Method and chip for adjusting chip parameter to match non-standard capacity ink box

A technology for matching parameters and adjusting chips, applied in printing and other directions, can solve problems such as unfavorable environmental protection, inability to achieve compatibility, waste of recording materials, etc., to achieve the effect of being conducive to environmental protection and promoting sales

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment approach

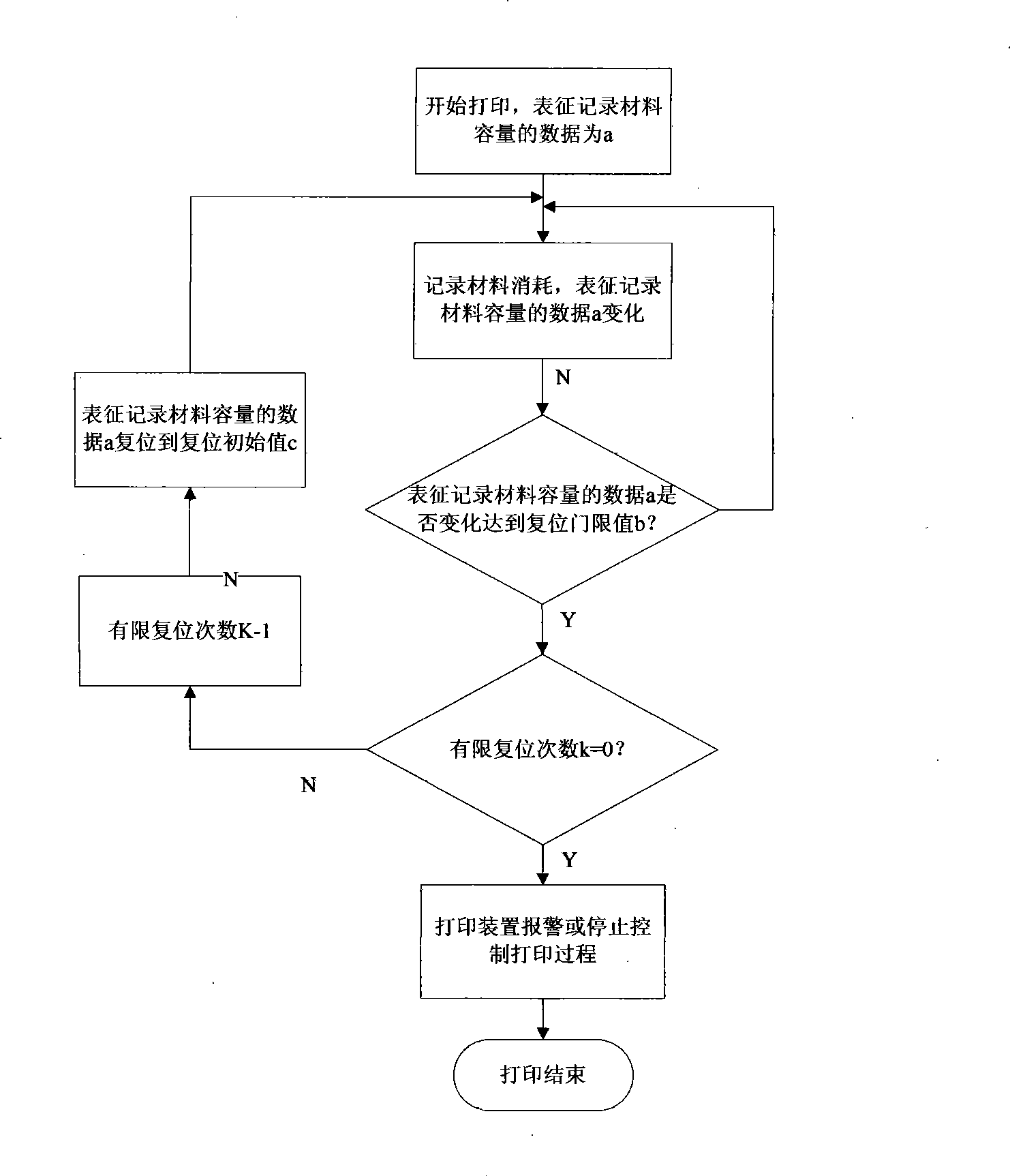

[0027] An implementation of the chip in the present invention during the entire printing process of the printing device is as follows:

[0028] 1. The computer on the chip and the printing device exchange information with each other, and the data representing the capacity of the recording material in the chip shows that the capacity of the recording material is full;

[0029] 2. During the printing process, the recording material in the ink cartridge is consumed, and the data representing the capacity of the recording material in the chip also changes accordingly;

[0030] 3. When the change in the data representing the capacity of the recording material in the chip reaches the set reset threshold value, it will be reset to the set reset initial value, and the remaining amount of the limited number of reset times will be reduced by one unit;

[0031] 4. Continue to print. The data representing the capacity of the recording material in the chip changes with the consumption of the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap