Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Improve drying efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrasonic washing machine

ActiveCN109877103AEasy maintenanceImprove drying efficiencyCleaning using liquidsCleaning using toolsDrying timeEngineering

Owner:玉环震浪超声股份有限公司

Underwear drying method and washing and drying integrated equipment

ActiveCN113584800AImprove drying efficiencyPrevent over-dry deformationControl devices for washing apparatusLaundry driersIndustrial engineeringMechanical engineering

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

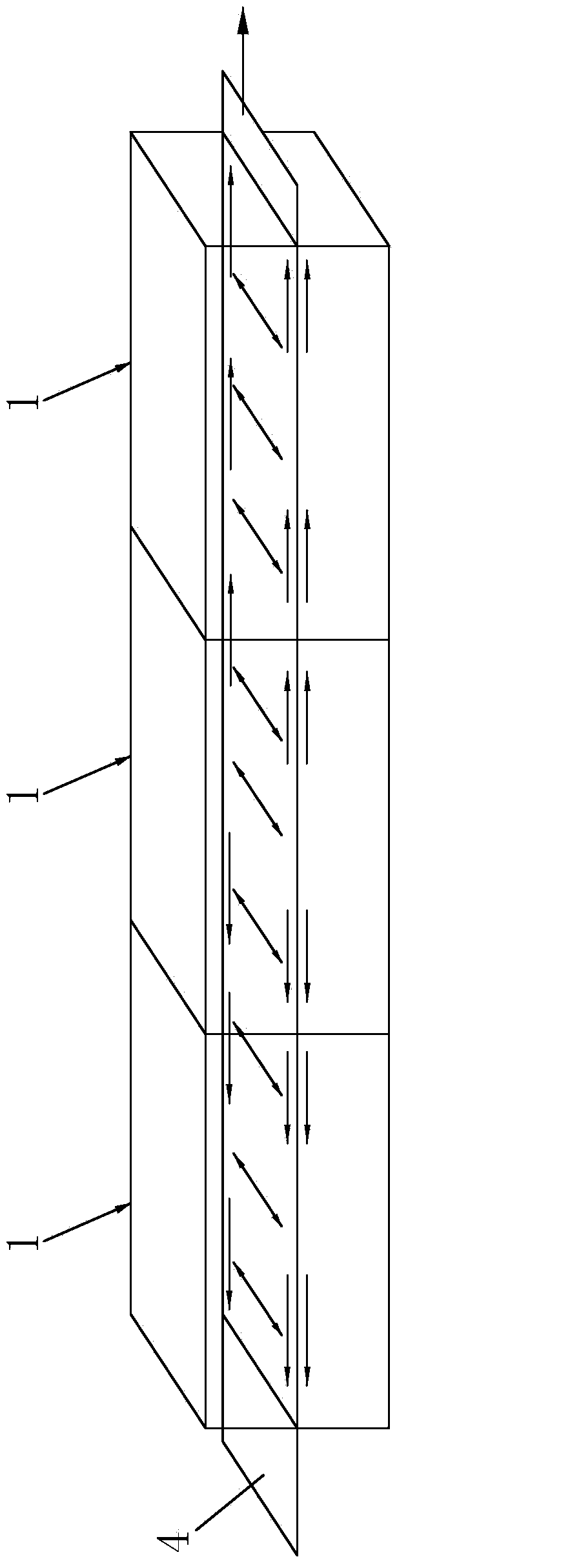

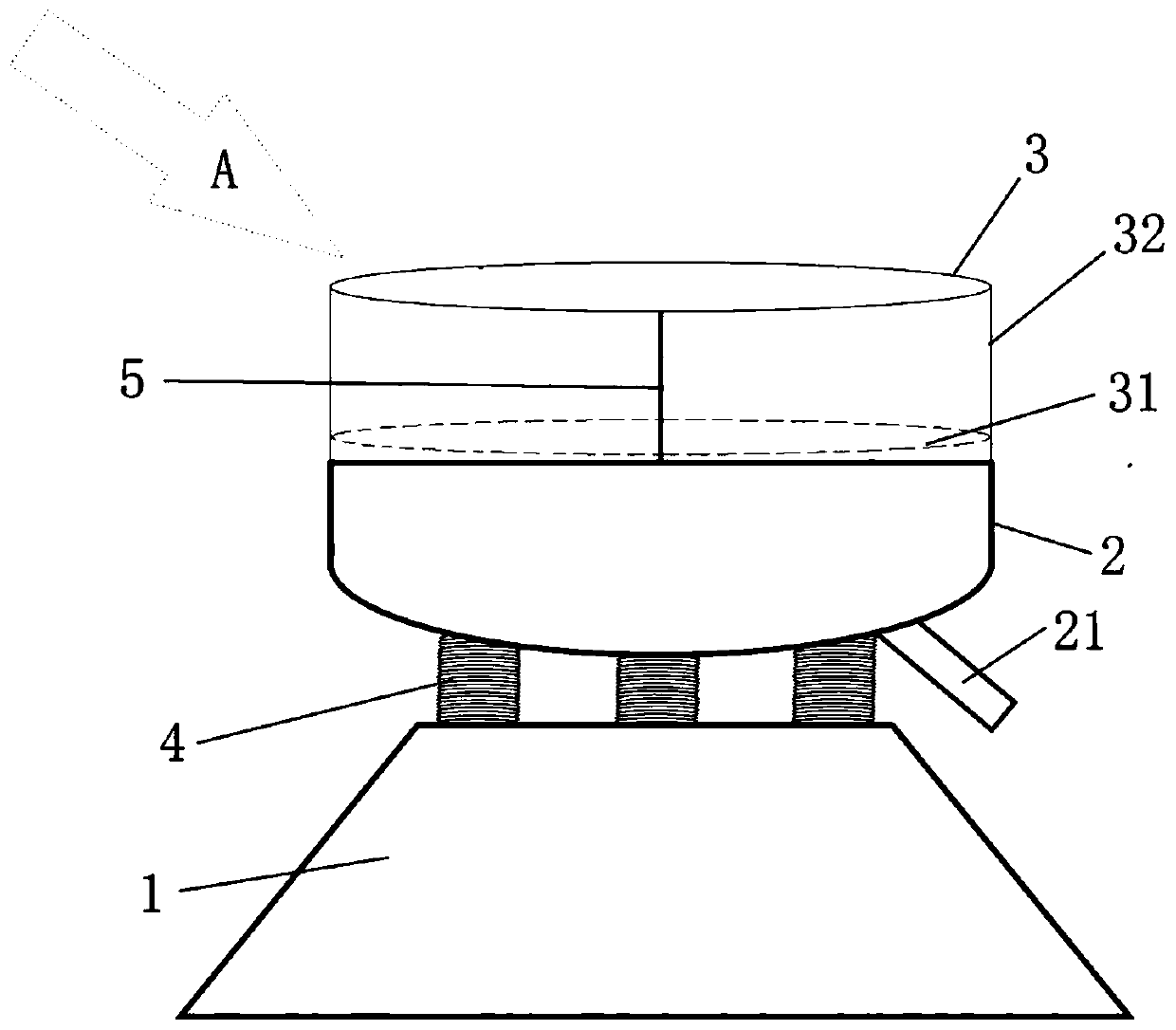

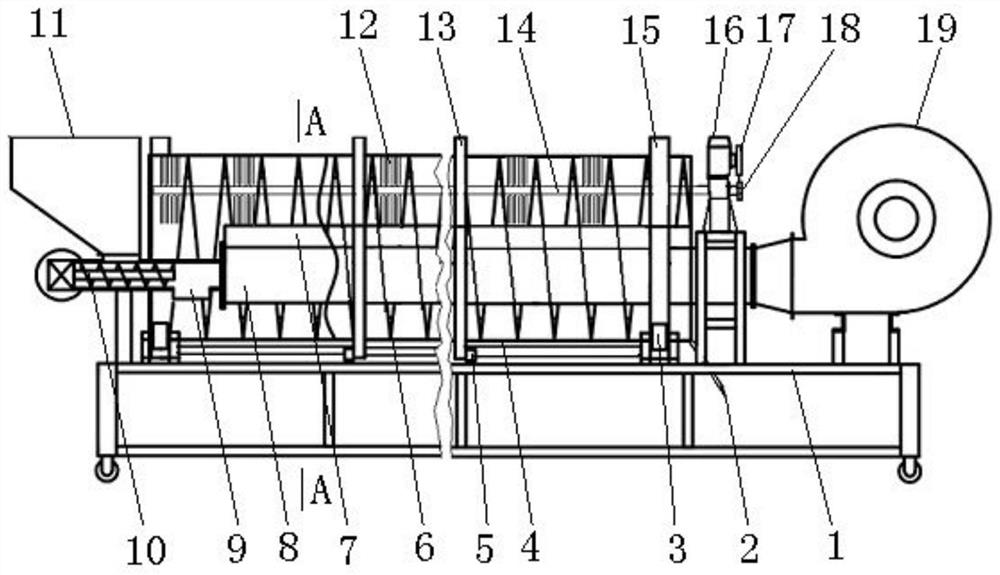

Screw walking type soft capsule drying device

ActiveCN105276959AReasonable structureLiquidityDrying solid materialsHeating arrangementEngineeringMotor drive

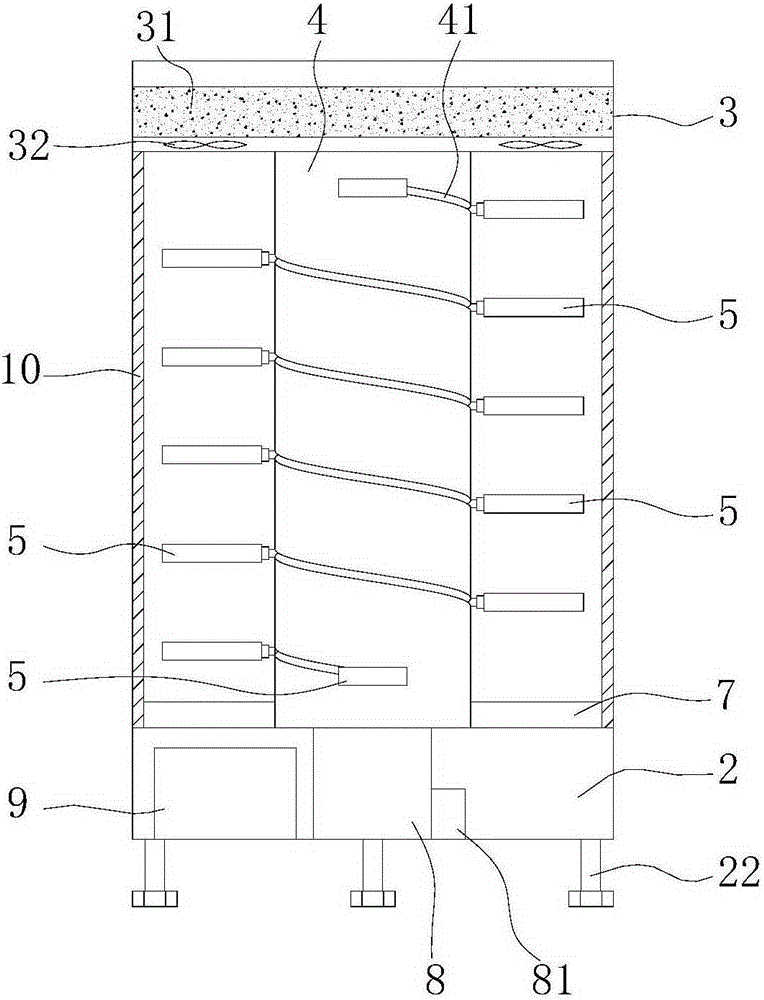

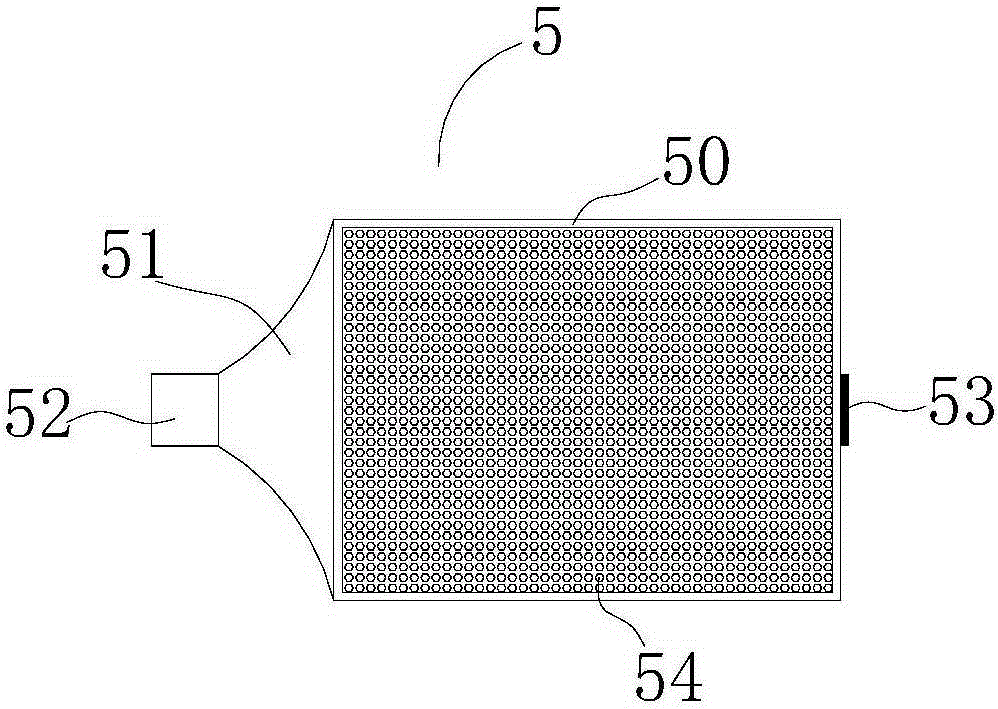

The invention discloses a screw walking type soft capsule drying device which comprises a drying room, a base, a dehumidifying device, a hollow cylindrical frame, trays, a screw conveying device, a heating device, a motor and a control device. The lower portion of the drying room is installed on the base. The base is internally provided with the motor, a motor driving device and the control device. The dehumidifying device is installed on the upper portion of the drying room. The hollow cylindrical frame is installed in the drying room. Screw channels are formed in the hollow cylindrical frame, and the screw conveying device is installed in the hollow cylindrical frame. The screw conveying device is connected with the motor and is provided with a plurality of conveying connecting blocks. The conveying connecting blocks are connected with the trays and walk along the screw channels. The screw walking type soft capsule drying device is reasonable in structure, the phenomenon that drying of a soft capsule is not uniform is improved, fluidity in the drying process is high, the phenomenon that external force is adopted, and consequently the soft capsule deforms is avoided, and the drying efficiency and the drying quality of the capsule are greatly improved.

Owner:浙江绿健胶囊有限公司

Organic fertilizer production drying equipment

PendingCN113267012AImprove drying efficiencyDrying chambers/containersDrying gas arrangementsAgricultural engineeringAir blower

Owner:李积恒

Drying method in marine shipborne processing of aquatic products

InactiveCN111486691AGood colorImprove drying efficiencyDrying chambers/containersDrying gas arrangementsAquatic productEnvironmental engineering

Owner:玉环市东海鱼仓现代渔业有限公司

Anti-corrosion spraying equipment for metal surface

PendingCN113198665AImprove drying efficiencyImprove processing and production progressCoatingsPretreated surfacesAnti-corrosionEngineering

Owner:程鹏

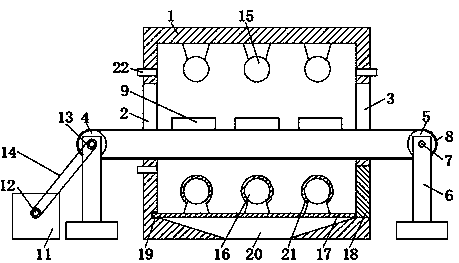

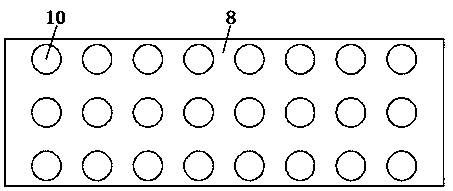

Textile drying box

InactiveCN108826912AImprove drying efficiencyEvenly heatedDrying solid materials without heatDrying gas arrangementsEngineeringSliding contact

The invention discloses a textile drying box, comprising a box body, wherein a plurality of exhaust holes are formed in the top of the box body, a multi-layer drying frame and a heating main pipe forproviding heat for the drying frame are arranged in the axial direction of the box body, and the multi-layer drying frame is driven by a rotating shaft to rotate; the drying rack comprises supportingnets fixedly sleeving the rotating shaft, the edges of the supporting nets are in sliding contact with the inner wall of the box body, a plurality of agitating blocks are arranged on each supporting net in a sliding contact manner, the agitating blocks are arranged in a ring shape around the rotating shaft, one ends of the agitating blocks are fixedly connected with the inner wall of the box body,and the same sides of the agitating blocks are smooth arc surfaces. Compared with the prior art, the supporting nets are driven by the rotating shaft to rotate, and the supporting nets and the agitating blocks cooperate with each other, so that the textile fabric is continuously rolled and agitated in the drying process, and the fabric on the supporting nets is heated uniformly, thereby improvingthe drying efficiency of the textile fabric.

Owner:HUBEI FUXING TEXTILE CO LTD

Drying device for food processing

InactiveCN111879073AHigh speedFully heatedDrying gas arrangementsDrying solid materialsElectric machineProcess engineering

The invention discloses a drying device for food processing, relates to the technical field of food processing, and mainly aims to solve the problem that existing raw materials are easy to accumulate.The drying device comprises a box body and a drying unit, a plurality of electric heating elements are installed on the two side walls of the box body, the drying unit comprises a dispersing assemblyused for dispersing materials and an air spraying assembly used for spraying hot air for drying, and the dispersing assembly comprises a supporting net, a first motor, a disc and a driving rod; the air spraying assembly comprises an air heater, a hollow rotating shaft, a driving mechanism used for driving the hollow rotating shaft to rotate, a hard air pipe, a sliding sleeve and a sliding block,the dispersing assembly is mounted, the supporting net is rapidly pulled outwards through the rapid return characteristic, raw materials on the supporting net are made to fly off upwards at a high speed and are fully and evenly heated, and the drying efficiency is improved; and the air spraying assembly is arranged, upward cyclone is formed, the drying effect is good, the air spraying angle is continuously changed, the drying range is enlarged, and the efficiency is improved.

Owner:马迎锋

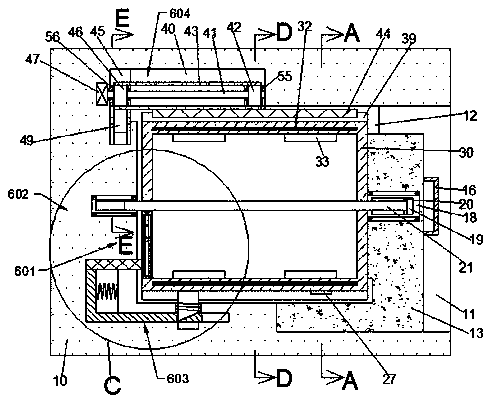

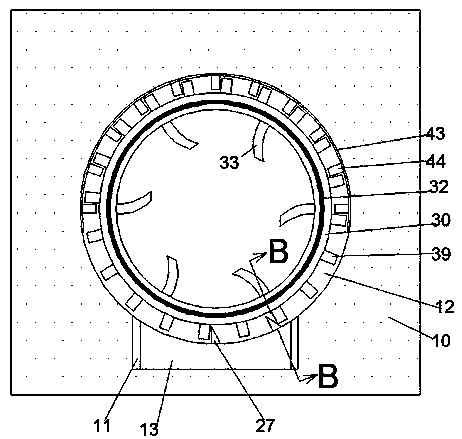

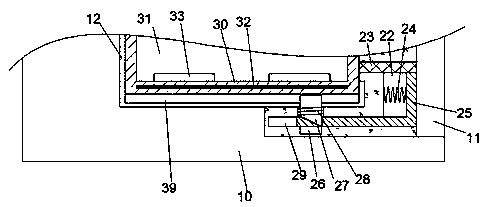

Drying oven for lithium battery coating machine and drying oven air current control method

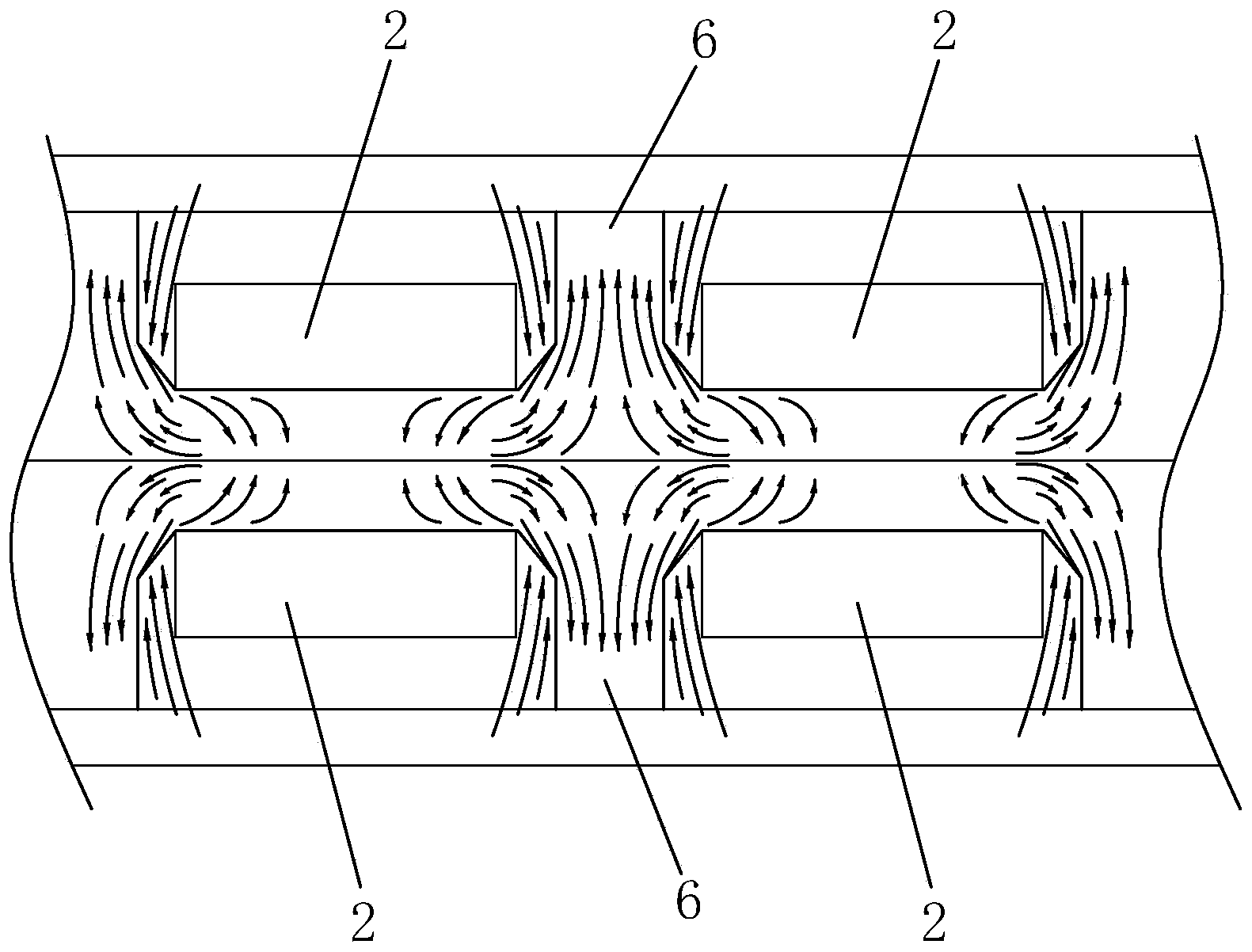

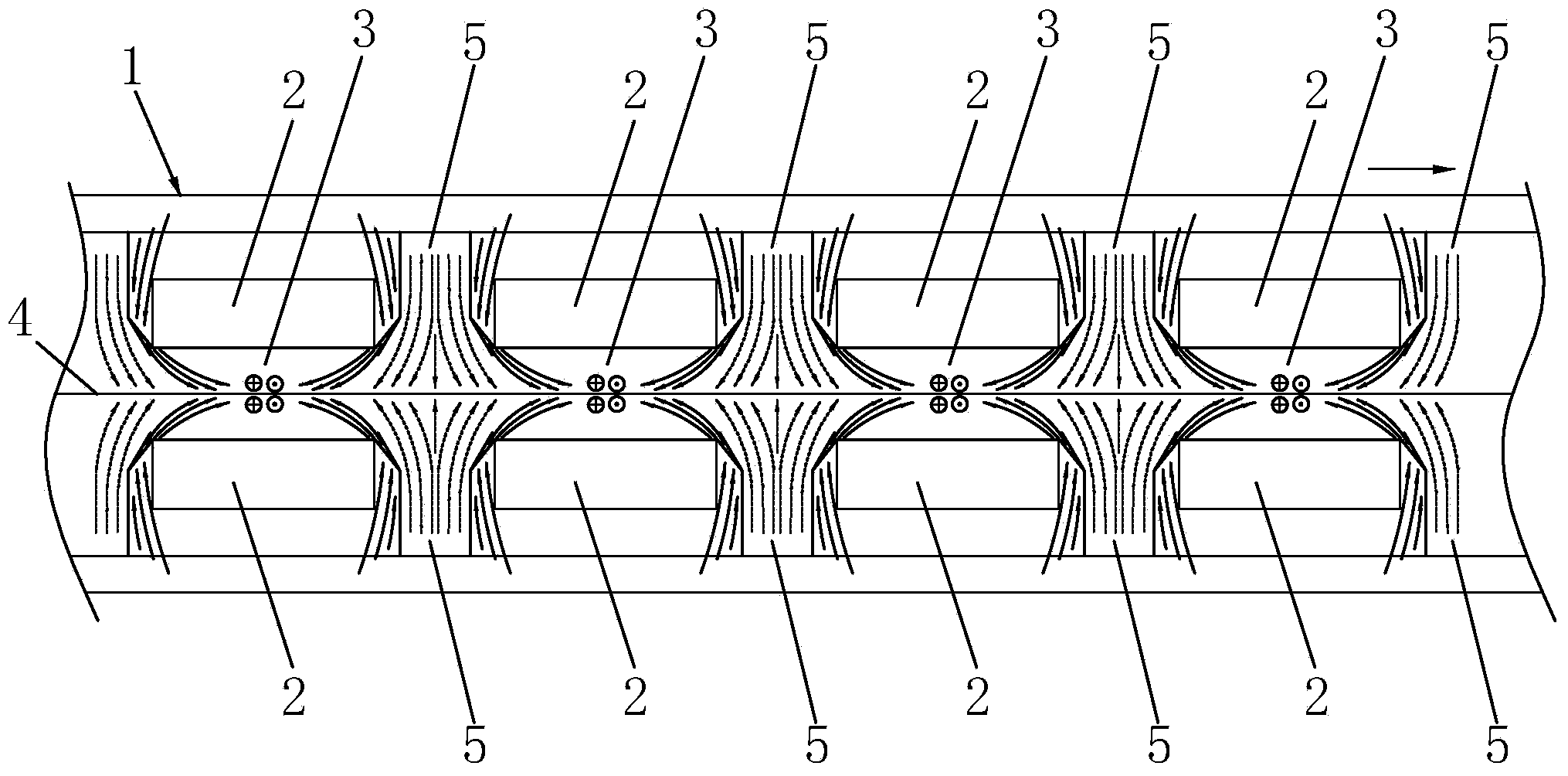

The invention discloses a drying oven for a lithium battery coating machine and a drying oven air current control method. The method includes: a negative-pressure air suction area is formed between each two adjacent air nozzles after air nozzles blow hot air to the surface of a material strap; the negative-pressure air suction area between each two adjacent air nozzles supplies air or hot air to the surface of the material strap; hot air gathered in a middle high-pressure area flows to low-pressure areas on two sides; hot air on the upper and lower surfaces of the material strap flows along the forward direction of the material strap or flows in a direction opposite to the forward direction of the material strap. Air current in the drying oven is controlled stably, air whirl is avoided, the hot air is discharged stably, staying time of the hot air in the drying oven is long, and consequently hot air utilization rate is increased, less energy is consumed for drying the material strap, effectiveness in material strap heating is achieved, and drying quality and drying efficiency are improved.

Owner:广东海中新能源设备股份有限公司

Drying device for pharmaceutical and chemical industry

InactiveCN110715524AExtend drying timeImprove drying efficiencyDrying chambers/containersDrying machines with non-progressive movementsAnnular arrayChemical industry

Owner:ZHUJI CHANGXUE MEDICAL TECH CO LTD

Vibration drying device and method for cigarette filter capsules

PendingCN110671911AAccelerate moisture evaporationImprove drying efficiencyGranular material dryingDrying gas arrangementsPhysicsEngineering

Owner:SHANGHAI TOBACCO GRP CO LTD

Variable-temperature drying integrated honeysuckle processing equipment

PendingCN114659350AEvenly heatedImprove drying efficiencyDrying chambers/containersDrying gas arrangementsEngineeringEnvironmental geology

Owner:江西赣盛农业发展有限公司

Drying device for clay sculpture

InactiveCN109367316AImprove drying efficiencyStable effectSpecial ornamental structuresCeramic shaping apparatusEngineeringConveyor belt

The invention discloses a drying device for a clay sculpture. The drying device comprises a drying room, wherein a charge hole and a discharge hole are separately formed in the outer side walls of twosides of the drying room; the two sides of the drying room are separately equipped with a drive roller and a driven roller; the bottom end of the drive roller and the bottom end of the driven rollerare equipped with supporting rods; two insertion rods are symmetrically mounted on the outer side wall of the drive roller and the outer side wall of the driven roller; the insertion rods separately penetrate through the supporting rods and extend to the outer sides of the supporting rods; a conveyor belt is co-wound on the outer side wall of the drive roller and the outer side wall of the drivenroller; the clay sculpture is placed on the conveyor belt; a drive device is connected on the drive roller; the top end and the bottom end of the drying room are uniformly equipped with a plurality offirst heaters and a plurality of second heaters separately; and a fragment outlet is formed in the bottom wall of the drying room. The de-moulded clay sculpture is placed into the drying room, and the clay sculpture is dried by the first heaters and the second heaters, so that drying efficiency of the clay sculpture is improved, and influences of a climatic environment are basically avoided in aclay sculpture drying process, and therefore, the effect of the clay sculpture is stable.

Owner:长沙承邦创业服务有限公司

Gluing machine with quick-drying function for abrasive paper production

ActiveCN113967880AGuaranteed drying effectEasy to useAbrasion apparatusGrinding devicesPaper productionEmery paper

The invention discloses a gluing machine with a quick-drying function for abrasive paper production, and relates to the technical field of abrasive paper production. The gluing machine comprises a bearing base and a drying assembly, a placement frame is arranged at the position, close to the edge, of the upper end of the bearing base, a conveying belt is arranged in the middle of the upper end of the bearing base, a detection frame is arranged in the middle of the left side of the bearing base, a detection camera is arranged at the upper end of the inner side of the detection frame, and an alarm lamp is arranged at the upper end of the outer side of the detection frame. According to the gluing machine with the quick-drying function for abrasive paper production, air outlets are connected with U-shaped connecting blocks through adjusting knobs, the angles of the air outlets can be adjusted through the thread loosening and tightening of the adjusting knobs, the angles between the air outlets and abrasive paper can be adjusted according to the actual use condition, the actual drying effect of the air outlets on the abrasive paper is optimal, meanwhile, due to the arrangement of the two air outlets, hot air forms convection on the upper surface of the abrasive paper, so that the actual drying efficiency of the abrasive paper is greatly improved, and the actual using effect of the gluing machine is improved.

Owner:JIANGSU SAILING ABRASIVE TECH CO LTD

Drying device for fluororesin particle production

InactiveCN108534492AEasy to moveImprove drying efficiencyGranular material dryingDrying gas arrangementsEngineeringAir heater

The invention discloses a drying device for fluororesin particle production. The drying device for fluororesin particle production comprises a drying barrel; a base is arranged on the lower side of the drying barrel, and a swinging device is connected between the drying barrel and the base; a feeding port is formed in the top of the end, away from the swinging device, of the drying barrel, and anair inlet is formed in the end, close to the feeding port, of the drying barrel; the end, away from the drying barrel, of the air inlet is connected with a corrugated pipe; the end, away from the airinlet, of the corrugated pipe is connected with an air heater; a stirring device is arranged in the drying barrel, and comprises a stirring rotating shaft, stirring rods and stirring balls; the stirring rotating shaft is rotationally connected in the drying barrel; the uniformly distributed stirring rods are arranged on the outer side of the stirring rotating shaft; each stirring rod is provided with the corresponding stirring balls at equal intervals; and a stirring motor is installed at the end, away from the air inlet, of the drying barrel through a screw. According to the drying device forfluororesin particle production, fluororesin particles are dried through hot air, in the drying process, the stirring device and the swinging device are used for increasing flowing of the fluororesinparticles, and the drying efficiency is improved.

Owner:HUZHOU HEXUANZHU NEW MATERIAL TECH CO LTD

Environment-friendly condenser

PendingCN114688768AGood drying effectImprove drying efficiencyEvaporators/condensersDrying tubeProcess engineering

Owner:广州全正汽车配件有限公司

Hot air circulation oven with tank cover

PendingCN111306902AImprove drying efficiencyReduce Fragmentation RateDrying gas arrangementsDrying machines with local agitationEngineeringHot blast

Owner:无锡釜川科技股份有限公司

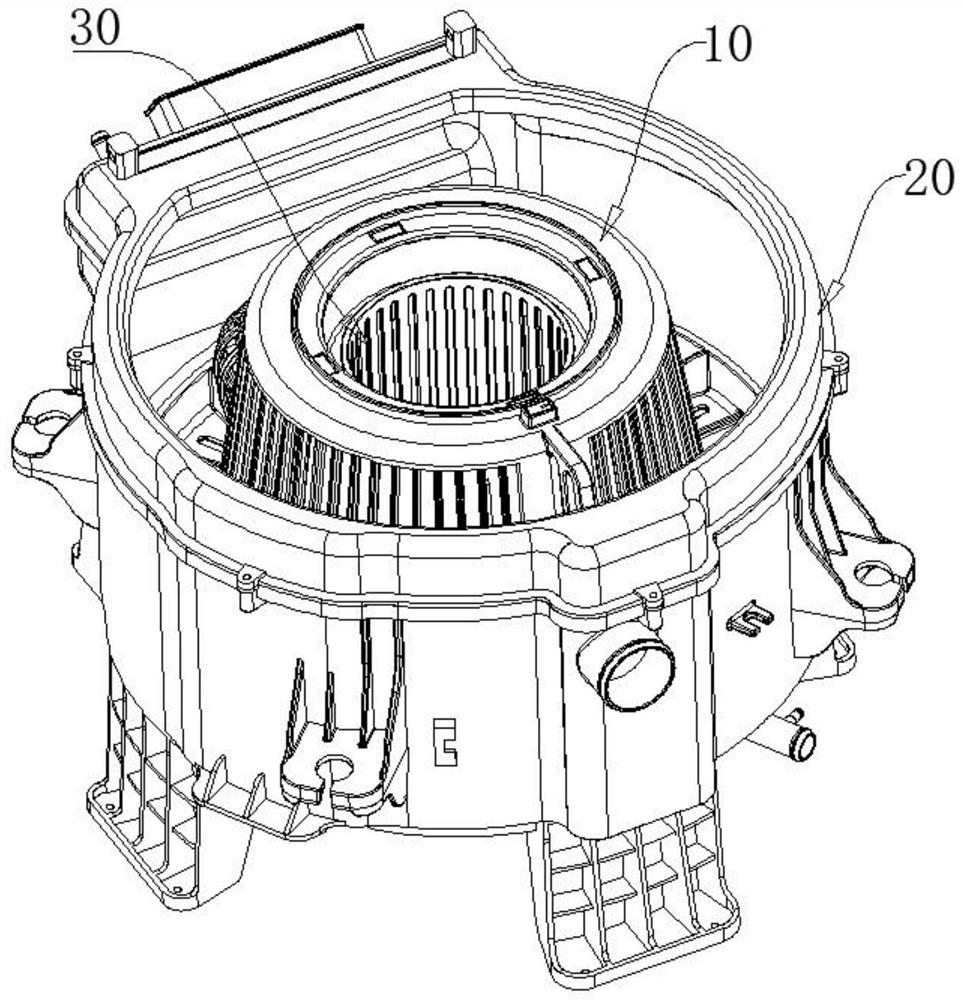

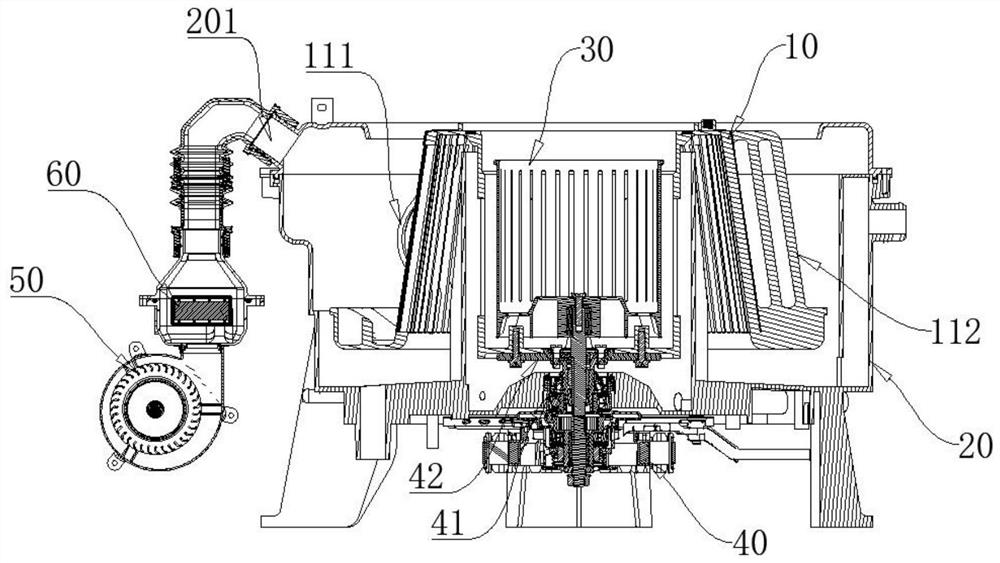

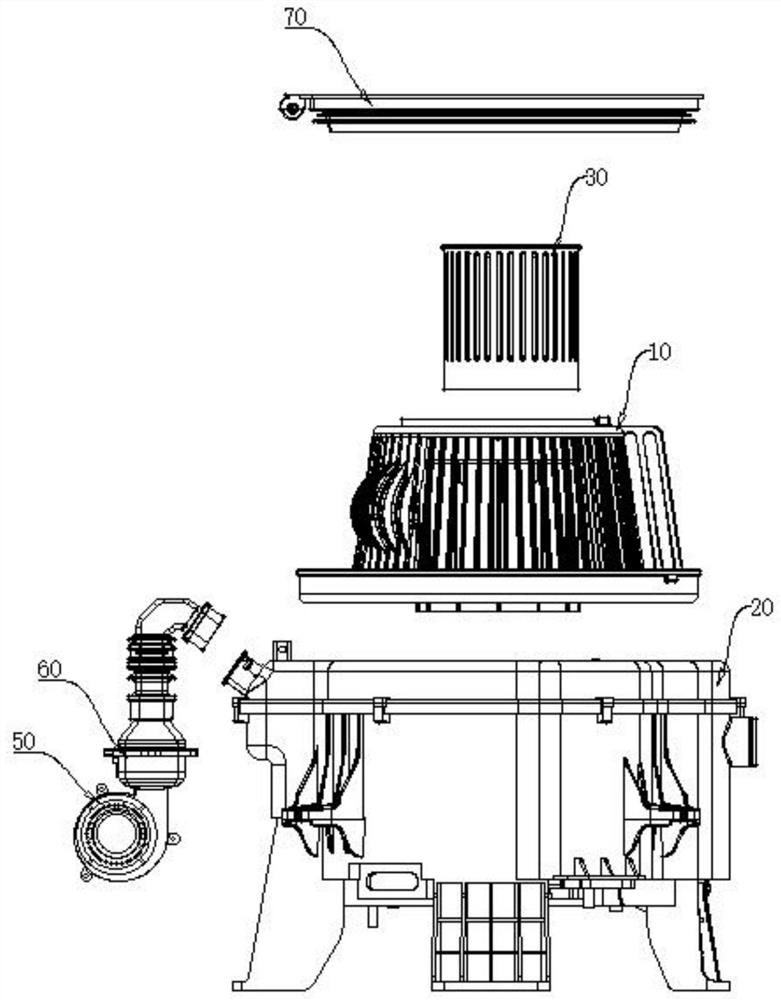

Cleaning systems and base stations for cleaning systems

PendingCN110881900AImprove drying efficiencyCarpet cleanersFloor cleanersBase stationMechanical engineering

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

Computer electronic display screen cleaning device

InactiveCN111715575AImprove air drying effectImprove drying efficiencyCleaning using liquidsCleaning using toolsEngineeringMechanical engineering

Owner:SUZHOU YUQIAN INFORMATION TECH CO LTD

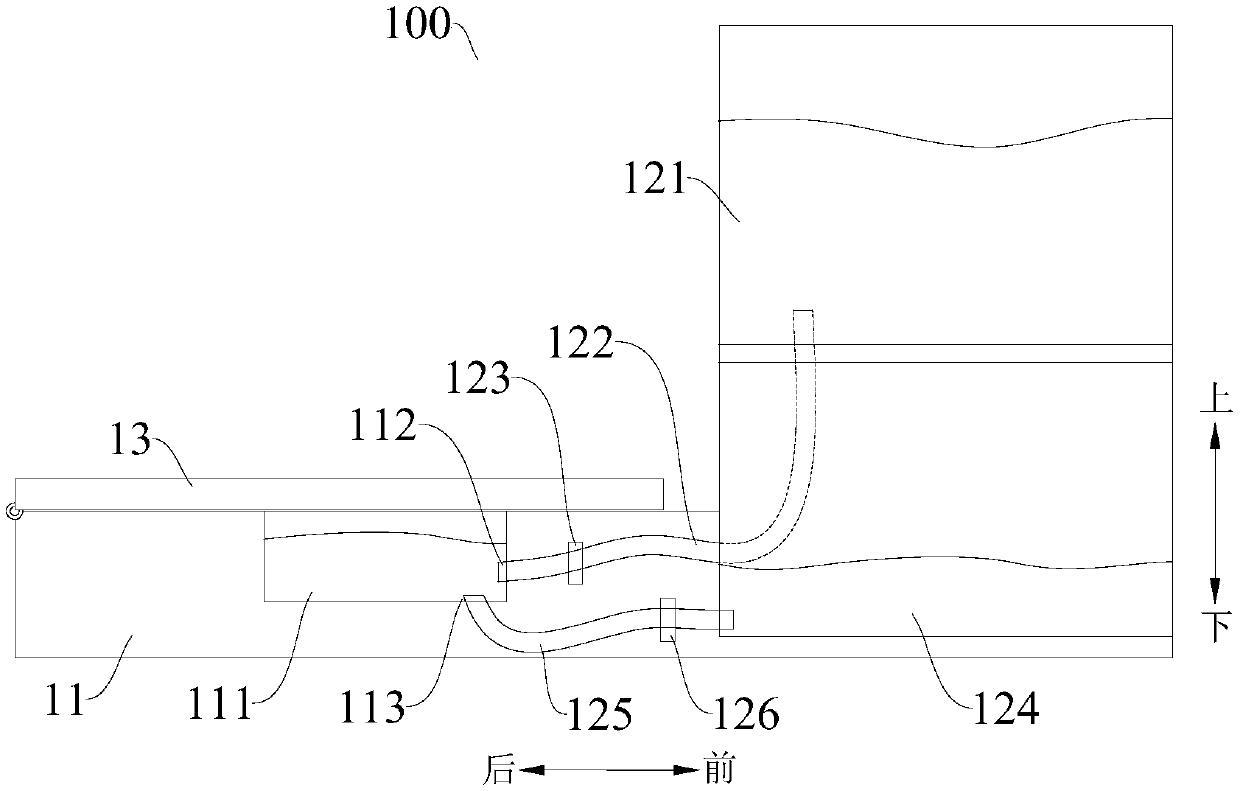

Low-pressure superheated steam energy-saving drying device and process for pineapples

PendingCN114451567AQuick changeAvoid burnsFood ingredient as antioxidantFood dryingThermodynamicsWater storage tank

The pineapple low-pressure superheated steam energy-saving drying device comprises a drying box, a superheated steam generating device is fixedly installed on one side of the drying box, a water storage tank is arranged on the other side of the drying box, and a water outlet pipe opening is formed in the side face of the water storage tank and used for being connected with a buffer tank and a vacuum pump. A door frame is embedded in the surface of the drying box, a sealing door is hinged to the surface of the door frame, a ceiling is fixedly installed at the top of the drying box, and pipe fasteners are installed at the bottom of the inner wall of the drying box. According to the energy-saving generation device and technology of the pineapple low-pressure superheated steam drying system, the sliding seat is arranged, the sliding rail is used for guiding the sliding seat, the sliding seat can directly slide out of the interior of the drying box, workers are prevented from making contact with the inner wall of the drying box, dried pineapple slices can be rapidly replaced, and the drying efficiency is improved.

Owner:TIANJIN UNIV OF SCI & TECH

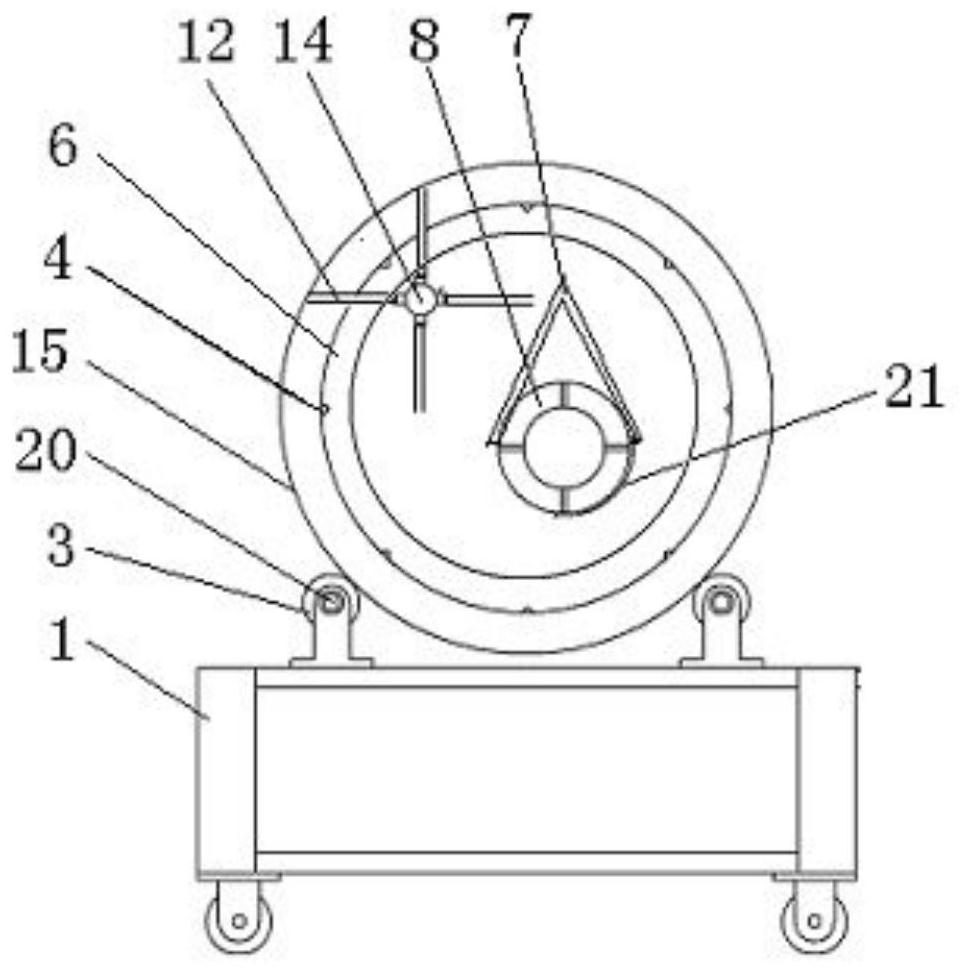

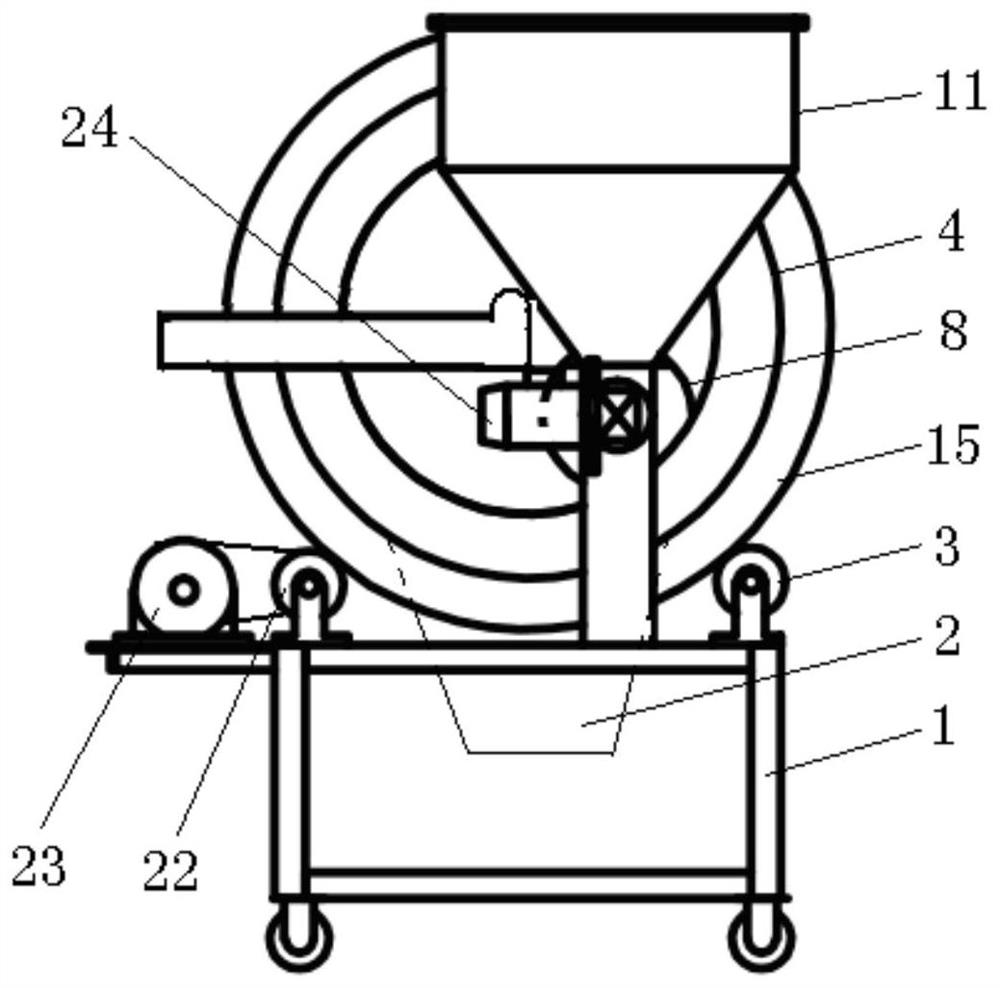

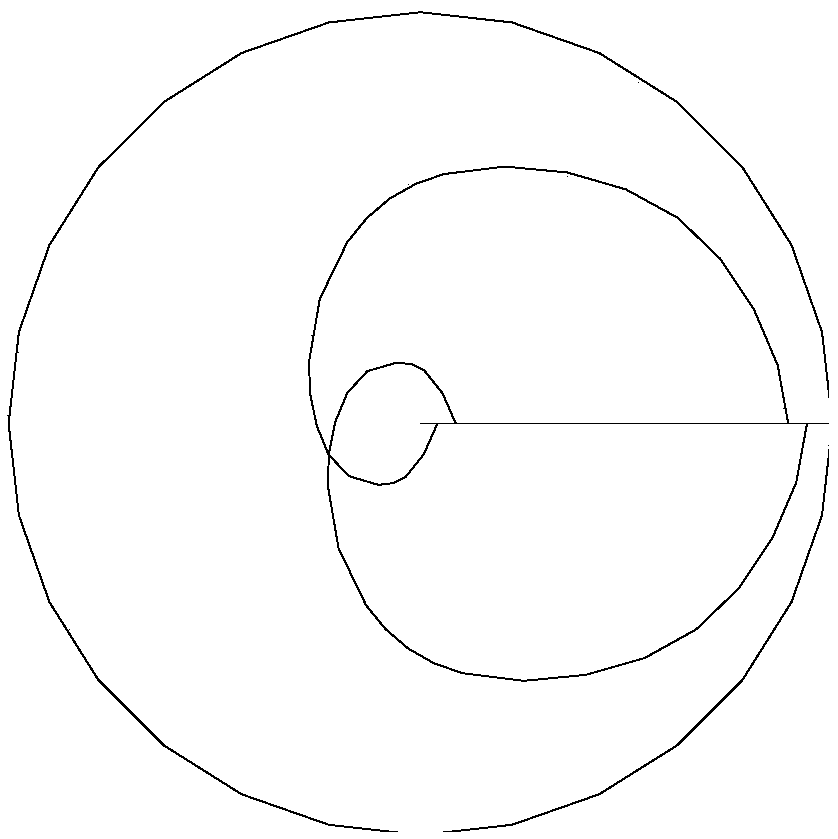

Drum-type coffee surface water air dryer

PendingCN112956713AImprove drying efficiencyLarge amount of processingFood treatmentCoffeaAutomatic processing

The invention provides a drum-type coffee surface water air dryer which comprises a rack and a rotary drum which is arranged on the rack, the rotary drum is provided with a feeding port and a discharging port, a cavity is provided in the rotary drum and a spiral pushing plate is provided in the cavity. The air dryer is characterized in that a first mesh wall is arranged on the rotary drum, an air pipe connected with an air source is arranged in the cavity of the rotary drum, and a second mesh wall is arranged on the air pipe. According to the invention, when the materials are moved from the feeding port to the discharging port, air drying can be completed at a time, water on the surfaces of the materials can be thoroughly removed, the air drying efficiency is high, the treatment capacity is large, the structure is simple, will not be affected by sites or weather, reliable guarantee can be provided for subsequent material processing, subsequent processing energy consumption is greatly reduced, the processing time is shortened, is conducive to mechanization and automatic processing, and the labor intensity is low.

Owner:普洱富民农业装备有限公司

Device for controlling cosmetic processing through rapid stirring and drying enhancement

InactiveCN111981825AImprove drying effectImprove drying efficiencyDrying machines with progressive movementsDrying solid materialsCosmeticsEngineering

Owner:广州世湖电子商务有限公司

Drying device capable of preventing drying speed from being affected by excessive water in textiles

InactiveCN112984966AAvoid affecting drying speedEasy to squeeze water outDrying solid materials without heatDrying gas arrangementsTextile technologyWater storage tank

The invention relates to the technical field of textiles, and discloses a drying device capable of preventing the drying speed from being affected by excessive water in the textiles. The drying device comprises a fixing seat, a water storage tank is welded to the top of the fixing seat, and a water drain valve is welded to the left side of the water storage tank. According to the drying device capable of preventing the drying speed from being affected by the excessive water in the textiles, a cam rotates, at the moment, a pressing rod can drive a water pressing plate to periodically slide up and down in a drying chamber, and thus the effect of preventing the drying speed from being affected by the excessive water in the textiles is achieved. A rotating disc is rotated, and at the moment, the distance between the water pressing plate and a cross rod can be changed, so that the effect of conveniently extruding the textiles of different thicknesses to discharge the water from the textiles is achieved; air generated by rotation of fan blades moves to the bottom of the water pressing plate through a first air guide pipe, then flows back to the interior of a second sealing cavity through a second air guide pipe, and finally circulates after the water is filtered through a connecting pipe, so that the effects of improving the drying efficiency of the textiles and reducing resource waste are achieved.

Owner:邓清源

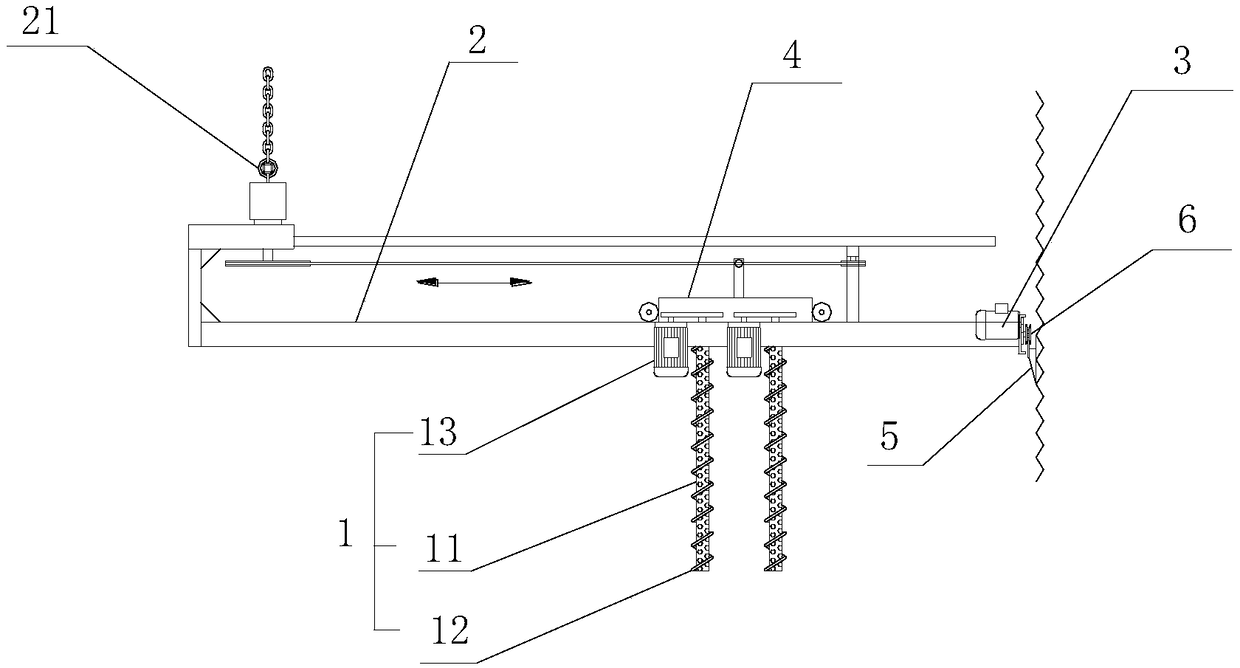

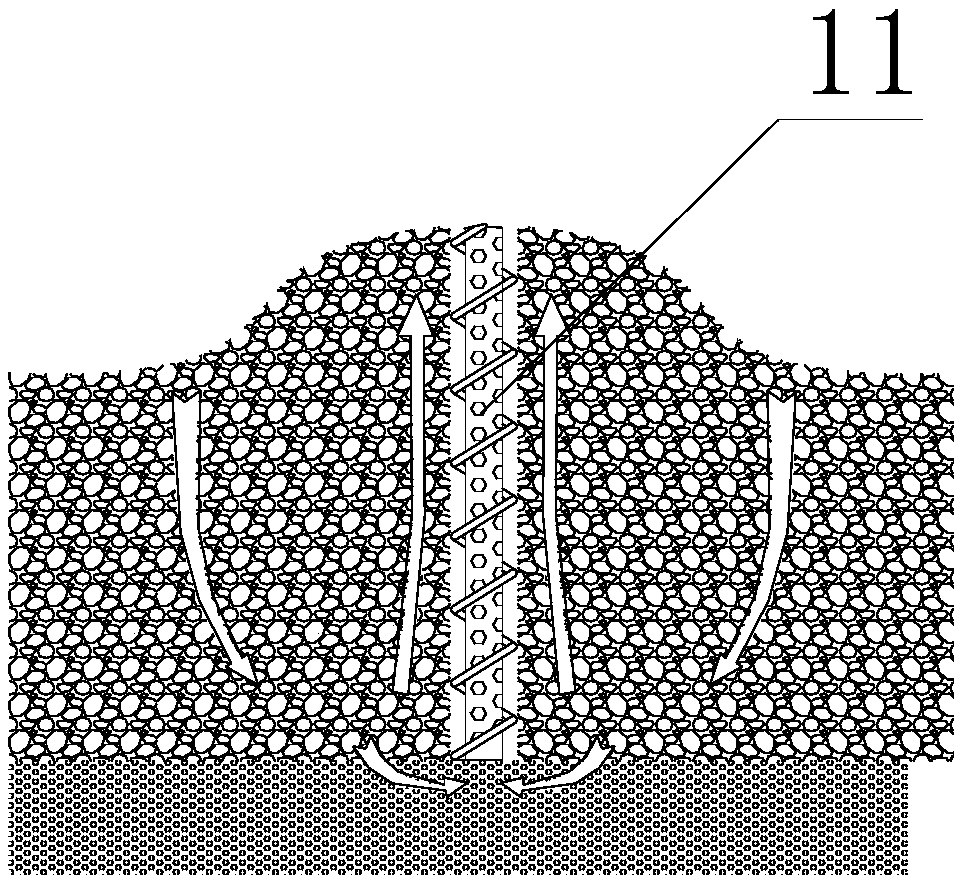

Silo material stirring device

PendingCN109186210AShorten drying timeImprove drying efficiencyDrying gas arrangementsSeed preservation by dryingPower unitEngineering

Owner:合肥弘恩机电科技有限公司

Intensive environmentally-friendly rotary S-shaped fertilizer production equipment

InactiveCN107131750AImprove drying efficiencyConvenient and smoothDrying gas arrangementsDrying chambers/containersAir preheaterHot air oven

The invention relates to intensive environmentally-friendly rotary S-shaped fertilizer production equipment, belongs to the technical field of fertilizer production equipment, and mainly aims to solve the technical problems of low heat energy utilization rate, non-uniform drying, complicated configuration, large occupation area, high electricity consumption, low drying efficiency and low fertilizer yield of existing fertilizer drying equipment. The technical scheme is that the intensive environmentally-friendly rotary S-shaped fertilizer production equipment comprises rotary drums, a material feeding bin, a large particle bin, a small particle bin, a finished product bin, supporting rollers, power conveying gears, an air preheater, an air heating furnace, a material feeding type lifting machine, a material discharging type lifting machine, a double-layer filter screen device and an induced draft fan, wherein the rotary drums comprise an outer rotary drum, a middle rotary drum and an inner rotary drum. The intensive environmentally-friendly rotary S-shaped fertilizer production equipment has the advantages of high heat energy utilization rate, small occupation area, reasonable structural design, high yield and the like.

Owner:李玉斌

Drying and dehydration device for natural perfume

InactiveCN107940908AEvenly heatedAvoid damageDrying solid materials without heatDrying machines with non-progressive movementsFiberDrive shaft

The invention discloses a drying and dehydration device for natural perfume. The device comprises a machine shell, a top cover, a base, a power box, a servo motor, a wind fence, a transmission rod, astirring assembly, a placing disc, a heating column, a blanket net assembly, a filter bag, a fixing net ring, a placing groove, a fixing groove, a main rotating shaft, a driven shaft, a stirring rod,a spiral pin and a suction fan. The drying and dehydration device has the beneficial effects that the sealed machine shell is used as a main working space, the heating column is placed to the center of the filter bag in a center heating mode, perfume in all corners in the filter bag can be evenly heated, and the filter bag is made from fiber, innocuous and harmless due to the fact that a net ringmade from metal will pollute perfume in the heating process. The main rotating shaft and the driven shaft are in engaged connection in a shaft pair connection mode, an auxiliary rotating shaft is driven to rotate through the mechanical principle, bent fan blades are utilized for pulling steam into the wind fence, and damage caused by steam accumulation on the device is prevented.

Owner:王信青

Activated carbon preparation process

ActiveCN111874904AReduce processing efficiencyReduce air pressureCarbon compoundsDrying gas arrangementsActivated carbonHoneycomb

The invention belongs to the technical field of activated carbon preparation, and particularly relates to an activated carbon preparation process which comprises the following steps: step 1, drying and grinding: carbonizing and grinding sawdust after drying to obtain dried carbon powder; step 2, processing and forming: processing the carbon powder into a cylindrical carbon block by using a mold, and forming a plurality of honeycomb-shaped through holes; step 3, cleaning of the carbon block: washing the formed carbon block with water to remove impurities on the surface of the carbon block; step4, drying of the carbon block: drying the cleaned carbon block to remove moisture in honeycomb-shaped through holes of the carbon block, wherein the drying process of the cleaned carbon block in thestep 4 is completed by adopting an activated carbon preparation machine in a matching manner. The invention solves the problems that at present, when the interiors of cylindrical activated carbon honeycomb holes are dried, part of moisture on the inner walls of the honeycomb holes permeates into the surface layers of activated carbon, sufficient drying is difficult, and moisture residues are likely to be caused, and conveying and drying cannot be conducted synchronously, and the machining efficiency is low.

Owner:JIANGSU QIANHUIHE ENVIRONMENTAL REGENERATION CO LTD

Drying device for color master batch processing

The invention provides a drying device for color master batch processing, and belongs to the technical field of color master batch processing. The drying device comprises a packaging part, a heating assembly, a color master batch transferring part, material stirring parts, a first driving part and a second driving part, wherein the heating assembly is arranged on the inner wall of the packaging part, the color master batch transferring part is arranged inside the packaging part, a plurality of groups of color master batch storage areas are arranged on the outer side of the color master batch transferring part, the material stirring parts are arranged in each group of the color master batch storage areas, and the second driving part is used for driving the color master batch transferring part to rotate so as to drive the plurality of color master batch storage areas to move to one side of the heating assembly in sequence. Compared with the prior art, the drying device has the advantages that efficient and continuous drying of color master batches can be realized, the drying efficiency is high, and the drying effect is good.

Owner:JIANGSU SHANGAOSEN NEW MATERIAL TECH CO LTD

Drying device for bathroom ceramic production line

PendingCN110849075AGuaranteed drying qualityImprove drying efficiencyCharacter and pattern recognitionDrying gas arrangementsAir filterDry box

Owner:FOSHAN KINGPENG ROBOT TECH CO LTD

Optical cable blow-drying process and device

InactiveCN111928614AImprove drying efficiencyIncrease productivityDrying gas arrangementsDrying machines with progressive movementsAir dryerAir drying

Owner:广州大鹏机械设计有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap