Reduced graphene oxide composite material

a graphene oxide and composite material technology, applied in the field of composite materials, can solve the problems of poor absorption capacity, laborious preparation process, environmental contamination problems, etc., and achieve the effect of low cost and high oil absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

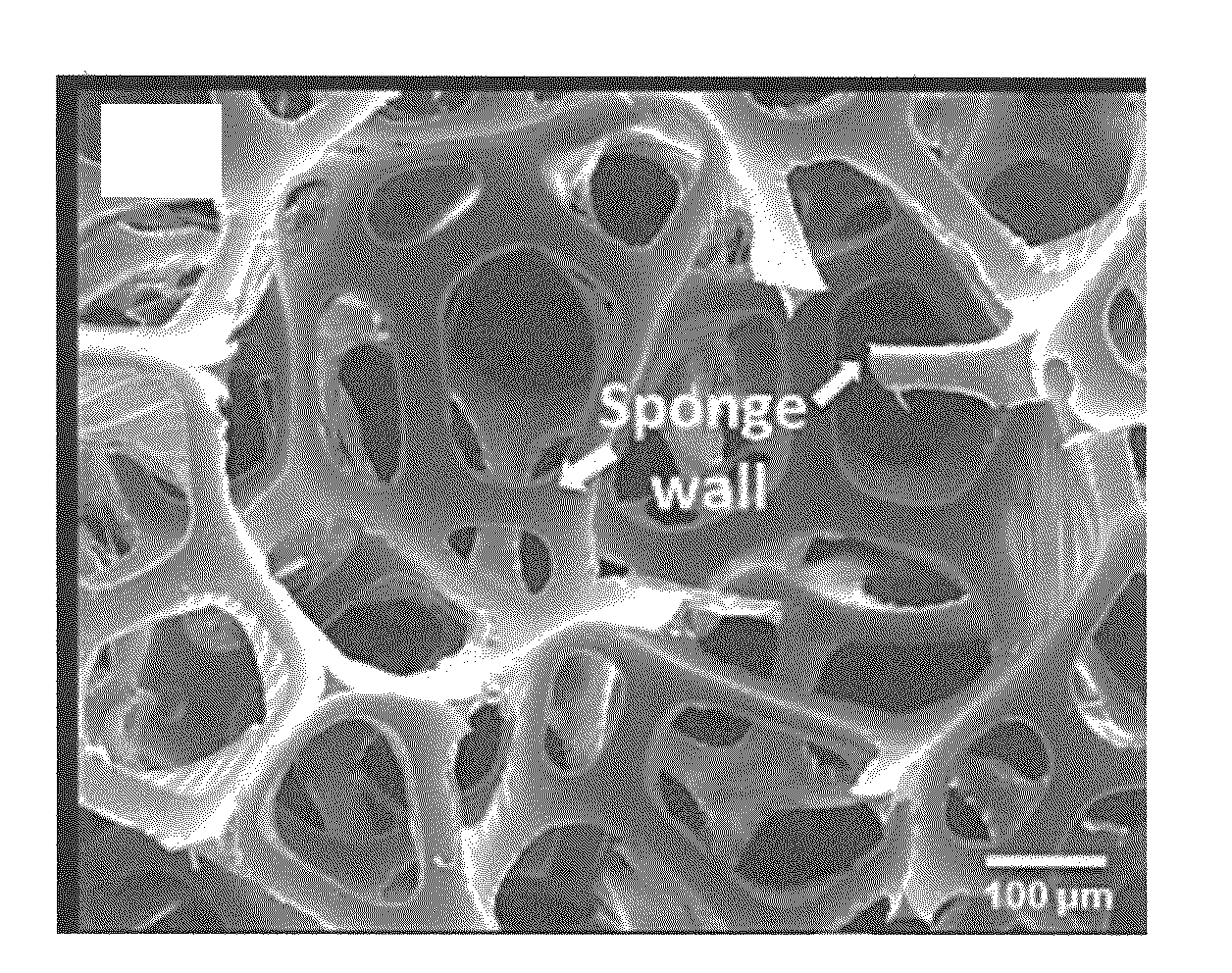

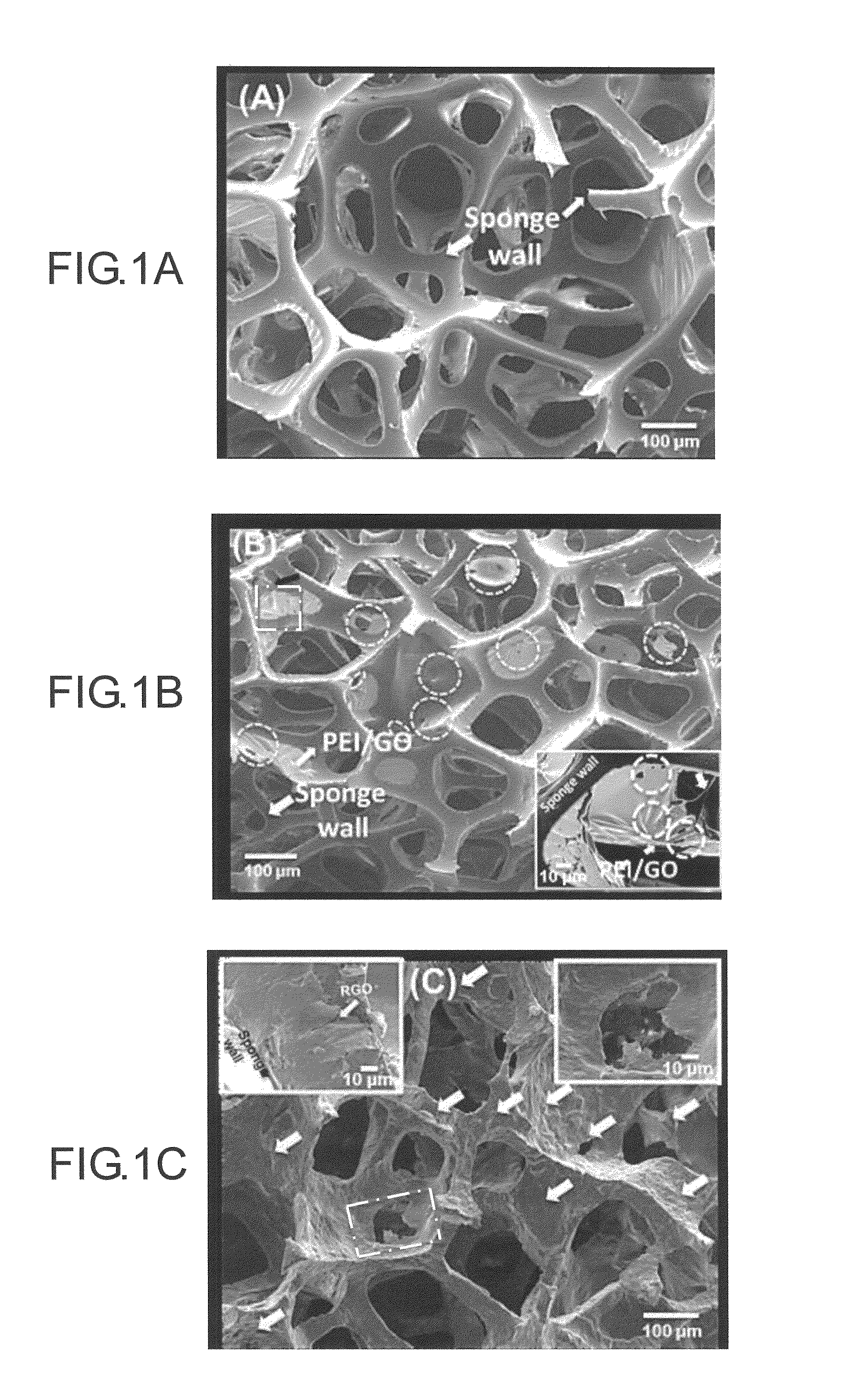

[0025]The preparation method disclosed in the present invention uses fibrous materials (such as natural or synthetic fabric / cloths) or porous materials (such as the natural or synthetic sponge) as the substrate to prepare the PTMOS-treated, PEI-functionalized RGO film coated on and / or into the substrate. The material of the porous substrate includes natural or synthetic materials and fibrous materials with large numbers of pores with different pore volumes.

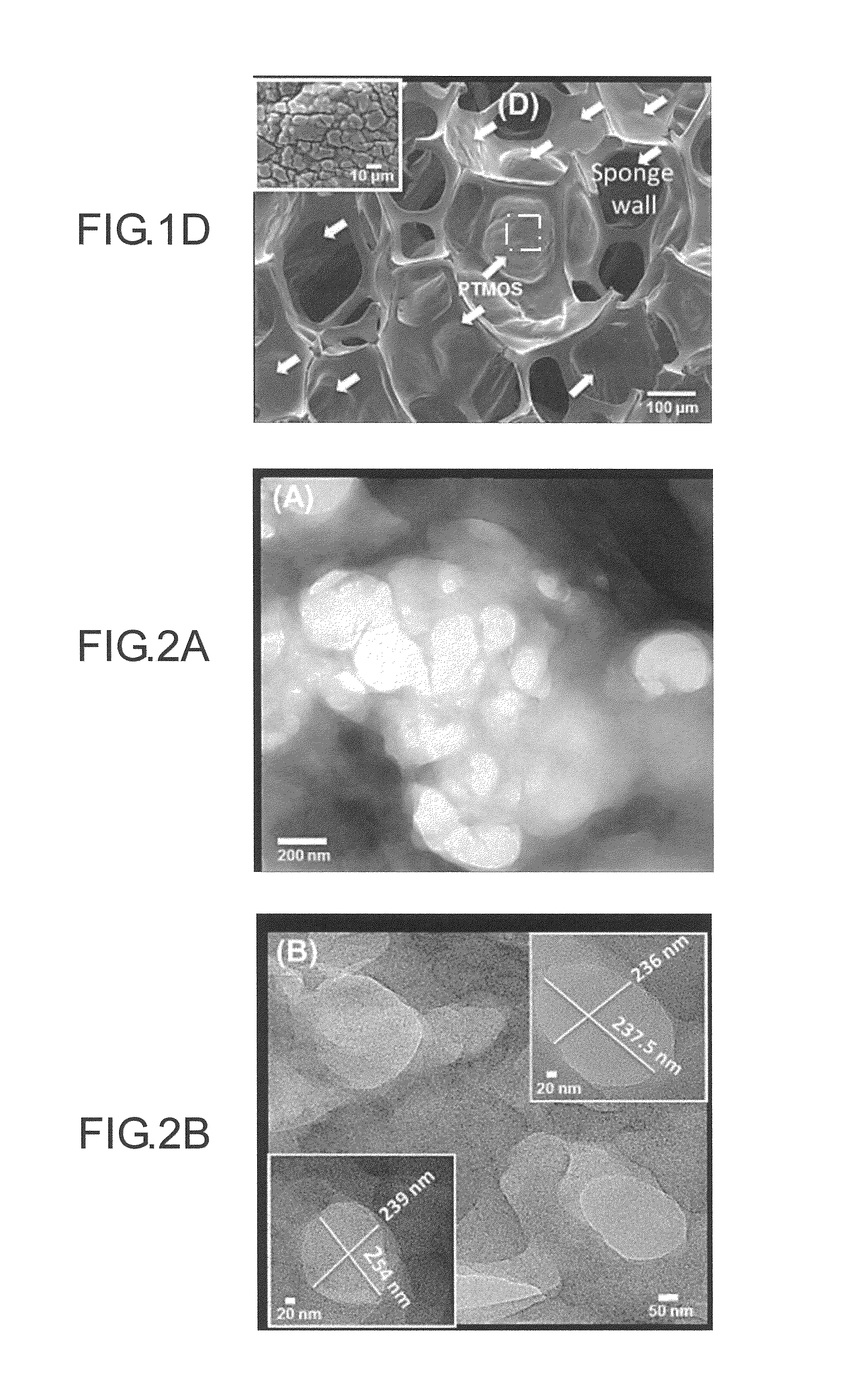

[0026]The RGO has not only hydrophobic surfaces and a large surface area but also it has a high mechanical strength, and is suitable to be used for absorbing oil. However, the smooth morphology of the RGO sheets decreases their oil absorption efficiency. Though functional graphene / polypyrrole foams have been used for removing oils, it is difficult to remove the oil from the RGO surface as a result of their strong absorption. Burning these materials absorbed oil has been suggested, but it raises safety and ecological concerns.

[0

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap