Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10 results about "Batch processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Computerized batch processing is the running of "jobs that can run without end user interaction, or can be scheduled to run as resources permit."

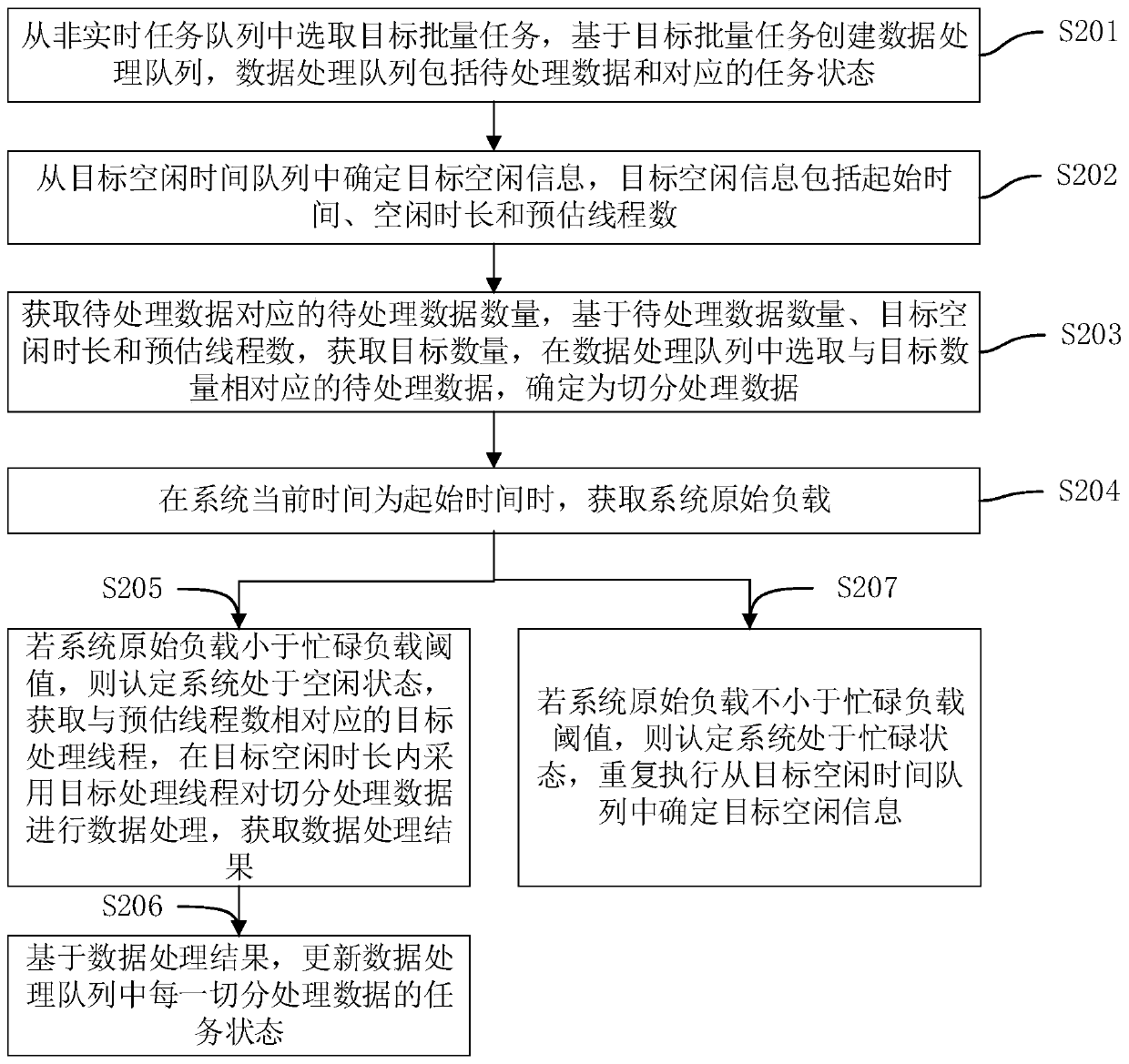

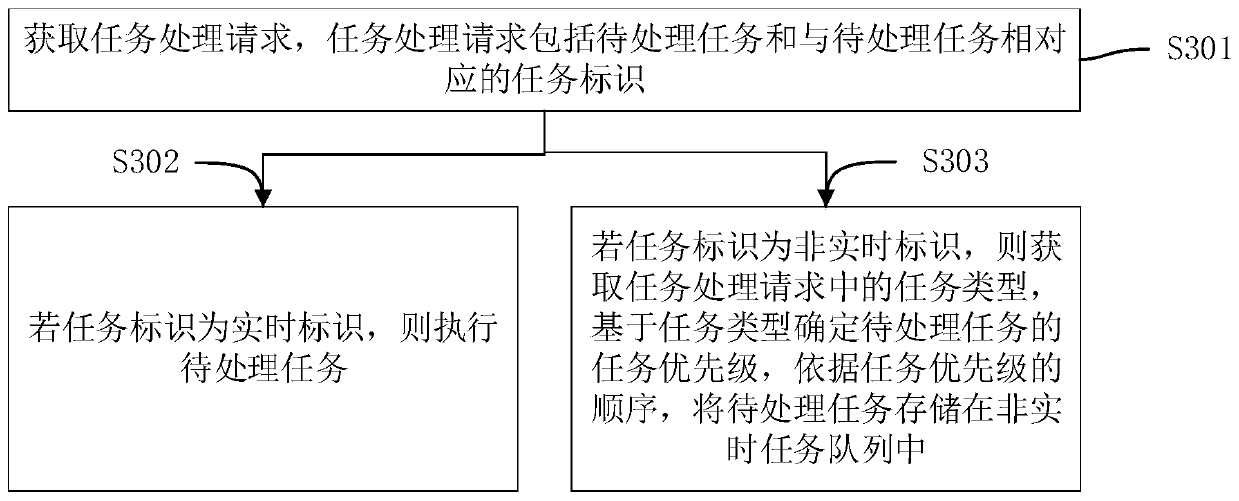

Batch data processing method and device, computer equipment and storage medium

PendingCN110297711AEnsure successful processingImprove determination efficiencyResource allocationMachine learningNon real timeBatch processing

Owner:PING AN TECH (SHENZHEN) CO LTD

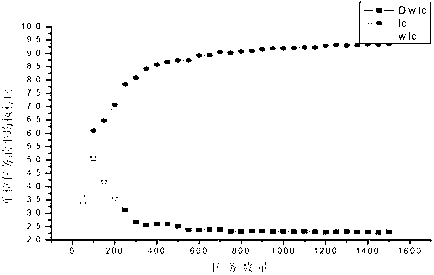

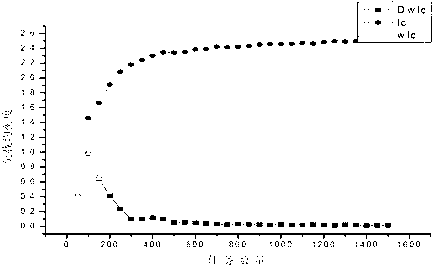

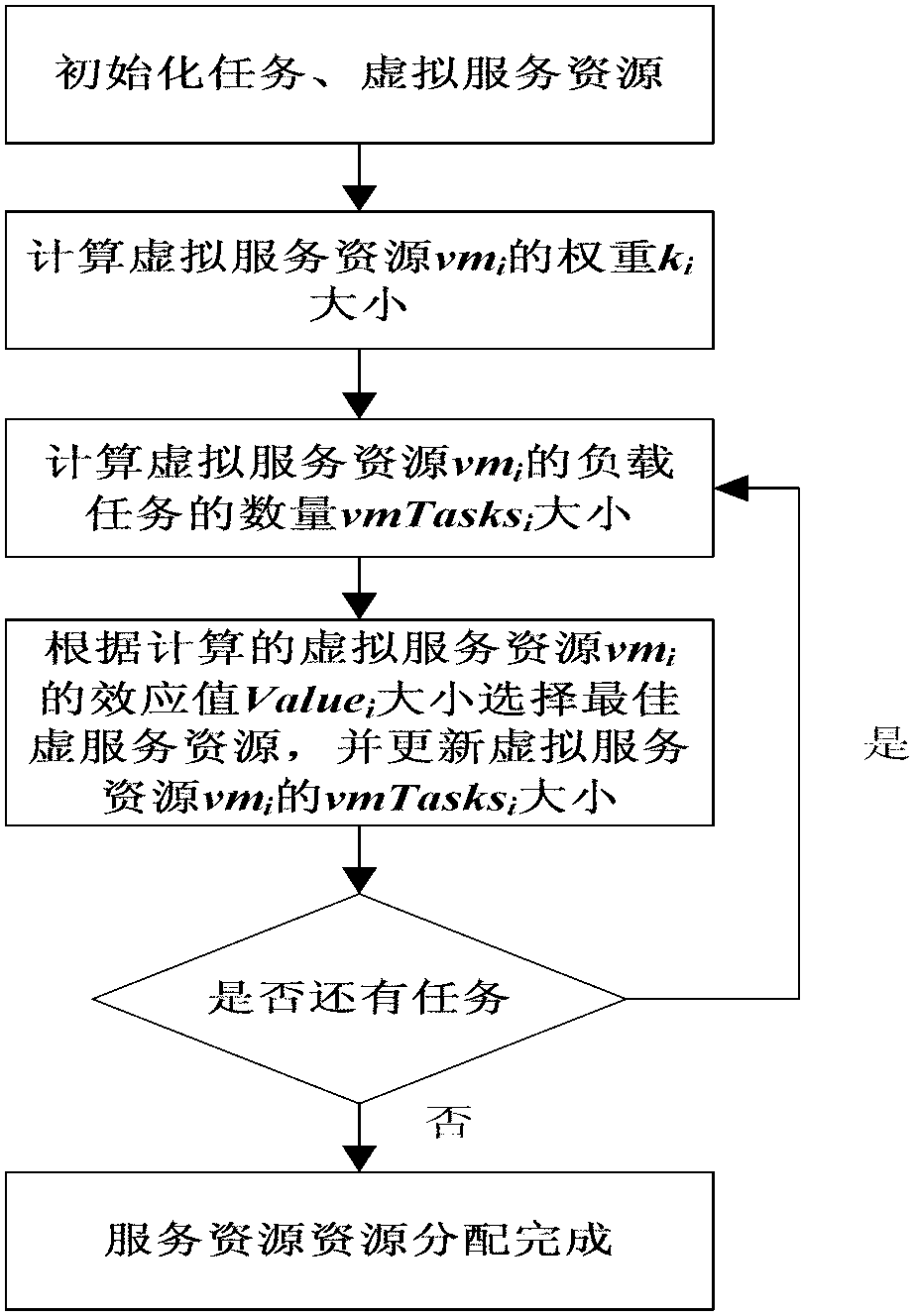

Load balance strategy for allocating service resource based on cloud computing environment

Owner:HEFEI UNIV OF TECH

Dish-washing drying machine

InactiveCN107374543ACompact designKeep dryTableware washing/rinsing machine detailsRadiationBatch processingPulp and paper industry

Owner:太仓市友联干燥粉碎设备有限公司

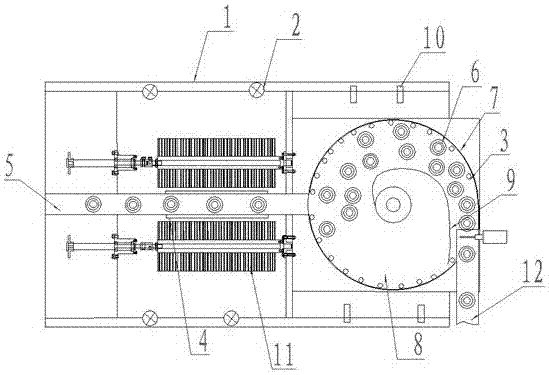

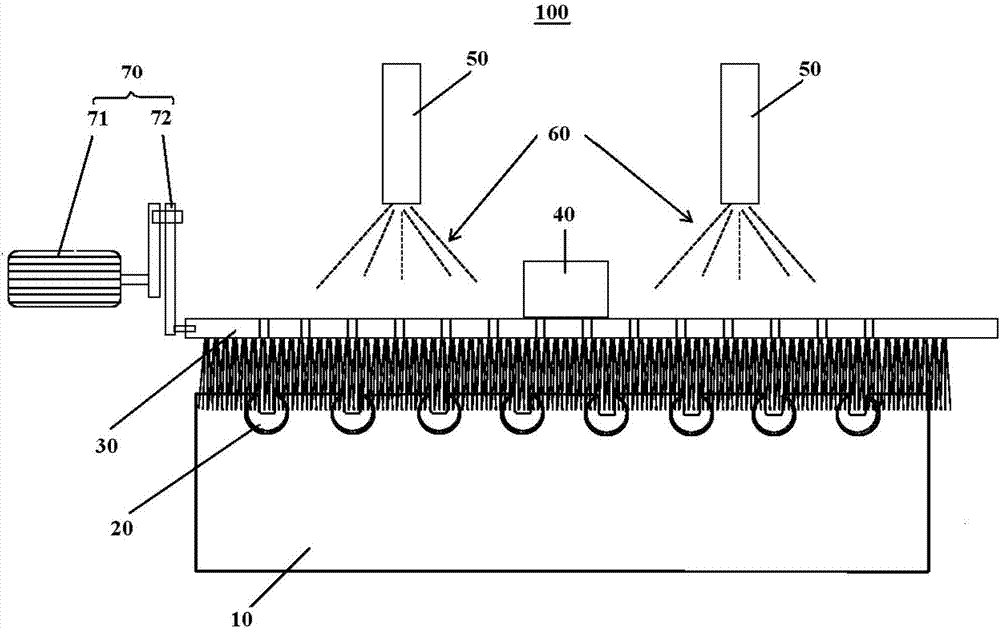

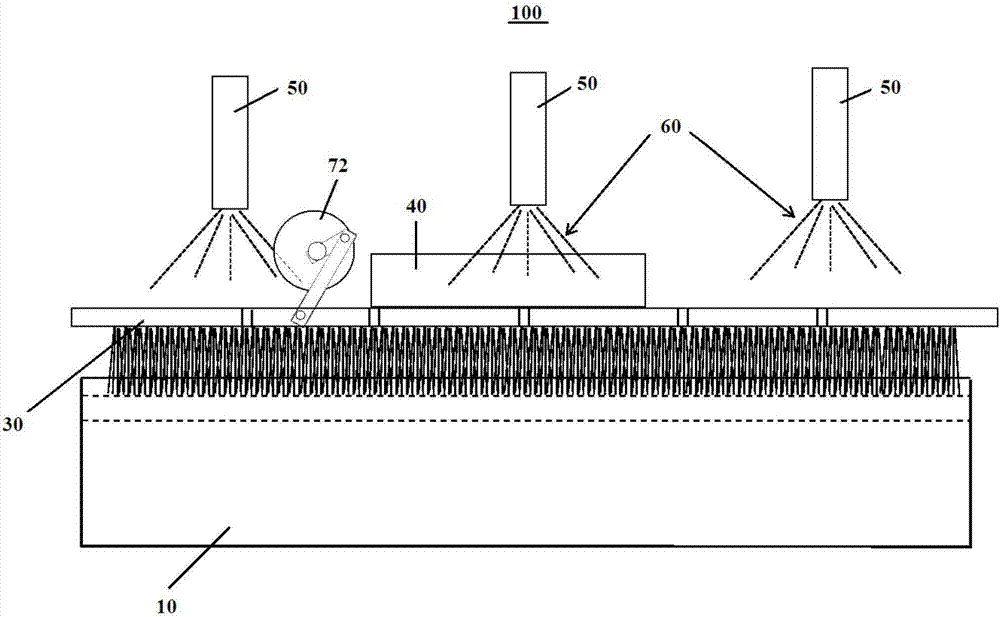

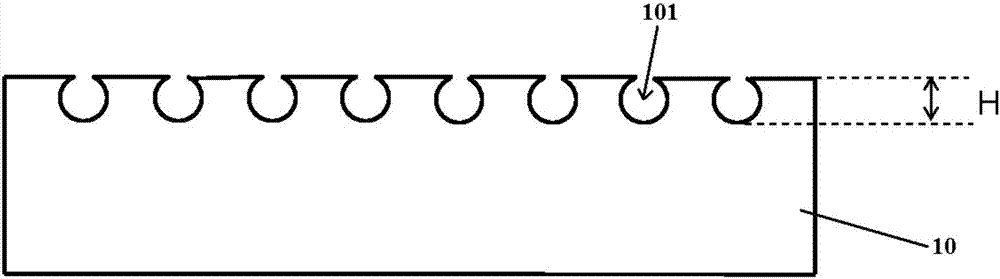

On-line atomic layer deposition device and deposition method

InactiveCN102644062ASimple structureEasy loading and unloadingChemical vapor deposition coatingBatch processingAtomic layer deposition

The invention discloses an on-line atomic layer deposition device, which comprises a substrate feeding system, a processing chamber, a precursor feeding system, at least one loading and unloading element, a lifting element, a control and detection system and an exhaust system, wherein a substrate is fed into the processing chamber by the substrate feeding system; the precursor feeding system is arranged on the side face of the processing chamber; the loading and unloading element is arranged at the inlet and outlet position of the processing chamber; the lifting element is arranged just below the processing chamber and is in contact with a substrate carrying device through an open groove on the processing chamber; and the control and detection system and the exhaust system are connected with the processing chamber respectively. According to the on-line atomic layer deposition device, the problem of the complex loading element and substrate carrying device can be solved, and atomic layer deposition on the surface of a substrate can be realized in a batch processing mode.

Owner:BEIJING SEVENSTAR ELECTRONICS CO LTD

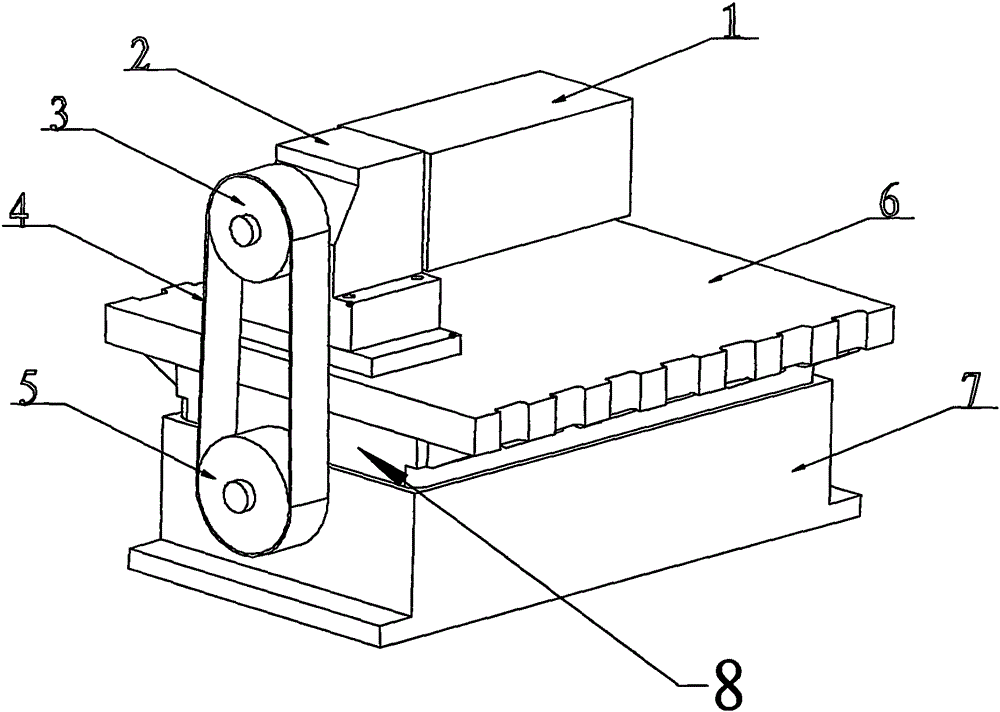

Device and method for treating rough face of the inner groove of quartz base plate for optical fiber coupler

InactiveCN106956185AIncrease the areaAvoid damageEdge grinding machinesPolishing machinesBristleBatch processing

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

Stamping process for large-table-board stamping device of metal sheet stamping and cutting automation equipment

Owner:LUOYANG YOUNENG AUTOMATION EQUIP CO LTD

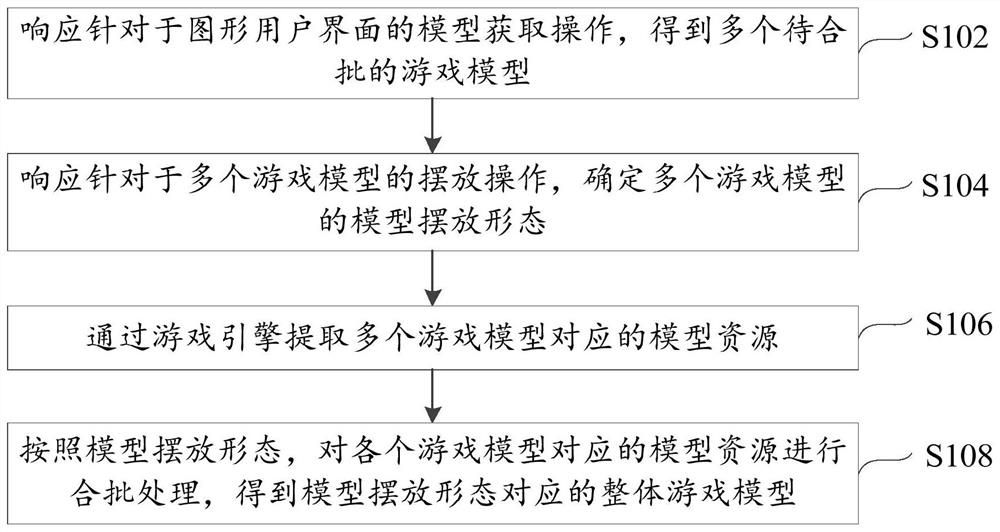

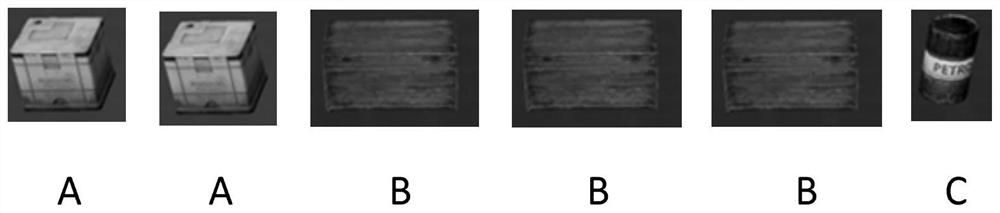

Game model blending processing method and device and electronic device

PendingCN112057868AImprove batching efficiencyShorten the timeVideo games3D modellingGraphical user interfaceBatch processing

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

Premna herbacea Roxb-flavored canned goat tripe

InactiveCN106473015AImprove loss of appetiteImprove the discomfort of people who do not think about eatingFood sciencePremnaBatch processing

Owner:NANLING DENDROBIUM IND ASSOC

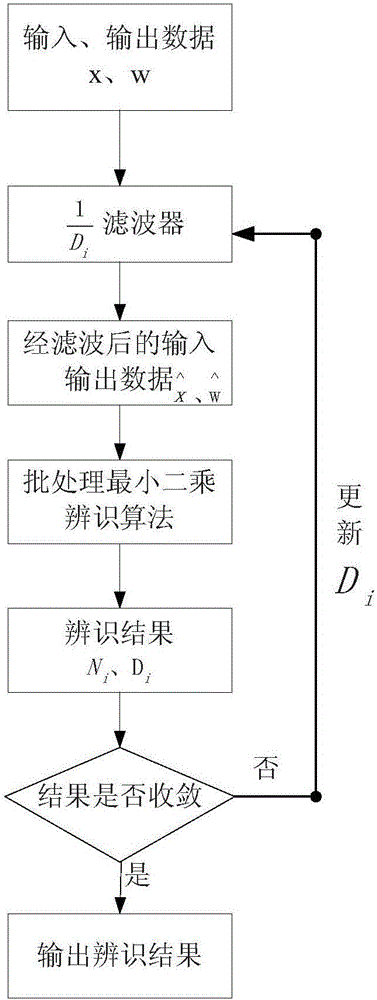

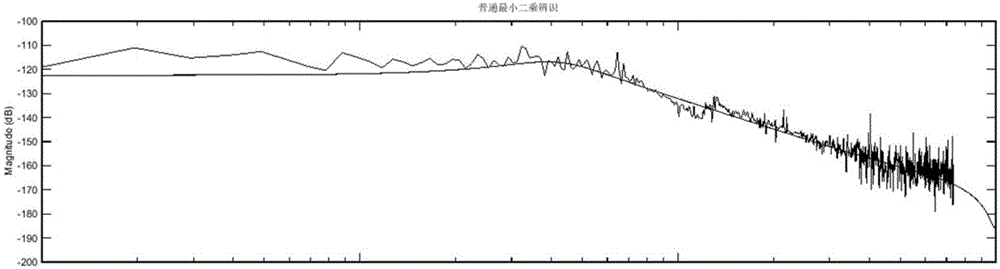

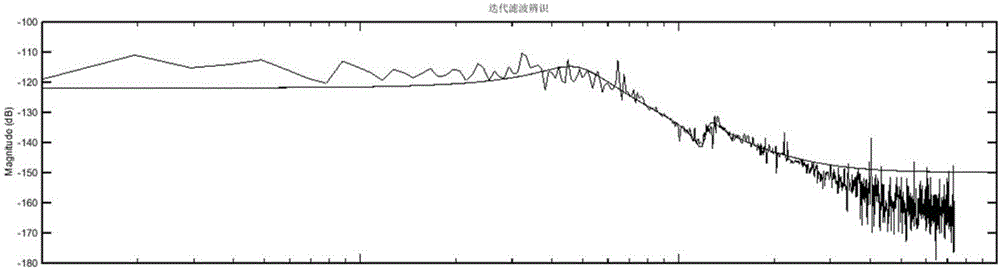

Iterative filtering identification method of linear motor transfer function

ActiveCN106650598ASimple designAccurate dataAC motor controlCharacter and pattern recognitionAnti jammingBatch processing

Owner:江苏希太芯科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap