Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5 results about "Settling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Settling is the process by which particulates settle to the bottom of a liquid and form a sediment. Particles that experience a force, either due to gravity or due to centrifugal motion will tend to move in a uniform manner in the direction exerted by that force. For gravity settling, this means that the particles will tend to fall to the bottom of the vessel, forming a slurry at the vessel base.

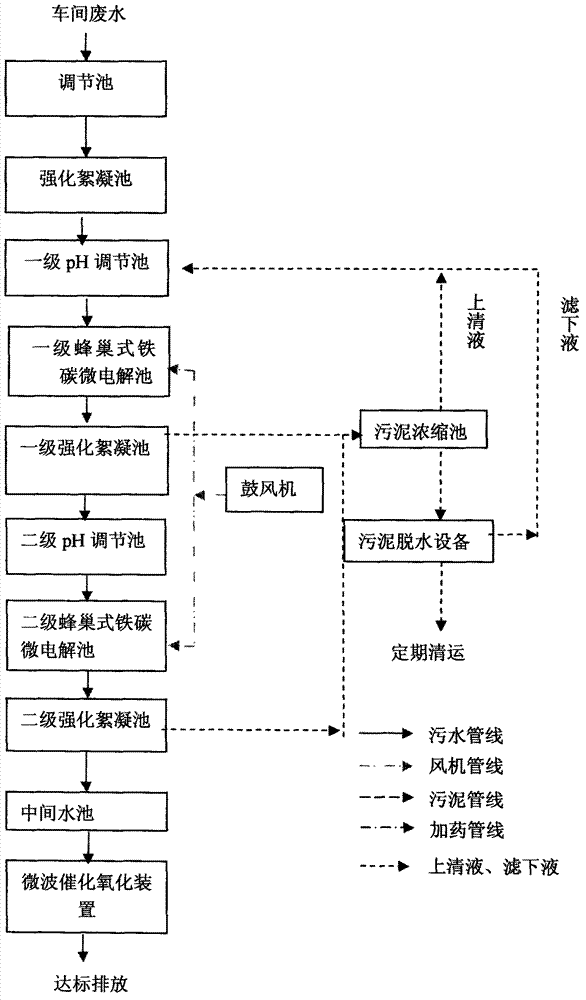

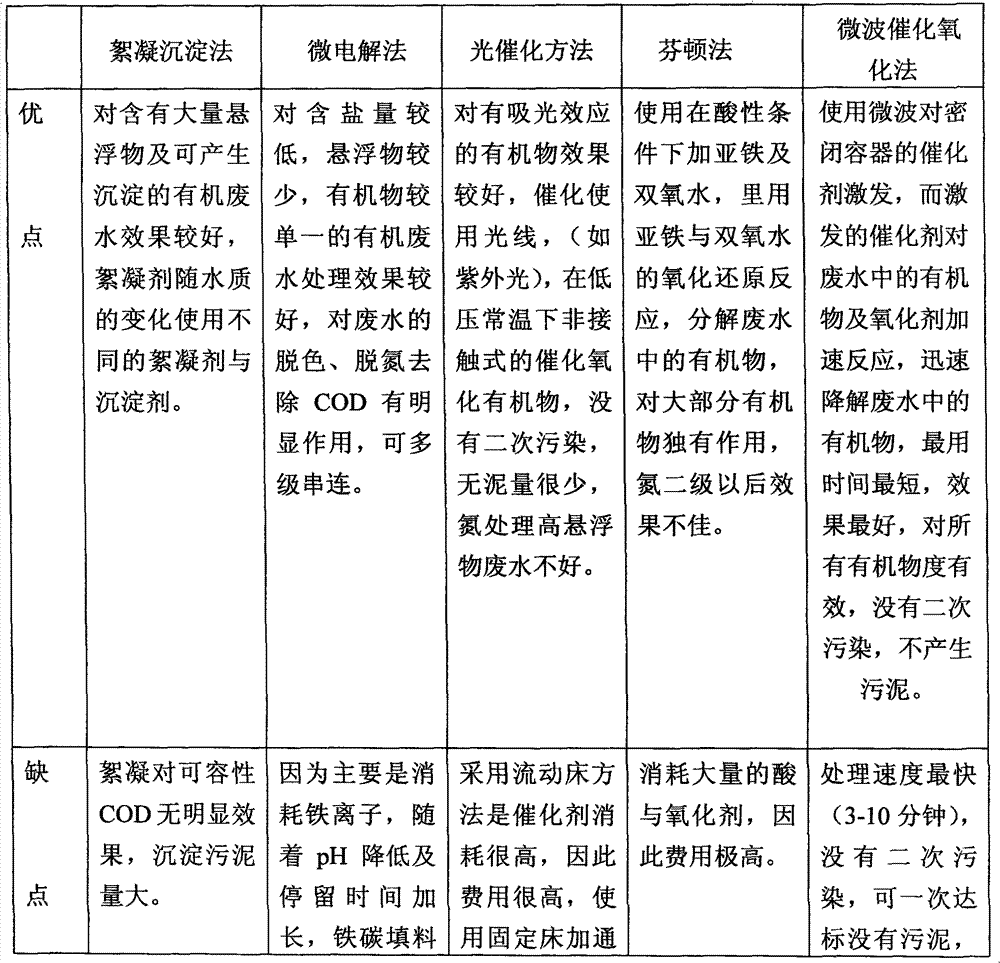

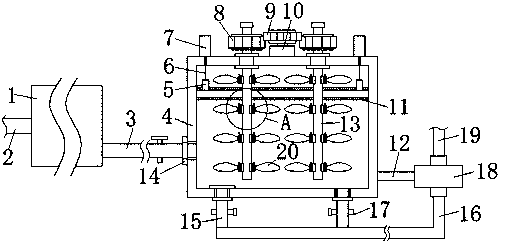

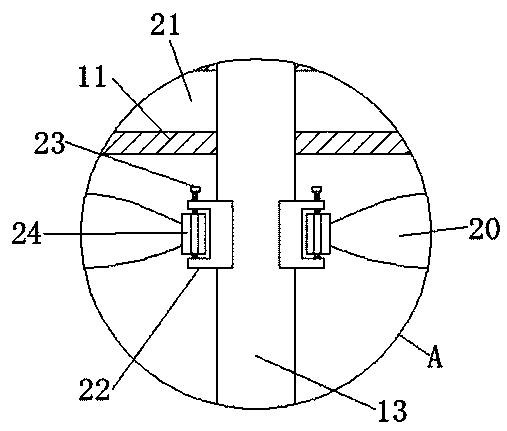

Method and system for modularized combined treatment of high-difficulty organic waste water

ActiveCN102826697AImprove applicabilityEasy to handleWater contaminantsMultistage water/sewage treatmentTreatment effectSludge

Owner:山东泰山行星环保科技有限公司

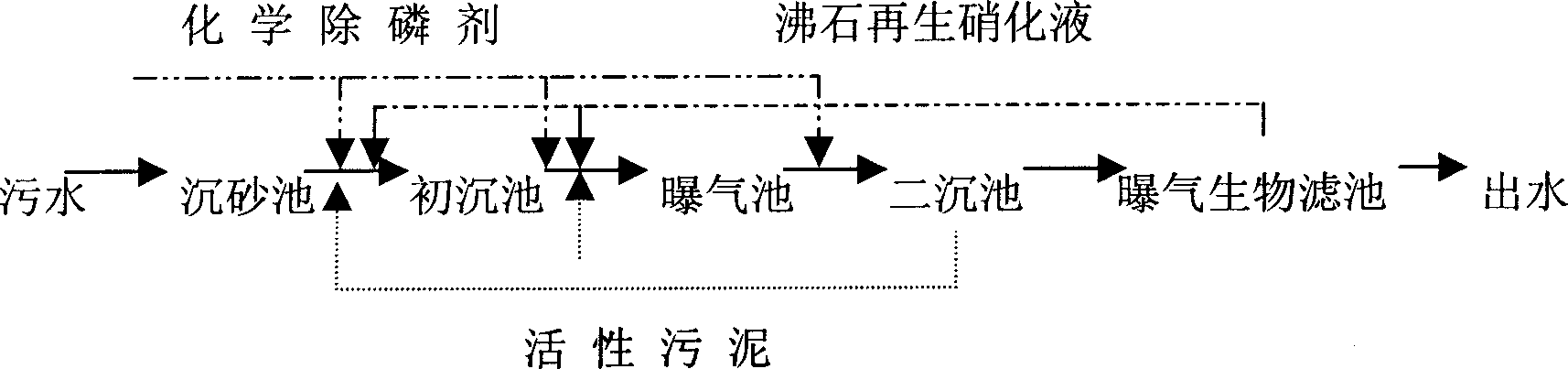

Process for removing nitrogen and phosphor using traditional waste water treatment process

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

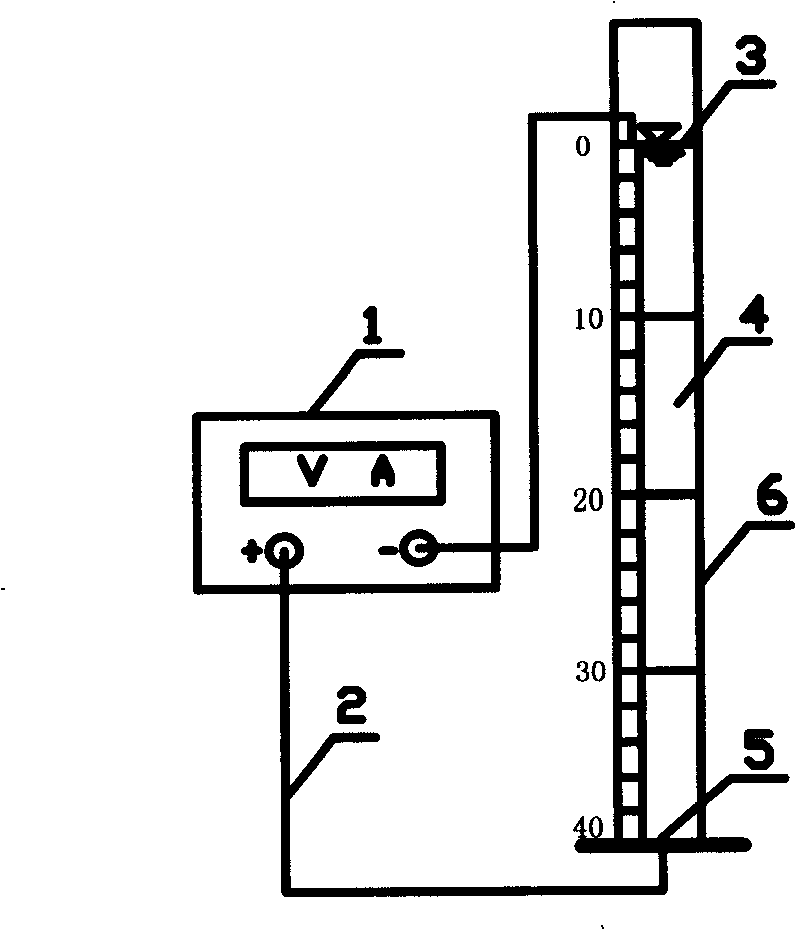

Device using vertical electrostatic field to accelerate sludge settling

InactiveCN101274791AWater/sewage treatment by magnetic/electric fieldsWater/sewage treatment by flocculation/precipitationElectric fieldSettling

Owner:BEIJING UNIV OF TECH

Apparatus and method for treating electroplating plant area sewage

InactiveCN110577301AFully processedNormal dischargeSpecific water treatment objectivesTreatment involving filtrationSewageEngineering

Owner:杨海琴

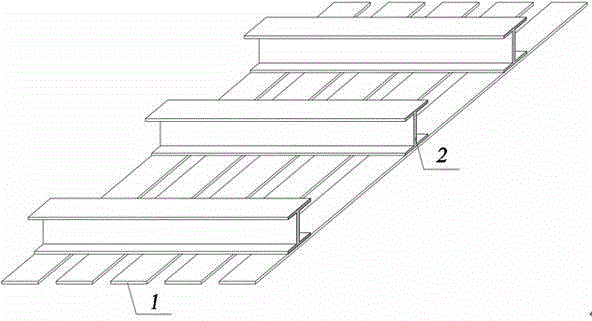

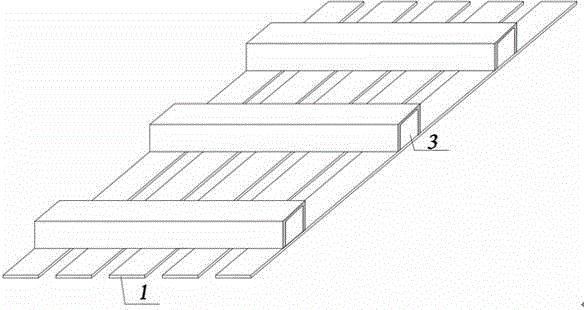

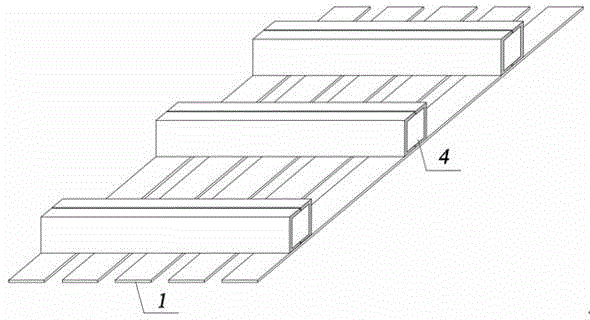

Composite type anti-settling plate basis with railing gaps in bottom plate and manufacturing method thereof

InactiveCN104631483ASimple preparation processGuaranteed stiffnessFoundation engineeringCarrying capacityEngineering

Owner:TIANJIN UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap