Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

17 results about "Chemical stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical stability when used in the technical sense in chemistry, means thermodynamic stability of a chemical system. Thermodynamic stability occurs when a system is in its lowest energy state, or chemical equilibrium with its environment. This may be a dynamic equilibrium, where individual atoms or molecules change form, but their overall number in a particular form is conserved. This type of chemical thermodynamic equilibrium will persist indefinitely unless the system is changed. Chemical systems might include changes in the phase of matter or a set of chemical reactions.

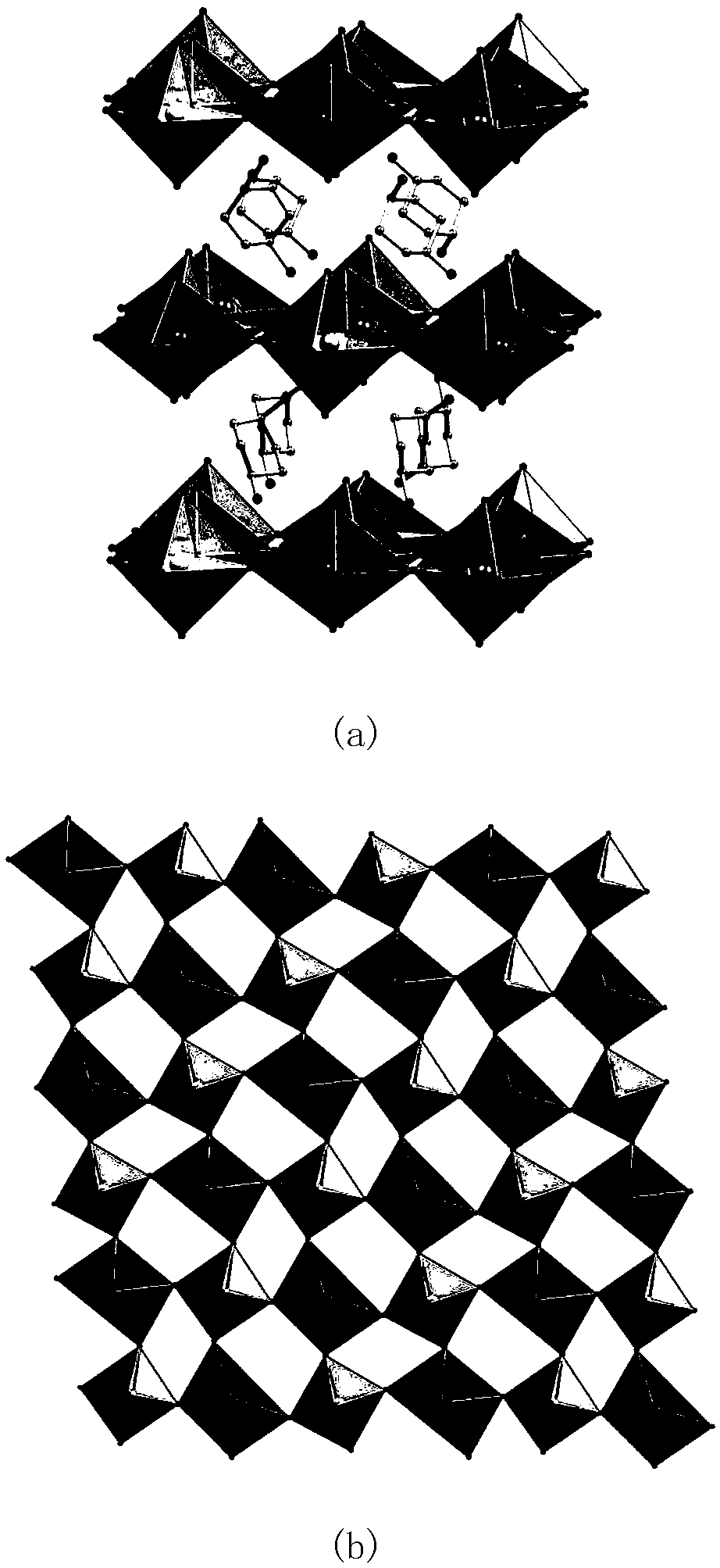

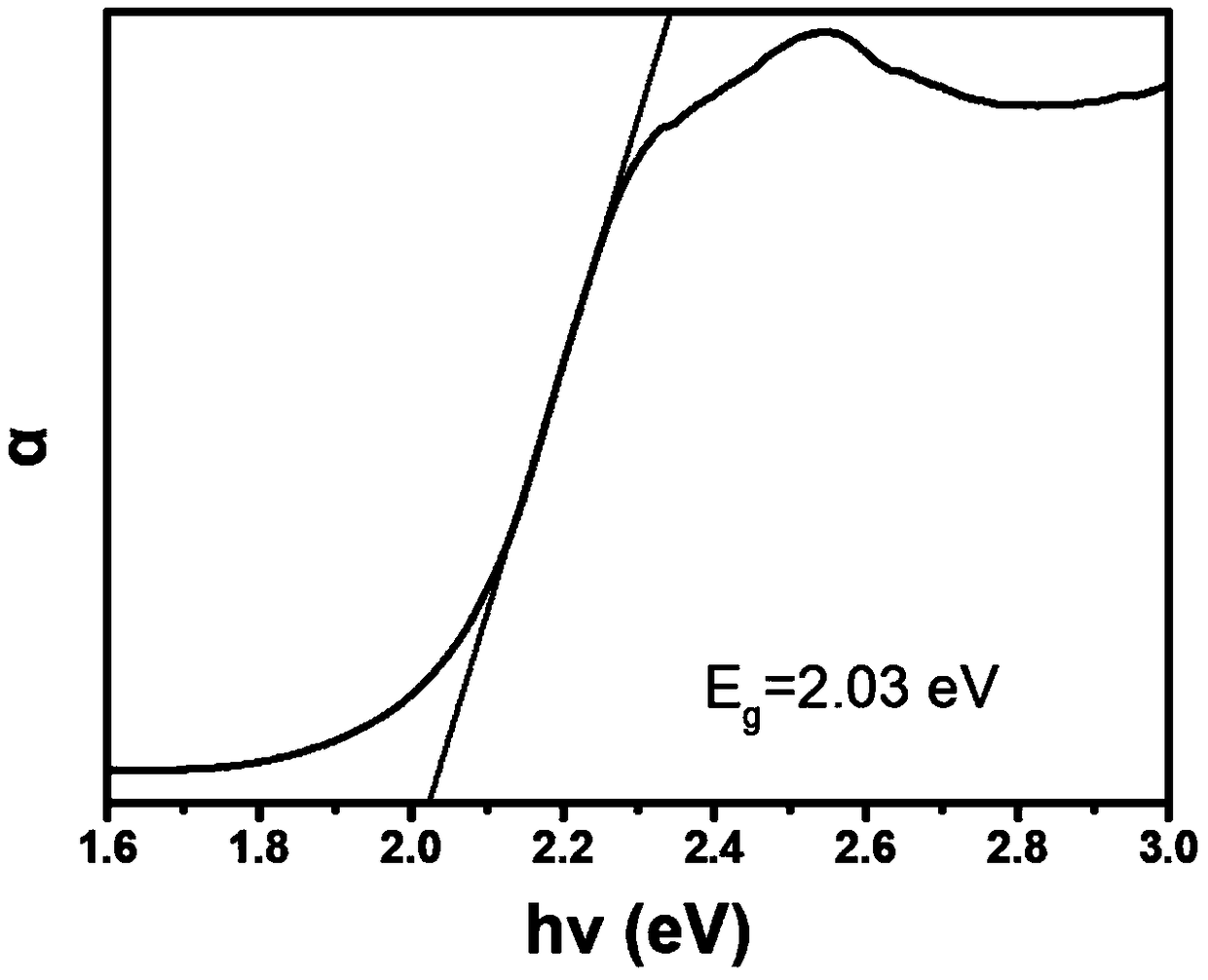

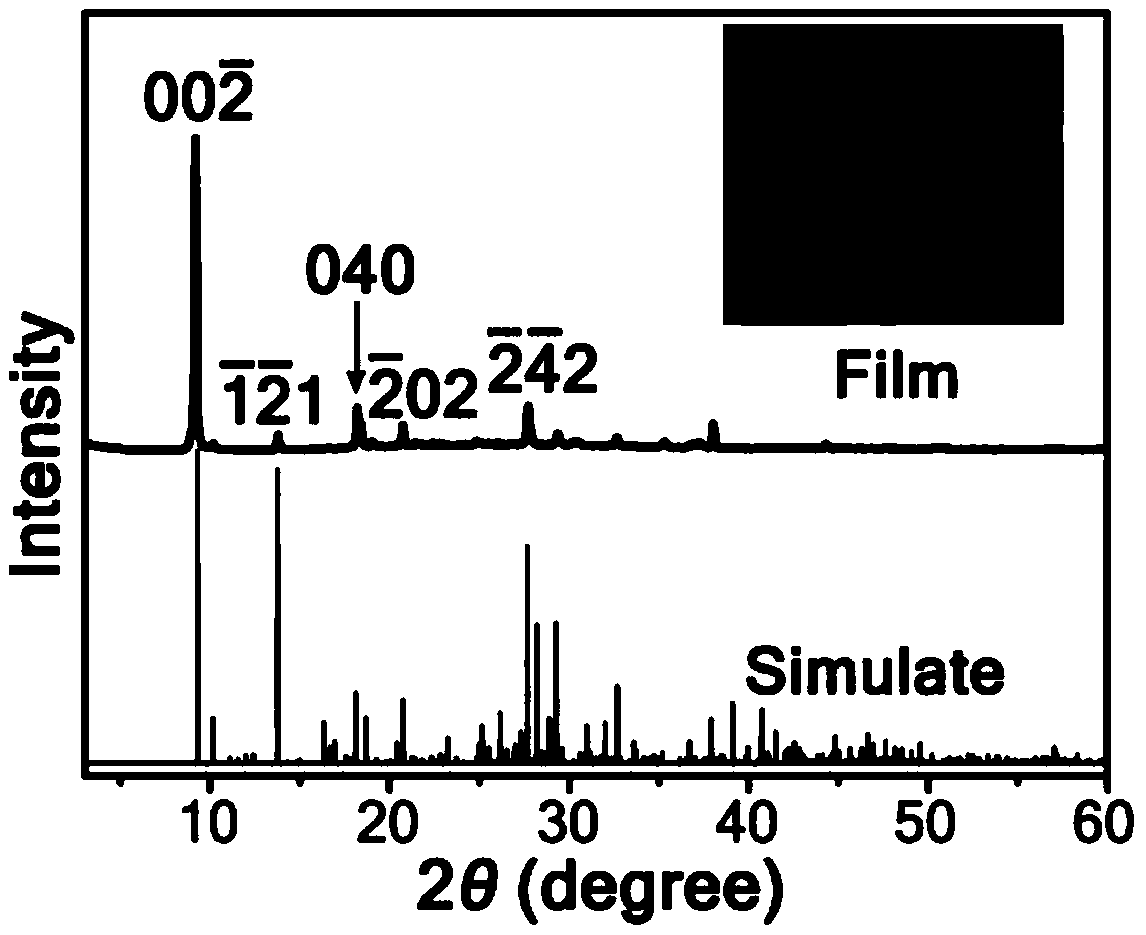

Lead-free hybrid two-dimensional double perovskite material and preparation method thereof

InactiveCN109369725AGood chemical stabilitySuitable and tunable optical absorption bandgapOrganic chemistry methodsBismuth organic compoundsPhoto stabilityOpto electronic

Owner:XI AN JIAOTONG UNIV

Preparation method and application of surface artemisinin molecule imprinting adsorbing material of vegetable sponge

InactiveCN102600813ASpecific recognition abilityHigh selectivityIon-exchange process apparatusOrganic chemistryCross-linkN dimethylformamide

Owner:UNIV OF JINAN

Fluorine-carbon surfactant and method of producing the same

InactiveCN101279217AReduce surface tensionReduce manufacturing costTransportation and packagingMixingAdditive ingredientHigh surface

Owner:上海亚孚化工科技有限公司

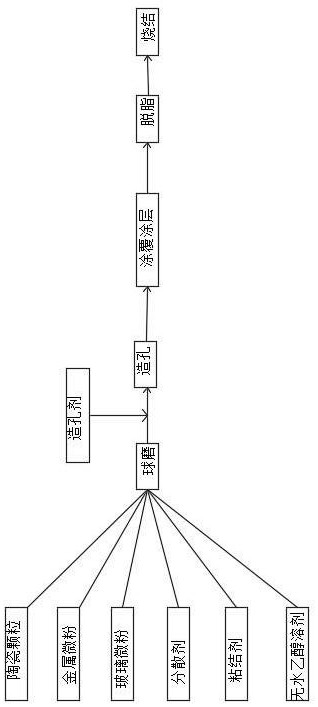

Method of preparing high-strength heat conducting graphite flakes with flow guiding and heat conducting functions

ActiveCN106316397AHigh purityQuality improvementLayered productsCooling/ventilation/heating modificationsHeat conductingGranularity

The invention discloses a method of preparing high-strength heat conducting graphite flakes with flow guiding and heat conducting functions. The method includes the steps of raw material preparing, pre-crushing, pre-screening, deironing, secondary crushing, secondary screening, mixing, profiling and heating, graphitizing at high temperature, back film preparing, heat conducting tank pressing and cutting. The machining process is scientific and reasonable in step, the machining process in the prior art is improved, the raw material is processed in a refined mode, the granularity of the graphite flakes is more uniform, the qualification rate of the finished product is increased, and electrical conductivity and heat conductivity of the heat conducting graphite flakes are improved; by means of the process, the chemical stability of the graphite flakes can be improved, thermal expansion is reduced, and the graphite flakes are easy to machine and shape.

Owner:DONGGUAN KAIDI CARBON CO LTD

Stainless steel crucible paint used for smelting aluminum-lithium alloy as well as preparation method thereof and coating method thereof

ActiveCN110172627AImprove stabilityImprove thermal shock resistanceMetallic material coating processesLithiumCrucible

Owner:NORTHEASTERN UNIV

Injection molding method

InactiveCN102127303AGood dispersionChemical stability stableCoatingsBlack spotInjection molding machine

Owner:NINGBO HENGFU AUTO PARTS DEV

Method for preparing P type ZnO ohmic electrode

InactiveCN1801460APromote interdiffusionLower the barrierSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor materialsOhmic contact

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

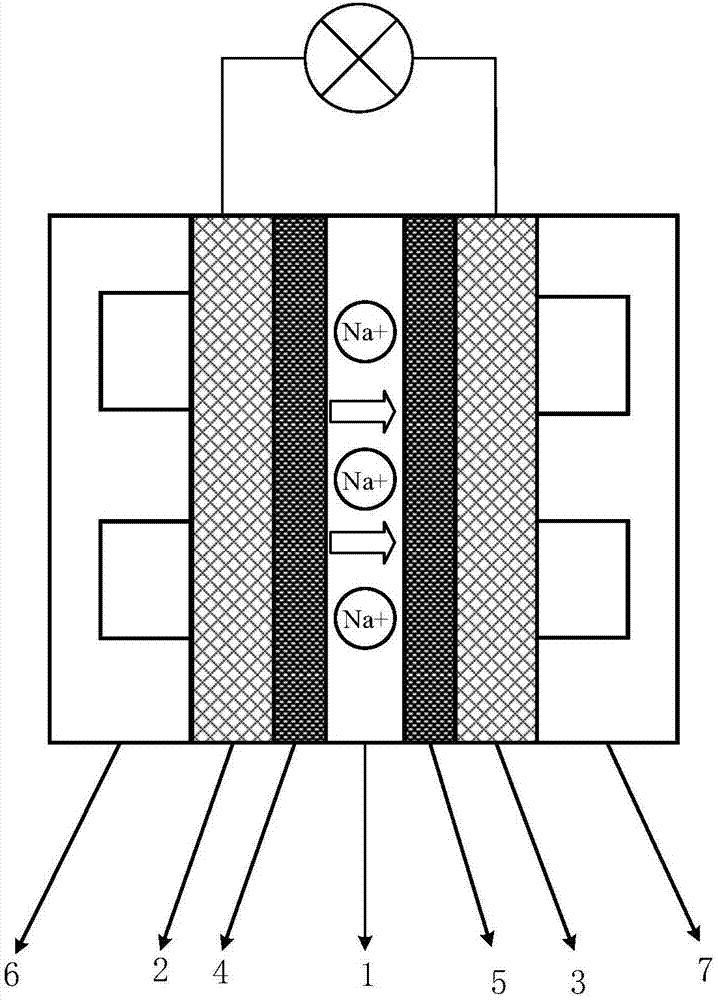

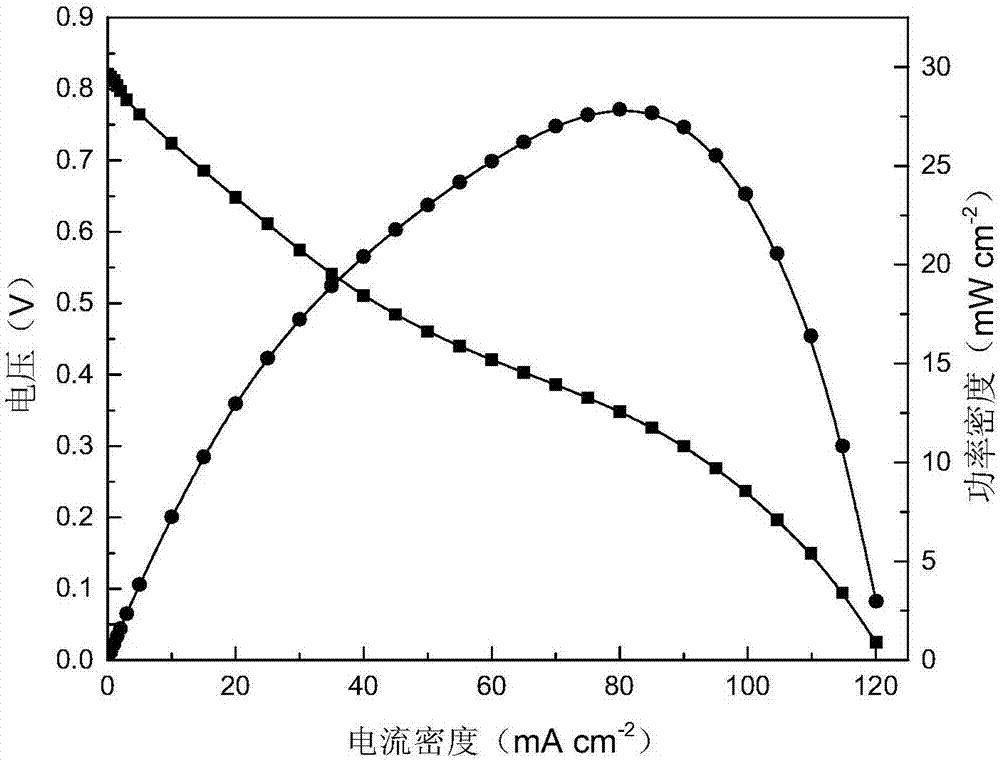

High temperature direct formate fuel cell with electricity and alkali salt co-production

ActiveCN106972176AOvercome stabilityLower internal resistanceCell electrodesFinal product manufactureFormateNon platinum

Owner:XI AN JIAOTONG UNIV

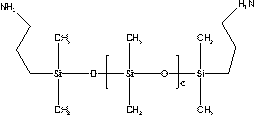

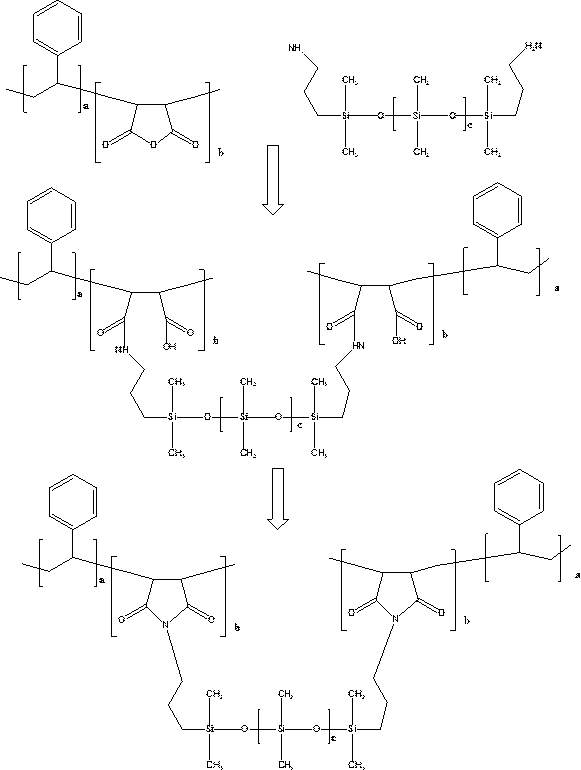

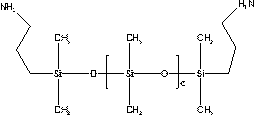

Synthesis of end amino silicone oil modified stryenemaleic anhydride copolymer

InactiveCN109337085AFlexible structure adjustmentControl Molecular Weight DistributionElastomerPolyolefin

Owner:YANTAI DARBOND TECH

Preparation method of filtering material for adsorbing fluorine ions in water

InactiveCN109929082AFully contactedGood chemical stabilityWater contaminantsWater/sewage treatment by flocculation/precipitationSorbentDiethylenetriamine

Owner:宁波市河清源技术转移服务有限公司

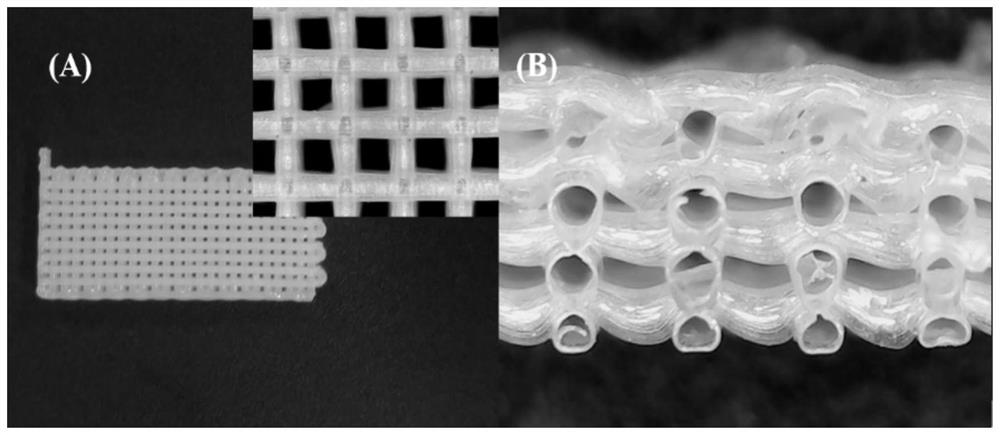

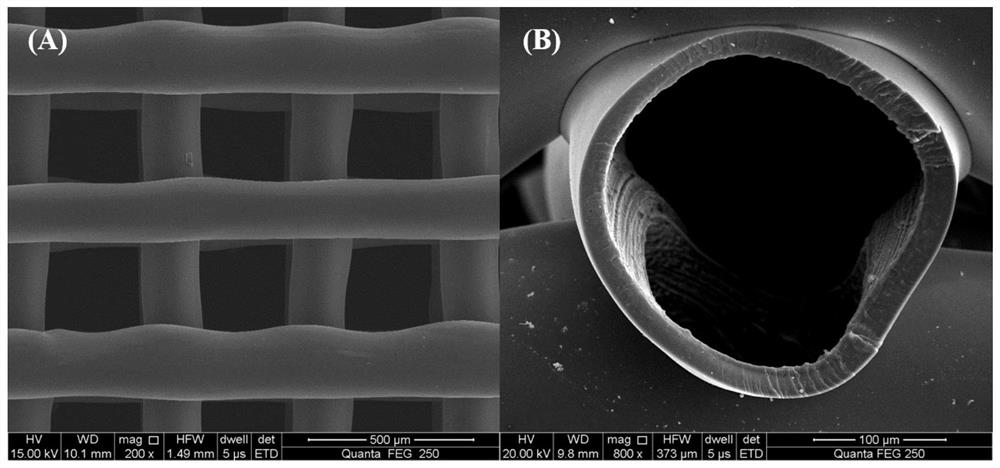

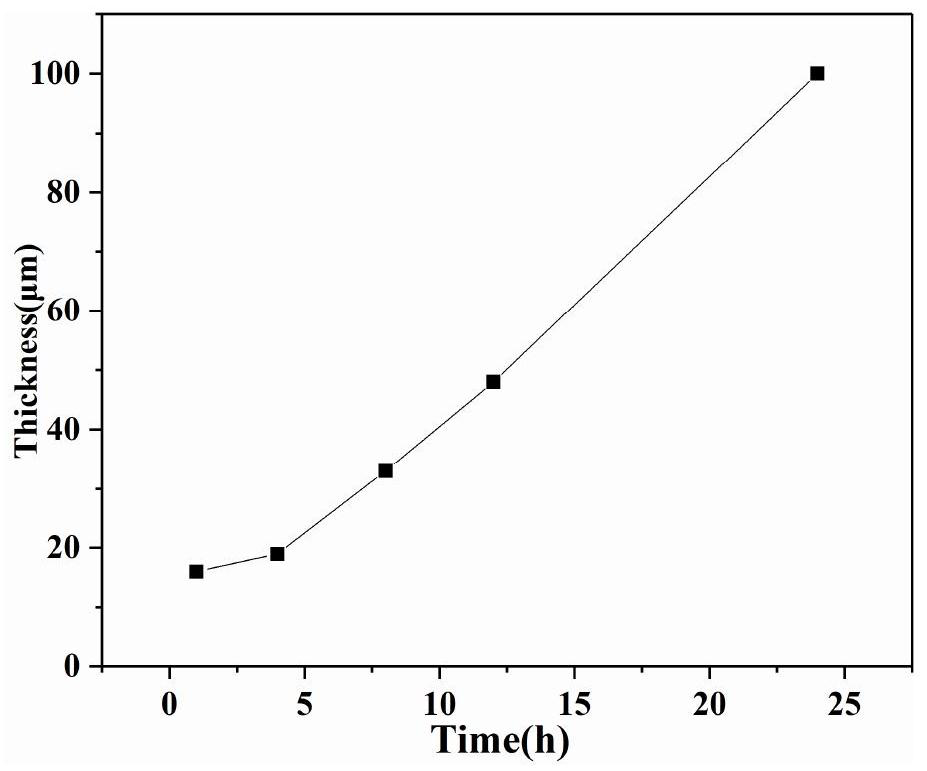

Preparation method of hollow tube micro-lattice structure ceramic material

ActiveCN111646804AReduce adverse effectsEasy to controlAdditive manufacturing apparatusAdditive manufacturing with liquidsMolten stateManufacturing technology

Owner:CENT SOUTH UNIV

New type alloy material

InactiveCN1760391AImprove mechanical propertiesSmall temperature coefficient of resistanceElectrical resistance and conductanceHigh resistance

An au-alloy is prepared from Pd (1-3 mass %), Gd (0.2-0.6) and Au (rest). Its advantages are the improved elasticity and yield point, low resistance temp coefficient, high recrystallizing temp, and high resistance to creep, electric corrosion and abrasion.

Owner:SINO PLATINUM METALS CO LTD

Composite electrolyte material and preparation method thereof

PendingCN112615052AImprove space efficiencyImprove adsorption efficiencySecondary cellsComposite electrolytesFiberComposite electrolyte

Owner:JIANGSU NADN SCI TECH CO LTD +1

Ceramic glaze and preparation method thereof

The invention discloses a ceramic glaze. The ceramic glaze is characterized by being prepared from the following raw materials in parts by weight: 35-50 parts of nano-silica, 55-75 parts of kaolin, 15-30 parts of albite, 5-15 parts of magnesium oxide, 5-15 parts of sodium oxide, 25-50 parts of dolomite, 25-40 parts of limestone, 3-8 parts of pigment and filler, 15-20 parts of property-modifying additive, and 55-70 parts of deionized water. The invention further discloses a preparation method of the ceramic glaze. The ceramic glaze disclosed in the invention has good brightness and glossiness,and the prepared pigment and filler are present in a nanometer-grade form, have a good coloring effect and are not easy to agglomerate; the ceramic glaze prepared from the activated kaolin, the pigment and filler and the property-modifying additive has not only good mechanical properties, but also good chemical stability and wear resistance, and can effectively protect a ceramic body and allow theceramic to have a better appearance.

Owner:CHANGSHA JIZHI INNOVATION IND DESIGN CO LTD

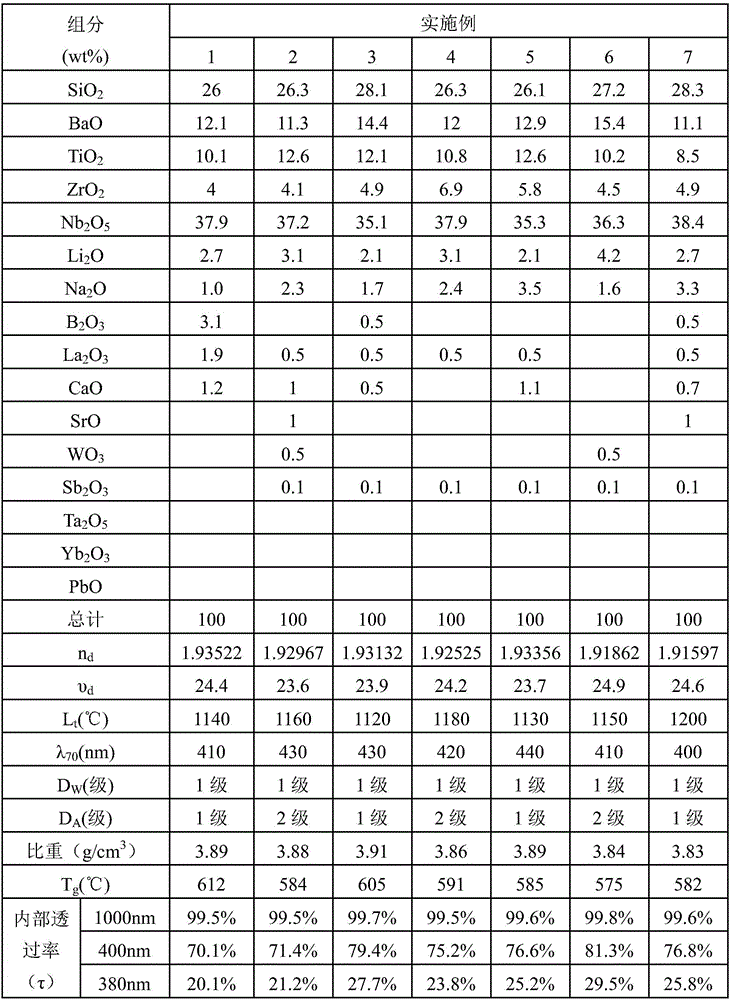

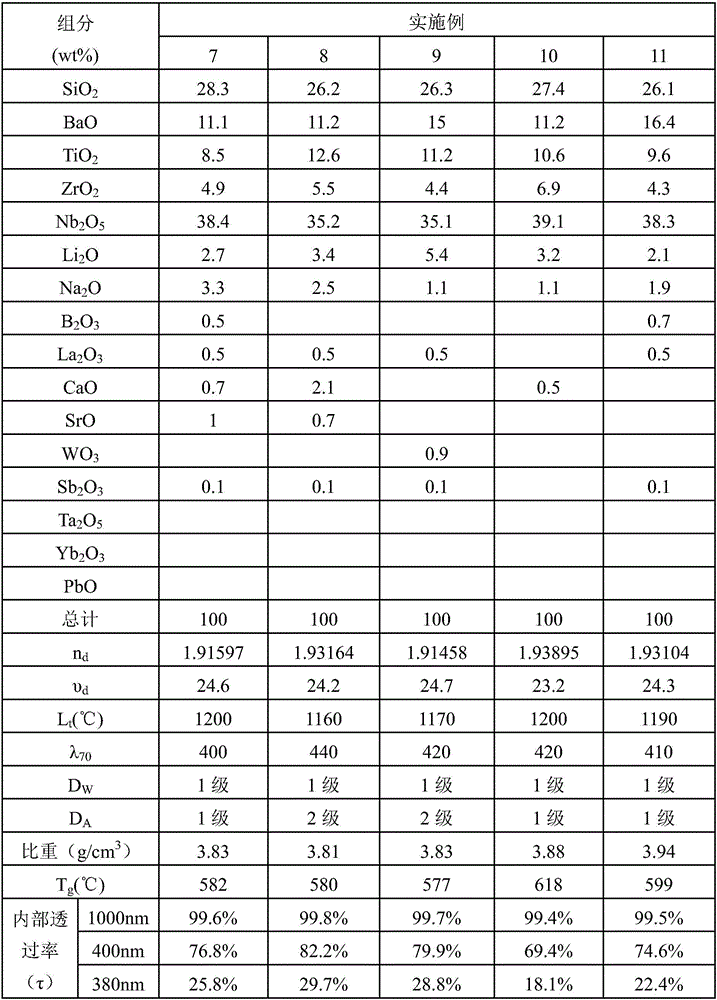

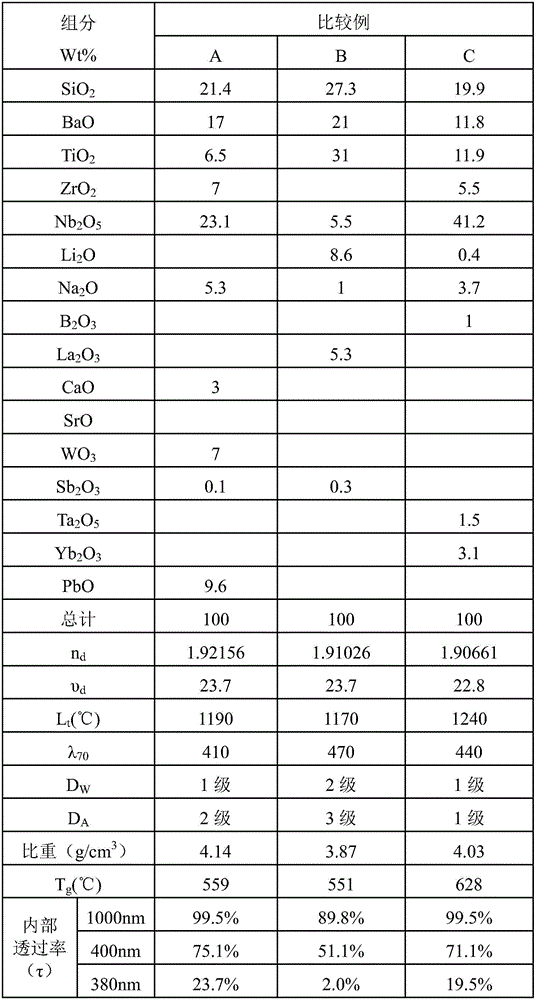

Optical glass, preparation method therefor and optical components thereof

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

Novel anti-electrostatic ceramic glaze as well as preparation method and application thereof

Owner:ZHONGSHAN ADVANCED ENG & TECH RES INST WUHAN UNIV OF TECH +1

Preparation method of dew-point-resistant protection coating for automobile oxygen sensor

InactiveCN113845376AGood chemical stabilityImprove thermal stabilityAnalysing gaseous mixturesClaywaresMicron scaleSpray coating

Owner:CHANGZHOU LAMBDA ELECTRONICS

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap