Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48 results about "Styrene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Styrene, also known as ethenylbenzene, vinylbenzene, and phenylethene, is an organic compound with the chemical formula C₆H₅CH=CH₂. This derivative of benzene is a colorless oily liquid that evaporates easily and has a sweet smell, although high concentrations have a less pleasant odor. Styrene is the precursor to polystyrene and several copolymers. Approximately 25 million tonnes of styrene were produced in 2010.

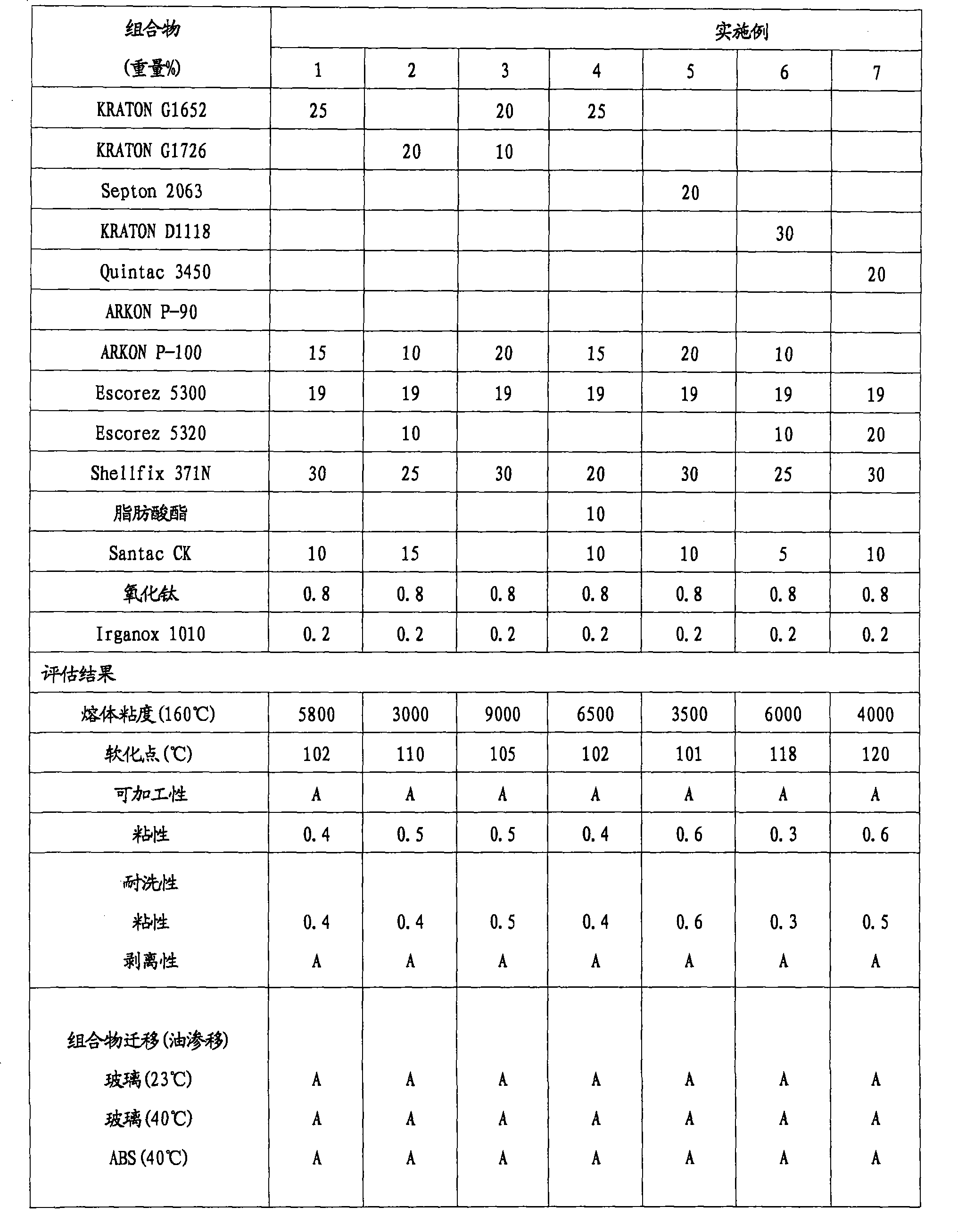

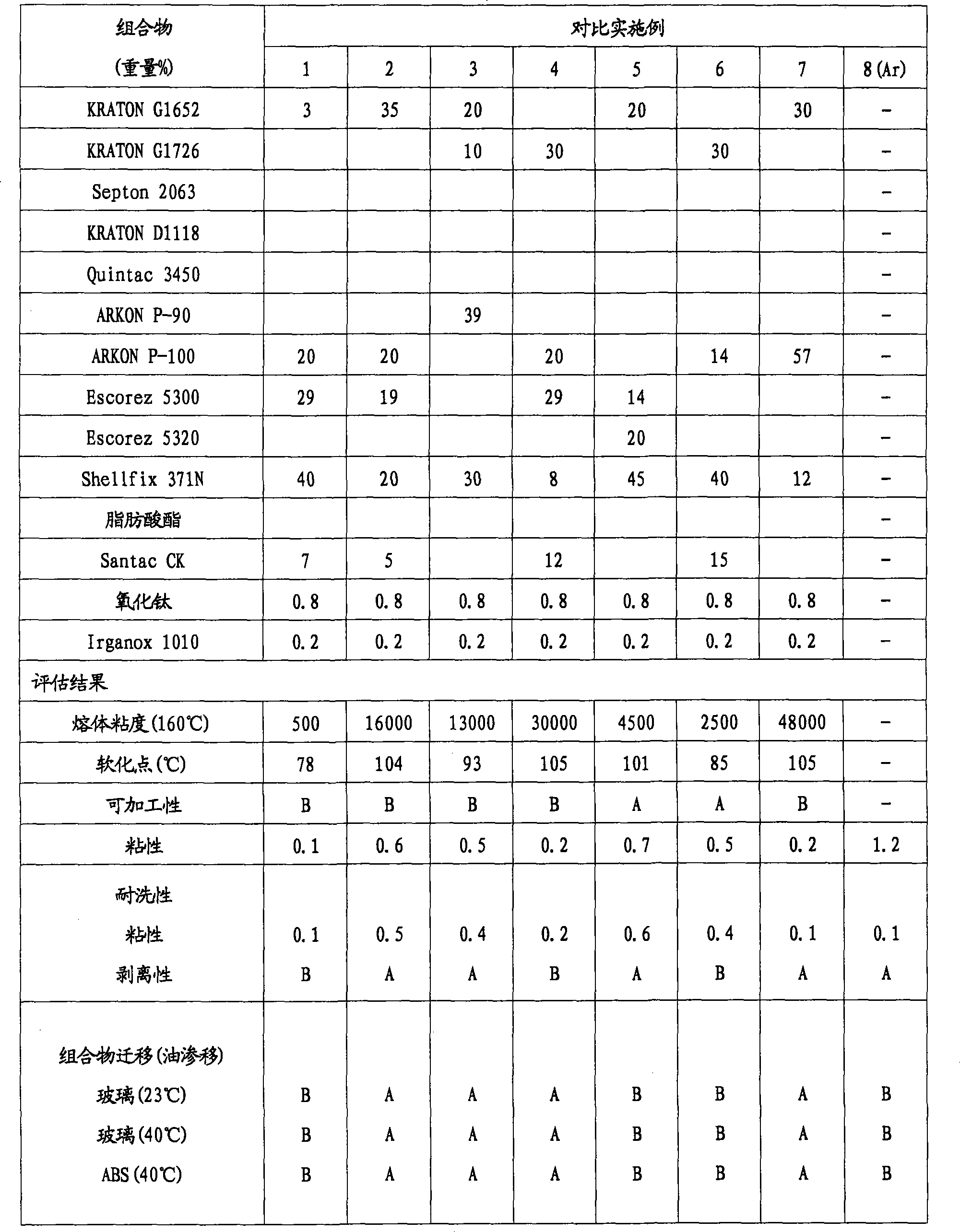

Pressure-sensitive adhesive product

InactiveUS20060154097A1Easy to peelSynthetic resin layered productsEster polymer adhesivesParaffin waxRosin

Owner:NITTO DENKO CORP

Aqueous texture wallpaper paint and method for making same

The invention relates to a watercraft texture wallpaper paint, characterized in that the invention comprises the following components: 31 percent to 35 percent of styrene-acrylic emulsion, 23.94 percent of superfine weight calcium, 1 percent to 2 percent of nano-titanium dioxide, 10 percent to 18 percent of titanium pigment, 8 percent to 9.8 percent of calcined kaolin, 1.2 percent to 1.8 percent of ethylene glycol, 0.2 percent to 0.5 percent of hydroxyethylcellulose, 0.8 percent to 1.5 percent of film forming additive, 0.15 percent to 0.25 percent of multi-functional additive, 0.3 percent to 0.5 percent of dispersant, 0.1 percent to 0.2 percent of wetting agent, 0.15 percent to 0.21 percent of defoamer, 0.08 percent of anticorrosion and insecticide, 0.8 percent to 2 percent of thickener and 20 percent to 22 percent of water. The invention is the watercraft texture wallpaper paint, is environment-friendly, has strong elastic tension, has good covering and anti-cracking effect on the fine cracking of wall, and has good scrape resistance performance, greatly enhancing the degree of wall surface protection; meanwhile, the invention still has strong waterproof performance, without color-changing and decortication and mildew and can fully solve the common problems existing in wall decoration.

Owner:FOSHAN SHUNDE QINGDA RUNCAI COATING CO LTD

Ink resin composite used for plastic gravure printing and preparation method thereof

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Hydrogenated styrene-conjugated diene copolymer as well as preparation method and application thereof in self-adhesive films

InactiveCN108219090AGood physical propertiesEasy to processFilm/foil adhesives without carriersPolymer scienceUltimate tensile strength

The invention discloses a hydrogenated styrene-conjugated diene copolymer as well as a preparation method and application thereof in self-adhesive films. The hydrogenated styrene-conjugated diene copolymer has the following expression: S1-EB1-S2-EB2, wherein S1 and S2 are styrene blocks; EB1 is a hydrogenated butadiene block; and EB2 is a hydrogenated conjugated diene block. The hydrogenated styrene-conjugated diene copolymer has good processing properties and can be used for preparing the self-adhesive films together with other poly stylene polymers; and the prepared self-adhesive films are less affected by temperature, humidity and other external conditions, have good stability, have adhesive strength capable of being controlled within a wide range, and are suitable for application requirements of various materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

Mixture of PPC (polyenyl phosphophatidyl choline), PHBV (Polyhydroxybutyrate Valerate), PLA (Poly lactic Acid), PBS (Polybutadiene Styrene), PBAT (polybutylene adipate terephthalate) and PCL (polycaprolactone) and preparation method thereof

The invention relates to a mixture of PPC (polyenyl phosphophatidyl choline), PHBV (Polyhydroxybutyrate Valerate), PLA (Poly lactic Acid), PBS (Polybutadiene Styrene), PBAT (polybutylene adipate terephthalate) and PCL (polycaprolactone) and a preparation method thereof. The mixture comprises the PPC, the PHBV, the PLA, the PBS, the PBAT, the PCL, an end-capping agent, a lubricating agent and modified light calcium carbonate. The preparation method comprises the following steps of: carrying out cold mixing on the PPC, the PHBV, the PLA, the PBS, the PBAT, the PCL, the end-capping agent, the lubricating agent and the modified light calcium carbonate in a high-speed stirrer at a temperature not more than 35 DEG C; and extruding and granulating cold mixing materials by using a screw extruder at a temperature not more than 200 DEG C. The invention has the advantages that the method has simple process and common equipment and is very suitable for industrialized production; in addition, raw materials used in the method are simple and easy to obtain and buy in the market, and the mixture processed by the method is greatly enhanced in tacky agglomeration temperature compared with pure PPC and superior to the pure PPC in mechanical property and can be completely biodegraded.

Owner:INNER MONGOLIA MENG XI HIGH TECH GRP CO LTD

Cured In Place Pipe Liner With Styrene Barrier

InactiveUS20100243154A1Promote migrationHigh hardnessPipe elementsRecord information storageEngineeringCured-in-place pipe

A liner for repairing damaged pipes, such as underground sewer or gas pipes is disclosed. The liner comprises a TPU coating on fibrous mat of non-woven fabric. The TPU coating contains a barrier layer to retard the migration of styrene from the liner to the media used to force the liner against the damaged pipe and to activate the thermoset resin. The thermoset resin converts the liner from a flexible state to a rigid state as the liner is cured in place inside the pipe.

Owner:LUBRIZOL ADVANCED MATERIALS INC

Preparation method of corrosion inhibitor of methanol gasoline

ActiveCN103725335AGood compatibilityAdd lessLiquid carbonaceous fuelsFuel additivesActive agentPolyethylene glycol

Owner:南通市通州区五接农业机电管理站有限公司

Flexible waterproof mortar and production method thereof

The invention discloses flexible waterproof mortar and a production method thereof. The method comprises a liquid material component and a powder material component. The liquid material component comprises styrene-acrylic emulsion, acetic acid emulsion, water, a defoaming agent, and a bactericide. The powder material component comprises quartz powder, wollastonite powder, ash concrete, a water-reducing agent, a dispersing agent, and a leveling thixotropic agent. The waterproof mortar is prepared from the liquid material and the powder material according to a ratio of 1:2. The waterproof mortar has good extensibility and high elasticity. With the mortar, slight cracks on a base layer can be resisted. During vertical surface construction, the waterproof mortar is prevented from flowing and dropping, and has good construction performance. After coating, the mortar surface is smooth as mirror. The mortar is suitable for underground space water prevention, seepage prevention, and moisture prevention. The mortar is especially suitable for water prevention of buildings with waterproof exposed underground. Soaking of underground condensed water and dew condensation to the building can be effectively resisted for a long time.

Owner:WEIFANG HONGYUAN WATERPROOF MATERIAL +3

Waterproof reinforced composite and preparation method thereof

The invention discloses a waterproof reinforced composite and a preparation method thereof. The waterproof reinforced composite is prepared from the following raw materials in parts by weight: 60-90 parts of epoxy resin modified polyurethane emulsion, 15-30 parts of organic silicon styrene-acrylic emulsion, 10-30 parts of methyl methacrylate, 10-20 parts of polyacrylate, 2-4 parts of N-hydroxymethyl acrylamide, 6-12 parts of oxide-coated titanium dioxide, 10-30 parts of composite filler, 3-8 parts of silane coupling agent, 3-6 parts of propanediol butyl ether, 3-6 parts of diethylene glycol monobutyl ether, 5-10 parts of sodium polyphosphate, 4-8 parts of polyvinyl butyral, 2-5 parts of urea-isobutyraldehyde-formaldehyde resin, 0.3-0.6 part of sodium perfluorous nonenoxybenzene sulfonate,0.4-0.9 part of polypropylene wax emulsion, 0.3-0.7 part of polyether modified polysiloxane, 0.5-1 part of hydroxypropyl methyl cellulose, 1-3 parts of epoxy phosphate ester, 1-5 parts of compound antiaging agent and 10-20 parts of water.

Owner:SUZHOU FUZHONG PLASTIC CO LTD

Fireproof anti-abrasion rubber shoe sole material and preparation method thereof

InactiveCN109354817AImprove wear resistanceGood mechanical propertiesSolesPolymer scienceMechanical property

Owner:JINJIANG XINQIMEI SHOES MATERIAL DEV

Preparation method of styrene-maleic anhydride-nitrophenyl maleimide terpolymer

The invention discloses a styrene-maleic anhydride-nitrophenyl maleimide terpolymer and a preparation method thereof. The terpolymer is characterized by comprising the following components by weight percentage: 50-90 parts of styrene, 1-20 parts of maleic anhydride, and 10-30 parts of nitrophenyl maleimide. The glass transition temperature is 150-200DEG C, a bulk polymerization way is employed forpreparation, firstly part of the styrene is added into a reaction kettle, then a styrene solution with dissolved maleic anhydride and nitrophenyl maleimide is added dropwise into the reaction kettle,the temperature of the reaction kettle is 90-140DEG C, and the pressure is atmospheric pressure, after reaction to a certain degree, high temperature vacuum devolatilization is carried out to obtainthe terpolymer. Compared with the prior art, the preparation method provided by the invention has the advantages of simple process, no waste water, and environment-friendly production process, and theprepared product has high purity, and is suitable for use as a low odor and low emission heat resistant agent for vehicle ABS and household appliance ABS.

Owner:JIAXING HUAWEN CHEM CO LTD

Thermoplastic elastomer composition

Owner:IDEMITSU KOSAN CO LTD

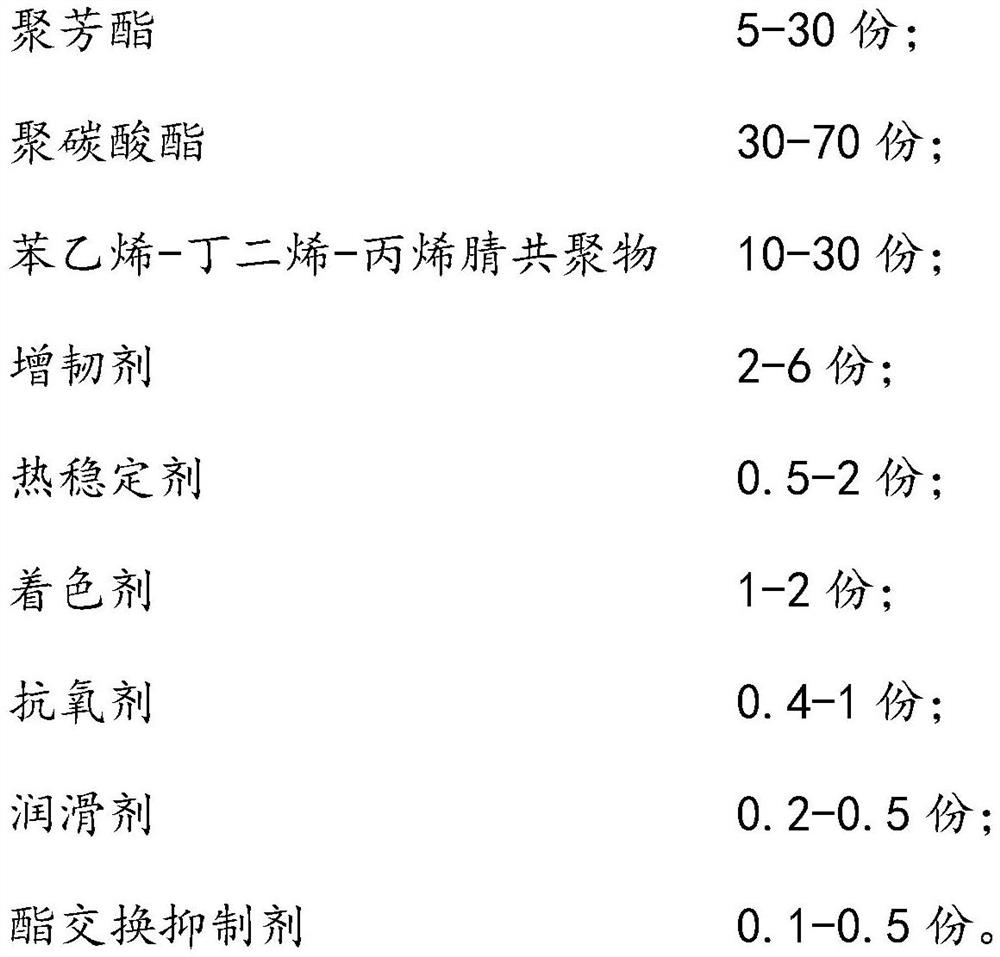

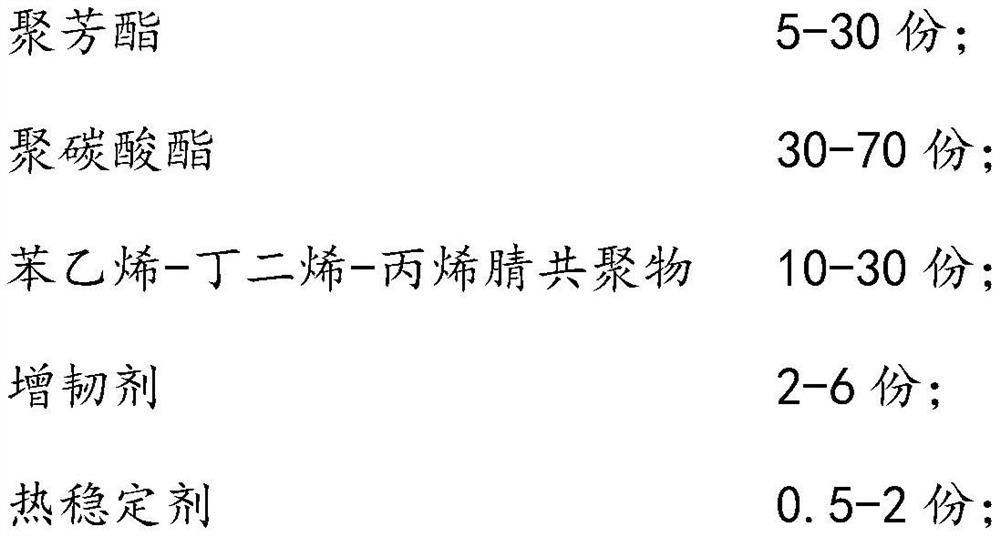

High-rigidity and high-toughness resin material for clothing buttons

Owner:HEBEI JIASHICHENG ENERGY TECH CO LTD

3, 3-difluoro-1, 5-hexadiene compound as well as preparation method and application thereof

ActiveCN113024349AHigh selectivityEasy to operateSugar derivativesCarboxylic acid nitrile preparationMeth-Silanes

The invention discloses a 3, 3-difluoro-1, 5-hexadiene compound as well as a preparation method and an application thereof. The preparation method comprises the following steps: in an inert gas atmosphere, sequentially adding alpha-trifluoromethyl styrene, allyltrimethylsilane, tetrabutylammonium fluoride and a solvent into a reaction tube, and magnetically stirring uniformly to obtain a mixture; performing a magnetic stirring reaction on the mixture for 12 h under the condition of a 130 DEG C oil bath, cooling the reaction mixture to the room temperature, and obtaining the 3, 3-difluoro-1, 5-hexadiene compound from the reaction mixture through rapid column chromatography separation. The compound can be used for synthesizing a precursor compound containing a CF2 organic framework. The preparation method has the advantages of high selectivity, economy, environmental protection, simple operation, cheap and easily available raw materials, and is suitable for industrial application.

Owner:NANJING TECH UNIV

Biodegradable 3D printing toughened material and preparation method thereof

InactiveCN106893279AImprove the shortcomings of low impact performanceHigh impact strengthAdditive manufacturing apparatusPolymer scienceGlycidyl methacrylate

Owner:四川鑫达企业集团有限公司

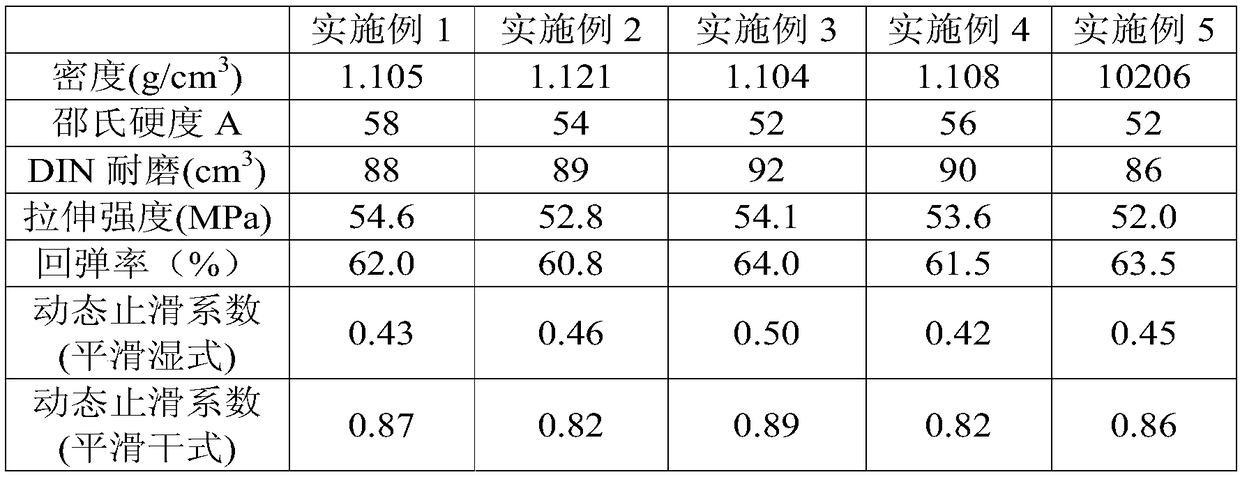

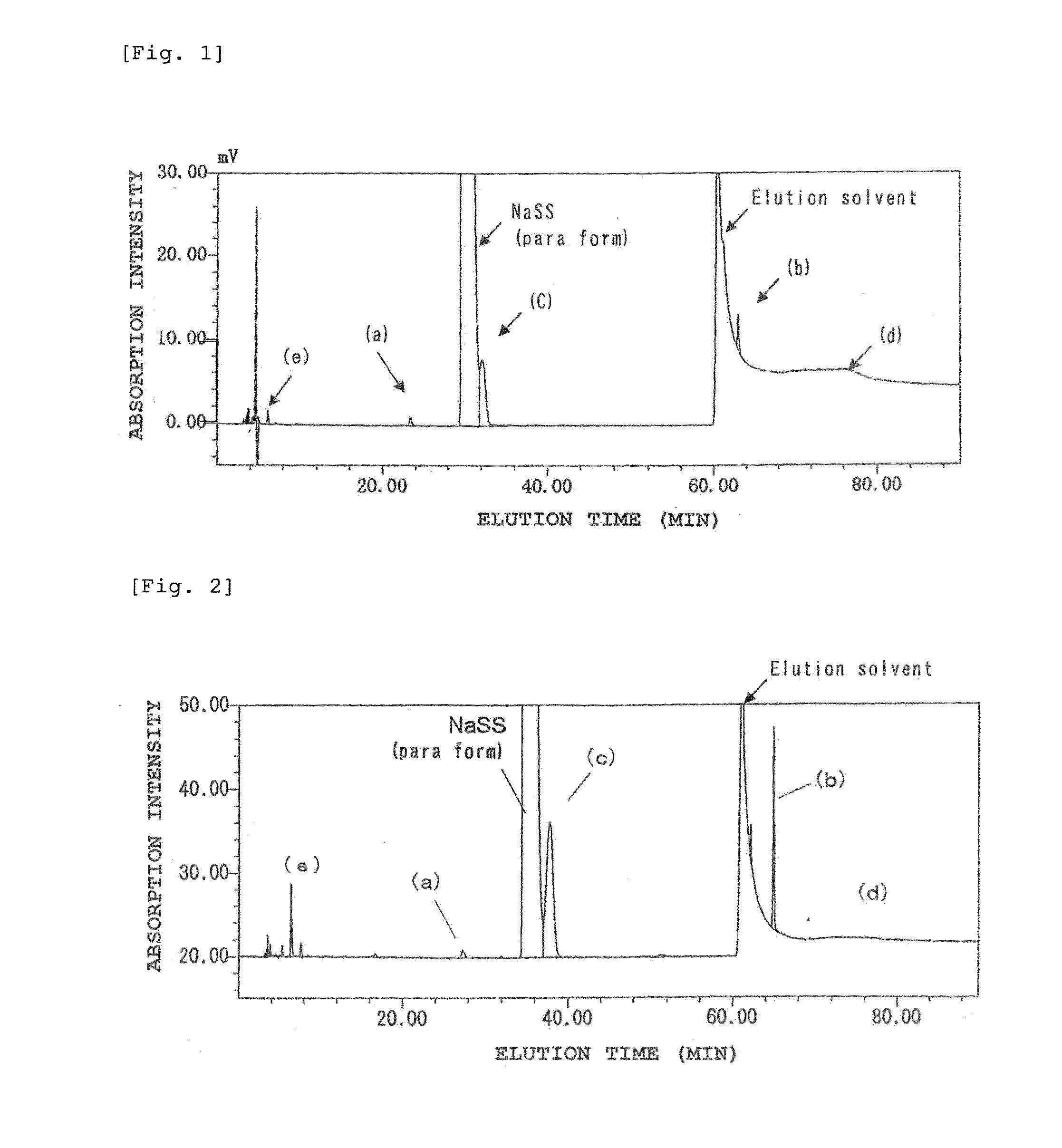

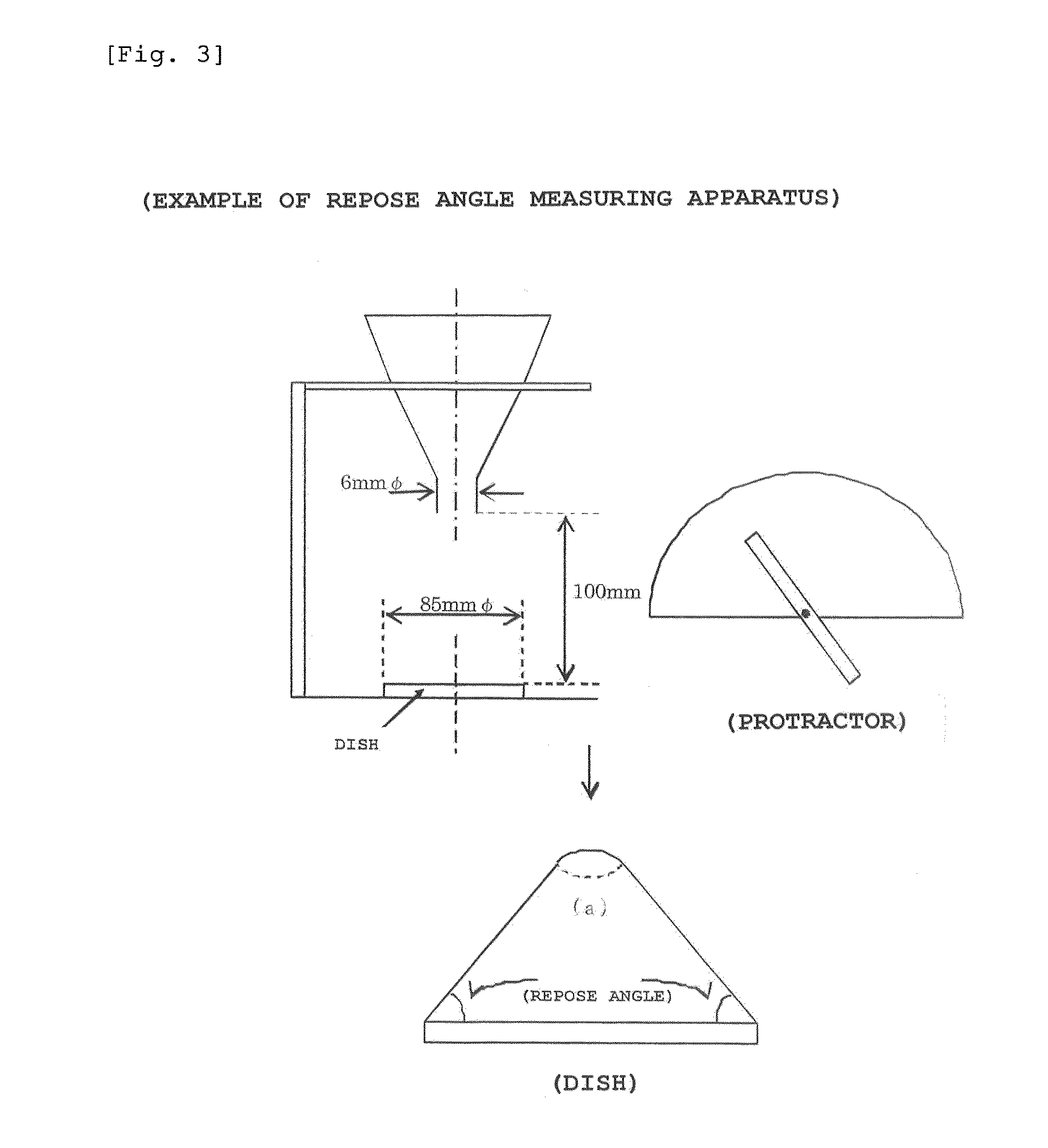

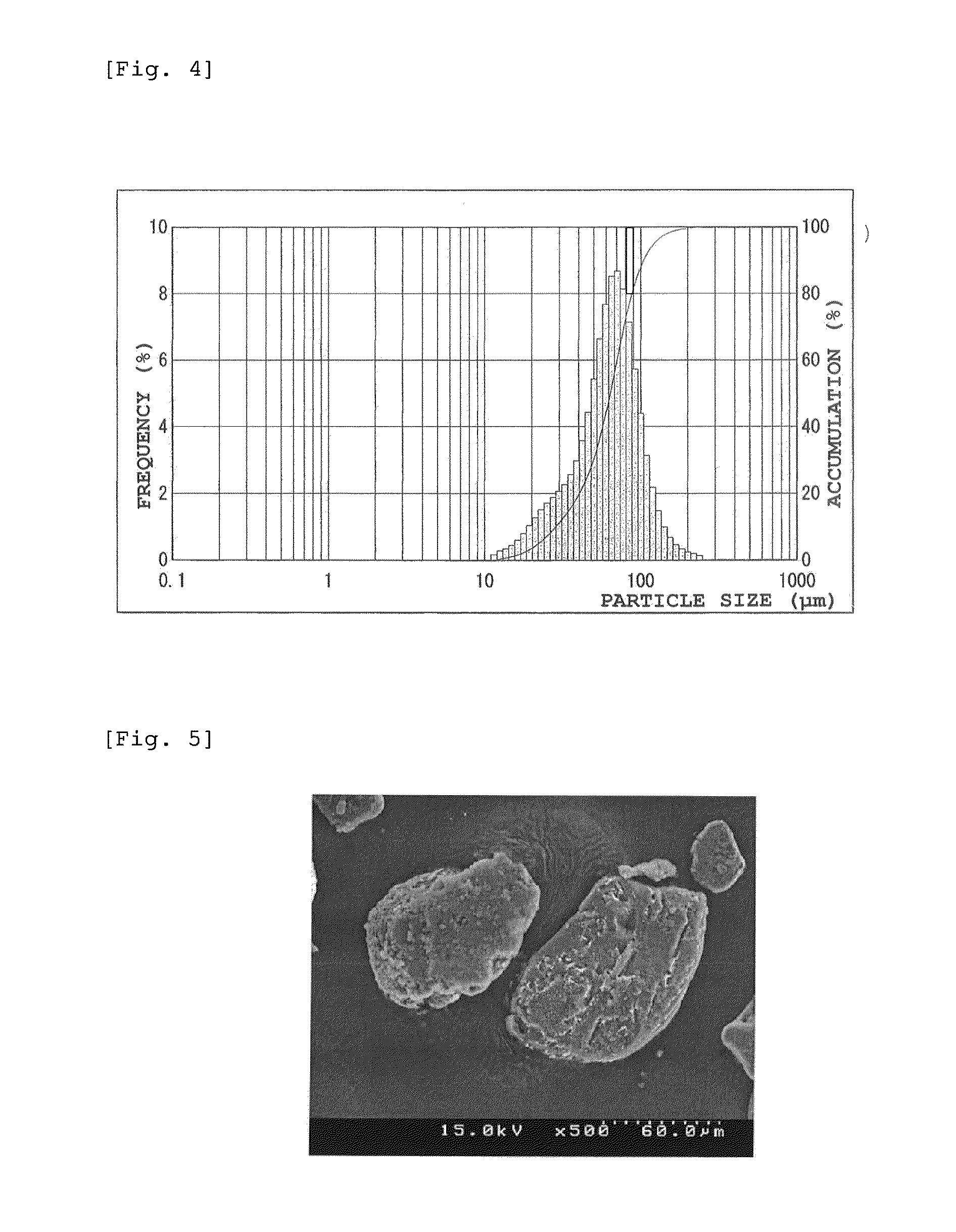

High-purity sodium p-styrenesulfonate with excellent hue, method for producing the same, poly (sodium p-styrenesulfonate) with excellent hue using the same, and dispersant and synthetic starch for clothing finishing using the poly ( sodium p-styrenesulfonate)

ActiveUS20150246876A1Excellent toneSmall contentOrganic compound preparationFibre treatmentSolubilitySulfonate

Owner:TOSOH ORGANIC CHEM

Method for preparing wear-resistant plastic particles by using waste polystyrene

InactiveCN110760138AImprove wear resistanceSolve the defect of poor wear resistanceCyclohexanoneSilicic acid

The invention discloses a method for preparing wear-resistant plastic particles by using waste polystyrene. The method specifically includes the following steps that (1) the waste polystyrene and liquid paraffin are put into a reactor for heat treatment under the nitrogen environment, then cobalt powder is added for natural cooling, and pretreated polystyrene is obtained; (2) tetraethyl orthosilicate is added into a chitosan solution, hydrochloric acid is added and then placed in a water bath, glutaraldehyde is added, and chitosan / silica particles are obtained by reaction; (3) the pretreated polystyrene is added into cyclohexanone after being cut into granules and dried, and polyvinyl pyrrolidone is added, stirred and dissolved, and then dried particles are added to obtain a coating solution; and (4) after the coating solution is treated, a film is scraped on a substrate, removed after phase transfer, and melted and extruded with a plasticizer and a lubricant through a twin-screw extruder. According to the method, by increasing the bond strength between the polystyrene and silicon dioxide, significant improvement of the wear resistance of the polystyrene is realized, and the methodis suitable for large-scale and industrial production.

Owner:ANHUI GUANHONG PLASTIC IND

Asphalt composition and method of using same in tack coats

PendingUS20210017388A1Facilitate cross-linkingReduce compositionClimate change adaptationBuilding insulationsPolymer scienceButadiene Dioxide

Owner:BASF AG

Hot melt composition for toilet seat sheet and toilet seat sheet

InactiveCN101381588AReduce manufacturing costIncrease productionBathroom coversAdhesivesPolyolefinEngineering

Owner:NISSHIN CHEM IND CO LTD

Laundry detergent composition for providing ultraviolet radiation protection for a fabric

ActiveUS20160130529A1Improves UV resistancePromote absorptionInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsBoronic acidZinc

Owner:THE SWEET LIVING GROUP

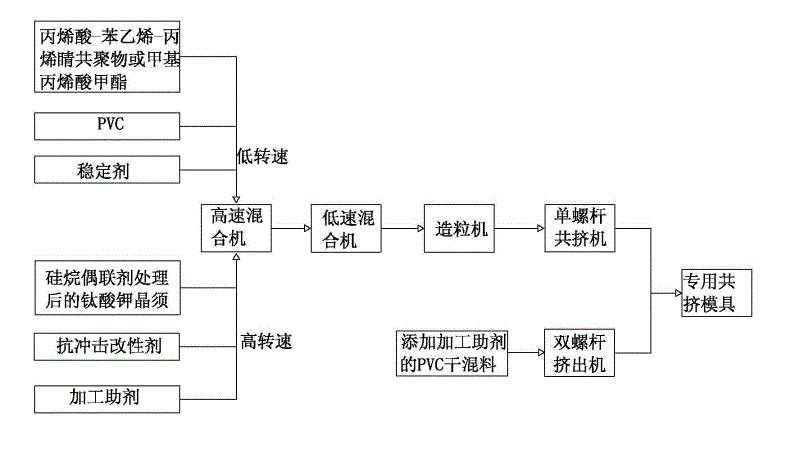

Color bending-resistant co-extruded section bar reflecting infrared rays and preparation method thereof

ActiveCN102617962AWith reflective infrared functionWith heat insulation functionInfraredPolyvinyl chloride

Owner:新疆蓝山屯河型材有限公司

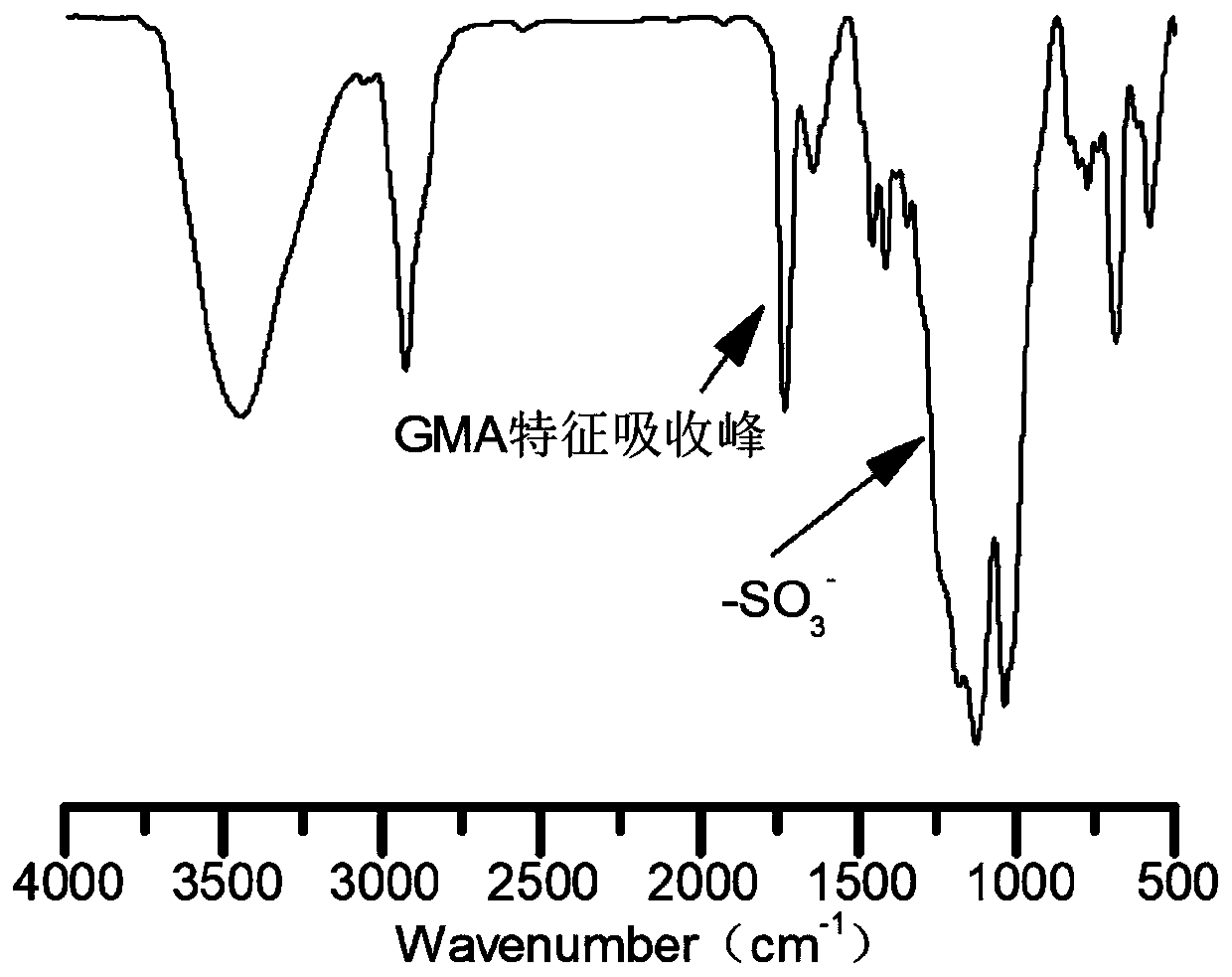

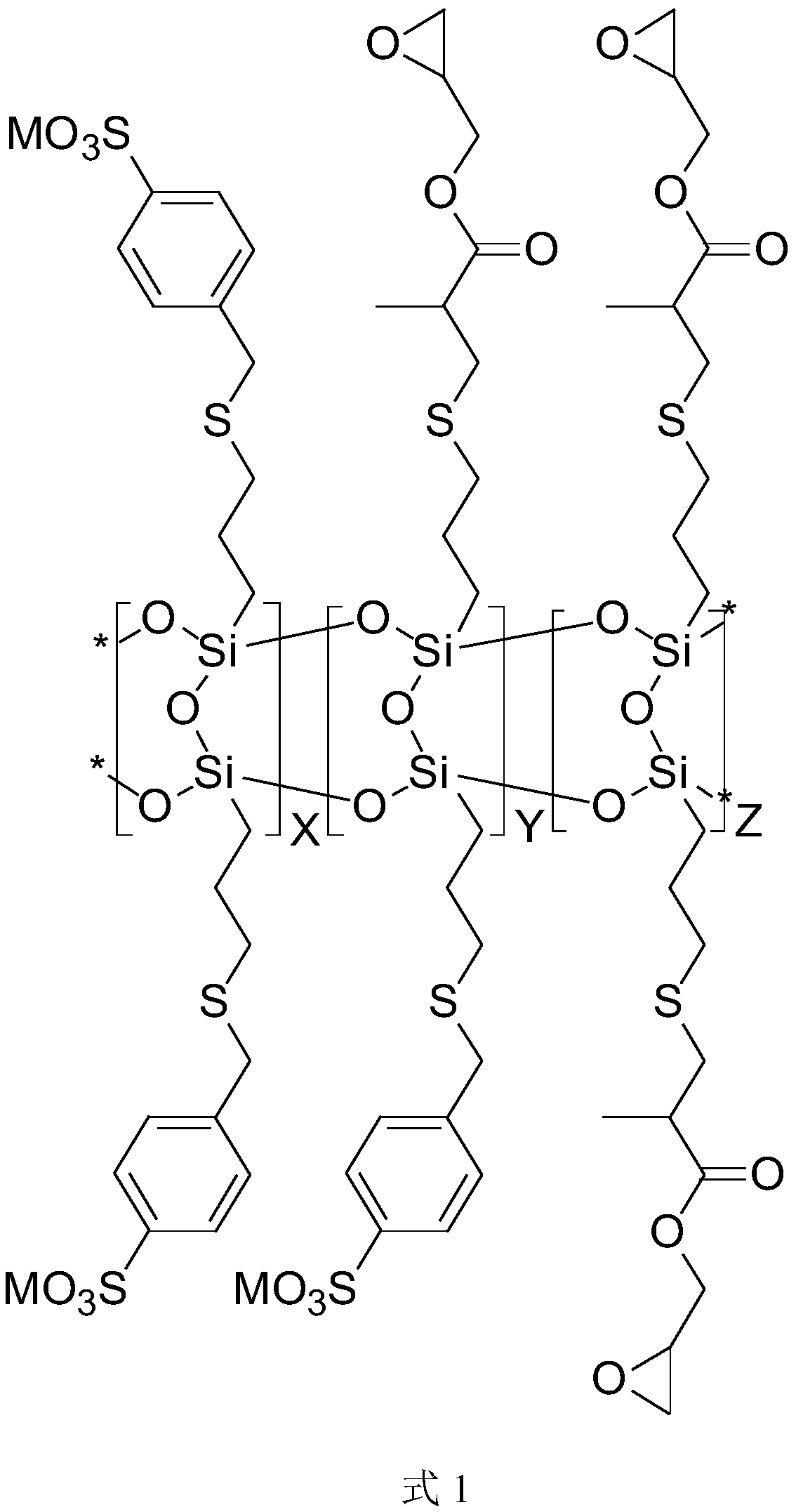

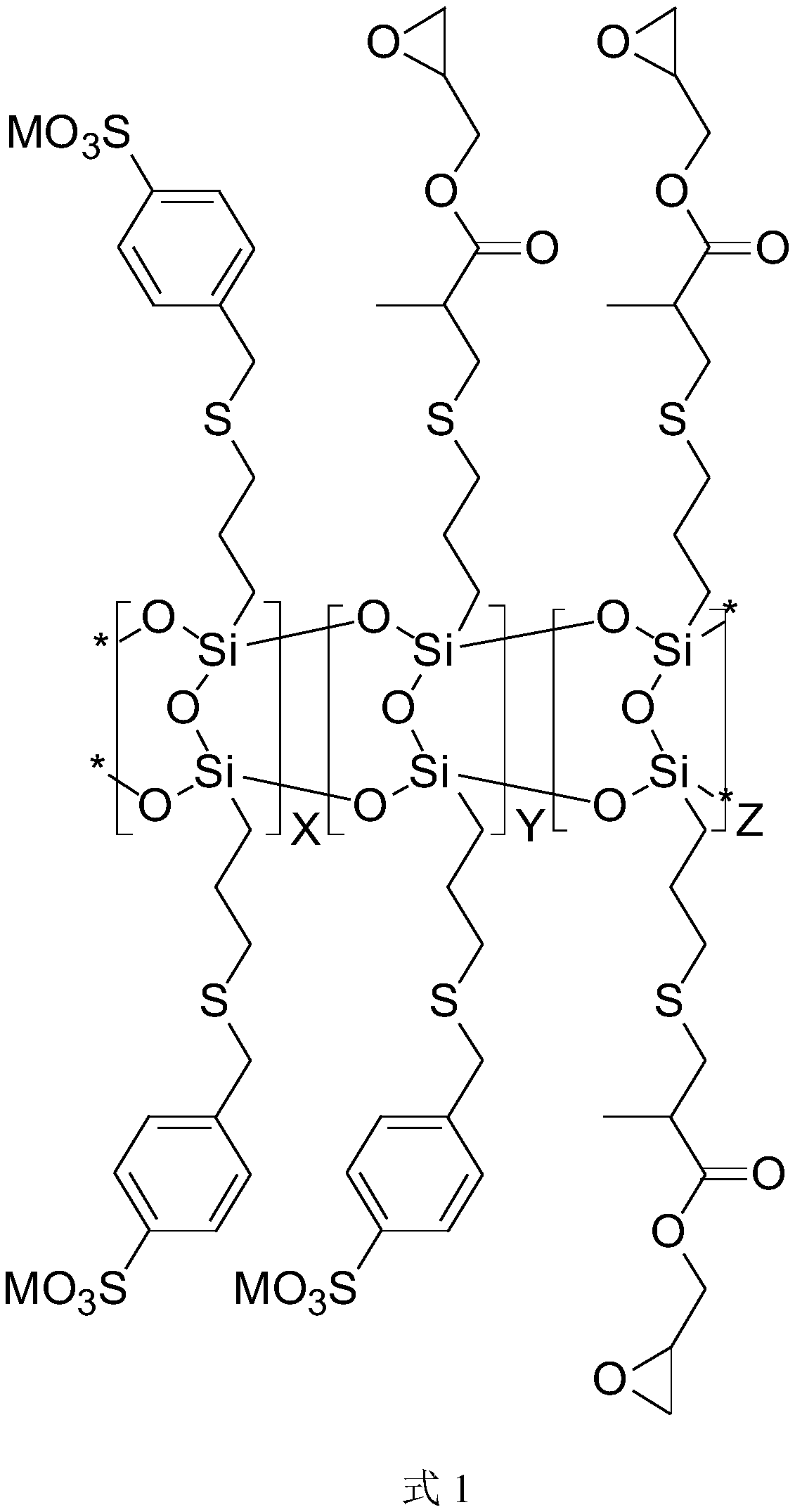

Epoxy group containing polysilsesquioxane sulfonate, and preparation method and applications thereof

ActiveCN110105576AExcellent capacity expansion and chain expansion effectImprove efficiencyEpoxySulfonate

Owner:广州摩库乐化工材料技术有限公司

Method for preparing sodium polystyrenesulfonate by sulfonating waste polystyrene and application of sodium polystyrenesulfonate in coal water slurry

InactiveCN113430022AReduce manufacturing costIncrease concentrationLiquid carbonaceous fuelsCoal waterRotary evaporator

The invention discloses a method for preparing sodium polystyrenesulfonate by sulfonating waste polystyreneand application of the sodium polystyrenesulfonate in coal water slurry. The preparation method comprises the following steps: step 1, cleaning and drying waste polystyrene foam; step 2, adding the waste polystyrene foam dried in the step 1 and an organic solvent into a container, and performing mechanical stirring to completely dissolve the waste polystyrene foam and the organic solvent; step 3, adding a sulfonating agent into the solution obtained in the step 2, and after the sulfonating agent is degraded, performing heating, and performing sulfonation reaction; and step 4, after the sulfonation reaction is finished, recovering the organic solvent by using a rotary evaporator, and adding a sodium hydroxide aqueous solution into a reaction product to obtain a sodium polystyrene sulfonate solution. The sodium polystyrenesulfonate prepared from the waste polystyrene can be used as a coal water slurry additive to realize clean utilization of coal resources, waste is turned into wealth, and social benefits and ecological benefits are remarkable. The preparation method has the advantages of simplicity in operation, short flow, high industrial application value and the like.

Owner:NANJING UNIV

Turbid liquid type drag reducer and preparation method and application thereof

ActiveCN112410013AIncrease contentIncrease viscosityDrilling compositionPolymeric surfacePolymer science

The invention provides a turbid liquid type drag reducer and a preparation method thereof. The drag reducer is prepared from, by mass, 15-60 wt% of water-soluble high-molecular polymer, 0.3-2 wt% of surfactant, 0.5-5 wt% of thickener and the balance oil solvent. The viscosity of the drag reducer is 50-200 thousand cP. The thickener is selected from one or more of polystyrene-ethylene-propylene, polystyrene-ethylene-butylene, polyethylene, polypropylene, polyurea, polyisoprene, polybutadiene, polystilbene-ethylene-propylene, poly(styrene-butadiene), polymethacrylate, polyisobutene, hydrogenated(styrene-isoprene) copolymer and fatty alcohol. According to the turbid liquid type drag reducer provided by the invention, aiming at polyacrylamide powder with specific dosage and molecular weight,the thickener with specific composition proportion is matched with a surfactant with specific composition and proportion, so that the obtained final drag reducer product has better drag reduction property, salt resistance and storage stability.

Owner:DESHI ENERGY TECH GRP CO LTD +1

Production process of environment-friendly water-based anti-corrosion coating

InactiveCN104449091AImprove anti-corrosion performanceGood resistance to nitro paintAnti-corrosive paintsWater basedWater resistant

Owner:QINGDAO SHOUSHENG IND

High-thermal-filament ignition polyphenyl ether composition as well as preparation method and application thereof

The invention discloses a high-thermal-filament ignition polyphenyl ether composition. The polyphenyl ether composition comprises the following components in parts by weight: 40-90 parts of polyphenylether, 2-40 parts of styrene resin, 1-10 parts of a toughening agent, 5-18 parts of a flame retardant, 0.1-3 parts of polyformaldehyde resin and 0.1-1 part of metal oxide. According to the heat-resistant wire ignition polyphenyl ether material, the quality of a carbon layer is greatly enhanced through the catalytic charring effect of metal oxide and POM in the early stage of ignition, the HWI performance of the material is obviously improved, a good effect on flame retardance is achieved, and the flame-retardant PPE material with the 0-grade HWI can be prepared through the method.

Owner:KINGFA SCI & TECH CO LTD

Polyester alloy composition for improving high-temperature welding performance and application thereof

Owner:安庆会通新材料有限公司

Cement nanometer toughening agent for natural gas well cementation

Owner:CNPC BOHAI DRILLING ENG

Use of aramid fiber conjunction with thermoplastic to improve wash-off resistance and physical properties such as impact and expansion

InactiveUS20060189722A1Excellent characteristicsIncrease resistanceEster polymer adhesivesEpoxy resin adhesivesThermoplasticPolymer science

One-part epoxy adhesive formulations, and methods of using the same, are described. The formulations include, among other things, powdered methacrylate butadiene styrene and aramid pulp to, among other things, improve the wash off resistance, T peel strength, and impact strength characteristics thereof. Additionally, the formulations exhibit desirable expansion characteristics. The formulations are especially suitable for use in joining automotive components.

Owner:DOW GLOBAL TECH LLC

Cold-resistant coating material

The invention relates to the technical field of adhesives, particularly to a cold-resistant coating material, which comprises, by mass, 10-20 parts of copper chloride, 3-12 parts of pentaerythritol, 7-15 parts of ethyl acrylate, 12-18 parts of styrene, 11-15 parts of calcium carbonate, 12-20 parts of a perchloroethylene resin, 8-15 parts of ethylene glycol, and 11-18 parts of carboxymethyl cellulose. The cold-resistant coating material of the present invention has excellent cold resistance.

Owner:CHANGZHOU NAIQIANG TRANSMISSION MASCH CO LTD

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap