Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32 results about "Acrylamide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acrylamide (or acrylic amide) is an organic compound with the chemical formula CH₂=CHC(O)NH₂. It is a white odorless solid, soluble in water and several organic solvents. It is produced industrially as a precursor to polyacrylamides, which find many uses as water-soluble thickeners and flocculation agents. It is highly toxic, likely to be carcinogenic, and partly for that reason it is mainly handled as an aqueous solution.

Method for preparing liquid fluorescent brightener composition of diphenylvinyl triazine compounds

ActiveCN102477227AImprove performanceWith strong fluorescenceStyryl dyesLuminescent/fluorescent substance additionRoom temperatureAniline

The present invention relates to a production process of a chemical additive special for papermaking, in particular to a method for preparing a liquid fluorescent brightener composition of diphenylvinyl triazine compounds. The invention mainly solves the problems of low fluorescence intensity and low brightness of a single-component liquid fluorescent brightener. The method adopts cyanuric chloride, 4,4'-diamino-2,2'-stilbenedisulfonic acid (DSD acid), aniline, monoethanolamine and 1-R1-2-R2-acrylamide as raw material, and employs four-step reaction. The inventive liquid fluorescent brightener composition has convenient usage, good acid resistance, and good storage stability at a room temperature, and is suitable for continuous adding and metering during automatic production.

Owner:JIANGSU JINGUANG CHEM TECH CO LTD

Preparation method and application of surface artemisinin molecule imprinting adsorbing material of vegetable sponge

InactiveCN102600813ASpecific recognition abilityHigh selectivityIon-exchange process apparatusOrganic chemistryCross-linkN dimethylformamide

Owner:UNIV OF JINAN

Agaricus bisporus SSR molecular marker specific primer system and application thereof

ActiveCN105255882AMicrobiological testing/measurementDNA/RNA fragmentationMolecular identificationAgaricus

Owner:JILIN AGRICULTURAL UNIV

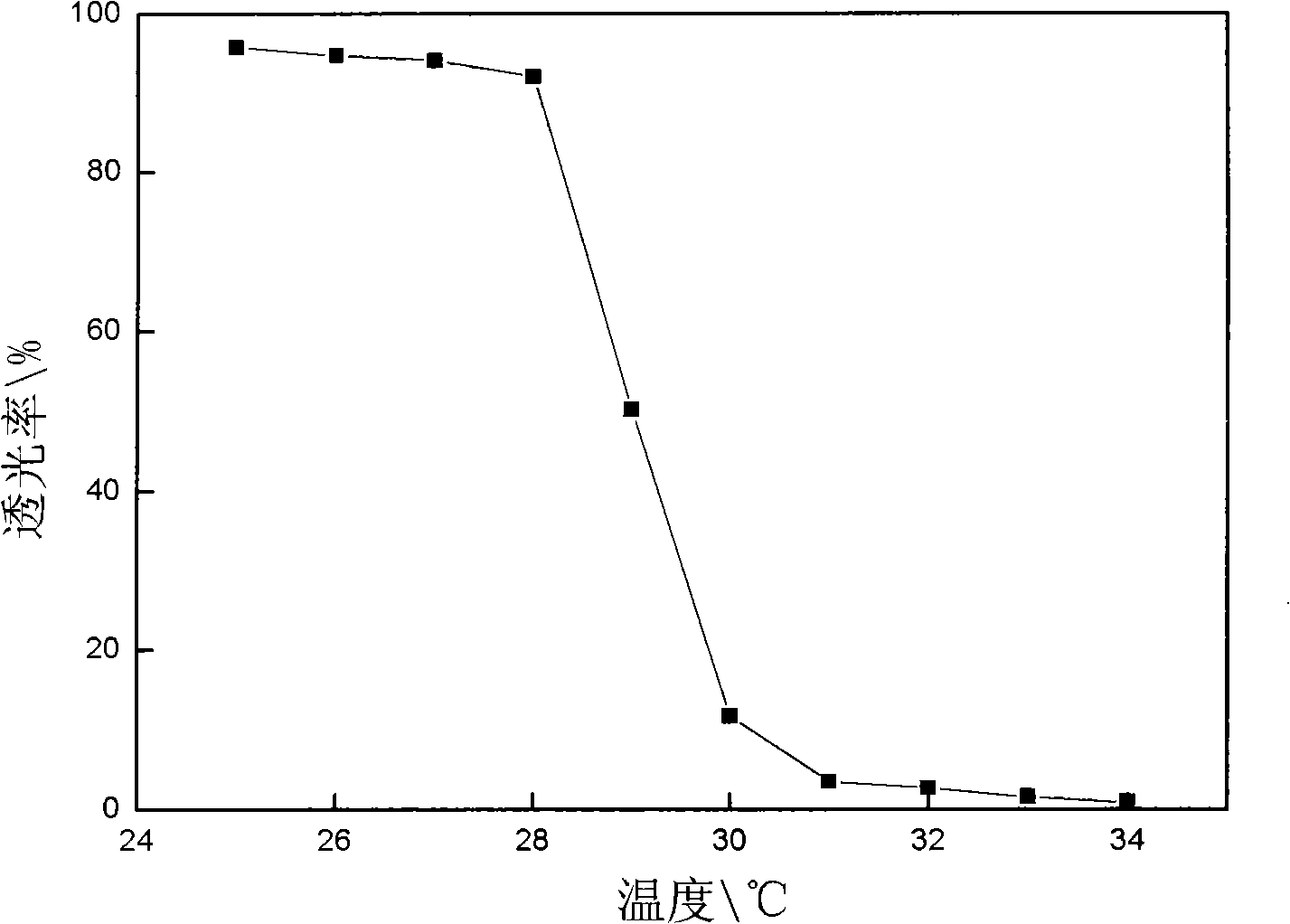

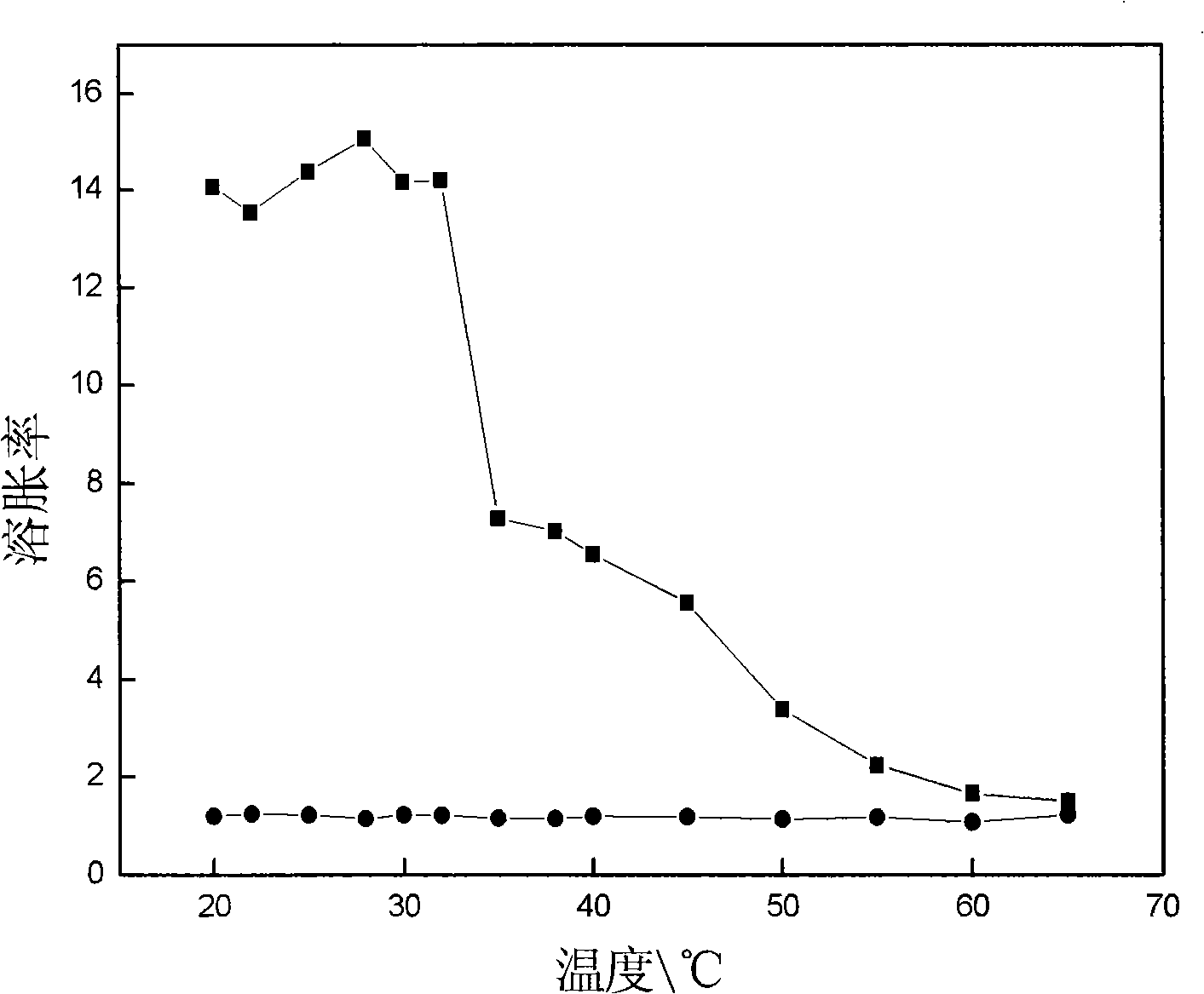

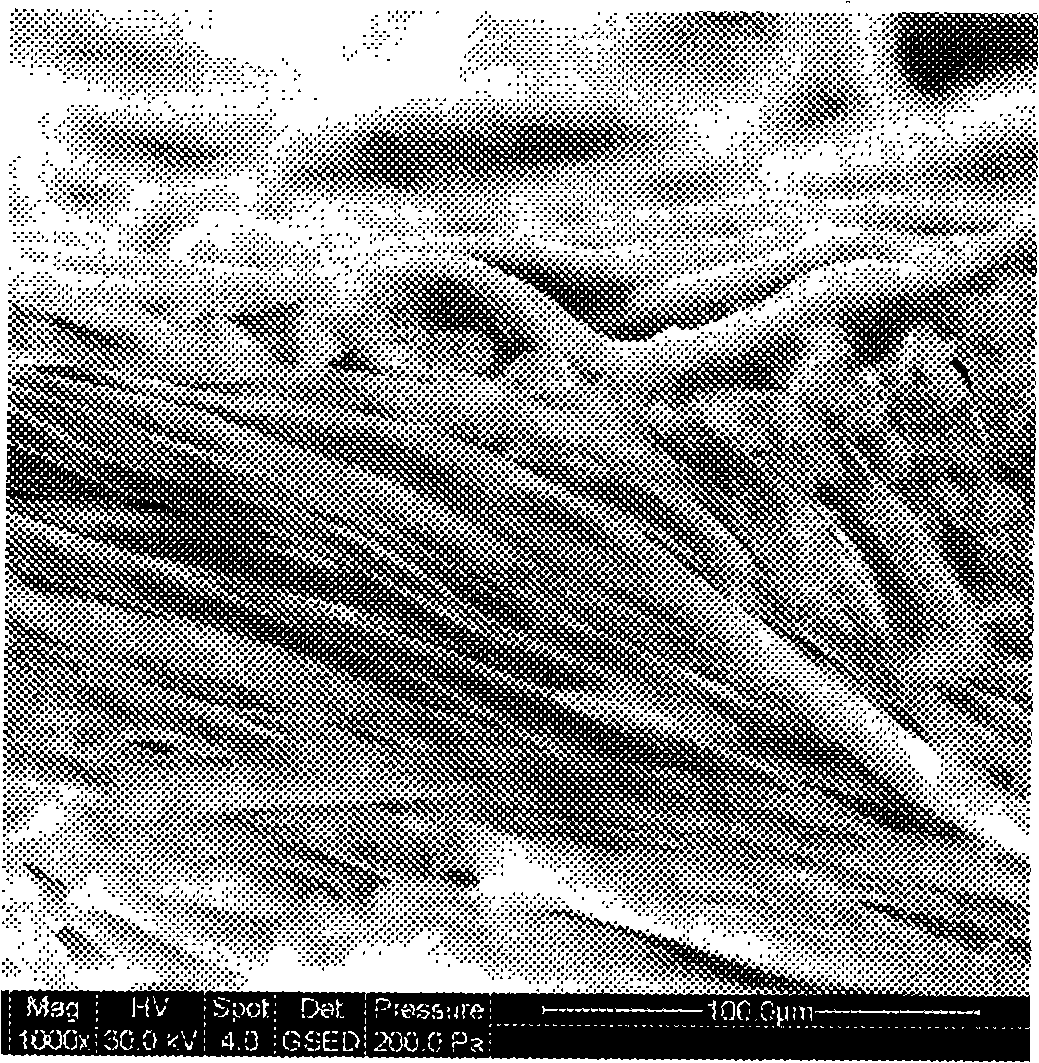

Method for preparing temperature sensitive intelligent anti-dip facing material and product thereof

InactiveCN101302718ATemperature-sensitive intelligenceReduce voidsTextiles and paperCarboxylic acidTert butyl

Owner:TIANJIN POLYTECHNIC UNIV

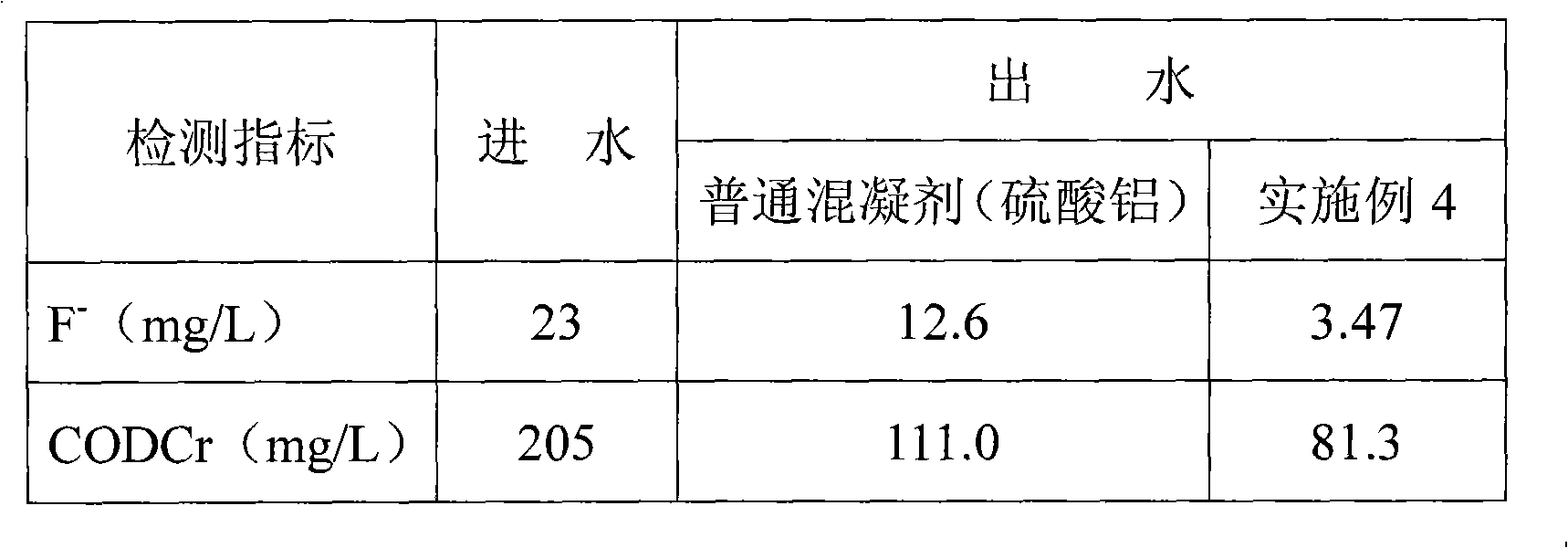

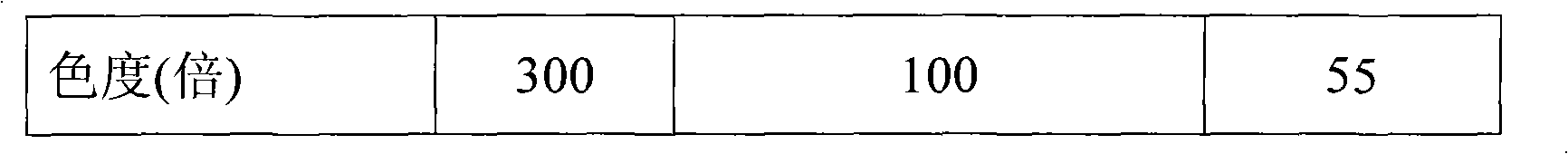

Coagulating agent for treating wastewater containing fluorine and use process thereof

ActiveCN101492192ALow priceLow investment costWater/sewage treatment by flocculation/precipitationAluminium chlorohydrateWastewater

Owner:HANGZHOU CHENGJIE ENVIRONMENTAL PROTECTION

Tackifier for drilling fluid and preparation method thereof

ActiveCN104311730AImproved rock carrying capacityThe preparation method is simple and feasibleDrilling compositionCross-linkSalt resistance

The invention relates to a tackifier for drilling fluid and a preparation method thereof, and belongs to the technical field of synthesis of processing agents for oil-field drilling fluids. The tackifier is a net-like polymer obtained by mixing acrylamide, a sulfo-group-containing monomer A and a pyrrolidone monomer B according to the mass ratio of 10:(3-5):(0.7-1.5), adjusting the pH value of the solution, adding a cross-linking agent C, a molecular-weight adjusting agent D and an initiator and performing copolymerization crosslinking. The preparation method is simple and practicable, and short in reaction time. The obtained tackifier has good salt resistance, has the temperature resistance up to 135 DEG C, has good effects of increasing shear viscosity and reducing filter loss when being applied to drilling fluids, is capable of substantially improving the cutting carrying capability of the drilling fluids under the condition of high temperature, has the effect obviously better than a tackifier normally used on site, is widely applicable to fresh-water drilling fluids and saturated brine drilling fluids, and has relatively good application prospect.

Owner:CHINA PETROCHEMICAL CORP +1

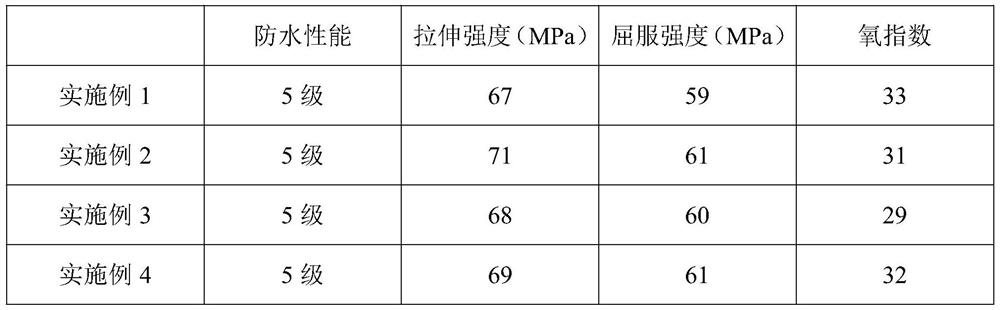

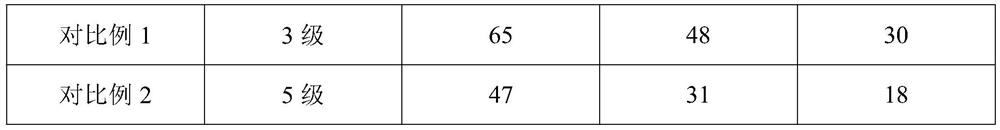

Waterproof reinforced composite and preparation method thereof

The invention discloses a waterproof reinforced composite and a preparation method thereof. The waterproof reinforced composite is prepared from the following raw materials in parts by weight: 60-90 parts of epoxy resin modified polyurethane emulsion, 15-30 parts of organic silicon styrene-acrylic emulsion, 10-30 parts of methyl methacrylate, 10-20 parts of polyacrylate, 2-4 parts of N-hydroxymethyl acrylamide, 6-12 parts of oxide-coated titanium dioxide, 10-30 parts of composite filler, 3-8 parts of silane coupling agent, 3-6 parts of propanediol butyl ether, 3-6 parts of diethylene glycol monobutyl ether, 5-10 parts of sodium polyphosphate, 4-8 parts of polyvinyl butyral, 2-5 parts of urea-isobutyraldehyde-formaldehyde resin, 0.3-0.6 part of sodium perfluorous nonenoxybenzene sulfonate,0.4-0.9 part of polypropylene wax emulsion, 0.3-0.7 part of polyether modified polysiloxane, 0.5-1 part of hydroxypropyl methyl cellulose, 1-3 parts of epoxy phosphate ester, 1-5 parts of compound antiaging agent and 10-20 parts of water.

Owner:SUZHOU FUZHONG PLASTIC CO LTD

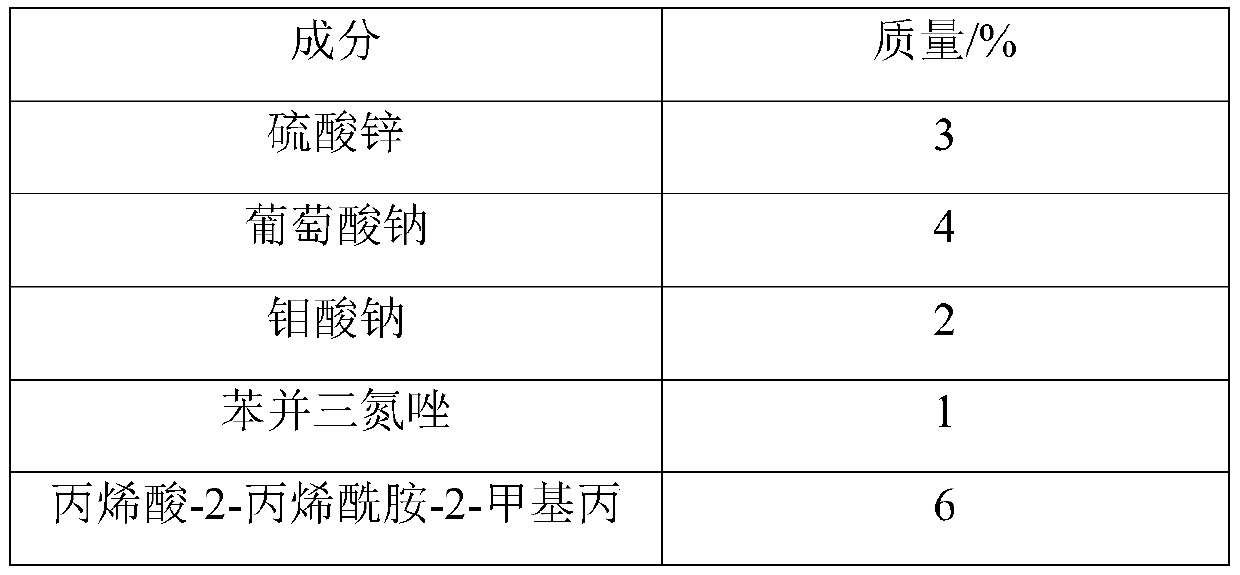

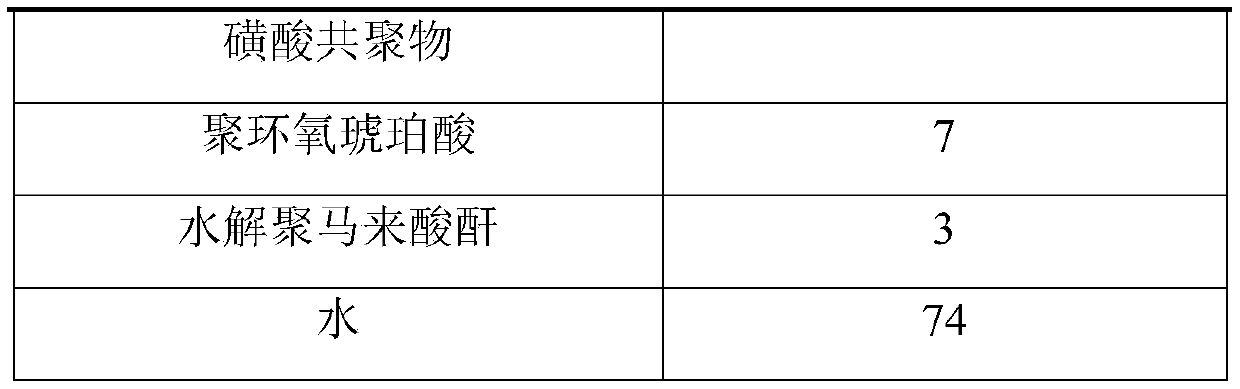

Phosphorus-free corrosion and scale inhibitor applicable to high-chlorine high-concentration-multiple circulating cooling water and preparation method of phosphorus-free corrosion and scale inhibitor

InactiveCN110655206AStrong targetingLow toxicitySpecific water treatment objectivesScale removal and water softeningMeth-Biology

Owner:RUITIAN SECURITY & ENVIRONMENTAL PROTECTION CO LTD PANZHIHUA GANGCHENG GRP

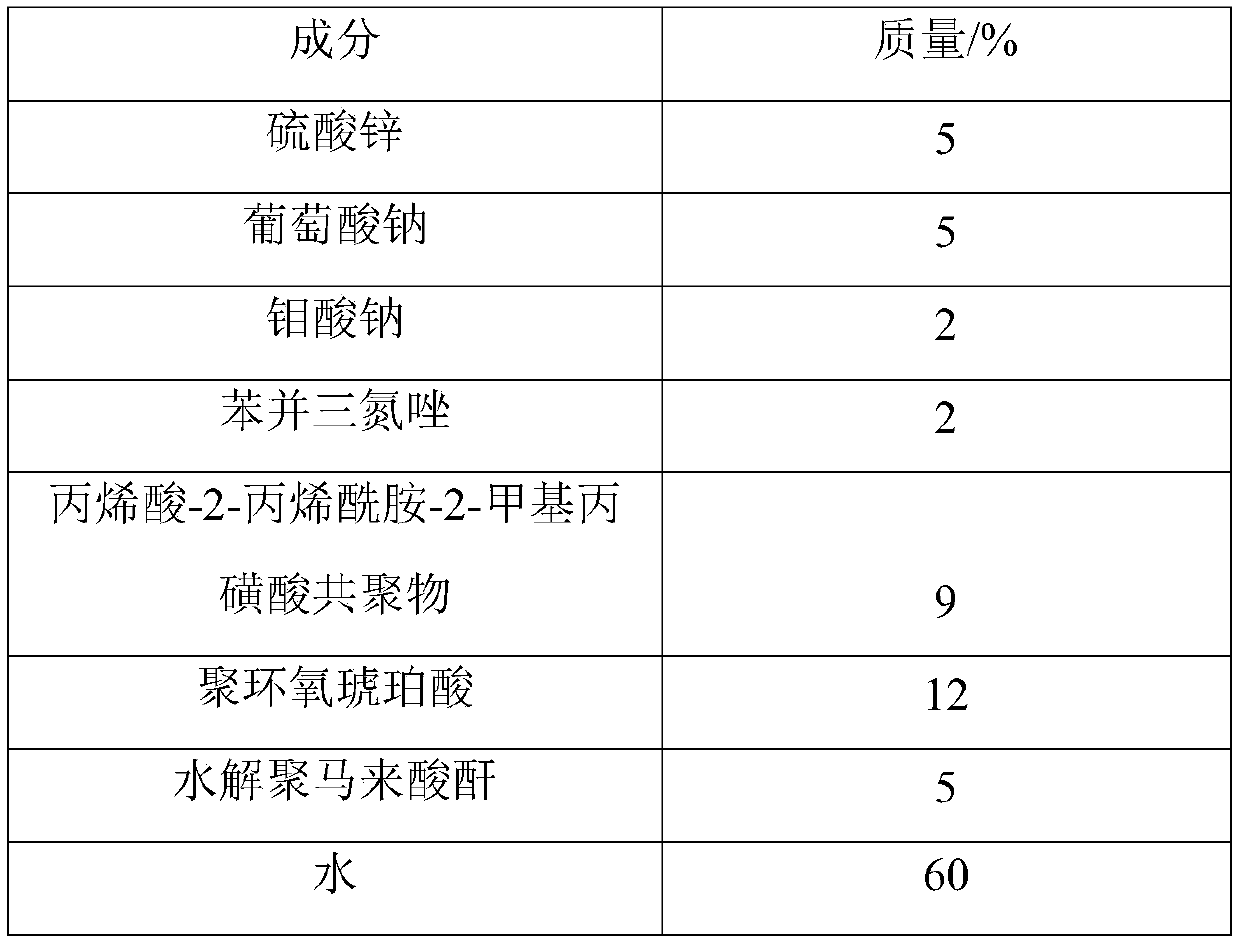

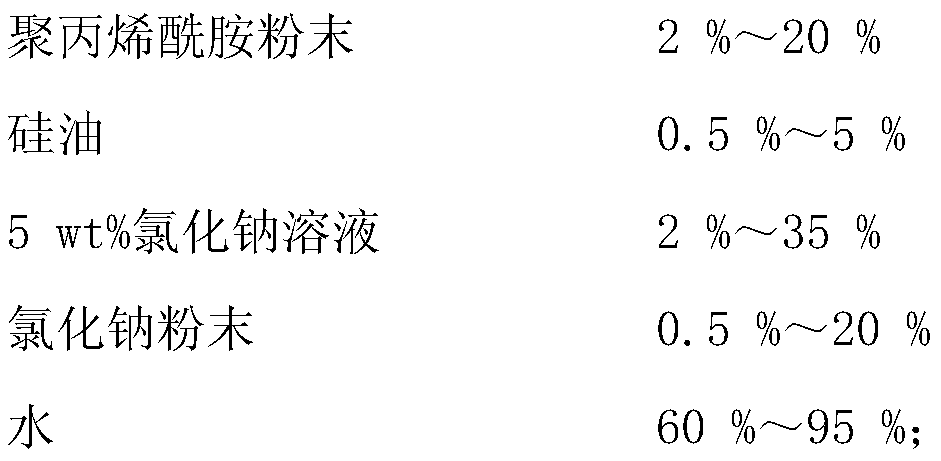

Preparation method of flexible electrode membrane based on polyacrylamide hydrogel

InactiveCN110724288AImprovement ingredientsOptimized formulaPhysical chemistryPolyacrylamide Hydrogel

Owner:SOUTHEAST UNIV

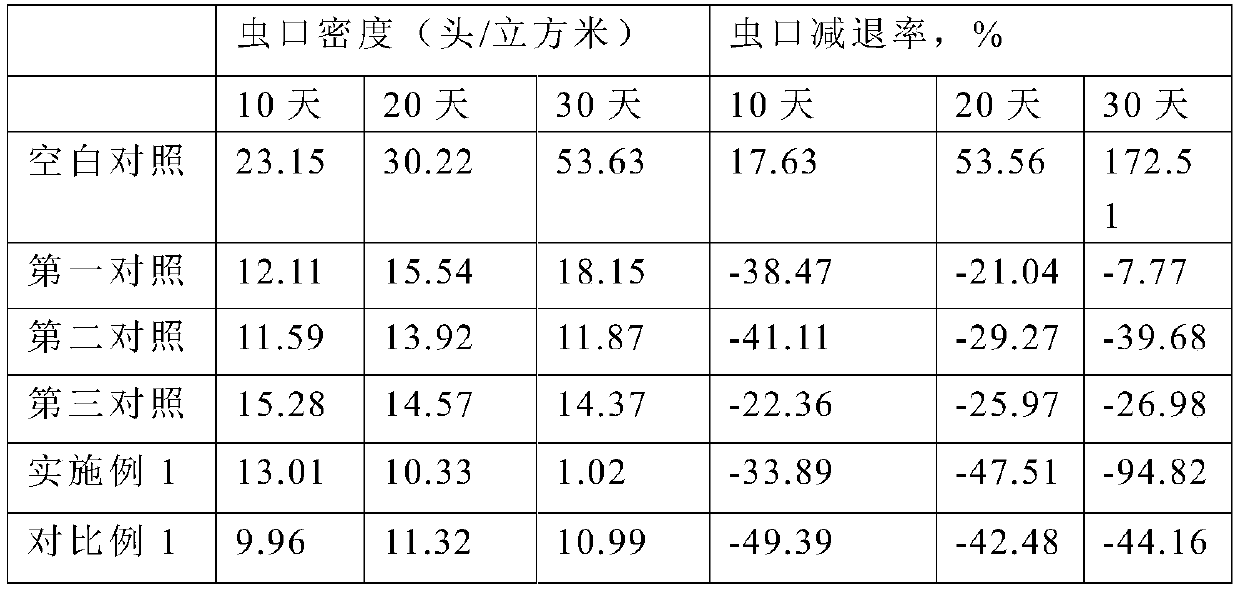

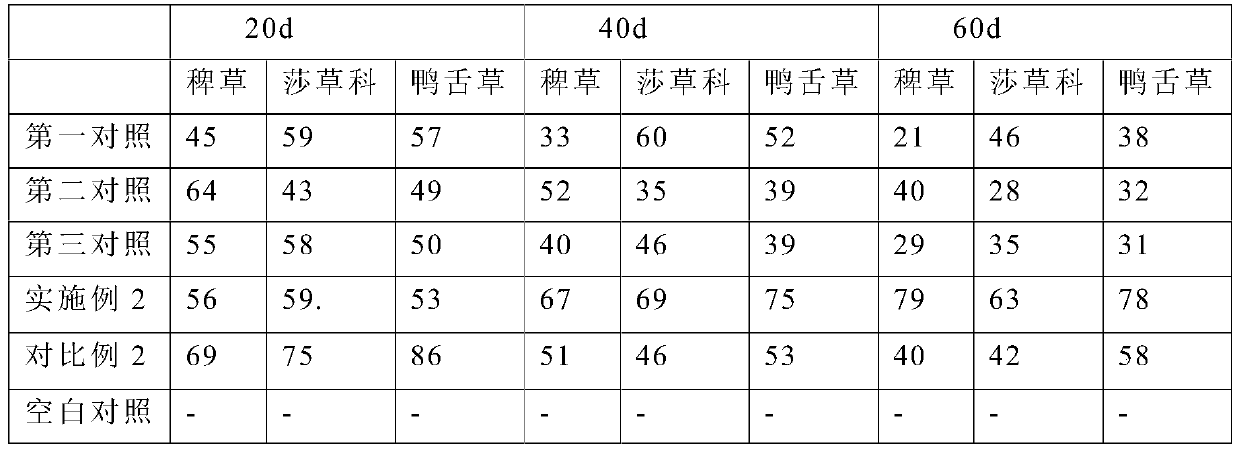

Temperature-sensitive wall material as well as microcapsule preparation and preparation method thereof

InactiveCN111226922AMany types of drug loadingStabilize each otherBiocideAnimal repellantsPyrrolidinonesGlycerol

Owner:SUZHOU FENGBEI BIOTECH CO LTD

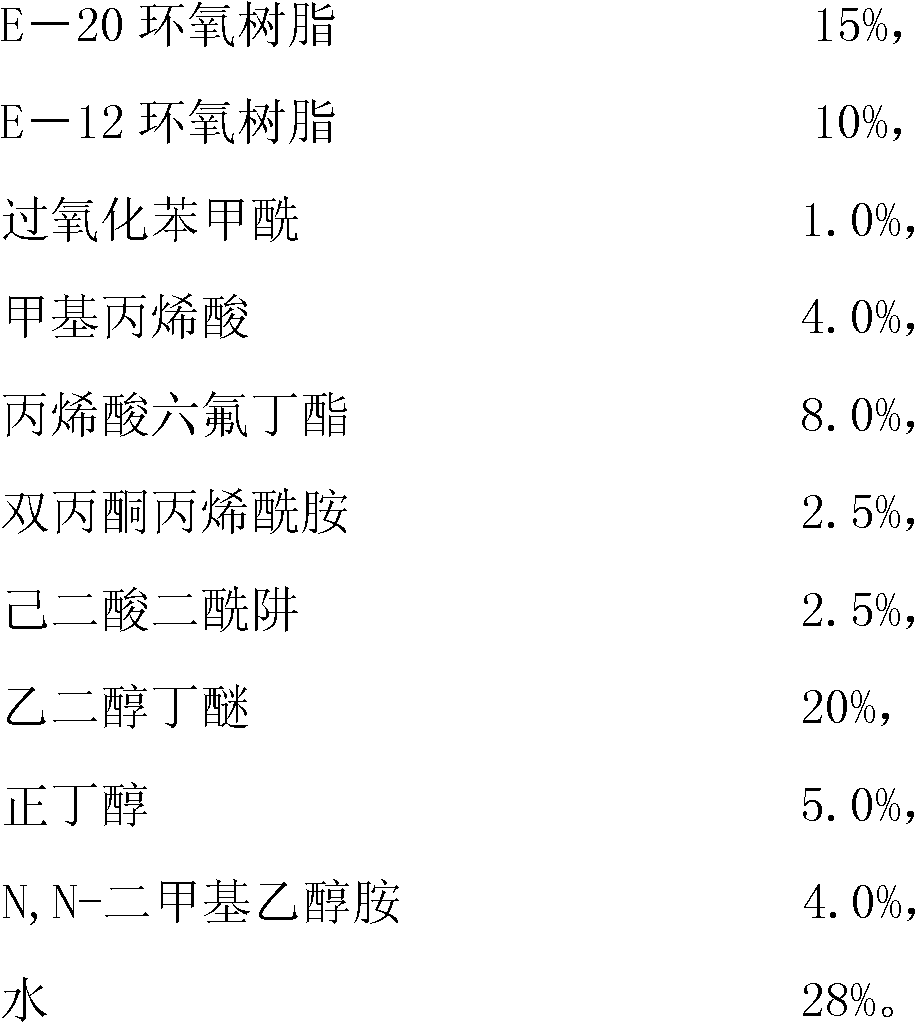

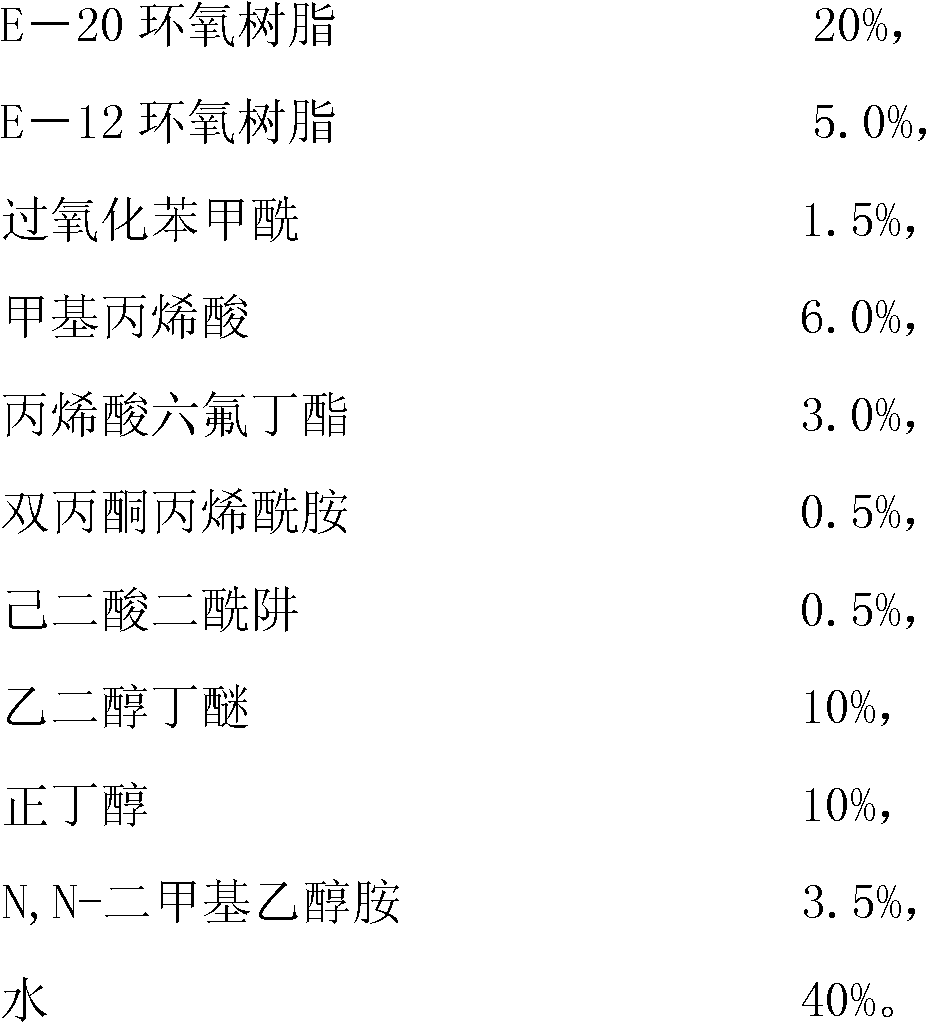

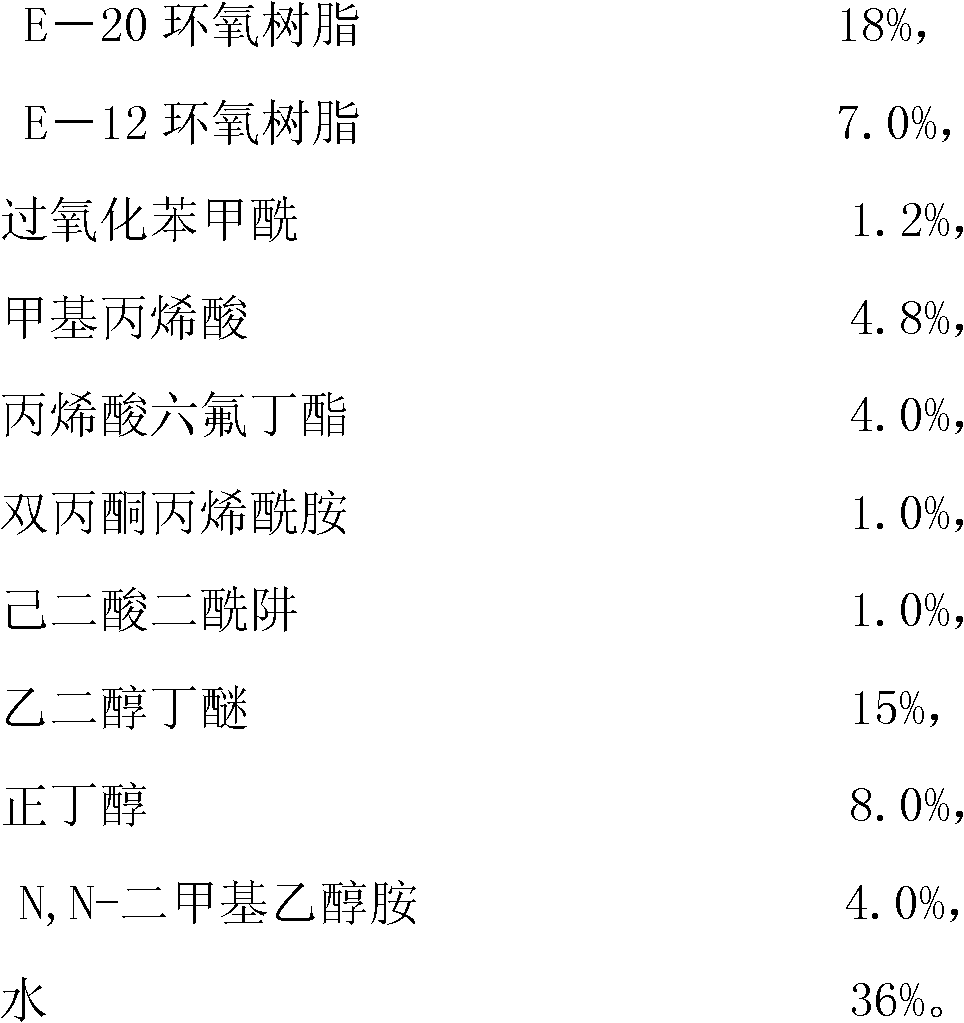

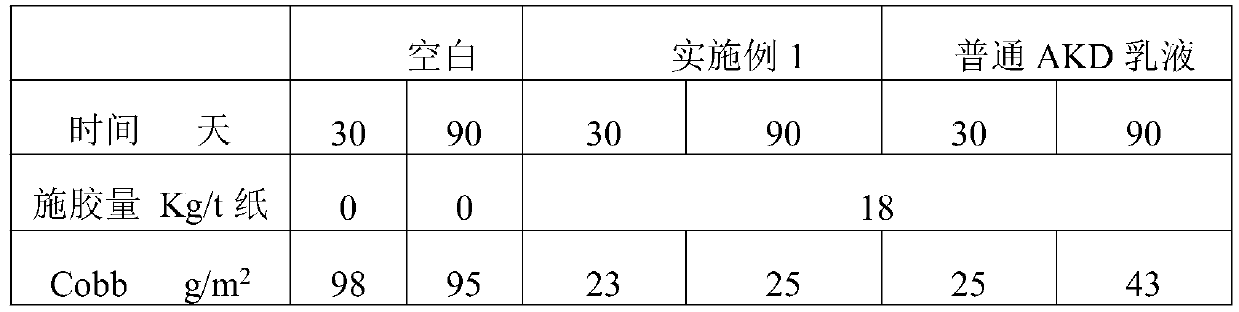

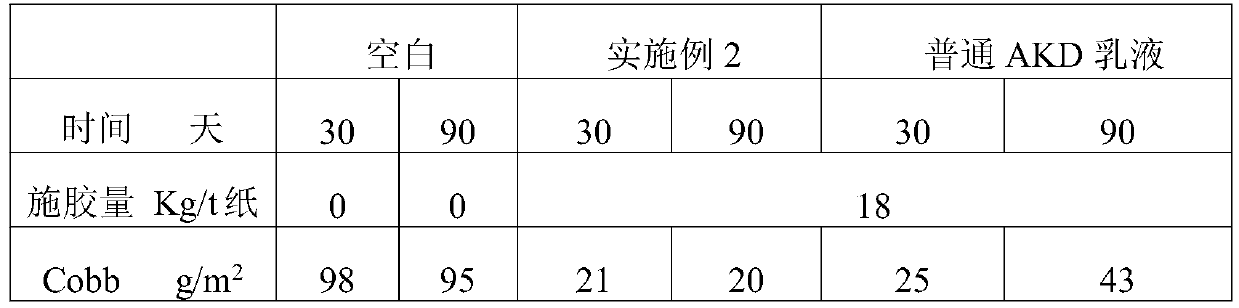

Epoxy emulsion cured at room temperature with high aquosity and weather resistance as well as preparation method of epoxy emulsion

InactiveCN102604047AGood film formingGood physical and mechanical propertiesCoatingsEpoxyBenzoyl peroxide

Owner:JIANGSU UNIV OF SCI & TECH

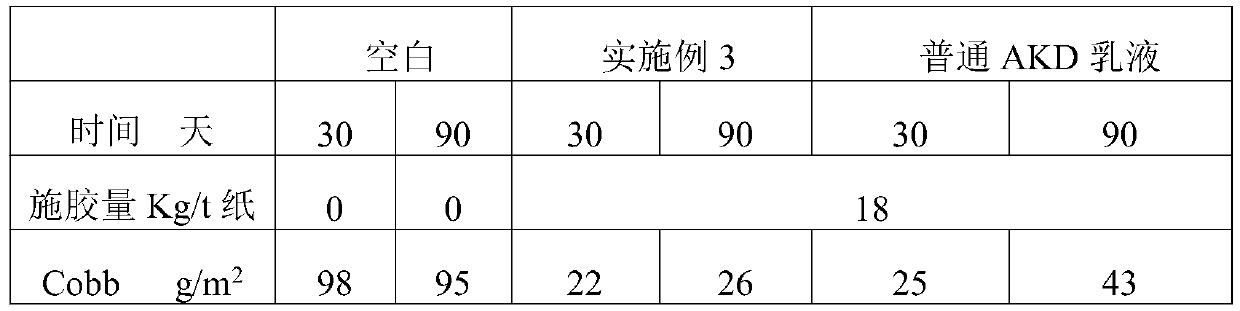

Straight-chain liquid AKD surface sizing agent and preparation method thereof

InactiveCN110983856ALimit hydrolysisLimit migratory propensityWater-repelling agents additionFiberPolymer science

Owner:JINING MING SHENG NEW MATERIALS CO LTD

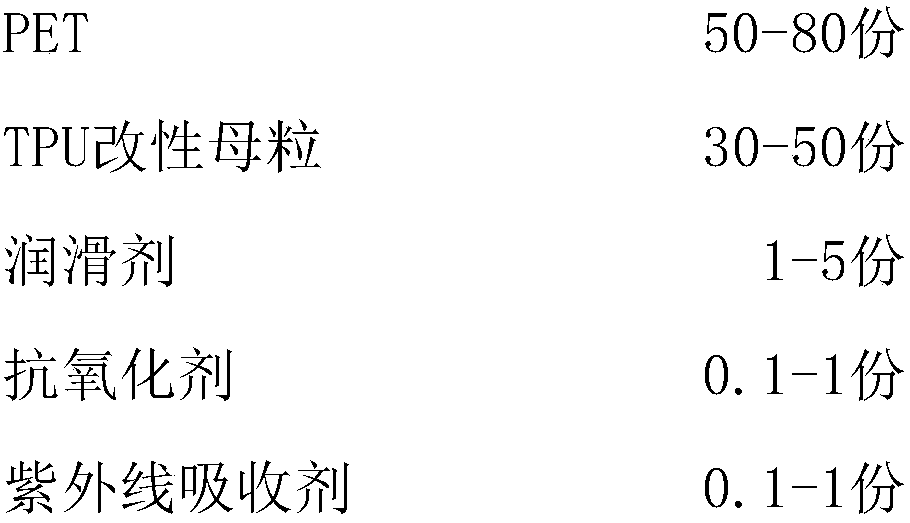

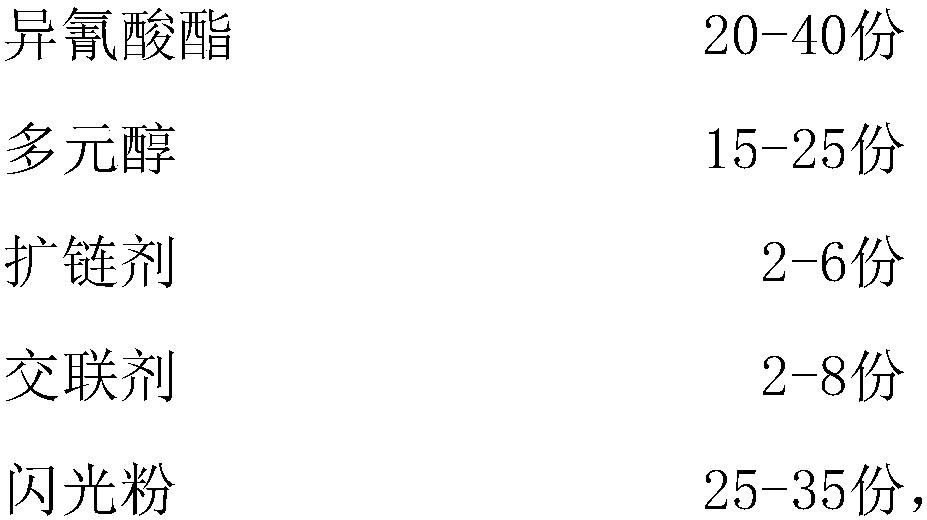

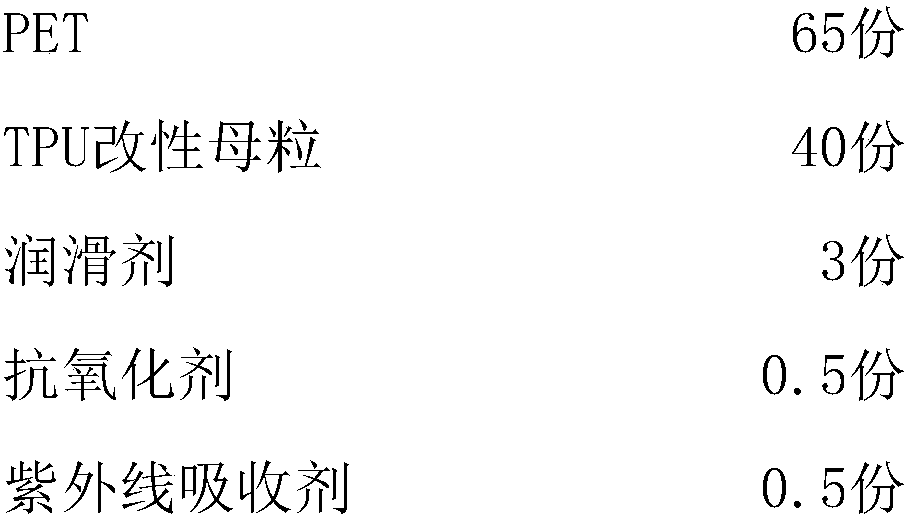

Transparent flashing polyester chain tooth, preparation method and zip fastener

Owner:东莞市瑞翔新型材料科技有限公司

Straw-based composite filler and preparation method of straw-based composite filler as well as paper sheet containing straw-based composite filler

InactiveCN106866897AHydrophilicCationicReinforcing agents additionPaper/cardboardCore shellToughening

Owner:GUANGDONG IND TECHN COLLEGE

Sports outdoor clothing fabric for mass

InactiveCN108505336AAvoid discomfortLittle effect on material strengthFibre typesWoven fabricsPolyesterEpoxy

Owner:SUZHOU INST OF TRADE & COMMERCE

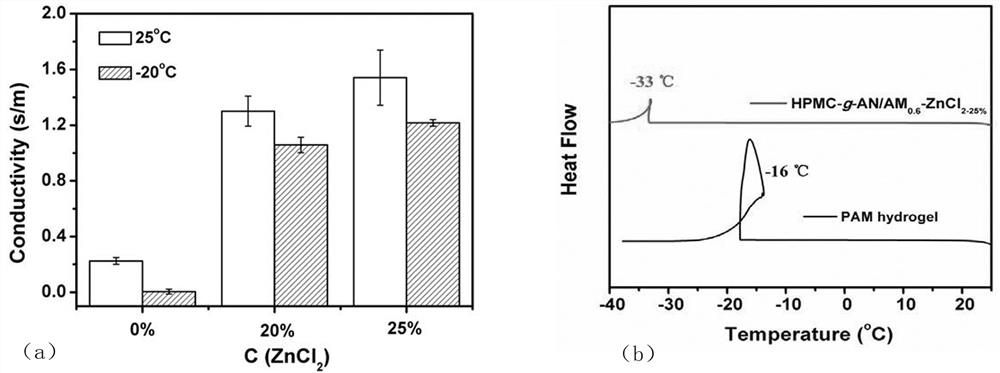

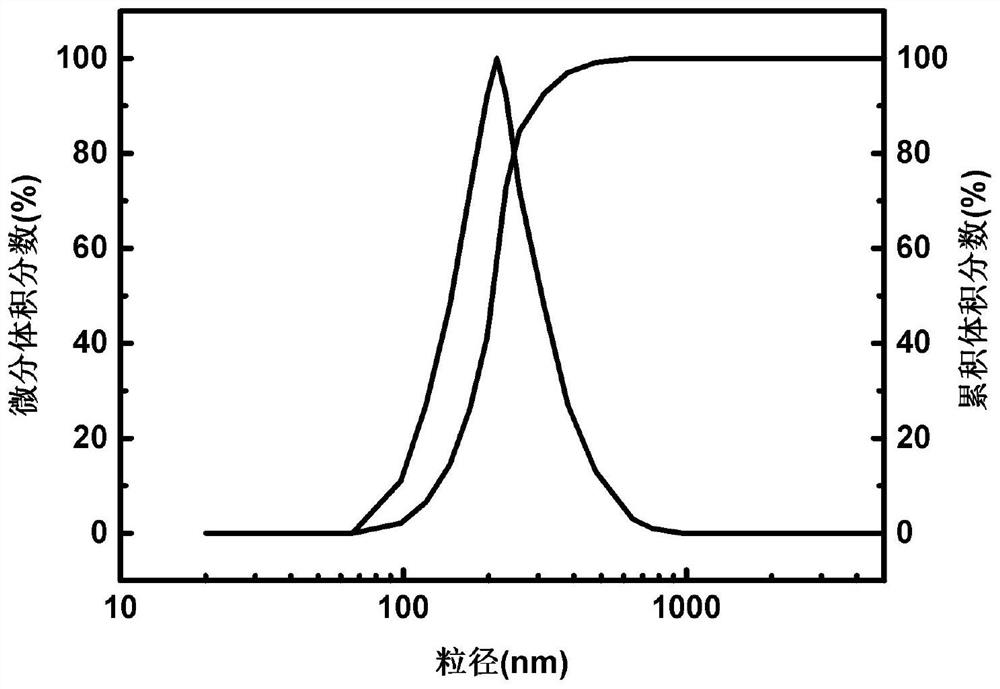

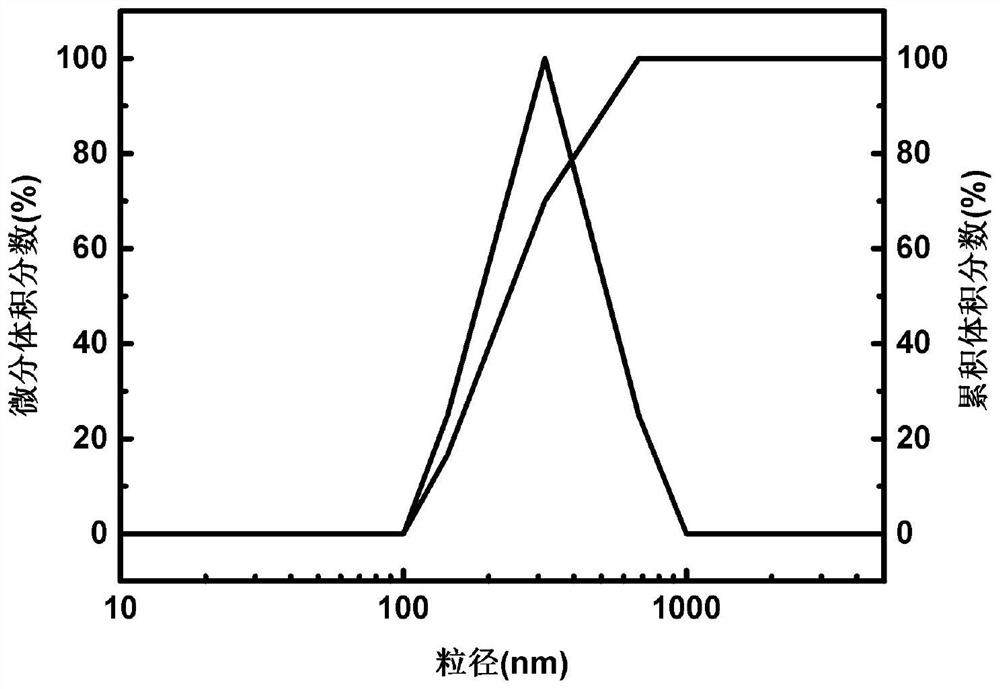

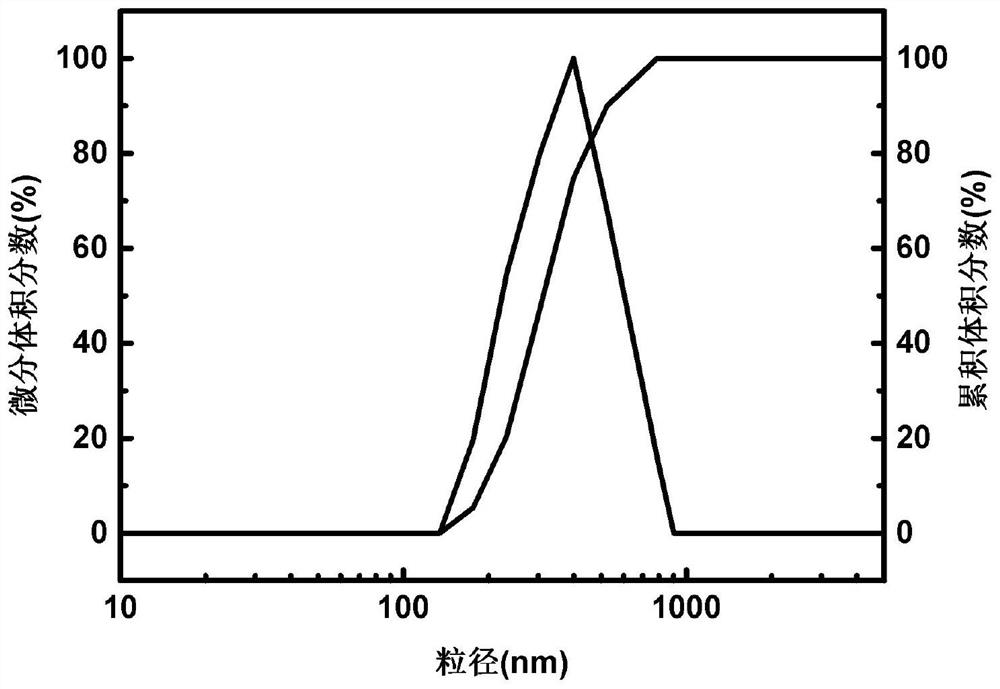

Preparation method of cellulose-based conductive hydrogel

ActiveCN112142918AImprove tensile propertiesImprove stress resistanceNon-conductive material with dispersed conductive materialCellulosePolymer science

Owner:NORTHWEST UNIV

Preparation method of filtering material for adsorbing fluorine ions in water

InactiveCN109929082AFully contactedGood chemical stabilityWater contaminantsWater/sewage treatment by flocculation/precipitationSorbentDiethylenetriamine

Owner:宁波市河清源技术转移服务有限公司

Polyacrylate grafted graphene oxide plugging agent and oil-based drilling fluid

InactiveCN114752365AImprove rheologyGood sealability and other aspects of performanceNanotechnologyDrilling compositionSilane compoundsPhysical chemistry

Owner:SOUTHWEST PETROLEUM UNIV

Binary retention system for spherical polyelectrolyte brush and method for improving retention rate of paper pulp

InactiveCN105088859ASimple structureStrong shear resistanceRetention agents additionPolyelectrolyte brushesPapermaking

The invention provides a binary retention system for a spherical polyelectrolyte brush for improving the retention rate of paper pulp. The binary retention system is composed of a cationic spherical polyelectrolyte brush and anionic polyacrylamide, wherein the cationic spherical polyelectrolyte brush regards SiO2 as an inner core and a copolymer of acrylamide and methacryloyloxyethyl trimethyl ammonium chloride as an outer brush. The invention further provides a method for improving the retention rate by using the binary retention system. The method comprises: sequentially adding the binary retention system composed of the cationic spherical polyelectrolyte brush and anionic polyacrylamide into scattered paper pulp to improve the retention rate of the slurry. The cationic spherical polyelectrolyte brush provided by the invention has high symmetric or quasi-symmetric structures, so that the anti-shear ability is relatively strong. The system has both the characteristics of a highly branched structure and high charge density and is easily to induce flocculation in high speed papermaking so as to improve the retention performance of a modern papermaking system. The binary system adopted by the invention remarkably improves the retention rate of the paper pulp and is simple and convenient to operate and less in use level of auxiliaries.

Owner:WUHAN UNIV

Preparation method of high-solid content polypropylene papermaking reinforcing agent

InactiveCN103242481AHigh molecular weightHigh solid contentReinforcing agents additionPaper/cardboardPolymer scienceSulfite salt

Owner:QINYANG PHARMA FACTORY

Environment-friendly impermeable composite bentonite and preparation process thereof

Owner:句容康泰膨润土有限公司

Preparation method of polyacrylamide reverse-phase emulsion

Owner:SHANDONG UNIV

Preparation method of composite efficient coagulant for treatment of textile printing and dyeing wastewater

InactiveCN110980909AEasy to reuseReduce processing costsWater treatment parameter controlWaste water treatment from textile industryTextile printerDyeing wastewater

Owner:安徽子延科技有限公司

Bone gelatin wastewater treatment method

InactiveCN114873840ALow acid valueDoes not increase concentrationTreatment using aerobic processesTreatment with anaerobic digestion processesGelatinPolyacrylamide

Owner:池州市琼琚信息技术服务有限公司 +1

Preparation method of high-water solubility polyacrylamide

InactiveCN110885390AWill not polluteImprove purityGas liquid chromatographicInfrared lamp

Belonging to the field of water-soluble polymer material synthesis, the invention provides a preparation method of high-water solubility polyacrylamide. The preparation method of the high-water solubility polyacrylamide includes the specific steps of: preparing a composite initiator, preparing raw materials for polymerization to form a preparation auxiliary material, dissolving the auxiliary materials in distilled water in a three-necked bottle to prepare an acrylamide solution, adding nitrogen into the acrylamide solution for reaction to form a reactant, pouring the reactant into a beaker toobtain a white solid, drying the obtained white solid under an infrared lamp, conducting detection, storage and warehousing. The method has the characteristics of complete reaction, no by-product or impurities, and no environmental pollution. The acrylamide involved in the invention does not contain metal copper ions, ion exchange is not needed for removal of copper ions generated in the production process, and the process flow is simplified, in addition, gas chromatography analysis indicates that the acrylamide product almost does not contain free acrylonitrile and has high purity.

Owner:WUDI RONGYE NET CO LTD

Flame-retardant waterproof wall cloth and preparation method thereof

PendingCN114409946AHigh strengthImprove flame retardant performanceSynthetic resin layered productsDomestic wallsLow-density polyethylenePolymer science

Owner:江苏奢艺新材料有限公司

OPP (oriented polypropylene) heat dissipating and insulating release film

Owner:TAICANG CUSTOM NEW MATERIALS CO LTD

Water-based plastic ink

Owner:重庆伟恒包装有限公司

3D honeycomb type paint mist filter bag and preparation method thereof

InactiveCN113499647AStrong resilienceSimple structureOther chemical processesDispersed particle filtrationCarboxymethyl starchGlass fiber

Owner:深创高新产业研究中心(深圳)有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap