Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5 results about "Ultrasonic welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrasonic welding is an industrial technique whereby high-frequency ultrasonic acoustic vibrations are locally applied to workpieces being held together under pressure to create a solid-state weld. It is commonly used for plastics and metals, and especially for joining dissimilar materials. In ultrasonic welding, there are no connective bolts, nails, soldering materials, or adhesives necessary to bind the materials together. When applied to metals, a notable characteristic of this method is that the temperature stays well below the melting point of the involved materials thus preventing any unwanted properties which may arise from high temperature exposure of the materials.

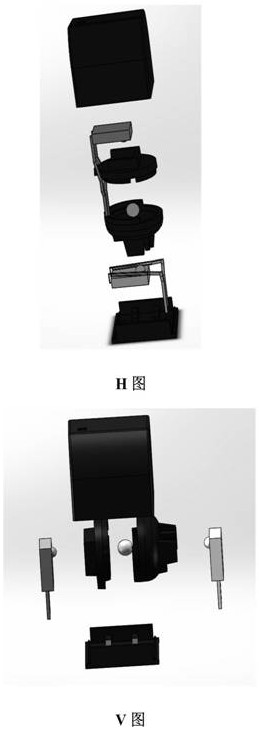

Ultrasonic welding device

PendingCN108247193AOvercoming usage defectsSimple designNon-electric welding apparatusUltrasonic weldingEngineering

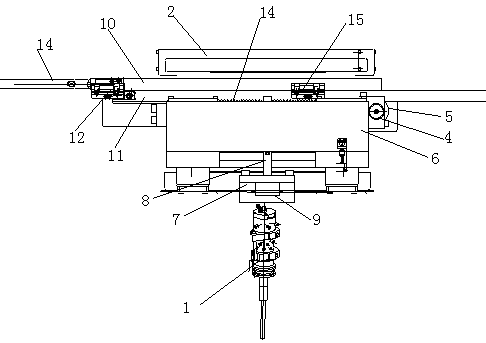

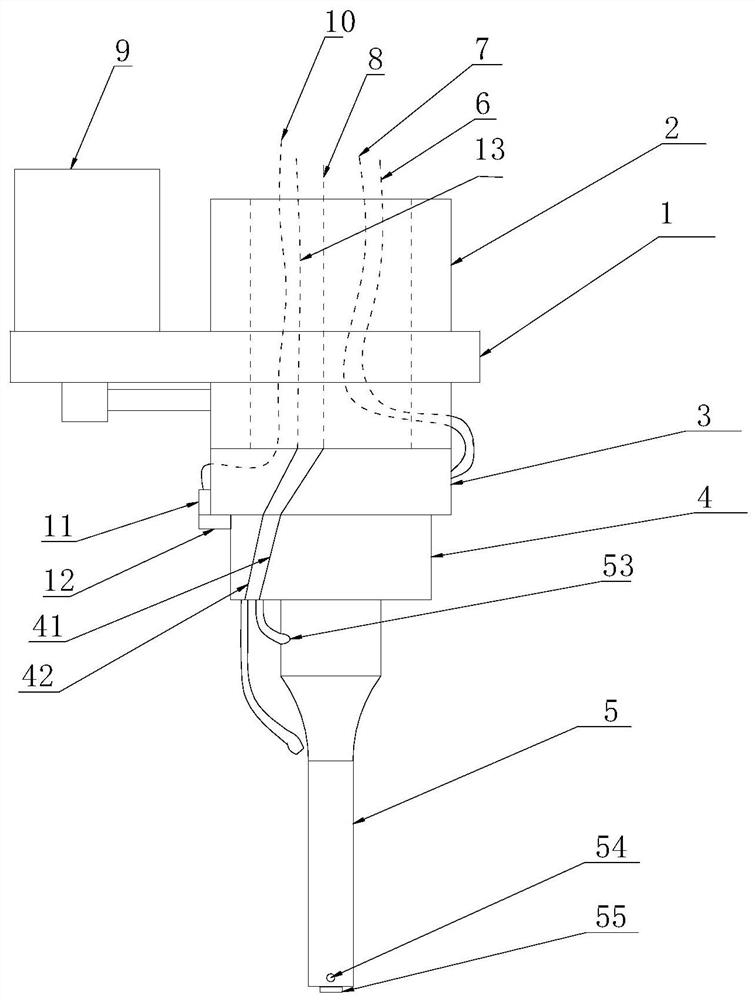

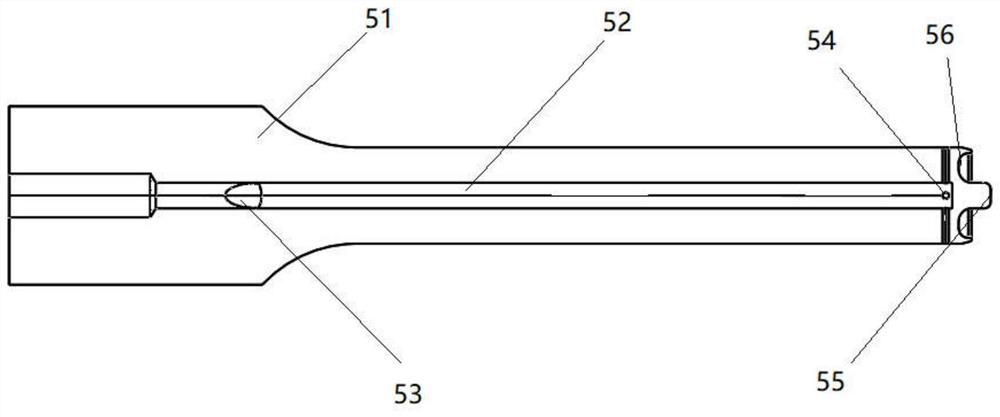

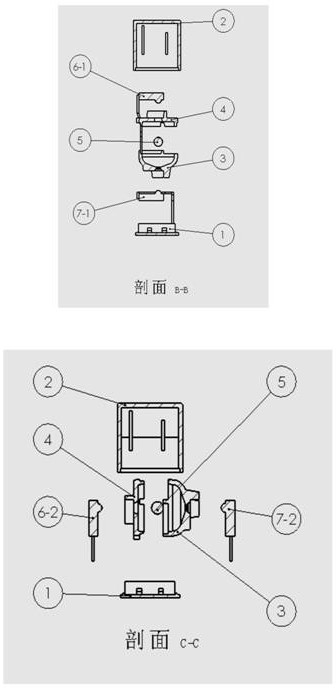

The invention relates to the technical field of welding, in particular to an ultrasonic welding device. The ultrasonic welding device mainly comprises a driving mechanism, a head portion and an energyexchange component and is characterized in that a supporting frame is arranged in the head portion and connected with a power output end of the driving mechanism, and the energy exchange component isarranged in front of the head portion and fixedly connected with the supporting frame. By structural optimization and improvement, a welding head is capable of flexibly adapting to incoming materialdirections in a welding process, adaptability is achieved no matter materials come from a longitudinal direction or a transverse direction and from the bottom of the head portion or left and right sides of the head portion, defects in use of traditional welding equipment are well overcome, and more supply choices are provided in an ultrasonic welding process. Especially in application to integration of automatic equipment, a wide application range is realized, production efficiency is greatly improved, a design structure of the automatic equipment is simplified, and design cost of the automatic equipment is reduced.

Owner:KEPU ULTRASONIC ELECTRONICS TECHCAL

Ultrasonic welding base structure

ActiveCN108581172ASimple structureEasy to useNon-electric welding apparatusUltrasonic weldingEngineering

Owner:苏州昕源辰机械设备有限公司

R-axis optimized ultrasonic welding device

Owner:广东富强科技股份有限公司

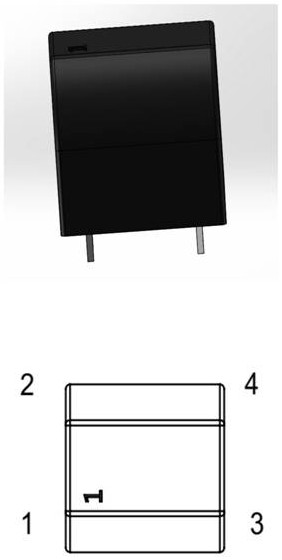

Photoelectric dumping switch

Owner:常德思高技术有限公司

Method for ultrasonic welding of copper thin plate and nickel thin plate

ActiveCN111843169AGood dispersionNot easily oxidizedWelding/soldering/cutting articlesNon-electric welding apparatusPower batteryElectrical resistance and conductance

The invention discloses a method for ultrasonic welding of a copper thin plate and a nickel thin plate. The method comprises the steps that the portion between the to-be-welded copper thin plate and the to-be-welded nickel thin plate is coated with nano nickel formate particles to form a middle layer with the thickness of 15-45 microns; before the middle layer is coated, the copper thin plate andthe nickel thin plate are immersed in a dilute hydrochloric acid solution with the concentration of 4.5%-8.8% to be washed for 5-10 minutes, and then the middle layer is cleaned with pure alcohol andair-dried; and the copper thin plate and the nickel thin plate coated with the nano nickel formate particles as the middle layer are subjected to ultrasonic welding for 0.20-0.75 seconds at the welding pressure of 30-60 psi, wherein the welding amplitude is 25-55 microns. According to the method, the nano nickel formate particles are used as the middle layer to assist ultrasonic welding of the copper thin plate and the nickel thin plate, the maximum shearing strength can reach 2898 N, the joint resistance is less than 102 microhm, the mechanical property and conductive performance of a joint are improved, and the requirement of the automobile power battery industry for ultrasonic welding of copper / nickel joints can be met.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap