Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

89 results about "Glass fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glass fiber (or glass fibre) is a material consisting of numerous extremely fine fibers of glass. Glassmakers throughout history have experimented with glass fibers, but mass manufacture of glass fiber was only made possible with the invention of finer machine tooling. In 1893, Edward Drummond Libbey exhibited a dress at the World's Columbian Exposition incorporating glass fibers with the diameter and texture of silk fibers. Glass fibers can also occur naturally, as Pele's hair.

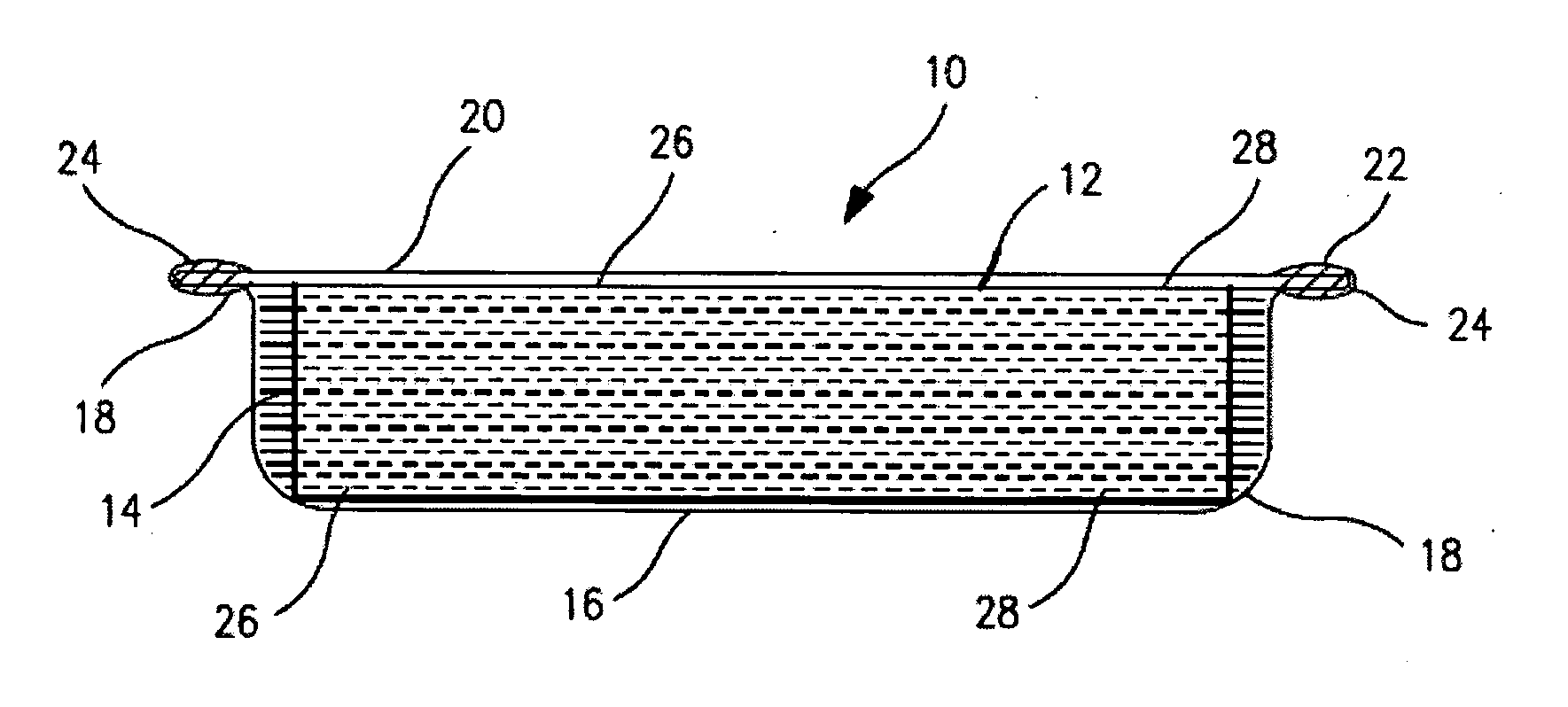

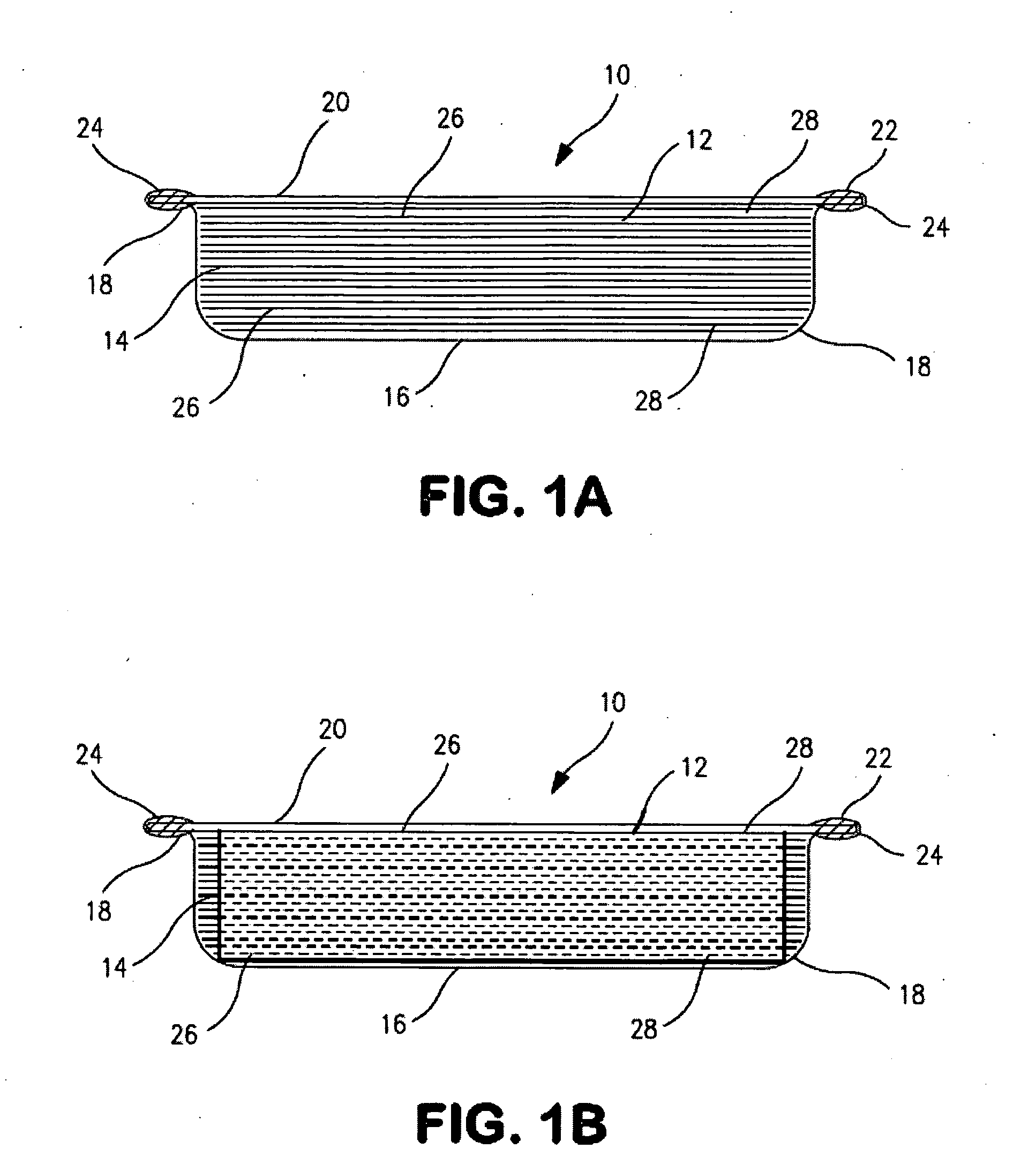

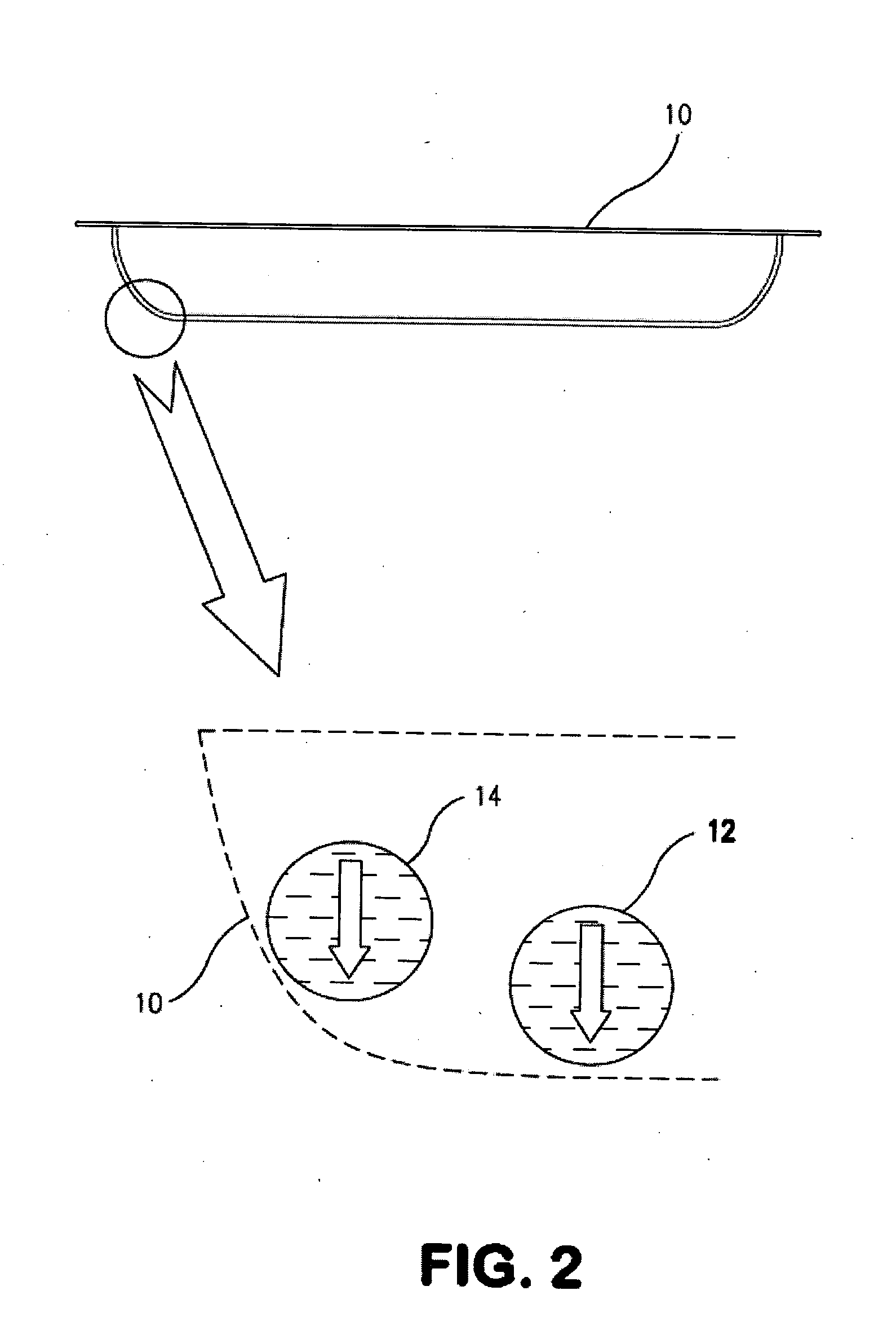

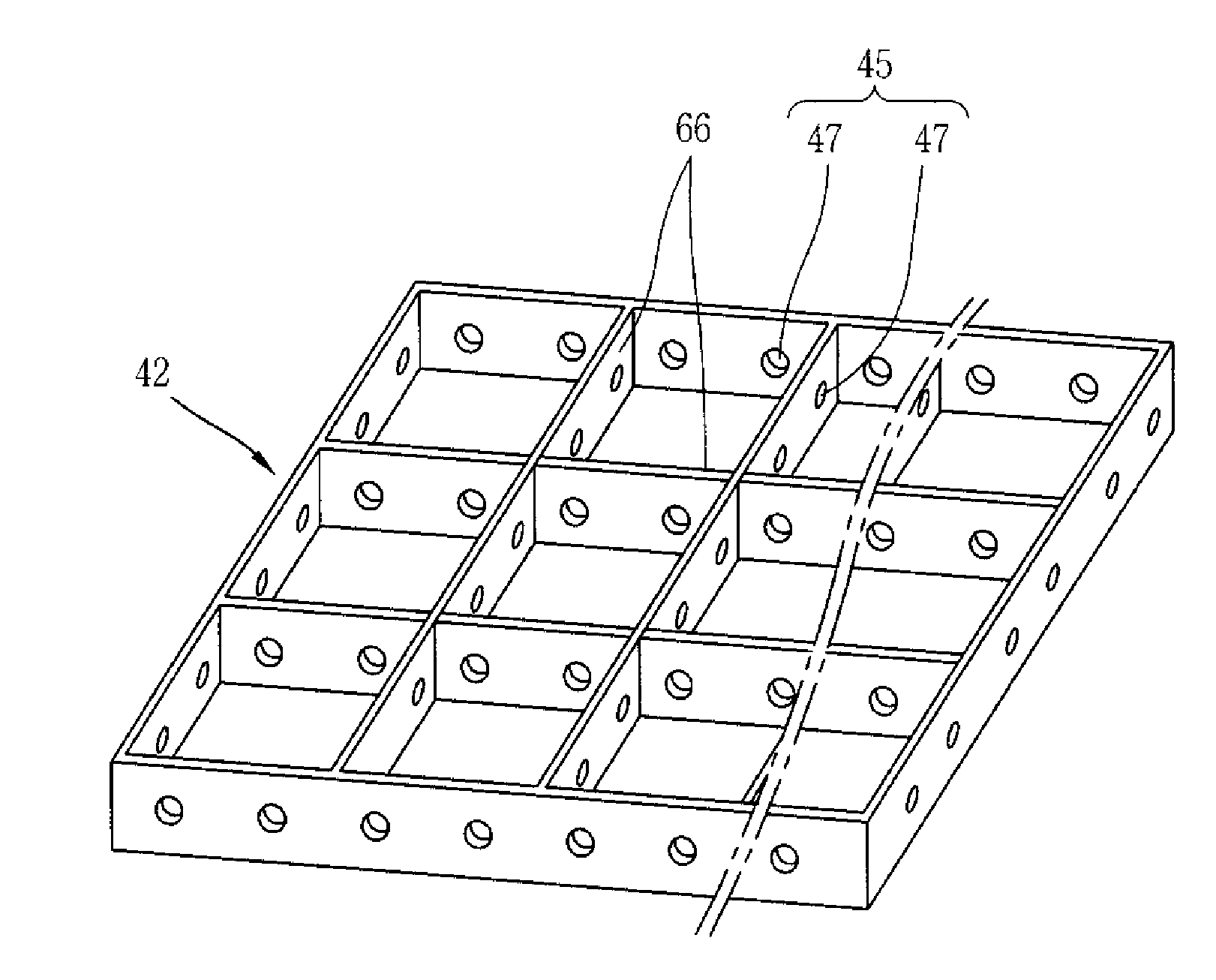

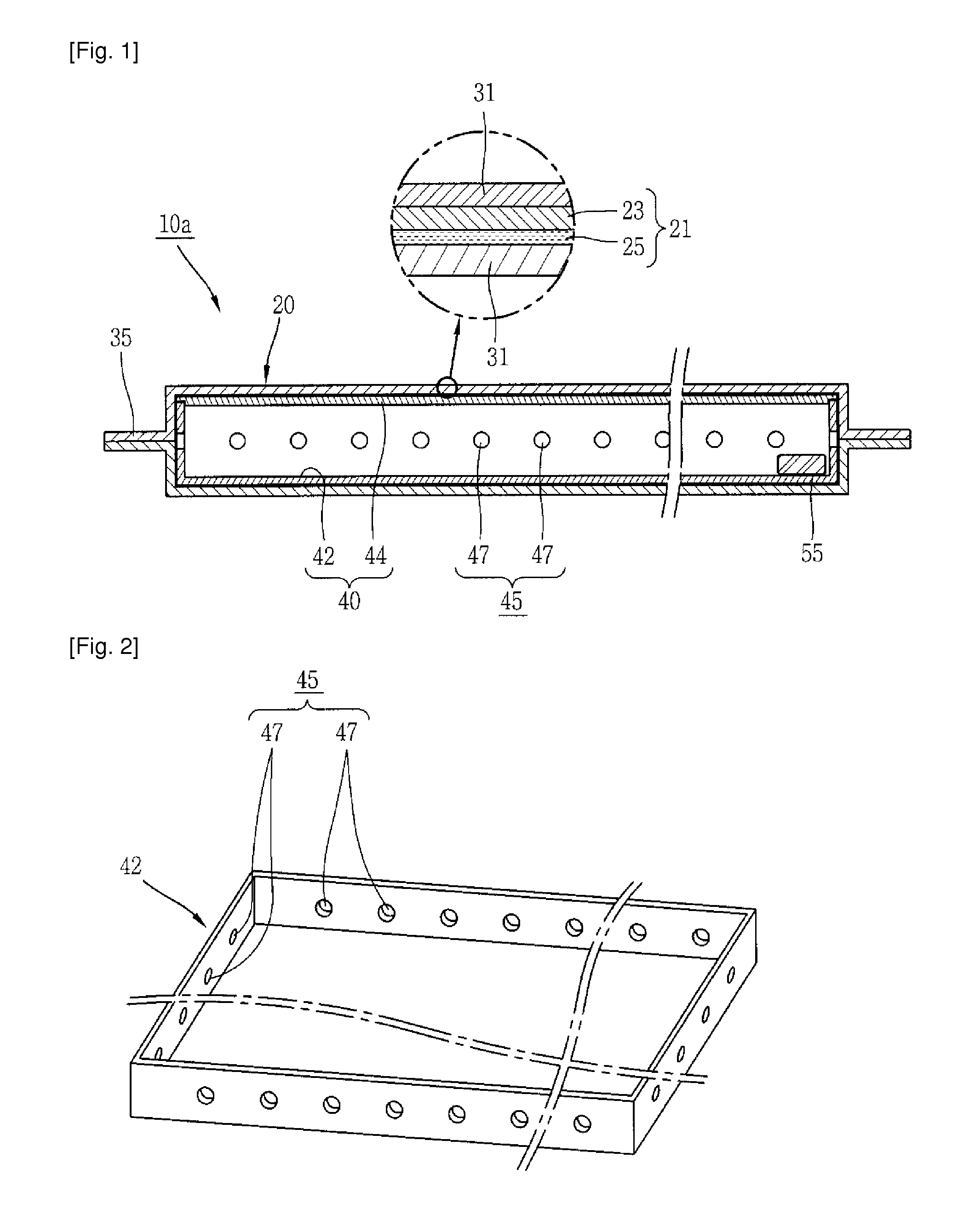

Vacuum Insulation Panel, Insulated Masonry Structure Comprising Same, And Method Of Construction

InactiveUS20120009376A1Easy to controlLevel of vacuum can be reducedClimate change adaptationInsulation improvementGlass fiberFilling materials

Owner:RUSEK JR STANLEY J

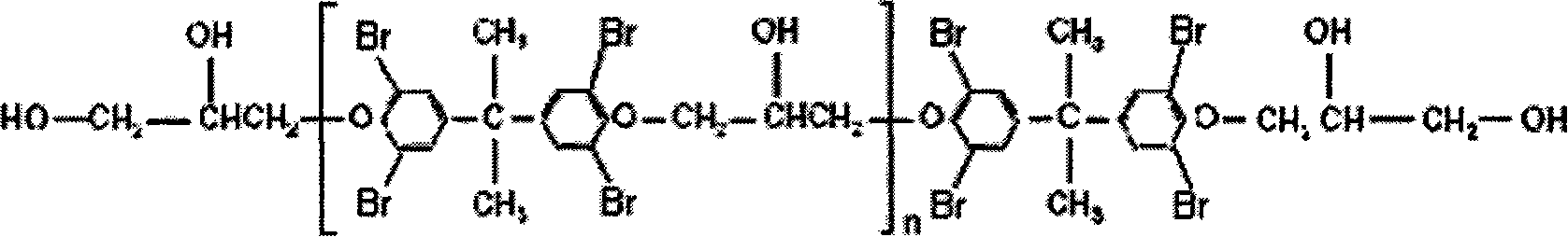

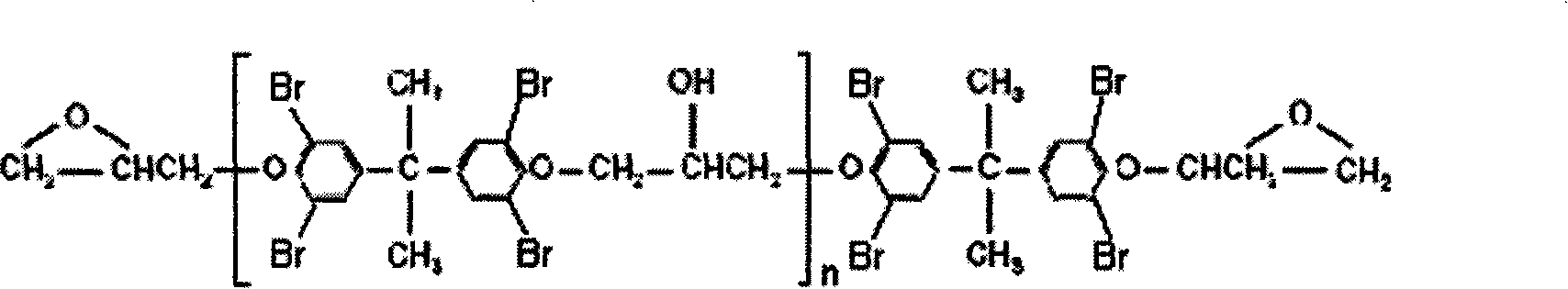

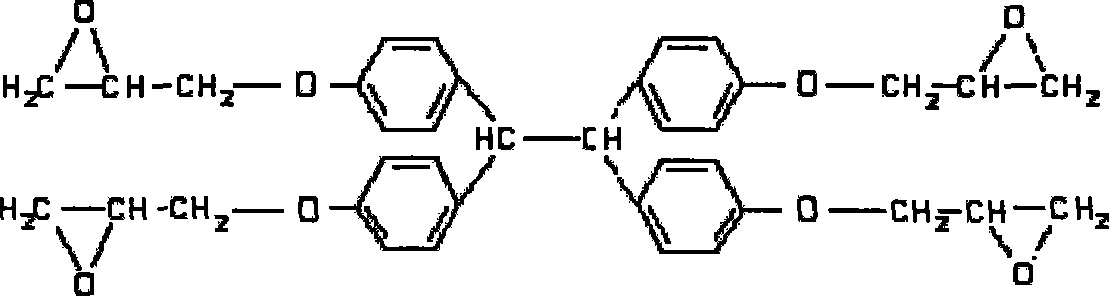

Resin composition and semi-solidifying sheet for printed board prepared from the same

Owner:GUANGDONG SHENGYI SCI TECH

Vacuum insulation member, refrigerator having vacuum insulation member, and method for fabricating vacuum insulation member

ActiveUS20120125039A1Easy to manufactureReduce manufacturing costLamination ancillary operationsThermal insulationGlass fiberEngineering

Owner:LG ELECTRONICS INC

Long-fiber enhanced thermoplastic composite material vane used for wind energy generator

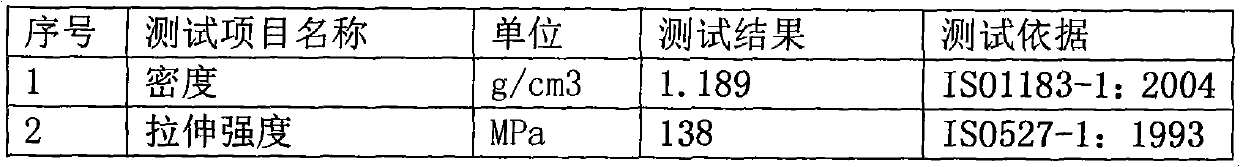

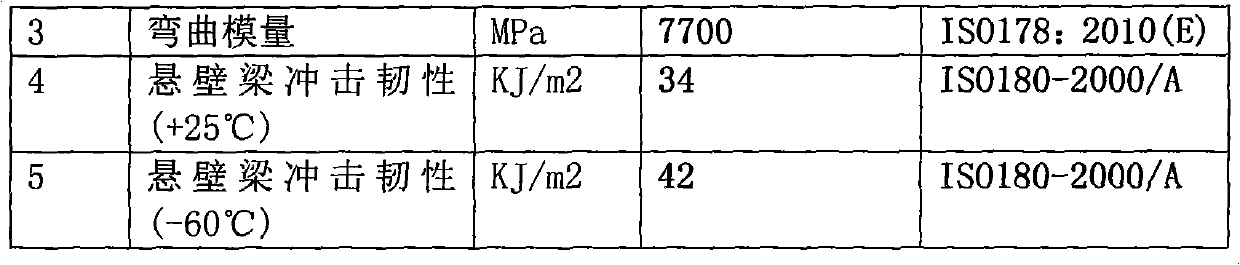

InactiveCN102675740ALow shrinkageLow temperature impact resistanceFinal product manufactureMachines/enginesGlass fiberPhoto aging

Owner:BEIJING NASHENGTONG ADVANCED MATERIAL & TECH CO LTD

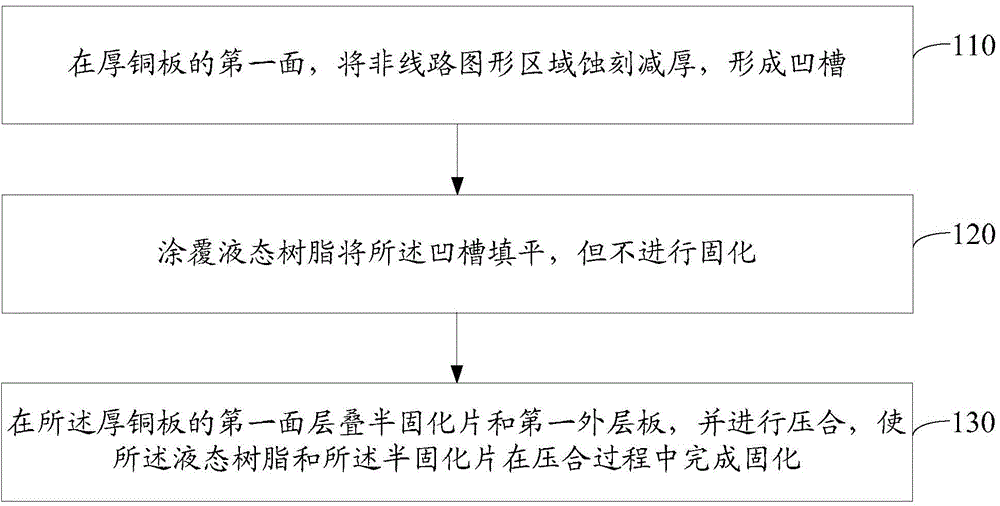

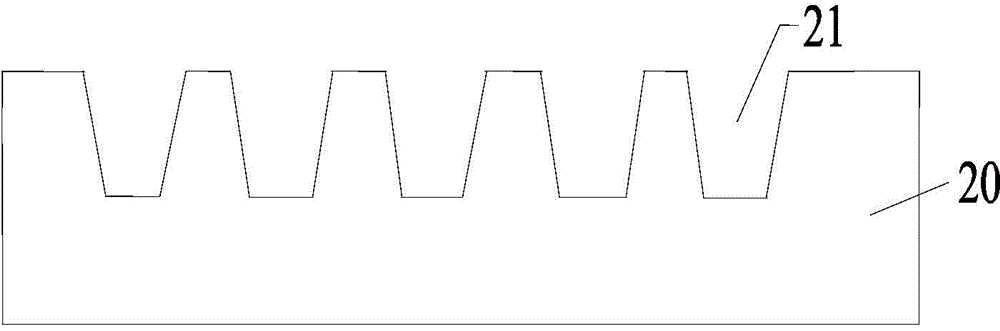

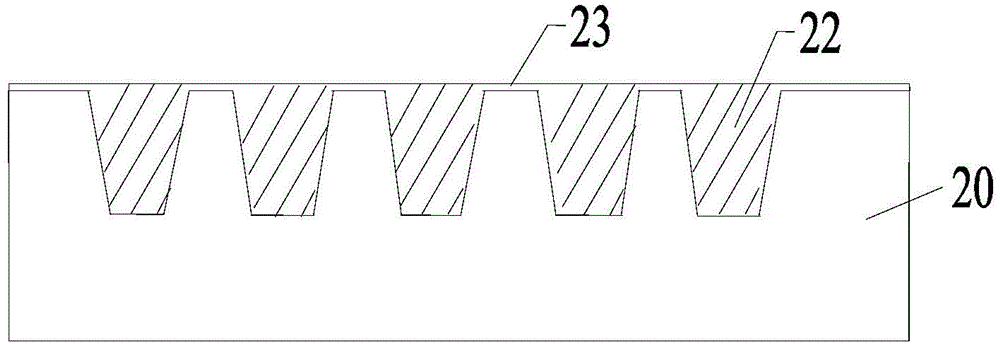

Thick copper circuit board processing method

ActiveCN104918419AImprove bindingAvoid explosionInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentGlass fiberInter layer

Owner:SHENNAN CIRCUITS

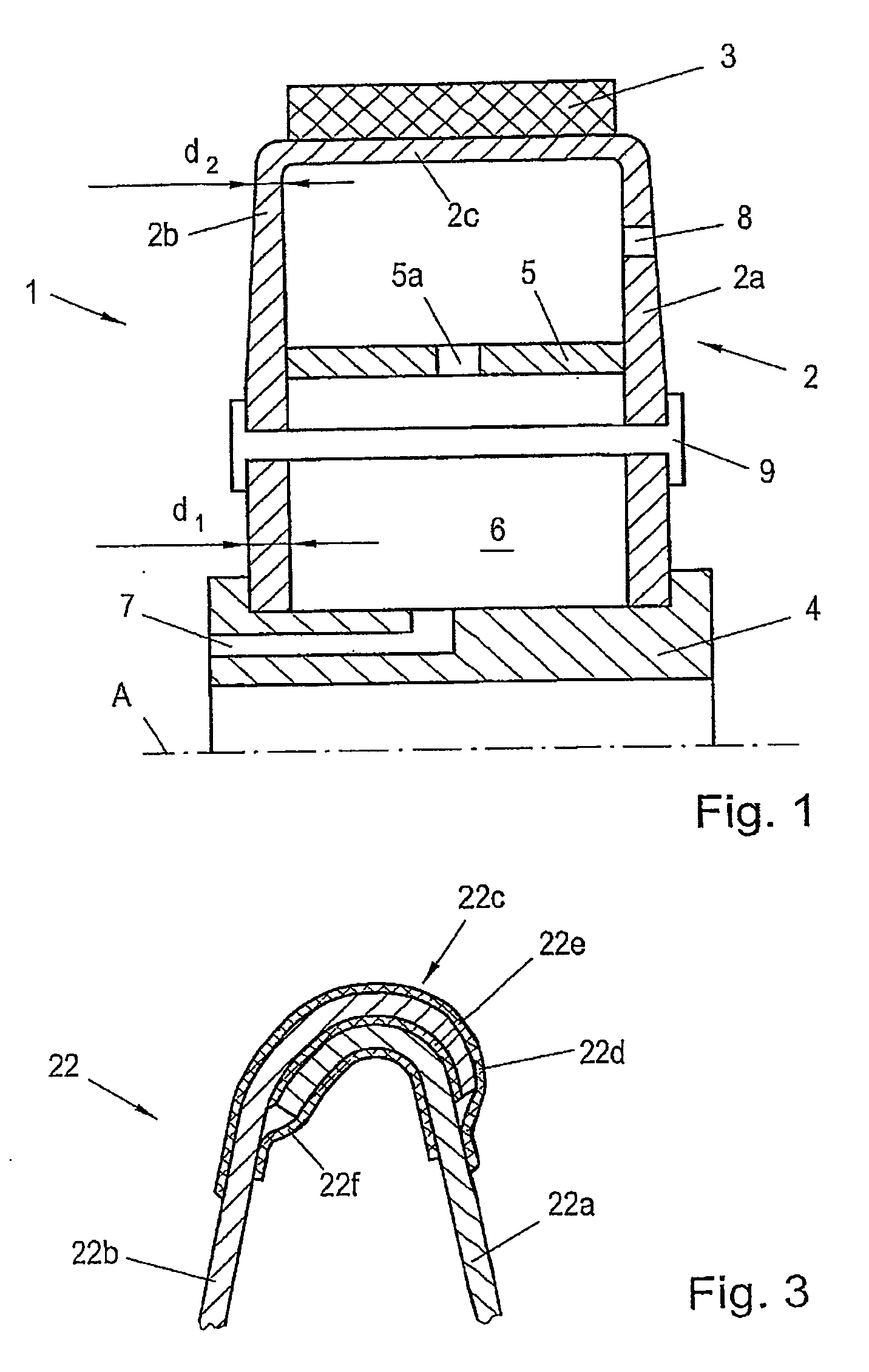

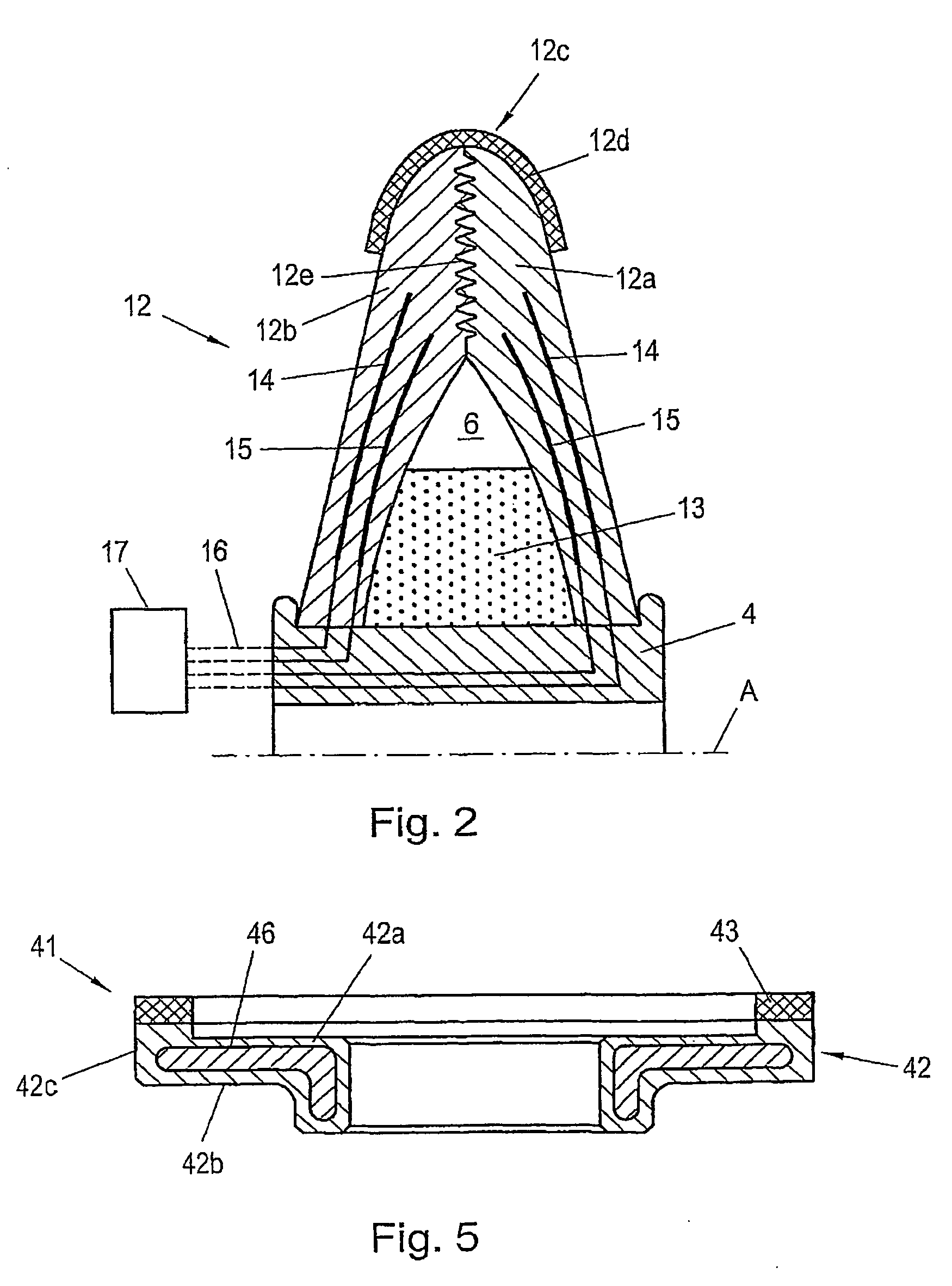

Base for a Rotating Grinding or Cutting Tool, and Grinding or Cutting Tool Produced Therefrom

ActiveUS20100022169A1Revolution surface grinding machinesOther chemical processesGlass fiberCarbon fibers

Owner:ASEN NORBERT

High-temperature iron-based zeolite molecular sieve honeycomb type denitration catalyst and preparation method thereof

ActiveCN107519926AEvenly dispersedSimple preparation processMolecular sieve catalystsDispersed particle separationFerrous saltsStearic acid

Owner:VALIANT CO LTD

Reinforced polyethylene glycol terephthalate-modified material and preparation method thereof

InactiveCN101875759AImprove low temperature resistanceImprove creep resistanceGlass fiberThermoplastic

The invention discloses a reinforced polyethylene glycol terephthalate-modified material and a preparation method thereof. The reinforced polyethylene glycol terephthalate-modified material comprises the following components in part by weight: 100 parts of polyethylene glycol terephthalate, 30 to 50 parts of glass fibers, 6 to 10 parts of flexibilizer, 0.5 to 1 part of antioxygen, 3 to 6 parts of compound nucleating agent and 10 to 15 parts of elastomer SEBS. The reinforced polyethylene glycol terephthalate-modified material has high low temperature resistance and creep resistance and can be used in place of the conventional thermoplastic ethylene-propylene diene methylene dynamically vulcanized elastomer to make frame seals and other parts and reduce use cost of the materials. A new application field of the modifying polyethylene glycol terephthalate is opened, the conventional thermoplastic ethylene-propylene diene methylene dynamically vulcanized elastomer can be replaced by the material, and the use cost of the material is reduced greatly.

Owner:SHENZHEN KEJU NEW MATERIAL

High-toughness high temperature-resistant modified PVC pipe

InactiveCN105440481AImprove toughnessImprove high temperature resistanceAcrylonitrileMaterials science

The invention discloses a high-toughness high temperature-resistant modified PVC pipe. The high-toughness high temperature-resistant modified PVC pipe comprises the following raw materials by weight: 80 to 120 parts of PVC resin, 30 to 60 parts of chlorinated polyethylene, 40 to 80 parts of liquid butadiene-acrylonitrile rubber, 10 to 30 parts of polyurethane elastomer, 2 to 8 parts of modified nanometer calcium carbonate, 1 to 5 parts of kaolin, 2 to 6 parts of fly ash, 4 to 8 parts of glass beads, 4 to 8 parts of glass fiber, 1 to 6 parts of titanium dioxide, 3 to 9 parts of PE wax, 2 to 5 parts of methyl methacrylate, 4 to 8 parts of acrylate, 1 to 5 parts of a heatproof modifier and 2 to 6 parts of a coupling agent. The PVC pipe provided by the invention has excellent toughness and high temperature resistance.

Owner:NINGGUO CITY GAOXIN PIPE CO LTD

Wind resistant concrete roof component and system and method for forming same

A roof system includes a roof panel formed of concrete and an architectural surface such as a corrugated surface. A first layer of reinforcing material is disposed along and spaced inwardly from a first surface of the roof panel, and an optional second layer of reinforcing material is disposed along and spaced inwardly from a second surface of the roof panel. The first layer of reinforcing material is spaced from the second layer of reinforcing material. The reinforcing material may be formed of fiber-reinforced polymer mesh, made with carbon fibers or glass fibers. FRP rebar may be used in conjunction with FRP mesh to provide added structural strength. The roof panel may include one or more elongated ribs having a thickness greater than adjacent portions of the roof panel. In other aspects, concrete structures with reinforcing material may be used for either roof panels or wall applications.

Owner:FLORIDA INTERNATIONAL UNIVERSITY

Photo-catalytic oxidation water treatment device based on solar fixed film double-layer thin plate

InactiveCN102180553ASimple structureIncrease reaction rateWater/sewage treatment by irradiationGeneral water supply conservationHigh concentrationPhotocatalytic reaction

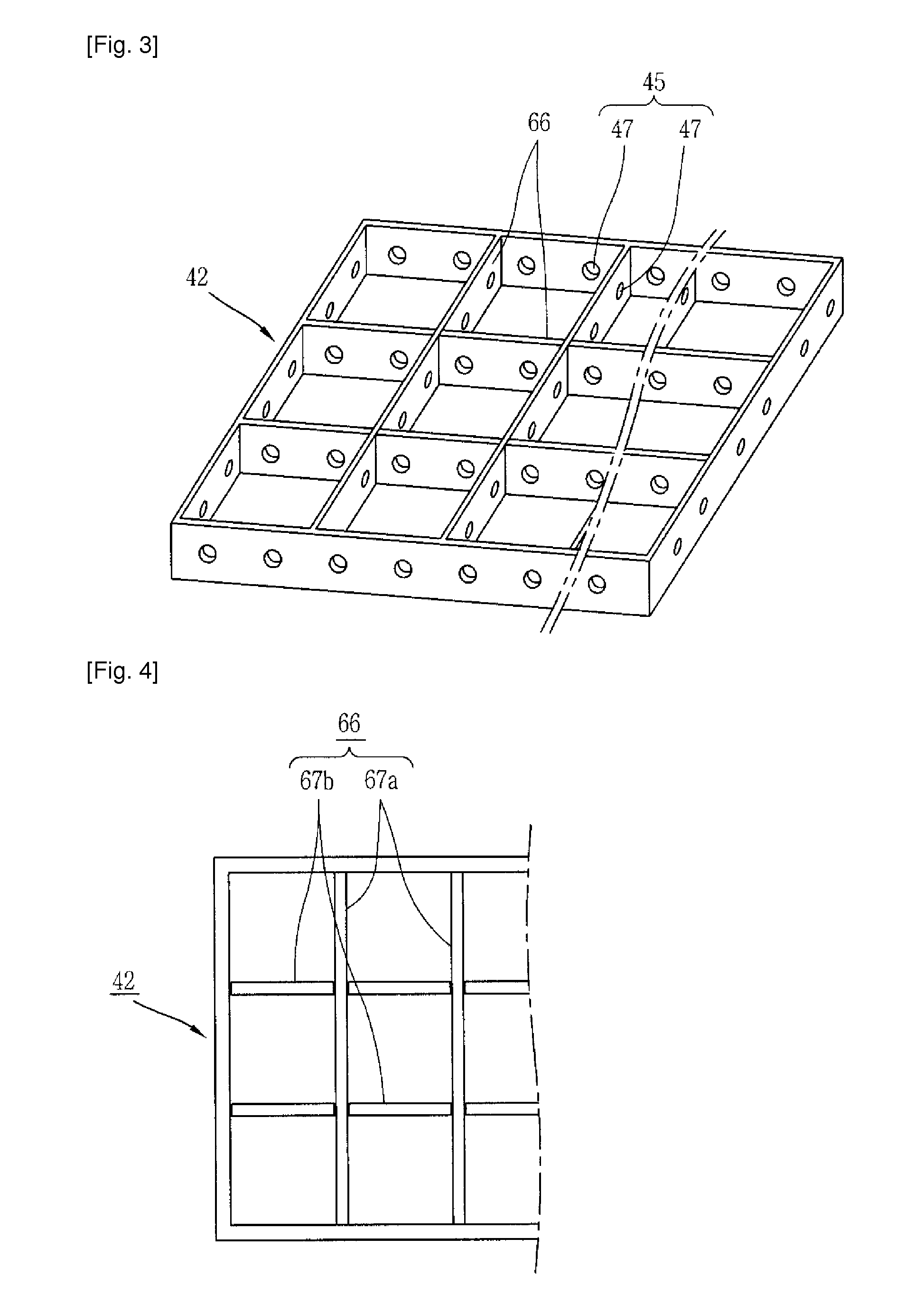

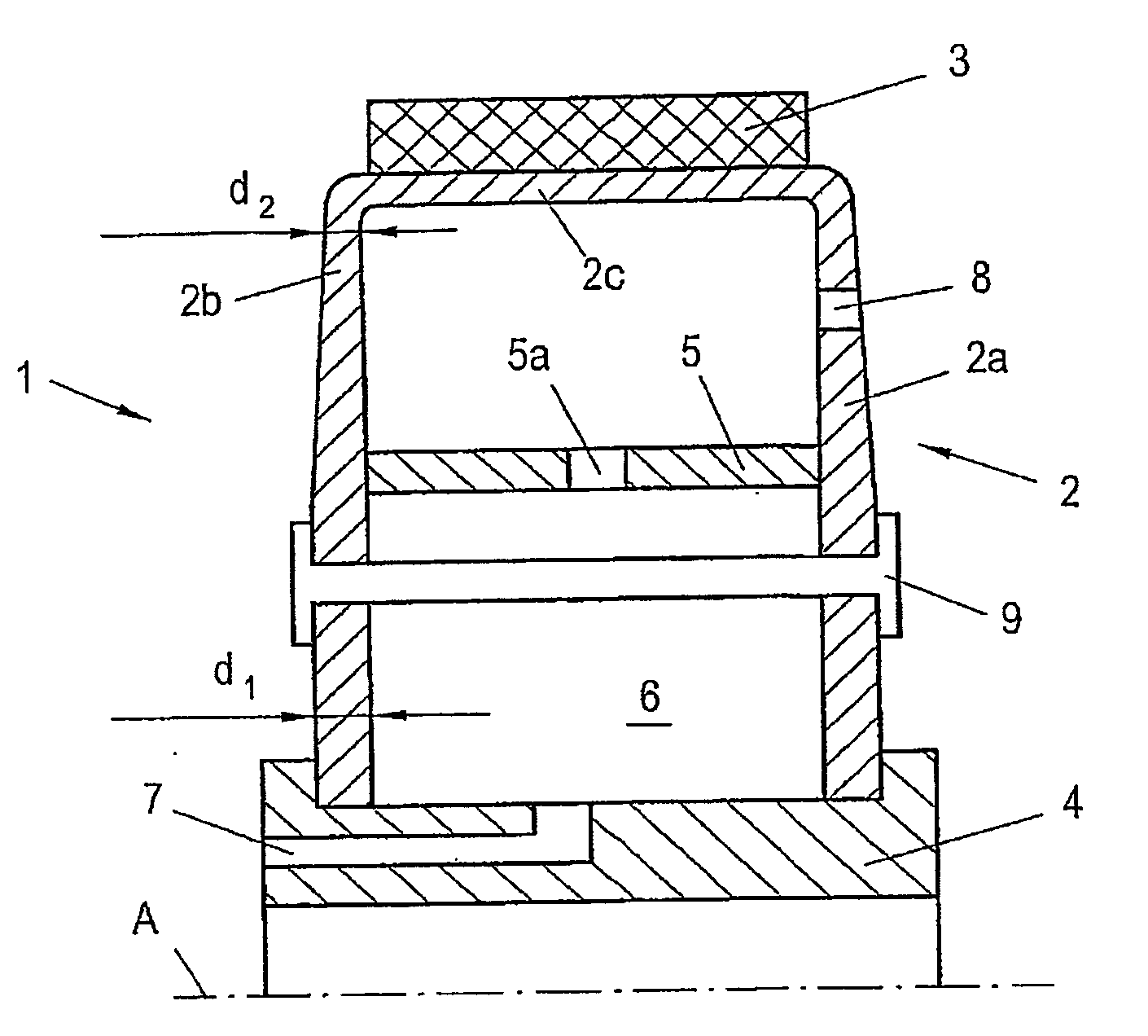

The invention provides a photo-catalytic oxidation water treatment device based on a solar fixed film. The device consists of a clear water storage box (1), a to-be-treated water storage box (2), a pretreater (3), a pump (4), a flowmeter (5) and a photo-catalytic reactor (6), wherein a photo-catalytic reactor main body is a box with a top cover through which ultraviolet light can penetrate; the inside of the photo-catalytic reactor is divided into multiple galleries (7) which are connected mutually; 2-5 layers of fixed film catalysts (8) are filled on the side wall and bottom flat of each gallery (7); the catalyst (8) is supported by a special stainless steel net skeleton (22) or long column type skeleton (23); and the catalyst film utilizes a partial euphotic glass fiber net as a carrier on which a permanent TiO2 film is supported. The device has the advantages of simple structure, large treatment amount, high reaction speed and low operation cost, is convenient for manipulation and stable to operate, and can be widely applied to deep treatment of drinking water and preparation of high-pure water or treatment of toxic, harmful, high-concentration and low-degradable inorganic waste water.

Owner:NANJING FORESTRY UNIV

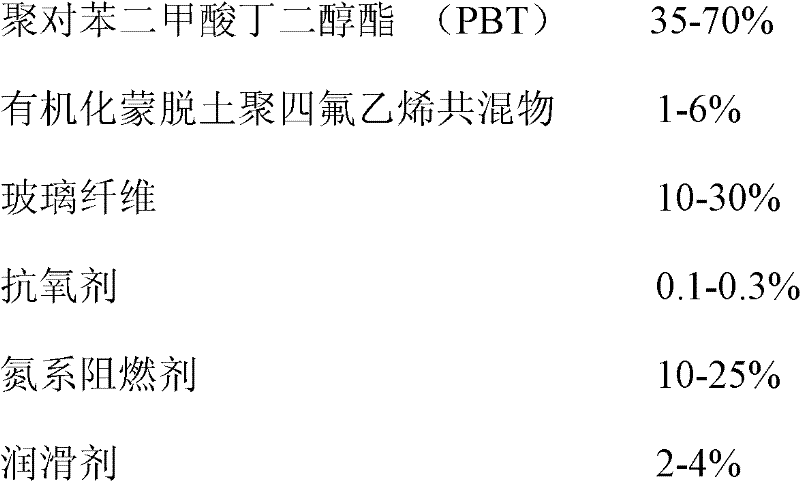

Halogen-free flame-retardant polybutylene terephthalate PBT (polybutylece terephthalate) composite material and preparation method thereof

ActiveCN102391624APhenomenon that limits floating fibersExcellent surface finishPolytetramethylene terephthalateAlkali free

Owner:LONGJAR SHANGHAI IND

Testing method for wettability of glass fiber cloth

Owner:SHENGYI TECH SUZHOU

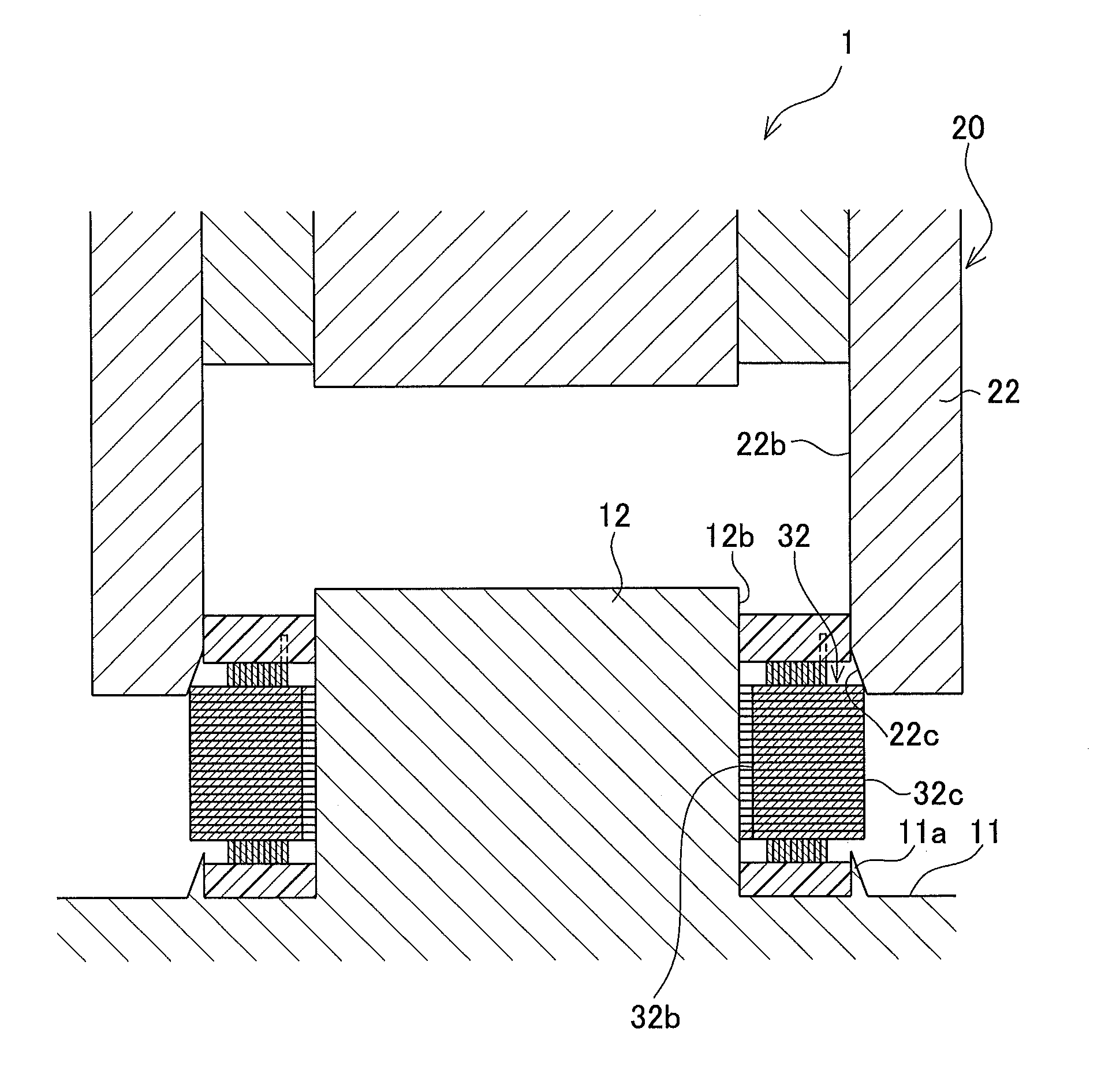

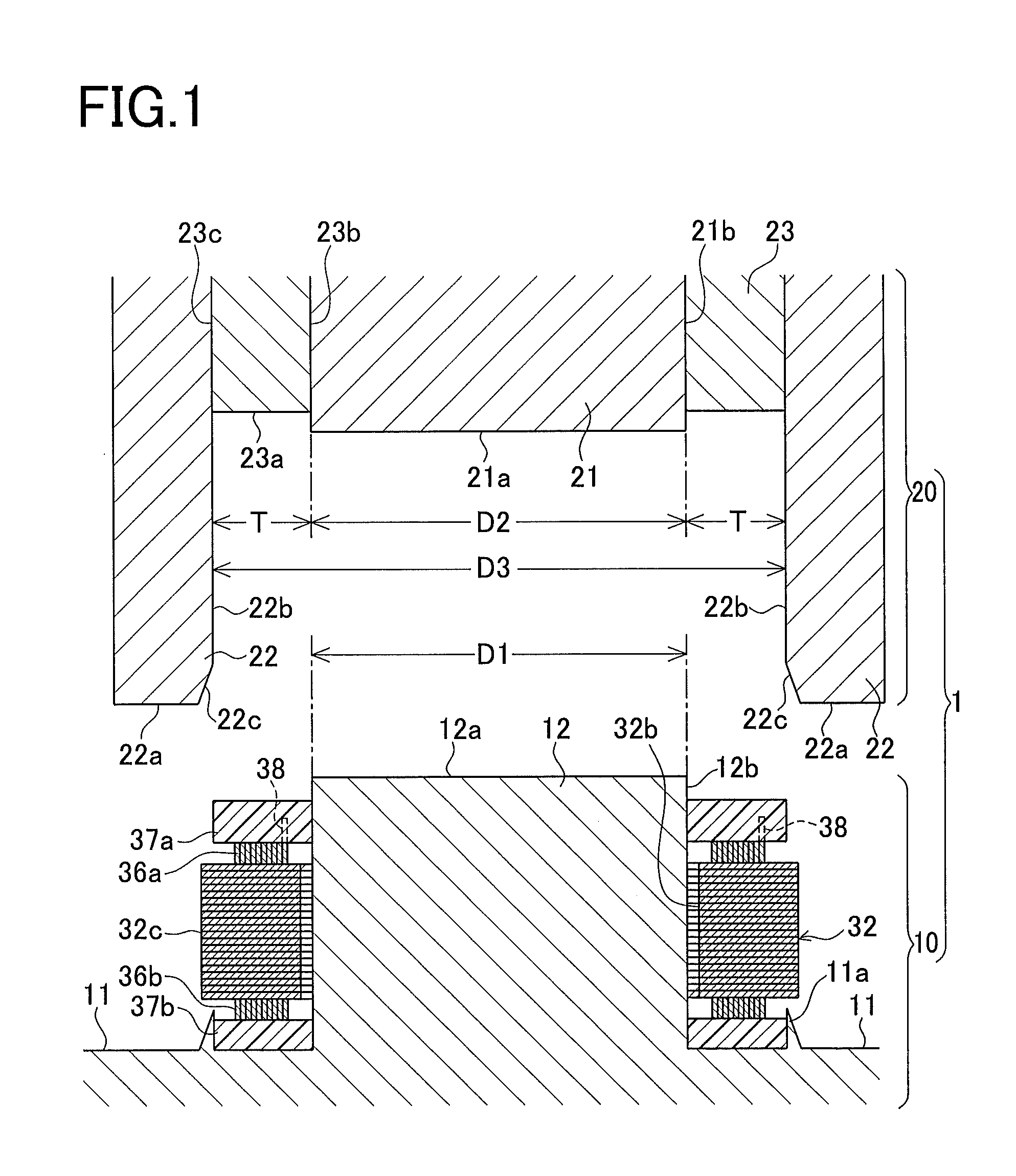

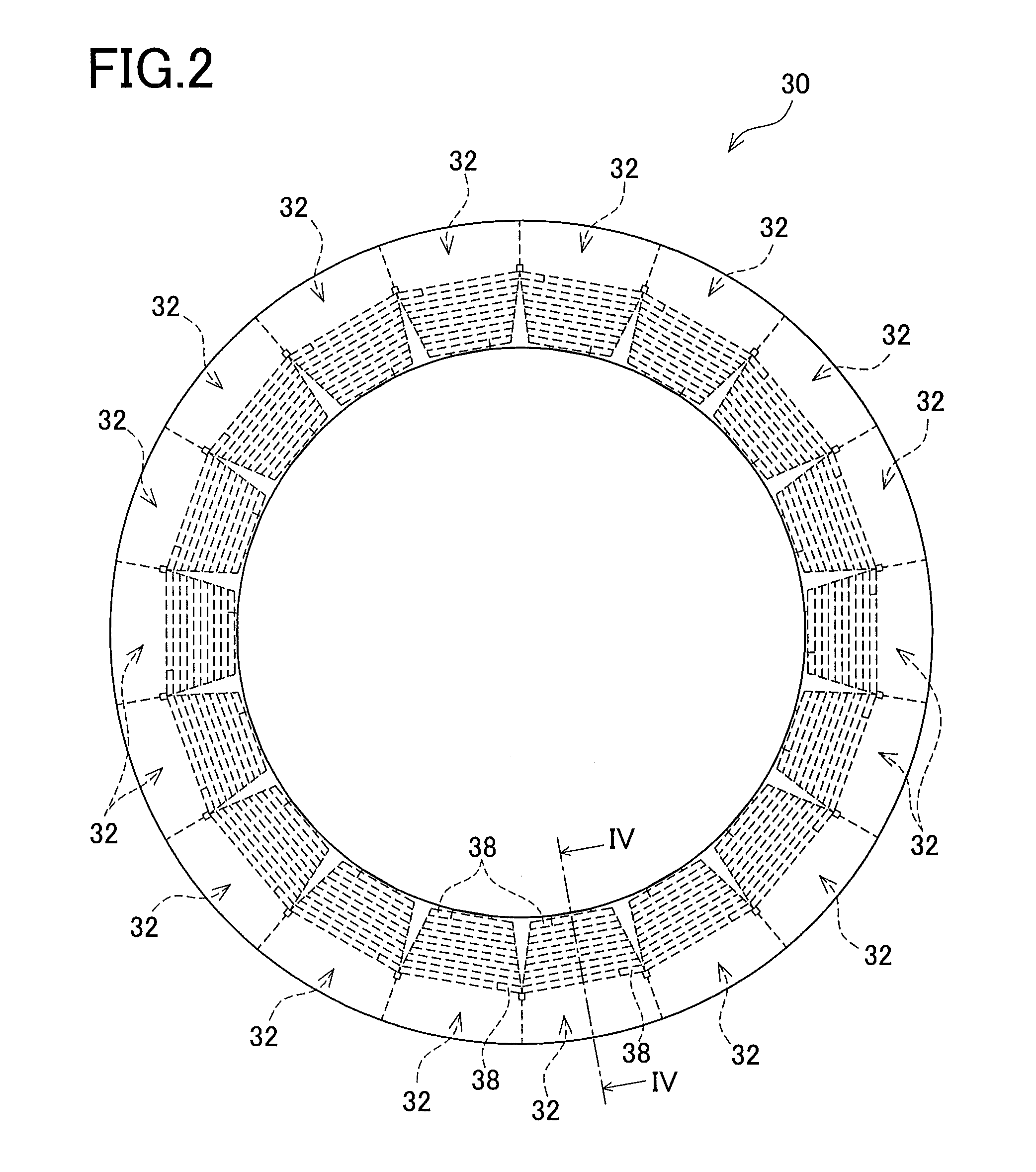

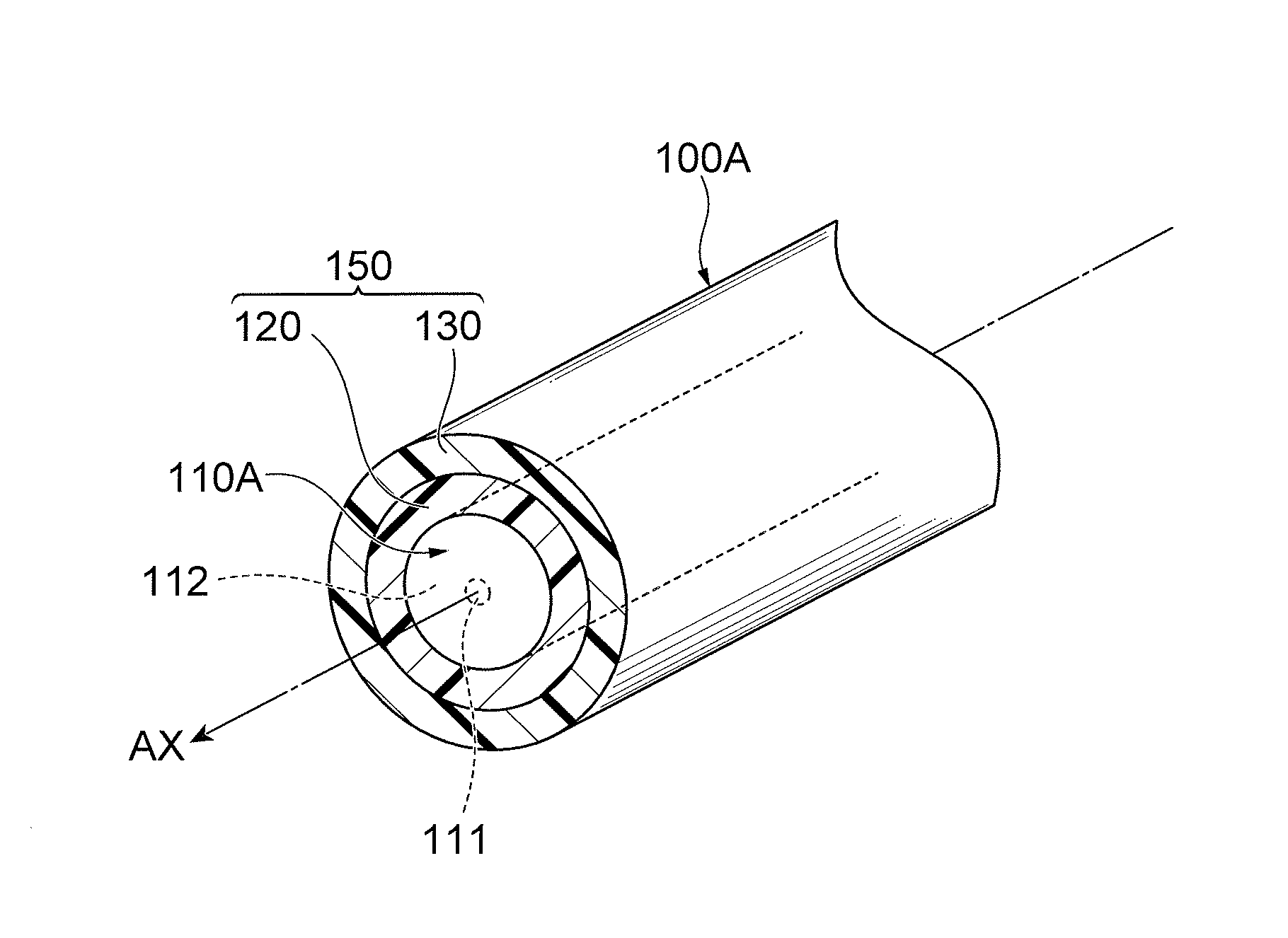

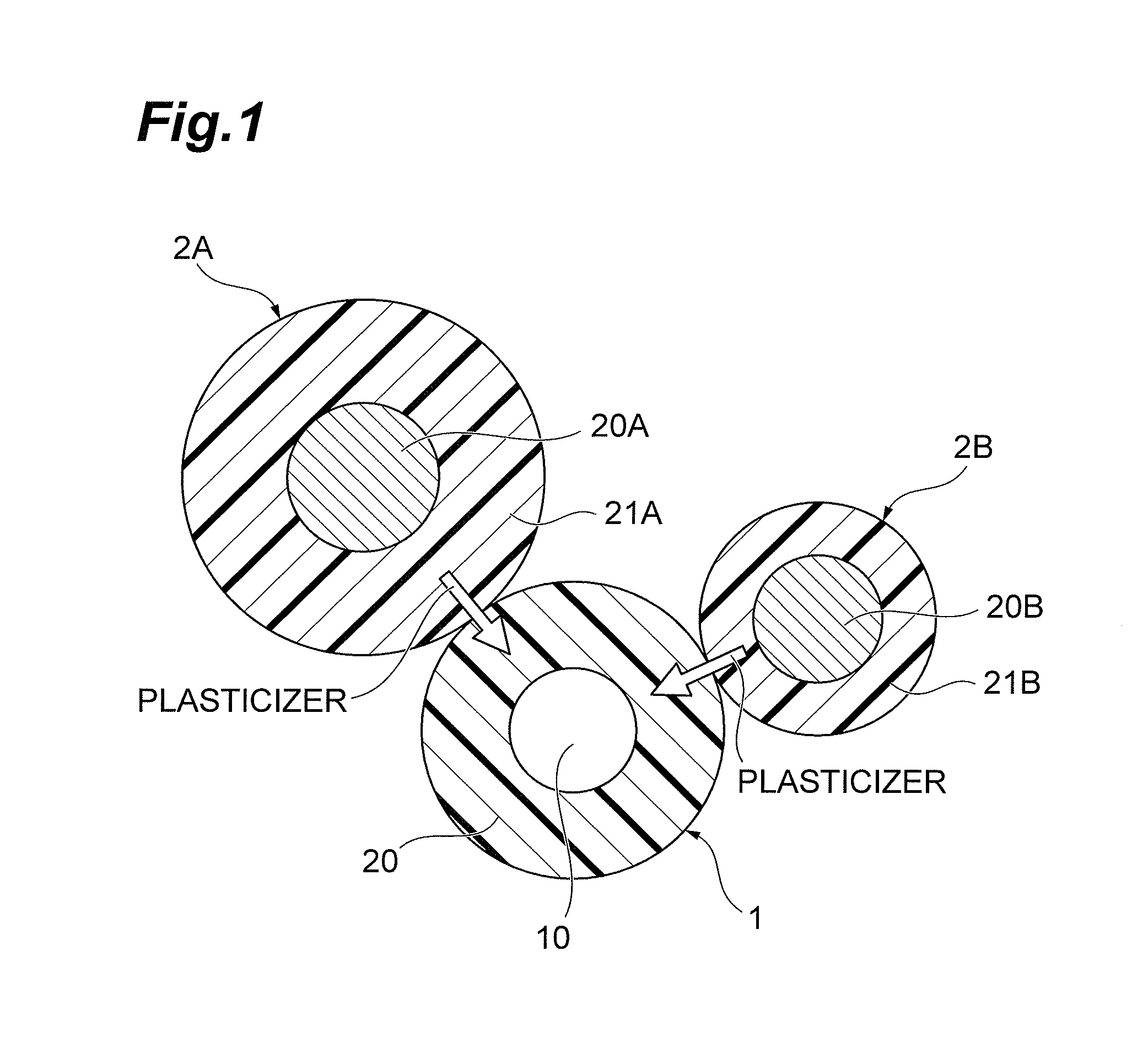

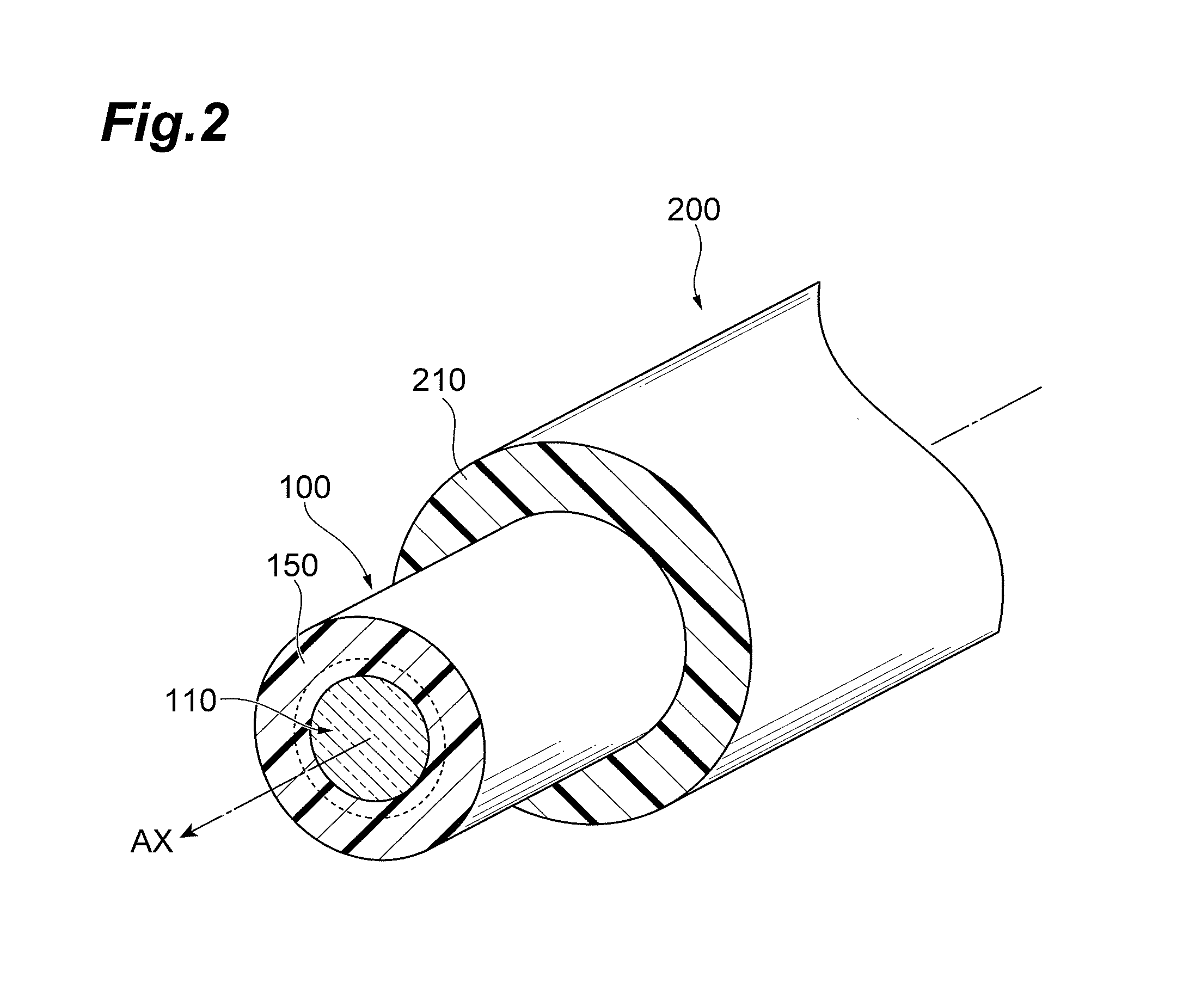

Stator manufacturing method and stator

Owner:TOYOTA JIDOSHA KK

Soccer box

A portable, lightweight soccer rebounding wall with good rebound characteristics, whereby the pace of the rebounding soccer ball is similar to that of the pace at which it was imparted against the wall. The system is easily assembled and disassembled and is sufficiently light to be carried by one person for several hundred yards. In a specific implementation, the rebounding wall includes a panel of pultruded, fiberglass cross bar grating.

Owner:ZUCCA MATTHEW +1

Method for preparing insulator

Owner:STATE GRID CORP OF CHINA +1

Hollow articles comprising fiber-filled polyester compositions, methods of manufacture, and uses thereof

Owner:SABIC GLOBAL TECH BV

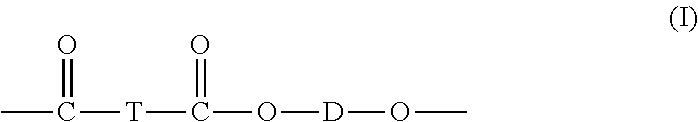

Optical fiber and optical cable

ActiveUS8923674B1Easy to crackInhibit migrationGlass optical fibreOptical fibre with multilayer core/claddingGlass fiberUV curing

Owner:SUMITOMO ELECTRIC IND LTD

Automobile roof sunroof reinforcement frame and hot die stamping forming process thereof

PendingCN110421940AGood dimensional stabilityIn line with the trend of lightweight developmentSynthetic resin layered productsLaminationGlass fiberAutomotive industry

The invention discloses an automobile roof sunroof reinforcement frame and a hot die stamping forming process thereof. The automobile roof sunroof reinforcement frame includes a base material; and thebase material at least includes a layer of core material made of a high-molecular polymer material having a hole-opening structure, the core material preferably selects a PU material, an upper reinforcement layer and a lower reinforcement layer is bonded on both sides of the base material, the surface of the upper reinforcement layer is bonded with a scarfskin layer, the bottom surface of the lower reinforcement layer is bonded with a bottom cloth layer, the upper reinforcement layer and the lower reinforcement layer are made of at least one layer of fiber glass filaments or glass fiber felt,and the automobile roof sunroof reinforcement frame adopts the hot die stamping forming process. Raw materials of the automobile roof sunroof reinforcement frame are made of the PU material and glassfiber, the automobile roof sunroof reinforcement frame is light in weight, enables the production cost to be greatly reduced, saves energy and is environmentally friendly, and conforms to the trend of light-weight development of an automobile industry; and at the same time, the hot die stamping forming process is adopted, steps of the process are simple, operation is convenient, and while the dimensional stability of the sunroof reinforcement frame is improved, and the production efficiency is also greatly improved.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

Impact-resistant composite insulating material and preparing method thereof

The invention discloses an impact-resistant composite insulating material and a preparing method thereof. The insulating material is prepared from 4-10 parts of polyimide resin, 3-6 parts of glass fibers, 5-12 parts of bisphenol-S epoxy resin, 5-15 parts of polycarbonate, 4-8 parts of dodecyl acrylate, 3-7 parts of dodecanol polyethenoxy ether, 2-5 parts of ethylene bis-oleamide, 3-6 parts of styrylphenol polyoxyethylene ether, 4-10 parts of phenolic epoxy vinyl ester resin and 2-5 parts of polyvinyl cinnamate. The preparing method includes the following steps that 1, the components are thrown into a high-speed mixer to be mixed; 2, the insulating material mixture mixed evenly is taken out of the high-speed mixer and extruded through a double-screw extruder; 3, the material extruded in the step 2 is granulated, and the impact-resistant composite insulating material is obtained after the granulated material is cooled to normal temperature.

Owner:SUZHOU YIXINYUAN PHOTOELECTRIC TECH

BMC material for molding decorative plate and preparation method thereof

The invention discloses a BMC material for a molding decorative plate. The BMC material comprises the following components: unsaturated polyester resin, calcium carbonate, aluminium hydroxide, zine stearate, potato starch, a low shrinkage agent, a curing agent, chopped glass fiber and stone toner. A preparation method of the BMC material comprises the following steps: (1) calcium carbonate, aluminium hydroxide, zine stearate and potato starch are added into a kneader to be mixed; (2) unsaturated polyester resin, the low shrinkage agent and the curing agent are mixed by a high-speed mixer; (3) a resin solution from the step (2) is added into the powder from the step (1) to be kneaded; (4) the stone toner is added into the mixture from the step (3) to be mixed and kneaded; and (5) chopped glass fiber is added into the pellet material from the step (4) to be kneaded, and discharging is carried out after kneading. The prepared BMC material for the decorative plate is fire retardant, has high plasticity, is easy to process, has good dimensional stability and has bright and lasting color.

Owner:GAOGANG DISTRICT DEYI NEW MATERIALS FACTORY

High-impact flame-retardant reinforced PC/ABS alloy material and preparation method thereof

Owner:四川鑫达企业集团有限公司

High-strength composite acrylic material

Owner:SUZHOU CITY XIANGCHENG DISTRICT MINGDA COMPOSITE MATERIAL FACTORY

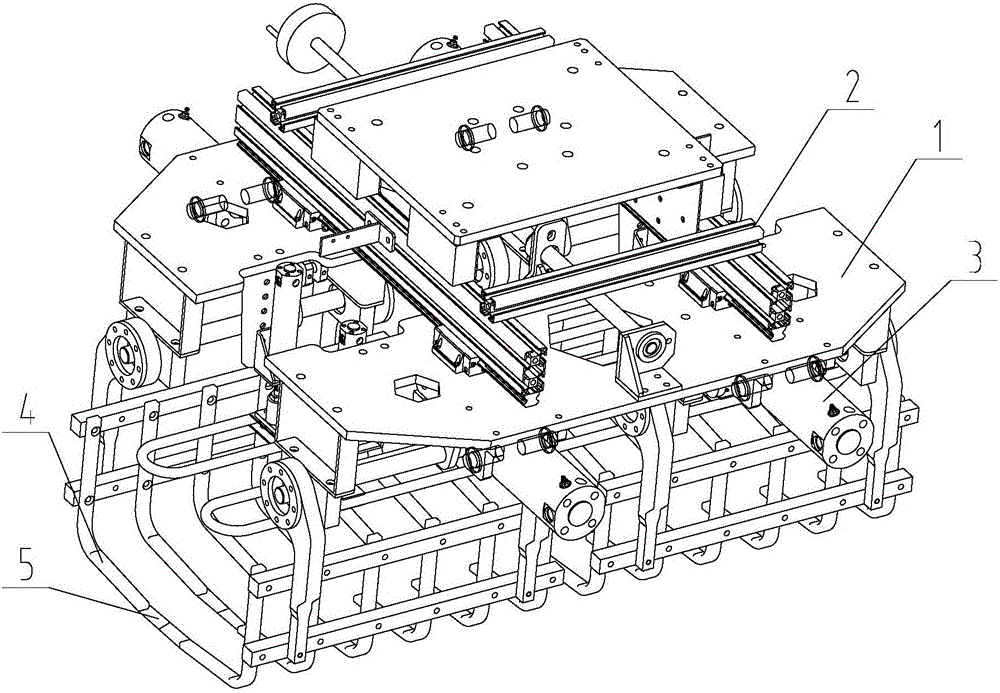

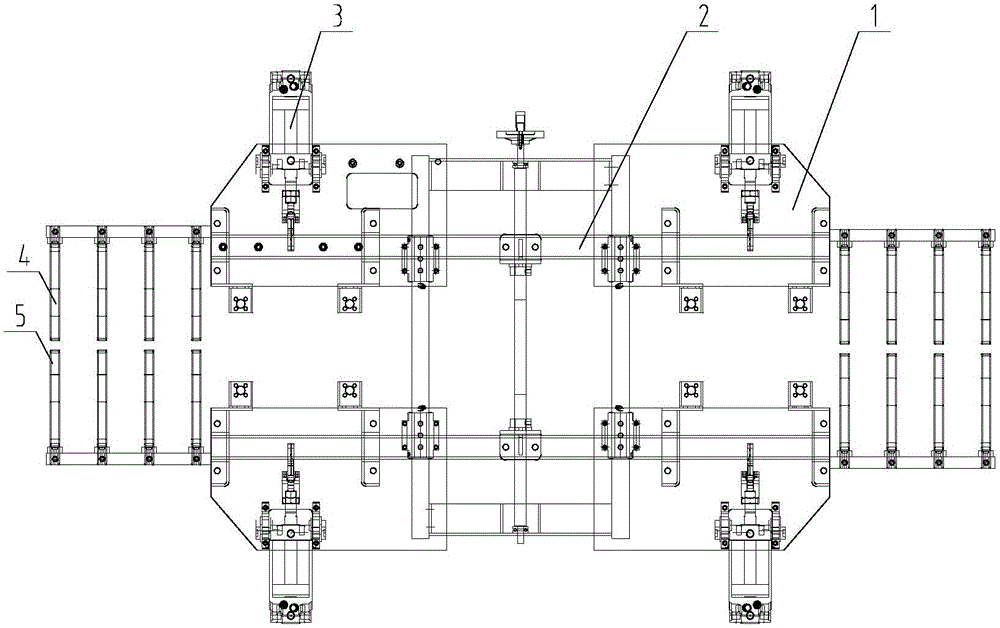

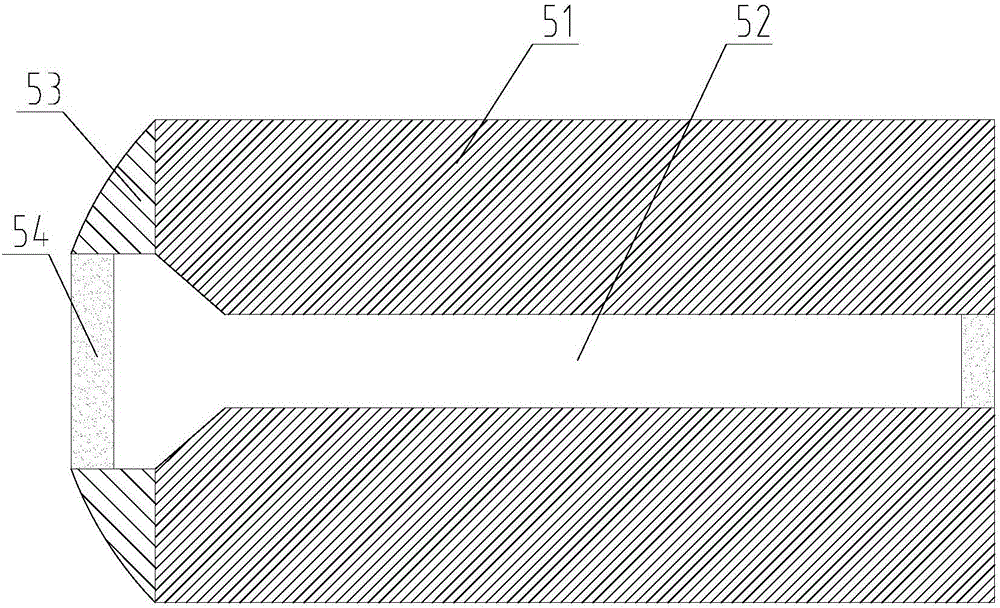

Intelligent robot gripper for stacking system

ActiveCN105084021AFree crawlingAchieve fixationProgramme-controlled manipulatorGripping headsRubber ringGlass fiber

Owner:东莞智动力电子科技有限公司

Light sandwich paperless gypsum board containing high-temperature phosphogypsum as well as preparation method and application thereof

ActiveCN111268987ANot easy to moldLight weightLaminationLamination apparatusFiberglass meshGlass fiber

The invention discloses a light sandwich paperless gypsum board containing high-temperature phosphogypsum. The paperless gypsum board is prepared from the following raw materials in parts by weight: 10-20 parts of high-temperature phosphogypsum, 80-90 parts of high-strength alpha-phosphogypsum, 3-10 parts of lime, 3-10 parts of heavy calcium carbonate, 1-3 parts of glass fiber gridding cloth, 0.05-1 part of a composite foaming agent and 0.01-0.1 part of a composite foam stabilizer. According to the invention, the core layer takes high-temperature phosphogypsum and high-strength alpha-phosphogypsum as main raw materials for the first time, and lime and coarse whiting inorganic powder are doped to serve as filler; by means of the idea of foaming by introducing a foaming agent and a foam stabilizer, a layered cast-in-place method, a combined pouring method and an integral assembly method after layered manufacturing are adopted for preparation. The production process is simplified, dryingis easy, the prepared paperless gypsum board is not prone to mildewing, the strength of a core layer is 0.6 MPa or above, the volume weight is smaller than 550 kg / m3, the volume weight of a paperlessgypsum board wall is reduced, and the heat preservation performance of the paperless gypsum board wall is improved.

Owner:GUIZHOU KAILIN PHOSPHOGYPSUM INTEGRATION UTILIZATION

Environment-friendly ceramic coating material for water faucet

InactiveCN106189561ACorrosion resistantWear-resistantAnti-corrosive paintsCarbon fibersPolybutylene terephthalate

Owner:朱燕华

Novel powder metallurgical gear

InactiveCN106041095AUniform densityLarge elongationTransportation and packagingMetal-working apparatusCarbon fibersALUMINUM STEARATES

Owner:黄宇

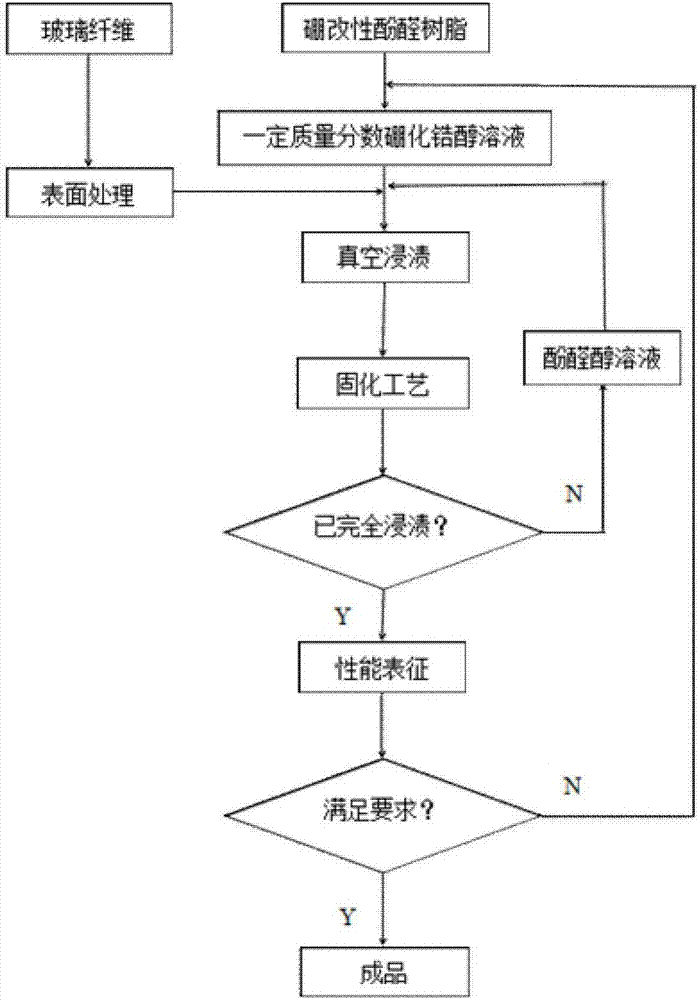

Preparation method of phenolic resin impregnation glass fiber composite material

Owner:BEIJING JIAOTONG UNIV

Calcium sulfate whisker/styrene-butadiene latex composite foaming material and preparation method thereof

ActiveCN108841060AImprove performanceImprove mechanical propertiesMechanical propertyButadiene-styrene rubber

The invention discloses a calcium sulfate whisker / styrene-butadiene latex composite foaming material and a preparation method thereof. Raw materials preparing the calcium sulfate whisker / styrene-butadiene latex composite foaming material comprise, in parts by weight: 50 to 70 parts of styrene-butadiene latex, 8 to 20 parts of natural rubber latex, 5 to 20 parts of modified calcium sulfate whiskers, 0.5 to 4 parts of a modified glass fiber, 2 to 6 parts of talcum powder, 0.02 to 0.15 part of calcium chloride, 2 to 6 parts of zinc oxide, 3 to 8 parts of liquid soap and 0.5 to 3 parts of benzoylperoxide, wherein the solid content of the styrene-butadiene latex is 55 to 68 percent. The calcium sulfate whisker / styrene-butadiene latex composite foaming material prepared by the method is low indensity, light in weight, high in bearing capacity, excellent in mechanical property such as breaking elongation and toughness and high in resilience performance; furthermore, the preparation method is simple, and the preparation process is easy to operate; a product is high in size stability.

Owner:RUIAN SAIBAO LATEX TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap