Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

12 results about "Melt extrusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hot melt extrusion (HME) is the processing of polymeric materials above their glass transition temperature (Tg) in order to effect molecular level mixing of thermoplastic binders and/or polymers and active compounds. Used in several industries, HME is a combination of melting and mechanical energy to improve continuous...

Method for preparing high-temperature resistant microporous membrane

ActiveCN103811704AClearly definedEasy to understandCell component detailsPolymer sciencePolypropylene

Owner:SUZHOU GREEN POWER NEW ENERGY MATERIALS CO LTD

Polylactic acid/polyester alloy and preparation method thereof

The invention relates to a polylactic acid / polyester alloy and a preparation method thereof. The polylactic acid / polyester alloy comprises the following components in percentage by weight: polylactic acid, polyester, a compatilizer, a flexibilizer, an antioxidant and a lubricant. The preparation method comprises the following steps: firstly, proportioning the raw materials and mixing at a room temperature; and respectively carrying out melting extrusion, carrying out ultrasonic treatment at the first late stage, extruding at the second stage and pelletizing, so as to obtain degradable, high-impact-resistant and high-heat-resistant polylactic acid / polyester alloy. Compared with an existing method, the controllable ultrasonic treatment is utilized; and a similar polylactic acid-g-polyester structure is formed by in-situ reaction, so that the heat resistance of the polyester and the biodegradability of the polylactic acid are reserved; and meanwhile, a toughening system with a core-shell structure is formed in an alloy system through interface interaction of a special toughening compatilizer, so that the alloy product with high impact resistance, high heat resistance and high biodegradability can be obtained.

Owner:FINE BLEND POLYMER SHANGHAI CO LTD

Thermal insulation material and preparation method thereof

InactiveCN107721451AEvenly dispersedEffective control of cell stabilityConstruction materialCeramicwareFoaming agentPolymer science

The invention discloses a thermal insulation material and a preparation method thereof. The thermal insulation material comprises a cement-based block skeleton and graphene modified polystyrene, wherein the cement-based block skeleton comprises multiple cavities; the multiple cavities are filled with graphene modified polystyrene; and graphene modified polystyrene is formed by performing melt extrusion on graphene and polystyrene resin according to a weight ratio of 1:(1-5) in the multiple cavities in the presence of an alkane foaming agent. According to the thermal insulation material disclosed by the invention, the strength and thermal insulation property are further improved.

Owner:ZHONGJING ECO IND CO LTD

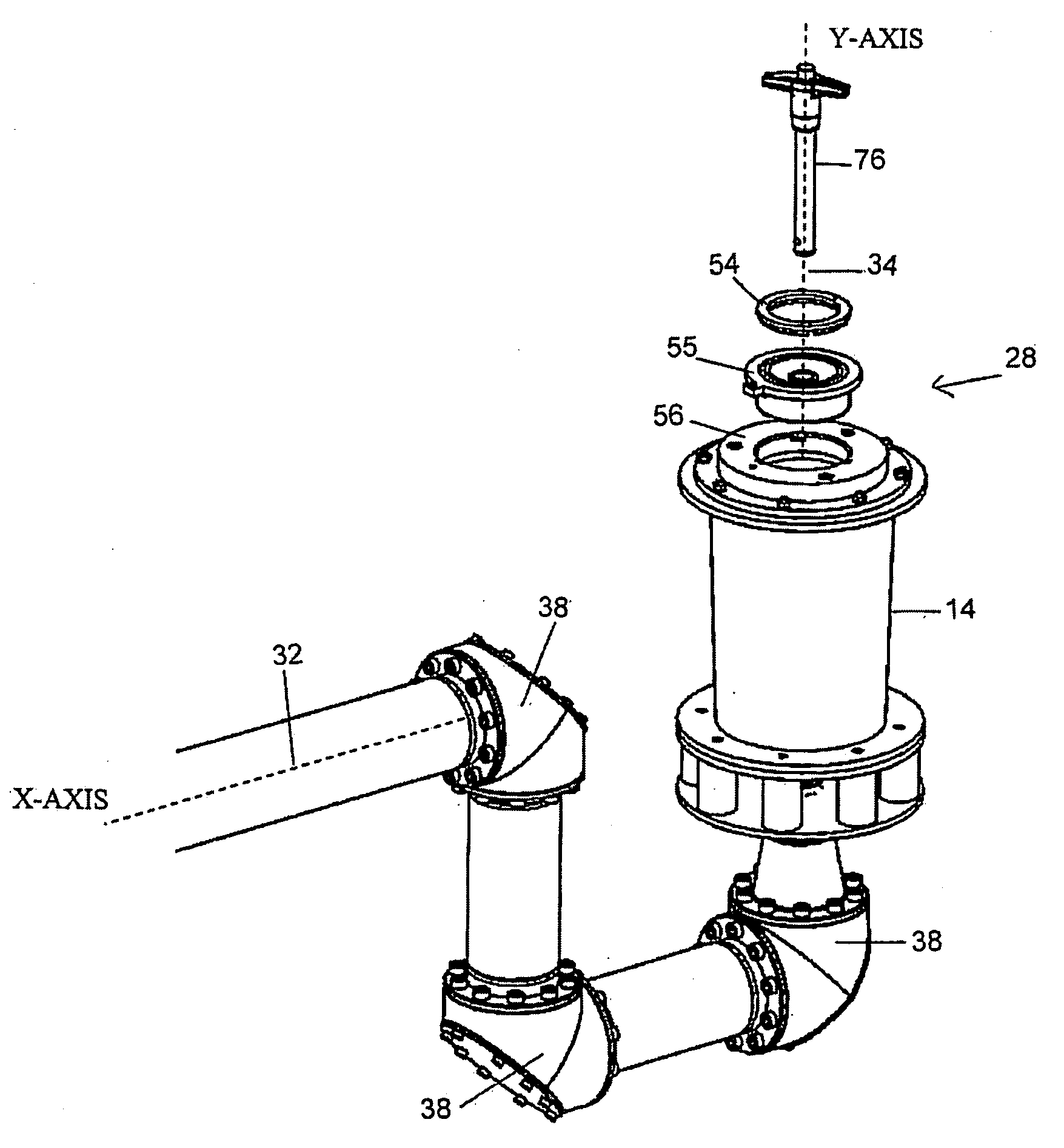

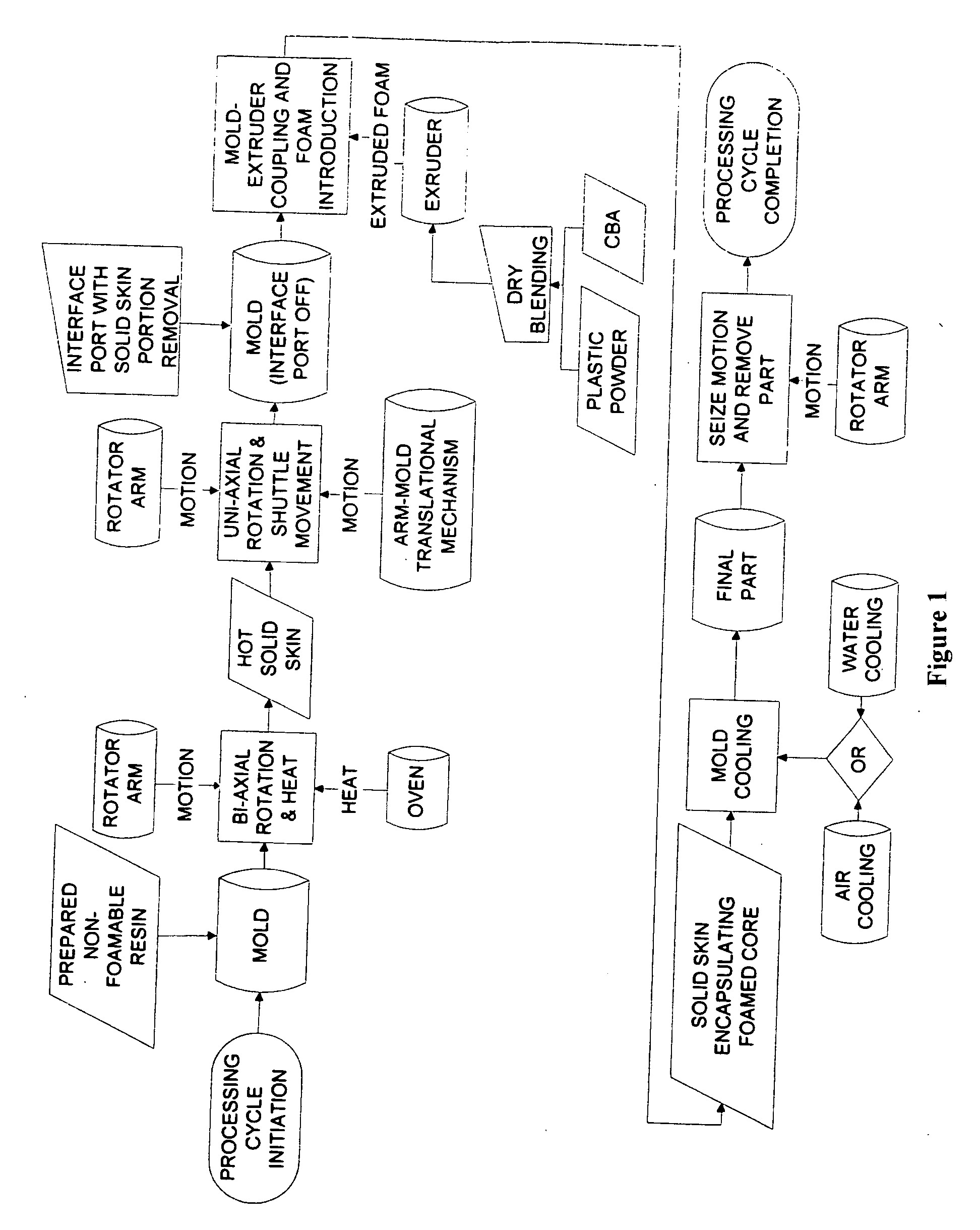

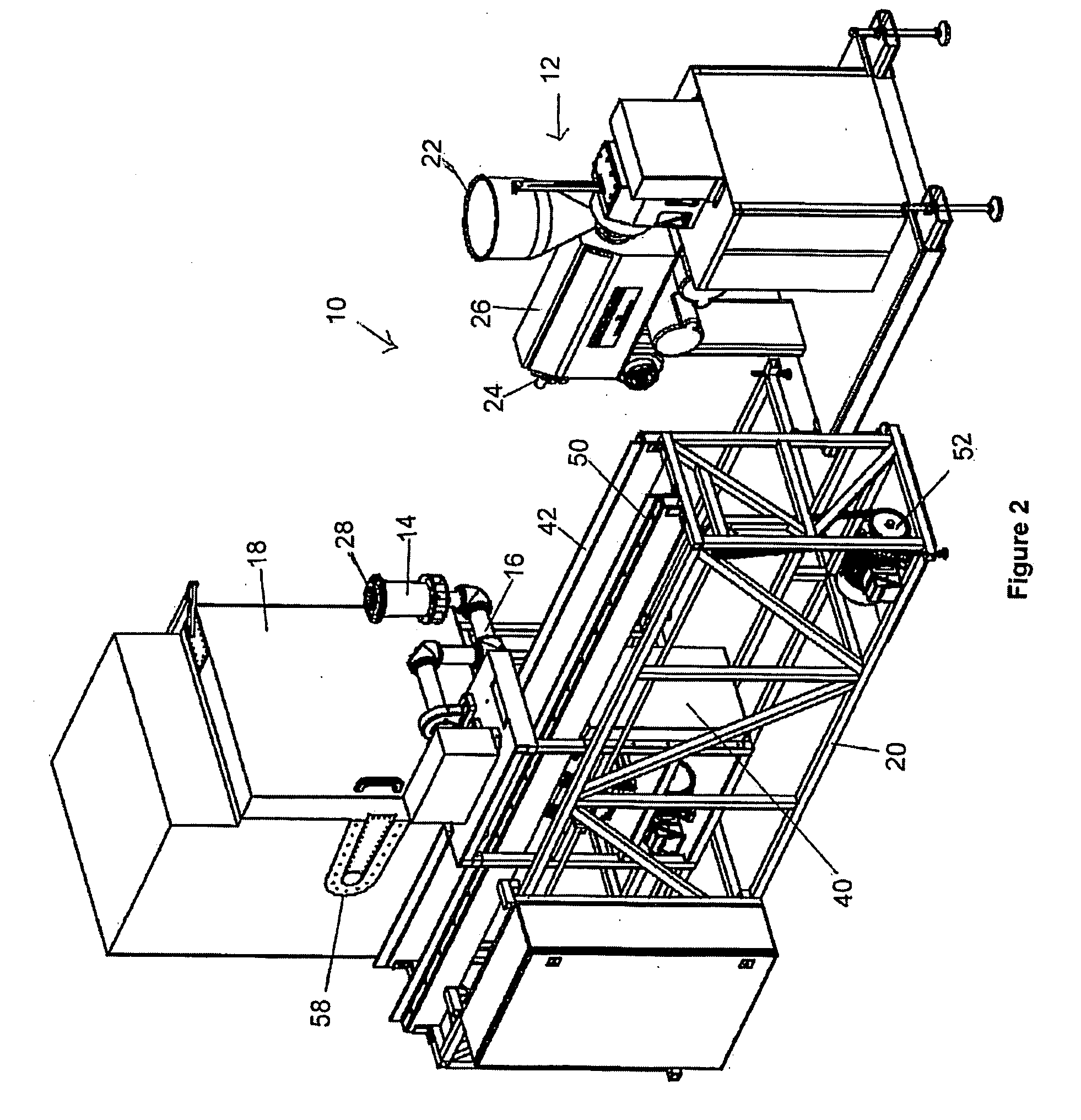

Rapid rotational foam molding process

Owner:POP ILIEV REMON +2

Preparation method of HAP/PLA composition bone repair stent loaded with strontium ranelate

InactiveCN111202870AConvenient 3D printingHigh strengthAdditive manufacturing apparatusTissue regenerationComputer printingBiocompatibility

The invention discloses a preparation method of an HAP / PLA composition bone repair stent loaded with strontium ranelate in the technical field of medical orthopedic materials. Nano hydroxyapatite powder, medical-grade PLA plastic particles and strontium ranelate powder are fully mixed to obtain a mixed raw material; and the mixed raw material is subjected to melt extrusion by a screw extruder to form filaments to obtain an HAP / PLA wire rod doped with the strontium ranelate for 3D printing, and the wire rod is printed on an FDM melting type printer to obtain the HAP / PLA composition bone repairstent doped with the strontium ranelate. The obtained bone repair stent has high strength, high hardness and high impact strength, has good antibacterial property and good biocompatibility, can be degraded and absorbed by the human body, reduces the probability of inflammation at bone defect parts and is a good choice for an implant material, due to the duality of the loaded strontium ranelate drug, bone absorption can be inhibited while osteogenesis is promoted, and repair of bone defect parts is accelerated.

Owner:YANGZHOU UNIV

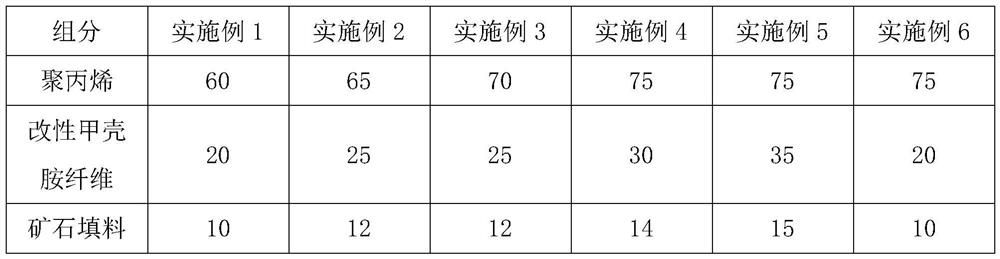

Scratch-resistant polypropylene material and preparation method thereof

ActiveCN111925591AImprove scratch resistanceEfficient deliveryPolypropylene compositesPolymer science

Owner:宁波精诚塑胶制品有限公司

Graphene magnetic injection molding masterbatch for nylon electrical appliance plastics, and preparation method thereof

Owner:CHENDU NEW KELI CHEM SCI CO LTD

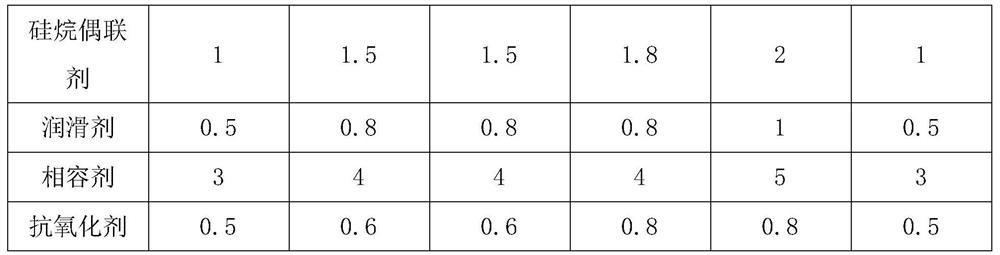

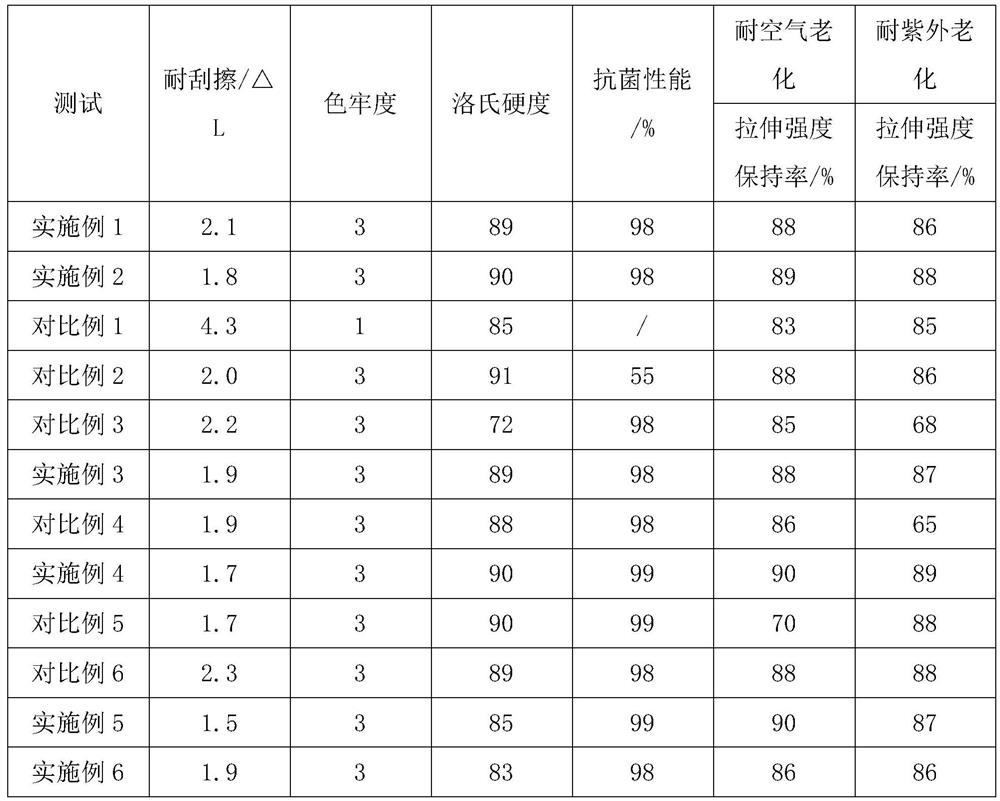

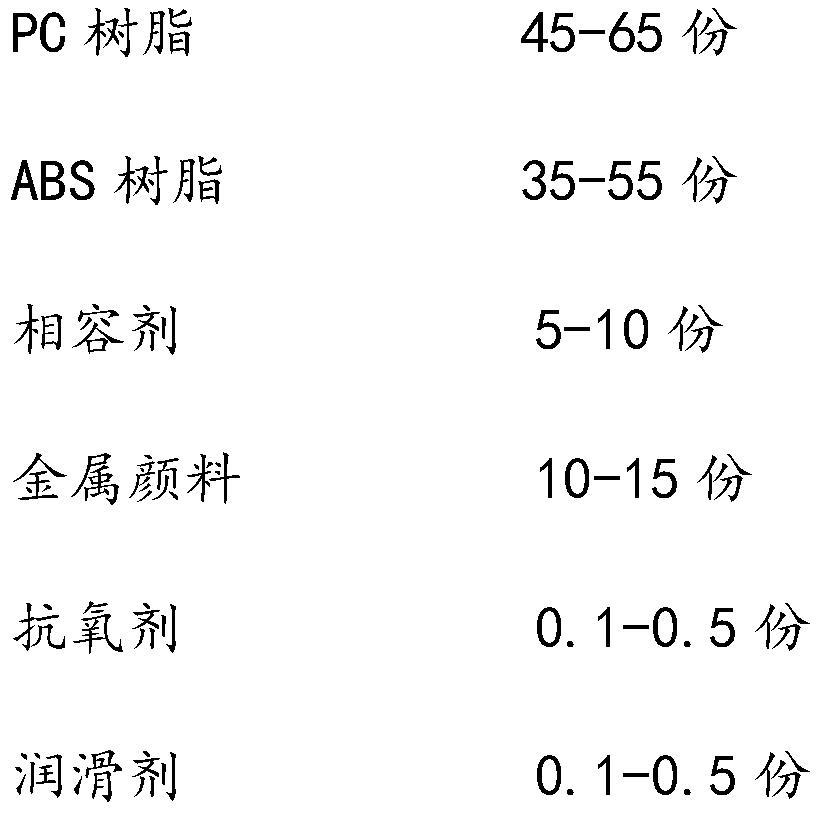

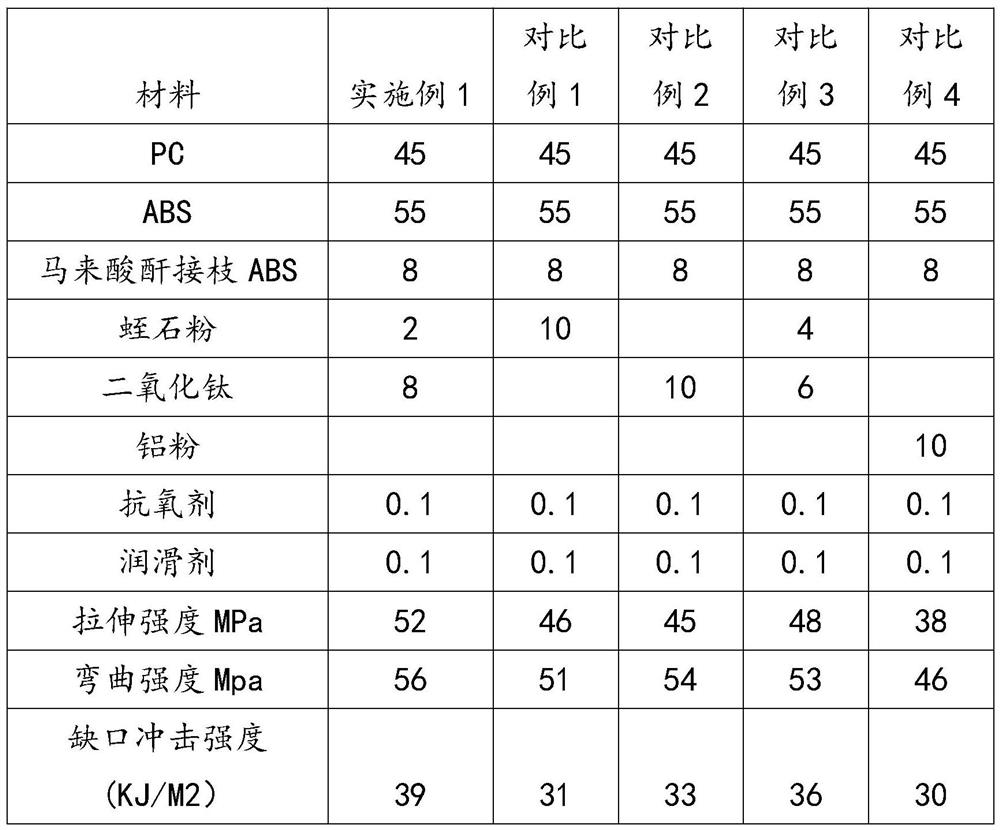

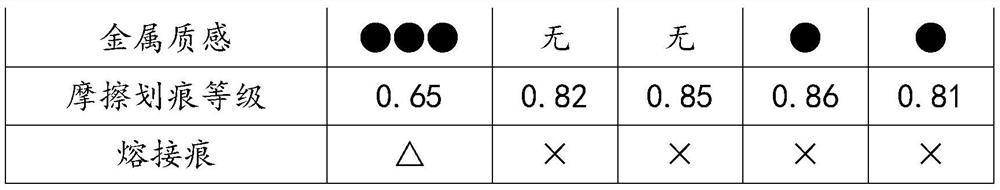

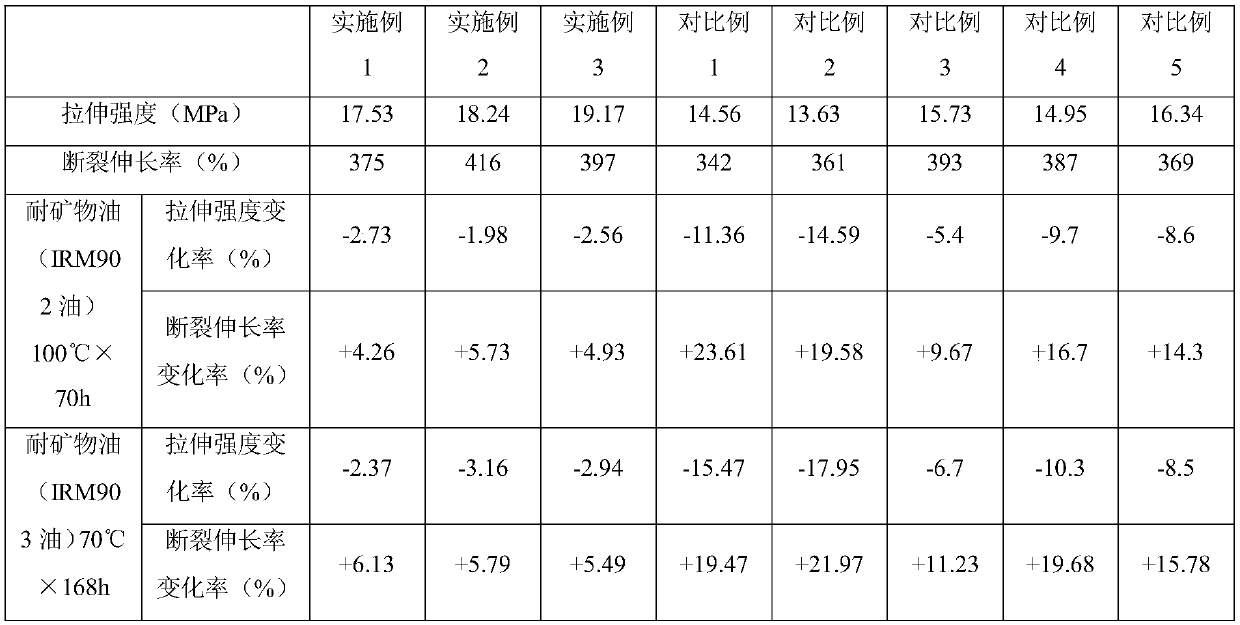

A kind of metallic texture, scratch-resistant PC/ABS composite material and preparation method thereof

Owner:CHUZHOU VOCATIONAL & TECHN COLLEGE

Polyester film

Owner:重庆中膜复合材料有限公司

Super-hydrophobic foamed polypropylene and preparation method thereof

Owner:SUZHOU WHOLENANO NEW MATERIAL TECH CO LTD

Oil-resistant EVA cable material and preparation technology thereof

ActiveCN109627666AGood oil resistanceExcellent flame retardancyPolyphenyl etherVinylsilane

Owner:STATE GRID SHANDONG ENERGY SAVING SERVICE +1

Shading polypropylene base film for photographic paper and preparation method of shading polypropylene base film

PendingCN114381067AGood shading rateIncrease shading rateSynthetic resin layered productsFlat articlesPolymer sciencePhotographic paper

The invention discloses a shading polypropylene base film for photographic paper and a preparation method of the shading polypropylene base film. The shading polypropylene base film for the photographic paper is characterized in that the shading polypropylene base film for the photographic paper is formed by sequentially compounding a surface polypropylene composition layer, a core polypropylene composition layer and a surface polypropylene composition layer, the surface layer polypropylene composition is prepared by mixing, melting and extruding polypropylene resin, an antistatic agent and a dispersing agent; the core layer polypropylene composition is prepared by mixing, melting and extruding polypropylene resin, filler, a coupling agent, an antioxidant, carbon black and a dispersing agent; and respectively putting the core layer polypropylene composition and the surface layer polypropylene composition into a main machine and an auxiliary machine of three-layer co-extrusion casting extrusion equipment, and carrying out melt extrusion, cooling shaping and the like to obtain the shading polypropylene base film for the photographic paper. The shading polypropylene base film for photographic paper has the characteristics of good shading performance, low water vapor transmittance, excellent surface glossiness, high surface energy, excellent antistatic performance and the like, and is suitable for the fields of ink-jet printing, inkjet films and the like.

Owner:SICHUAN DONGFANG INSULATING MATERIAL CO LTD +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap