Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44 results about "Cvd graphene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

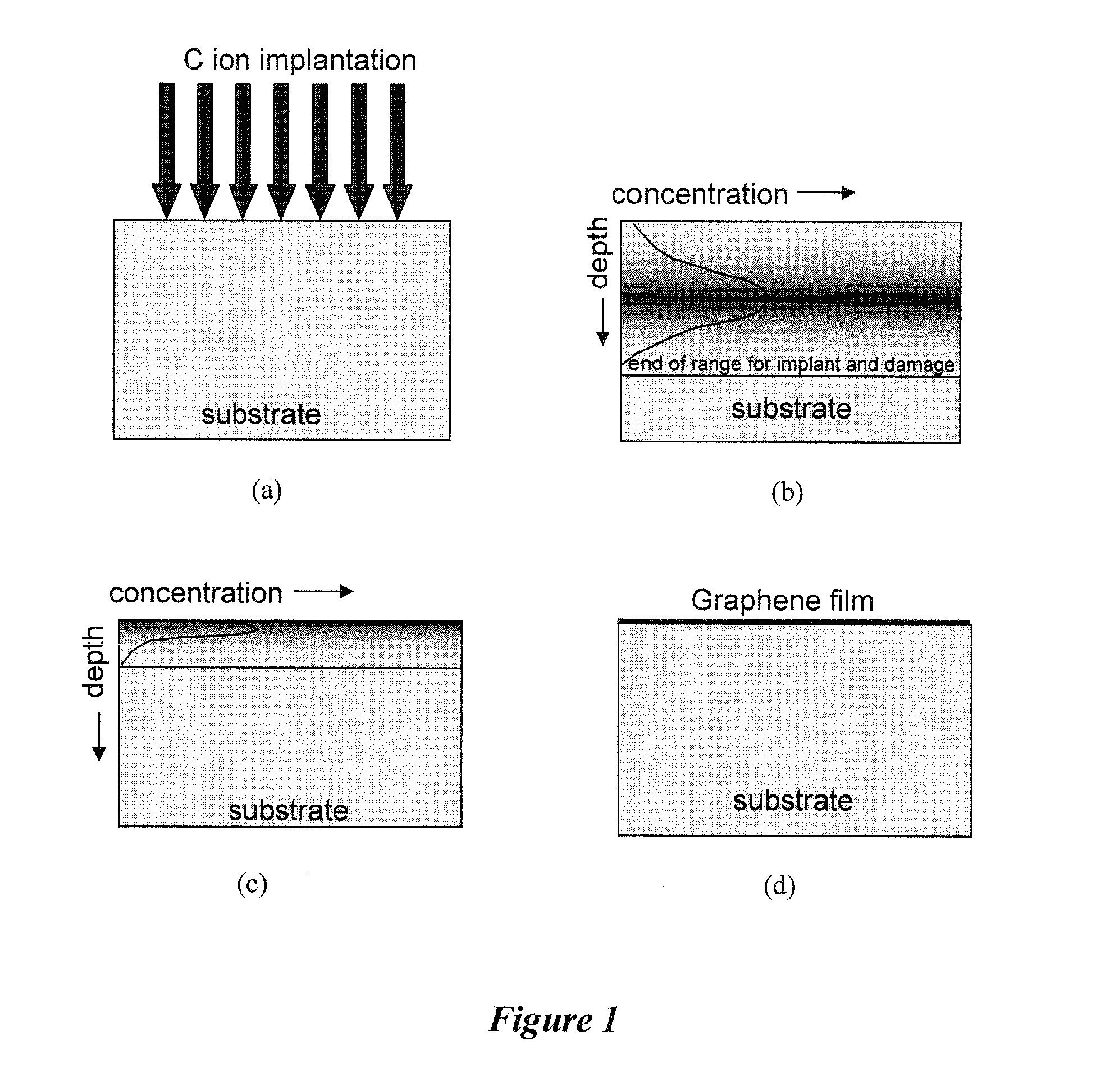

Description of CVD graphene. CVD, Chemical vapor deposition, is a chemical process used to produce high purity materials. When the CVD method is applied in graphene manufacturing, CH4 is often used as the carbon source. This method results in high-quality graphene with great homogeneity.

Graphene processing for device and sensor applications

Owner:UNIV OF FLORIDA RES FOUNDATION INC

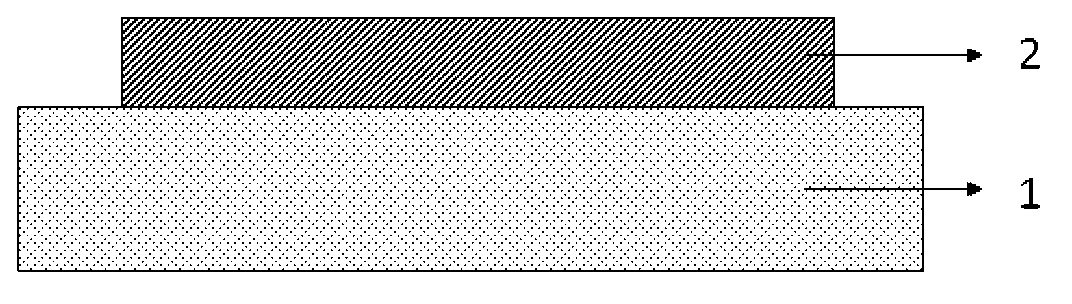

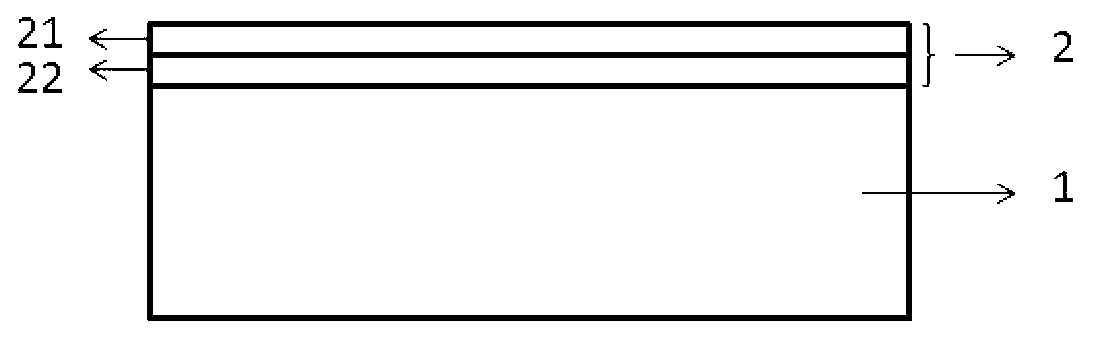

Transparent conducting thin film and preparation method thereof

InactiveCN102938262AHigh visible light transmittanceReduce square resistanceConductive layers on insulating-supportsMetal/alloy conductorsCvd grapheneTransmittance

The invention discloses a transparent conducting thin film and a preparation method thereof. The transparent conducting thin film is located on a transparent substrate and comprises a graphene sheet and a silver nanowire, the transparent conducting thin film is a combined layer formed by a graphene sheet layer and a silver nanowire layer, or the transparent conducting thin film is formed by blending the graphene sheet and the silver nanowire. The transparent conducting thin film and the preparation method thereof have the advantages that the visible light transmittance is high, the square resistance is low, the complexity of the preparation process is reduced, and the production cost is lowered.

Owner:SHANGHAI JIAO TONG UNIV

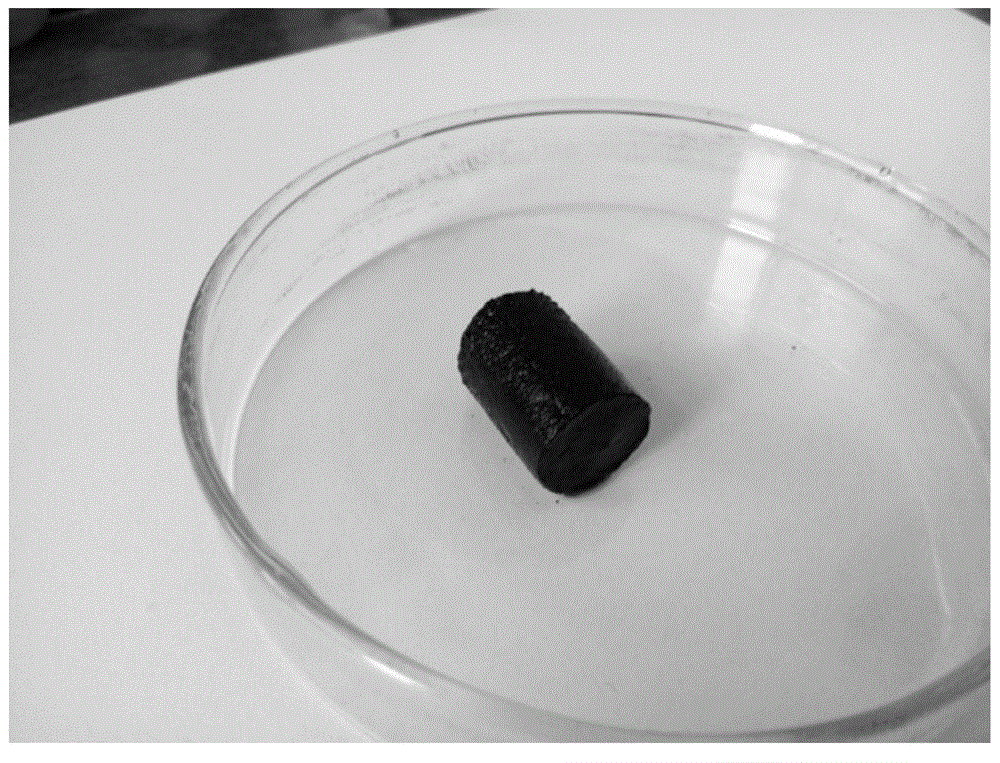

Hydrothermal preparation method of graphene-coated sulfur/porous carbon composite positive electrode material

Owner:HARBIN INST OF TECH

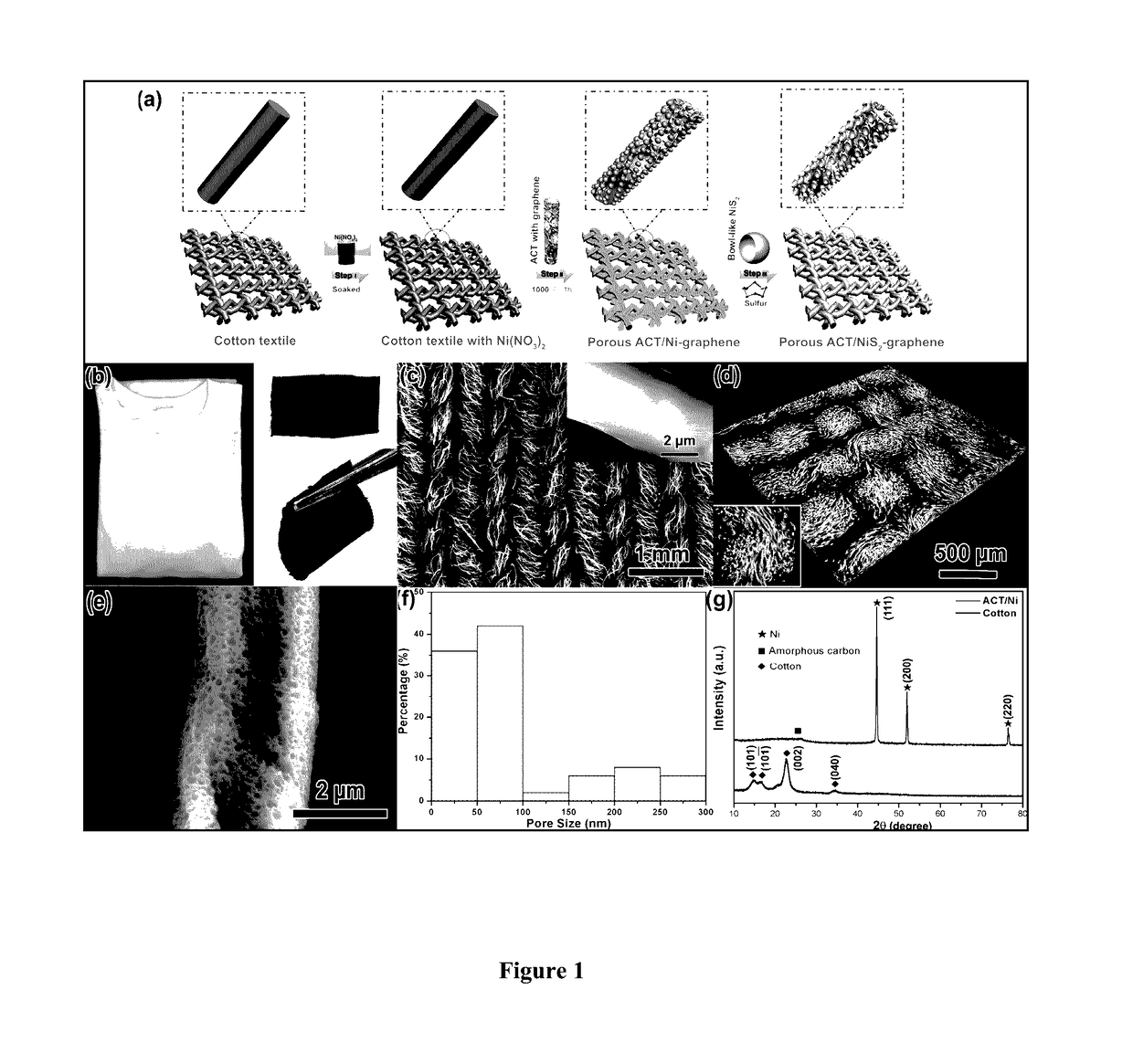

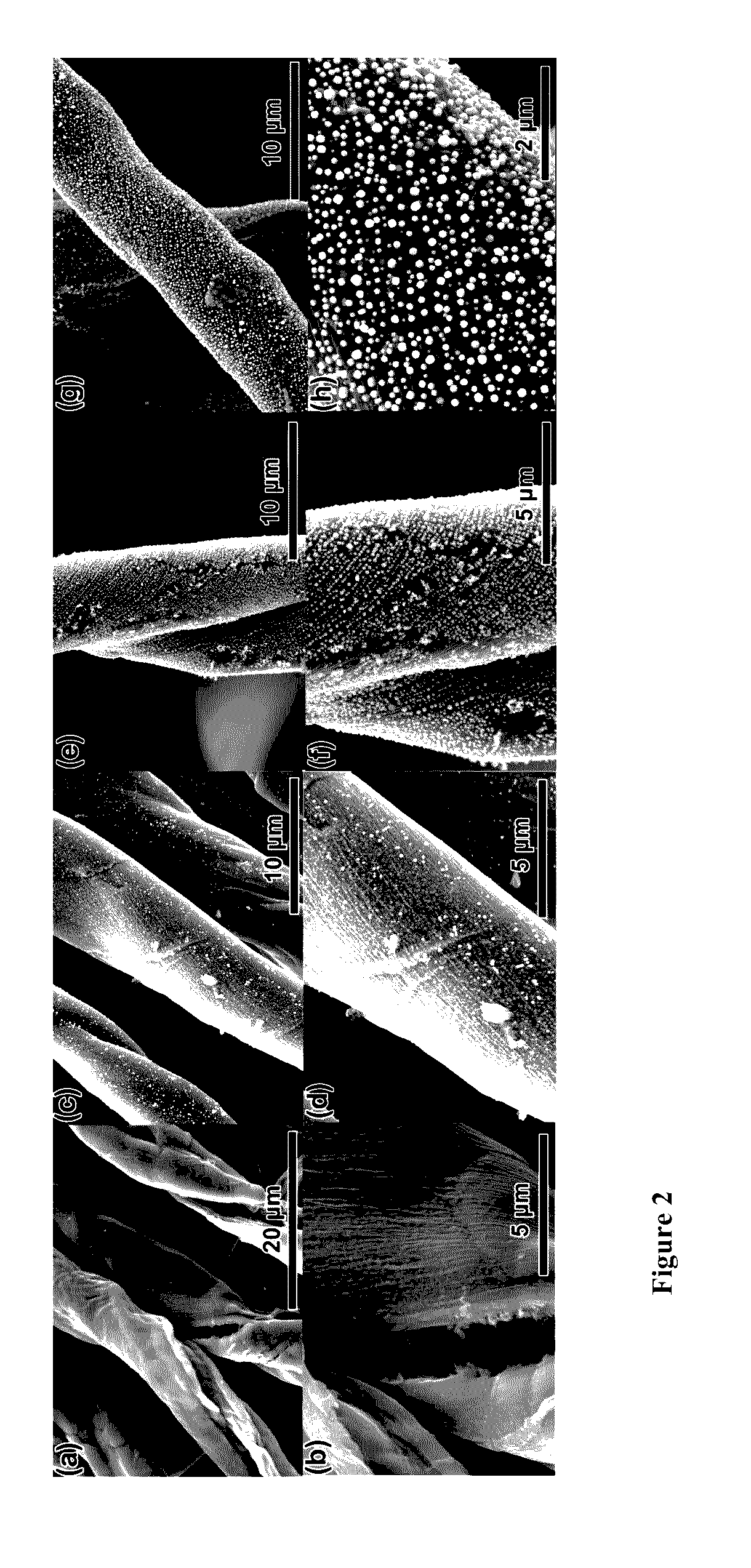

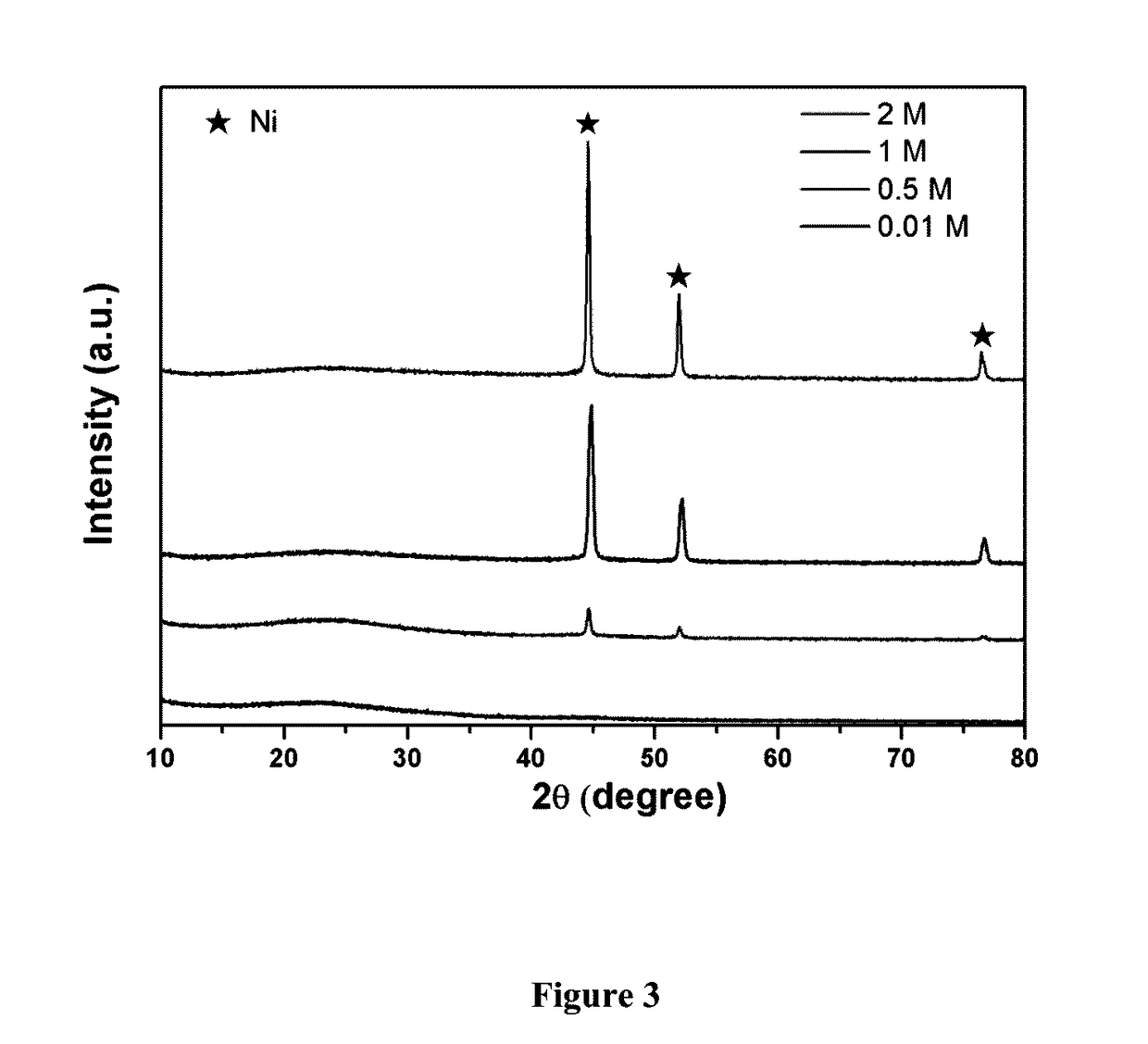

Process of forming electrodes and products thereof from biomass

ActiveUS20170084924A1Improve electrochemical performanceImprove rate performanceElectrode thermal treatmentHybrid capacitor electrodesCvd grapheneActivated carbon

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

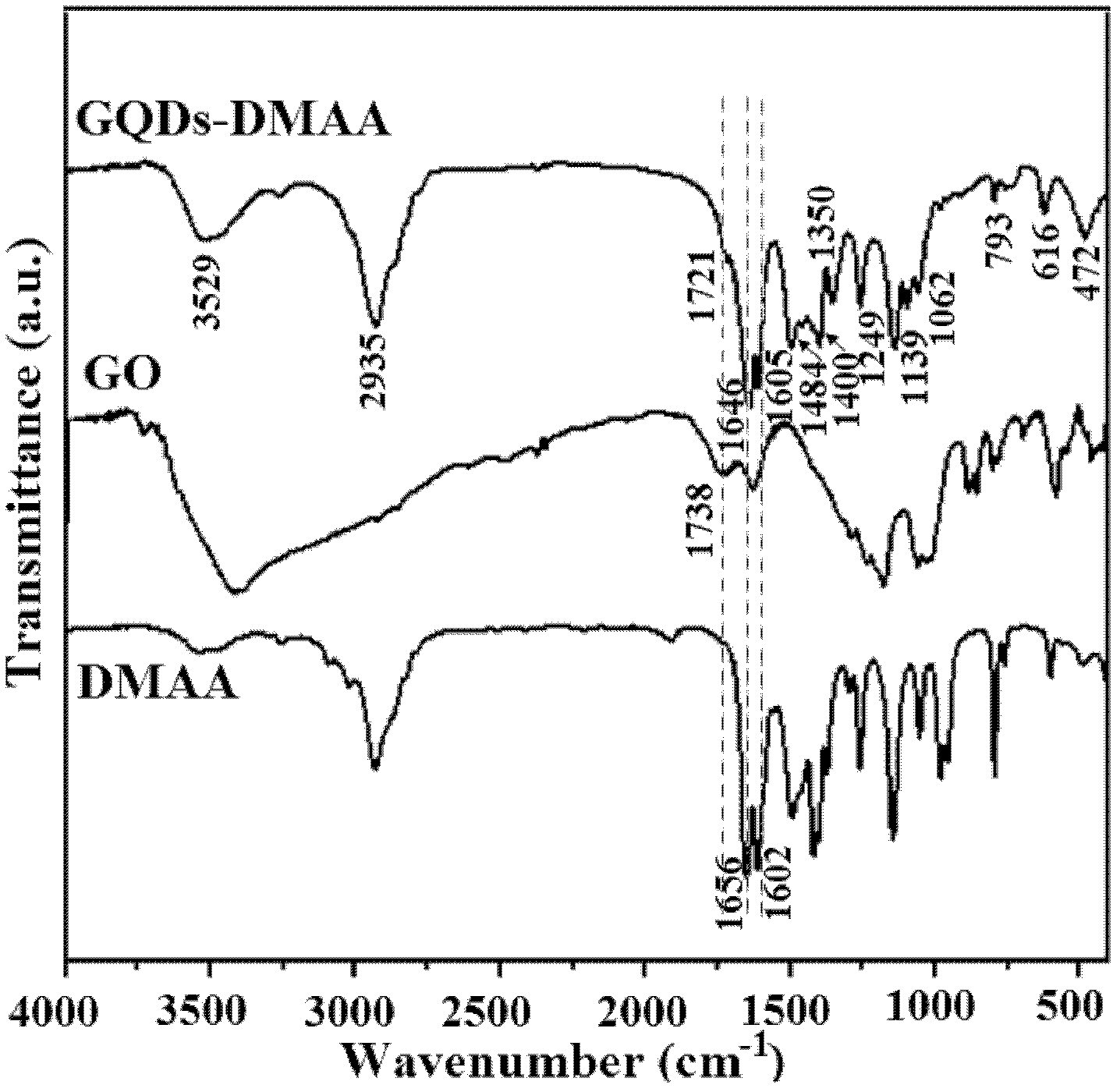

Transparent high-refractivity graphene quantum-dot/polymer nano composite film and preparation method thereof

ActiveCN102643501AGood compatibilityAvoid the downside of refractive index dropComposite filmNano composites

Owner:JILIN UNIV

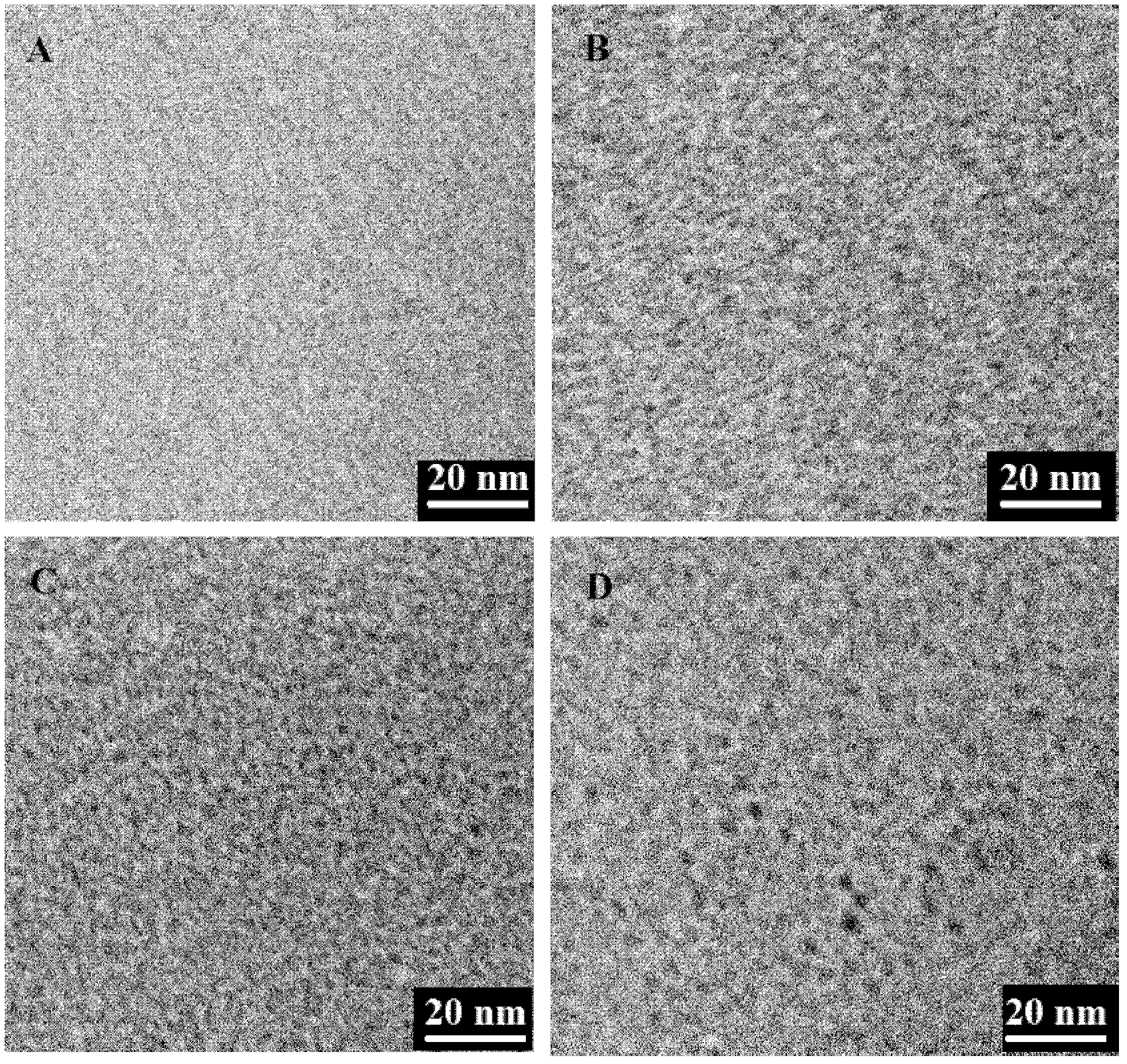

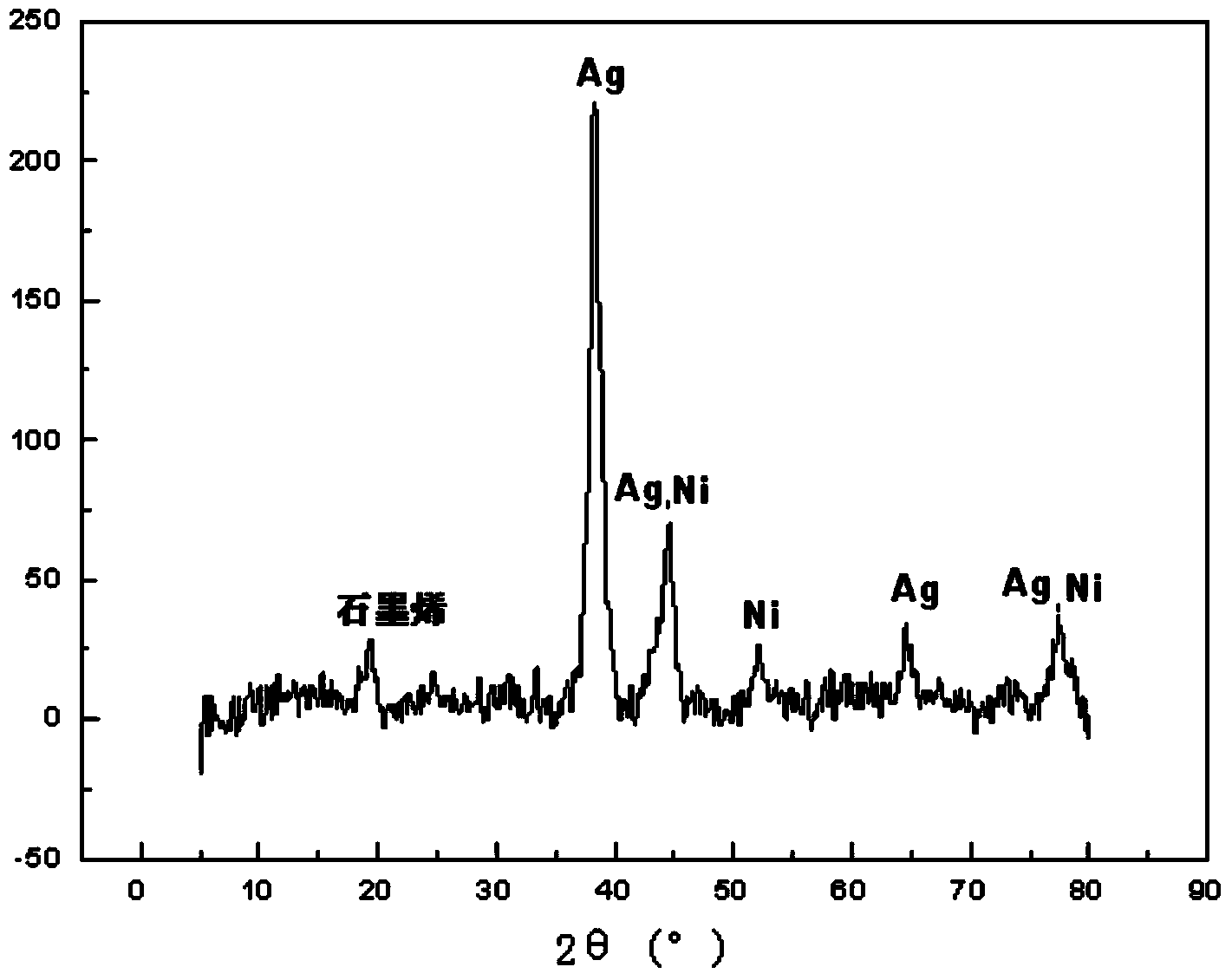

Method for preparing graphene load nano silver-nickel alloy composite powder materials

Owner:HEILONGJIANG UNIV

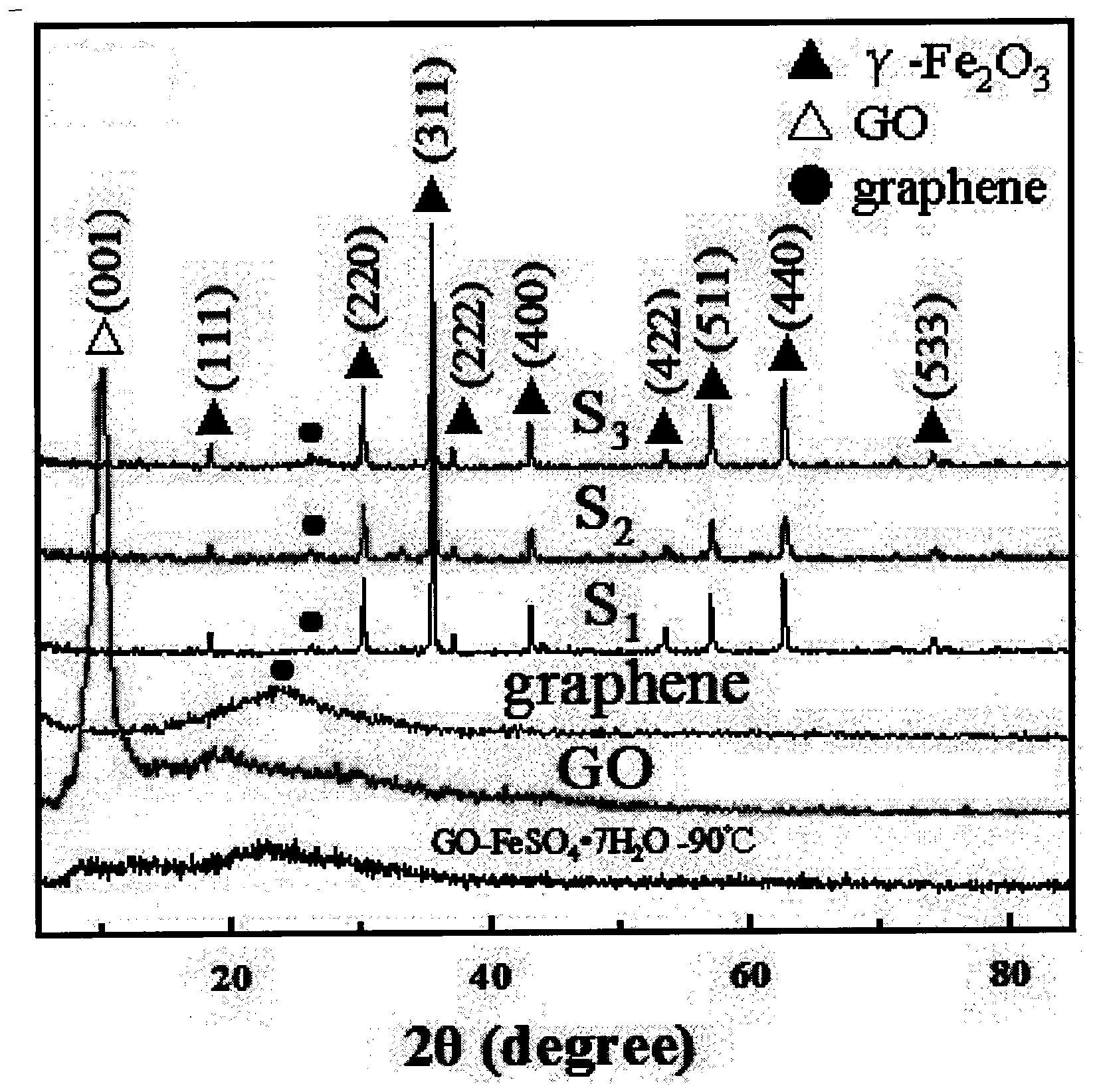

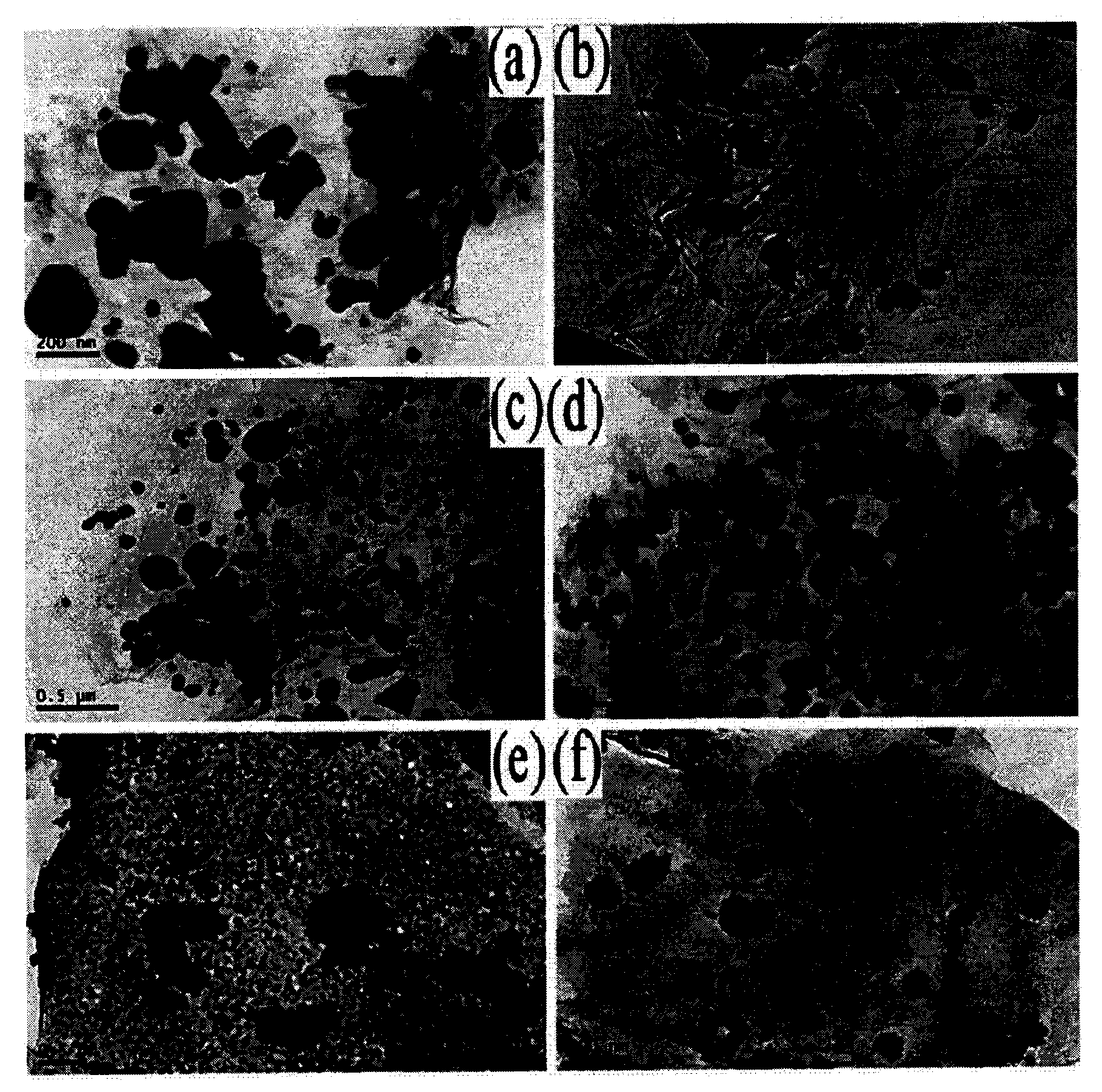

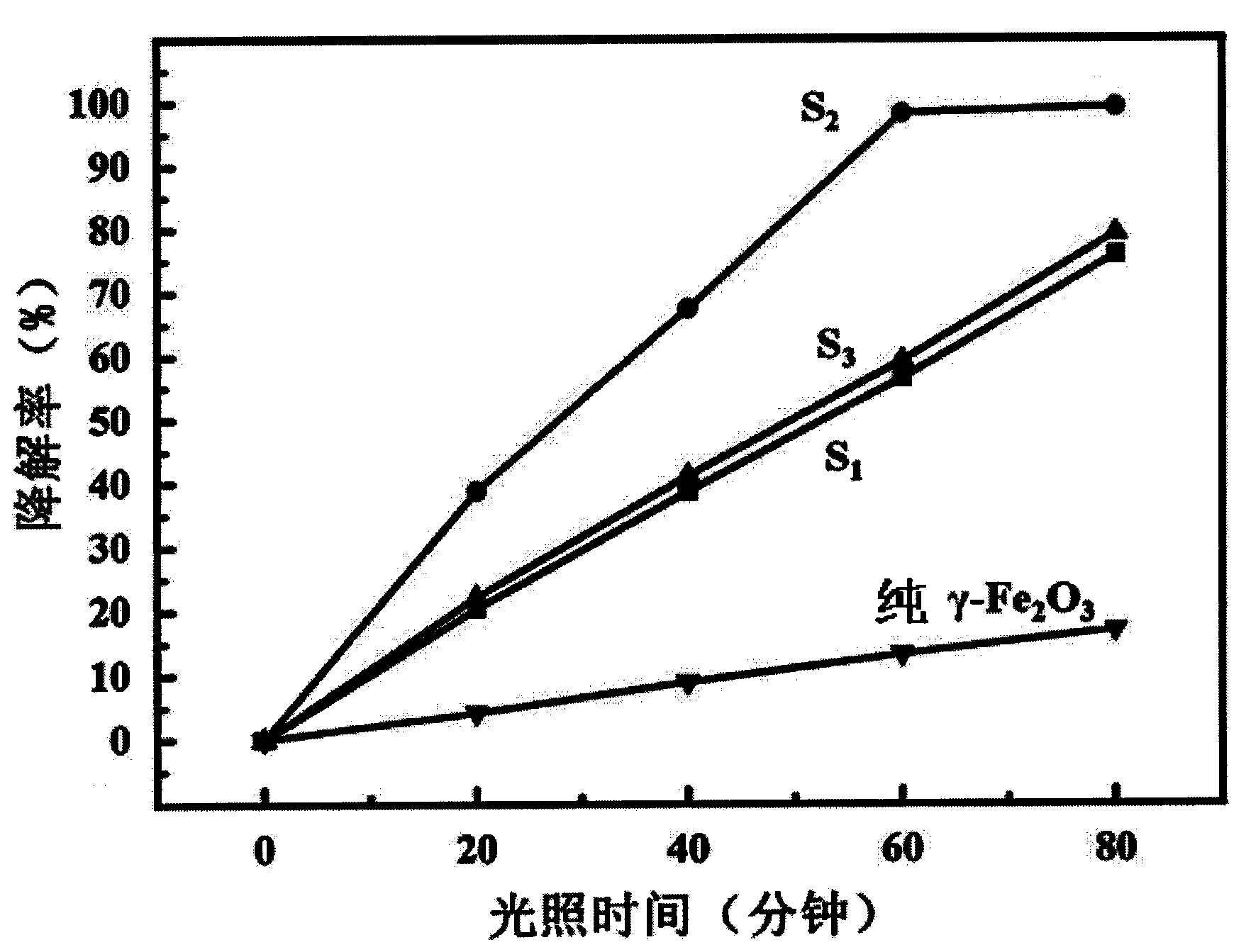

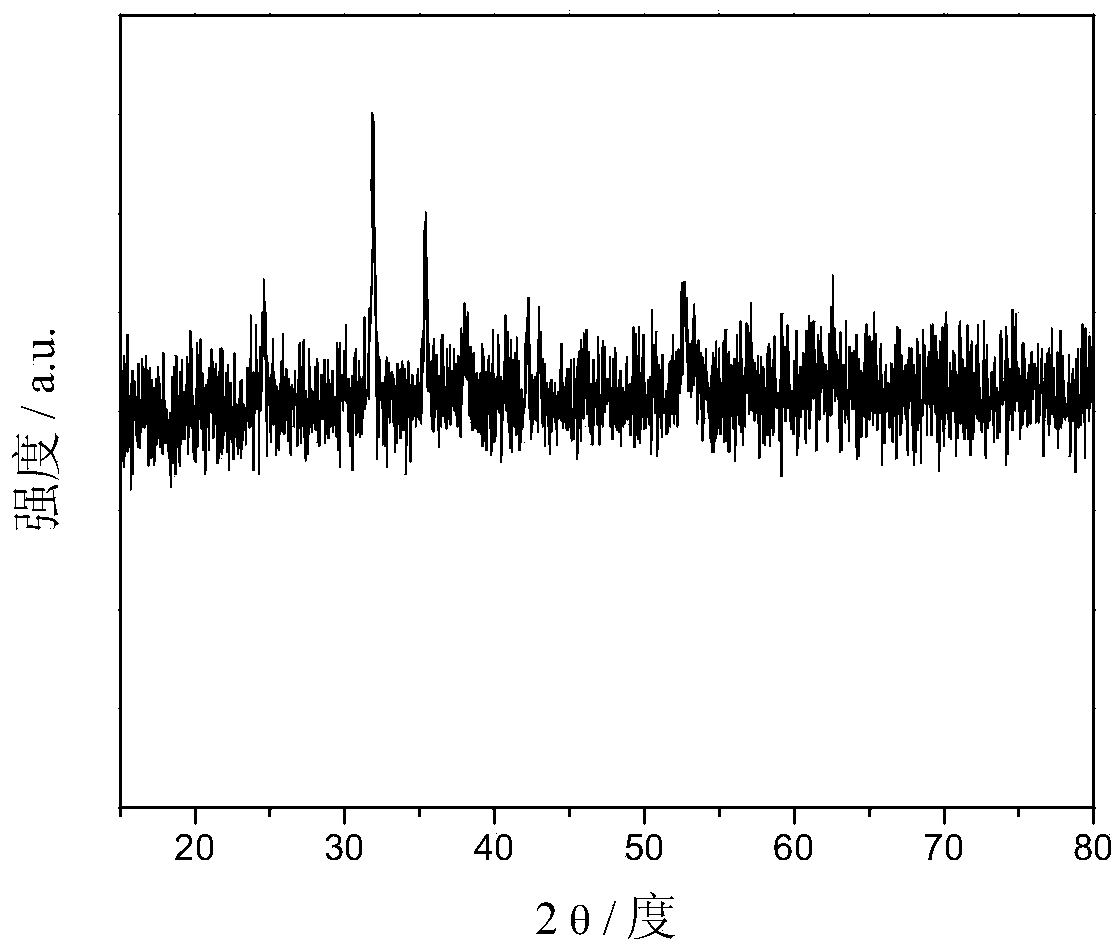

Graphene-based gamma-FeO2O3 composite material photocatalyst, and preparation method and use thereof

InactiveCN103706364AReduced band gapLarge specific surface areaMetal/metal-oxides/metal-hydroxide catalystsIron sulfateOrganic matter

Owner:魏颖

Method for preparing ferric vanadate-graphene negative electrode composite material

ActiveCN104766975AUniform textureGood dispersionNegative electrodesSecondary cellsDispersityReaction rate

Owner:SHENZHEN PANGU ENVIRONMENTAL PROTECTION TECH CO LTD

Laser-assisted graphene tooth 3D printing process

Owner:GUANGZHOU FENGSHANG ELECTRIC APPLIANCE

Manufacturing process of graphene transparent conductive film

Owner:苏州瑞邦塑胶有限公司

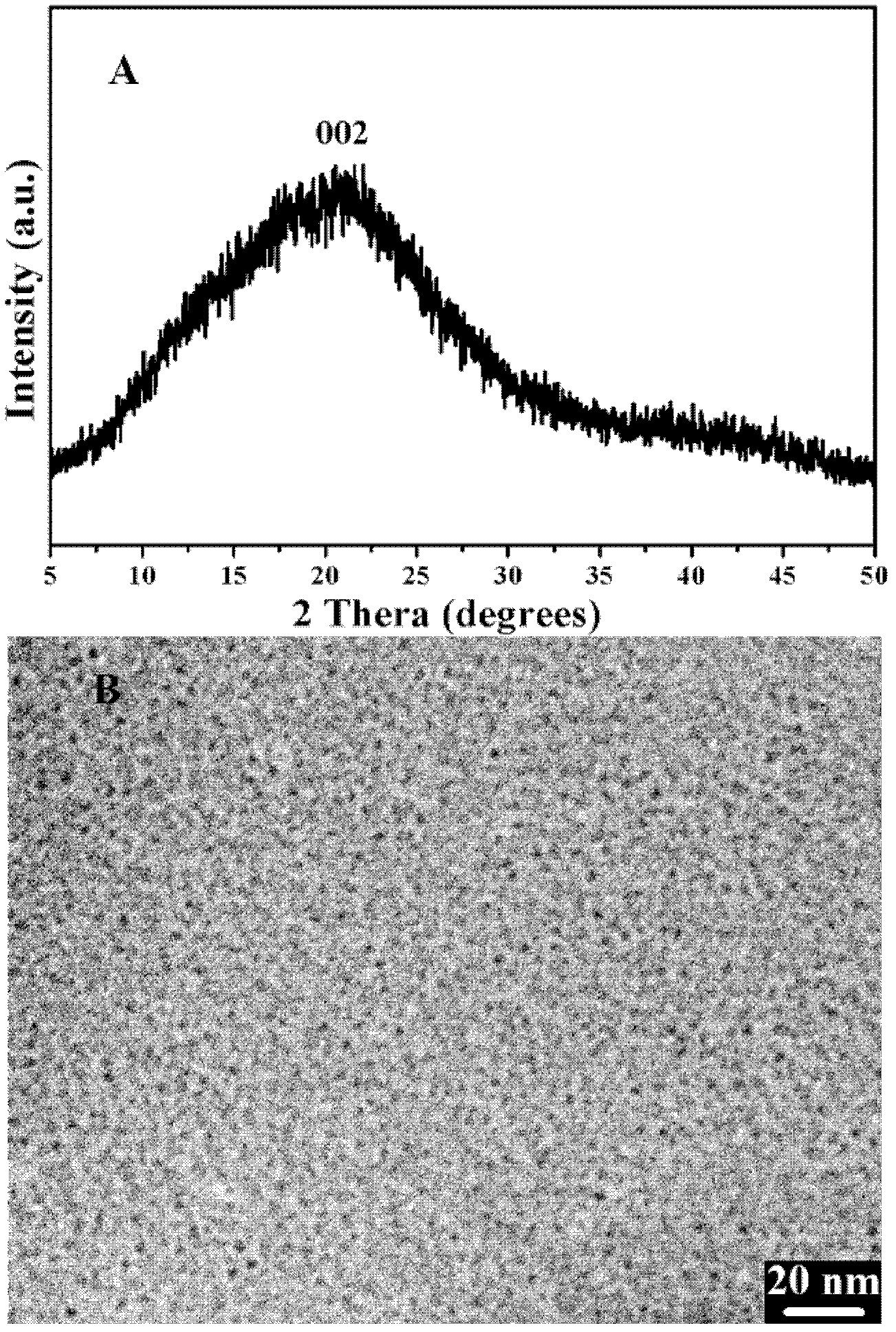

Porous graphene composite material supported by micropore and preparation method of material

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

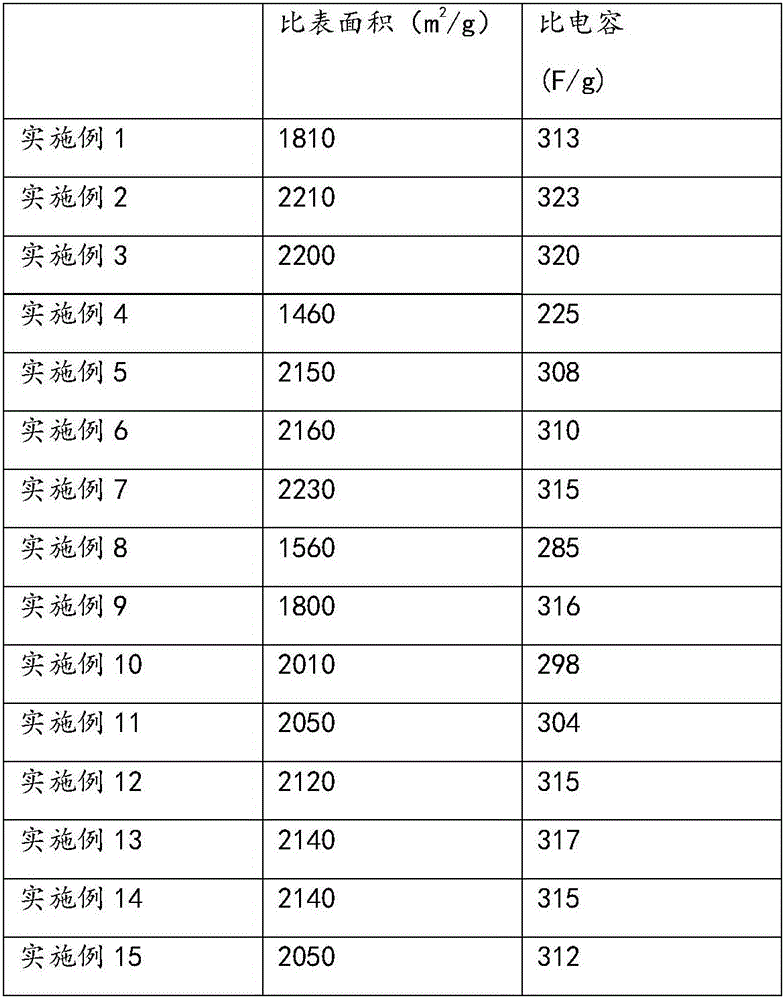

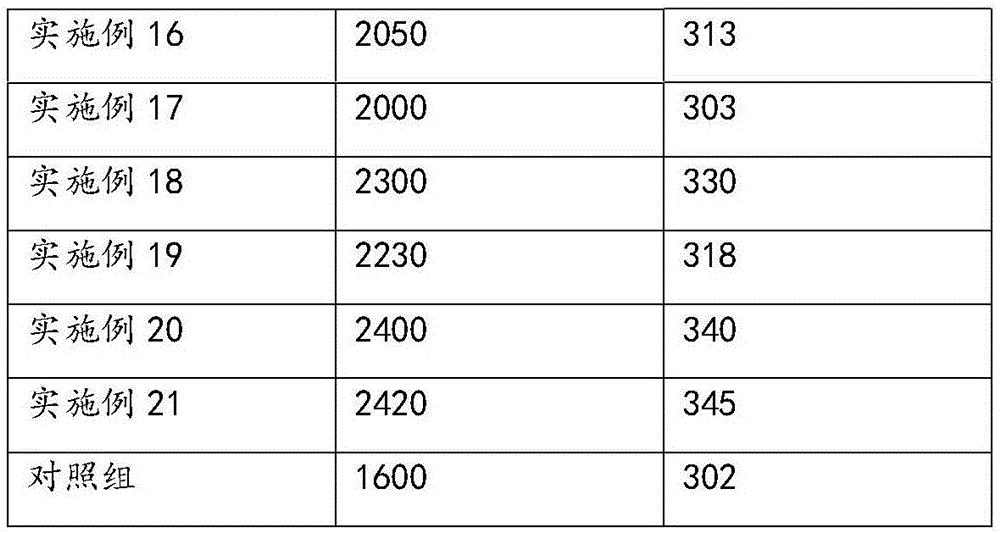

Graphene-based hierarchical pore capacitor carbon and preparation method thereof as well as capacitor

InactiveCN106467299ACurl suppressionSuppress stackingHybrid capacitor electrodesGrapheneCross-linkPorosity

Owner:山东圣泉新能源科技有限公司

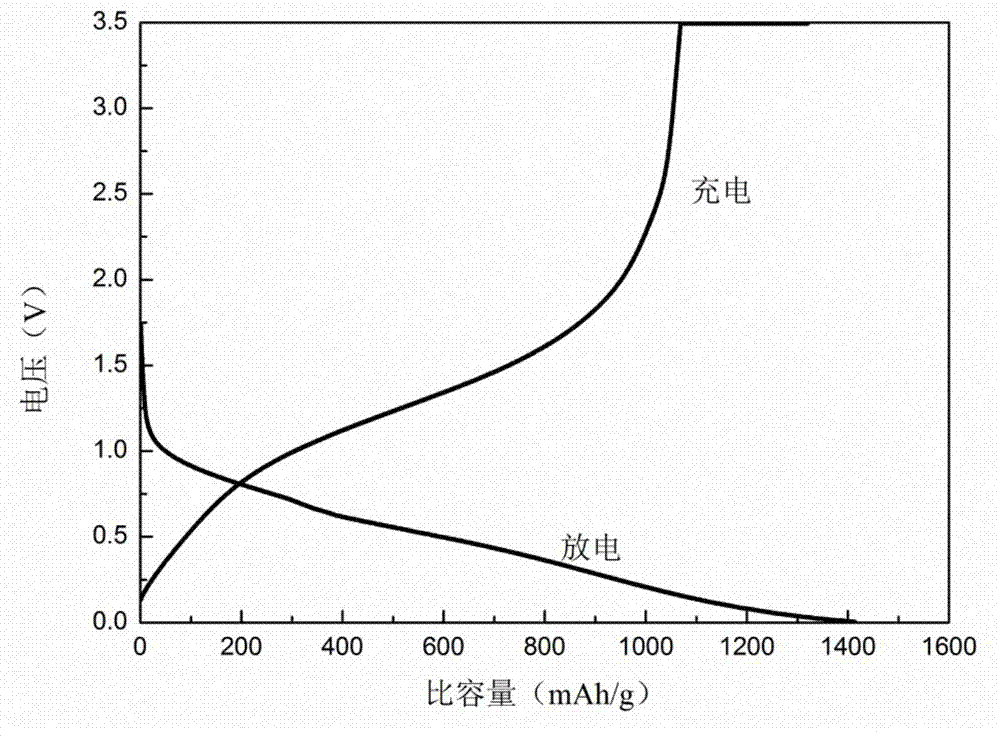

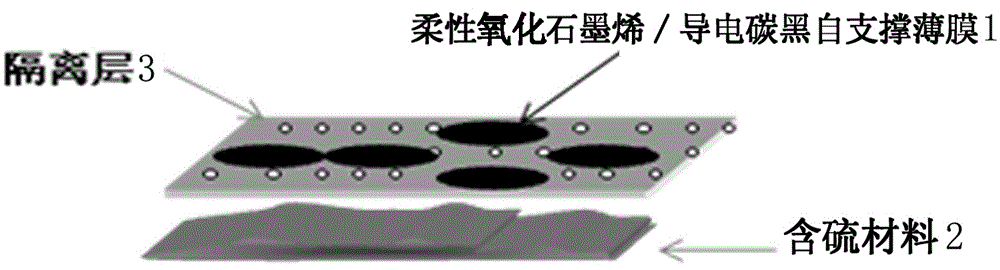

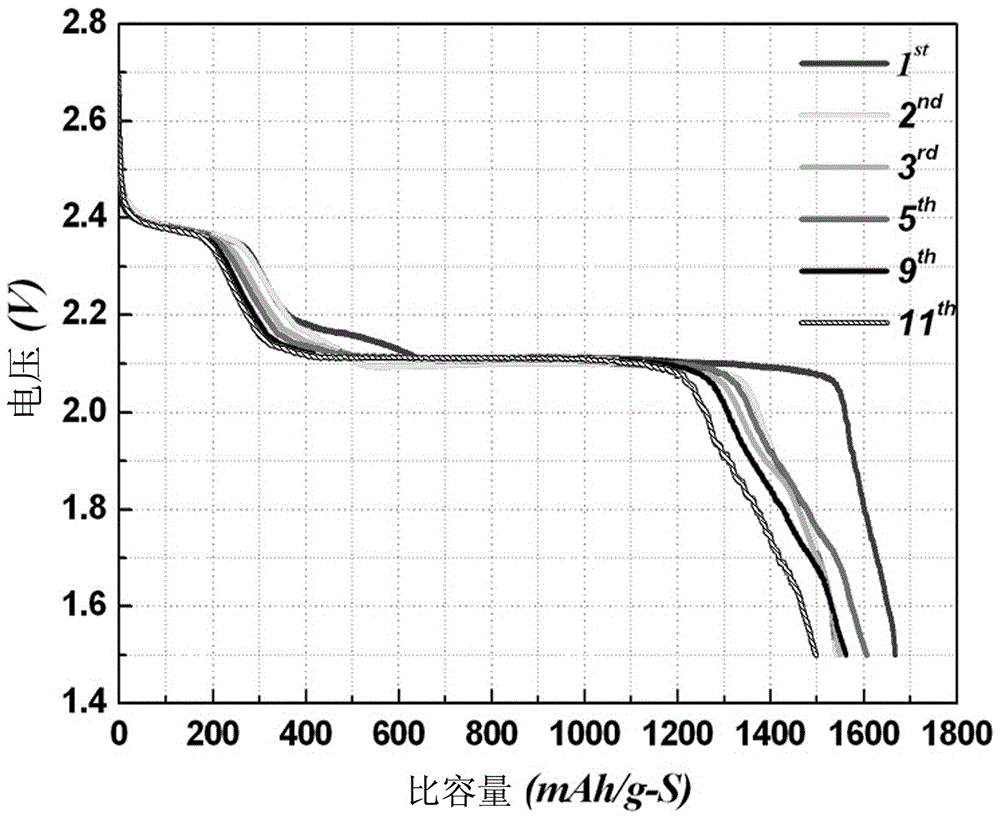

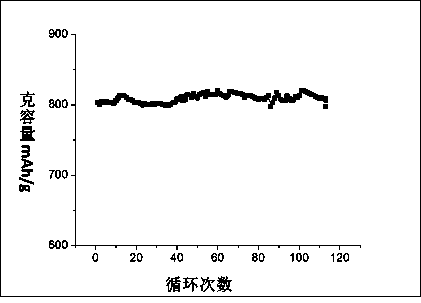

High-specific-energy flexible integrated electrode and preparation method therefor

ActiveCN106450423ASolve the problem of high specific energy characteristicsSolve the problem without degrading the high specific energy characteristics of the electrodeElectrode carriers/collectorsLi-accumulatorsCharge dischargePolysulfide

Owner:SHANGHAI INST OF SPACE POWER SOURCES

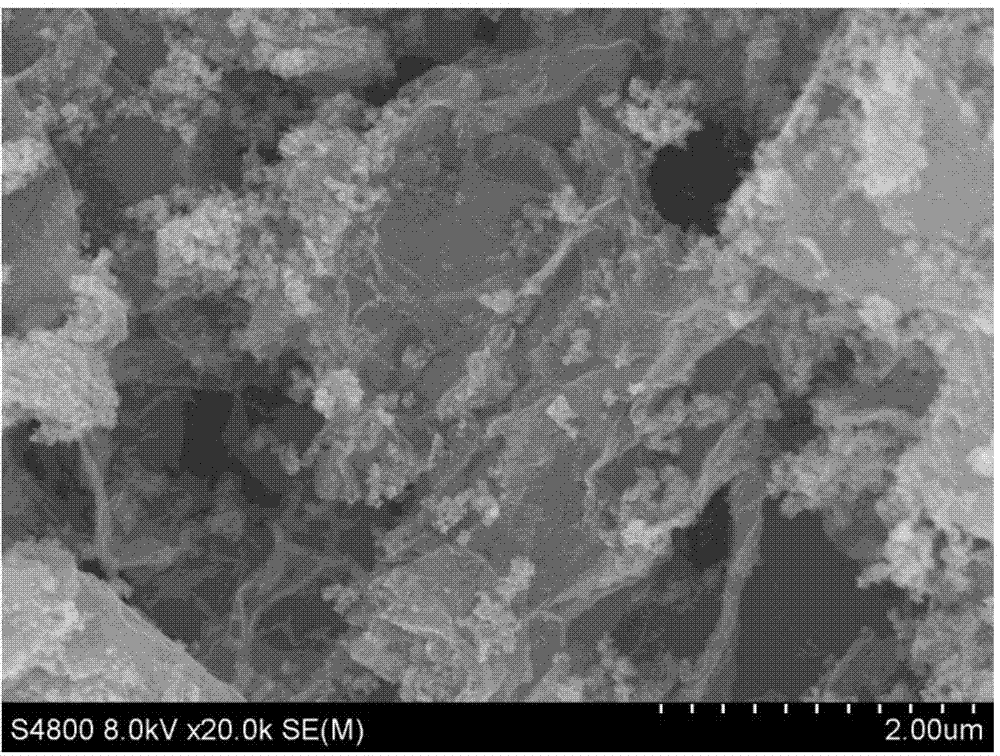

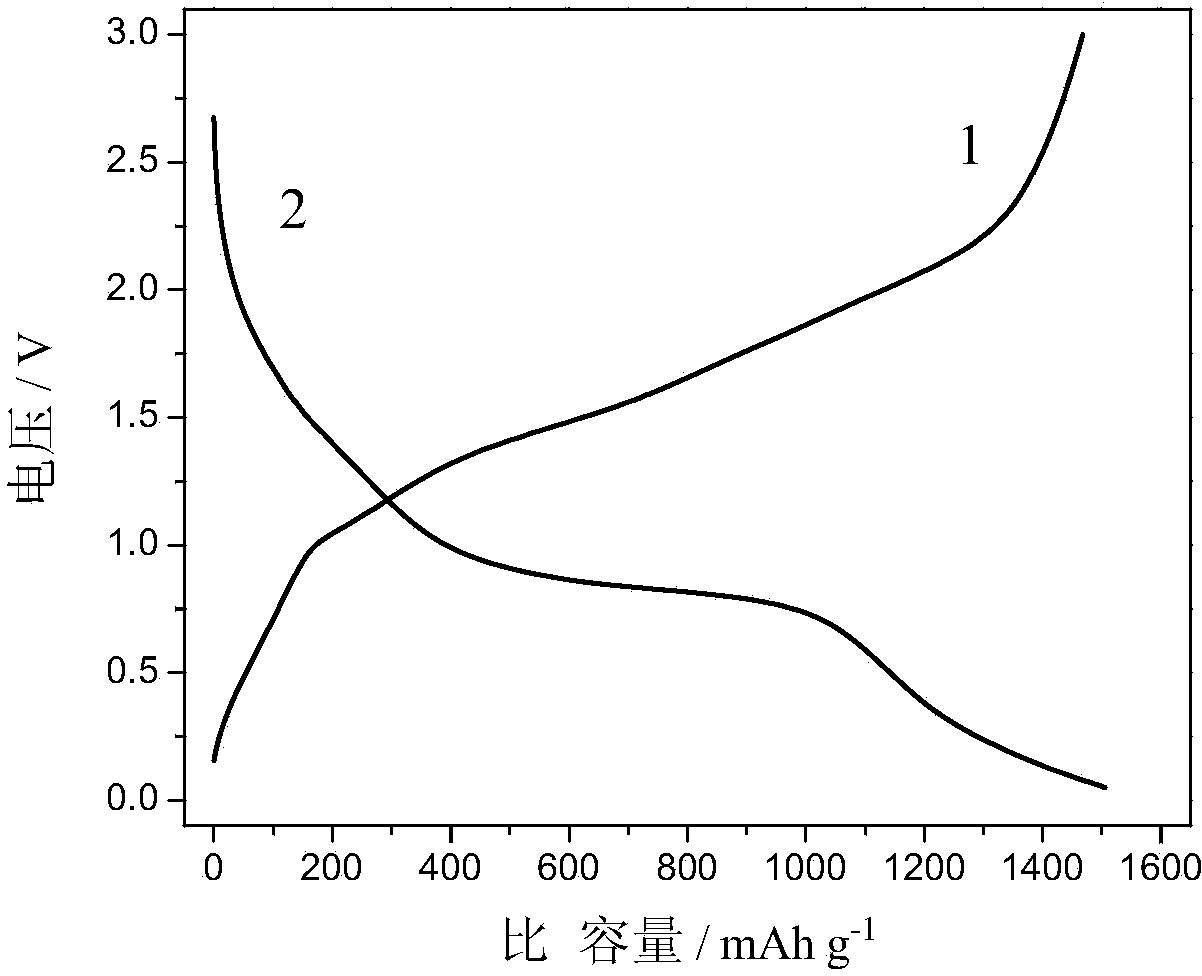

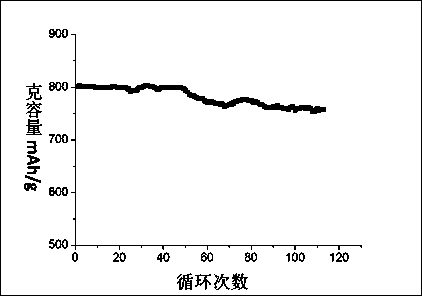

Ferrous carbonate/graphene composite material and preparation method and applications thereof

ActiveCN103840132AHigh specific capacityImprove cycle performanceNegative electrodesSecondary cellsMass ratioConcentration ratio

Owner:HUNAN YACHENG NEW MATERIAL CO LTD

Method for preparing lithium ion battery material

Owner:深圳市梅莎新能源科技有限公司

Preparation method of graphene aerogel epoxy resin composite fracturing proppant

Owner:西安鸿钧睿泽新材料科技有限公司

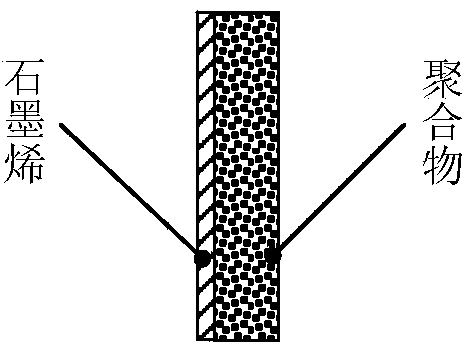

Graphene coated carbon-sulfur composite material

InactiveCN104201354AImprove adsorption capacityBound to dissolveCell electrodesSecondary cellsEnvironmental resistanceCompound a

Owner:NANJING ZHONGCHU NEW ENERGY

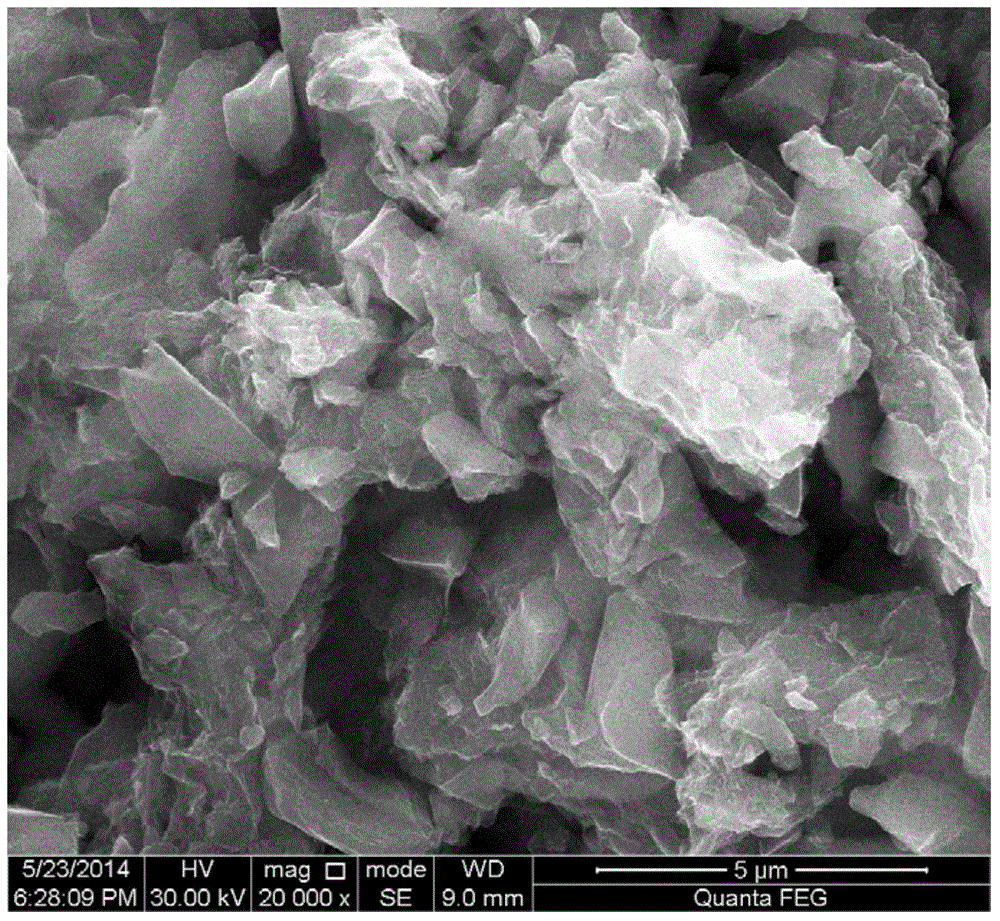

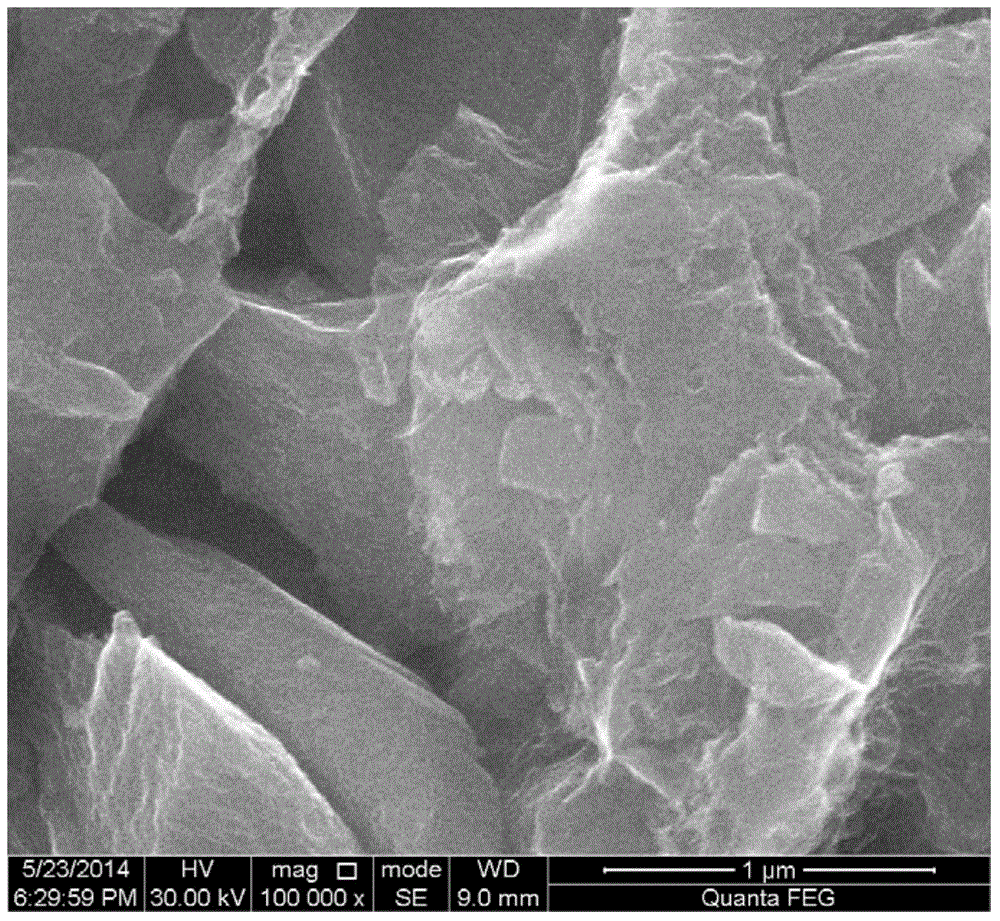

Preparation method of transition metal oxide/graphene nano composite material

InactiveCN106058233ASmall particle sizeUniform sizeMaterial nanotechnologyCell electrodesGraphene nanocompositesOrganic fuel

A preparation method of a transition metal oxide / graphene nano composite material comprises the following steps: (1) according to the loading amount of a transition metal oxide on graphene and the preparation amount of a target product, weighing transition metal nitrate, and dissolving the transition metal nitrate in an aqueous dispersion liquid of graphene oxide; (2) adding a proper amount of an organic fuel into the dispersion liquid of the step (1), and stirring and carrying out ultrasonic treatment to obtain an uniform dispersion liquid; and (3) heating and concentrating the dispersion liquid obtained in the step (2) to be viscous, then putting into a heating furnace with the temperature of 300-900 DEG C, igniting, and after completing combustion, cooling to room temperature to obtain a final product. The preparation method has the advantages of low synthesis temperature, short time, simple implementation, low cost, small particle size of transition metal oxide, uniform size and uniform dispersion in graphene, and is suitable for industrialized production.

Owner:NANCHANG UNIV

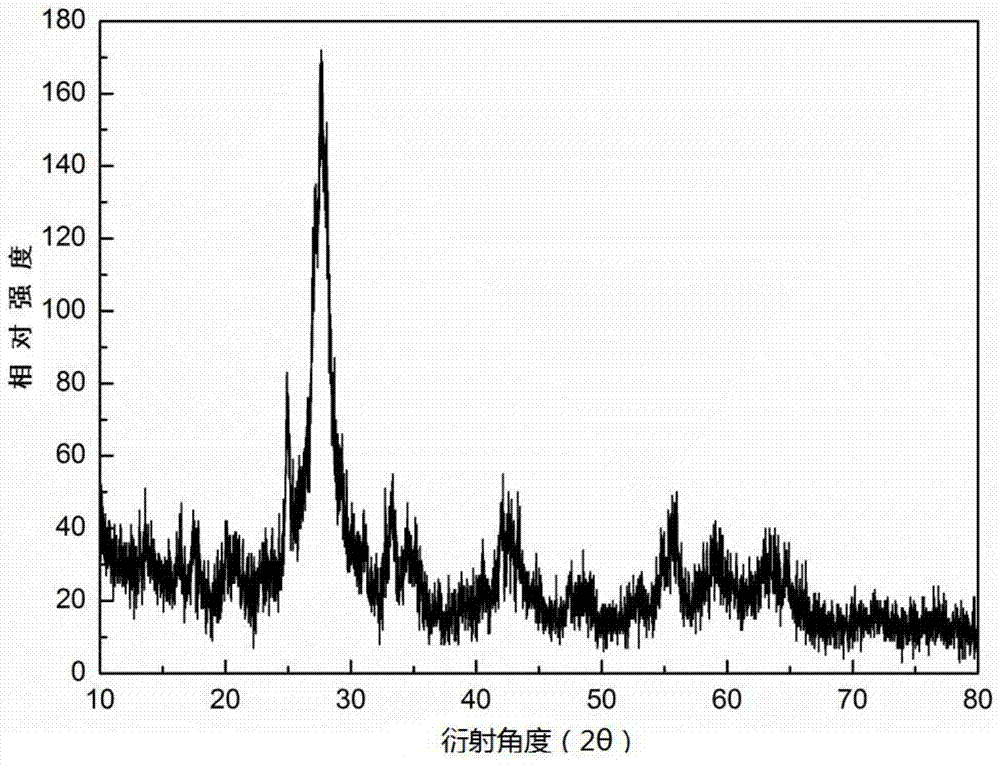

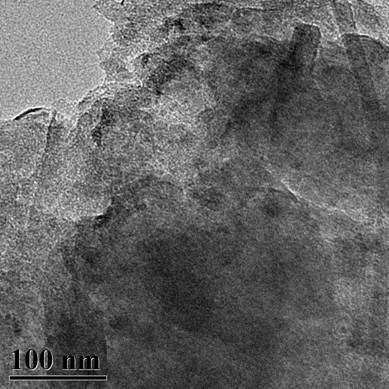

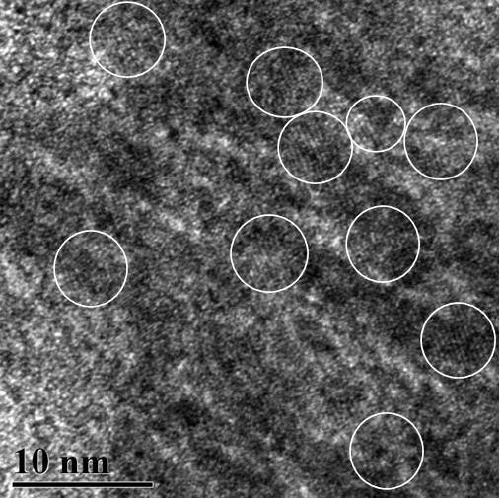

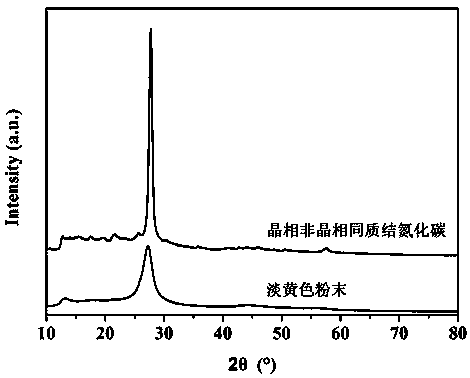

G-C3N4 crystal phase/amorphous phase homojunction as well as preparation method and application thereof

ActiveCN109534307APhysical/chemical process catalystsNanotechnologyCvd grapheneVisible light photocatalytic

Owner:UNIV OF JINAN

Method for preparing graphene chemically modified electrode through in-situ growth

InactiveCN103529099AEasy to operateImprove production efficiencyMaterial electrochemical variablesOxygenMaterials science

Owner:SOUTHWEST JIAOTONG UNIV

Preparation method of graphene quantum dots

ActiveCN110540192AHigh fluorescence yieldImprove stabilityMaterial nanotechnologyGrapheneFluorescenceFiltration

Owner:SHANGHAI SIXTH PEOPLES HOSPITAL

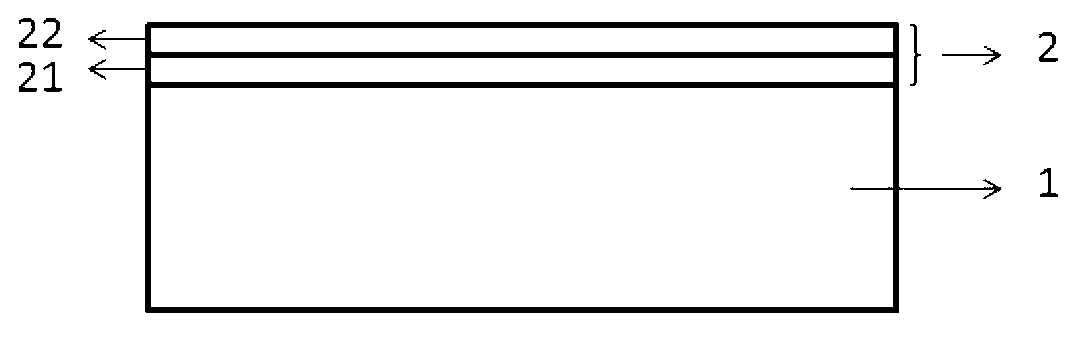

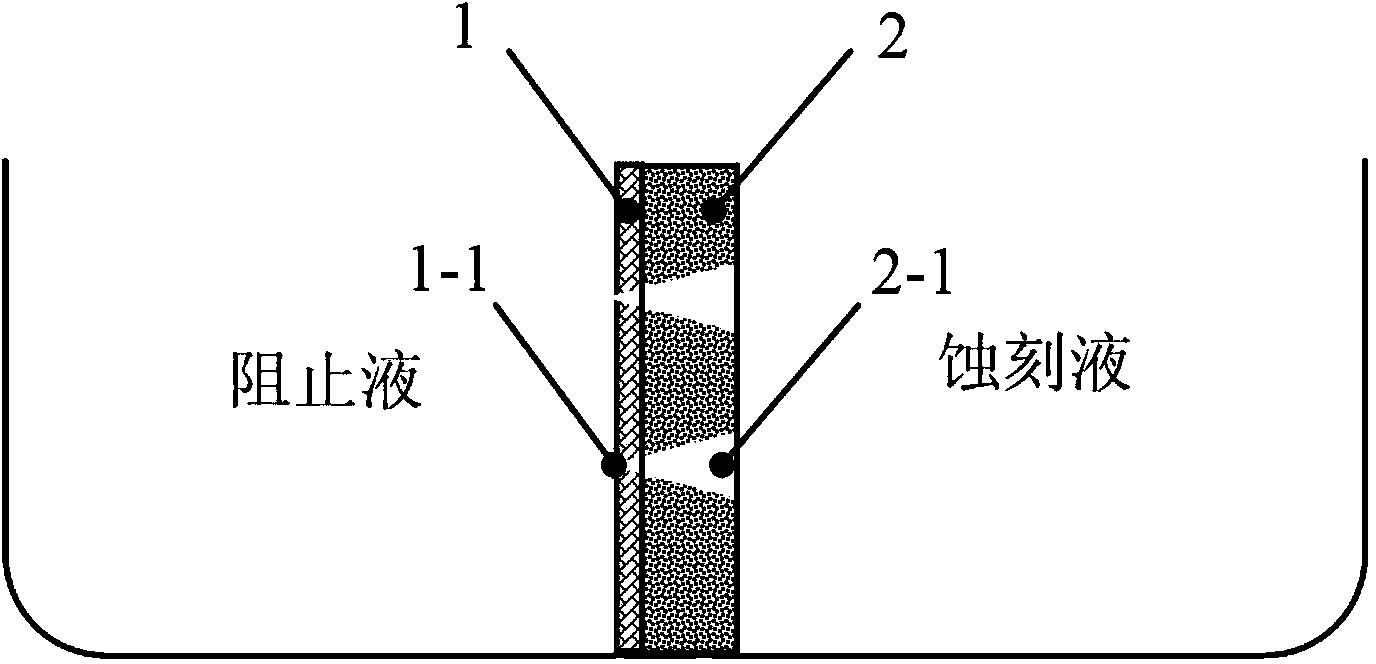

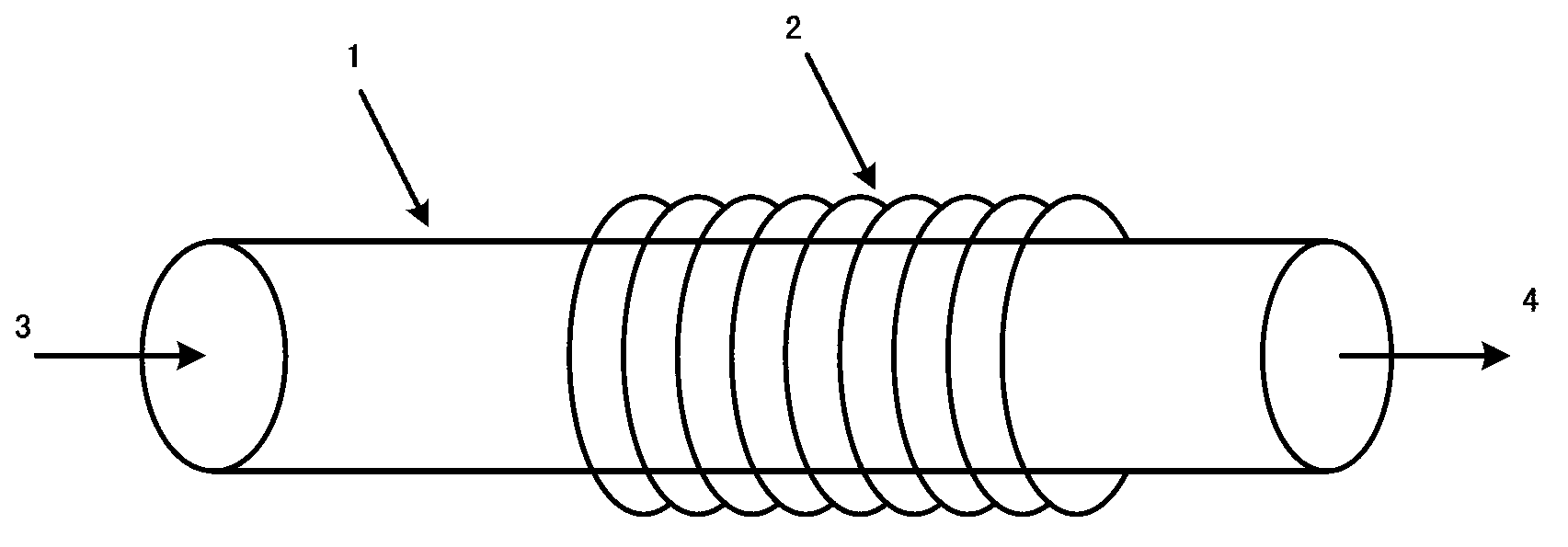

Pallet system used for plasma dry etching

InactiveCN105448776AEasy to disperseIncrease etch rateElectric discharge tubesSemiconductor/solid-state device manufacturingMetallurgyCvd graphene

The invention relates to the technical field of semiconductor processing and provides a pallet system used for plasma dry etching, which introduces a grapheme material or grapheme composite material layer to improve the surface heat dissipation capability and the temperature uniformity of a wafer. The pallet system comprises an aluminum pallet, helium hole, a sealing ring, a cover plate and the embedded grapheme material (or grapheme composite material) layer high in heat conductivity. The pallet system has the advantages and active effects that: the high-heat-conductivity grapheme material or grapheme composite material are used in the pallet system used for the r plasma dry etching, the instant heat dissipation capability of the wafer in the etching process is substantially improved, the temperature uniformity of the surface of the wafer is conveniently controlled, the qualified rate of etched products is improved, and the operation window of the etching process is enlarged.

Owner:SINO NITRIDE SEMICON

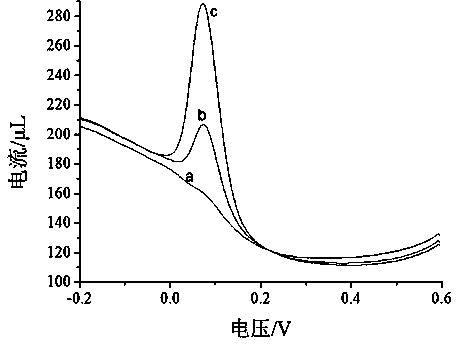

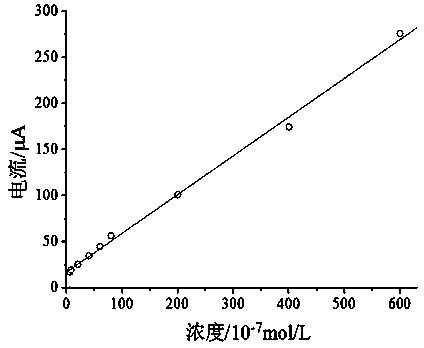

Method for detecting trace hydroquinone by using graphene/carbon nano tube modified electrode

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

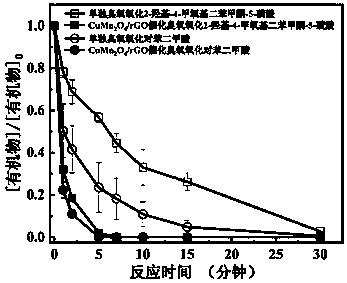

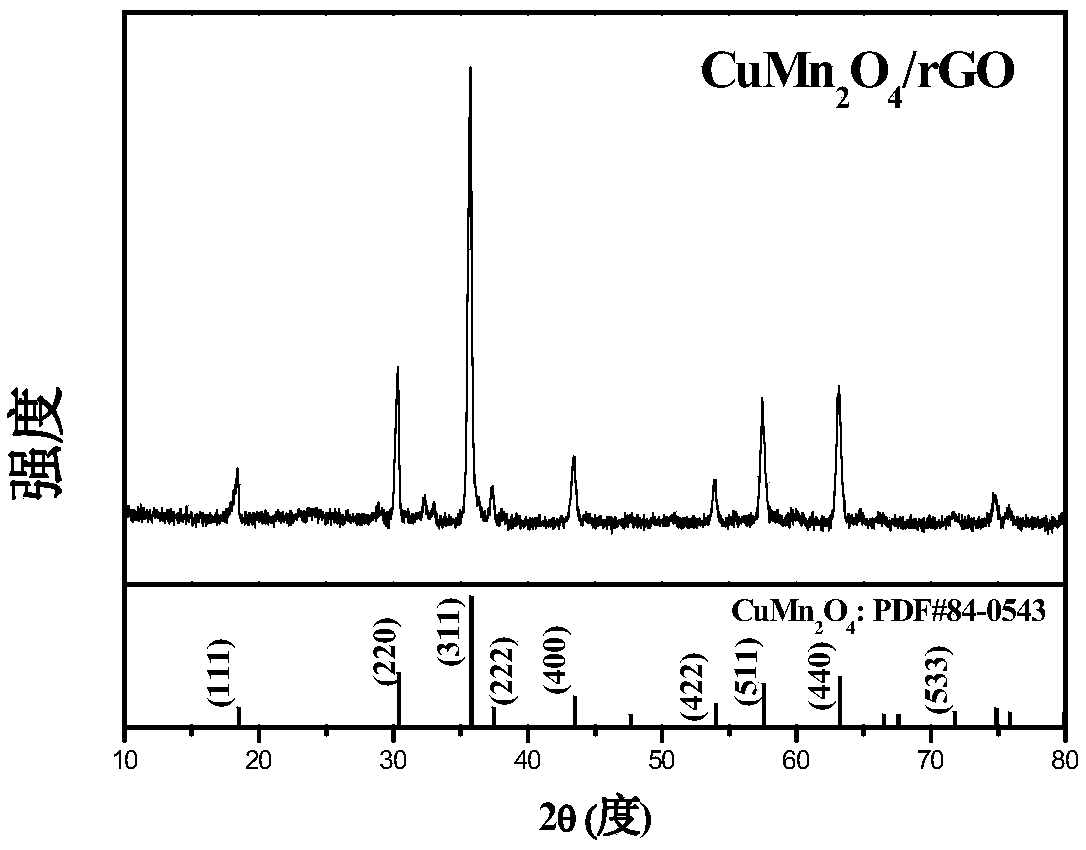

CuMn2O4/rGO composite material catalytic ozonation pollutant-removal water treatment method

ActiveCN109621974AWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsCvd grapheneSide product

Owner:BEIJING FORESTRY UNIVERSITY

Electromagnetic shielding heat dissipation film and preparation method and application thereof

InactiveCN110602934AHigh thermal conductivityImprove conductivityMagnetic/electric field screeningSynthetic resin layered productsAdhesiveCarbon nanotube

Owner:SHENZHEN XIWAN TECH CO LTD

Preparation method and application of high-efficiency graphene heat-dissipation material

The invention discloses a preparation method and application of a high-efficiency graphene heat-dissipation material. The method comprises the following steps: 1, preparing a food anti-oxidant solution; 2, preparing a colloidal solution of graphene; 3, adding neutral salt into the colloidal solution, uniformly mixing to obtain oxidized graphene neutral salt solution, wherein the neutral salt is at least one of potassium chloride, sodium chloride, potassium sulfate and sodium sulfate; and 4, adding the food antioxidant solution into the oxidized graphene neutral salt solution, heating and reducing to obtain graphene. According to the method, the graphene has high-efficiency uniform-dispersion comprehensive indexes, is capable of improving technical levels of materials, including physico-mechanical performance, heat dissipation performance, electrical performance and the like, can be used for preventing the materials from being caked, and is suitable for industrial production. Serving as a main material of heat dissipation, the high-efficiency graphene heat-dissipation material can be widely applied to LED lamps in the photoelectric industry and communication equipment, can be used for greatly improving the heat dissipation performance of LED lamps, solving the critical problem of heat dissipation of LED lamps and prolonging the service life of LED.

Owner:DONGGUAN PUWAN PHOTOELECTRIC COOLING TECH CO LTD

Vanadium pentoxide/graphene-hollow carbon sphere nano composite material and preparation method thereof

InactiveCN108123127AReduce the number of layersAvoid re-stackingMaterial nanotechnologySecondary cellsElectrical performanceCvd graphene

Owner:林荣铨

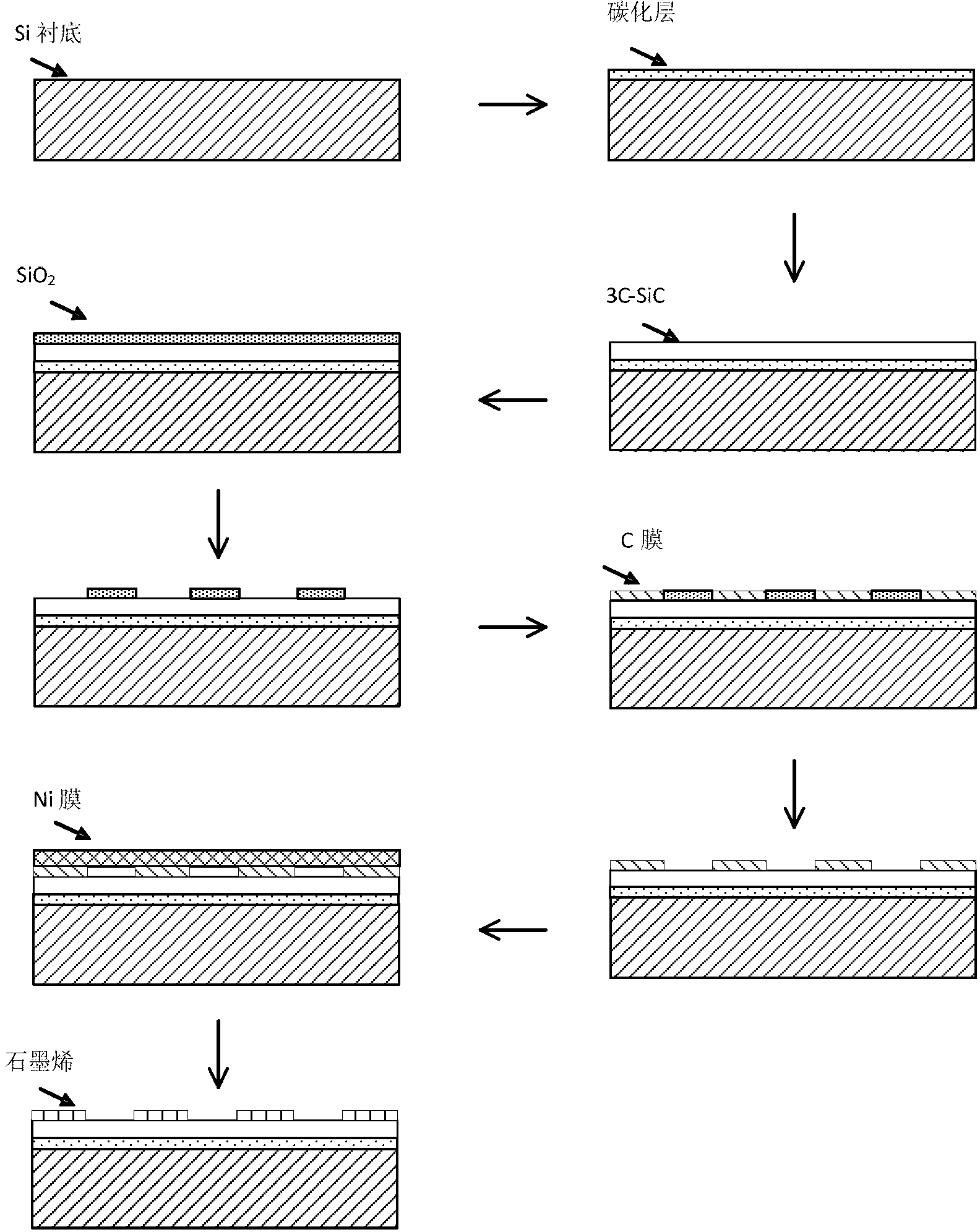

Ni film annealing patterned graphene preparation method based on 3C-SiC/chlorine gas reaction

InactiveCN102936011AEasy to refactorImprove continuityGrapheneCarbon filmState of art

Owner:XIDIAN UNIV

Resin graphene composite material, preparation method and application thereof

InactiveCN108329520AImprove conductivityImprove thermal conductivityElectroconductive/antistatic filament manufactureAnti-corrosive paintsSlurryCvd graphene

The invention provides a resin graphene composite material, a preparation method and an application thereof, which belong to the technical field of the graphene composite material. The preparation method comprises the following steps: 1) mixing a metal auxiliary agent, a graphene material and water and stirring a mixture to obtain a slurry; 2) drying the slurry to obtain metal graphene; and 3) heating the metal graphene and thermoplastic resin and heating the materials under inert gas atmosphere to the temperature of 50-300 DEG C for a reaction. The preparation method composites the graphene material and the thermoplastic resin, through a Pi bond electron cloud of the graphene material, free electron transmission is carried out, the obtained resin graphene composite material has good conductivity and thermal conductivity, and can be used as a novel electric conduction and heat conduction composite material.

Owner:BEIJING NORTH GUONENG TECH CO LTD

Method for Preparing Graphene-Containing Inorganic Coating Composition for Coating Non-Ferrous Metal Objects and Graphene-Containing Inorganic Coating Composition Prepared Thereby

ActiveUS20190055415A1Increased durabilityImprove thermal conductivityMaterial nanotechnologyLuminescent paintsSolventCvd graphene

Owner:YOON WOONG TAE +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap