Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37 results about "Ultrasound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrasound is sound waves with frequencies higher than the upper audible limit of human hearing. Ultrasound is not different from "normal" (audible) sound in its physical properties, except that humans cannot hear it. This limit varies from person to person and is approximately 20 kilohertz (20,000 hertz) in healthy young adults. Ultrasound devices operate with frequencies from 20 kHz up to several gigahertz.

Combined sight oil level gage and ultrasonic sensor

InactiveUS20080173088A1Pump testingPositive displacement pump componentsUltrasonic sensorEngineering

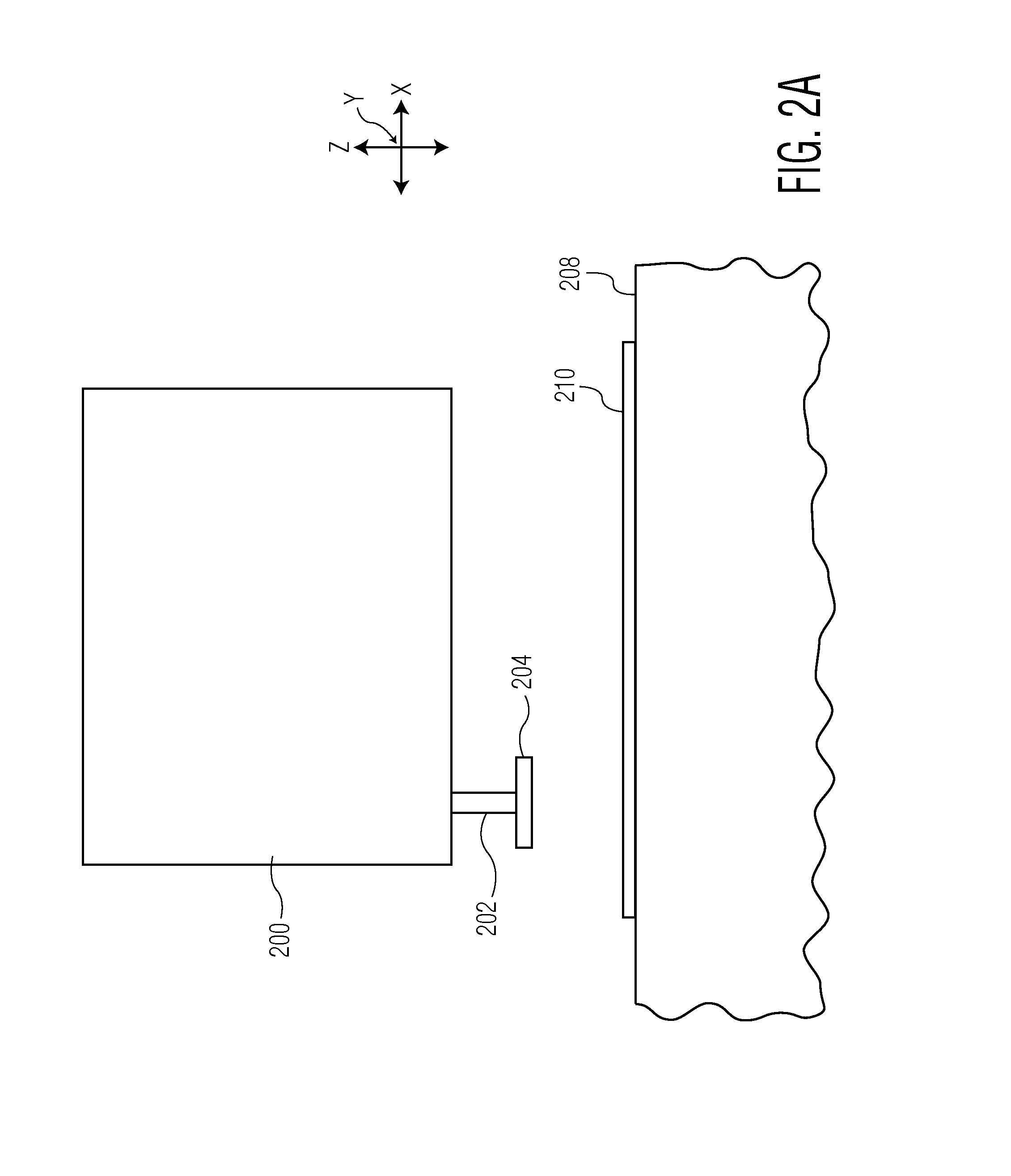

The invention provides a combined fluid level sight gage and ultrasonic sensor featuring a fluid level sight gage having a housing for containing a fluid and having a sight glass for viewing the level of the fluid therein, and an ultrasonic sensor coupled to the housing, responsive to the level of fluid in the housing, for providing an ultrasonic sensor signal containing information about the level of fluid in the housing. In operation, the sight glass provides a visual verification that the ultrasonic sensor is working correctly in relation to the fluid visible in the sight glass. The ultrasonic sensor signal may be used to automatically annunciate alarms or warnings either locally at the equipment or by wired or wireless electronic means. In some embodiments according to the present invention, the housing has a centerline for indicating a normal fluid level therein. The ultrasonic sensor may be arranged in the housing on the centerline, or slightly below the centerline, or slightly above the centerline.

Owner:GERBER LIONEL +1

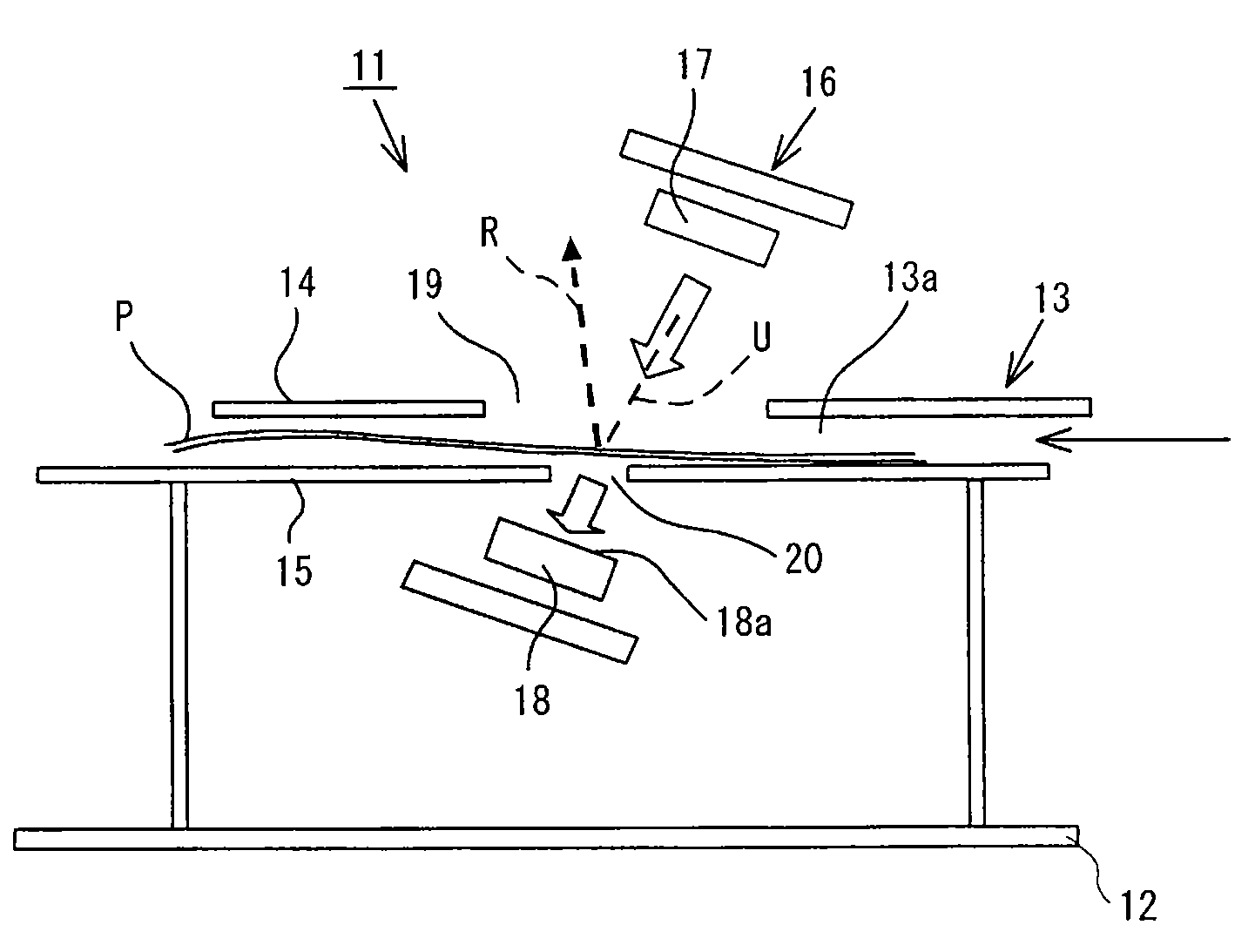

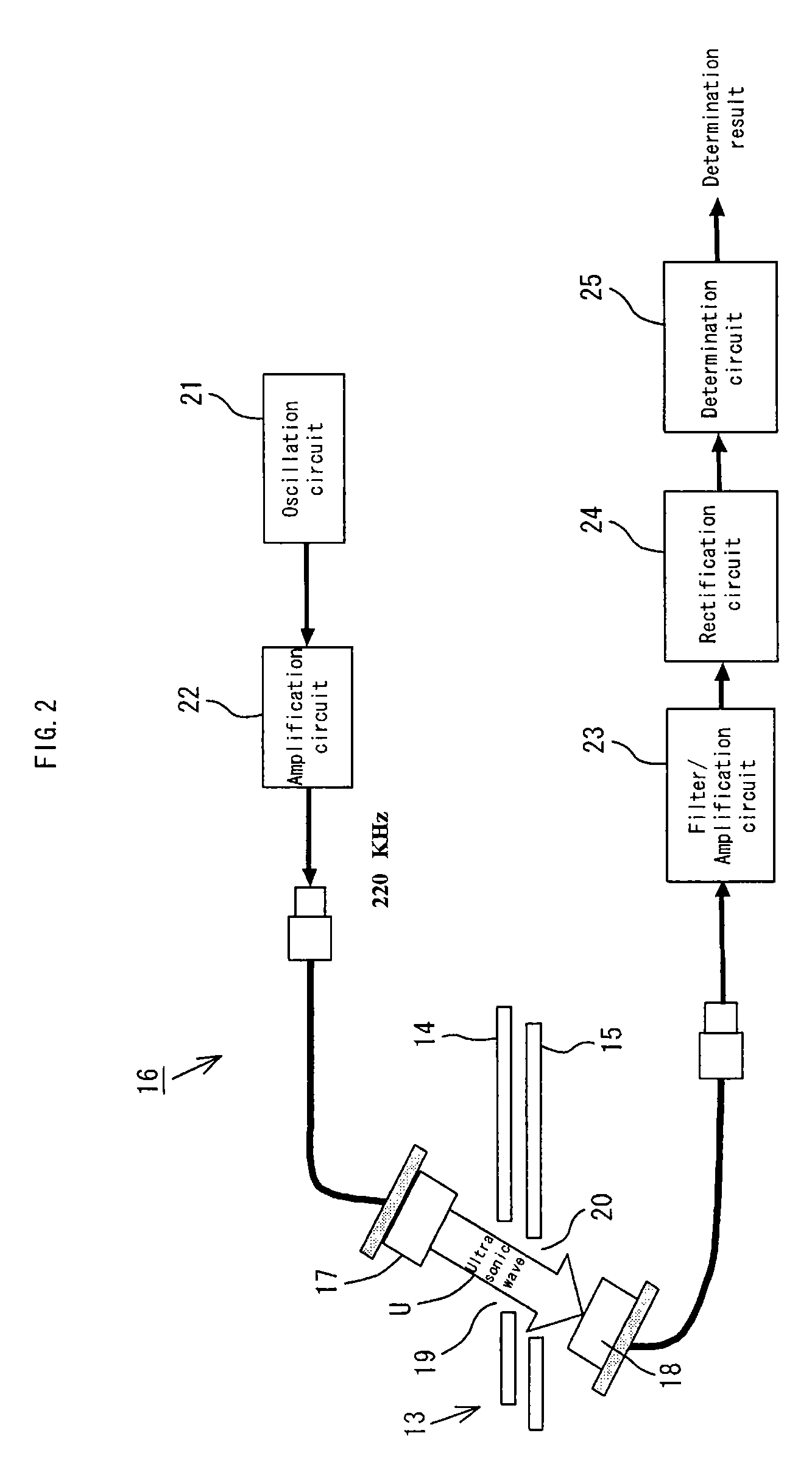

Paper multi-feed detection apparatus and paper multi-feed detection method

InactiveUS20080203654A1Improve transmission performanceEasy to getFunction indicatorsArticle feedersEngineeringUltrasound

Owner:SHARP KK

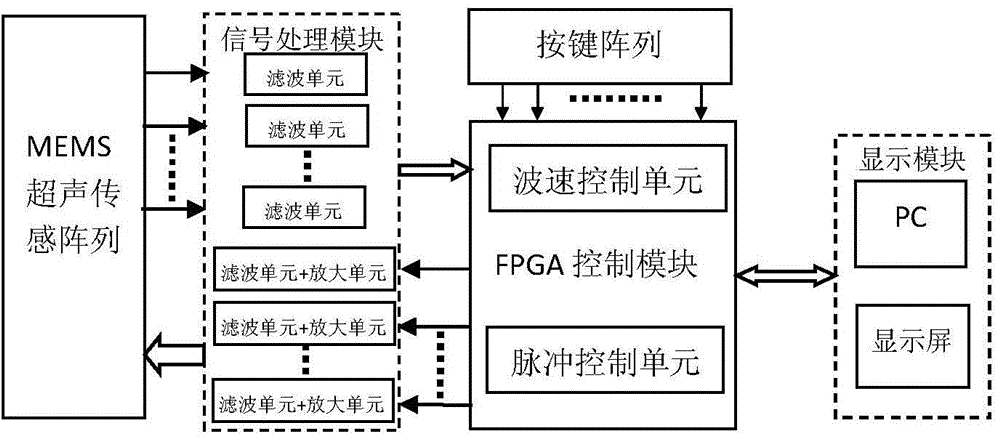

Ultrasonic phased array detector with low power consumption and capability of transforming styles of arrays

InactiveCN104820023AEasy to exploreGood choiceMaterial analysis using sonic/ultrasonic/infrasonic wavesHardware structureUltrasonic sensor

Owner:SOUTHWEAT UNIV OF SCI & TECH

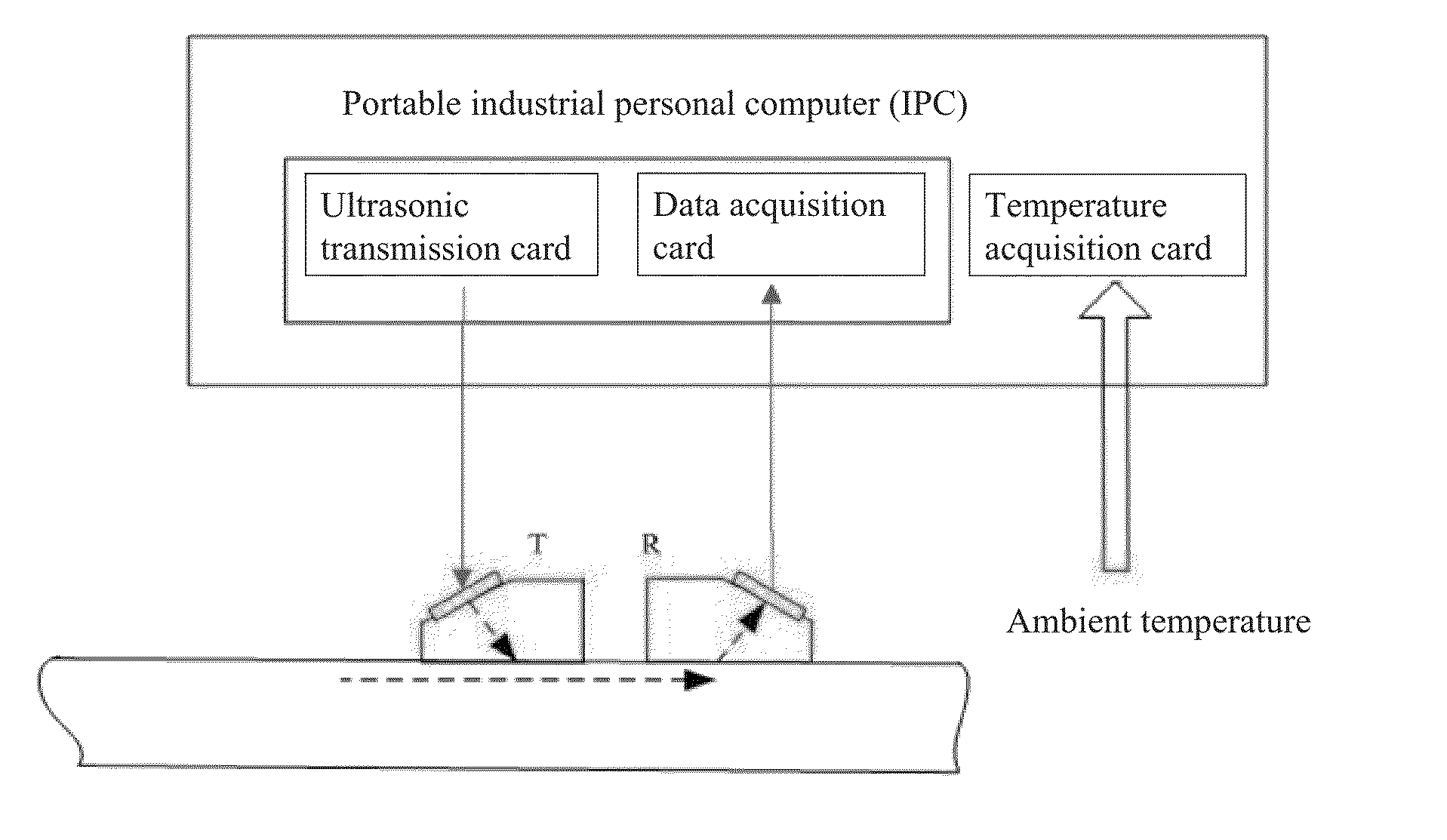

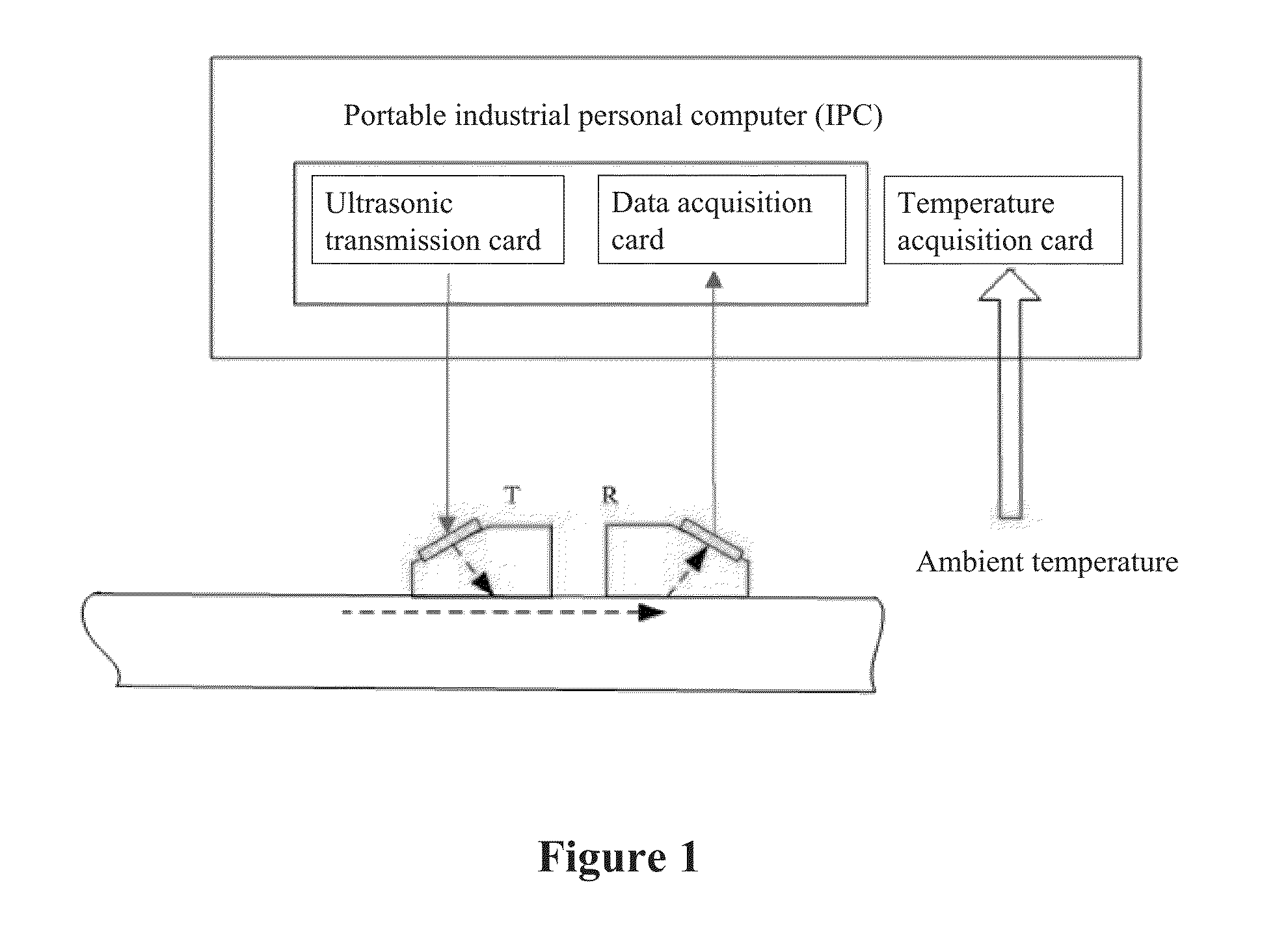

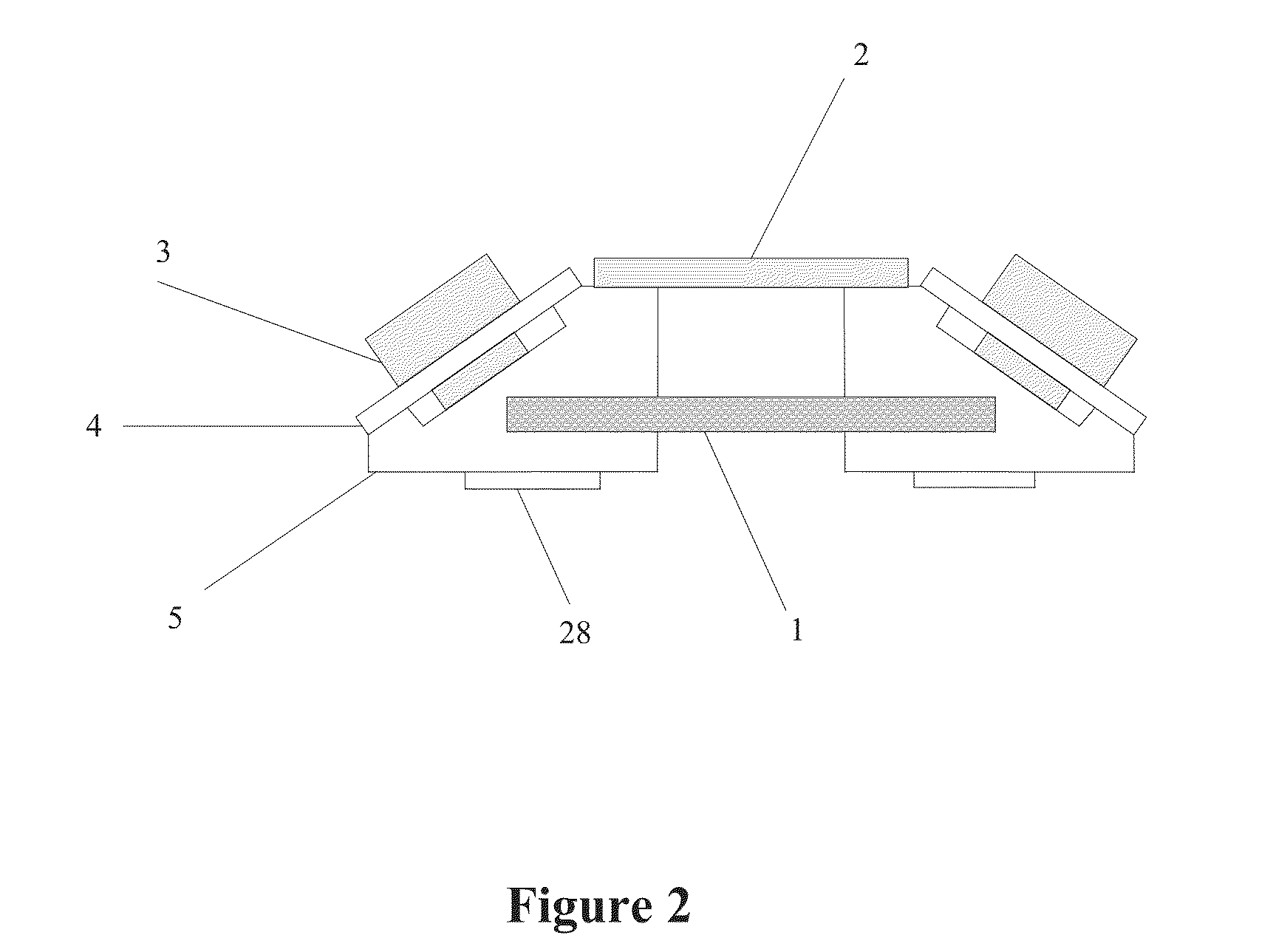

Sensor device and residual stress detection system employing same

ActiveUS20150300897A1Easy to integrateImprove reliabilityAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesTransducerData acquisition

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

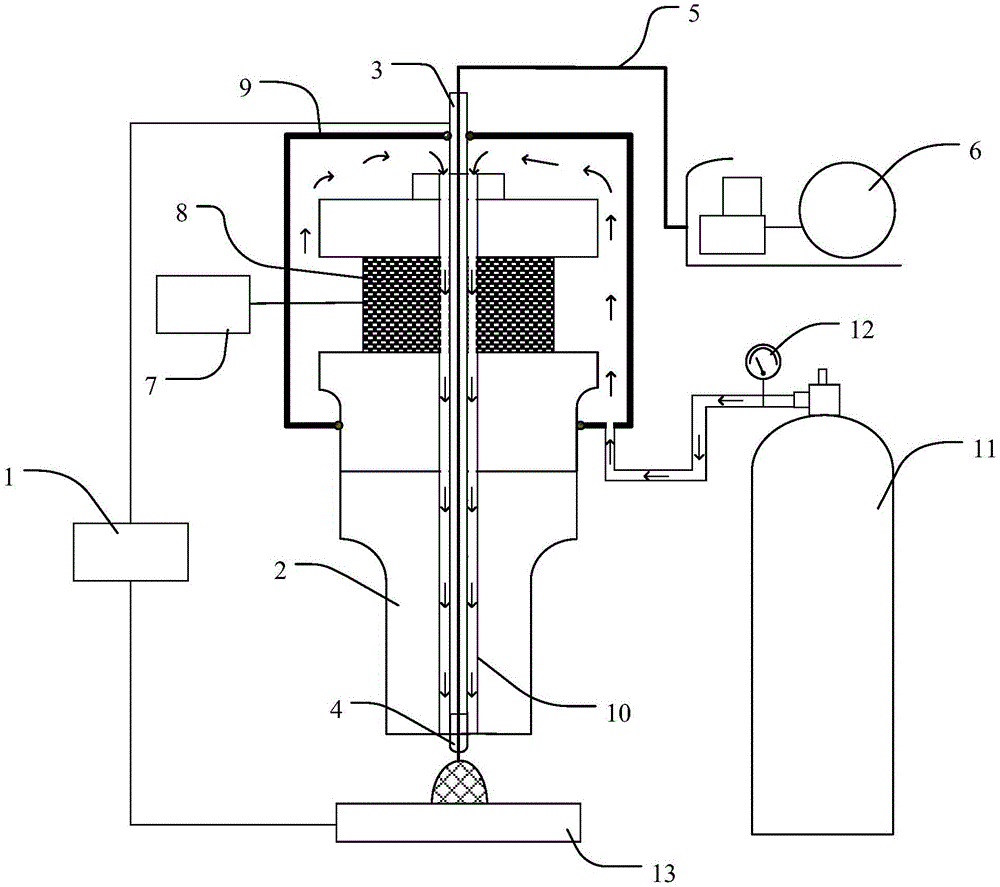

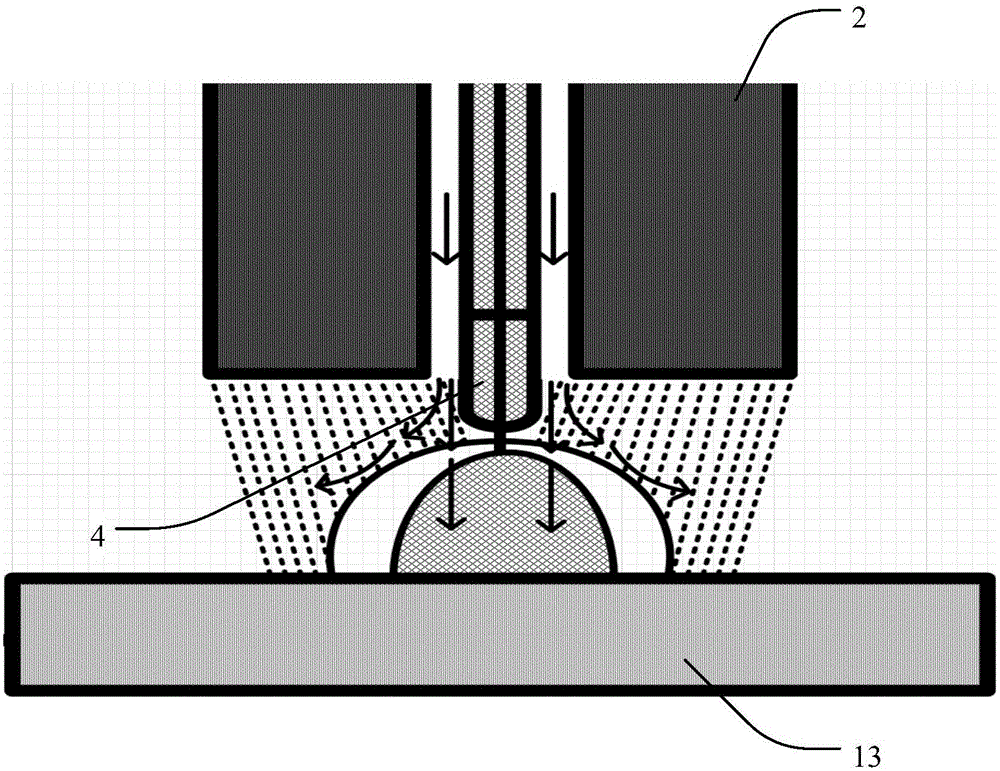

Ultrasonic-assisted and gas-shielded welding device and method adopting underwater wet method

ActiveCN105149747AFacilitated ionizationImprove stabilityWelding accessoriesUltrasonic assistedShielding gas

Owner:HARBIN INST OF TECH AT WEIHAI

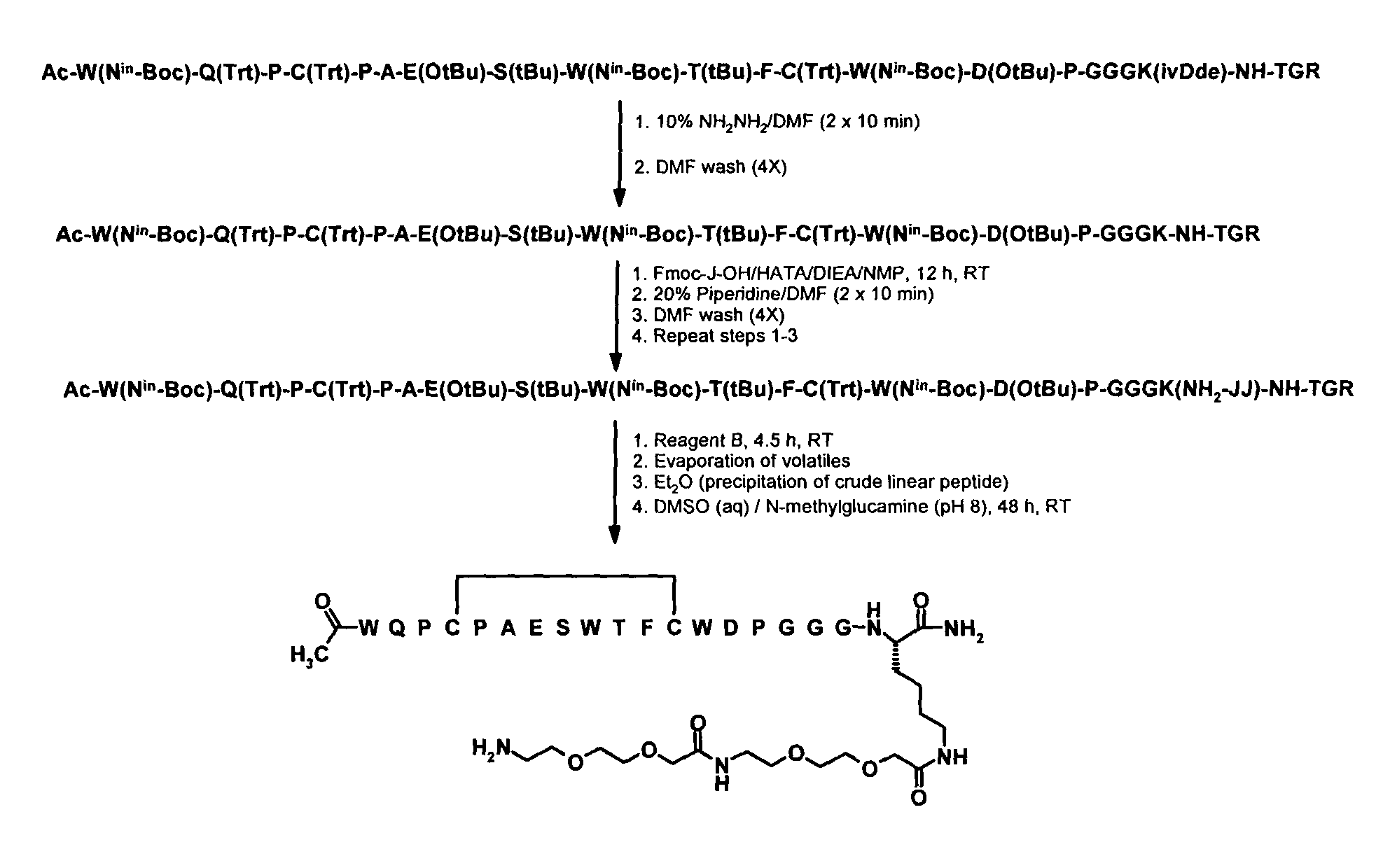

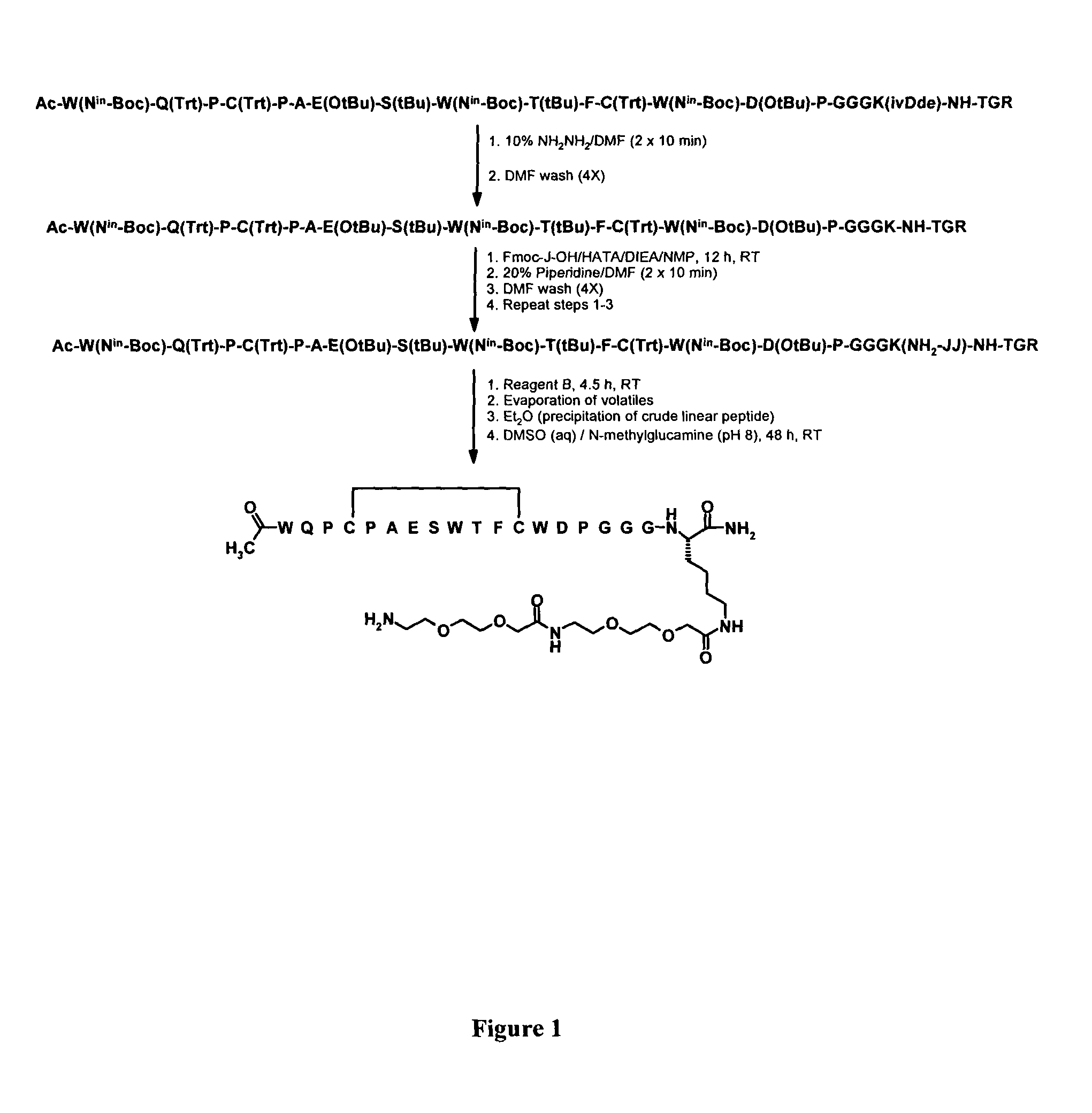

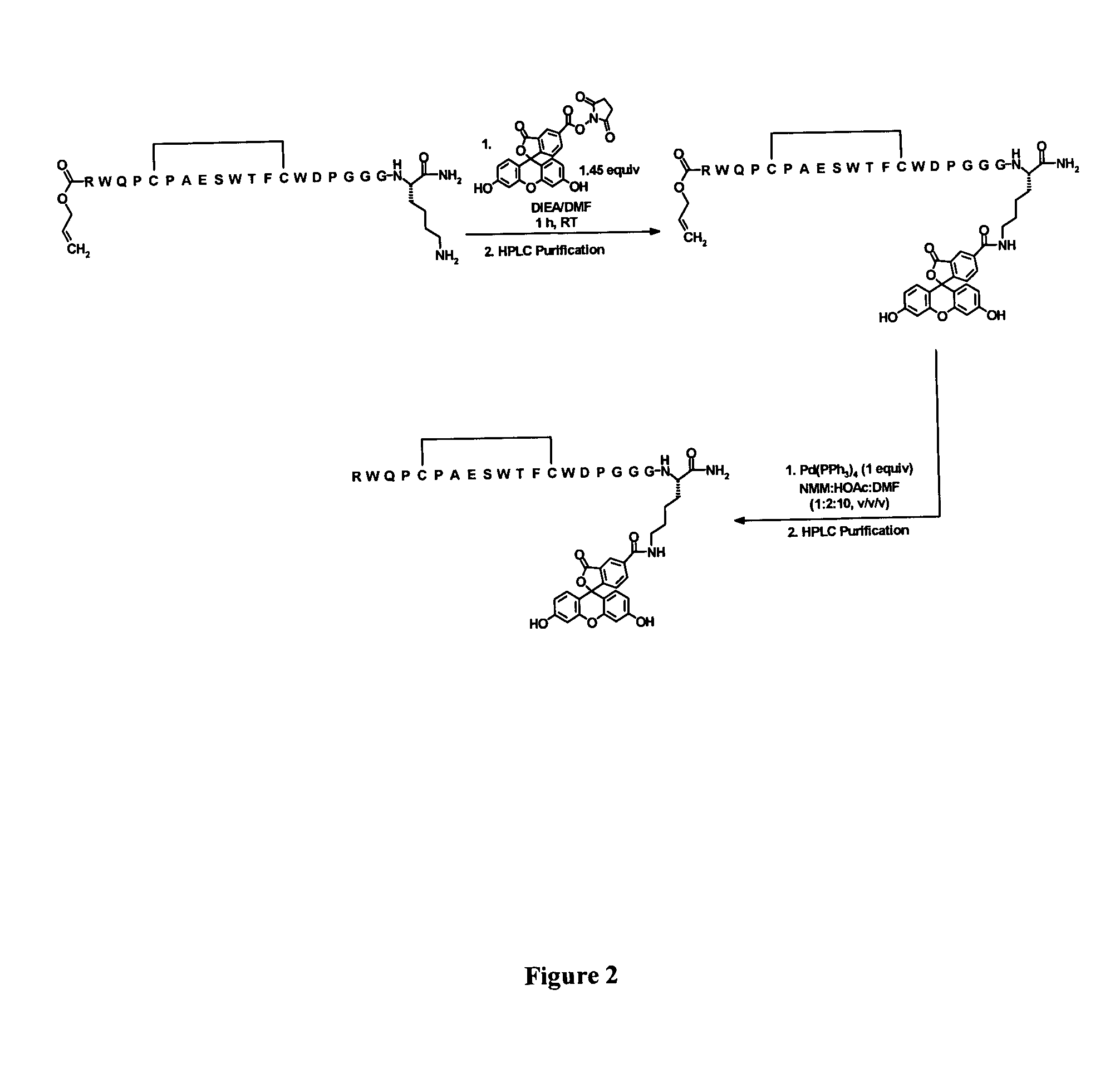

Fibrin-Binding Peptides and Conjugates Thereof

ActiveUS20100158814A1High degreeSuperior fibrin specific bindingUltrasonic/sonic/infrasonic diagnosticsCompound screeningBinding peptideCompanion animal

Owner:BRACCO IMAGINIG SPA

Ultrasonic continuous sterilization device and method thereof

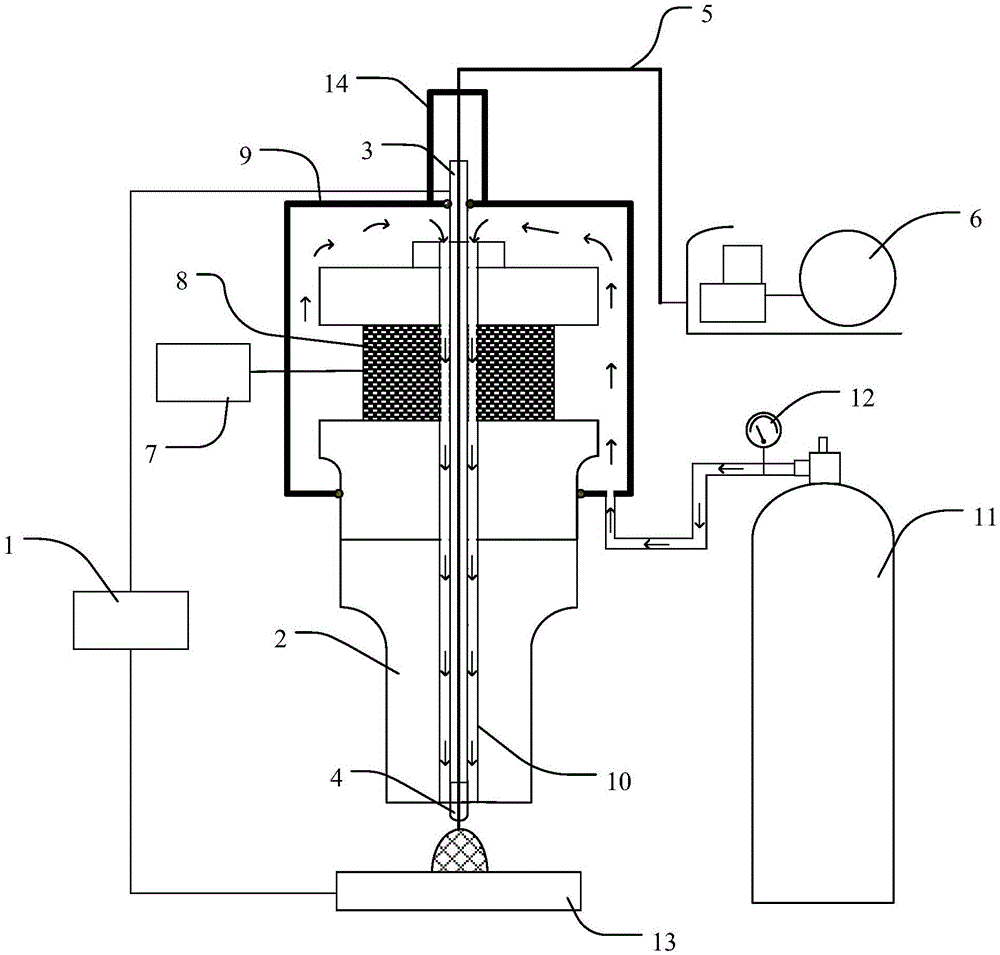

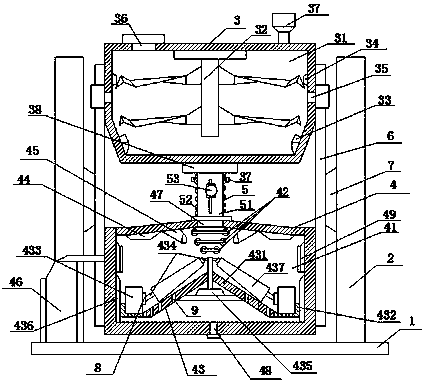

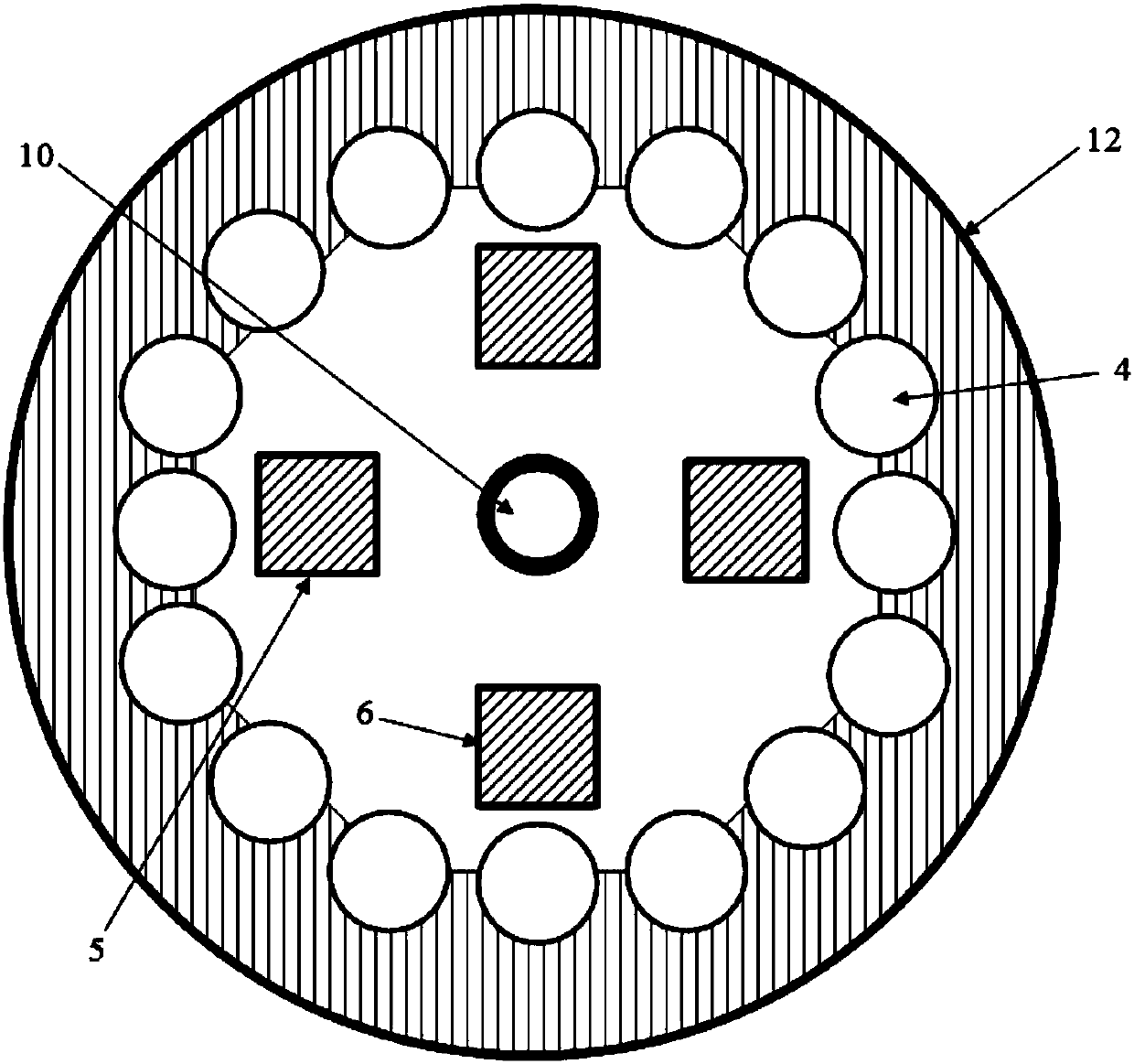

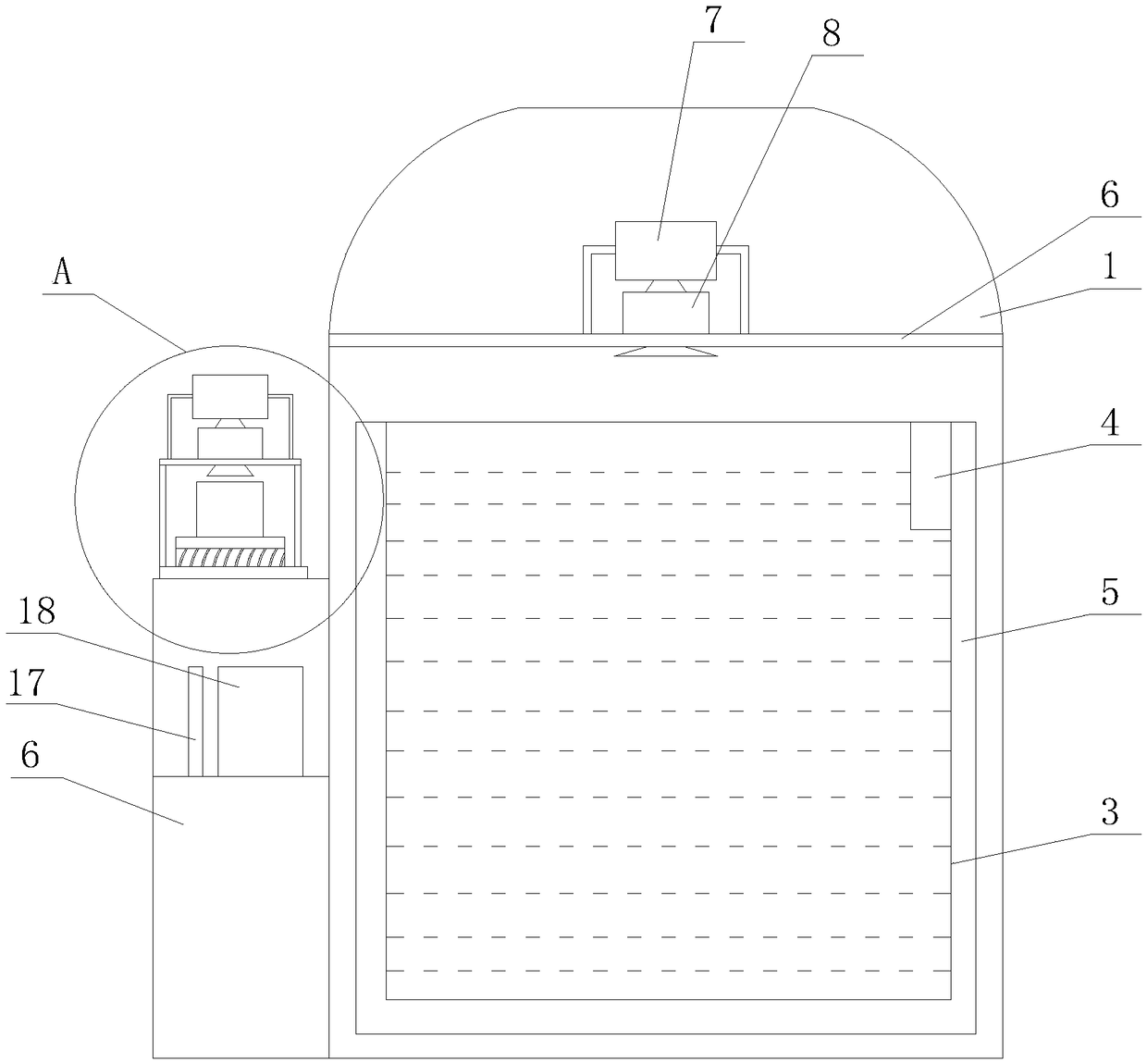

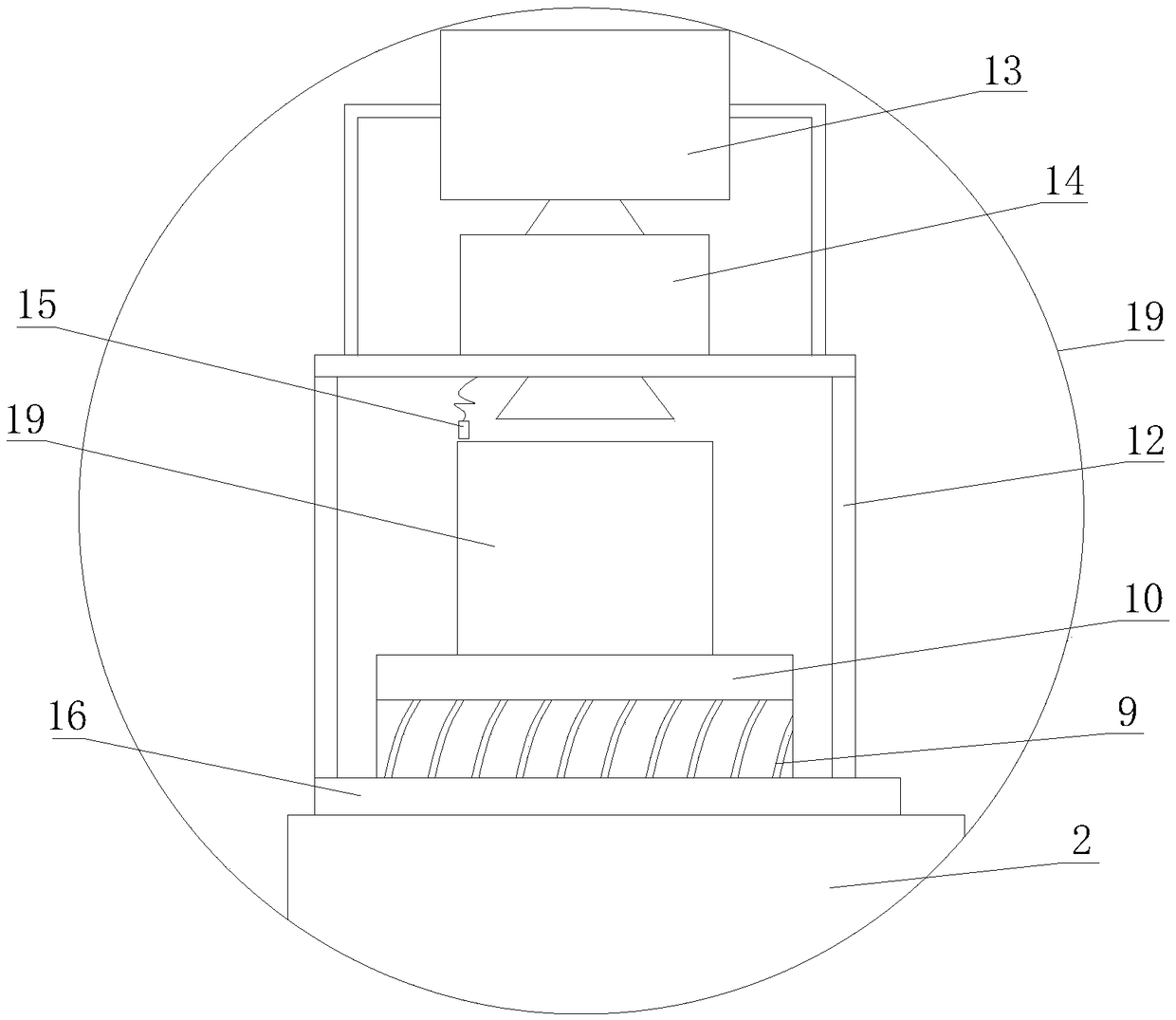

The invention provides an ultrasonic continuous sterilization device, comprising a raw material tank, a heating device, a heat exchanging device, an ultrasonic processing device, a liquid storage device and a controller. The heating device is connected with the heat exchanging device. The raw material tank, the heat exchanging device, the ultrasonic processing device and the liquid storage device are sequentially connected through pipelines. The controller is respectively connected with the heating device, the heat exchanging device, the ultrasonic processing device and control valves on the pipelines. The ultrasonic processing device comprises an ultrasonic barrel, a plurality of ultrasonic probes, ultrasonic transducers and ultrasonic generators, wherein the ultrasonic transducers and the ultrasonic generators are arranged corresponding to the ultrasonic probes, the ultrasonic generators adopt different frequencies and are all arranged in the controller, and the ultrasonic probes are correspondingly distributed on the periphery of the ultrasonic barrel in a stagered junction mode. The invention also provides a method realized by the devices, i.e. feed liquid is firstly heated by the heat exchanging device, and then dynamic and continuous ultrasonic sterilization processing is carried out by the ultrasonic processing device. The invention adopts the technology combining low-temperature heating and ultrasonic processing, and has the advantages of good sterilization effect, high efficiency and the like.

Owner:SOUTH CHINA UNIV OF TECH

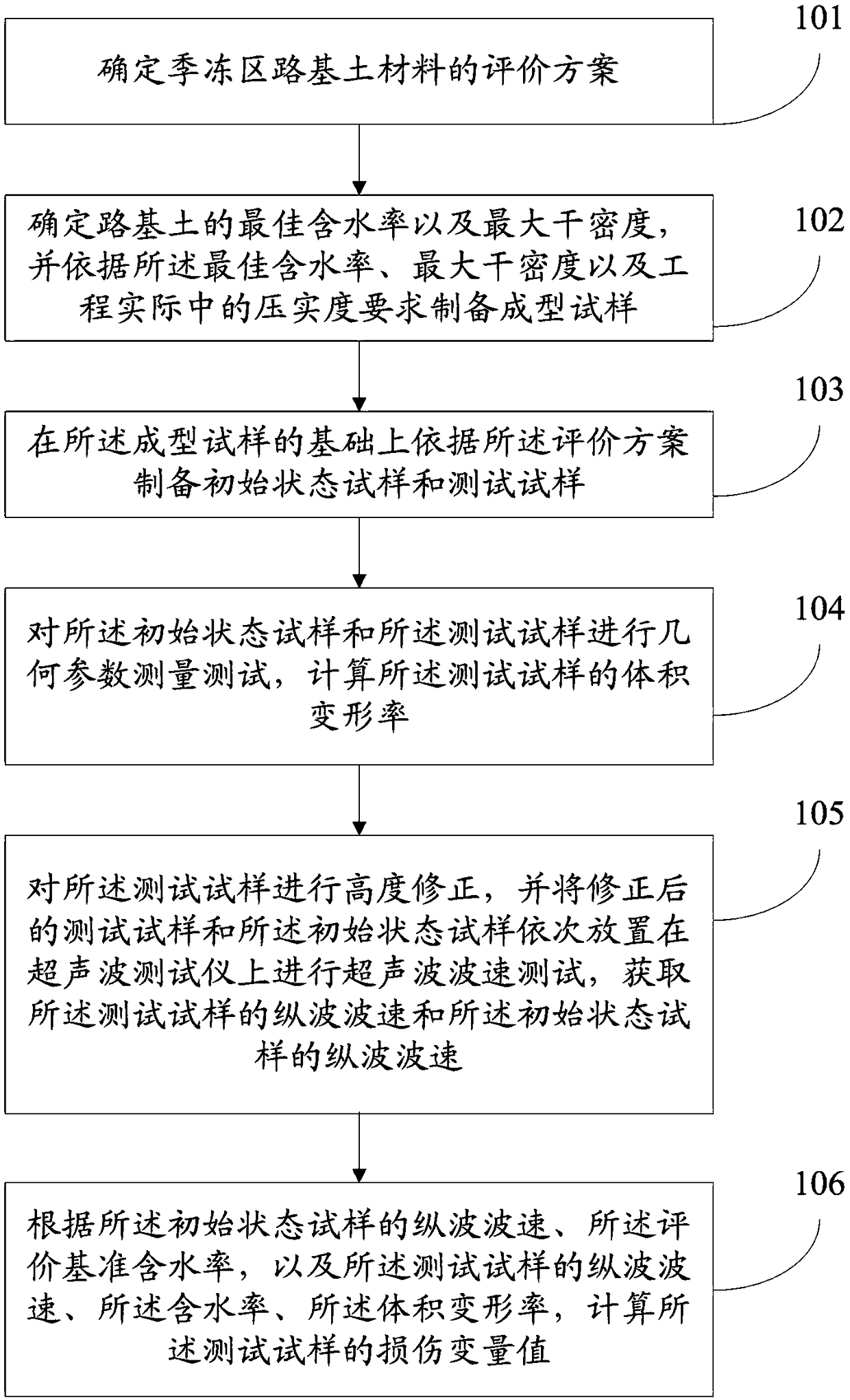

Ultrasonic technology-based method for detecting and evaluating damage of subgrade soil materials in seasonal frozen regions

ActiveCN108645676AComprehensive evaluationAnalysing solids using sonic/ultrasonic/infrasonic wavesPreparing sample for investigationFreeze and thawMoisture

Owner:JILIN JIANZHU UNIVERSITY +1

Efficient bone powder preparing system and using method

PendingCN107552202AIncrease productivityImprove product qualityGrain treatmentsProcess specificationUltrasonic vibration

Owner:郑州中技联创环境技术有限公司

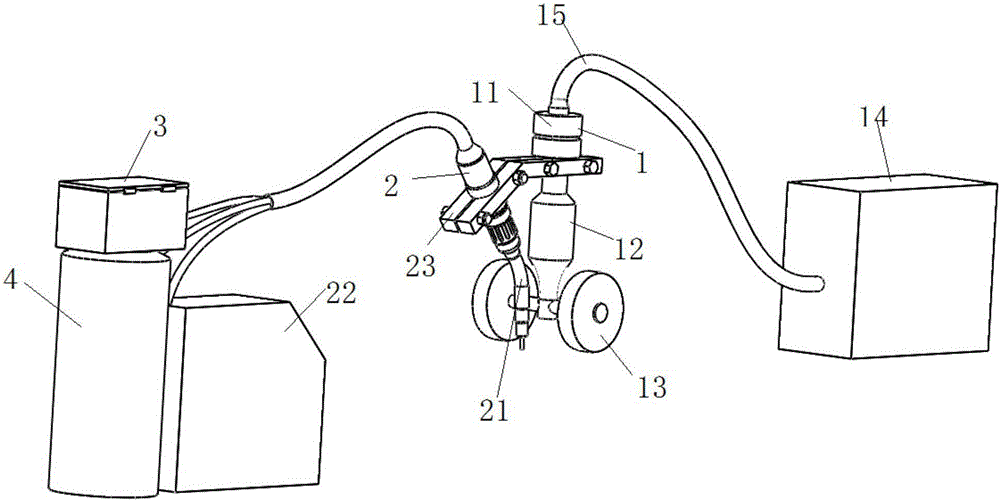

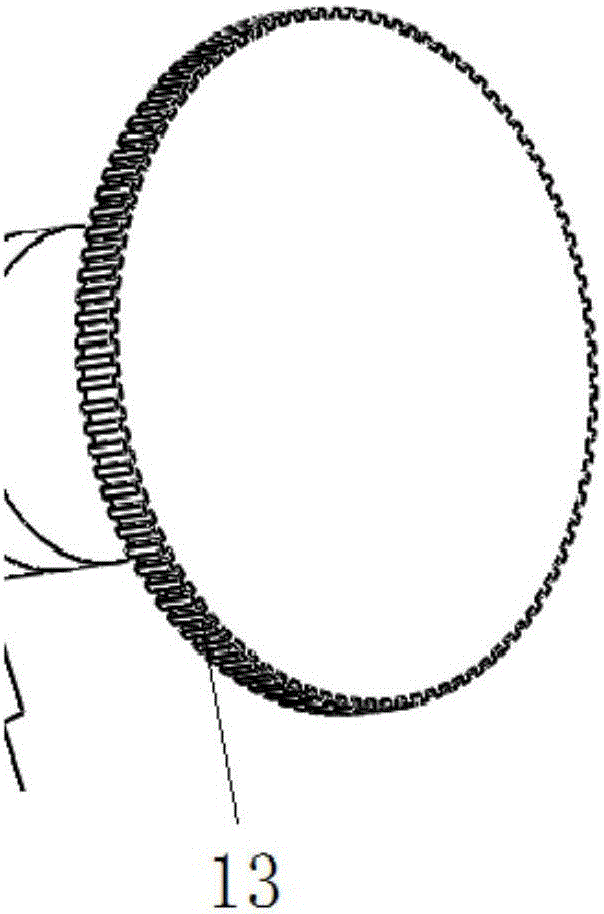

Rolling type ultrasonic arc composite welding device

PendingCN106624401AGrain refinementImprove weld structureWelding apparatusMechanical propertyHigh frequency vibration

Owner:GUANGDONG INST OF INTELLIGENT MFG

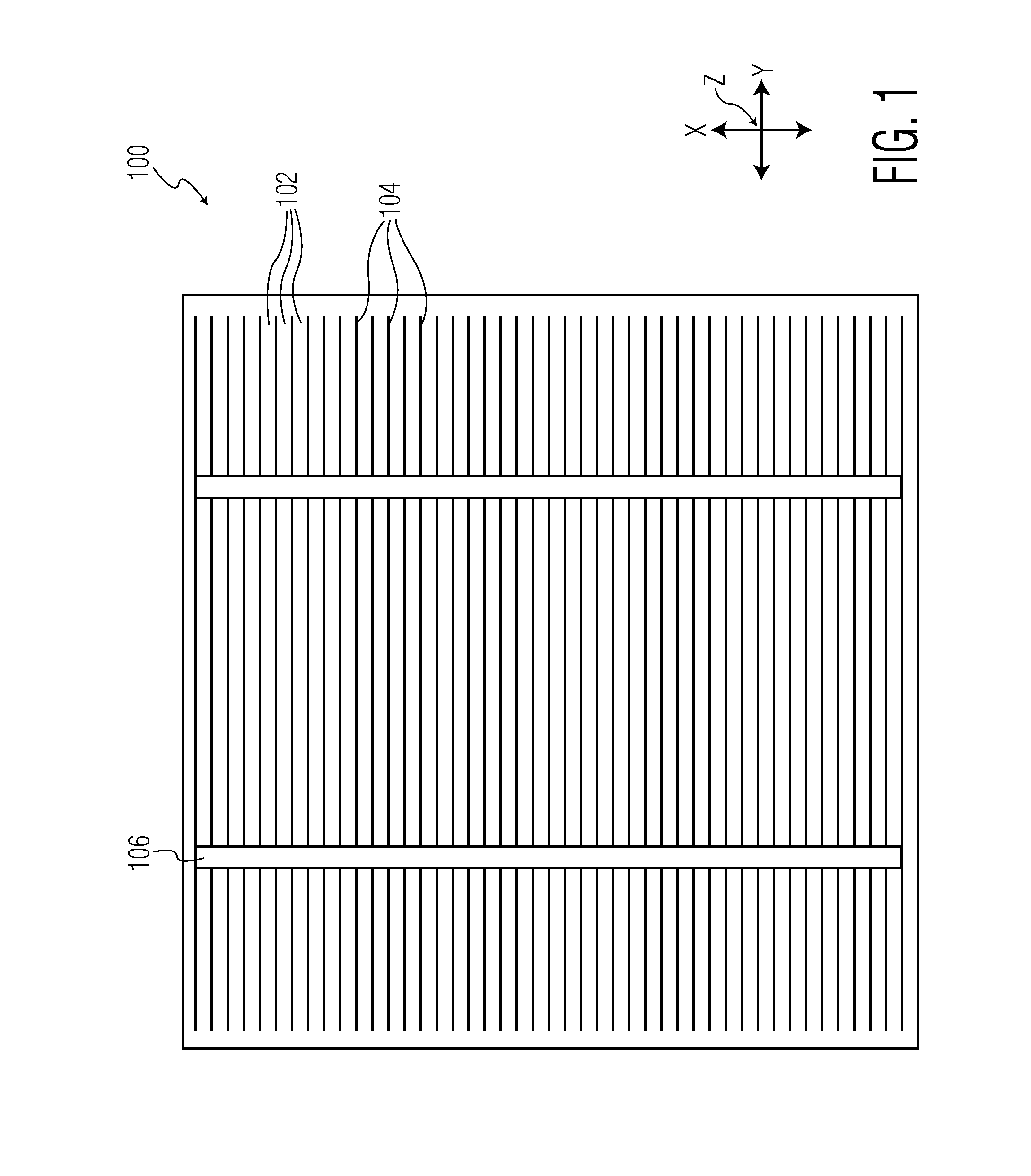

Ultrasonic bonding systems and methods of using the same

Owner:ORTHODYNE ELECTRONICS

Acousto optic element

InactiveUS7054055B2High light-fading ratioAvoid it happening againNon-linear opticsElectricityUltrasonic sensor

Owner:PANASONIC CORP

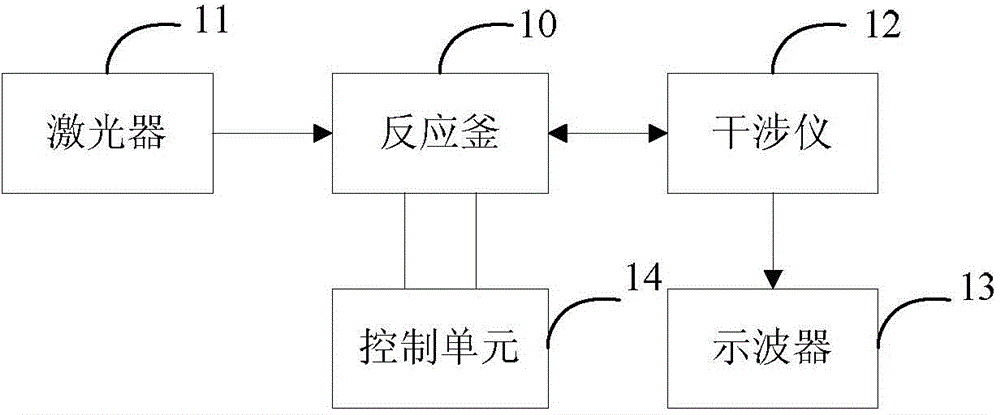

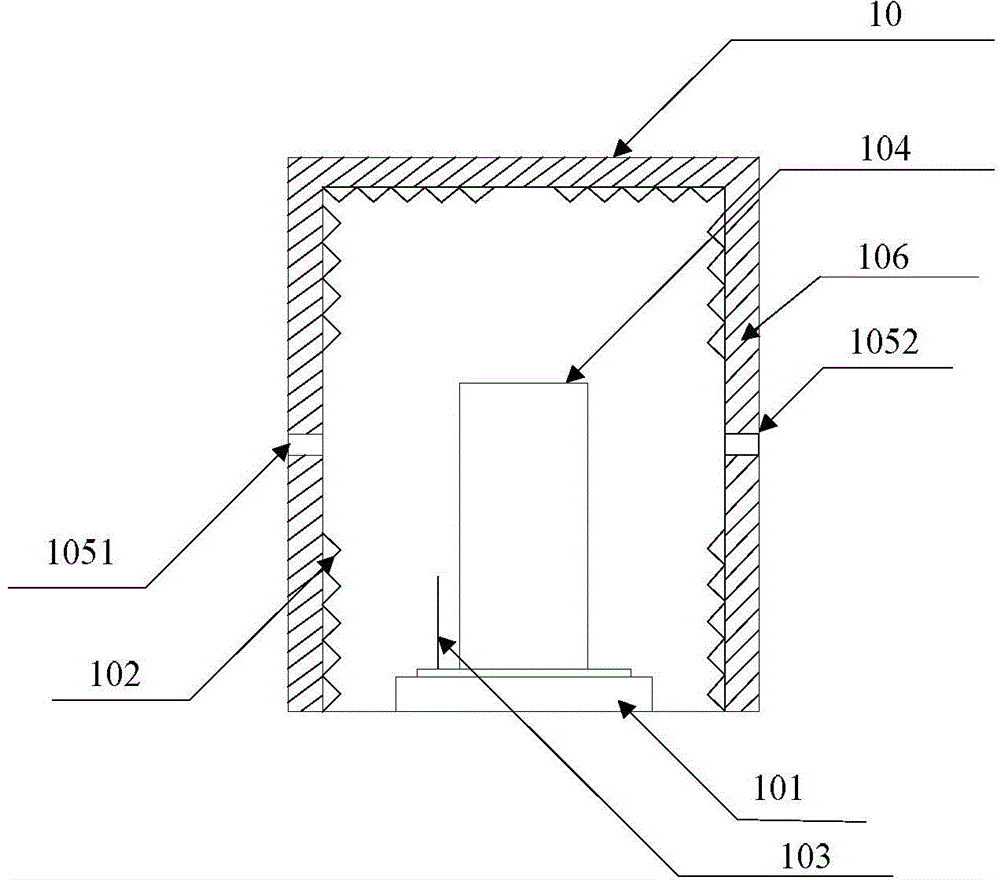

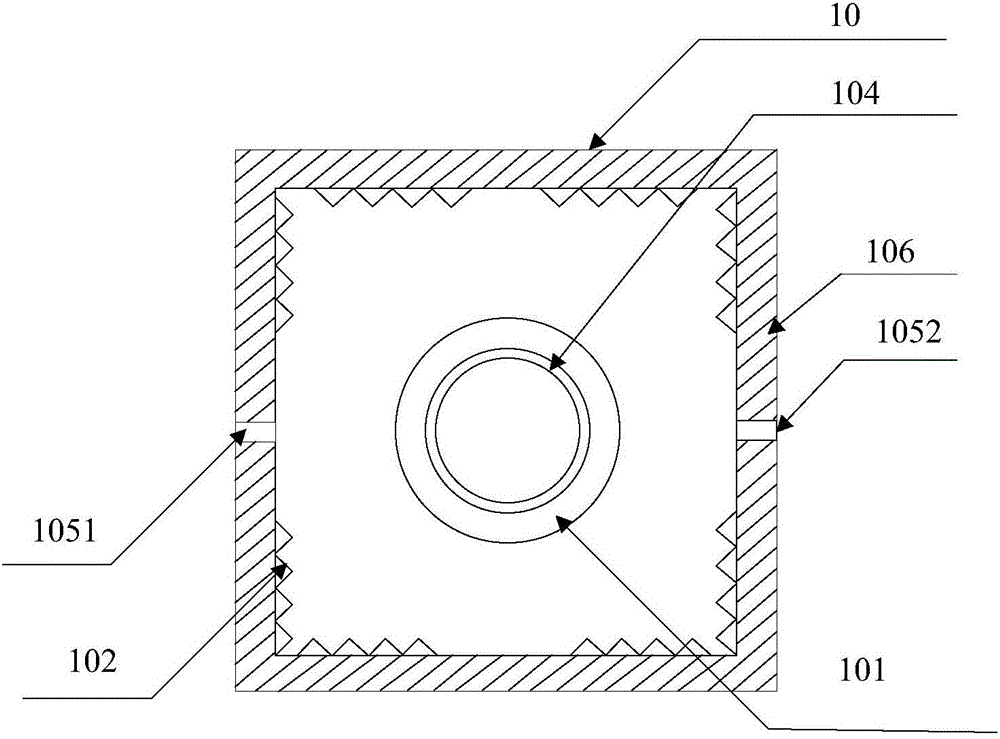

Rock anisotropy detection system

InactiveCN104459084AAchieve heatingAnisotropy detection implementationEarth material testingLaserUltrasound

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Ultrasonic assisted production technology for extracting rosemary antioxidant

InactiveCN101475807ASpeed up extractionShorten the timeChemical inhibitorsUltrasonic assistedOrganic solvent

Owner:高政

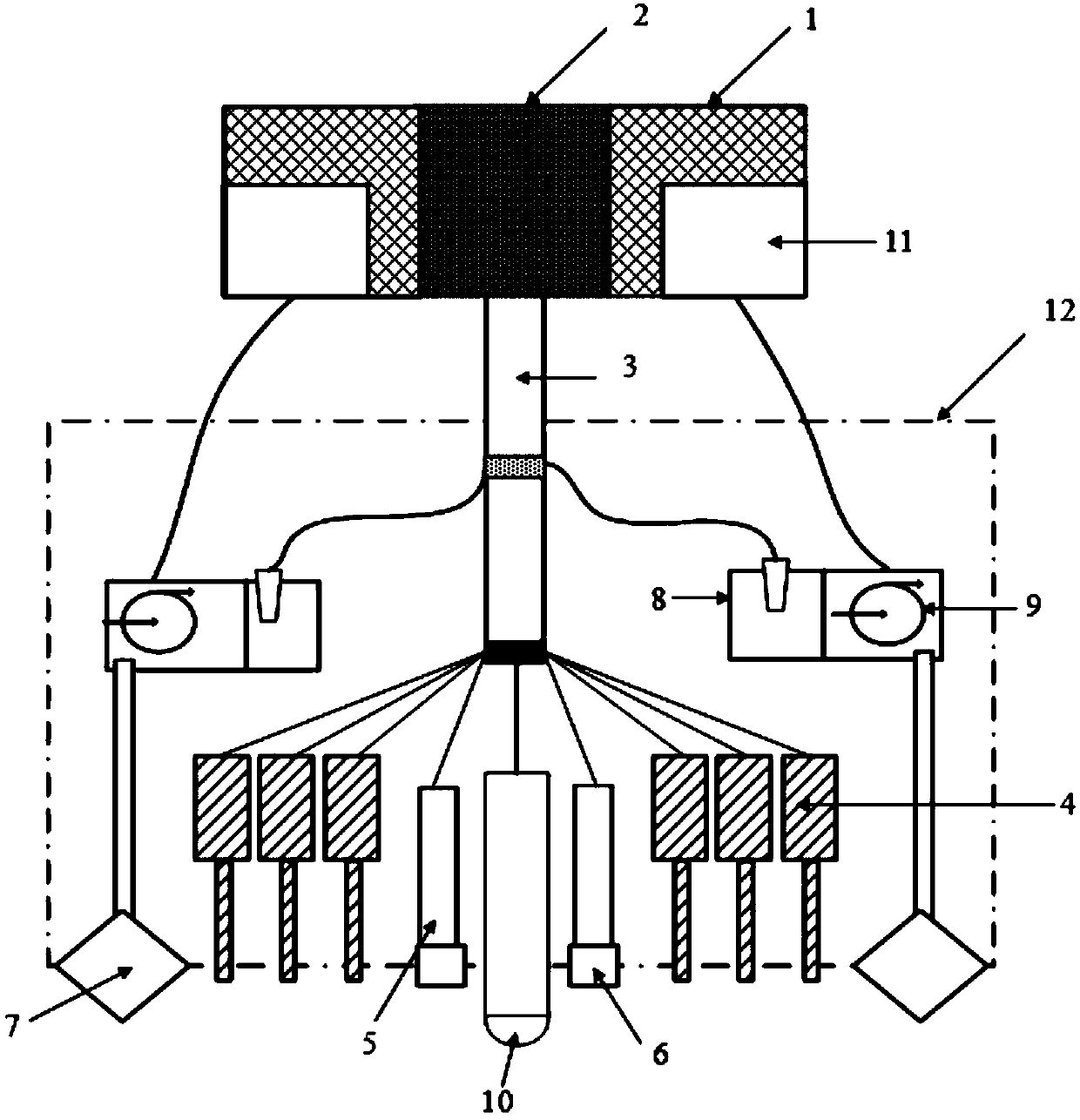

Ultrasonic laser drilling device

ActiveCN107620566ARock breaking drillingGood effectDrilling machines and methodsLaser arrayWater circulation

Owner:CHINA WEAPON EQUIP RES INST

Ultrasonic focusing liquid vibration polishing method based on spherical shell piezoelectric transducer

The invention discloses an ultrasonic focusing liquid vibration polishing method based on a spherical shell piezoelectric transducer. The method comprises the steps that a workpiece to be processed isput in an open container, wherein the open container is filled with a polishing solution; the spherical shell piezoelectric transducer which can be moved to change the position in the horizontal or perpendicular direction is placed above the workpiece to be processed, and soaked in the polishing solution all the time, and the concave side points to the surface, to be processed, of the workpiece to be processed; and an ultrasonic power source is started to generate high-frequency electricity so as to excite the spherical shell piezoelectric transducer to generate ultrasonic vibration, the spherical shell piezoelectric transducer is moved according to a preset processing path and the retention time of focused ultrasonic waves on each processing point, ultrasonic vibration is transmitted bythe polishing solution to be focused on the workpiece to be processed, and the surface of the workpiece to be processed is polished. The ultrasonic focusing liquid vibration polishing method based onthe spherical shell piezoelectric transducer can achieve accurate correction of the surface of the workpiece.

Owner:TIANJIN UNIV

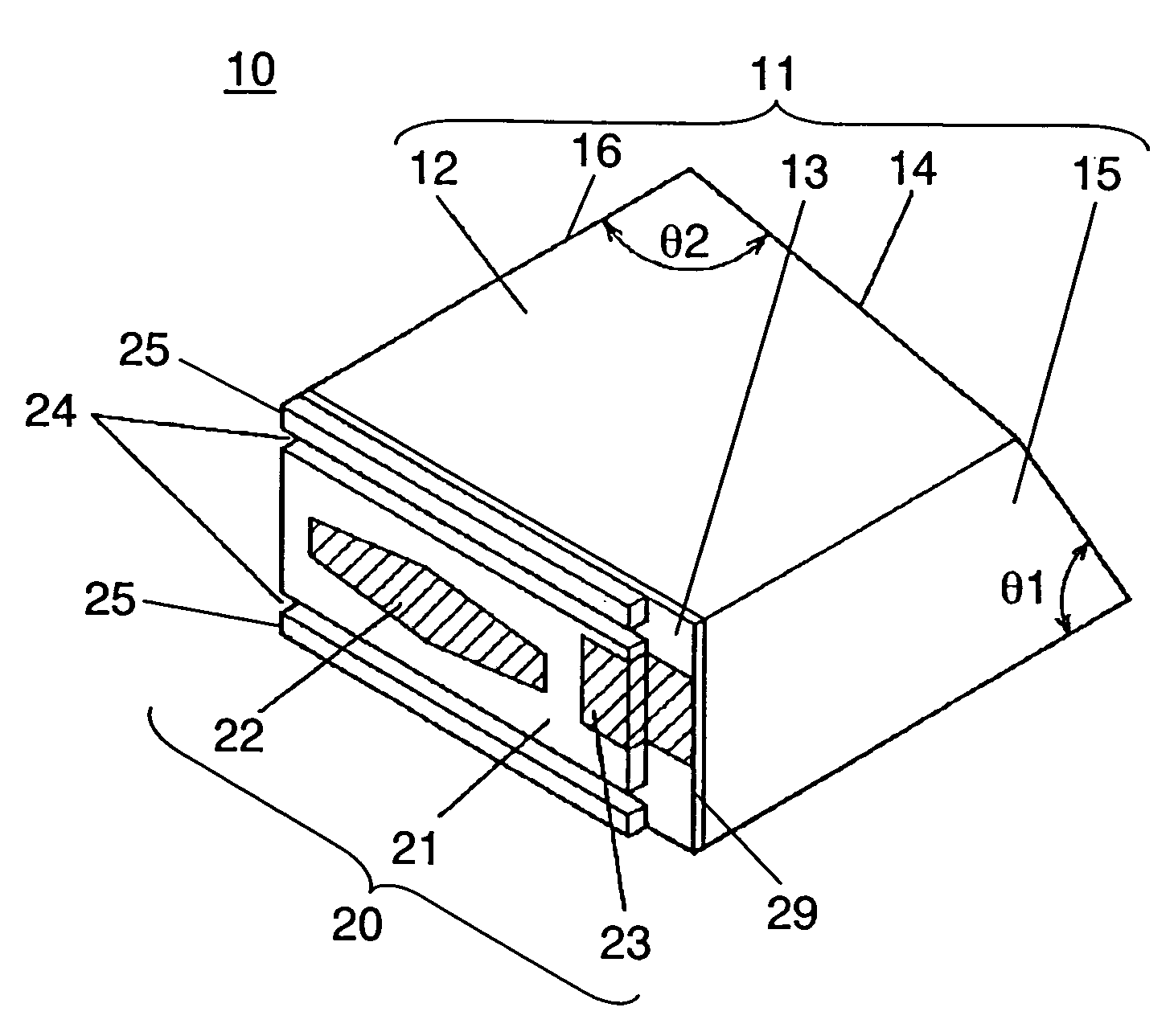

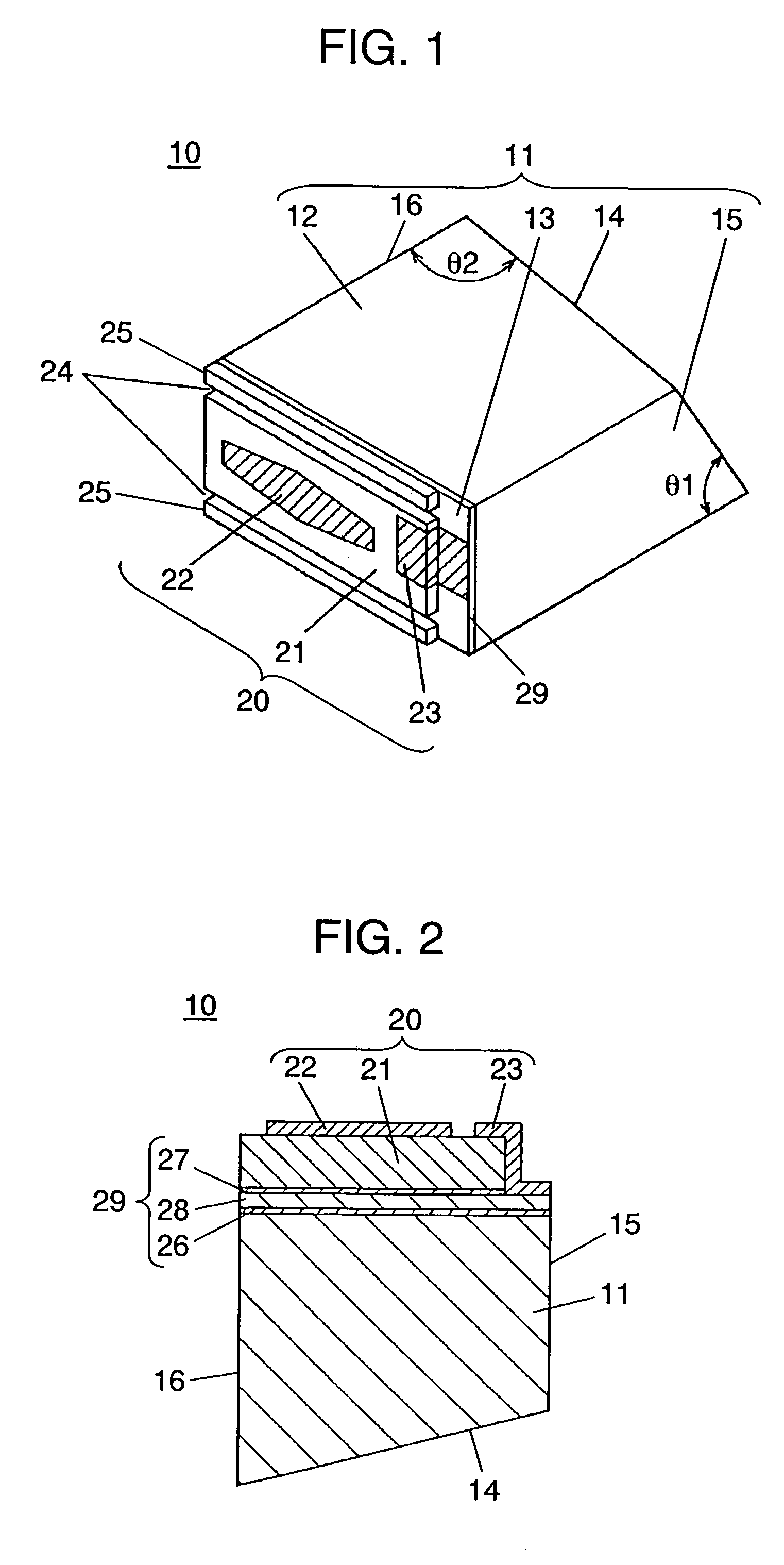

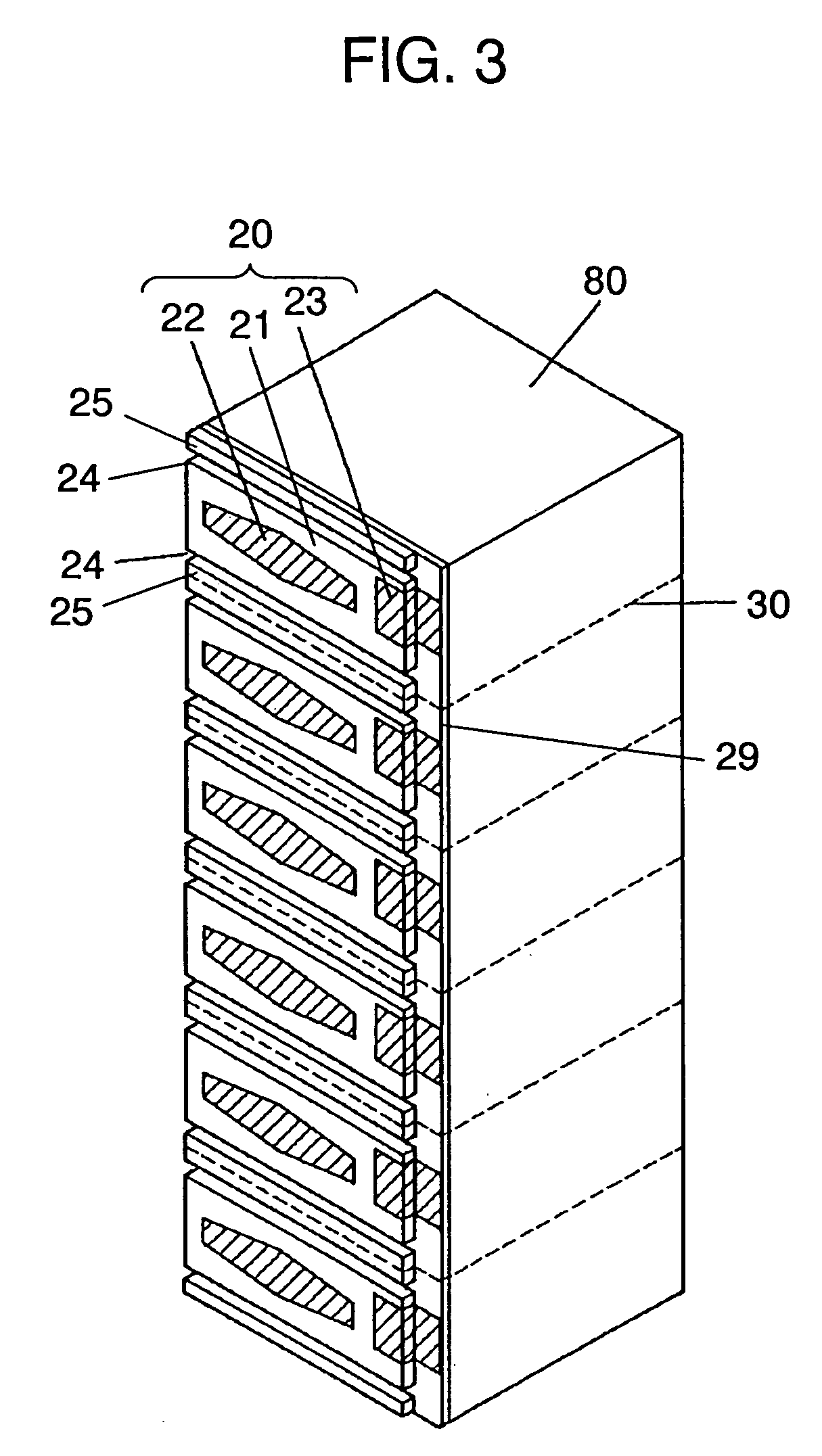

Ultrasonic module and display screen

ActiveCN110275577ASolve the problem of low ultrasonic conversion rateUltrasonic conversion rate is highDigital data processing detailsMechanical vibrations separationUltrasoundElectrode

The invention provides an ultrasonic module and a display screen, and belongs to the technical field of display, which can at least partially solve the problem of low ultrasonic conversion rate of an existing ultrasonic module. The ultrasonic module comprises a piezoelectric material layer; a first electrode unit which is arranged on one side of the piezoelectric material layer; a second electrode unit which is arranged on the side, away from the first electrode unit, of the piezoelectric material layer, wherein the second electrode unit comprises a plurality of first sub-electrode layers and first conductive elastic materials, wherein the first sub-electrode layers and the first conductive elastic materials are spaced from one another, and the first conductive elastic materials are located in at least a part of areas between the first sub-electrode layers and the piezoelectric material layer.

Owner:BOE TECH GRP CO LTD

Control circuit for removing rainwater of automobile rearview mirror by using ultrasonic wave

InactiveCN102442273AEnsure driving safetyOvercome securityVehicle cleaningEngineeringRear-view mirror

The invention discloses a control circuit for removing rainwater of an automobile rearview mirror by using ultrasonic wave. The control circuit comprises a storage battery, an ignition switch, a wiper control switch, a normally-open wiper motor control relay, a wiper motor, a normally-open ultrasonic wave generator control relay and an ultrasonic wave generator, wherein the negative electrode of the storage battery is grounded; the positive electrode of the storage battery is grounded after passing through the ignition switch, the wiper control switch and an electromagnetic coil of the normally-open wiper motor control relay, is grounded after passing through a control contact of the normally-open wiper motor control relay and the wiper motor, and is grounded after passing through the normally-open ultrasonic wave generator control relay and the ultrasonic wave generator; and the electromagnetic coil of the normally-open ultrasonic wave generator control relay is connected in parallel with the electromagnetic coil of the normally-open wiper motor control relay. Through the control circuit for removing the rainwater of the automobile rearview mirror by using the ultrasonic wave, the defects such as poor application effect, high potential safety hazard and the like in the prior art can be overcome to realize a good application effect and low potential safety hazard.

Owner:龚文资

Road obstacle detector

InactiveCN106093953AReduce lossesAccurate measurementAcoustic wave reradiationControl signalComputerized system

The invention provides a road obstacle detector. The road obstacle detector comprises an ultrasonic wave range finding sensor, a control unit, a computer system, an alarm device and a power supply device, wherein the ultrasonic wave range finding sensor includes an ultrasonic wave emitter and an ultrasonic wave receiving device; the ultrasonic wave emitter is used for emitting an ultrasonic wave signal to a front portion; the ultrasonic wave receiving device is used for receiving a reflected ultrasonic wave signal; the control unit calculates a difference value of time for emitting the ultrasonic wave signal and time for receiving the reflected ultrasonic wave signal, compares the difference value and a preset time difference value and determines whether there is an obstacle in front of a road, and if there is the obstacle, the control unit further calculates an obstacle height; the computer system receives the obstacle height and compares the obstacle height with a preset height threshold, if the obstacle height is greater than the preset height threshold, a vehicle can not pass through and an alarm control signal is emitted; the alarm device emits an alarm signal according to an alarm control signal; and the power supply device provides power for an internal source of the vehicle and the ultrasonic wave range finding sensor. By using the detector of the invention, an early warning effect can be reached so that unnecessary losses during a vehicle running process are reduced.

Owner:SHIJIAZHUANG UNIVERSITY

Casting device and casting method

InactiveCN105642869AProlong ultrasonic vibration timeImprove Sonication EfficiencyFoundry mouldsFoundry coresDie castingUltrasonic vibration

Owner:QINGDAO TAIWEI MACHINE TOOL

Method for determining service life and reliability of high-temperature high-pressure component by utilizing ultrasonic

InactiveCN101509898ADetermine service lifeAnalysing solids using sonic/ultrasonic/infrasonic wavesProperty distributionState parameter

The invention discloses a method used for obtaining the service life and the reliability of a high-temperature high-pressure component by utilizing ultrasonic, belonging to the technical field of high-temperature component service life prediction. The method is characterized by comprising the steps of obtaining the ultrasonic velocity V1 in the material to be detected by using an ultrasonic apparatus; according to the ultrasonic velocity V1, obtaining a material damage state parameter Dv, and further obtaining a mean value * of the deviation of high-temperature permanent properties of the damaged material; and according to * is equal to A plus f (P (tr, T)) minus log (Sigma), calculating the service life tr of the component under the set temperature t and the stress Sigma, wherein A is a permanence property distribution parameter and obtained by the following formula: R is equal to Phi (A / s), wherein R is the selected reliability, Phi (A / s) is a normal distribution function, and s is distribution variance. The invention has the beneficial effects that the method not only can determine the service life of the high-temperature high-pressure component under the set reliability, but also can be used for determining the service reliability of the high-temperature high-pressure component under the set temperature, stress and service time.

Owner:DALIAN UNIV OF TECH

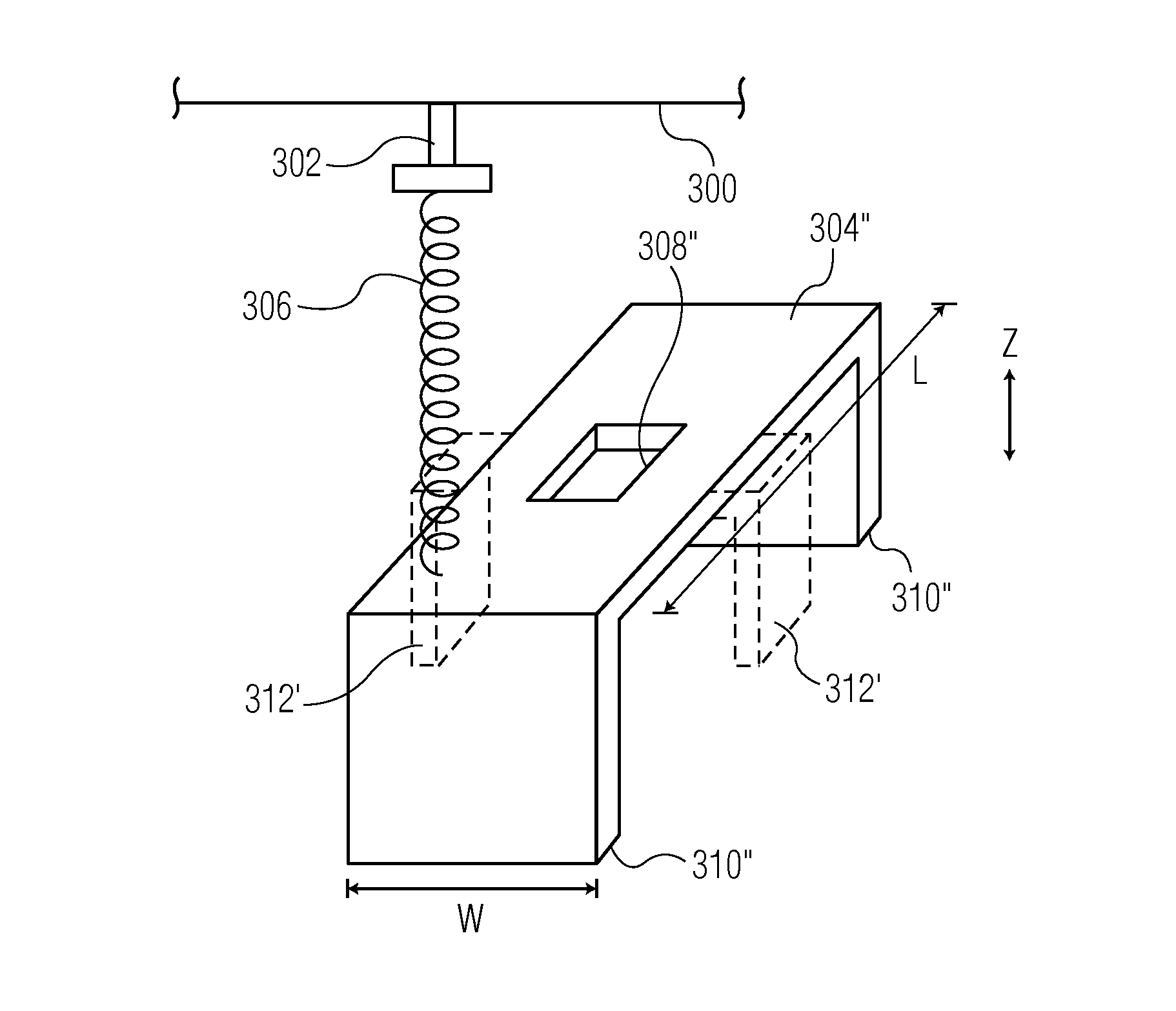

Ultrasonic welding device

PendingCN108247193AOvercoming usage defectsSimple designNon-electric welding apparatusUltrasonic weldingEngineering

The invention relates to the technical field of welding, in particular to an ultrasonic welding device. The ultrasonic welding device mainly comprises a driving mechanism, a head portion and an energyexchange component and is characterized in that a supporting frame is arranged in the head portion and connected with a power output end of the driving mechanism, and the energy exchange component isarranged in front of the head portion and fixedly connected with the supporting frame. By structural optimization and improvement, a welding head is capable of flexibly adapting to incoming materialdirections in a welding process, adaptability is achieved no matter materials come from a longitudinal direction or a transverse direction and from the bottom of the head portion or left and right sides of the head portion, defects in use of traditional welding equipment are well overcome, and more supply choices are provided in an ultrasonic welding process. Especially in application to integration of automatic equipment, a wide application range is realized, production efficiency is greatly improved, a design structure of the automatic equipment is simplified, and design cost of the automatic equipment is reduced.

Owner:KEPU ULTRASONIC ELECTRONICS TECHCAL

Ultrasonic improved fabric dyeing device and process thereof

InactiveCN108914457AImprove dye uptakeEnhance stirringTextile treatment machine partsVibration treatmentWater bathsLongitudinal wave

Owner:南通东屹高新纤维科技有限公司

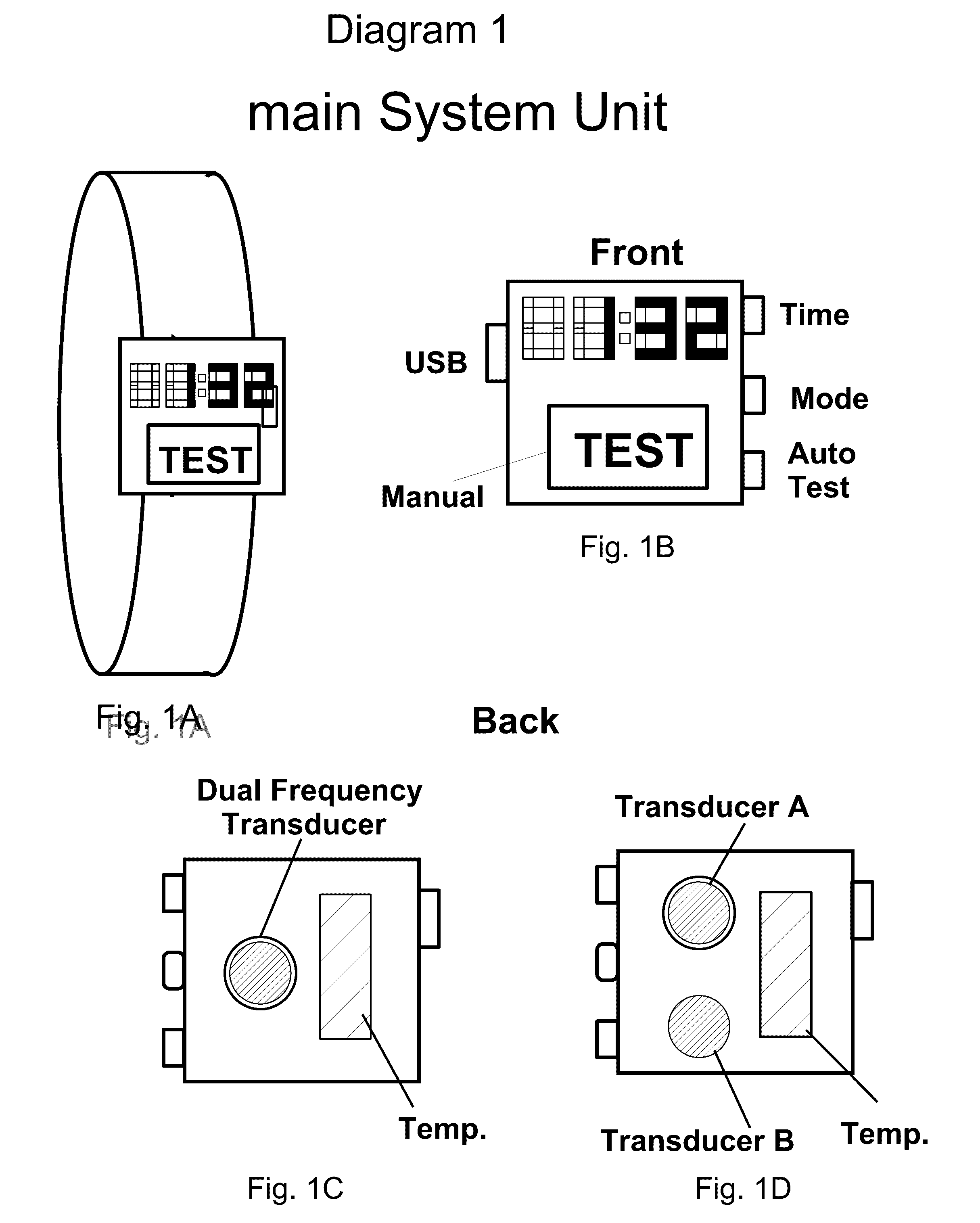

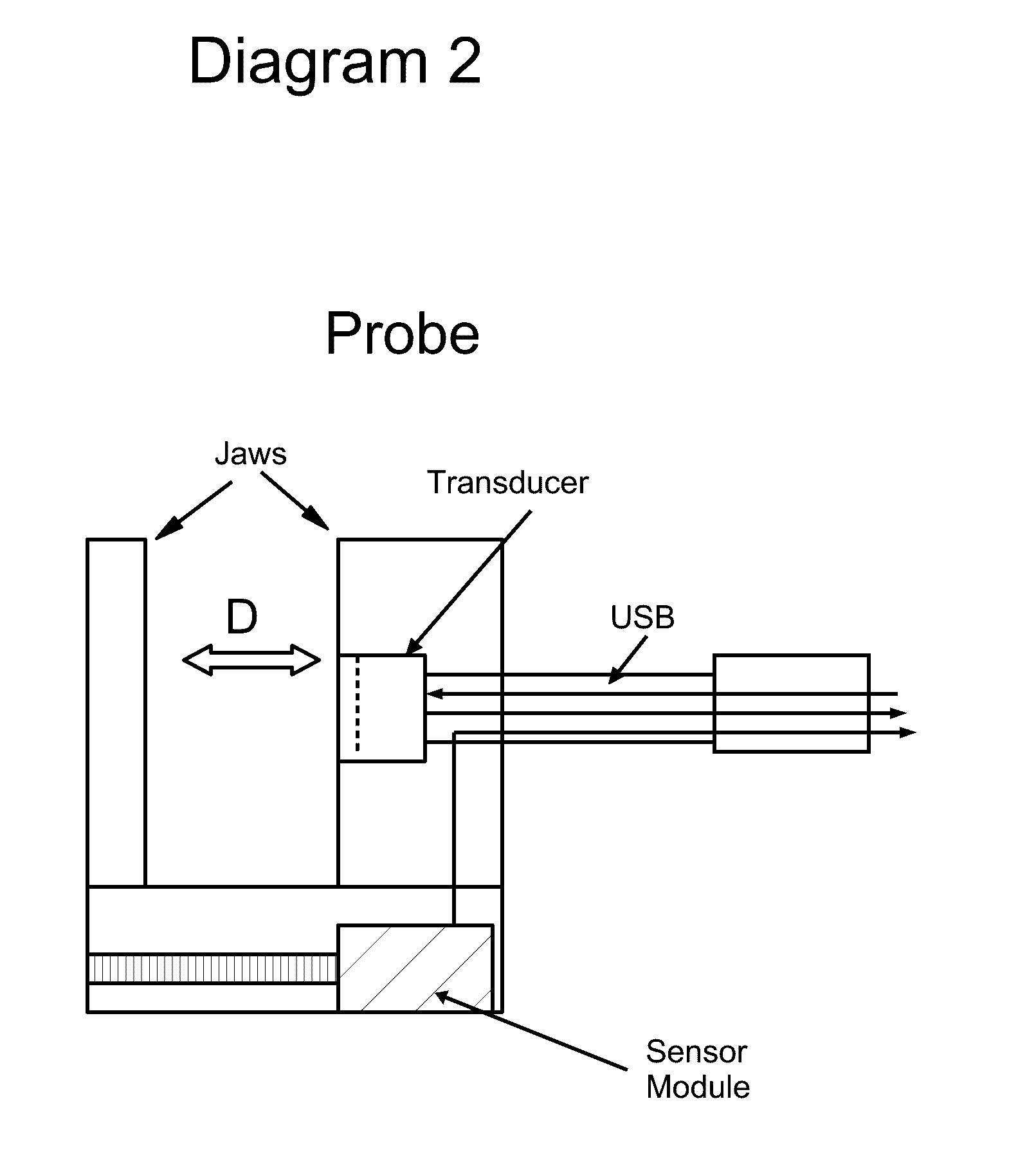

Method and apparatus for non-invesive blood glucose monitoring system

InactiveUS20160374599A1Great tendencyDegree of effectivenessDiagnostic probe attachmentBlood flow measurement devicesHuman bodySonification

Owner:FRATTAROLA JOSEPH RALPH

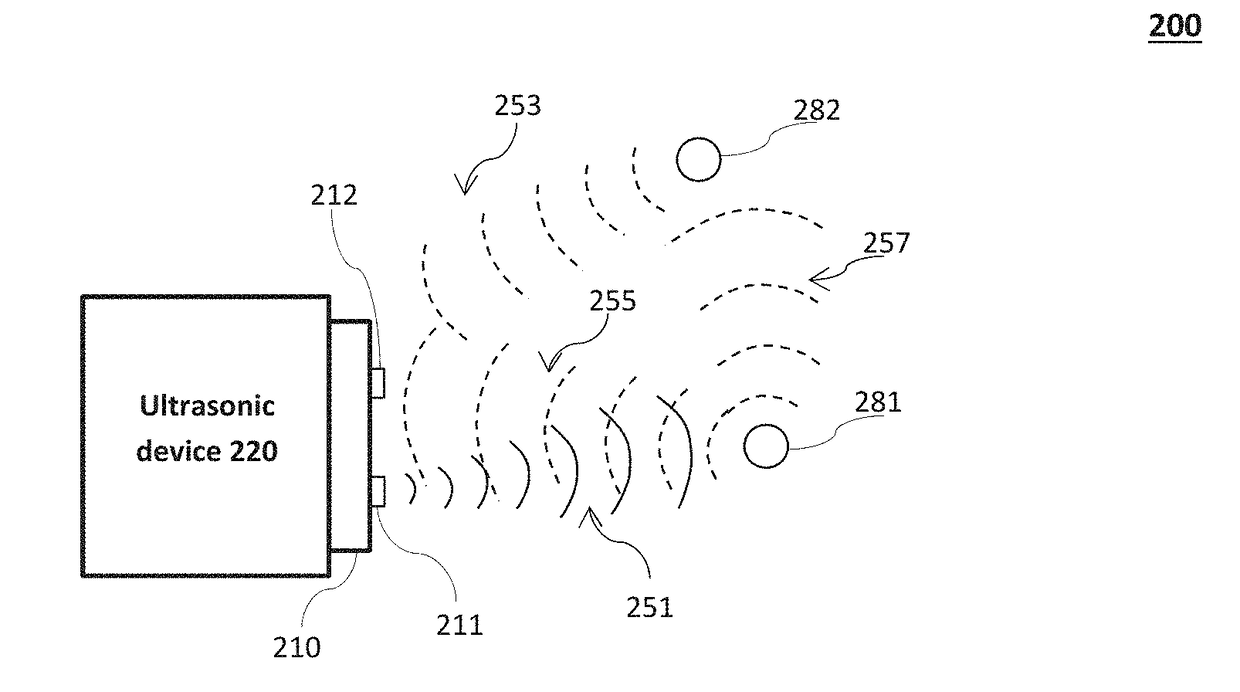

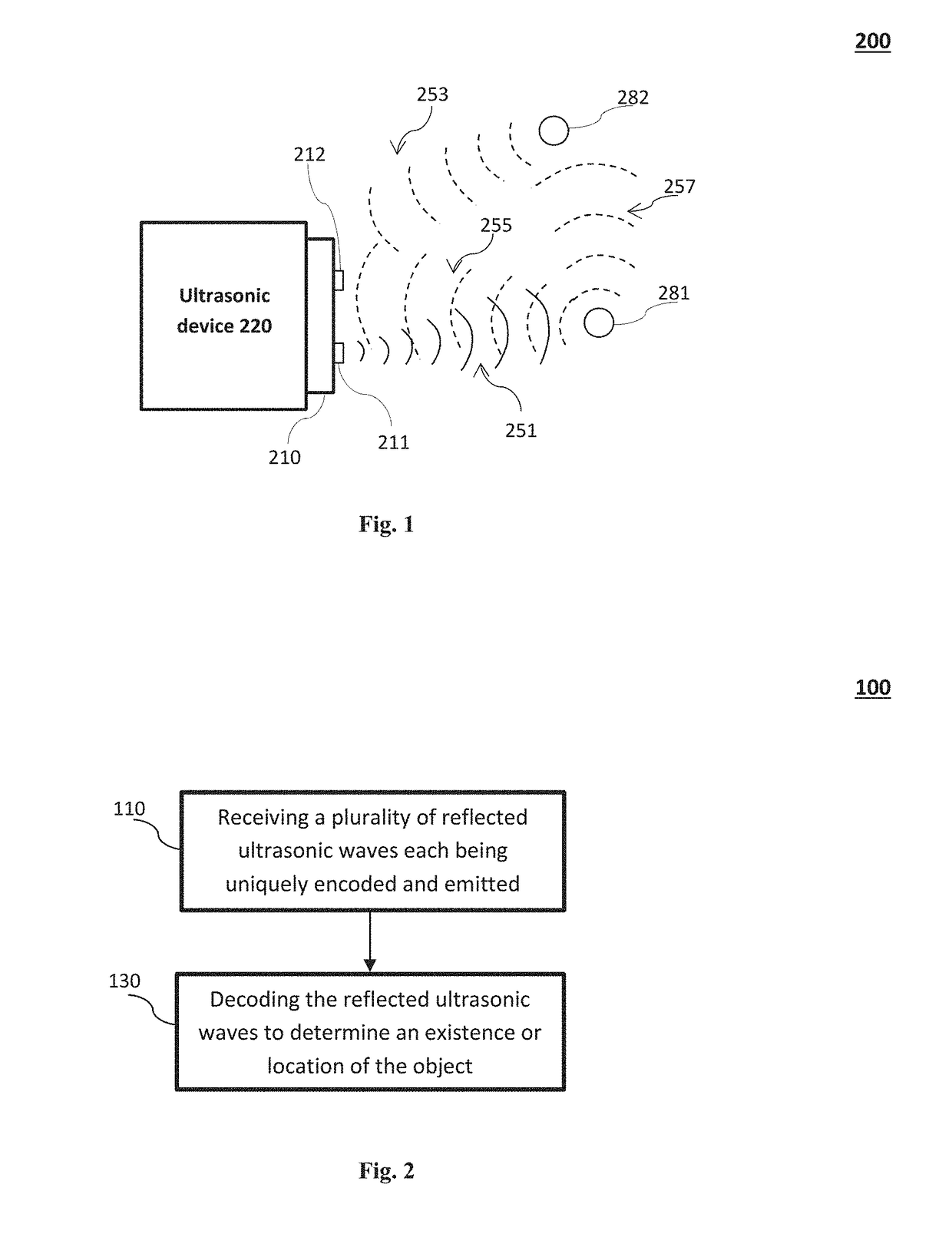

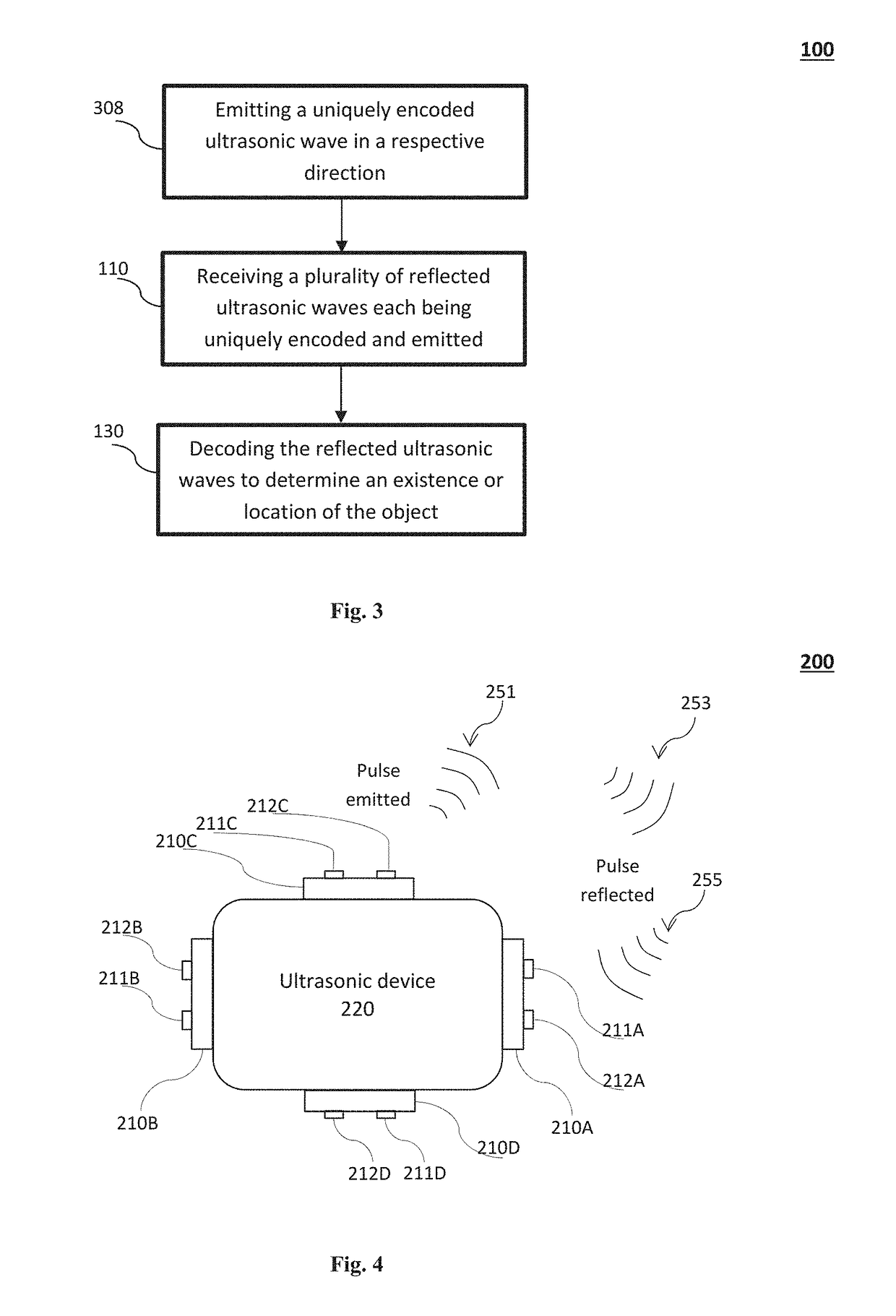

System and method for detecting an object

Owner:SZ DJI TECH CO LTD

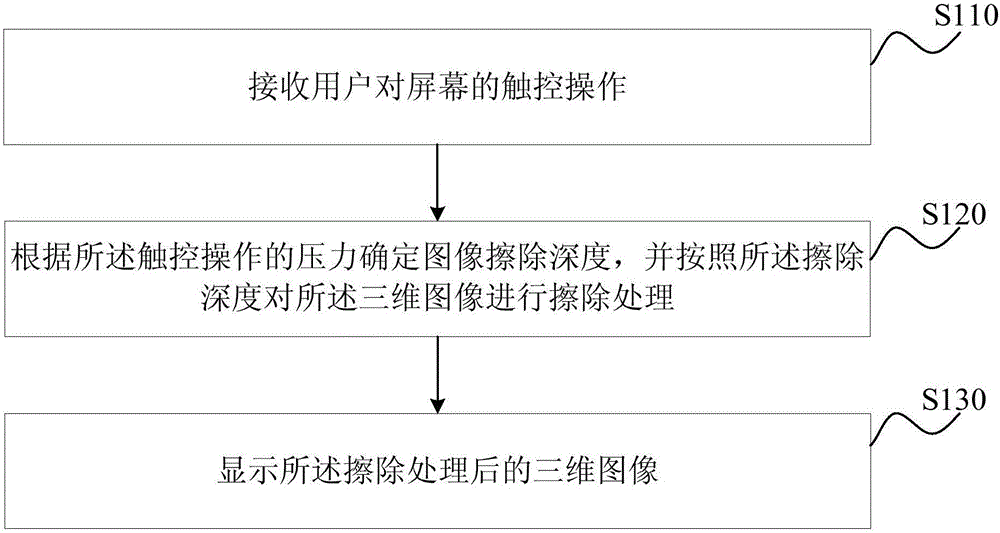

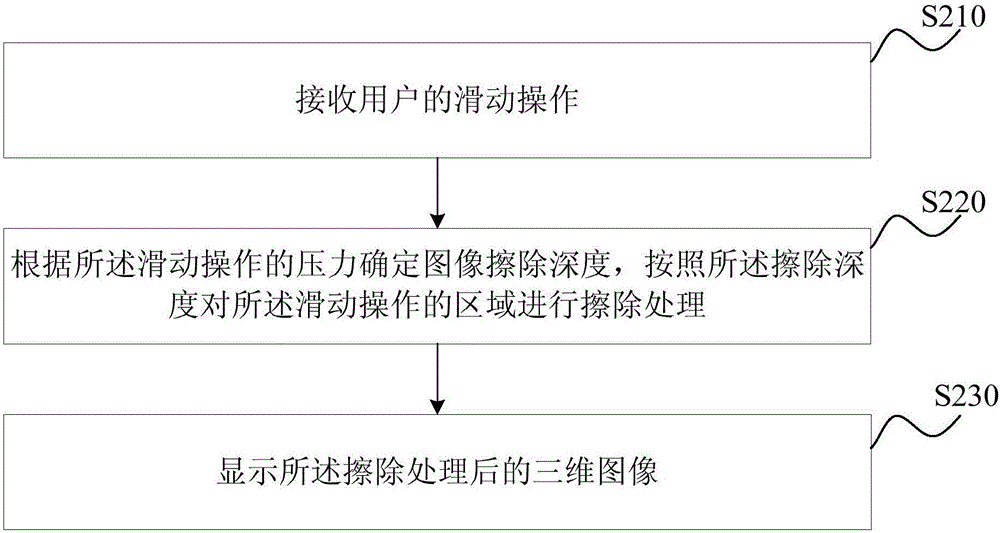

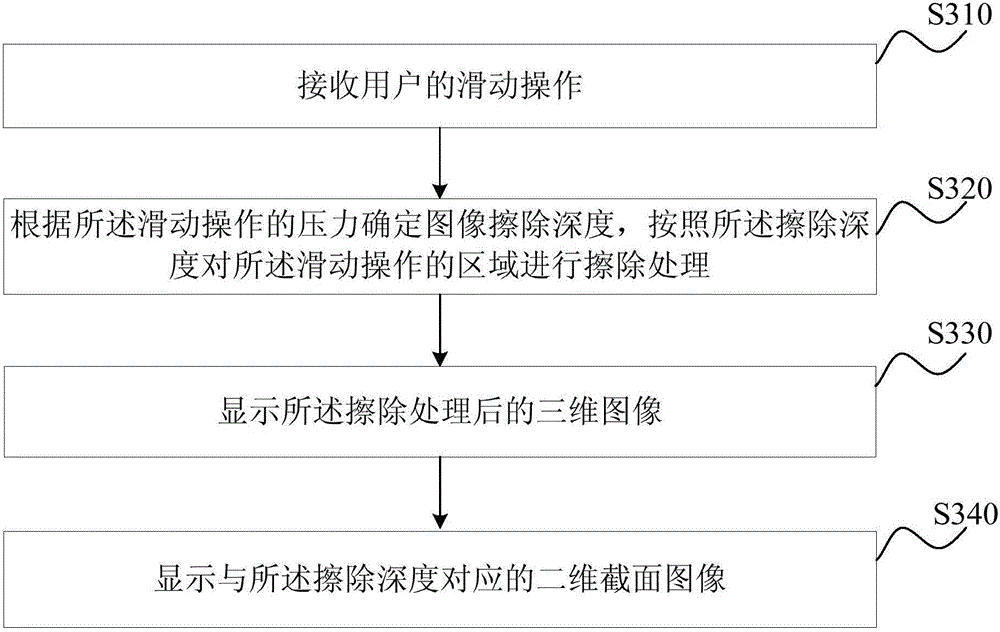

Ultrasonic three-dimensional image display method and device

ActiveCN106108944AAdjust wipe parametersIntuitive adjustmentUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsComputer graphics (images)Display device

Owner:VINNO TECH (SUZHOU) CO LTD

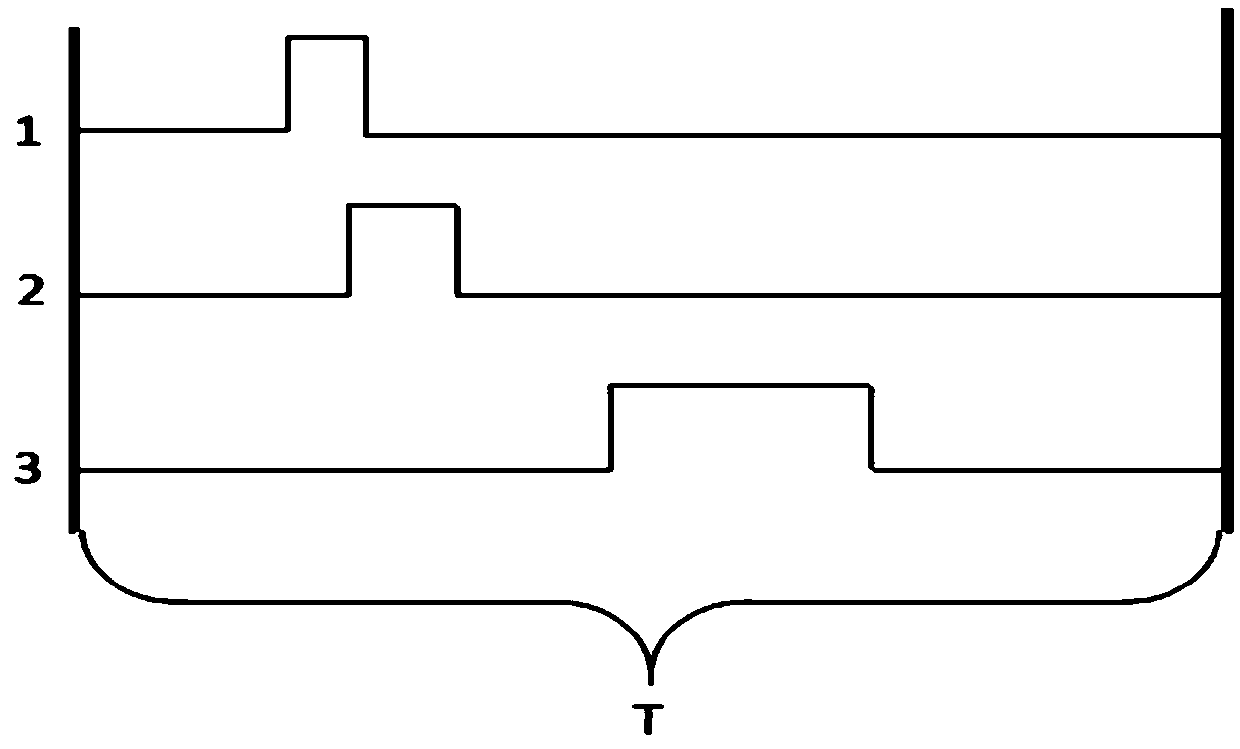

Three-dimensional spatial positioning method and system

InactiveCN110376549AImprove spatial positioning accuracyPosition fixationSpatial positioningThree-dimensional space

Owner:NOLO CO LTD

Method of extracting active ingredients of Dendropanax dentiger leaves with ultrasonic waves

ActiveCN104840497AImprove immunitySimple extraction methodImmunological disordersPlant ingredientsSolventBULK ACTIVE INGREDIENT

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

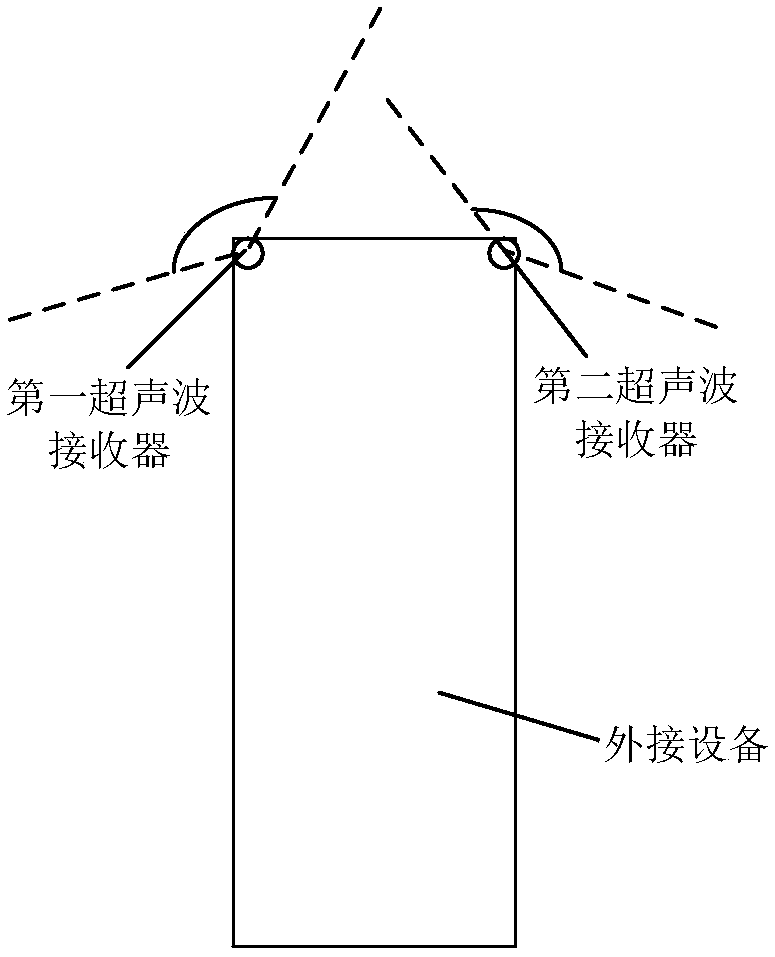

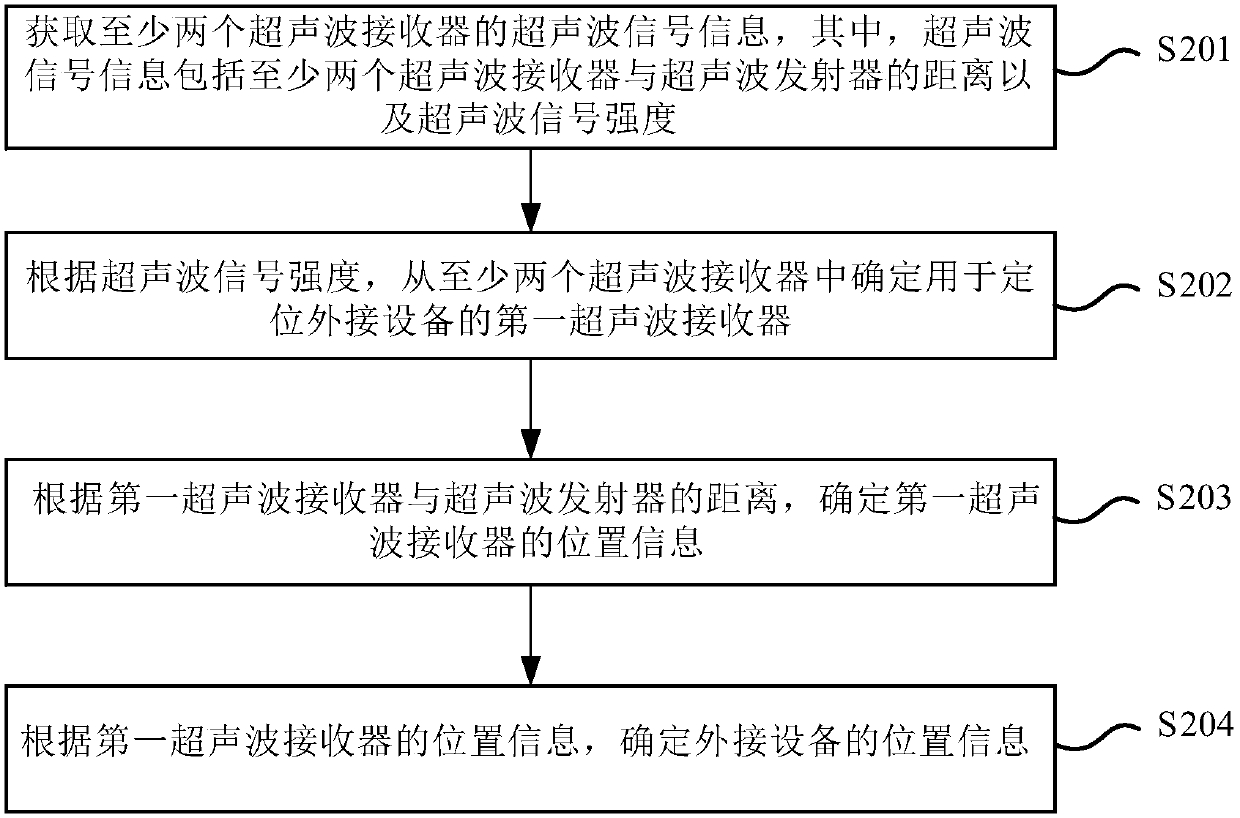

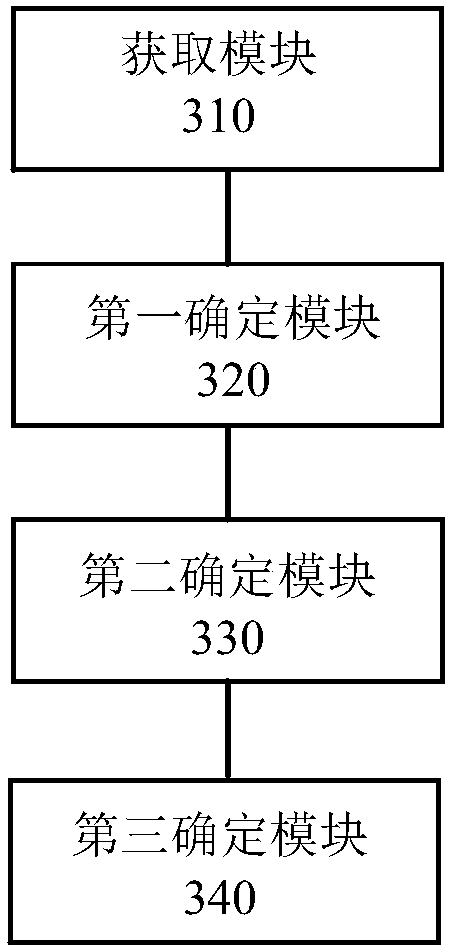

External device positioning method and device, and virtual reality device and system

InactiveCN108169713AInput/output for user-computer interactionPosition fixationEngineeringUltrasound

Owner:QINGDAO PICO TECH CO LTD

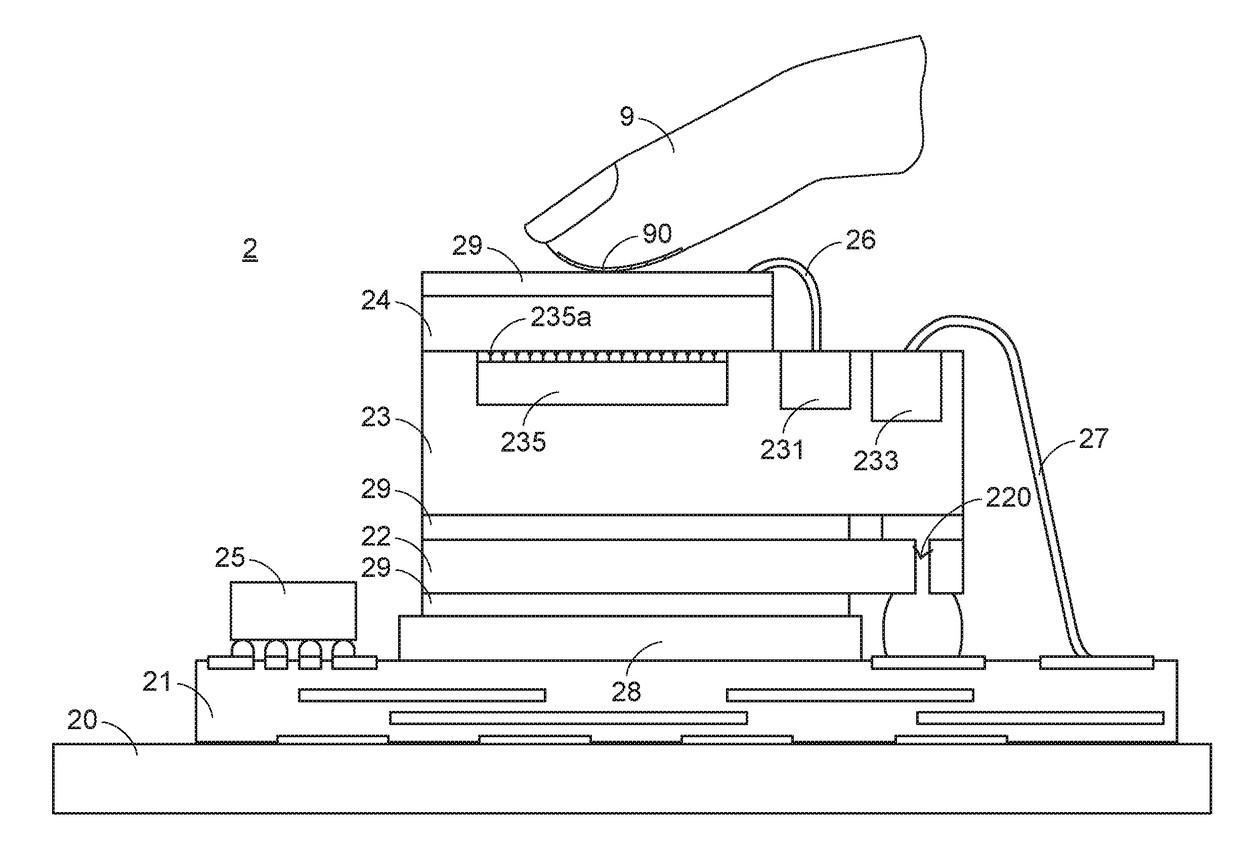

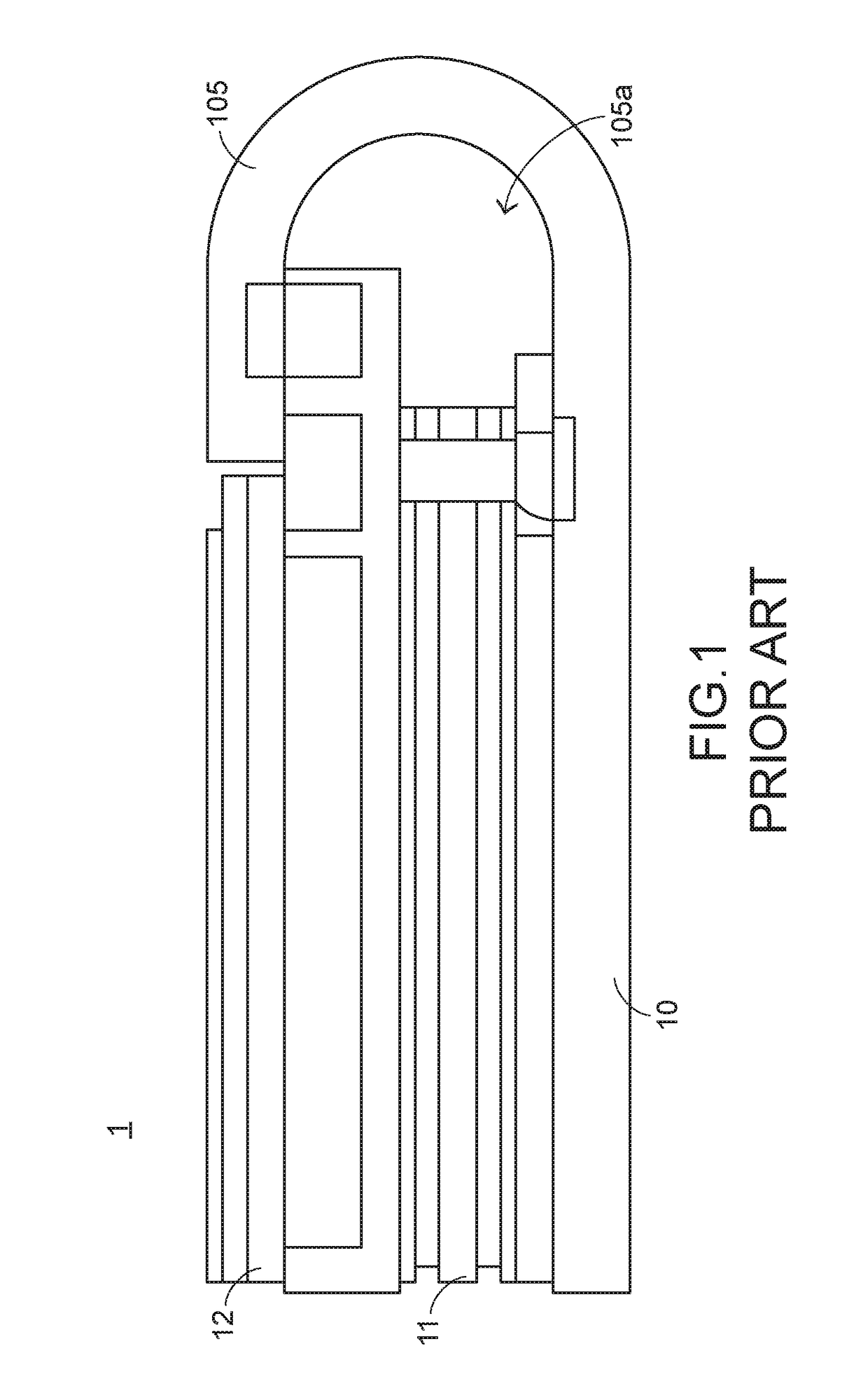

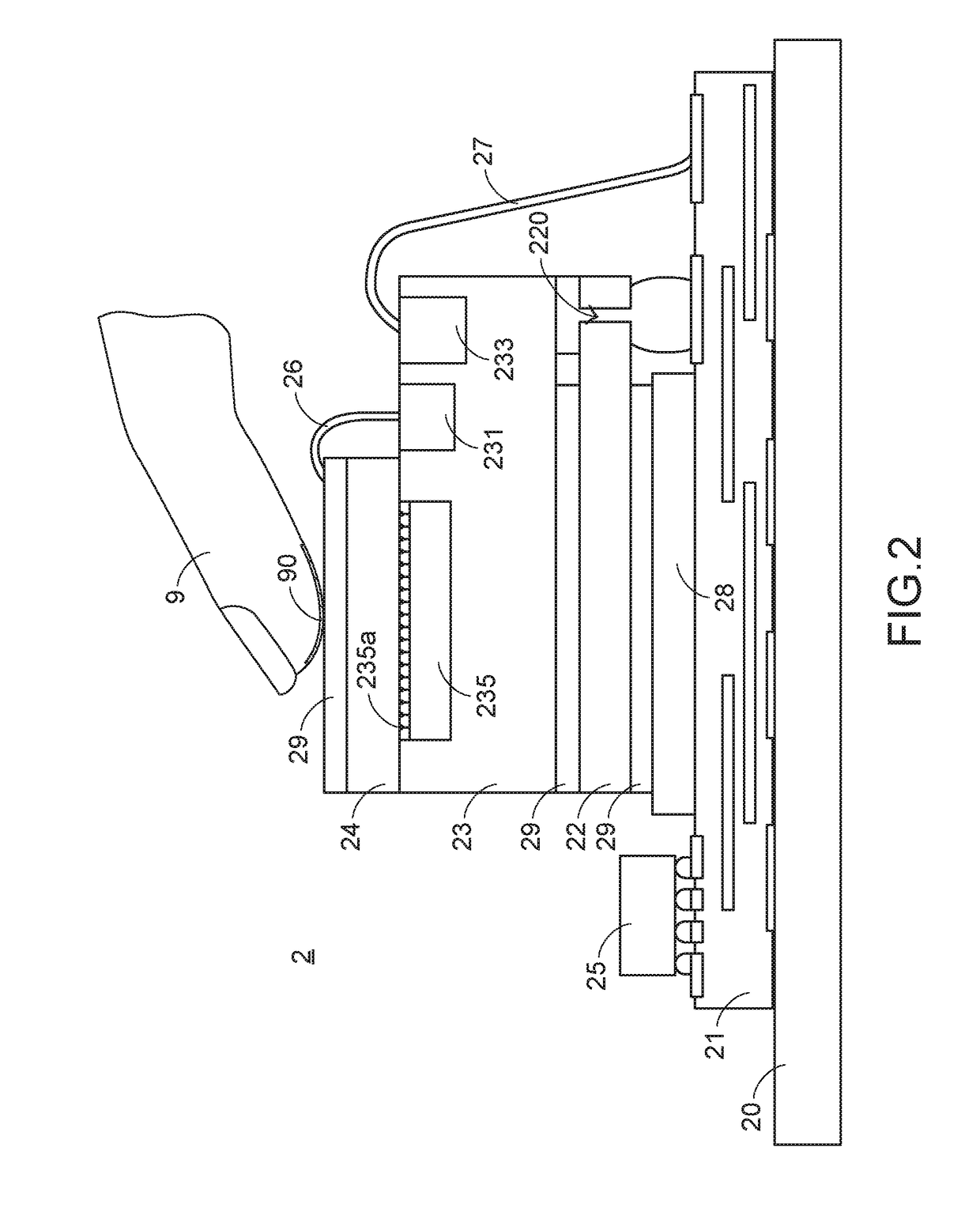

Ultrasonic fingerprint recognition module and manufacturing method thereof

InactiveUS20180005002A1Lower the volumeSimple structureSemiconductor/solid-state device detailsSolid-state devicesEngineeringUltrasound

Owner:PRIMAX ELECTRONICS LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap