Oil-resistant EVA cable material and preparation technology thereof

A cable material and oil-resistant technology, applied in the field of cable materials, can solve the problem that the demand for oil resistance of cable materials has not been well resolved, and achieve the effect of improving oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

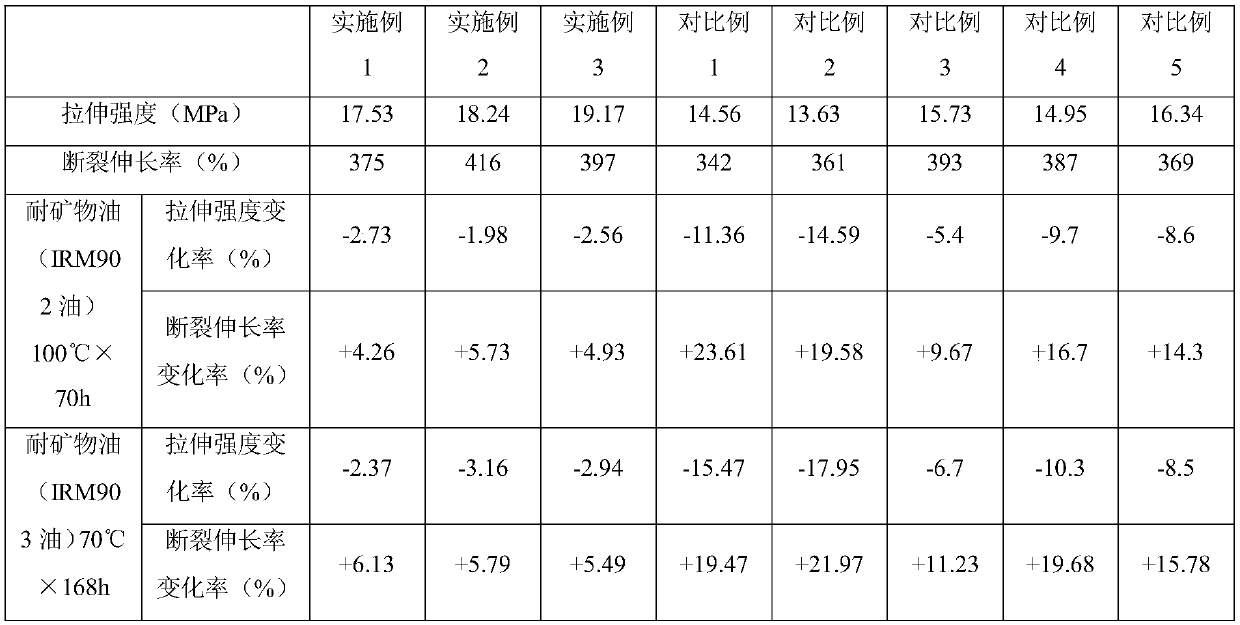

Examples

Embodiment 1

[0027] Preparation of vinyl silane / styrene grafted ethylene-vinyl acetate copolymer: EVA with a VA content of 20% is used as raw material, and the mass ratio of vinyl to ethylene-vinyl acetate copolymer is 1:100 and 5:100. Silane and styrene, as well as a certain amount of initiator DCP, are fully dissolved with an appropriate amount of acetone, and then mixed evenly with a proportional amount of EVA. After the acetone was completely volatilized, it was melt-extruded and granulated at 200° C. on a twin-screw extruder, wherein the rotational speed of the twin-screw extruder was 50 rpm.

[0028] Preparation of oil-resistant EVA cable material: Weigh 60 parts of vinylsilane / styrene grafted ethylene-vinyl acetate copolymer, 15 parts of polyphenylene ether resin, 25 parts of aluminum hydroxide and 4 parts of silane coupling agent KH550. Mix aluminum hydroxide and silane coupling agent KH550 uniformly in a high-speed mixer, then add vinylsilane / styrene grafted ethylene-vinyl acet

Embodiment 2

[0030] Preparation of vinyl silane / styrene grafted ethylene-vinyl acetate copolymer: EVA with a VA content of 20% is used as raw material, and the mass ratio of vinyl to ethylene-vinyl acetate copolymer is 3:100 and 7:100. Silane and styrene, as well as a certain amount of initiator BPO, are fully dissolved with an appropriate amount of acetone, and then mixed evenly with a proportional amount of EVA. After the acetone was completely volatilized, it was melt-extruded and granulated at 200° C. on a twin-screw extruder, wherein the rotational speed of the twin-screw extruder was 50 rpm.

[0031] Preparation of oil-resistant EVA cable material: Weigh 60 parts of vinylsilane / styrene grafted ethylene-vinyl acetate copolymer, 15 parts of polyphenylene ether resin, 25 parts of zinc borate and 4 parts of borate coupling agent. Mix zinc borate and silane coupling agent KH550 uniformly in a high-speed mixer, then add vinyl silane / styrene grafted ethylene-vinyl acetate copolymer and p

Embodiment 3

[0033] Preparation of vinyl silane / styrene grafted ethylene-vinyl acetate copolymer: take EVA with VA content of 20% as raw material, weigh the vinyl with ethylene-vinyl acetate copolymer mass ratio of 2:100 and 8.5:100 Silane and styrene, as well as a certain amount of initiator BPO, are fully dissolved with an appropriate amount of acetone, and then mixed evenly with a proportional amount of EVA. After the acetone was completely volatilized, it was melt-extruded and granulated at 200° C. on a twin-screw extruder, wherein the rotational speed of the twin-screw extruder was 50 rpm.

[0034] Preparation of oil-resistant EVA cable material: Weigh 60 parts of vinylsilane / styrene grafted ethylene-vinyl acetate copolymer, 15 parts of polyphenylene ether resin, 12 parts of magnesium hydroxide, 13 parts of antimony oxide and 4 parts of silane coupling agent KH550. Mix zinc borate and silane coupling agent KH550 uniformly in a high-speed mixer, then add vinyl silane / styrene grafte

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap