High temperature direct formate fuel cell with electricity and alkali salt co-production

A fuel cell and formate technology, which is applied in the direction of fuel cells, battery electrodes, circuits, etc., can solve the problems of increasing system complexity and input costs, poor thermal and chemical stability, and reducing the theoretical energy density of the system. Reduce activation loss and battery internal resistance, increase theoretical energy density, and facilitate promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further explained and illustrated below in conjunction with the accompanying drawings and specific embodiments.

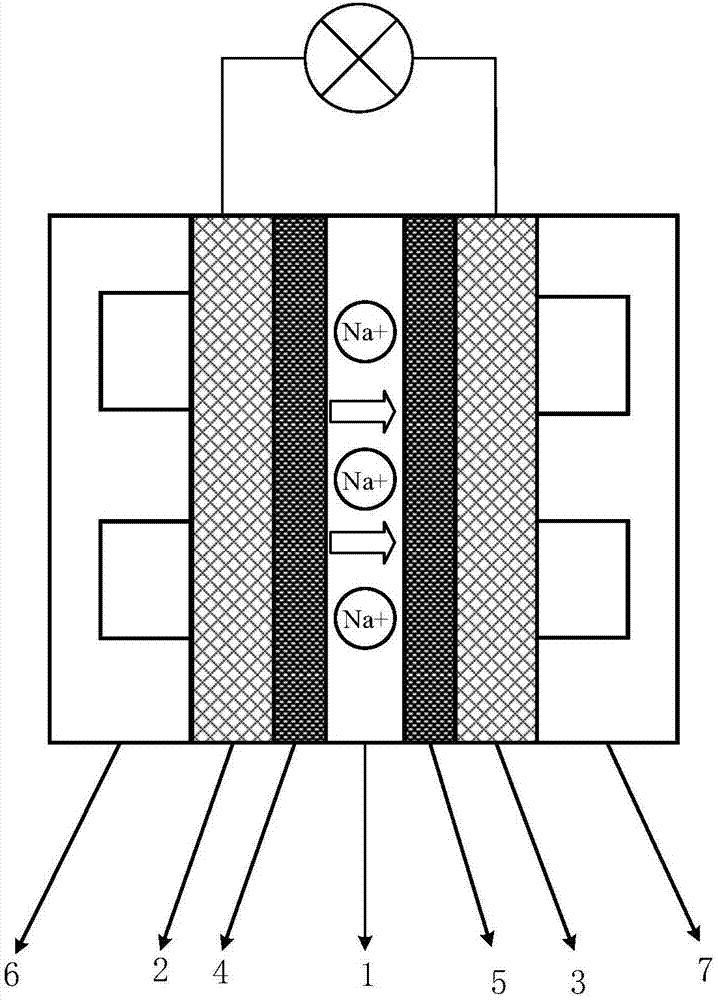

[0019] see figure 1 , the present invention comprises an anode plate 6, a cathode plate 7 and a cation-exchange membrane 1 that separates it into an anode cavity and a cathode cavity for conducting sodium ions. Water, the oxidant uses pure oxygen or oxygen from the air, and the anode chamber side of the cation exchange membrane 1 that conducts sodium ions is provided with an anode catalytic layer 4 and an anode diffusion layer 2 in sequence from the inside to the outside, and the cation exchange membrane that conducts sodium ions The cathode chamber side of the membrane 1 is provided with a cathode catalytic layer 5 and a cathode diffusion layer 3 sequentially from the inside to the outside. The anode and cathode diffusion layers 2 and 3 use carbon paper with a microporous layer as a supporting material, and the catalyst The slurr

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap