Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about "Hollow articles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

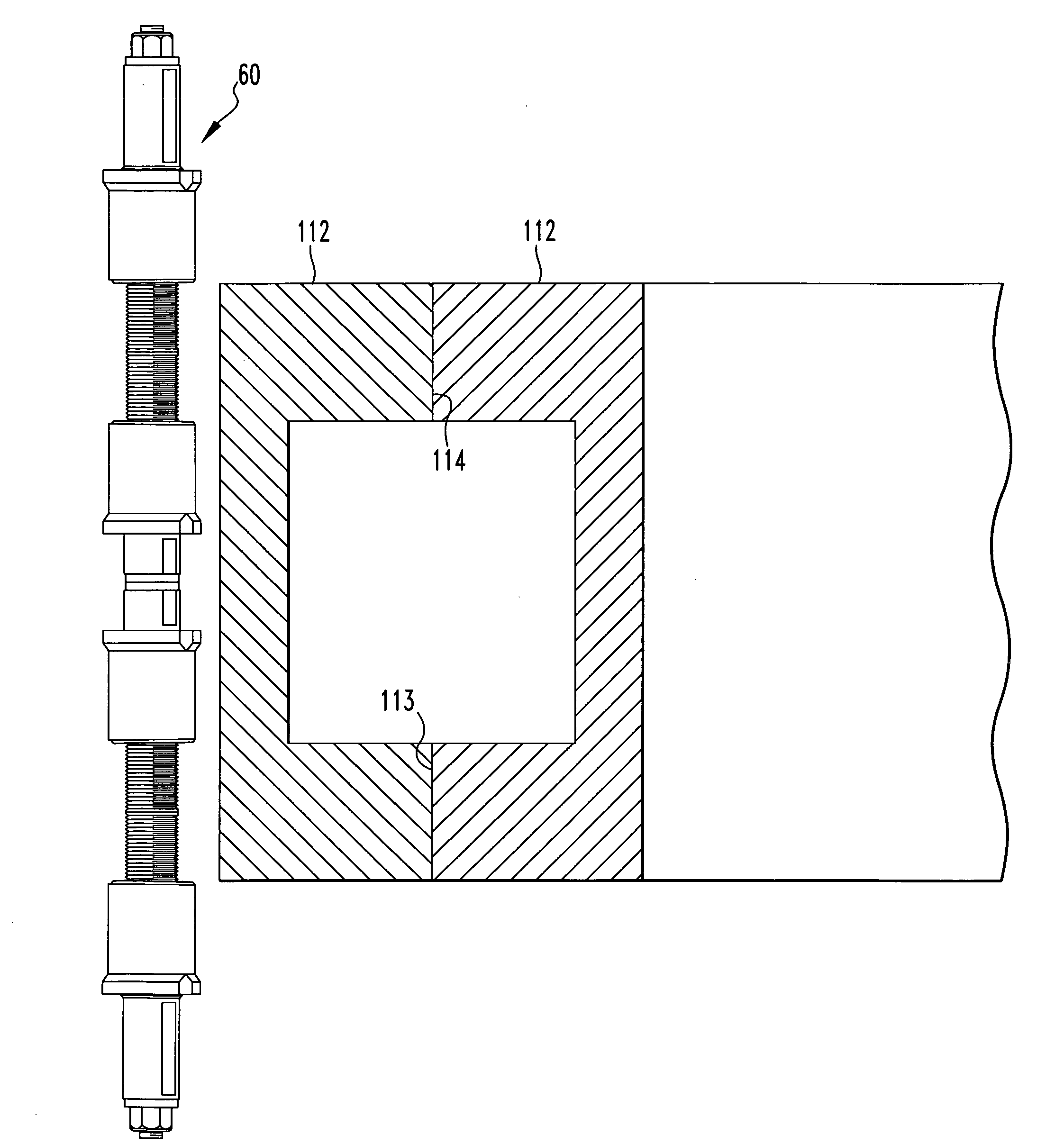

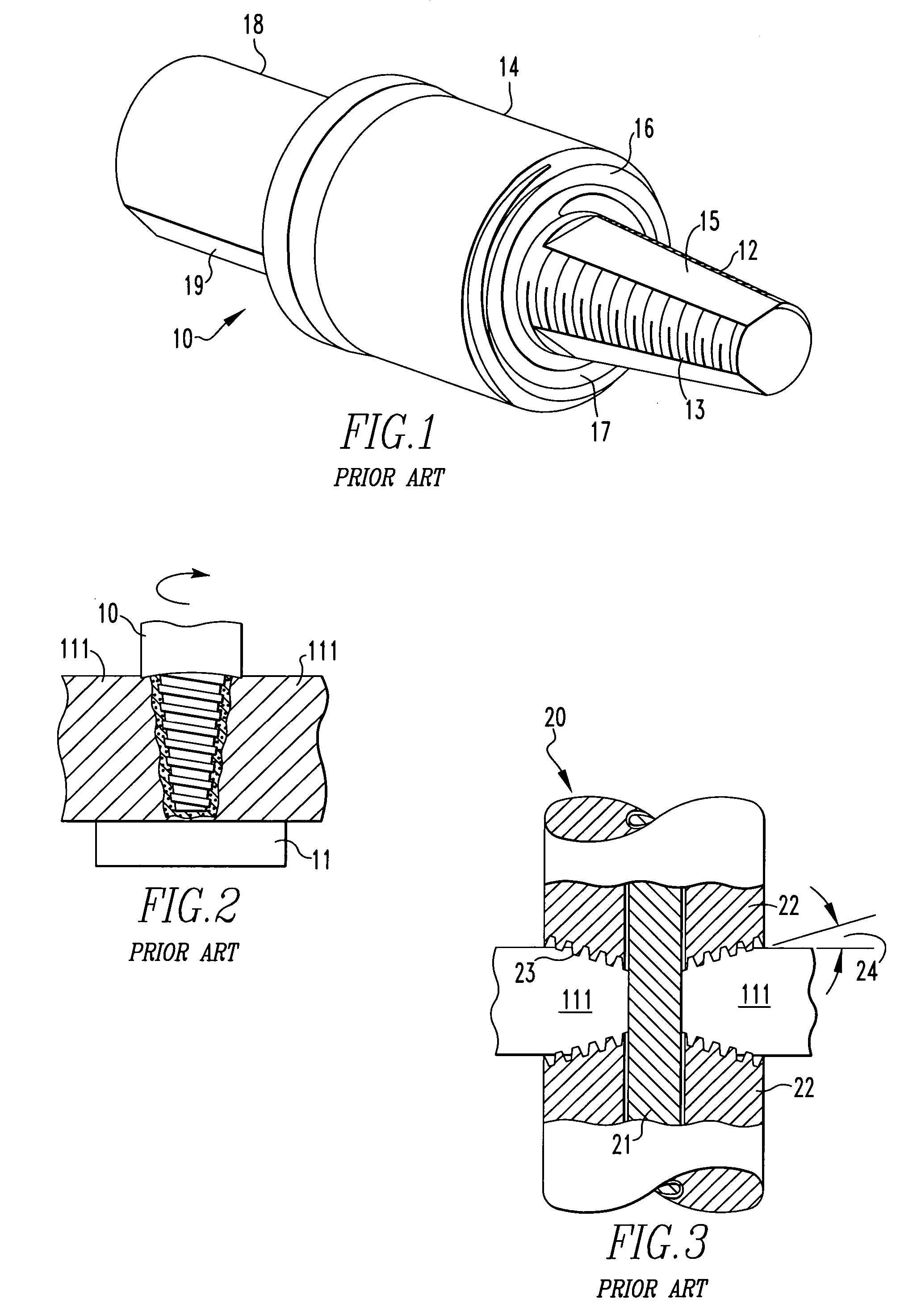

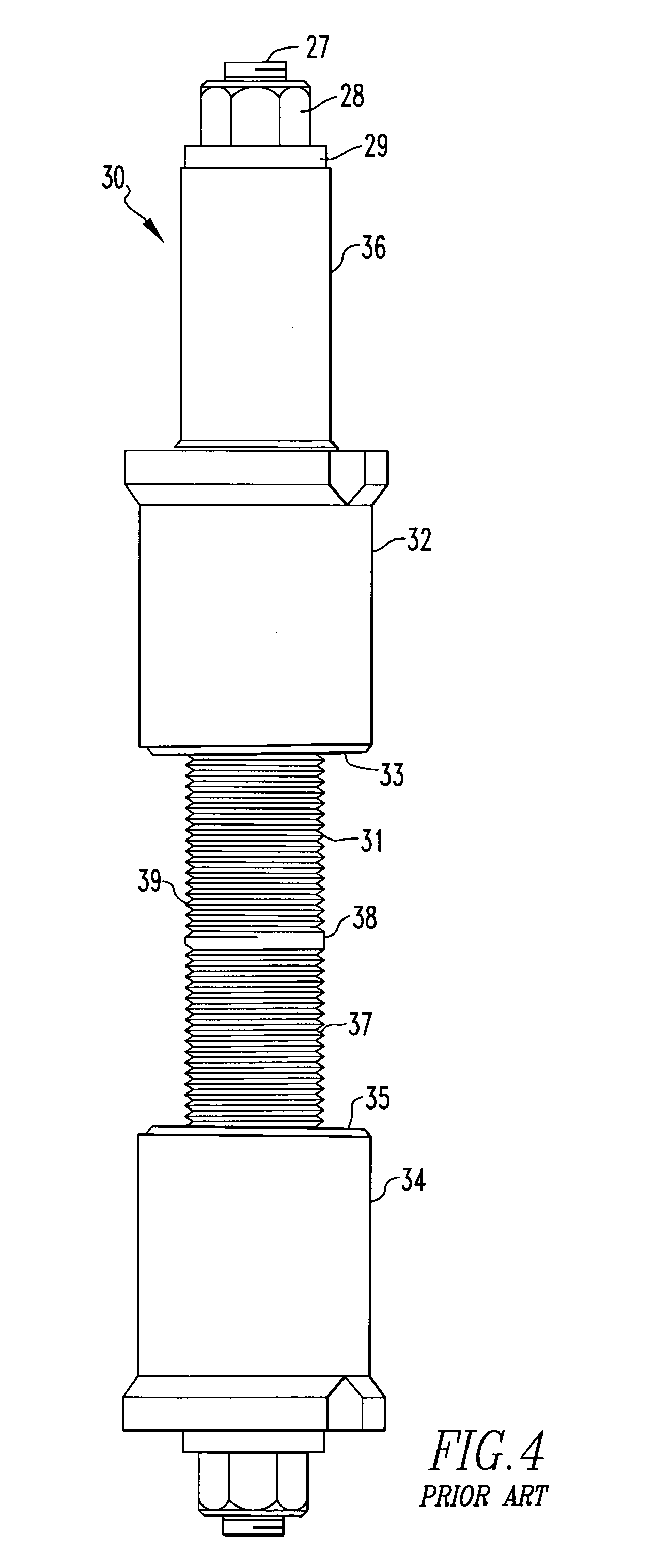

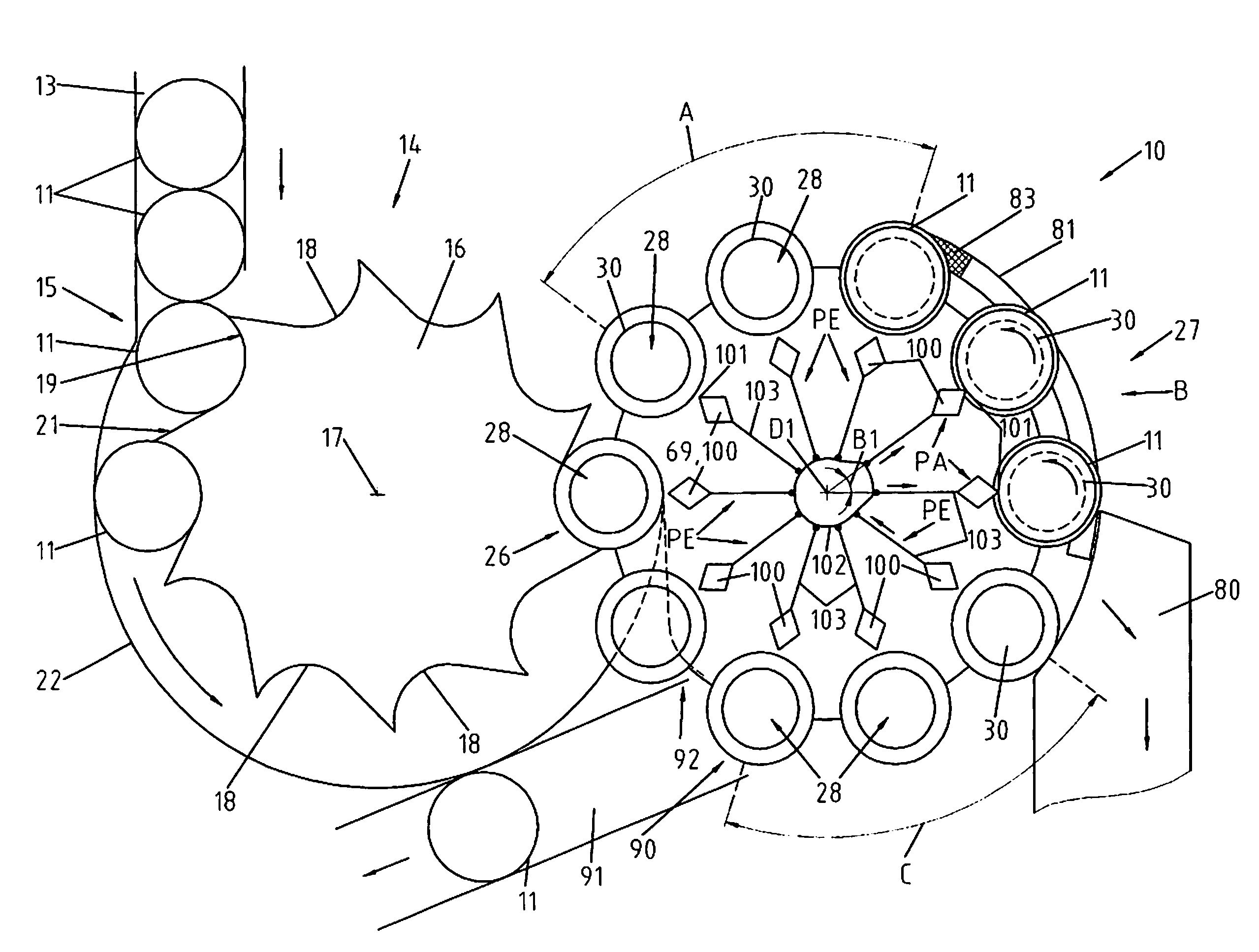

Multi-shouldered fixed bobbin tools for simultaneous friction stir welding of multiple parallel walls between parts

Owner:ARCONIC INC

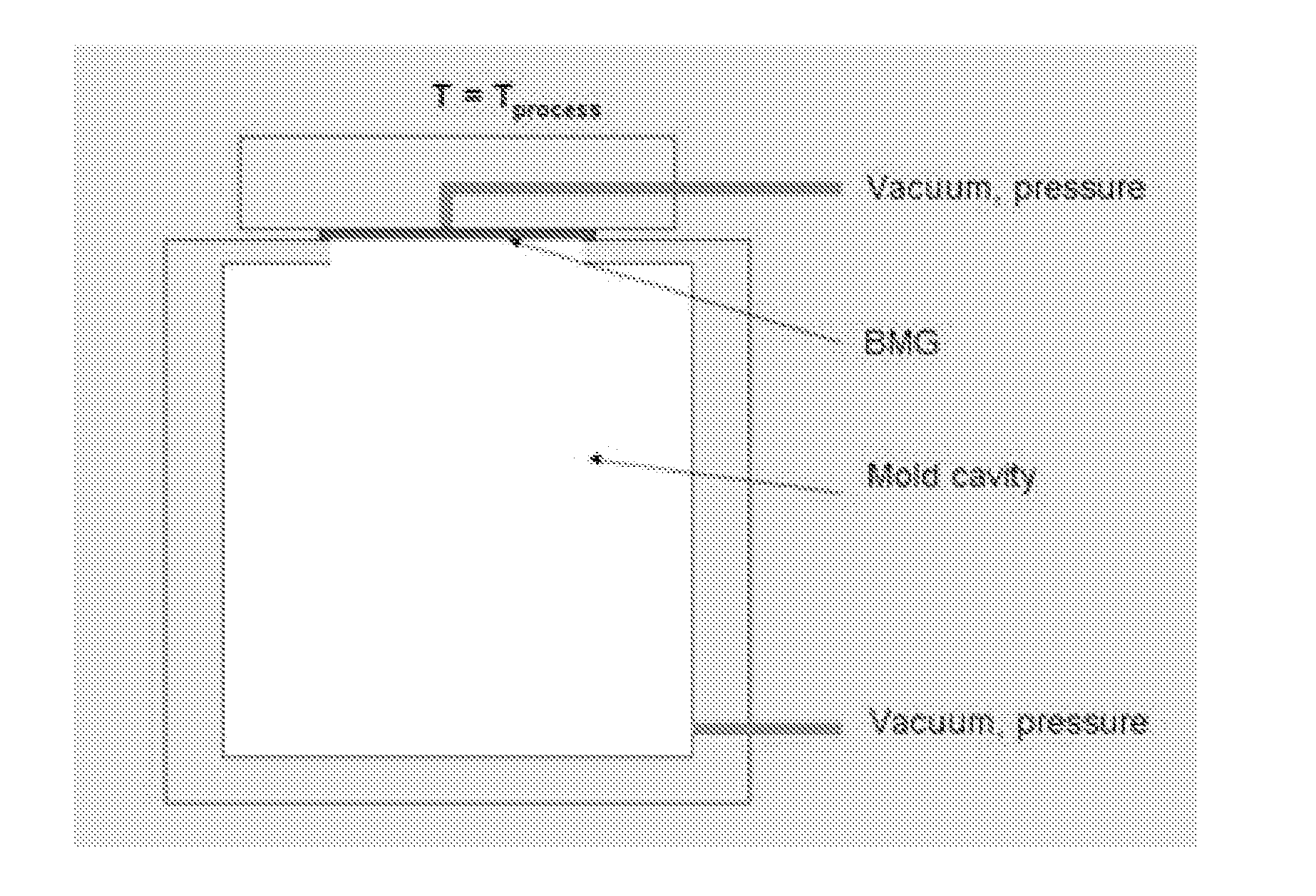

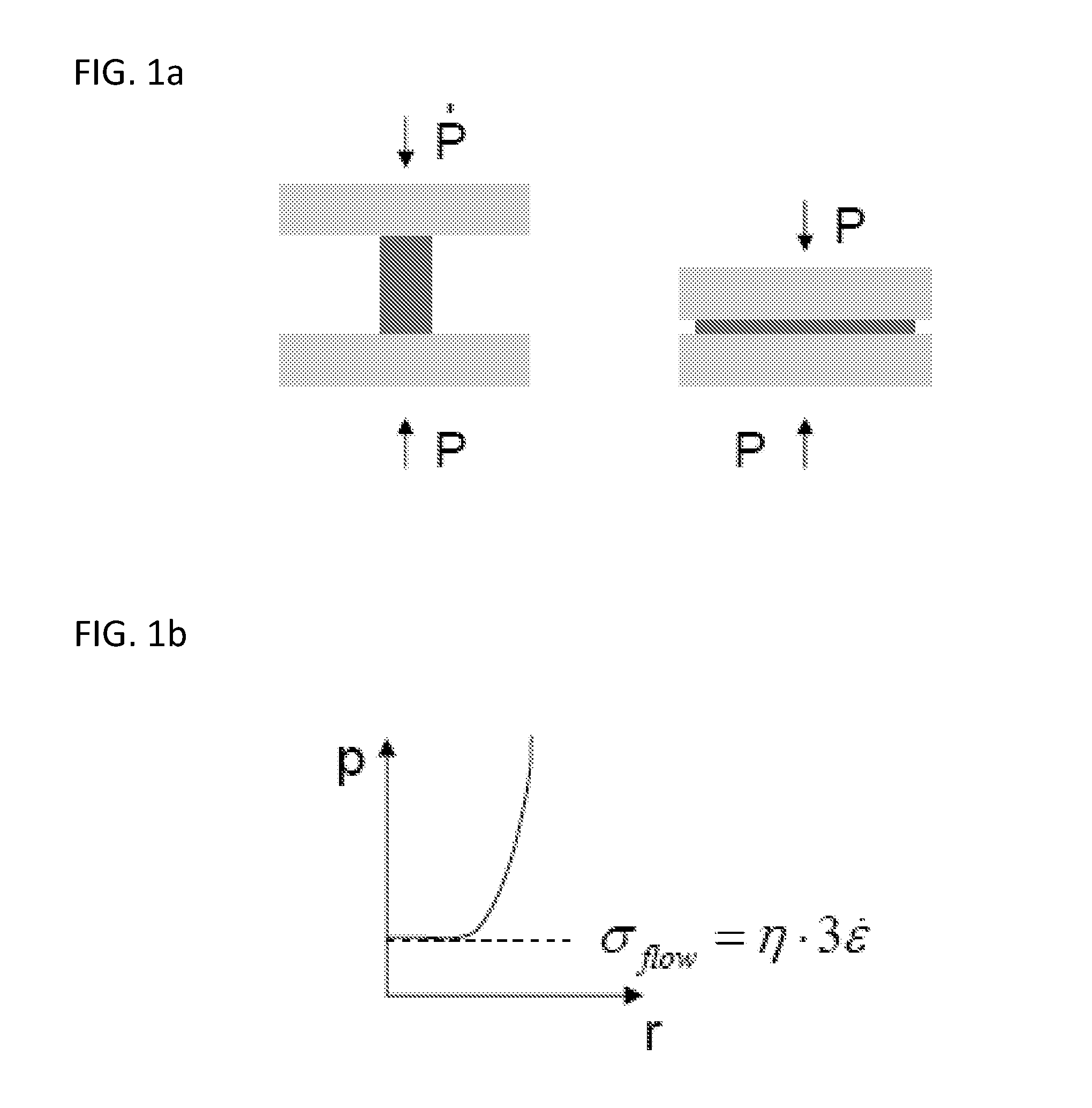

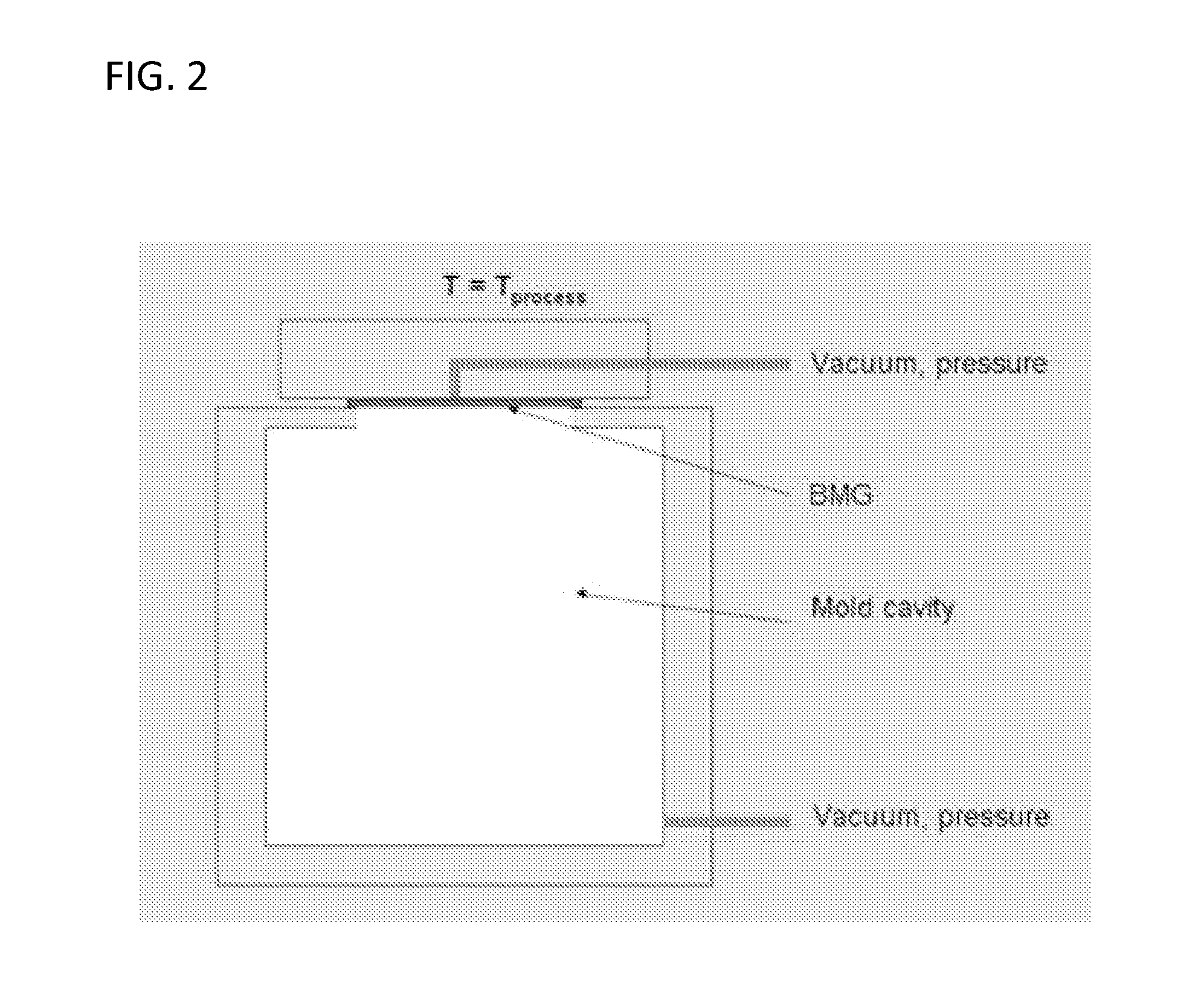

Method of blow molding a bulk metallic glass

Owner:YALE UNIV

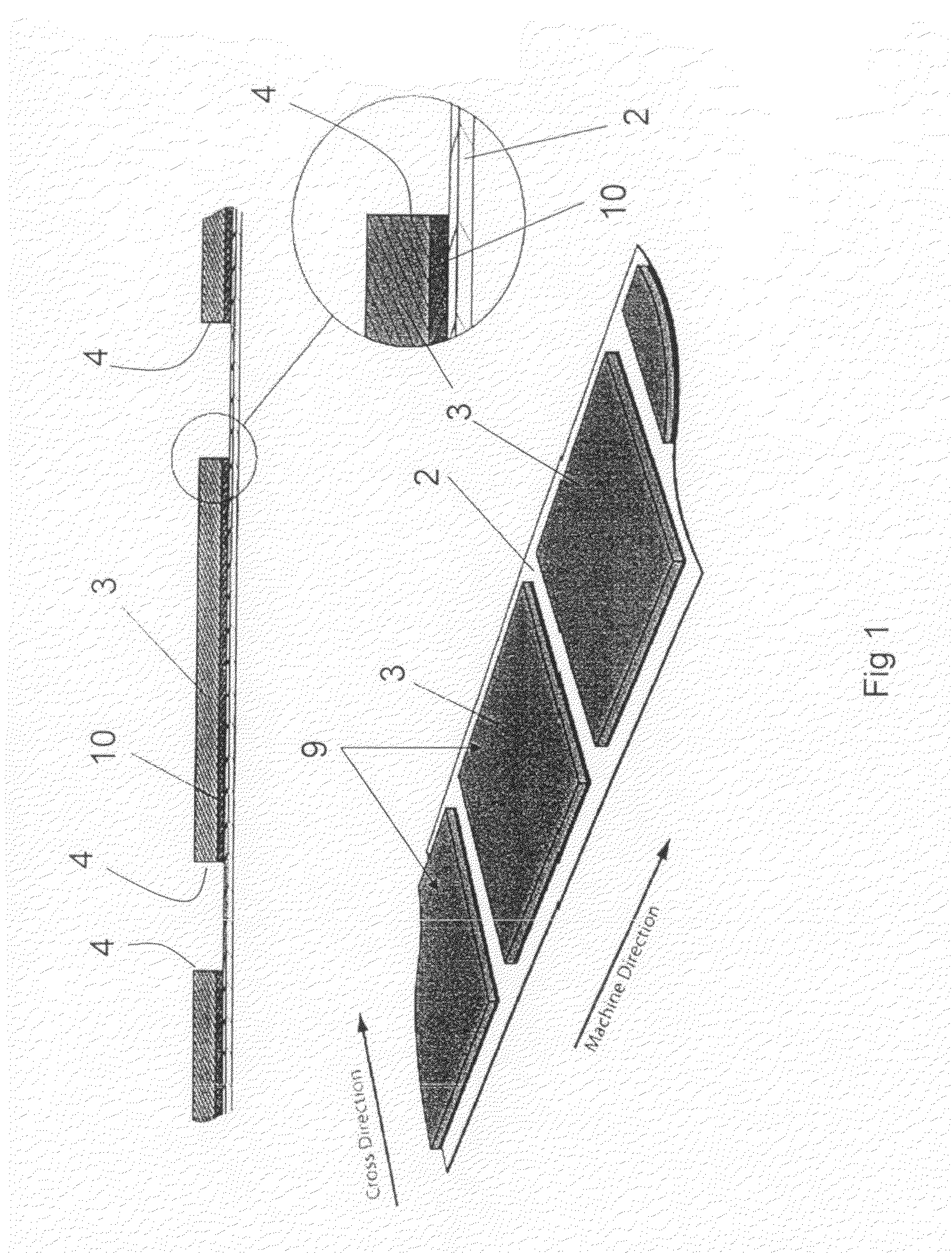

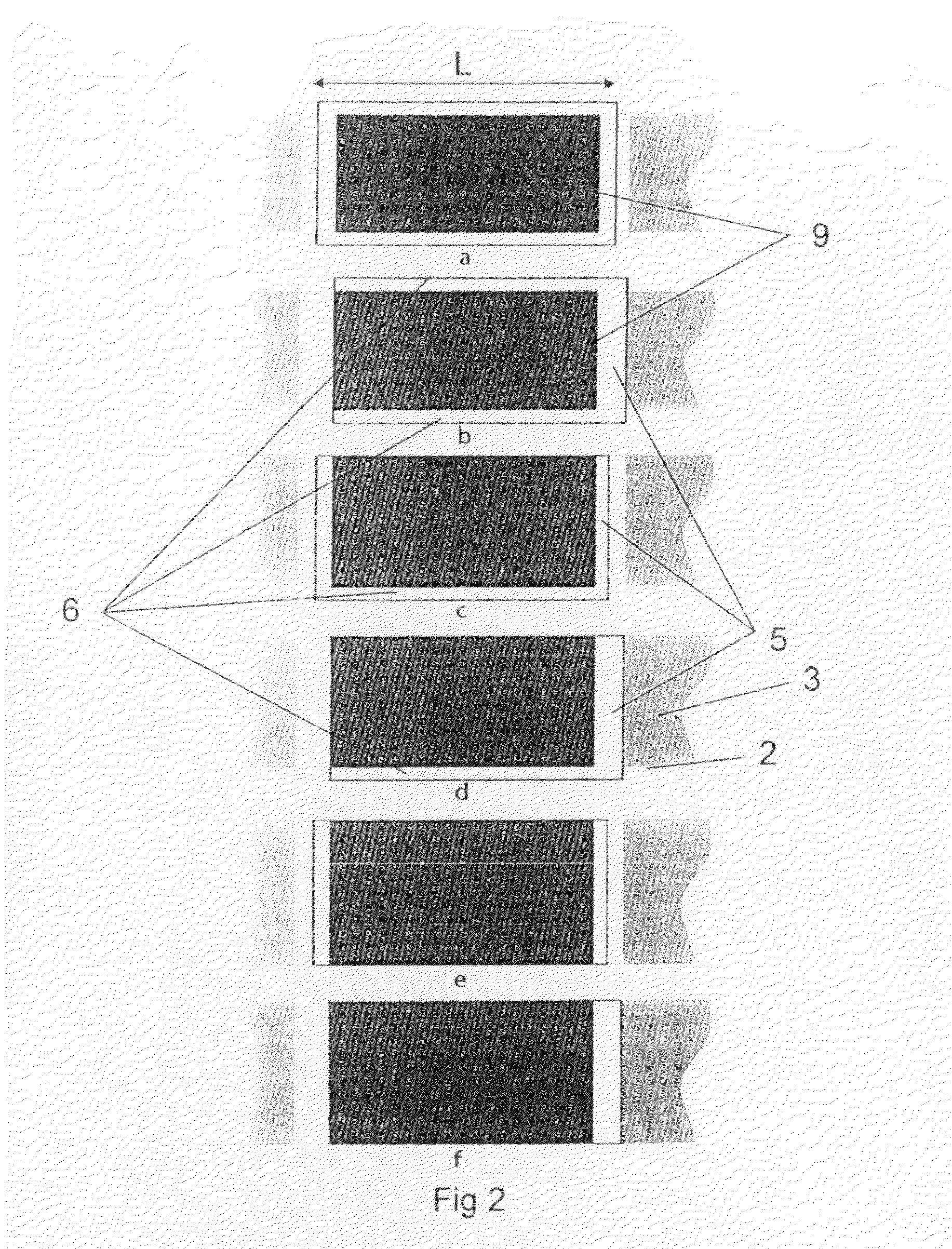

Irradiated biaxially oriented film

InactiveUS6869686B1Wrappers shrinkageShrinkage connectionsDeceneVinyl chloride

Owner:BEMIS COMPANY INC

Magazine quick-release blocking apparatus and method

ActiveUS20110010977A1Simple methodInexpensive apparatusSafety arrangementBreech mechanismsFast releaseBiomedical engineering

Apparatuses, methods, and kits are disclosed for preventing quick release of a magazine from a magazine well of a Sa vzor 58 rifle without the need to substantially disassemble the rifle, thereby providing a means to modify Sa vzor 58 rifles to bring such rifles within permissible limitations of certain local, state, and federal guns laws.

Owner:QUIS TOMAS

Sulfonated aromatic copolyesters containing hydroxyalkanoic acid groups and shaped articles produced therefrom

Owner:EI DU PONT DE NEMOURS & CO

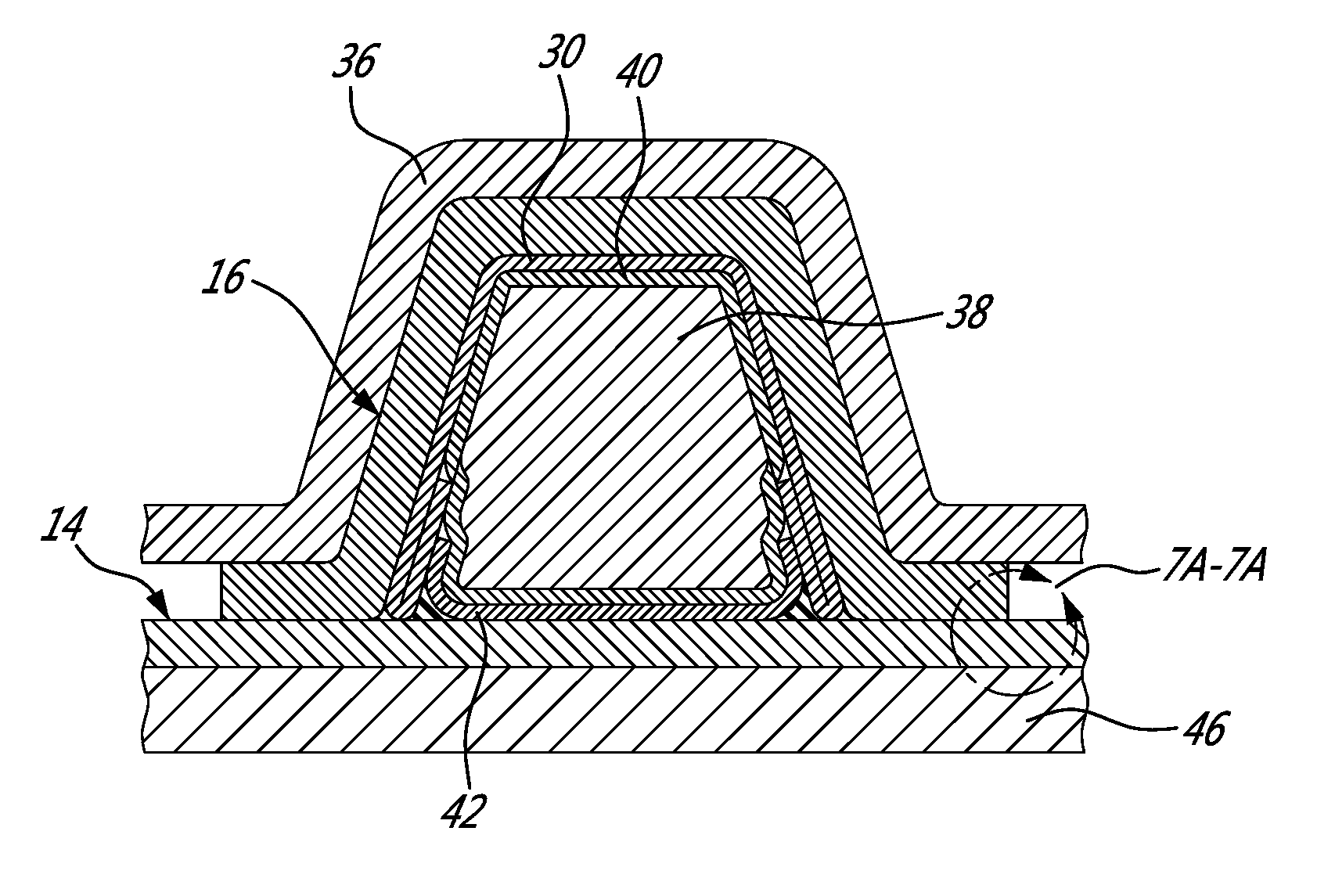

Method of forming a composite member and assembly therefor

Owner:BOMBARDIER CORP

Enhanced oxygen barrier performance from modification of ethylene vinyl alcohol copolymers (EVOH)

Owner:CRYOVAC INC

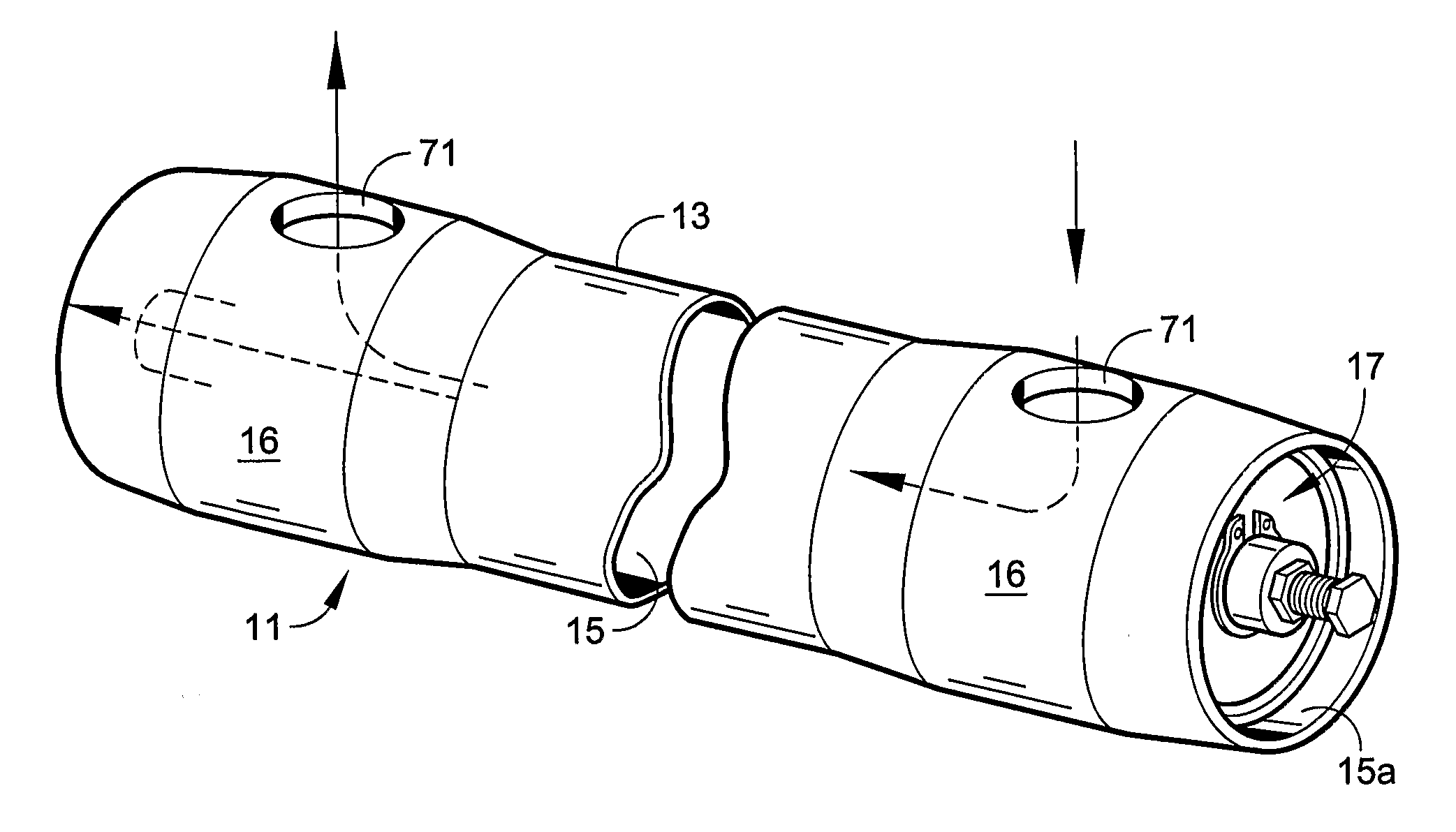

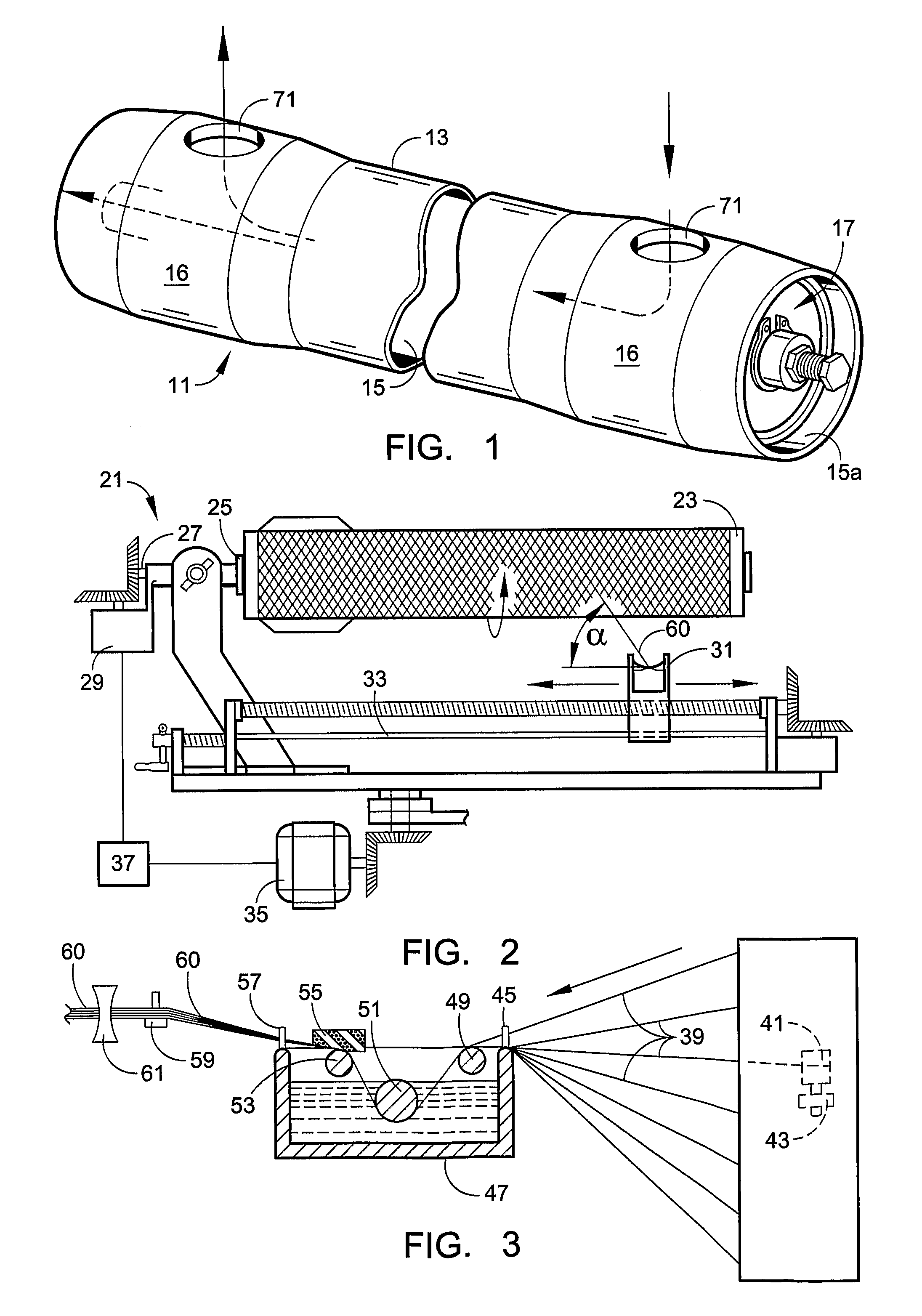

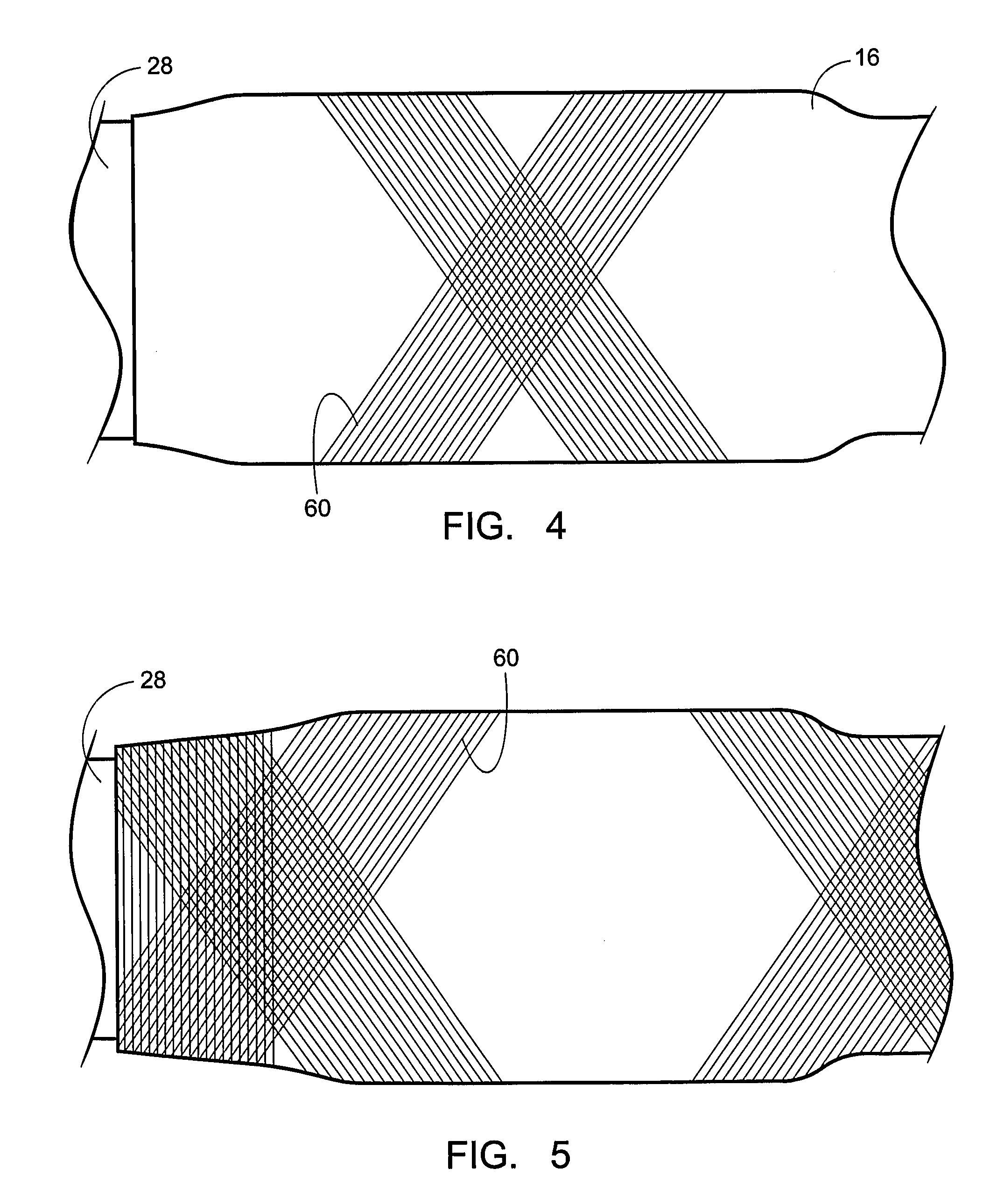

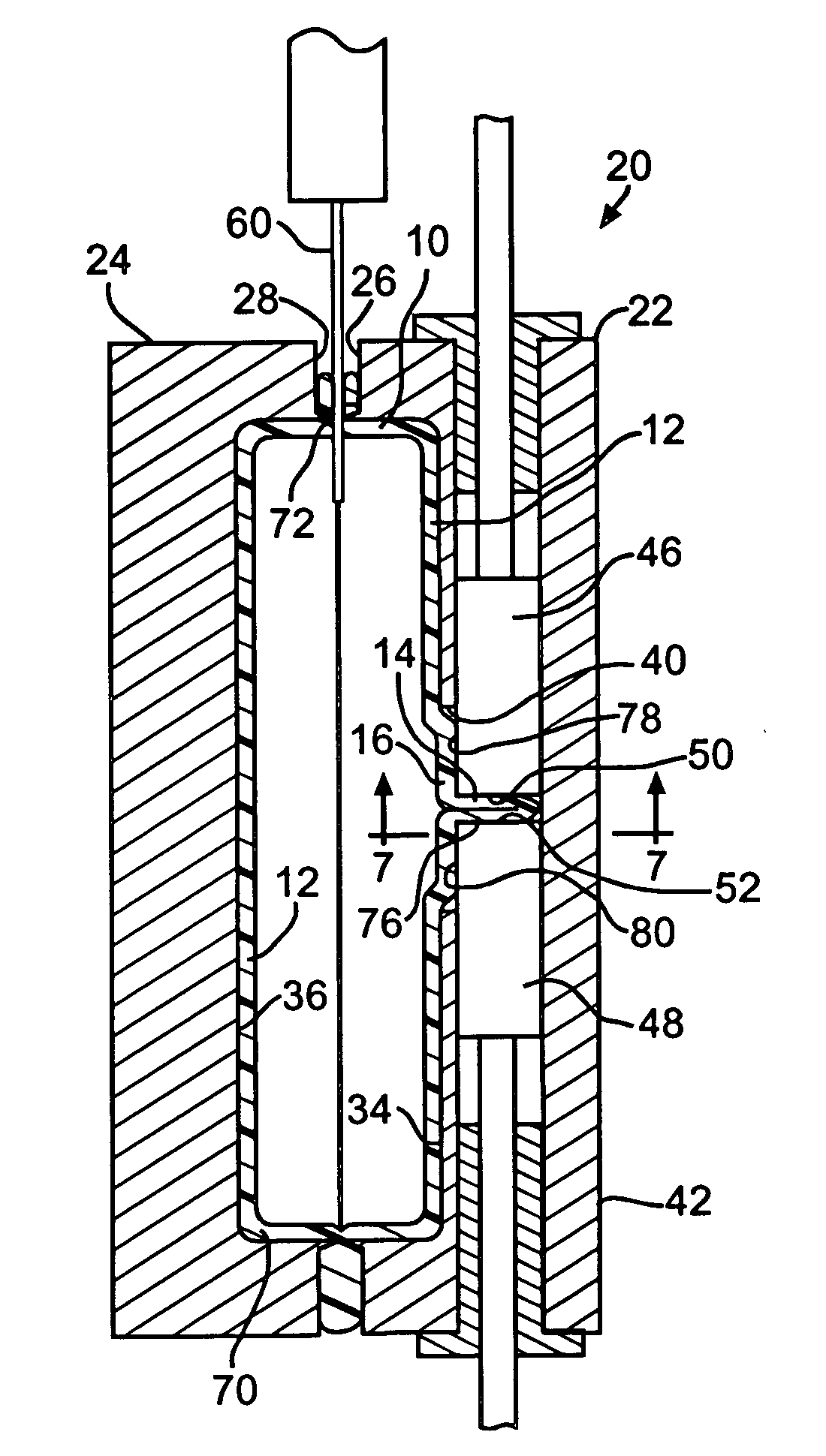

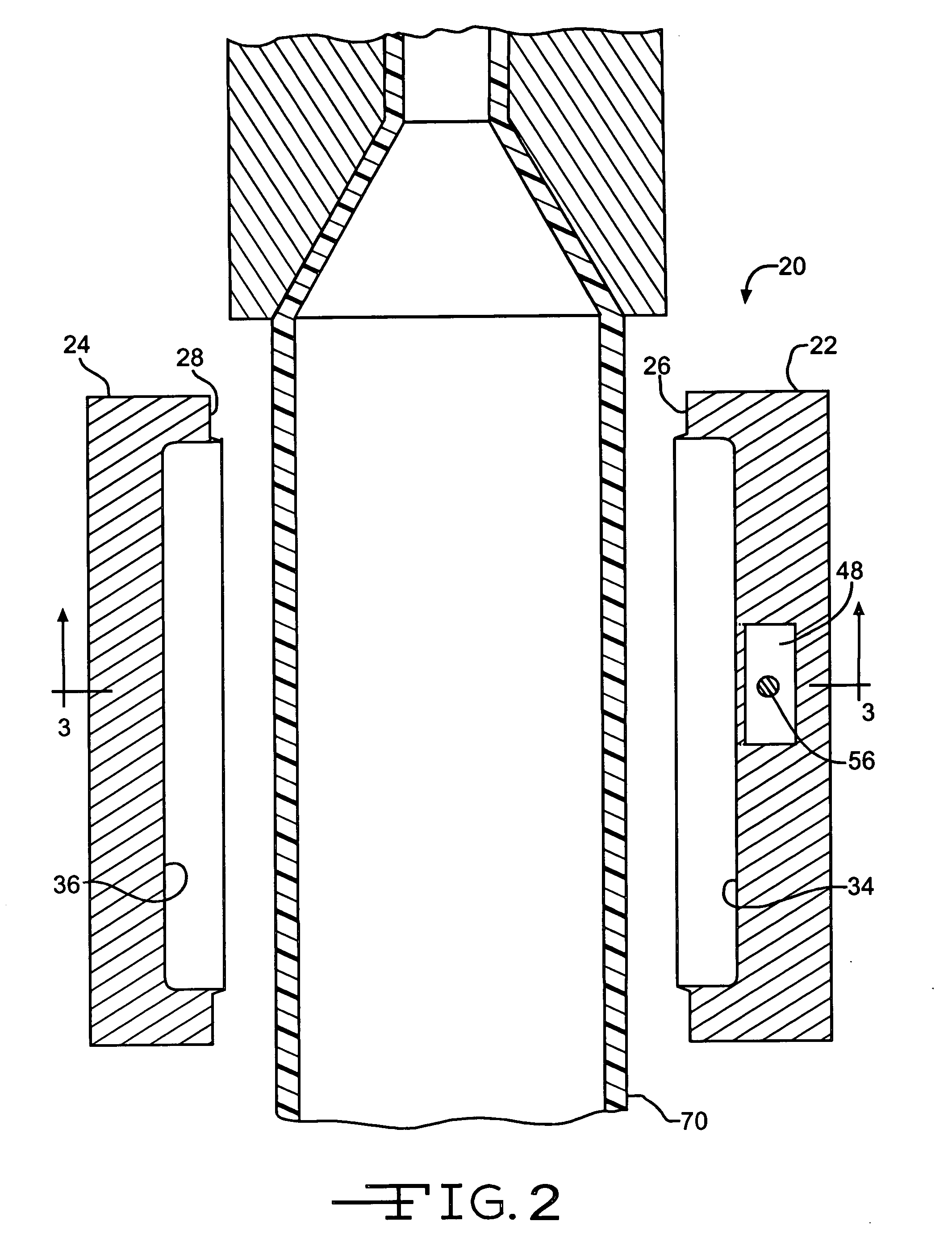

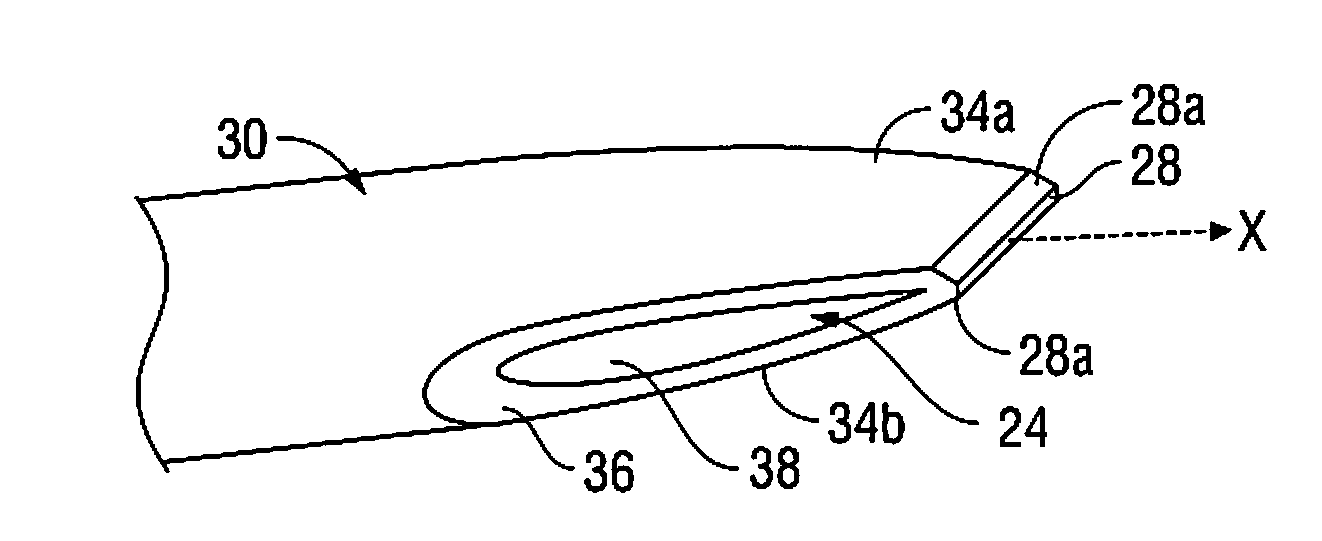

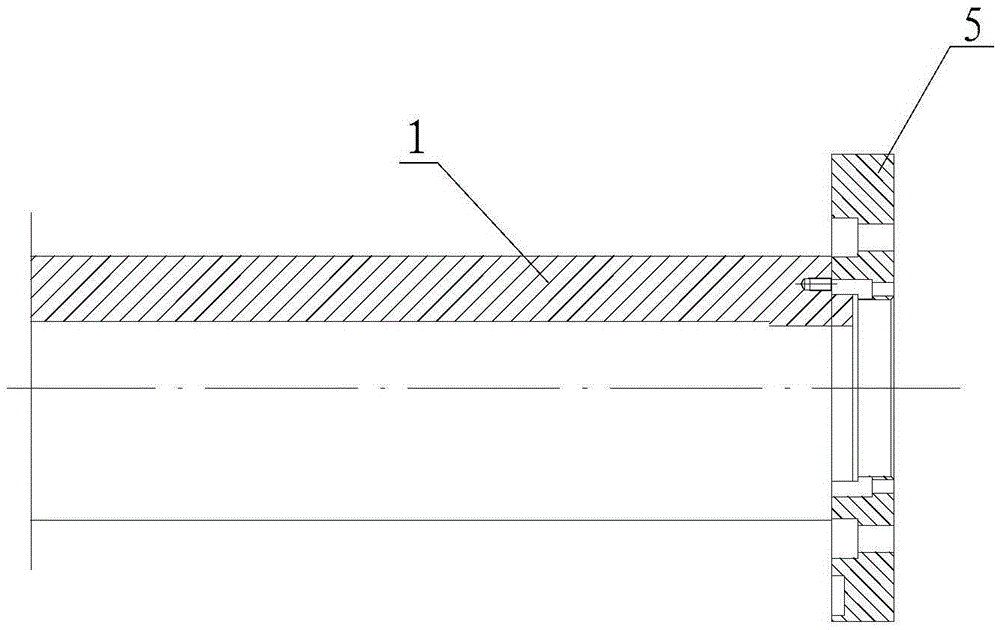

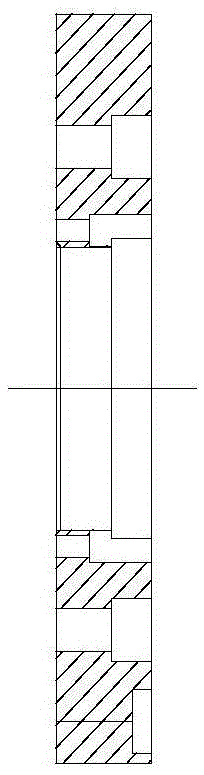

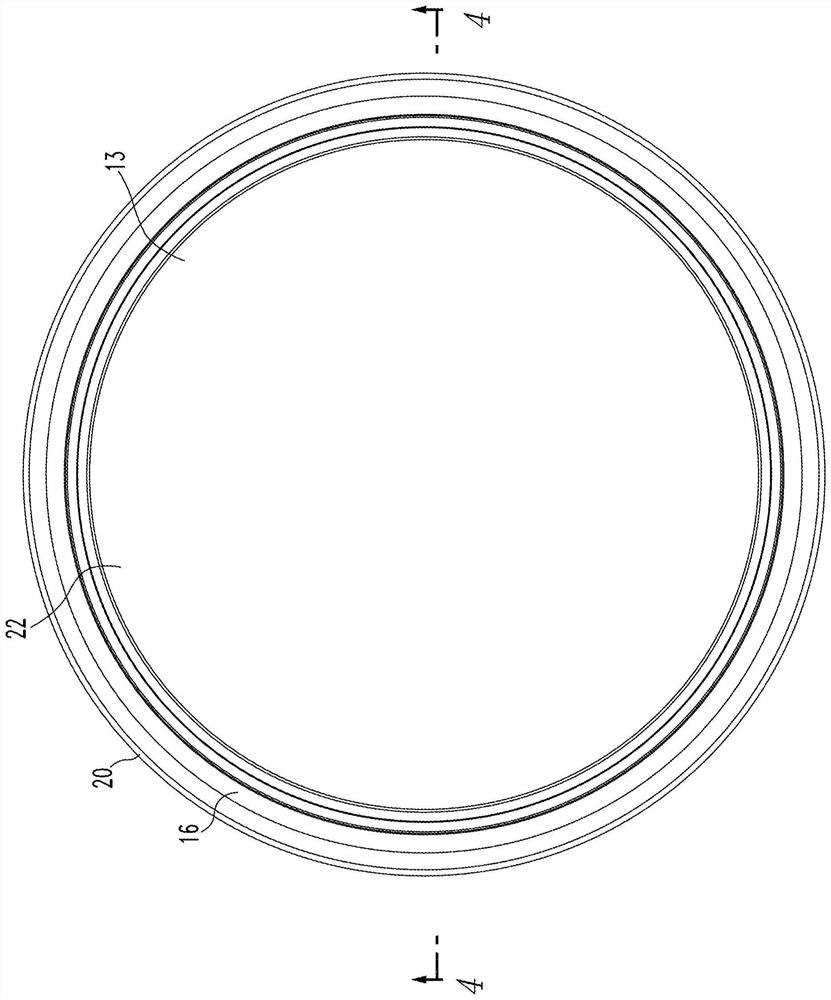

Side-Ported Filament Wound Pressure Vessels

ActiveUS20080093367A1Efficient constructionReduce labor costsVessel mounting detailsVessel manufacturingEngineeringFilament winding

Owner:PROTEC ARISAWA AMERICA

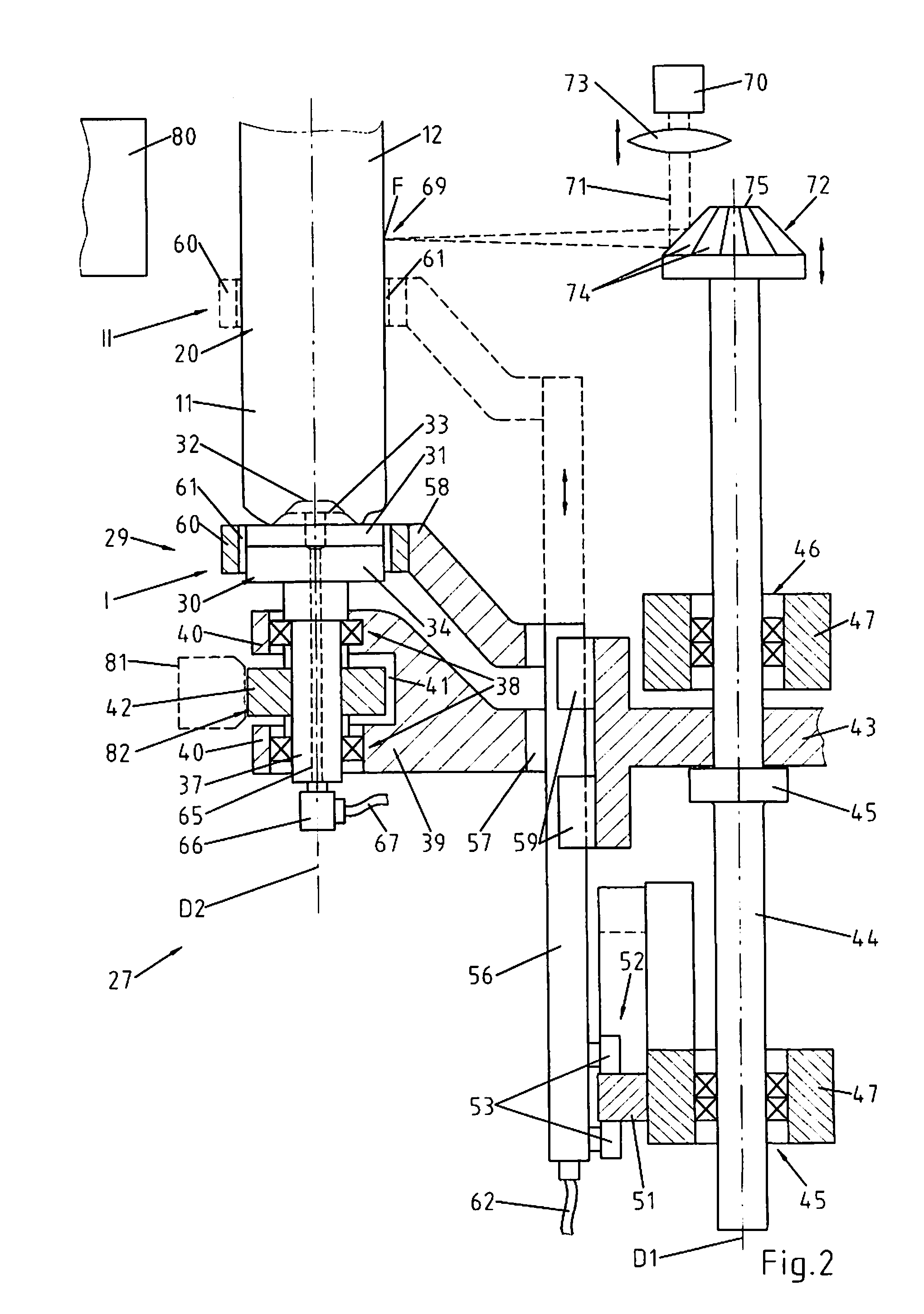

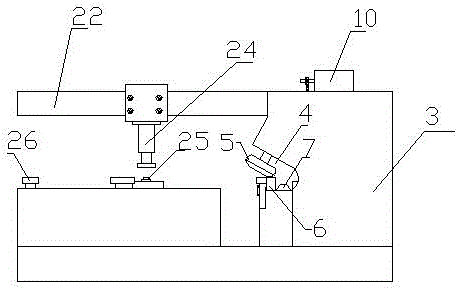

Device and method for cutting off an end section of a can blank

InactiveUS20140346154A1Sufficient time availableStock shearing machinesMetal working apparatusEngineeringLaser cutting

Owner:SCHULER PRESSEN GMBH & CO KG

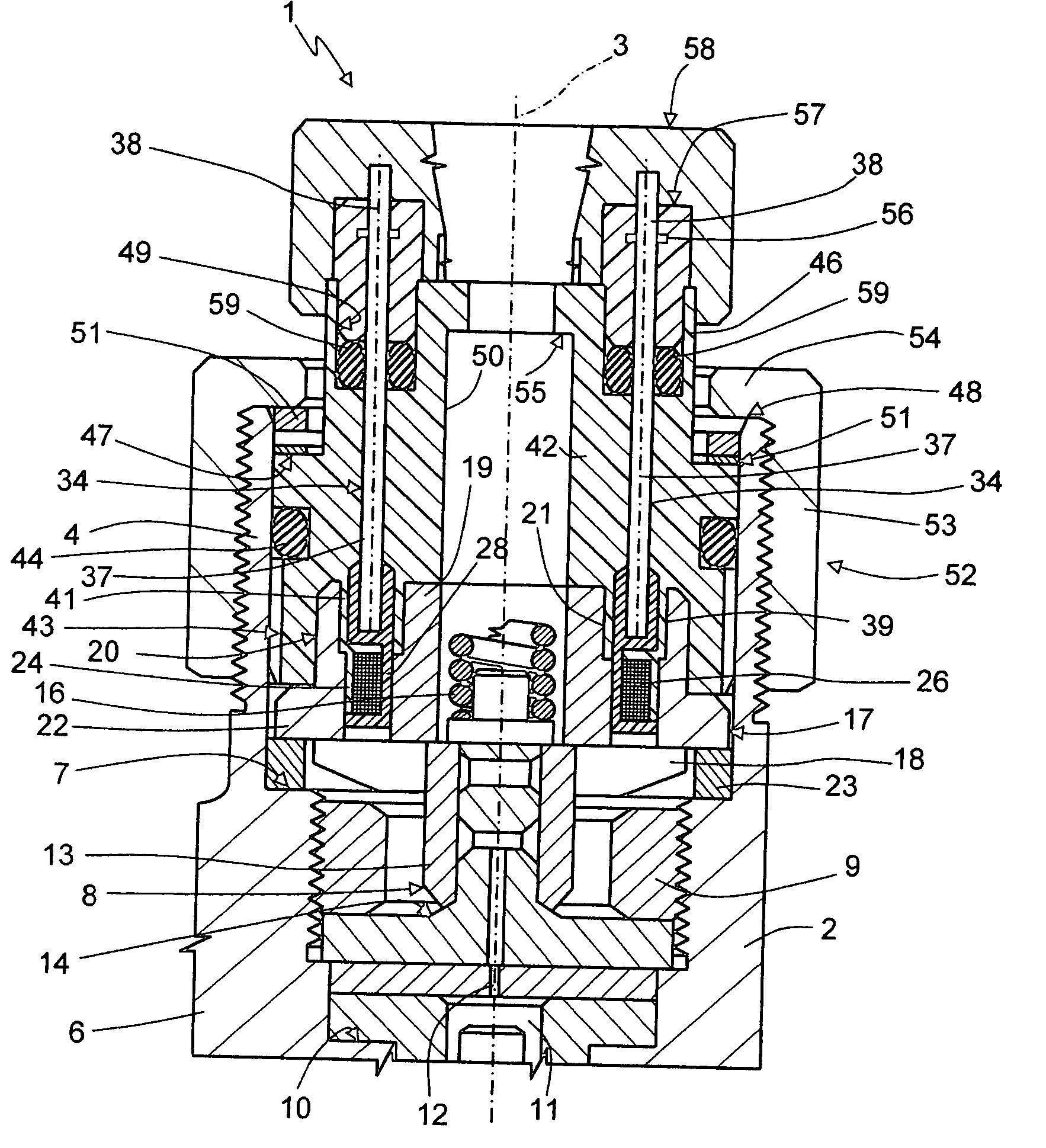

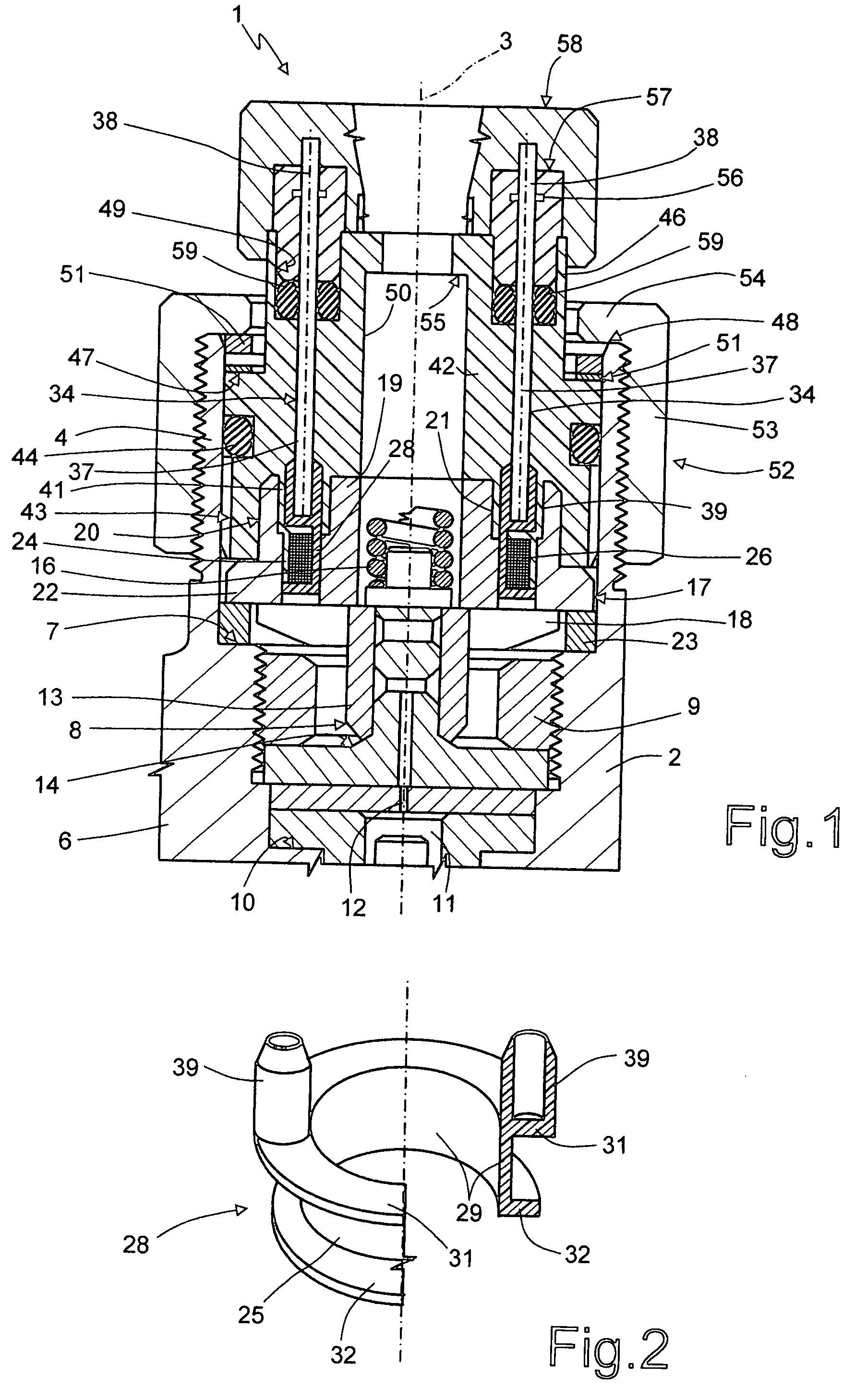

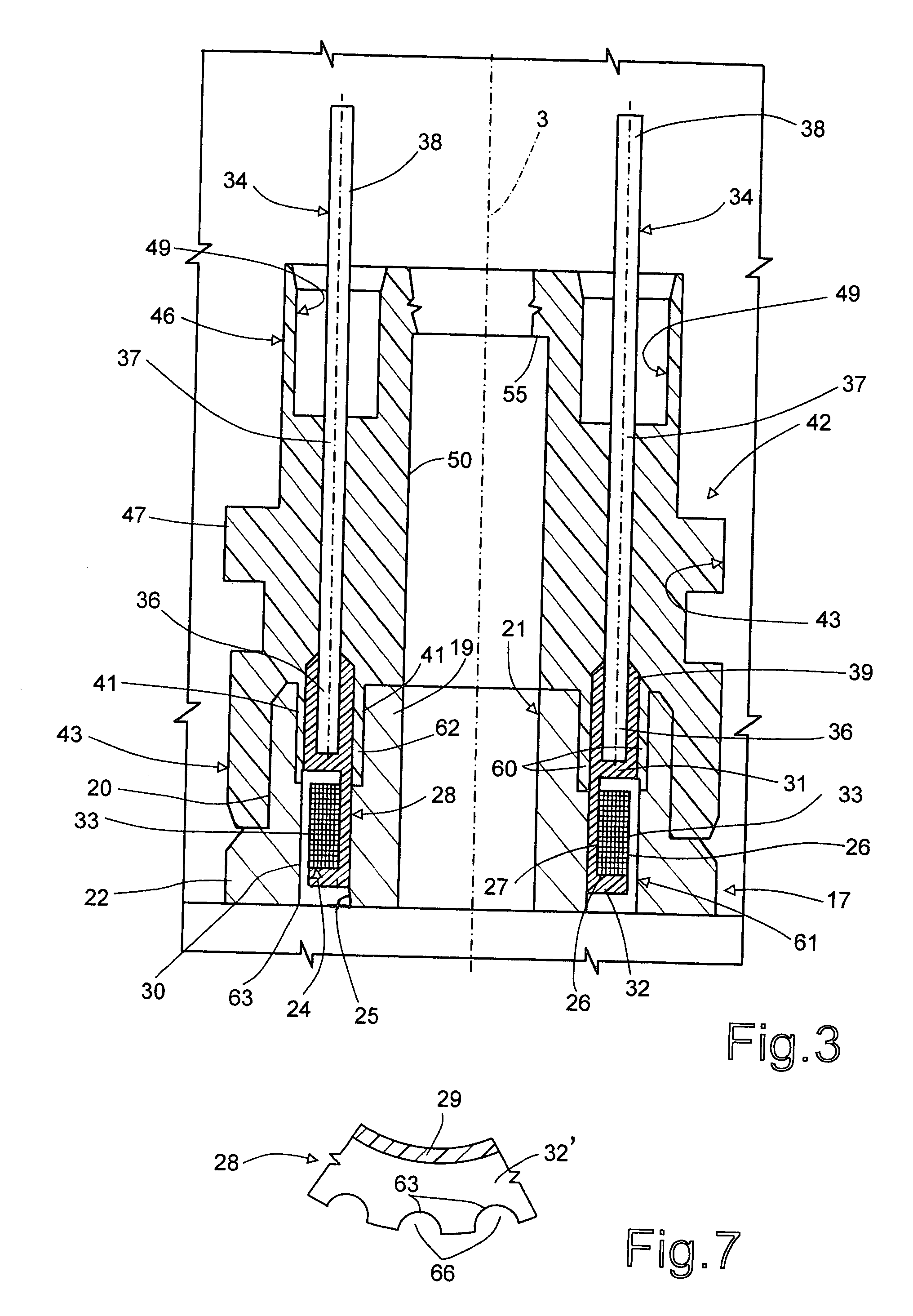

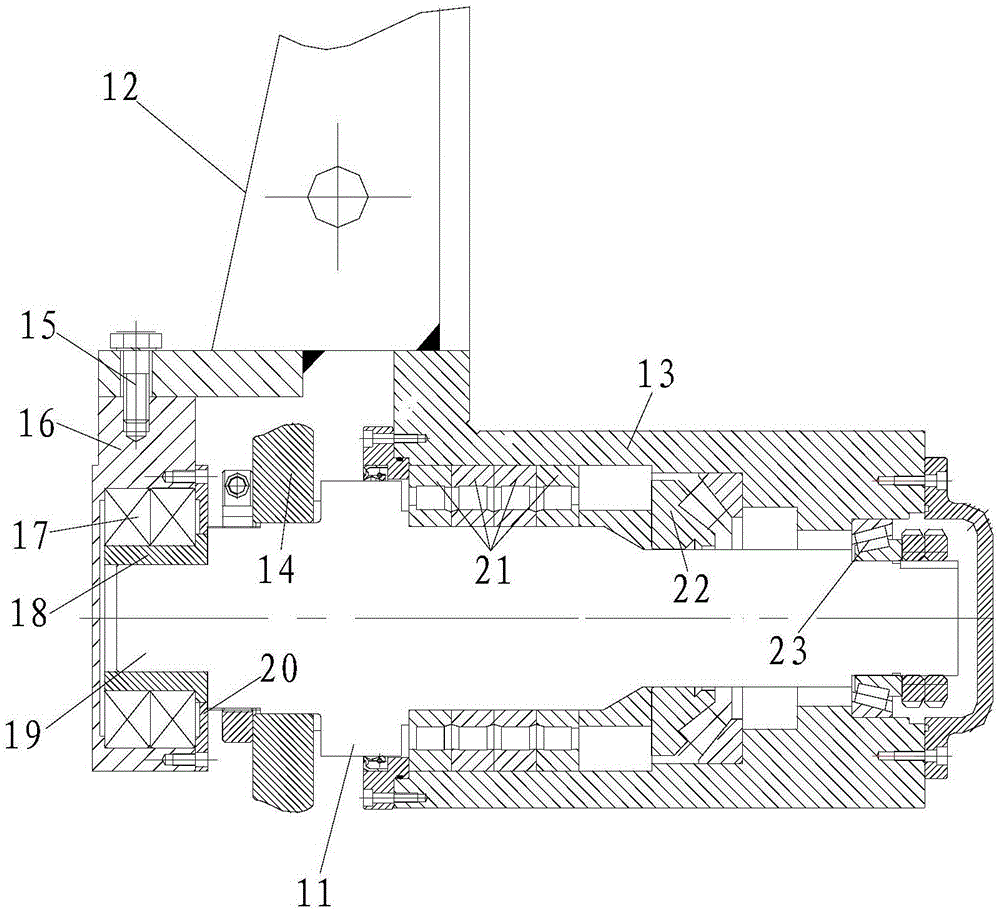

Fuel injector for internal combustion engine and corresponding method of manufacture

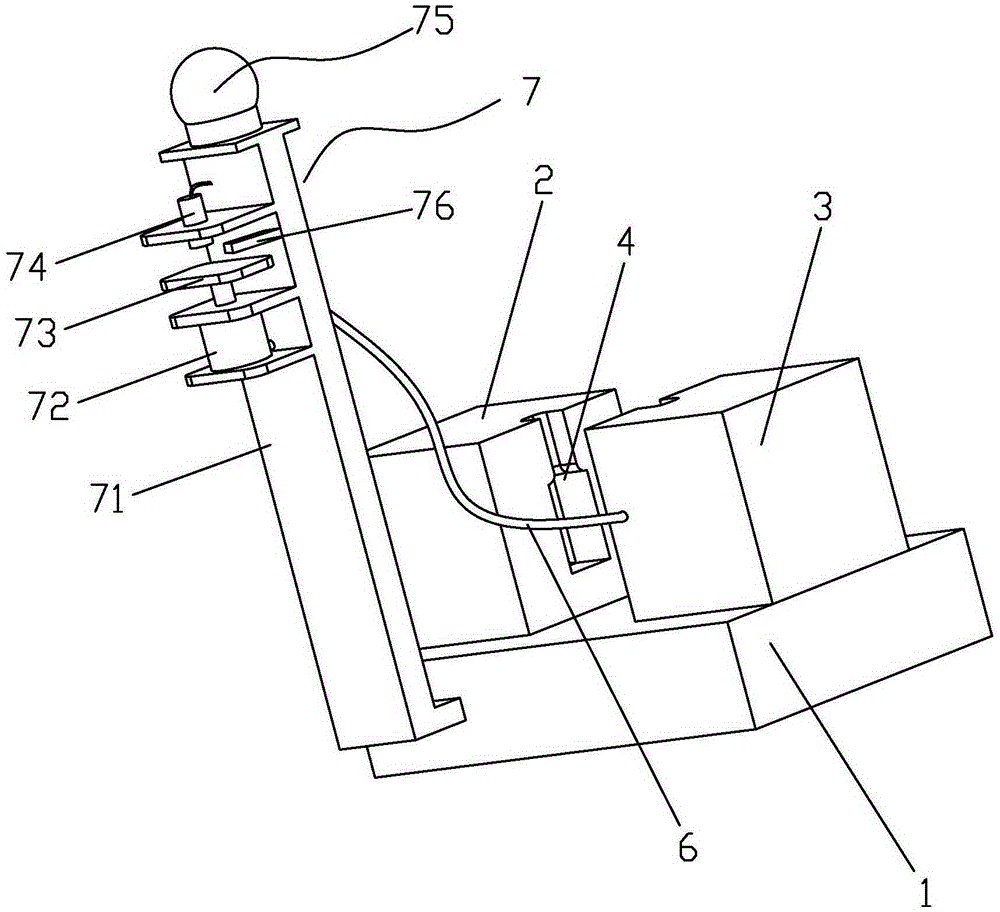

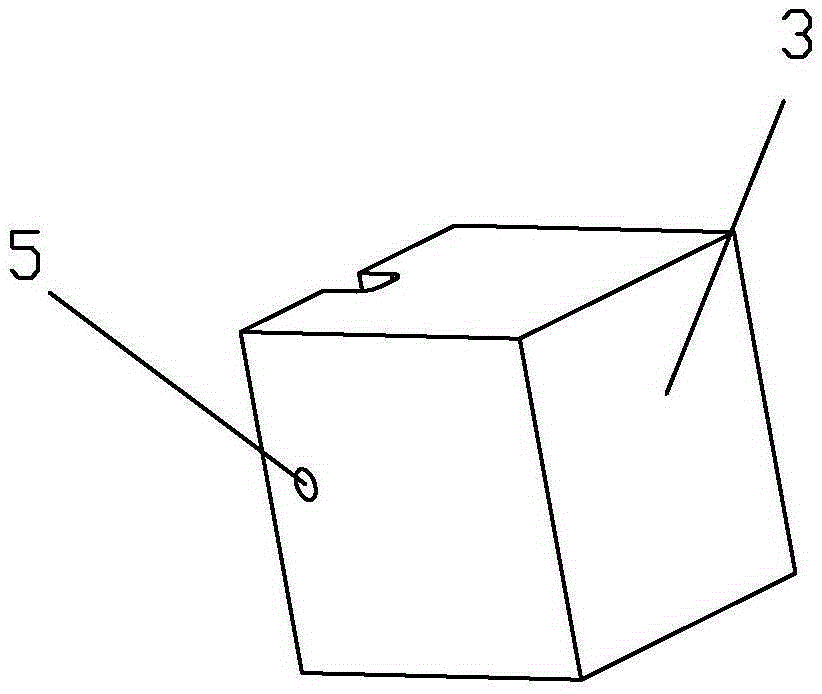

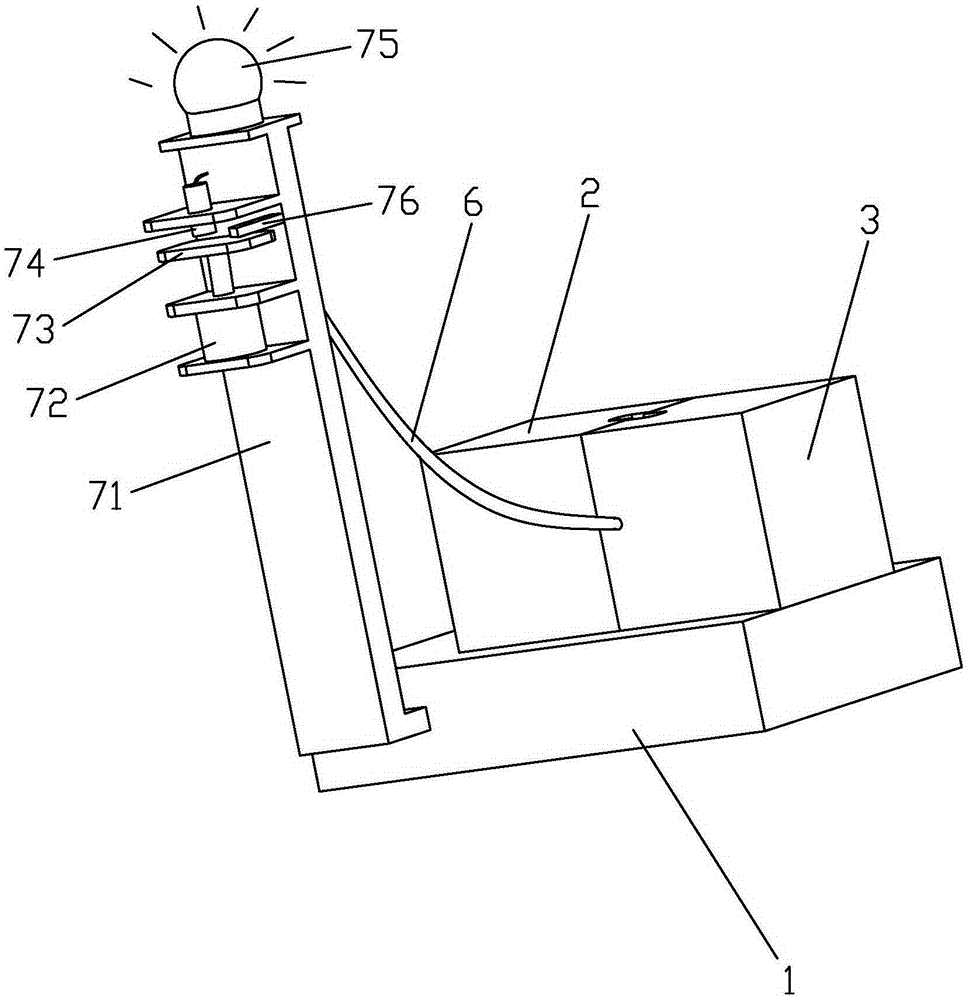

ActiveUS20070289578A1Contained costDrawback can be obviatedOperating means/releasing devices for valvesSpray nozzlesComing outBobbin

Owner:C R F SOC CONSORLILE PER AZIONI

Multi additive multifunctional composite for use in a non-metallic fuel conveyance system

A multifunctional composite material may include a polymer matrix, at least one nano-additive, micro-additive, and / or a spherical nano-additive. The non-metallic composite material may be used to make non-metallic parts for fuel conveyance systems for use in aircraft.

Owner:EATON INTELLIGENT POWER LTD

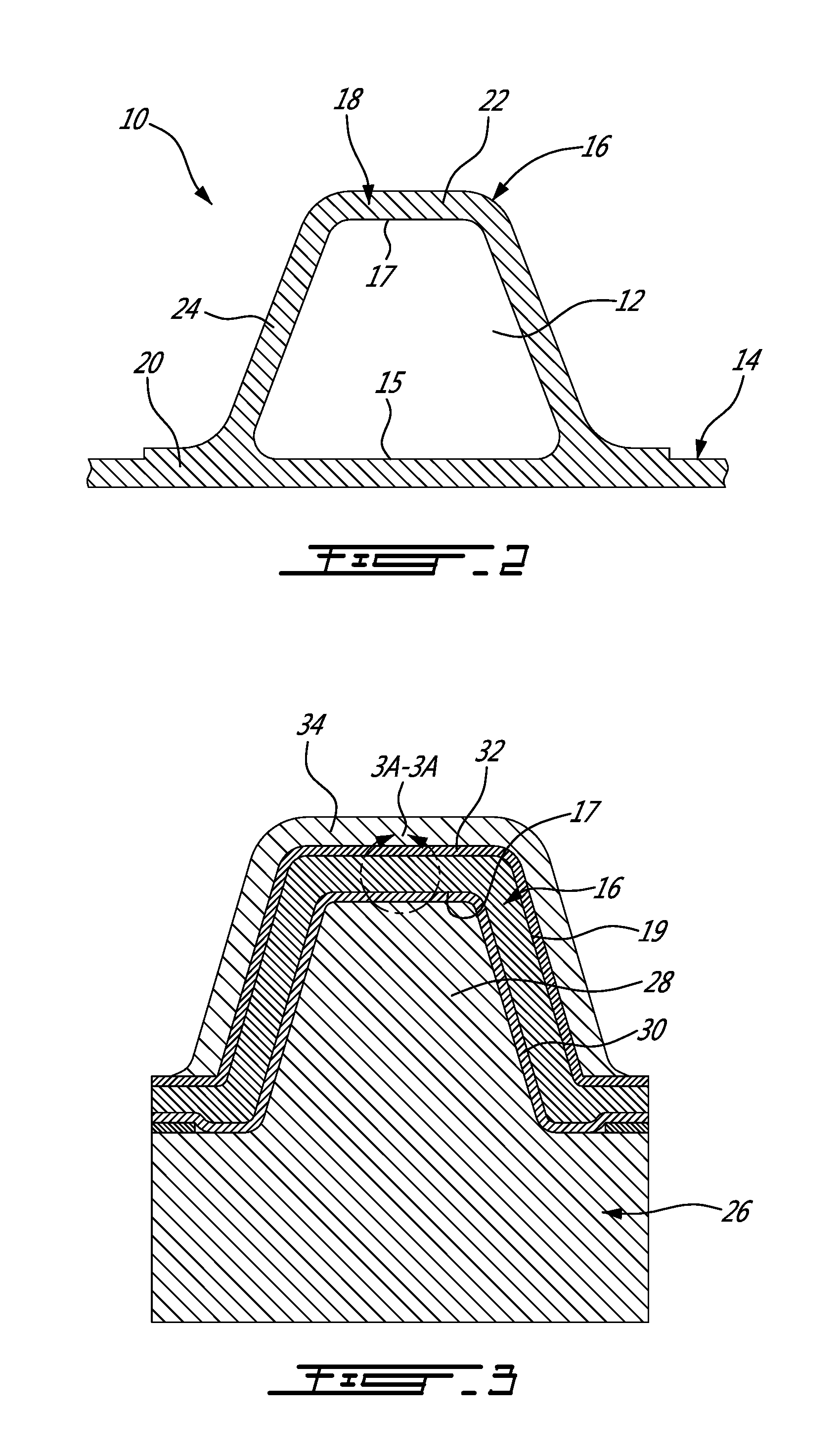

Process for forming a part having an integral feature, a part produced thereby and apparatus therefor

Owner:TOLEDO MOLDING & DIE

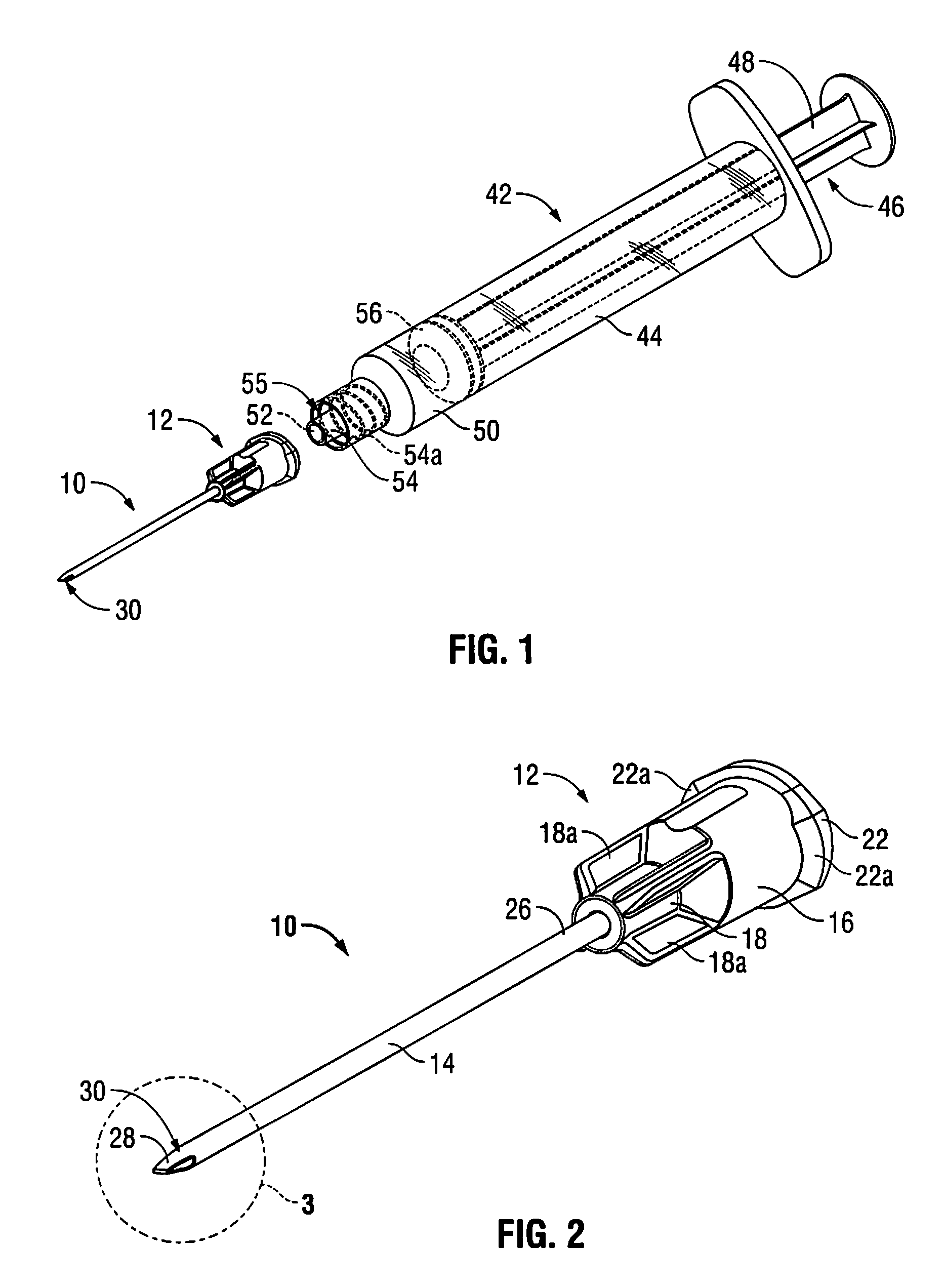

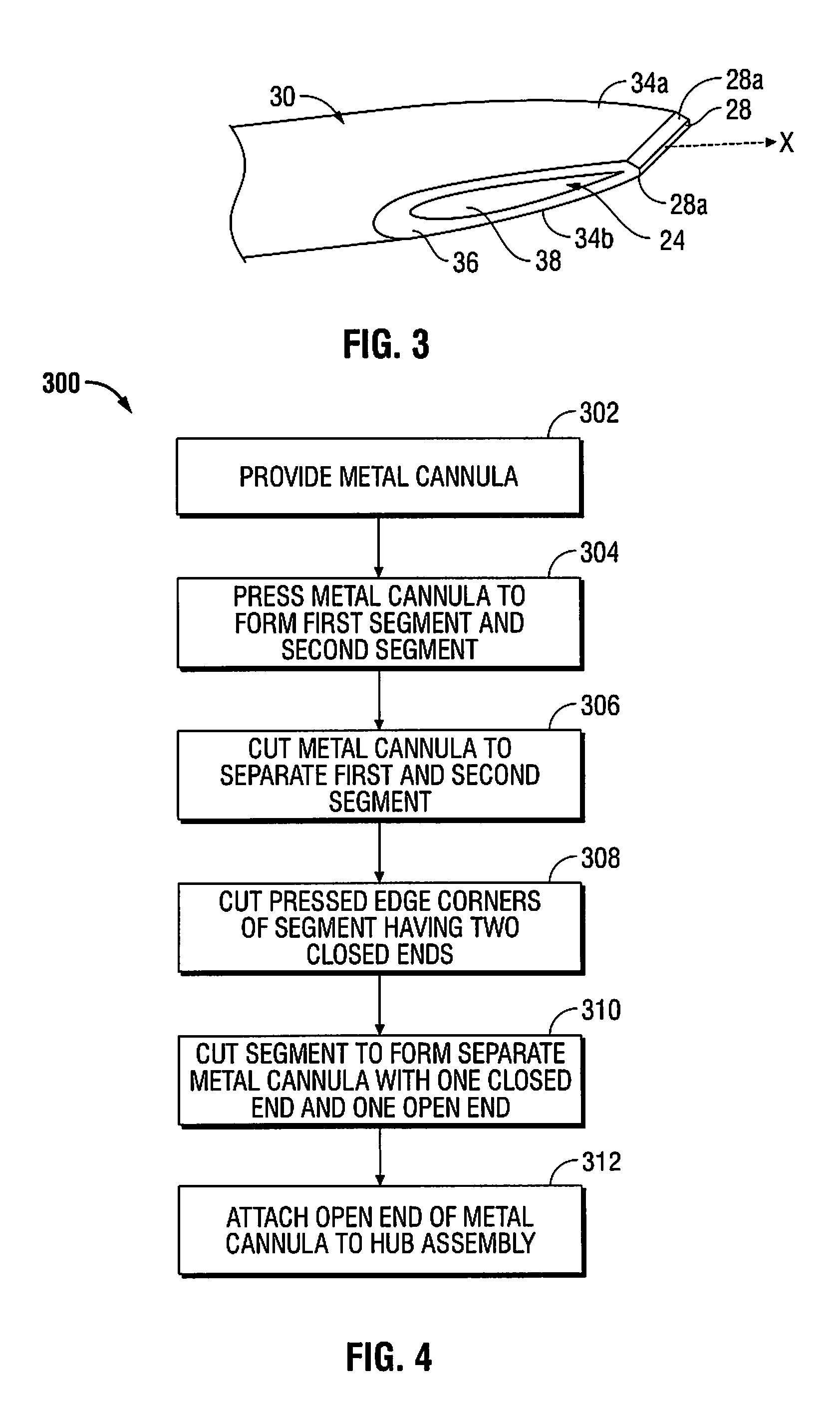

Blunt tip vial access cannula and method for manufacture

Owner:KPR U S LLC

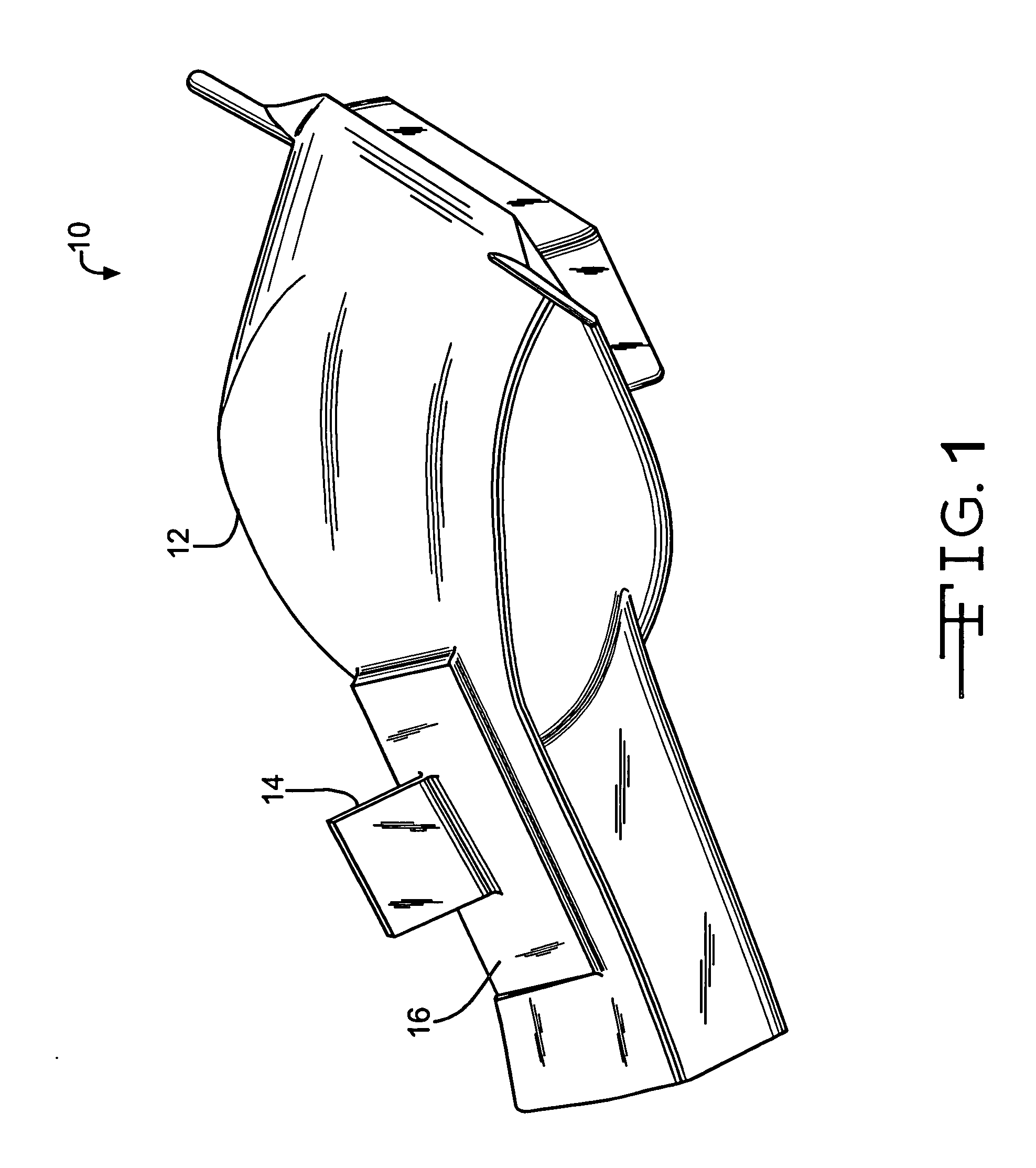

Tailorable Stiffness Shape Morphing Flow-Path

An apparatus and method for an improved morphing flow path. A flexible structure has a plurality of sections which include a first section and a second section. An actuator system is connected to the flexible structure and includes a number of actuators. The actuator system is capable of changing a configuration of the flexible structure. A controller is connected to the actuator system. The controller is capable of changing a position of a number of actuators within the actuator system.

Owner:THE BOEING CO

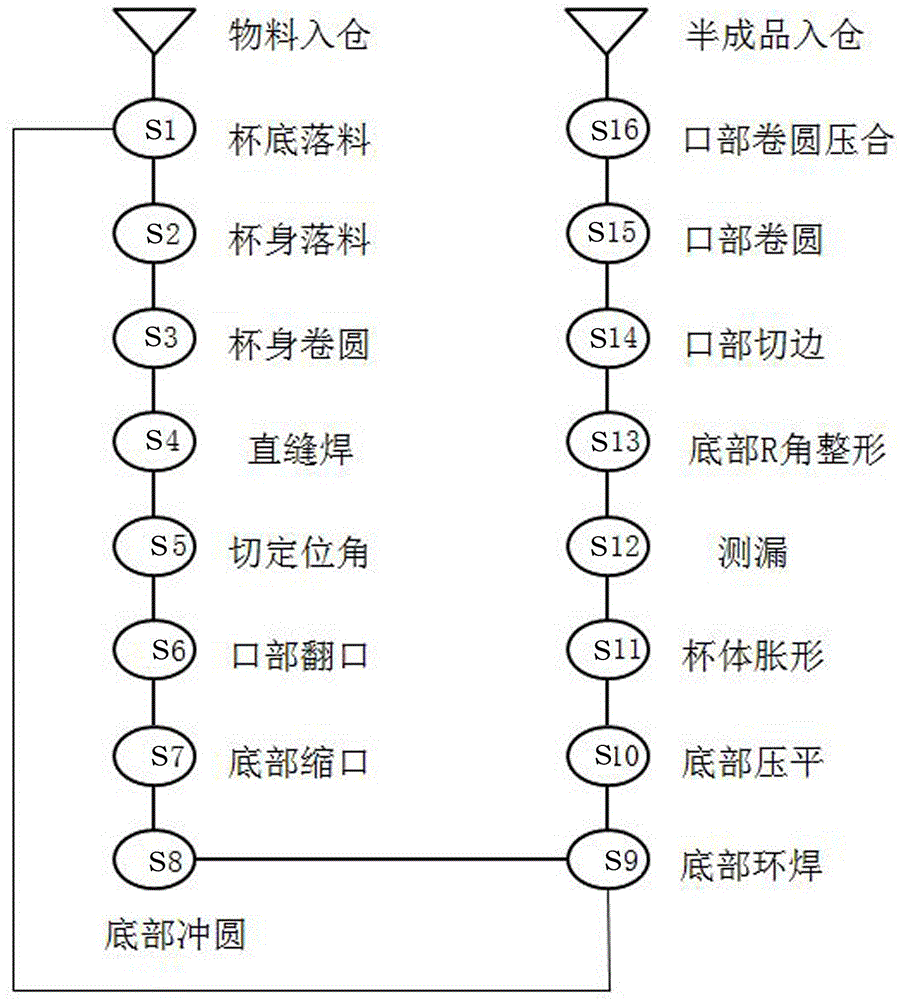

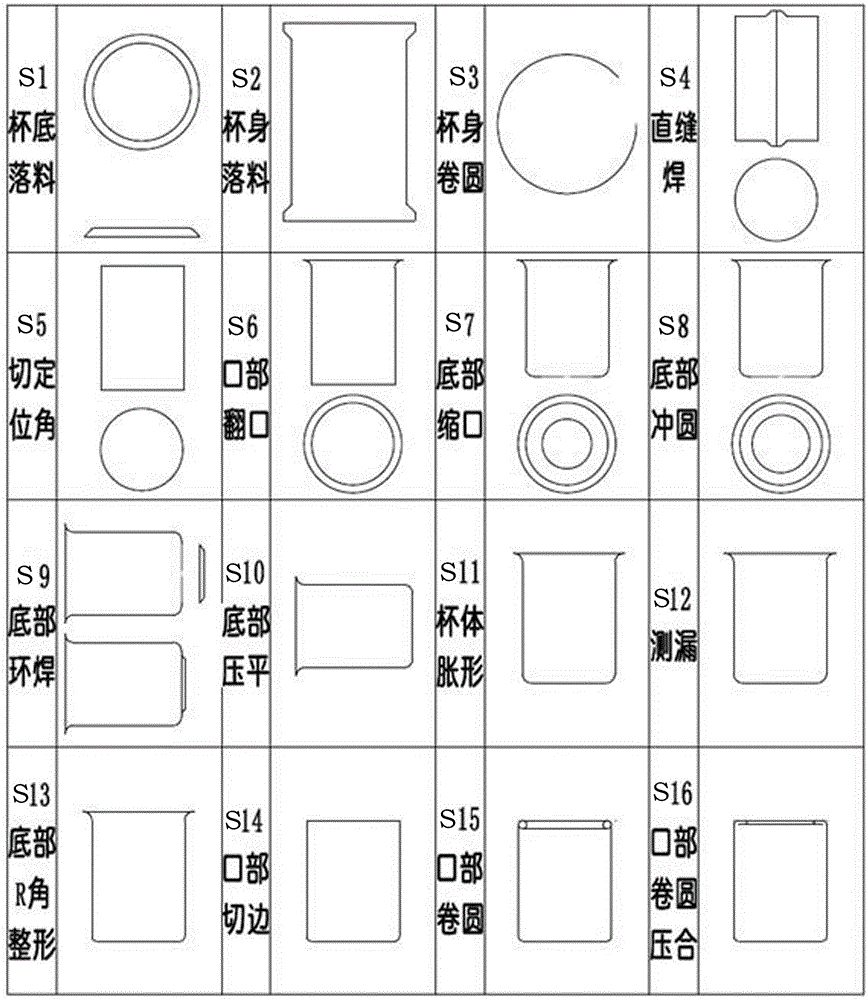

Cup body processing method

Owner:山东胜宁电器有限公司

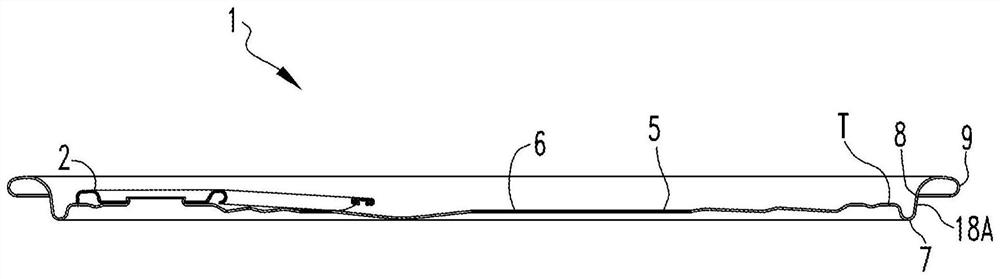

Cord plate for photovoltaic module

InactiveUS20120037202A1PV power plantsMetal-working apparatusSealantElectrical and Electronics engineering

Owner:JPMORGAN CHASE BANK NA

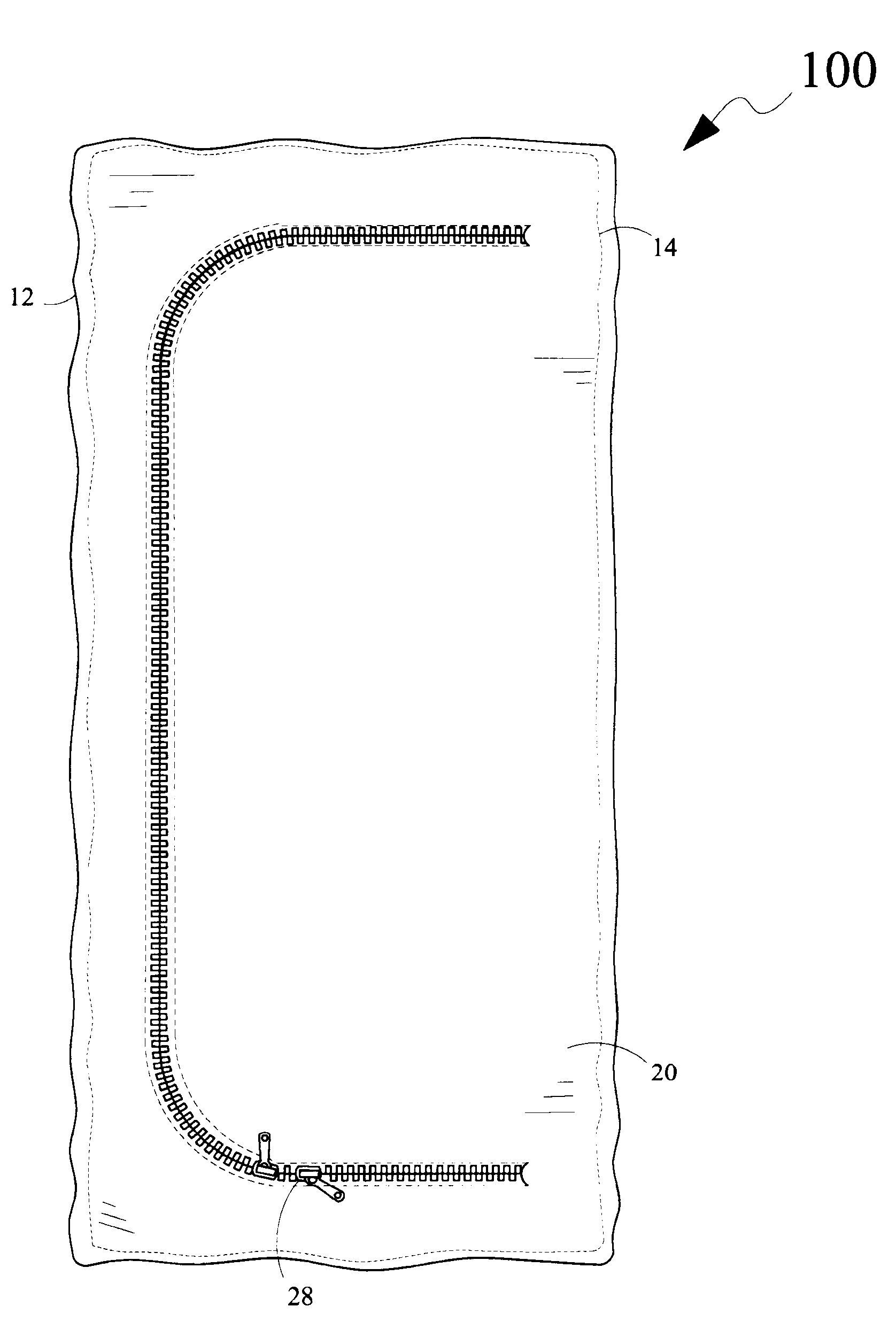

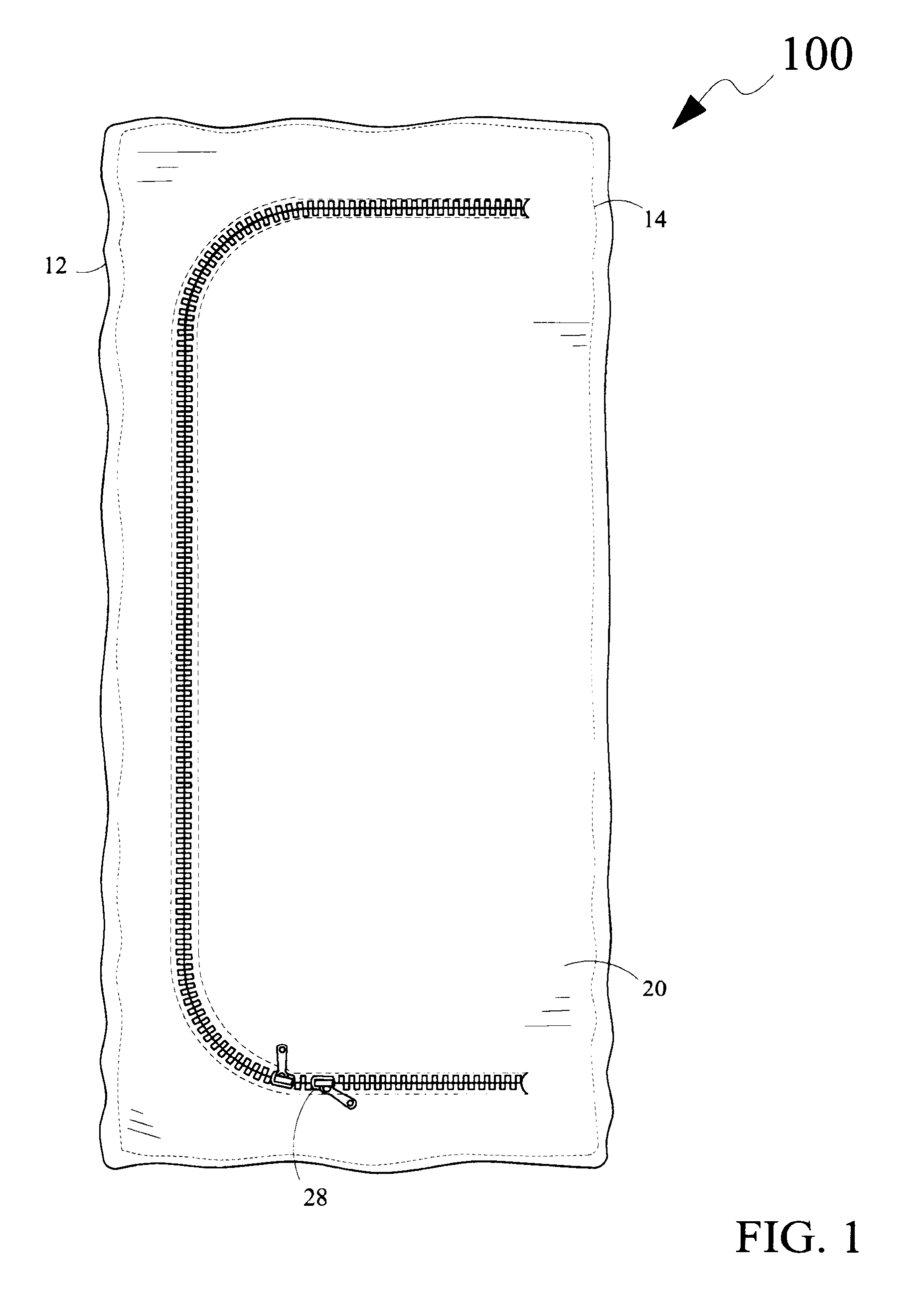

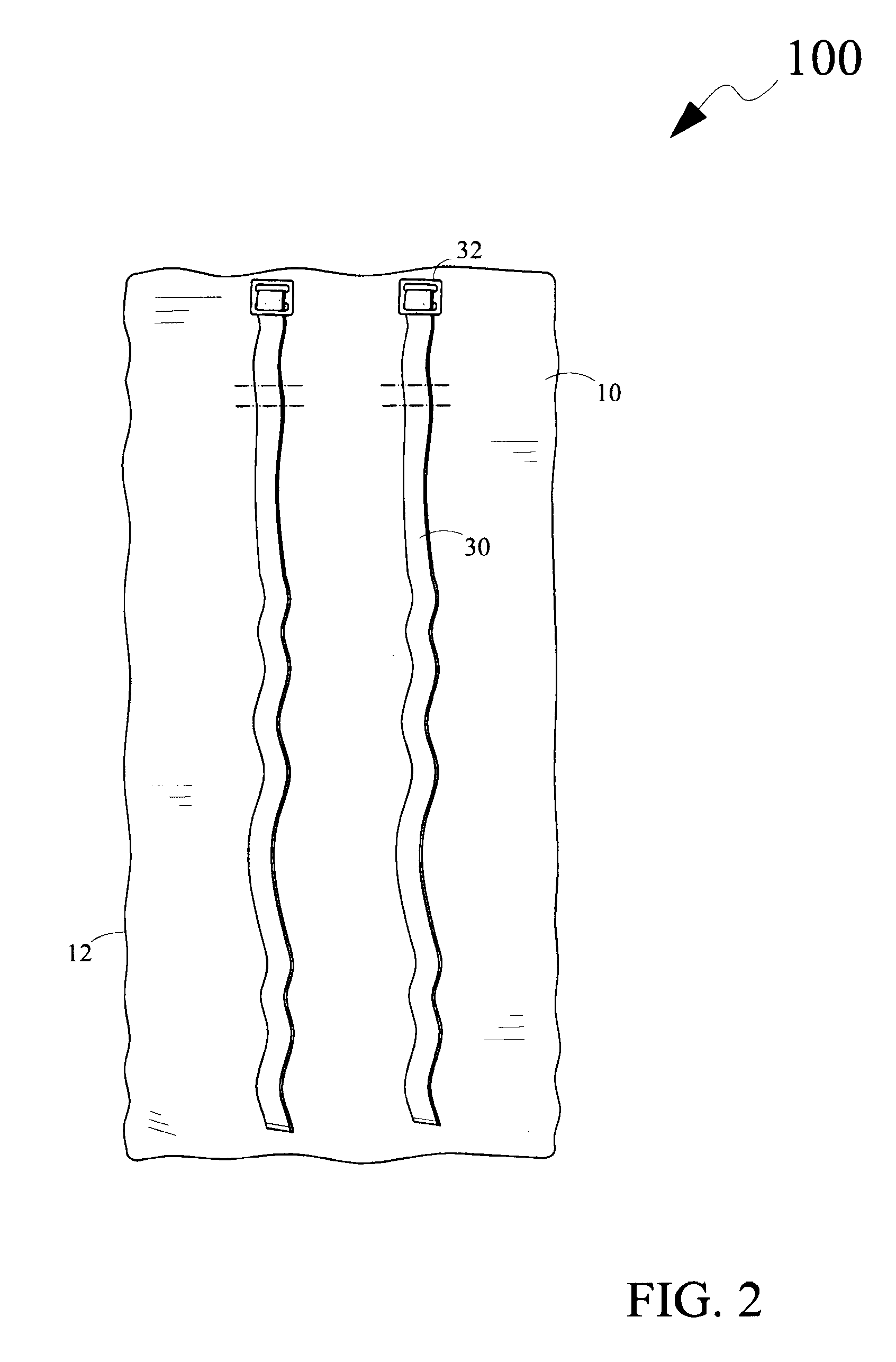

Bedroll Protector

InactiveUS20090035499A1Increase temperature ratingSynthetic resin layered productsLuggageEngineeringWater resistant

Owner:WANDEL TOM

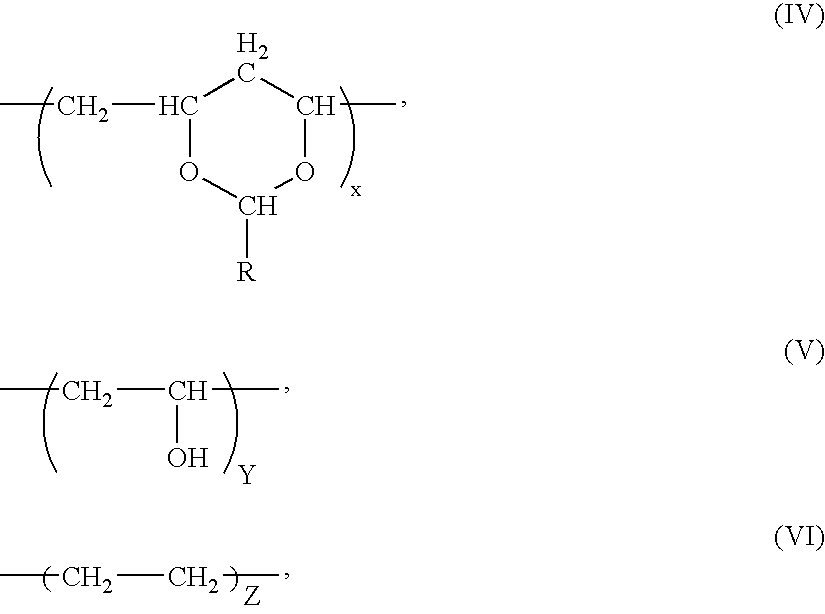

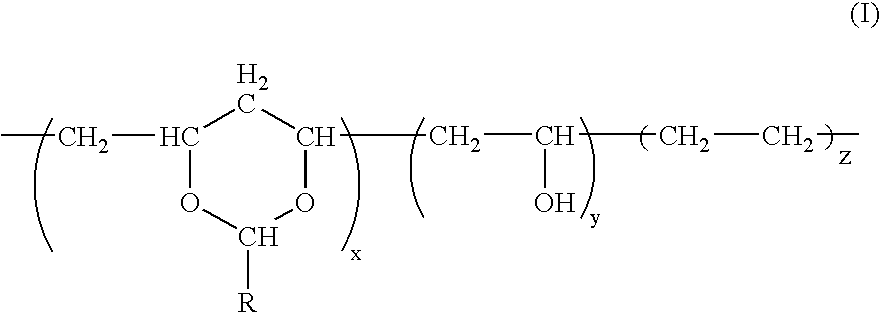

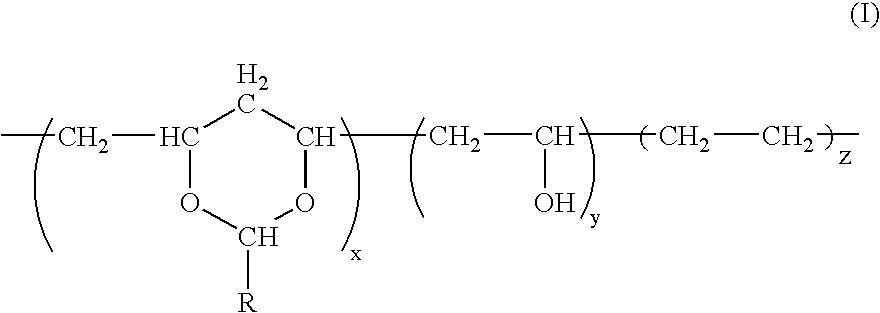

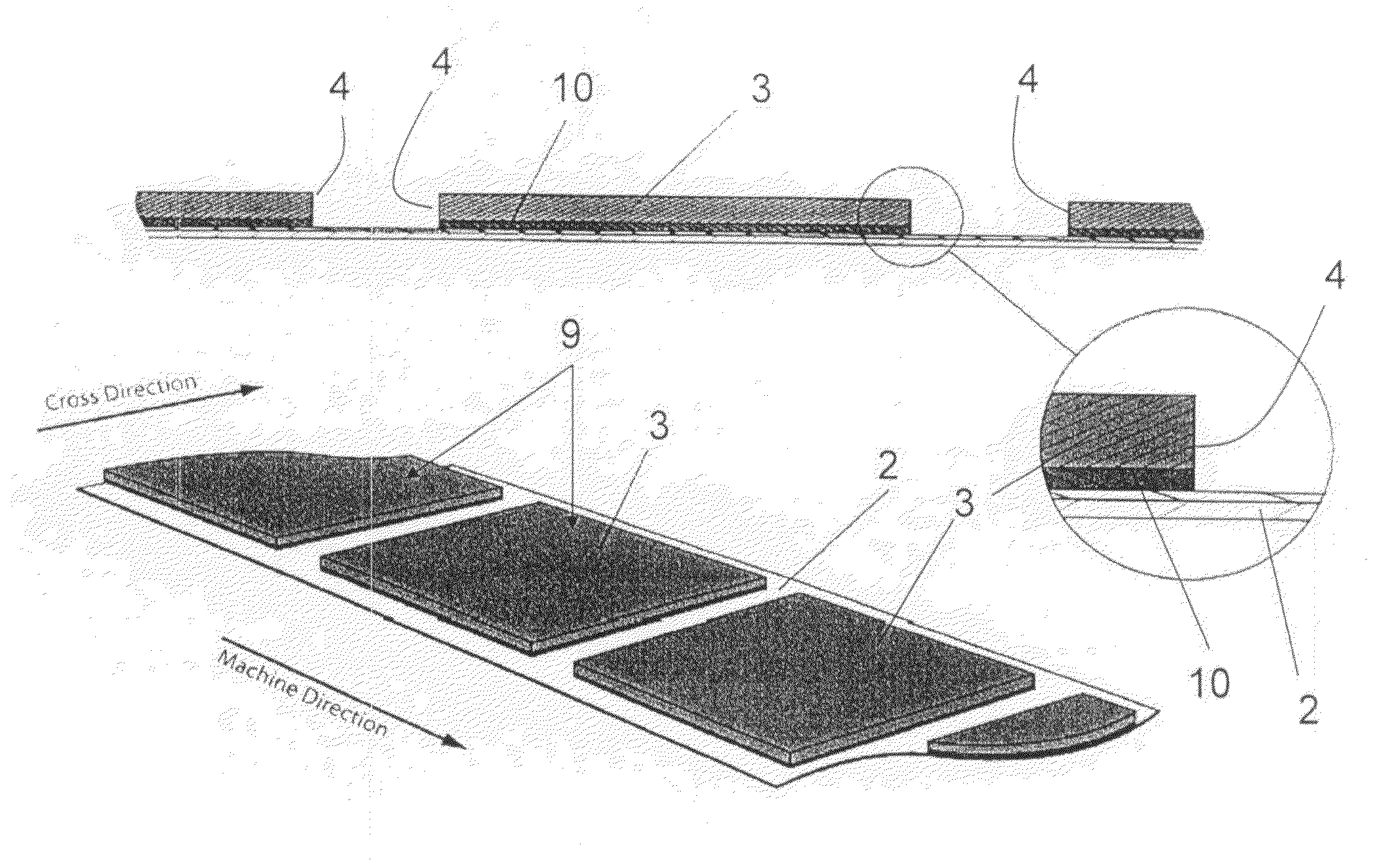

Hollow articles comprising fiber-filled polyester compositions, methods of manufacture, and uses thereof

Owner:SABIC GLOBAL TECH BV

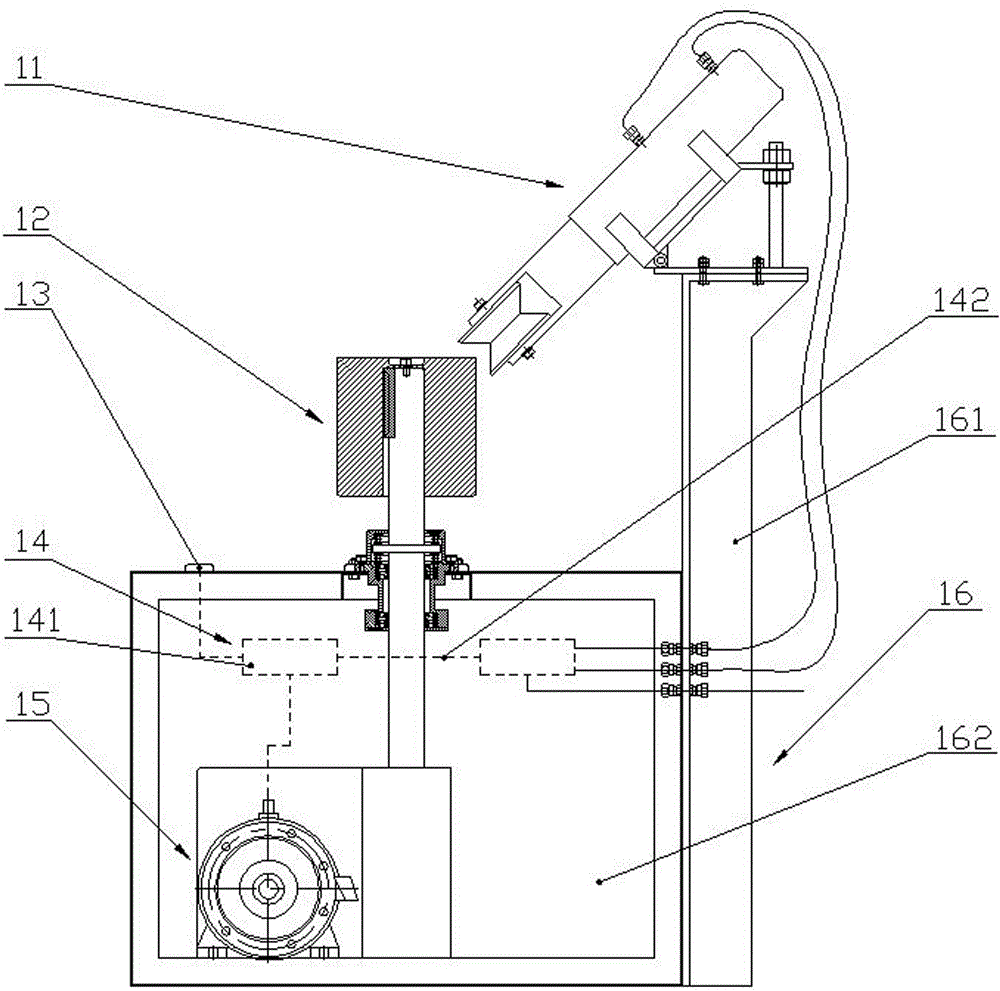

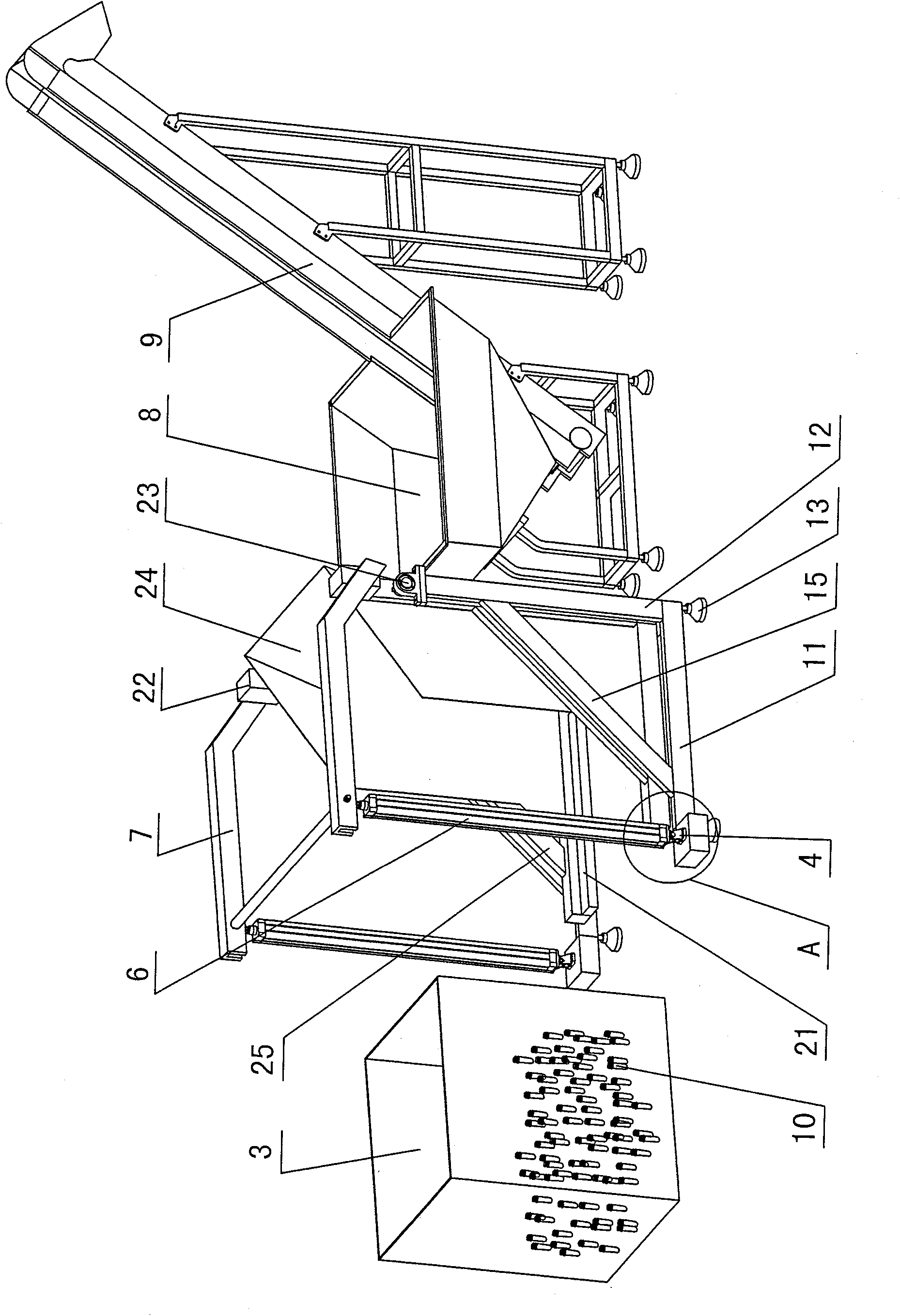

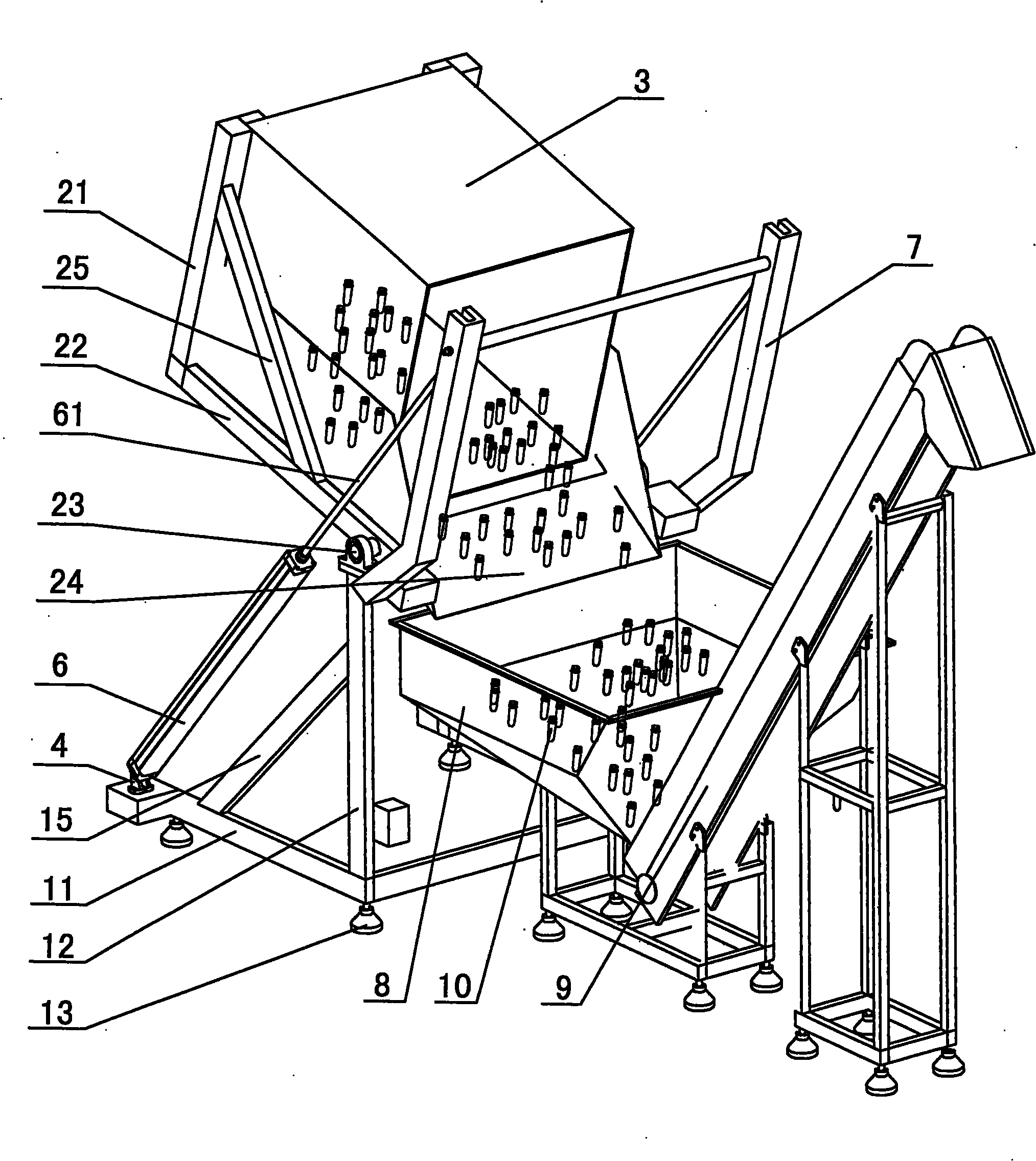

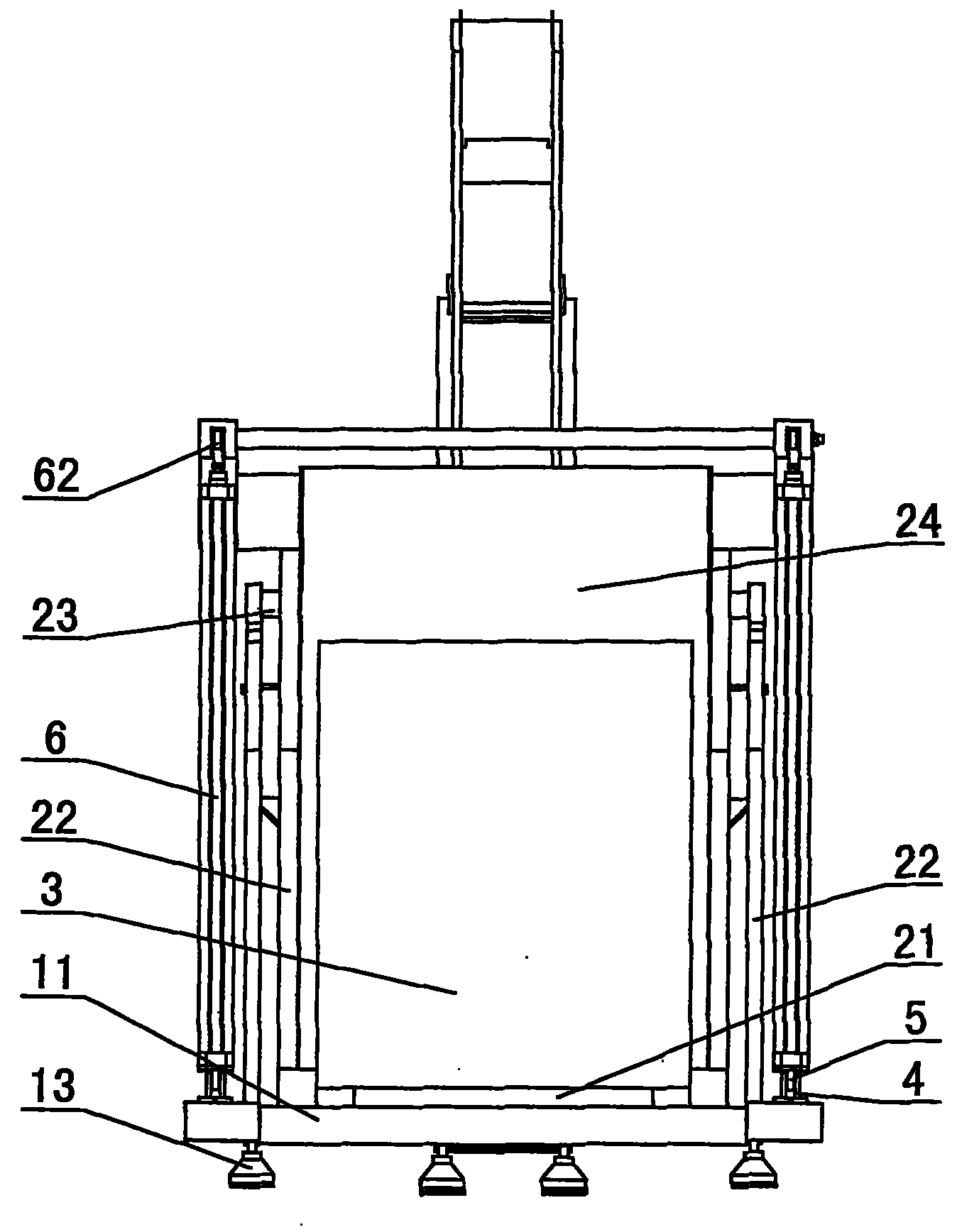

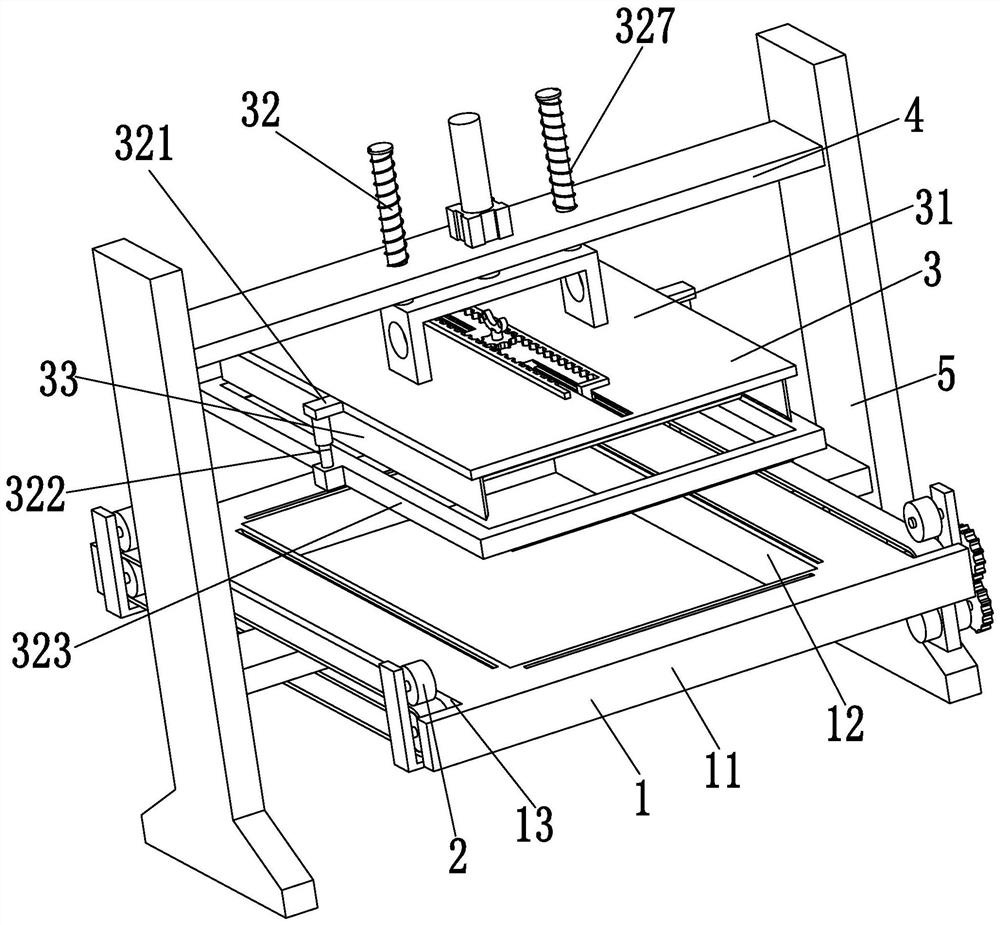

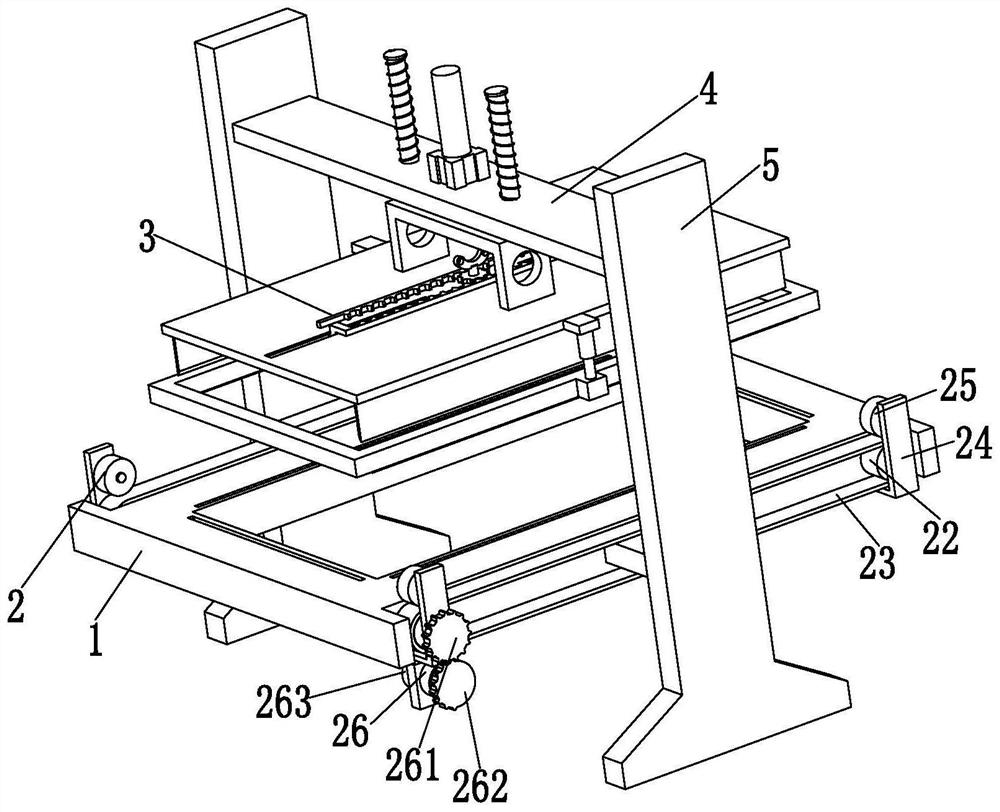

Automatic feeding hopper turnover mechanism of plastic container forming machine

Owner:ZHEJIANG DEMARK MACHINERY

Method for fabricating radiating pipes of water tank in car heat exchanger made from aluminum alloy, and dedicated device

InactiveCN101092000AOvercoming Pollution DefectsRealize green industrial productionLiquid surface applicatorsWelding/cutting media/materialsEngineeringMachining process

The invention relates to a machining method and special device for vehicle aluminum alloy heat exchange water tank radiator pipe. It puts the machining radiator pipe between two rollers of special device, which has flux on the surface. The flux would coat equally onto the surface of radiator pipe. The special device includes upper roller and down roller. The down part of driving upper roller drainage wheel and down roller is dipped in stock solution slot containing flux solution. The invention decreases a machining process, shortens machining time, improves producing efficiency, and decreases pollution to environment. The defective fraction of using the method could be under 0.3%. And the surface of the product is smoothing and bright.

Owner:林世东

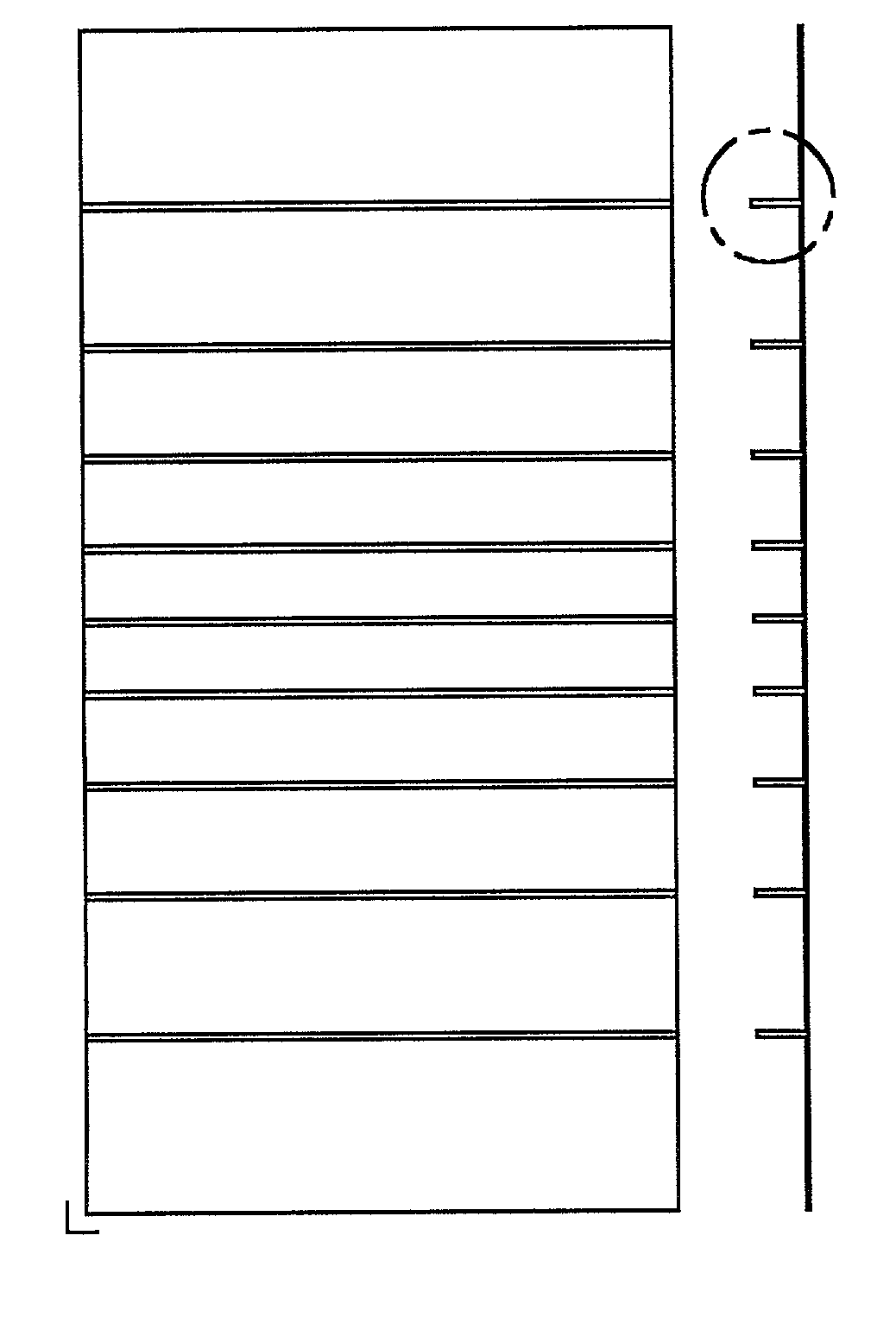

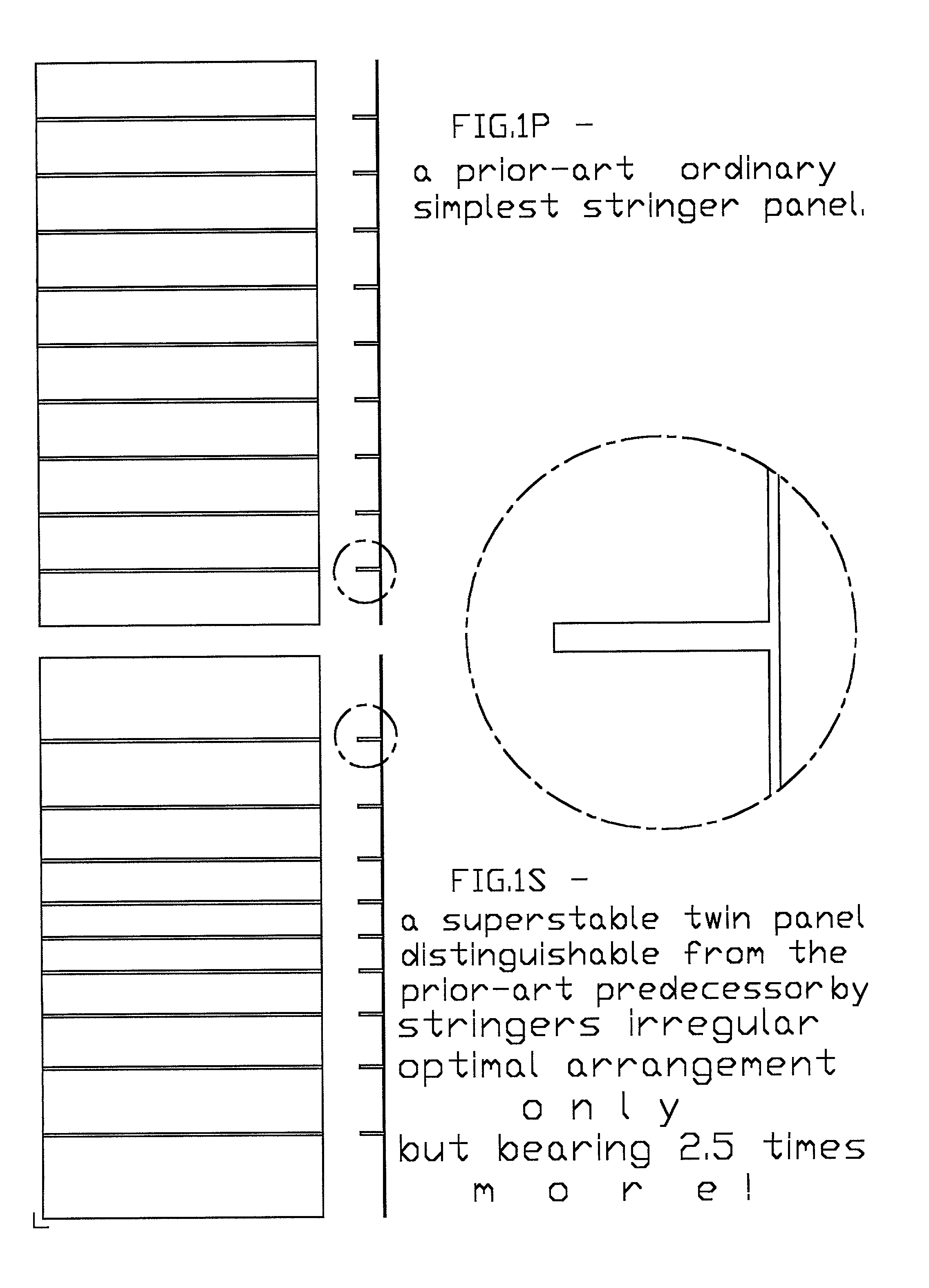

Superstability of thin-walled structures

InactiveUS20020132068A1Stability is lostEnvelopes/bags making machineryLayered productsAviationLoad distribution

Owner:ONANOV HERMAN GEORGE

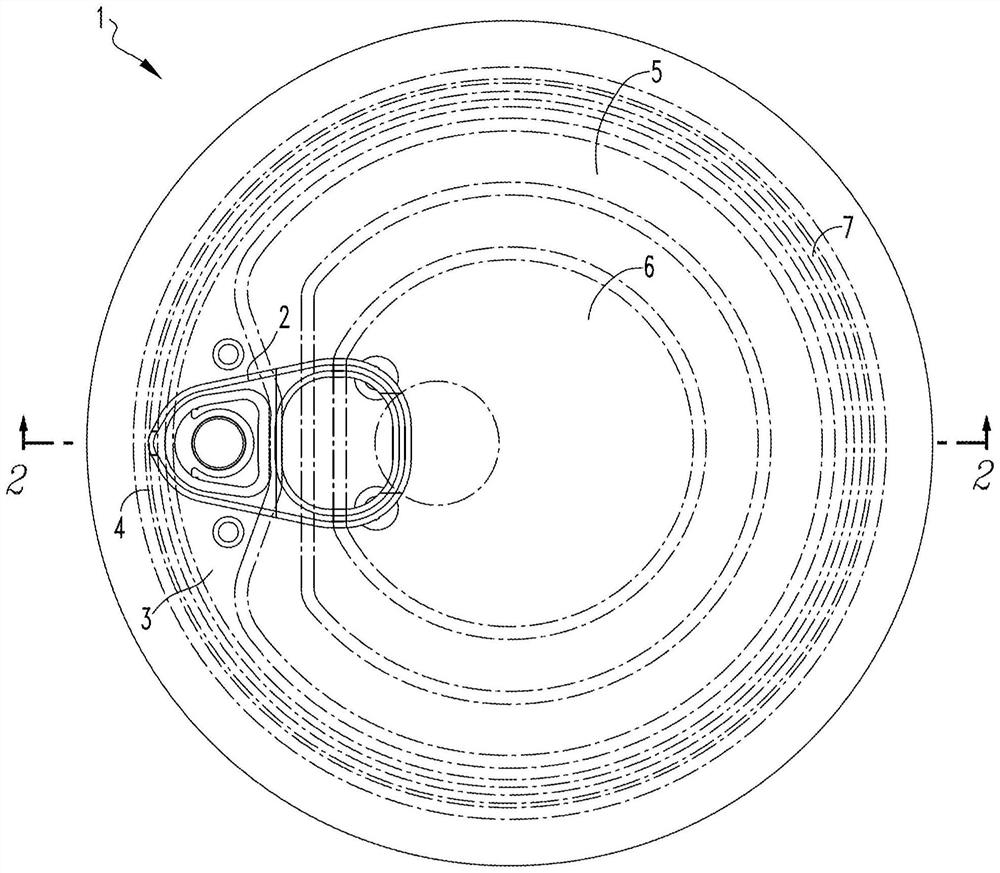

System and method of forming a metallic closure for a threaded container

An apparatus and methods of forming a metallic closure for a metallic bottle are provided. The present disclosure provides a pre-formed metallic closure and apparatus and methods of forming the metallic closure. The metallic closure can be reformed with a peripheral channel before the metallic closure is positioned on a metallic bottle. An inner tool and an outer tool can form the channel in one operation. Optionally, a thread can be formed on a metallic closure prior to use of the metallic closure to seal a metallic bottle. A capping apparatus of the present disclosure uses less force to seal a metallic bottle with a metallic closure of the present disclosure compared to the force required with a prior art ROPP closure. Accordingly, a metallic closure of the present disclosure can seal a metallic bottle formed of less material (such as by being thinner) than prior art metallic bottles.

Owner:BALL CORP

Metal packaging tin forming machining machine and machining method

Owner:义乌市伟硕包装科技有限公司

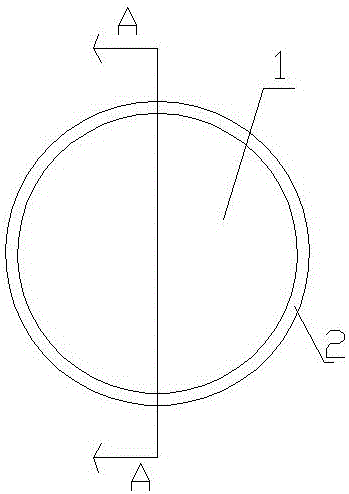

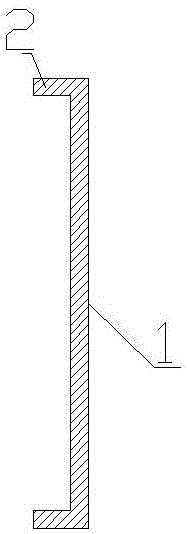

Circular end cover edge spinning device

Owner:SHANDONG LONGTAI OIL EQUIP LIMITED

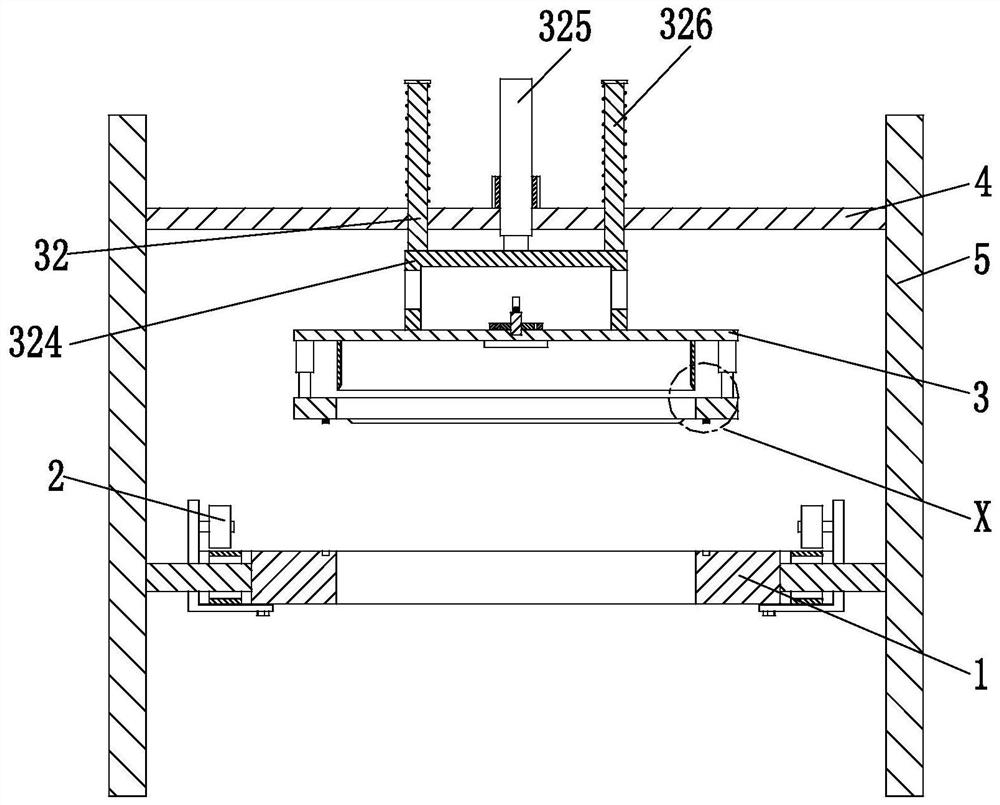

Heat exchanger pipe and pipe plate welding process

InactiveCN110883441AAchieve isolationGuaranteed to be fullWelding/cutting auxillary devicesAuxillary welding devicesEngineeringNitrogen gas

The invention discloses a heat exchanger pipe and pipe plate welding process. The heat exchanger pipe and pipe plate welding process comprises the following steps that the surfaces of the marked positions of a heat exchanger pipe and a pipe plate are polished through a special polisher, and an oxidation layer or a grease layer on the surfaces is removed through polishing; the polished heat exchanger pipe and pipe plate are fixedly mounted on a multi-freedom-degree clamp, the polishing position of the heat exchanger pipe corresponds to the polishing position of the pipe plate, and the pipe plate and the heat exchanger pipe are oppositely arranged in parallel; the to-be-welded position and the position nearby the to-be-welded position are heated through a flame spray gun, and the temperatureof the to-be-welded position is increased to 200 DEG C to -230 DEG C; and a nitrogen isolation device is moved to the position below the welding position of the heat exchanger pipe and the pipe plate, the welding position is filled with nitrogen, and oxygen is isolated. The invention relates to the technical field of heat exchanger pipes. By means of the heat exchanger pipe and pipe plate weldingprocess, the purposes of pretreating the welding position and improving the welding precision and quality are achieved.

Owner:NANJING YANGZI PETROCHEMICAL MAINTENANCE & INSTALLATION CO LT

Bottle body blowing machine capable of online detecting whether gas leakage exists in bottle body or not

Owner:湖北汇伟塑胶科技有限公司

Insulating label and method for manufacturing such label

InactiveUS20100196635A1High efficiency and low costFlat surfaceEnvelopes/bags making machineryStampsEngineeringElectrical and Electronics engineering

Owner:ANHEUSER BUSCH INBEV SA

Processing technology for longilineal and cylindrical parts

Owner:仪征市福斯特机械制造有限责任公司

Cold spinning device used for steel seamless gas cylinder

Owner:浙江金盾压力容器智造股份有限公司

Reverse pressure can end

Owner:STOLLE MACHINERY

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap