Polyacrylate grafted graphene oxide plugging agent and oil-based drilling fluid

A polyacrylate, oil-based drilling fluid technology, applied in the field of oil and gas field drilling, can solve problems such as wellbore instability, achieve the effects of good performance, good compatibility, and reducing permeation fluid loss and fluid loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] ①Weigh 1g of graphene oxide, disperse it in 180mL of absolute ethanol and stir ultrasonically for 30min, slowly add 80mL of (3-aminopropyl)trimethoxysilane ethanol solution, and stir at 35°C for 13h. The product was precipitated in n-hexane, then centrifuged at 6000rpm for 10min, washed with acetone, and finally dried at 60°C for 25h to obtain product A;

[0041]②Weigh 1g of product A, disperse product A in 12mL methanol solution, stir ultrasonically for 30min, then transfer to the reactor, under nitrogen protection and the temperature is 0 ℃, slowly add 12mL methyl acrylate methanol solution, and react The device was placed in a dark place, and stirred at 25 °C for 3 days. After stirring, the product was washed with ethanol, and the product was precipitated in n-hexane. Finally, it was dried at 60 °C for 25 hours to obtain product B;

[0042] 3. Weigh 1 g of product B, disperse product B in methanol solution, stir ultrasonically for 30 min, slowly add 80 mL of acrylamide

Embodiment 2

[0044] ①Weigh 1g of graphene oxide, disperse it in 190mL of absolute ethanol and stir ultrasonically for 35min, slowly add 80mL of (3-aminopropyl)trimethoxysilane ethanol solution, and stir at 40°C for 13h. The product was precipitated in n-hexane, then centrifuged at 8000rpm for 10min, washed with acetone, and finally dried at 60°C for 25h to obtain product A;

[0045] ②Weigh 1g of product A, disperse product A in 12mL methanol solution, stir ultrasonically for 35min, then transfer to the reactor, under nitrogen protection and the temperature is 1 ℃, slowly add 12mL ethyl methacrylate methanol solution, The reactor was placed in a dark place and stirred at 30°C for 3 days. After stirring, the product was washed with ethanol, and the product was placed in n-hexane for precipitation. Finally, it was dried at 60°C for 25 hours to obtain product B. ;

[0046] 3. Weigh 1 g of product B, disperse product B in methanol solution, stir ultrasonically for 35 min, slowly add 80 mL of N-is

Embodiment 3

[0048] ①Weigh 1g of graphene oxide, disperse it in 190mL of absolute ethanol and stir it ultrasonically for 35min, slowly add 80mL of 3-aminopropyltriethoxysilane ethanol solution, and stir at 40°C for 13h. Placed in n-hexane for precipitation, then centrifuged at 7000rpm for 12min, washed the product with acetone, and finally dried at 70°C for 28h to obtain product A;

[0049] ②Weigh 1g of product A, disperse product A in 14mL methanol solution, stir ultrasonically for 35min, then transfer to the reactor, under nitrogen protection and the temperature is 2 ℃, slowly add 14mL ethyl acrylate methanol solution to react The device was placed in a dark place, and stirred at 30 °C for 3 days. After stirring, the product was washed with ethanol, and the product was precipitated in n-hexane. Finally, it was dried at 70 °C for 28 hours to obtain product B;

[0050] 3. Weigh 1 g of product B, disperse product B in methanol solution, stir ultrasonically for 35 min, slowly add 80 mL of N-ter

PUM

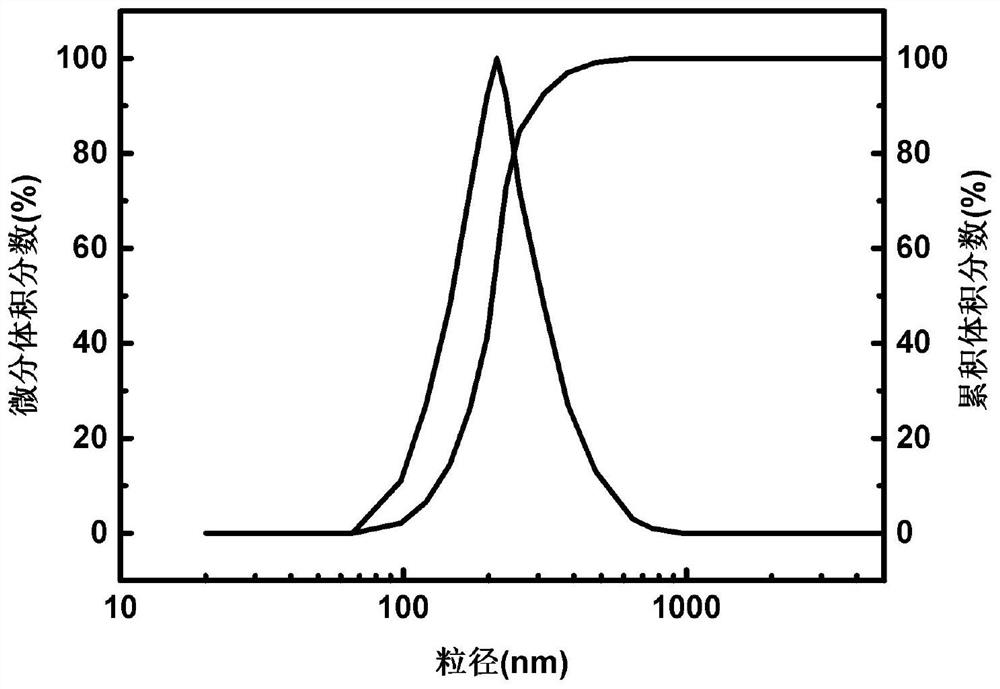

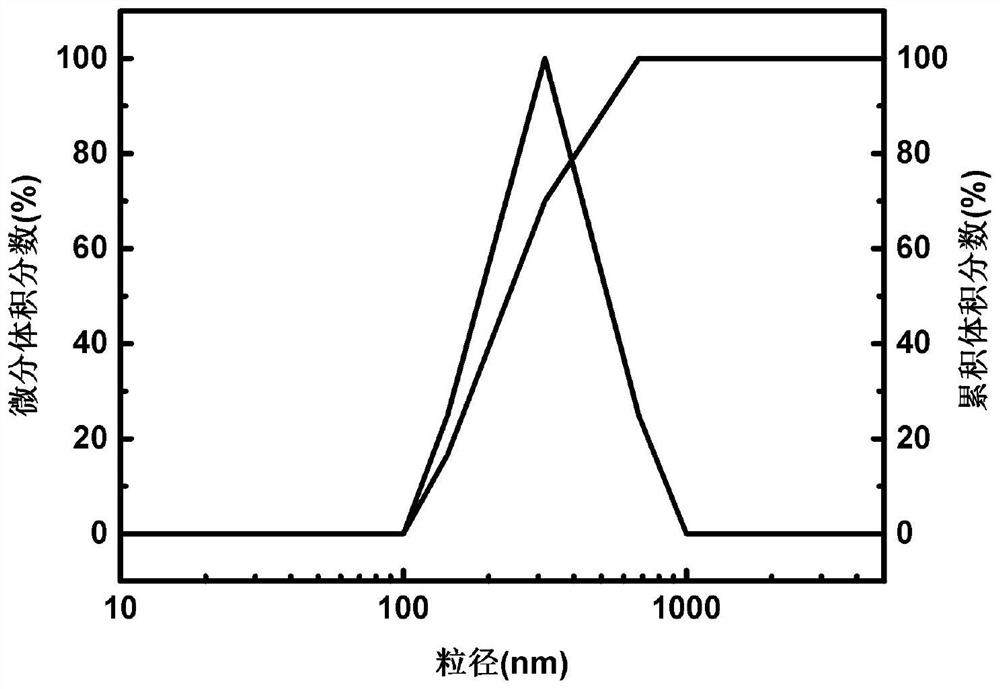

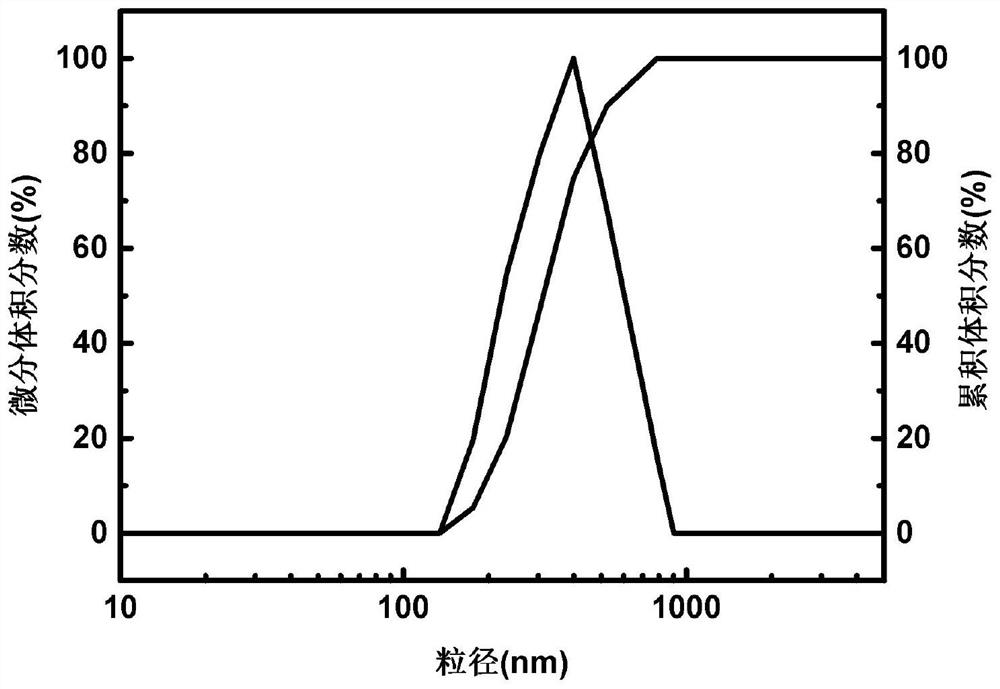

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap