Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

79 results about "Control valves" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A control valve is a valve used to control fluid flow by varying the size of the flow passage as directed by a signal from a controller. This enables the direct control of flow rate and the consequential control of process quantities such as pressure, temperature, and liquid level.

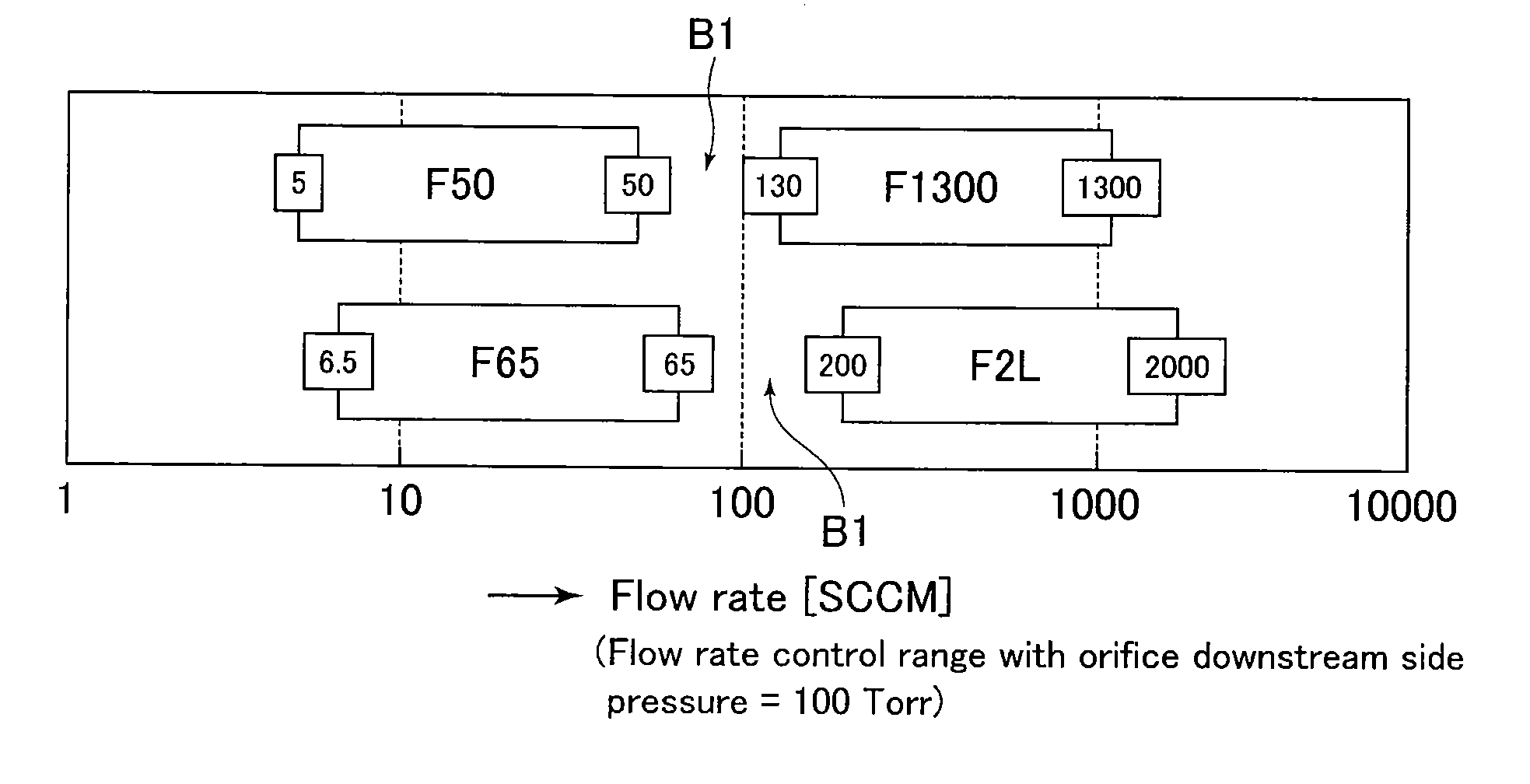

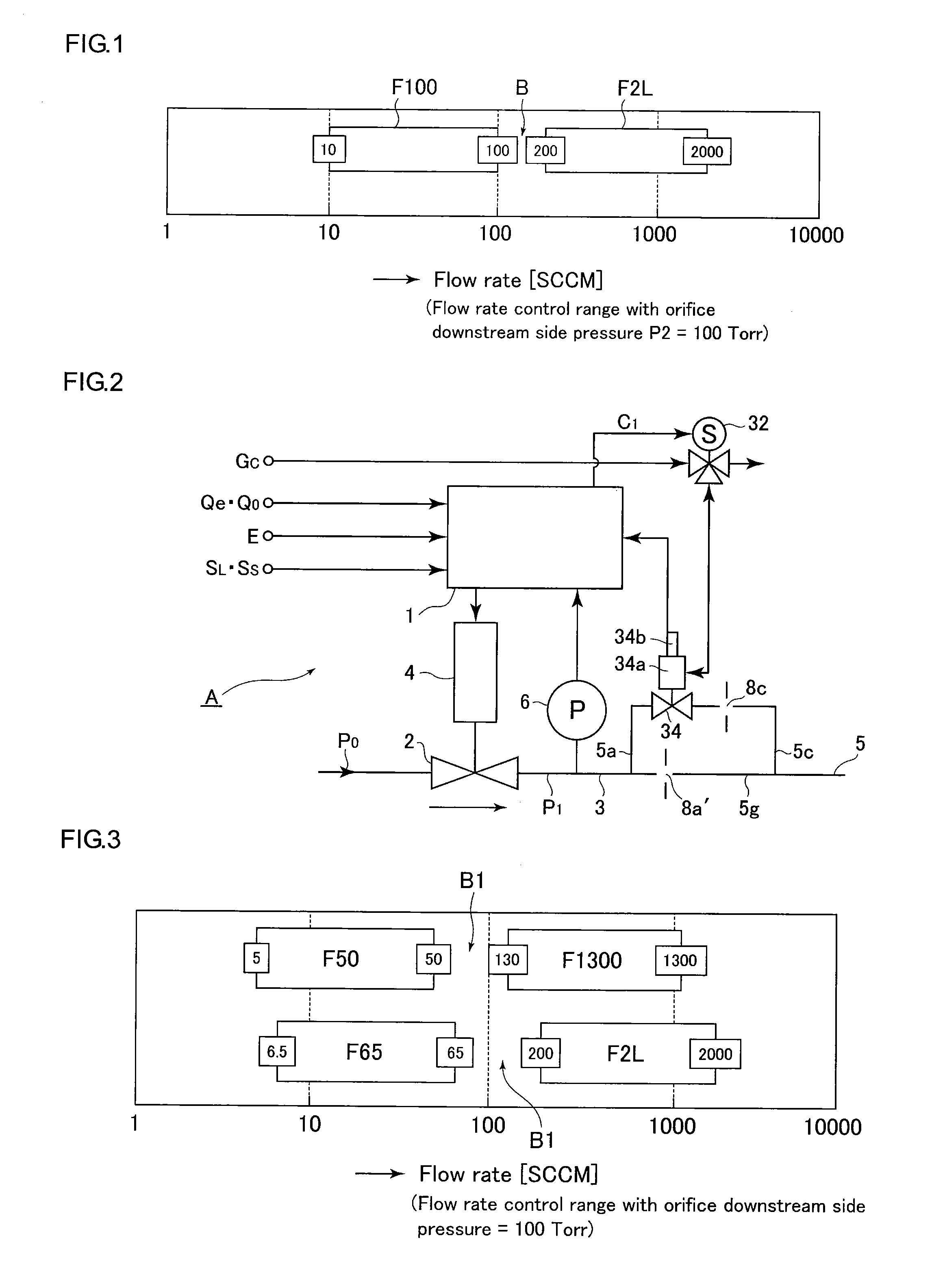

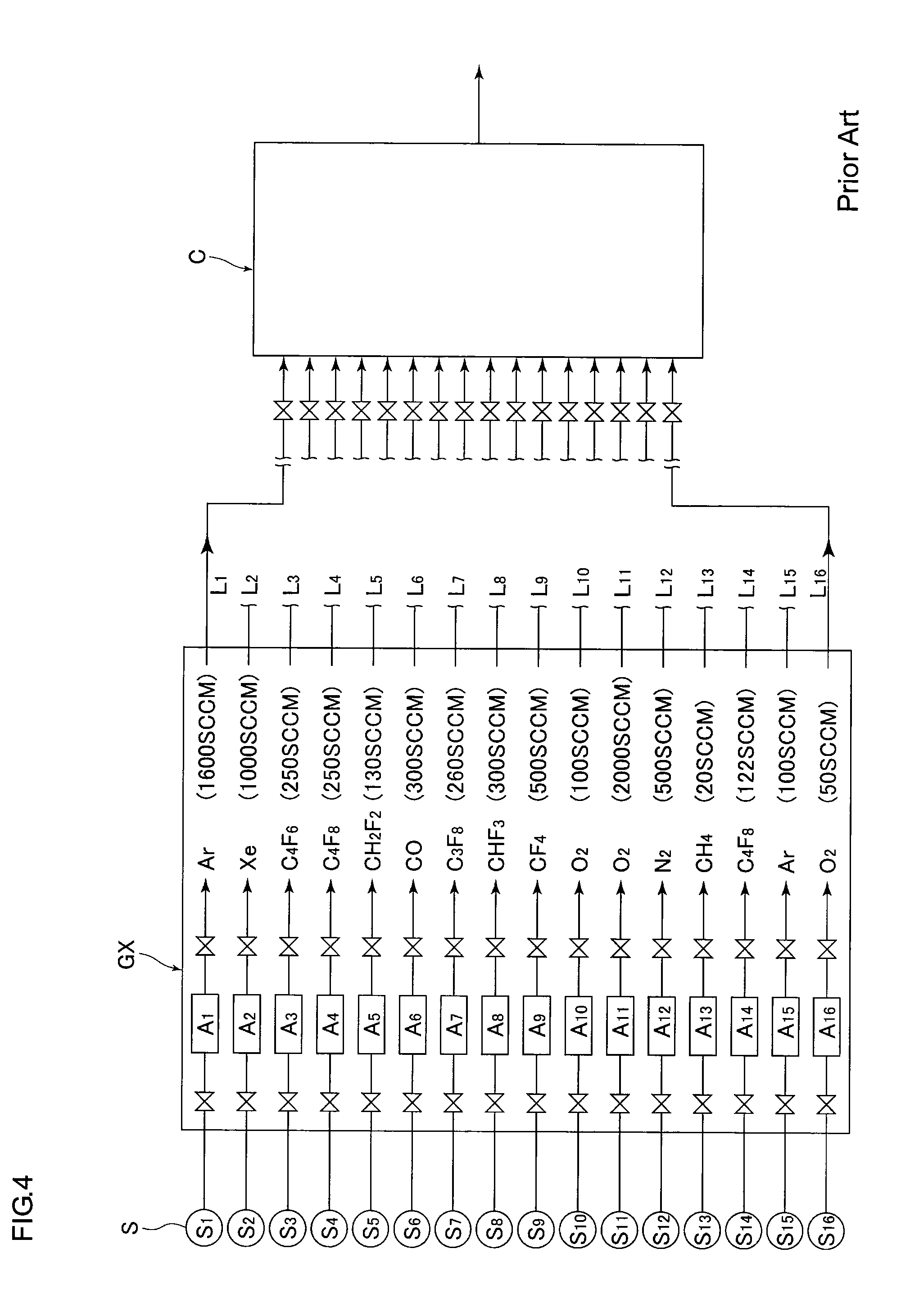

Discontinuous switching fluid flow rate control method using pressure type flow rate control device

InactiveUS20110120566A1Improve accuracySimple structurePipeline systemsVolume flow measuring devicesEngineeringControl valves

Owner:FUJIKIN INC +2

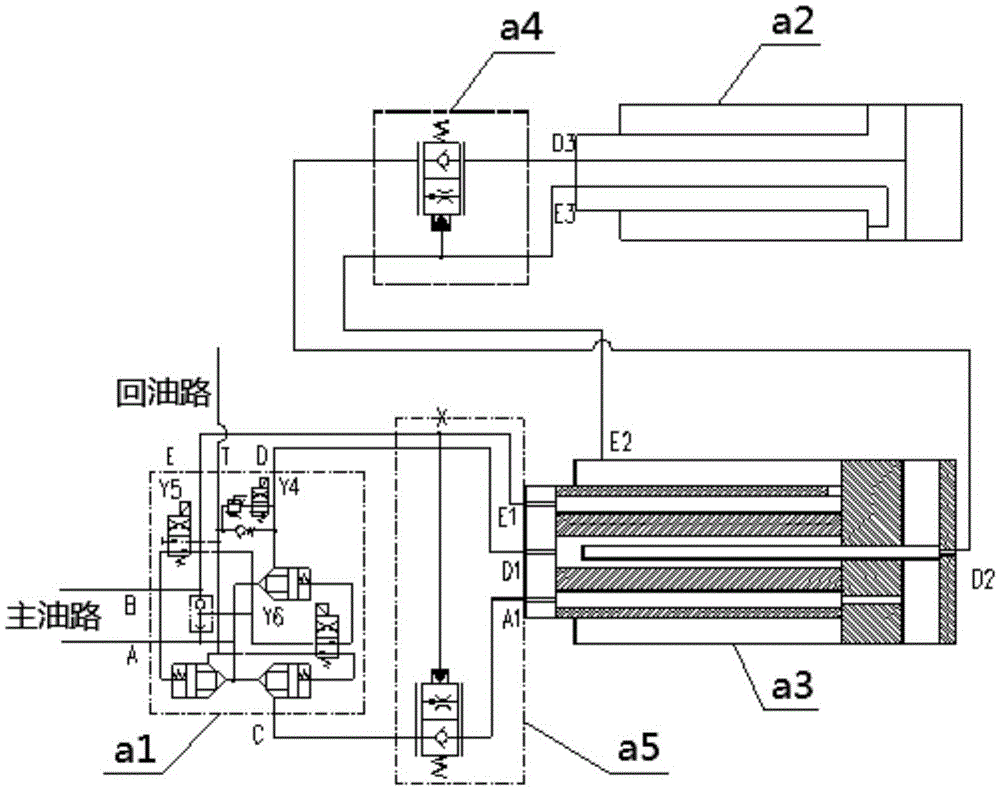

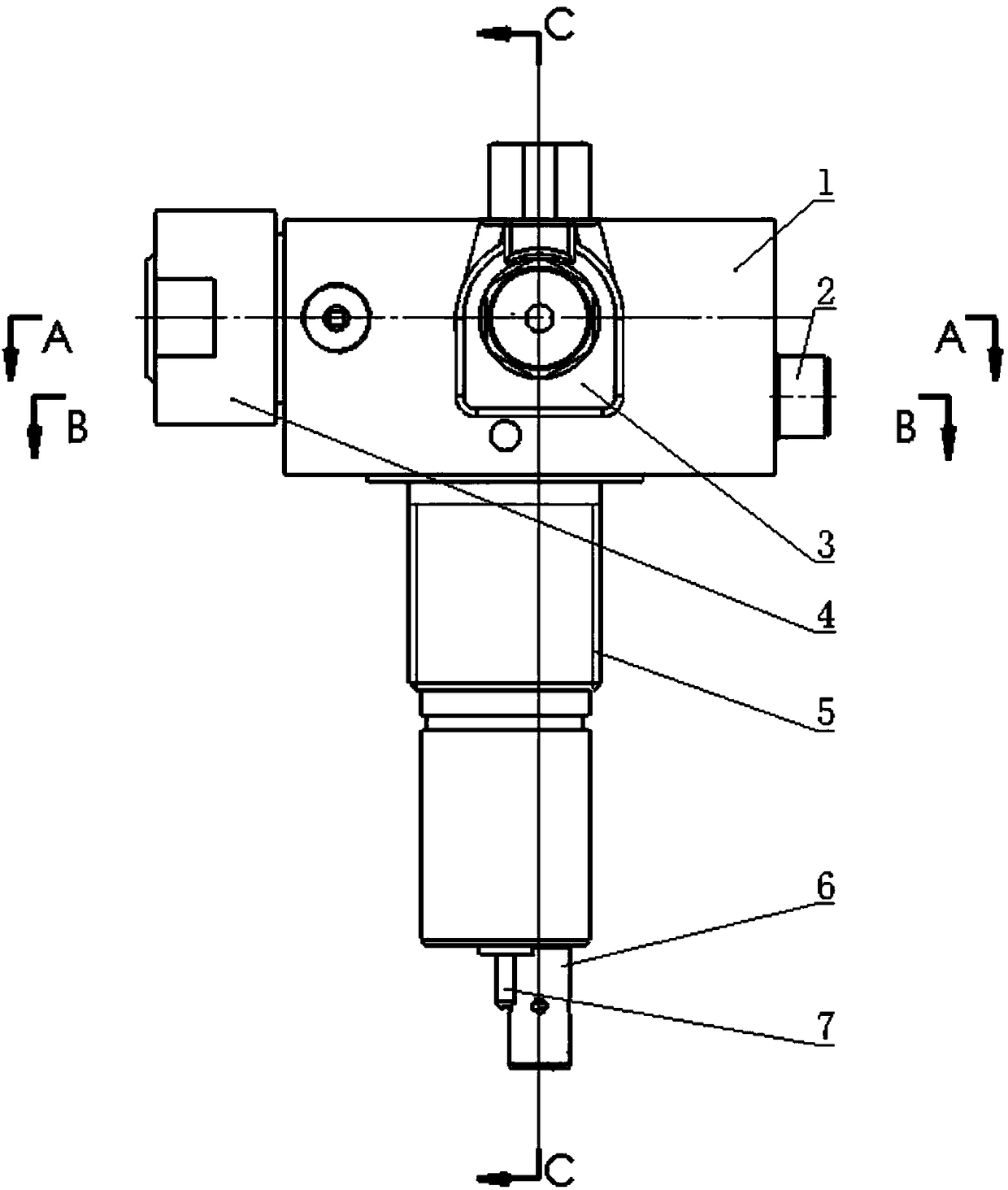

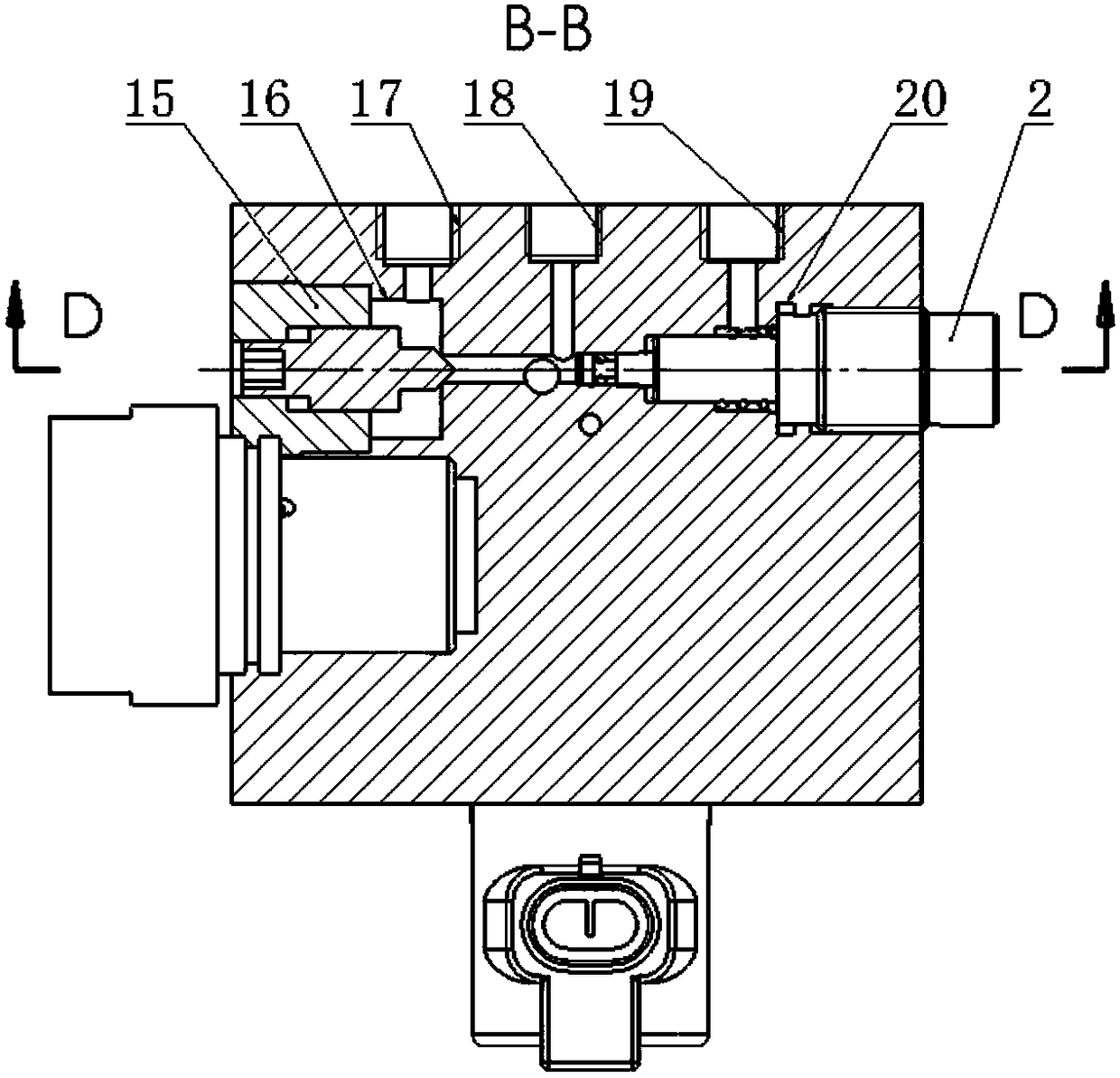

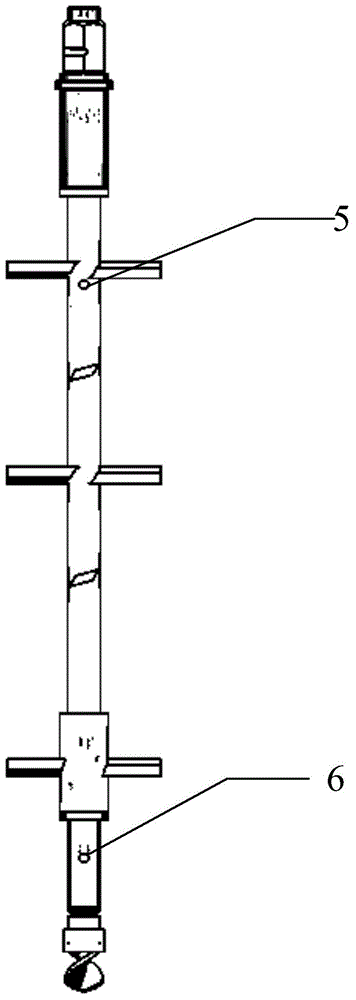

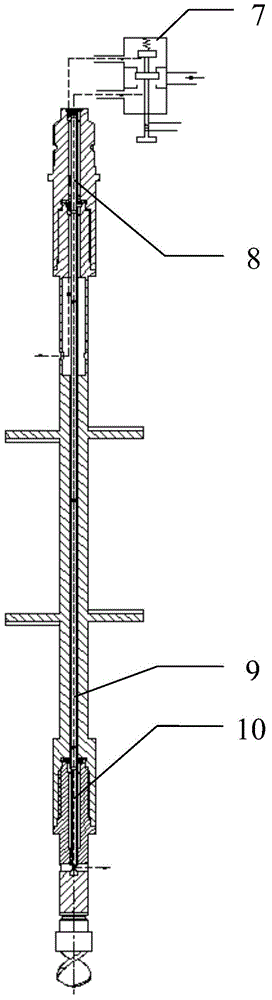

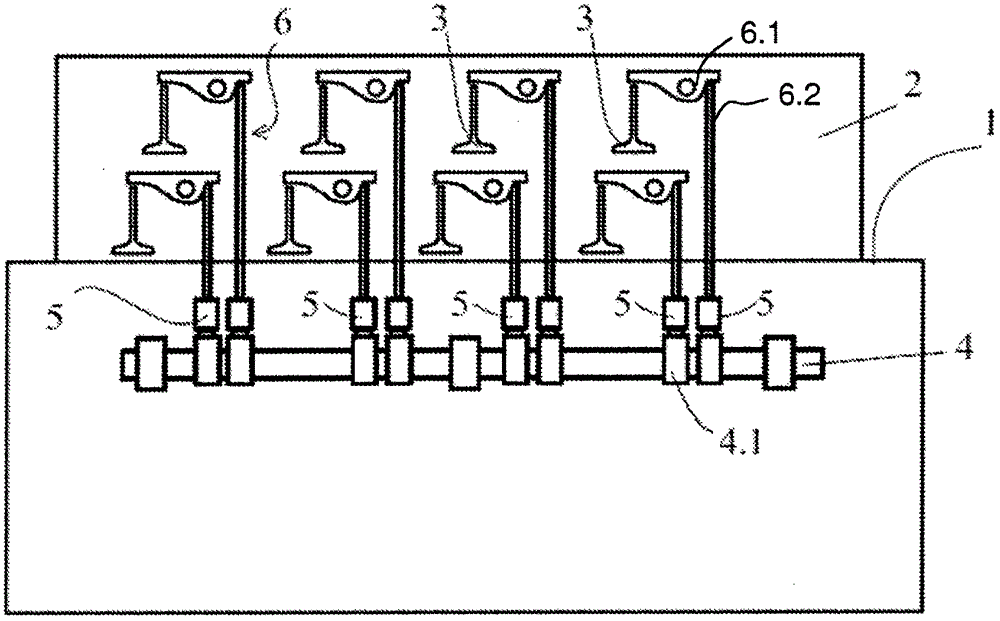

Telescopic control valve, multi-stage telescopic hydraulic system and hoist jib telescopic hydraulic control system

ActiveCN105545853AEasy to controlAchieve conductionServomotor componentsCranesControl valvesPetroleum engineering

Owner:XUZHOU HEAVY MASCH CO LTD

Heat supply secondary pipe network distributed balance control system and control method thereof

ActiveCN102494365AAchieve dynamic balanceGuaranteed differential pressureLighting and heating apparatusEfficient regulation technologiesMicrocontrollerGeneral Packet Radio Service

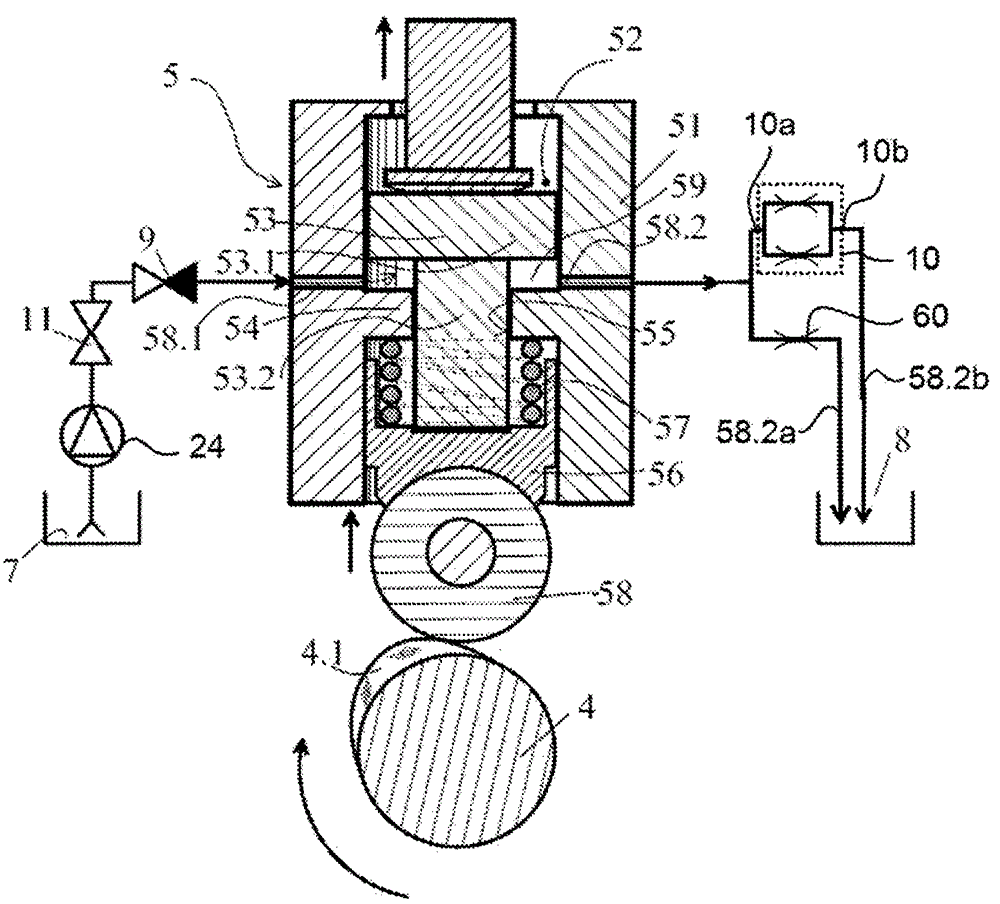

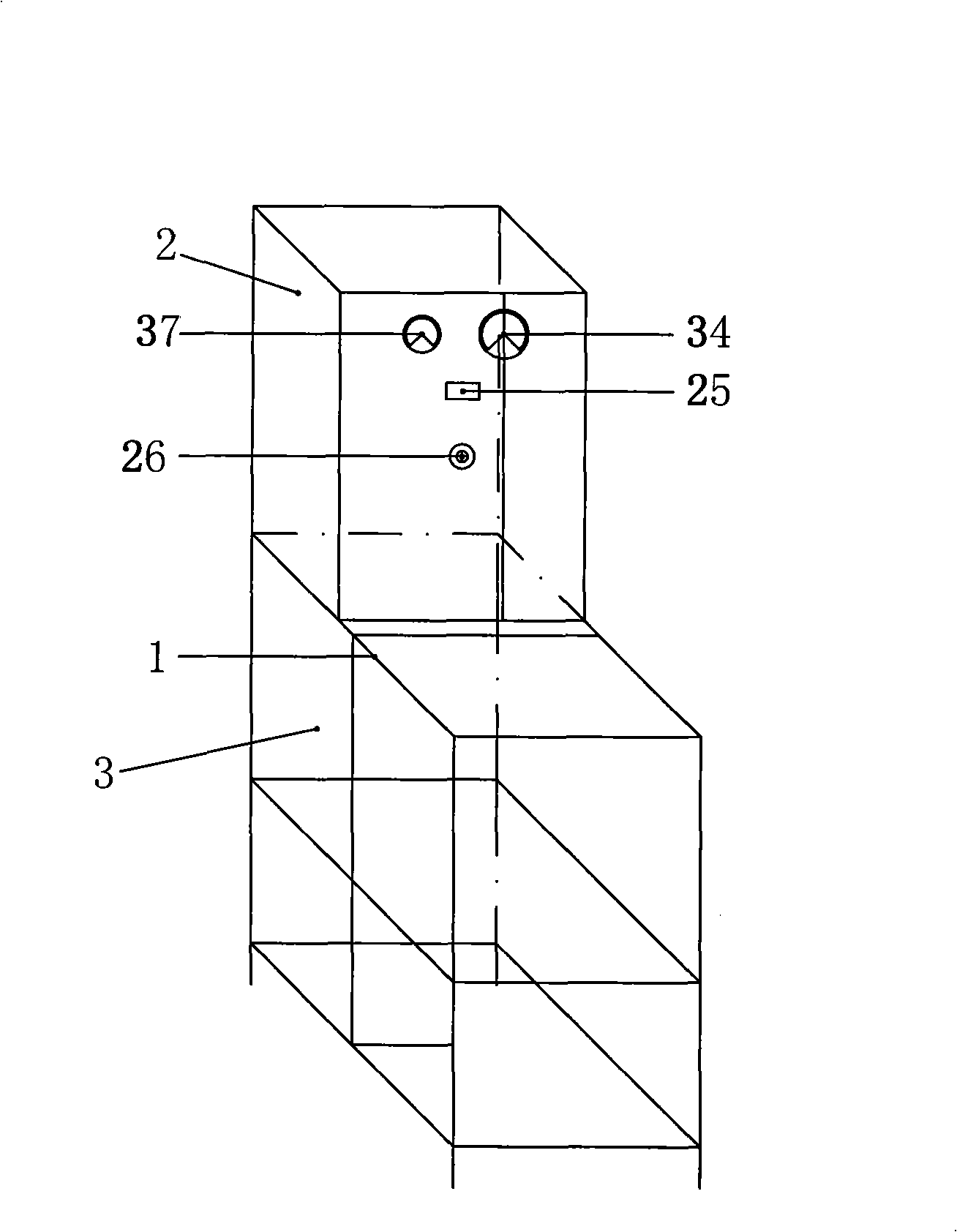

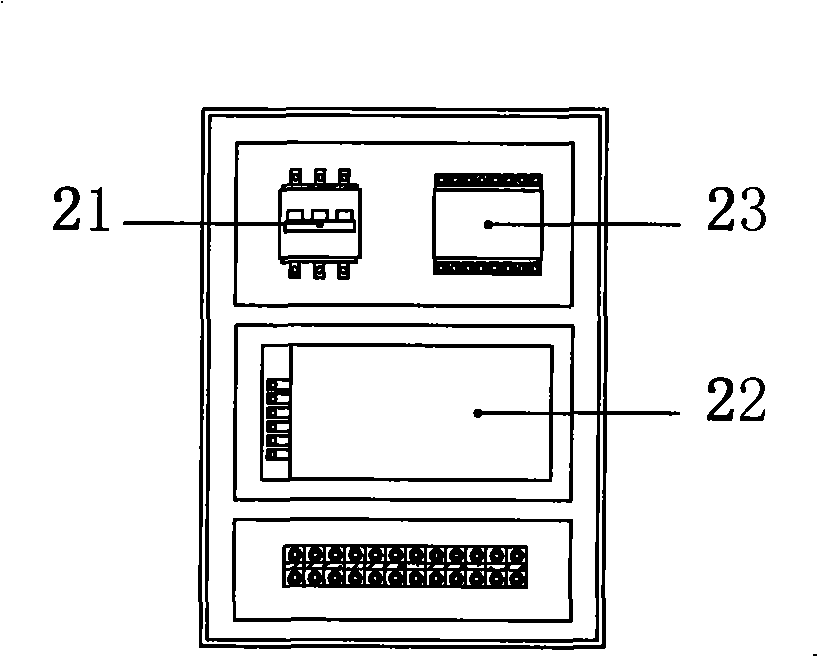

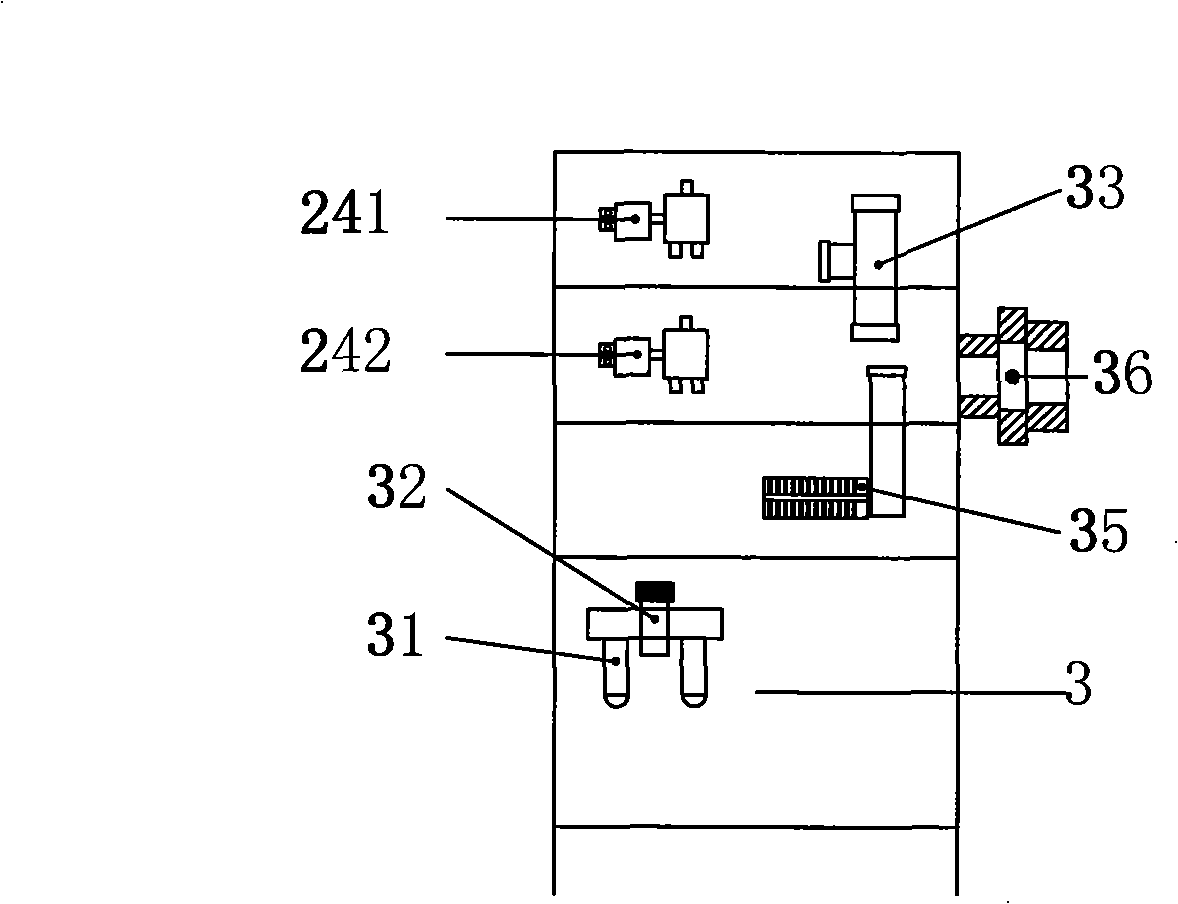

The invention discloses a heat supply secondary pipe network distributed balance control system and a control method thereof. The system comprises a front-end control system and a tail-end control system and is provided with a master control machine and microcontrollers; and the system is characterized in that: the master control machine is connected with a plurality of microcontrollers through wireless communication; a first pressure transmitter, a second pressure transmitter, a header pipe flowmeter, a variable frequency pump, an electric control valve and a general packet radio service (GPRS) module are connected to the master control machine respectively; and a third pressure transmitter, a fourth pressure transmitter, a branch pipe flowmeter, a balancing control valve and a GPRS module are connected to the microcontrollers respectively. The invention has the advantages that: the pressure difference and flow of a pipe network in each building can be detected, pressure difference between an input end and an output end of the pipe network in each building is guaranteed, pressure difference between a heat supply header pipe and a backflow header pipe is guaranteed, and flow balance between the heat supply header pipe and a heat supply branch pipe is monitored simultaneously; and therefore, the secondary pipe network is operated stably, pipelines are prevented from vibrating, and the service life of the pipelines is prolonged.

Owner:CHONGQING WECAN PRECISION INSTR

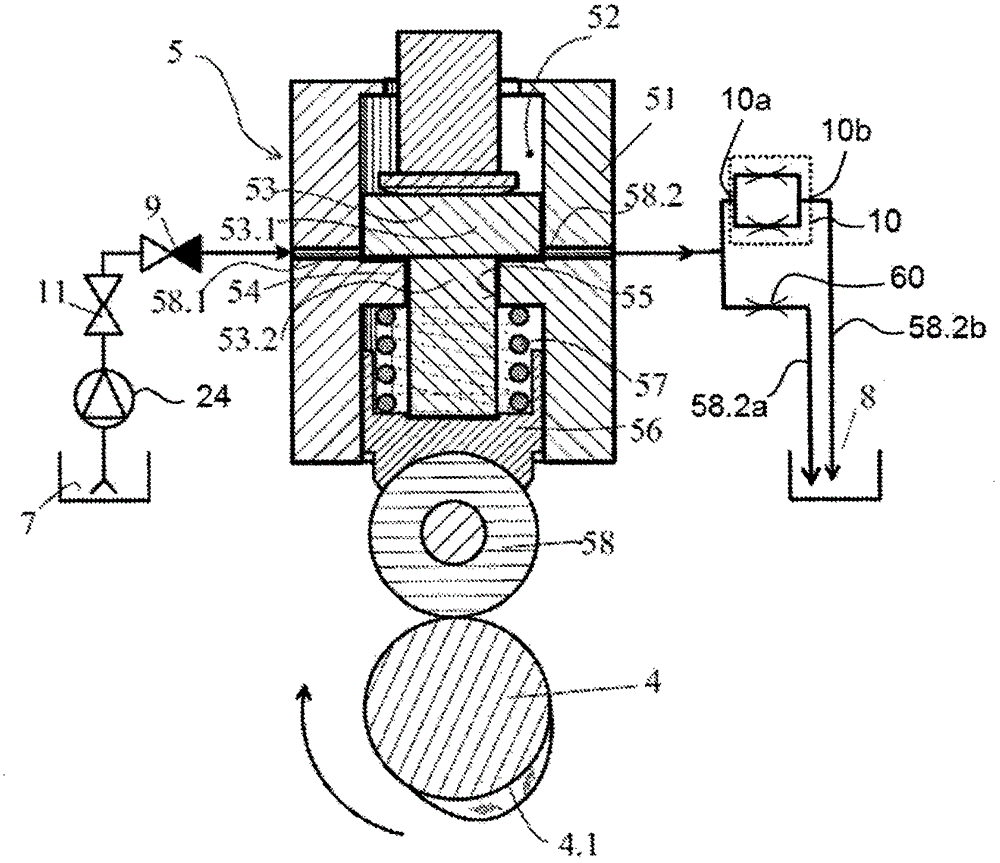

Method for controlling temperature of crude oil for emulsion of rolling mill and control device

InactiveCN101575044AUniform temperatureImprove the heating effectTank wagonsTemperature controlEmulsion

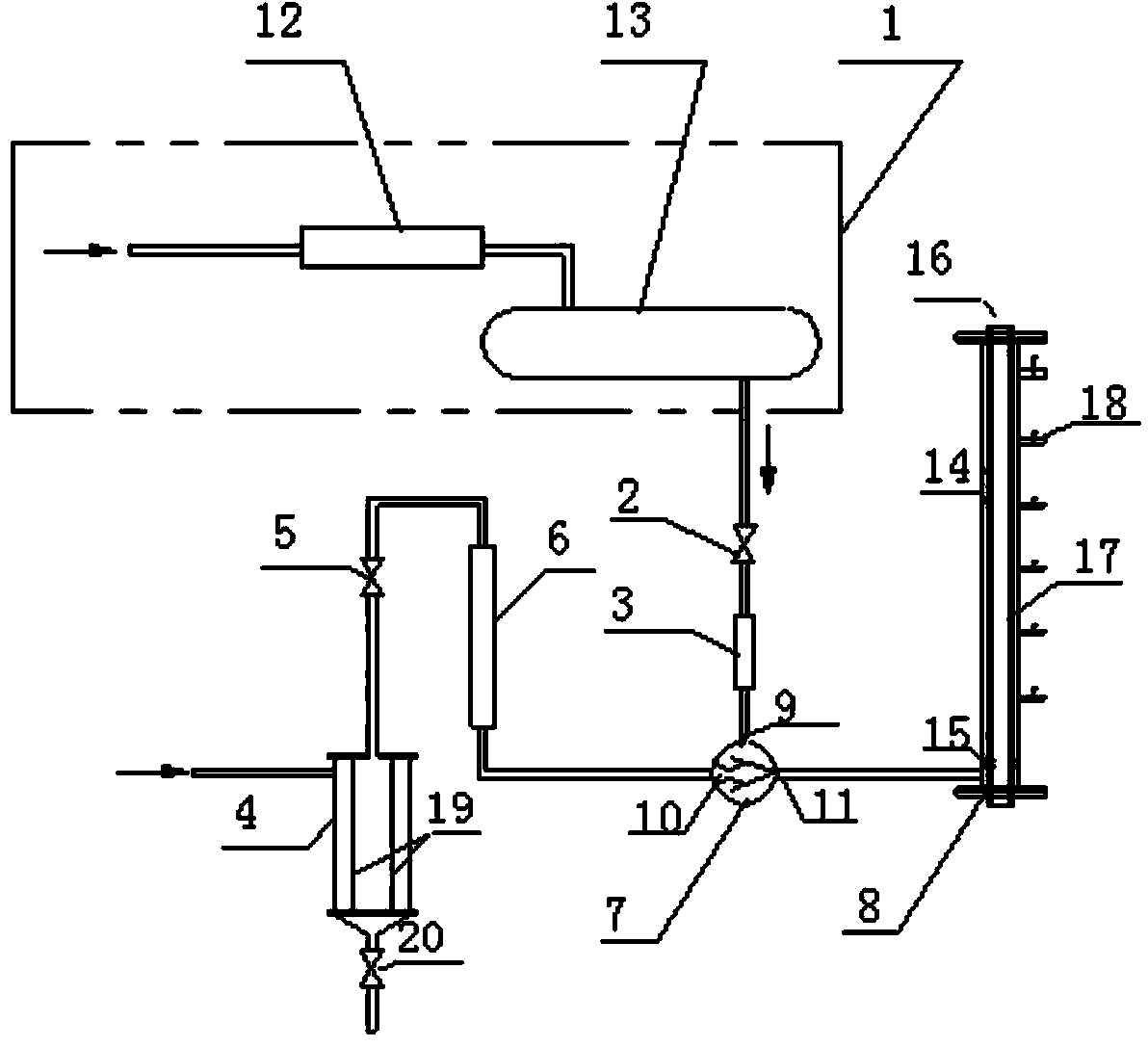

The invention relates to a method for controlling temperature of crude oil for emulsion of a rolling mill and a control device. The method comprises the steps of: arranging a heating device on the outer part of a crude oil tank; adopting a circulation heating pump arranged at the tail of the crude oil tank to transfer crude oil to a heat exchanger for heat exchange; simultaneously adopting a temperature controller on the crude oil tank to control the on and off of the heating device; and transferring crude oil to the top of the crude oil tank for outer circulation heating so as to keep the temperature of crude oil inside the crude oil tank at a preset value. A control device comprises the heating device consisting of the circulation heating pump and the heat exchanger, the temperature controller, a steam control valve, a steam trap and pipelines connecting the components, wherein the circulation heating pump is arranged at the tail of the crude oil tank, the heat exchanger is arranged on the side of the crude oil tank and the temperature controller is arranged on the crude oil tank. The invention has the advantages of good heating effect, equal crude oil temperature, high temperature-control property and precision, simple and convenient operation process, non-steam entering the crude oil and non-impact on crude oil quality.

Owner:BAOSTEEL ENG & TECH GRP

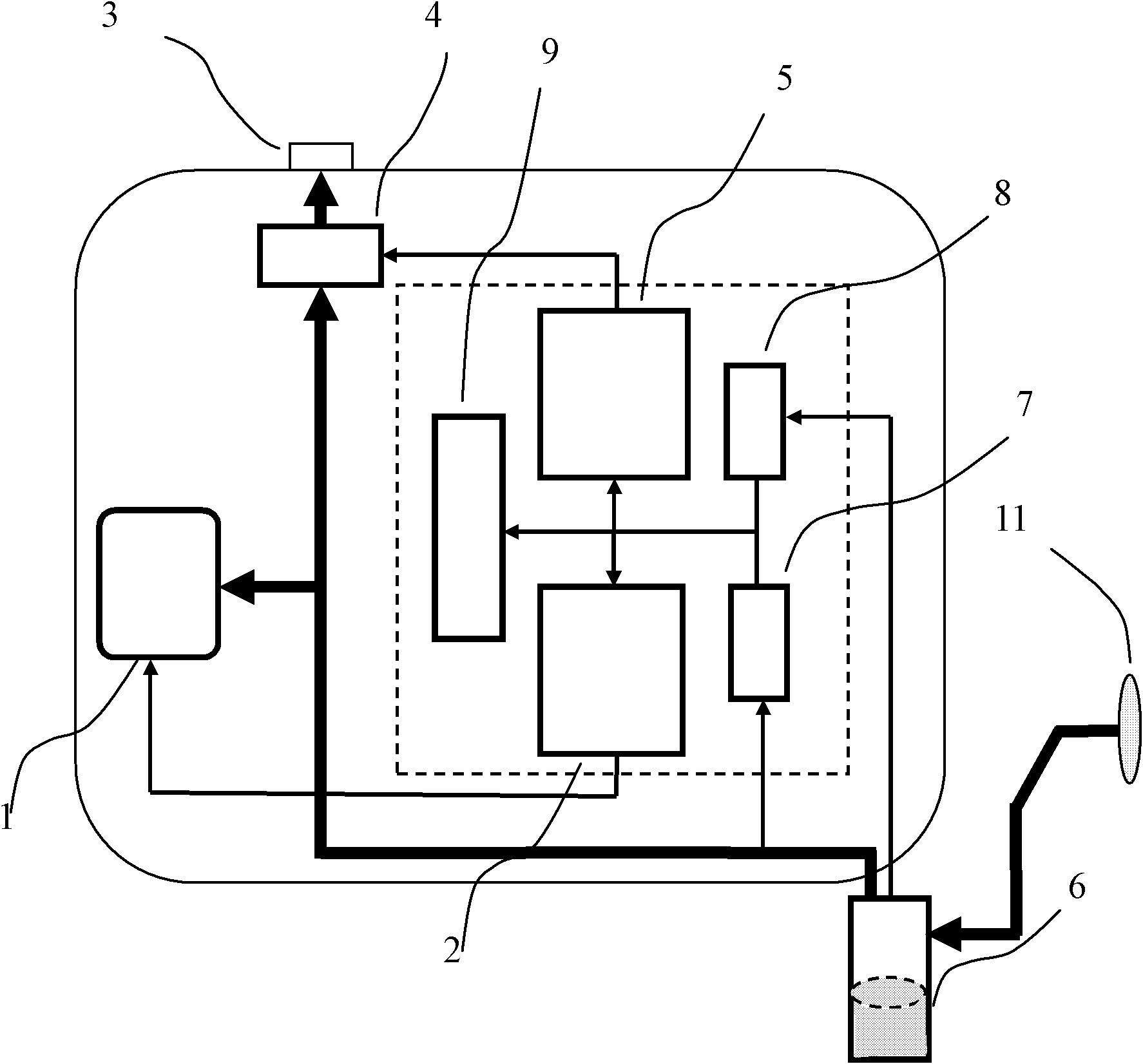

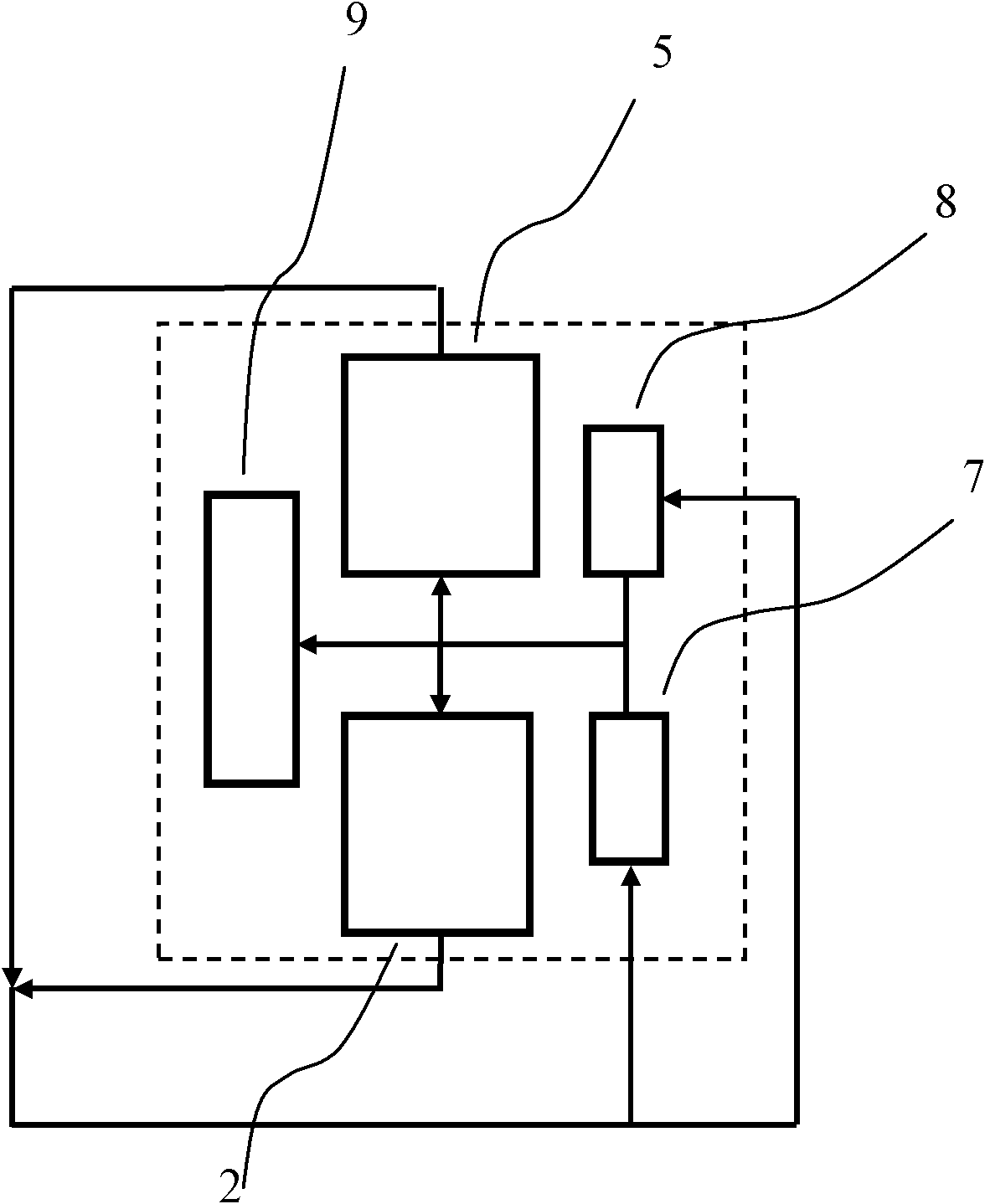

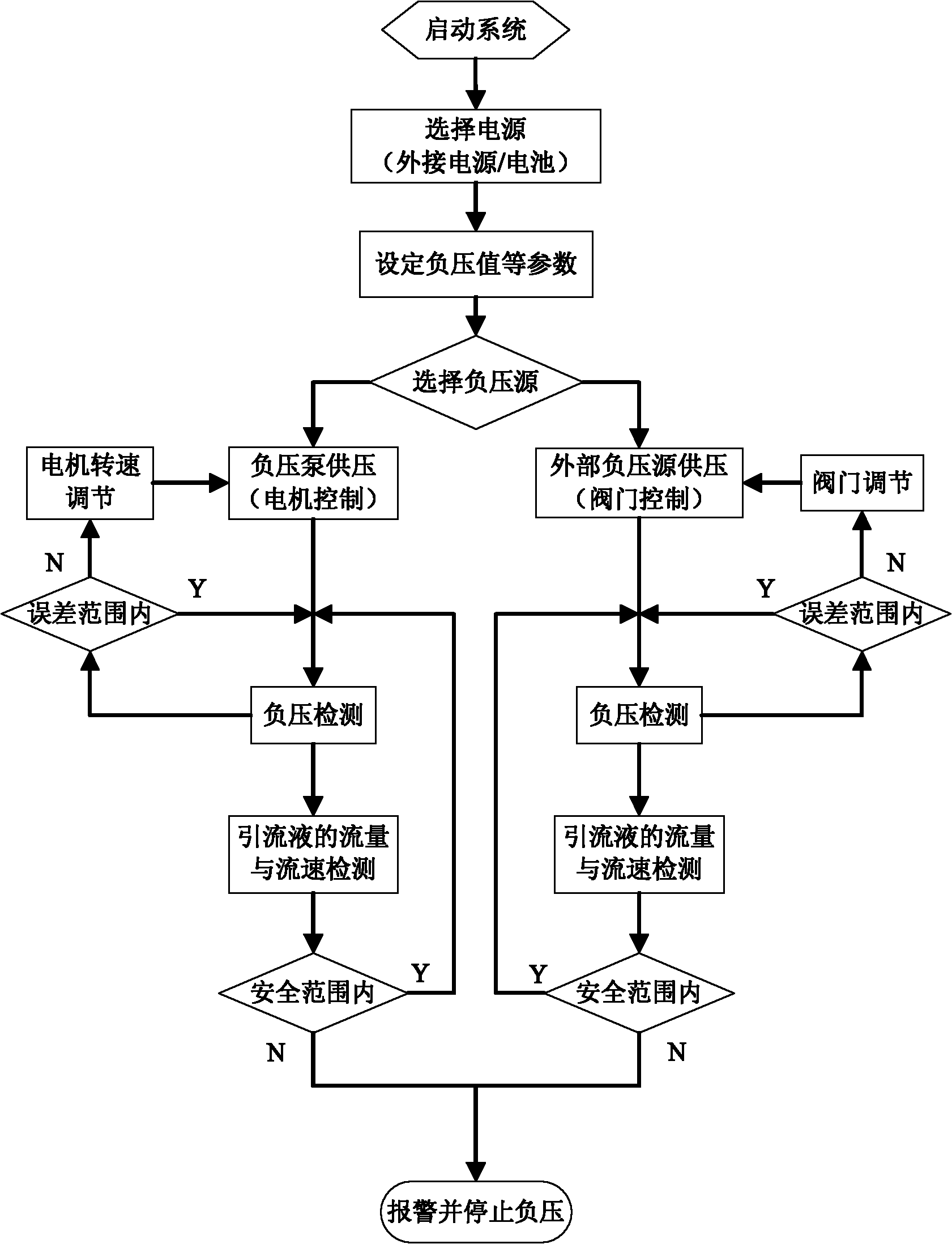

Dual negative pressure adjustable wound negative pressure therapy device based on microprocessor core

Owner:BEIHANG UNIV

Ultrasonic continuous sterilization device and method thereof

The invention provides an ultrasonic continuous sterilization device, comprising a raw material tank, a heating device, a heat exchanging device, an ultrasonic processing device, a liquid storage device and a controller. The heating device is connected with the heat exchanging device. The raw material tank, the heat exchanging device, the ultrasonic processing device and the liquid storage device are sequentially connected through pipelines. The controller is respectively connected with the heating device, the heat exchanging device, the ultrasonic processing device and control valves on the pipelines. The ultrasonic processing device comprises an ultrasonic barrel, a plurality of ultrasonic probes, ultrasonic transducers and ultrasonic generators, wherein the ultrasonic transducers and the ultrasonic generators are arranged corresponding to the ultrasonic probes, the ultrasonic generators adopt different frequencies and are all arranged in the controller, and the ultrasonic probes are correspondingly distributed on the periphery of the ultrasonic barrel in a stagered junction mode. The invention also provides a method realized by the devices, i.e. feed liquid is firstly heated by the heat exchanging device, and then dynamic and continuous ultrasonic sterilization processing is carried out by the ultrasonic processing device. The invention adopts the technology combining low-temperature heating and ultrasonic processing, and has the advantages of good sterilization effect, high efficiency and the like.

Owner:SOUTH CHINA UNIV OF TECH

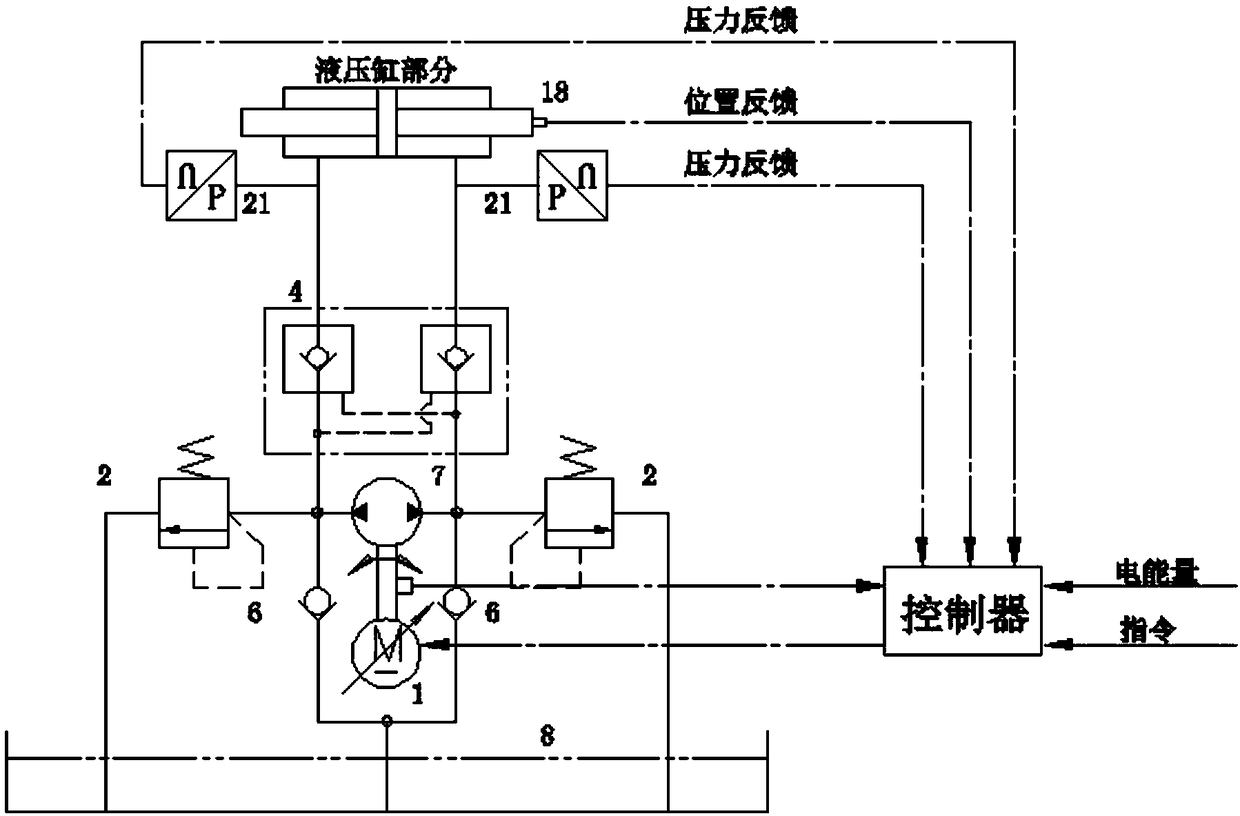

Electric static liquid actuator for deep sea

ActiveCN109340220AHigh level of integrationReduce volumeFluid-pressure actuator componentsHydraulic cylinderElectric machine

Owner:BEIJING UNIV OF TECH

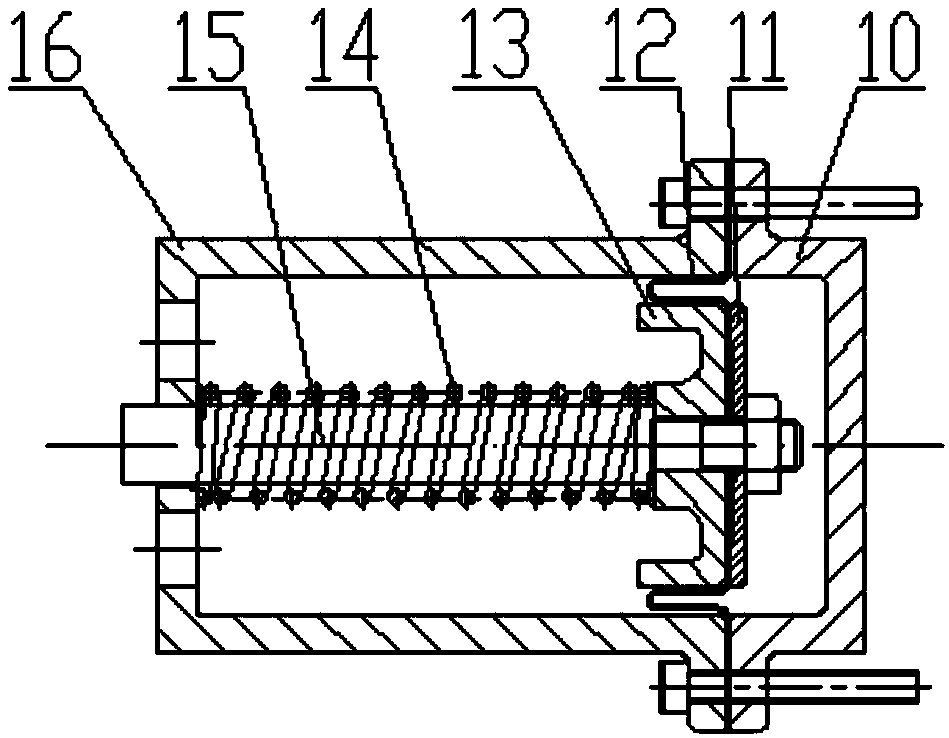

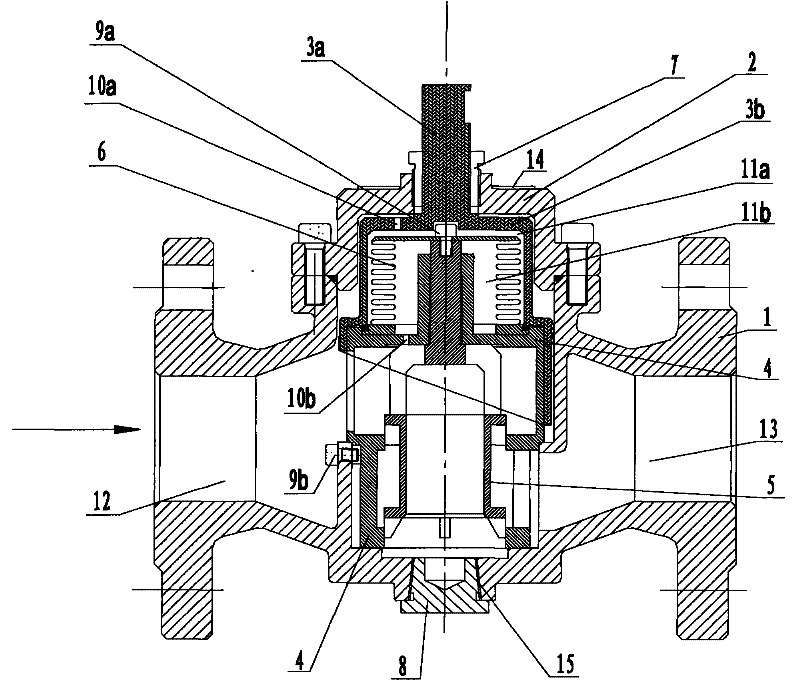

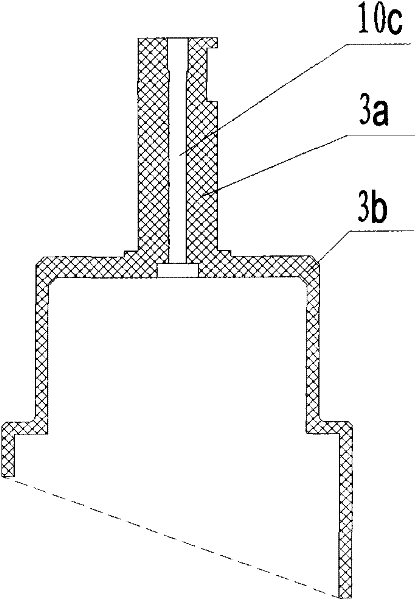

Multi-functional constant flow control valve

InactiveCN102162539ARealize on-site disassemblyRealize online sewageEqualizing valvesSafety valvesAutomatic controlDifferential pressure

Owner:北京天箭星节能技术有限公司 +1

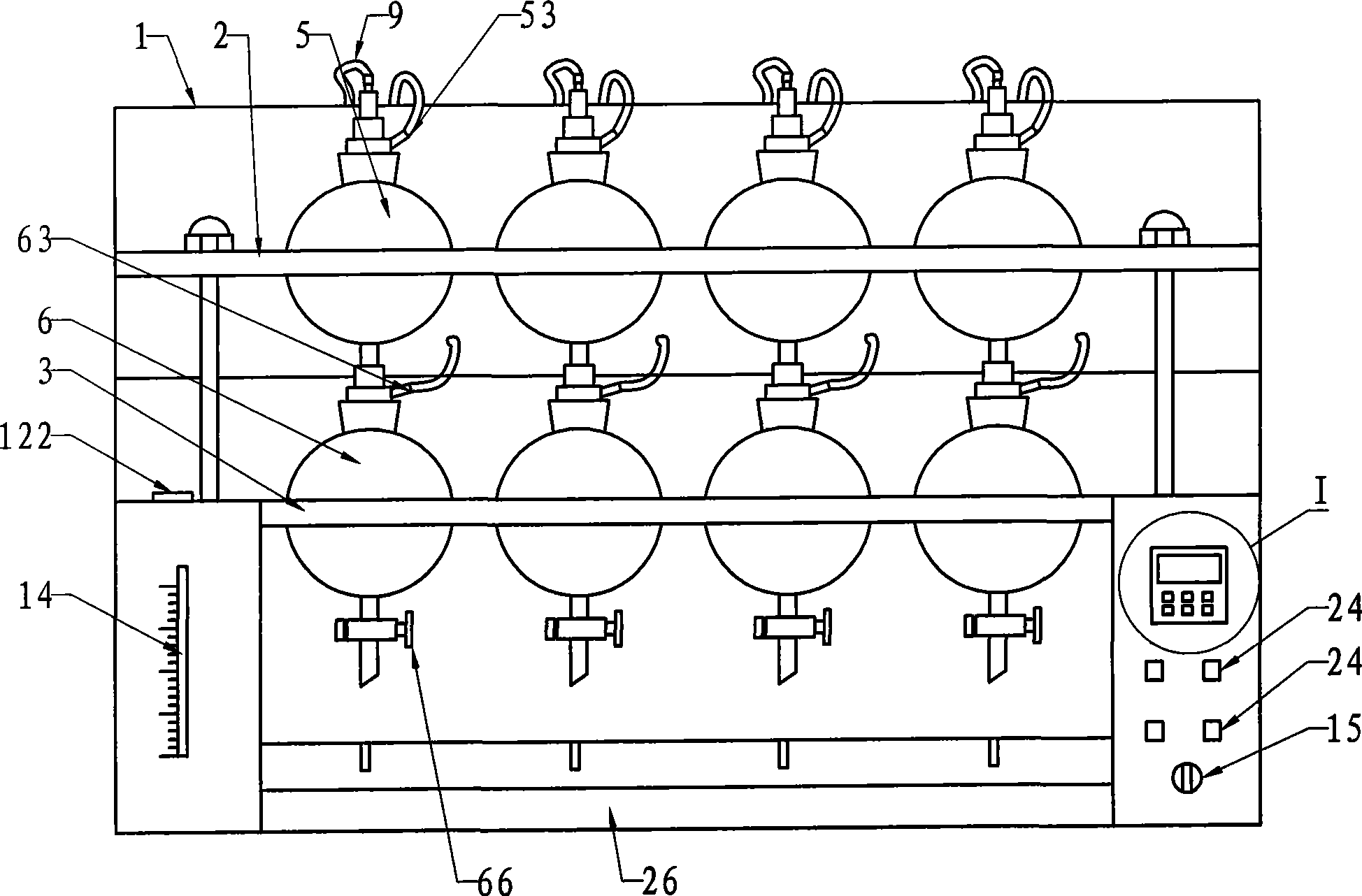

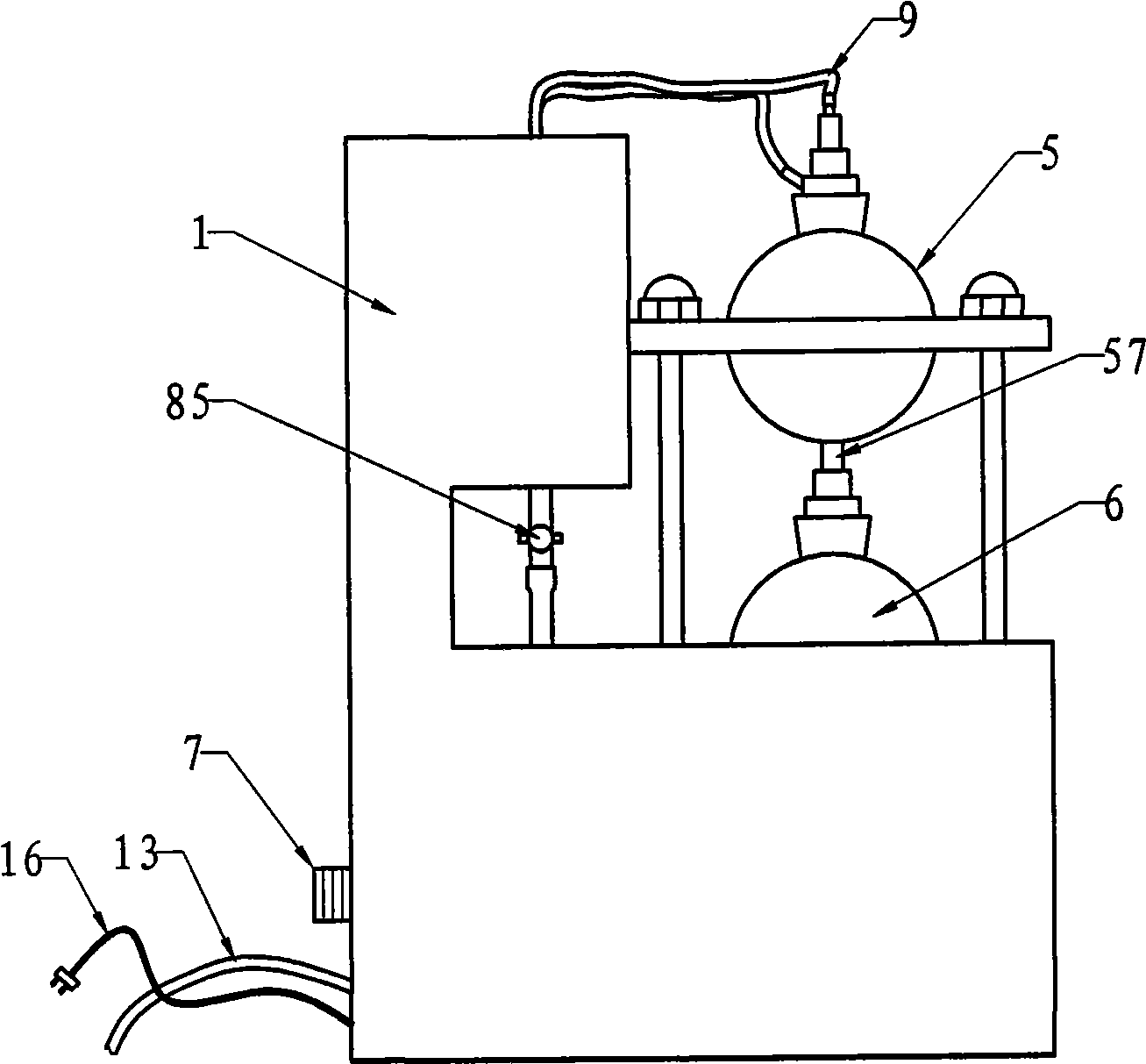

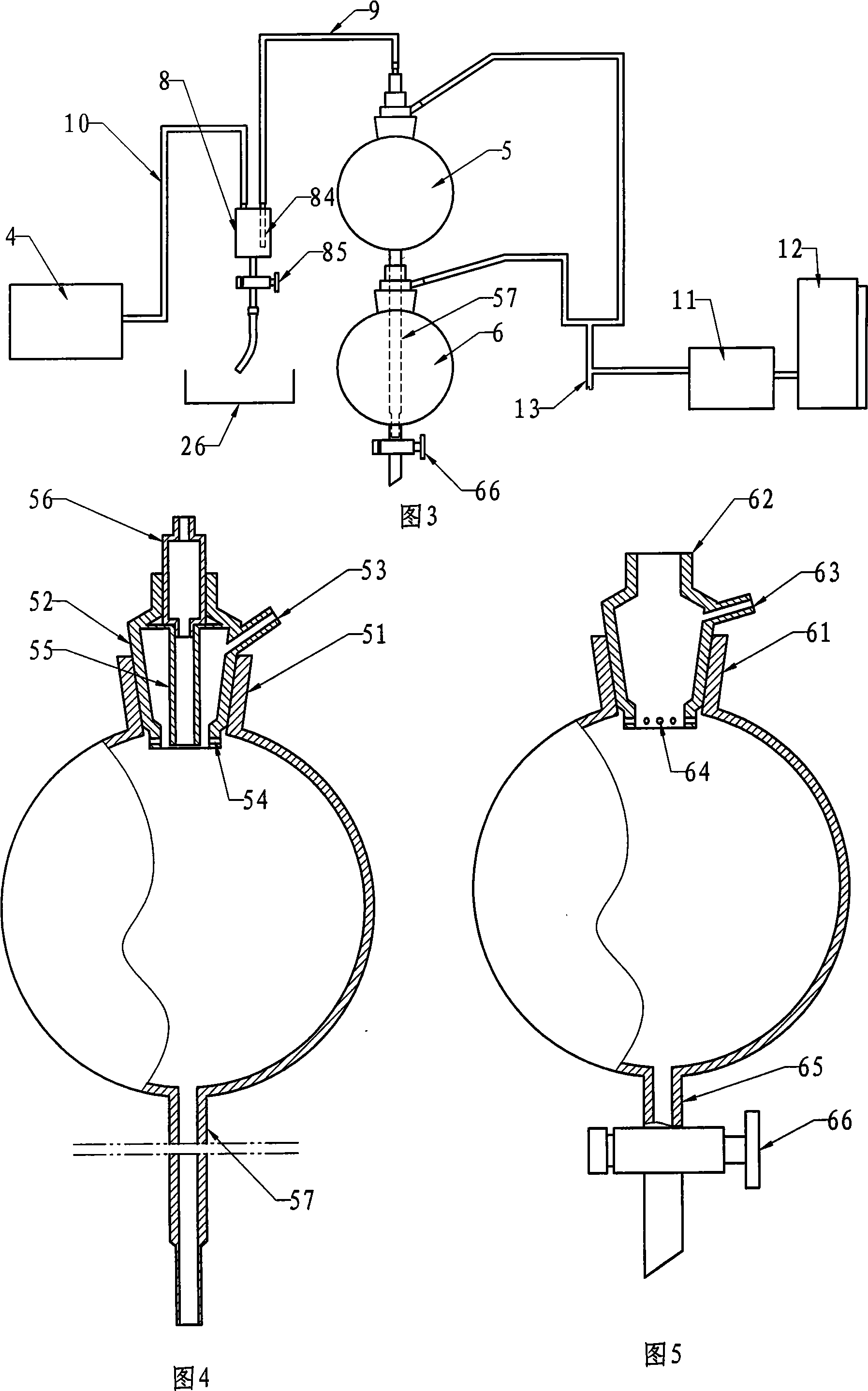

Full automatic extraction device

InactiveCN101530673AWon't inhaleSolvent extractionLaboratory glasswaresControl valvesSeparatory funnel

Owner:段作敏

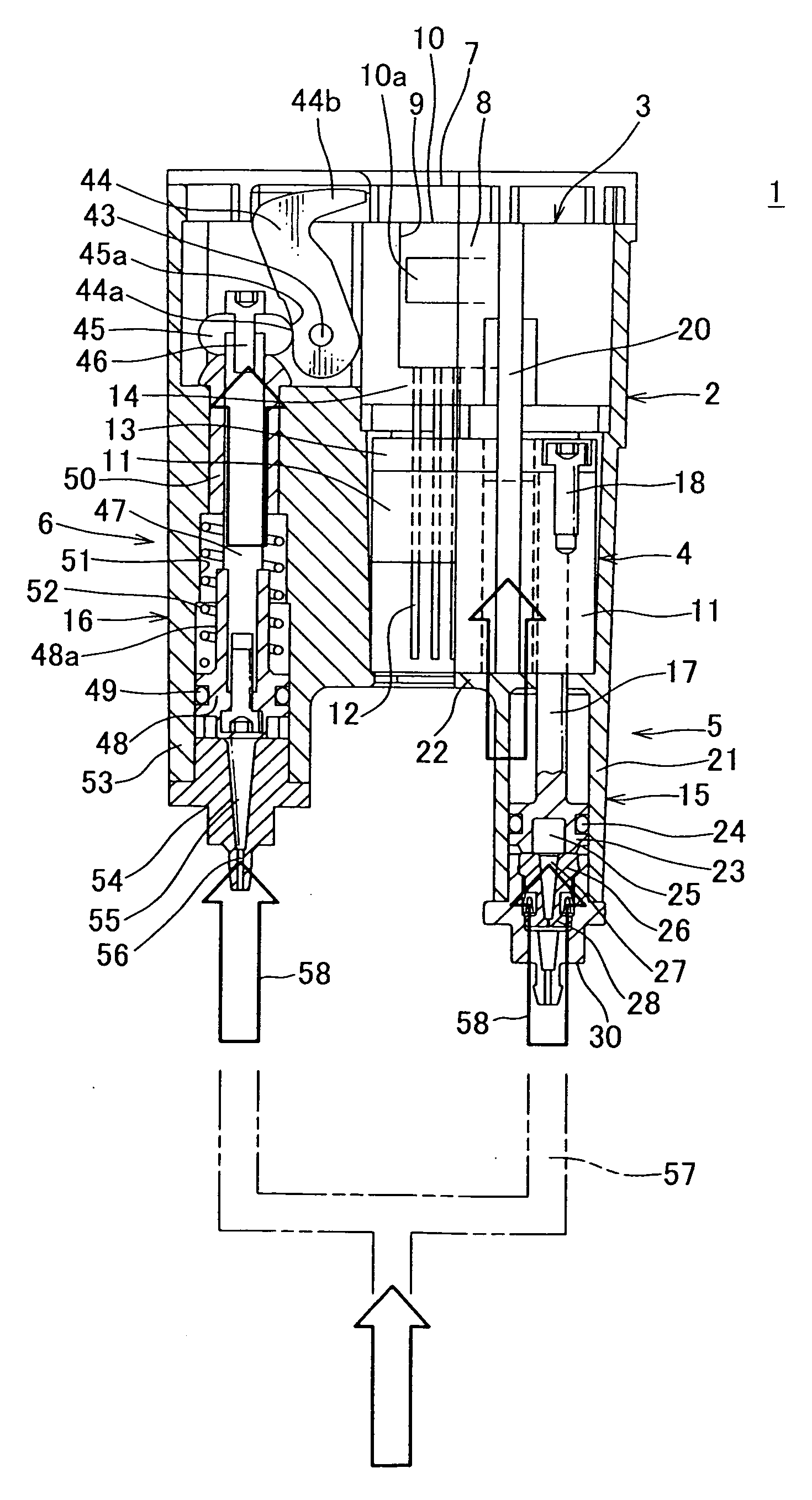

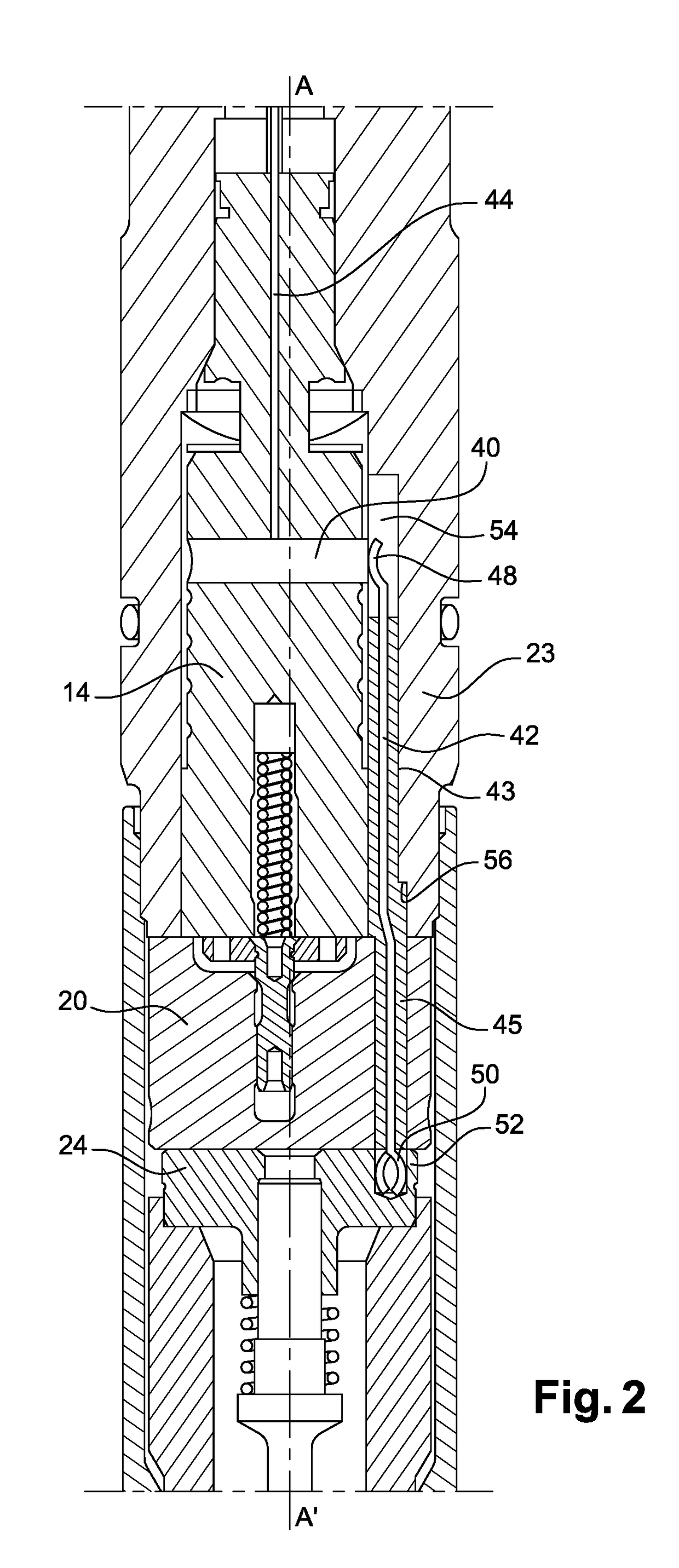

Fuel injection valve

InactiveUS20040069863A1Spray nozzlesFuel injection with piezoelectric/magnetostrictive elementsEngineeringInternal combustion engine

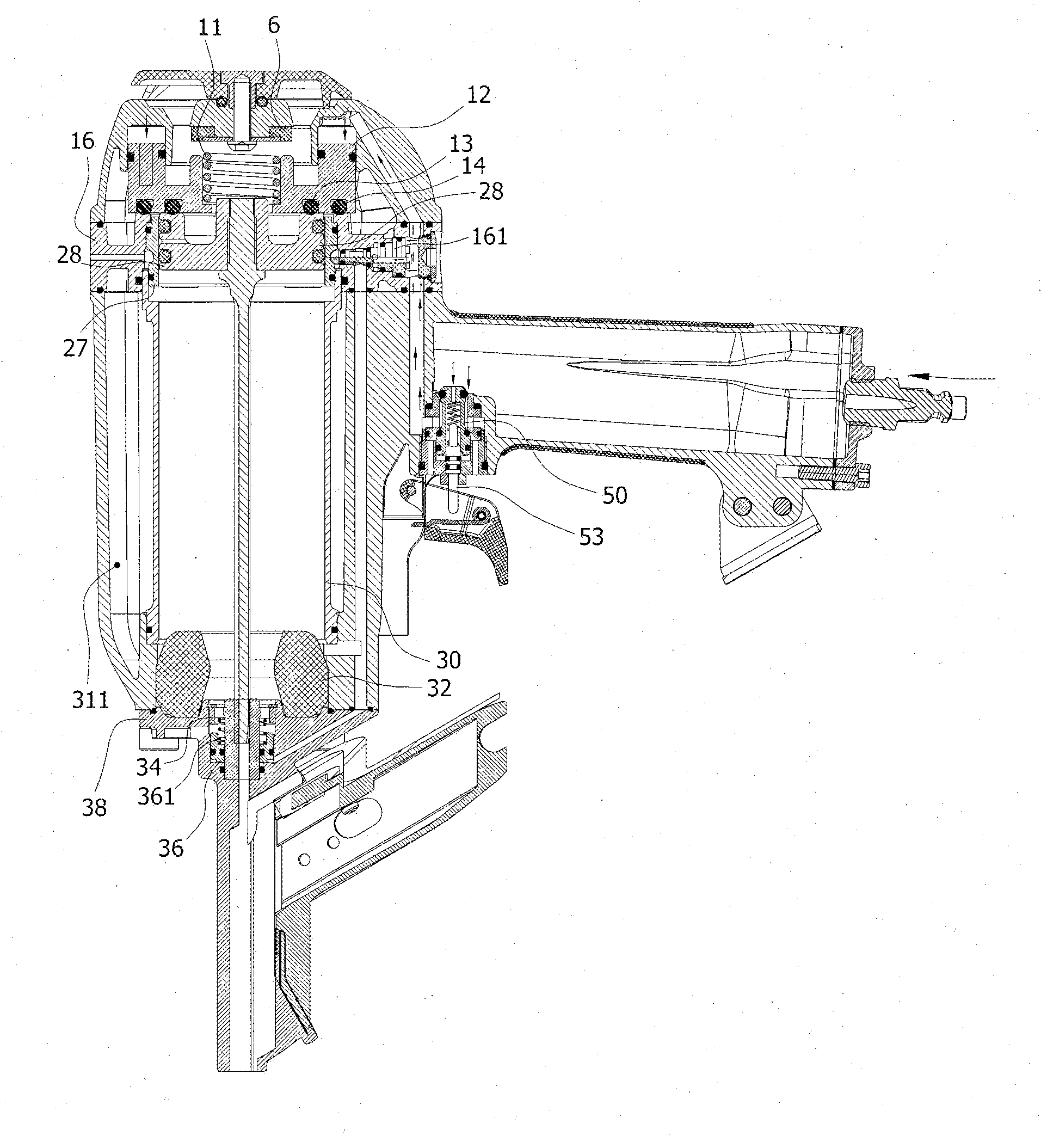

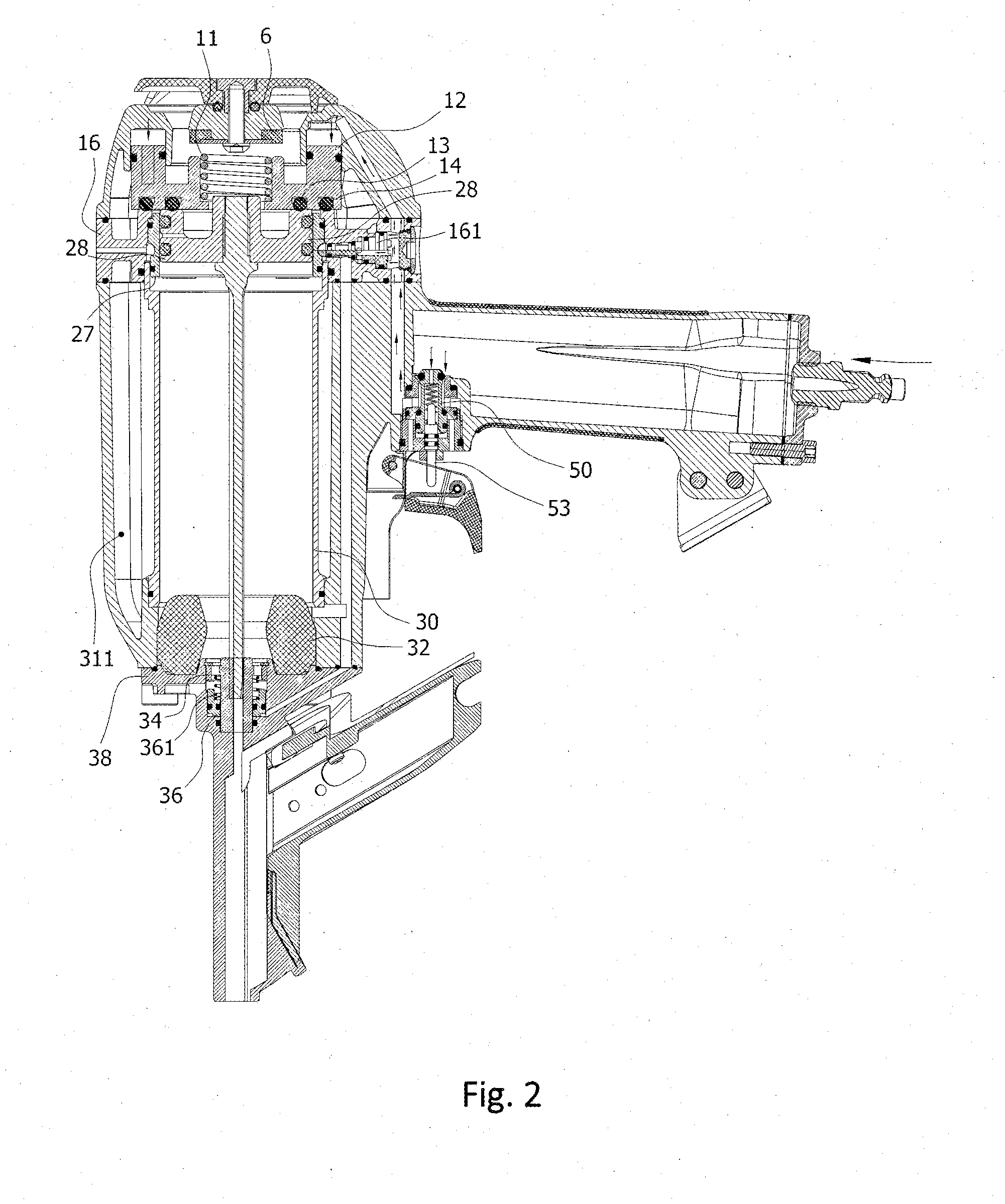

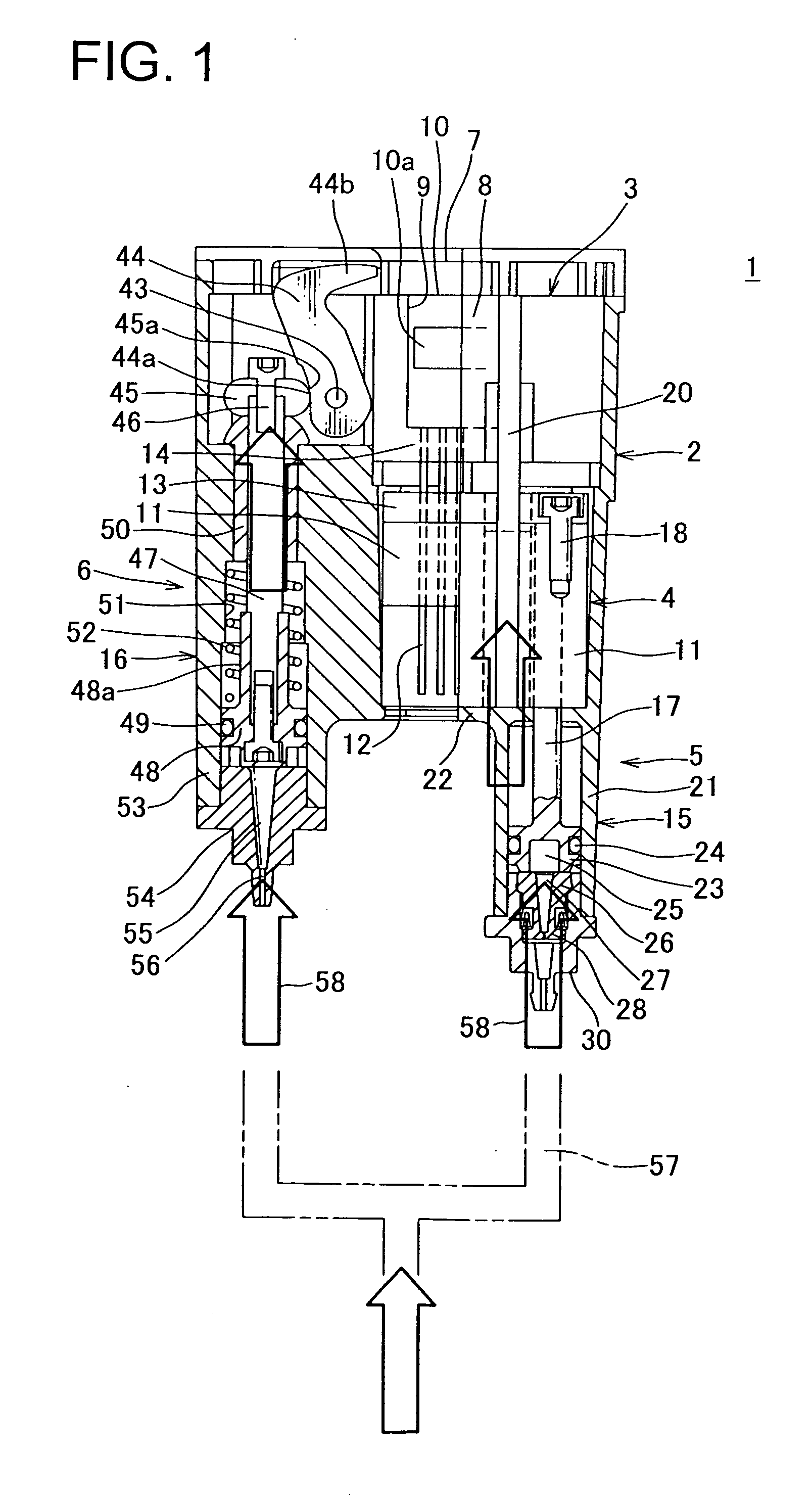

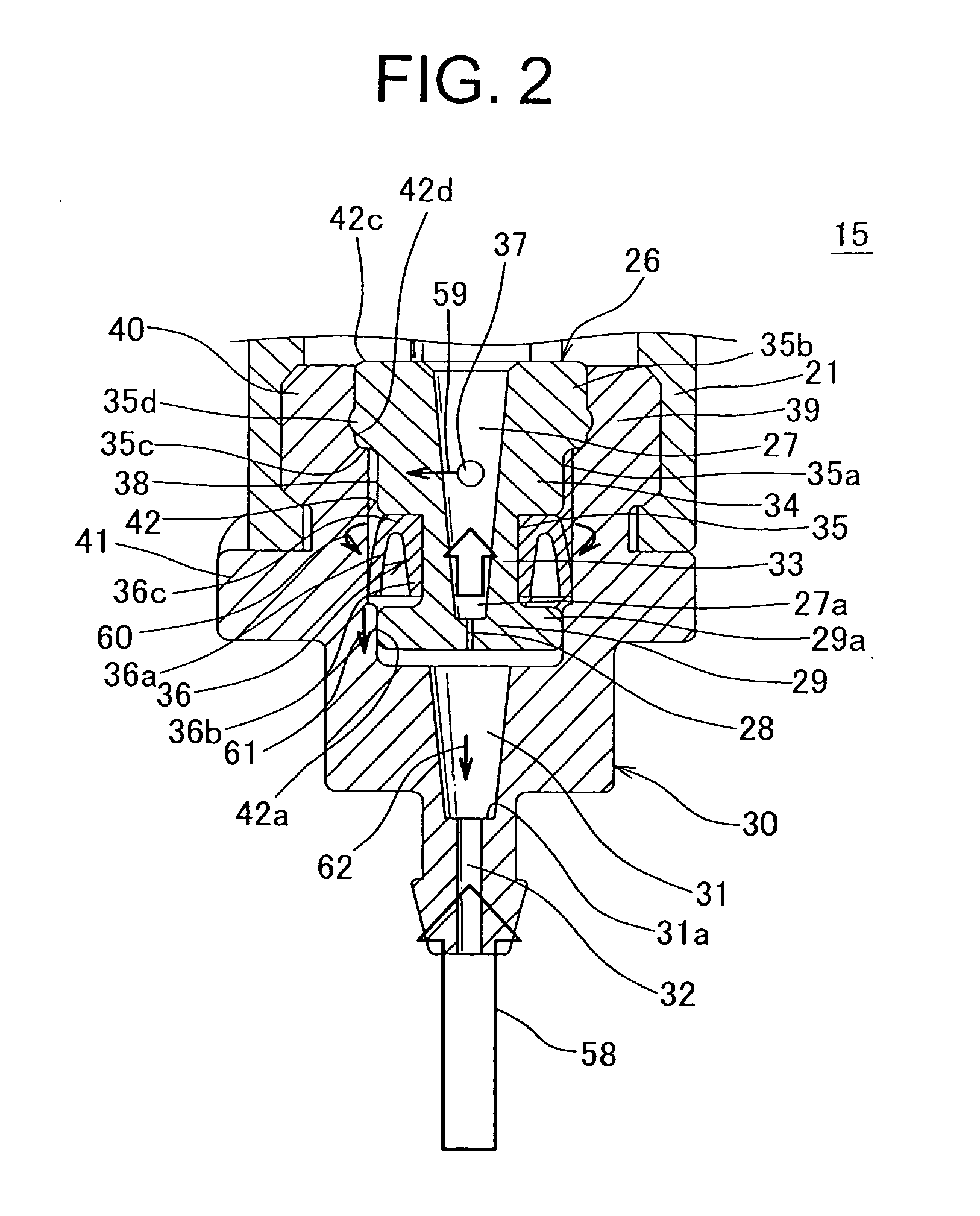

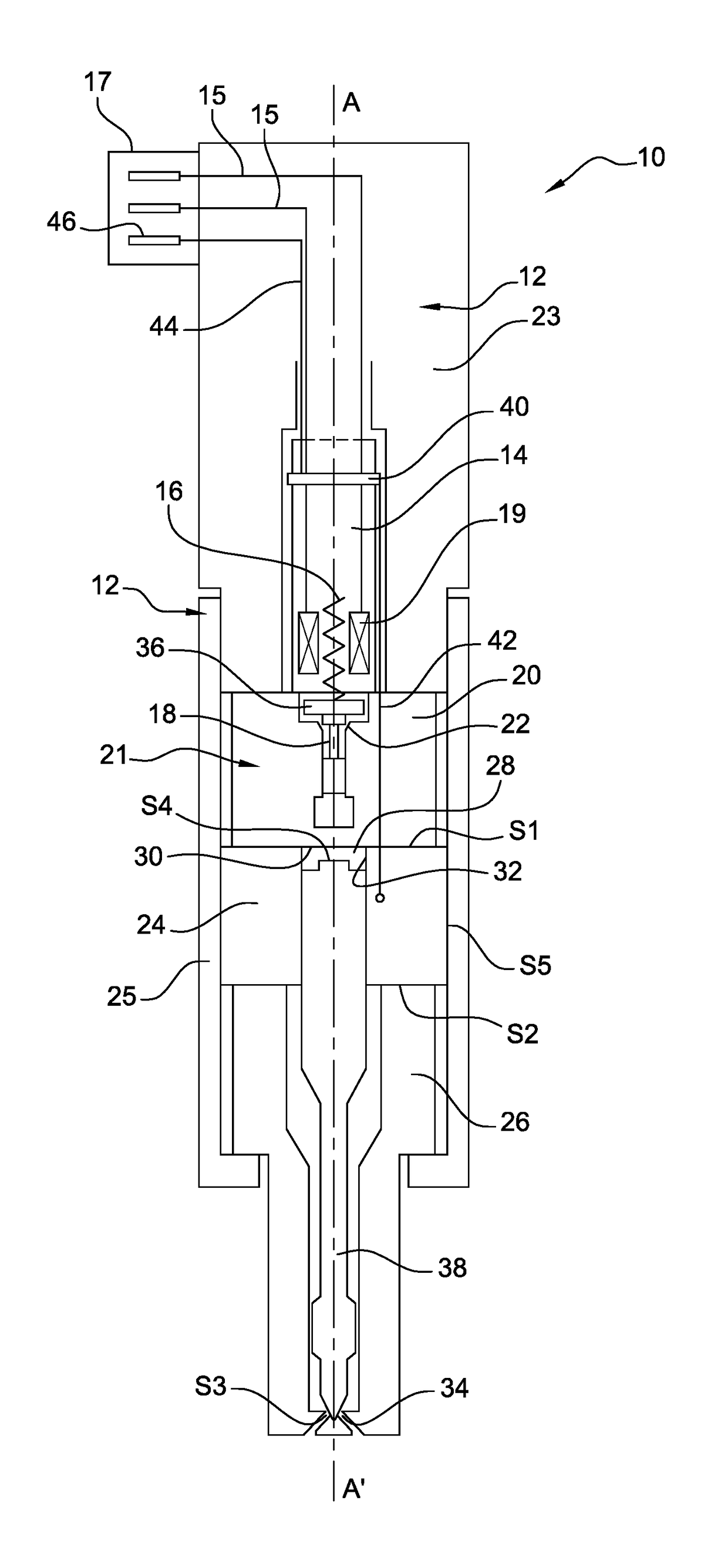

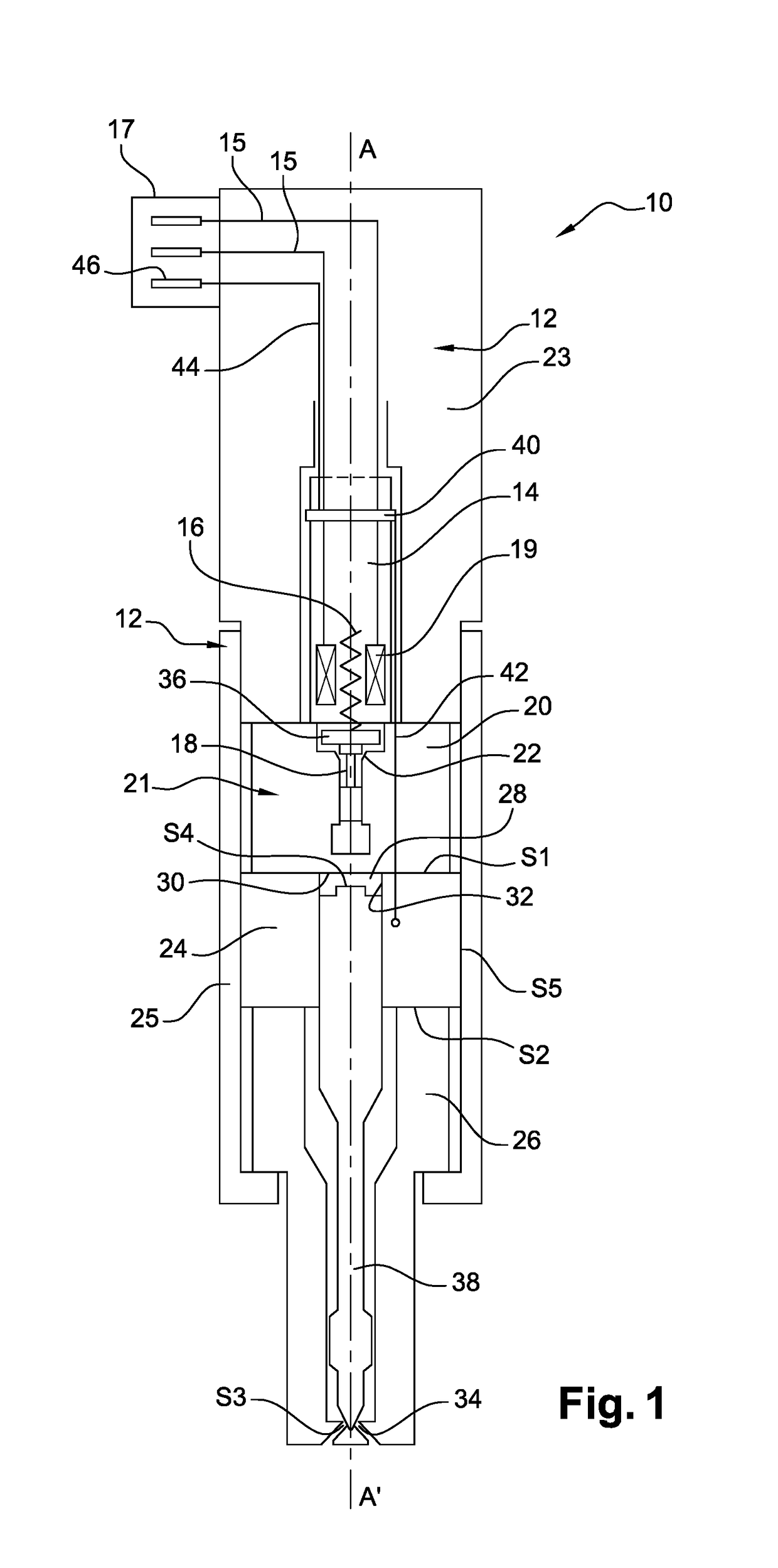

In a fuel injection valve for internal combustion engines, having a valve housing, having an axially movable valve member for opening and closing an injection opening of the injection valve, and having a part, which acts in the closing direction of the valve member, which is guided with its end remote from the injection opening in a bore of a first valve piece inserted into the valve housing and with this end, encloses a control pressure chamber in the first valve piece, which control pressure chamber can be connected to a high-pressure fuel connection via an inlet conduit, which is provided with at least one inlet throttle, and can be connected to a low-pressure fuel connection via an outlet conduit, which has an outlet throttle and can be closed by a movable control valve member, where the injection process can be controlled by means of the fuel pressure in the control pressure chamber, the proposal is made that at least the section of the inlet conduit provided with the inlet throttle be disposed in a second valve piece inserted into the valve housing, which second valve piece is connected to an opening embodied in the first valve piece in such a way that the section of the inlet conduit of the second valve piece provided with the inlet throttle feeds into the control pressure chamber of the first valve piece.

Owner:ROBERT BOSCH GMBH

Method and device for quickly decreasing temperature

InactiveCN106325063ARealize automatic controlFast cooling rateCompression machinesThermometer testing/calibrationAutomatic controlEngineering

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

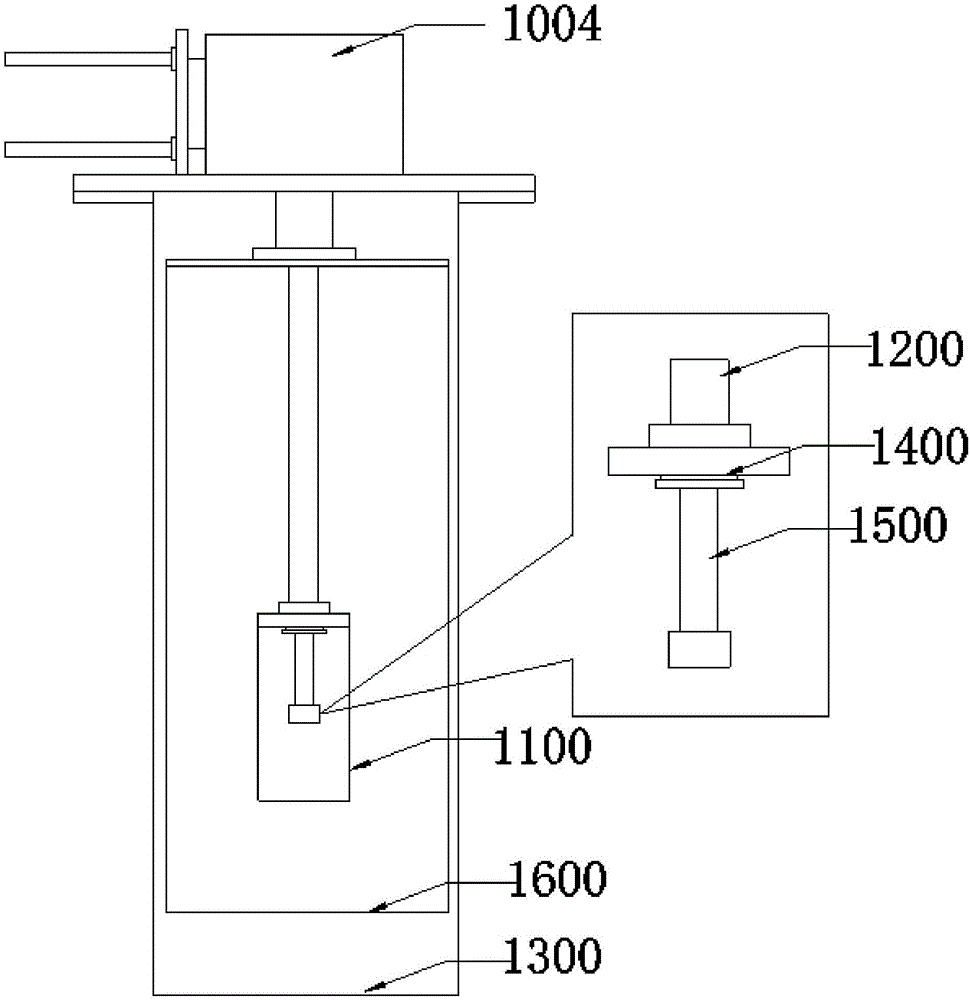

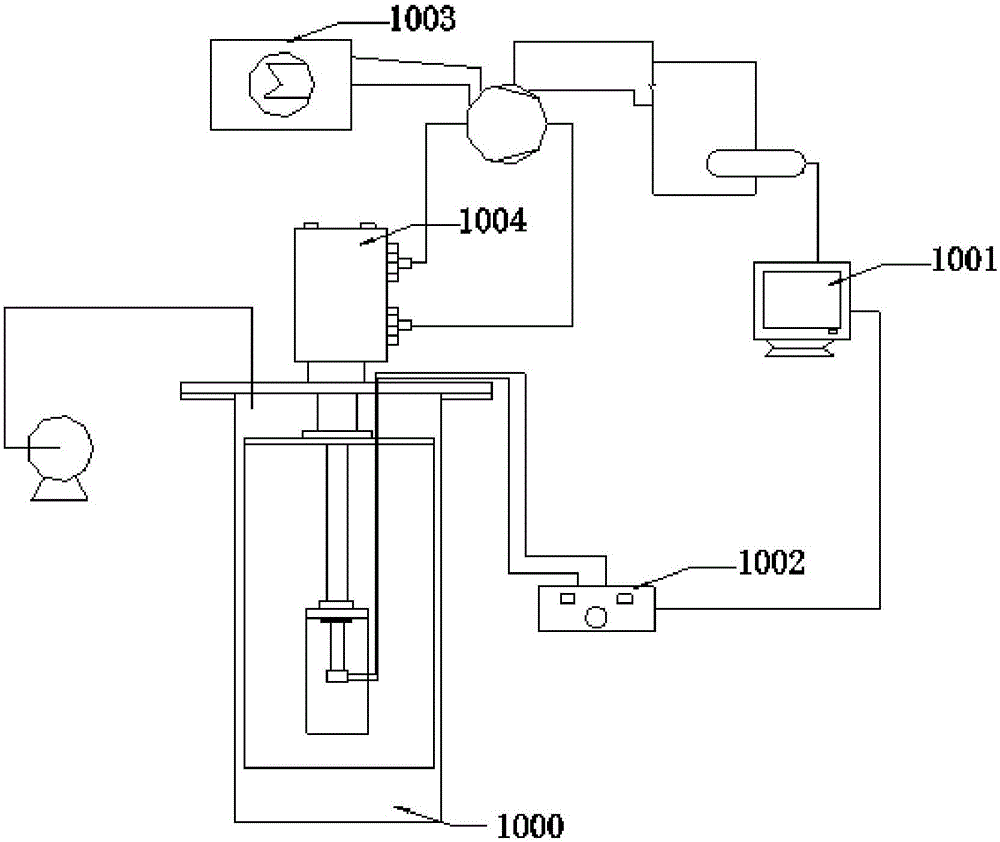

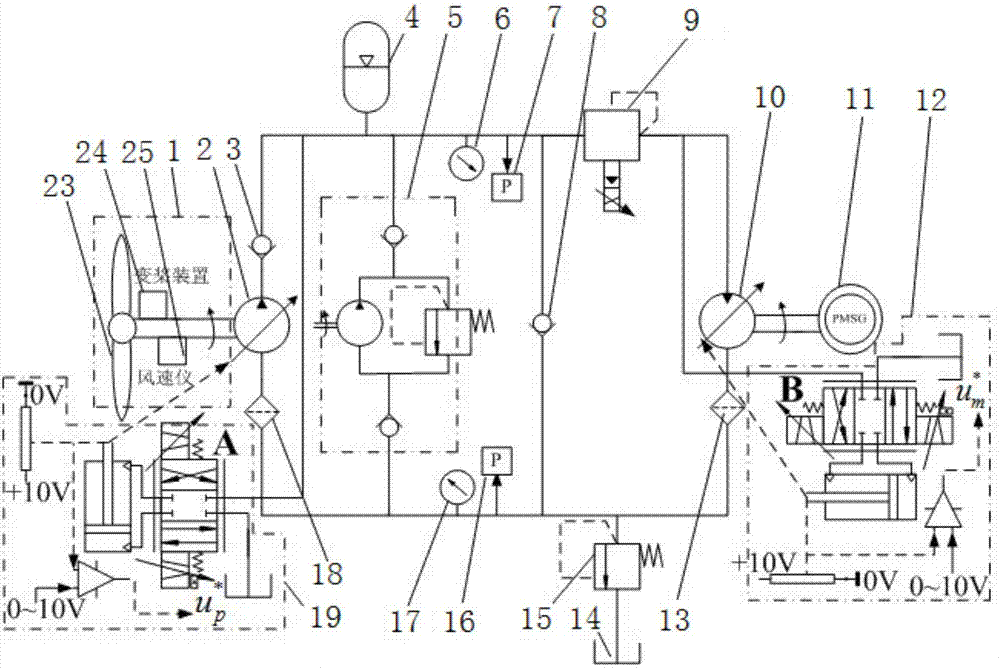

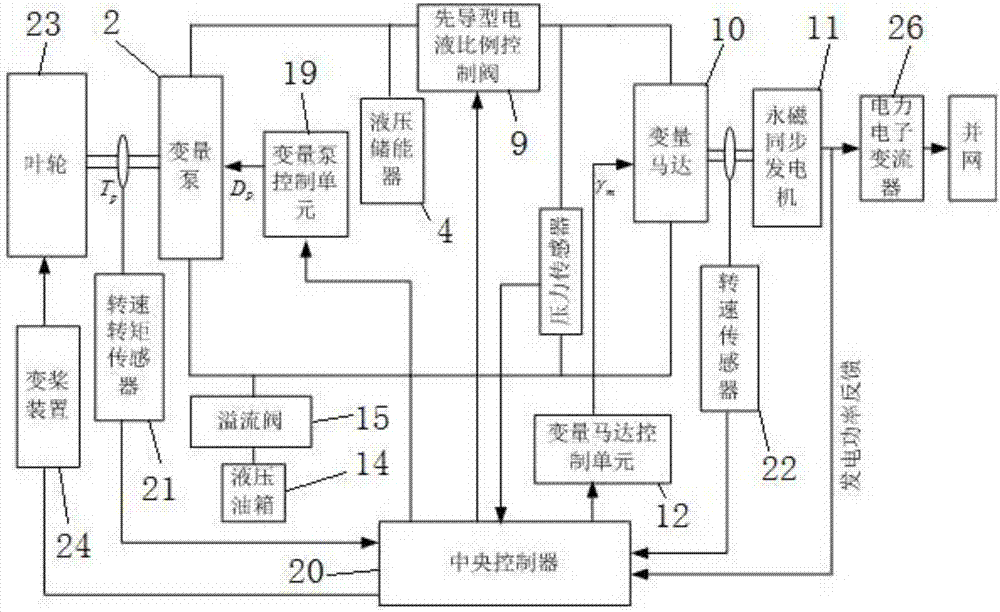

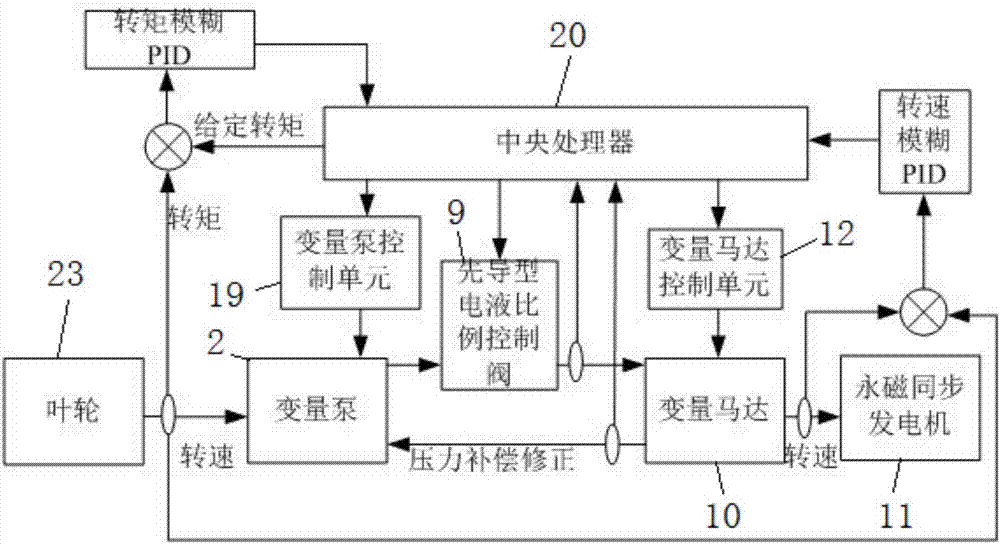

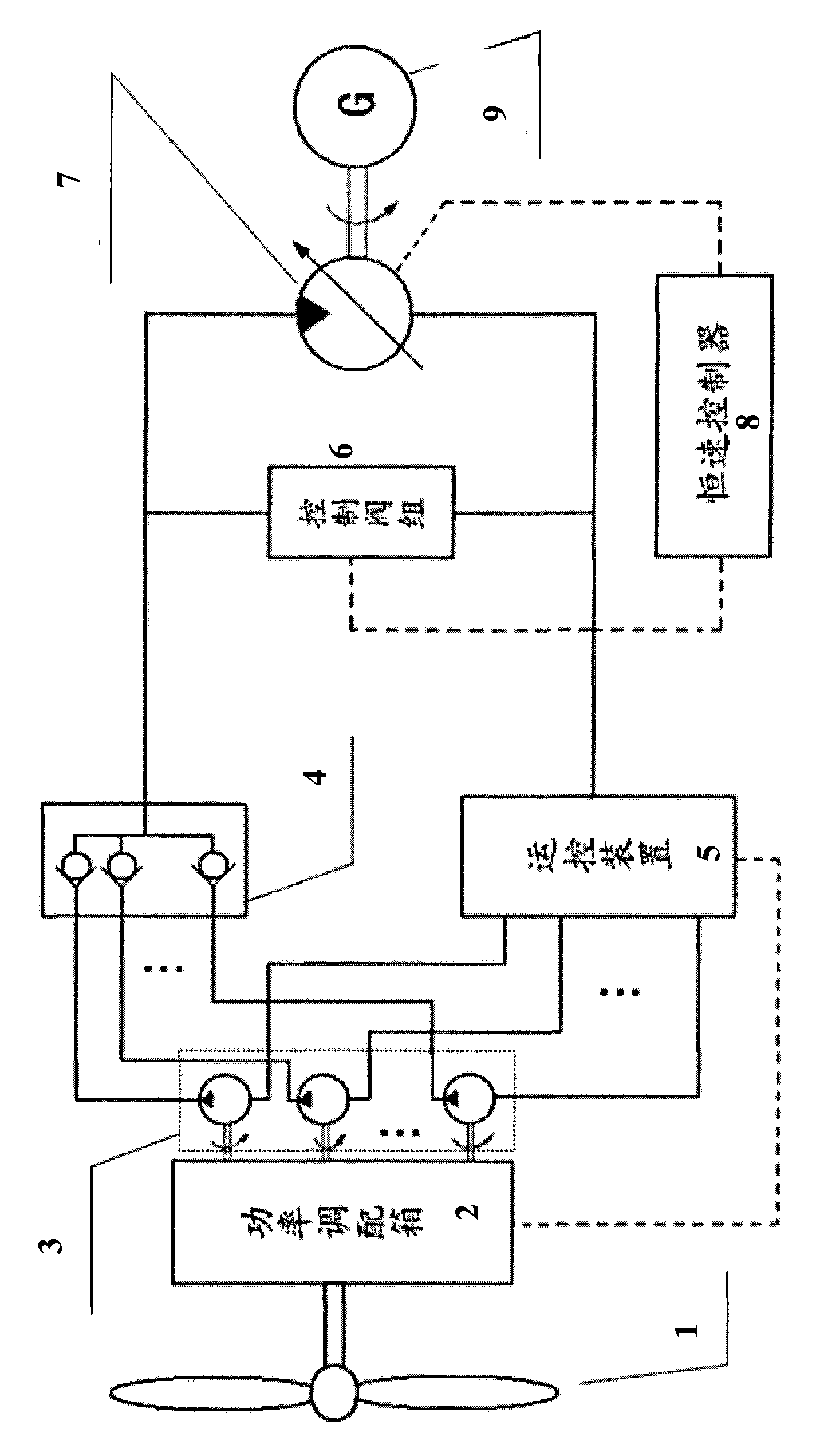

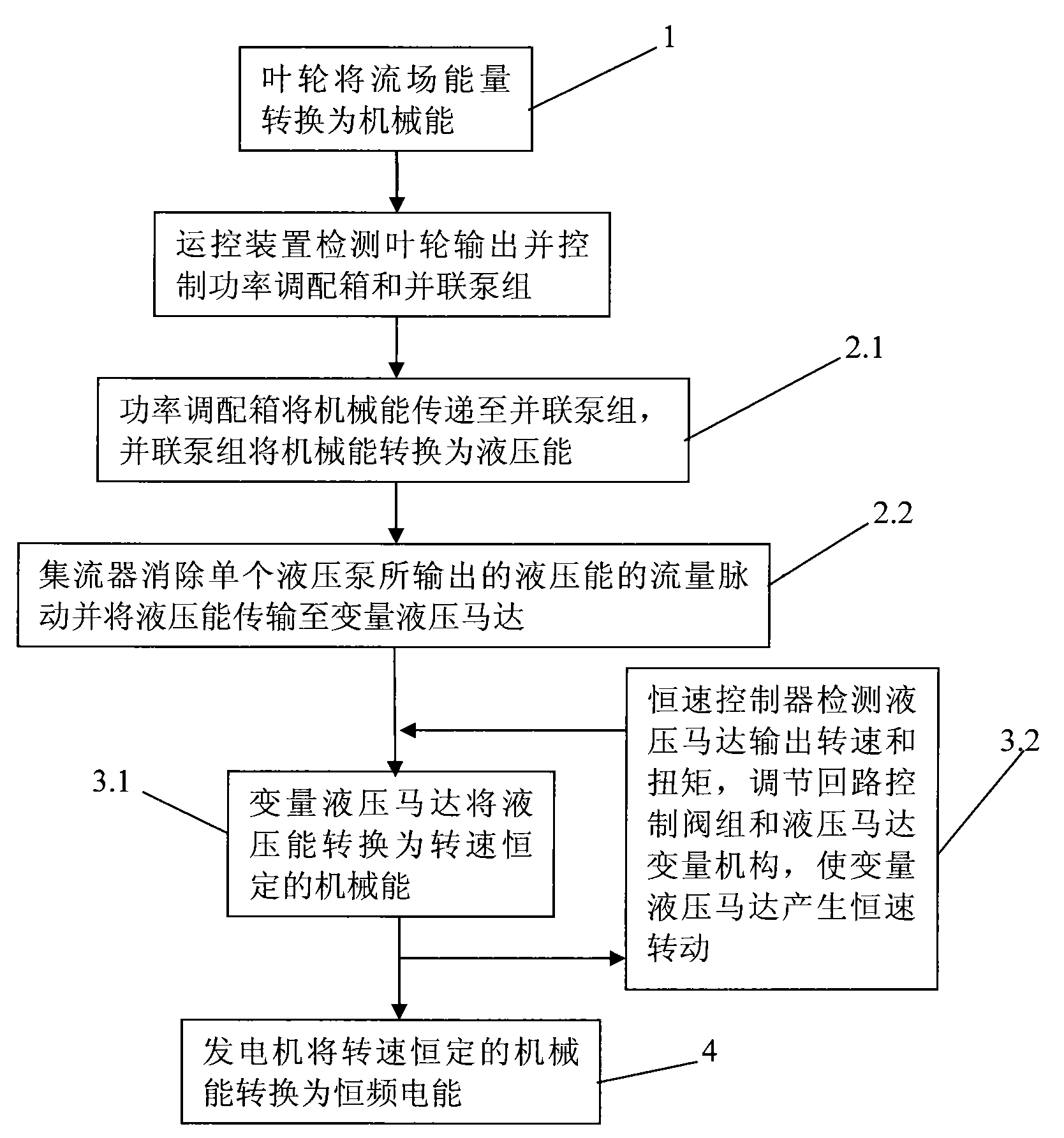

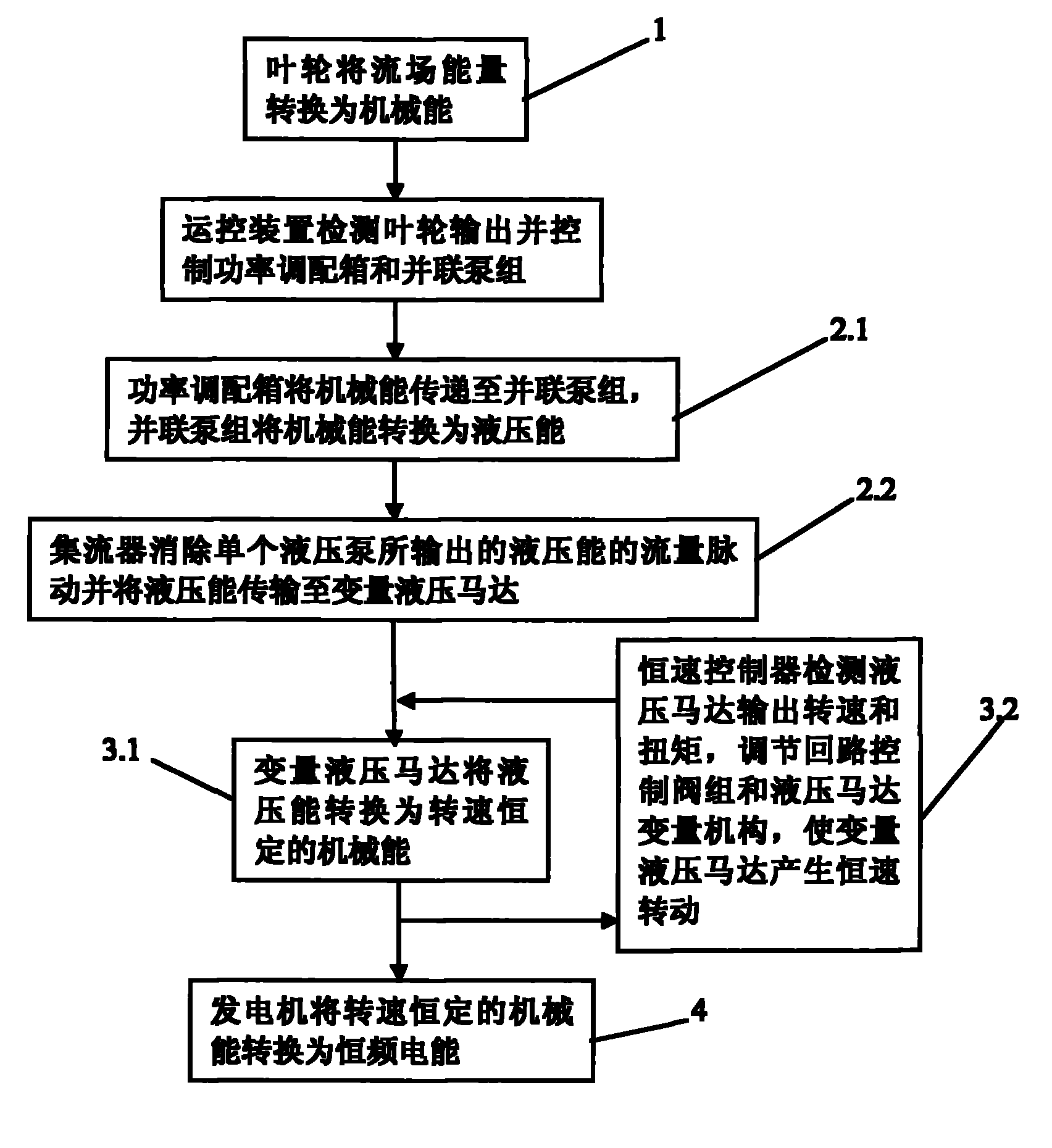

Variable-pitch hydraulic transmission wind turbine and control method thereof

ActiveCN107269466AImprove running qualityRealize variable speed constant frequency controlWind motor controlMachines/enginesProportional controlFuel tank

Owner:XIAN UNIV OF TECH

Ultrahigh-pressure hydrogen electromagnetic valve having pressure relief function and applied to vehicle

PendingCN108278395AExtended service lifeGuaranteed stabilityOperating means/releasing devices for valvesEqualizing valvesHydrogenUltra high pressure

Owner:DANYANG FEILUN GAS VALVE

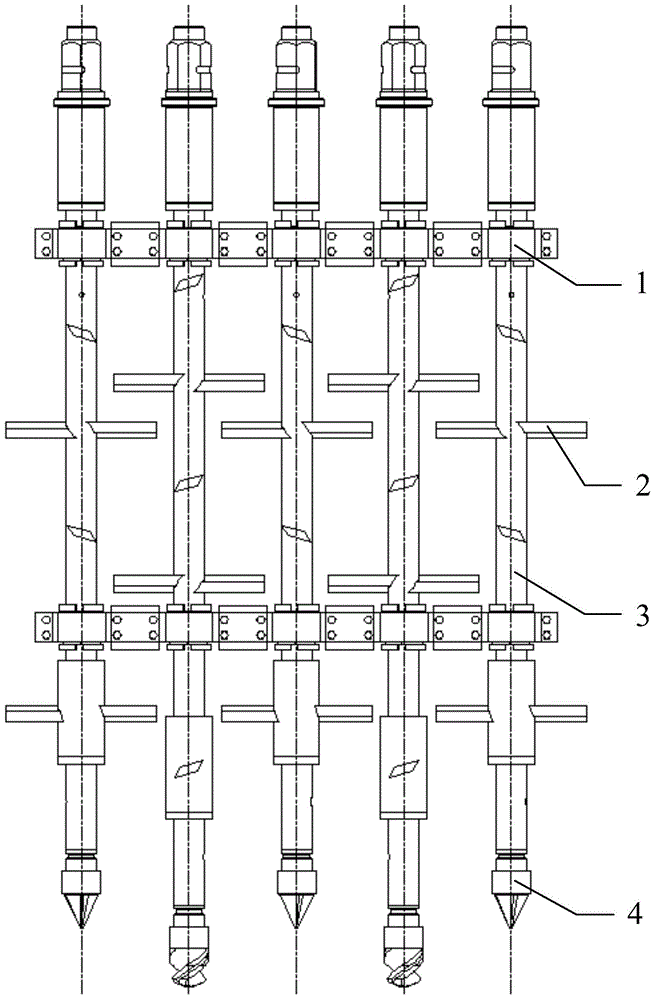

Cement-soil mixing pile device capable of vertically converting for spraying slurry and operation method of cement-soil mixing pile device

InactiveCN104563124AImprove mixing uniformityShorten the mixing timeBulkheads/pilesSoil mixingEngineering

Owner:SHANGHAI CHENGDI CONSTR +1

Hydrogen production device and hydrogenation system

PendingCN110589759ASimple structureEasy constructionVessel geometry/arrangement/sizeGas handling/storage effectsWater storage tankAgricultural engineering

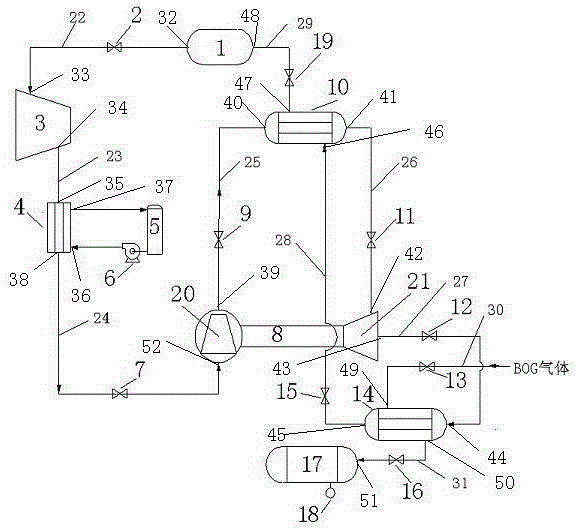

The invention provides a hydrogen production device and a hydrogenation system and belongs to the field of hydrogenation equipment. The hydrogen production device comprises a water storage tank and areaction tank, wherein the reaction tank is internally provided with a hydrogen production material; the upper part of the water storage tank communicates with the upper part of the reaction tank through a gas tube; a control valve is arranged on the gas tube; the lower part of the water storage tank communicates with the lower part of the reaction tank through a water tube; and when the control valve is opened, water in the water storage tank is fed into the reaction tank through the water tube. The hydrogenation system adopts the hydrogen production device and is simple in overall structureand convenient in construction, and development of a hydrogen energy terminal can be greatly promoted.

Owner:HENAN CHINA HYDROGEN POWER RES INST CO LTD

Full-automatic cutting fluid magnetic filter device

PendingCN108262158AImprove adsorption capacityAdsorption fineCleaning using toolsMagnetic separationFiltrationEngineering

The invention discloses a full-automatic cutting fluid magnetic filter device. The full-automatic cutting fluid magnetic filter device comprises a filter cylinder. A water inlet is formed in one sideof the filter cylinder, and a water outlet is formed in the other side of the filter cylinder. A scrap outlet is formed in the lower end of the filter cylinder. The filter cylinder is internally provided with a powerful magnetic bar connected with an air cylinder, and the air cylinder is located at the upper portion of the filter cylinder. The water inlet, the water outlet and the scrap outlet areprovided with control valves correspondingly. According to the provided full-automatic cutting fluid magnetic filter device, cutting fluid filtration is convenient and fast, full automation is achieved, and the labor cost is reduced.

Owner:ZHONGSHAN MLTOR CNC TECH CO LTD

Gas exchange valve arrangement

Owner:WARTSILA FINLAND OY

Waste collecting and cleaning device and method for tire rubber workshop

ActiveCN103706235AReduce suction volumeImprove collection effectDispersed particle separationMultistage water/sewage treatmentWater treatment systemControl valves

The invention relates to a waste collecting and cleaning device and method for a tire rubber workshop. The device comprises at least one vulcanizing machine induced draft device, control valves, waste gas treatment equipment and a water treatment system, wherein one end of each vulcanizing machine induced draft device is opposite to a vulcanizing machine at a horizontal angle of 45 degrees; each vulcanizing machine induced draft device is linked with a vulcanizing machine die through the corresponding control valve; the other end of each vulcanizing machine induced draft device is communicated with a main air duct; waste gas in the main air duct is introduced into the waste gas treatment equipment through a fan; a wastewater discharge opening of the waste gas treatment equipment is connected with the water treatment system; wastewater is recycled after being treated. According to the device and the method, the collection and treatment of the waste gas, treatment equipment arrangement, waste gas discharging and product recycling are integrated specially according to the characteristics of the structure of the tire rubber workshop, a production process and the generation of the waste gas, and a complete set of waste gas treatment system specially applied to the tire rubber workshop is formed.

Owner:NEW UNIVERSAL SCI TECH CO LTD

Pneumatic nail gun

ActiveUS20150197001A1Reduce pressure oscillationsImprove efficiencyStapling toolsNailing toolsEngineeringControl valves

Owner:ZHEJIANG RONGPENG AIR TOOLS

Efficient and energy-saving BOG (boil-off gas) recycling device

Owner:JIANGSU AEROSPACE HEWLETT ENVIRONMENTAL PROTECTION TECH

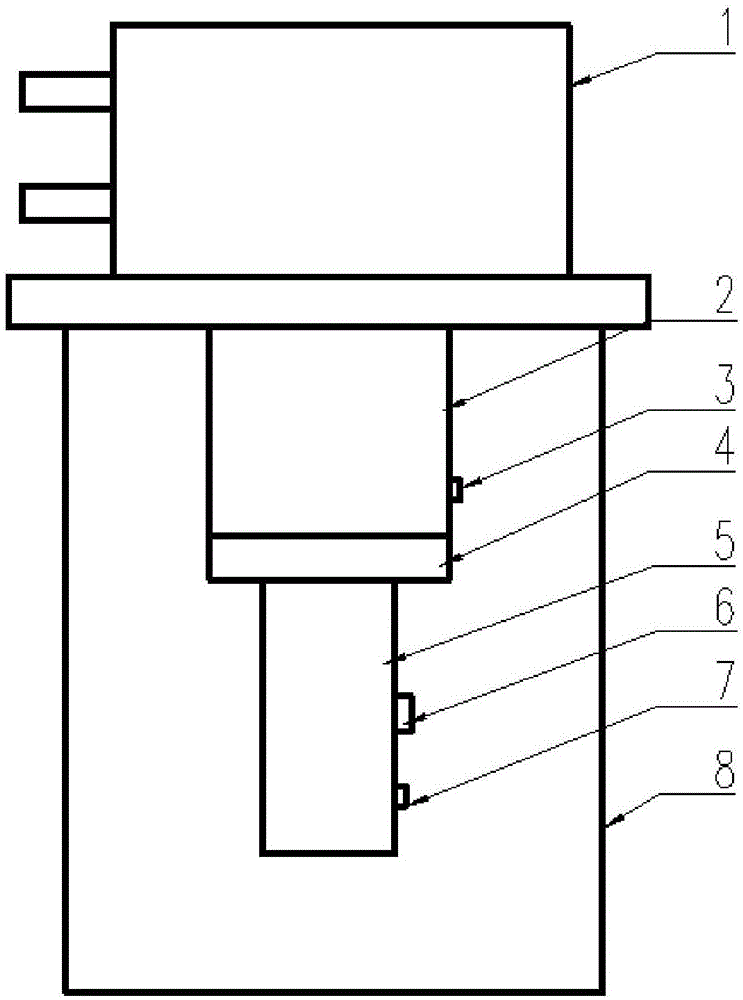

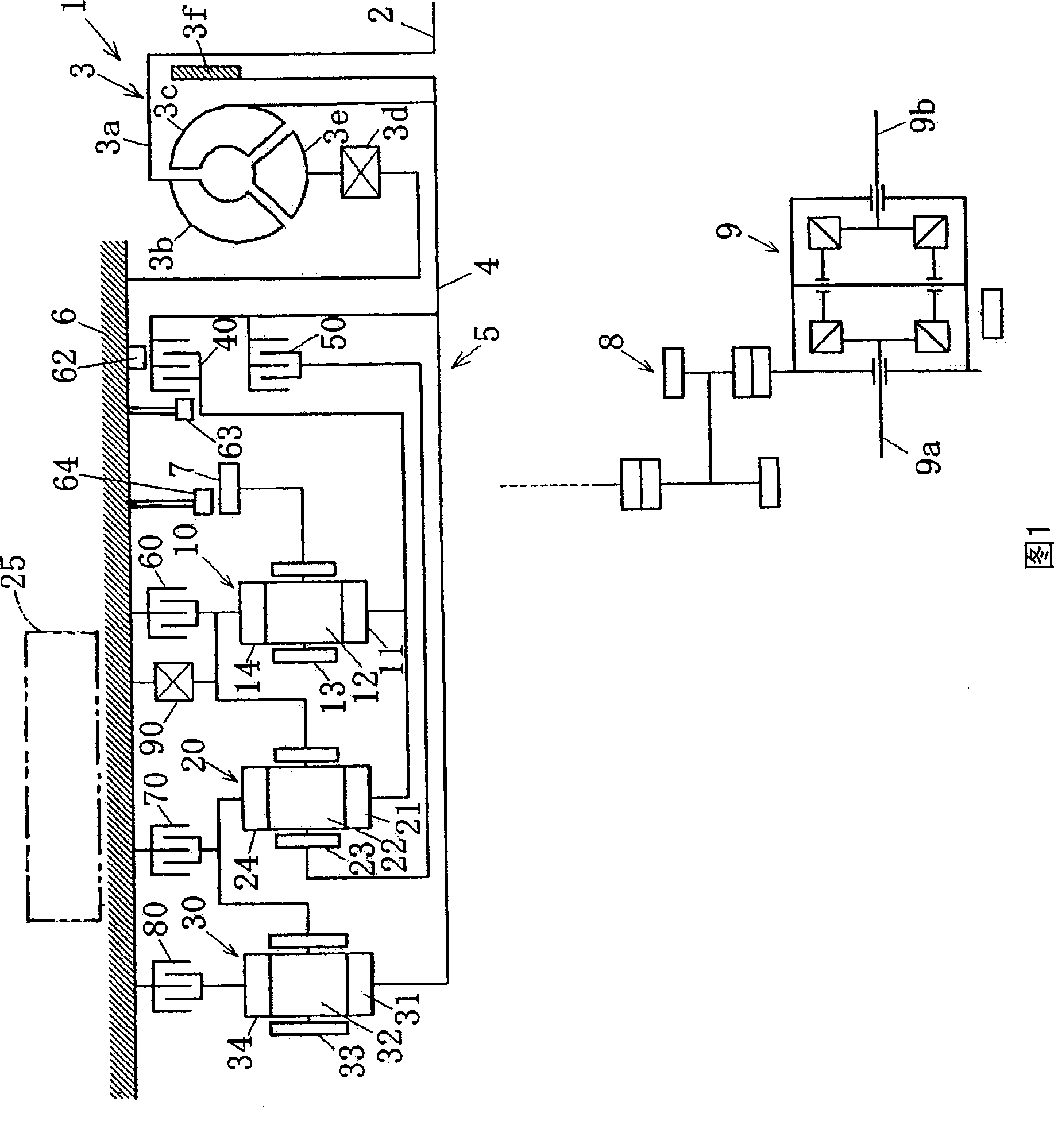

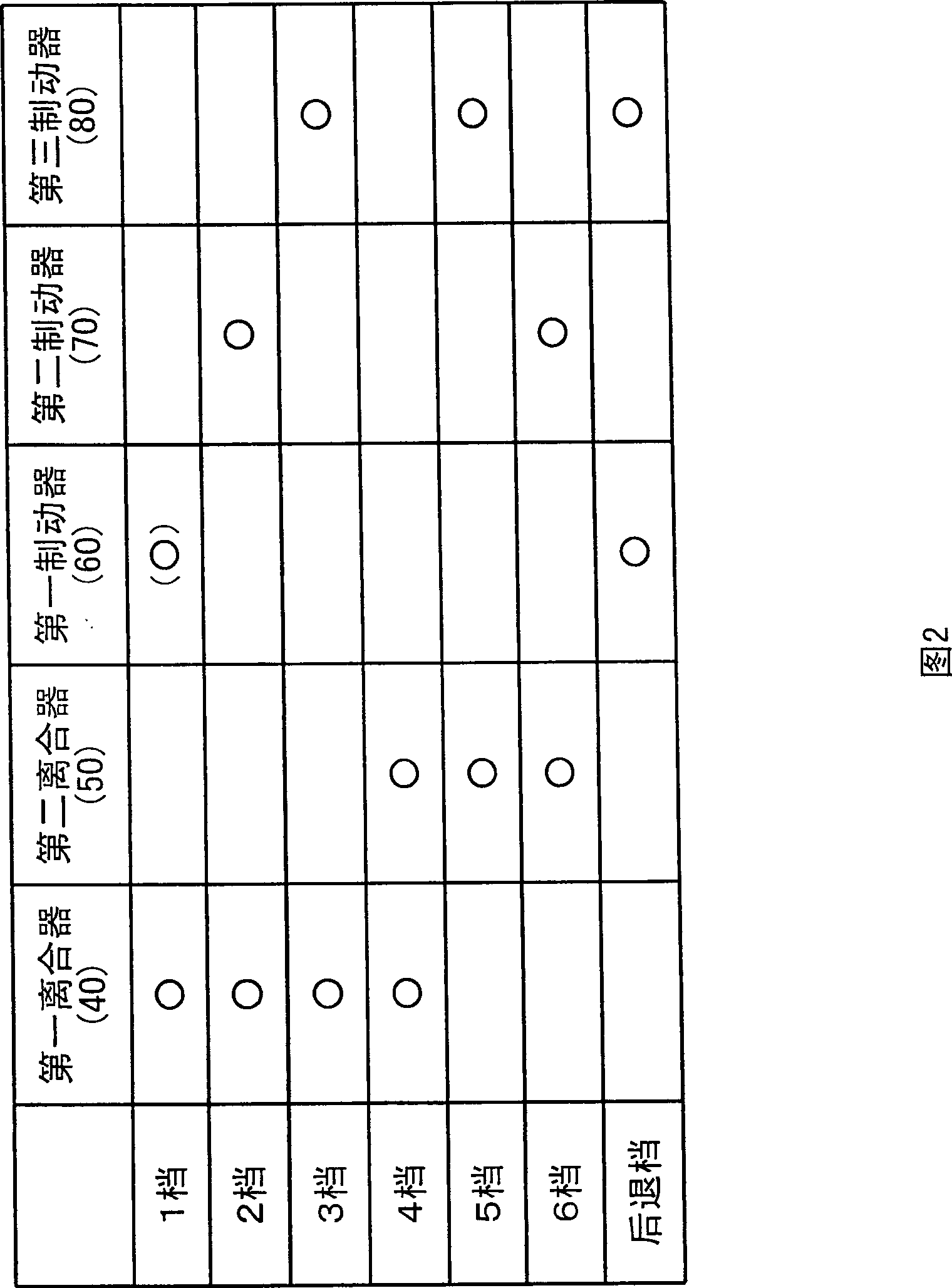

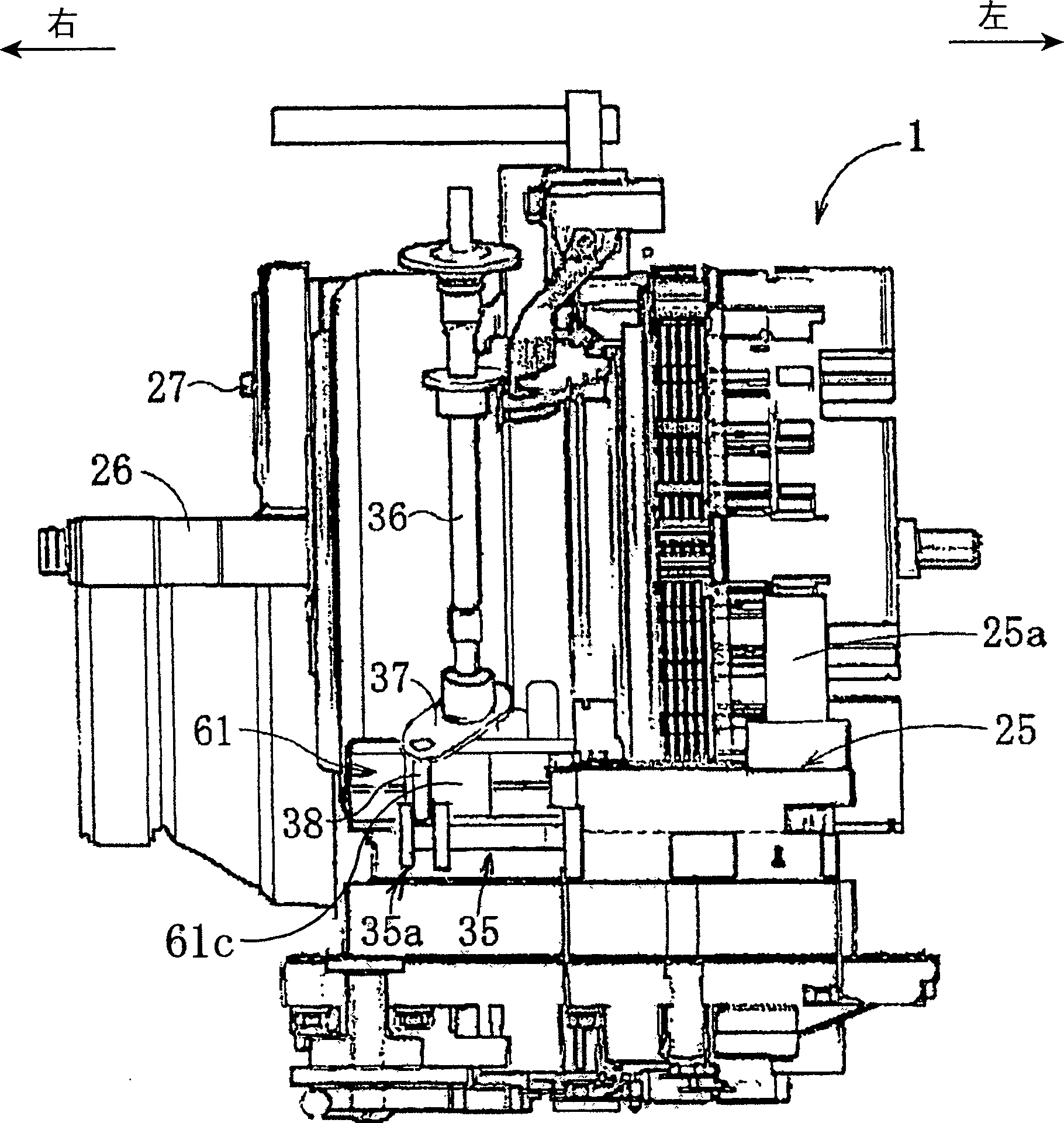

Control device for automatic transmission

InactiveCN101398073AReduced durabilityShorten the lengthGearboxesGearing controlAutomatic transmissionEngineering

Owner:MAZDA MOTOR CORP

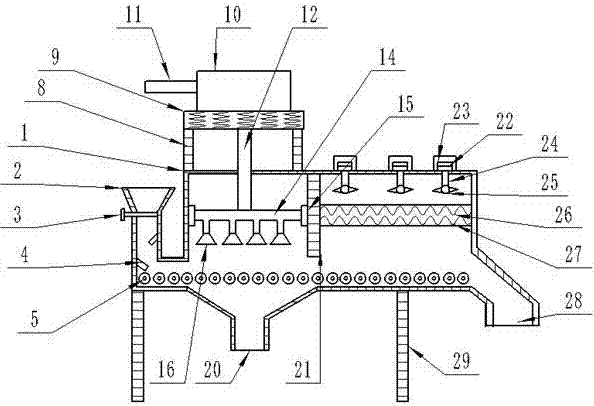

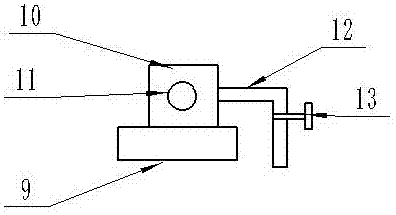

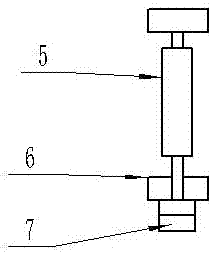

Hydraulic control system for scooptram

ActiveCN102535574AUse less componentsSimple structureSoil-shifting machines/dredgersGear pumpControl system

The invention discloses a hydraulic control system for a scooptram. The hydraulic control system comprises a braking loop which is subjected to oil supply through a right pump of a duplex gear pump and a steering loop which is subjected to oil supply through a left pump of the duplex gear pump, wherein the braking loop or the steering loop is also connected with a backup oil supply branch circuit; the backup oil supply branch circuit is controlled by an electromagnetic reversing valve to alternatively supply oil to the braking loop and the steering loop; the input end of the electromagnetic reversing valve is connected to a part behind a gathering point between the backup oil supply branch circuit and the braking loop or connected to a part behind a gathering point between the backup oil supply branch circuit and the steering loop; and one of two output ports of the electromagnetic reversing valve is connected with the input port of a steering control valve of the steering valve, and the other output port of the electromagnetic reversing valve is connected with the braking loop. According to the hydraulic control system, only one electric hydraulic pump is needed to supply oil to a brake and a steering oil cylinder, so that the technical shortcoming that the scooptram cannot be quickly started and steered at the same time in the prior art when the hydraulic system fails is overcome.

Owner:SINOSTEEL HENGYANG MASCH CO LTD

Operation control structure for a continuity test device

ActiveUS20120019276A1Reduce part costAddressing slow performanceCoupling device connectionsElectrical measurement instrument detailsContinuity testEngineering

Owner:YAZAKI CORP

Fuel injector

ActiveUS20170211533A1Inhibit injectionMachines/enginesSpecial fuel injection apparatusElectrical connectionEngineering

Owner:DELPHI TECH IP LTD

Deep shale gas drilling and exploiting method and fracturing device adopted in same

The invention relates to a deep shale gas drilling and exploiting method and a fracturing device adopted in the method. The method and the device mainly aim to solve the problem that the shale gas drilling and exploiting depth is limited currently. The method includes the steps that a vertical well and a horizontal well are drilled, and the fracturing device is arranged; the diameter of the vertical well is enlarged close to a fracturing working face, an expansion screen pipe is fed into an enlarged section, the diameter of the expansion screen pipe is enlarged, a pressurizer is installed in the enlarged section, a water inlet of an intermediate-pressure water pump arranged on the ground is connected with a water source through a pipeline, water, output by the intermediate-pressure water pump, 2 MPa -10 MPa in pressure is injected into the underground fracturing working face and serves as a power source of the pressurizer at the same time, a high-pressure cavity of the pressurizer conveys high-pressure water with the maximum pressure of 140 MPa to the high-pressure pipeline communicated with the fracturing working face, and accordingly shale can be easily fractured. The fracturing device comprises an acidizing device, a sand mulling device, a program control device, the pressurizer, the intermediate-pressure water pump and a control valve. The deep shale gas drilling and exploiting method and the fracturing device adopted in the method have the advantages that deeper shale gas can be exploited.

Owner:王及元

Hydraulically controlled frequency stabilization power generating method

ActiveCN101793232AImprove qualityReduce manufacturing difficultyWind motor controlEnergy industryFrequency stabilizationConstant frequency

Owner:SHANGHAI XISHUNLAI MACHINERY & ELECTRIC EQUIP MFG CO LTD

Pipeline diversion device, system and method for in and out overflow pipe

PendingCN109372076ACompressed air is safe and controllableEasy accessSewerage structuresSewage drainingMeasuring instrumentFlow diverter

The invention relates to a pipeline diversion device for an in and out overflow pipe. The system comprises a compressed air source, at least one control valve, at least one gas delivery main pipe, a controller and a measuring instrument; inlets of the control valves are communicated with the compressed air source, and the gas delivery main pipes are communicated with outlets of the control valves;a pneumatic divider is composed of a divider body and at least one pneumatic control component, the divider body is provided with an inlet, a first outlet and a second outlet, the first outlet is used for communicating the inlet with a sewage pipe or an initial rain pipe to form a cut-off channel, the pneumatic control components are arranged in the cut-off channel, and the second outlet is usedfor communicating the inlet with a drain pipe on the down stream of the divider body; the pneumatic control components are connected with the gas delivery main pipe through gas delivery branched pipes; the controller is connected with the control valves; the measuring instrument controls the control valves to act to connect the compressed air source with the pneumatic control components accordingto the measurement information after the measurement information is received, the pneumatic control components act to control cut-off and conducting states of the cut-off channel, and sewage and / or initial rainwater and later period rainwater in the drain pipe are diverted.

Owner:WUHAN SHENGYU DRAINING SYST

Multifunctional membrane testing device

ActiveCN101514949AIncrease vacuumEasy to operateWeather/light/corrosion resistanceProgramme control in sequence/logic controllersPositive pressureEngineering

Owner:ZHANJIANG DENI VEHICLE PARTS

Ozone-assisted photocatalytic sterilization device

InactiveCN104355358ASimple processEasy to operateWater/sewage treatment by irradiationWater treatment compoundsJet flowPhotocatalytic reaction

Owner:天津未来生物技术发展有限公司

Pearl cleaning and drying device

InactiveCN107051952AEasy to pourConvenient whereaboutsDrying gas arrangementsCleaning using liquidsControl valvesRotating hinge

Owner:龚俏枚

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap