Ink box chip, ink box and structural body

A technology of ink cartridge chip and structure, which is applied in the field of inkjet printers, can solve the problems that it is difficult to ensure good contact of ink cartridge chip printer contact pins, and achieve the effect of reducing positioning accuracy requirements and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides an ink cartridge chip, which is suitable for ink cartridges, especially for ink cartridges of inkjet printers. The ink cartridge chip of this embodiment is detachably mounted on the ink cartridge.

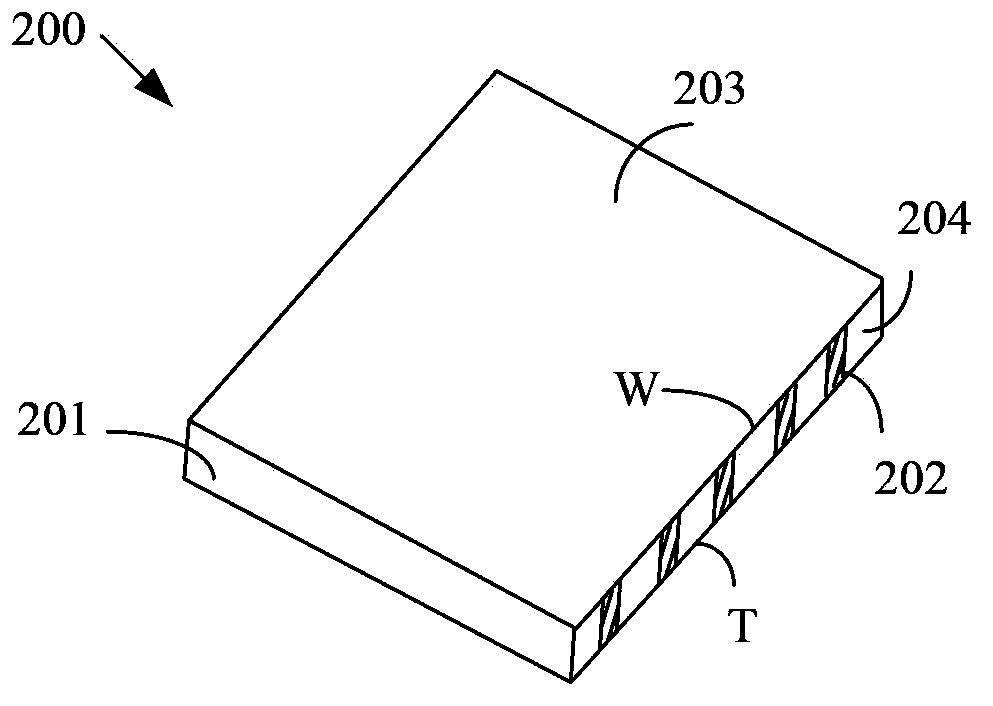

[0034] Such as figure 2 Shown is a schematic diagram of the three-dimensional structure of the ink cartridge chip according to this embodiment. The cartridge chip 200 of this embodiment includes a circuit board 201 and a plurality of container-side terminals 202 .

[0035] Wherein, the circuit board 201 includes a first plane 203 and a second plane 204 perpendicular to the first plane 203, the surface area of the second plane 204 is smaller than the surface area of the first plane 203; each container side terminal 202 is arranged on the second plane 204 , and one end of each container-side terminal 202 intersects the first plane 203, the other end of each container-side terminal 202 intersects a third plane (not shown in the figure), the third pl

Embodiment 2

[0040] This embodiment provides an ink cartridge chip based on the first embodiment.

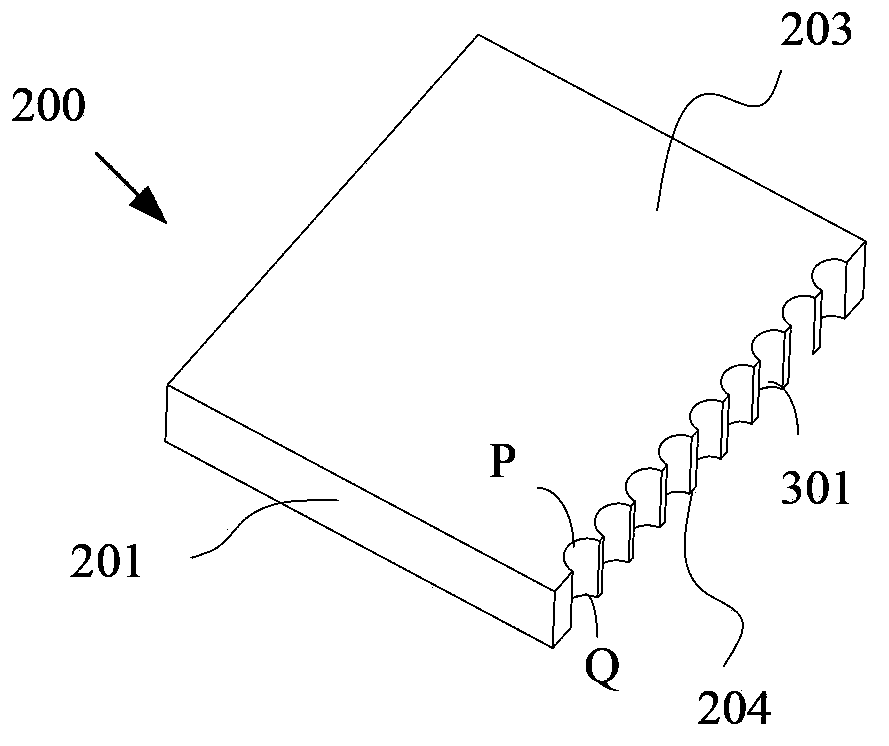

[0041] Such as Figure 3A As shown, it is a schematic diagram of the three-dimensional structure of the ink cartridge chip 200 according to this embodiment; Figure 3B As shown, it is a schematic top view structure diagram of the ink cartridge chip 200 according to this embodiment; Figure 3C Shown is a left view of the ink cartridge chip 200 according to this embodiment, as Figure 3D Shown is a schematic diagram of the second plane 204 of the ink cartridge chip 200 according to this embodiment.

[0042] The second plane 204 of the ink cartridge chip 200 of this embodiment includes a plurality of grooves 301, and a container-side terminal 202 is arranged in each groove 301, that is, the number of the grooves 301 is consistent with the number of the container-side terminals 202. The number of slots 301 may also be more or less than the number of container-side terminals 202 . Specifically,

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap