Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41 results about "Water based" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-based lubricants are specifically those fluids or gels that are made from a base of water and typically a cellulose or glycerin solution. A water-based lubricant is water soluble and can therefore be fairly easily washed off.

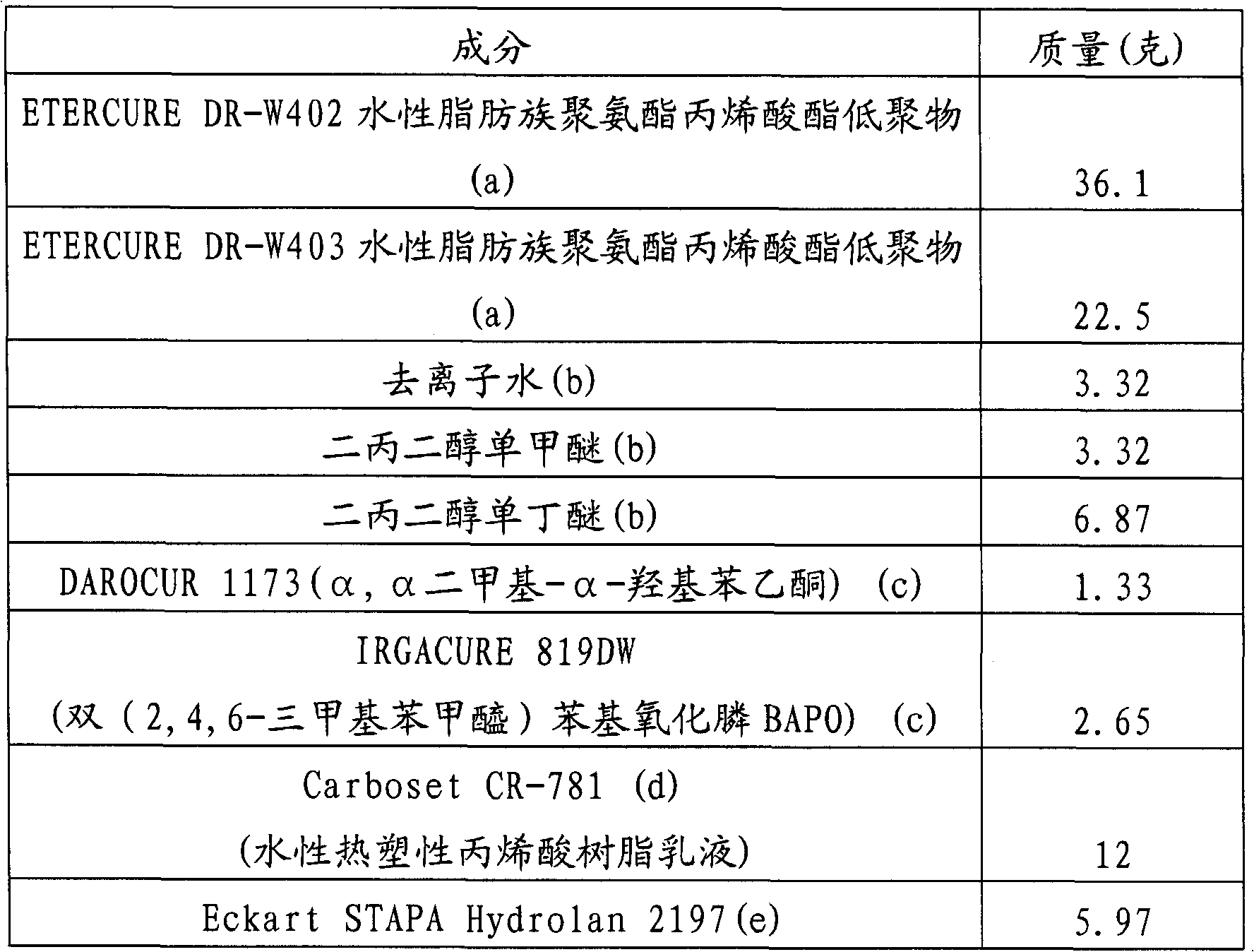

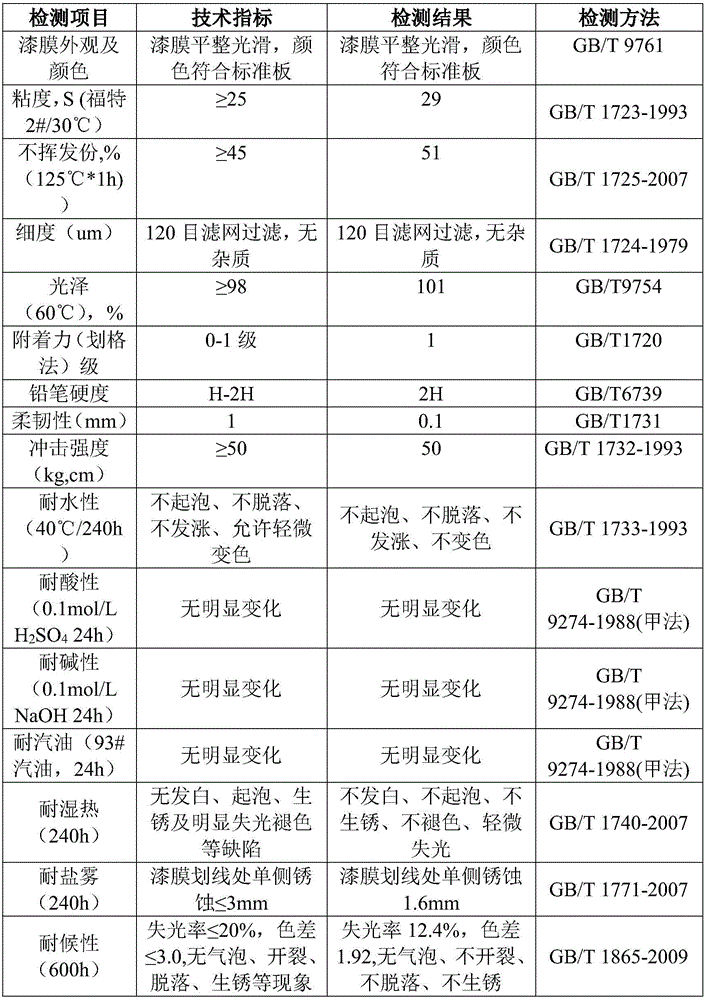

Ultraviolet-curable water-based colored paint composition

Owner:CHUANGXING FINE CHEM SHANGHAI

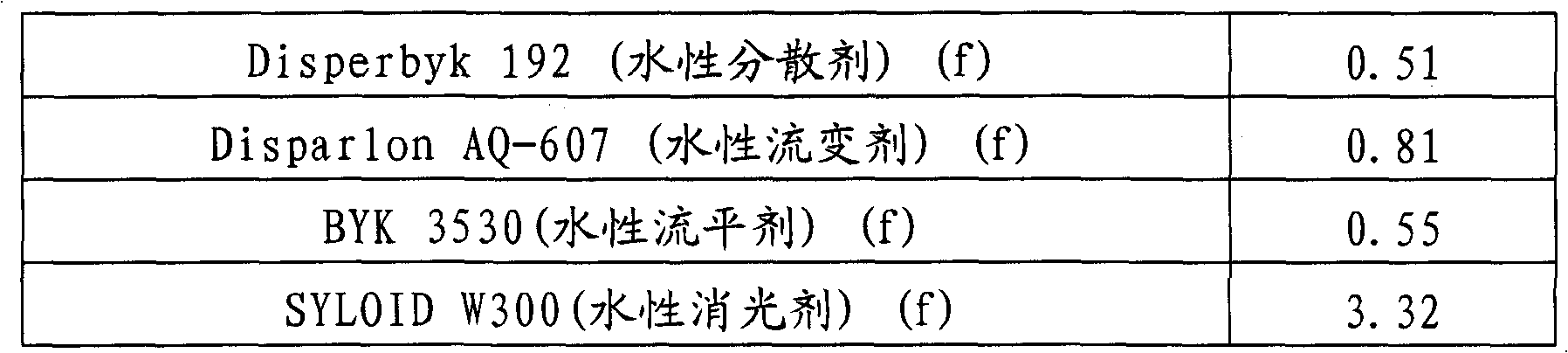

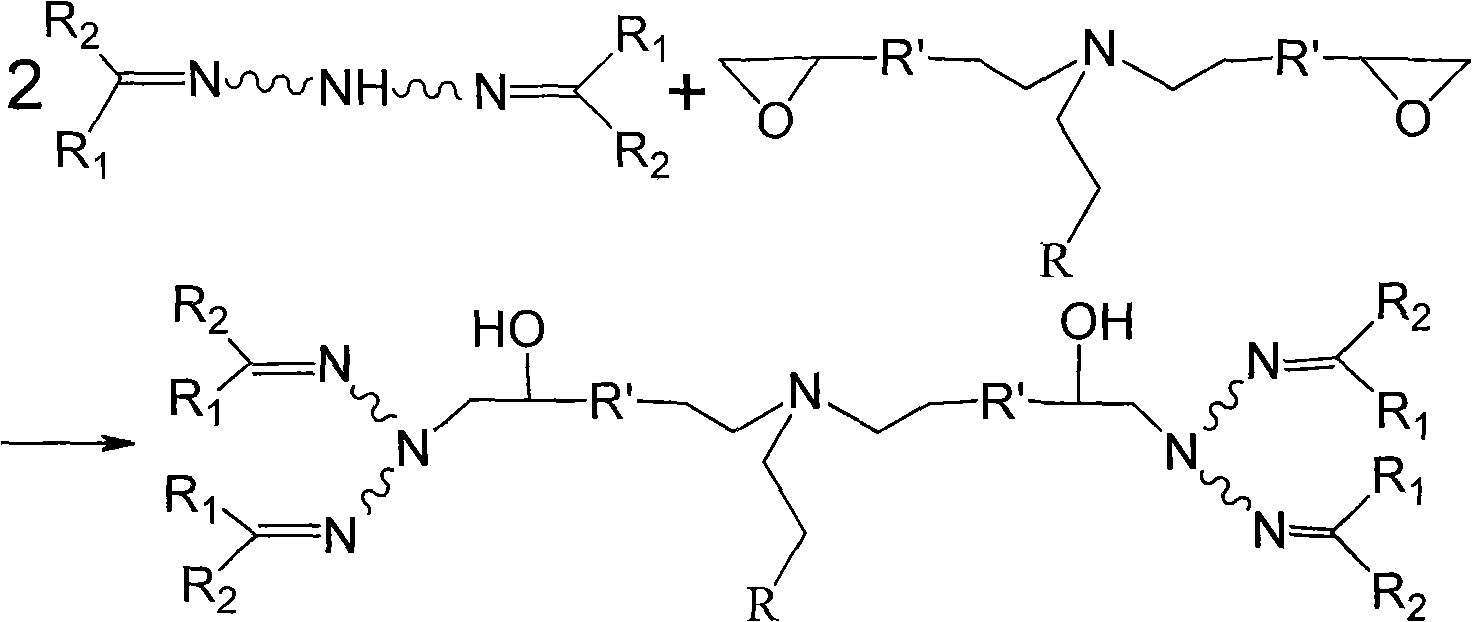

Preparation and application of latent nonionic self-emulsifying epoxy curing agent

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

Water-based airplane surface cleaning agent and preparation method thereof

ActiveCN101955854AThe formula is scientific and reasonableSimple production processInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsWater basedSurface cleaning

The invention relates to a water-based airplane surface cleaning agent, which is prepared by uniformly mixing the following components in percentage by weight: 21 to 30 percent of degradable surfactant, 5 to 7 percent of metal corrosion inhibitor, 0.3 to 2 percent of pH regulating agent, 1.7 to 5 percent of stabilizer, and the balance of deionized water. A preparation method comprises the following steps: (1) weighing the pH regulating agent, the degradable surfactant, the metal corrosion inhibitor, the stabilizer and the deionized water according to the ratio of weight percent; (2) adding the pH regulating agent, the metal corrosion inhibitor, the degradable surfactant and the stabilizer into the deionized water at the room temperature of between 23 and 25 DEG C; and (3) stirring the liquid at constant speed of 60 to 80r / min for 20 to 40 minutes to ensure that no bubble is generated in the liquid to prepare the cleaning agent after uniform mixing. The invention has scientific and reasonable formula and simple process without special equipment, and the cleaning agent has the advantages of strong cleaning capability, short cleaning time, low cost, high efficiency and is safe and reliable for use.

Owner:BEIJING KAILAN AVIATION TECH CO LTD

Water-Based Ink Set For Ink-Jet Recording

ActiveUS20070186812A1Improves not recovery performanceImprove the problemDuplicating/marking methodsInksWater basedMagenta

Owner:BROTHER KOGYO KK

Good-weather and water resistance water-based alkyd resin

Owner:深圳海德新材料科技有限公司

Method for manufacturing holographic aluminized paper material

InactiveCN101725077AWith molded holographic propertiesShort stayCoated paper substrateCoatingsWater basedPaper based

Owner:GUANGDONG MAGNOLIA PACKING MACHINERY

High-performance water-based bicomponent epoxy zinc rich primer and preparation method thereof

ActiveCN107573816AReduce usageImprove protectionAnti-corrosive paintsEpoxy resin coatingsEpoxyCollocation

The invention relates to a high-performance water-based bicomponent epoxy zinc rich primer and a preparation method thereof. A water-based bicomponent epoxy zinc rich coating A in the high-performancewater-based bicomponent epoxy zinc rich primer comprises a water-based epoxy curing agent, an additive A, a complex solubilizer, zinc powder, zinc and an anti-settling agent; a water-based bicomponent epoxy zinc rich coating B comprises a water-based epoxy emulsion and an additive B; the weight ratio of the coating A to the coating B is at 100 to (10-30). The preparation method comprises the following steps: (1) uniformly mixing the components in the coating A at ratio and using a 100-mesh screen for filtering; (2) uniformly mixing the components in the coating B at ratio; and uniformly mixing the coating A with the coating B at the weight ratio in a use process and regulating the construction viscosity. When the high-performance water-based bicomponent epoxy zinc rich primer is used, water is taken as a solvent, so that the use of the organic solvent is greatly reduced and the environmental protection is benefited. The collocation of the anti-settling agent is utilized to solve the problems of storage and construction.

Owner:SHANDONG QIWEI NEW MATERIALS CO LTD

Water-based ink set for ink-jet recording and ink-jet recording method

InactiveUS20070046750A1Reduce graininessExcellent gas resistanceMeasurement apparatus componentsDuplicating/marking methodsWater basedHigh density

Owner:BROTHER KOGYO KK

Water-based anti-doodling paint and preparation method thereof

ActiveCN105482604ALow VOC emissionsLow weather resistanceAntifouling/underwater paintsPaints with biocidesWater basedDefoaming Agents

Owner:HANGZHOU JIHUA POLYMER MATERIAL CO LTD

Inorganic water-based metallic paint and preparation method thereof

Owner:佛山市南海万磊建筑涂料有限公司

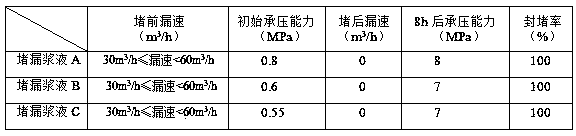

Drilling water based plugging agent and using method thereof

InactiveCN107603574ADehydration fastHigh fluid lossDrilling compositionSealing/packingWater basedSolubility

Owner:成都瑞吉星化工有限责任公司

High-strength curb and manufacturing method thereof

InactiveCN101817695AHigh compressive strengthLow costPaving gutters/kerbsTraffic signalsWater basedHigh intensity

The invention discloses a high-strength curb and a manufacturing method thereof. The surface of the curb is treated by the following method in turn: firstly, curing the surface of the demoulded curb for 5 to 10 days by using a concrete nano curing agent; secondly, performing surface solidification on the cured curb surface by using a concrete sealer; and finally, polishing the consolidated surface by using a water-based permeating brightener. The high--strength curb with the unique formula, and the manufacturing method have the advantages of high strength, low cost and environmental protection and the like.

Owner:SHENZHEN HUILI DEBANG ENVIRONMENTAL PROTECTION TECH CO LTD

Water-based flashing paint suitable for ordinary aluminum powder and preparation method thereof

ActiveCN106634377AMeet environmental protection requirementsCoating performance is not lowLuminescent paintsWater basedAcrylic resin

Owner:徐州海太新材料科技有限公司

Water-based environment-friendly color-changing nail polish

PendingCN109381372AImprove stabilityKeep for a long timeCosmetic preparationsToilet preparationsWater basedRetention time

Owner:胡余飞

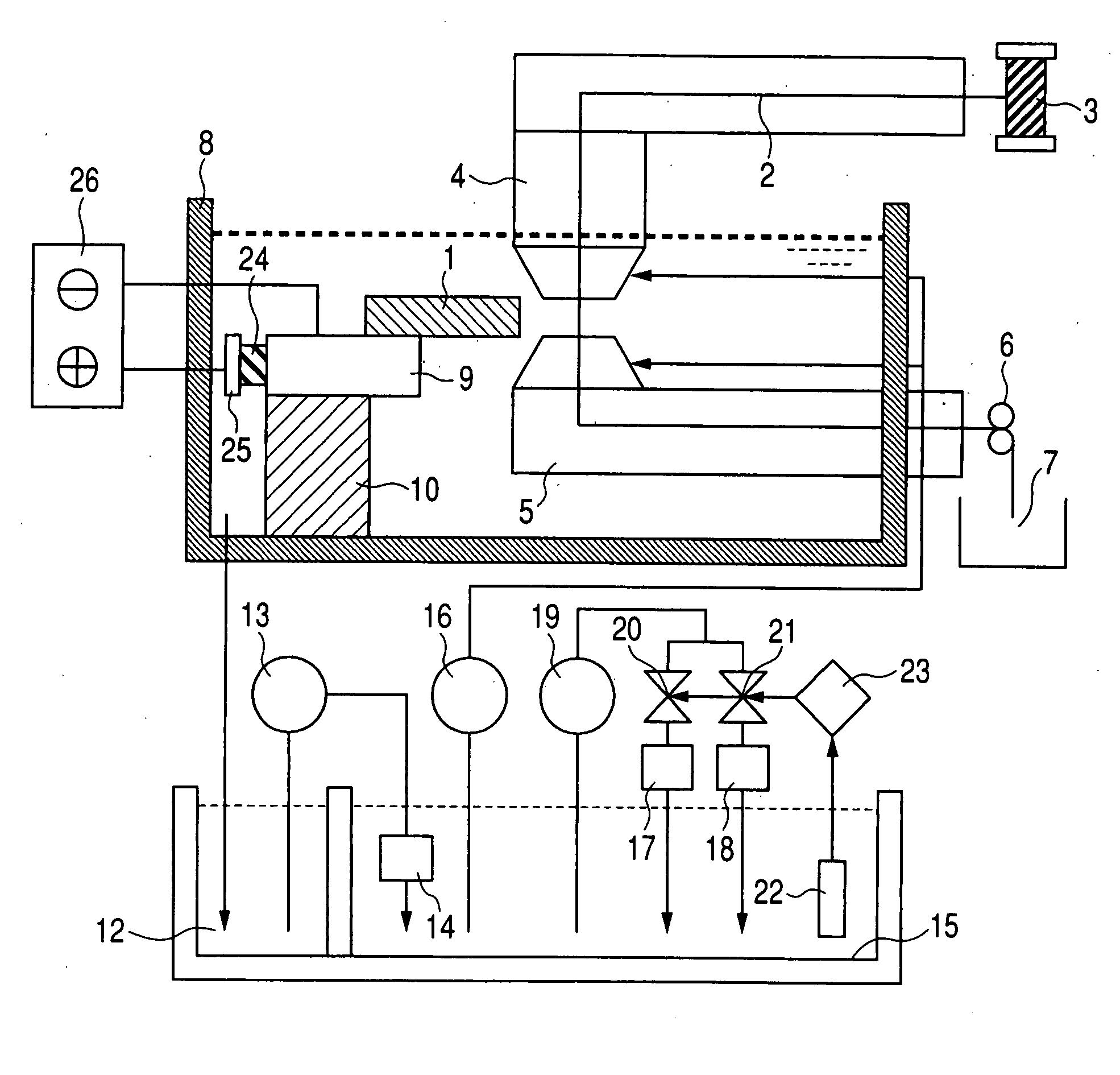

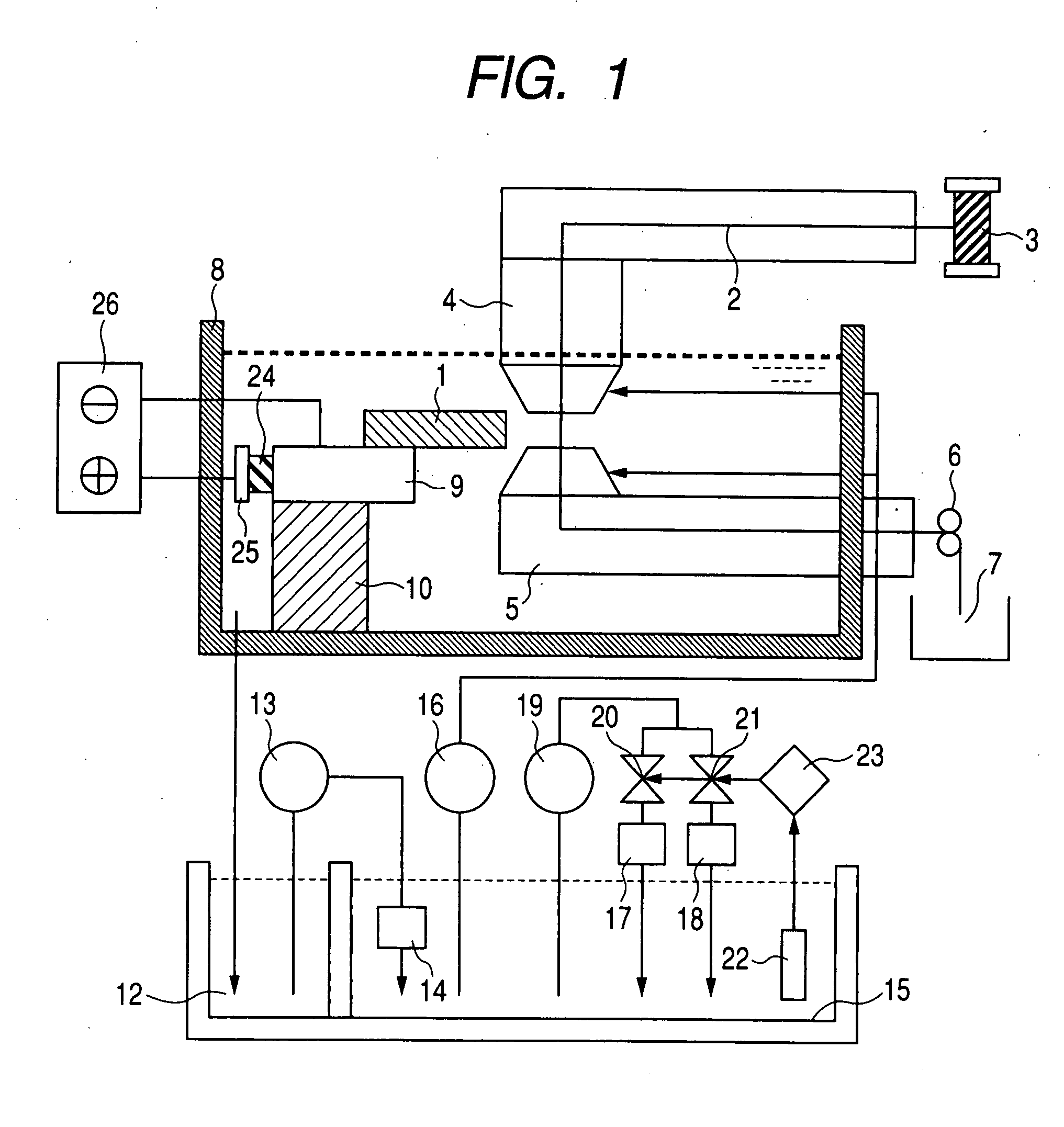

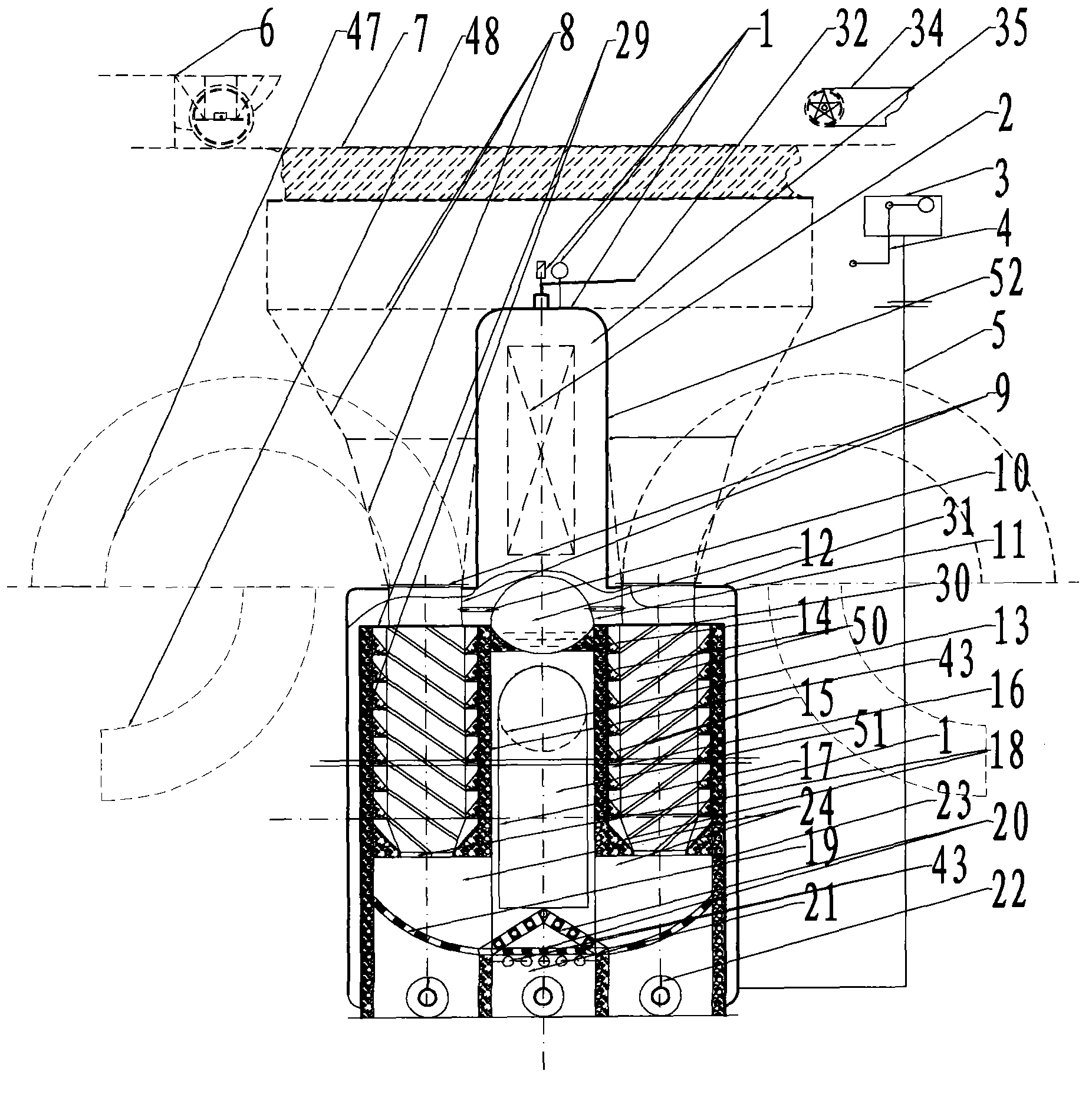

Electric discharge machine and electric discharge machining method

Owner:MITSUBISHI ELECTRIC CORP

Preparation method of pearlescent anti-crease waterproof moisture-permeable polyurethane synthetic leather

InactiveCN105568701AImprove wear resistanceImprove wrinkle resistanceTextiles and paperWater basedFiber

Owner:HANGZHOU FUYANG WEIWEN ENVIRONMENTAL PROTECTION TECH CO LTD

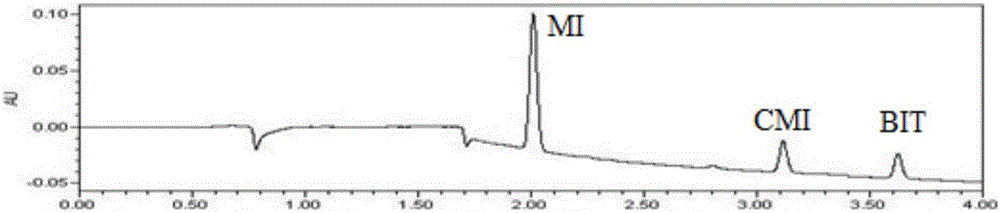

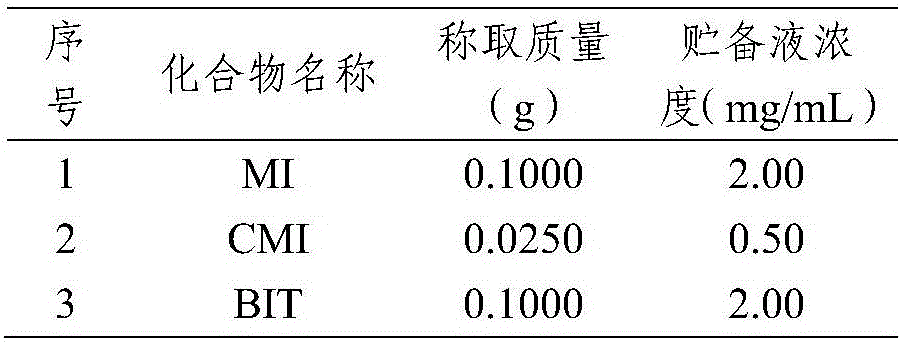

Method for rapid determination of isothiazolinone compounds in water-based adhesive for cigarettes

Owner:CHINA TOBACCO GUIZHOU IND

Room-temperature self-crosslinking fluorine-containing water-based PU dispersion, preparation method and application thereof

Owner:江苏裕廊石油化工有限公司

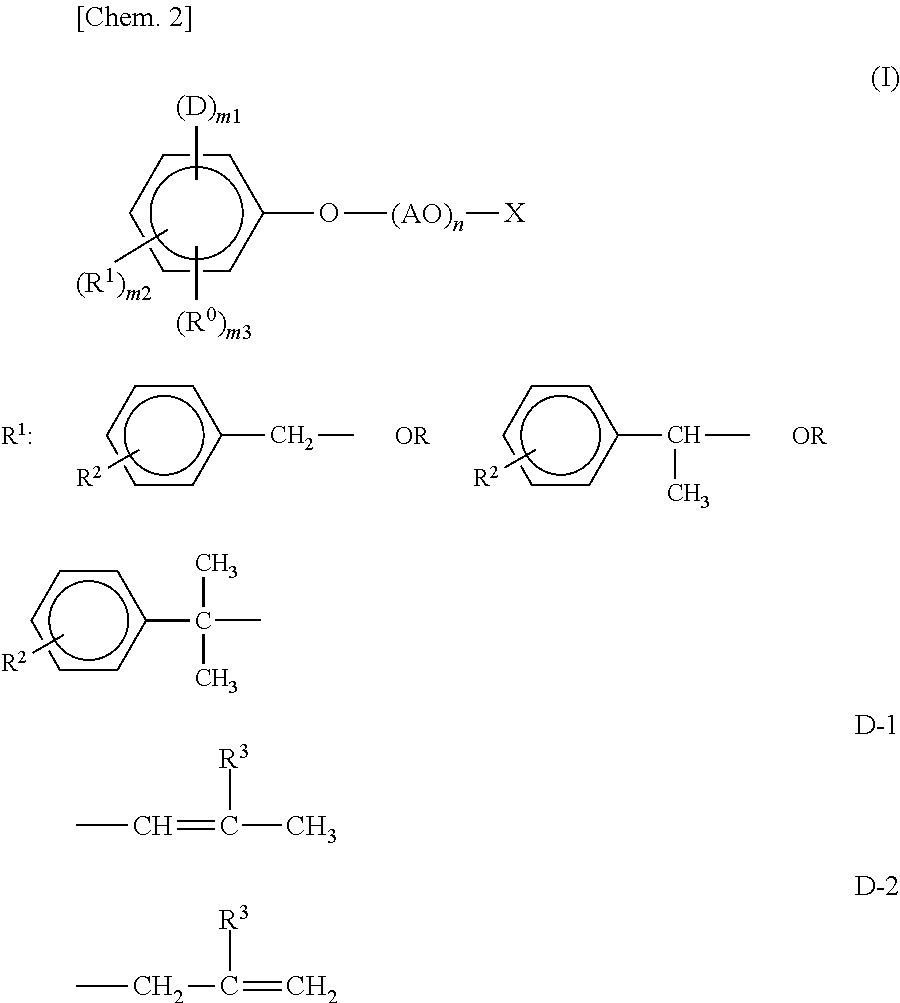

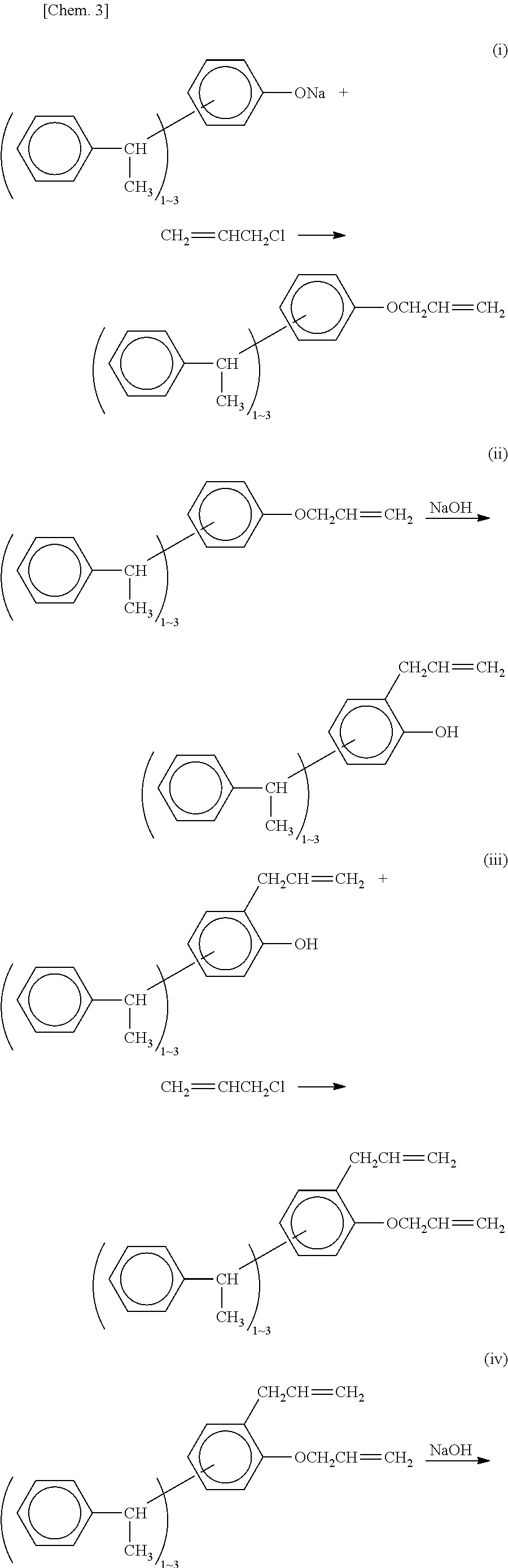

Water-based resin dispersion and coating material

ActiveUS20170327602A1InhibitionLow water resistanceTransportation and packagingMixingWater basedEmulsion polymerization

Owner:DAI ICHI KOGYO SEIYAKU CO LTD

Antibacterial finishing agent, antibacterial yarn and preparation method and application of antibacterial yarn

InactiveCN107217481AHas antibacterial propertiesPrevent mildewBiochemical fibre treatmentGrip property fibresYarnWater based

Owner:湖南莎丽袜业股份有限公司 +1

Abrasive-containing emulsifying compound metal cutting solution and preparation method thereof

ActiveCN104120020AExcellent lubricating and anti-wear propertiesImprove the lubrication effectLubricant compositionWater basedSodium metasilicate

Owner:山东斯瑞药业有限公司

Polyvinyl alcohol water-based architectural paint

Owner:苏州市超邦涂料有限公司

Water-based combustion-supporting straw particle boiler-kiln universal burner with fuel such as coal, gas and oil

InactiveCN104235832AKeep aliveResponse is continuous and stableCombustion using multiple fuelsCombustion using catalytic materialWater basedBrick

Owner:管理

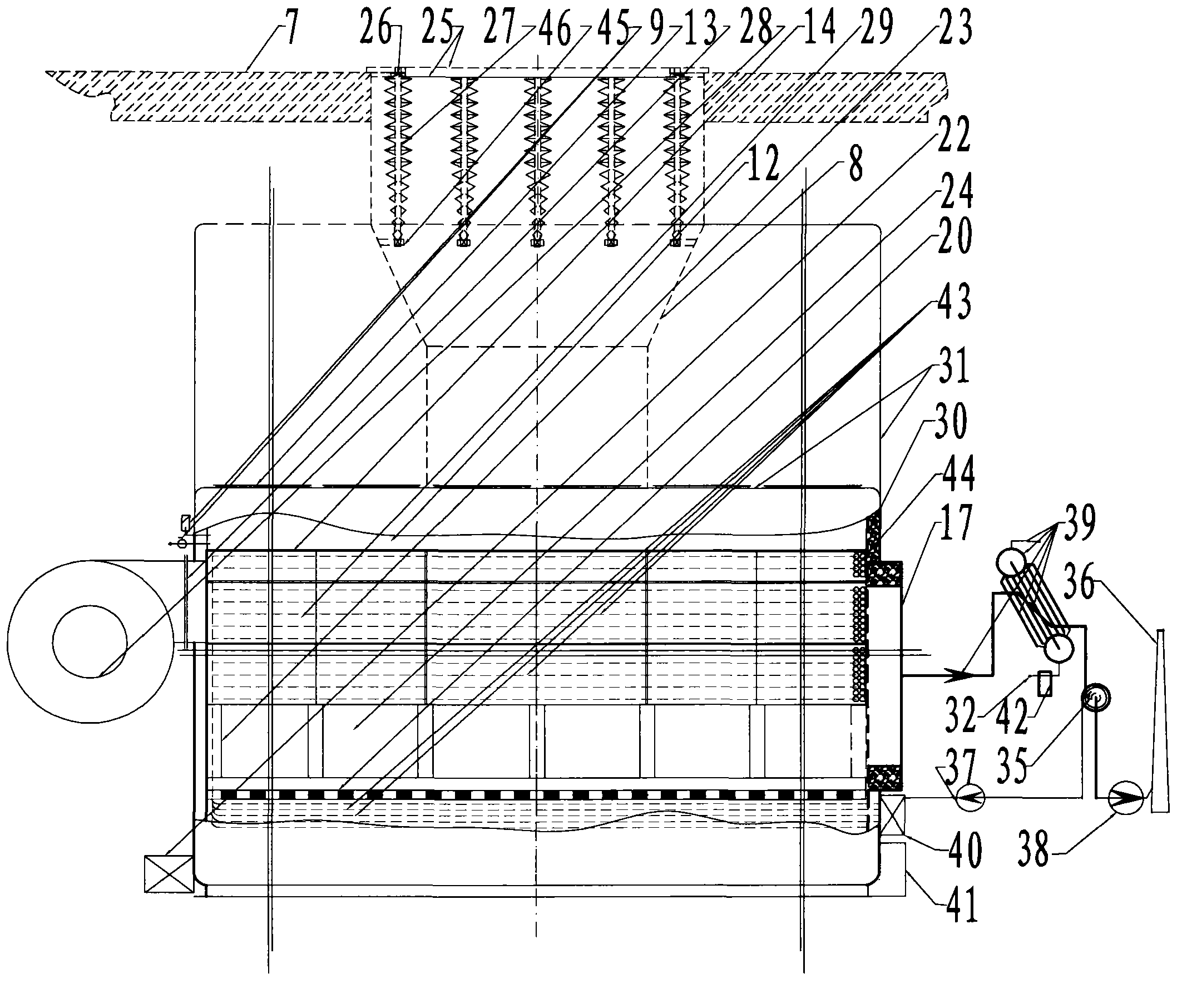

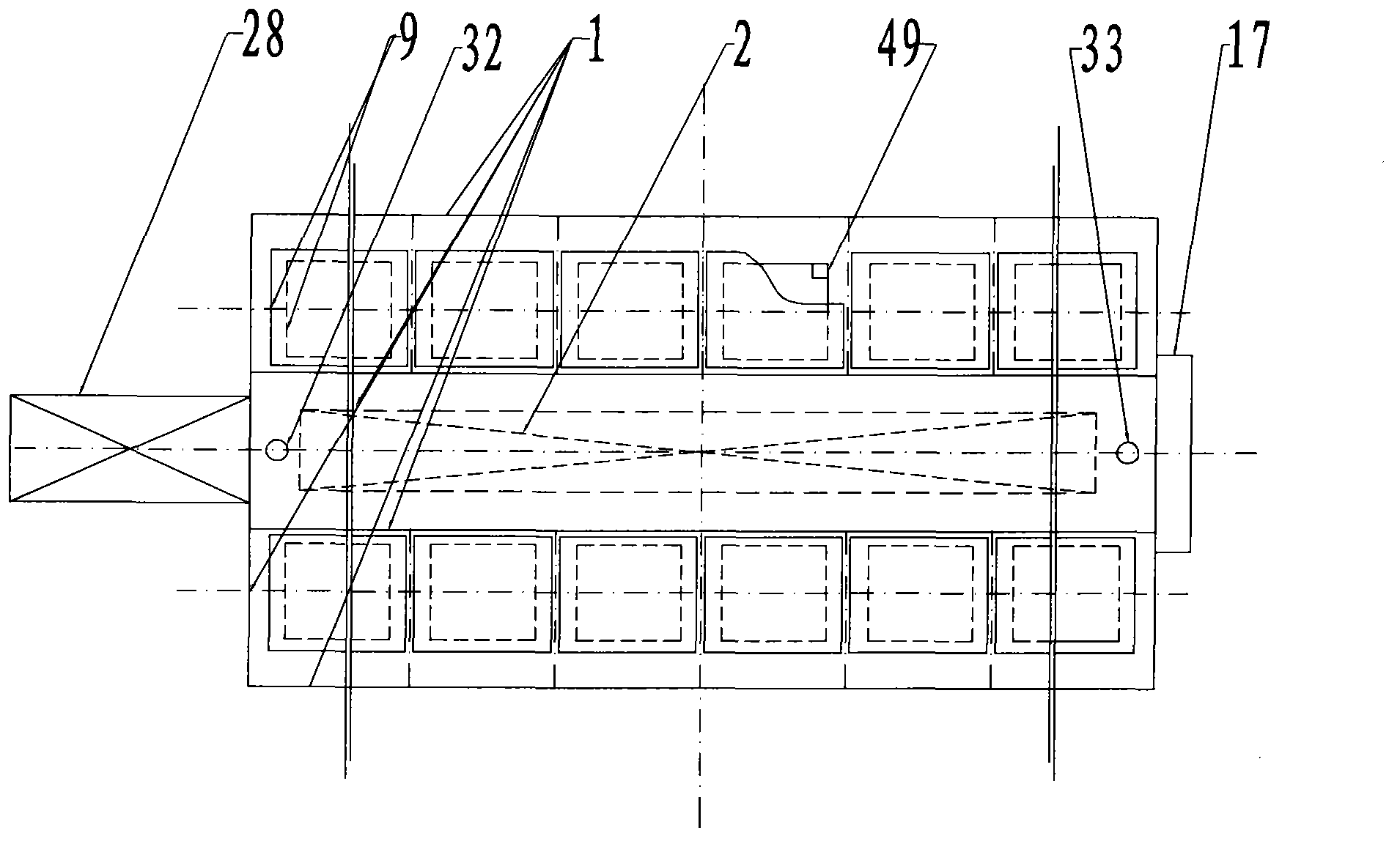

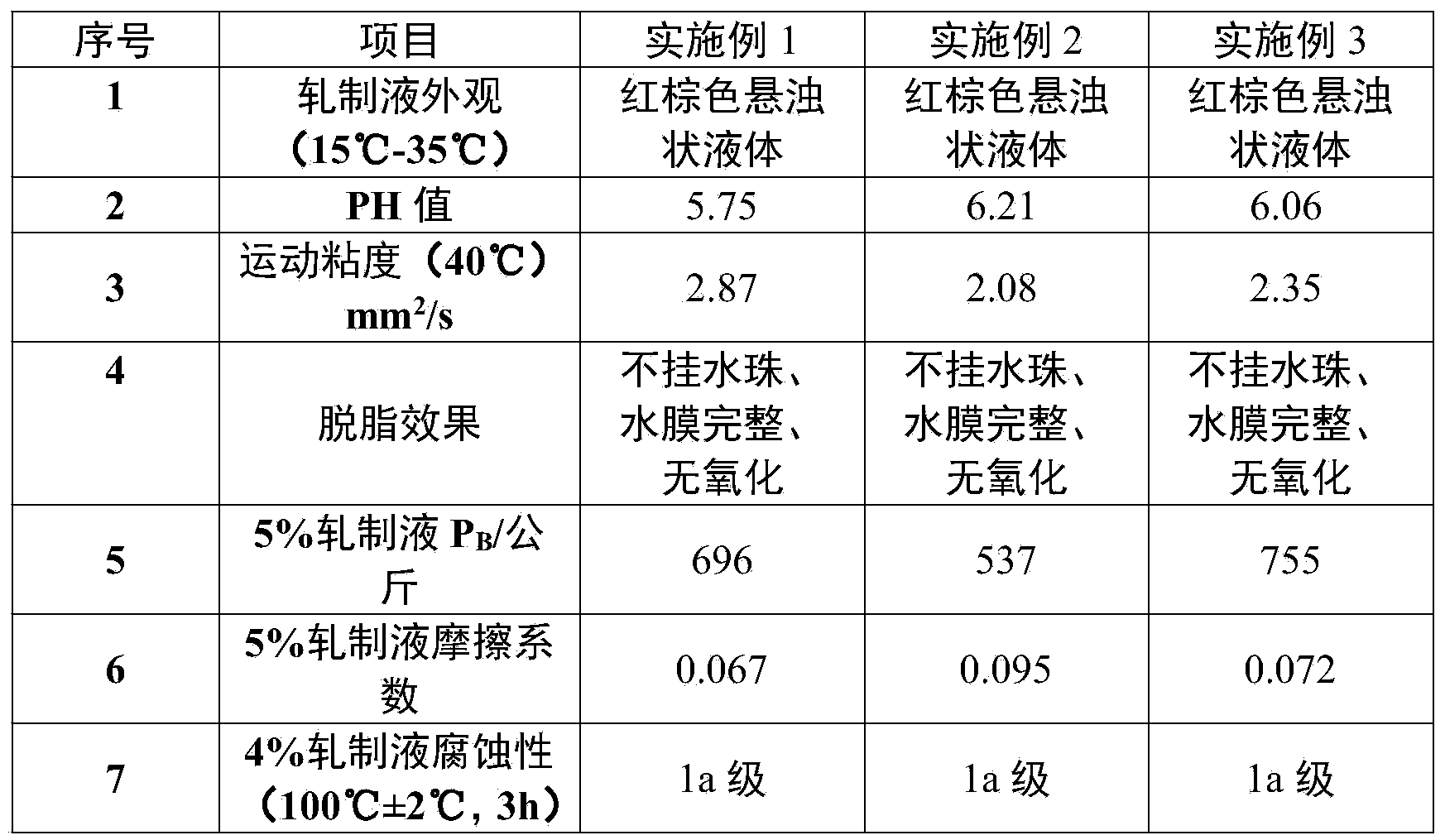

Functional rolling liquid of water-based nano Cu and preparation method of functional rolling liquid

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of electrostatic spinning lithium ion battery negative electrode plate

InactiveCN108735976AIncrease transfer rateLower internal resistanceElectrode manufacturing processesSecondary cellsWater basedElectrical battery

The invention discloses a preparation method of an electrostatic spinning lithium ion battery negative electrode plate. The preparation method comprises the following steps of dissolving polyoxometallate salt into deionized water to form a polyoxometallate solution; adding graphite into the polyoxometallate solution, and adding a surfactant sodium dodecyl benzene sulfonate and a water-based adhesive La13<x> to form a spinning solution; putting the spinning solution into an electrostatic spinning instrument for spinning, and performing spinning of the spinning solution on a copper foil, whereinwire strips are dense and are uniformly adhered to the copper foil; and then drying the copper foil adhered with the wire strips to obtain the battery negative electrode plate. Compared with a traditional stirring and coating process, the preparation method adopting the electrostatic spinning process has the advantages that the process time is shortened, and the production efficiency is improved.

Owner:DONGFANG ELECTRIC CORP

Water-based wood protective agent and preparation method thereof

InactiveCN107914328AAvoid bloomingPrevent mildewWood treatment detailsWood impregnation detailsWater basedAlkylphenol

Owner:BEIJING FORESTRY UNIVERSITY

Water-based acid pickling corrosion inhibition passivator for stainless steel

InactiveCN107326352ANon-toxicEnvironmentally friendlyMetallic material coating processesWater basedPhosphate

The invention discloses a water-based pickling corrosion inhibitor and passivator for stainless steel, which comprises the following substances in parts by weight: 2-3 parts of phenylalanine, 1-5 parts of acetic acid, 1-2 parts of lactic acid, 1-2 parts of dipotassium hydrogen phosphate, Potassium dihydrogen phosphate 0.5~1 part, phosphoric acid 1~2 part, thiourea 0.1~0.3 part, aniline 1~1.5 part, ethanol 1~2 part, DTPMPA 1~2 part, calcium chromate 0.2~0.5 part, potassium nitrate 1~2 parts, 0.1~0.5 parts of EDTA, 3~8 parts of water. The water-based pickling corrosion inhibitor passivator for stainless steel has the advantages of non-toxicity, environmental protection, good passivation effect and the like.

Owner:SUZHOU JILI STAINLESS STEEL PROD

Environment-friendly water-based ink cleaning agent and preparation method thereof

Aiming at the disadvantages that the cleaning effect of water-based ink cleaning agents on the current market is not ideal, the surface of cleaned workpiece is corroded by added strong alkaline assistants, the environment is easily polluted and the like, the invention provides an environment-friendly water-based ink cleaning agent which has high cleaning efficiency, does not easily corrode the surface and is easily biodegrade, and a preparation method of the ink cleaning agent. The water-based ink cleaning agent comprises the following components in percentage by mass: 5-10% of an anionic-cationic surfactant compound, 6%-15% of a polar solvent, 2%-5% of a solubilizer, 5%-10% of other auxiliary agents and the balance of water.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

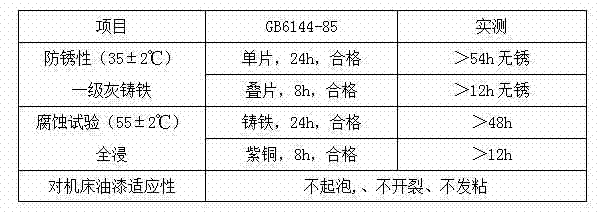

Production process of environment-friendly water-based anti-corrosion coating

InactiveCN104449091AImprove anti-corrosion performanceGood resistance to nitro paintAnti-corrosive paintsWater basedWater resistant

Owner:QINGDAO SHOUSHENG IND

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap