Graphene-based hierarchical pore capacitor carbon and preparation method thereof as well as capacitor

A graphene and capacitive carbon technology, which is applied in graphene, hybrid capacitor electrodes, chemical instruments and methods, etc., can solve the problems of not fully exerting the effects of cellulose and graphene, and the specific capacitance value needs to be improved, so as to achieve enhanced mechanical stability. properties, improve overall strength and stability, and increase the effect of specific area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

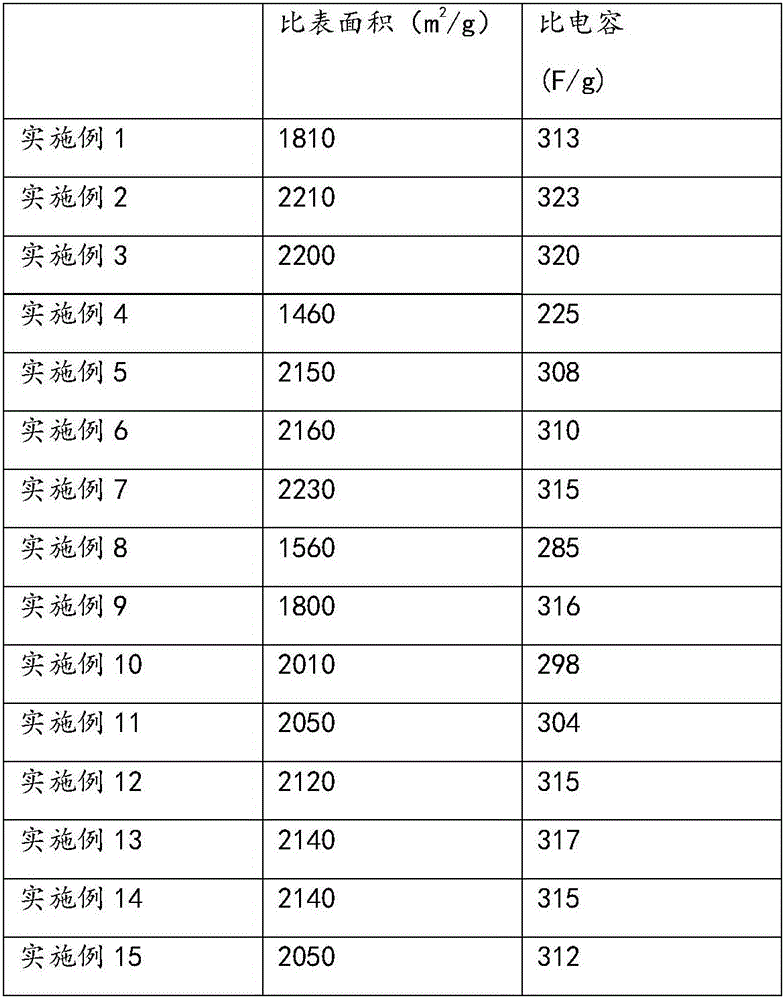

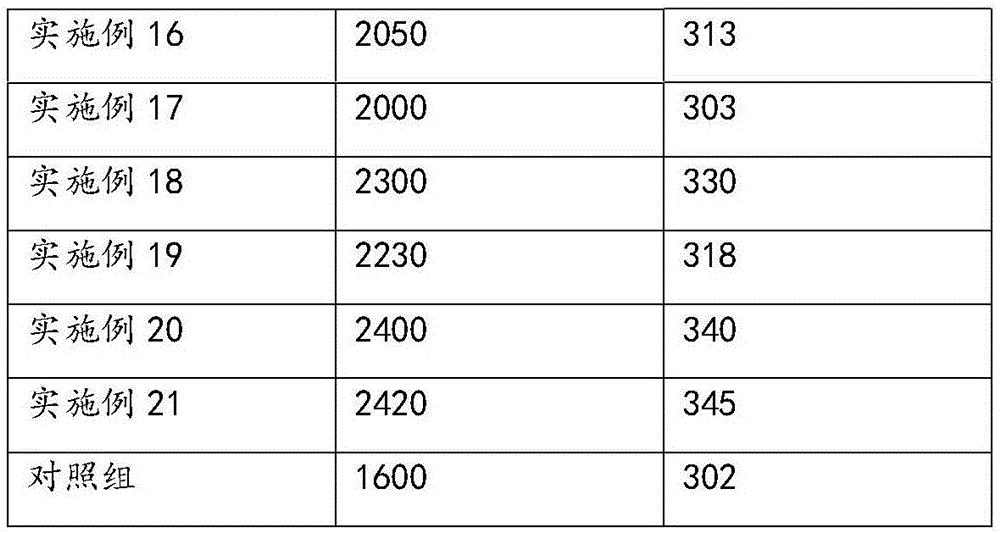

Examples

preparation example

[0045] Graphene-like substances can be prepared by the following methods, but are not limited to the following methods:

[0046] Prepare the cellulose first:

[0047] (1) After the wheat straw is pulverized and pretreated, use the organic acid solution whose total acid concentration is 80wt% formic acid and acetic acid to cook the treated wheat straw, the quality of acetic acid and formic acid in the organic acid solution of the present embodiment Ratio is 1:12, and before adding raw material, add the hydrogen peroxide (H 2 o 2 ) as a catalyst, control the reaction temperature at 120°C, react for 30min, and have a solid-liquid mass ratio of 1:10, and carry out the first solid-liquid separation of the obtained reaction solution;

[0048] (2) the solid that solid-liquid separation obtains for the first time is added the organic acid liquid that total acid concentration is 75wt% formic acid and acetic acid to carry out acid washing, wherein the organic acid solution that above-men

Embodiment 1

[0064] A preparation method of a three-dimensional graphene-based capacitor carbon with a hierarchical pore structure, comprising the steps of:

[0065] (1) 1g of graphene A is dissolved in water, and ultrasonically obtains a uniformly dispersed graphene aqueous solution;

[0066] (2) Add 25g of soluble starch, stir, and sonicate to obtain a mixed and uniform solution;

[0067] (3) Add the above mixed solution into the high-pressure polytetrafluoroethylene hydrothermal reaction kettle, set the temperature to 160°C for reaction, and gradually add 5g of hexamethylenediamine when the temperature reaches 160°C, and start stirring, and then turn off the stirring after completion, Hydrothermal reaction for 6 hours; natural cooling to room temperature, suction filtration and washing of the solid-liquid mixture in the reactor to obtain multidimensional graphene-based capacitor carbon;

[0068] (4) Mix the multi-dimensional graphene-based capacitor carbon with 80gKOH evenly, and activate

Embodiment 2

[0071] The difference from Example 1 is that the graphene-like substance is graphene oxide A.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap