Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

79 results about "Heat exchanger" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A heat exchanger is a system used to transfer heat between two or more fluids. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contact. They are widely used in space heating, refrigeration, air conditioning, power stations, chemical plants, petrochemical plants, petroleum refineries, natural-gas processing, and sewage treatment. The classic example of a heat exchanger is found in an internal combustion engine in which a circulating fluid known as engine coolant flows through radiator coils and air flows past the coils, which cools the coolant and heats the incoming air. Another example is the heat sink, which is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant.

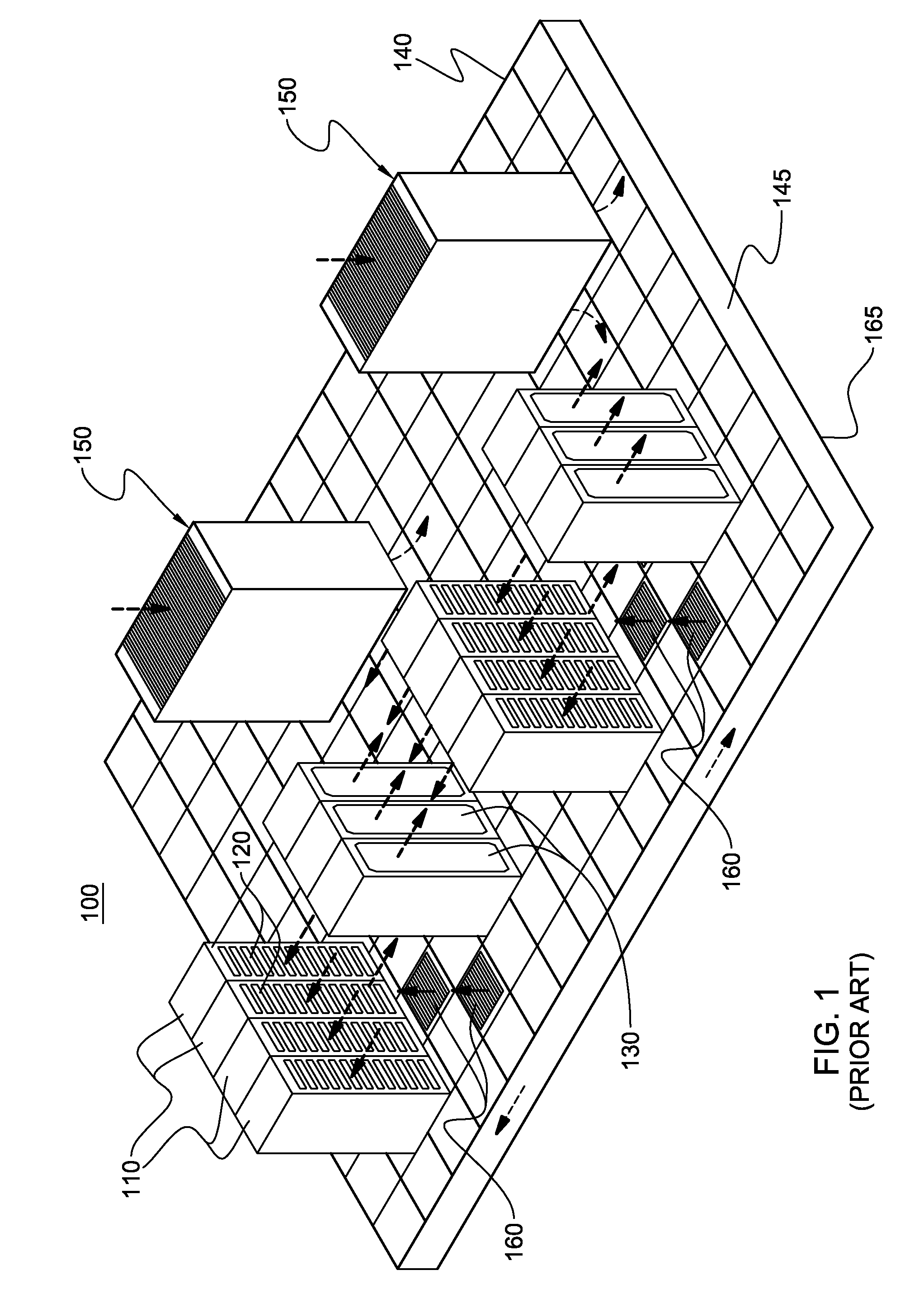

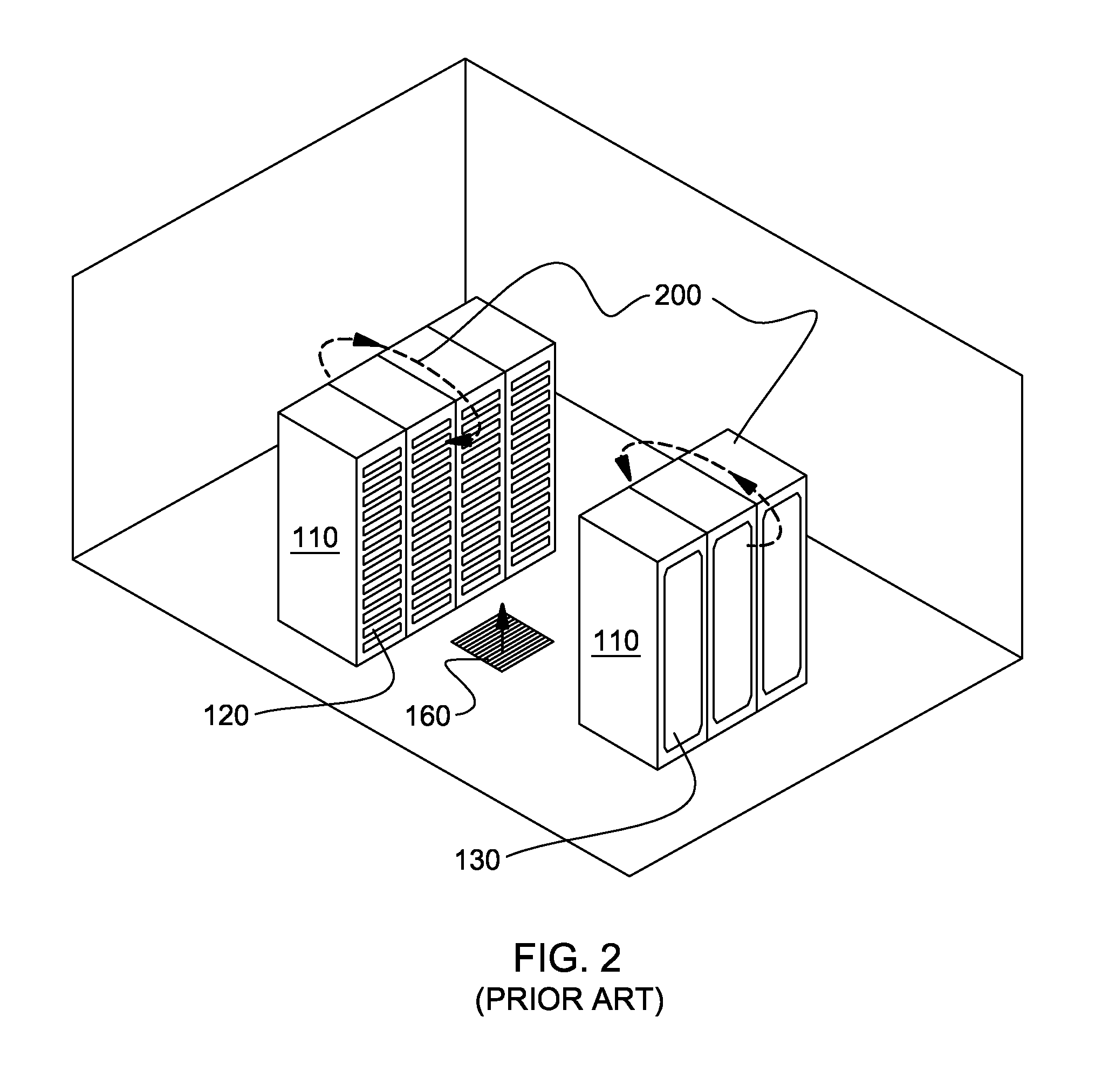

Noise-reducing attachment apparatus for heat exchanger door of an electronics rack of a data center

InactiveUS20090201640A1Facilitates egressReduce noiseShow cabinetsDigital data processing detailsUltrasound attenuationData center

Owner:IBM CORP

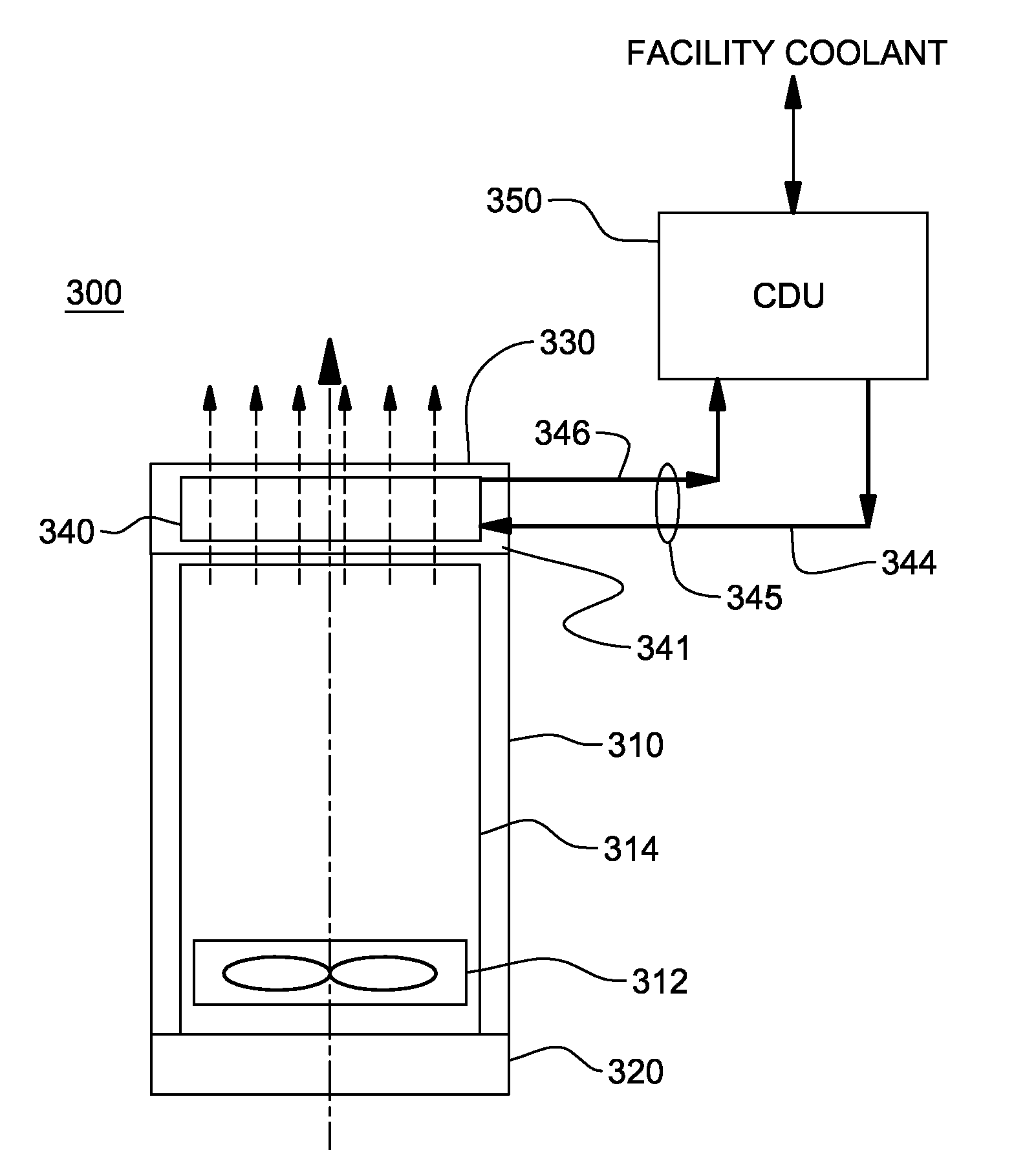

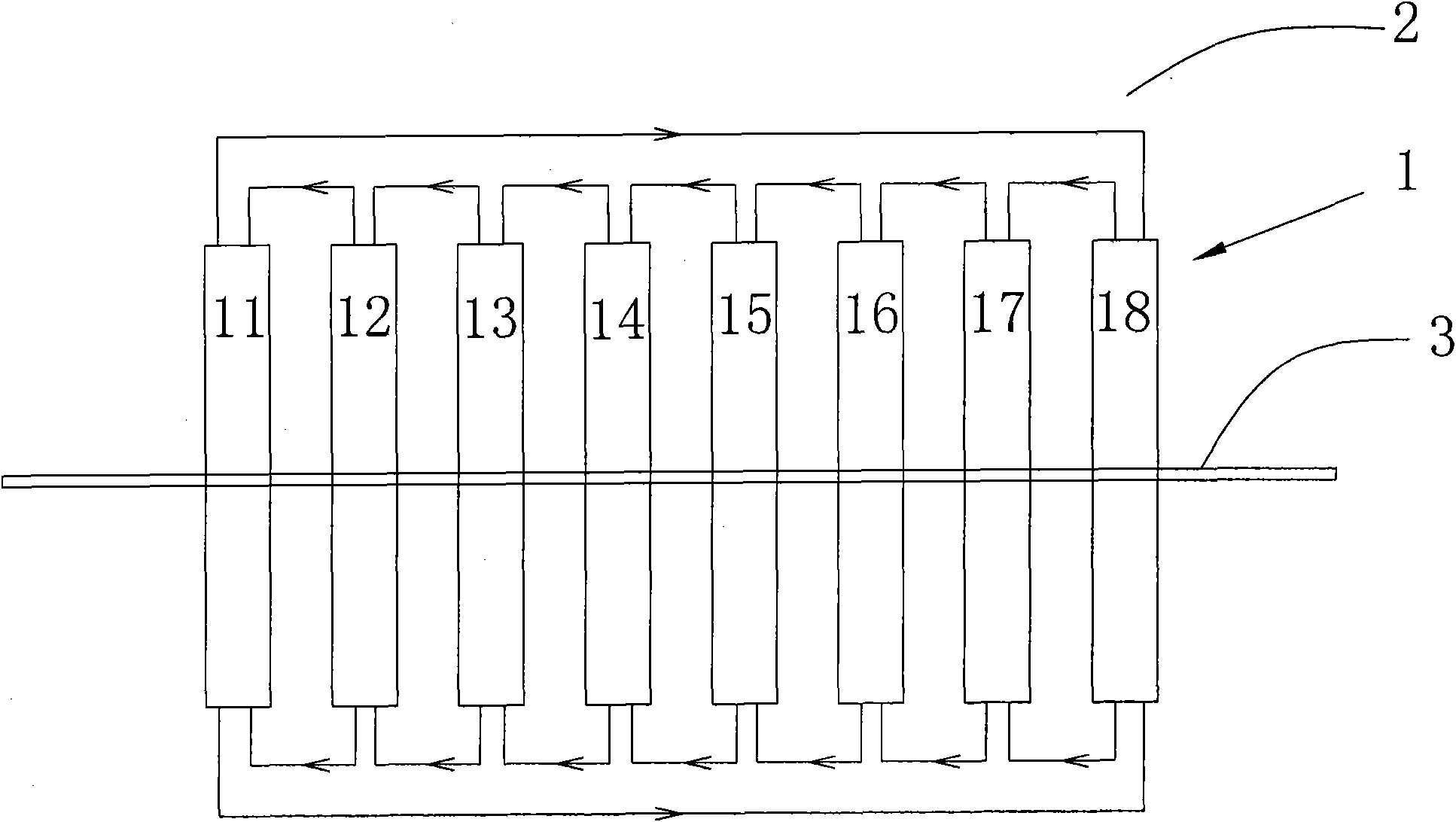

Integrated cooling system for electronic devices

ActiveUS20060034052A1Printed circuit aspectsCircuit fluid transportElectronic assembliesHeat exchanger

Owner:DELPHI TECH IP LTD

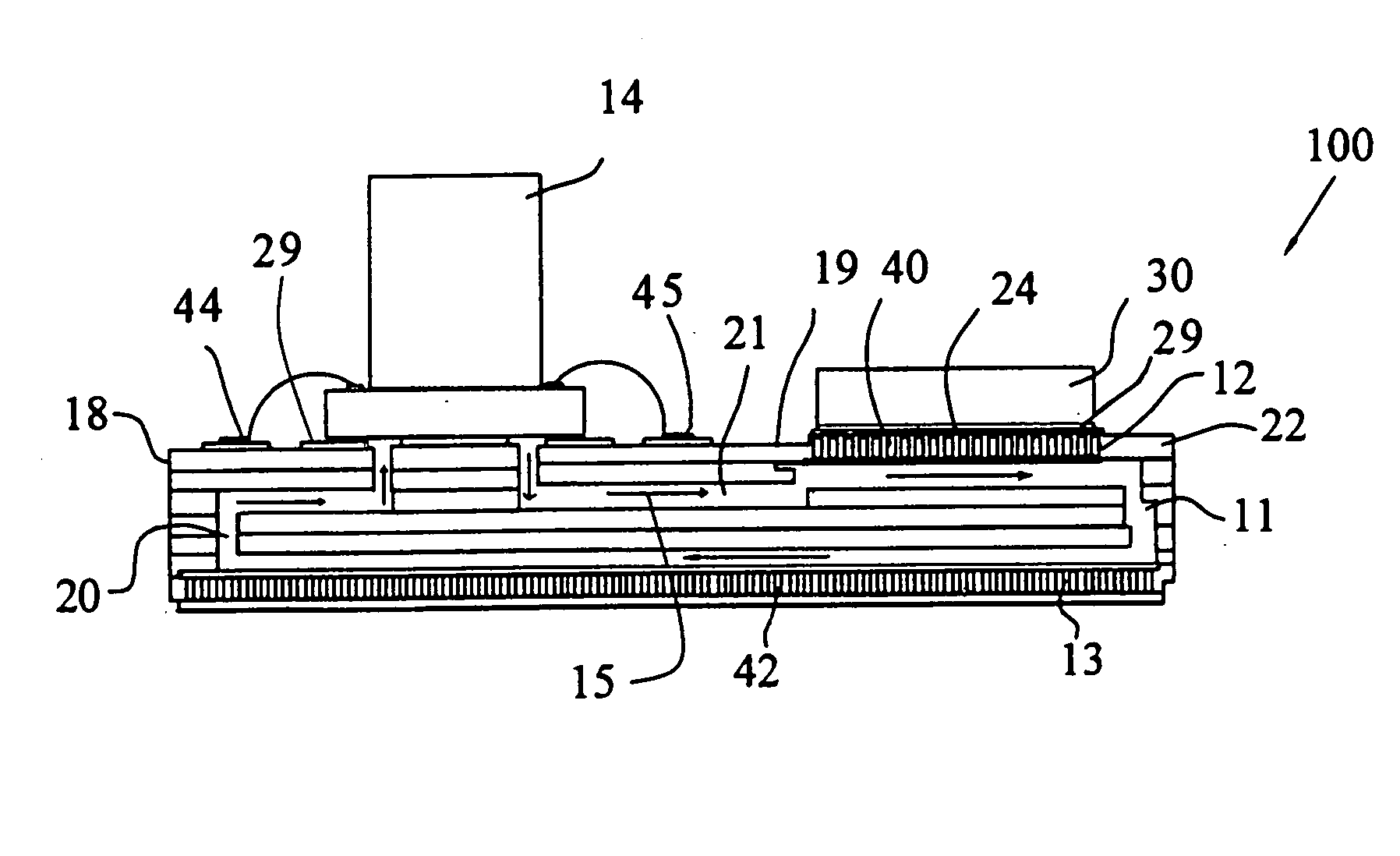

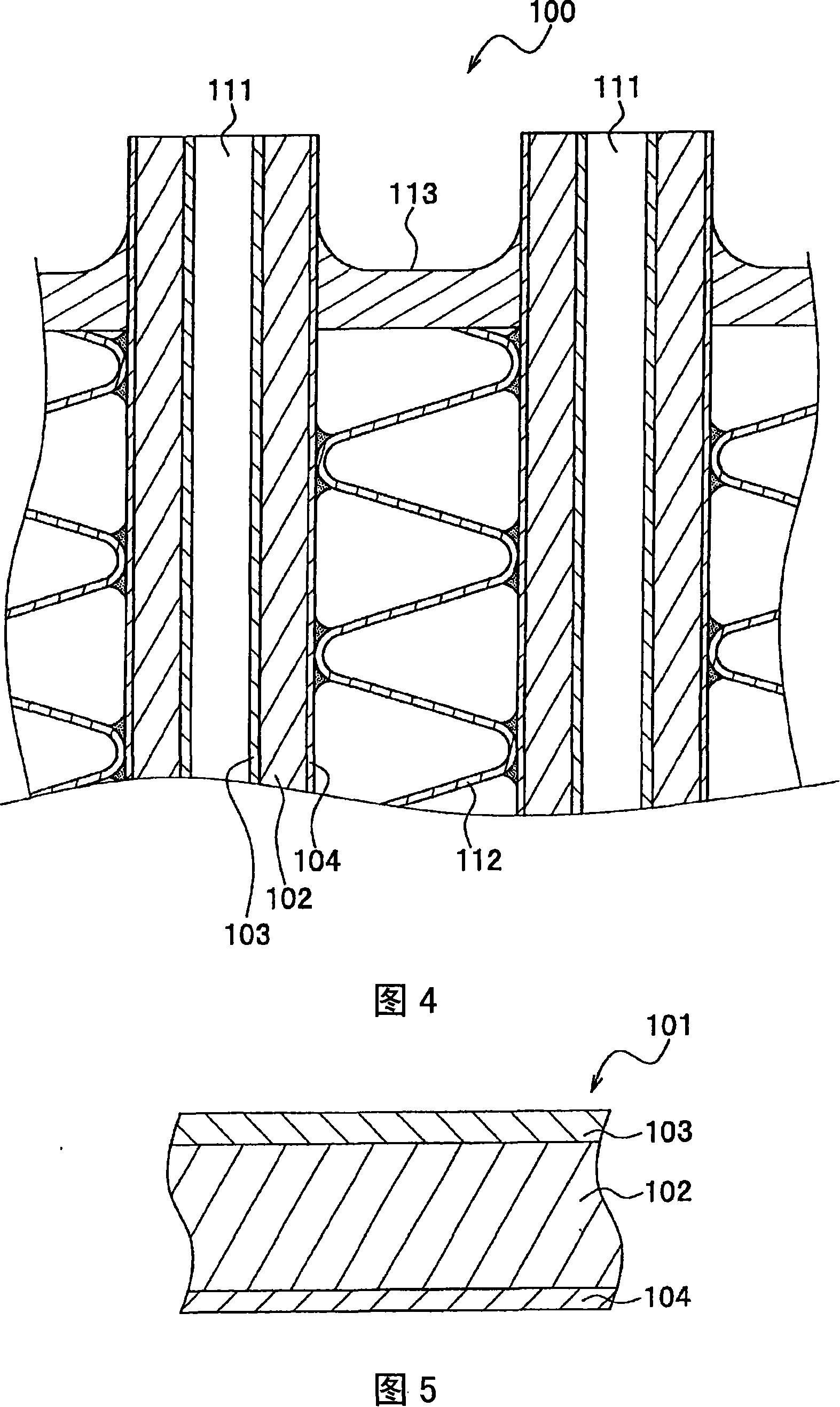

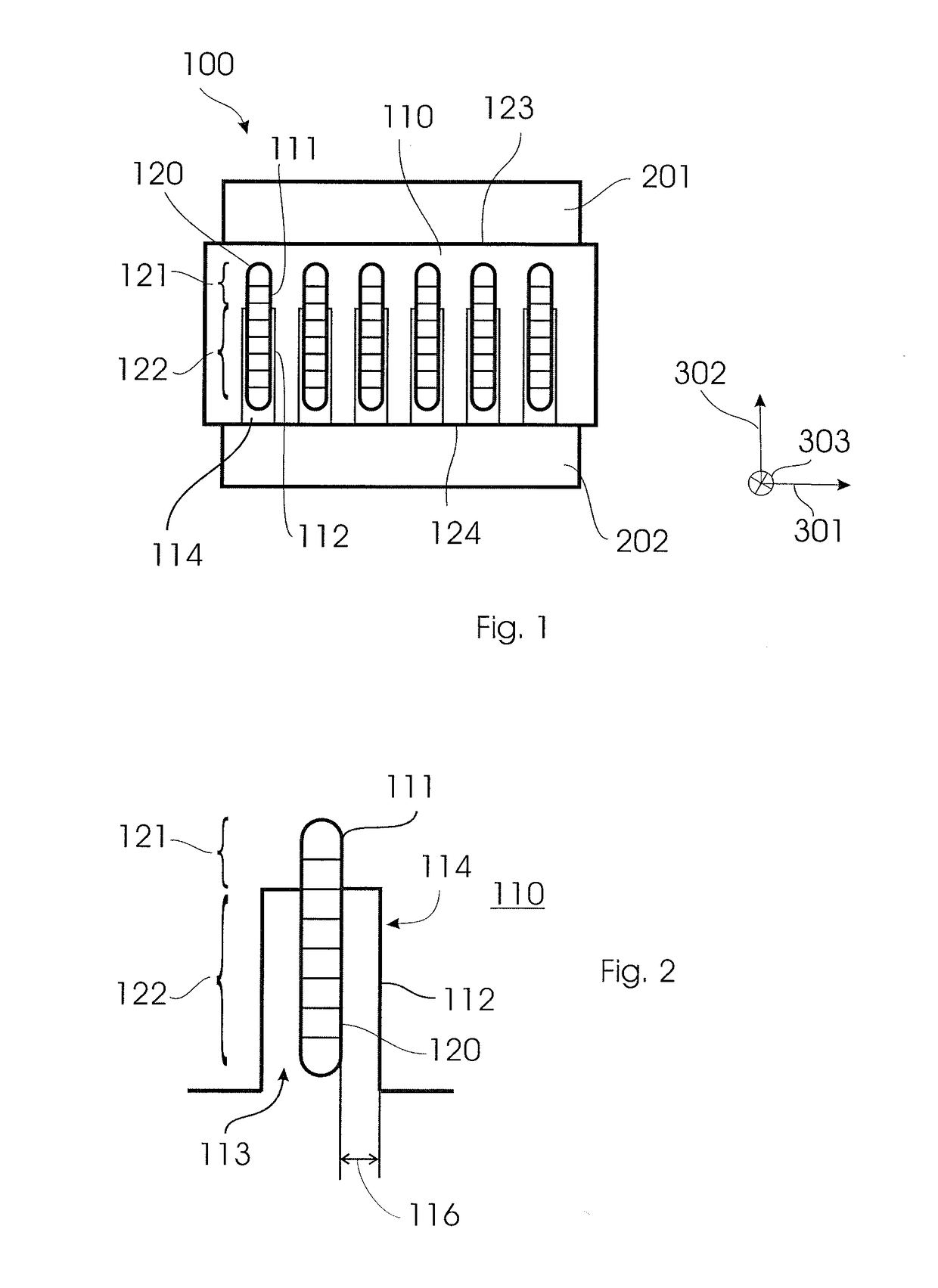

High performance compact heat exchanger

InactiveUS20100038056A1Improve thermal efficiencyLow costSemiconductor/solid-state device detailsSolid-state devicesEngineeringCoolant

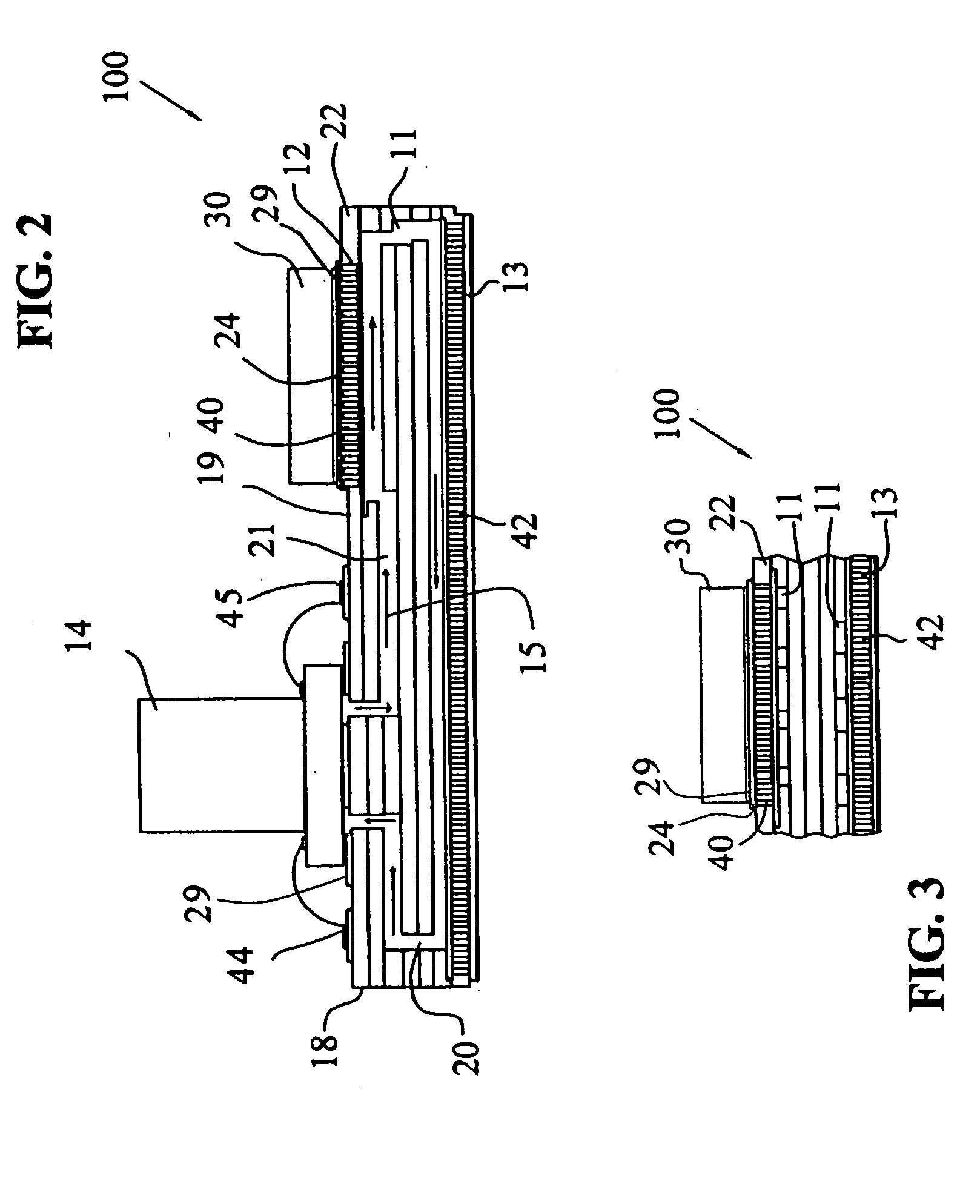

A high performance compact heat exchanger includes a base plate with evaporator channels for cooling a heat source adjacent to the base plate. A condenser is connected to the base plate and includes fins with channels therein for the coolant. A pump delivers the coolant to the evaporator channels of the base plate after passing through the fins of the condenser.

Owner:RAYTHEON CO

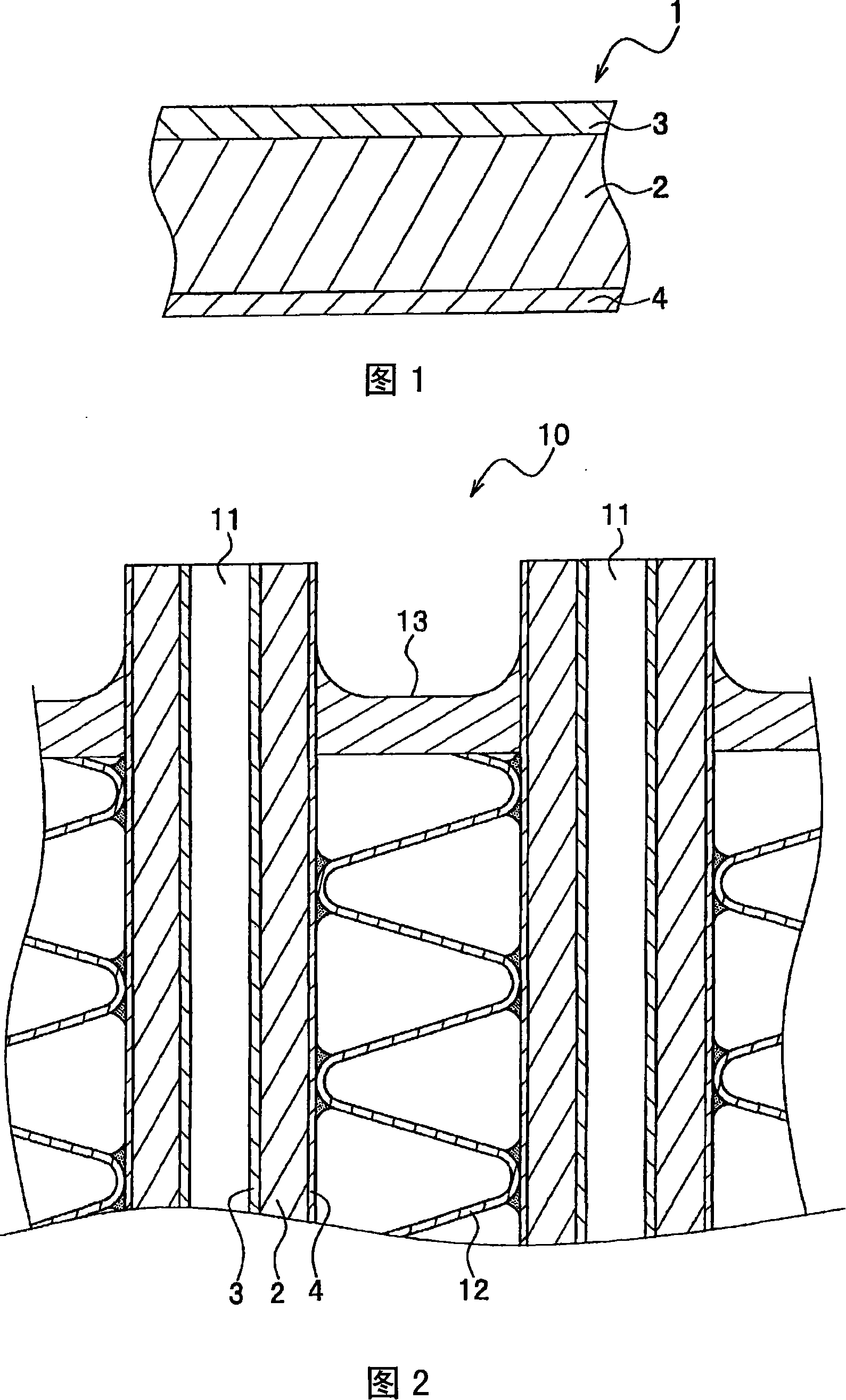

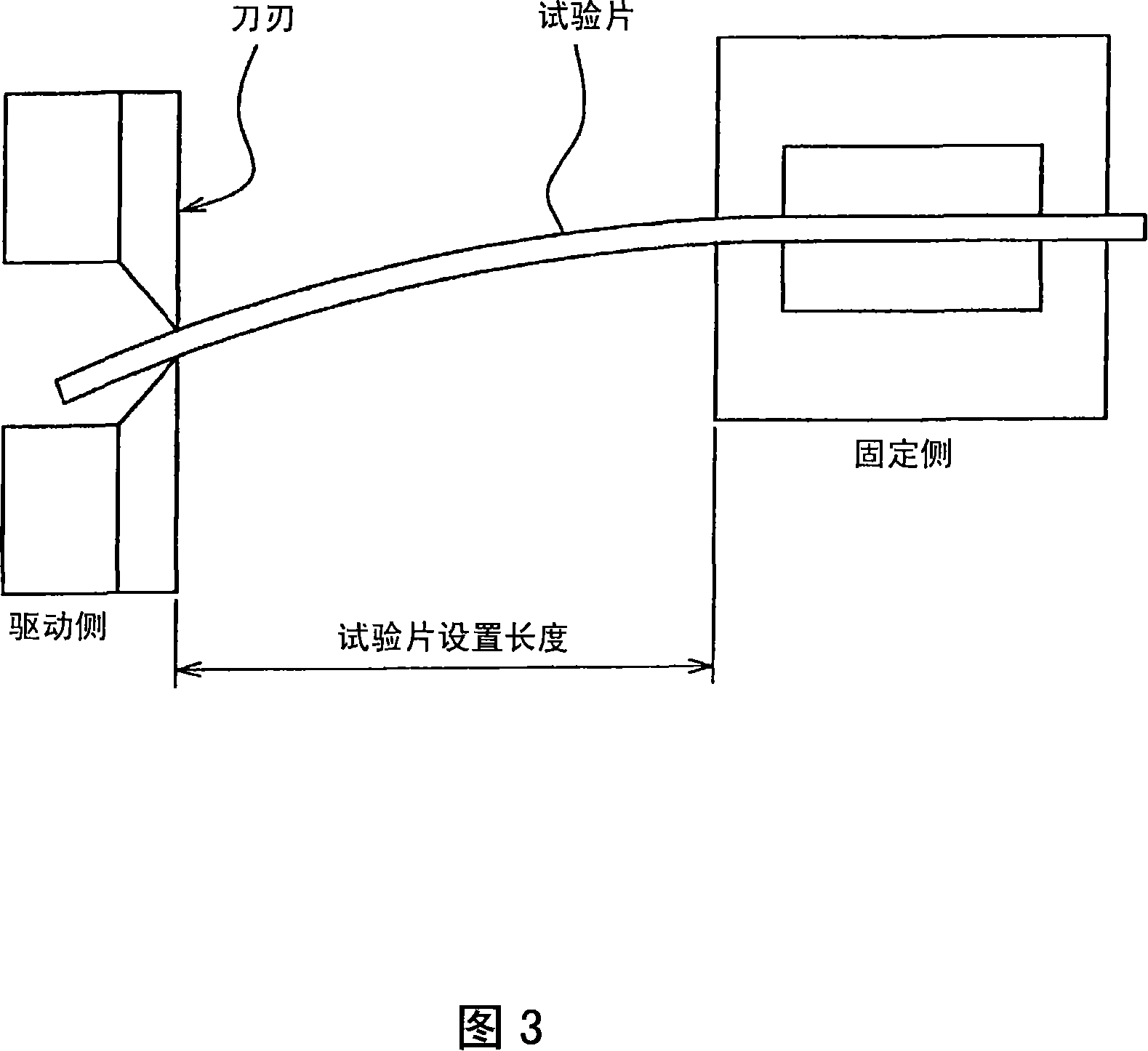

Heat exchanger and manufacturing method thereof

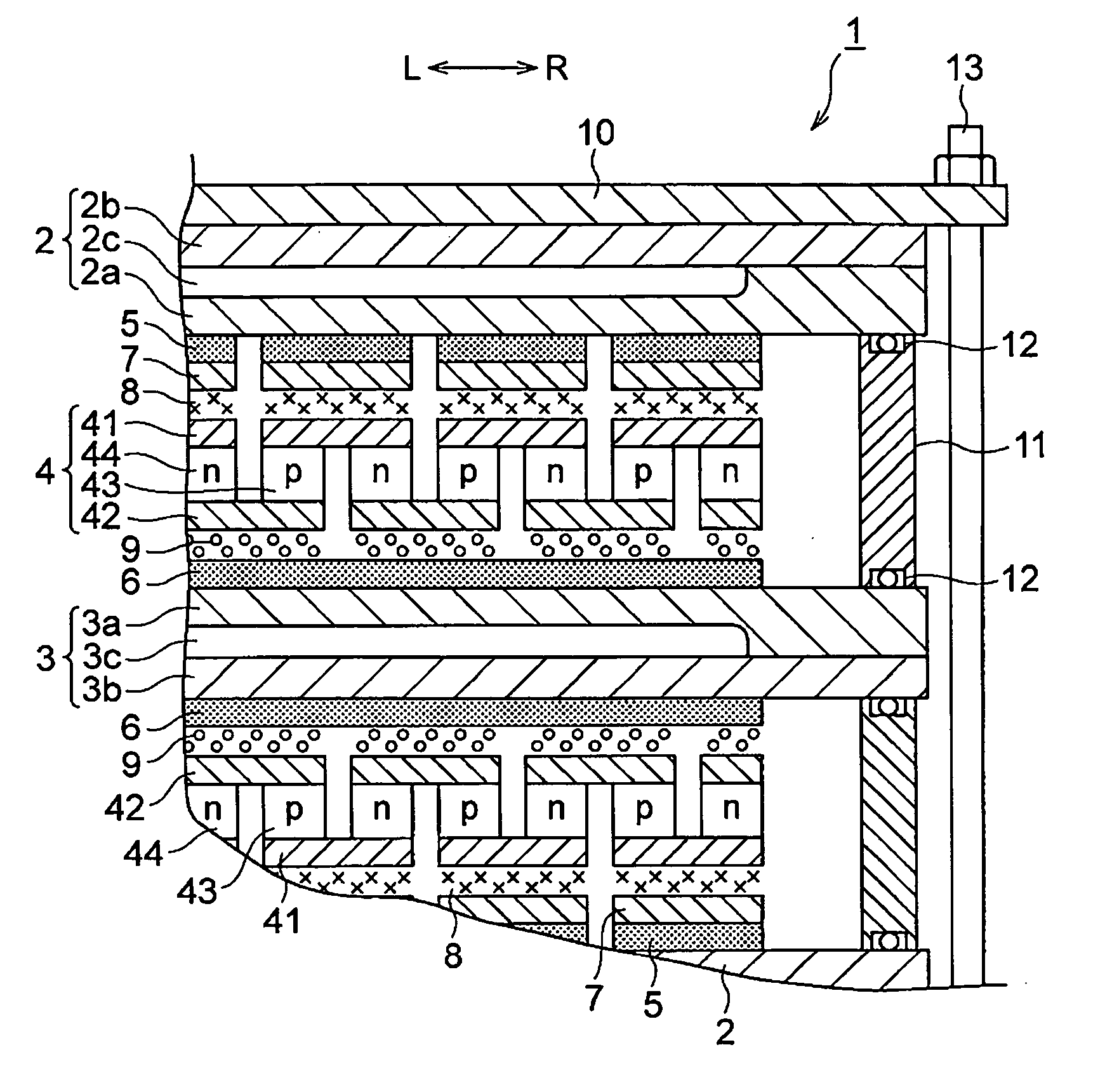

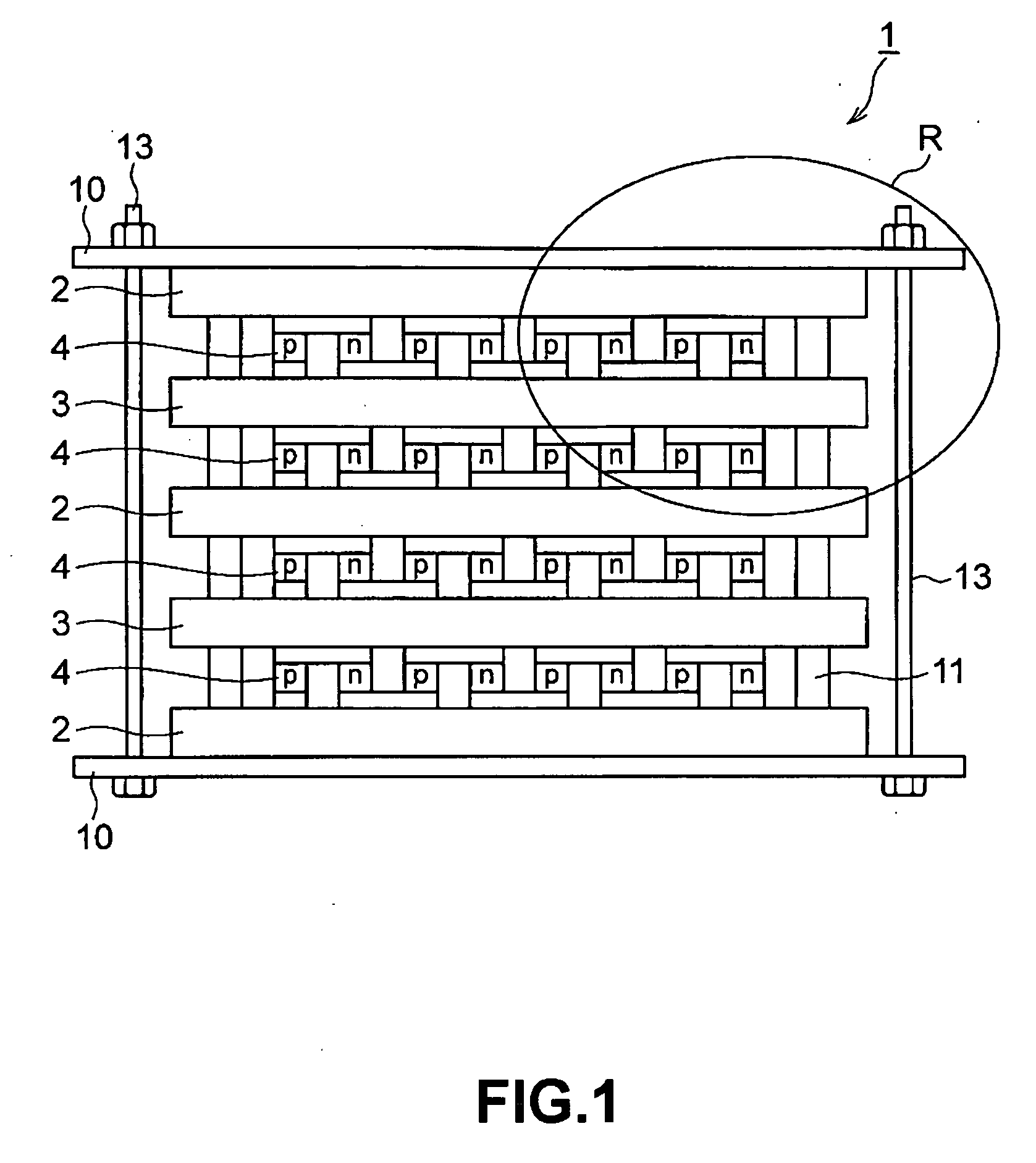

ActiveUS20060191271A1Produced in advanceIncrease productionThermoelectric device with peltier/seeback effectStationary conduit assembliesEngineeringThermal radiation

Owner:KELK LTD

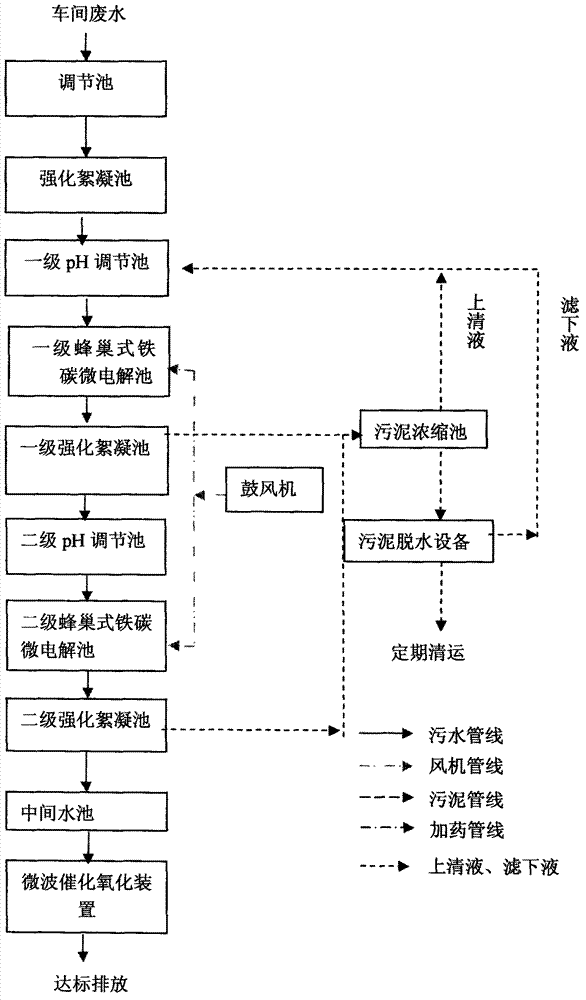

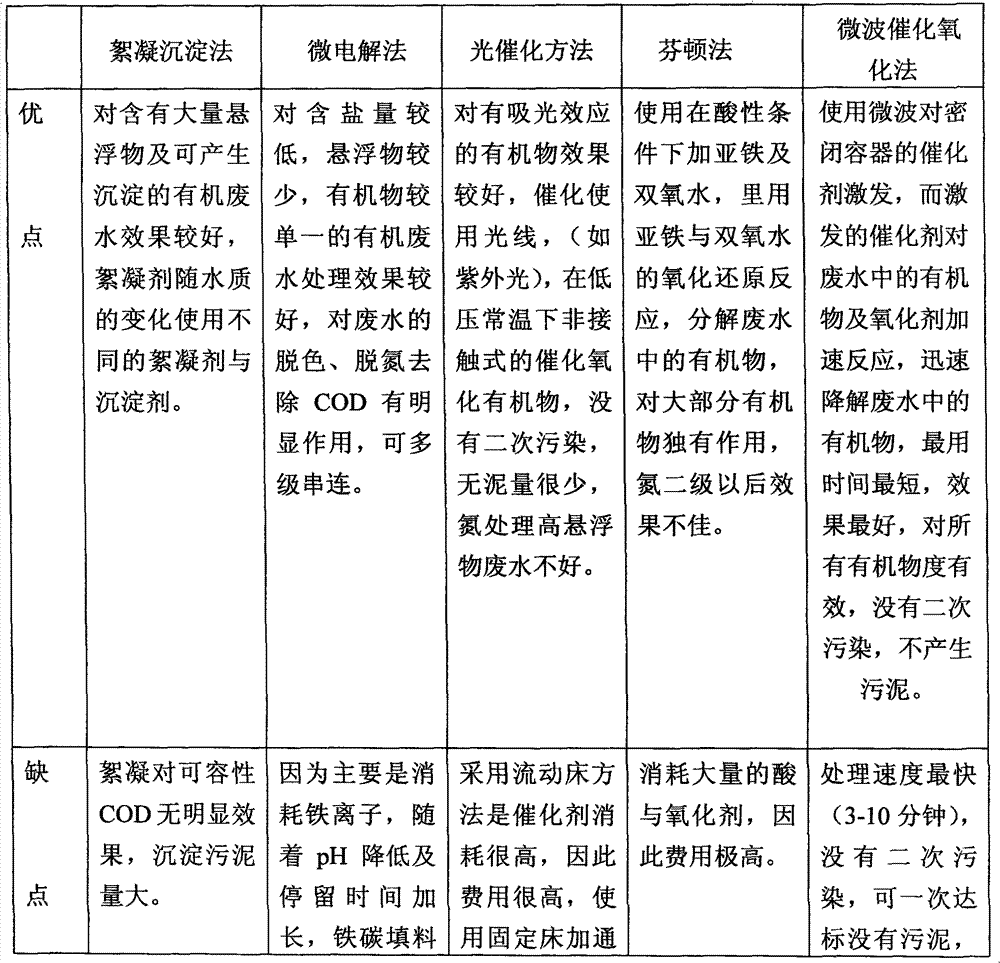

Method and system for modularized combined treatment of high-difficulty organic waste water

ActiveCN102826697AImprove applicabilityEasy to handleWater contaminantsMultistage water/sewage treatmentTreatment effectSludge

Owner:山东泰山行星环保科技有限公司

Air conditioner running control method and device and air conditioner system

ActiveCN106871366AEasy to operate and controlImprove ease of useMechanical apparatusLighting and heating apparatusTarget controlFlue

The invention provides an air conditioner running control method and device and an air conditioner system. An air conditioner comprises an outdoor unit shell, an air inlet, an air outlet and an air flue, wherein the air inlet and the air outlet are defined by the shell, and the air flue communicates with the air inlet and the air outlet and is internally provided with a draught fan and a heat exchanger. The running control method comprises the following steps that the voice of a target user using the target air conditioner is collected, the voice of the target user is subjected to voice recognition, and feature information of the target user is obtained; for various reference air conditions within the area range where the target air conditioner is located, a reference user matched with the feature information is inquired from users using the reference air conditioners, target control parameters are calculated according to historical control parameters set by the reference user, and then the target air conditioner is controlled through the target control parameters. According to the method, the air conditioner control operation can be simplified, and the using convenience of the air conditioner is improved.

Owner:MIDEA GRP CO LTD

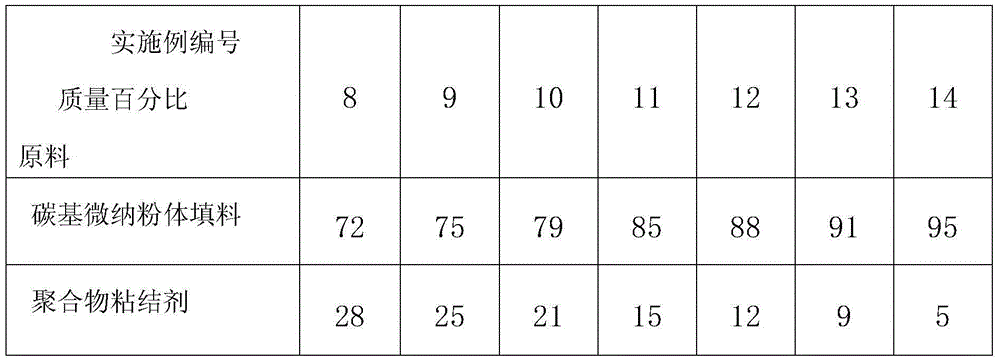

High-thermal-conductivity high-electrical-conductivity carbon nano-grade composite material and preparation method thereof

InactiveCN104130753AImprove production efficiencyGood thermal conductivityHeat-exchange elementsDisplay deviceElectron

Owner:SOUTHWEAT UNIV OF SCI & TECH

Hydrogen on demand electrolysis fuel cell system

InactiveUS20140262819A1Improve fuel economyEmission reductionCellsPhotography auxillary processesElectrolysisHydrogen

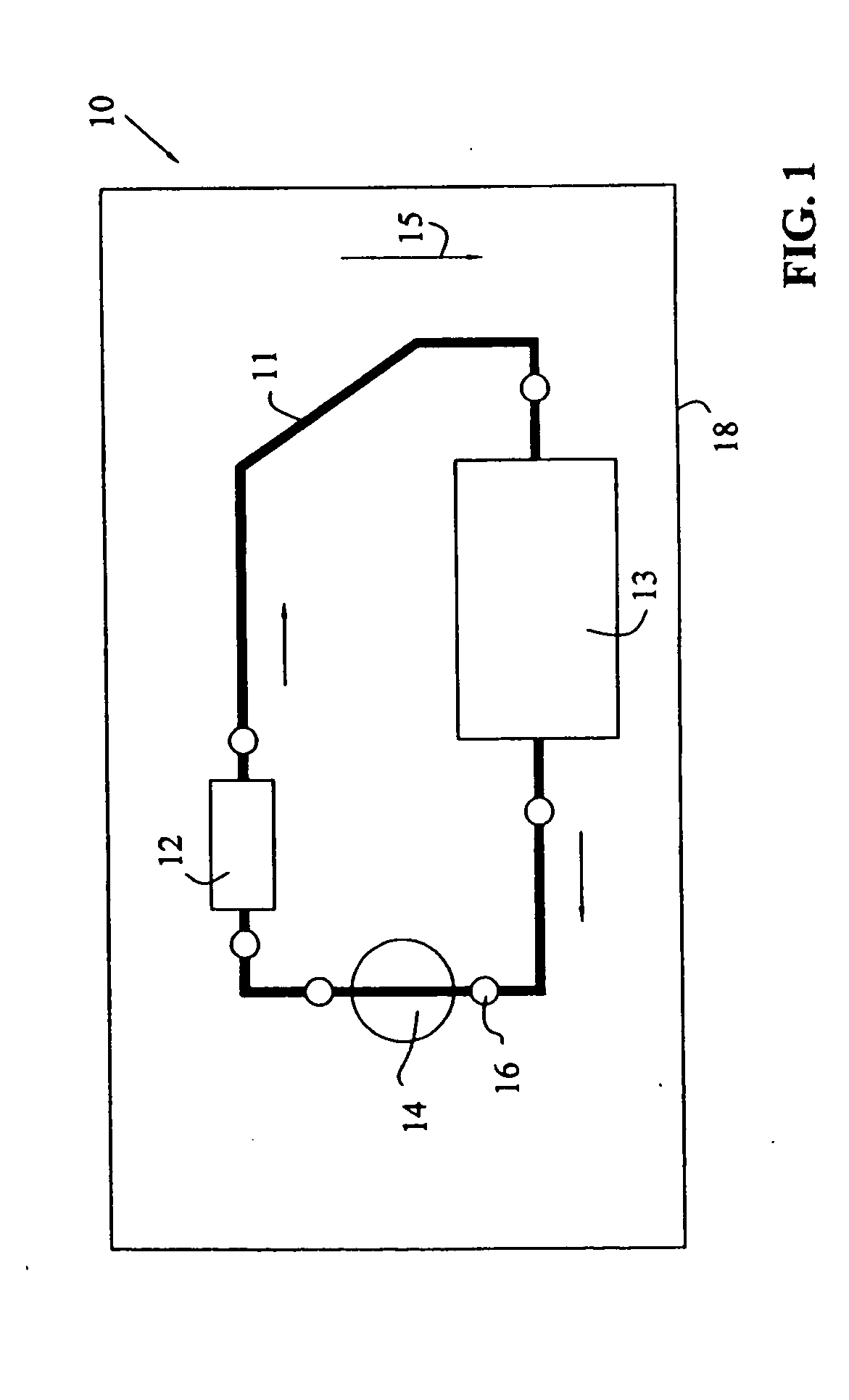

A hydrogen and oxygen (HHO) gas on-demand electrolysis fuel cell system for use with internal combustion engines is disclosed. This hydrogen on-demand (HOD) system integrates with the engine control module (ECM) or other control system that regulates the operation of an internal combustion engine in order to supply HHO to the engine and improve the engine's overall fuel efficiency. This system includes an electrolyte fluid reservoir outfitted with level, pressure and temperature sensors; a pump and heat exchanger; a uniquely-configured electrolyzer; and a filter. The combined engine and HOD system is controlled and regulated by an electronic control system (ECS) and a combustion control module (CCM). The CCM is installed on the engine such that it actively intercepts the electronic signals from the engine manufacturer's ECM to continuously coordinate the functions and operations of the HOD system and the engine.

Owner:NRG LOGISTICS

Solar photoelectric photo-thermal integrated assembly and solar combined heat and power generation system thereof

InactiveCN103594538AEliminates the effects of thermal contact resistanceEliminate the effects ofPV power plantsEnergy industryCells panelMetal sheet

The invention relates to a solar photoelectric photo-thermal integrated assembly and a solar combined heat and power generation system of the solar photoelectric photo-thermal integrated assembly. The solar photoelectric photo-thermal integrated assembly is characterized by comprising a photovoltaic cell panel provided with a metal outer frame, a metal sheet type heat exchanger and a heat-preservation material layer, wherein the metal sheet type heat exchanger and the heat-preservation material layer are sequentially arranged on the back surface of the photovoltaic cell panel in parallel and in an overlapped mode, and are rapidly fixed in the metal outer frame of the photovoltaic cell panel through a metal fixing clamp, and the standard photovoltaic cell panel can be rapidly modified into the photoelectric photo-thermal integrated assembly. The photoelectric photo-thermal integrated assembly has the advantages of being compact in structure, high in efficiency, small in pressure loss, light in weight, flexible to install, high in pressure bearing performance, resistant to corrosion, low in cost and the like, further reduces the initial investment and installation space of a medium and low temperature solar thermoelectric system, lowers the operation expenses of the system, and is suitable for civil and industrial occasions requiring for both heat and power.

Owner:SHANGHAI LVJIAN ENERGY TECH

Method for controlling temperature of crude oil for emulsion of rolling mill and control device

InactiveCN101575044AUniform temperatureImprove the heating effectTank wagonsTemperature controlEmulsion

The invention relates to a method for controlling temperature of crude oil for emulsion of a rolling mill and a control device. The method comprises the steps of: arranging a heating device on the outer part of a crude oil tank; adopting a circulation heating pump arranged at the tail of the crude oil tank to transfer crude oil to a heat exchanger for heat exchange; simultaneously adopting a temperature controller on the crude oil tank to control the on and off of the heating device; and transferring crude oil to the top of the crude oil tank for outer circulation heating so as to keep the temperature of crude oil inside the crude oil tank at a preset value. A control device comprises the heating device consisting of the circulation heating pump and the heat exchanger, the temperature controller, a steam control valve, a steam trap and pipelines connecting the components, wherein the circulation heating pump is arranged at the tail of the crude oil tank, the heat exchanger is arranged on the side of the crude oil tank and the temperature controller is arranged on the crude oil tank. The invention has the advantages of good heating effect, equal crude oil temperature, high temperature-control property and precision, simple and convenient operation process, non-steam entering the crude oil and non-impact on crude oil quality.

Owner:BAOSTEEL ENG & TECH GRP

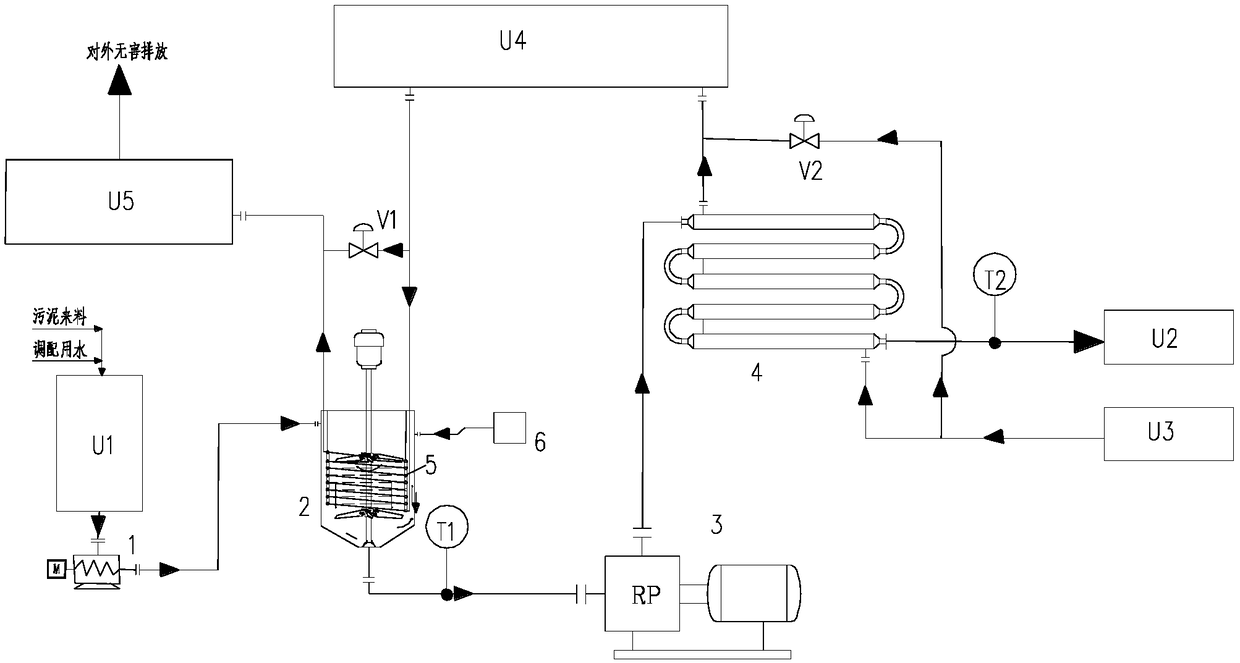

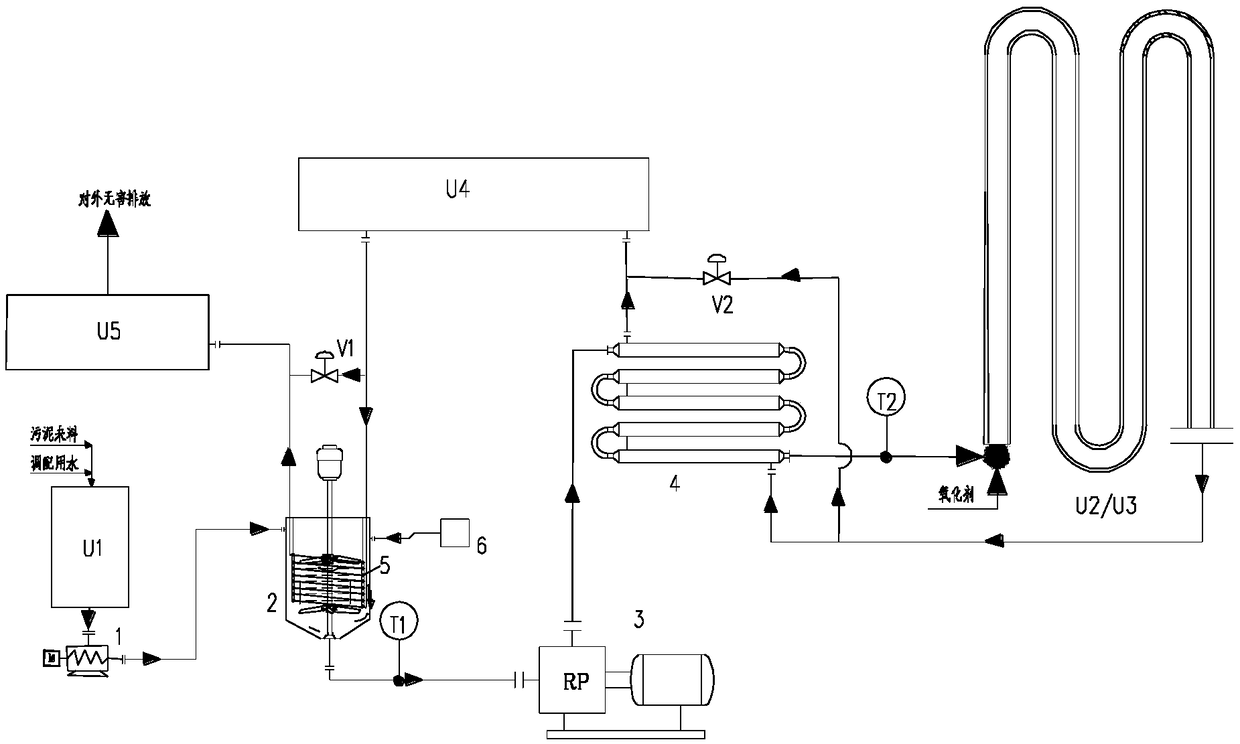

Step-by-step heating system for high-viscosity slurry

InactiveCN108862971AImprove heat transfer coefficientImprove homogeneityWater treatment compoundsSludge treatment by oxidationReduction treatmentResource utilization

Owner:XI AN JIAOTONG UNIV

Device for testing contamination characteristic of segmental temperature control coal burning boiler

InactiveCN102879415AImprove stabilityIncrease flexibilityMaterial thermal analysisTemperature controlCombustor

Owner:中国东方电气集团有限公司

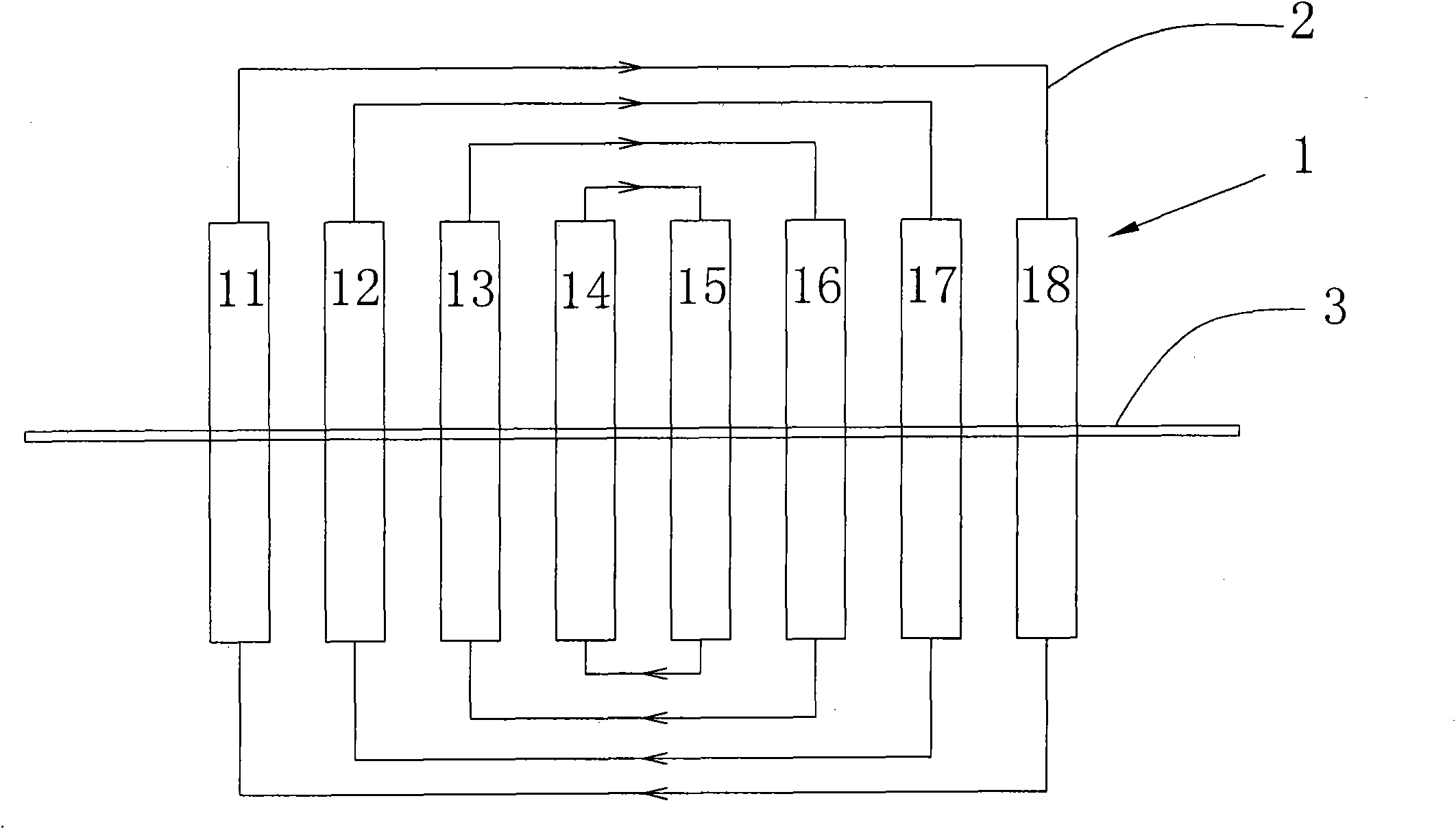

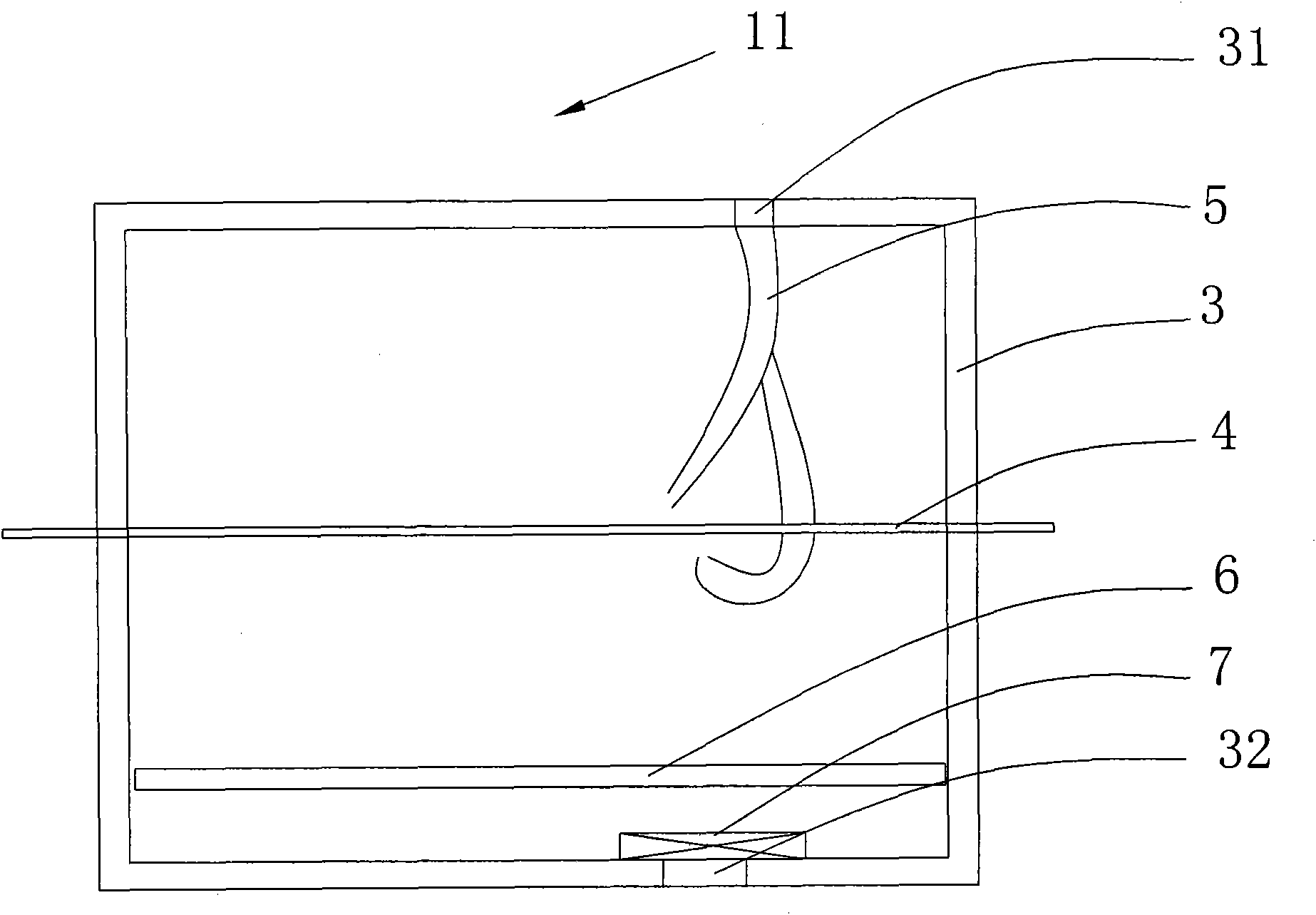

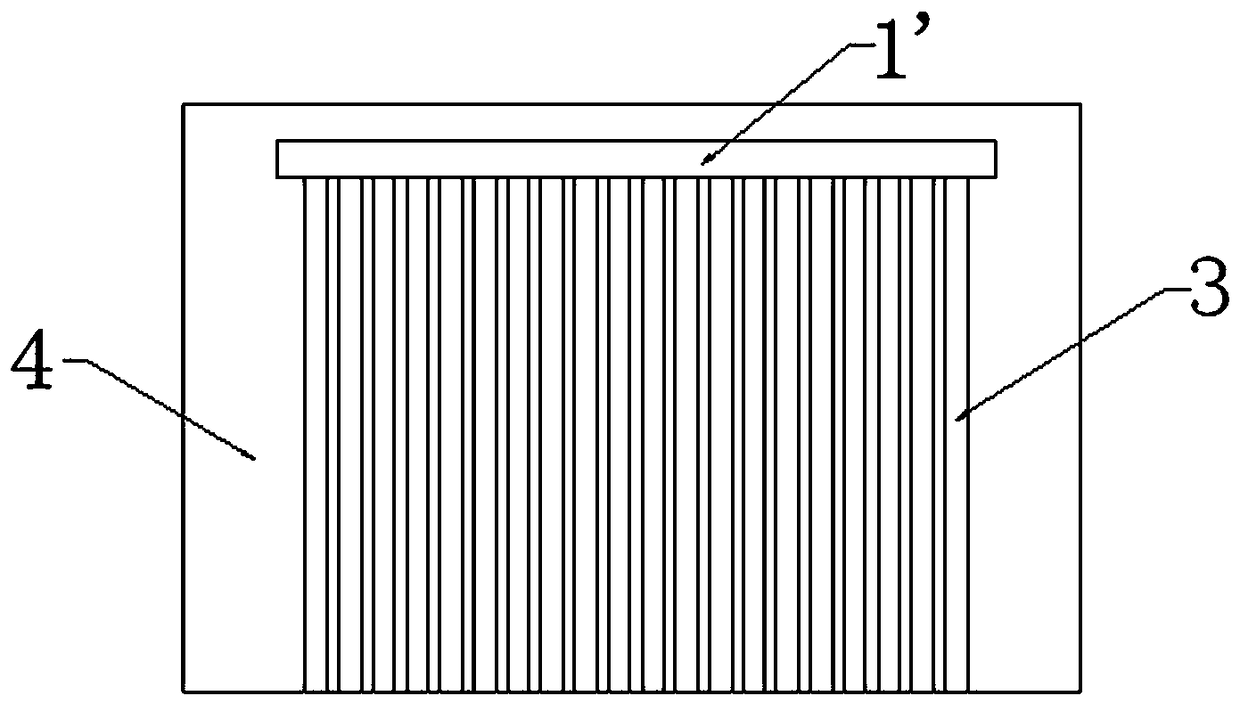

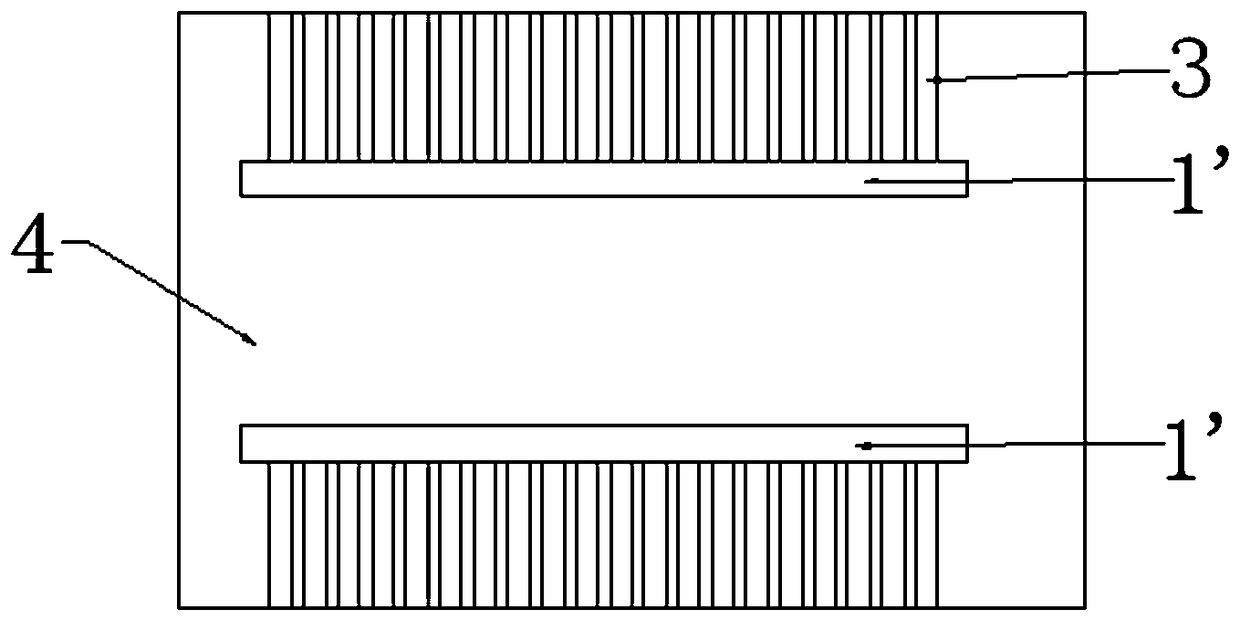

Microchannel heat exchanger and air conditioner

InactiveCN105864888AImprove drainage efficiencyReduce heat transferCondensate preventionLighting and heating apparatusEngineeringHeat exchanger

The invention discloses a microchannel heat exchanger and an air conditioner and relates to the technical field of air conditioners. The microchannel heat exchanger and the air conditioner are invented to solve the problem that in the prior art, heat exchange wind resistance and heat transfer resistance are increased due to the fact that condensate water or defrosted water at the roots of fins are not liable to be guided out. The microchannel heat exchanger comprises microchannel flat pipes arranged transversely. The upper surfaces of the microchannel flat pipes incline downwards from the windward side to the leeward side of the microchannel heat exchanger. The microchannel heat exchanger is used for conducting heat exchange with airflow.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

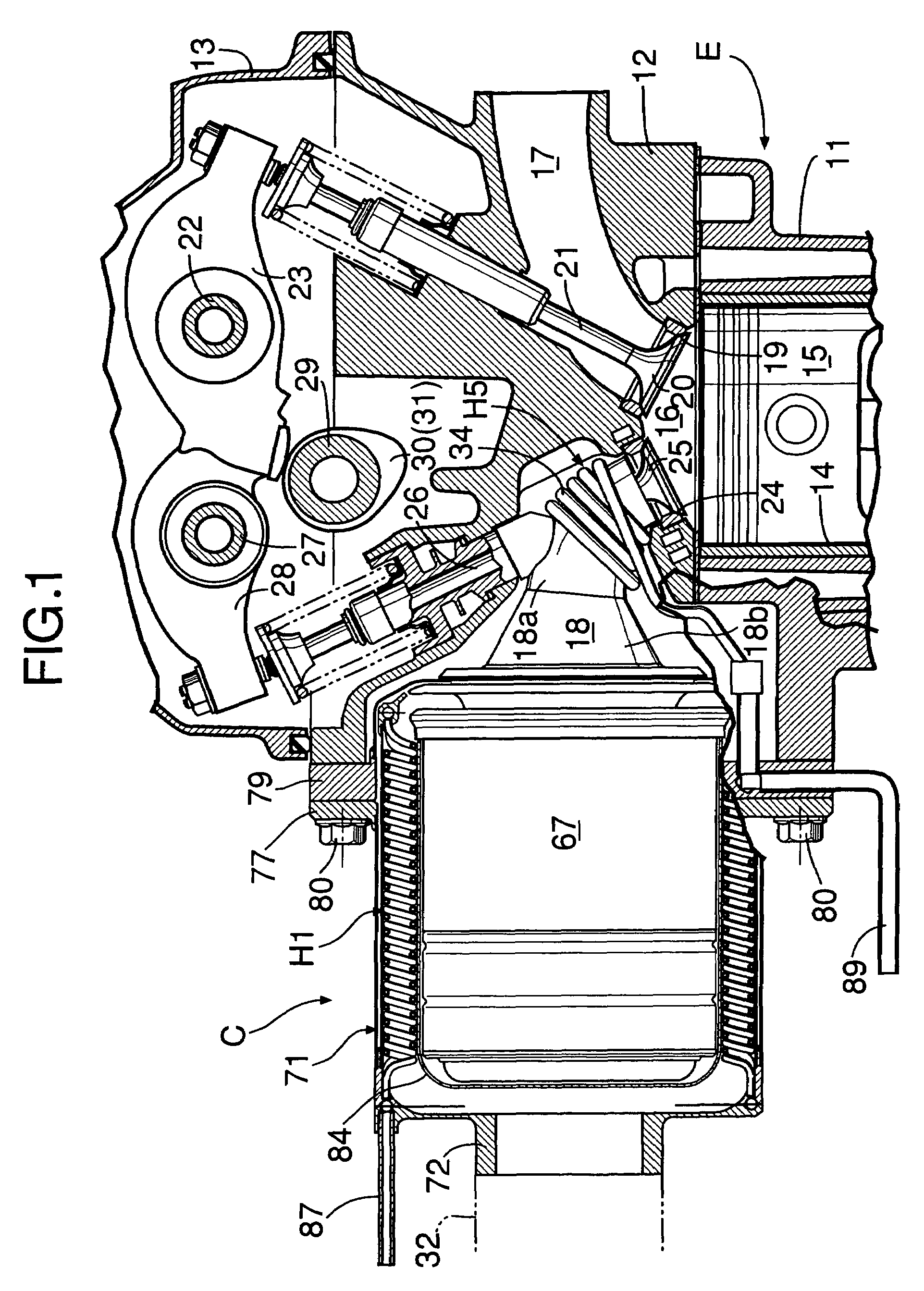

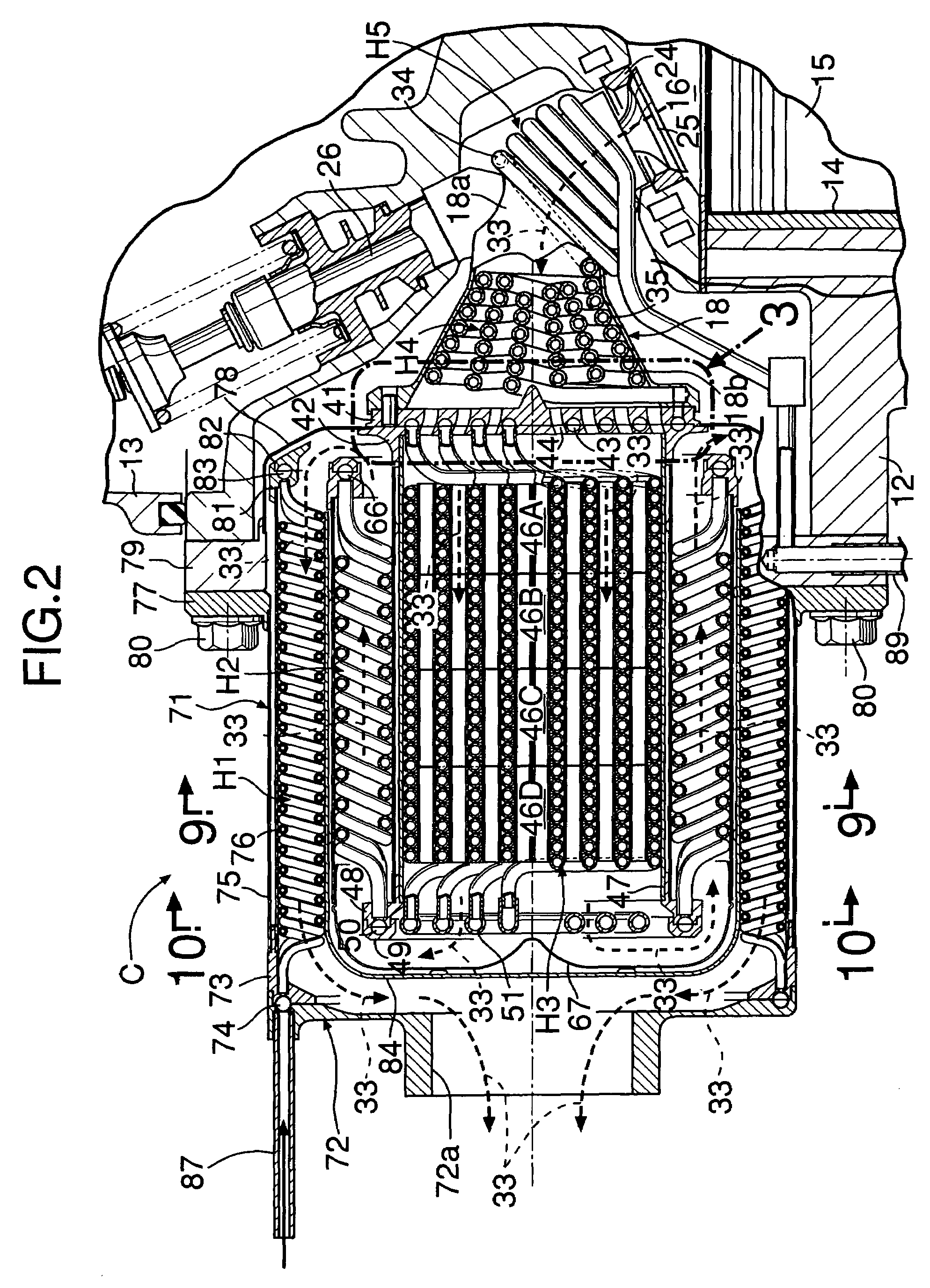

Internal combustion engine

InactiveUS7096664B2Improve exhaust gas purification performanceEfficient use ofInternal combustion piston enginesExhaust apparatusEngineeringTemperature difference

Owner:HONDA MOTOR CO LTD

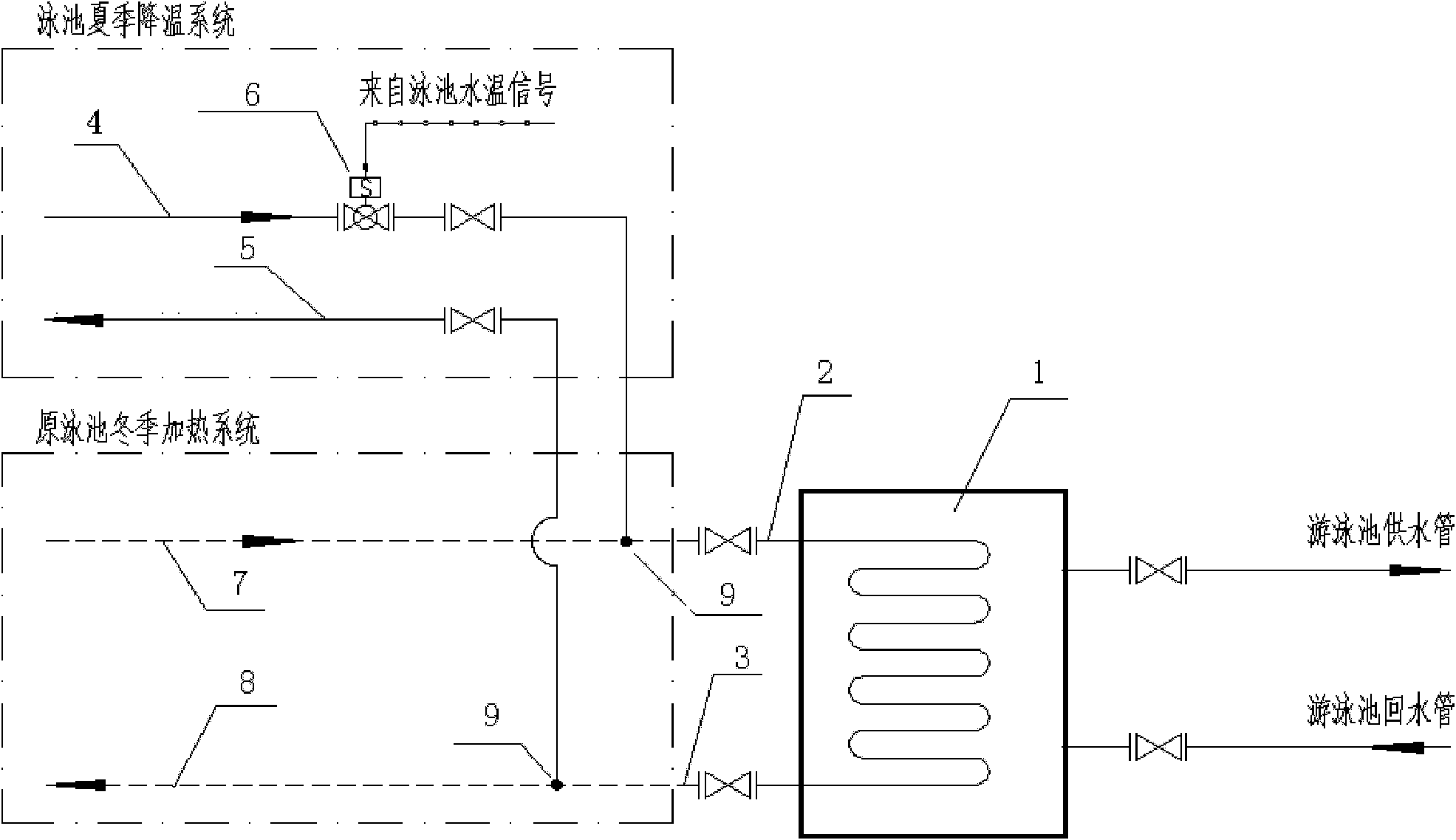

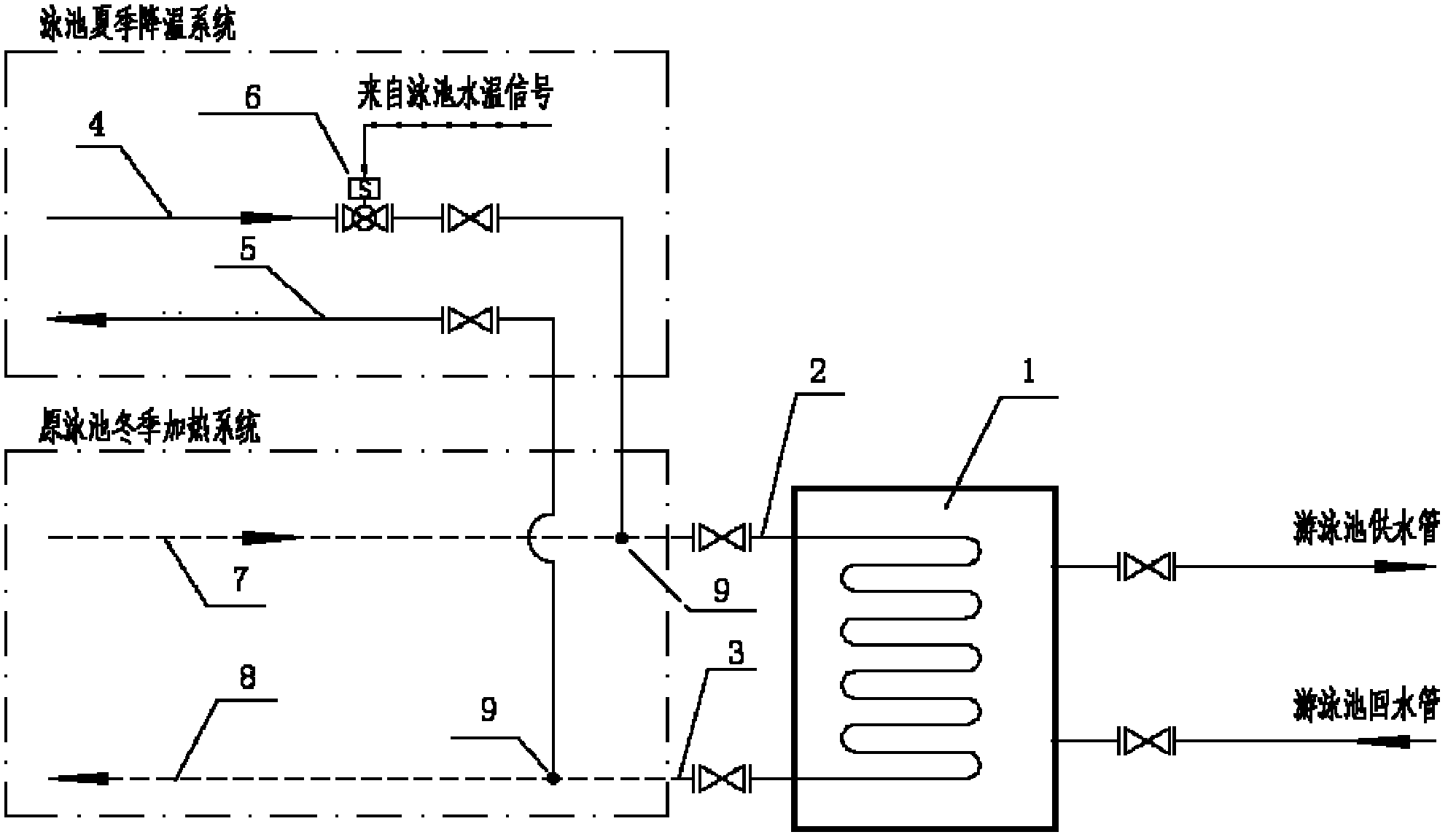

Water temperature adjustment device and water temperature control method for swimming pool

InactiveCN102493683ALow costNo human controlGymnasiumSwimming poolsTemperature controlControl signal

Owner:上海现代建筑设计(集团)有限公司

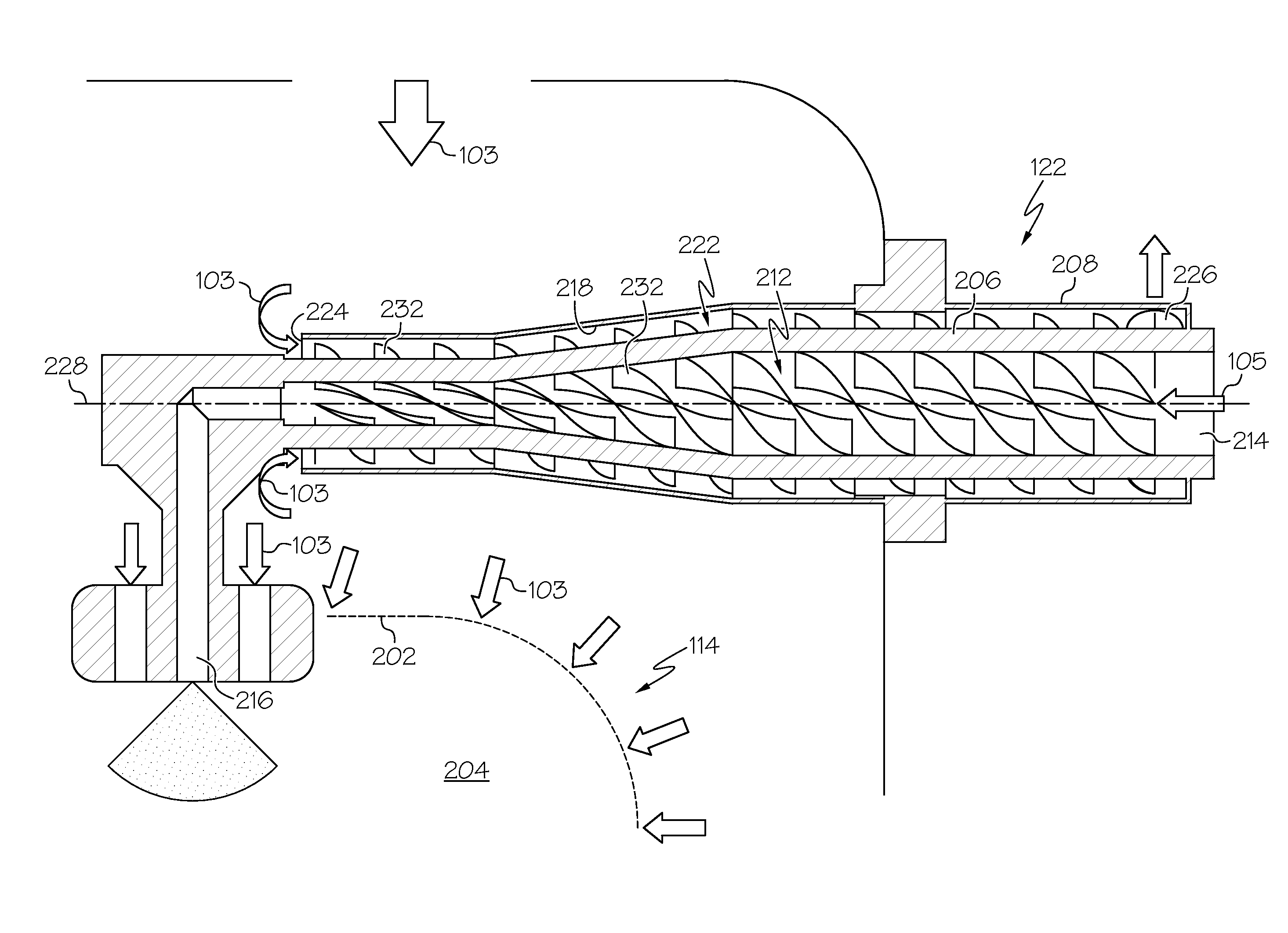

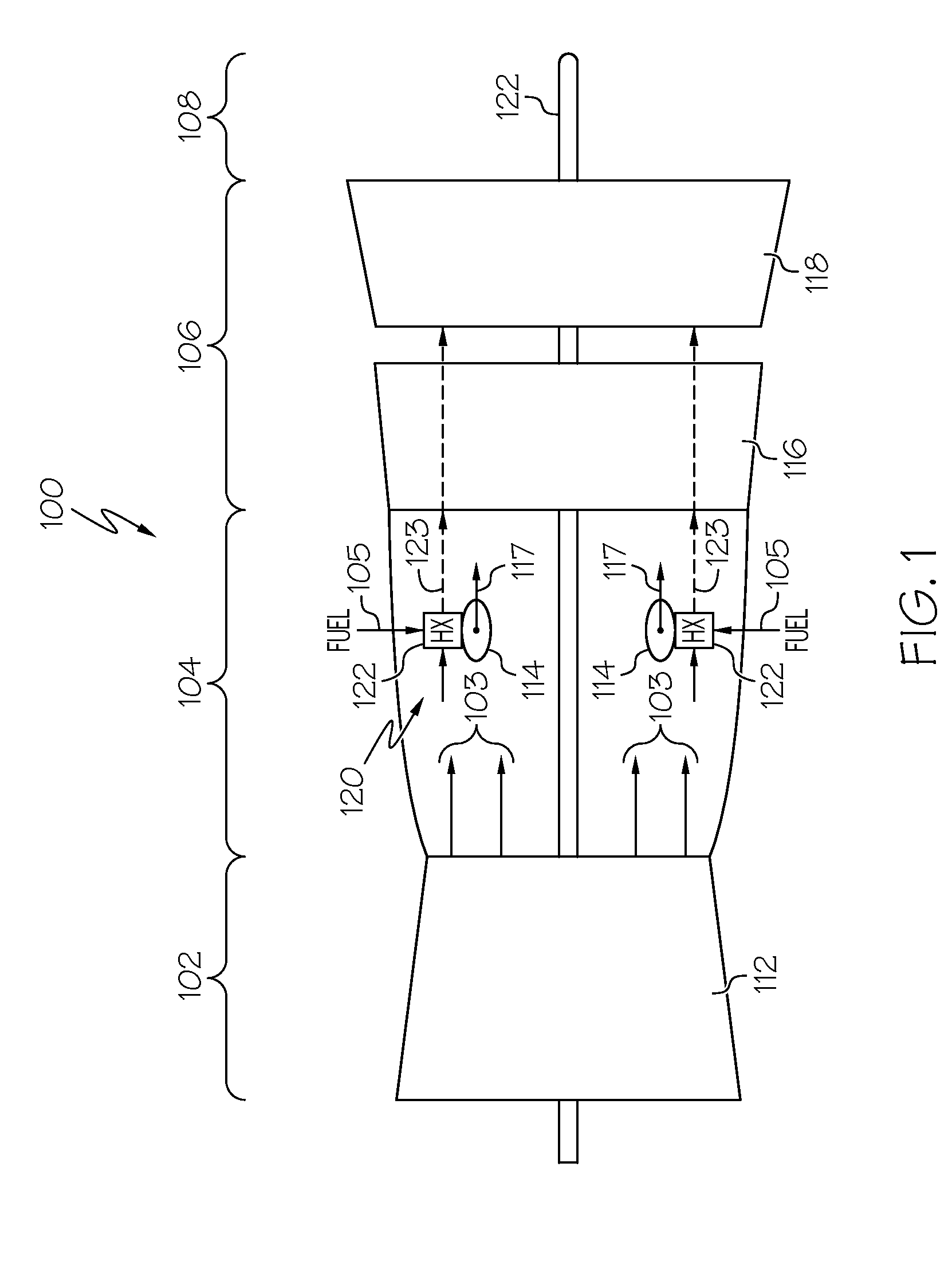

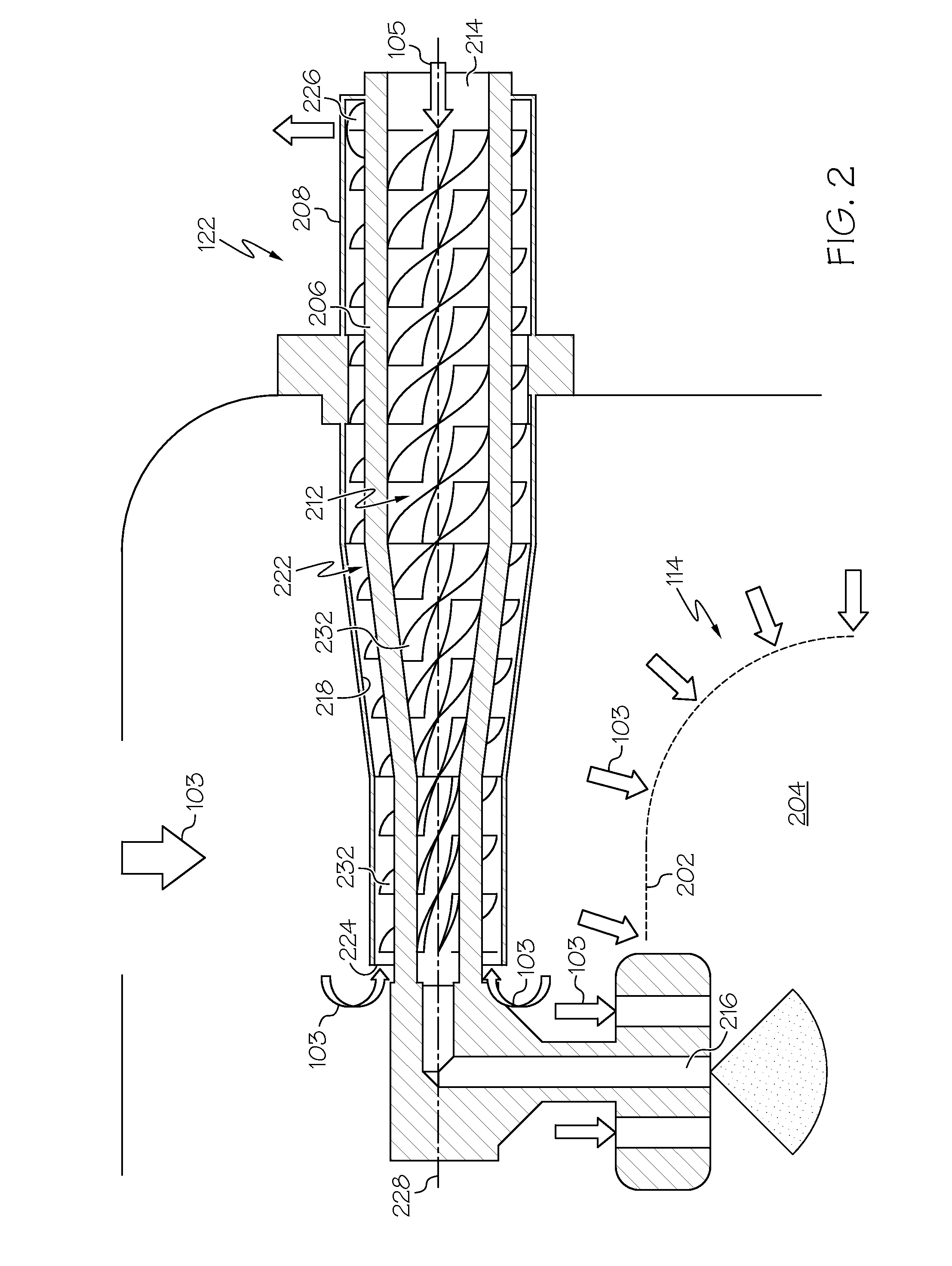

Gas turbine engine fuel cooled cooling air heat exchanger

ActiveUS20160290290A1SFC also risesReduce trafficBurnersContinuous combustion chamberTurbineGas turbines

Owner:HONEYWELL INT INC

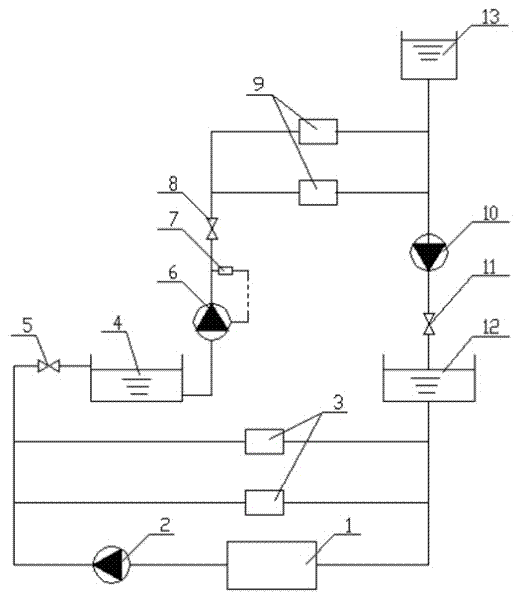

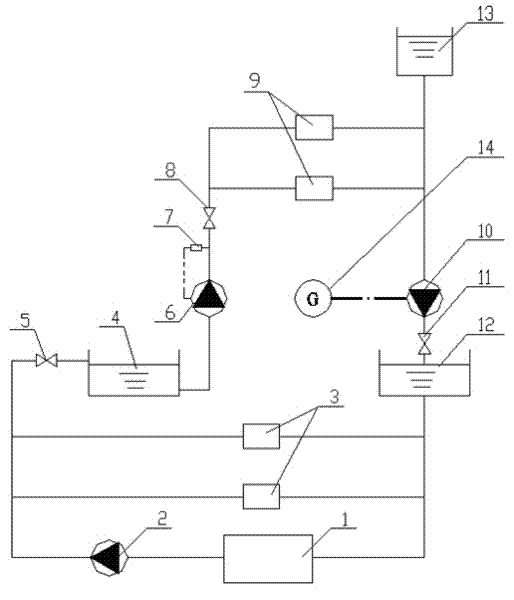

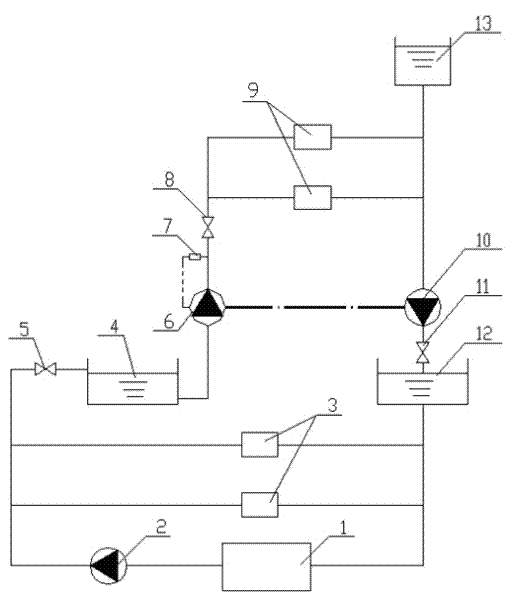

Chilled water system for central air-conditioning system of high-rise building and control method thereof

InactiveCN102519095AReduce energy consumptionImprove operational efficiencyLighting and heating apparatusSpace heating and ventilation safety systemsEngineeringChilled water

Owner:GUANGZHOU INST OF RAILWAY TECH

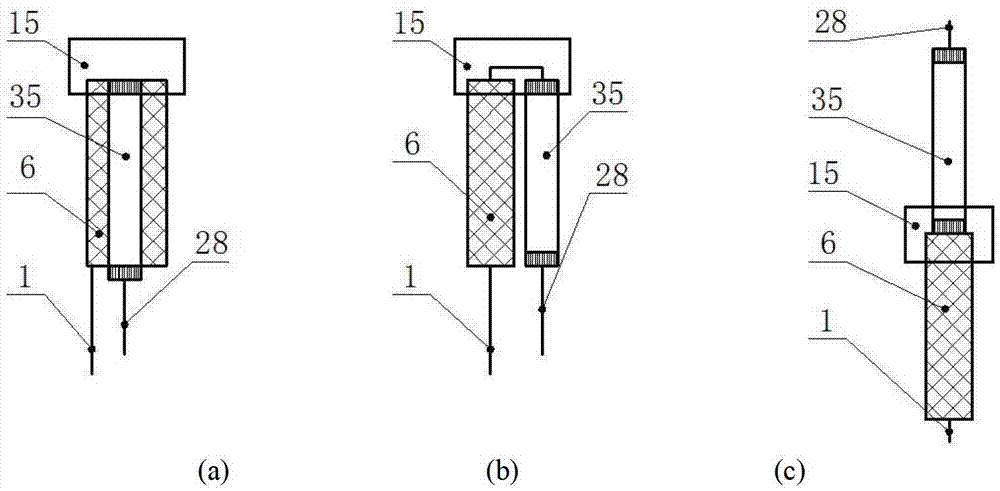

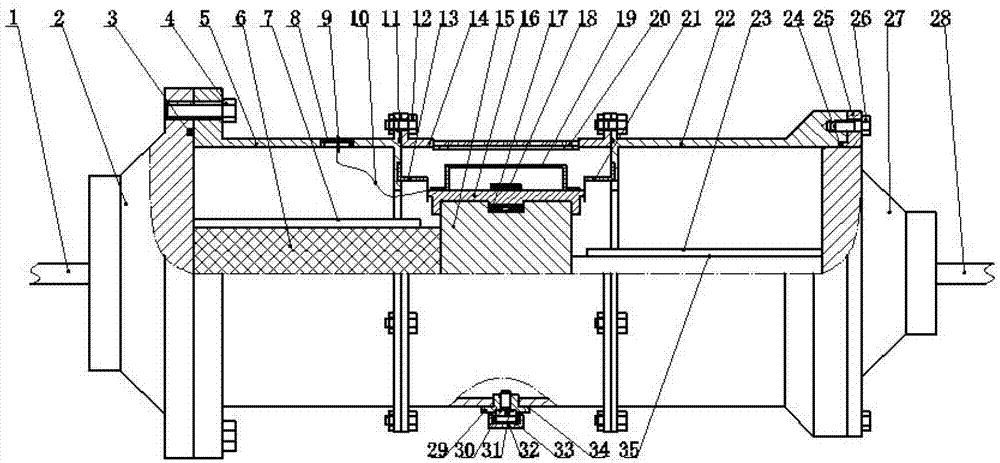

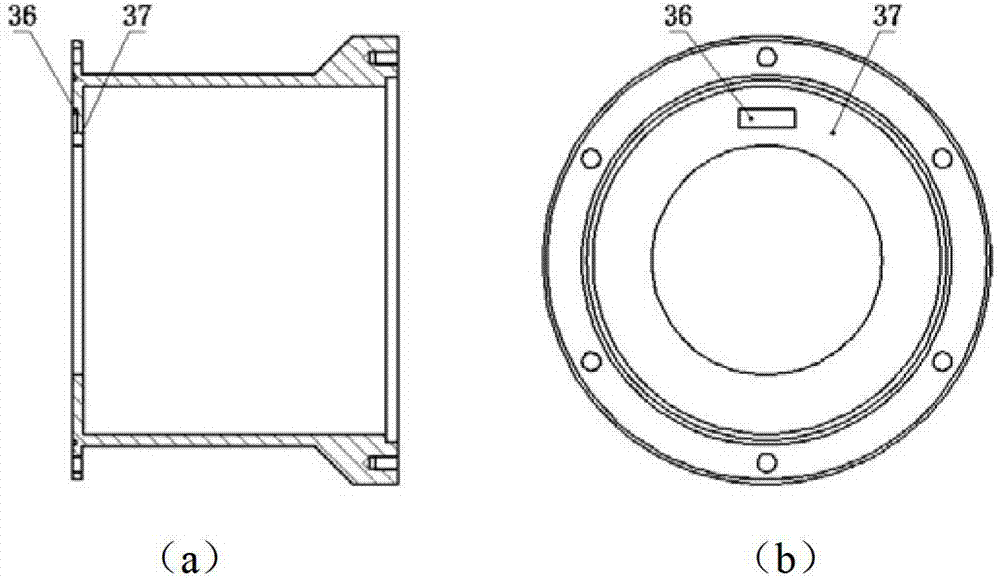

Integrated Dewar applied to linear pulse tube refrigerator and method for manufacturing integrated Dewar

InactiveCN103245120AAvoid axial forceCompression machinesGas cycle refrigeration machinesPulse tube refrigeratorEngineering

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

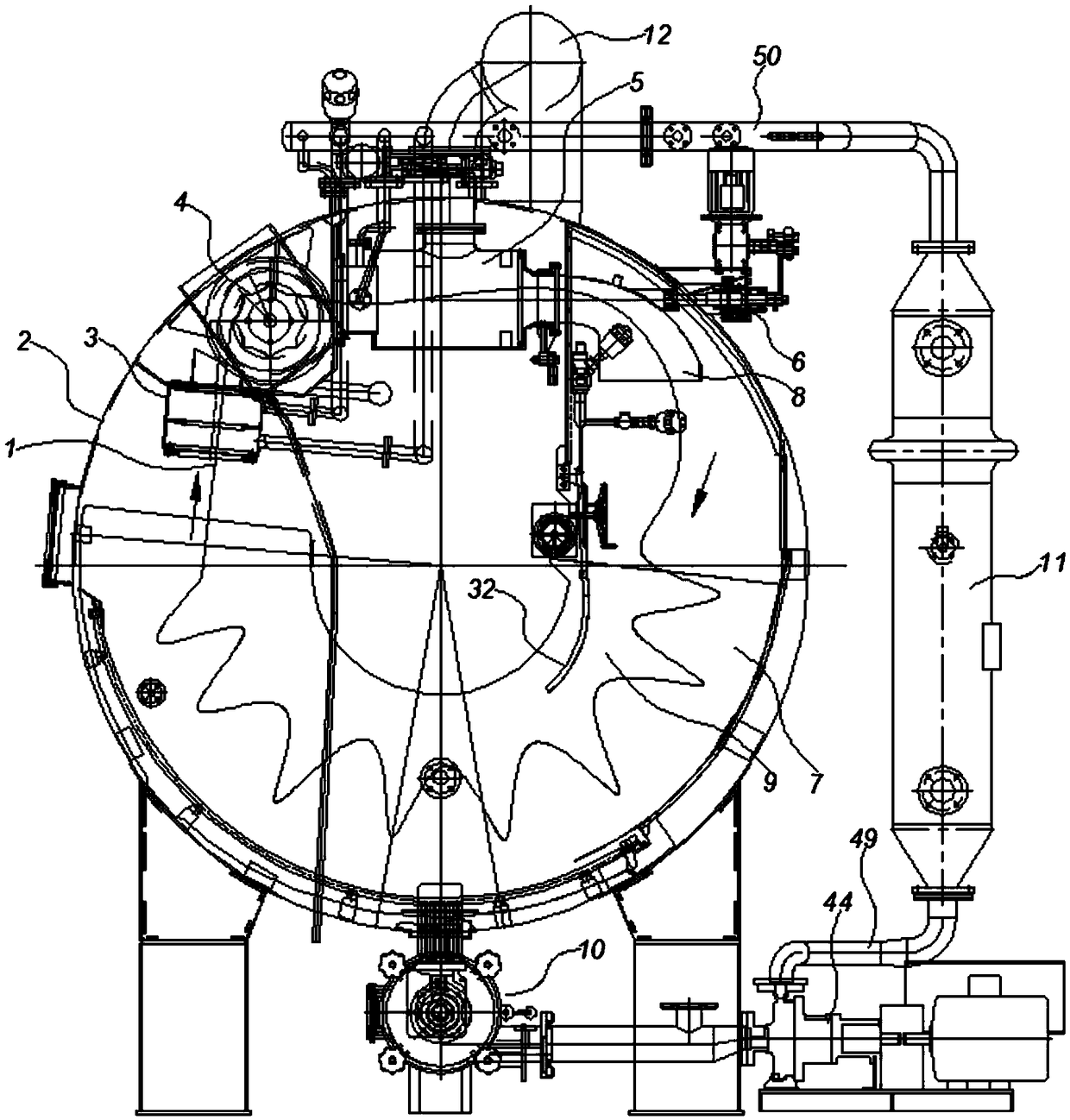

High-temperature gas-liquid dyeing machine

PendingCN109440331AReduce creasesImprove Cloth EffectsLiquid/gas/vapor treatment of propelled fabricsTextile treatment machine arrangementsElectricityEngineering

Owner:FOSHAN SON TECH PRECISION MACHINERY

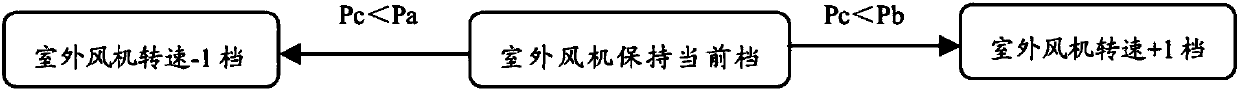

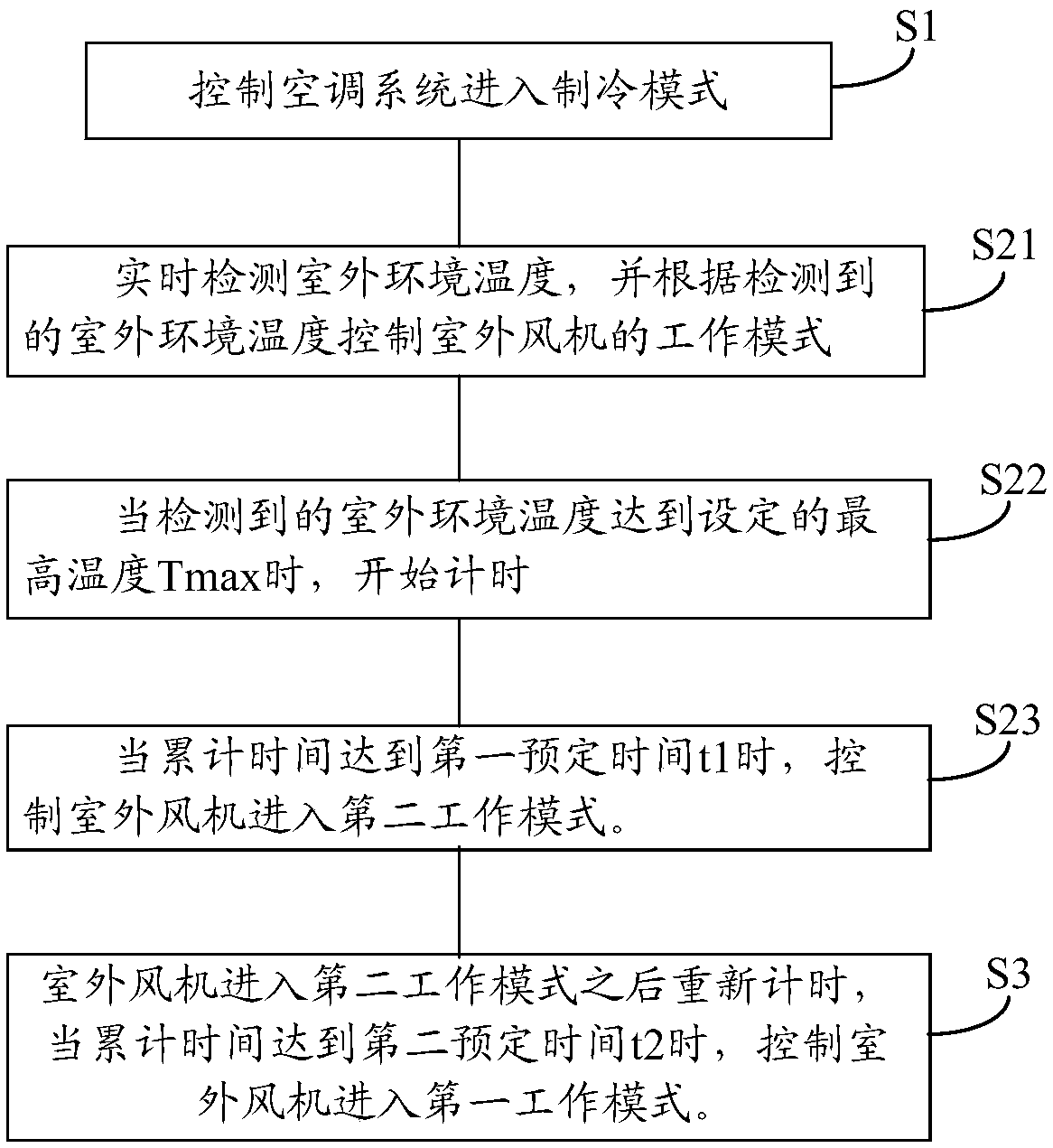

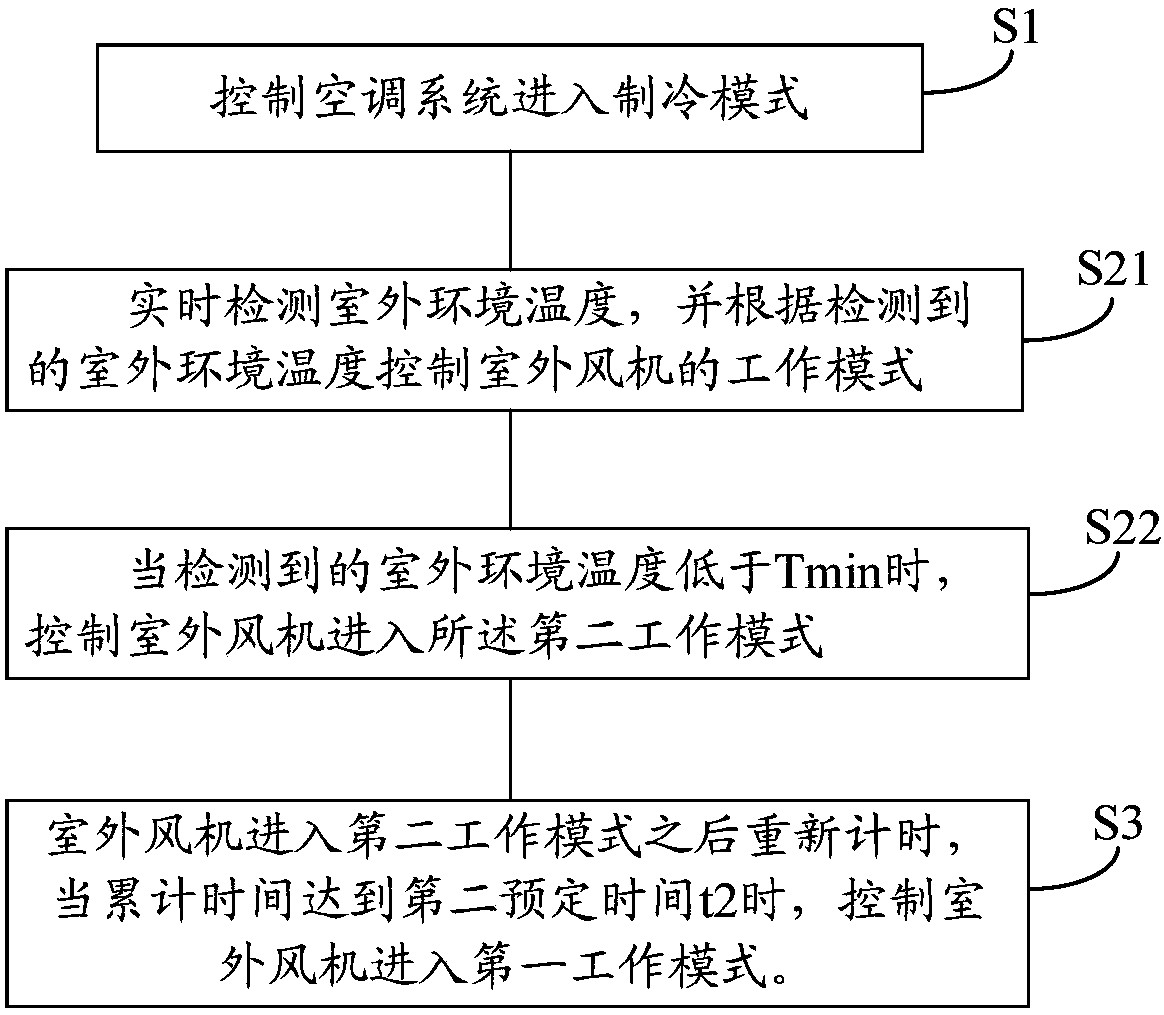

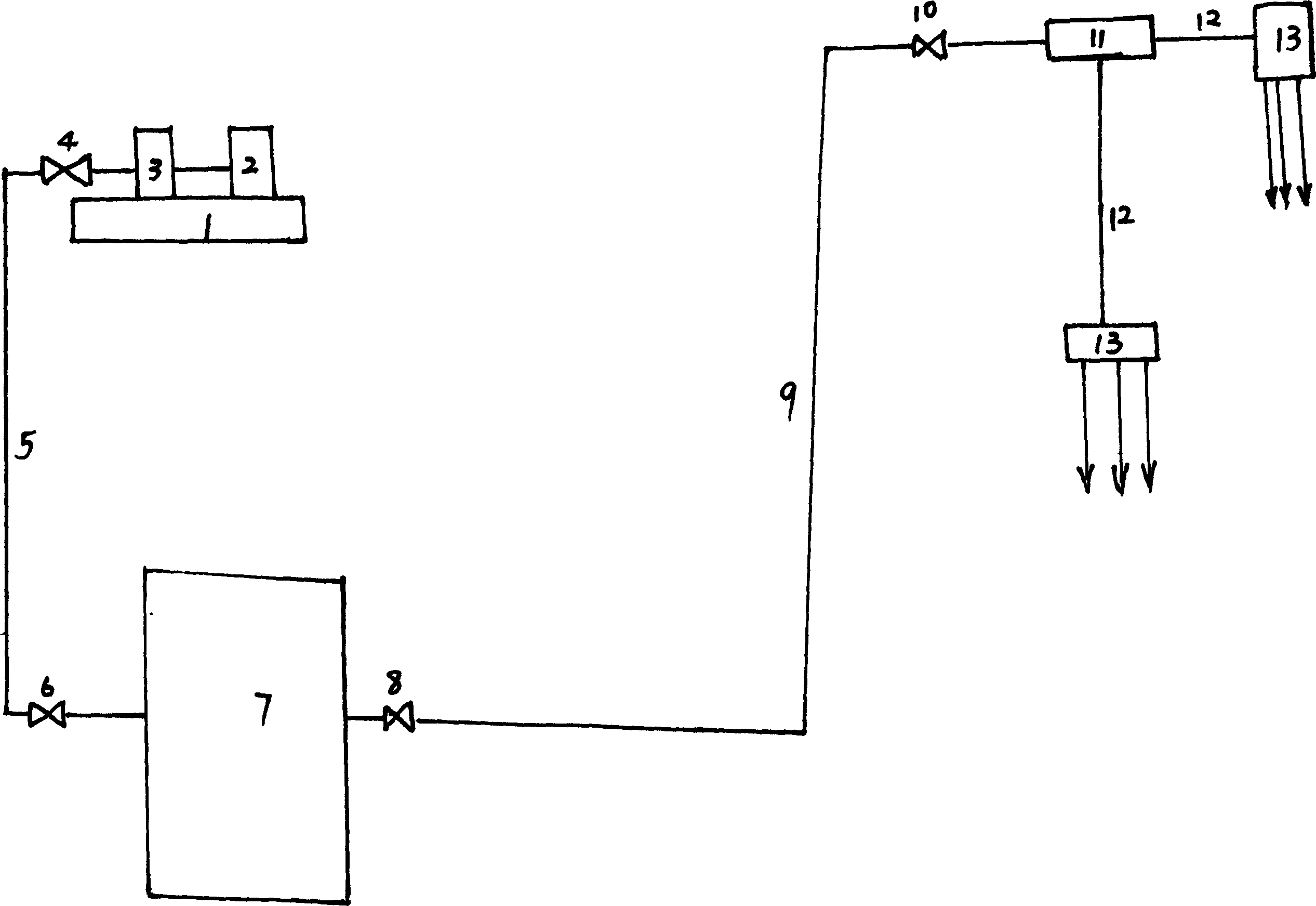

Air conditioning system and control method thereof

InactiveCN107796064AGuaranteed reliabilityGuaranteed comfortMechanical apparatusLighting and heating apparatusEngineeringHeat exchanger

The invention discloses an air conditioning system and a control method thereof. The air conditioning system comprises an air conditioning outdoor unit; the air conditioning outdoor unit comprises a compressor, an outdoor heat exchanger and an outdoor fan; the outdoor fan is at least provided with a first working mode and a second working mode; and when the outdoor fan runs in the first working mode, a wind gear is higher than that when the outdoor fan runs in the second working mode. The control method comprises the following steps that S1, the air conditioning system is controlled to enter arefrigeration mode; S2, according to the outdoor environment temperature and / or preset hours, the outdoor fan is controlled to enter the first working mode or the second working mode. According to the control method of the air conditioning system, the air conditioning system can control the outdoor fan to enter the first working mode or the second working mode according to the outdoor environmenttemperature and / or the preset hours, and when the outdoor fan runs in the second working mode, the wind gear of the outdoor fan is lowered, so that the use reliability the air conditioning system cannot be affected, and the requirement of a user on comfortableness can be met.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

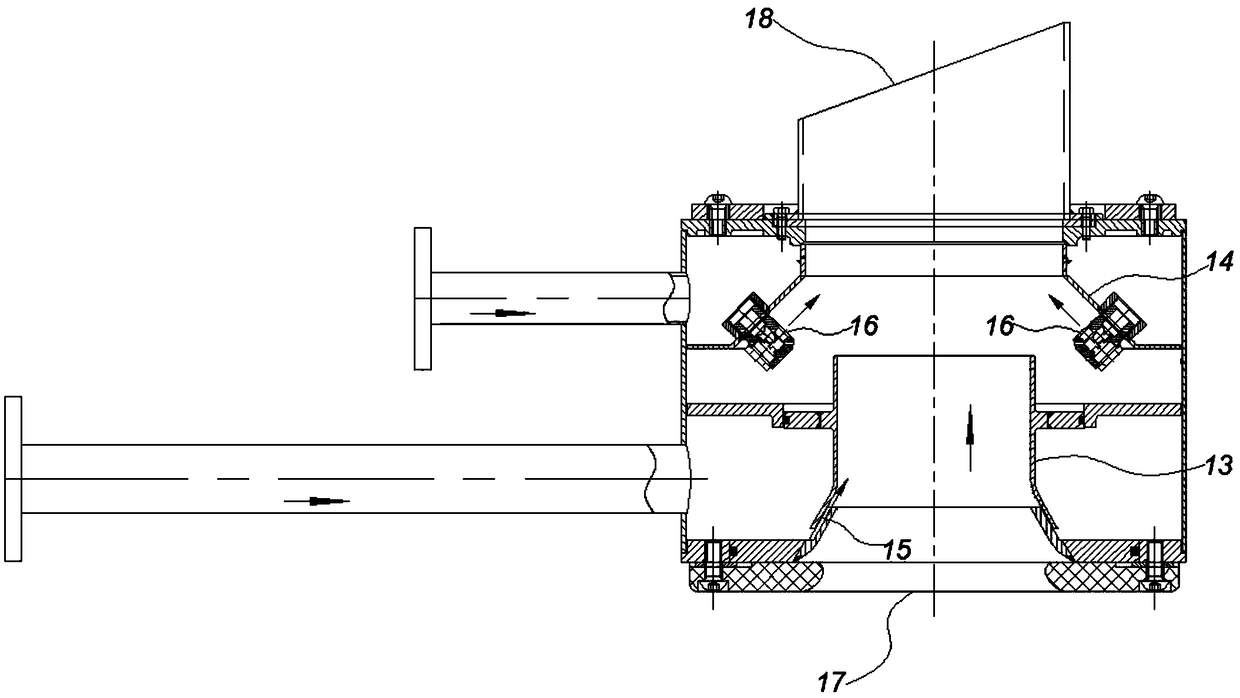

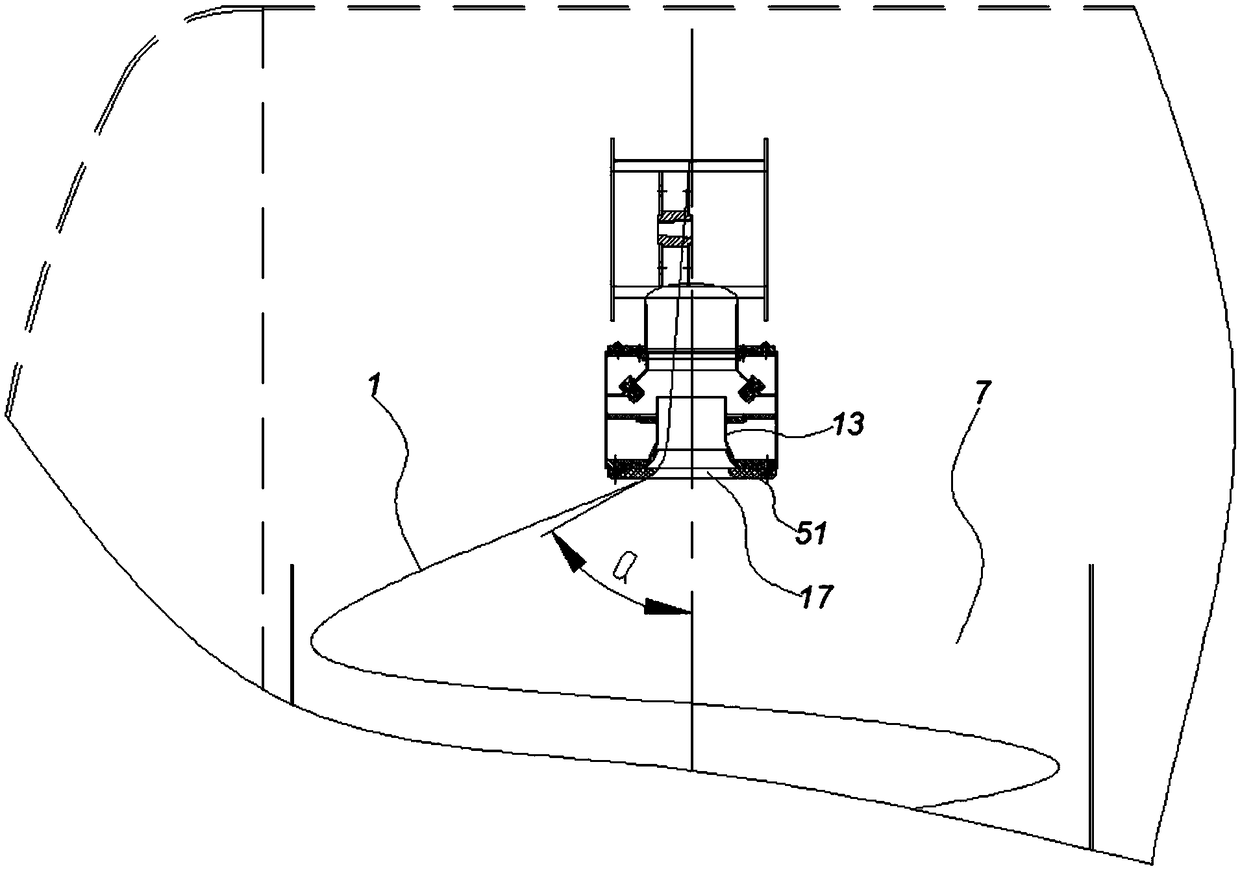

Duct system of sea wind (air) air conditioner by deep sea water cooling

InactiveCN1786597AImprove working environmentImprove the living environmentLighting and heating apparatusAir conditioning systemsOcean bottomEngineering

Owner:孙洪福

Drying device as well as fabric cloth drying machine and setting machine using same

ActiveCN101956307APlay a protective effectImprove drying efficiencyHeating/cooling textile fabricsLiquid/gas/vapor removalHigh humidityEngineering

Owner:GUANGDONG JINGYING TEXTILE GROUP

Aluminum alloy brazing sheet and aluminum alloy tube for heat exchanger

InactiveCN101155937AImprove fatigue lifeExtend your lifeStationary conduit assembliesWelding/cutting media/materialsX-rayUltimate tensile strength

Owner:KOBE STEEL LTD

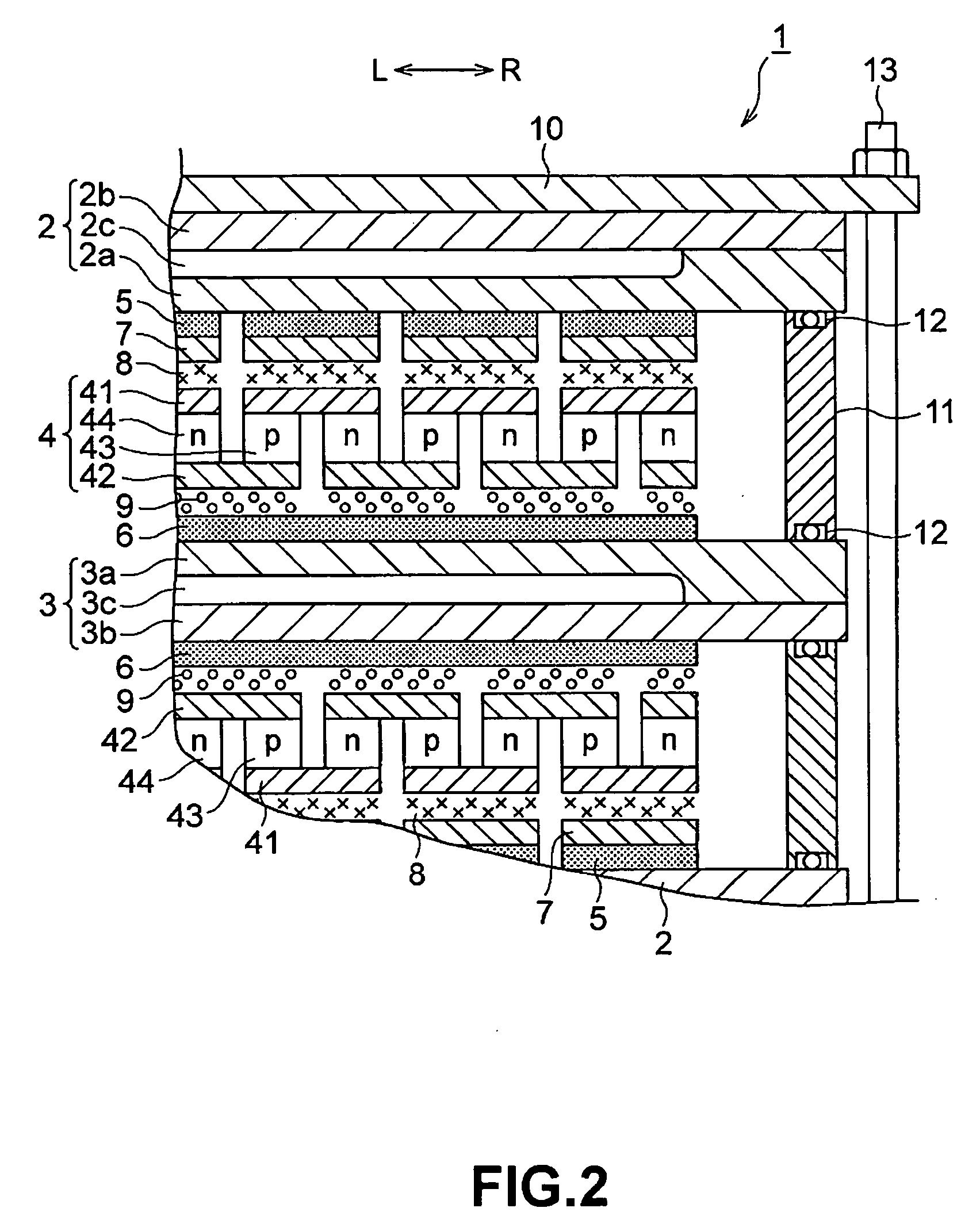

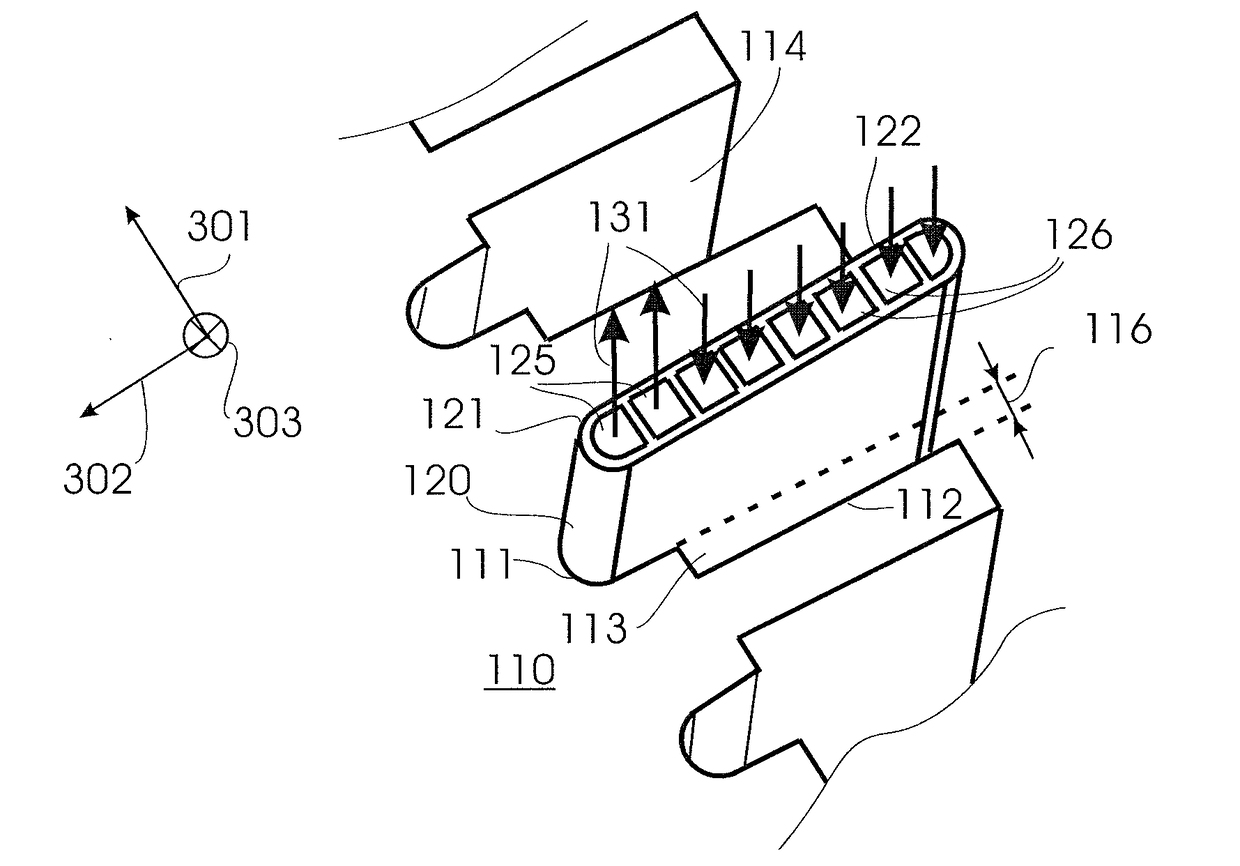

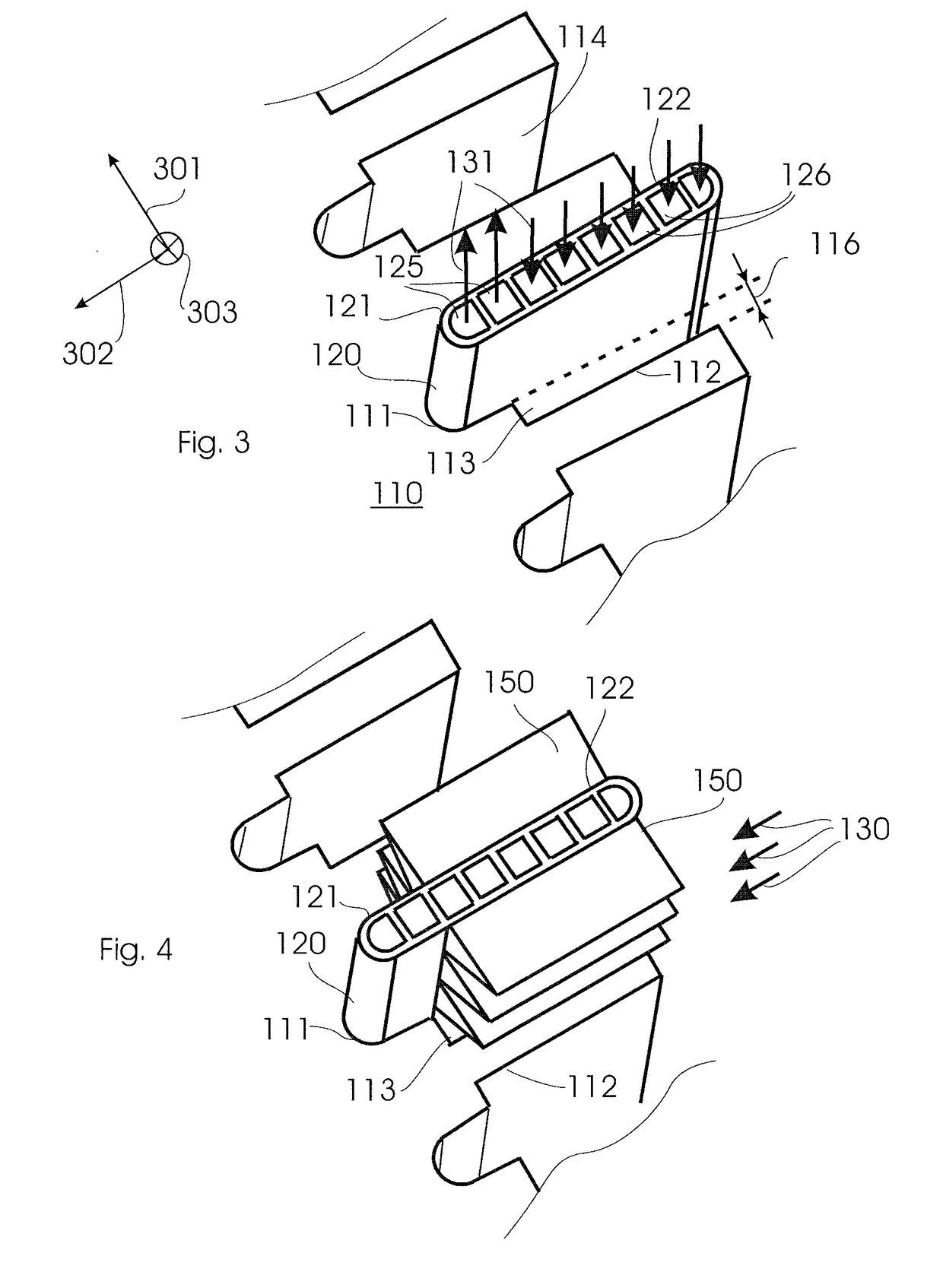

Heat exchanger for power-electronic components

ActiveUS20170202108A1Improve cooling effectReduce filter sizeThermal insulationIndirect heat exchangersEngineeringElectronic component

Owner:ABB (SCHWEIZ) AG

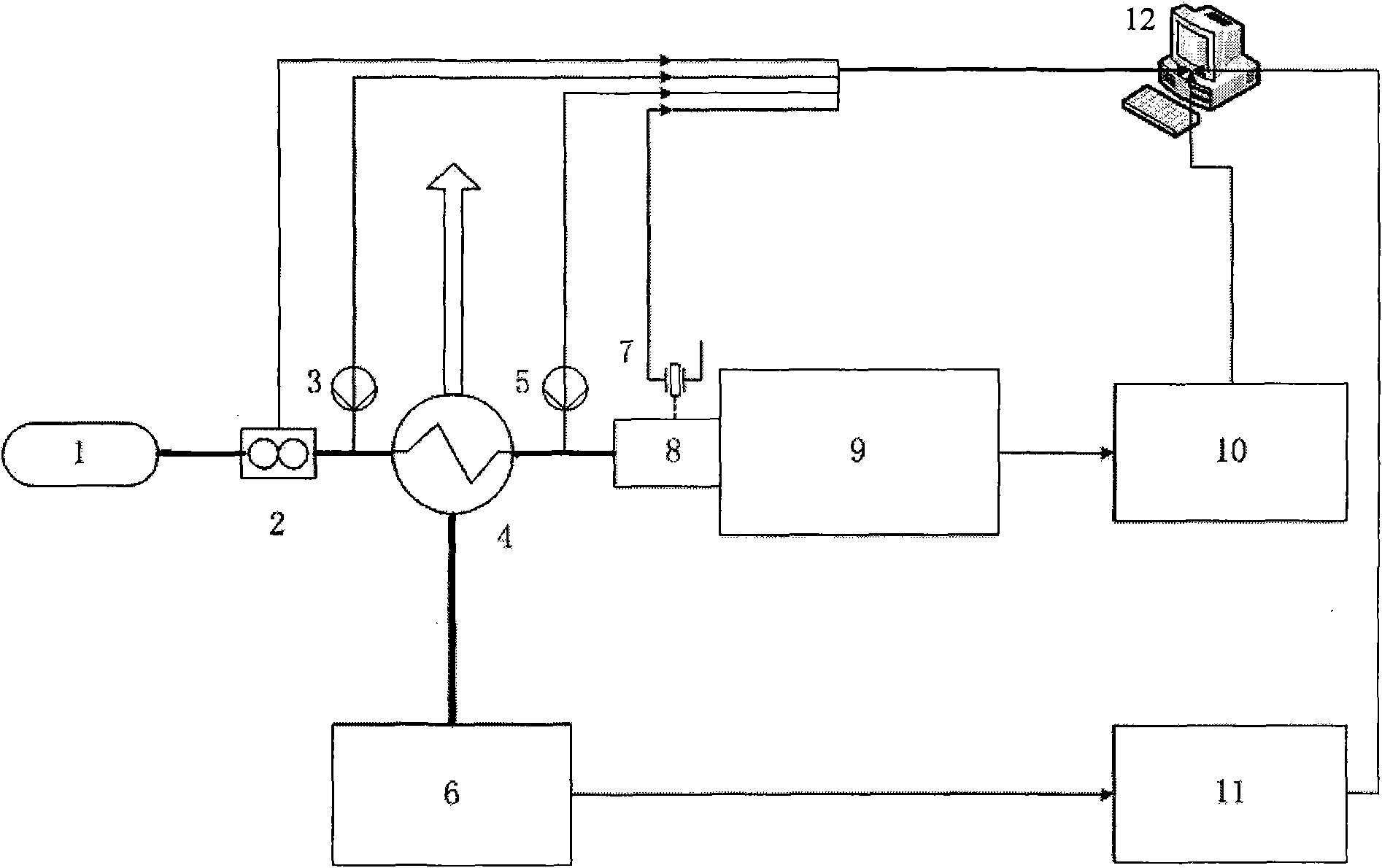

Air-fuel mixed power test system

InactiveCN101551298AReliable Experimental ParametersEngine testingPilot systemAtmospheric air

Owner:ZHEJIANG UNIV

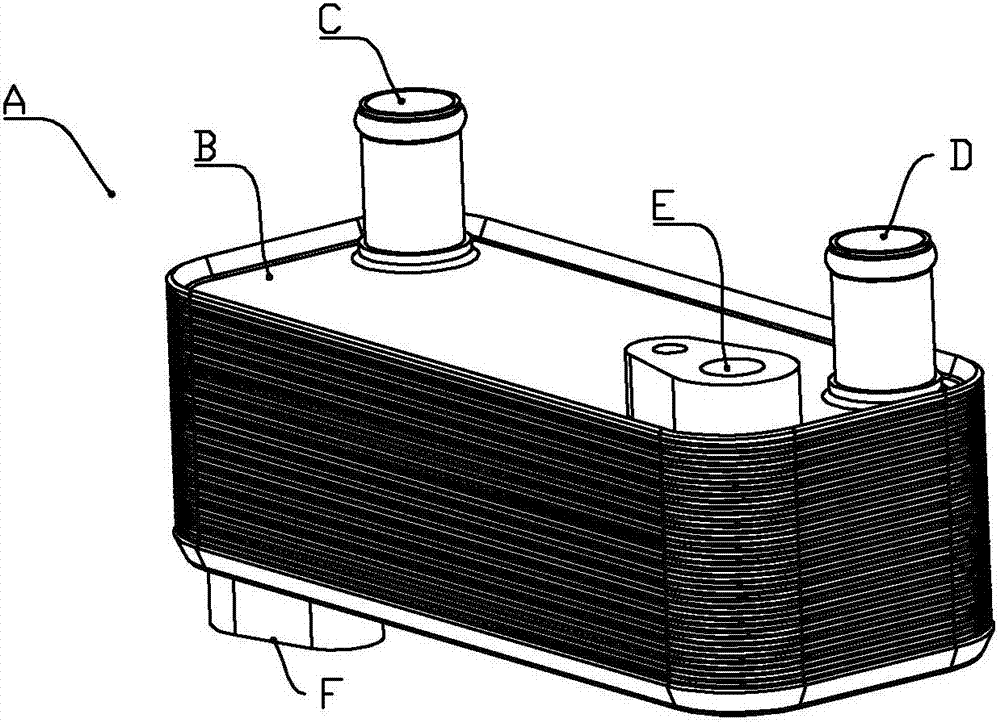

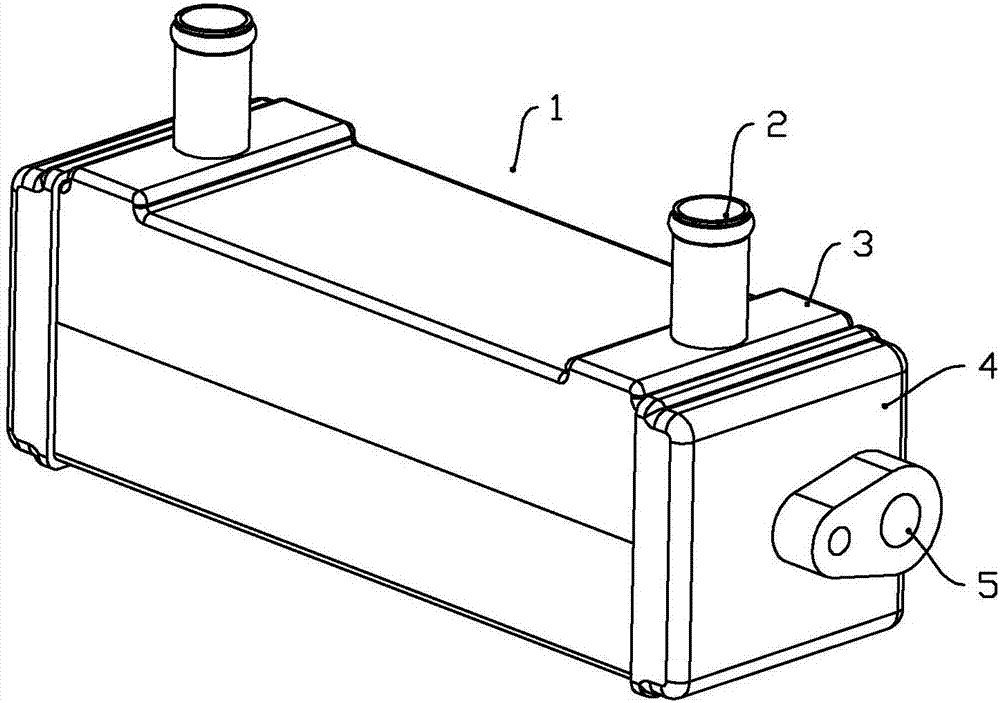

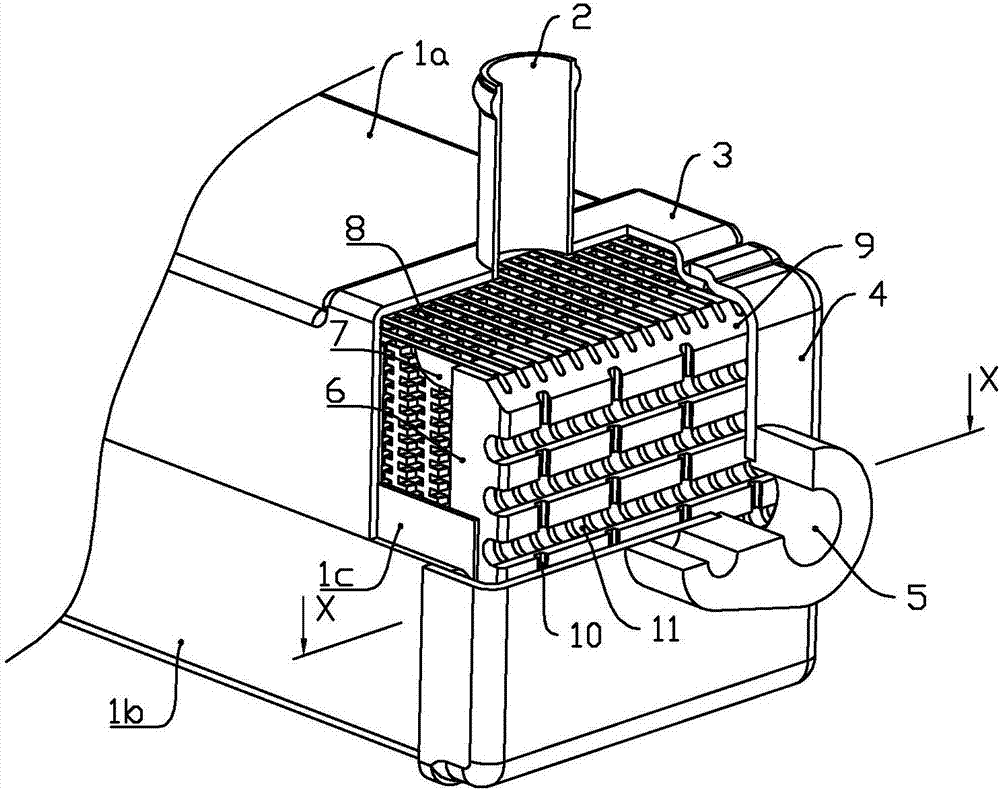

Liquid cold and hot exchanger for air-conditioning device

Owner:ZHEJIANG YINLUN MACHINERY

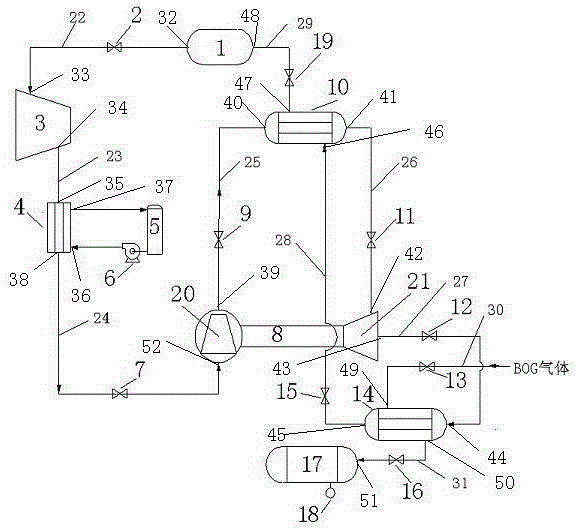

Efficient and energy-saving BOG (boil-off gas) recycling device

Owner:JIANGSU AEROSPACE HEWLETT ENVIRONMENTAL PROTECTION TECH

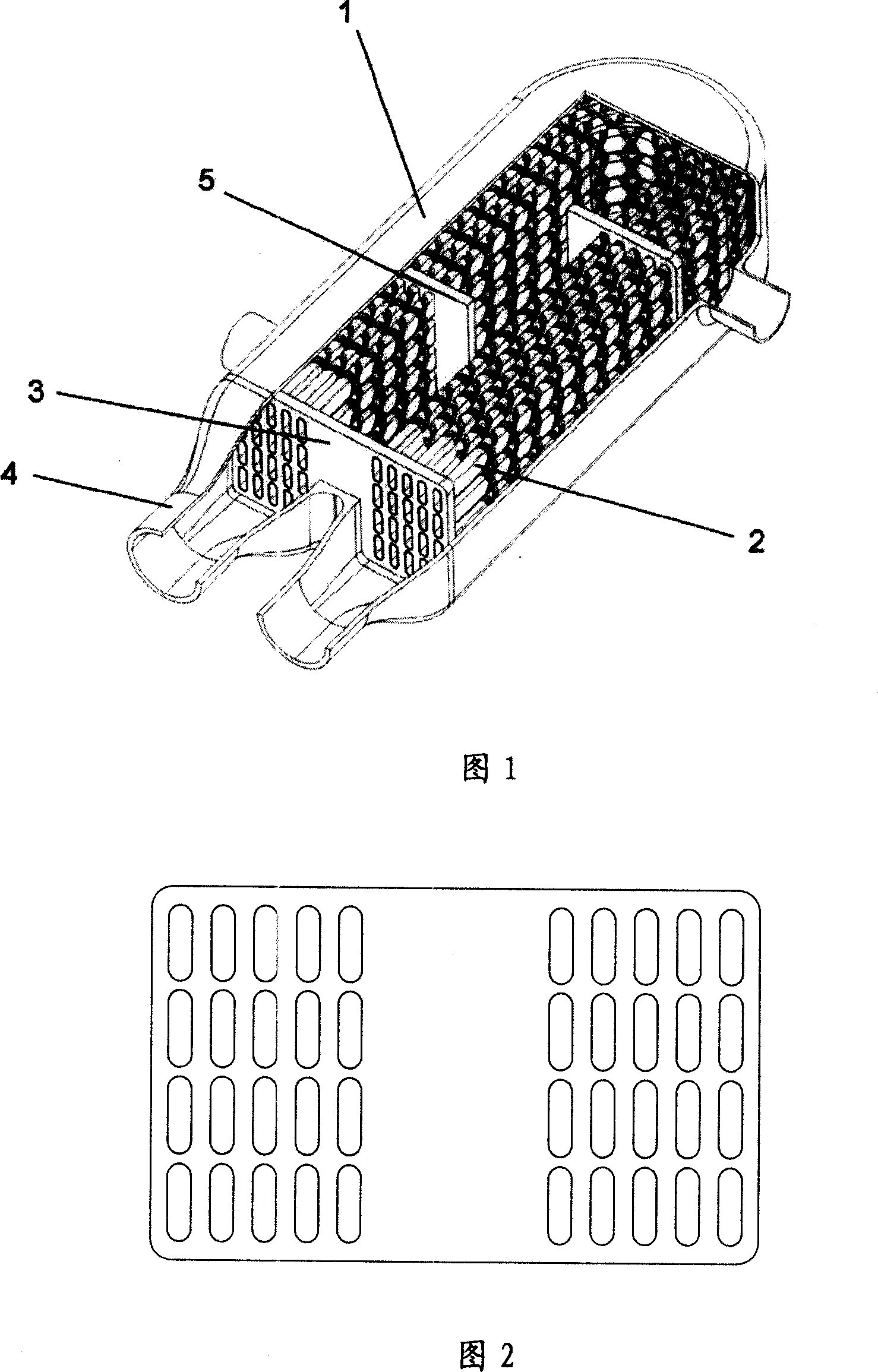

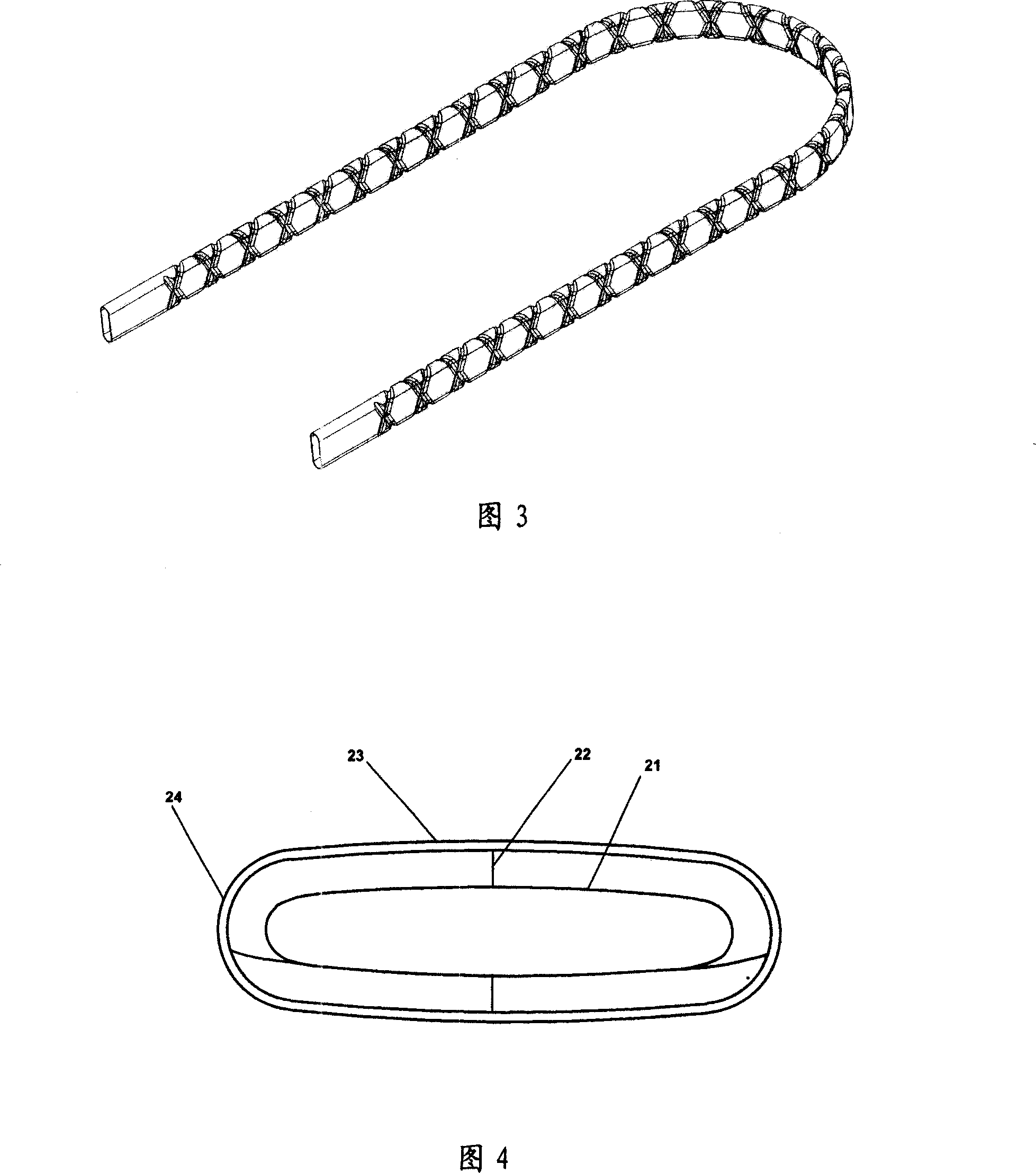

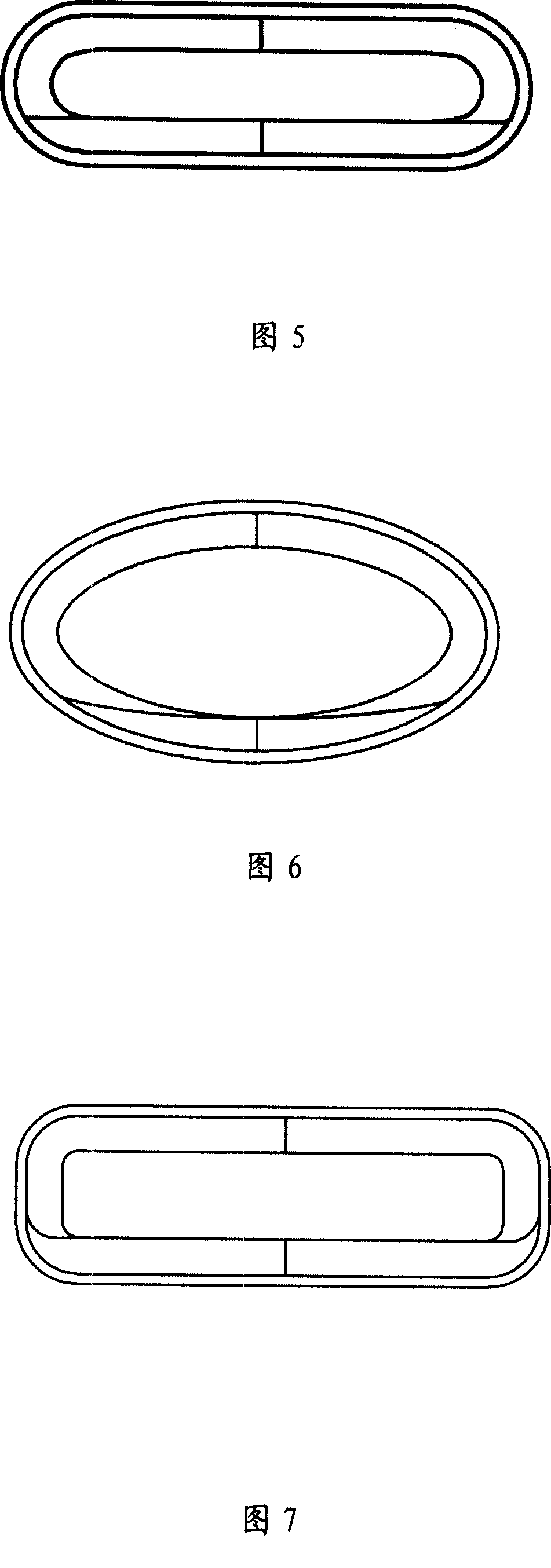

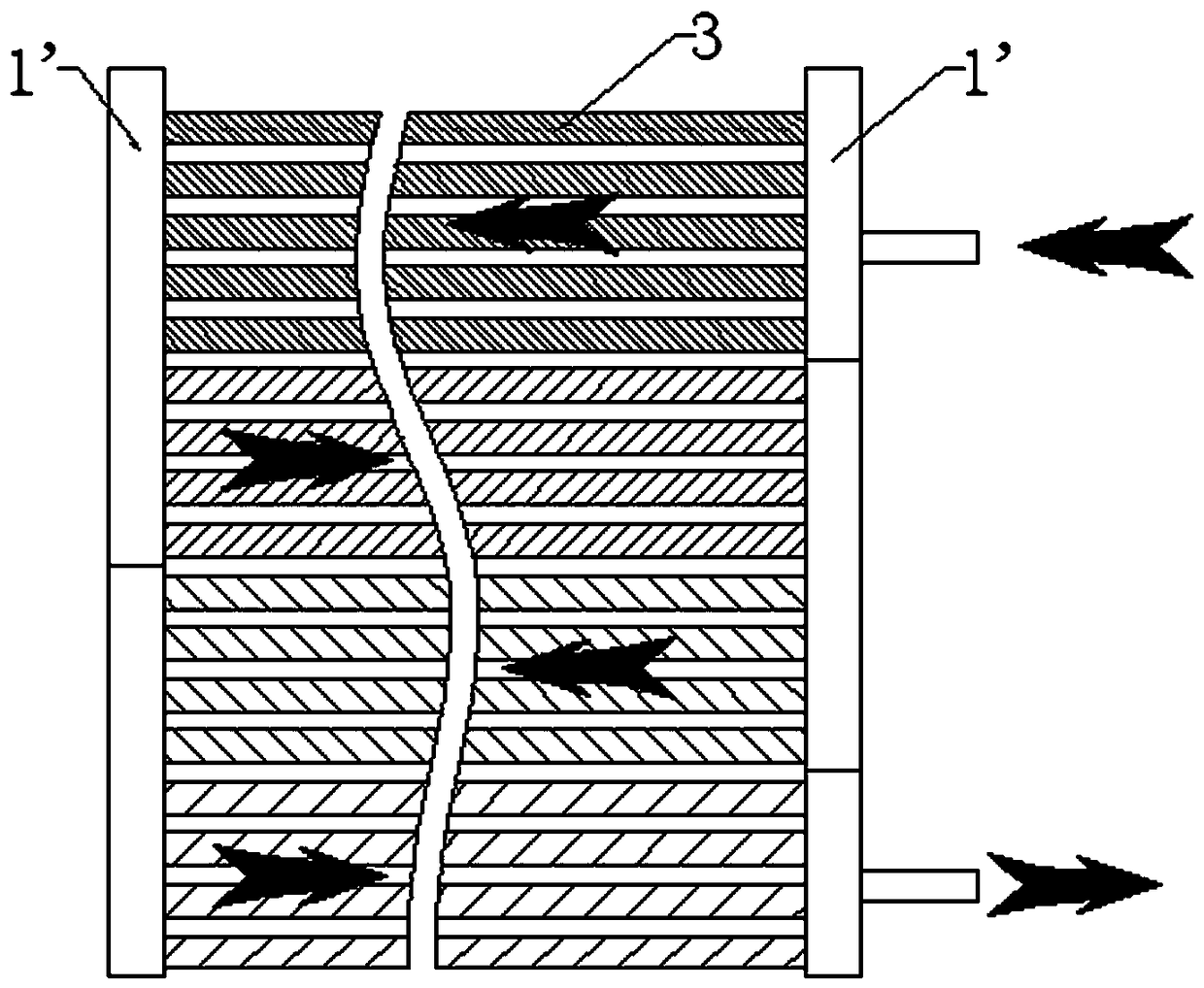

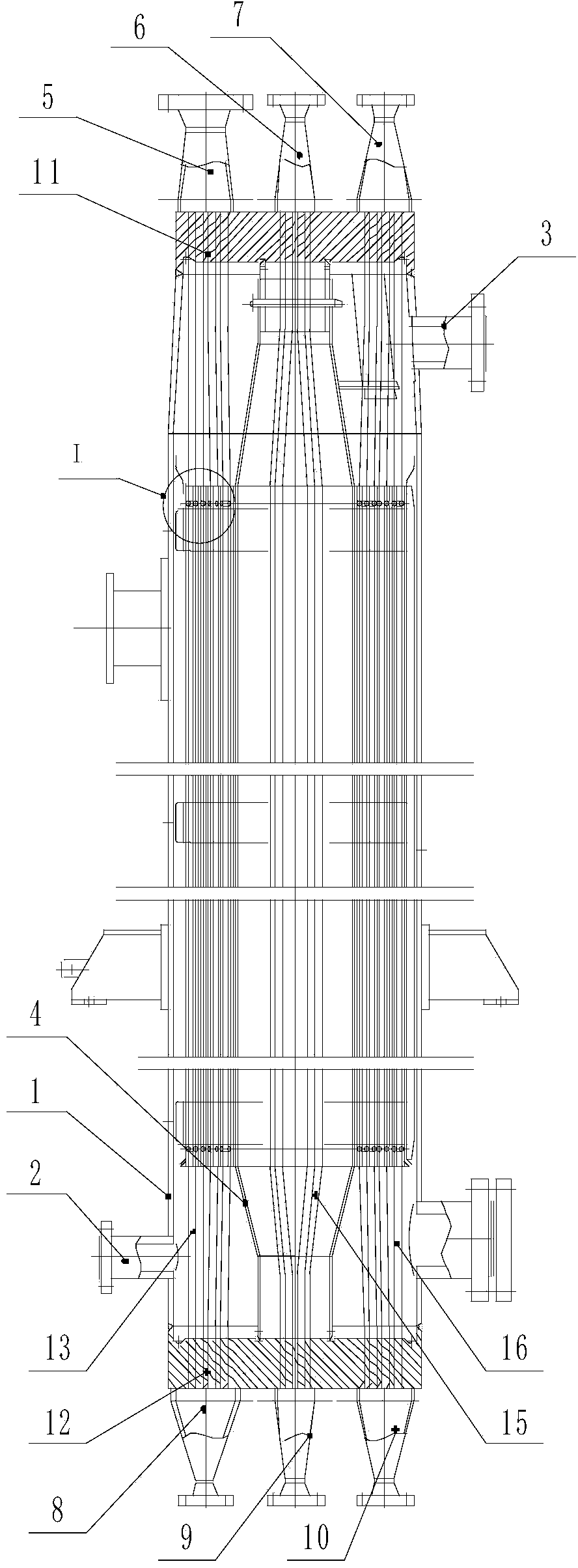

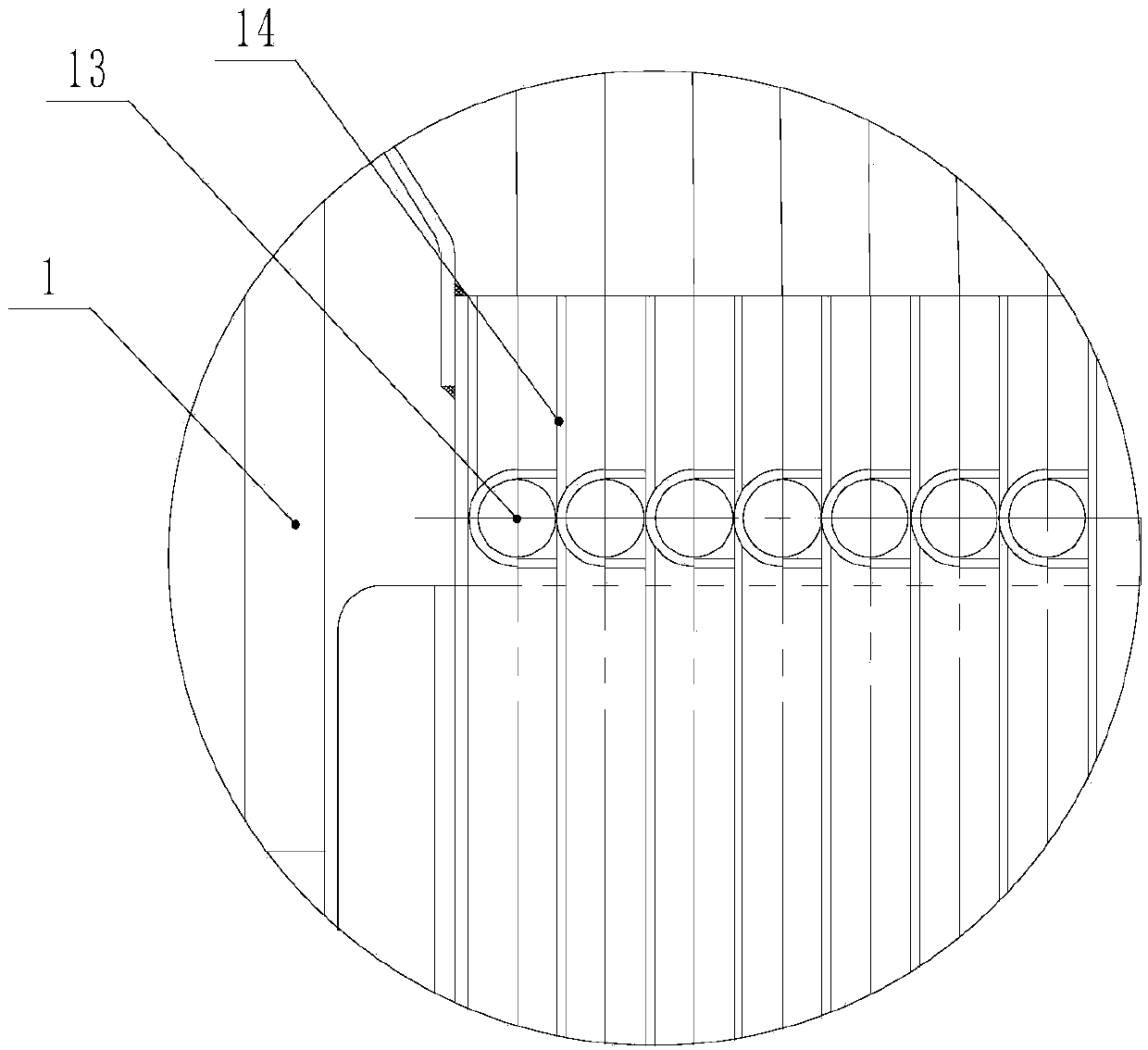

Shell-and-tube type heat exchanger employing crossed spiral tube

ActiveCN101101186ACompact layoutRapid coolingStationary conduit assembliesTubular elementsSiphonEngineering

Owner:BEIJING U BRIDGE CHAOYANG +1

Water heater water tank and air energy water heater

PendingCN108548326AImprove heat transfer efficiencyImprove heat transfer effectFluid heatersEngineeringWater heater

Owner:GREE ELECTRIC APPLIANCES INC

Heat exchanger for polypropylene chemical process

InactiveCN104215098AMeet the requirements of chemical technologyImprove heat transfer efficiencyChemical industryStationary tubular conduit assembliesPolymer scienceEngineering

Owner:张家港市华菱化工机械有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap