Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39 results about "Polystyrene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polystyrene (PS) /ˌpɒliˈstaɪriːn/ is a synthetic aromatic hydrocarbon polymer made from the monomer styrene. Polystyrene can be solid or foamed. General-purpose polystyrene is clear, hard, and rather brittle. It is an inexpensive resin per unit weight. It is a rather poor barrier to oxygen and water vapour and has a relatively low melting point. Polystyrene is one of the most widely used plastics, the scale of its production being several million tonnes per year. Polystyrene can be naturally transparent, but can be coloured with colourants. Uses include protective packaging (such as packing peanuts and CD and DVD cases), containers, lids, bottles, trays, tumblers, disposable cutlery and in the making of models.

Microcapsule composition

InactiveUS20050164116A1Lower resistanceGood workmanshipPhotosensitive materialsRadiation applicationsPolymer sciencePolystyrene

This invention relates to a composition comprising microcapsules suspended in an aqueous media, said microcapsules comprising a water immiscible material contained within an encapsulating wall of polymeric material, wherein the aqueous media contains a stabilizer comprising an anionic polymer mixture comprising a first sulfonated polystyrene polymer and a second sulfonated polystyrene polymer wherein the ratio of the weight average polymer molecular weight of the first polymer to the second polymer is greater than 2. It further relates to an imaging element comprising said microcapsules.

Owner:EASTMAN KODAK CO

Composition of styrene resin, thermoplastic resin and rubber

InactiveUS6013726AImprove heat resistanceHigh mechanical strengthLiquid surface applicatorsFilm/foil adhesivesPolyamidePolystyrene

Owner:IDEMITSU KOSAN CO LTD

Compound biochip based on photon crystal

InactiveCN101358242AImprove performanceEnhanced signal selectivityMicrobiological testing/measurementMicrosphereComposite substrate

Owner:SOUTHEAST UNIV

Phosphor-silicon-containing aggregated flame retardant and preparation method thereof

ActiveCN107266685AOvercome the disadvantage of easy precipitationHigh flame retardant efficiencyGroup 5/15 element organic compoundsEpoxyPolymer science

Owner:宁波塑之华塑化有限公司

Ceramic floor tile with diatom mud and method for manufacturing ceramic floor tile

InactiveCN105298081AReduce processing difficultyNice appearanceCeramic shaping apparatusFlooringSurface layerEthylic acid

Owner:佛山市高明区生产力促进中心

Thermal insulation material and preparation method thereof

InactiveCN107721451AEvenly dispersedEffective control of cell stabilityConstruction materialCeramicwareFoaming agentPolymer science

The invention discloses a thermal insulation material and a preparation method thereof. The thermal insulation material comprises a cement-based block skeleton and graphene modified polystyrene, wherein the cement-based block skeleton comprises multiple cavities; the multiple cavities are filled with graphene modified polystyrene; and graphene modified polystyrene is formed by performing melt extrusion on graphene and polystyrene resin according to a weight ratio of 1:(1-5) in the multiple cavities in the presence of an alkane foaming agent. According to the thermal insulation material disclosed by the invention, the strength and thermal insulation property are further improved.

Owner:ZHONGJING ECO IND CO LTD

Environmental-friendly foaming plastic and preparing method thereof

Owner:ANHUI GUANGYUAN TECH DEV

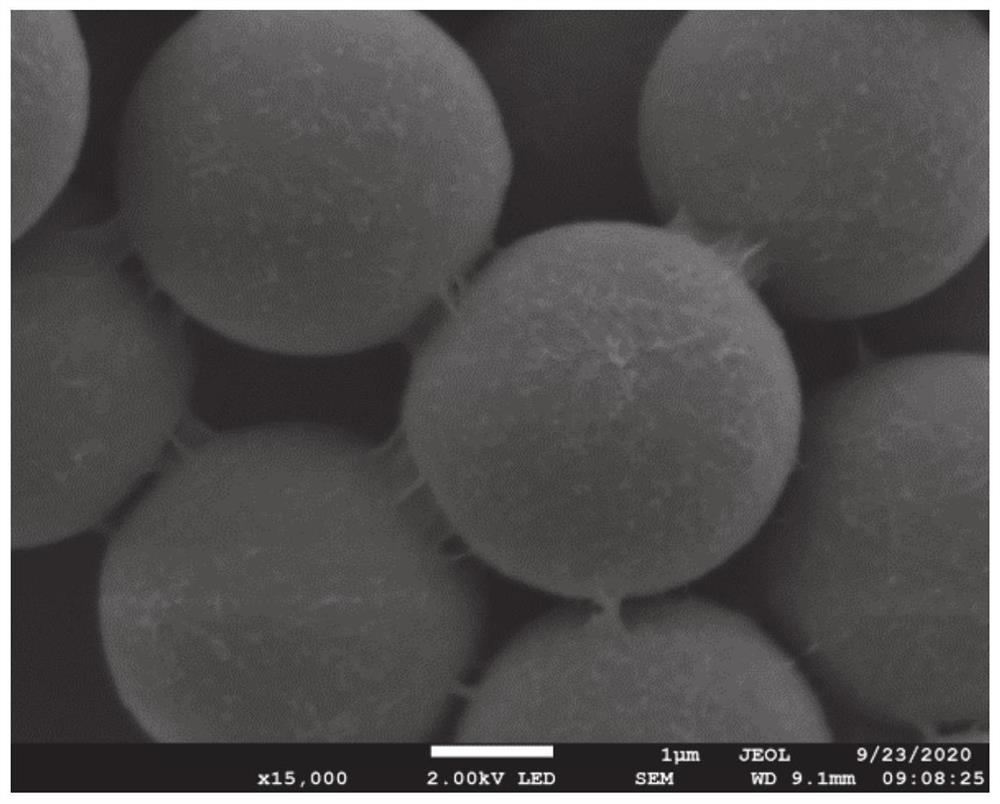

Plasma preparation method of polystyrene fluorescent microspheres and reaction equipment of plasma preparation method

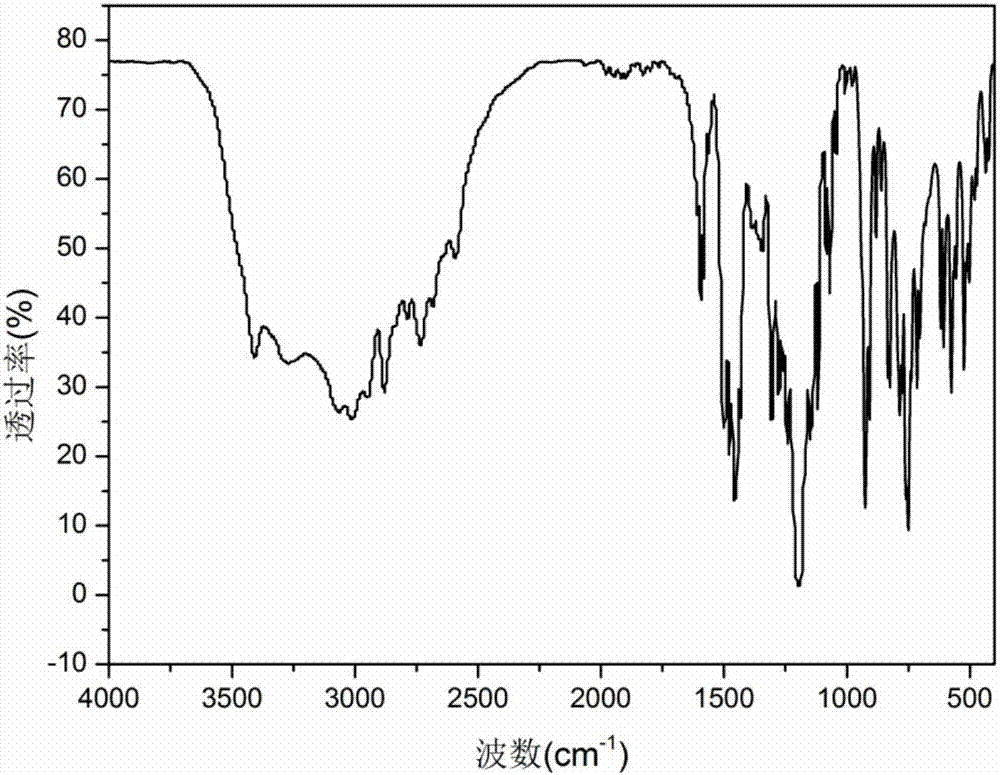

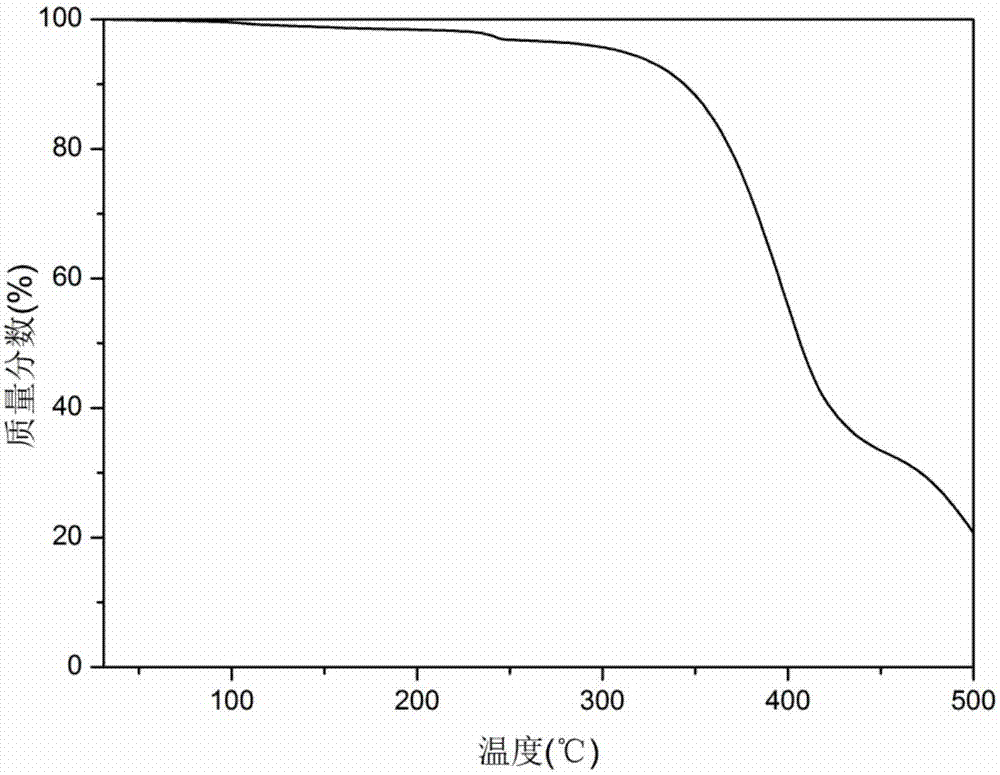

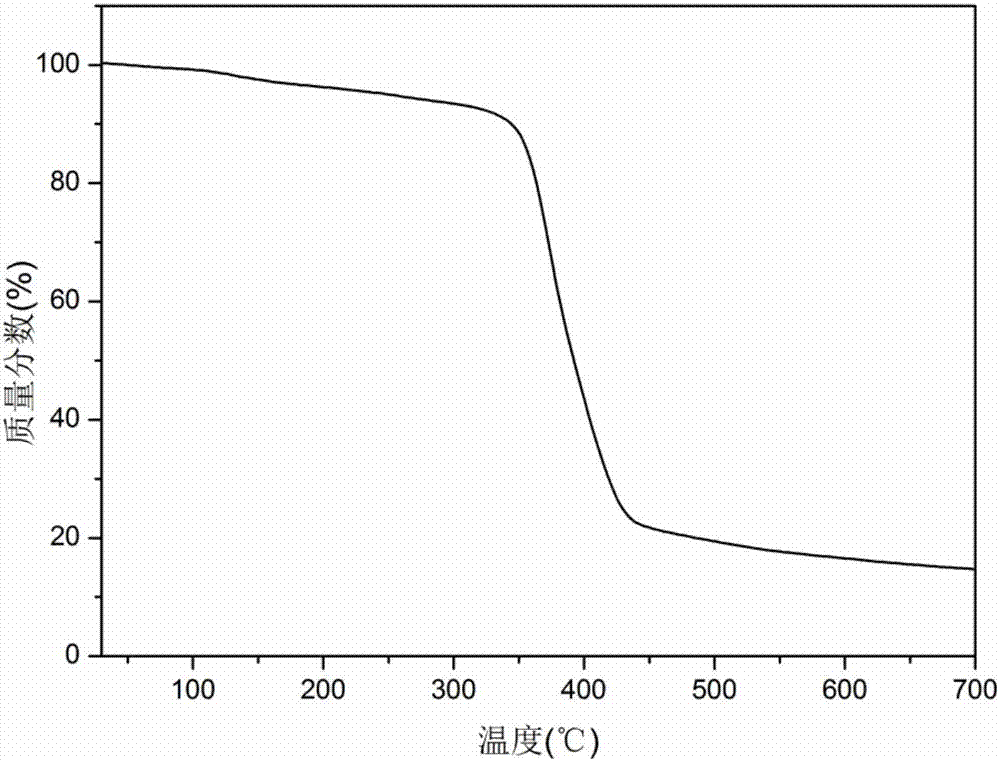

ActiveCN105713126ALong fluorescence lifetimeImprove thermal stabilityLuminescent compositionsOrganic synthesisPolystyrene

The invention discloses a plasma preparation method of polystyrene fluorescent microspheres and reaction equipment of the plasma preparation method, and relates to the technical field of organic synthesis of fluorescent microspheres. A rare earth organic complex is adopted as a starting raw material, plasma of polystyrene is polymerized on the surface of the rare earth organic complex to coat the surface of the rare earth organic complex with a layer of polystyrene, and thus polystyrene fluorescent microspheres are formed. The method includes the main steps of 1, performing plasma pretreatment of the rare earth organic complex; 2, performing plasma polymerization, wherein plasma of polystyrene monomers is polymerized and deposited on the surface of the rare earth organic complex. The polystyrene fluorescent microspheres obtained through the preparation method have a long fluorescent lifetime and good heat stability, and the preparation process is simple, easy to perform and free of environmental pollution.

Owner:HEBEI NATAI CHEM IND CO LTD

Preparation and testing method for supercapacitor based on strong-correlation oxide combined electrode

InactiveCN105047431AImprove conductivityEfficient use ofHybrid capacitor electrodesMaterial electrochemical variablesComposite electrodePolystyrene

The invention discloses a preparation and testing method for a supercapacitor based on a strong-correlation oxide combined electrode. The strong-correlation oxide combined electrode takes a polystyrene film as a template for the electrochemical deposition of a vanadium oxide conductive skeleton. After the polystyrene film is removed, vanadium oxide is taken as a template for the electrochemical deposition of a transition metal oxide, thereby obtaining a composite electrode. Electrodes meeting the requirements are symmetrically disposed at two sides of a diaphragm, thereby obtaining the supercapacitor. Finally, the assembled capacitor directly enters into Na2SO4 solution for electrochemical testing. The method is simple, and is easy to operate. The prepared supercapacitor is excellent in circulation stability, in large in power density, and is high in energy density.

Owner:JILIN UNIV

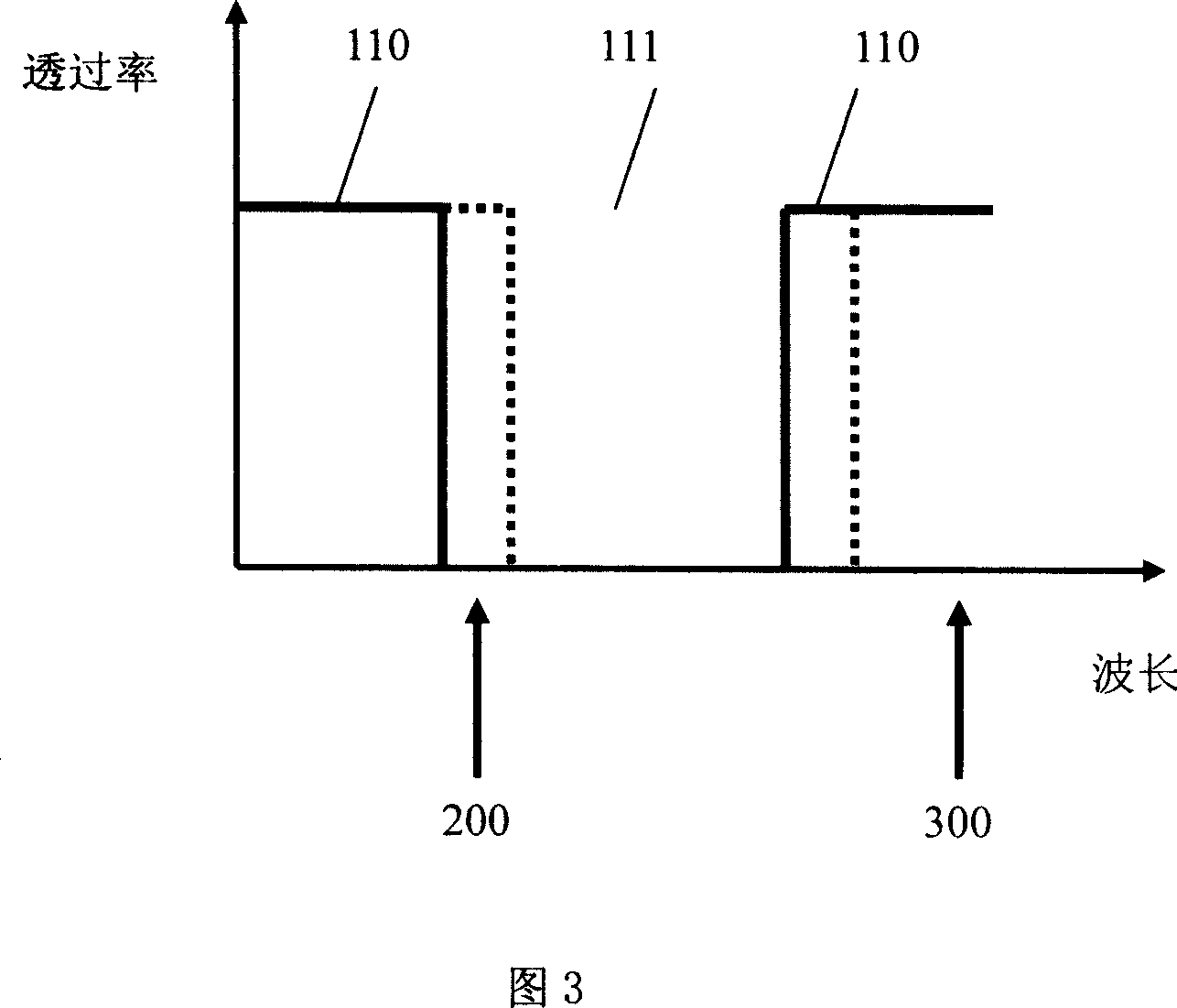

Polystyrene photon crystal and polystyrene photon crystal optical switch

InactiveCN101055399AFast optical switchSmall time responseNon-linear opticsTime responseBasal lamina

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Novel acrylic pressure-sensitive adhesive

ActiveCN108192019AWide range of bondingGood adhesionNon-macromolecular adhesive additivesAmide/imide polymer adhesivesFiberPolyester

Owner:SHANGHAI BAOLIJIA NEW MATERIAL CO LTD

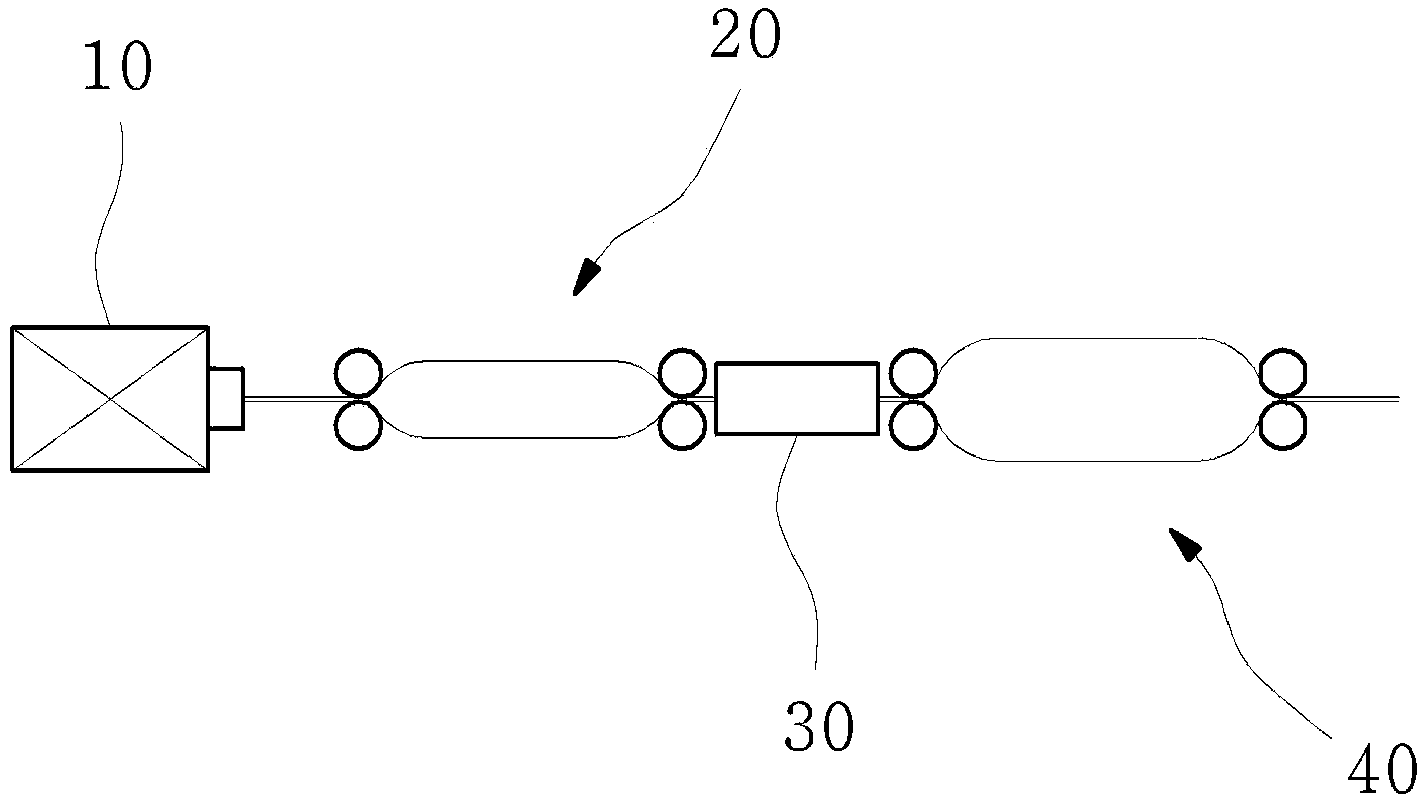

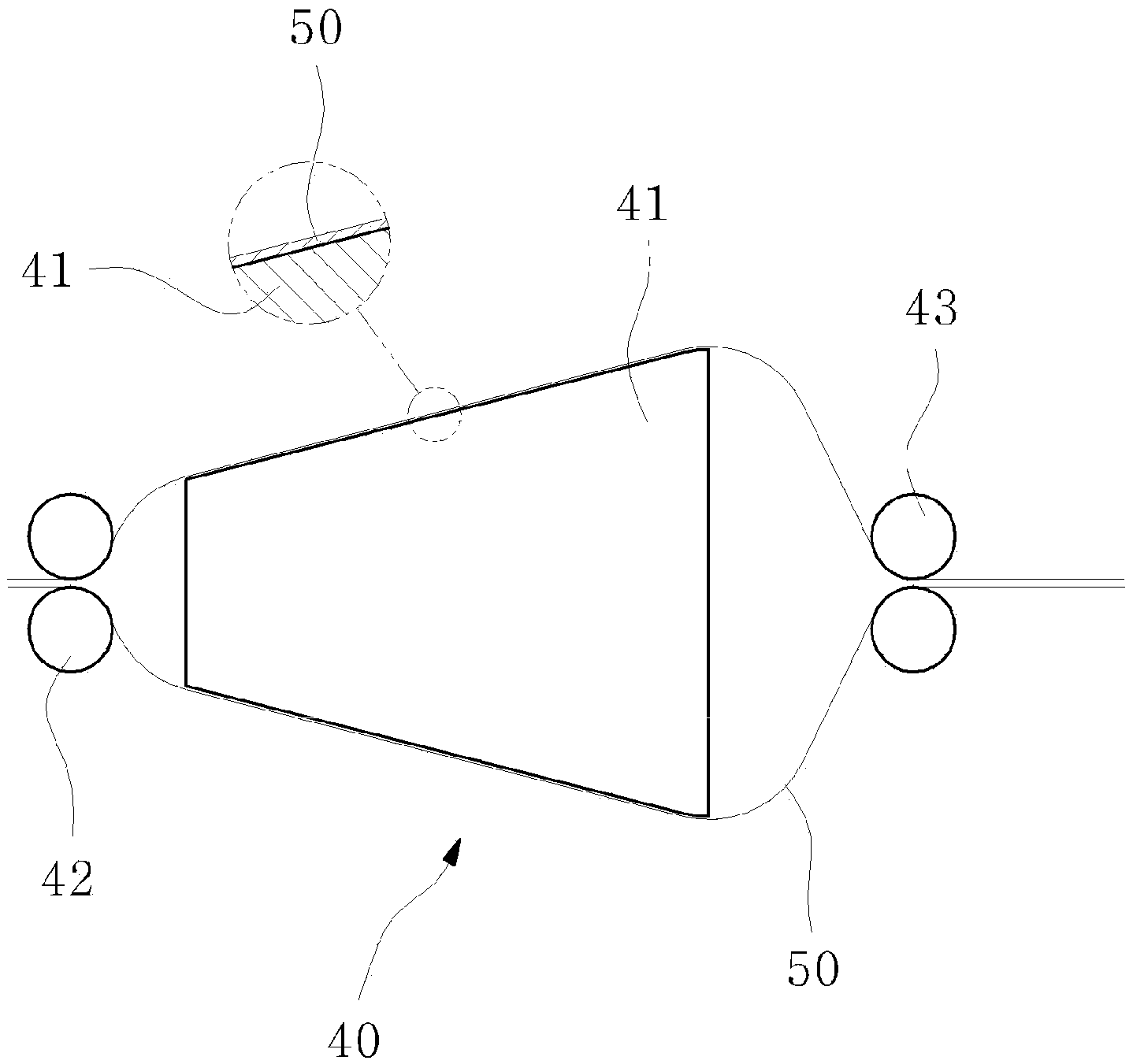

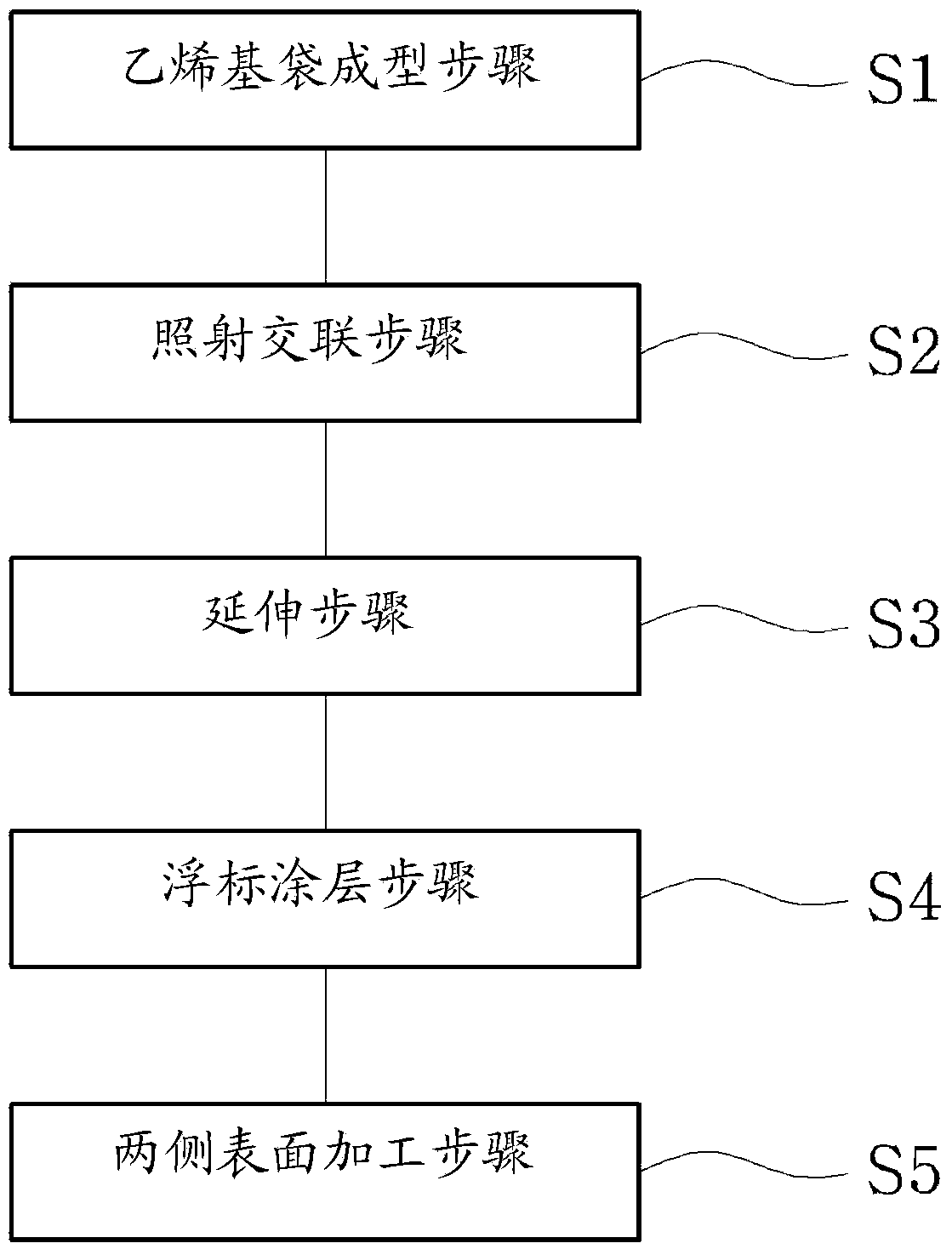

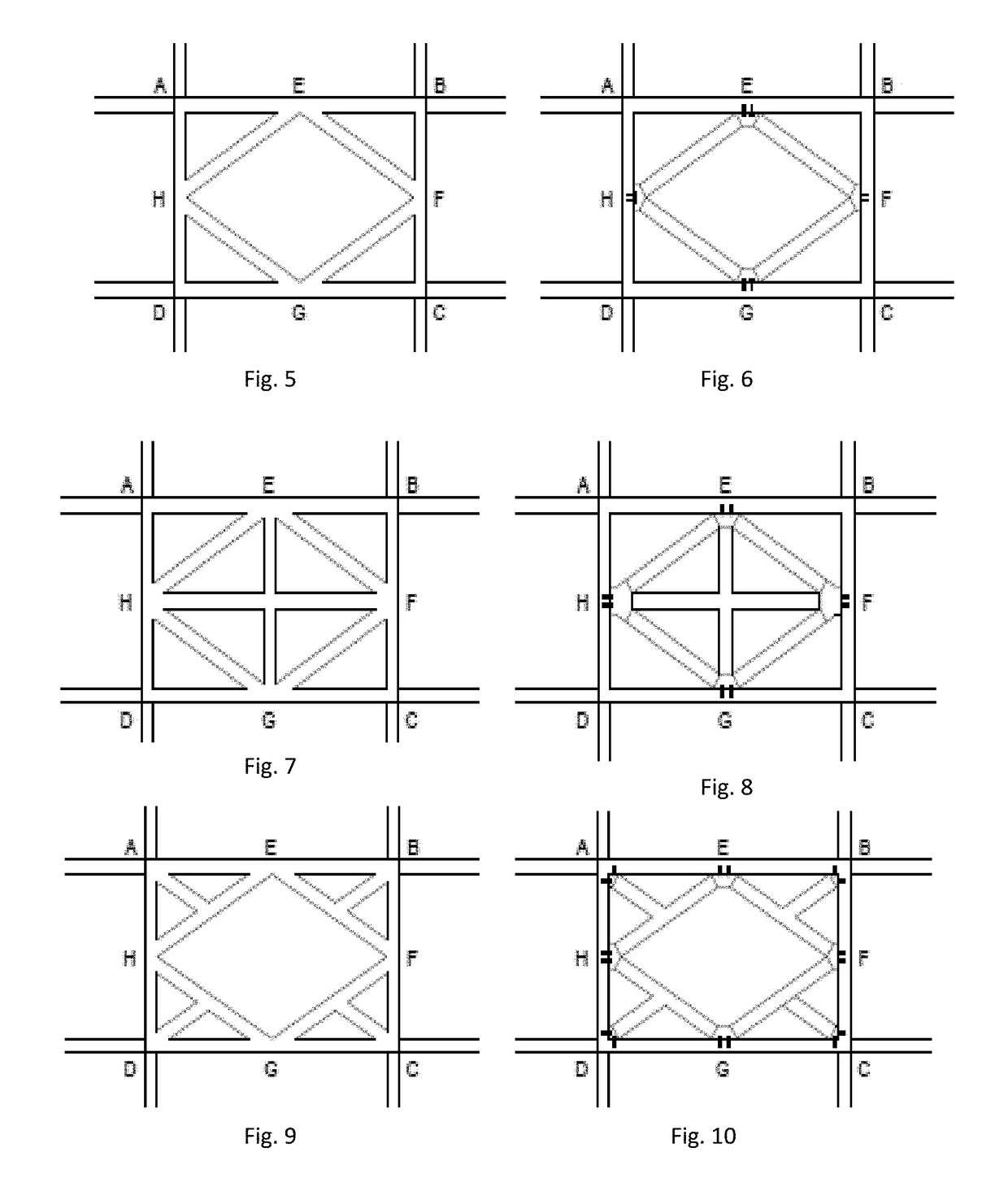

Buoy for aquaculture and manufacturing metho

ActiveCN103563802AImprove COPExtend your lifeClimate change adaptationPisciculture and aquariaAquaculture industryPolystyrene

Owner:广东联塑农业设施科技有限公司

Method for preparing wear-resistant plastic particles by using waste polystyrene

InactiveCN110760138AImprove wear resistanceSolve the defect of poor wear resistanceCyclohexanoneSilicic acid

The invention discloses a method for preparing wear-resistant plastic particles by using waste polystyrene. The method specifically includes the following steps that (1) the waste polystyrene and liquid paraffin are put into a reactor for heat treatment under the nitrogen environment, then cobalt powder is added for natural cooling, and pretreated polystyrene is obtained; (2) tetraethyl orthosilicate is added into a chitosan solution, hydrochloric acid is added and then placed in a water bath, glutaraldehyde is added, and chitosan / silica particles are obtained by reaction; (3) the pretreated polystyrene is added into cyclohexanone after being cut into granules and dried, and polyvinyl pyrrolidone is added, stirred and dissolved, and then dried particles are added to obtain a coating solution; and (4) after the coating solution is treated, a film is scraped on a substrate, removed after phase transfer, and melted and extruded with a plasticizer and a lubricant through a twin-screw extruder. According to the method, by increasing the bond strength between the polystyrene and silicon dioxide, significant improvement of the wear resistance of the polystyrene is realized, and the methodis suitable for large-scale and industrial production.

Owner:ANHUI GUANHONG PLASTIC IND

A method of constructing earthquake resistant structure with reinforced foundation and wall structure

Owner:YASHRAJ MAHESH +1

Water-proof roof glue

InactiveCN101225288AImprove waterproof and thermal insulation performanceGood weather resistanceBituminous material adhesivesHydrocarbon polymer adhesivesAdhesivePolystyrene

The invention relates to a building waterproof material, in particular to a waterproof roof adhesive, which aims to solve the problems in prior roof waterproof material of poor weatherability, easy bubbling and peeling, and poor permeability and air permeability, comprising asphalt, coal tar, waste polystyrene foam, lime and sawdust. Firstly, the waste polystyrene foam is ground to particles; secondly, the coal tar is added into a vessel and heated to 650 to 700 degrees; and the asphalt is added into the vessel, and then the former mixture is agitated homogeneously and keep on warming up to 750 degrees, after the asphalt is dissolved, the mixture is cooled to 400 to 500 degrees; at last, waste polystyrene foam, lime and sawdust are added into mixture successively, the mixture is agitated homogeneously and cooled to a paste shape, and then the finished product is obtained. The building waterproof material has the advantages that: the building waterproof material integrates the advantages of waterproof, heat preservation and heat insulation and has admirable waterproof and heat preservation effect, good weatherability, no fluid and cracks, high adhesive strength; meanwhile, the material meet the national specified standard; more importantly, the aim of waste reuse, pollution treatment, environment protection and cost saving are realized by using the waste polystyrene foam.

Owner:亢吉田

Oil-extended natural rubber and method for producing the same rubber composition and tire using the same

Owner:BRIDGESTONE CORP

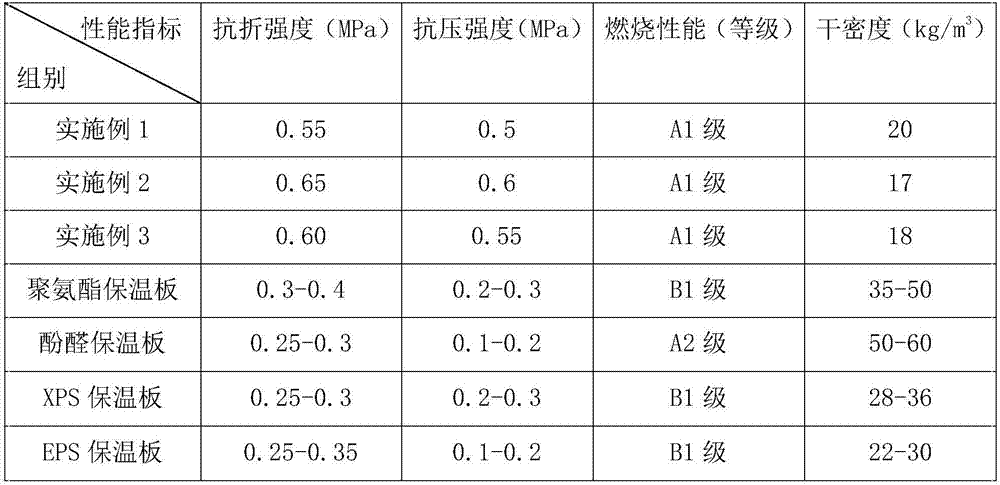

High-strength light insulation board and production method thereof

Owner:合肥天沃能源科技有限公司

Method for preparing sodium polystyrenesulfonate by sulfonating waste polystyrene and application of sodium polystyrenesulfonate in coal water slurry

InactiveCN113430022AReduce manufacturing costIncrease concentrationLiquid carbonaceous fuelsCoal waterRotary evaporator

The invention discloses a method for preparing sodium polystyrenesulfonate by sulfonating waste polystyreneand application of the sodium polystyrenesulfonate in coal water slurry. The preparation method comprises the following steps: step 1, cleaning and drying waste polystyrene foam; step 2, adding the waste polystyrene foam dried in the step 1 and an organic solvent into a container, and performing mechanical stirring to completely dissolve the waste polystyrene foam and the organic solvent; step 3, adding a sulfonating agent into the solution obtained in the step 2, and after the sulfonating agent is degraded, performing heating, and performing sulfonation reaction; and step 4, after the sulfonation reaction is finished, recovering the organic solvent by using a rotary evaporator, and adding a sodium hydroxide aqueous solution into a reaction product to obtain a sodium polystyrene sulfonate solution. The sodium polystyrenesulfonate prepared from the waste polystyrene can be used as a coal water slurry additive to realize clean utilization of coal resources, waste is turned into wealth, and social benefits and ecological benefits are remarkable. The preparation method has the advantages of simplicity in operation, short flow, high industrial application value and the like.

Owner:NANJING UNIV

Filter paper with high filtering efficiency, and preparation method thereof

InactiveCN103437249AEvenly distributedFacilitate cross-linkingSynthetic cellulose/non-cellulose material pulp/paperFiltration separationFiberFiltration

The invention relates to filter paper with high filtering efficiency, and a preparation method thereof. The filter paper with high filtering efficiency disclosed by the invention is composed of the following raw materials by weight: 50-60 parts of jute pulp, 45-50 parts of wood pulp, 20-25 parts of polystyrene fibers, 3-5 parts of sodium carboxymethyl cellulose, 3-4 parts of a nano carbon powder, 1-2 parts of feldspar powder, 1-2 parts of alum powder, 1-2 parts of 4,4'-diphenylmethane diisocyanate, 2-3 parts of diethylene triamine, 2-3 parts of polyamide wax micropowder, 0.8-1 part of bis(P,P-bis-ethylhexyl diphosphato)ethanediolato titanate, 0.4-0.6 part of an antioxidant DSTP, 0.5-0.6 part of sodium persulfate, 2-3 parts of ethylene glycol, 6-7 parts of rosin, 15-20 parts of absolute ethyl alcohol, 3-4 parts of nano diatomite, 0.8-1 part of polyoxyethylene octyphenyl ether, 0.3-0.4 part of Gamma-(2,3-epoxypropoxy)propyl trimethoxysilane and a proper amount of water. The filter paper produced by the invention has high filtration precision, high filtration efficiency, small air resistance and strong pollutant-holding capacity, and is environment-friendly.

Owner:BENGBU PIONEER FILTER

Turbid liquid type drag reducer and preparation method and application thereof

ActiveCN112410013AIncrease contentIncrease viscosityDrilling compositionPolymeric surfacePolymer science

The invention provides a turbid liquid type drag reducer and a preparation method thereof. The drag reducer is prepared from, by mass, 15-60 wt% of water-soluble high-molecular polymer, 0.3-2 wt% of surfactant, 0.5-5 wt% of thickener and the balance oil solvent. The viscosity of the drag reducer is 50-200 thousand cP. The thickener is selected from one or more of polystyrene-ethylene-propylene, polystyrene-ethylene-butylene, polyethylene, polypropylene, polyurea, polyisoprene, polybutadiene, polystilbene-ethylene-propylene, poly(styrene-butadiene), polymethacrylate, polyisobutene, hydrogenated(styrene-isoprene) copolymer and fatty alcohol. According to the turbid liquid type drag reducer provided by the invention, aiming at polyacrylamide powder with specific dosage and molecular weight,the thickener with specific composition proportion is matched with a surfactant with specific composition and proportion, so that the obtained final drag reducer product has better drag reduction property, salt resistance and storage stability.

Owner:DESHI ENERGY TECH GRP CO LTD +1

Building exterior wall heat preserving decorative composite plate and manufacturing process thereof

Owner:刘士彬

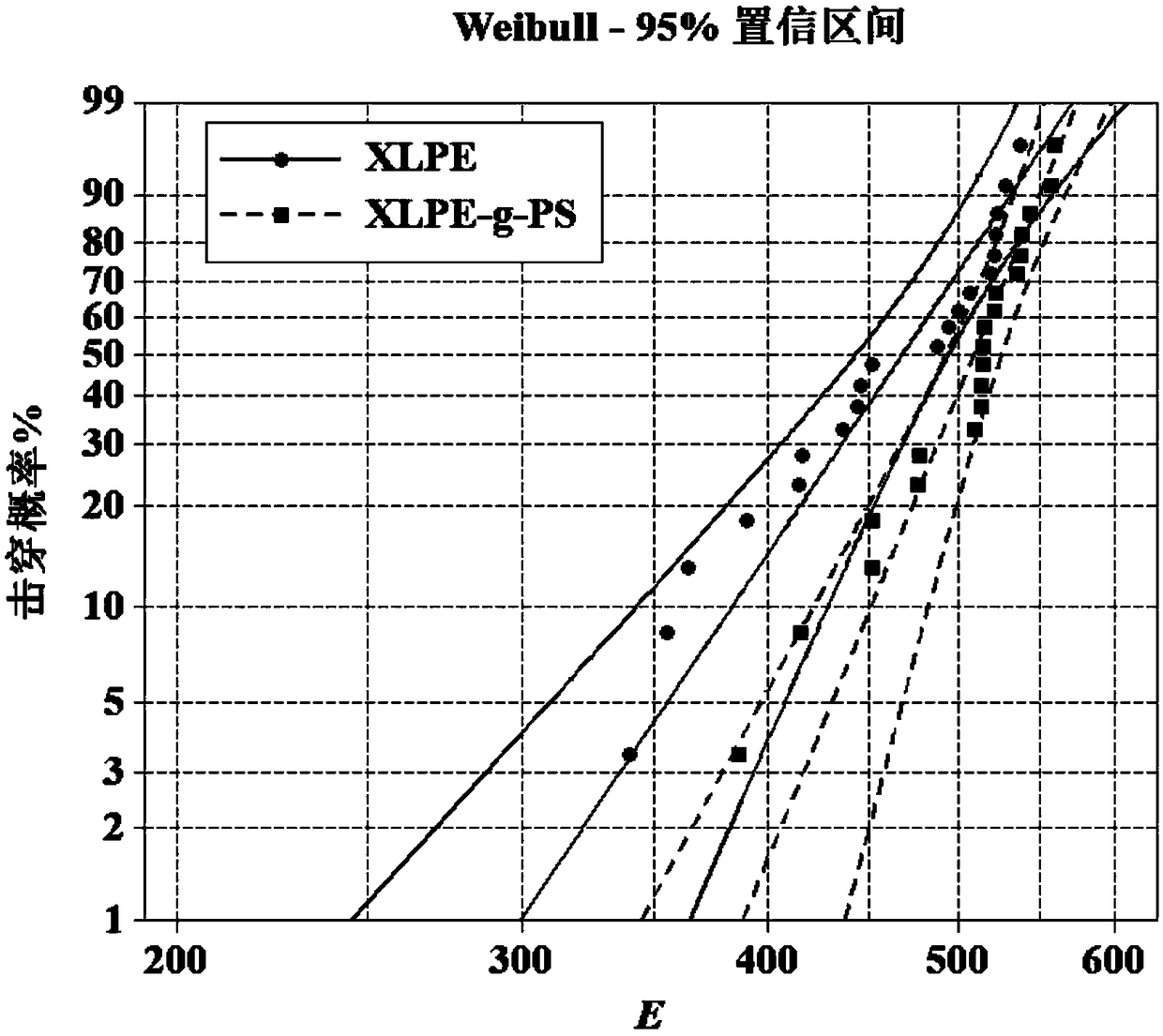

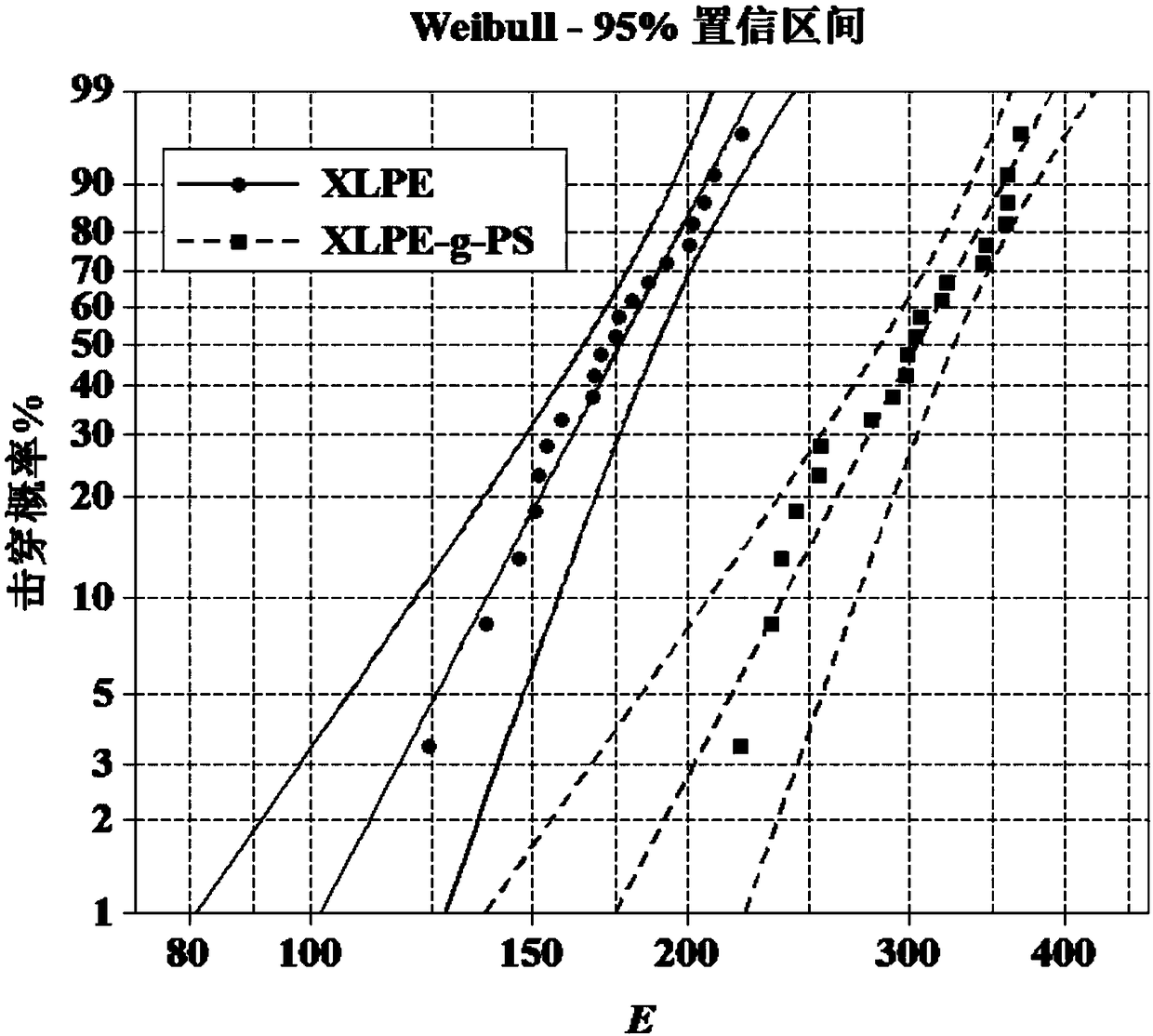

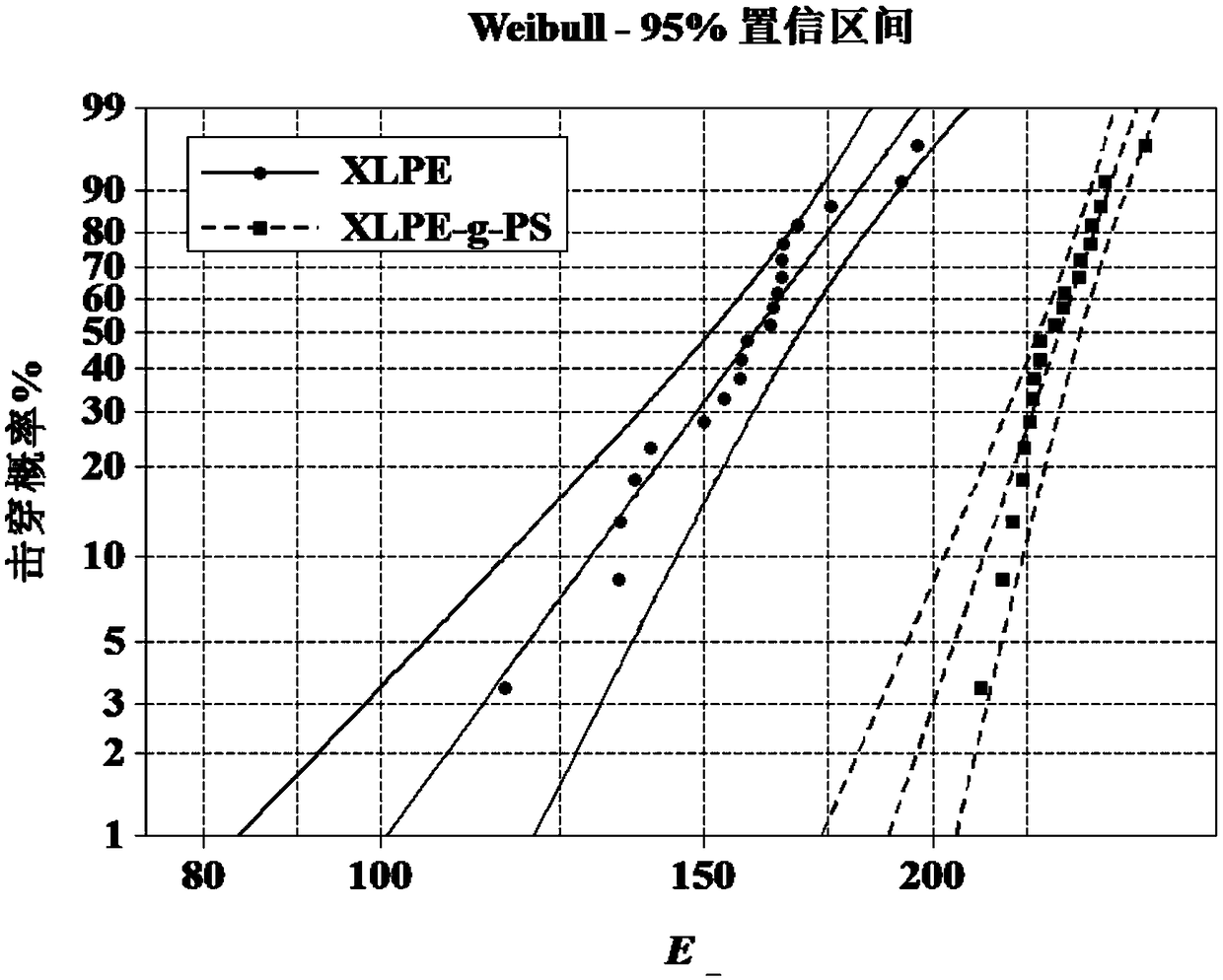

High voltage direct current cable insulating material and preparation method thereof

ActiveCN109265791AHigh DC breakdown field strengthIncreased DC breakdown field strengthPlastic/resin/waxes insulatorsLow-density polyethyleneCross-link

Owner:XI AN JIAOTONG UNIV +1

Energy-saving and environment-friendly thermal insulation material and preparation method thereof

The invention provides an energy-saving and environment-friendly thermal insulation material and a preparation method thereof. The energy-saving and environment-friendly thermal insulation material comprises the following components in parts by weight: 60 to 80 parts of polystyrene, 2 to 6 parts of nanometer titania, 2 to 4 parts of nano-aluminium hydroxide, 10 to 14 parts of cross-linking agent, 20 to 30 parts of PPF fiber, 15 to 22 parts of mineral waste residue, 10 to 14 parts of epoxy resin, 8 to 16 parts of foaming agent, and 45 to 60 parts of water. The preparation method comprises the steps of uniformly mixing the components, injecting into a mold, extruding in a spacing way, and maintaining for 8 to 12h under sustained pressure. The thermal insulation material has a higher flame retardant property, a lower heat conductivity coefficient and higher breaking strength.

Owner:HEFEI GUANGNENG NEW MATERIAL TECH CO LTD

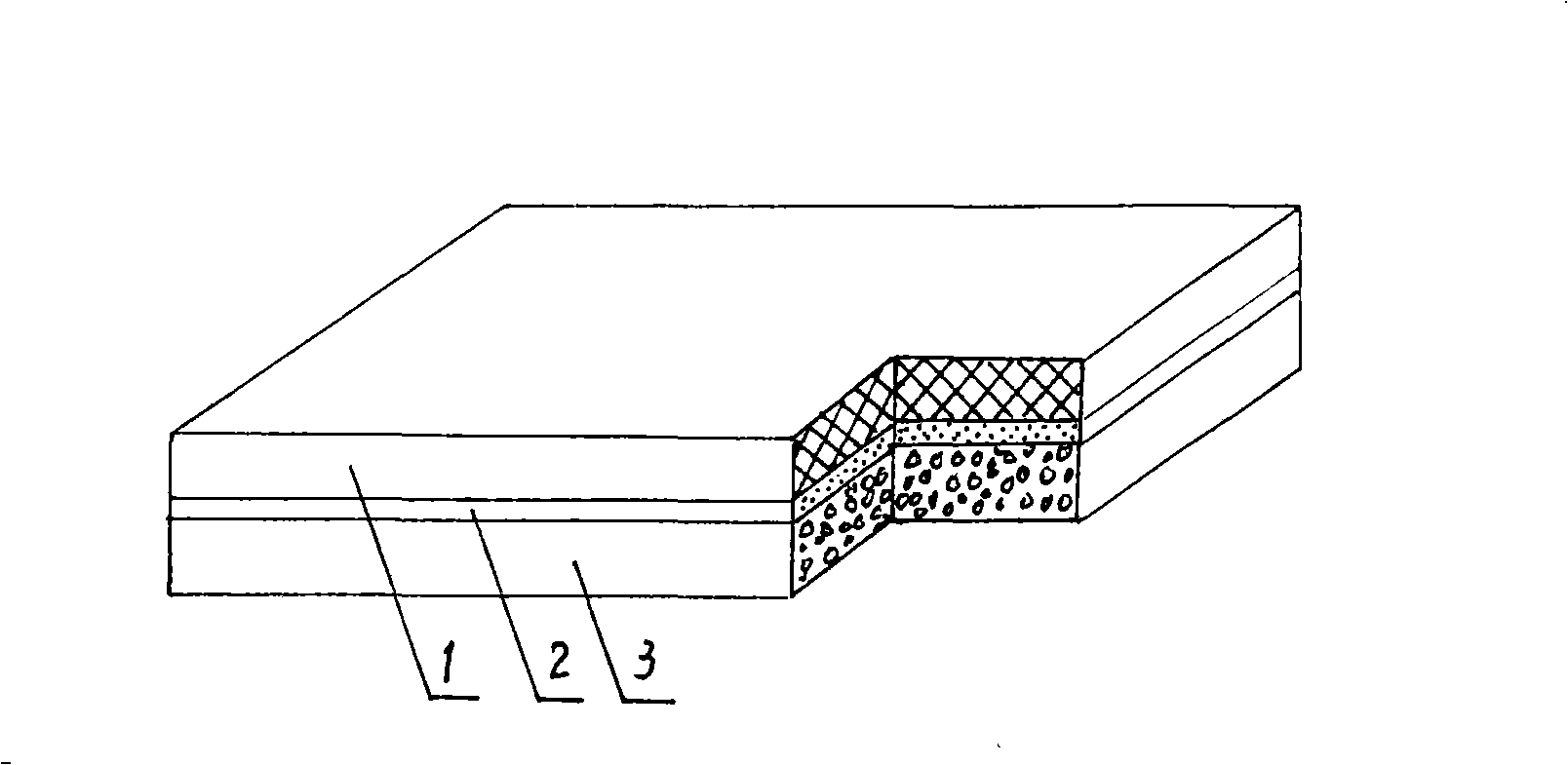

Firm-type A-grade fireproof polystyrene board and manufacturing method thereof

The invention discloses a firm-type A-grade fireproof polystyrene board and a manufacturing method thereof. The firm-type A-grade fireproof polystyrene board comprises a molding foam polystyrene boardand an HMW adsorbent used for modification; and the HMW adsorbent used for the modification is adsorbed in the molding foam polystyrene board. The firm-type A-grade fireproof polystyrene board provided by the invention adopts a bi-directional pressurization production process combining positive and negative pressure, the HMW adsorbent used for the modification enters gaps among molding foam polystyrene board particles to completely isolate and wrap the molding foam polystyrene board particles, so that each particle has excellent flame-retardant smoke-suppressing properties; a honeycomb-shapedstructure formed after the HMW adsorbent used for the modification is solidified with cement slurry has an excellent heat-insulation skeleton function, so that the compressive and tensile resistanceof the molding foam polystyrene board are enhanced; the polystyrene board effectively solves contradiction between heat preservation and fire resistance of a heat-preservation material used for outerwall bodies and a poor firmness defect, has outstanding heat-preservation fireproof effects and good firmness, and improves a safety factor of a heat-preservation system; and the method has a novel production process and high production efficiency.

Owner:赵俊儒

Energy-saving waste plastic crushing and cleaning system and implementing method thereof

ActiveCN104227872AAchieve brokenAchieve batchPlastic recyclingMechanical material recoveryWater cyclingPolystyrene

The invention discloses an energy-saving waste plastic crushing and cleaning system and an implementing method thereof. The energy-saving waste plastic crushing and cleaning system and the implementing method thereof can solve the problem that existing cleaning devices cannot clean waste plastics in batches and are low in impurity removal rate. The energy-saving waste plastic crushing and cleaning system comprises a crusher, a first rinsing tank, a desalted water recycling device, a second rinsing tank, an environment-friendly material processing system and a sediment processing system, wherein the first rinsing pool is connected with the discharging port of the crusher and provided with rinsing liquor, which is formed by mixing sodium chloride, calcium chloride and water and is at a salinity of 15-25; the desalted water recycling device is communicated with the first rinsing pool; the second rinsing pool is communicated with the first rinsing pool and provided with rinsing liquor, which is formed by mixing sodium chloride, calcium chloride and water and is at a salinity of 7-8; the environment-friendly material processing system and the sediment processing system are communicated with the second rinsing pool. The energy-saving waste plastic crushing and cleaning system is reasonable in design, convenient to operate, high in automation degree, capable of stably cleaning PS (polystyrene) or ABS (acrylonitrile butadiene styrene) waste plastics, high in impurity removal rate and capable of cleaning environment-friendly materials and non-environment-friendly materials simultaneously.

Owner:SICHUAN PLASTIC GOLD TECH CO LTD

Setting agent used after wool stretch and refinement

InactiveCN106702736AGuaranteed stabilityImprove oxidation efficiencyAnimal fibresPolystyreneButanone

Owner:HUZHOU PINCHUANG INCUBATOR

Preparation method of resin based fiber reinforced composite

Owner:HEFEI CHENXU INFORMATION SCI & TECH CO LTD

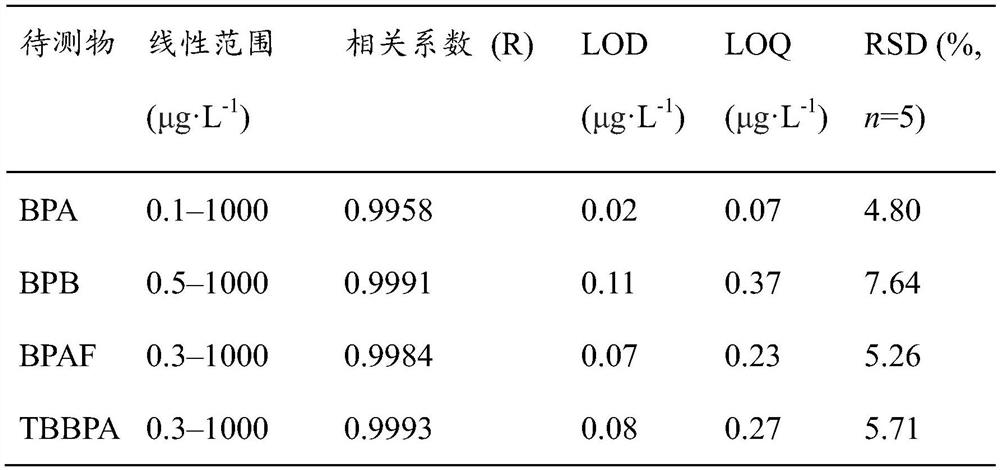

Graphene oxide composite microspheres, preparation method thereof and application of graphene oxide composite microspheres in bisphenol compound detection

PendingCN113648981AHigh enrichment factorLow detection limitComponent separationOther chemical processesMicrosphereOxide composite

Owner:ZAOZHUANG UNIV

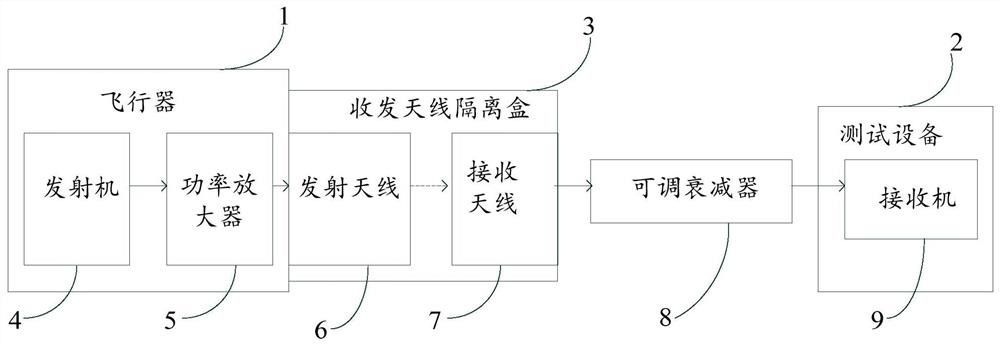

Data link multi-product open-loop parallel test method, device and system

PendingCN114024883AAvoid mutual interferenceSolve the technical problems of low test efficiencyTransmitters monitoringReceivers monitoringFlight vehiclePolystyrene

Owner:JIANGXI HONGDU AVIATION IND GRP

Preparation process and formula of thermal insulation board special for refrigeration house

PendingCN111808381AImprove fire protectionImprove fire and flame retardant performanceCoatingsPolymer scienceThermal insulation

Owner:太仓幕阳节能科技有限公司

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap