Printing system having printhead bypass

a printing system and printhead technology, applied in the field of fluid systems and apparatuses, can solve the problems of unwieldy individual pressure regulators integrated into each printhead, unfavorable multi-color printing, and inability to achieve the effect of reducing the number of printing heads, improving the efficiency of printing, and improving the reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

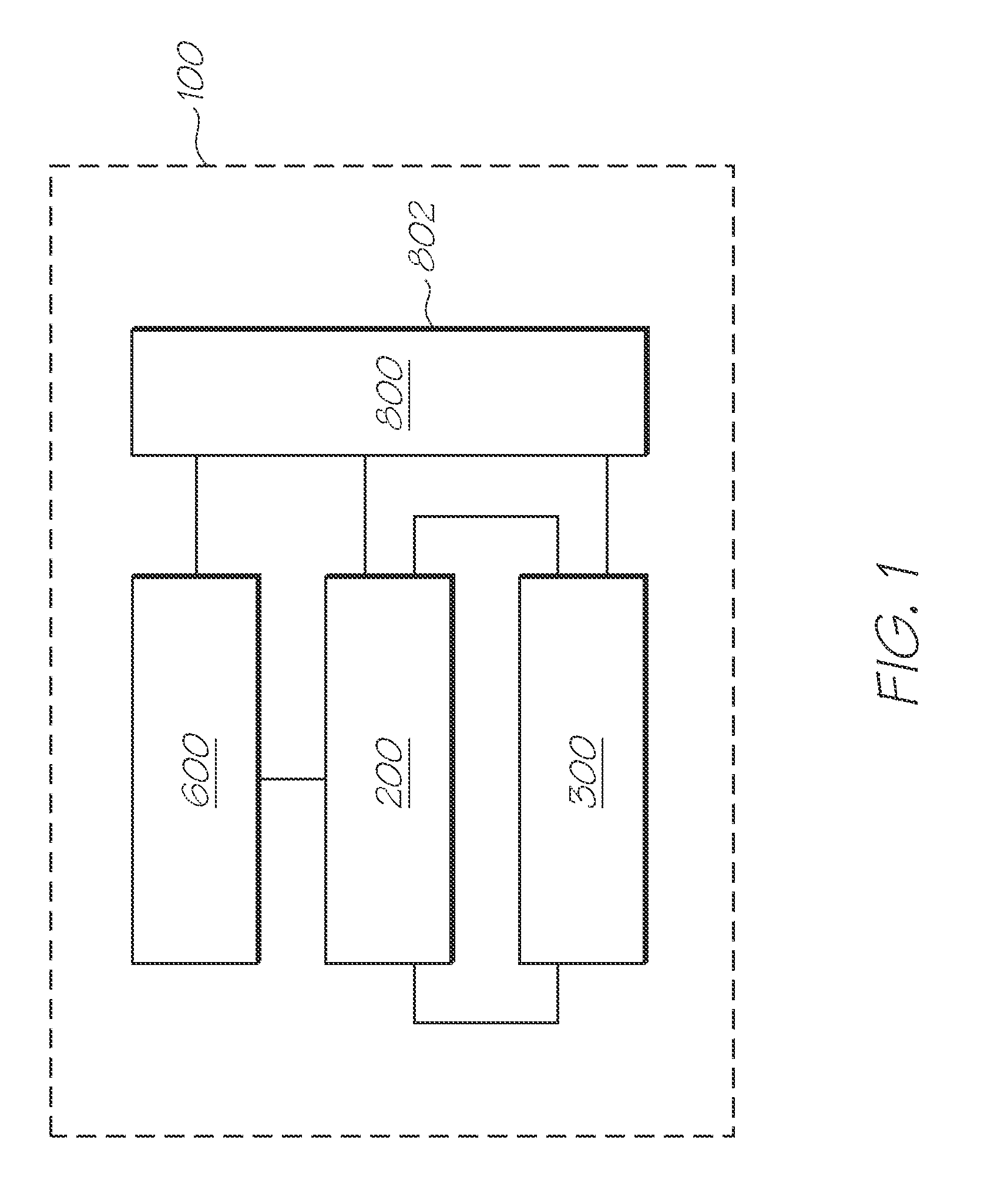

[0620]An exemplary block diagram of the main system components of a printer 100 is illustrated in FIG. 1. The printer 100 has a printhead 200, fluid distribution system 300, maintenance system 600 and electronics 800.

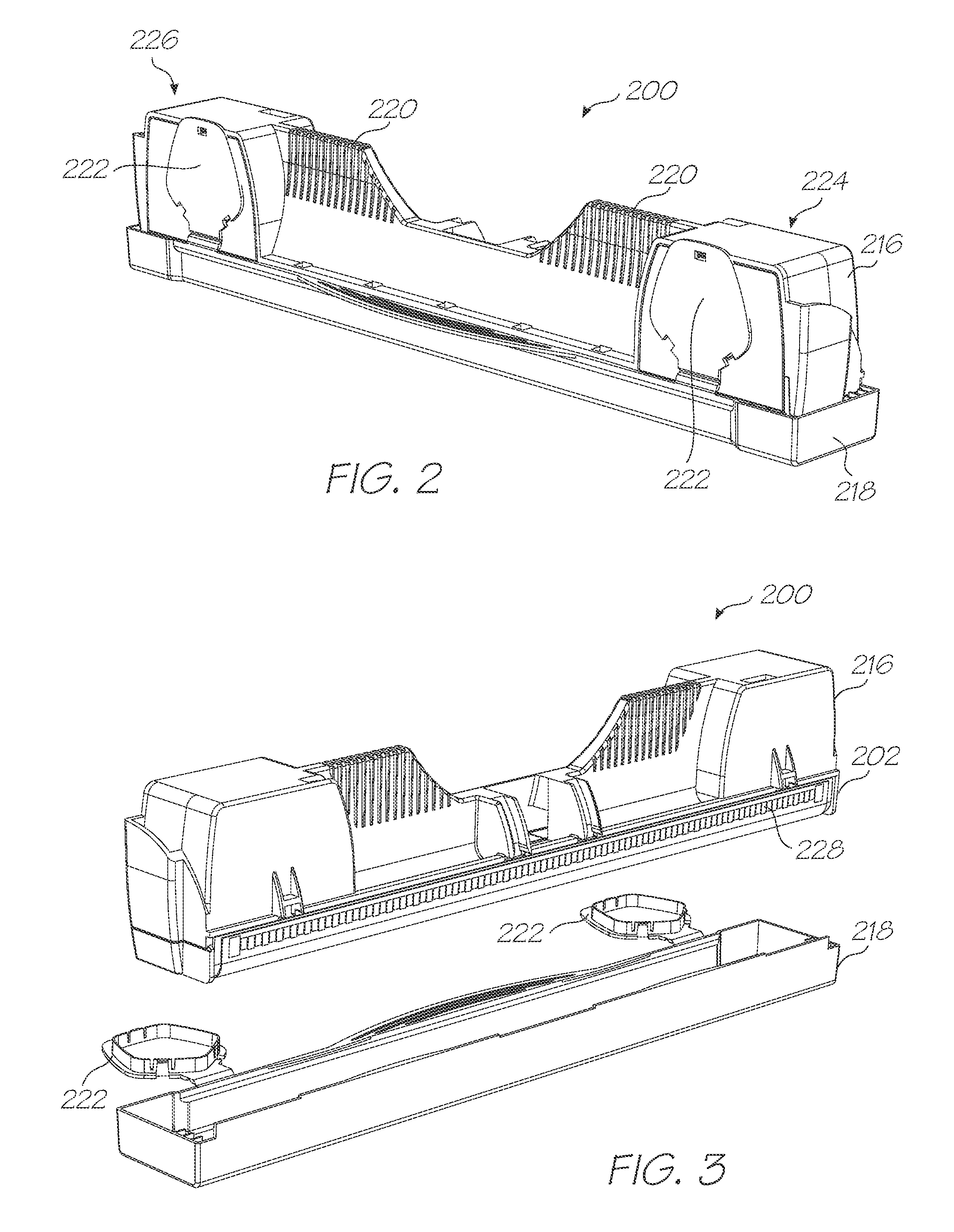

[0621]The printhead 200 has fluid ejection nozzles for ejecting printing fluid, such as ink, onto passing print media. The fluid distribution system 300 distributes ink and other fluids for ejection by the nozzles of the printhead 200. The maintenance system 600 maintains the nozzles of the printhead 200 so that reliable and accurate fluid ejection is provided.

[0622]The electronics 800 operatively interconnects the electrical components of the printer 100 to one another and to external components / systems. The electronics 800 has control electronics 802 for controlling operation of the connected components. An exemplary configuration of the control electronics 802 is described in US Patent Application Publication No. 20050157040 (Applicant's Docket No. RRC001US), the cont

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap