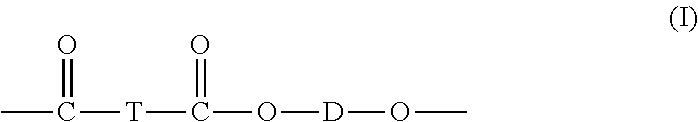

Hollow articles comprising fiber-filled polyester compositions, methods of manufacture, and uses thereof

a technology of polyester composition and fiber-filled polyester, which is applied in the direction of furniture parts, process and machine control, mechanical control devices, etc., can solve the problems of surface roughness and achieve excellent surface gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

Materials

[0062]The following materials are used in Examples 1 to 2 and Comparative Examples A to F. Table 1 shows the nomenclature used as well as a description.

TABLE 1Raw MaterialsDescriptionPBT 195Poly(1,4-butylene terephthalate), intrinsic viscosity(IV) = 0.66 dl / g, Mw weight-average molecularweight = 53400 g / mol, Tm 215° C.PBT 315Poly(1,4-butylene terephthalate), intrinsic viscosity(IV) = 1.10 dl / g, Mw weight-average molecularweight = 110000 g / mol, Tm 217° C.Low IV PET0.535 dl / g IV PET, 0.8% DEG, Tm 257° C.Hi IV PET0.83 dl / g IV PET, 0.8% DEG, Tm 242° C.Glass FiberOwens Corning 183F 13 micron diameter E glassMold ReleasePenta erythritol tetra stearate (PETS)Antioxidant 1PEPQ phosphonite from ClariantAntioxidant 2Diphenyl isodecyl phosphiteCarbon black25 wt % 17 nm particle size carbon black in PBT 195SilicaPrecipitated amorphous silica process aid

General Testing Techniques and Procedures:

[0063]Gloss was measured per ASTM D523 at six different locations in a glossy region

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap