Photoelectric dumping switch

A photoelectric switch technology, applied in the field of photoelectric dump switch, can solve the problems of long production cycle, complicated assembly, easy to fall off, etc., and achieve the effect of simple manufacture, convenient packaging and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

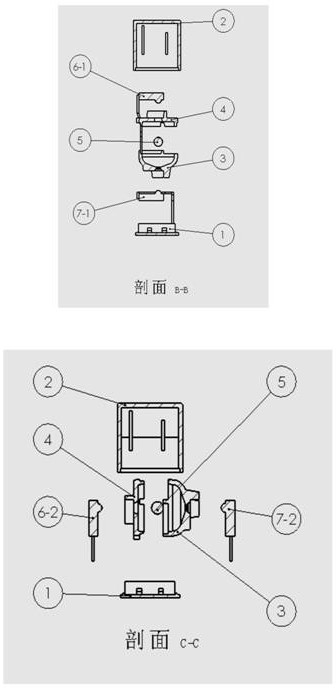

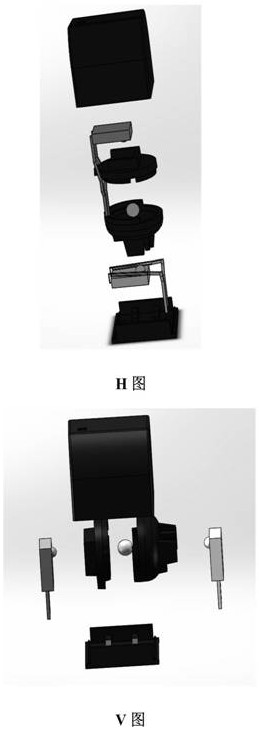

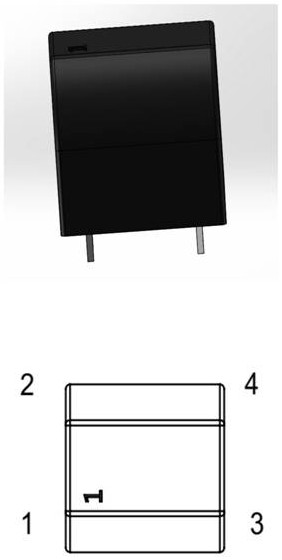

[0025] Such as Figure 1-10 As shown, the present invention provides a photoelectric dump switch, which is characterized by comprising: a housing 2 with an inner cavity, and a vertical ball bin assembly is arranged in the inner cavity of the housing 2, and the ball bin assembly includes a bin body 3 , Canopy cover 4, ball 5, photoelectric emission tube 6-1 and photoelectric receiving tube 7-1, by the ball bin assembly with ball 5, the bottom of ball bin assembly is provided with photoelectric emission tube 6-1, and the top is provided with photoelectric receiving tube 7 -1, and the emitting end cylinder of the photoelectric emitting tube 6-1 and the receiving end cylinder of the photoelectric receiving tube 7-1 are arranged opposite to the center of the ball 5, the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap