Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8 results about "Grease" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Grease is a semisolid lubricant. Grease generally consists of a soap emulsified with mineral or vegetable oil. The characteristic feature of greases is that they possess a high initial viscosity, which upon the application of shear, drops to give the effect of an oil-lubricated bearing of approximately the same viscosity as the base oil used in the grease. This change in viscosity is called shear thinning. Grease is sometimes used to describe lubricating materials that are simply soft solids or high viscosity liquids, but these materials do not exhibit the shear-thinning properties characteristic of the classical grease. For example, petroleum jellies such as Vaseline are not generally classified as greases.

Simple and convenient synthesis method and application of waste grease based polyhydric alcohol

InactiveCN104262561ALow costSolve pollutionFatty acid esterificationPolyureas/polyurethane adhesivesTransesterification reactionAlcohol products

Owner:ZHEJIANG HENGFENG NEW MATERIAL

Grease-based epoxy polymer and epoxy copolymer, and preparation methods thereof

InactiveCN110804109AImprove mechanical propertiesIn line with the theme of sustainable developmentEpoxyPolymer science

Owner:ANHUI AGRICULTURAL UNIVERSITY

Grease-based polyamine curing agent as well as preparation method and application thereof

ActiveCN112759565ASpatial structure is stableImprove toughnessOrganic chemistryPolymer scienceVegetable oil

The invention discloses a grease-based polyamine curing agent and a preparation method and application thereof, and the preparation method comprises the following steps: (1) mixing castor oil, hydrogen peroxide, formic acid and concentrated sulfuric acid and / or p-toluenesulfonic acid for reaction to generate epoxy castor oil; (2) enabling the epoxy castor oil obtained in the step (1) and fatty acid group dibasic acid to generate epoxy castor oil based dibasic acid monoester in an organic solvent under the catalysis of p-toluenesulfonic acid; (3) reacting the epoxy castor oil-based dibasic acid monoester obtained in the step (2) with polyethylene polyamine to generate a grease-based polyamine curing agent. The invention also discloses polyurethane of which the raw materials comprise the grease-based polyamine curing agent. The grease-based polyamine curing agent prepared by the method can be used as a curing agent to react with cyclic carbonate, the spatial structure of polyurethane formed after polymerization is more stable due to the multi-branched chain structure in molecules, the prepared vegetable oil-based polyurethane is endowed with excellent toughness and strength, and meanwhile, the weather resistance and the chemical stability are enhanced.

Owner:SUZHOU FENGBEI BIOTECH CO LTD

Oil-resistant ABS modified material

Owner:NINGBO HENGTUO POLYMER MATERIAL

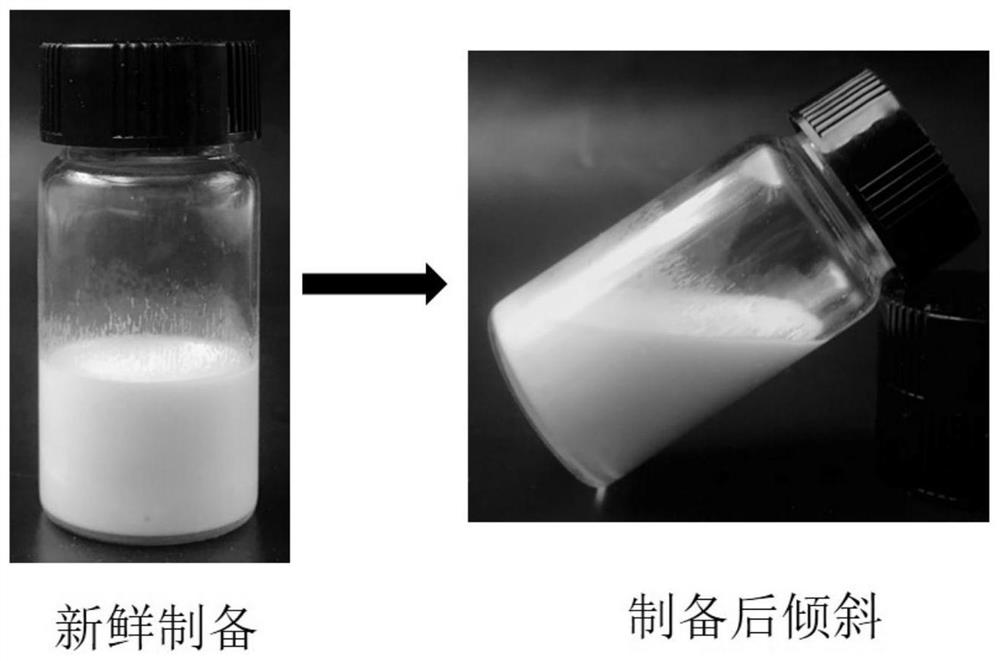

Water-in-oil type high-internal-phase emulsion carrying bitter substances and preparation method of water-in-oil type high-internal-phase emulsion

PendingCN114680332AAdjust viscosityHigh encapsulation efficiencyLipidic food ingredientsNatural extract food ingredientsGlycerolOil phase

Owner:杭州佰倍优生物科技有限公司

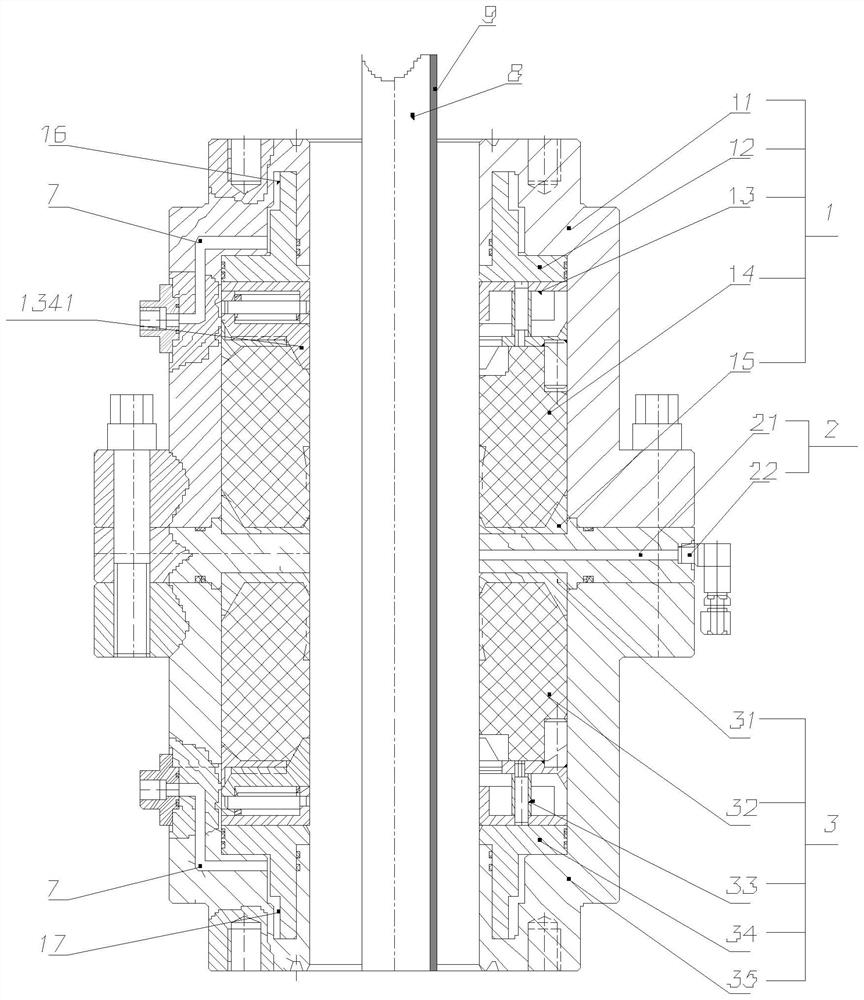

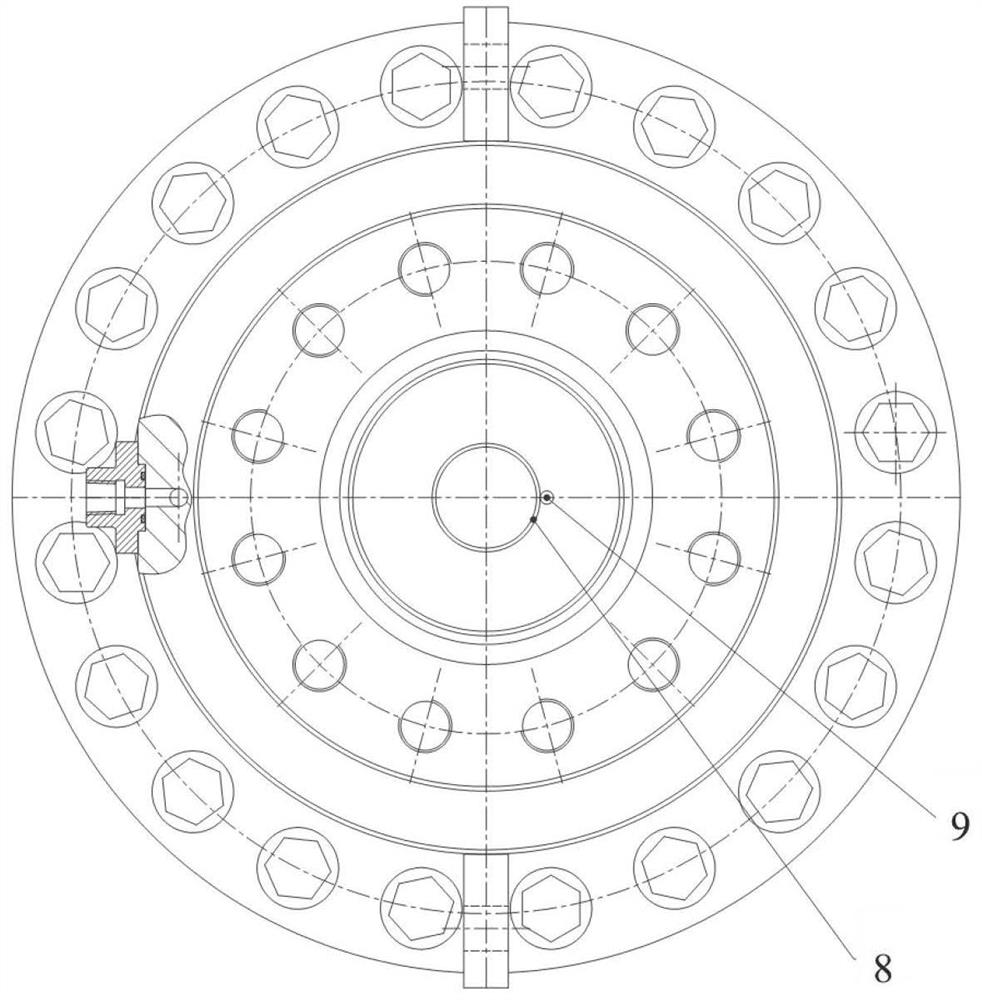

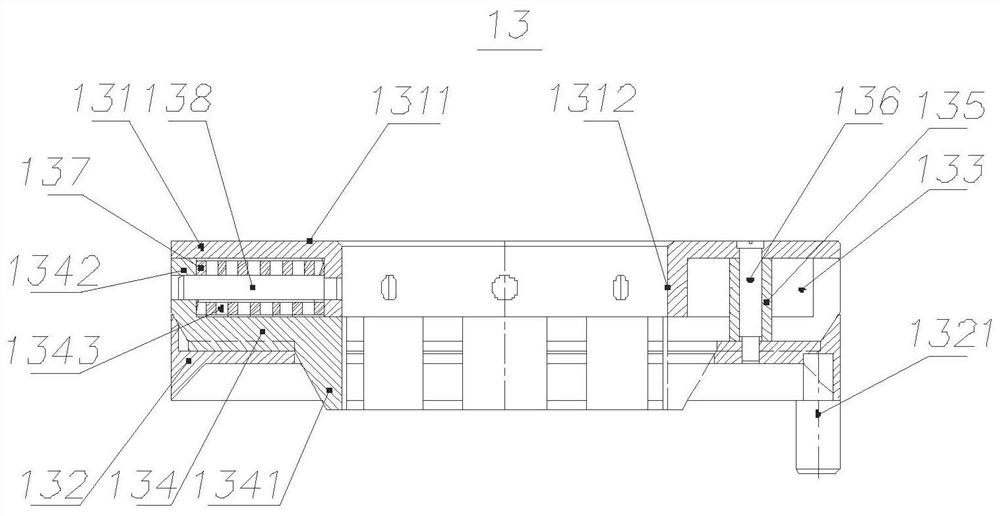

Blowout prevention device for sealing external cable oil pipe, static sealing under-pressure operation blowout prevention system and under-pressure construction operation method

ActiveCN114482905AImprove reliabilityMeet the sealing requirements of construction under pressureSealing/packingElectric cablesPiston

Owner:西安宇星石油机械新技术开发有限公司

Grease composition for rolling bearing

InactiveUSRE48187E1Excellent acoustic durabilityReduction of bearing torqueBearing componentsThickenersFiberPolymer science

A grease composition for rolling bearing comprising a metal soap-based thickening agent containing a long fiber-like material having a major axis length of at least 3 μm incorporated in a base oil comprising a lubricant having a polar group in its molecular structure and a non-polar lubricant blended in combination.

Owner:NSK LTD +1

Molded self-lubricating joint bearing and use method thereof

Owner:福建省德源智能科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap