Drying device as well as fabric cloth drying machine and setting machine using same

A drying device and heating device technology, applied in textiles and papermaking, fabric surface trimming, heating/cooling fabrics, etc., can solve the problems of fabric strength decline, uneven drying, unqualified quality, etc., to improve drying efficiency, drying Good, even drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

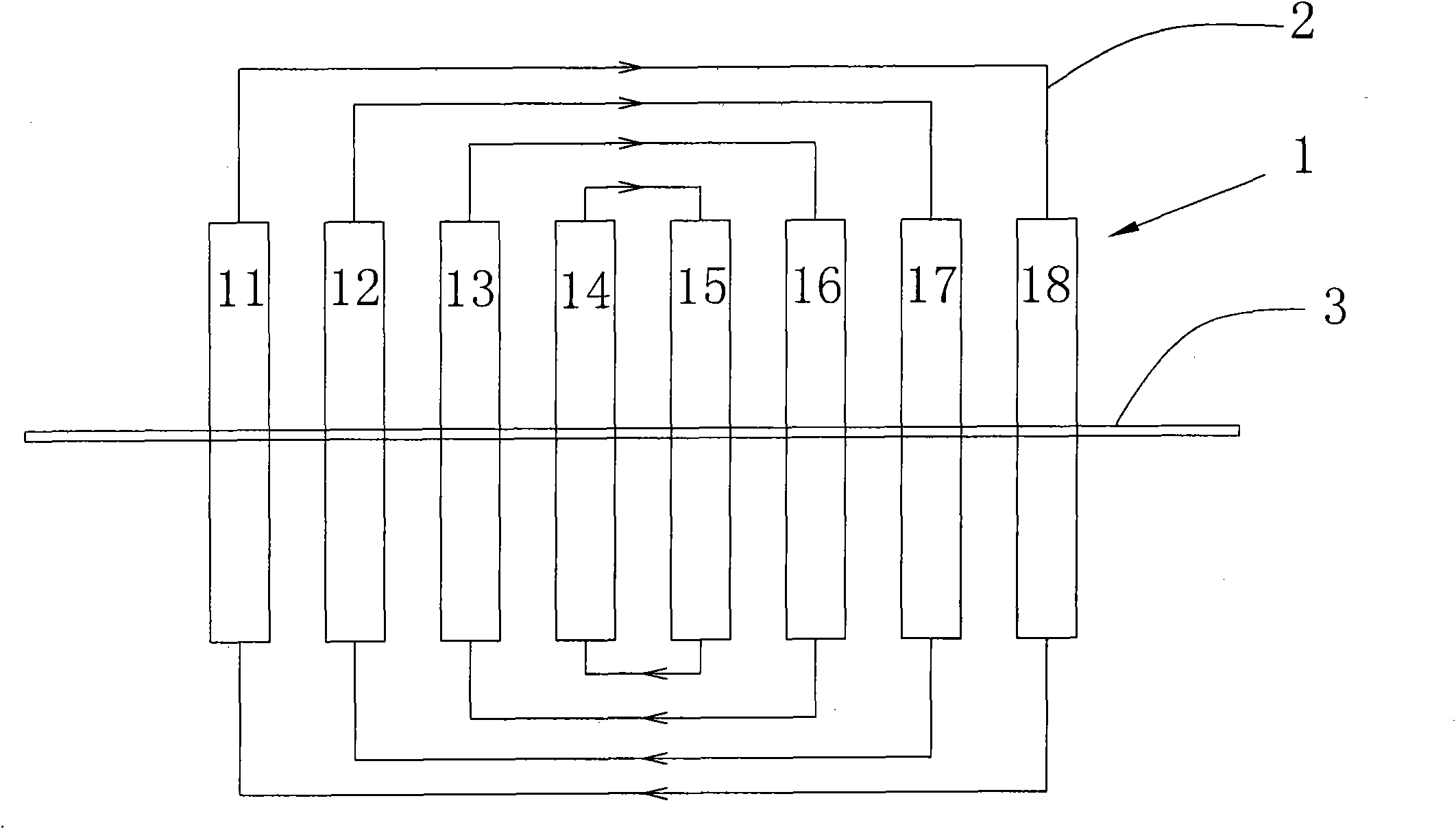

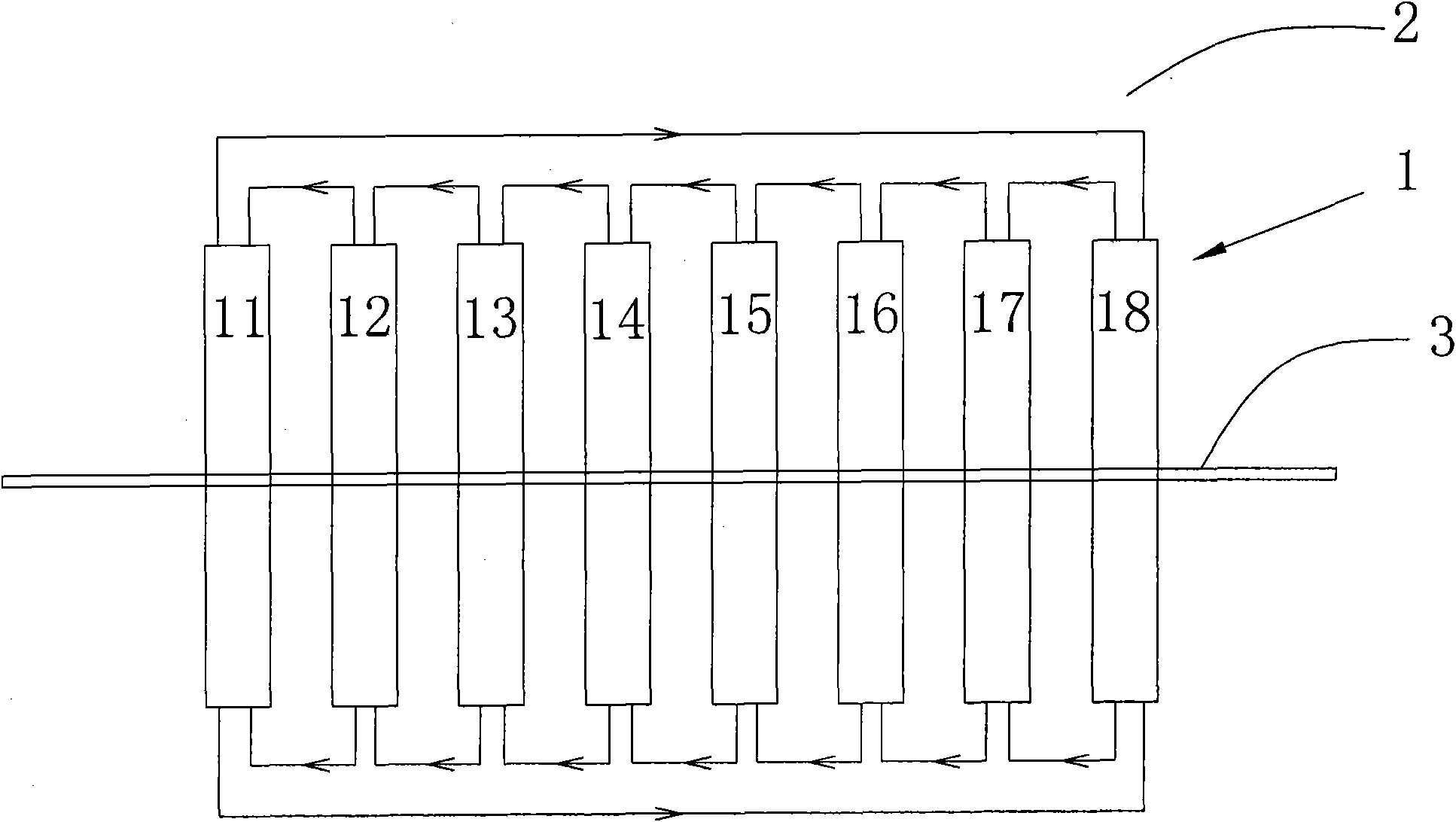

[0014] The present invention will be further elaborated below in conjunction with accompanying drawing, wherein, the direction of the present invention is with figure 2 As a standard, the arrow indicates the flow direction of the air between the ovens.

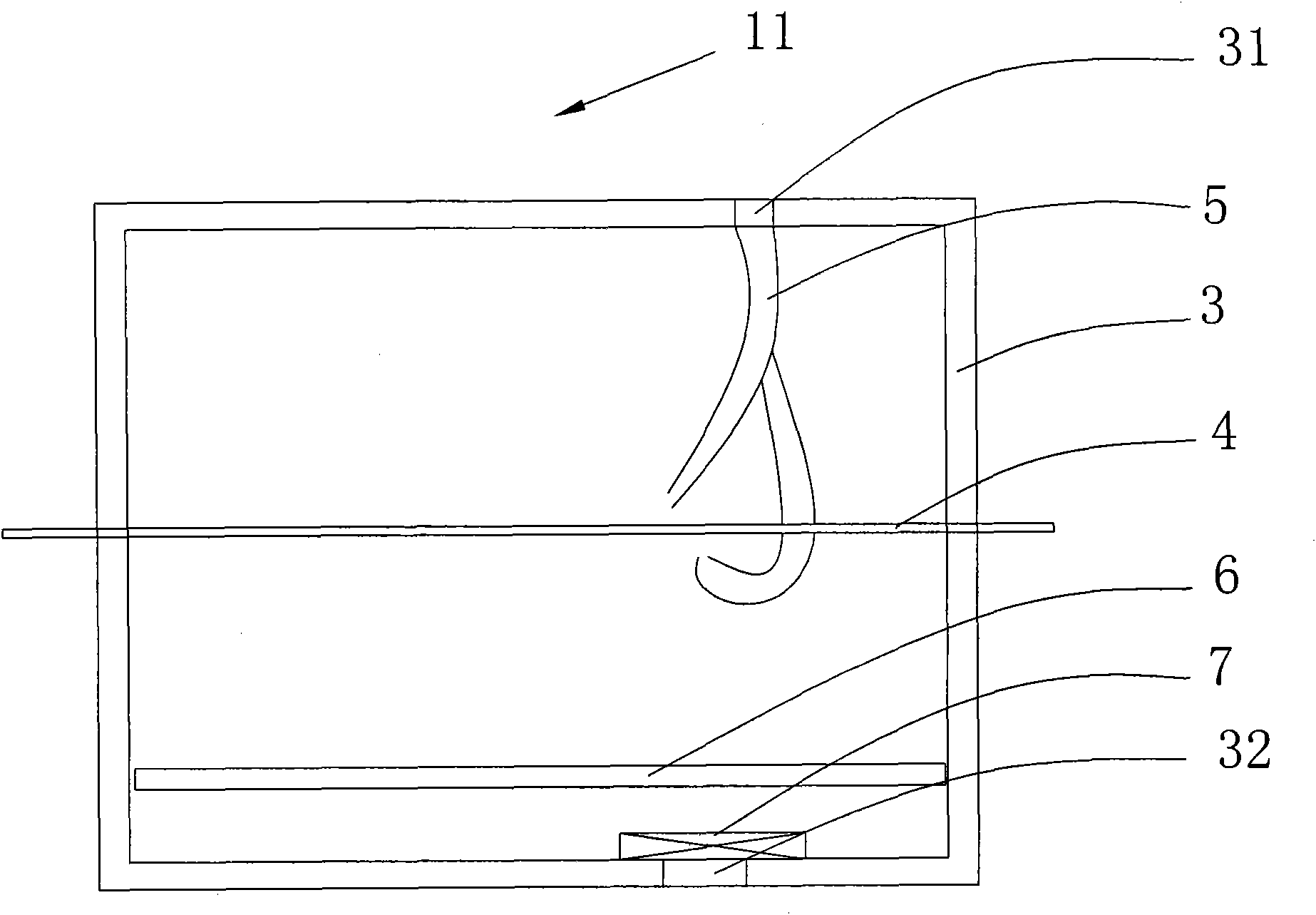

[0015] Such as figure 1 and figure 2 As shown, the drying device of the present invention includes several ovens 1, and what the general industrial cloth drying machine and the setting machine adopts are all eight ovens (11~18). Of course, the specific quantity can be adjusted according to the needs of actual production. Each oven 1 is equipped with a heating device 3 , the top of the oven 1 is provided with an air inlet 31 , and the bottom of the oven 1 is provided with an air outlet 32 , and a heat circulation channel is formed between any one oven or multiple ovens. That is, one oven can form an independent heat circulation passage, and two, three or more ovens can form an independent heat circulation passage. The optima

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap