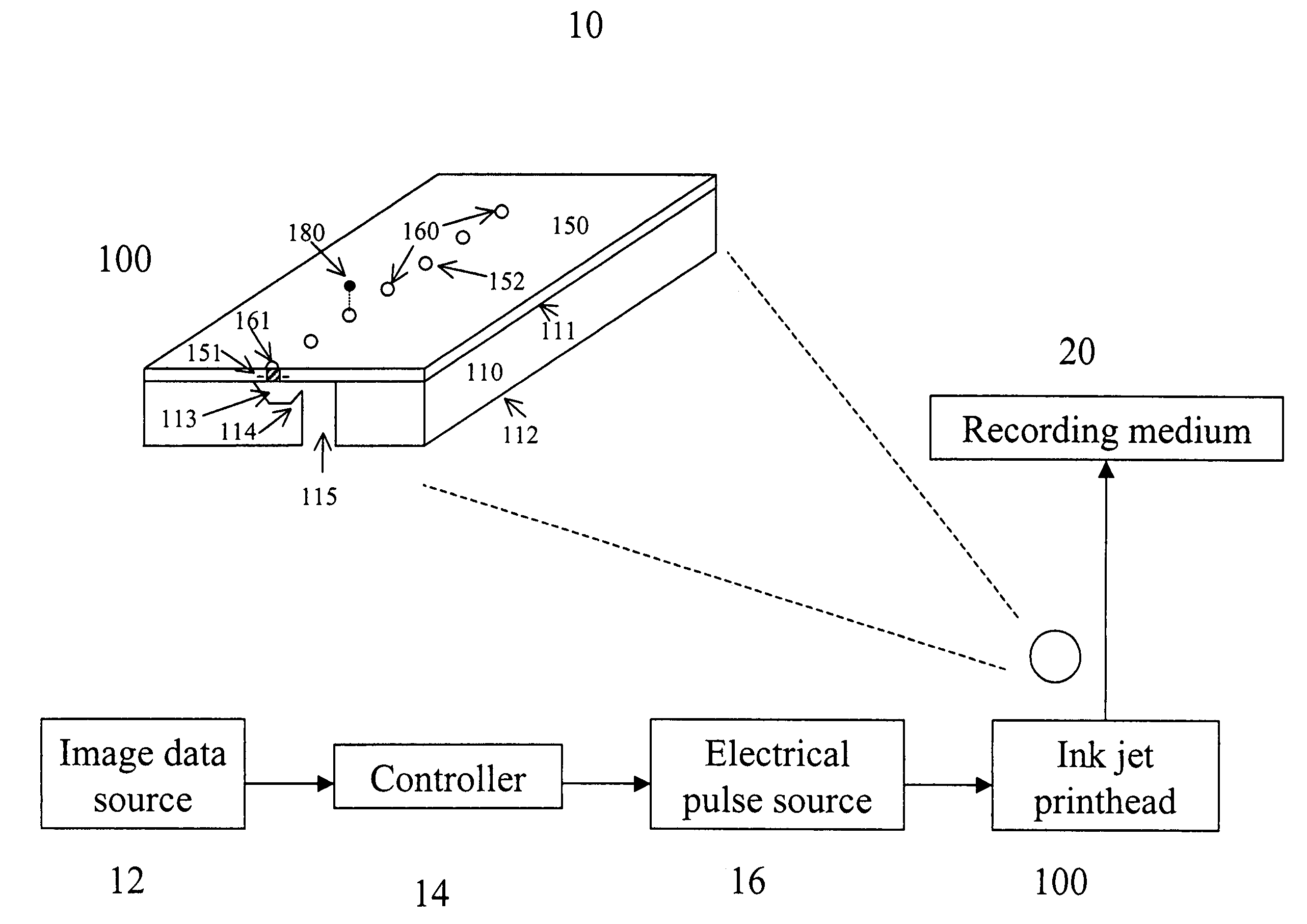

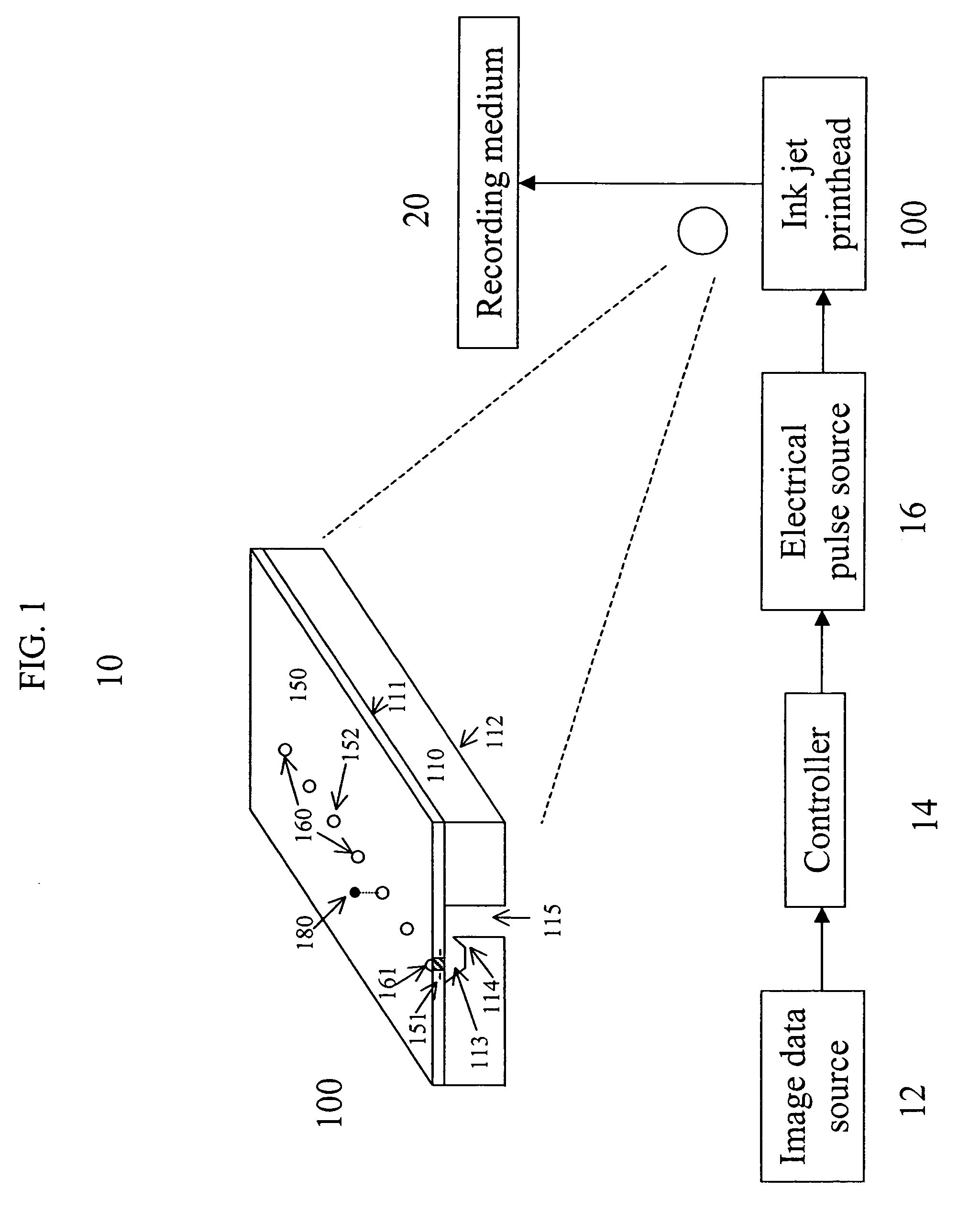

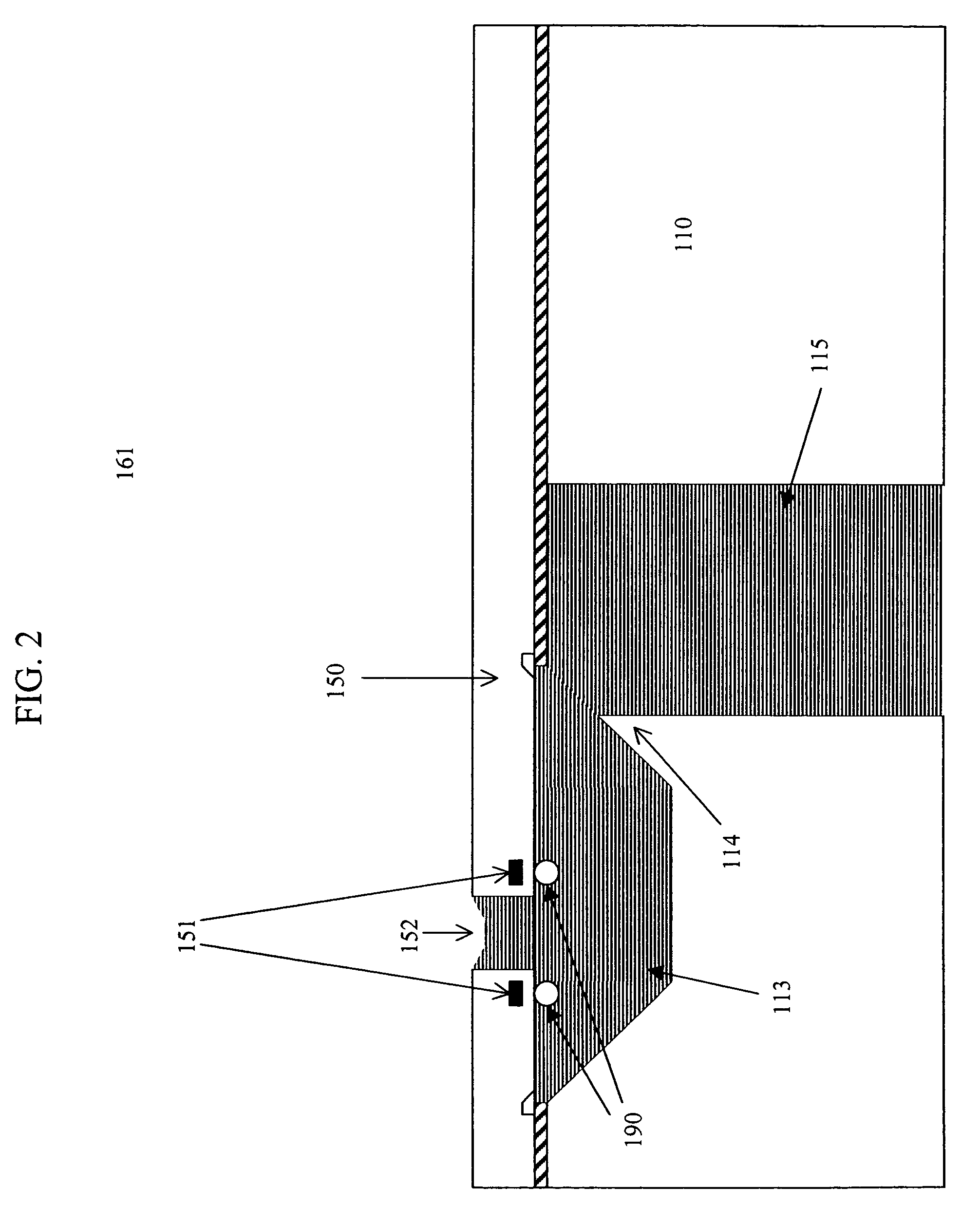

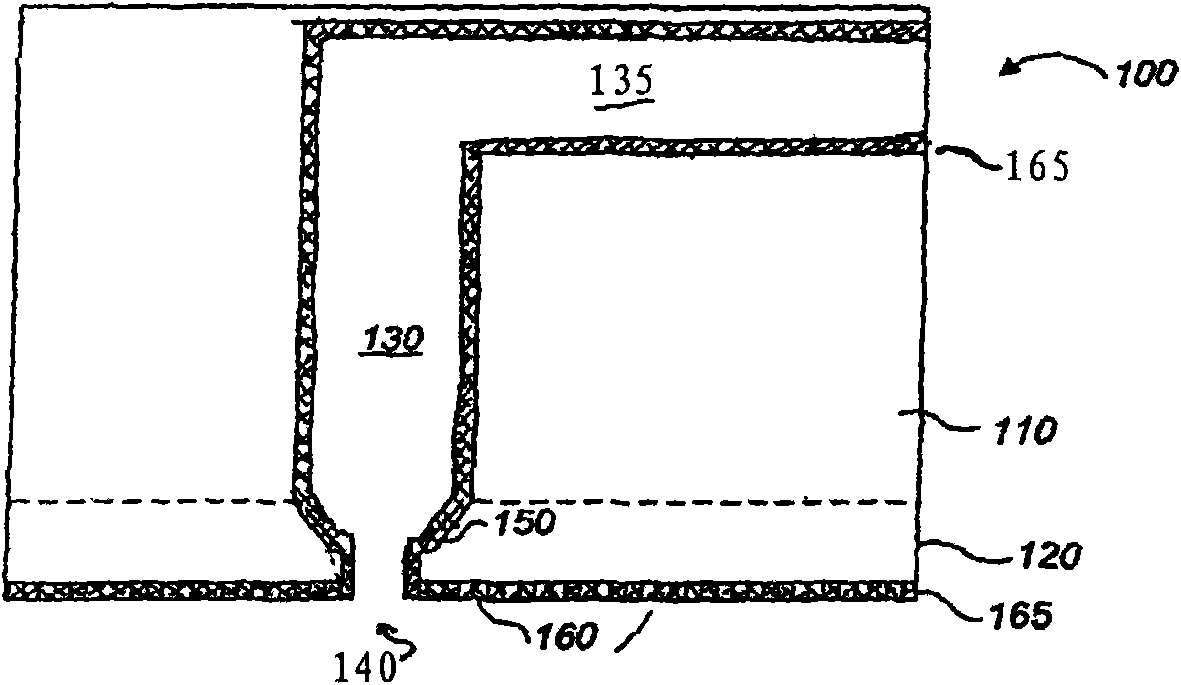

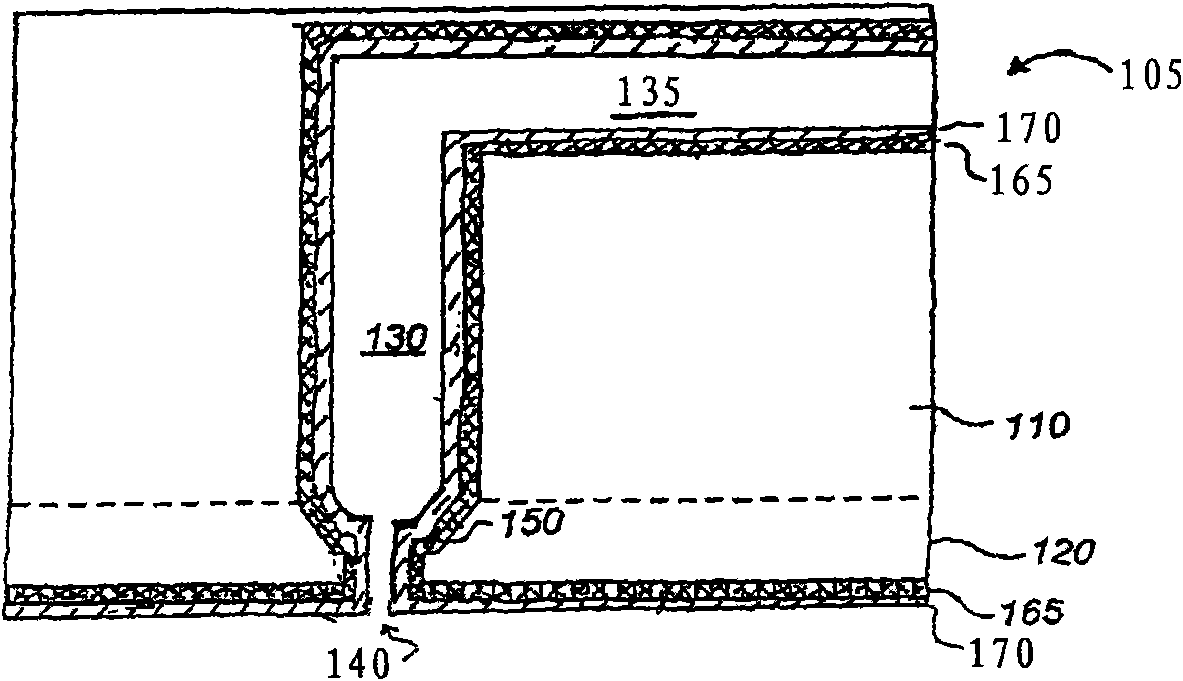

Fluid ejector having an anisotropic surface chamber etch

Owner:EASTMAN KODAK CO

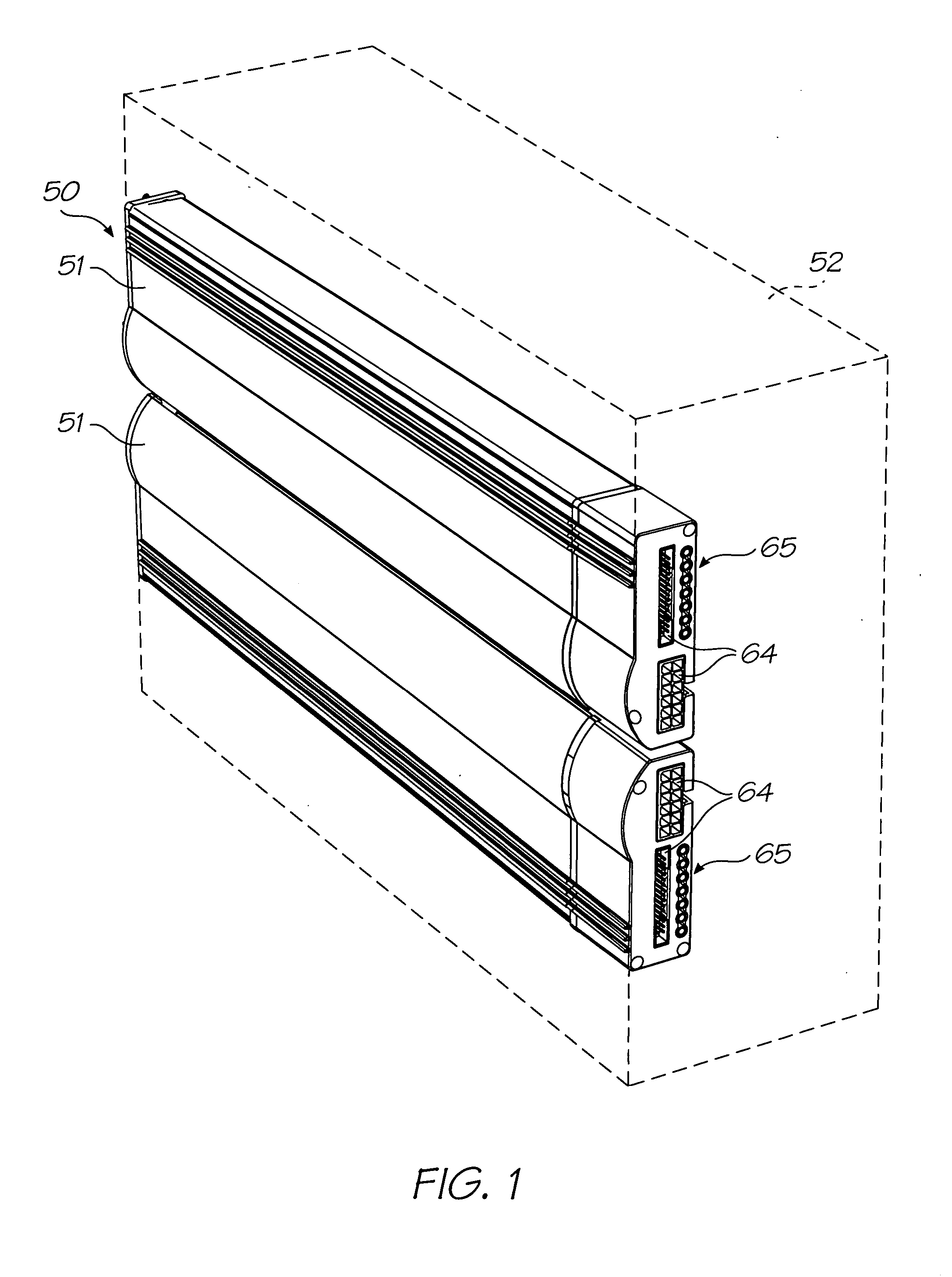

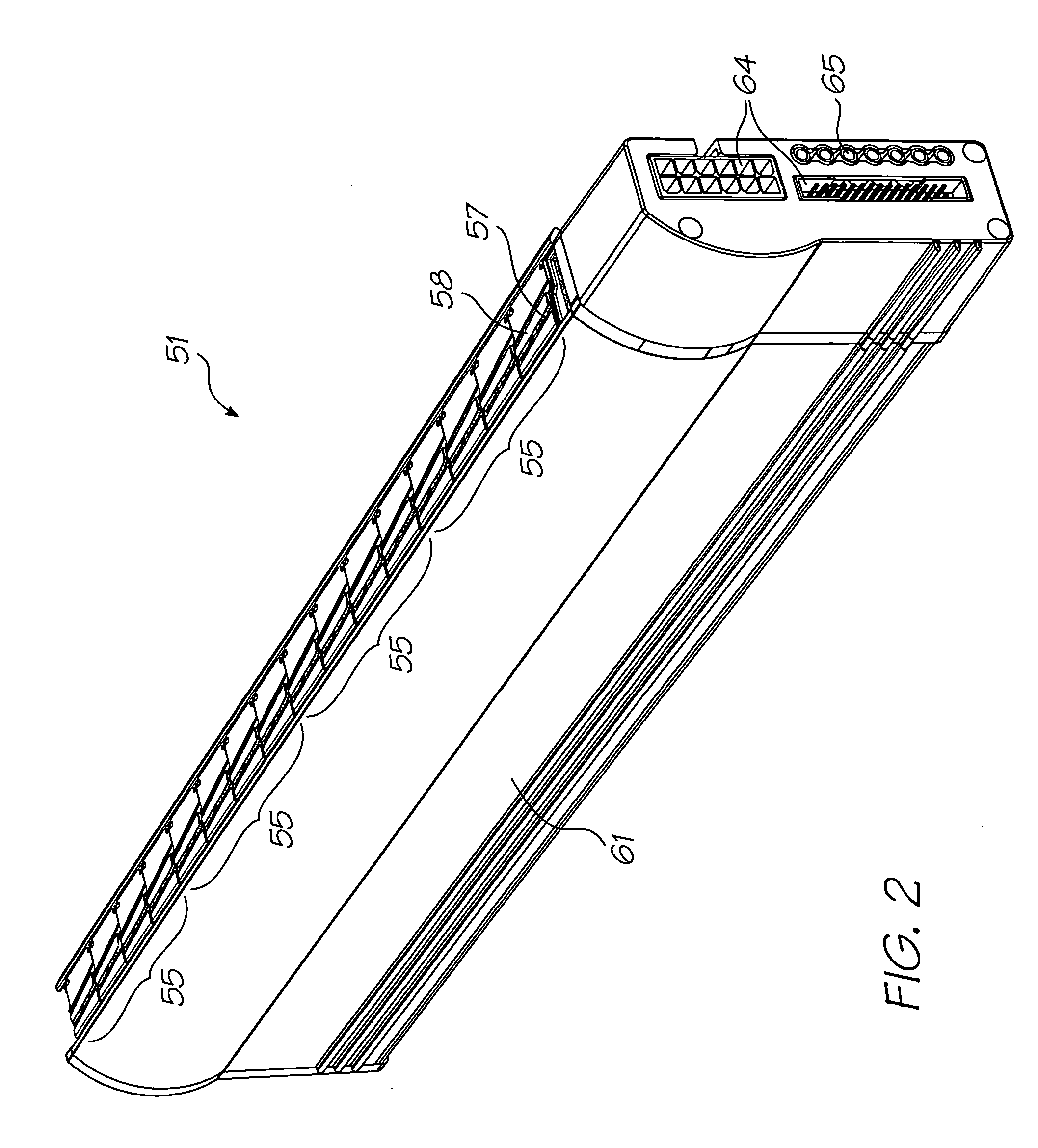

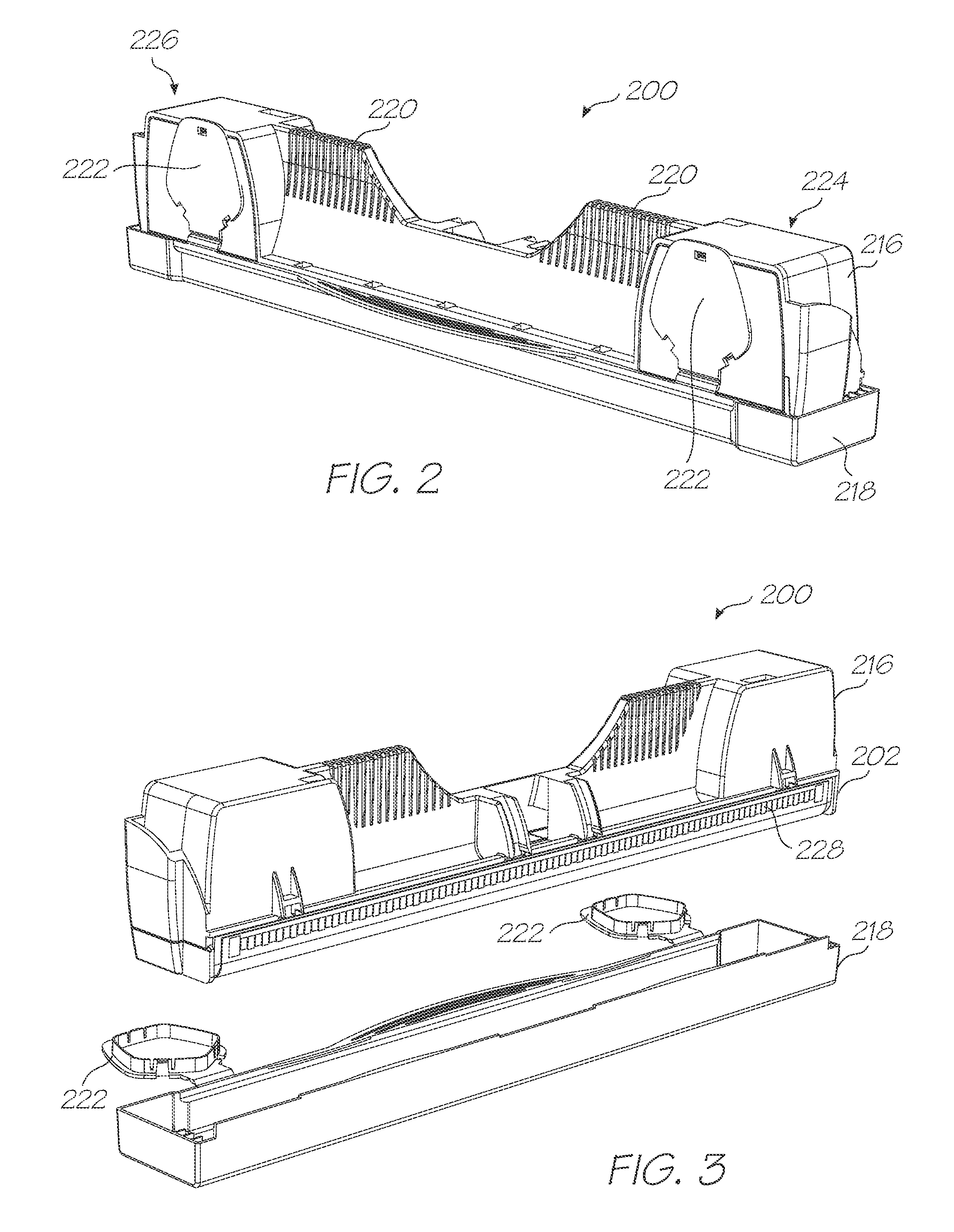

Inkjet printer with interposing printhead capping mechanism

Owner:MEMJET TECH LTD +1

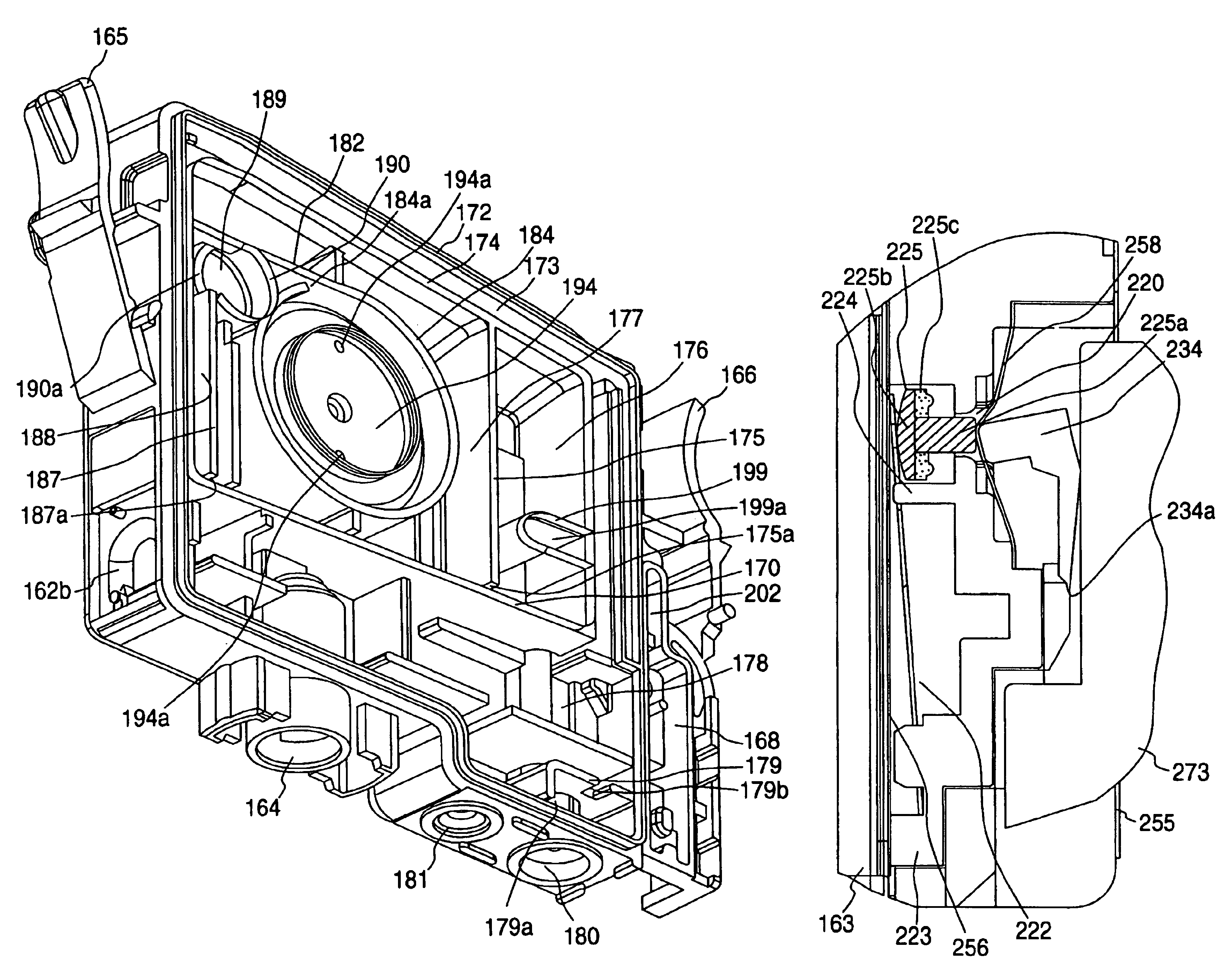

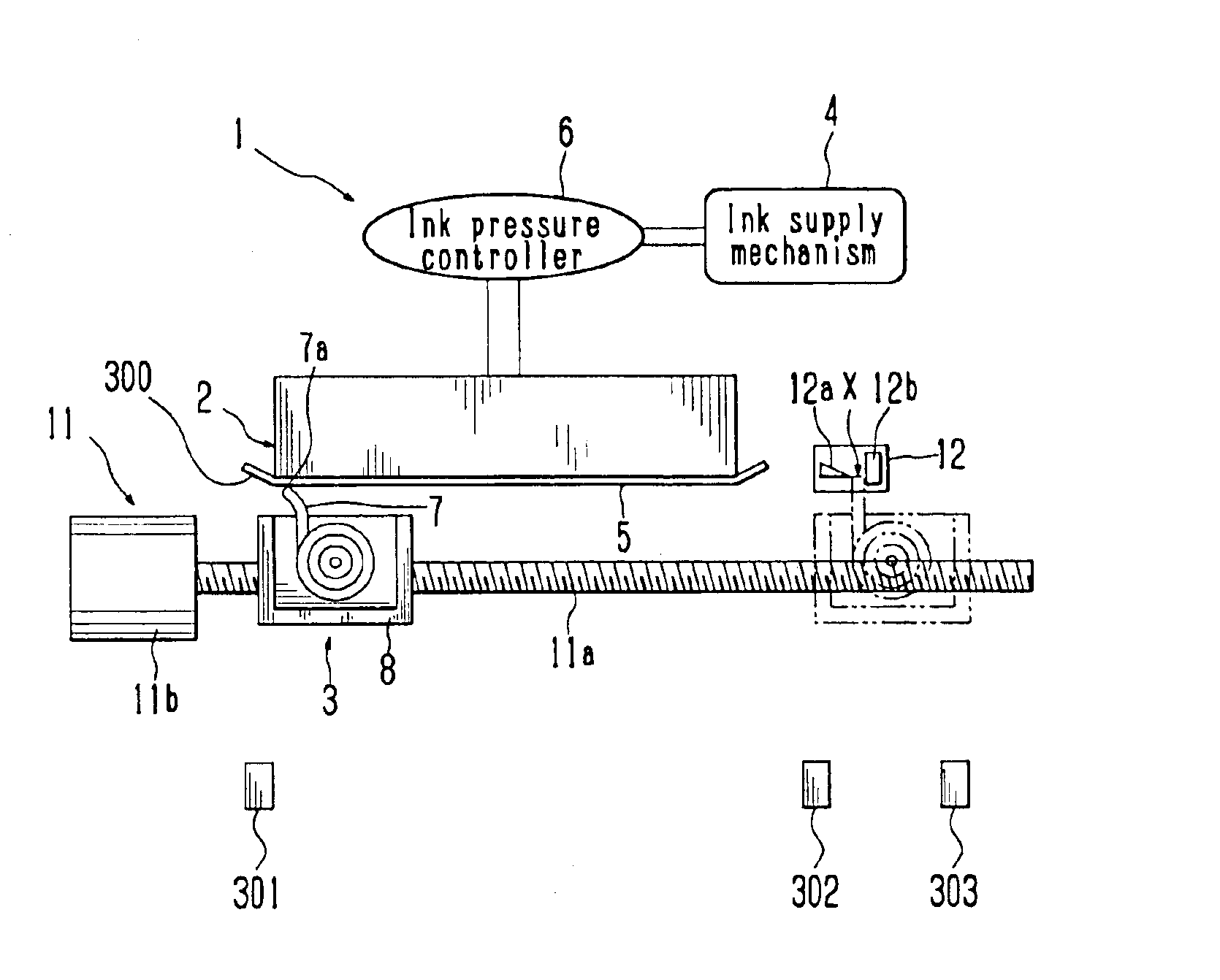

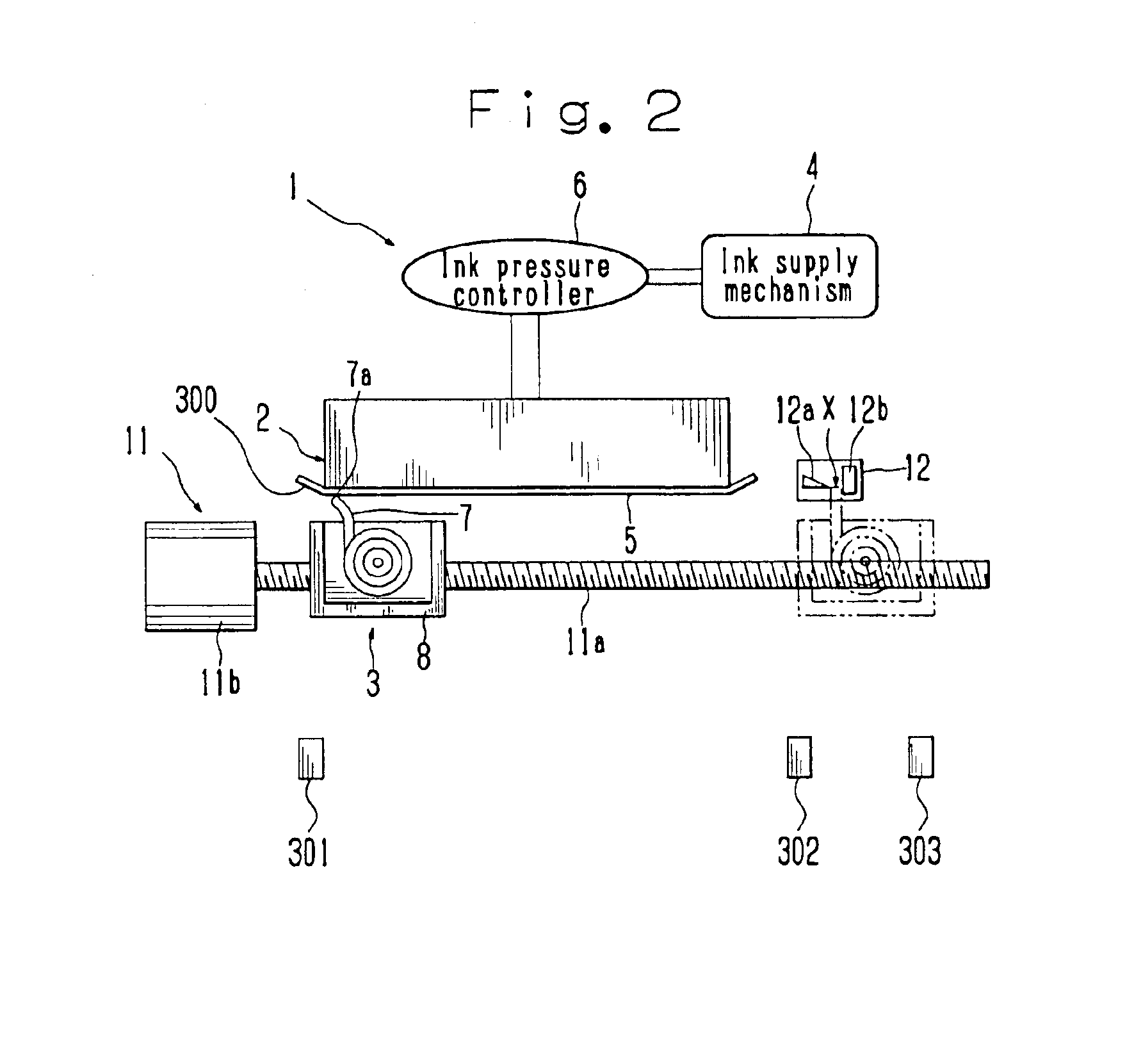

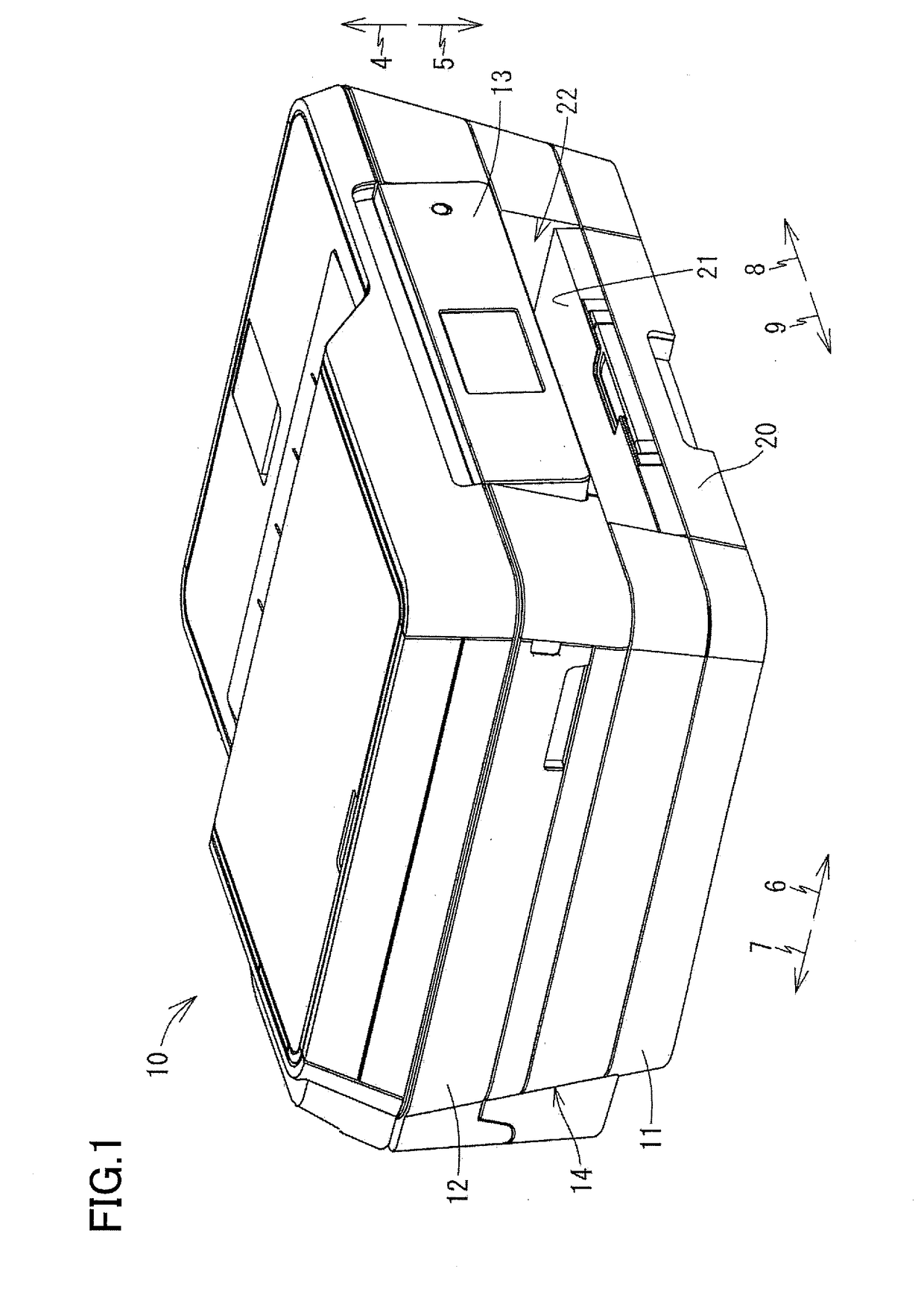

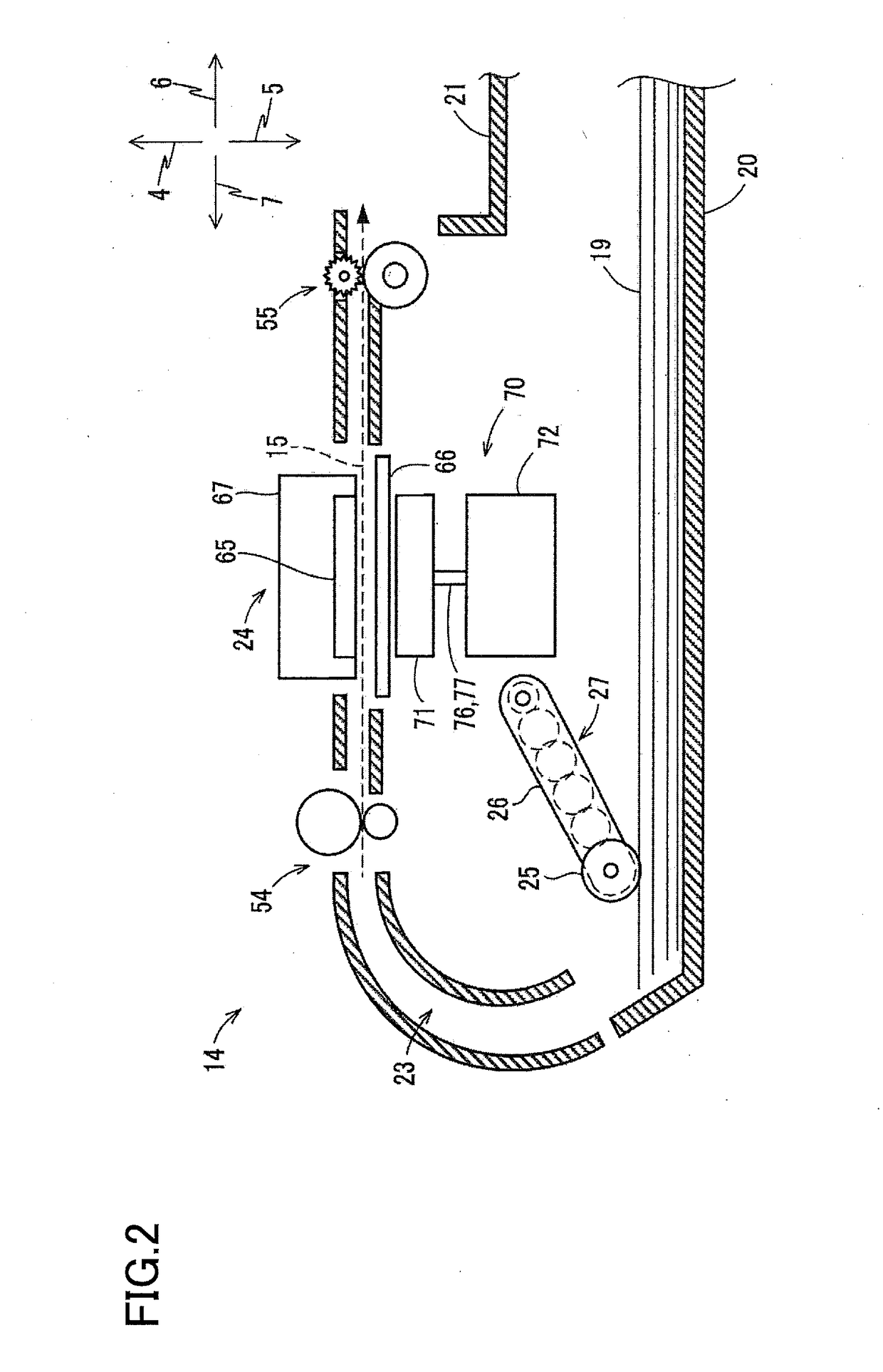

Ink Jet recording apparatus having maintenance means for cleaning an ink jet recording head

InactiveUS6866362B2Satisfactory delivery performanceImprove reliabilityPrintingRecording headForeign matter

Owner:TOSHIBA TEC KK

Microelectronic temperature sensor and preparation method thereof

InactiveCN105967136AHigh sensitivityReduce the effect of fringe capacitancePrecision positioning equipmentThermometers using electric/magnetic elementsElectricityElectron temperature

Owner:HOHAI UNIV CHANGZHOU

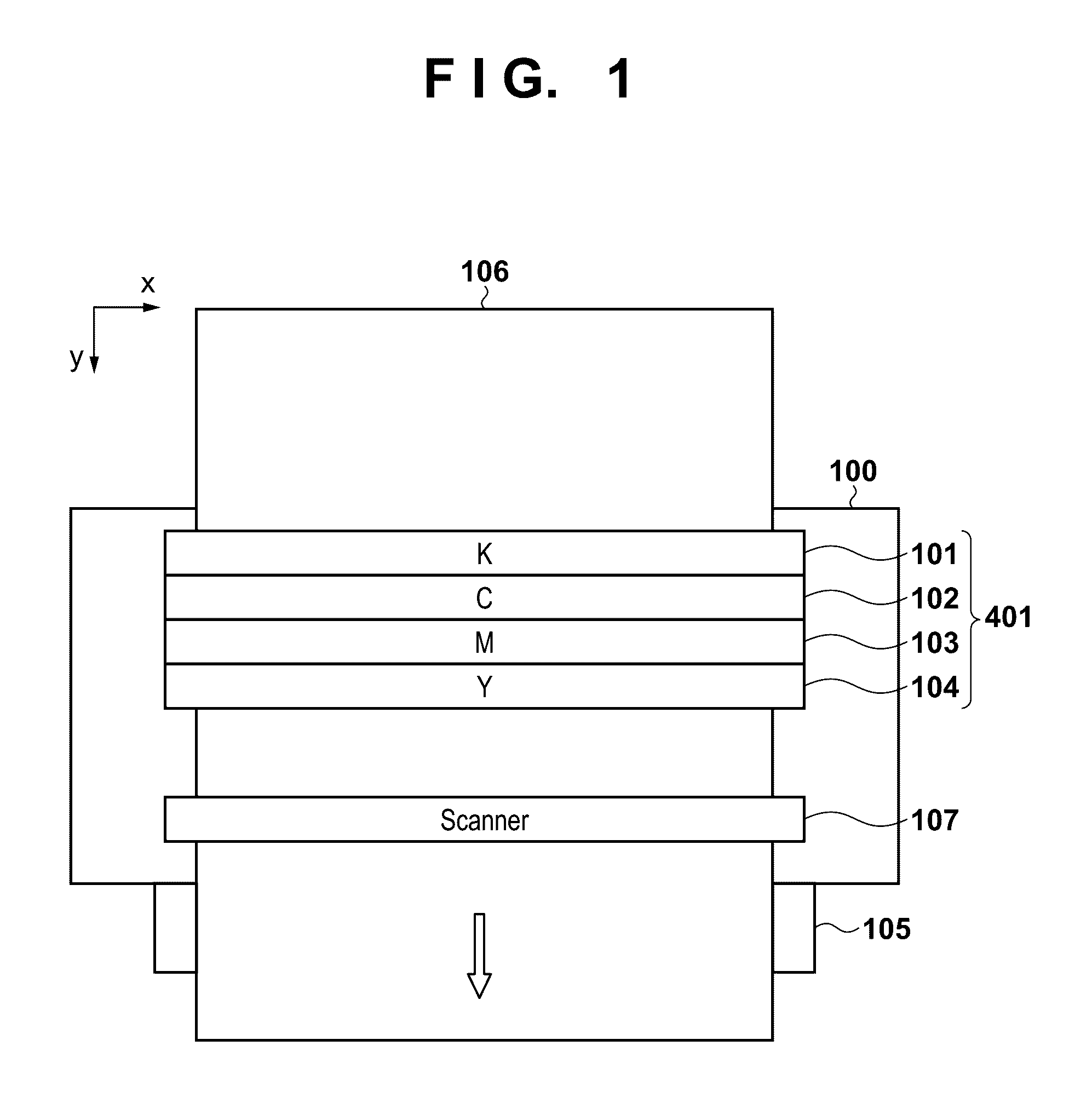

Ink jet printing apparatus

Owner:CANON KK

Printing system having printhead bypass

InactiveUS20110279568A1Simpler and reliable and effectivePrintingThin material handlingBiomedical engineering

Owner:ZAMTEC

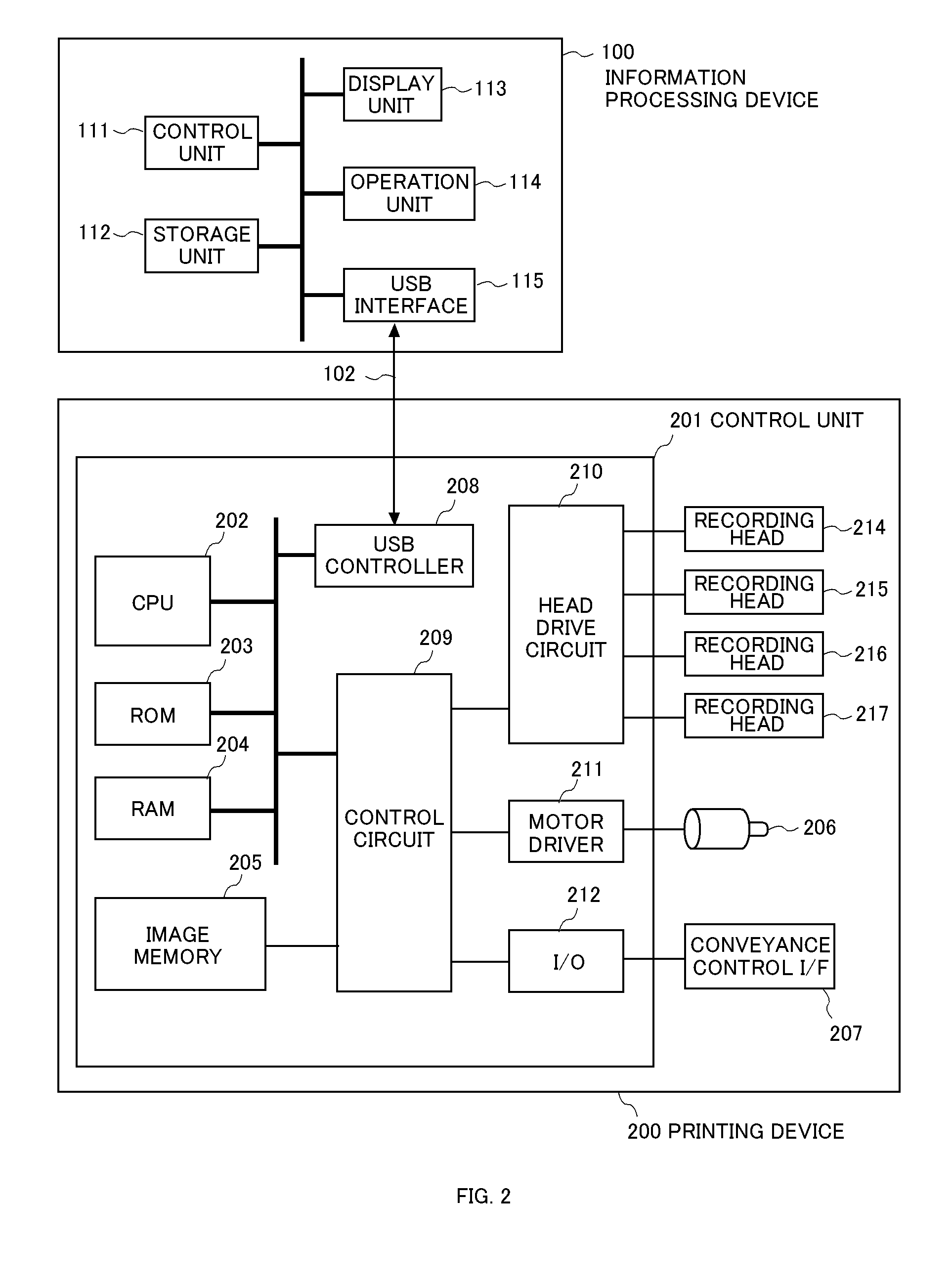

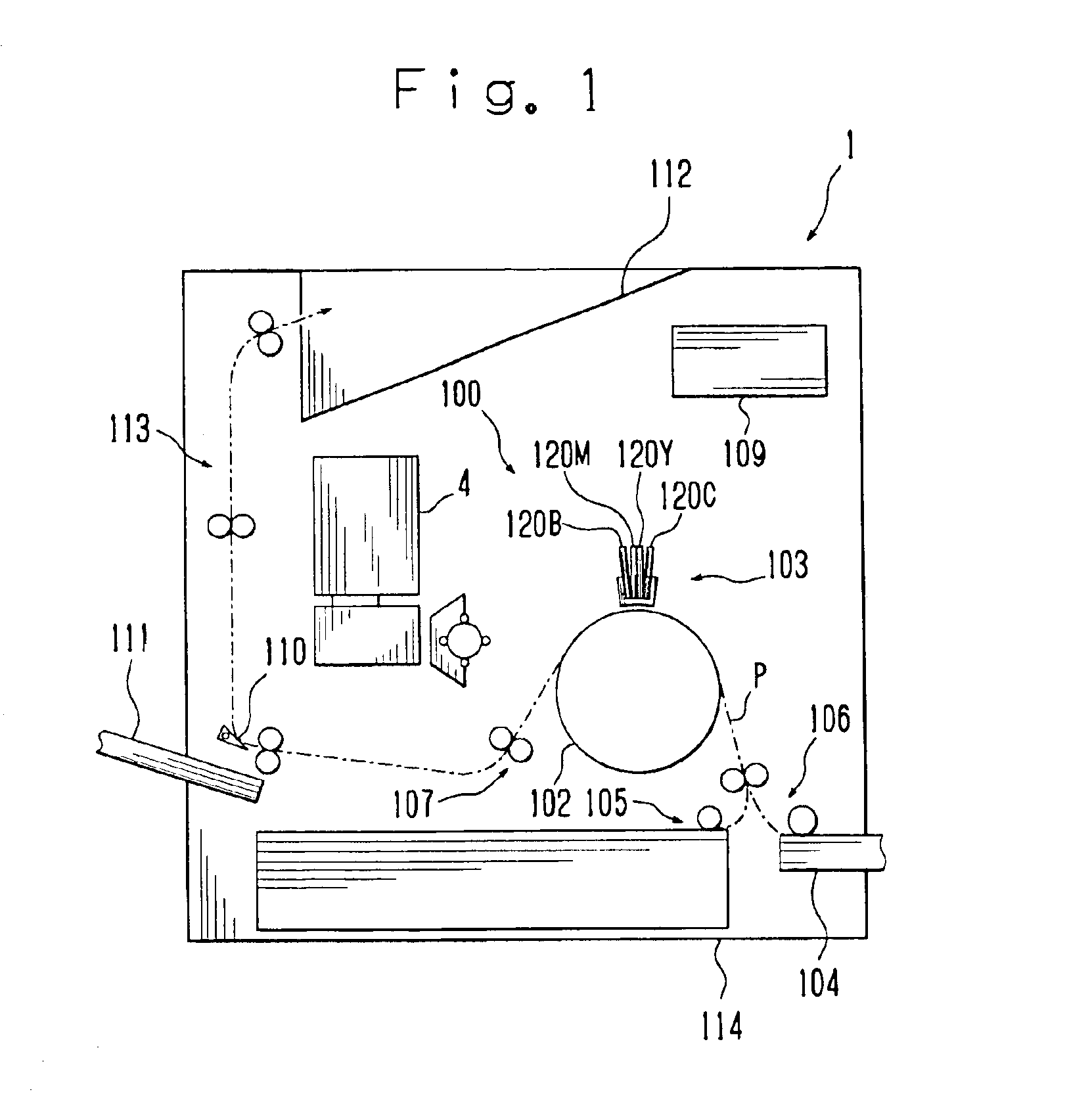

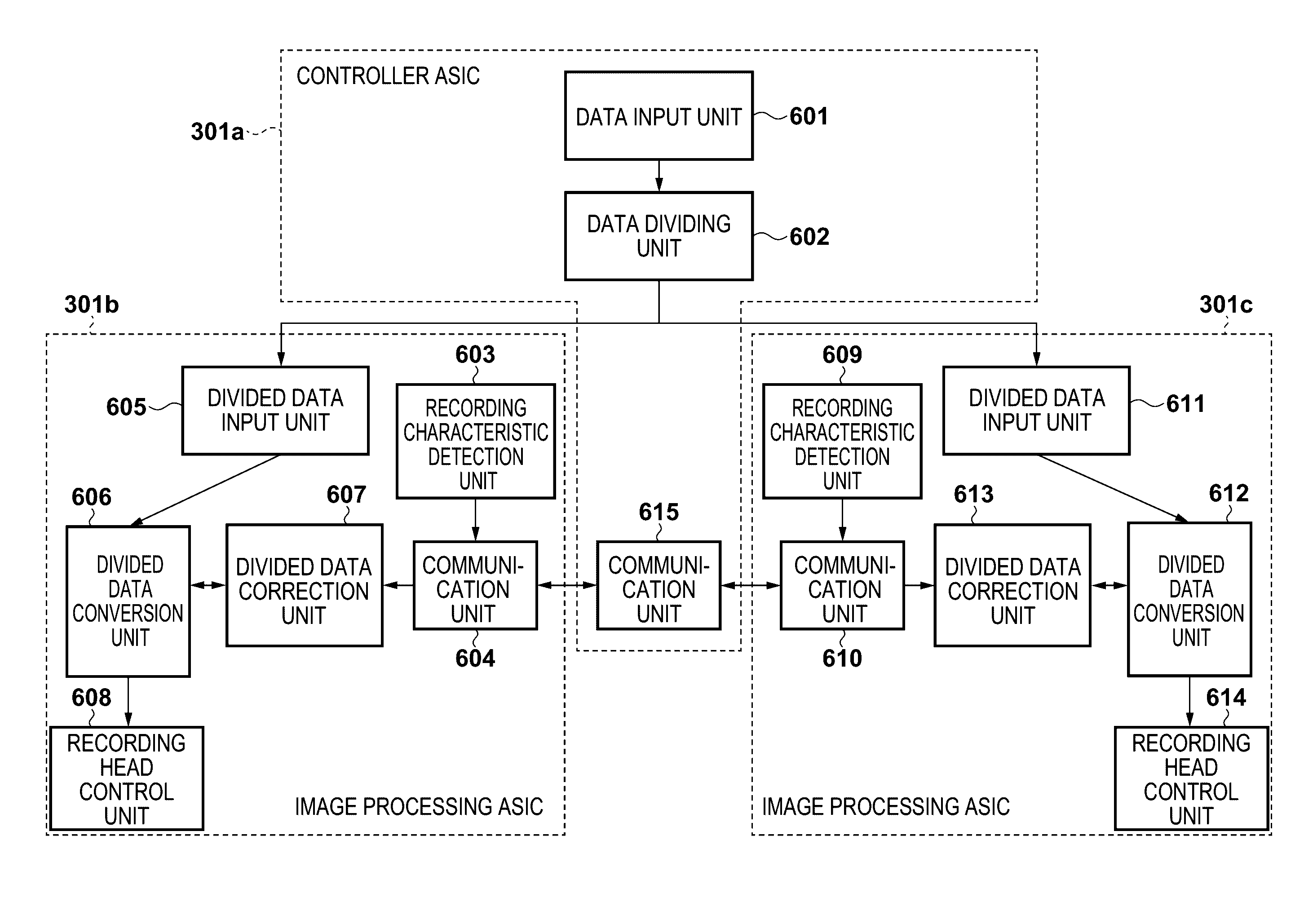

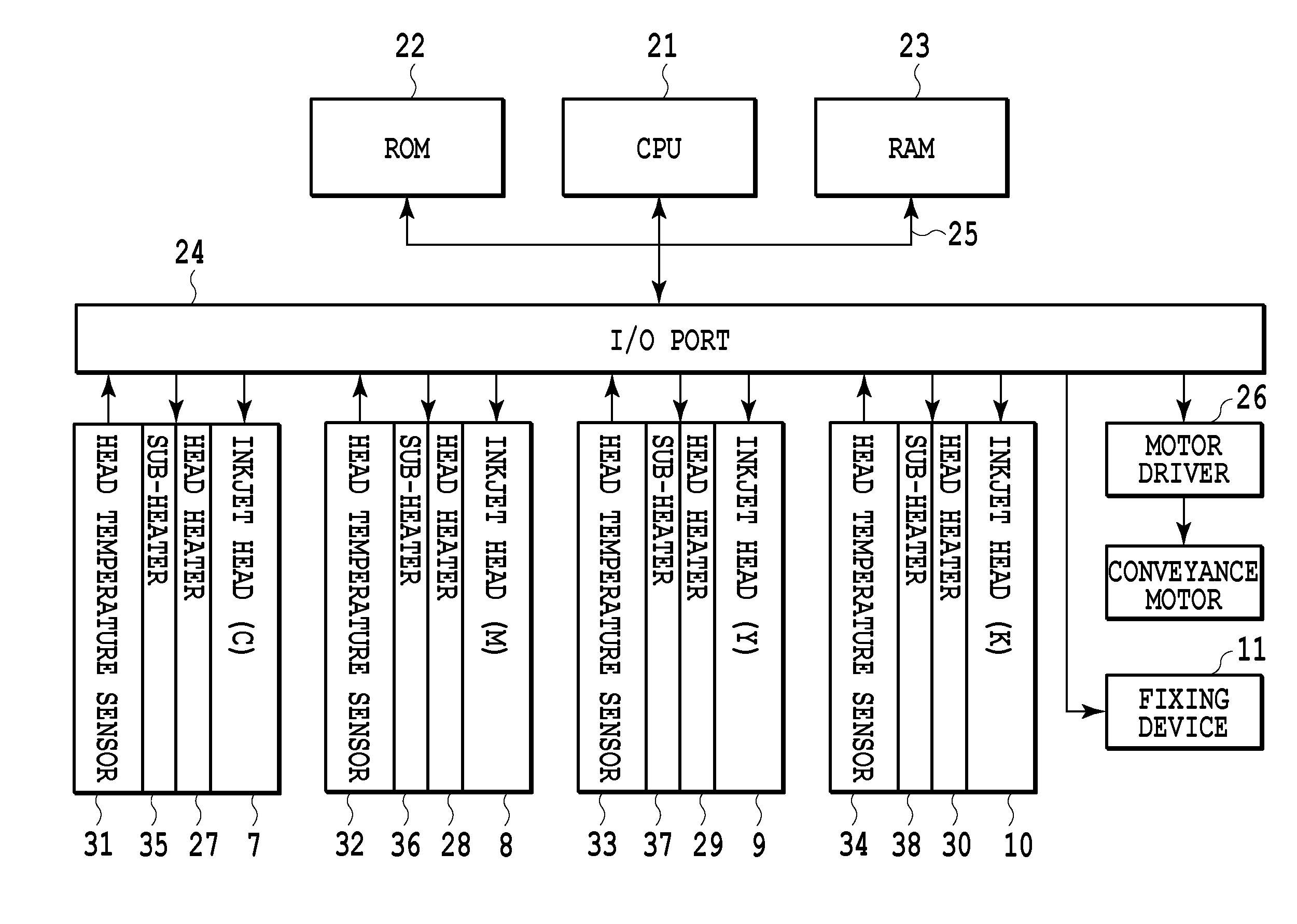

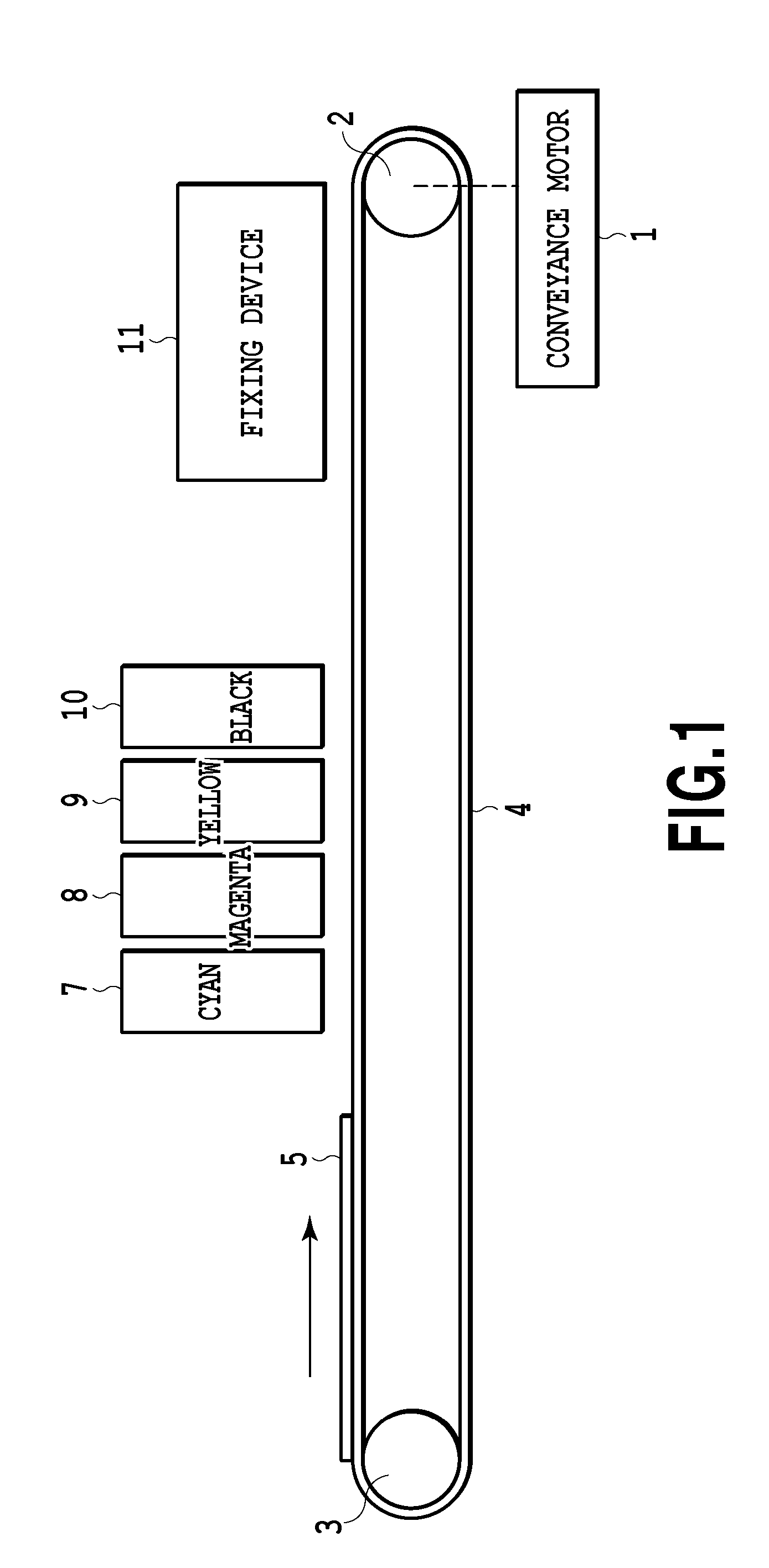

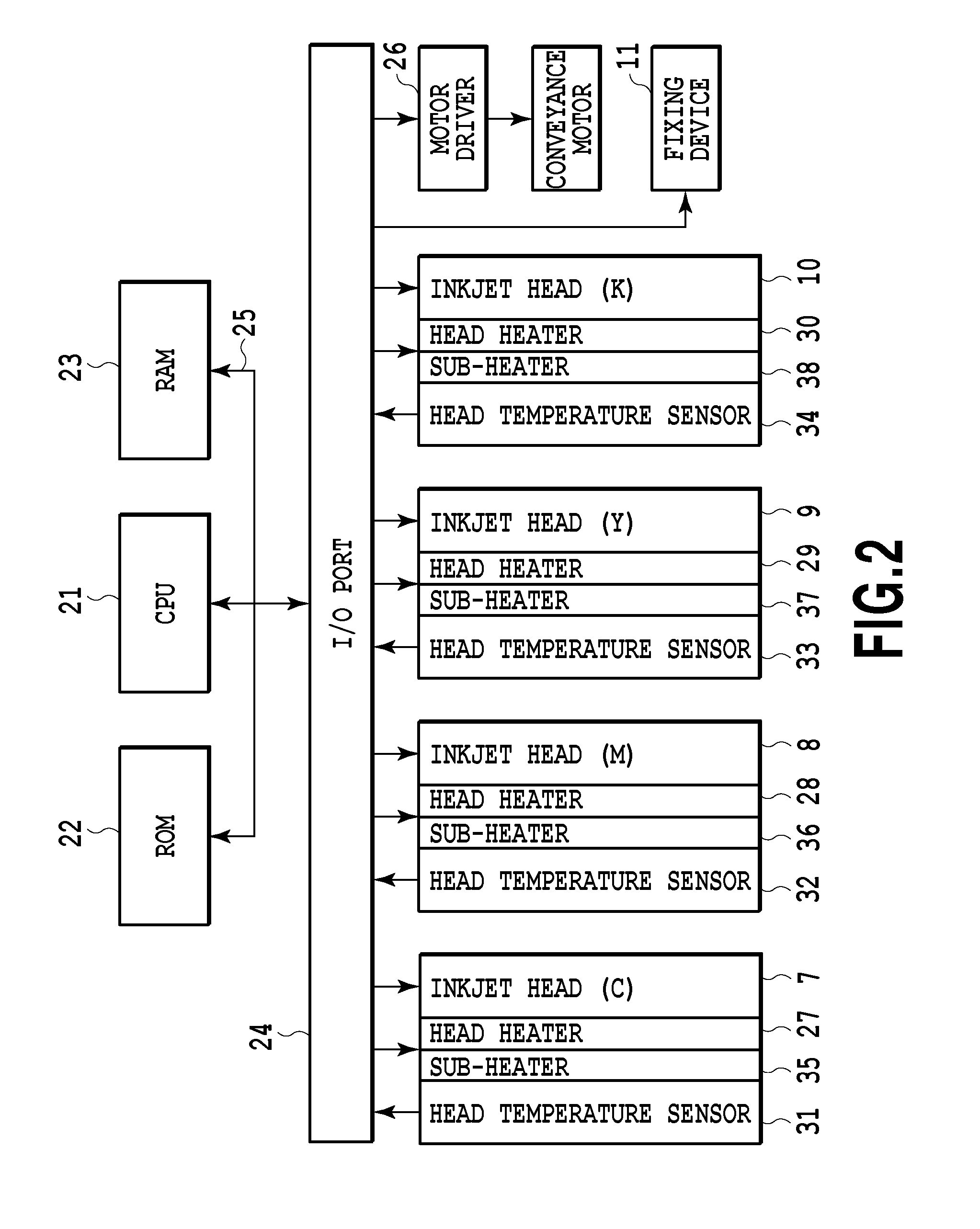

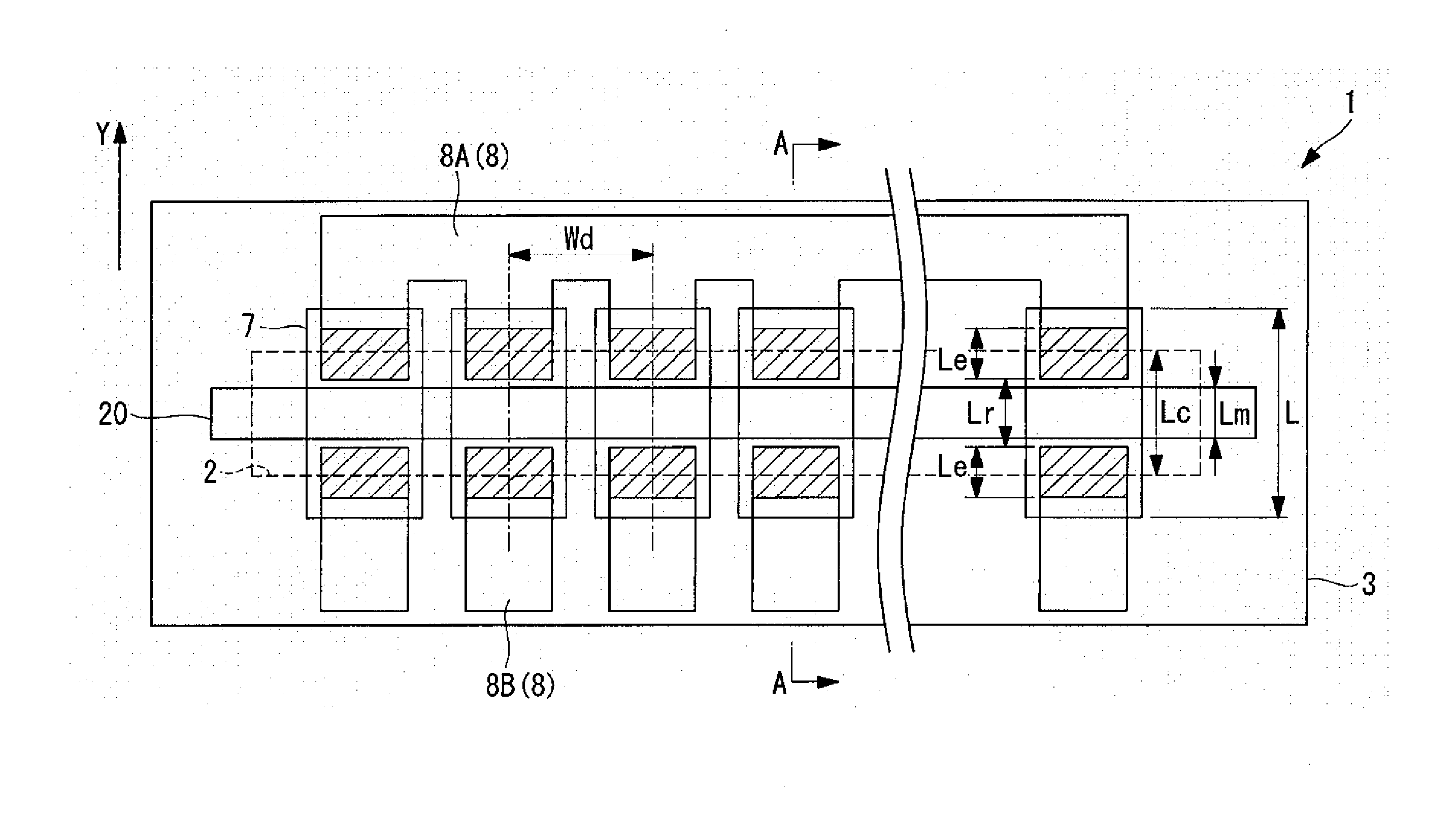

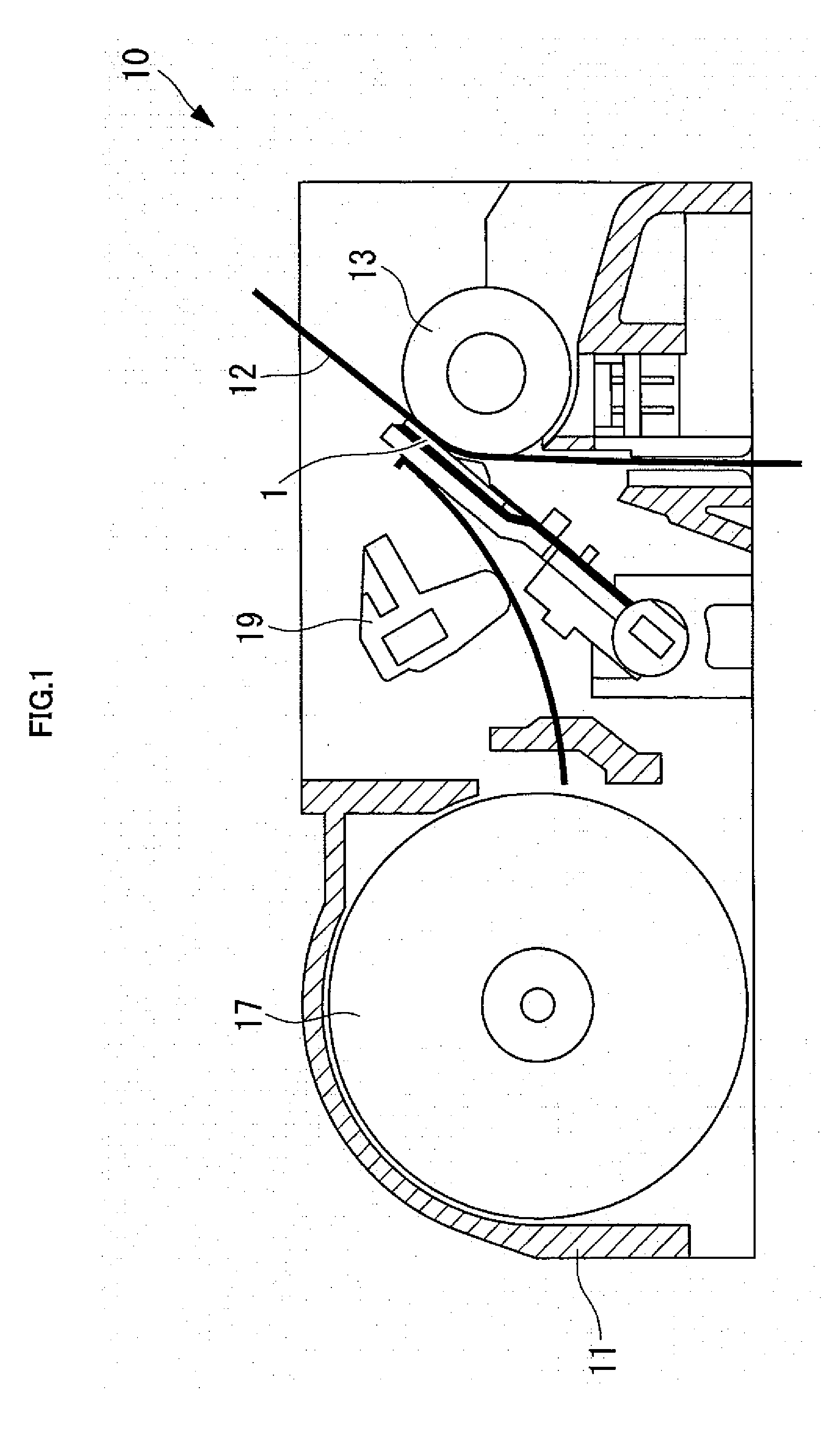

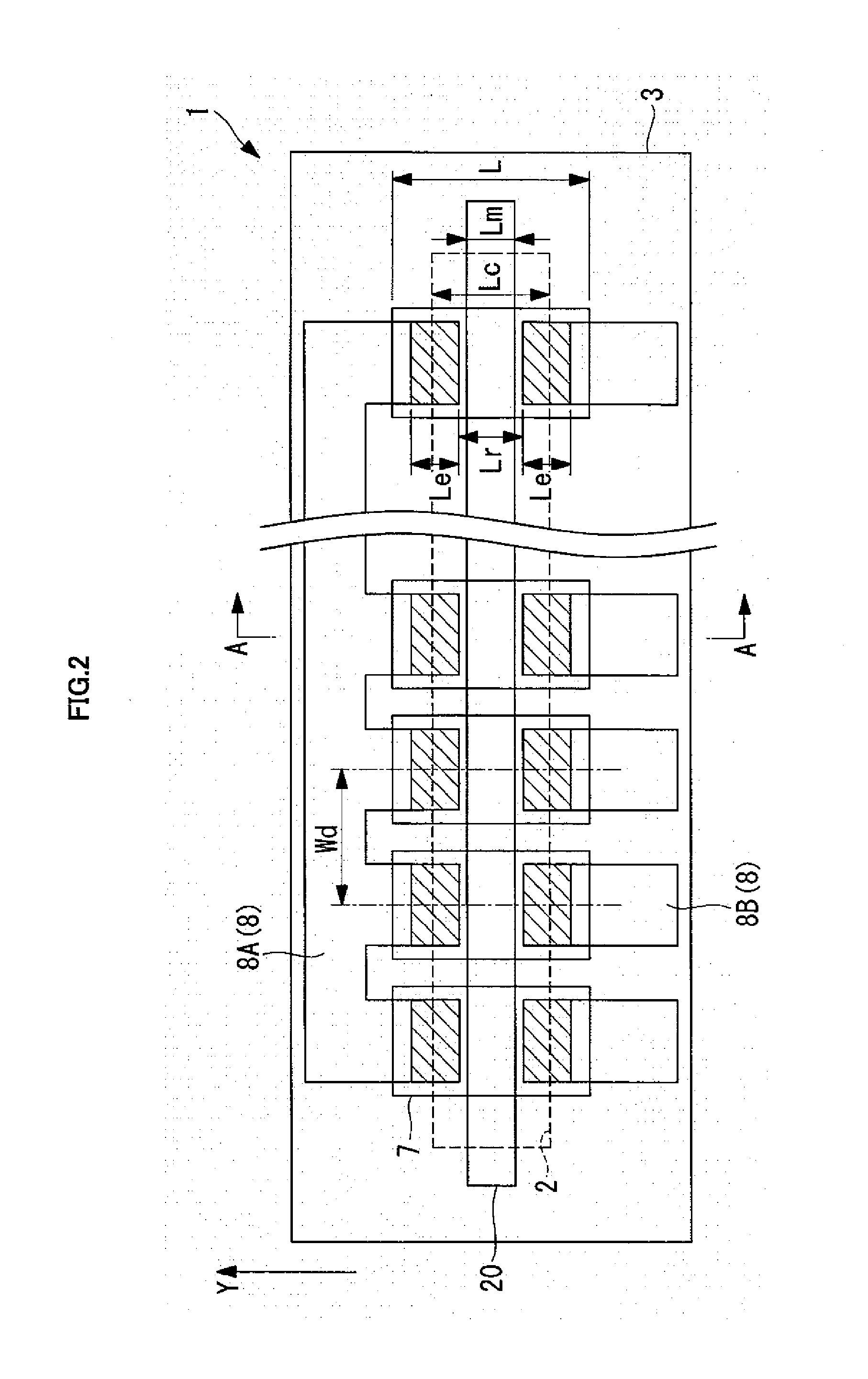

Image recording apparatus and control method therefor

ActiveUS20160297191A1Reduce image deteriorationReduce processing speedPrintingImage recordingProcessing element

Owner:CANON KK

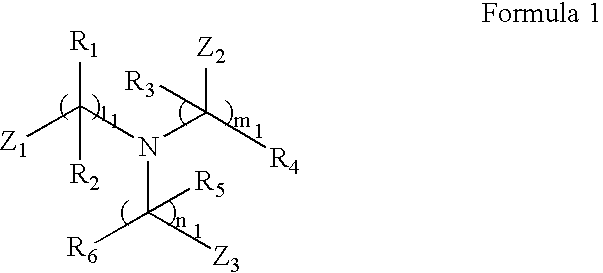

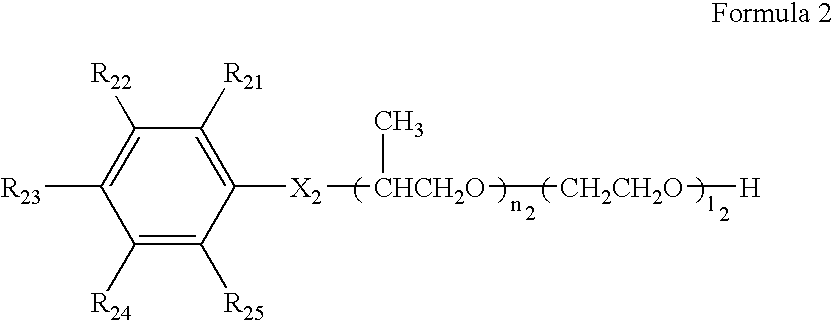

Ink composition for inkjet recording

InactiveUS20080066644A1Eject evenlyDecreasing amountInksPrintingElectrical and Electronics engineering

Owner:SAMSUNG ELECTRONICS CO LTD

Electrostatic suction type jettint device

InactiveUS20060170753A1Reduce exerciseMechanical recordingRecord information storageEngineeringTaylor cone

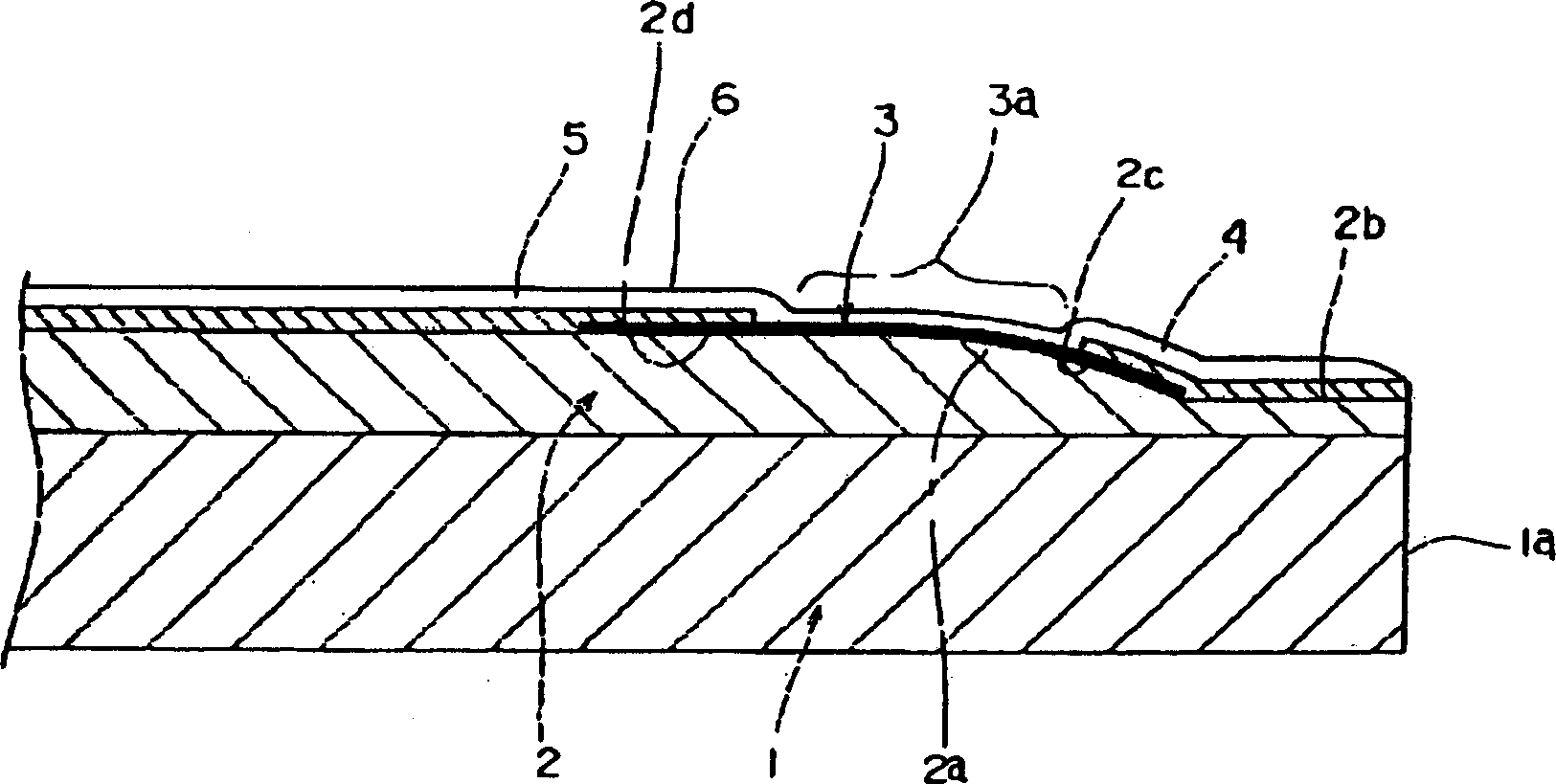

An electrostatic attraction fluid jet device of the present invention is so arranged that a nozzle (4) is formed so as to correspond to a meniscus equivalent to a tip portion in the form of a taylor cone formed in a process of an electrostatic attraction of ink (2) as a conventional fluid. A diameter of an ink-ejecting hole (4b) of the nozzle (4) is set to be substantially the same as a diameter of the tip portion, which is about to be ejected, of the meniscus (14) of ink. Moreover, the diameter of the ink-ejecting hole (4b) of the nozzle (4) is set to be equal to or less than a droplet diameter of the ink (2) which has just been ejected. Therefore, it is possible to provide an electrostatic attraction fluid jet device which can realize a recording device which has high resolution, is safe and is highly versatile.

Owner:KONICA MINOLTA INC +1

Liquid consuming apparatus and ink-jet printer

ActiveUS20170120597A1Smooth communicationPrintingElectrical and Electronics engineeringLiquid storage

Owner:BROTHER KOGYO KK

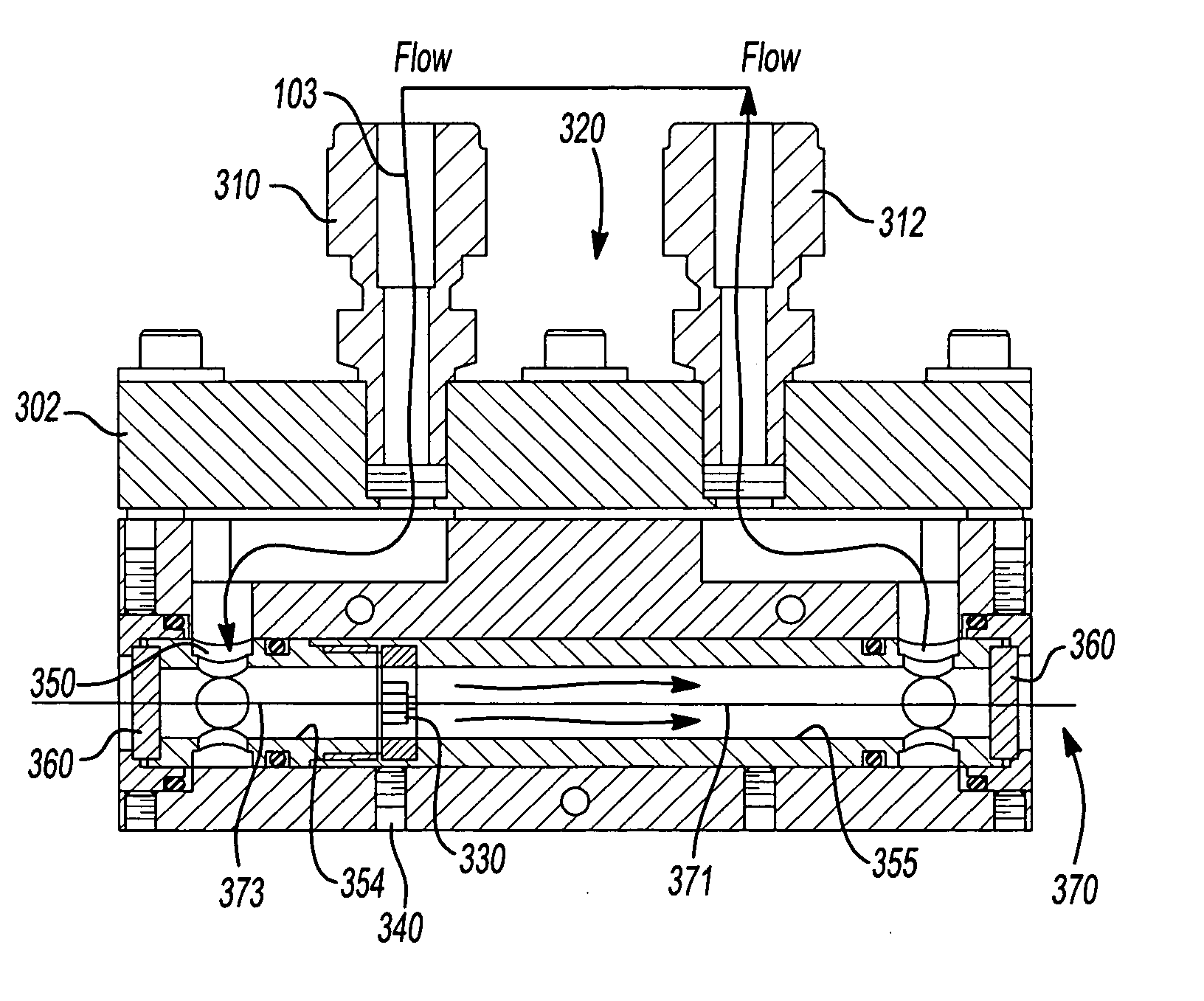

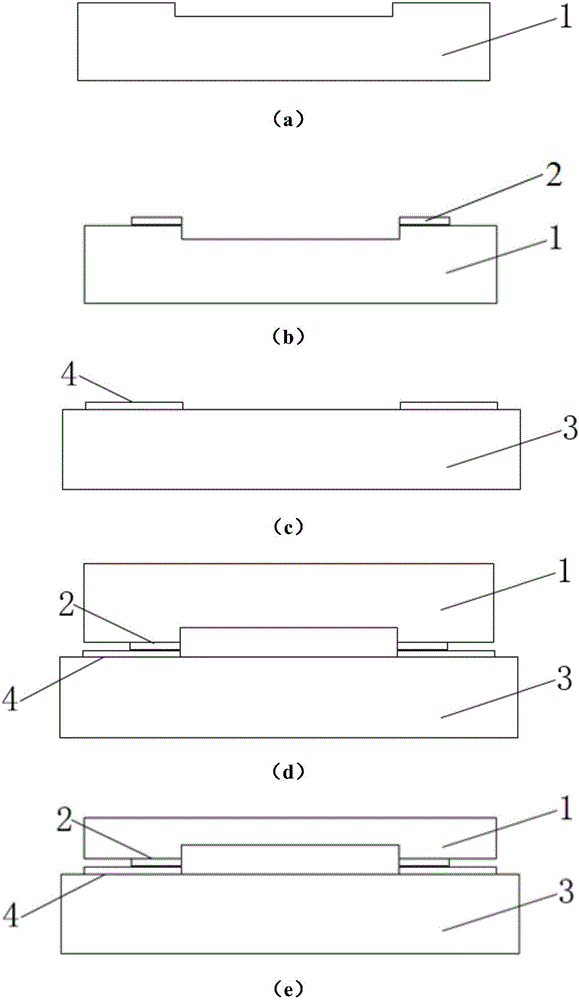

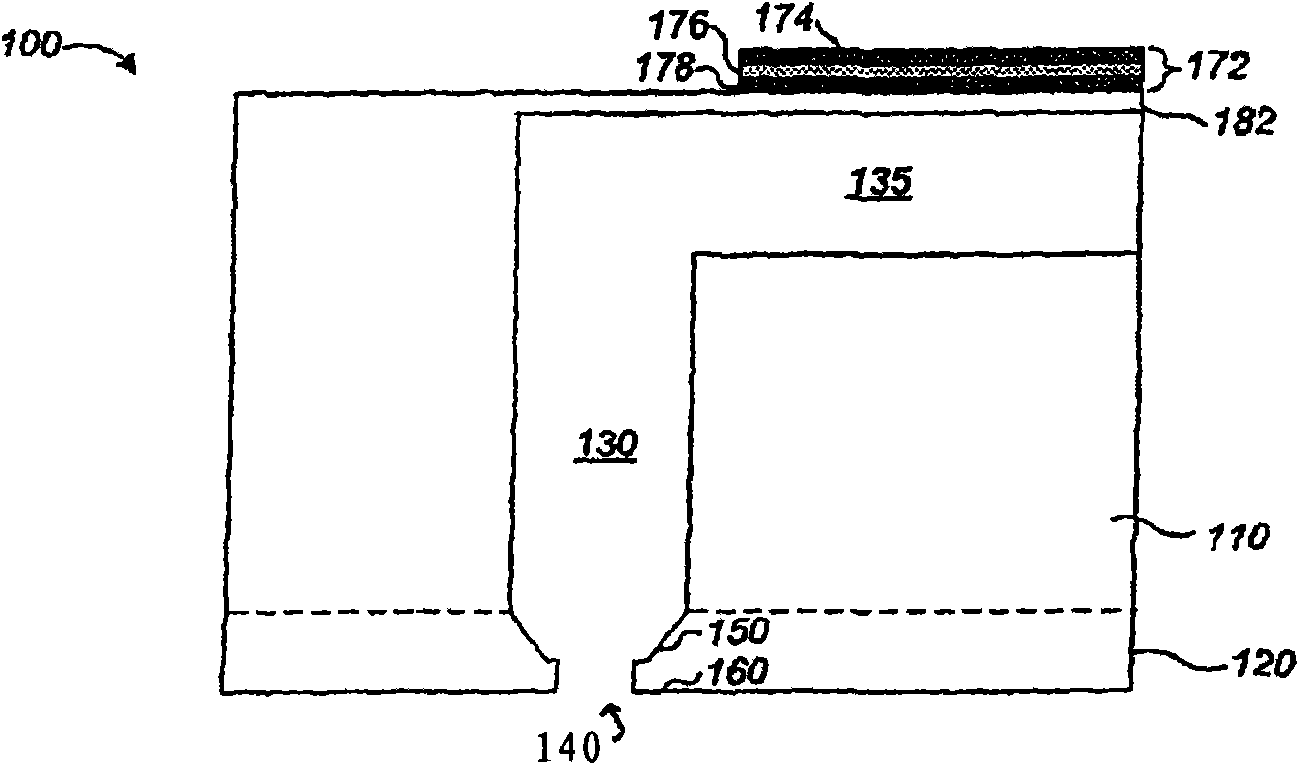

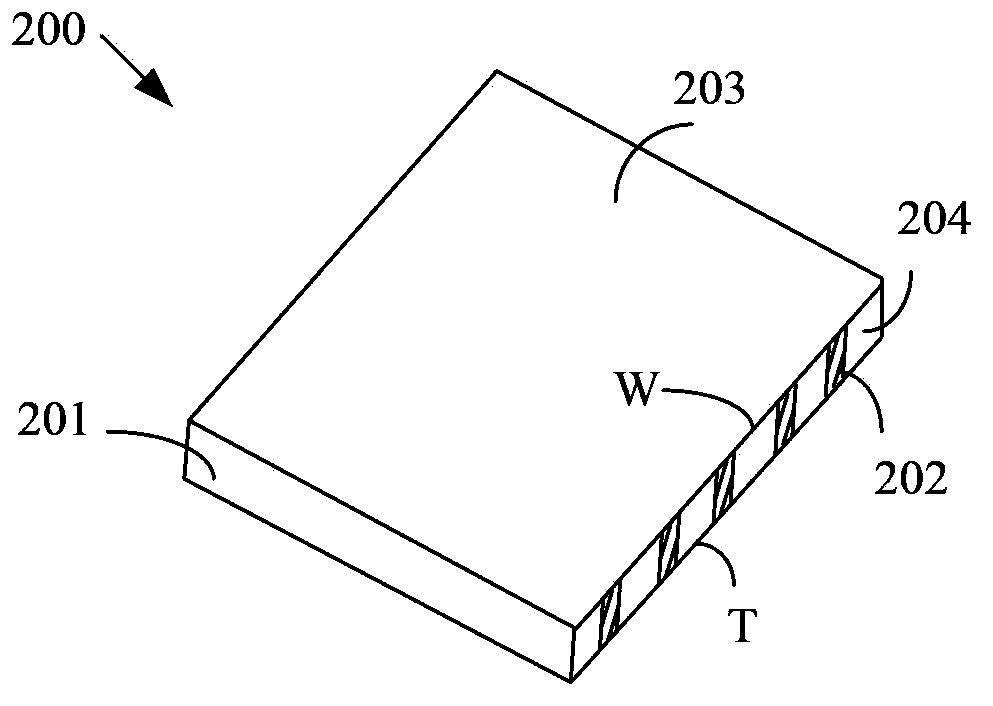

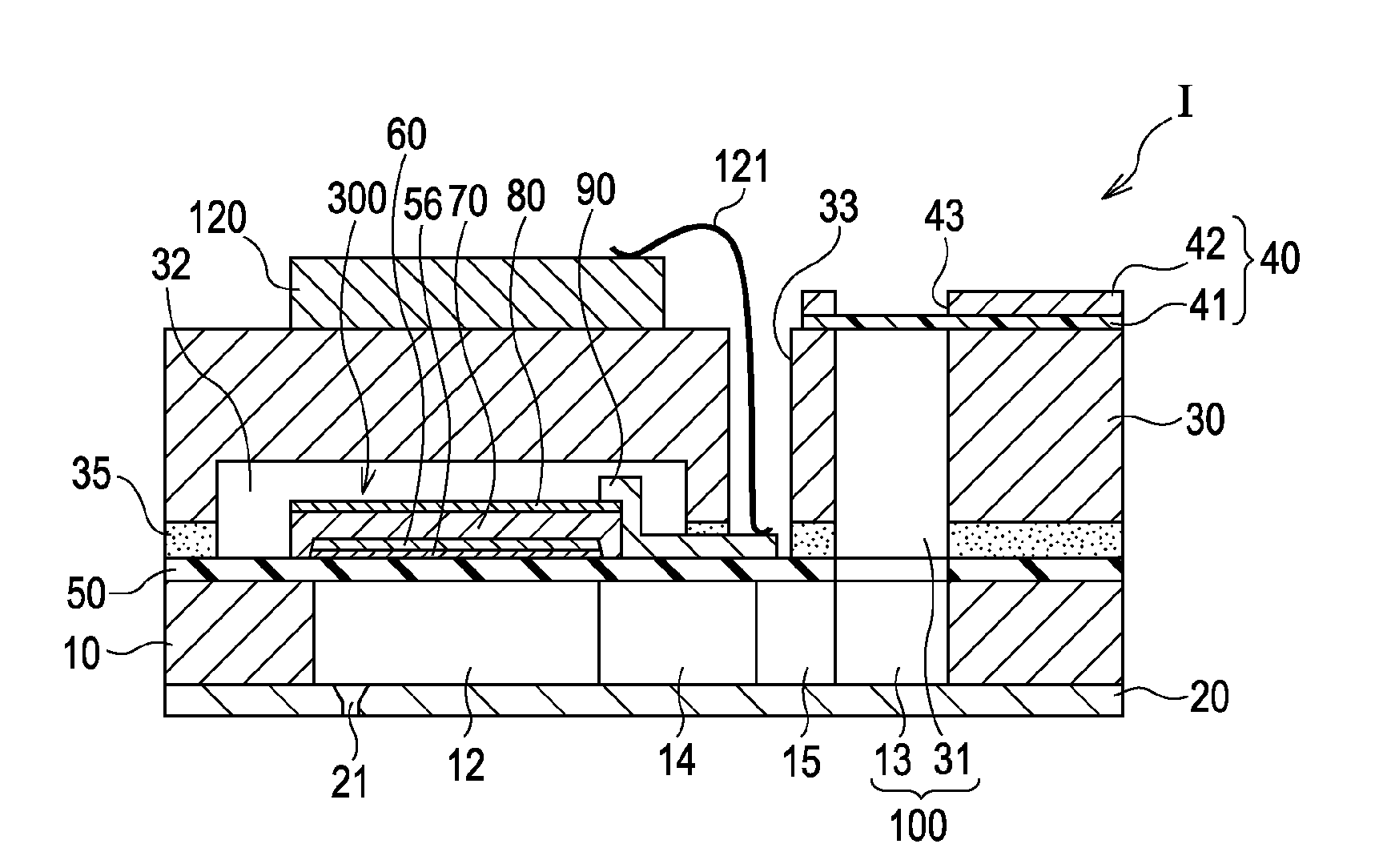

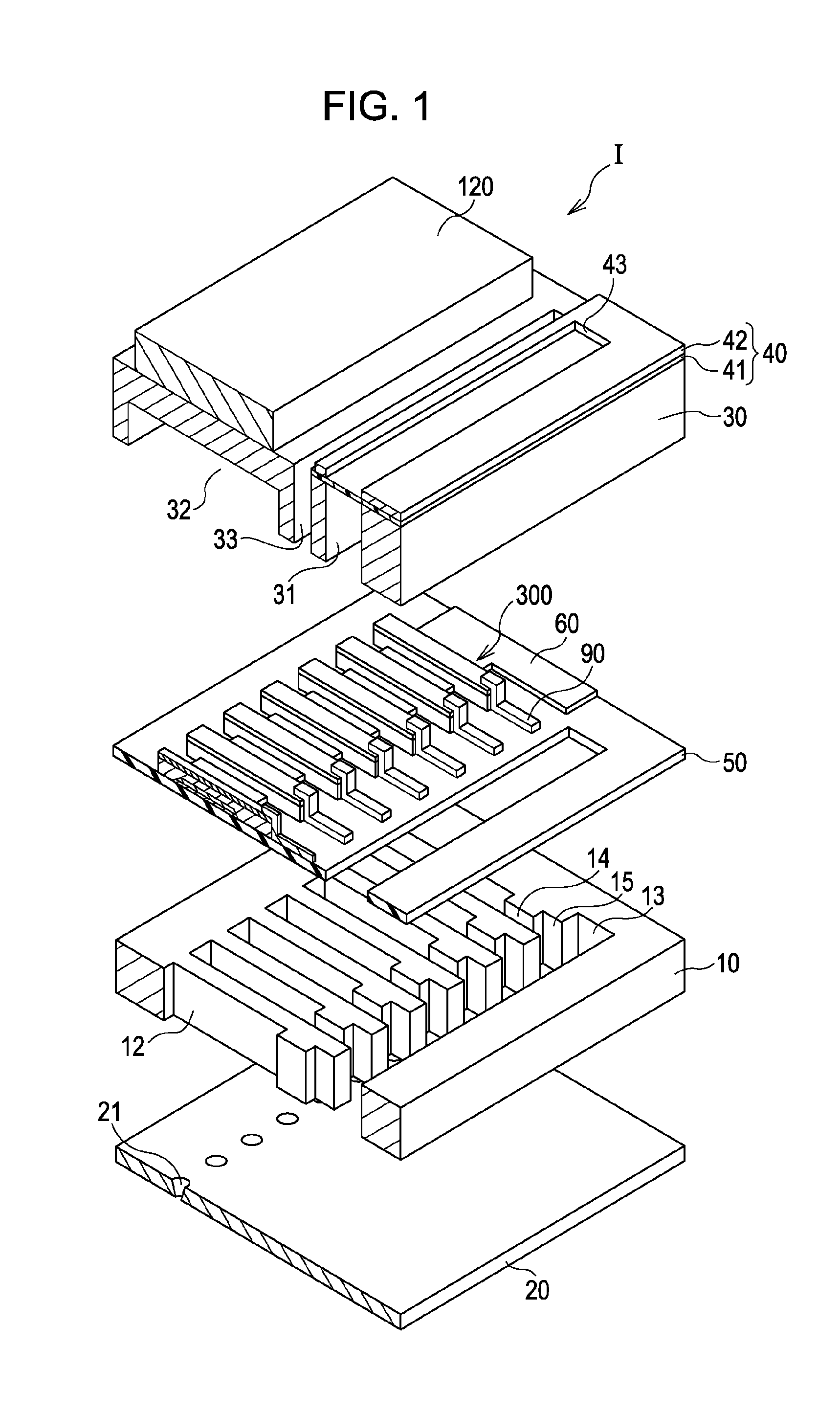

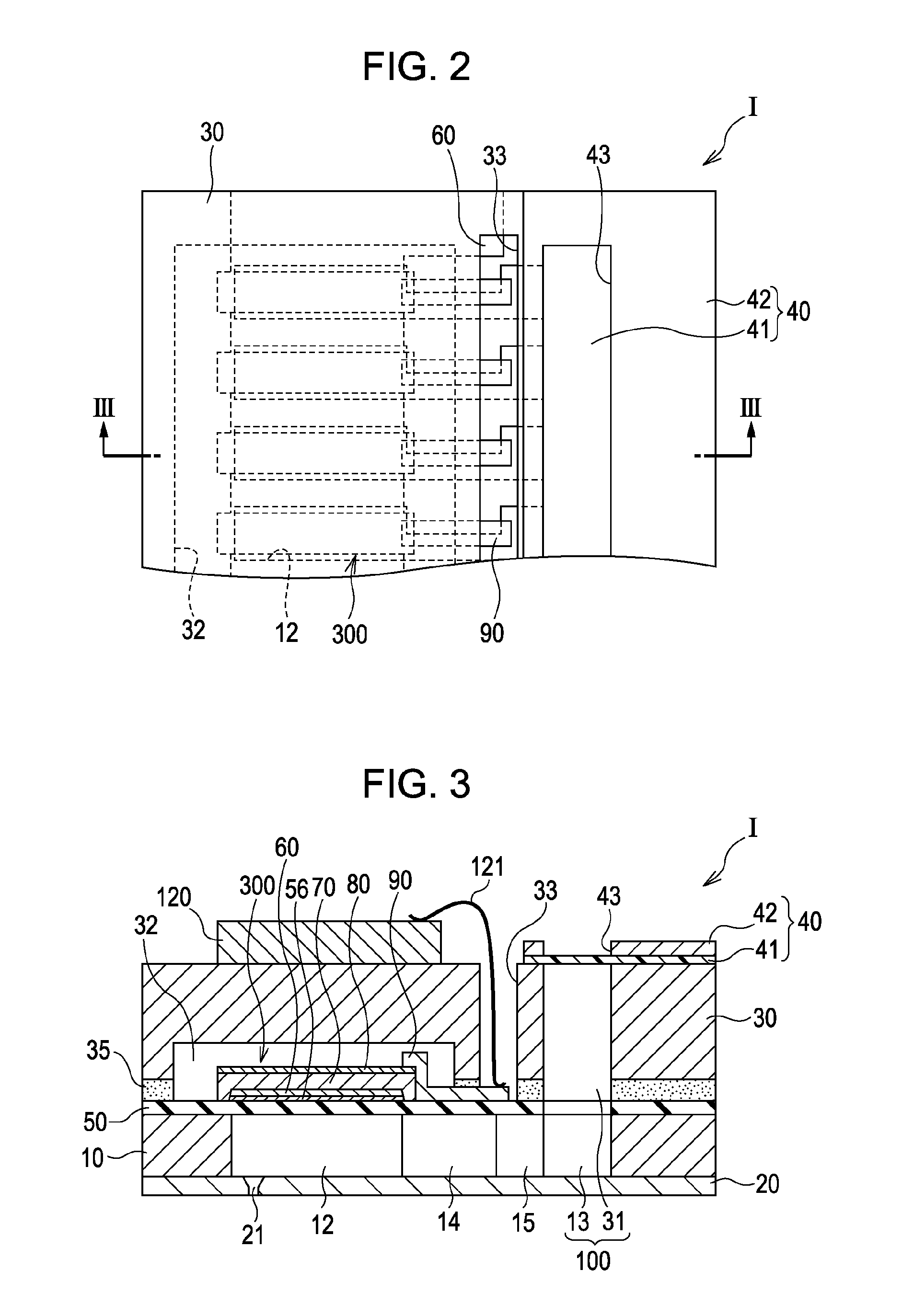

Microfluidic MEMS device with piezoelectric actuation and manufacturing process thereof

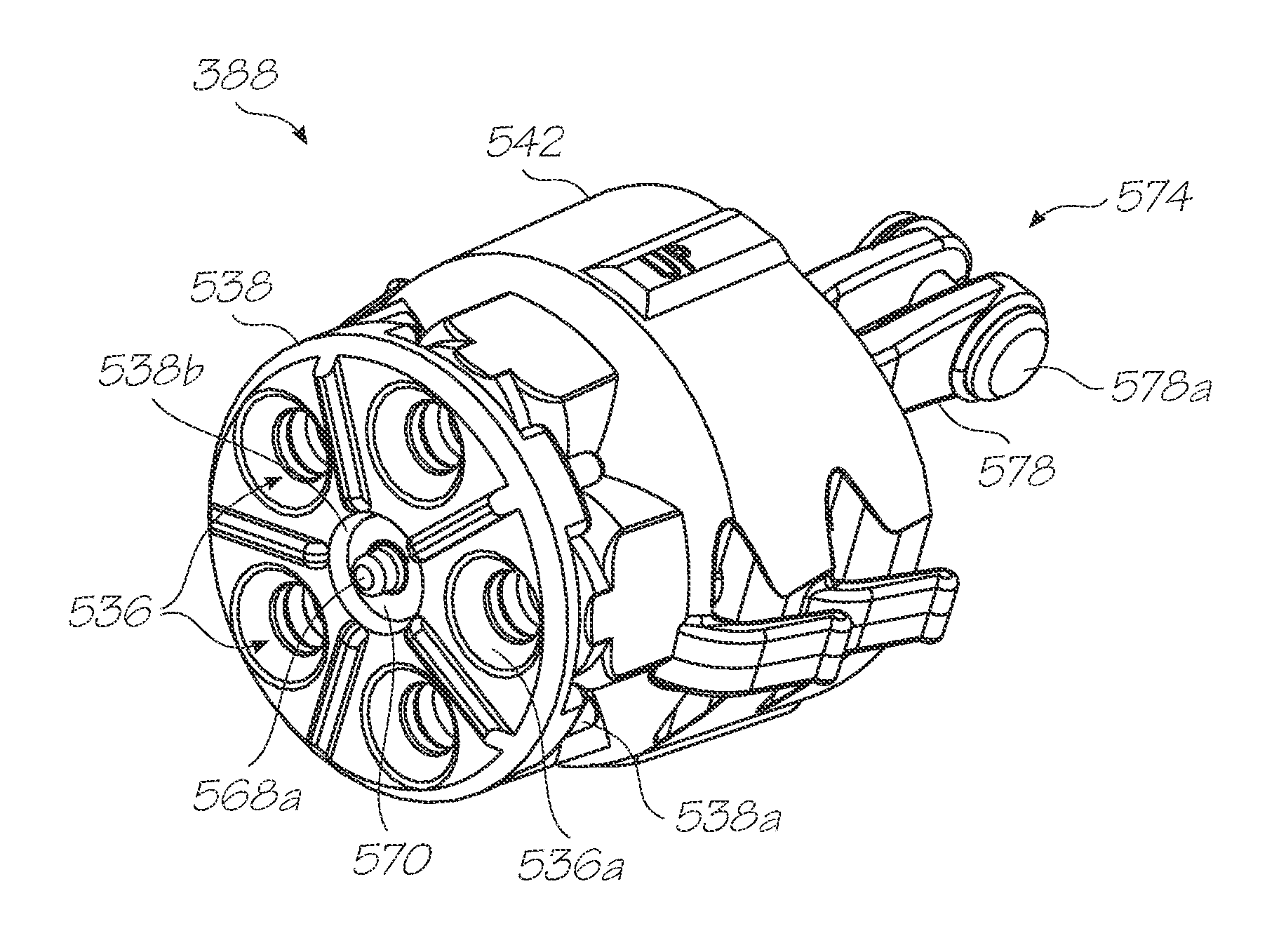

The microfluidic device has a plurality of ejector elements. Each ejector element includes a first region, accommodating a first fluid flow channel and an actuator chamber; a second region, accommodating a fluid containment chamber; and a third region, accommodating a second fluid flow channel. The fluid containment chamber is fluidically coupled to the first and to the second fluid flow channels. The second region is formed from a membrane layer, from a membrane definition layer, mechanically coupled to the membrane layer and having a membrane definition opening, and a fluid chamber defining body, mechanically coupled to the membrane definition layer and having a chamber defining opening, with a width greater than the width of the membrane definition opening. The width of the membrane is thus defined by the width of the chamber defining opening.

Owner:STMICROELECTRONICS SRL

Non-wetting coating on a fluid ejector

Owner:FUJIFILM DIMATIX

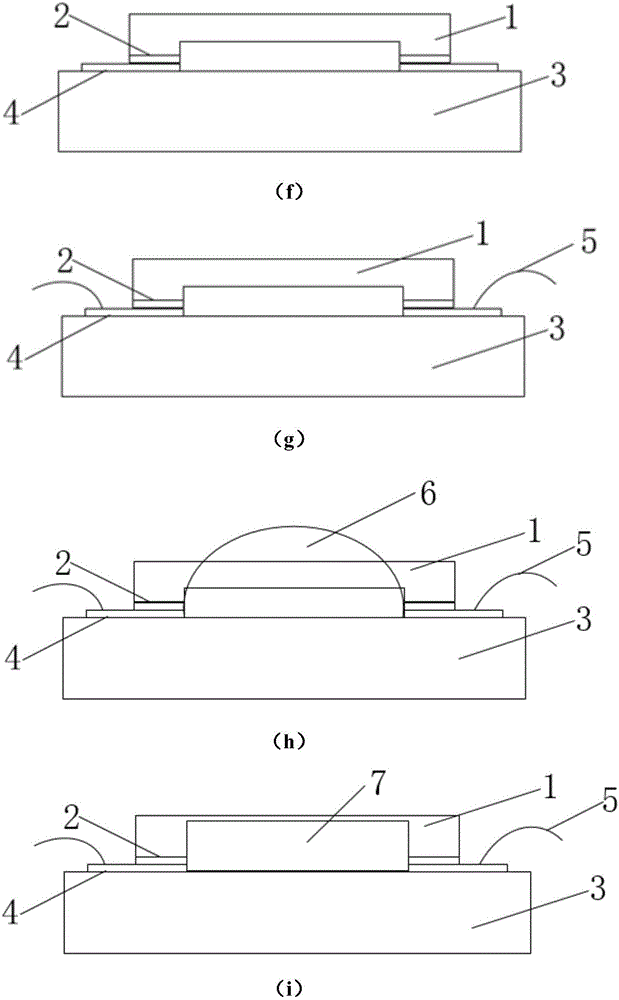

MEMS switch

InactiveUS20070159510A1Simple structureReduce insertionPiezoelectric/electrostriction/magnetostriction machinesPrintingPiezoelectric actuatorsSignal lines

A Micro Electro Mechanical System (MEMS) switch includes a substrate, a fixed signal line formed on the substrate, a movable signal line spaced apart from one of an upper surface and a lower surface of the fixed signal line, and at least one piezoelectric actuator connected to a first end of the movable signal line so as to bring or separate the movable signal line in contact with or from the fixed signal line. The piezoelectric actuator includes a first electrode, a piezoelectric layer formed on the first electrode, a second electrode formed on the piezoelectric layer, and a connecting layer formed on the second electrode and connected with the movable signal line.

Owner:SAMSUNG ELECTRONICS CO LTD

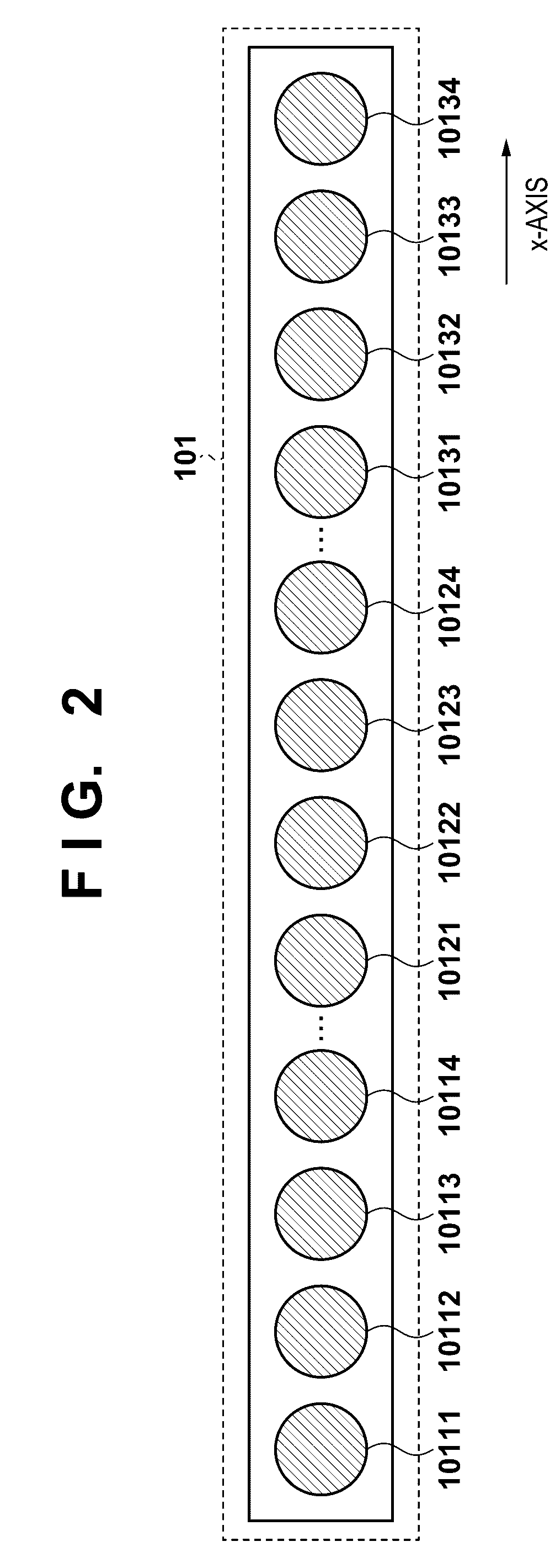

Element substrate, printhead, head cartridge, and printing apparatus

This element substrate is an element substrate for a printhead which includes a plurality of printing elements to which a first voltage is applied, a plurality of driving elements which drive the plurality of printing elements, a logical circuit which outputs a driving signal to control the plurality of driving elements, and a driving voltage converter circuit which converts the voltage of the driving signal output from the logical circuit into a second voltage lower than the first voltage and outputs the second voltage to the plurality of driving elements. The element substrate includes a driving voltage generating circuit which generates, on the basis of the first voltage, the second voltage to drive the driving voltage converter circuit. The driving voltage generating circuit has a constant current source for generating a constant current based on the first voltage and generates the second voltage based on the constant current.

Owner:CANON KK

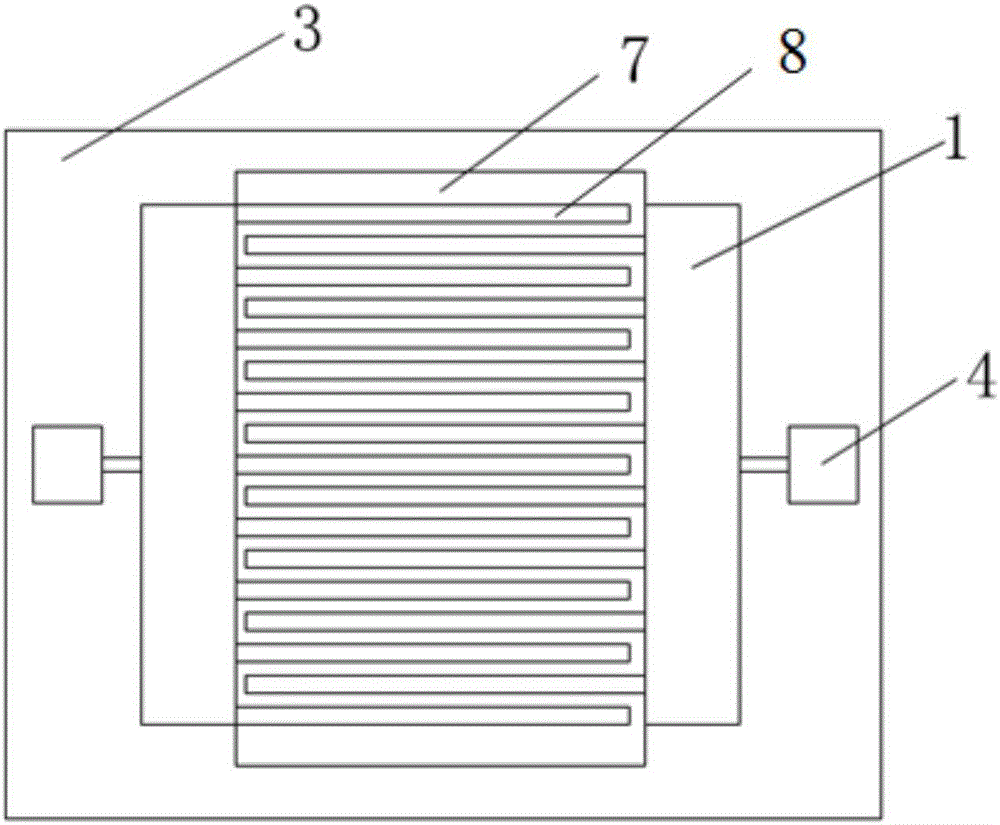

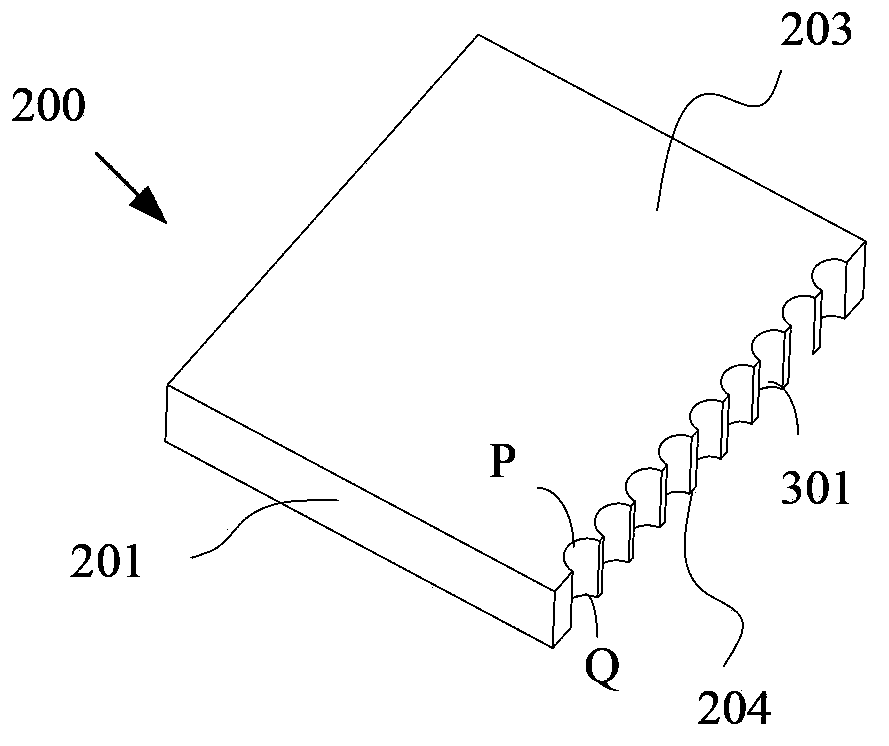

Ink box chip, ink box and structural body

ActiveCN104163043ALow positioning accuracy requirementsImprove stabilityPrintingElectricityElectrical connection

Owner:ZHUHAI NINESTAR MANAGEMENT CO LTD

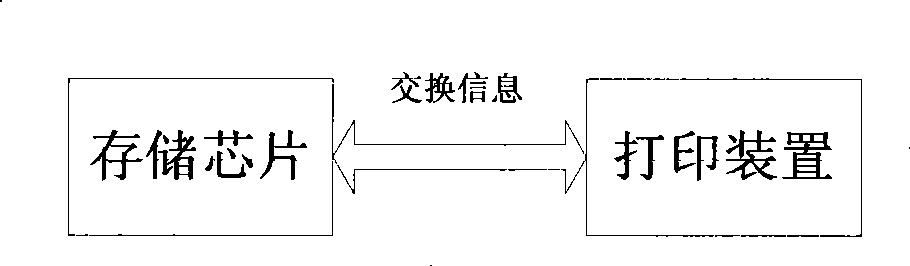

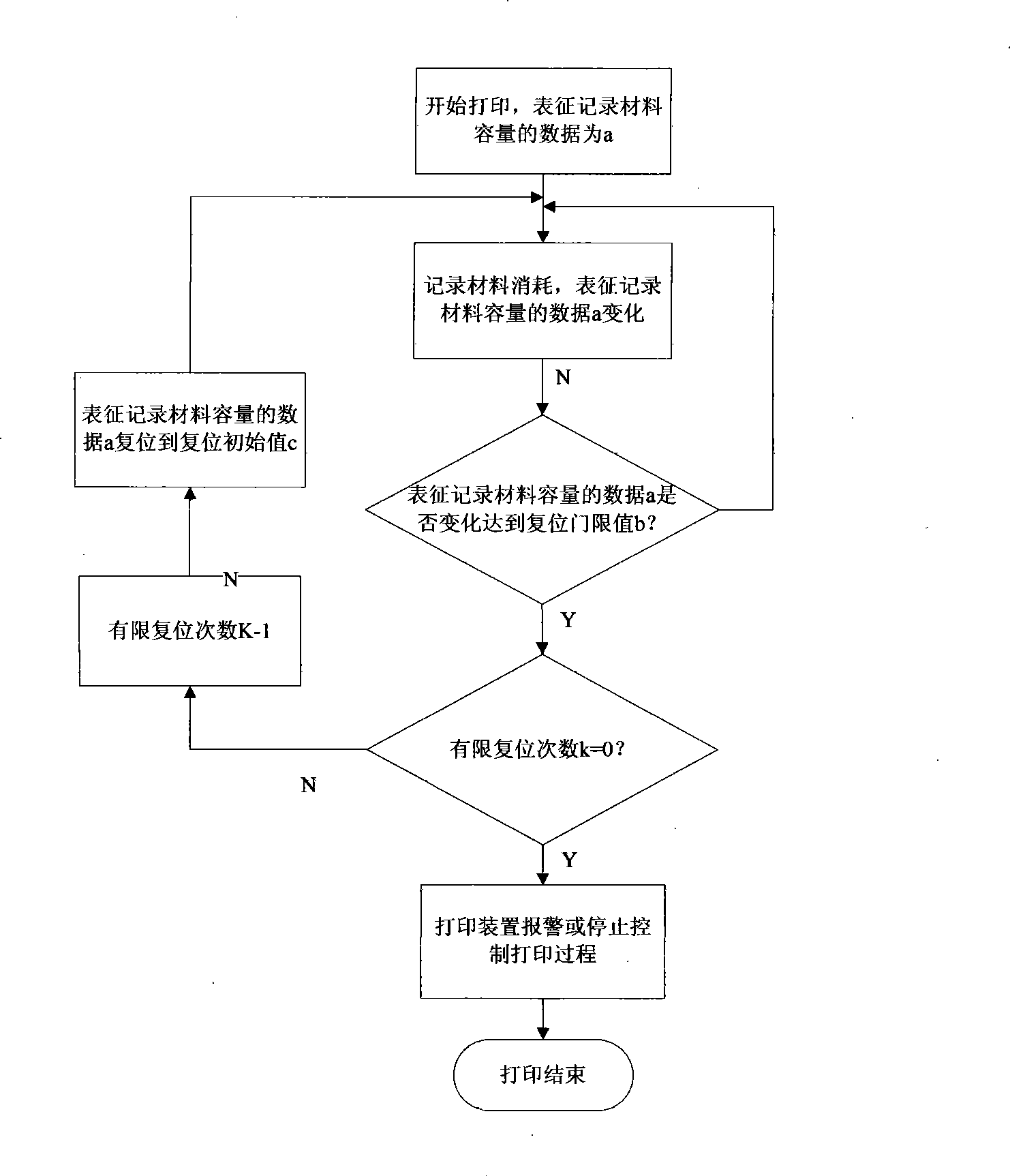

Method and chip for adjusting chip parameter to match non-standard capacity ink box

ActiveCN101380848AIncrease salesLow costPrintingStorage materialElectrical and Electronics engineering

Owner:APEX MICROELECTRONICS CO LTD

Applicator and method for transferring dispersion liquid

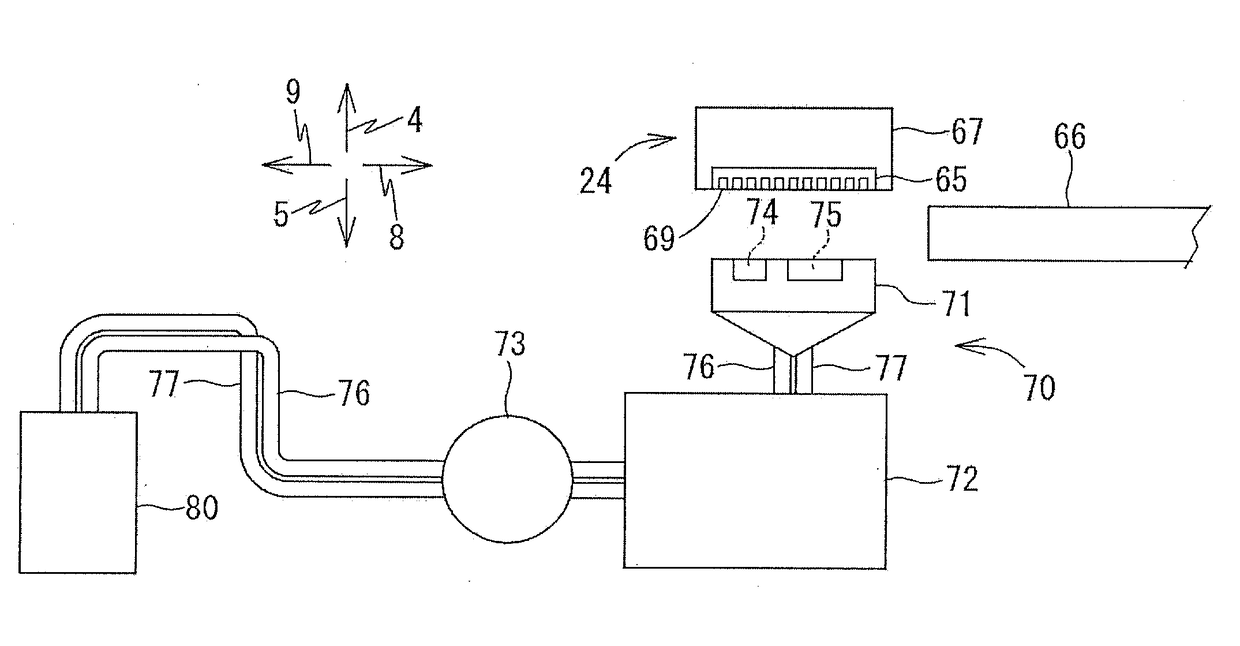

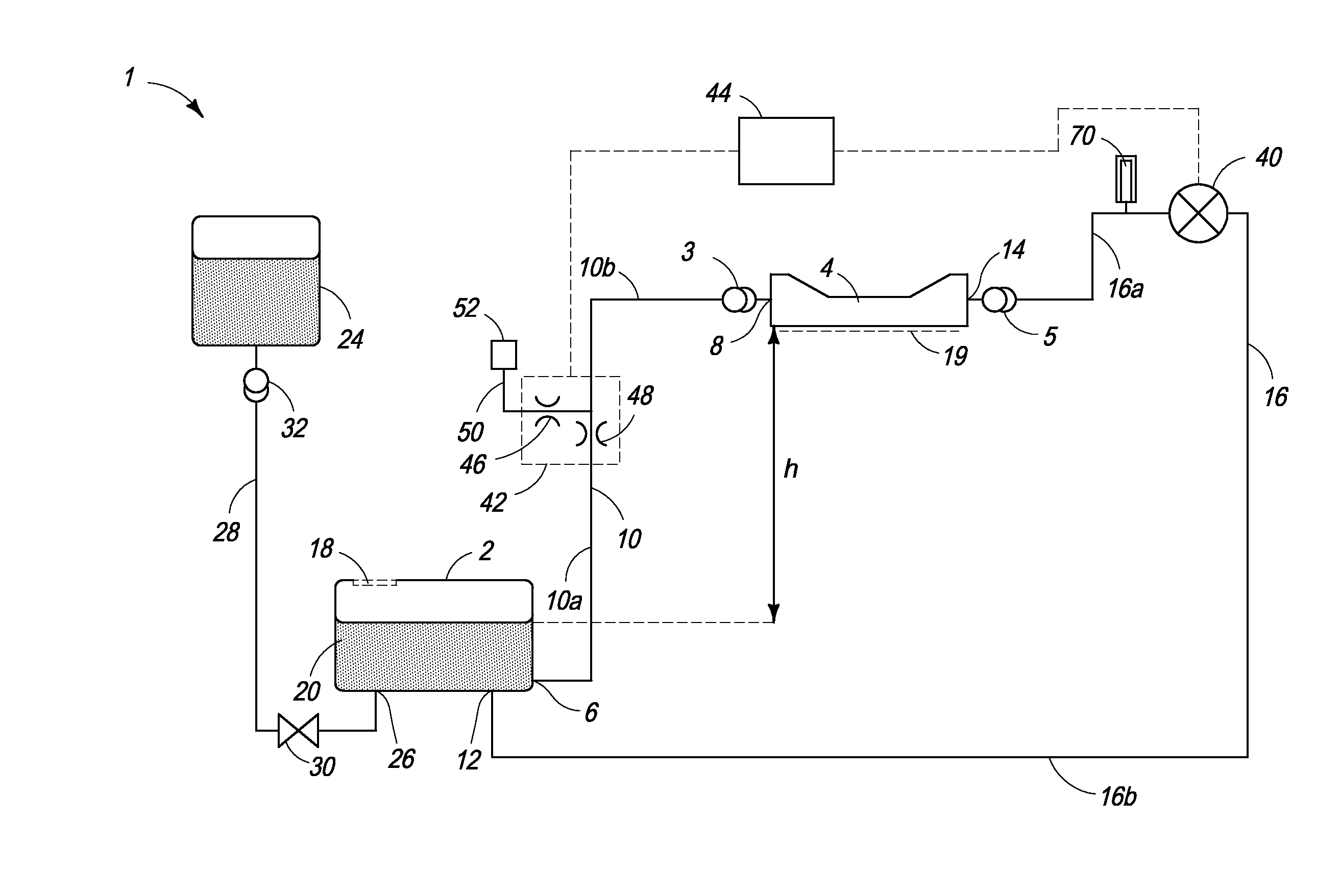

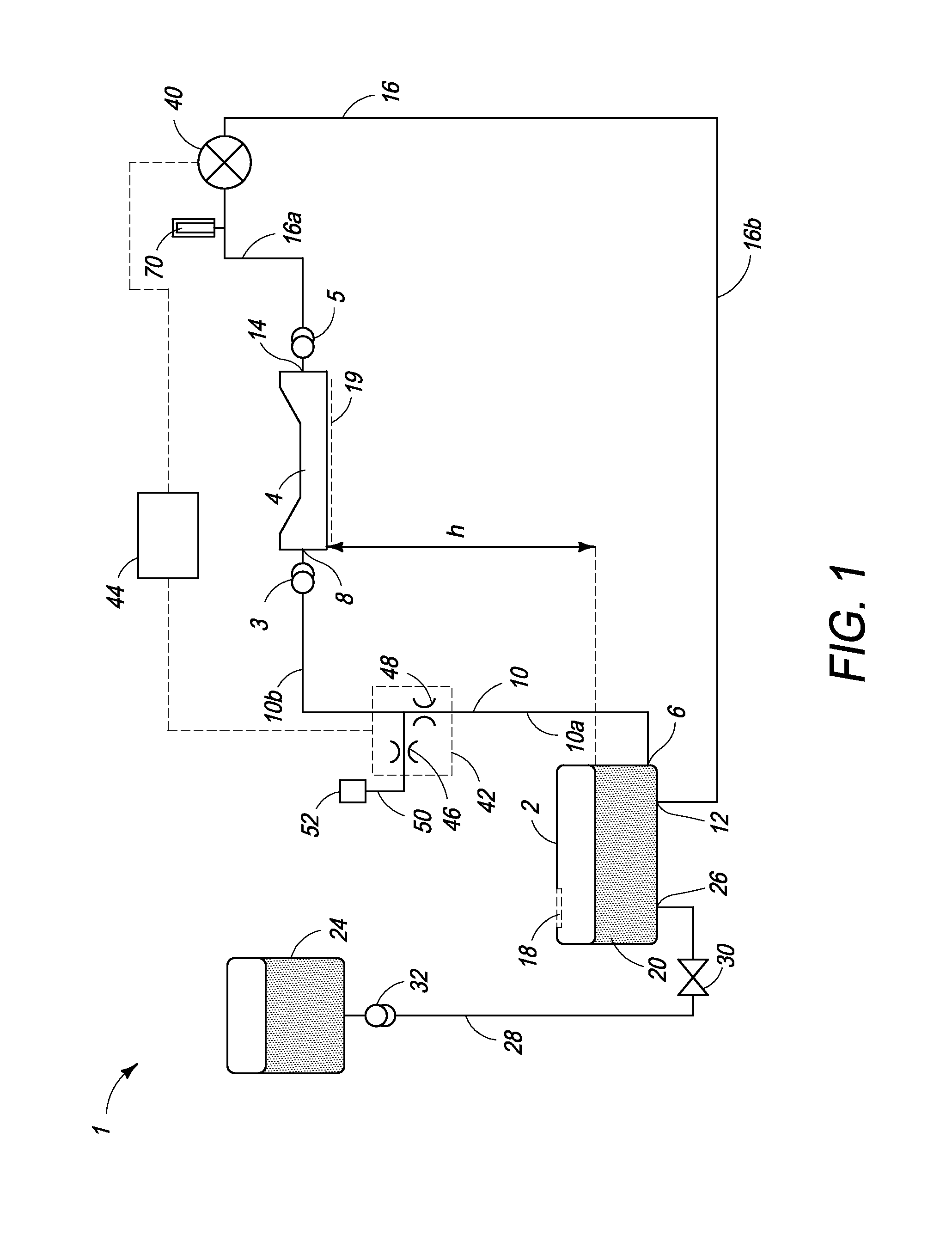

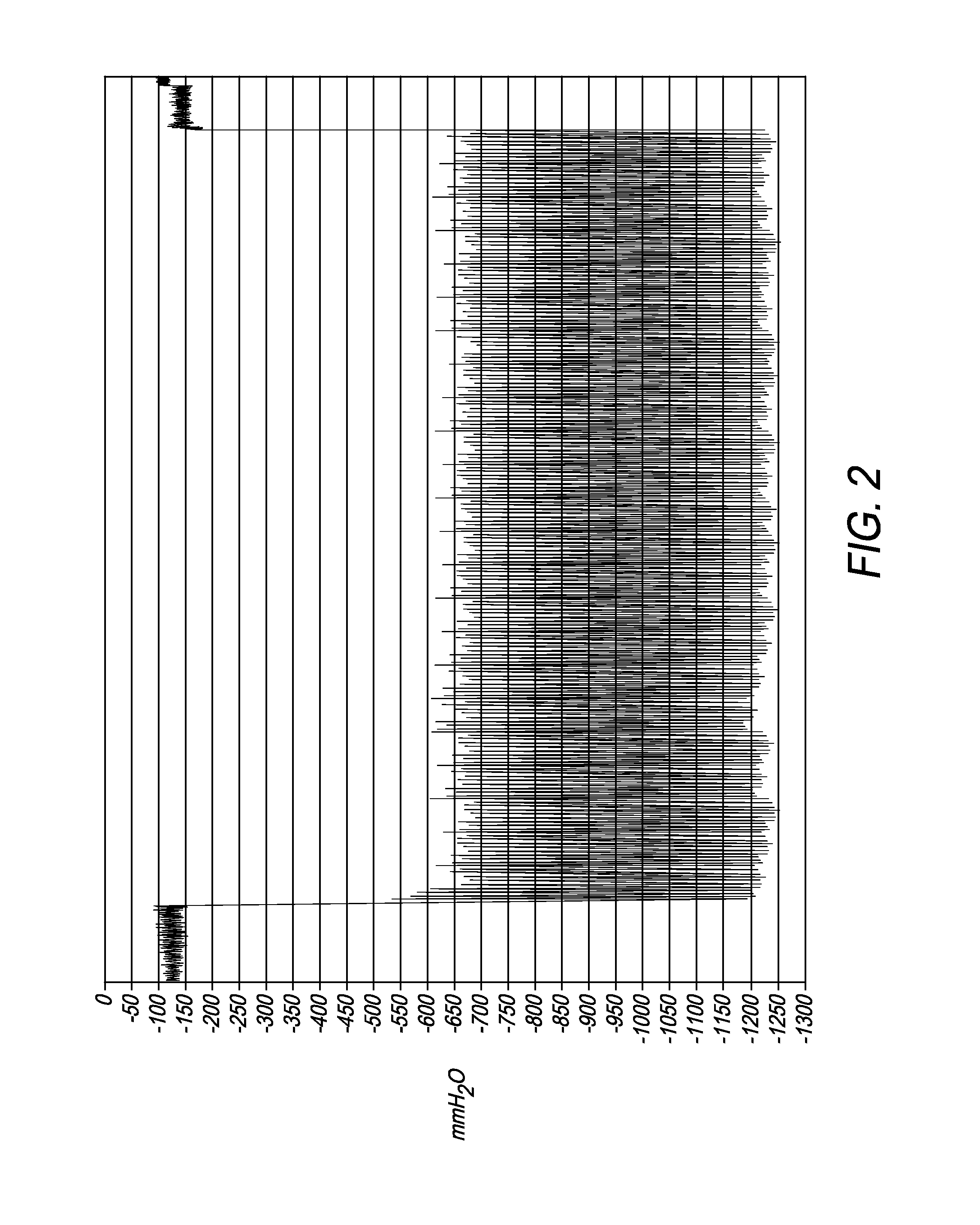

ActiveUS20080210160A1Bubble generating areReduce solubilityLiquid degasificationPressure pumpsBuffer tankDissolution

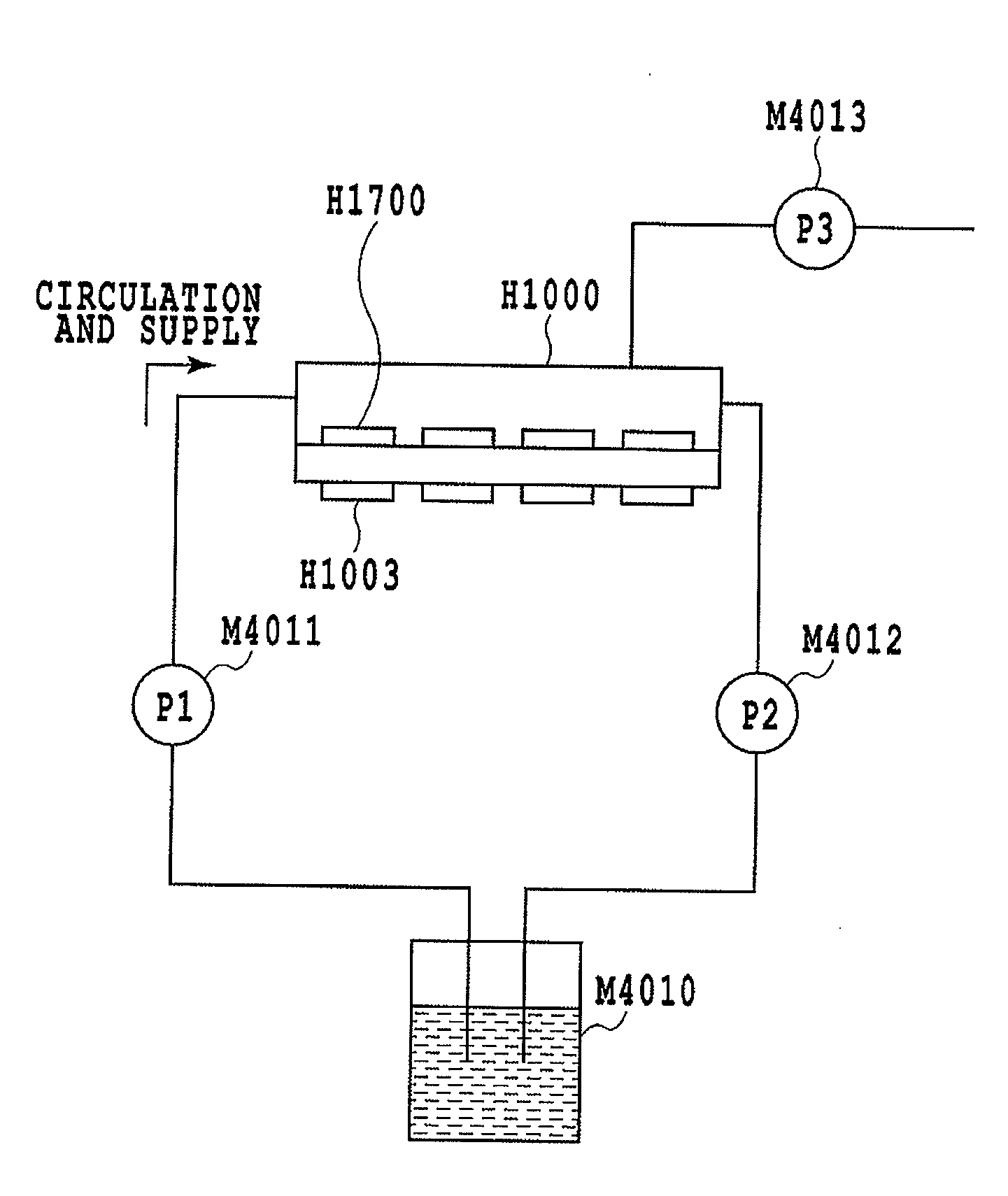

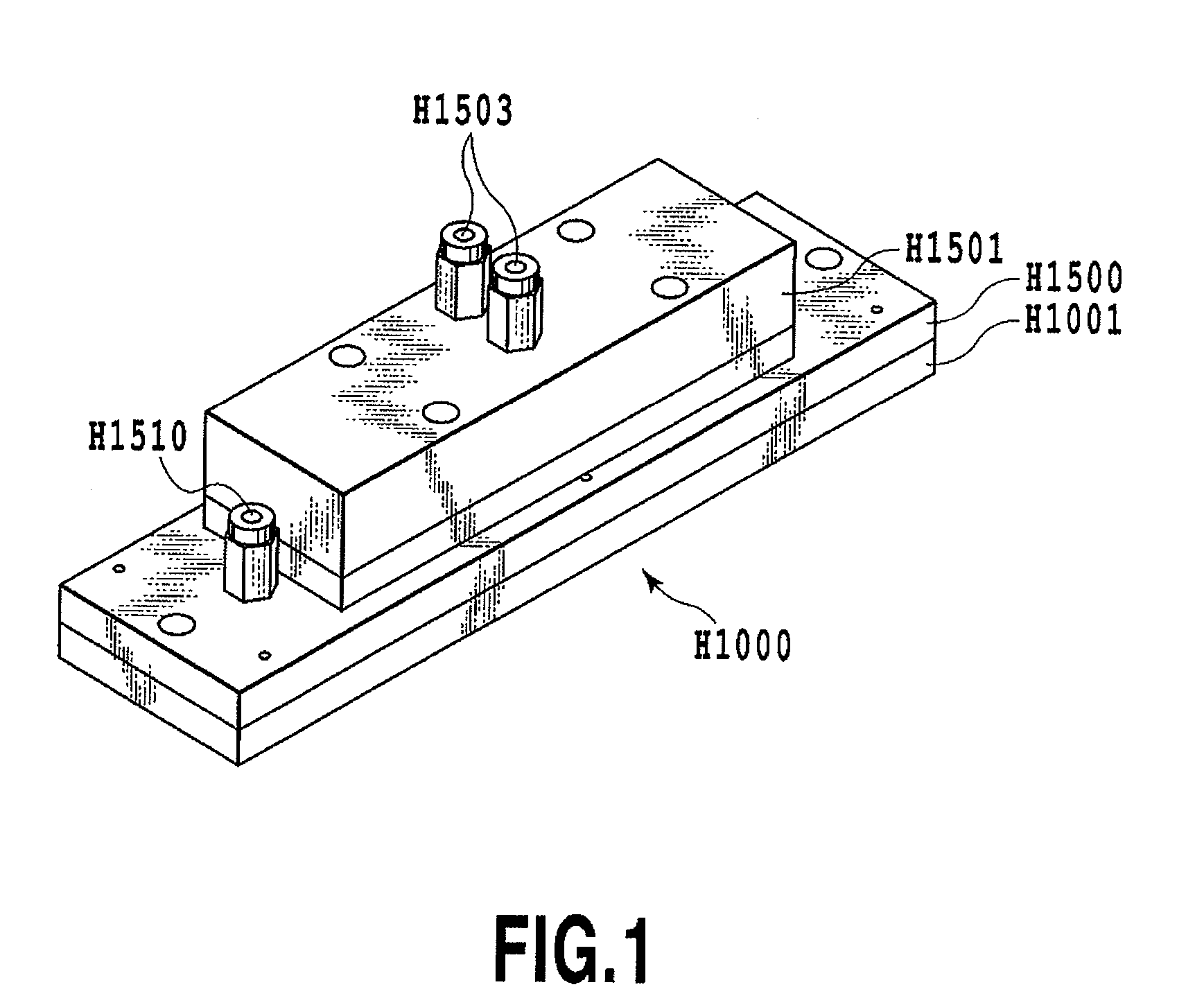

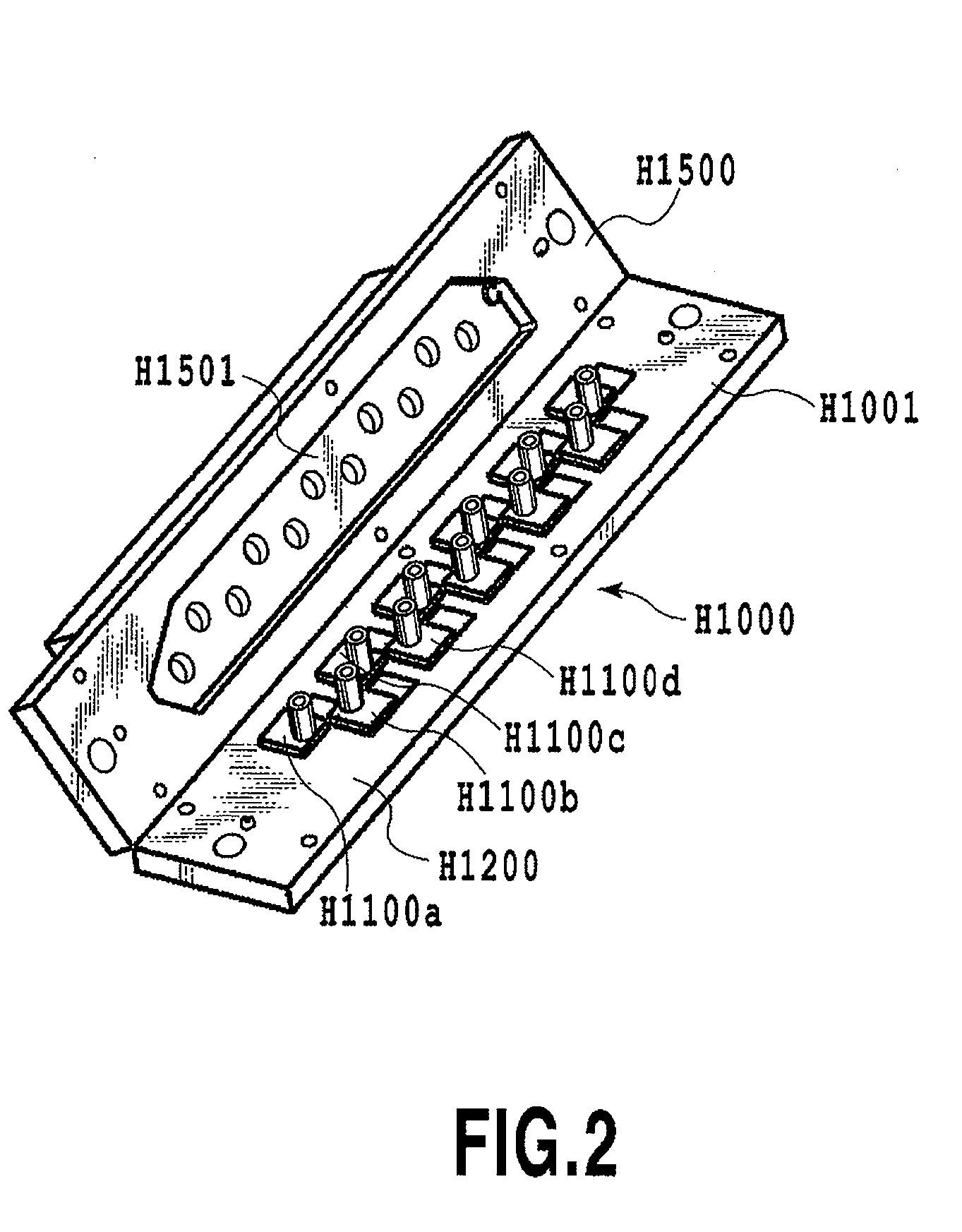

The present invention provides applicators reducing generating bubble. Dispersion liquid is supplied while the pressure of a circulation tank on the delivery side is lower than the atmospheric pressure but higher than the pressure of the space in buffer tanks. The dispersion liquid in the discharge chambers is recovered while the pressure in a circulation tank serving as recovery destination is lower than the atmospheric pressure. Gas dissolution can be reduced because the dispersion liquid does not come into contact with gases at pressures higher than the atmospheric pressure and engulffing gas or deformation of solid microparticles can be avoided because no pump is used.

Owner:ULVAC INC

Piezoelectric element, liquid ejecting head, and liquid ejecting apparatus

ActiveUS20120147098A1Piezoelectric/electrostriction/magnetostriction machinesPrintingBismuthOptoelectronics

Owner:SEIKO EPSON CORP

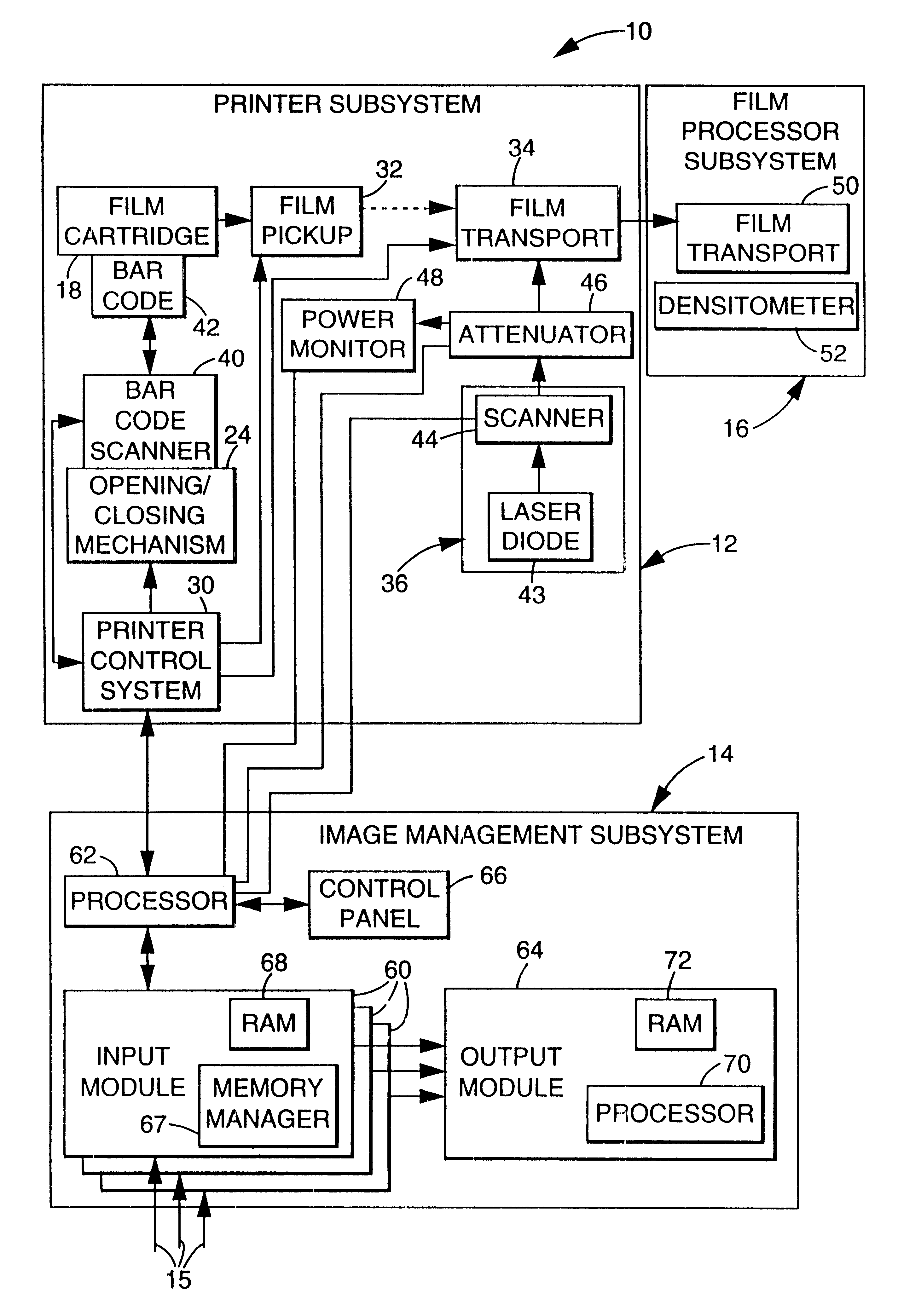

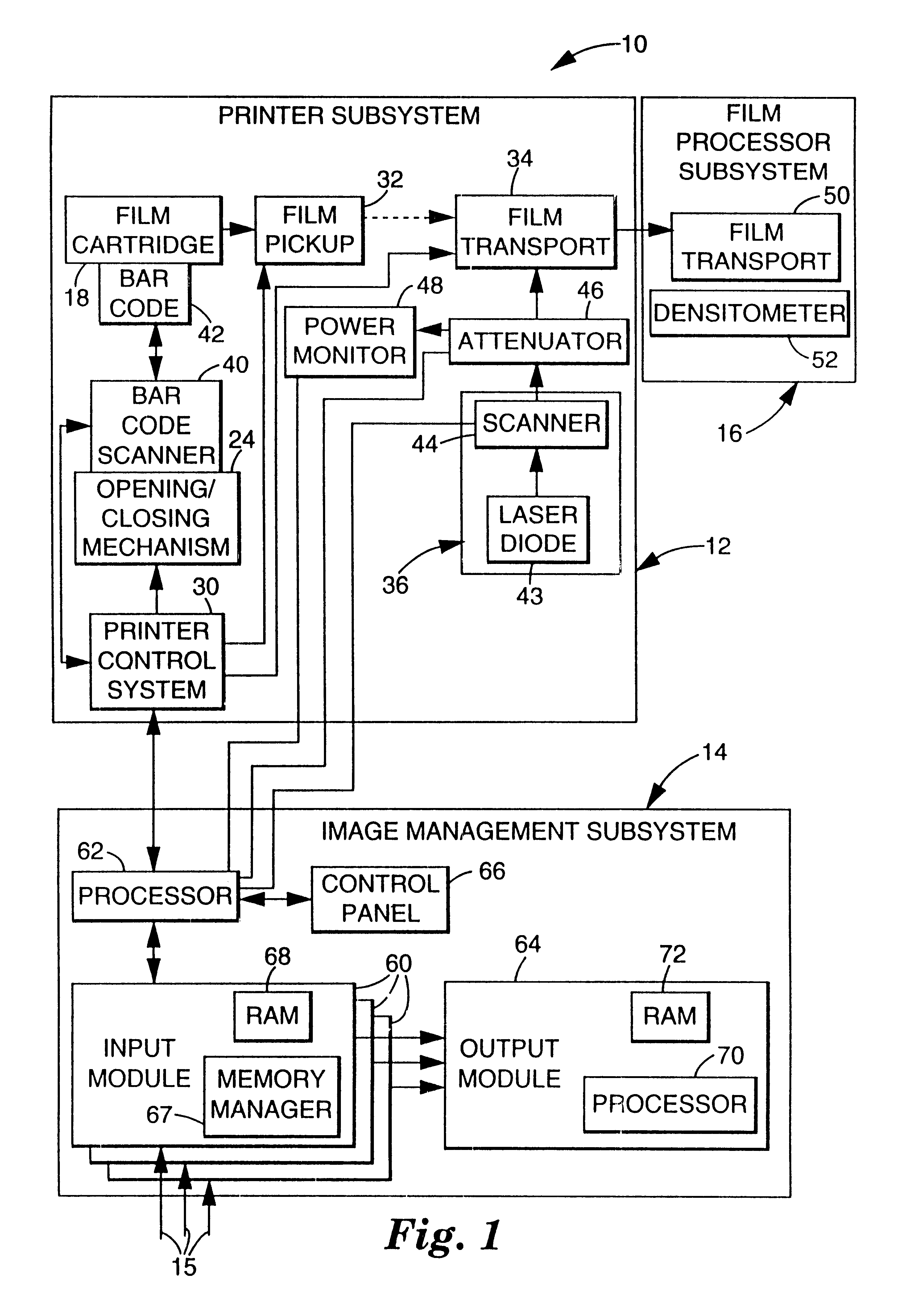

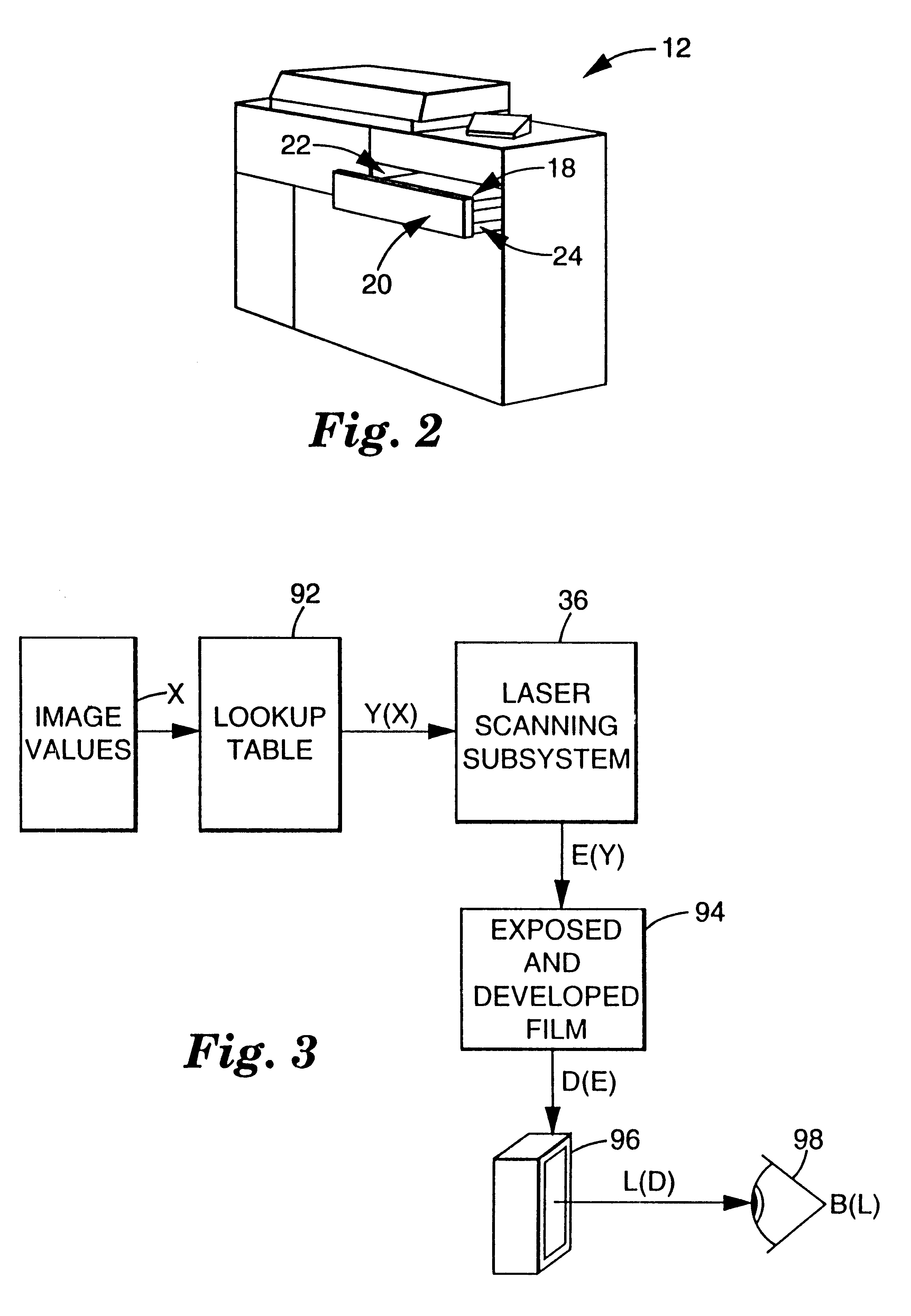

Multi-user digital laser imaging system

InactiveUSRE38005E1Minimize the differenceAddressing slow performanceCathode-ray tube indicatorsImage data processing detailsLaser imagingBarcode

Owner:CARESTREAM HEALTH INC

Printer having ink delivery system with air compliance chamber

Owner:MEMJET TECH LTD

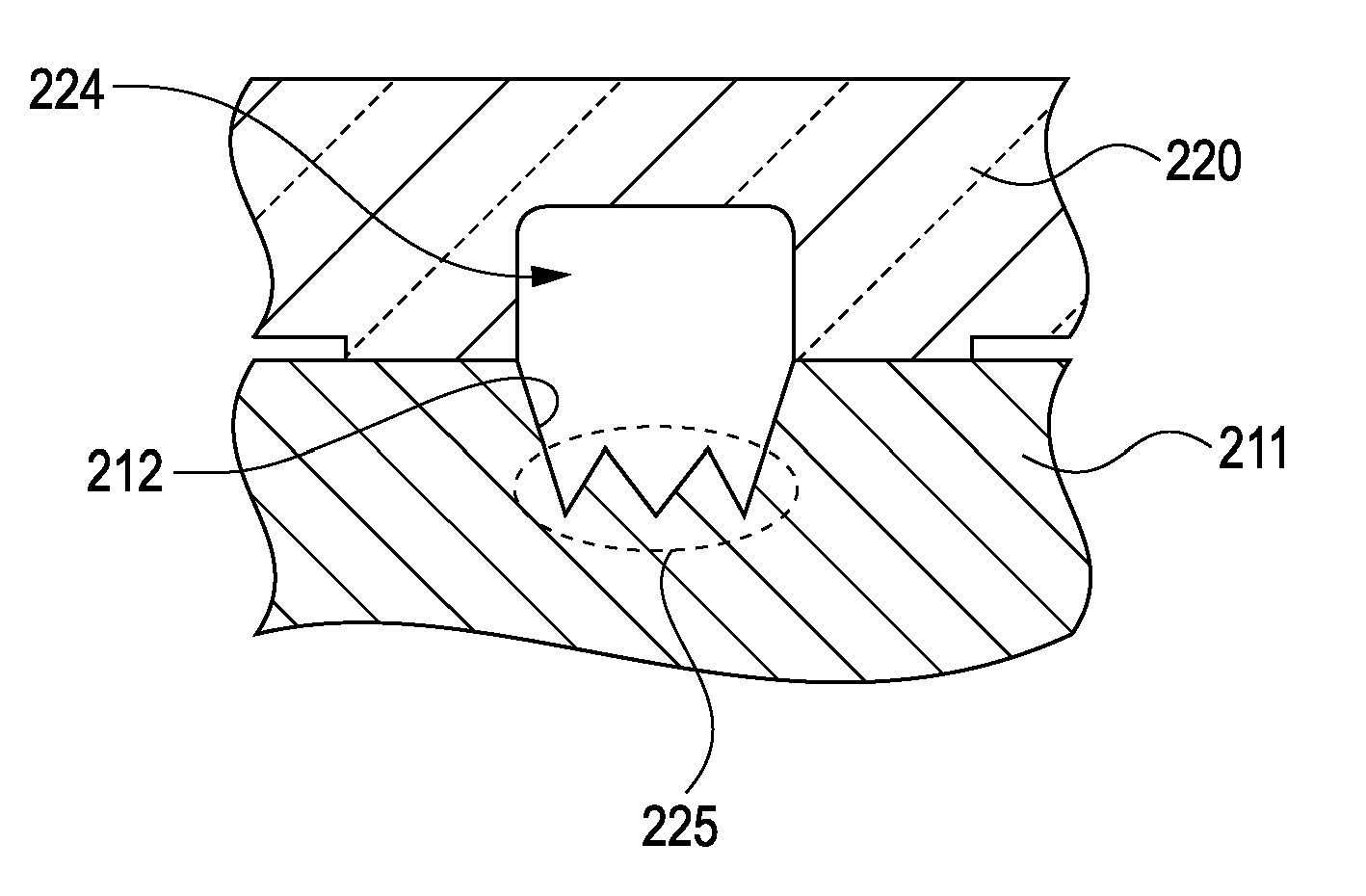

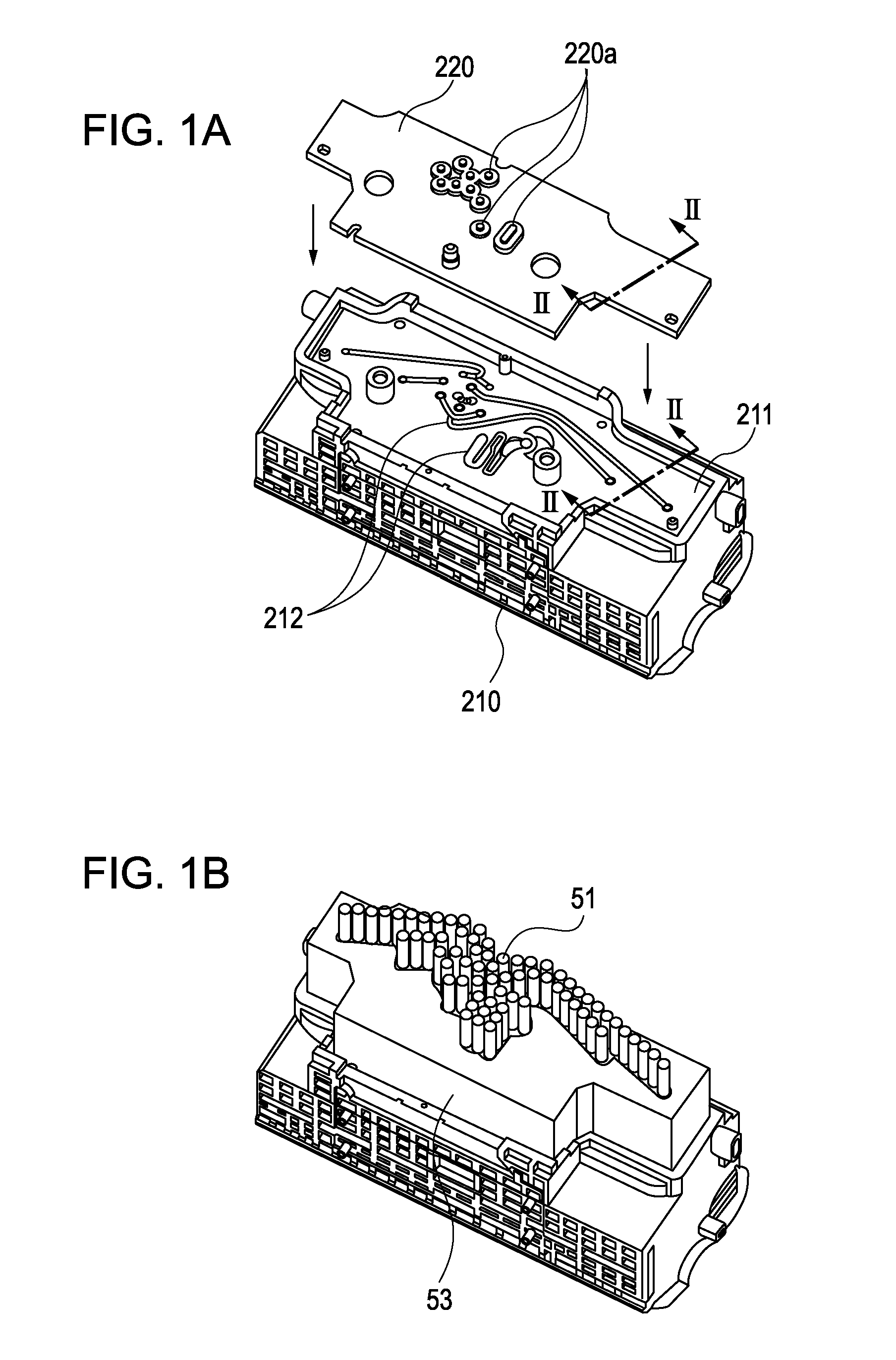

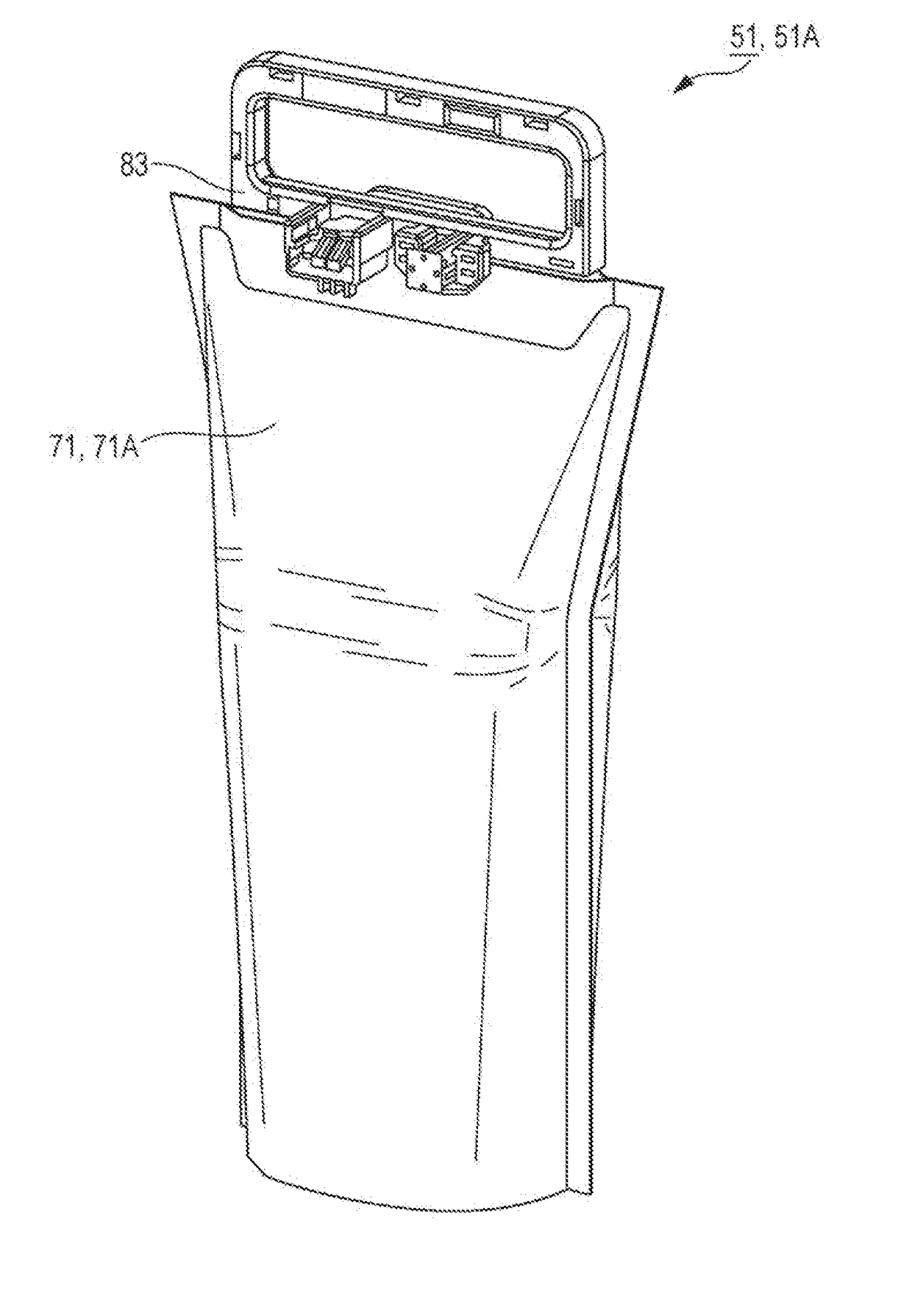

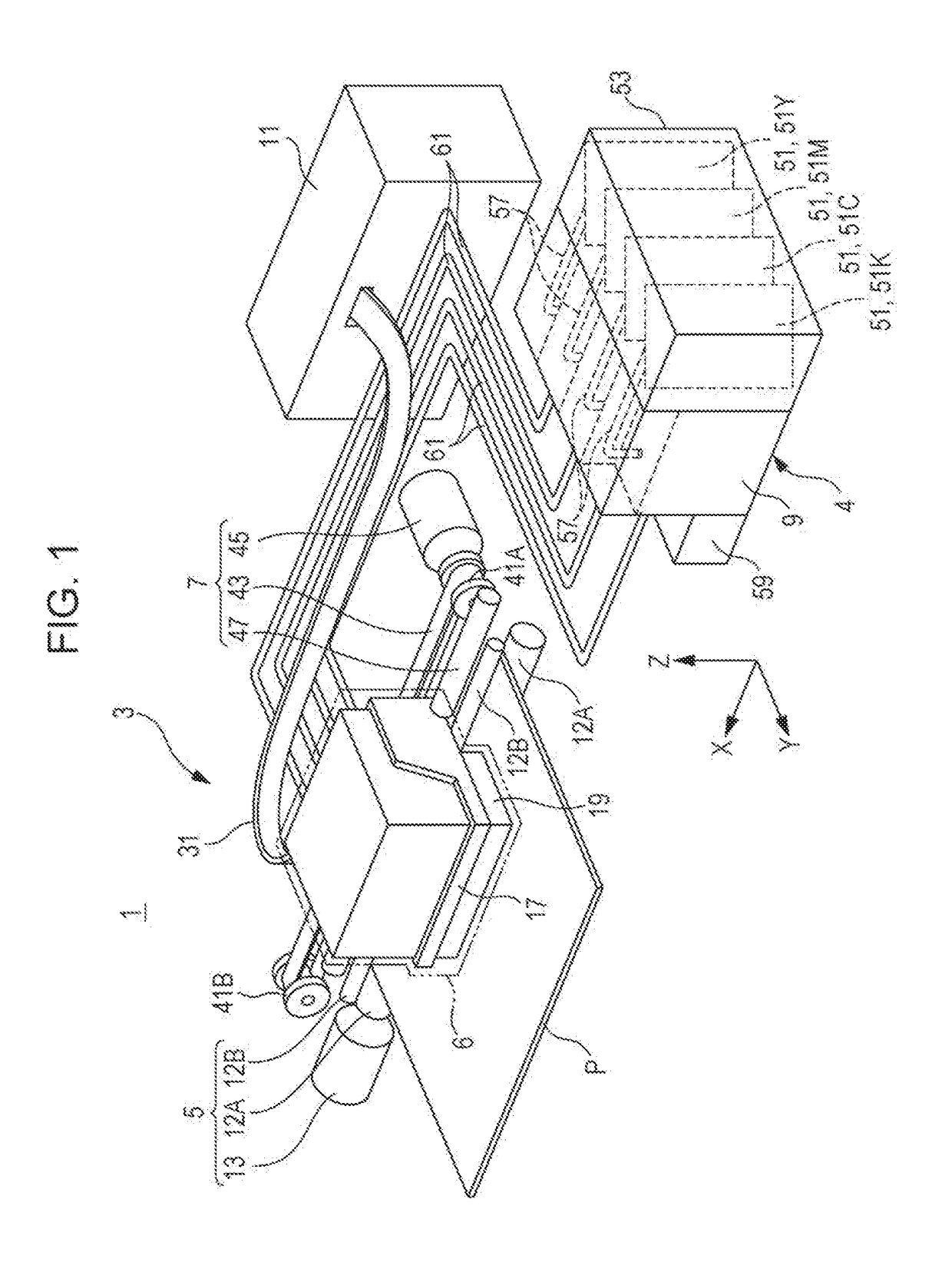

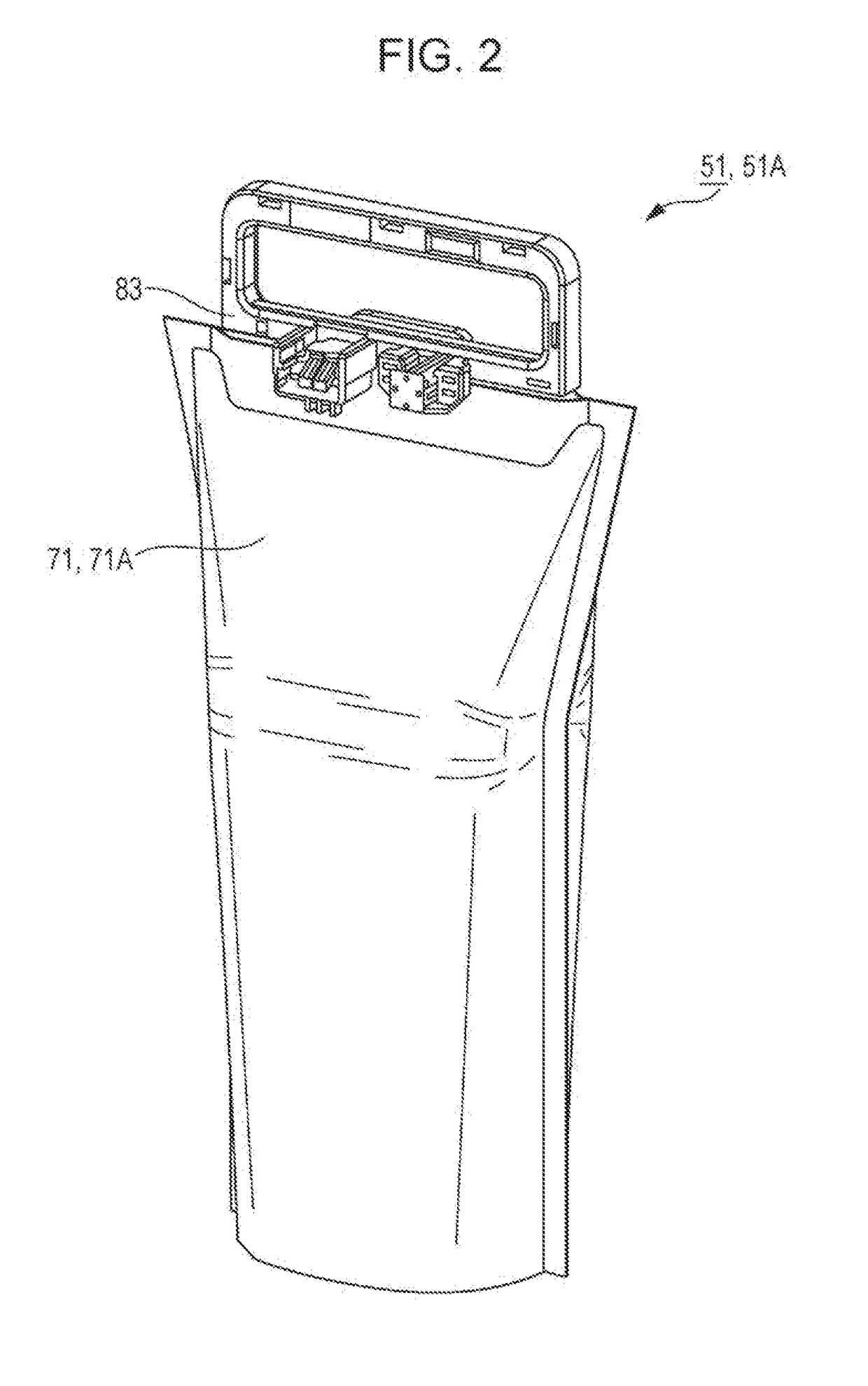

CAP and inkjet recording apparatus

ActiveCN103963457ASimple structureReduce manufacturing costPrintingManufacturing cost reductionCommunication unit

The invention provides a cap and an inkjet recording apparatus. The cap for capping an ink discharge opening of a nozzle head includes a cap main body and an atmosphere communication unit. The cap main body is configured to cap the ink discharge opening. The atmosphere communication unit is configured to couple an internal space of the cap main body to atmosphere in a state where the cap main body caps the ink discharge opening. The cap main body is configured to couple the internal space to the ink discharge opening in a state where the ink discharge opening is capped. The atmosphere communication unit includes a venthole integrally formed to the cap main body, and a tube coupled to the venthole so as to couple the internal space to atmosphere. The tube includes one end coupled to the venthole using press fitting. The cap and the inkjet recording apparatus have simplified structure and reduced manufacturing cost.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

Thermosensitive head

Owner:ALPS ALPINE CO LTD

Inkjet printing apparatus and inkjet printing method

In an inkjet printing apparatus, the colors of ink dots are controlled to make it possible to change the colors of an image to be printed. More specifically, ink temperatures, ink permeation speeds, and the capillary occupancy rates of inks in a print medium are used to control a permeation area formed by performing printing with preceding cyan and subsequent magenta, thereby controlling the colors realized by the inks which are ejected in an overlapping manner.

Owner:CANON KK

Ink composition and container

Owner:SEIKO EPSON CORP

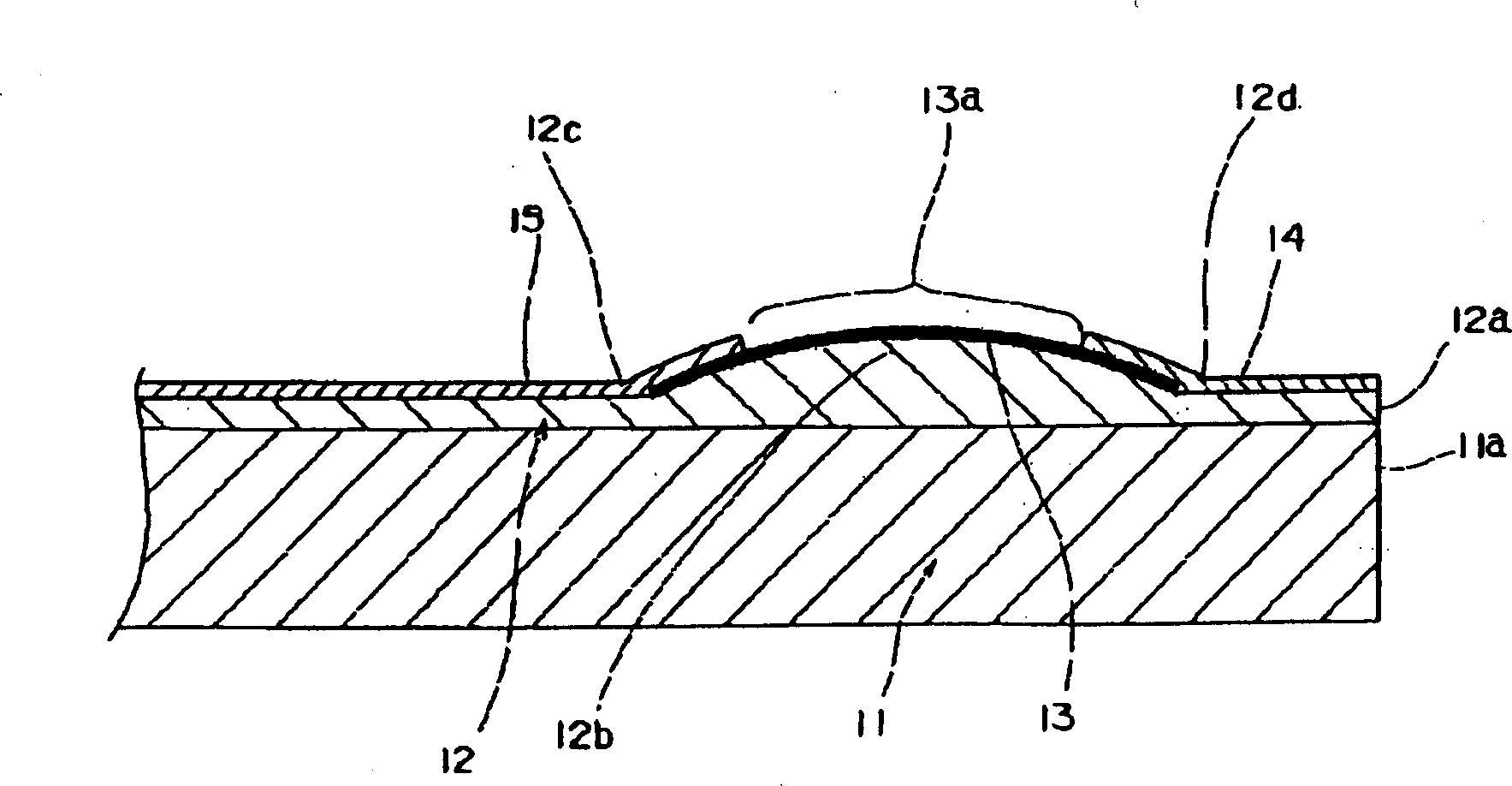

Thermal head and method of manufacturing the same, and printer

InactiveUS20120212558A1Reduce the amount requiredImprove thermal efficiencyPrintingEngineeringHeat sensitive

Owner:SEIKO INSTR INC

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap