Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41 results about "Graphite oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphite oxide, formerly called graphitic oxide or graphitic acid, is a compound of carbon, oxygen, and hydrogen in variable ratios, obtained by treating graphite with strong oxidizers. The maximally oxidized bulk product is a yellow solid with C:O ratio between 2.1 and 2.9, that retains the layer structure of graphite but with a much larger and irregular spacing.

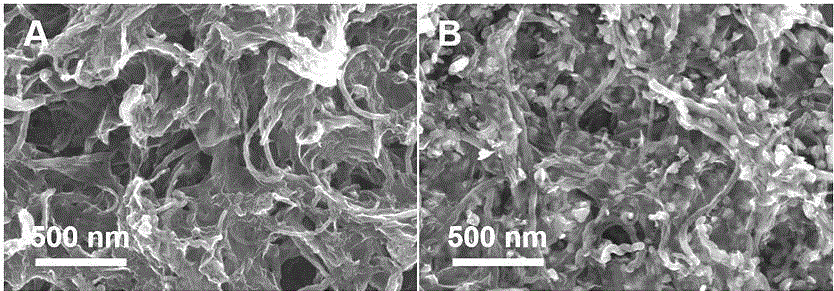

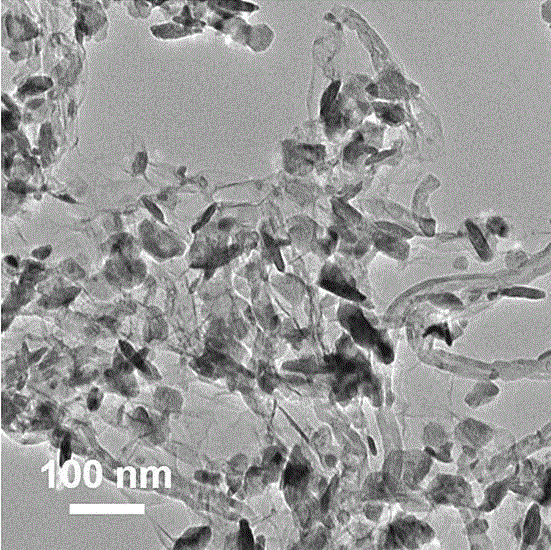

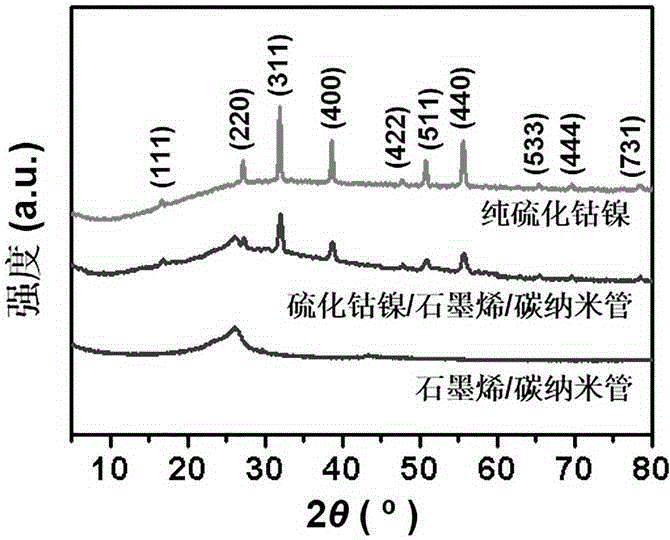

Nickel cobalt sulfide/graphene/carbon nanotube composite material and preparation method and application thereof

Owner:FUDAN UNIV

Hydrothermal preparation method of graphene-coated sulfur/porous carbon composite positive electrode material

Owner:HARBIN INST OF TECH

Reduced graphene oxide composite material

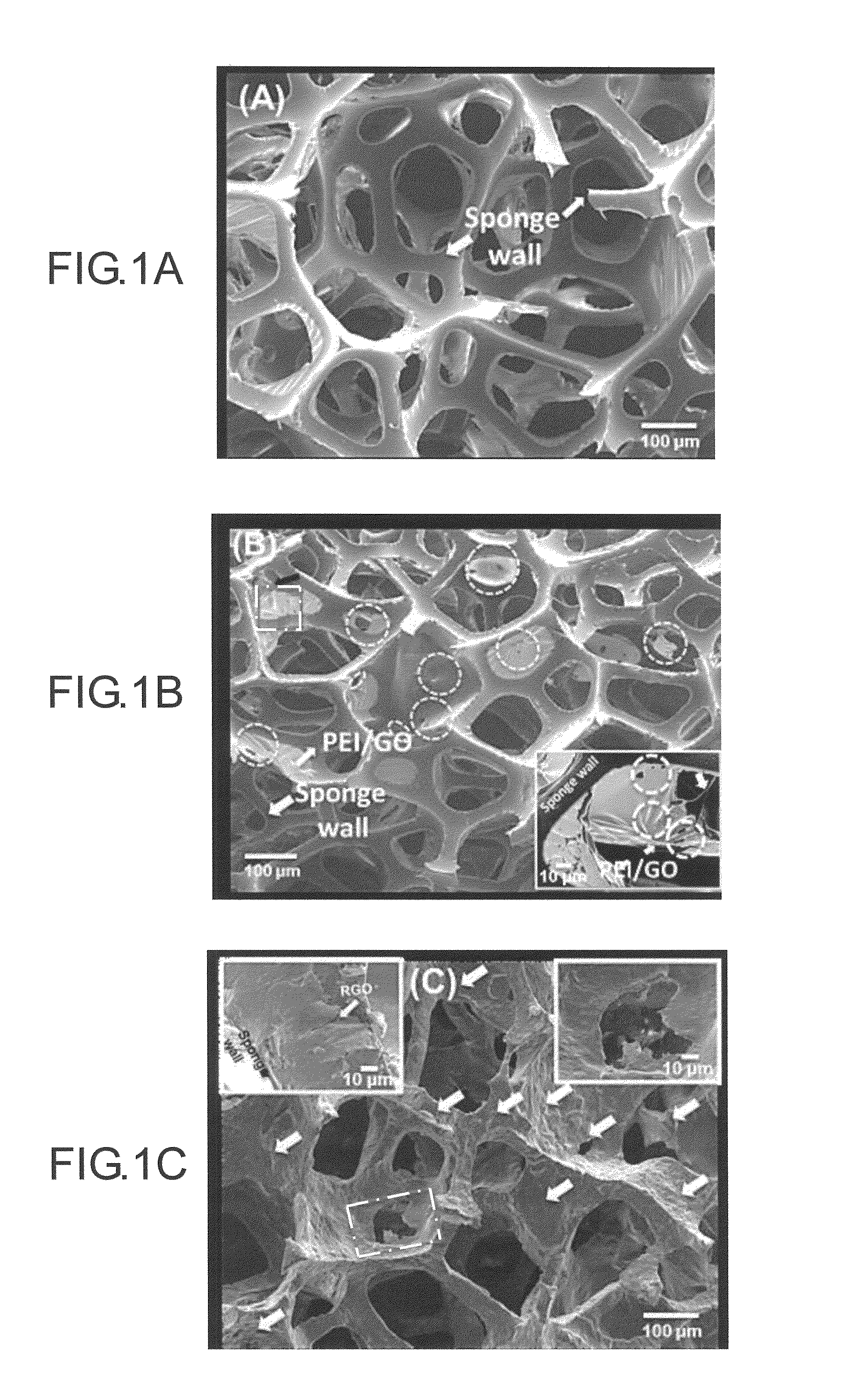

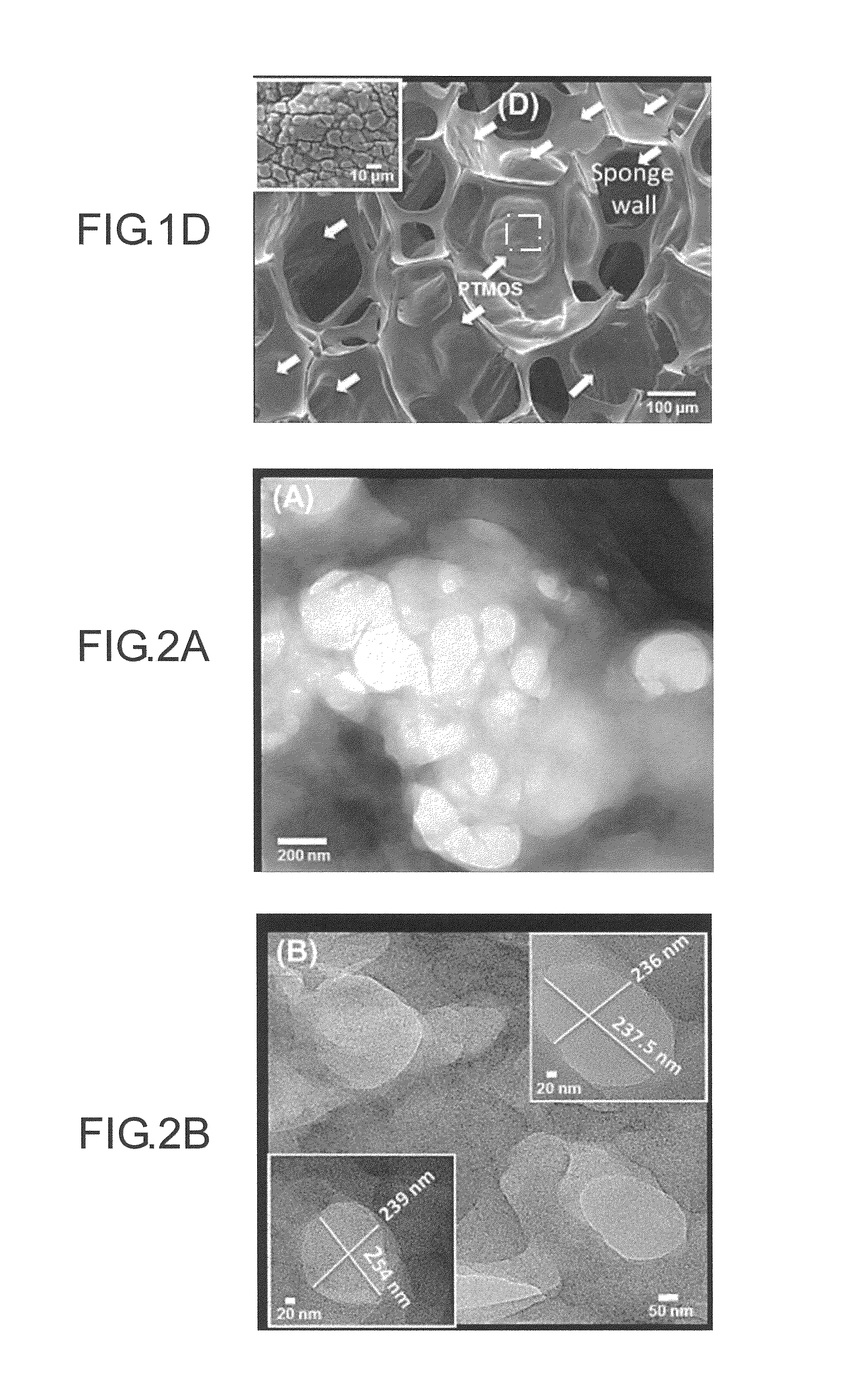

InactiveUS20160121299A1Improve oil absorption capacityLow costOther chemical processesFiberAbsorption capacity

Owner:NAT TAIWAN UNIV

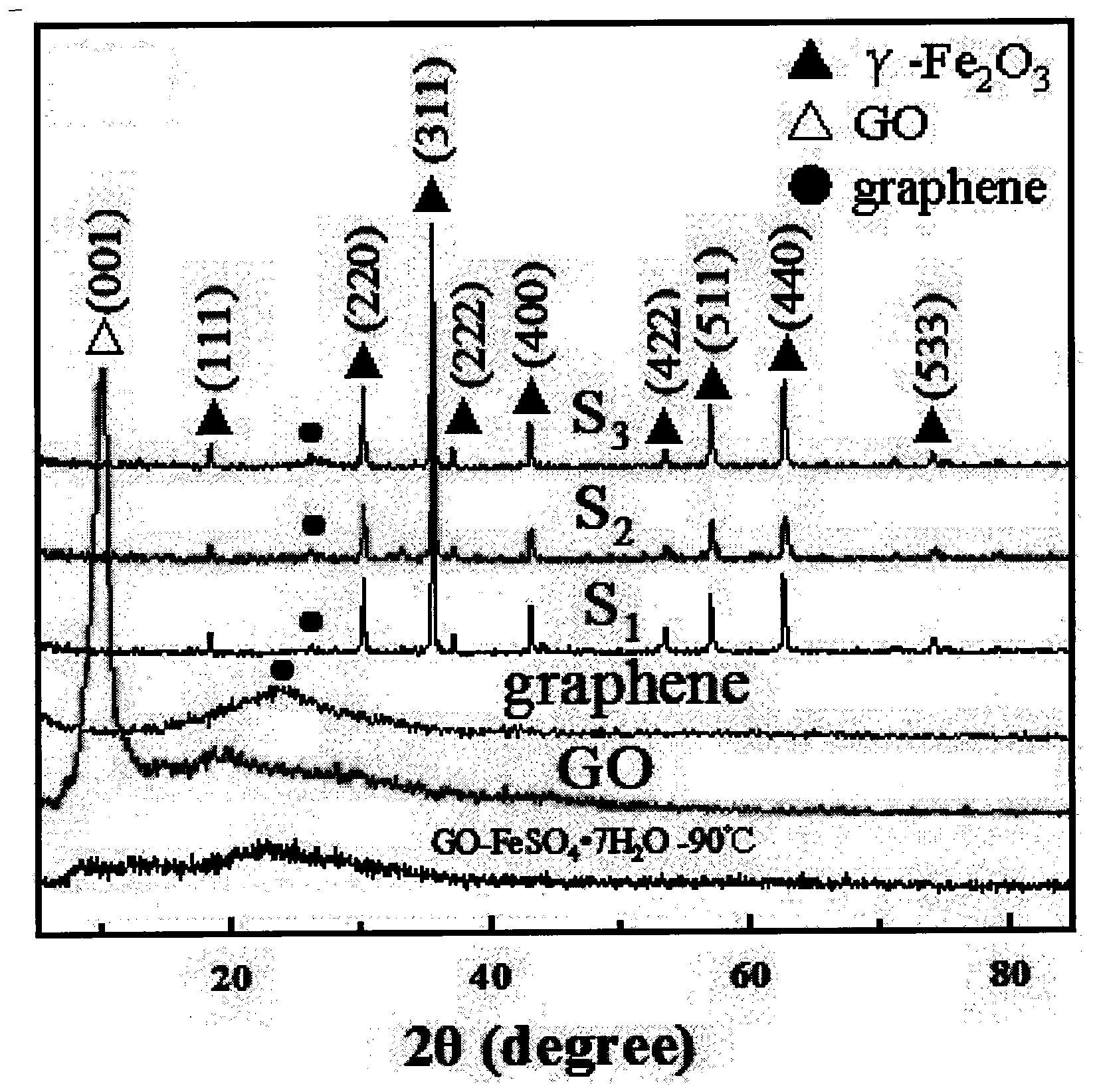

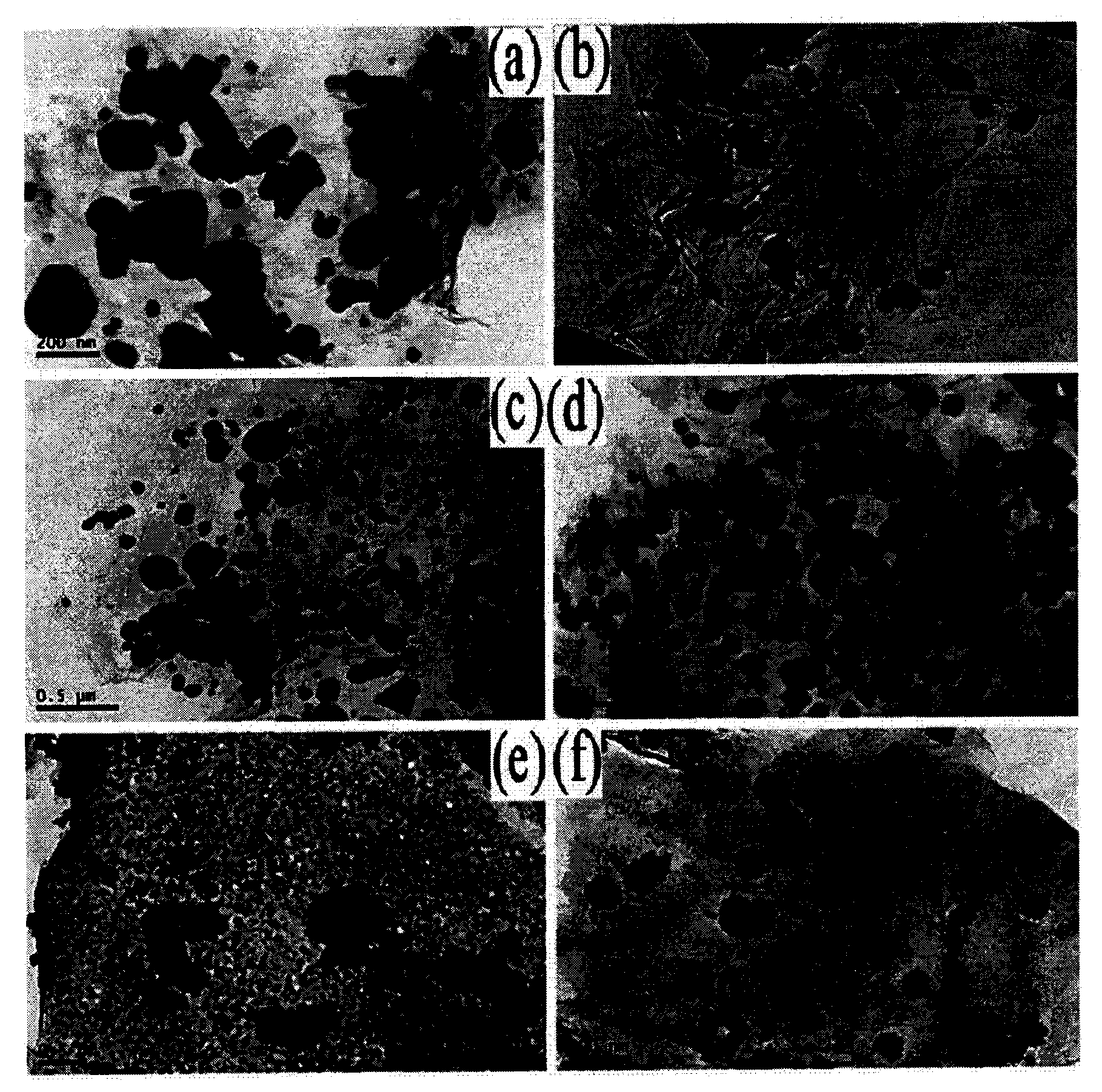

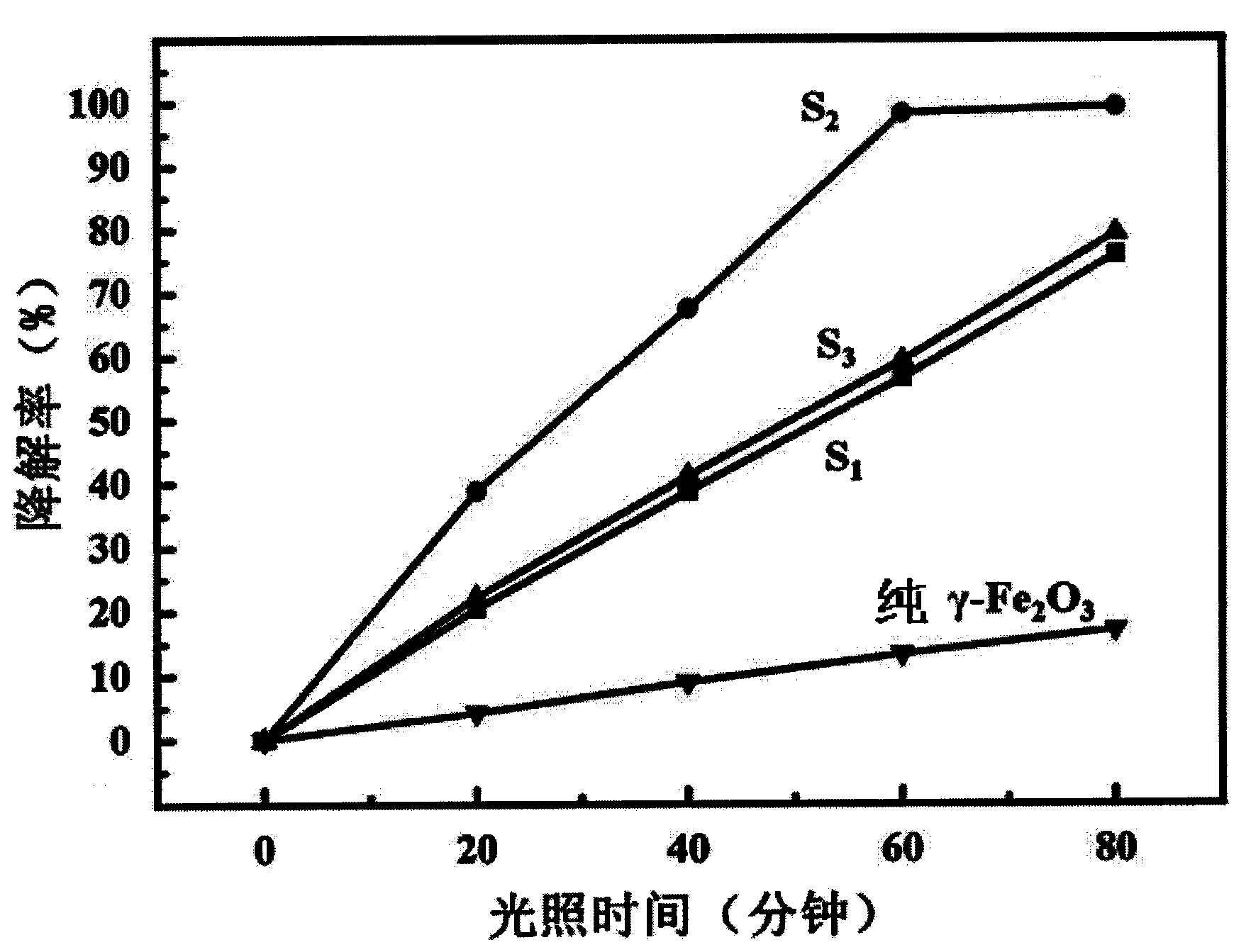

Graphene-based gamma-FeO2O3 composite material photocatalyst, and preparation method and use thereof

InactiveCN103706364AReduced band gapLarge specific surface areaMetal/metal-oxides/metal-hydroxide catalystsIron sulfateOrganic matter

Owner:魏颖

Method for preparing light cement-based graphene oxide composite adsorption material

Owner:宁夏亿昀特种工程材料有限公司

Lightweight porous MXene-based composite film electromagnetic shielding material and preparation method thereof

ActiveCN113329603APlay a supporting rolePromote absorptionMagnetic/electric field screeningClimate change adaptationComposite filmThin membrane

The invention discloses a lightweight porous MXene-based composite film electromagnetic shielding material and a preparation method thereof, and belongs to the technical field of film electromagnetic shielding materials and preparation thereof. Self-assembly of MXene and graphene oxide is realized by taking electrostatic interaction force as driving force on MXene modified by a cationic surface modifier and graphene oxide, and then the lightweight porous MXene-based composite electromagnetic shielding material with ultrahigh specific performance is obtained through film casting and high-temperature annealing. The prepared composite film material has excellent electromagnetic shielding effectiveness and specific effectiveness, and when the thickness is only 15 [mu]m, the porous MXene-based composite film obtained by adding 5 wt% of graphene oxide can keep the electromagnetic shielding effectiveness of 49 dB or above in the whole X wave band. The preparation process is simple and easy to operate, and the material is expected to be applied to the fields of aerospace, military equipment, micro electronic equipment, civil electric appliances and the like.

Owner:JIANGNAN UNIV

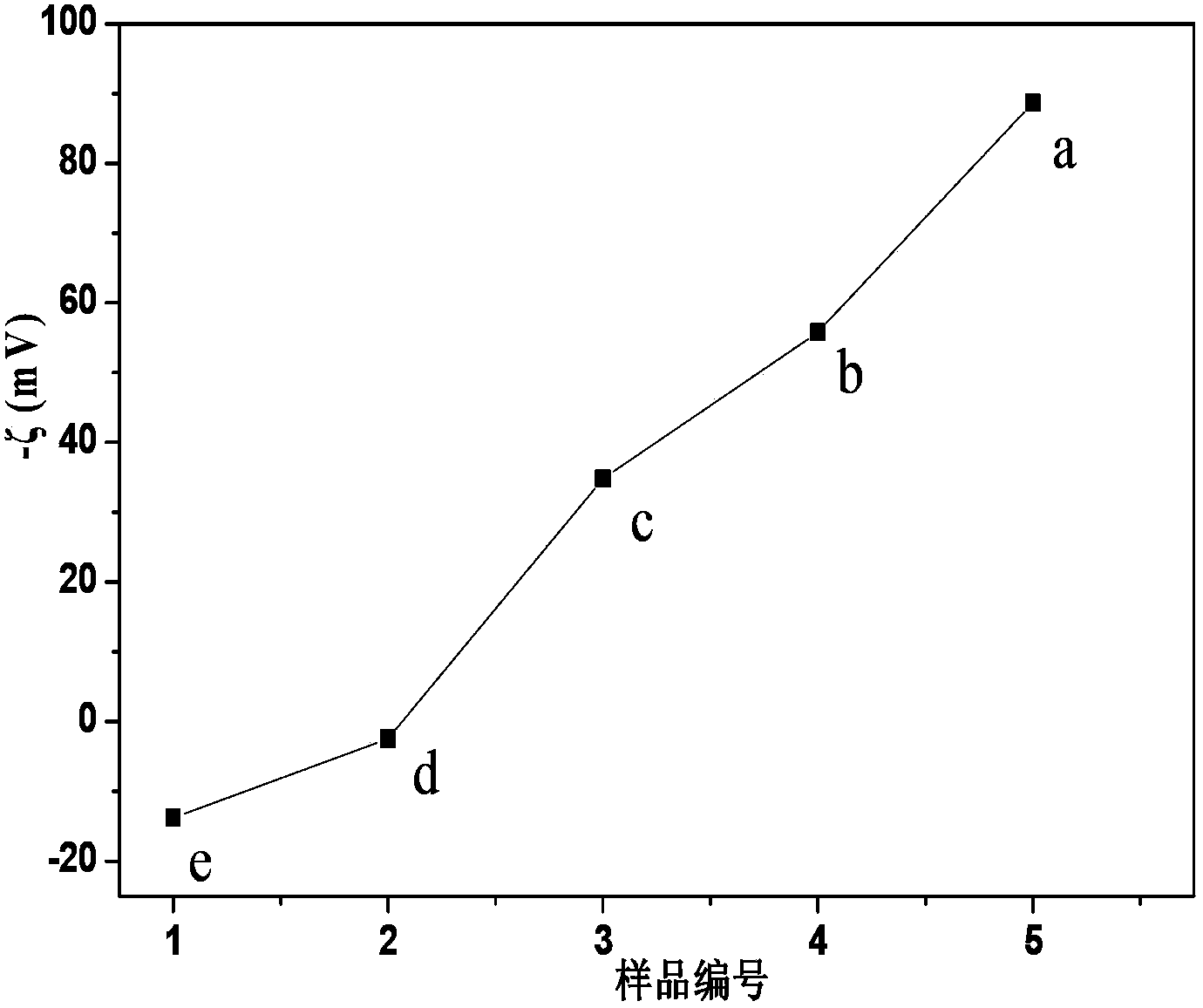

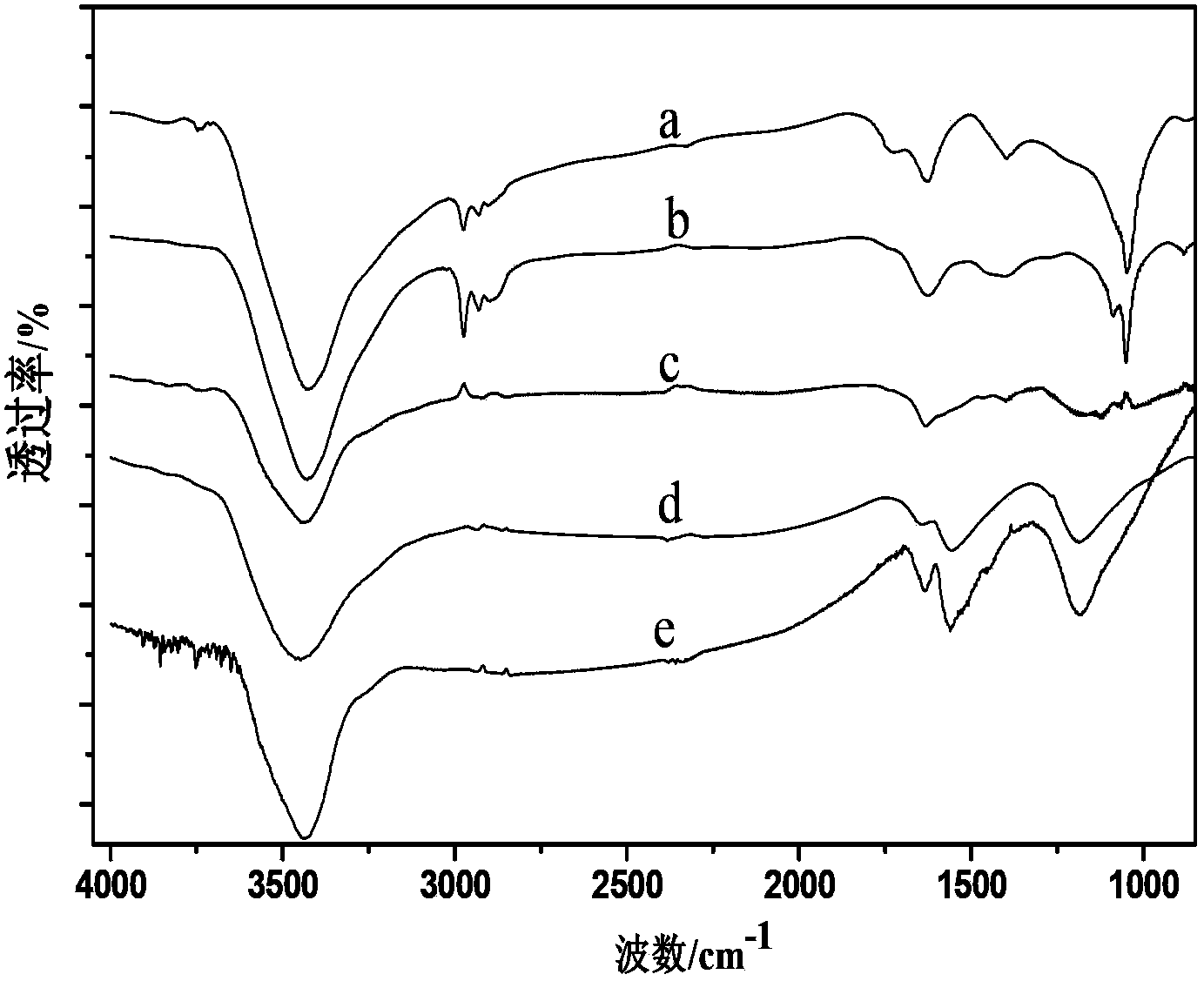

Method for controlling surface potentials of graphene-based material

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Oxidation-resistant polymer film with memory function

InactiveCN105670128ASimple componentsLow costFixed capacitor dielectricBulk chemical productionPolymer scienceOxidation resistant

Owner:汤卓群

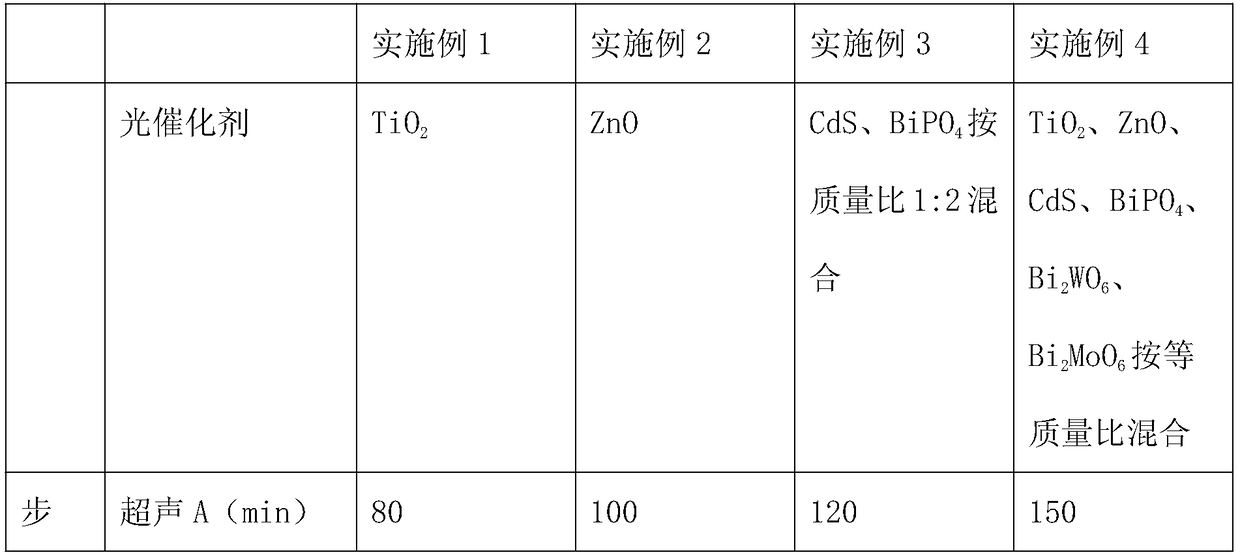

Preparation method of transition metal oxide/graphene nano composite material

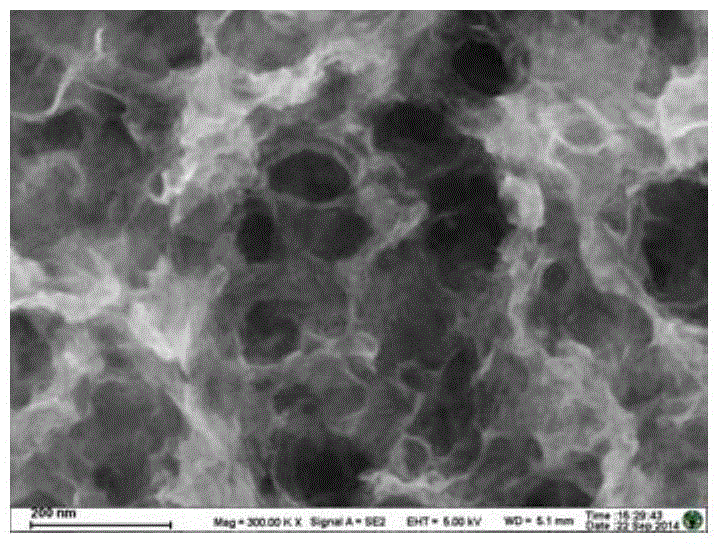

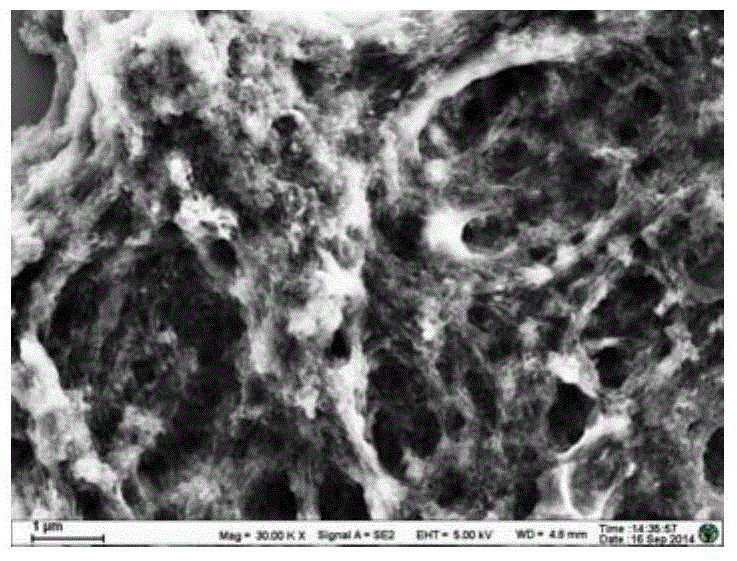

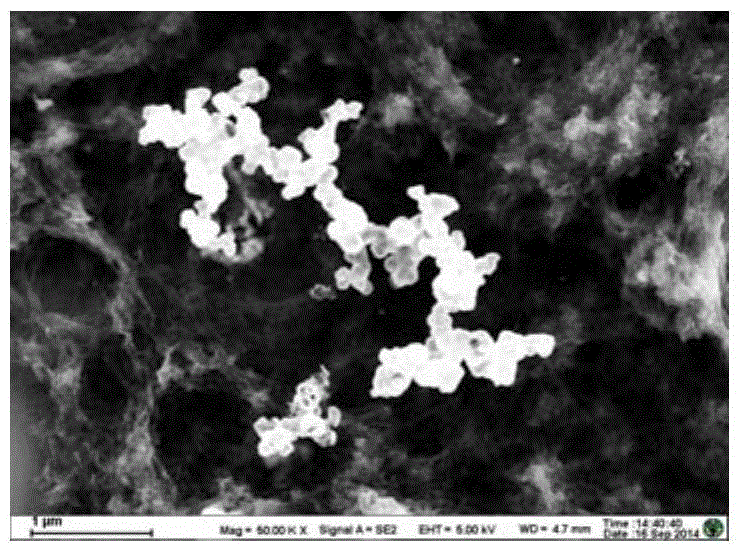

InactiveCN106058233ASmall particle sizeUniform sizeMaterial nanotechnologyCell electrodesGraphene nanocompositesOrganic fuel

A preparation method of a transition metal oxide / graphene nano composite material comprises the following steps: (1) according to the loading amount of a transition metal oxide on graphene and the preparation amount of a target product, weighing transition metal nitrate, and dissolving the transition metal nitrate in an aqueous dispersion liquid of graphene oxide; (2) adding a proper amount of an organic fuel into the dispersion liquid of the step (1), and stirring and carrying out ultrasonic treatment to obtain an uniform dispersion liquid; and (3) heating and concentrating the dispersion liquid obtained in the step (2) to be viscous, then putting into a heating furnace with the temperature of 300-900 DEG C, igniting, and after completing combustion, cooling to room temperature to obtain a final product. The preparation method has the advantages of low synthesis temperature, short time, simple implementation, low cost, small particle size of transition metal oxide, uniform size and uniform dispersion in graphene, and is suitable for industrialized production.

Owner:NANCHANG UNIV

Preparation method of adsorption material for selectively adsorbing silver ions

ActiveCN106861646ASimple processEasy to operateOther chemical processesWater contaminantsOxide compositeSilver ion

Owner:DONGHUA UNIV

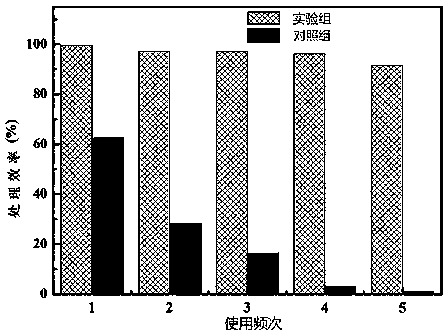

Graphene hybridized photocatalyst hydrogel

ActiveCN108126682AGood dispersionAvoid gatheringWater/sewage treatment by irradiationWater treatment compoundsCross-linkPhotocatalytic degradation

Owner:河北燕园众欣石墨烯科技有限公司

Preparation method of high-activity waterproof soap-free emulsion polymer

InactiveCN110669169AHigh activityEntanglement effect is significantCoatingsHydrophilic monomerPolymer science

Owner:HUBEI UNIV OF TECH

Preparation method of amination graphene oxide reinforced fibers

InactiveCN106521687AMonocomponent polyamides artificial filamentArtifical filament manufactureGraphite oxideNylon 6

Owner:过冬

Graphene reinforced waterborne polyurethane high-barrier material and condom

ActiveCN111995860AImprove mechanical propertiesImprove barrier propertiesMale contraceptivesCompatibilizationFree-radical reaction

The invention provides a graphene reinforced waterborne polyurethane high-barrier material and a condom. According to the high-barrier material, the compatibility with a polyurethane material is improved by adopting modified graphene oxide, the interaction between graphene and a polyurethane molecular chain is increased, and the purpose of improving the mechanical property and barrier property ofpolyurethane is achieved; meanwhile, carbon-carbon double bonds are introduced into the tail end of a polyurethane molecular chain, so that the carbon-carbon double bonds are bonded with the carbon-carbon double bonds on the natural latex molecular chain through a free radical reaction, and the interface fusion between the natural latex layer and the graphene / waterborne polyurethane interlayer isrealized. The material can be used for manufacturing a condom with a graphene / polyurethane / natural latex composite structure and having good barrier property and low cost.

Owner:CHONGQING MENDUO NEW MATERIAL TECH CO LTD

High-adsorption polylactic acid composite biofilm carrier material and preparation method thereof

InactiveCN107841037ALarge surface activation areaImprove liquiditySustainable biological treatmentConjugated synthetic polymer artificial filamentsSodium BentoniteWater quality

Owner:HENAN ZHILIAN HUANYU INTPROP OPERATION CO LTD

Night vision compatible film and preparation method and application thereof

ActiveCN112409619AHigh light transmittanceImproves UV protectionAnti-corrosive paintsRadiation-absorbing paintsUv absorbanceAcrylic resin

The invention belongs to the field of materials, and discloses a night vision compatible film and a preparation method and application thereof. The night vision compatible film comprises a layer of transparent base material and a coating applied to the transparent base material. The coating is mainly prepared from acrylic resin, amino resin, nano TiO2 sol, graphene oxide, an ultraviolet absorbent,filler, a resin curing agent and a solvent. The night vision compatible film is high in light transmittance within the range of 400nm to 630nm and high in ultraviolet-proof capacity. The light transmittance within the range of 400nm to 630nm is 55% or above; the light transmittance within the range of 660nm to 930nm is 1.0% or less; and the light transmittance at 320-400nm is 1.2% or less. The night vision compatible film has good water mist resistance and salt mist resistance, can adapt to severe environments and is wide in application scene. The night vision compatible film can be applied to a night vision device.

Owner:BEIJING FALCON TECH CO LTD

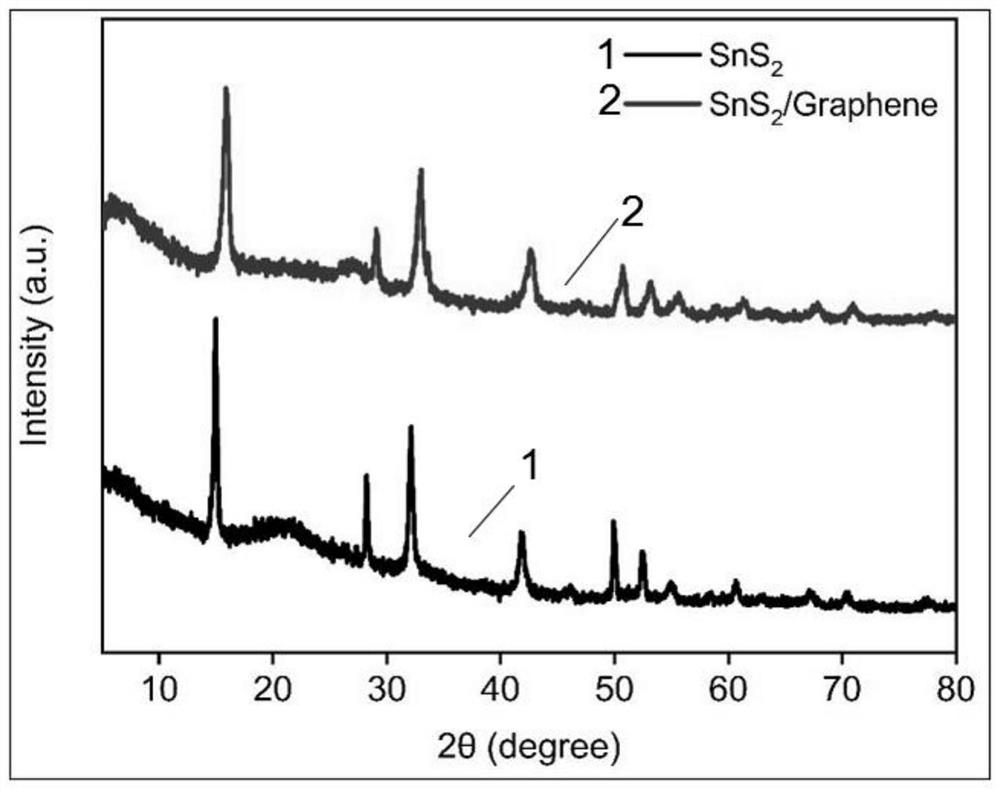

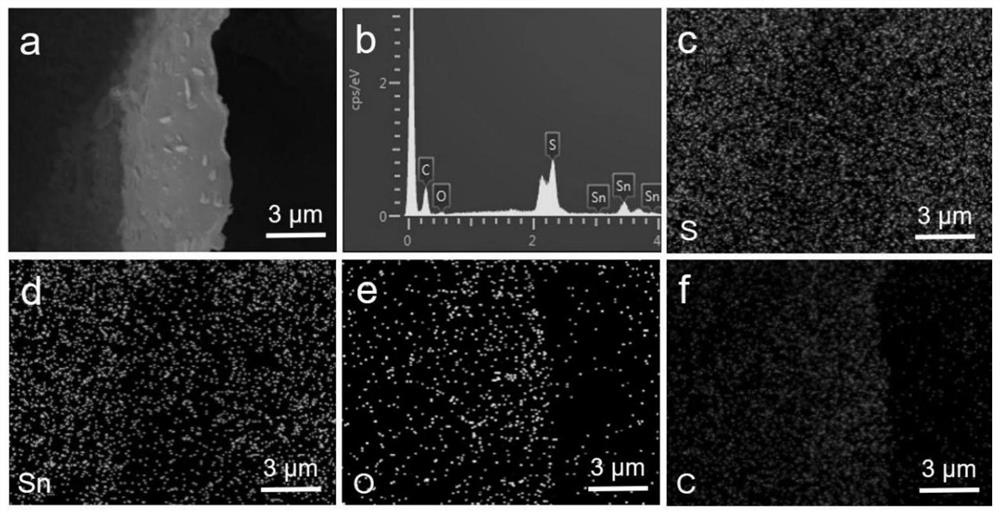

Preparation method of SnS2 nanosheet loaded graphene-based nanocomposite

Owner:安徽光特新材料科技有限公司

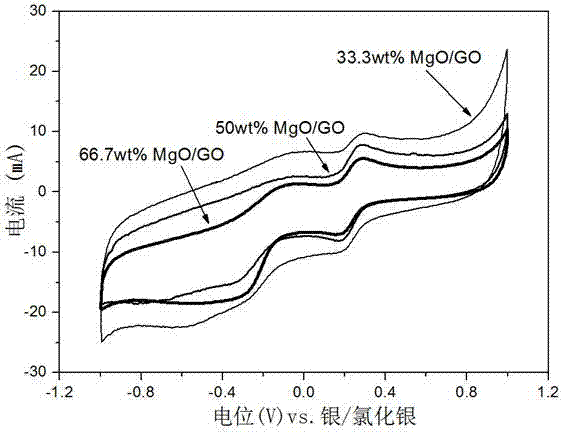

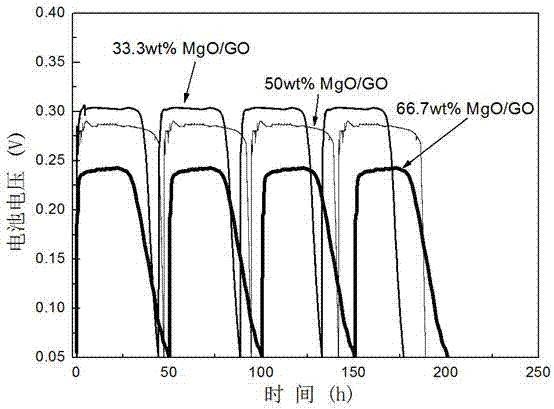

Composite cathode of microbial fuel cell and preparation method and application thereof

PendingCN107221682AWide variety of sourcesLow priceHybrid capacitor electrodesBiochemical fuel cellsOxide compositeAlloy

Owner:SOUTH CHINA UNIV OF TECH +1

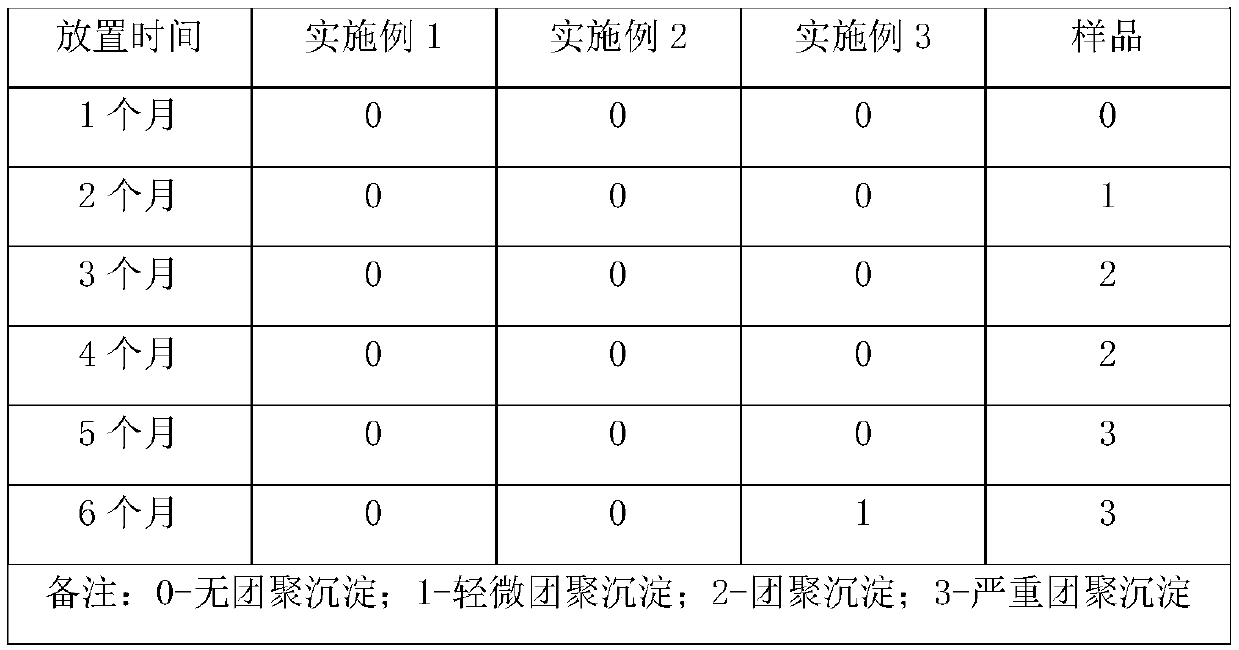

Preparation method of porous graphene-based air purification agent

InactiveCN108772040AEfficient catalytic performanceReduce the precipitation ratePhysical/chemical process catalystsOther chemical processesPorous graphenePorous carbon

The invention relates to the technical field of vehicle purification agents, in particular to a preparation method of a porous graphene-based air purification agent. The preparation method of the porous graphene-based air purification agent includes the steps of: (1) adding a foaming agent into polypropylene resin and mixing the substances evenly, then conducting electrospinning to obtain polypropylene fiber, and performing calcining to obtain porous carbon fiber; (2) subjecting the porous carbon fiber, a soluble metal salt, a silane coupling agent and organic titanate to thermal reaction in asolvent to obtain modified porous carbon fiber; (3) modifying graphene oxide to obtain porous modified graphene oxide; and (4) mixing the modified porous carbon fiber with the porous modified graphene oxide to obtain the composite porous graphene-based air purification agent. The porous graphene-based air purification agent obtained by the method provided by the invention can adsorb harmful gasesin the air and catalyze harmful gases in situ at an adsorption point, and has the advantages of high catalytic efficiency and high removal rate.

Owner:ANHUI LEJIN ENVIRONMENT TECH CO LTD

Novel method for preparing recyclable graphene composite titanium dioxide nano material

InactiveCN111821979AEasy to operateReaction conditions are easy to controlHeterogenous catalyst chemical elementsCatalyst activation/preparationPhoto catalysisCalcination

Owner:江苏康德龙环保有限公司

Preparation method of high-dielectric-performance polymer-based composite microporous material

Owner:SHAANXI UNIV OF SCI & TECH

Polyacrylate grafted graphene oxide plugging agent and oil-based drilling fluid

InactiveCN114752365AImprove rheologyGood sealability and other aspects of performanceNanotechnologyDrilling compositionSilane compoundsPhysical chemistry

Owner:SOUTHWEST PETROLEUM UNIV

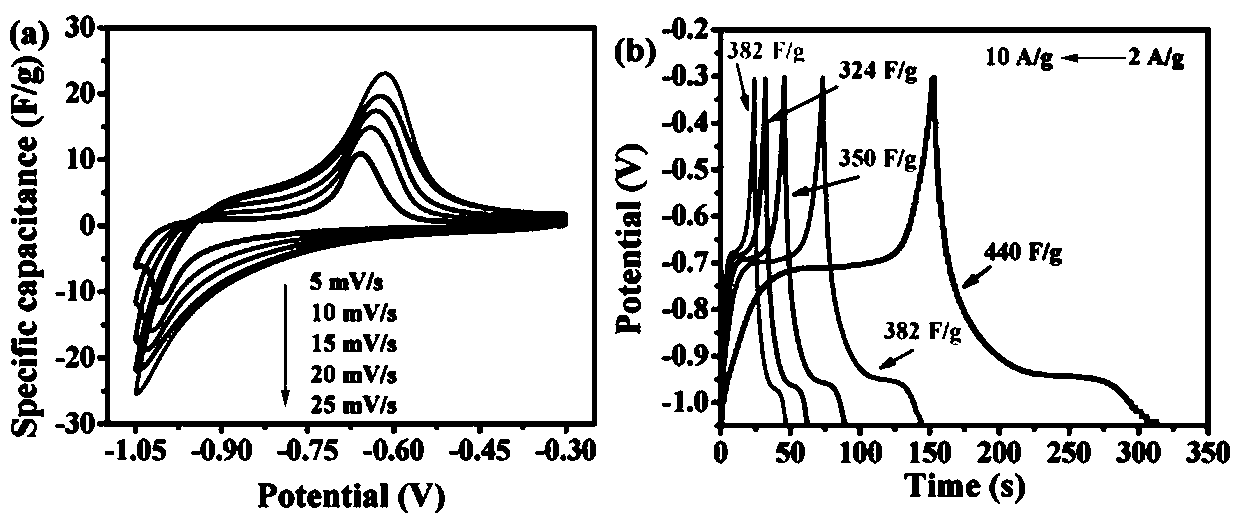

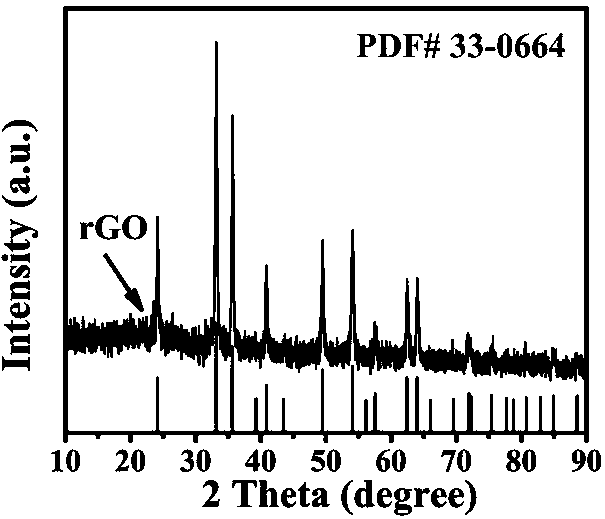

Reduced graphene/alpha-Fe2O3 supercapacitor material and preparation method and application thereof

ActiveCN110136978ALight in massQuality improvementHybrid capacitor electrodesHybrid/EDL manufactureThioureaSupercapacitor

Owner:ZHOUKOU NORMAL UNIV

Graphene antibacterial film and air-exhaust-free cube vacuum compression bag

InactiveCN111944298AAntibacterial and effectiveImprove film formationBagsGarmentsPolymer sciencePhenolic content in tea

The invention discloses a graphene antibacterial film and an air-exhaust-free cube vacuum compression bag. The graphene antibacterial film comprises 45-55 parts of graphene oxide, 25-30 parts of polyurethane resin, 15-20 parts of polyethersulfone resin, 10-15 parts of polytetrafluoroethylene resin, 8-10 parts of polyethylene resin, 50-60 parts of an organic solvent, 5-8 parts of a mugwort extract,2-5 parts of sodium carboxymethyl cellulose, 1-2 parts of tea polyphenol and 3-6 parts of a cationic nano-silver antibacterial agent. Graphene oxide powder is used as a raw material. The graphene oxide is used for resisting bacteria, the mugwort extract, the sodium carboxymethyl cellulose and the tea polyphenol are matched for resisting oxidation and preventing mildew, the structural stability isimproved, the mildew-proof and antibacterial functions of the vacuum compression bag are further guaranteed, and the requirements of more and more skin diseases for life hygiene and safety of peopleare met. The graphene antibacterial film is prepared by a uniform mixing and multi-layer co-extrusion process, and the vacuum compression bag is further prepared, so that the vacuum compression bag can effectively prevent mildew and inhibit bacteria in a vacuum state after being filled with clothes, quilts and other articles.

Owner:NINGBO HUAFENG PACKAGE

Silica gel pad printing conductive ink as well as preparation method and application thereof

Owner:HUNAN SOKAN NEW MATERIAL

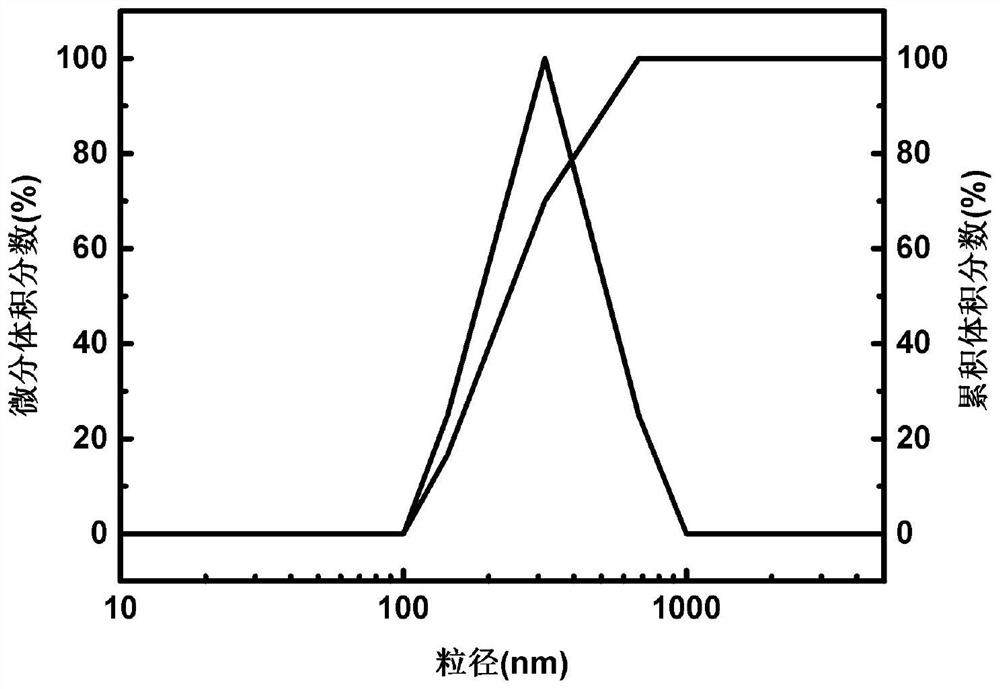

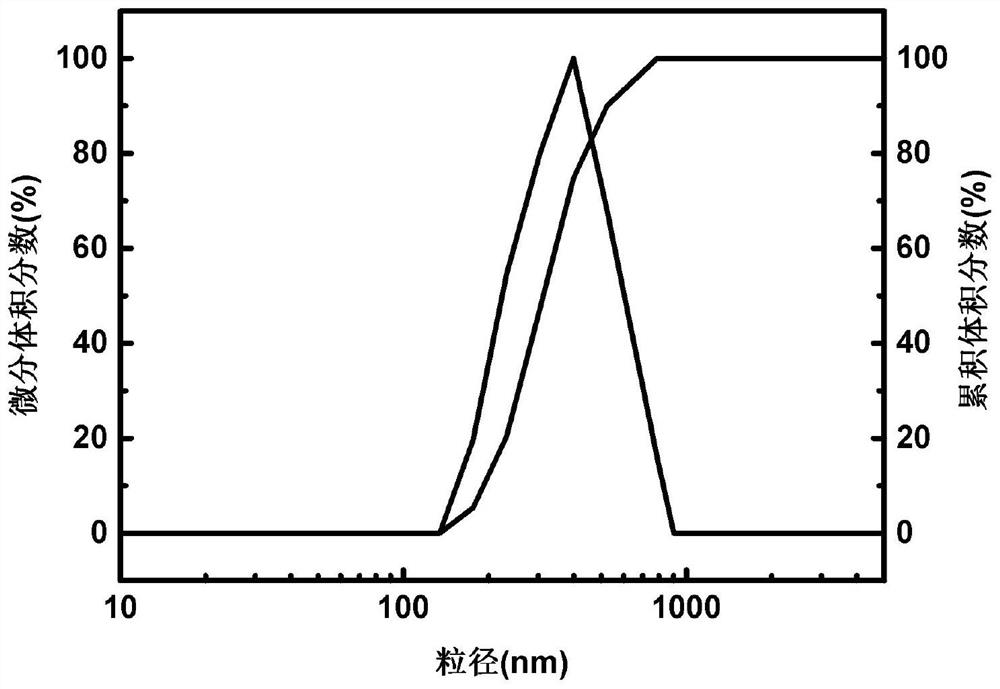

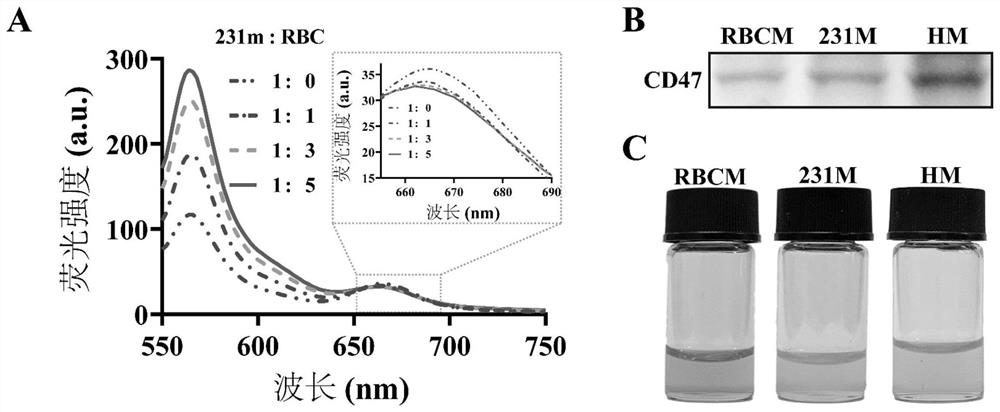

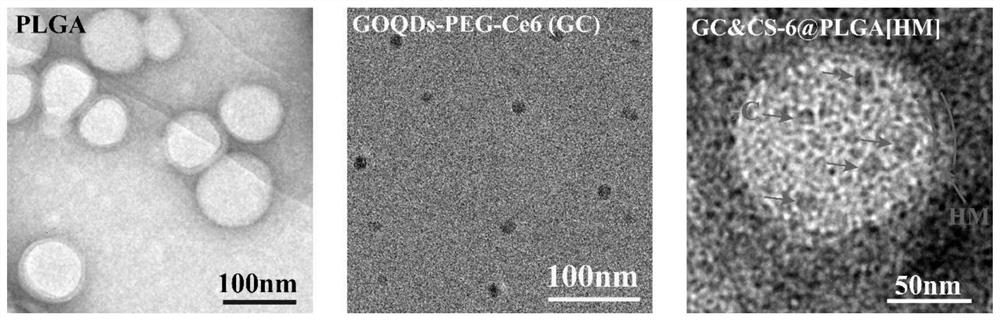

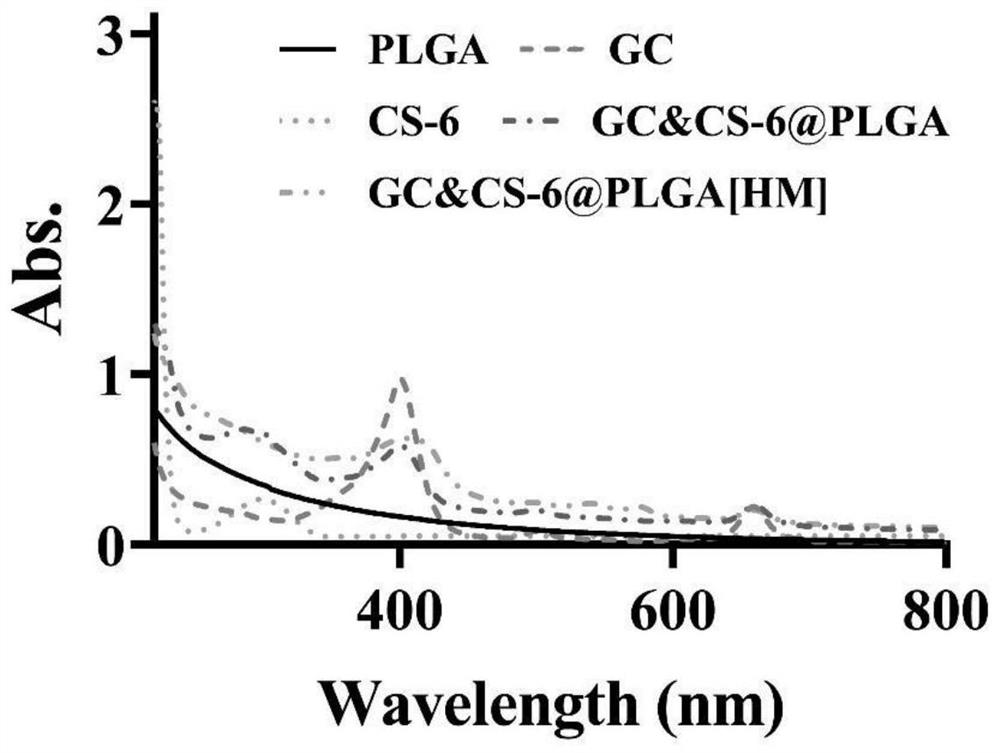

Particle size variable anti-tumor bionic nano preparation based on PLGA and preparation method and application thereof

PendingCN113456614AImplement featuresImprove permeabilityOrganic active ingredientsEnergy modified materialsCombined treatmentChemo therapy

Owner:CHANGSHA WANOU CHEM TECH CO LTD

Graphene/fluorine-silicon self-crosslinking resin composite heavy-duty anti-corrosion finish paint and preparation method thereof

PendingCN110642970AAvoid the disadvantages of easy reunionEvenly dispersedAnti-corrosive paintsEthyleneglycol monobutyl etherIn situ polymerization

The invention relates to graphene / fluorine-silicon self-crosslinking resin composite heavy-duty anti-corrosion finish paint and preparation thereof. The finish paint is prepared from the following rawmaterials in parts by weight through in-situ polymerization: 30 to 40 parts of hydroxyethyl allyl ether, 50 to 60 parts of vinyl acetate, 25 to 35 parts of undecylenic acid, 10 to 20 parts of ethylene glycol monobutyl ether, 8 to 10 parts of vinyl siloxane, 50 to 60 parts of chlorotrifluoroethylene CTFE, 4 to 20 parts of graphene oxide, 125 to 150 parts of a solvent and 5 to 6 parts of an initiator. A graphene fluorine-silicon self-crosslinking resin composite is prepared by performing in-situ polymerization on a part of free double bonds of graphene oxide and an olefin monomer, namely, dispersing graphene in a polymer monomer for monomer-monomer polymerization and monomer-graphene-monomer polymerization. The preparation process is simple; the graphene oxide is uniformly dispersed in theresin and is firmly combined with the resin; and the defect that the graphene is easy to agglomerate is avoided. After the finish paint is cured, interface strength is improved, so the corrosion resistance of the graphene paint is improved.

Owner:CP NANOMATERIALS RES CENT (DALIAN) CO LTD

Method for preparing iron-cobalt-nitrogen codoped graphene at low temperature

Owner:SOUTHEAST UNIV

Preparation method of graphene modified polyurethane adhesive

InactiveCN110964474AGood dispersionNot easy to reunitePolyureas/polyurethane adhesivesPolyesterPolyurethane adhesive

Owner:SHANDONG WESTBORAN CHEM CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap