Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

217 results about "Energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Energy consumption is the amount of energy or power used.

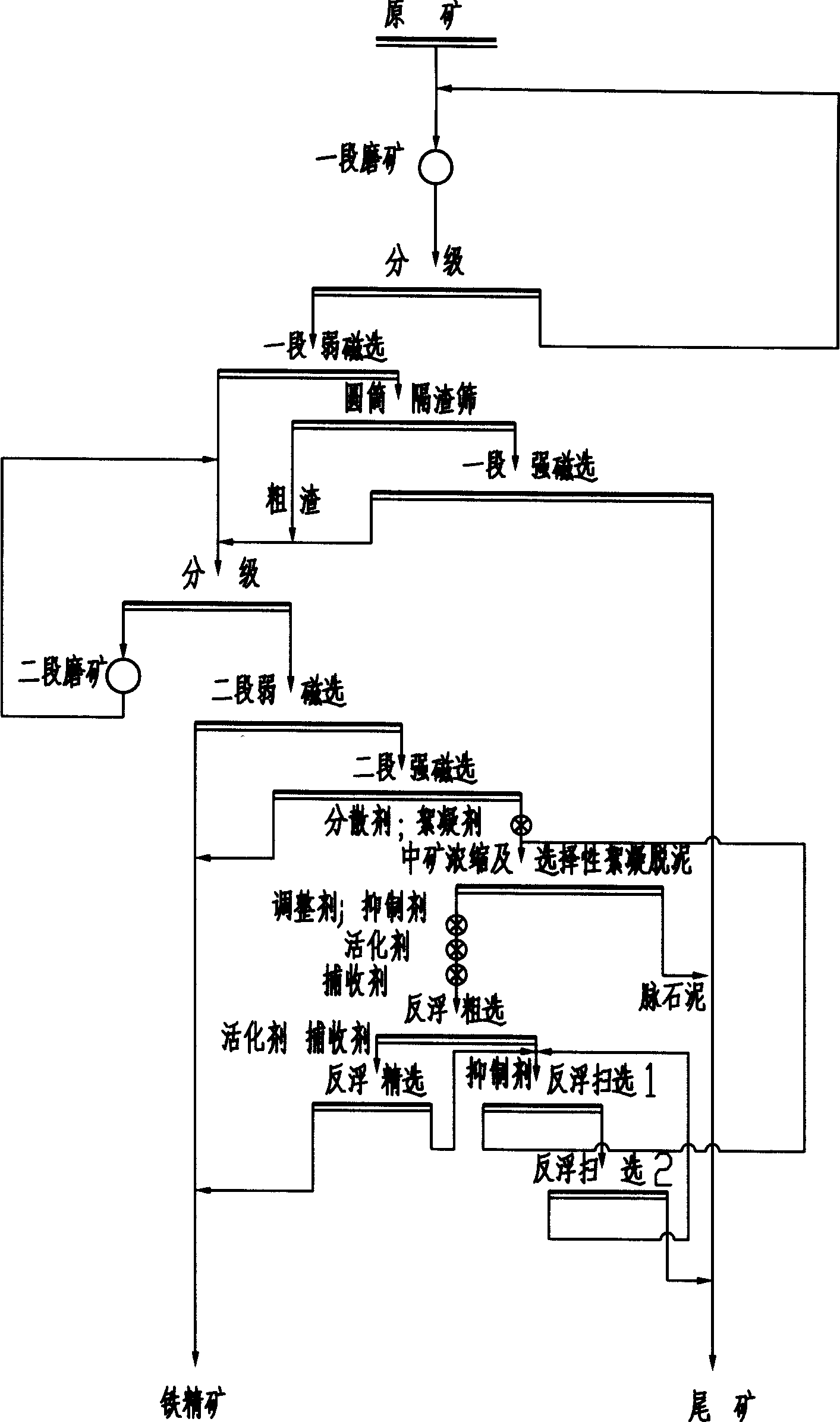

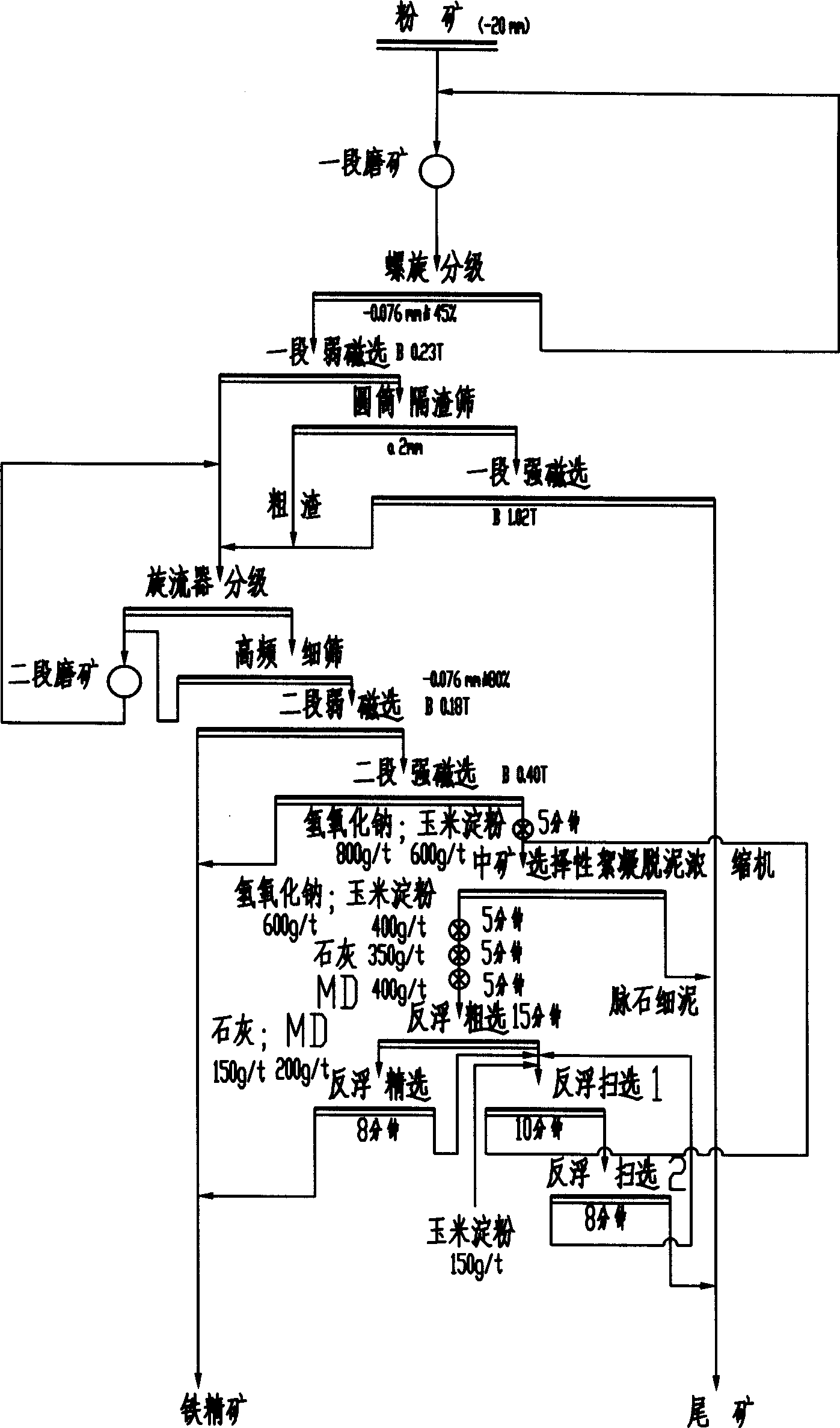

Beneficiation method for recycling specularite

InactiveCN101428248AReduce consumptionReduce the number of equipmentDifferential sedimentationFlotationIronstoneSlag

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

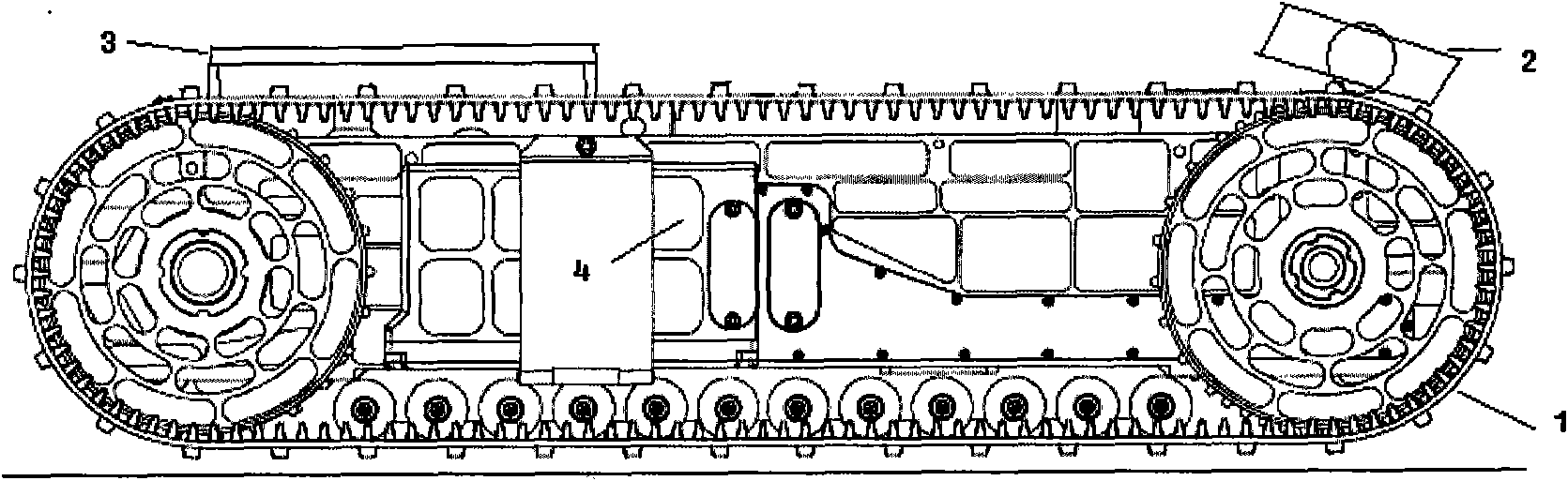

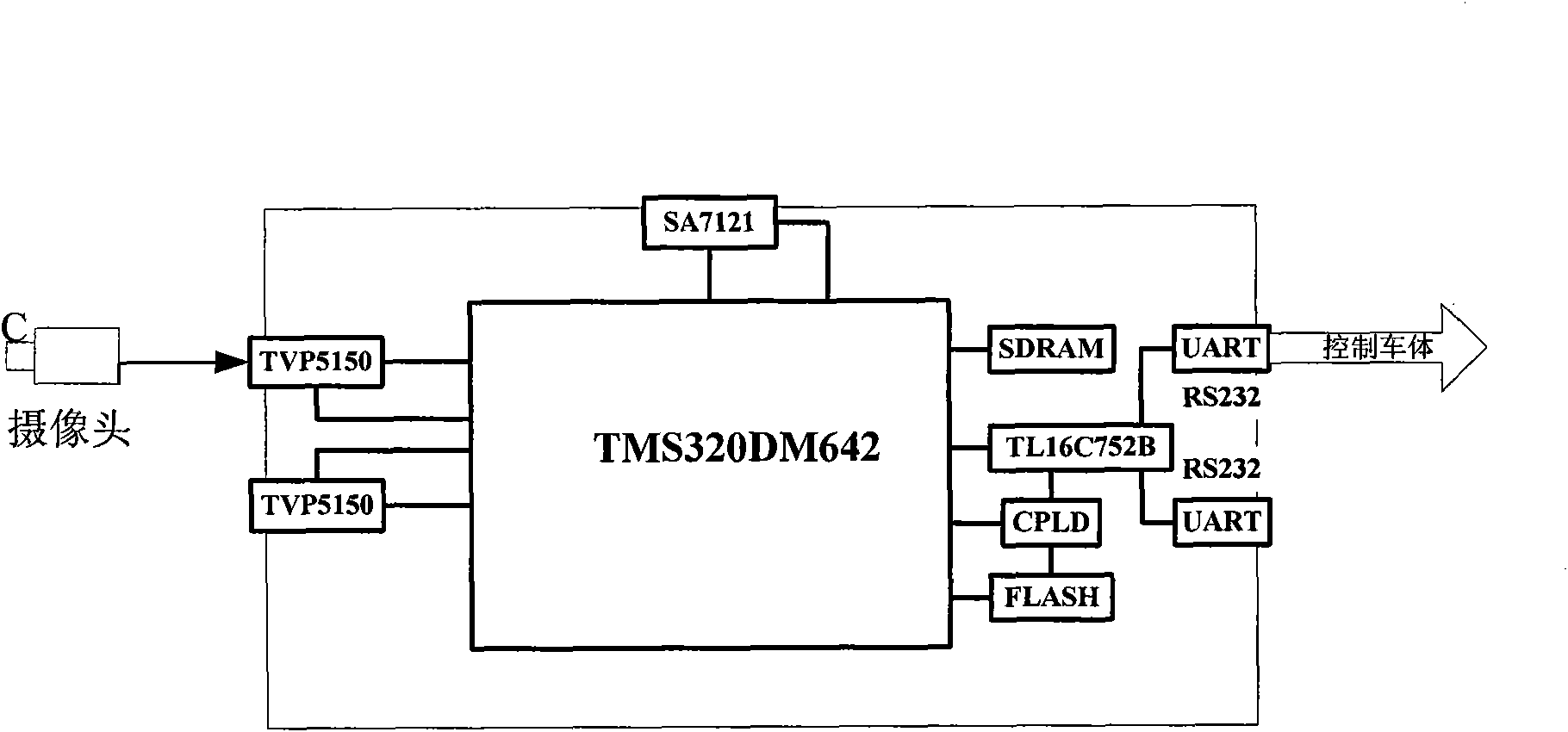

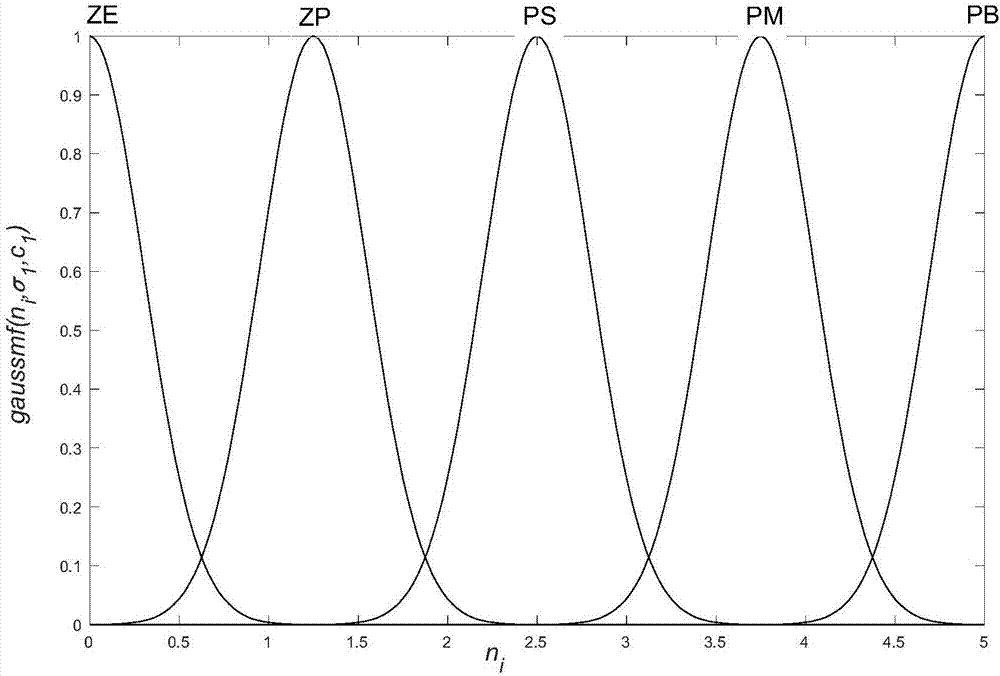

Intelligent navigation control system and method

InactiveCN101976079AImprove environmental adaptabilityImprove work efficiencyInstruments for road network navigationPosition/course control in two dimensionsRobustificationClosed loop

Owner:北京环宇信科技术发展有限公司

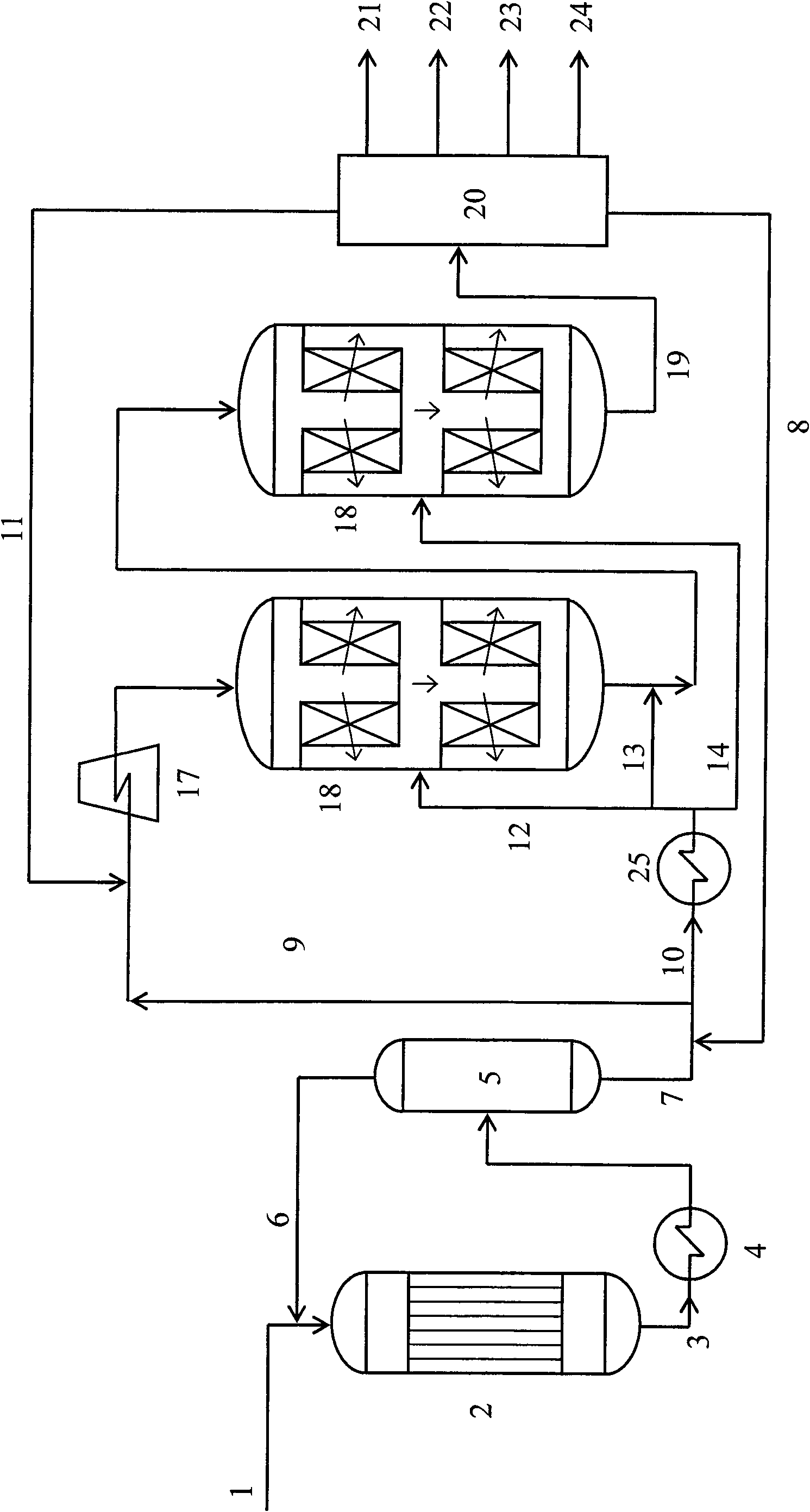

Method for extracting multiple chemical products from coal-tar oil

ActiveCN101139527AIncrease added valueQuality improvementTar working-up by water removalTar working-up by distillationAnthraceneHigh concentration

The invention discloses a method for extracting a plurality of chemicals from a coal tar, which comprises such procedures as heating the coal tar to 120-130 DEG C, dehydrating, fore running, separating, fine rectifying, and heavy-oil distilling, and getting 95 naphthalene, methyl naphthalene, anthracene oil, asphalt and heavy oil. The invention is of simple process, easy operation, rectifies coal tar several times; the extracted chemical products are of steady quality, the naphthalene is of high concentration, and the asphalt is of good quality. The invention is of low energy consumption, hence improves better the added value in processing coal tar in China.

Owner:ZHEJIANG MEIYANG INTL PETROCHEMICAL MEDICINE DESIGN CO LTD

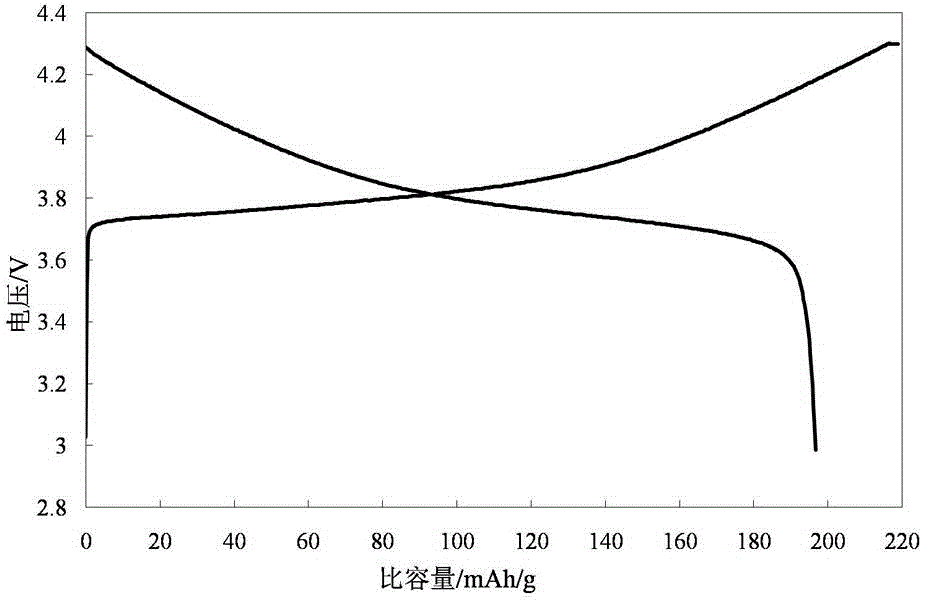

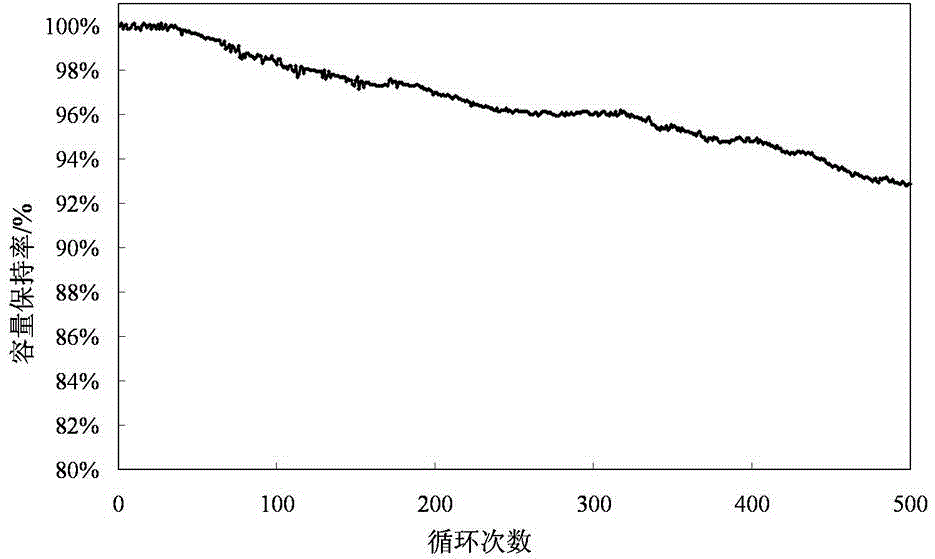

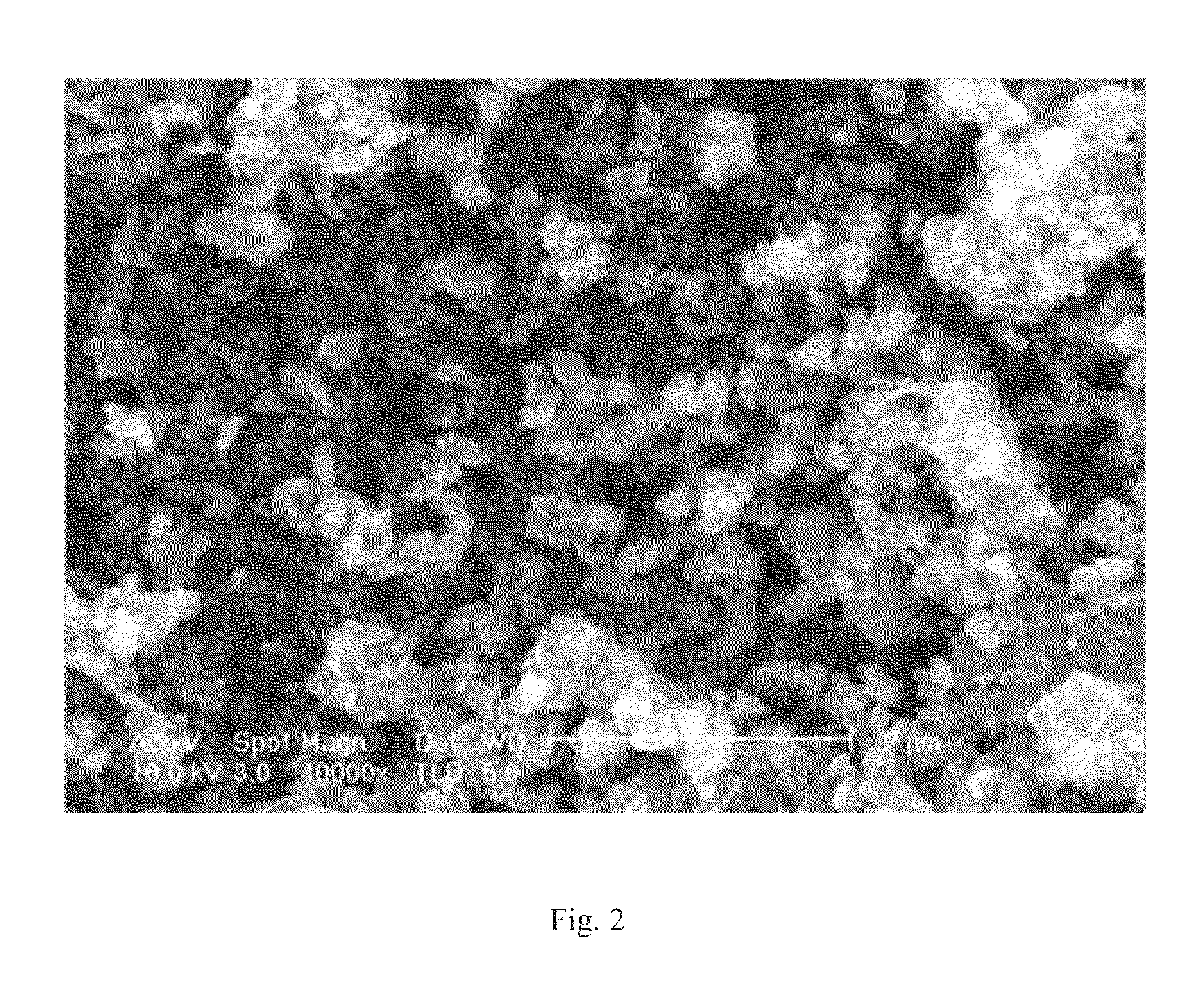

Surface coating modified lithium ion battery cathode material and preparation method thereof

InactiveCN104577093AImprove securityNo significant reduction in specific capacityCell electrodesLithium iron phosphatePhysical chemistry

Owner:ZHEJIANG MEIDARUI NEW MATERIAL TECH CO LTD

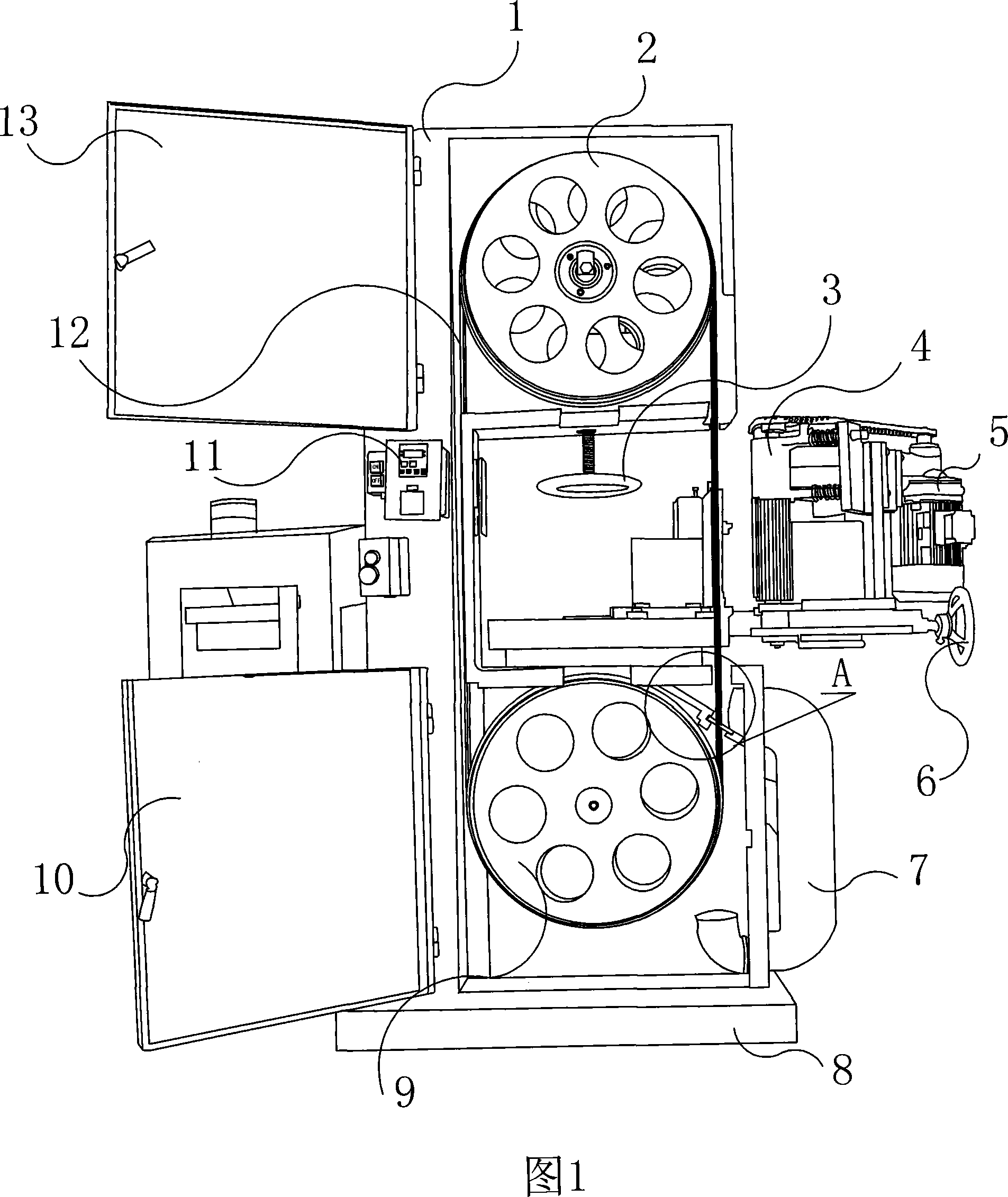

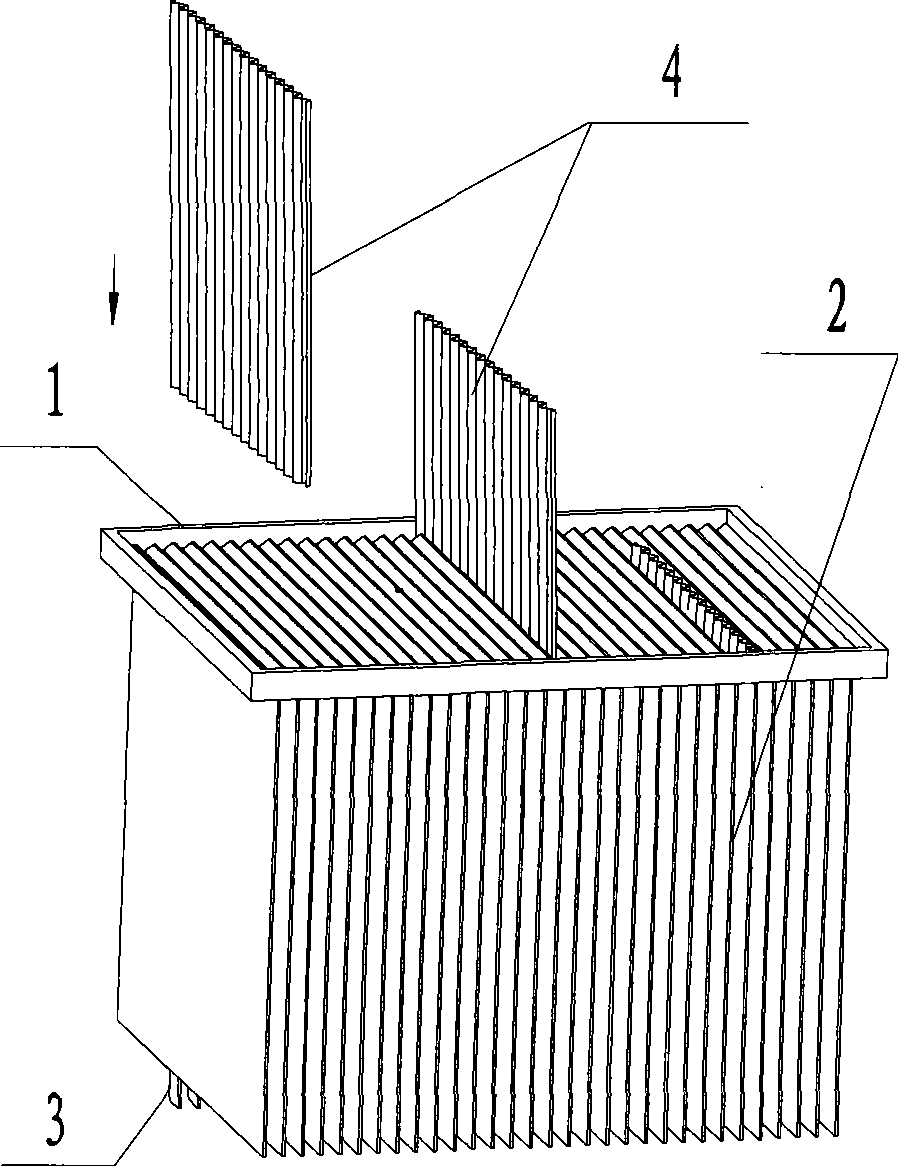

Short tranverse crankshaft connecting rod device of warp knitting machine

The invention discloses a short-stroke crankshaft connecting rod device for a tricot machine. The invention comprises eccentric shafts, a first shaft journal (4), a second shaft journal (5), a central wall plate (7), a grooved needle bed connected with a first eccentric shaft (1), a yarn guide needle bed crankshaft connecting rod mechanism, a stylet bed crankshaft connecting rod mechanism connected with a second eccentric shaft (2), and a sinker bed crankshaft connecting rod mechanism connected with a third eccentric shaft (3). The first shaft journal (4) and the second shaft journal (5) are respectively and fixedly connected with the end parts of the second eccentric shaft (2) and the third eccentric shaft (3). The second eccentric shaft (2), the first eccentric shaft (1) and the third eccentric shaft (3) are connected with each other in turn and are rotated around the first and second shaft journals (4, 5). The short-stroke crankshaft connecting rod device effectively shortens the motion stroke of weaving elements; the grooved needle travel is between 8 and 12 millimeters; the moving time of yarn guide needles is between 1.5 and 1.8 microseconds; the engine speed is improved to be 2500 to 3000 turns per minute; the noise is less than or equal to 85 decibels; the vibration is small; the energy consumption is low; the device is suitable for high-speed rotation; the power is small; and the productivity is obviously improved.

Owner:NEWTRY COMPOSITE

Method for directly preparing propylene from crude methanol

ActiveCN101659592ADistillation purification process omittedReduce energy consumptionHydrocarbon from oxygen organic compoundsEthylene productionMolecular sieveDiluent

Owner:WISON ENG

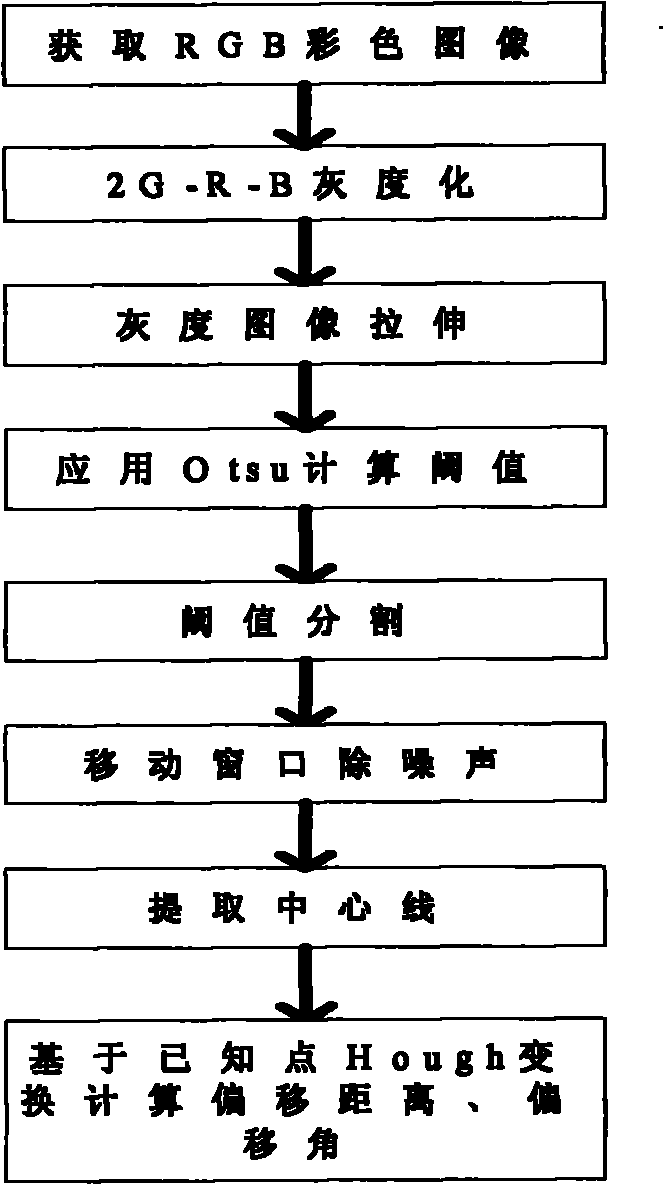

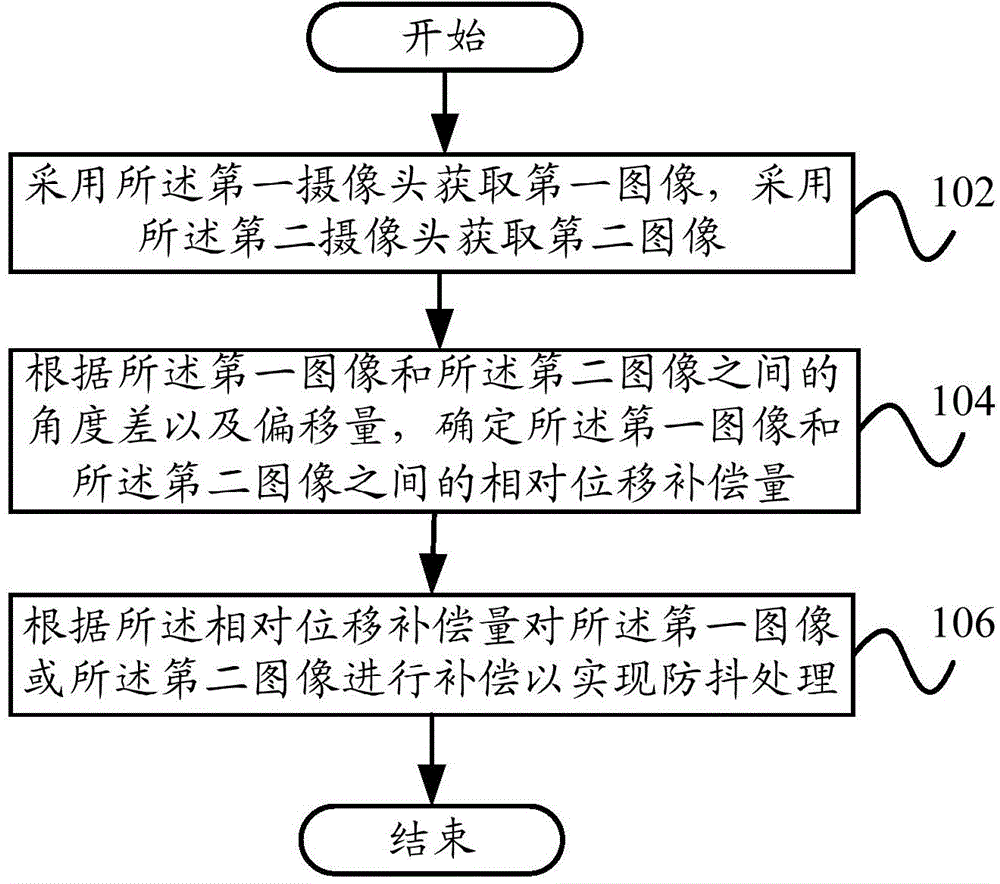

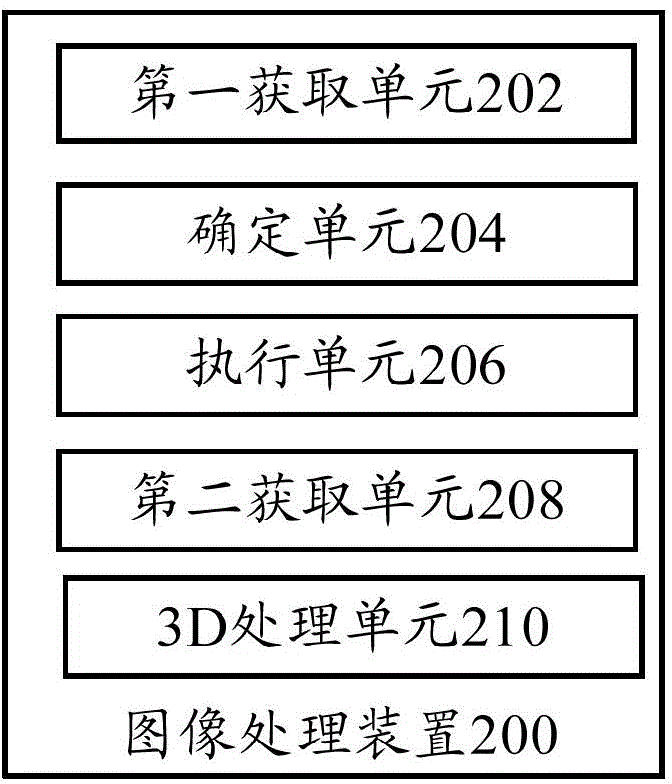

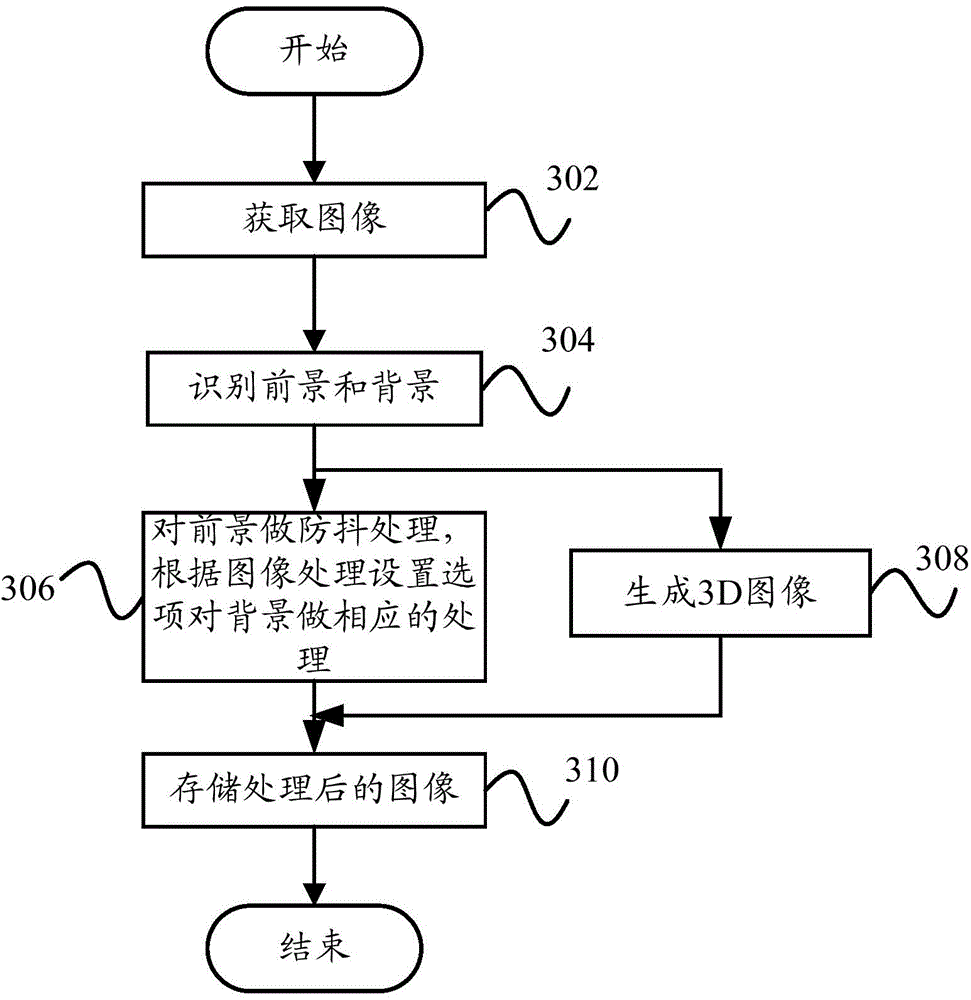

Image processing method and image processing device

InactiveCN104093014AShorten the timeReduce energy consumptionTelevision system detailsColor television detailsRelative displacementImaging processing

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

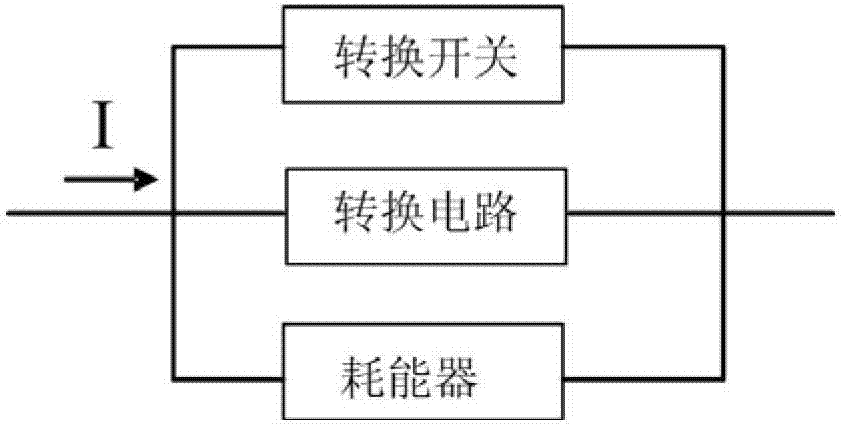

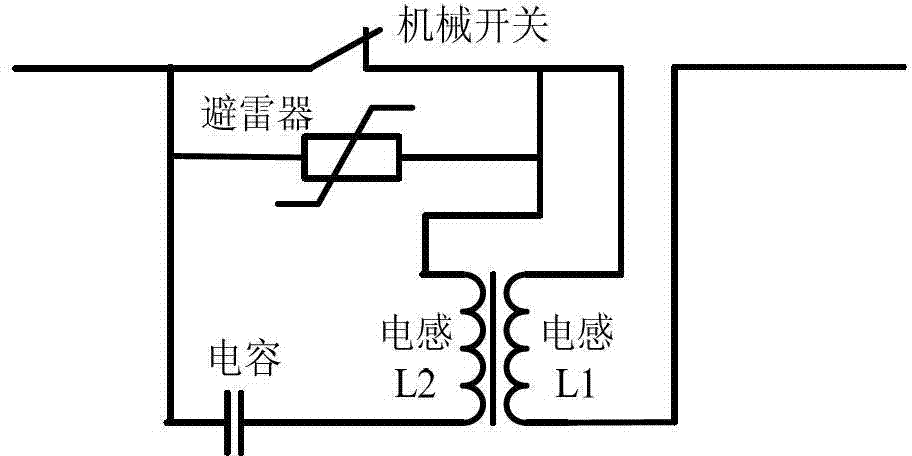

Series coupling inductance high-voltage direct current breaker and control method thereof

ActiveCN103117196ARealize no arc breakingMeet the demand for fast cut-off fault currentProtective switch terminals/connectionsProtective switch operating/release mechanismsDc circuit breakerCoupling

Owner:CHINA EPRI ELECTRIC POWER ENG CO LTD +1

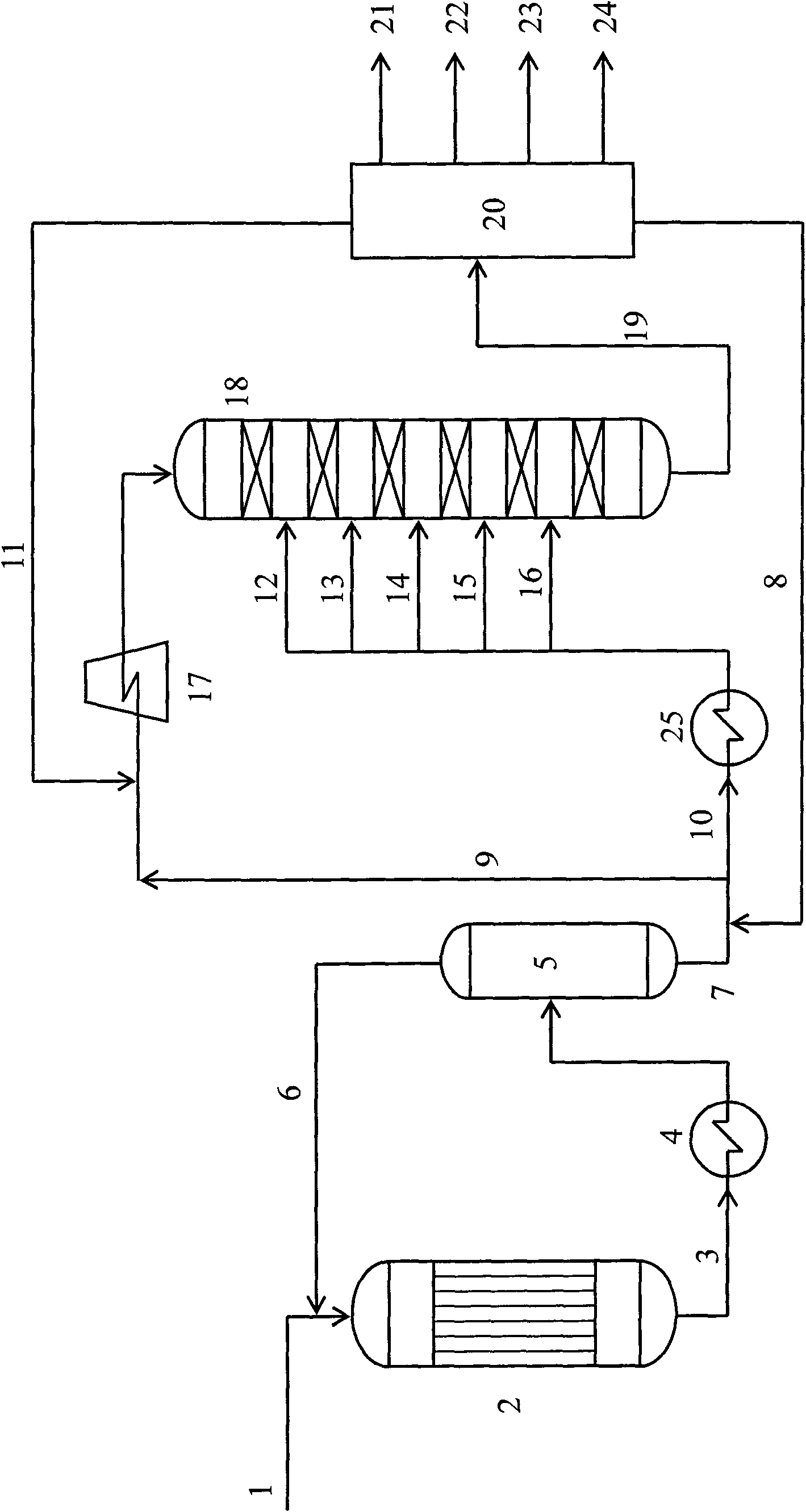

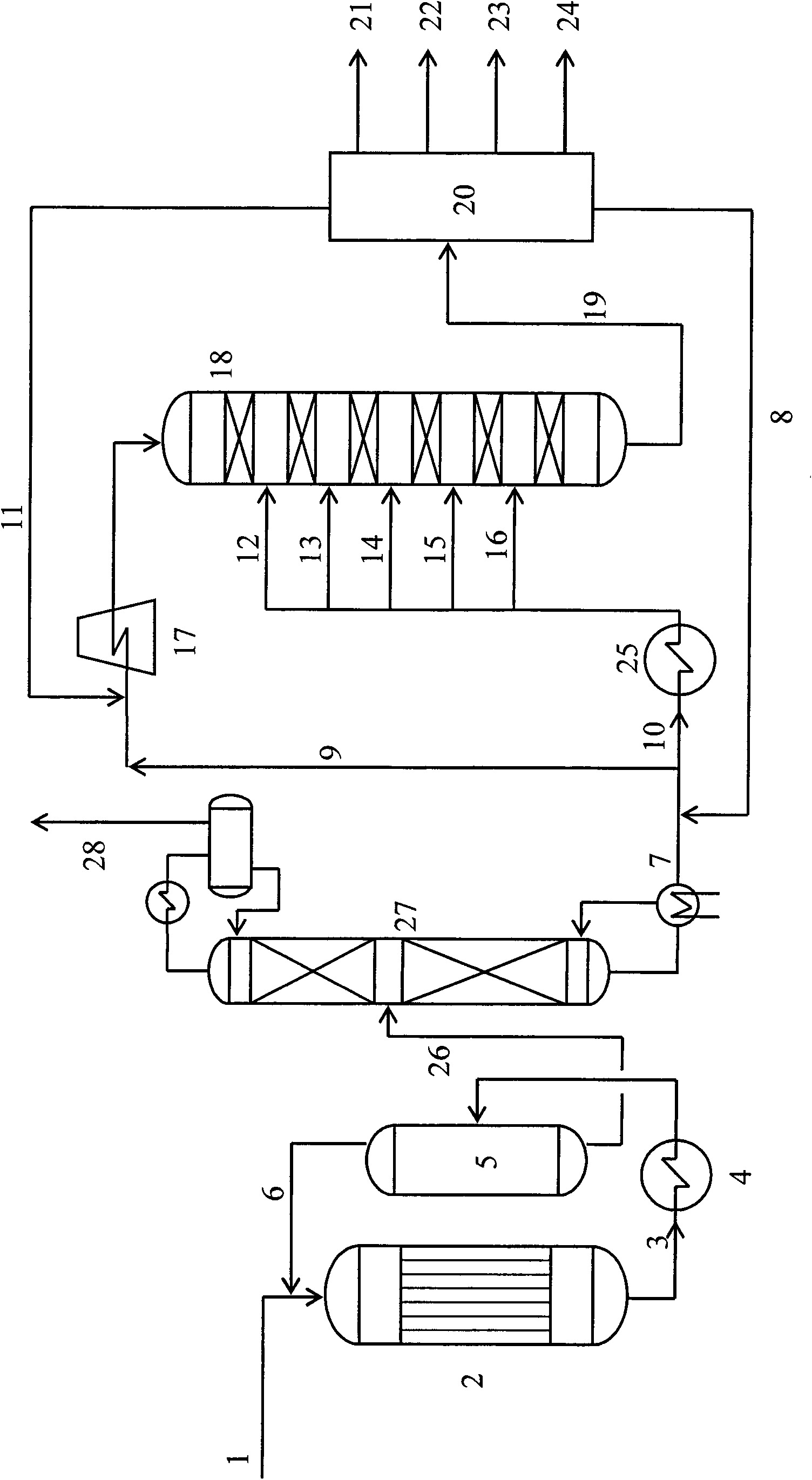

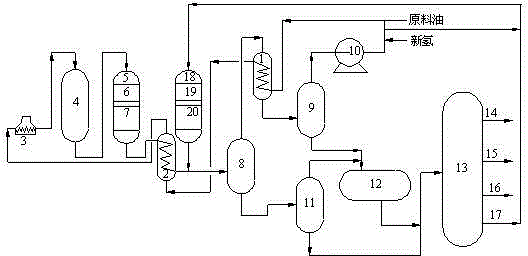

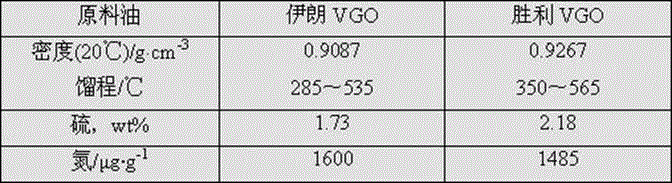

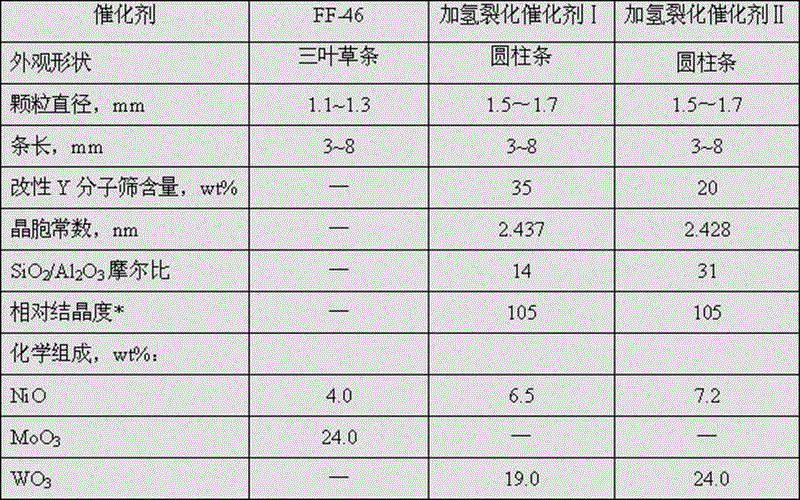

Hydrocracking method of low-energy-consumption, productive and high-quality jet fuel

ActiveCN105018137AReduce engineering investmentReduce operating energy consumptionTreatment with plural serial stages onlyMolecular sieveHydrogen

Owner:CHINA PETROLEUM & CHEM CORP +1

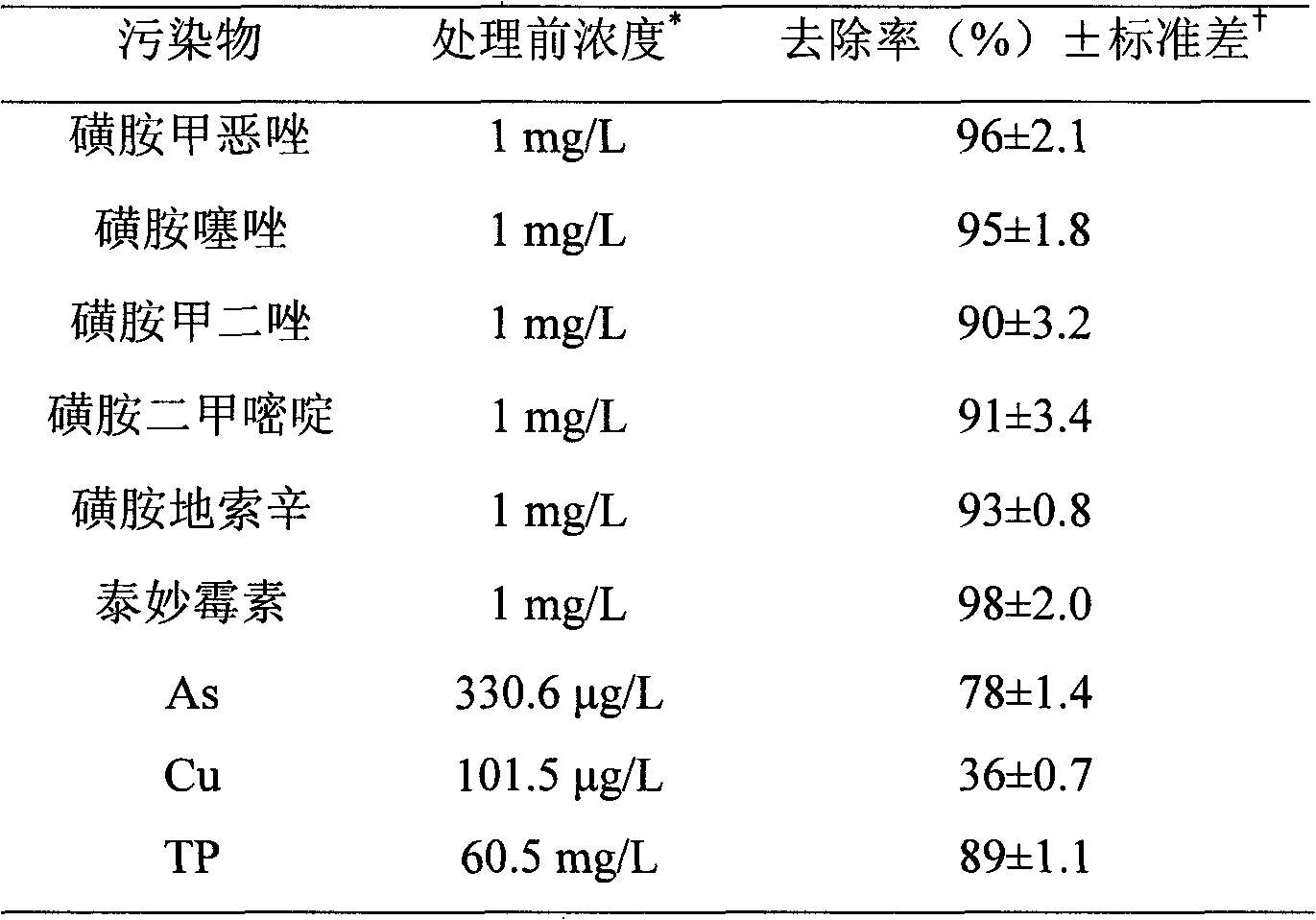

Scale advanced treatment method for livestock and poultry farming waste water

InactiveCN101805093ACost-effective advanced processing methodGuaranteed uptimeWaste water treatment from animal husbandryMultistage water/sewage treatmentPerturbateurs endocriniensTreatment effect

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

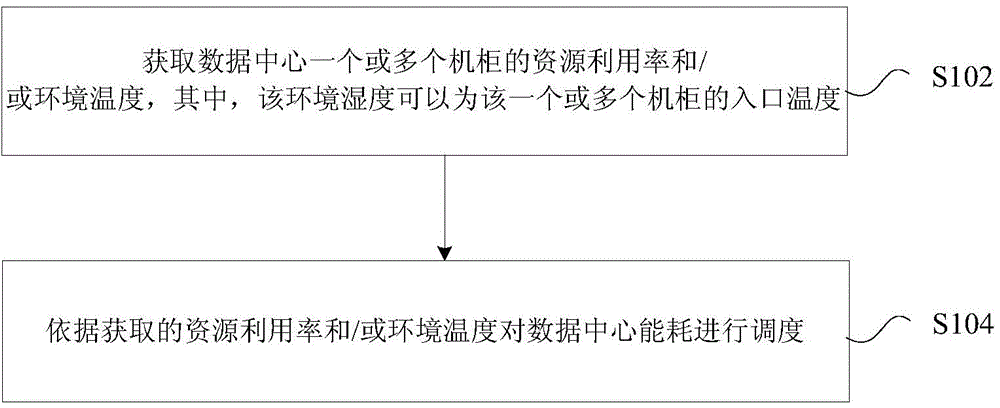

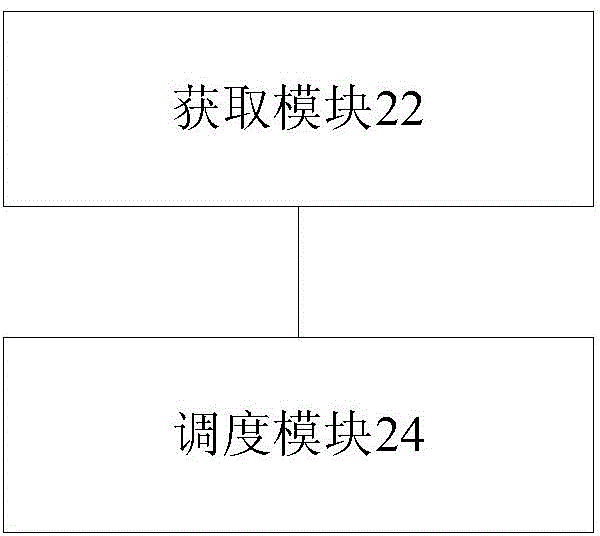

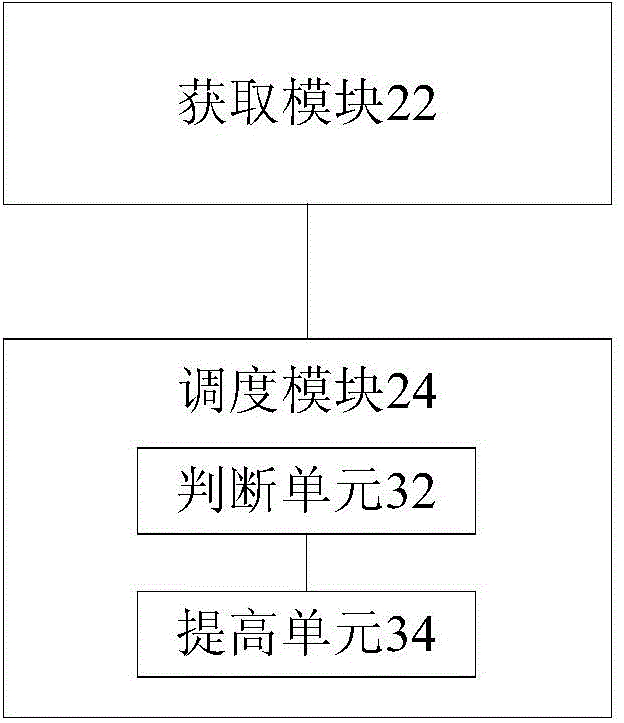

Data center energy consumption scheduling method and data center energy consumption scheduling device

InactiveCN104423531ASolve the problem of low energy utilization efficiencyReduce energy consumptionResource allocationPower supply for data processingReduction treatmentResource utilization

Owner:ZTE CORP

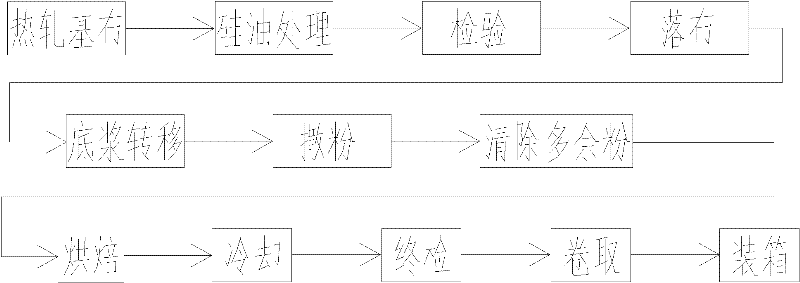

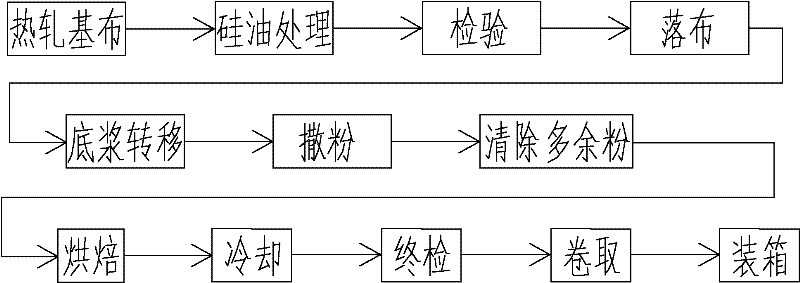

Production process of double-point non-woven fusible interlining

InactiveCN102389174AConsider softnessTaking into account the costPolyureas/polyurethane adhesivesFibre typesInterliningPolyester

Owner:温州鸿马科技有限公司

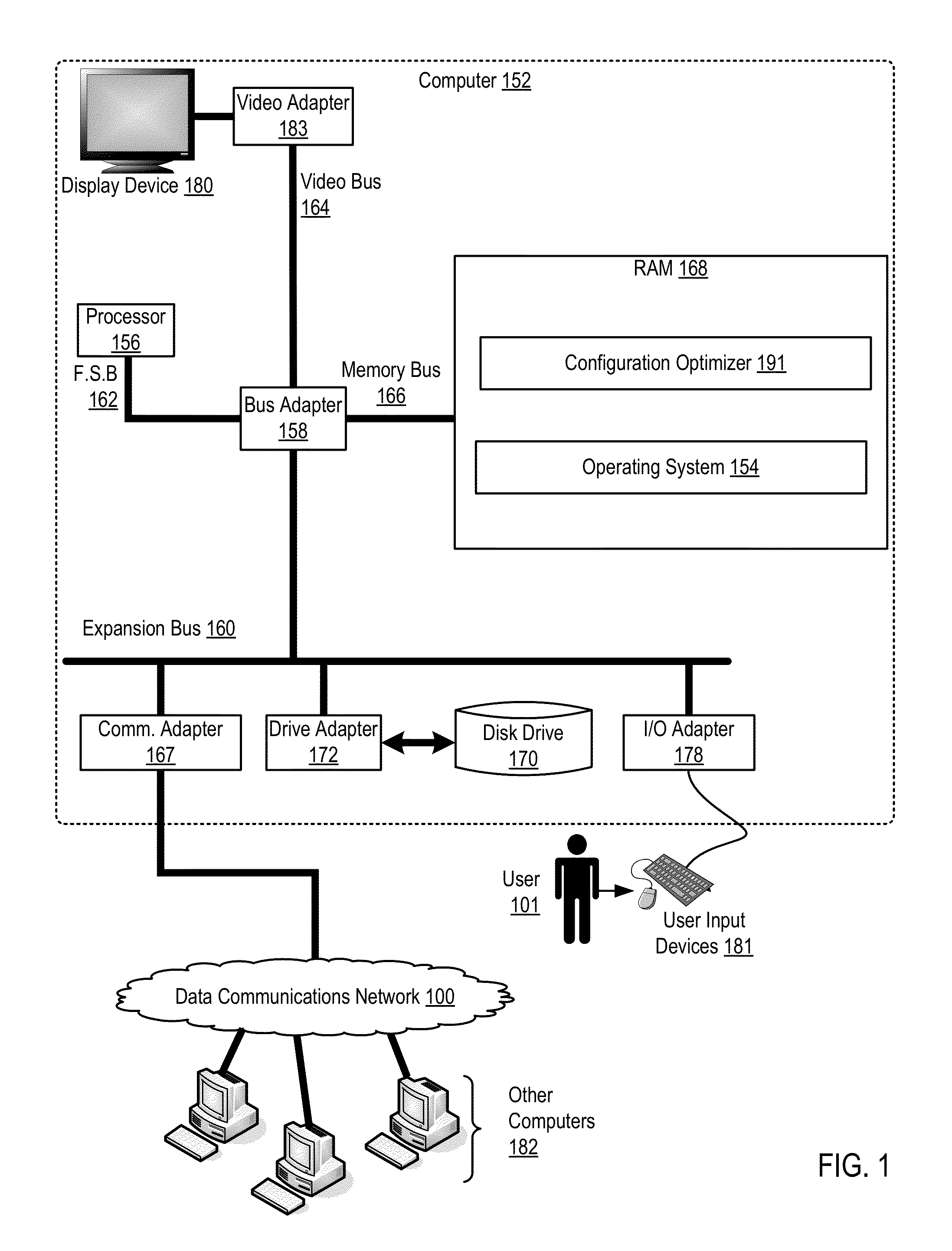

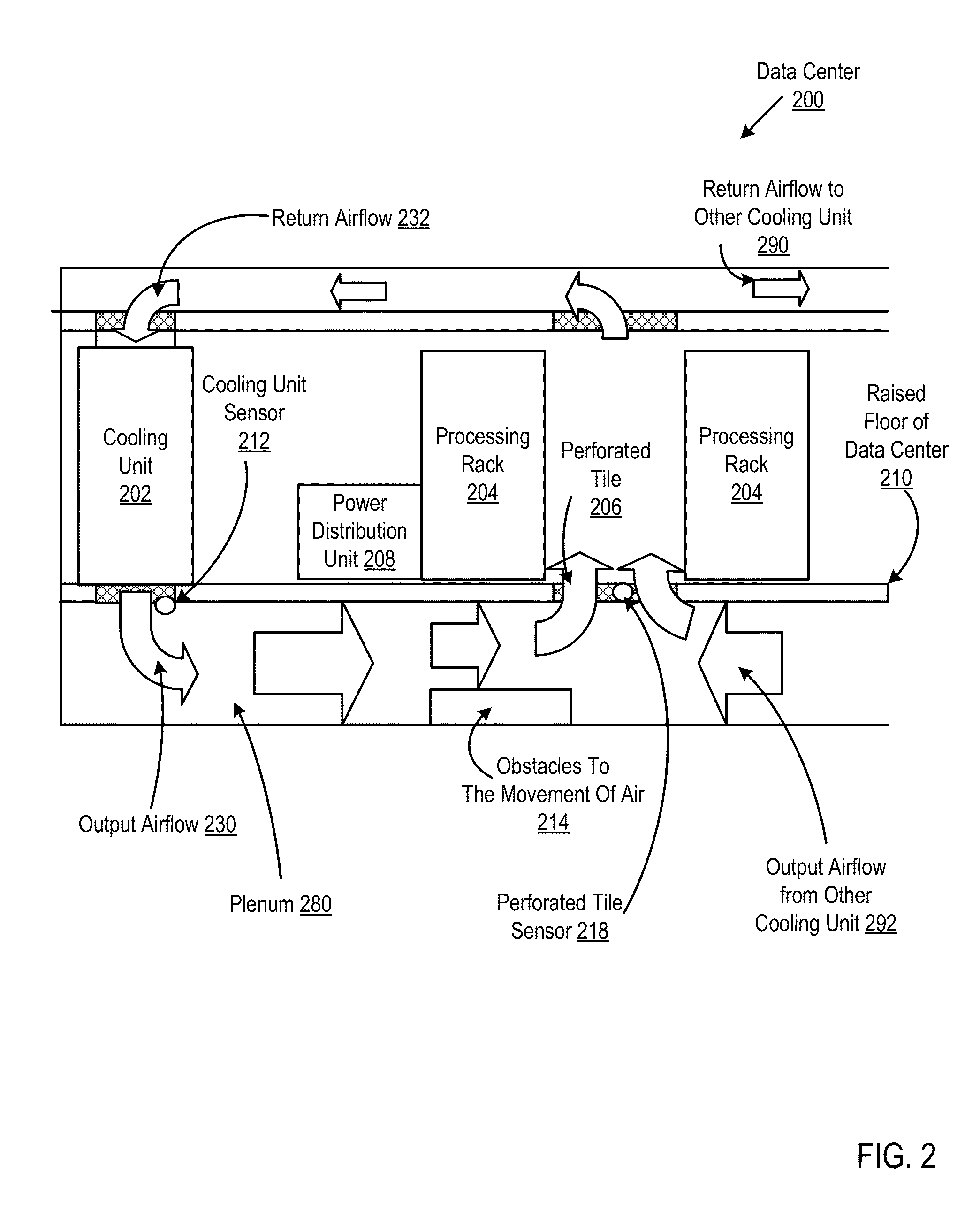

Provisioning aggregate computational workloads and air conditioning unit configurations to optimize utility of air conditioning units and processing resources within a data center

InactiveUS20130103218A1Improve overall utilizationConsume least amount of energyMechanical power/torque controlProgramme controlData centerParallel computing

Owner:IBM CORP

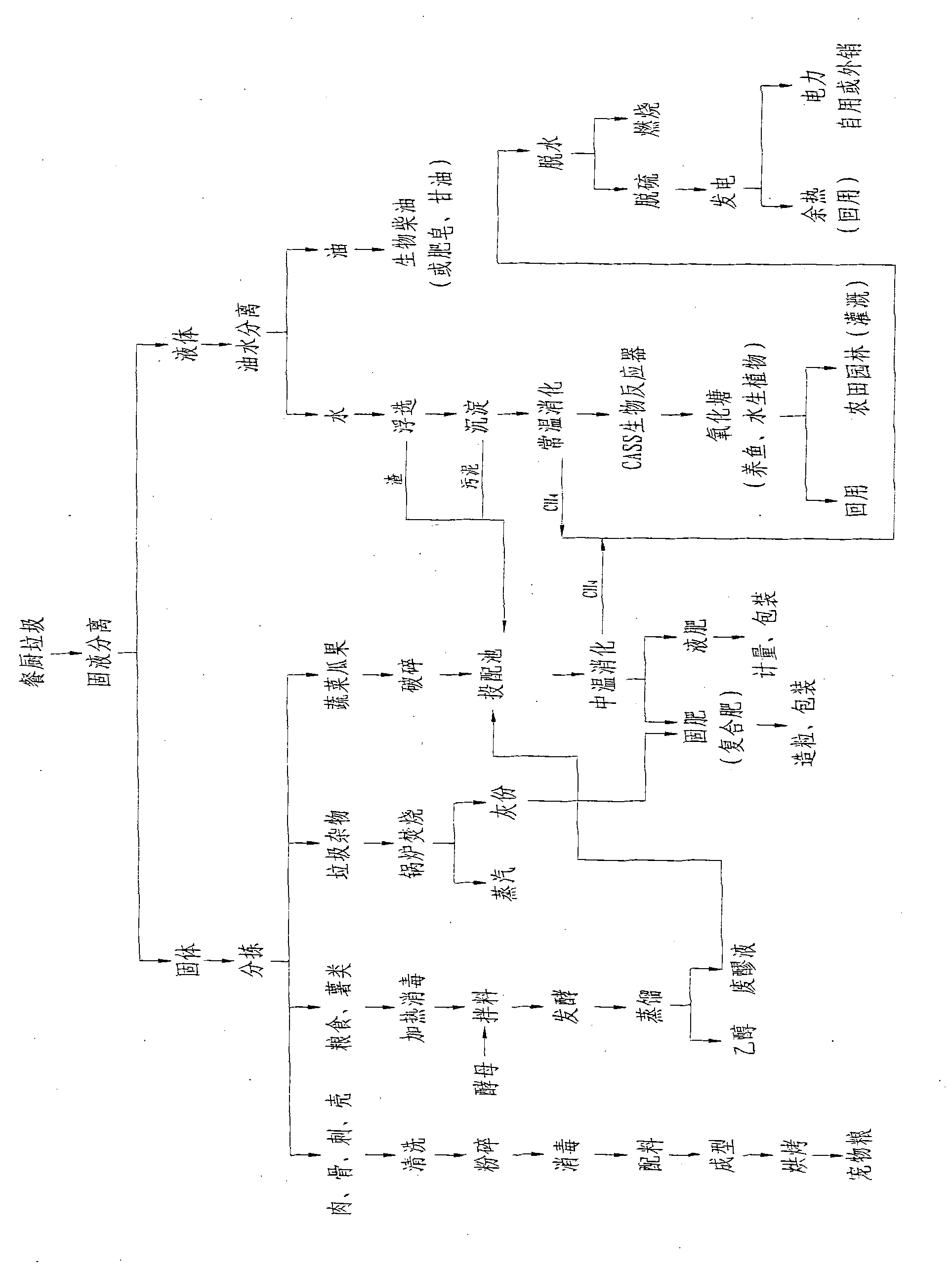

Processing method of changing food waste into resources

InactiveCN101850349AIncrease valueEmission reductionFatty oils/acids recovery from wasteBio-organic fraction processingWater useBiodiesel

Owner:云南天兰环保科技开发有限公司 +1

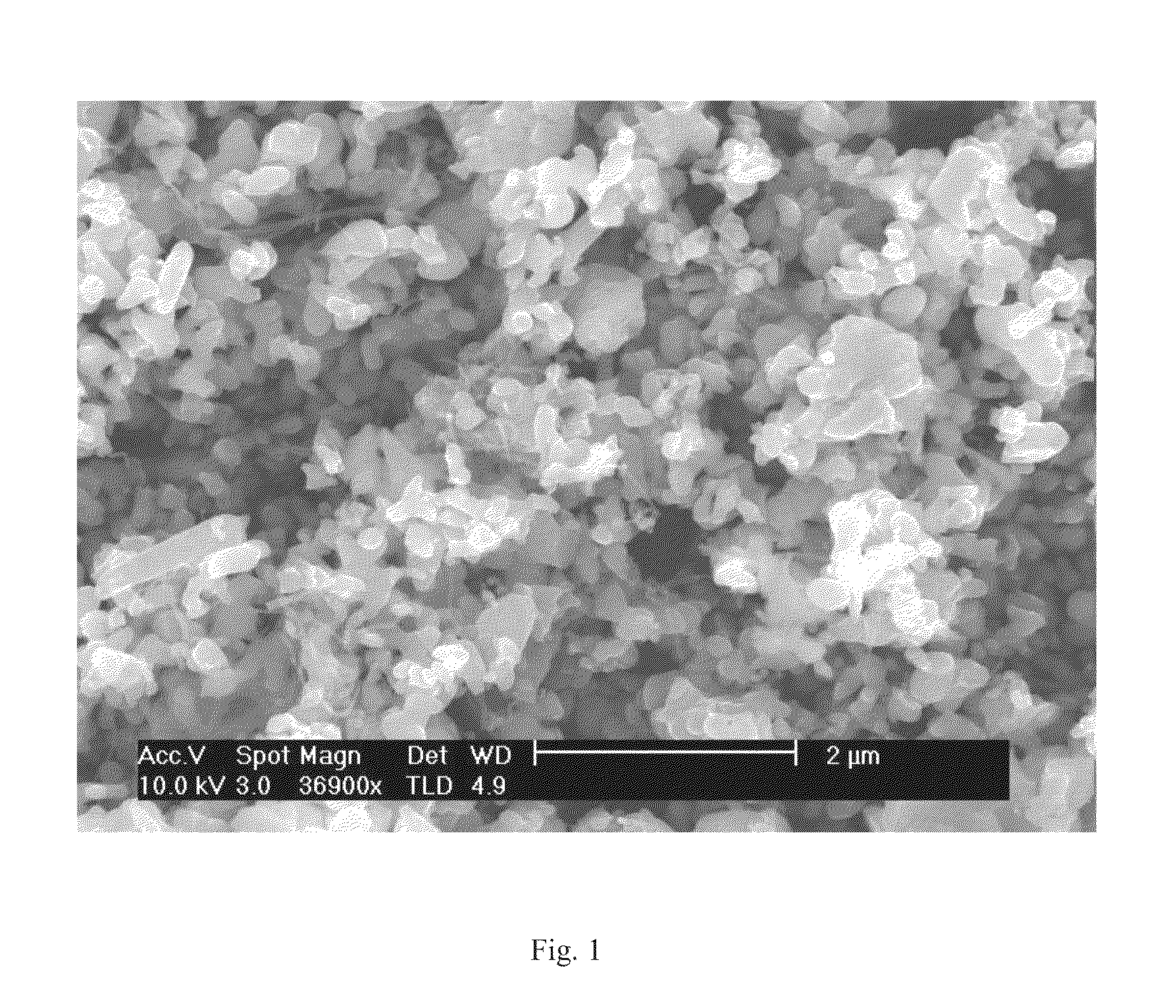

Auto-thermal evaporative liquid-phase synthesis method for cathode material for battery

InactiveUS20140239235A1Simple processReduce energy consumptionNon-metal conductorsPhosphatesInternal resistanceSynthesis methods

Owner:SHENZHEN DYNANONIC

Ultrahigh-toughness concrete and a preparing method thereof

Owner:INNER MONGOLIA UNIV OF SCI & TECH +1

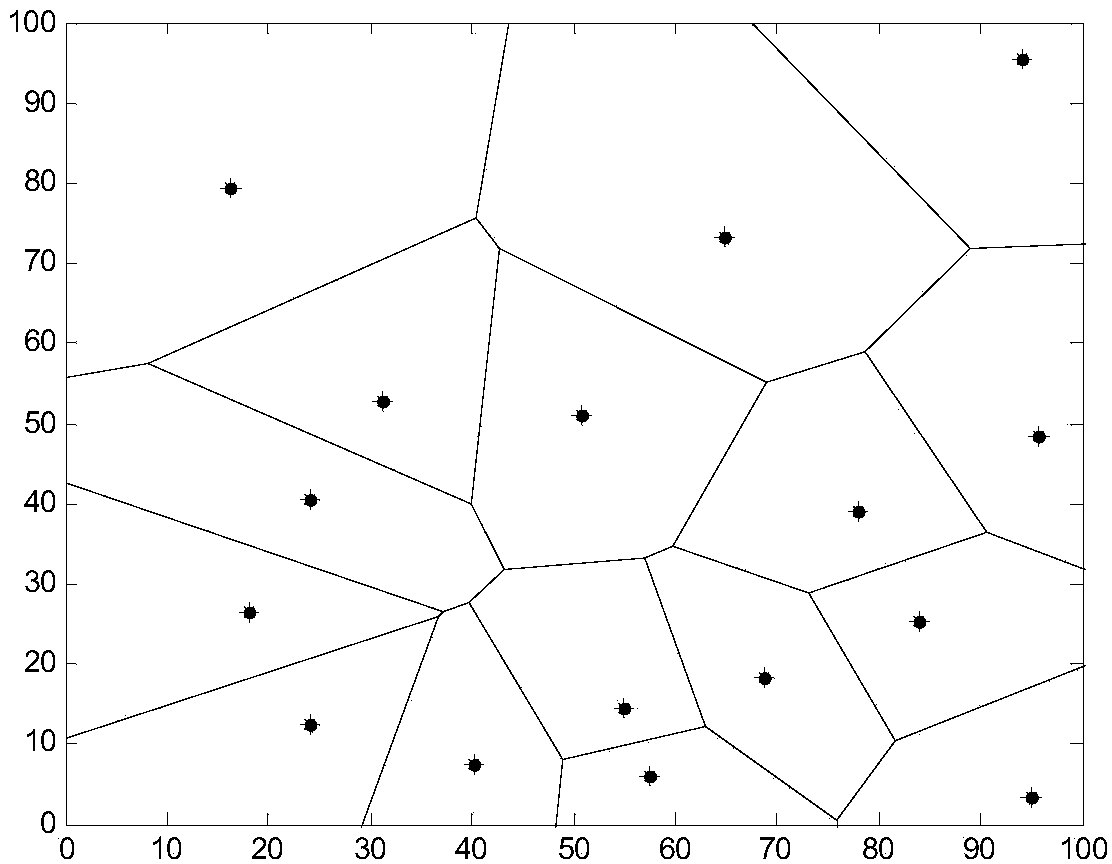

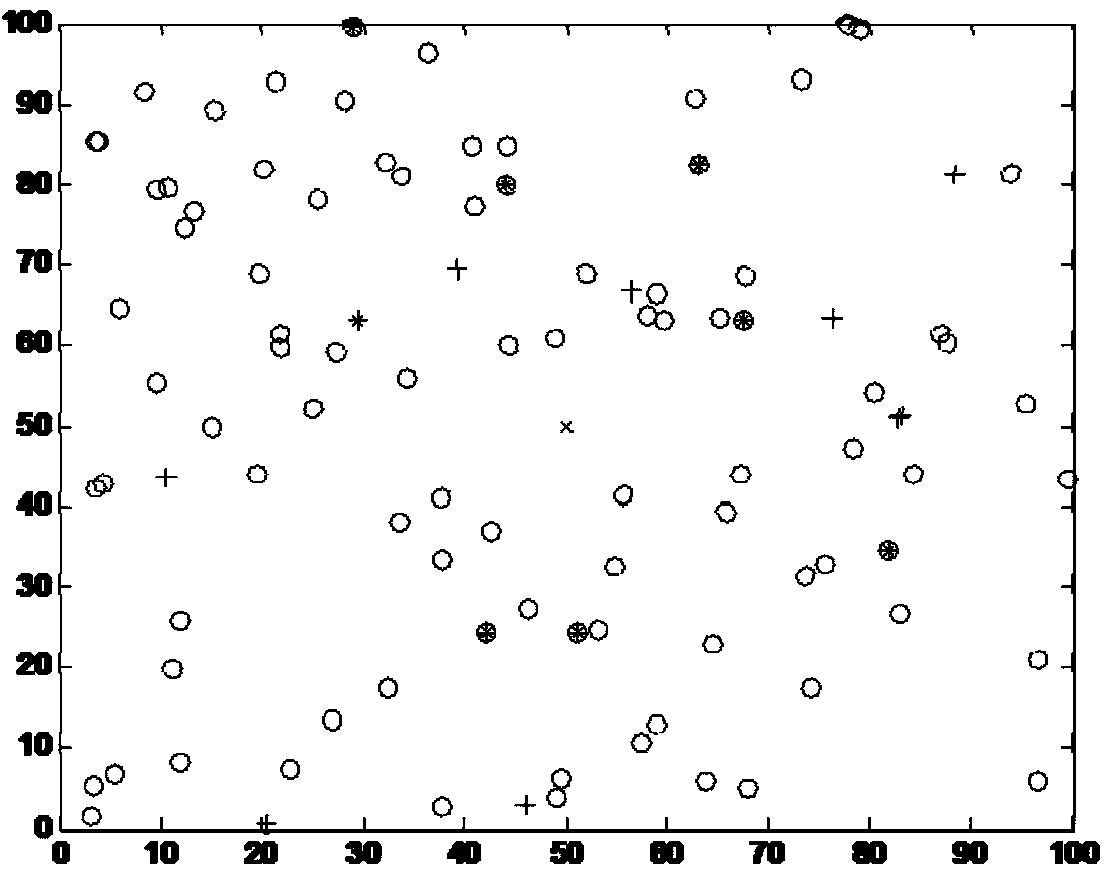

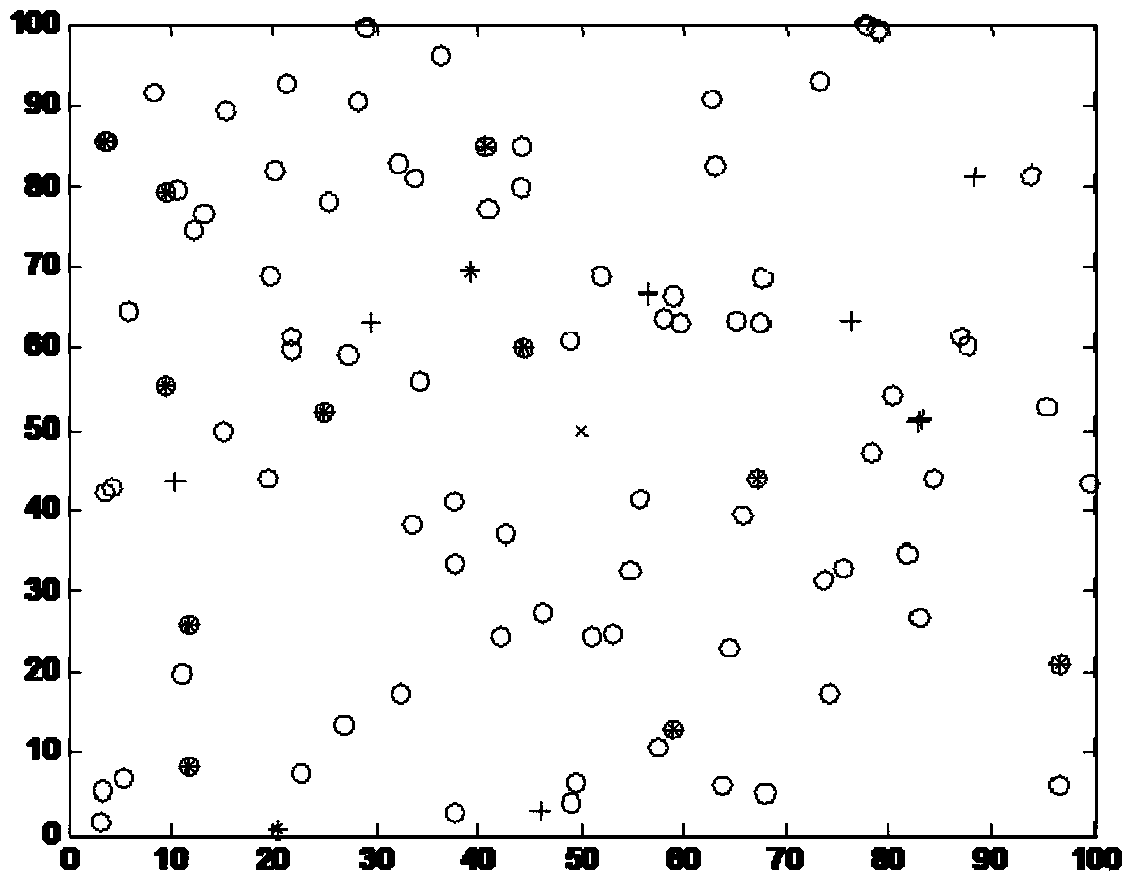

Wireless medical sensor network dynamic clustering method

InactiveCN103634870AAddresses the lack of a dedicated clustering protocolNetwork topologiesHigh level techniquesThree stageSensor node

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

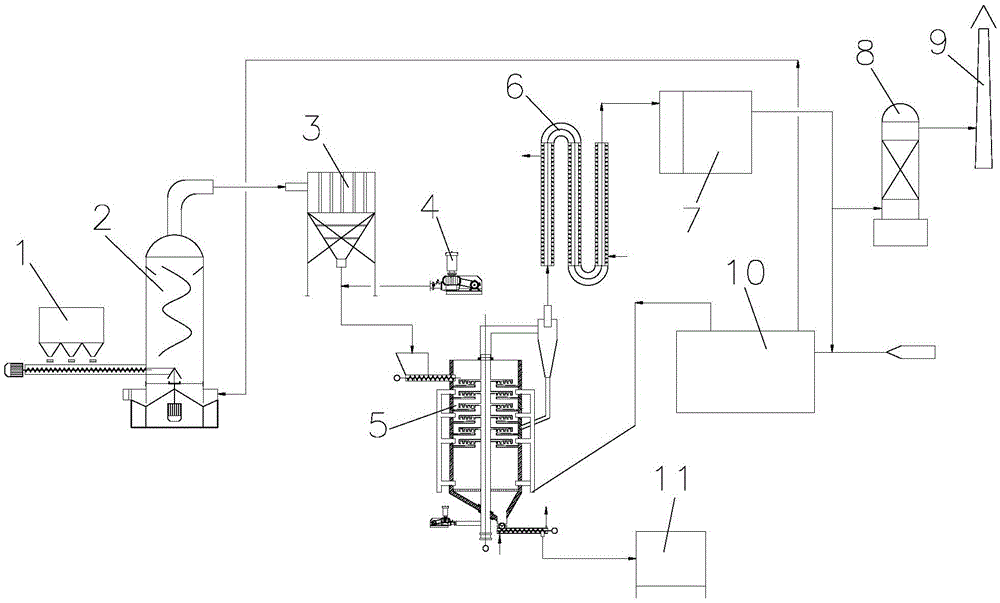

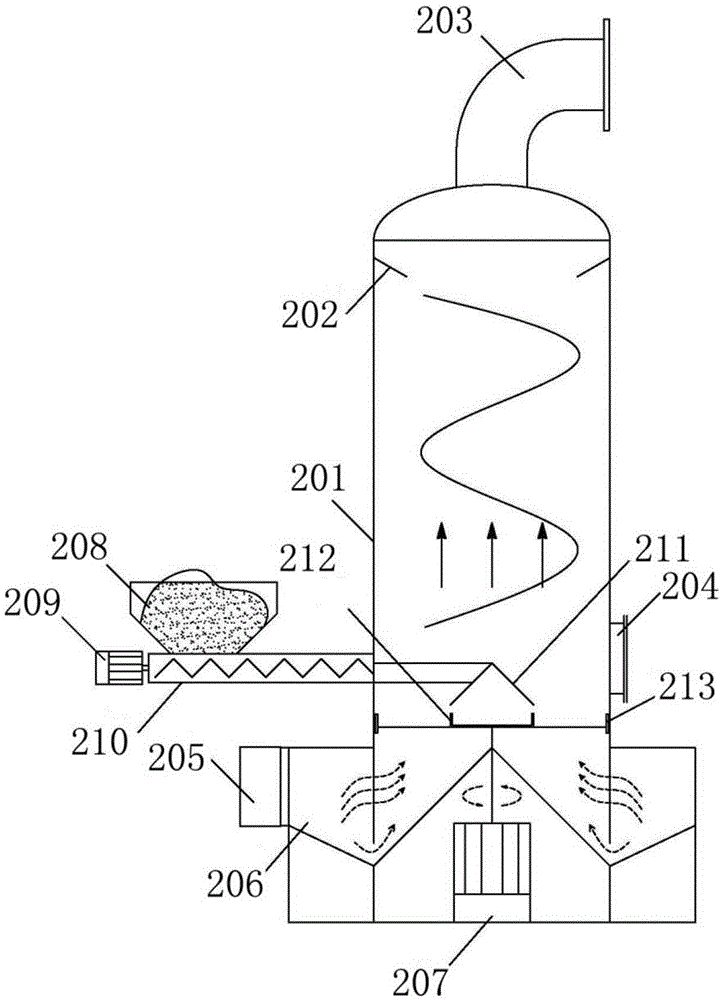

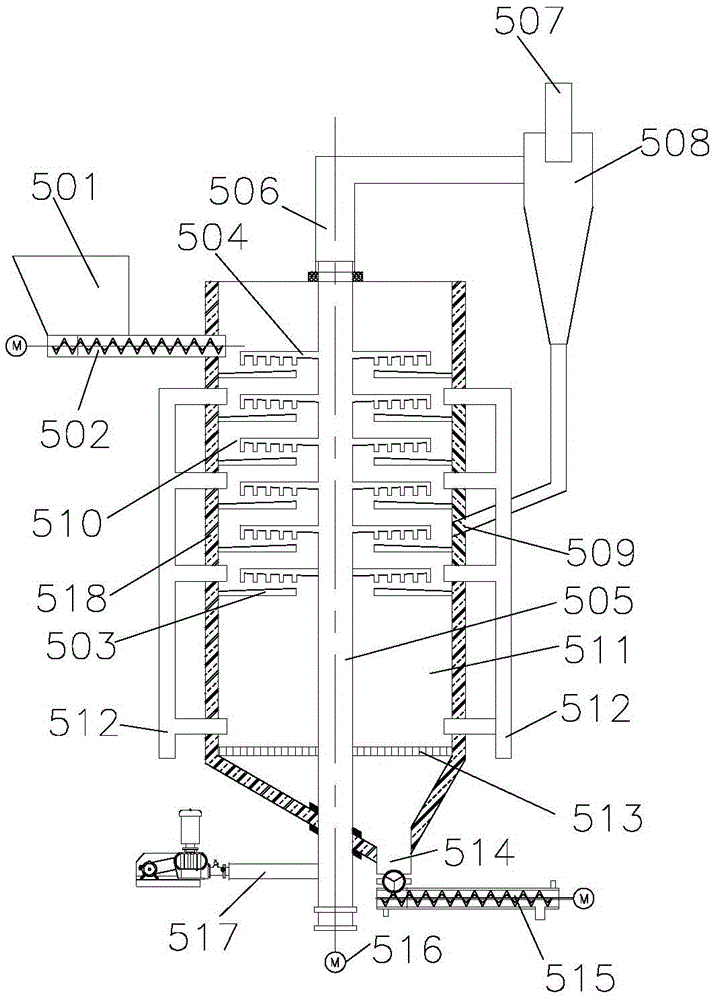

System for urban sludge flue gas drying middle-temperature pyrolysis carbonization

InactiveCN105602586AAvoid cokingAvoid blockingSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesEnergy gradientSludge

Owner:HUBEI JIADE TECH

Titanium-carbide-based steel-bonded cemented carbide material and preparation method thereof

Owner:WUXI XINQUN NEW MATERIAL TECH CO LTD

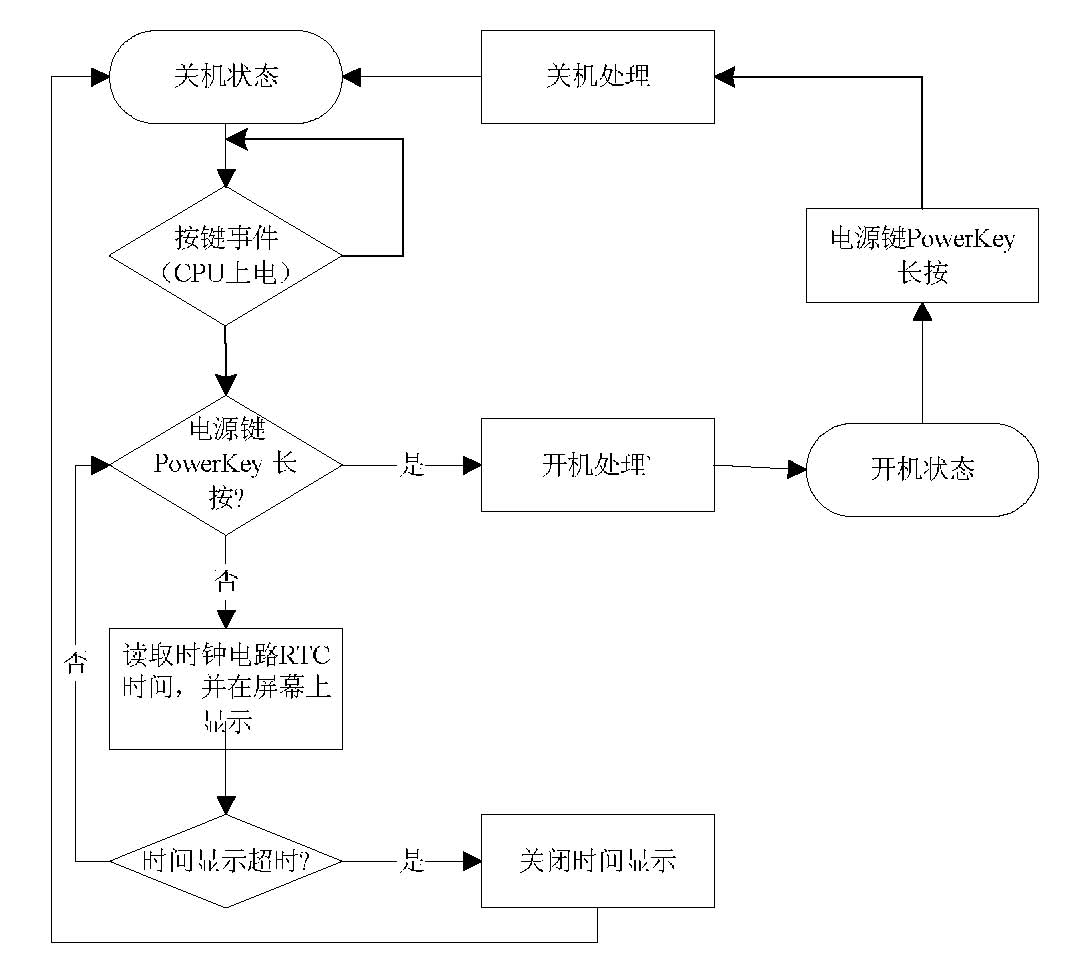

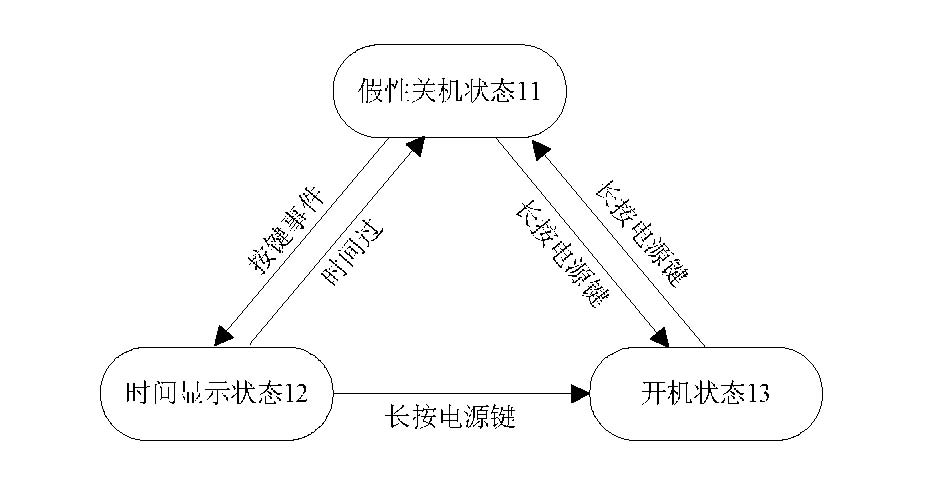

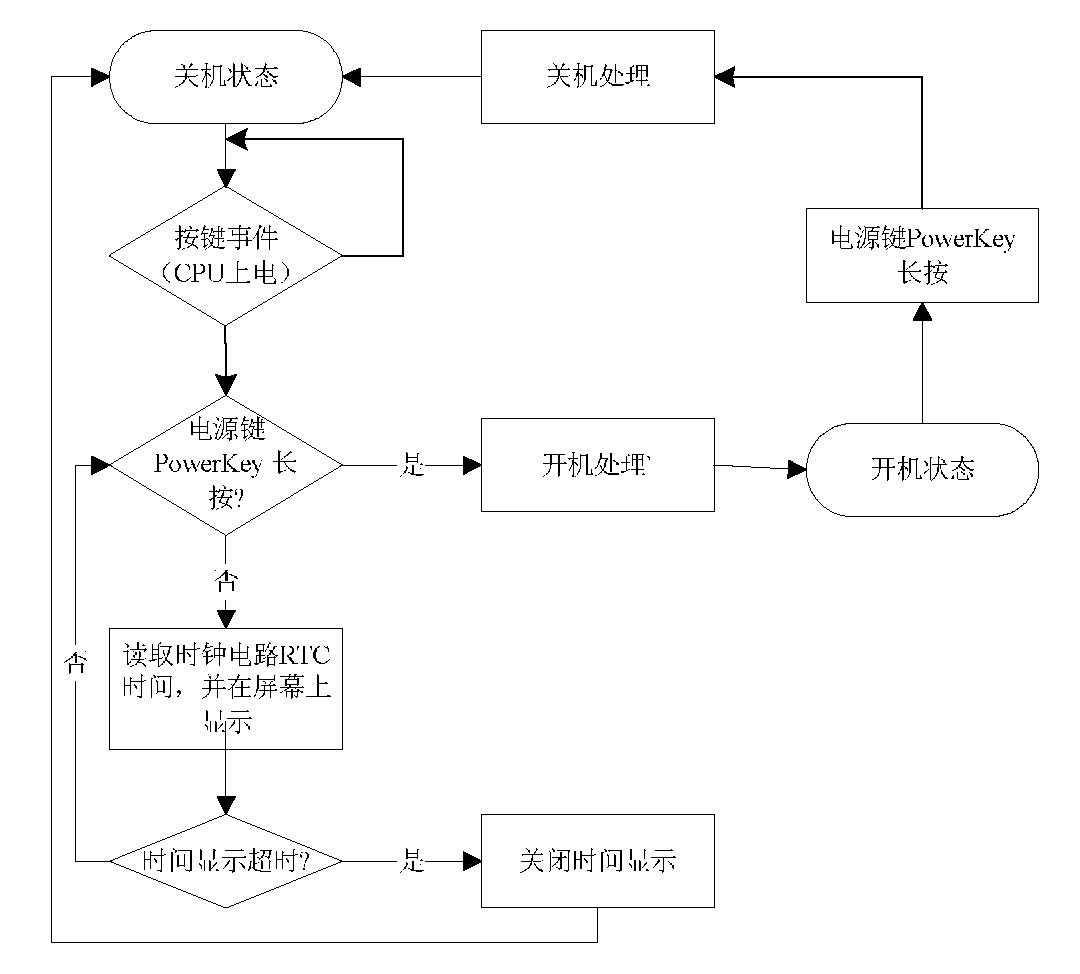

Method for displaying time of handheld mobile terminal

InactiveCN101937342AReduce energy consumptionConvenient lifeSubstation equipmentSpecific program execution arrangementsElectricityComputer terminal

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

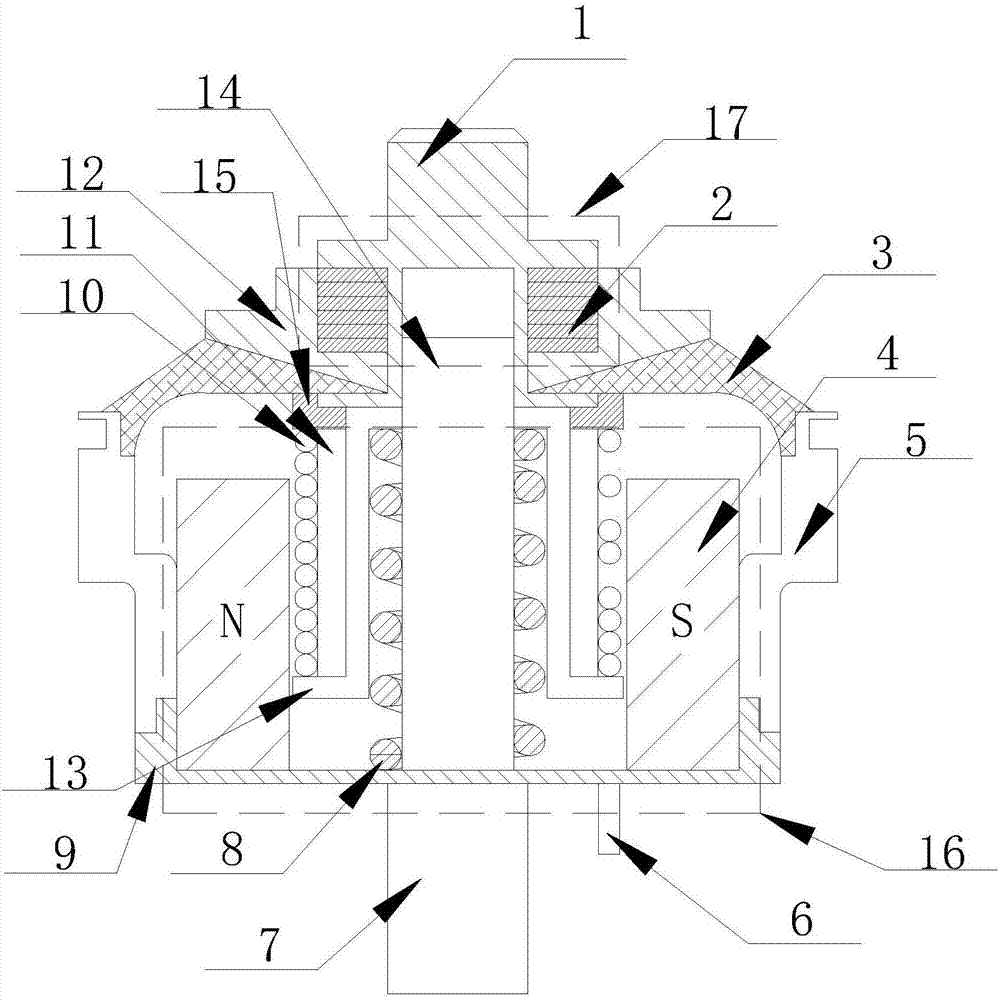

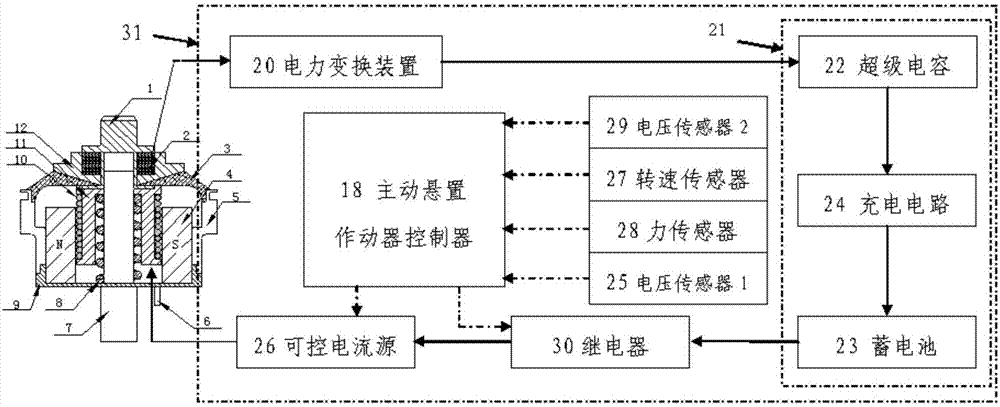

Automotive active engine mount capable of energy regeneration and transmitting force perception and control method thereof

ActiveCN107972466AActive suspension structure is simple and compactInnovative designBatteries circuit arrangementsPiezoelectric/electrostriction/magnetostriction machinesVehicle frameMetal framework

Owner:JIANGSU LUOSHI DAMPING MEMBER CO LTD

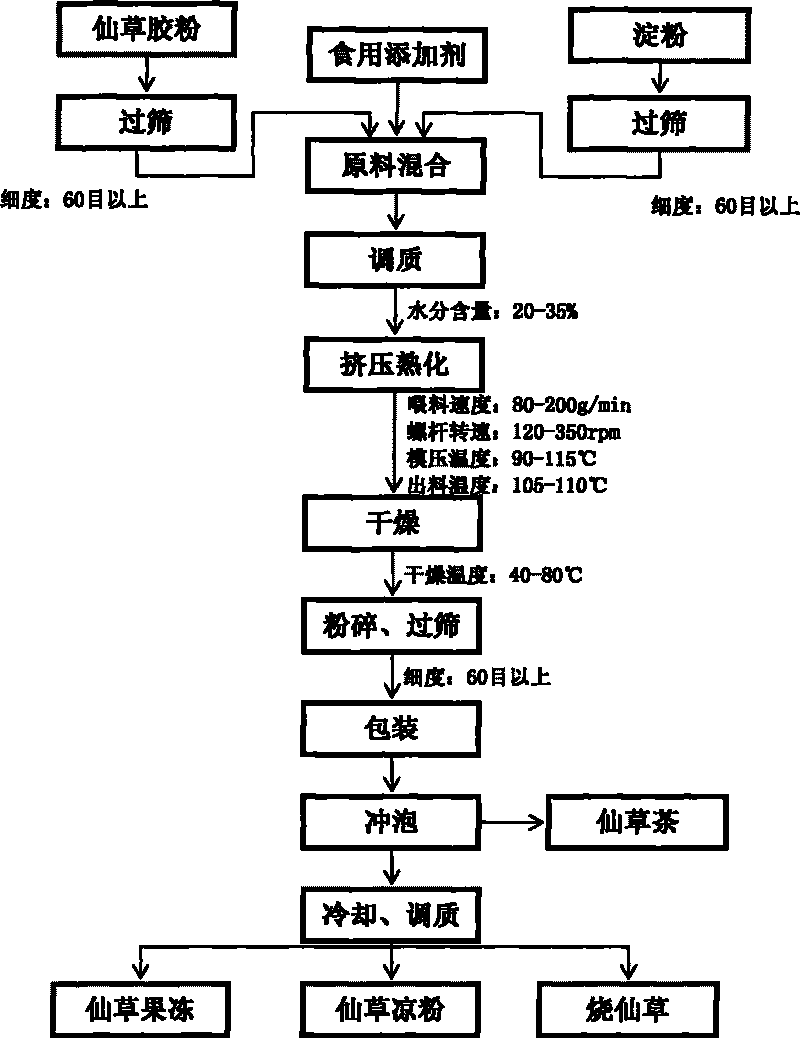

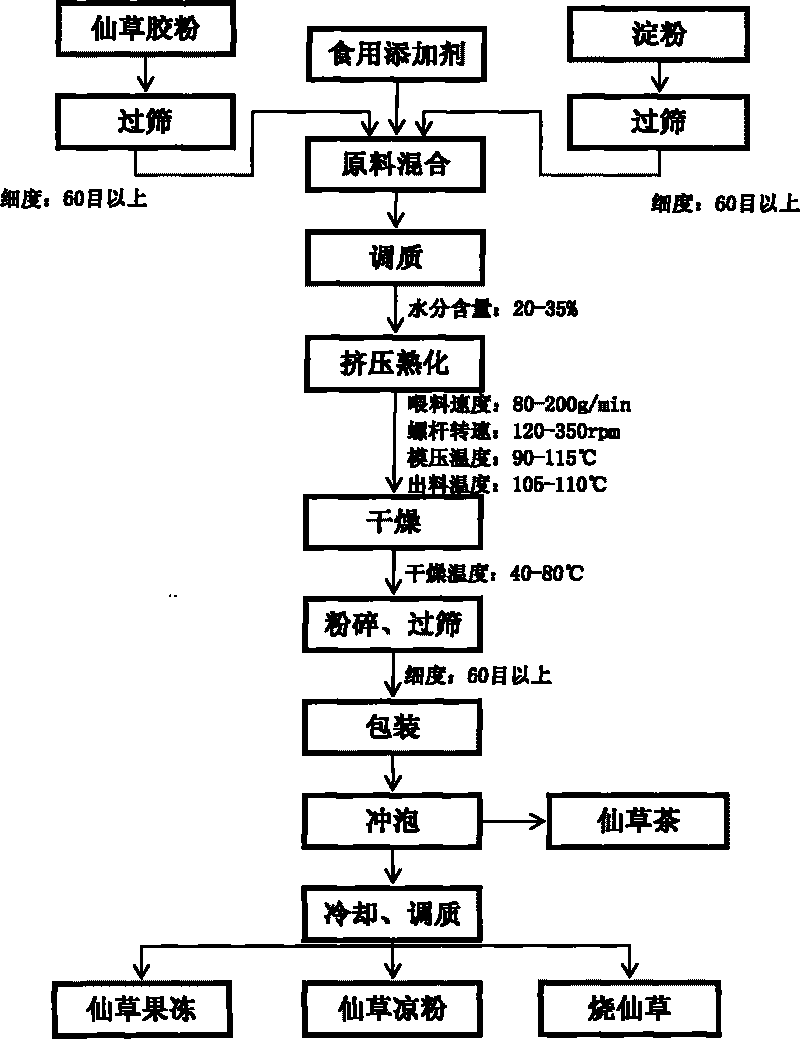

Fast Mesona powder and preparation method and application thereof

Owner:SHANGHAI INSTITUTE OF TECHNOLOGY

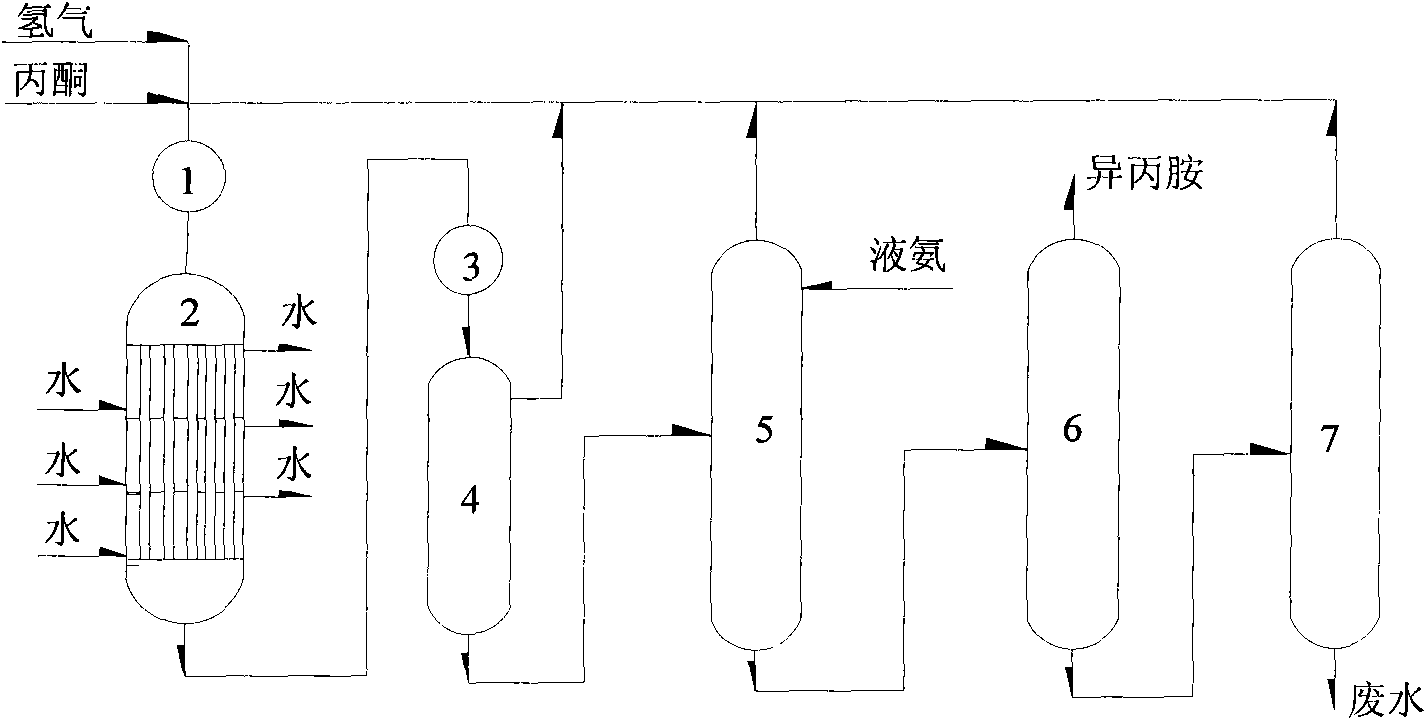

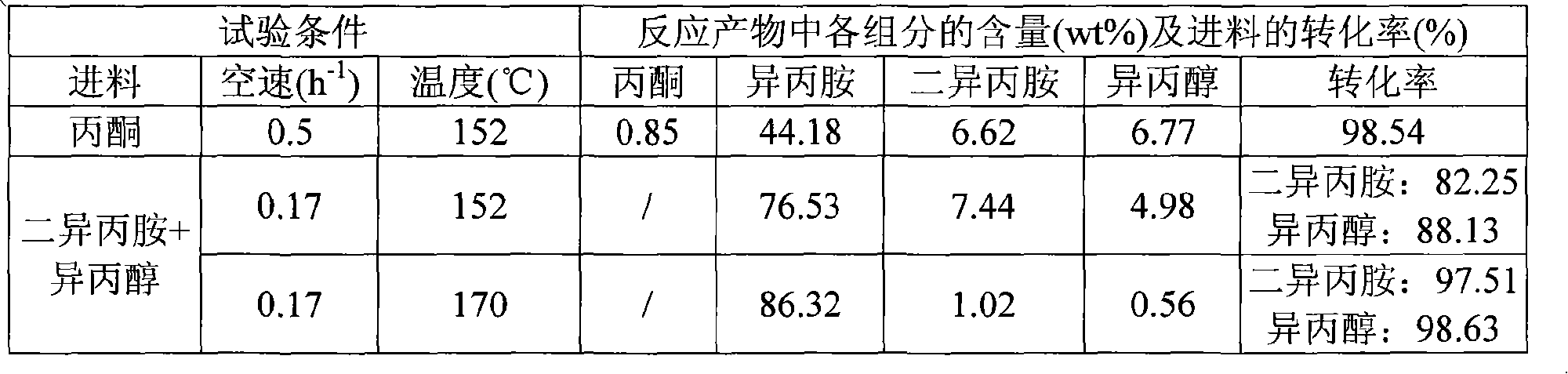

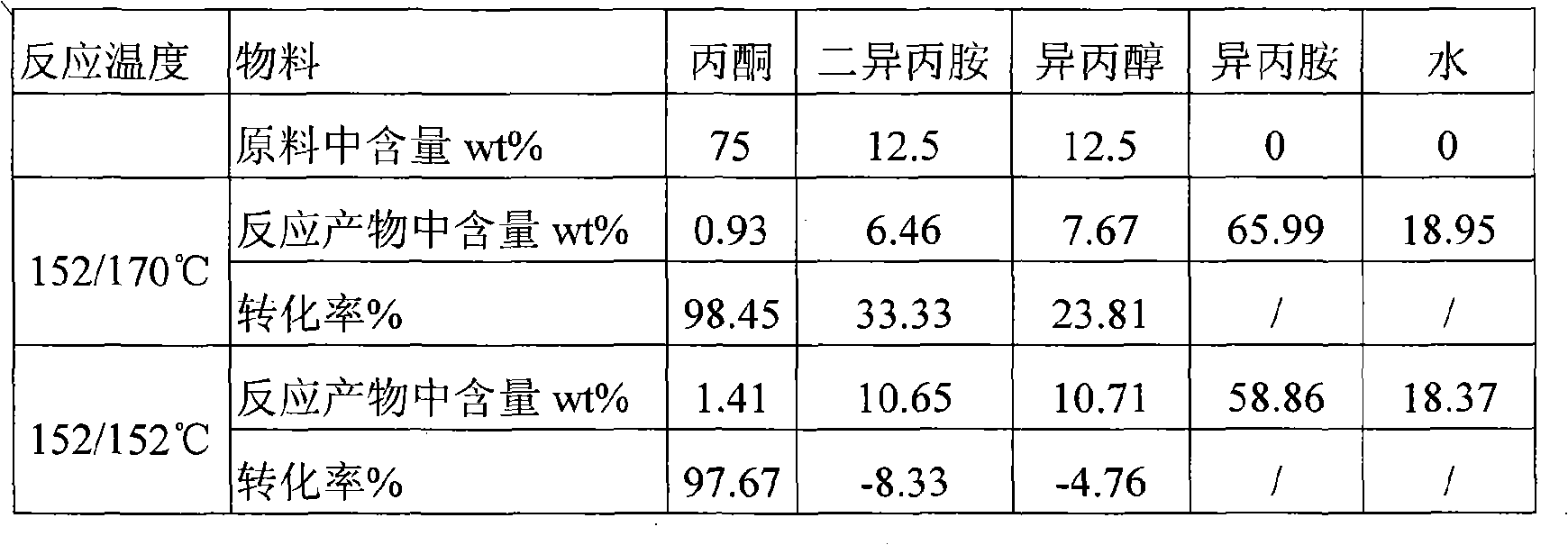

Method for producing isopropylamine

ActiveCN101684073AReduce heatReduce energy costsAmino compound purification/separationPreparation by reductive alkylationReaction temperatureEconomic benefits

Owner:CHINA PETROLEUM & CHEM CORP +1

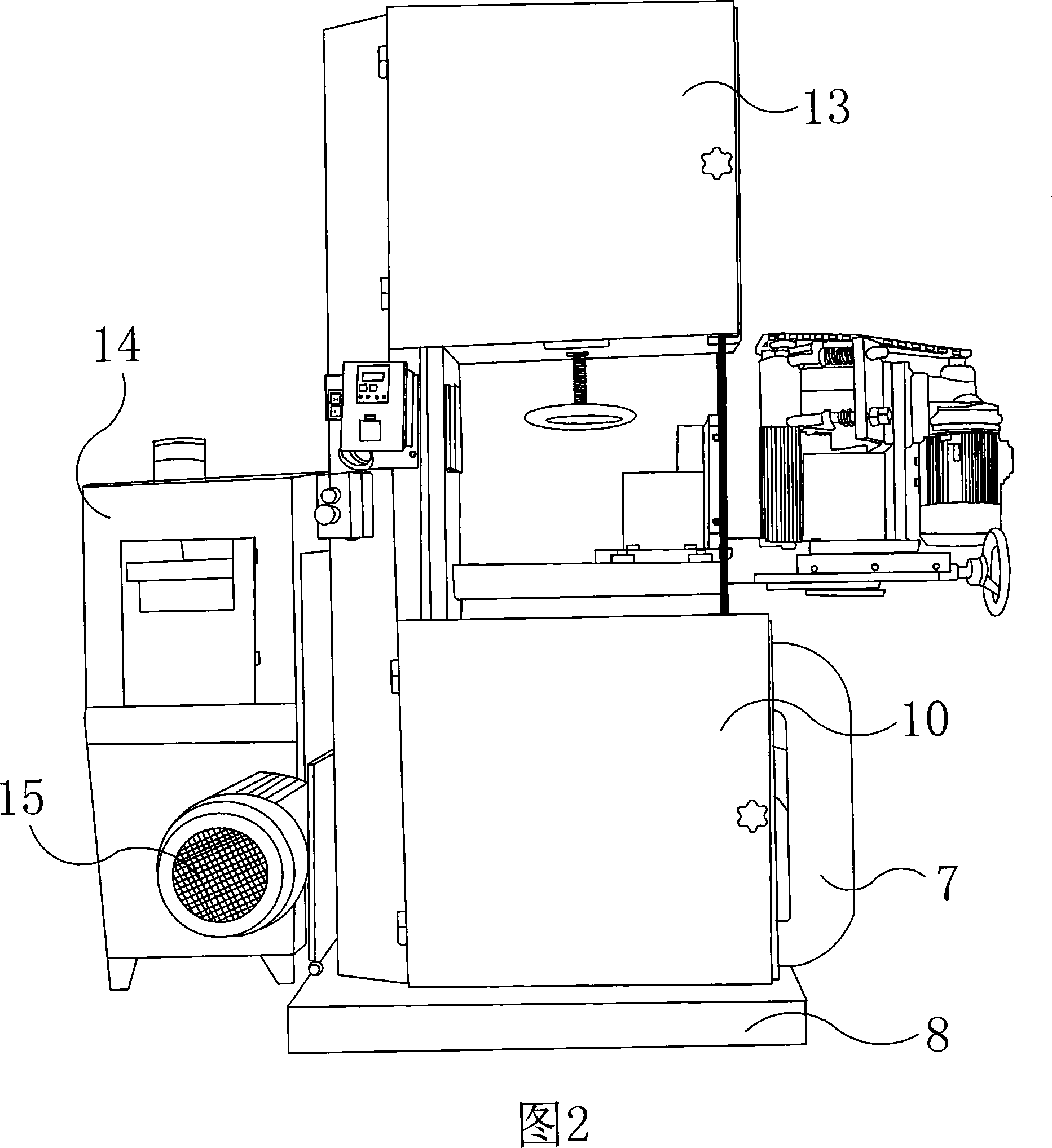

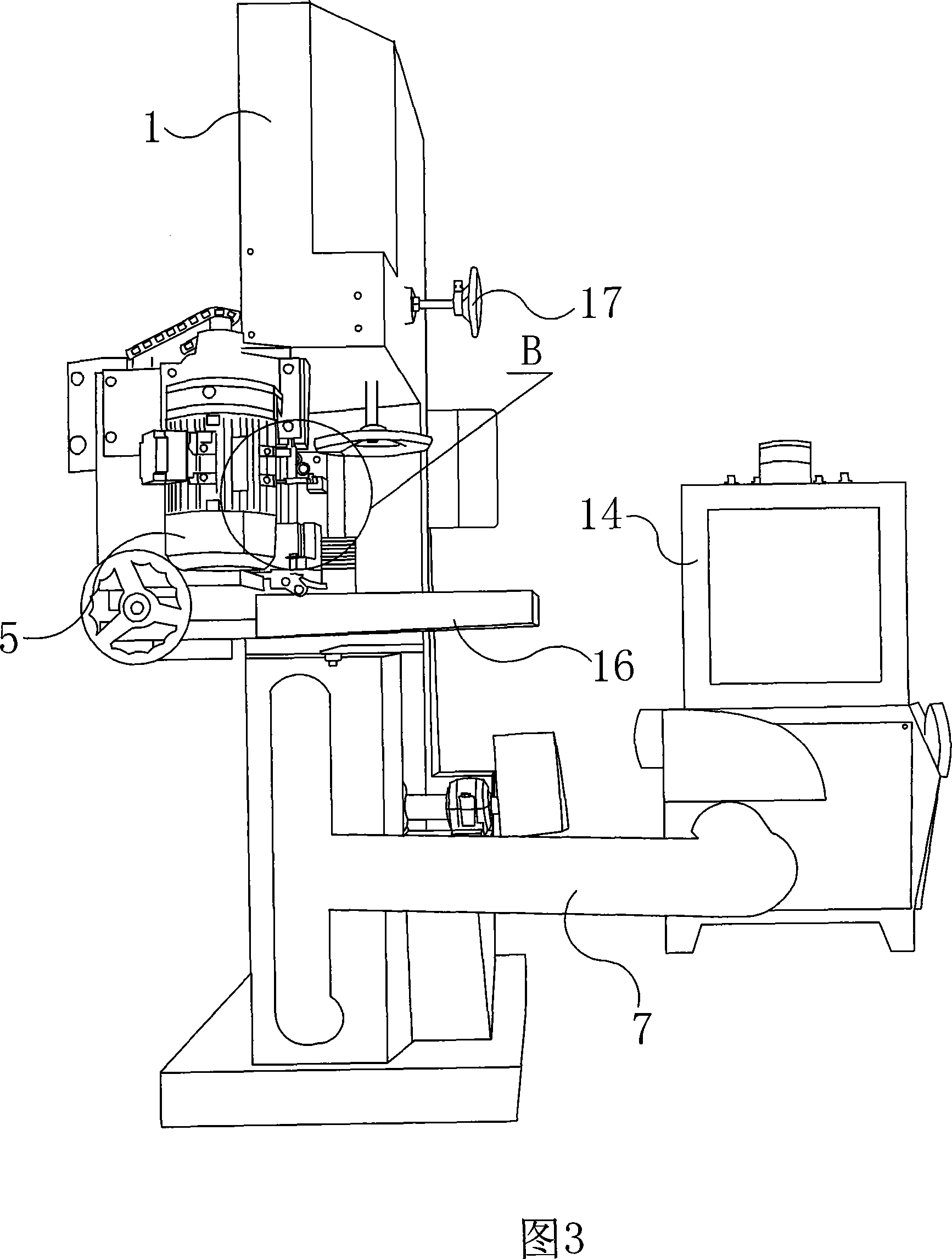

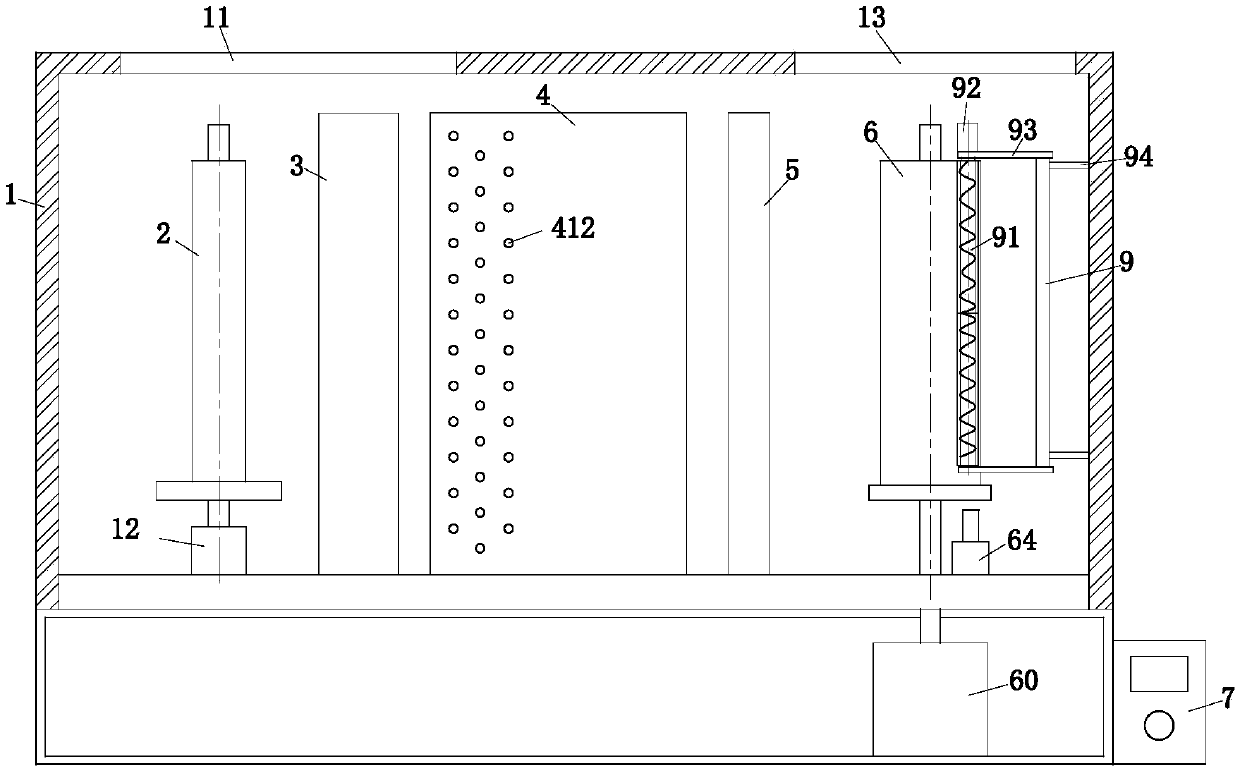

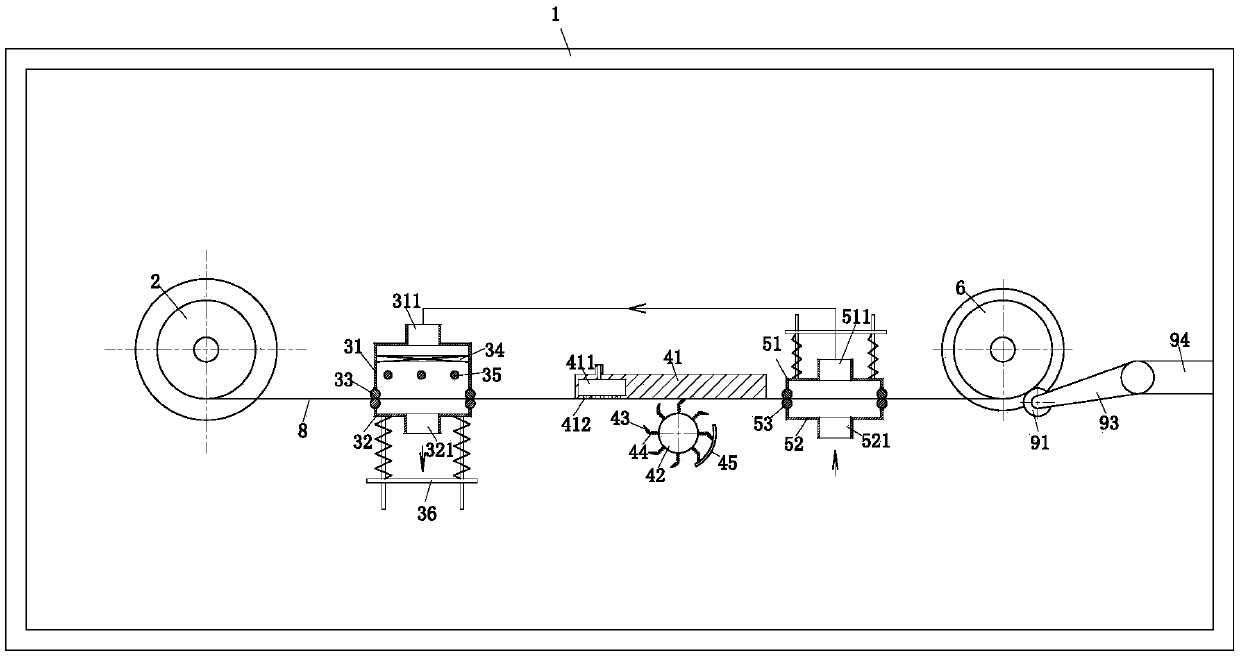

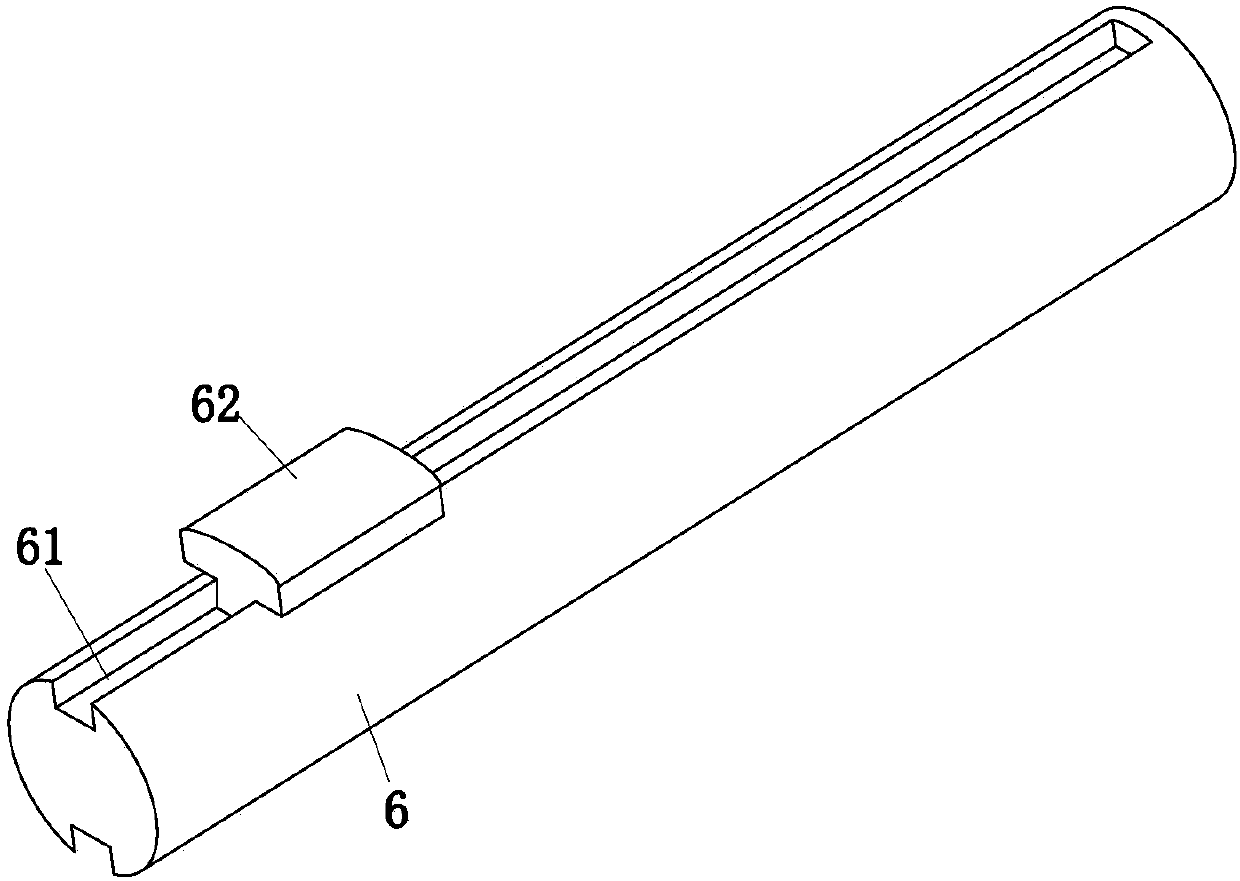

Clothing cloth drying equipment

ActiveCN107677084AEasy to acceptSmall footprintDrying gas arrangementsDrying machines with progressive movementsAir dryingEnergy consumption

The invention relates to the technical field of drying equipment, in particular to clothing cloth drying equipment. The clothing cloth drying equipment comprises a box body, a discharging shaft for discharging cloths, a drying module, an ironing module, an air-drying module, a rolling shaft for rolling the cloths and a controller. The top of the left side of the box body is provided with a storinghole for storing the cloths, a damping piece mounted at the bottom of the box body is arranged under the storing hole, and the discharging shaft is vertically mounted on the damping piece. The dryingmodule is used for drying the cloths, the ironing module is used for ironing the cloths, and the air-drying module is used for air-drying the ironed cloths. The rolling shaft is located on the rightside of the air-drying module, a material taking hole for taking out the cloths is formed in the top of the box body over the rolling shaft, the rolling shaft is driven through a rolling motor, and the rolling motor is electrically connected with the controller. The clothing cloth drying equipment is mainly suitable for being used in a clothing manufacturing shop and has the characteristics that the size is small, the weight is small, the price is low, and energy consumption is little.

Owner:安徽衣信纺织科技有限公司

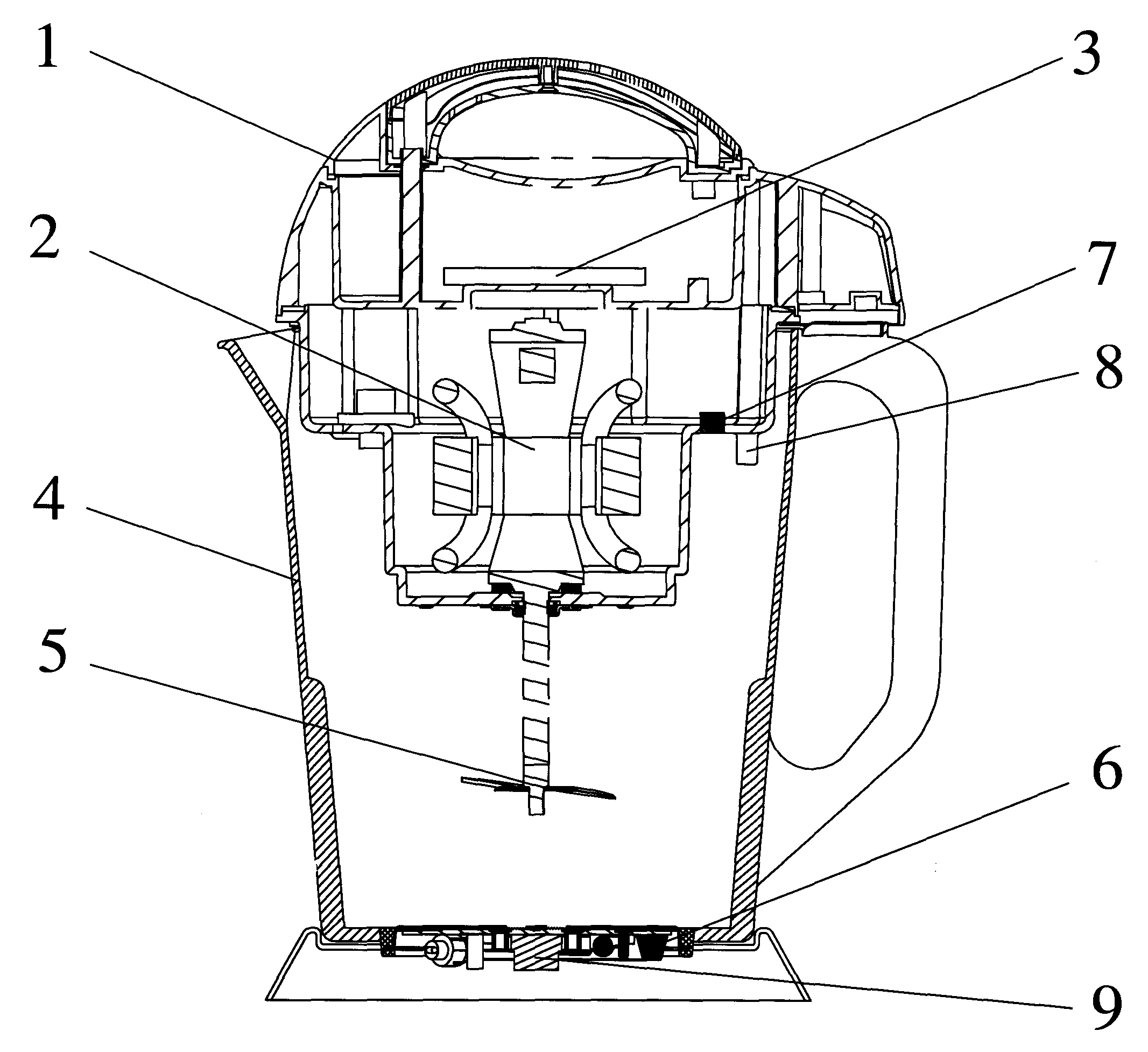

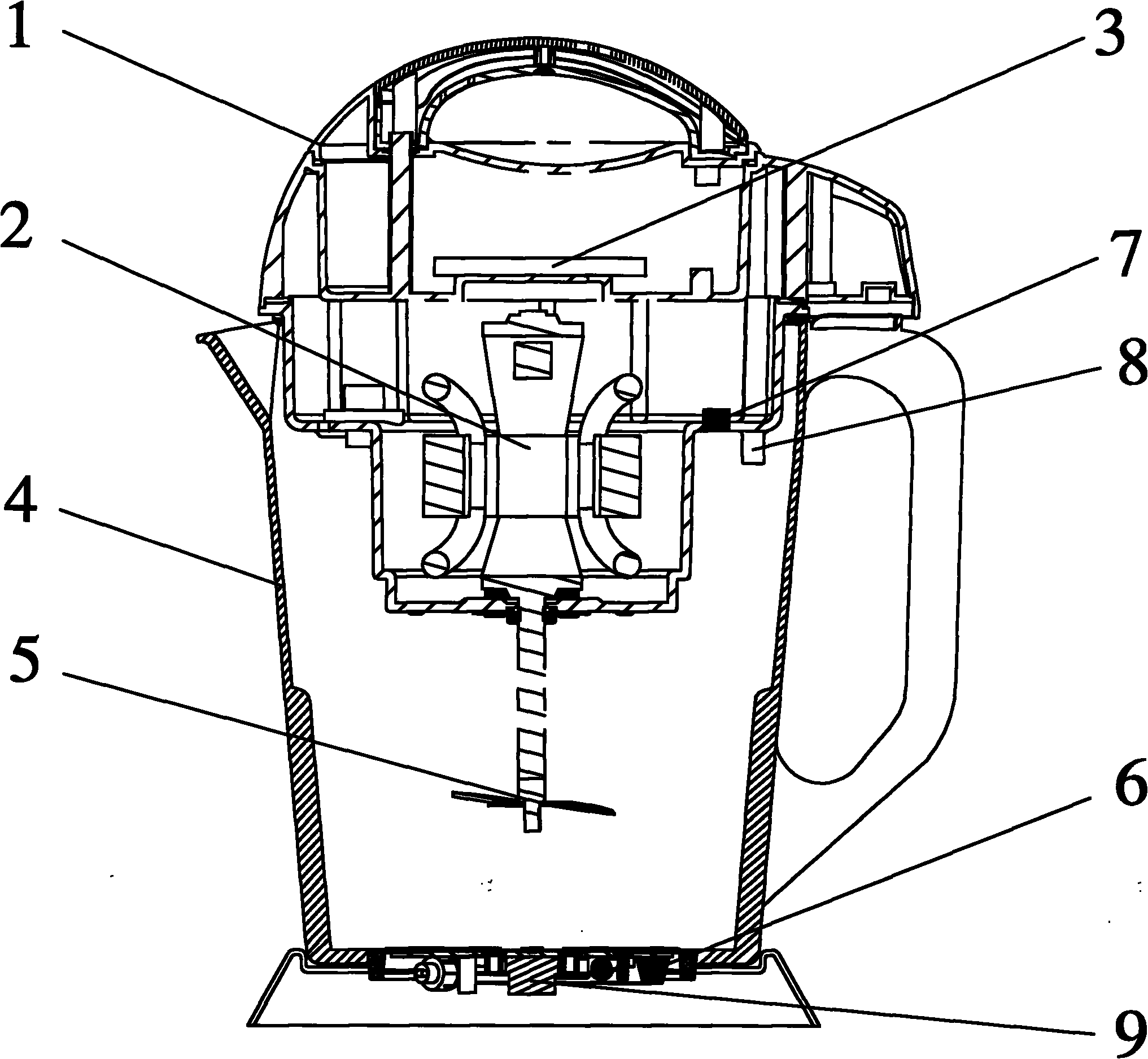

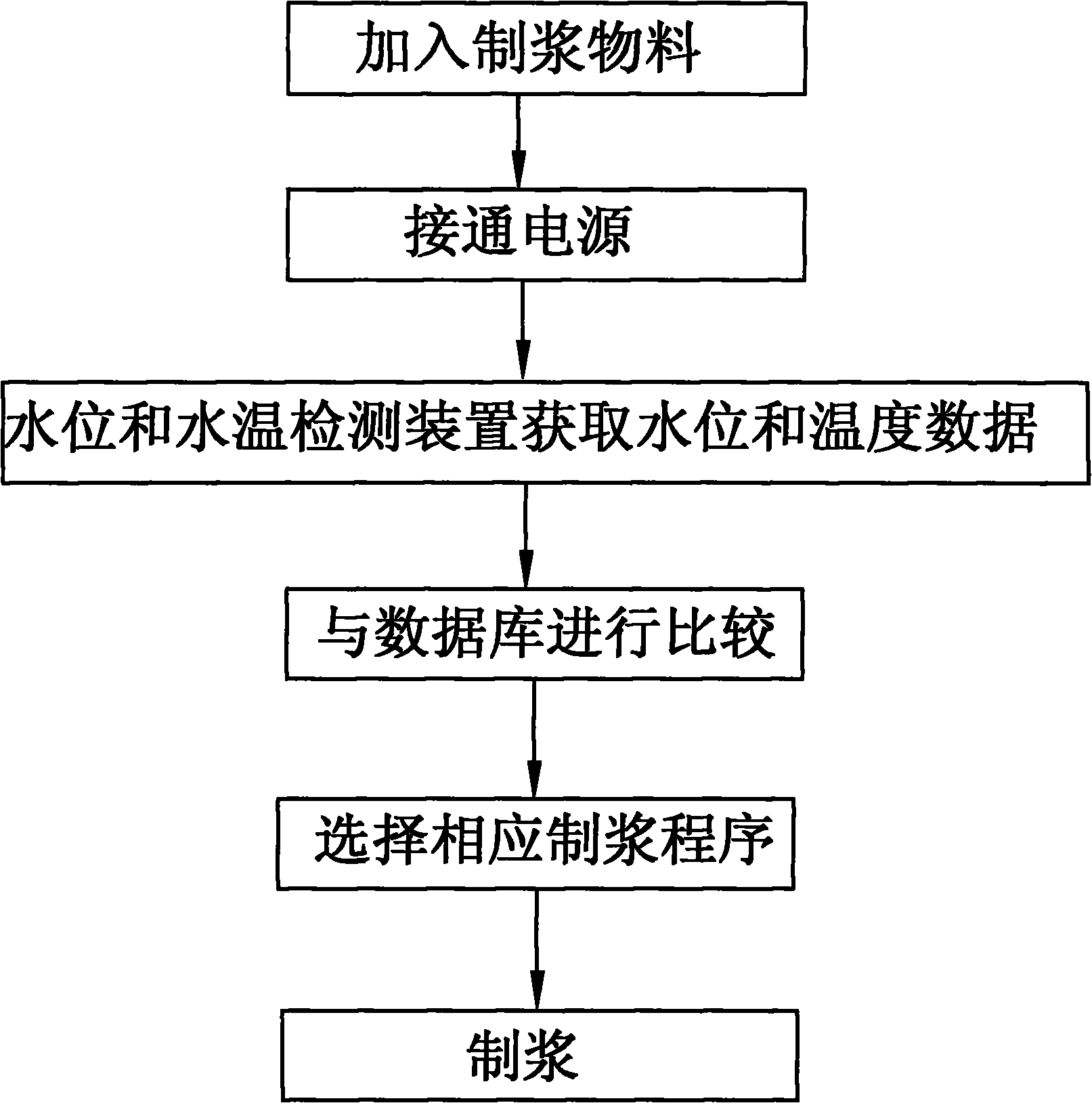

Intelligent pulping machine and control process method thereof

InactiveCN101810441APrevent overflowAvoid insufficient crushingBeverage vesselsMilk substitutesHigh concentrationEngineering

Owner:MIDEA GRP CO LTD

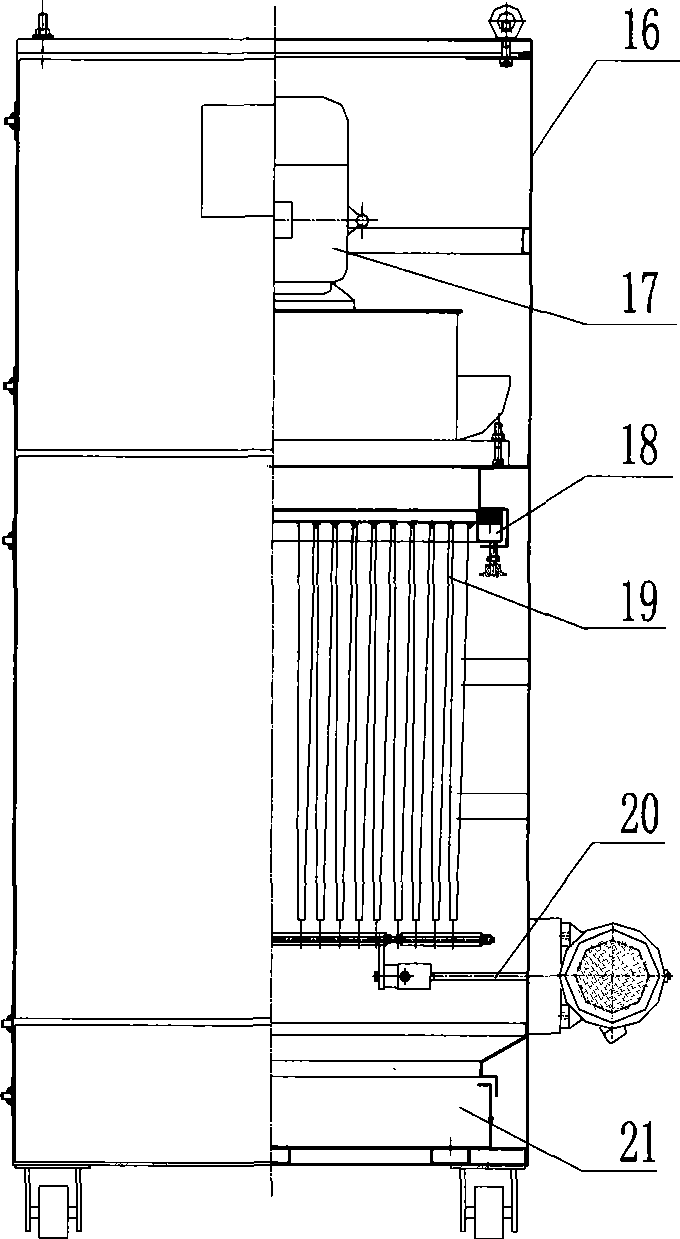

Efficient filter-bag dust separation device

InactiveCN101385928AExtended service lifeGood vibration effectDispersed particle filtrationConvex structureEngineering

Owner:NANFANG ENVIRONMENT PURIFYING EQUIP HANGZHOU

Method for concentrating titanium white waste acid by utilizing sulfuric-acid production tail gas

InactiveCN101691210ALess investmentLow running costSulfur compoundsDispersed particle separationWater vaporTitanium

The invention discloses a method for concentrating titanium white waste acid by utilizing sulfuric-acid production tail gas. The method comprises the following steps: (1) supplying sulfuric-acid production tail gas to titanium white waste acid sprayed to be in a mist state, concentrating the titanium white waste acid and turning the sulfuric-acid production tail gas from dry gas into wet gas containing steam and titanium white waste acid foam; (2) performing gas-liquid separation on the wet gas, treating and then emptying separated gas, mixing separated liquid with the titanium white waste acid concentrated in a step (1) and then repeatedly concentrating the mixture; and (3) performing sampling test on the titanium white waste acid repeatedly concentrated and recovering the titanium white waste acid when the sulfuric acid content of the titanium white waste acid in percentage by mass is detected to reach over 55 percent. The method has the advantages of simple equipment, convenient operation, low investment, low energy consumption, low operation-maintenance cost, capability of avoiding pipeline blockage because of high-temperature scaling and capability of reducing the pressure to treat sulfuric-acid production tail gas.

Owner:WUHAN QINGJIANG CHEM IND

Heat-preservation wall body of wood-frame shear wall

InactiveCN101929207AQuality improvementHigh precisionWallsClimate change adaptationWall studEngineering

The invention belongs to the technical field of structural engineering, and particularly relates to a heat-preservation wall body for a mixed structure of a wood frame and a wooden shear wall, and assembly technology. The assembled heat-preservation wall body consists of wall studs, a wood base structural slab, a gypsum board, heat-preservation cotton, a wood-frame pillar, a mudsill board and a top beam board, wherein a horizontal interval between every two adjacent wall studs is 400 to 600 millimeters, and the wall studs on both sides are connected with the wood-frame pillar through nails; the wood base structural slab covers the wall body, is connected with the wall studs, the top beam board and the mudsill board through the nails, and is flush with the outer side of the wood-frame pillar; the gypsum board is covered on the inner side of a wallboard and is connected with the wall studs through screws; and the heat-preservation cotton is filled between inner and outer cladding boards. Materials for the assembled wall body provided by the invention can improve the natural environment in the process of growth, have the advantages of low energy consumption in the machining process, regeneration and natural degradation after abandonment, and have the functions of quick construction, vibration prevention, energy conservation, heat preservation, heat insulation and the like; the heat-preservation wall body has the advantages of high industrial production degree, high production efficiency, less on-site wet operation, a plurality of operational surfaces and quick construction; and the materials, such as dimension stocks, connectors, plywood, laminated wood and the like can be localized to reduce the construction cost.

Owner:TONGJI UNIV

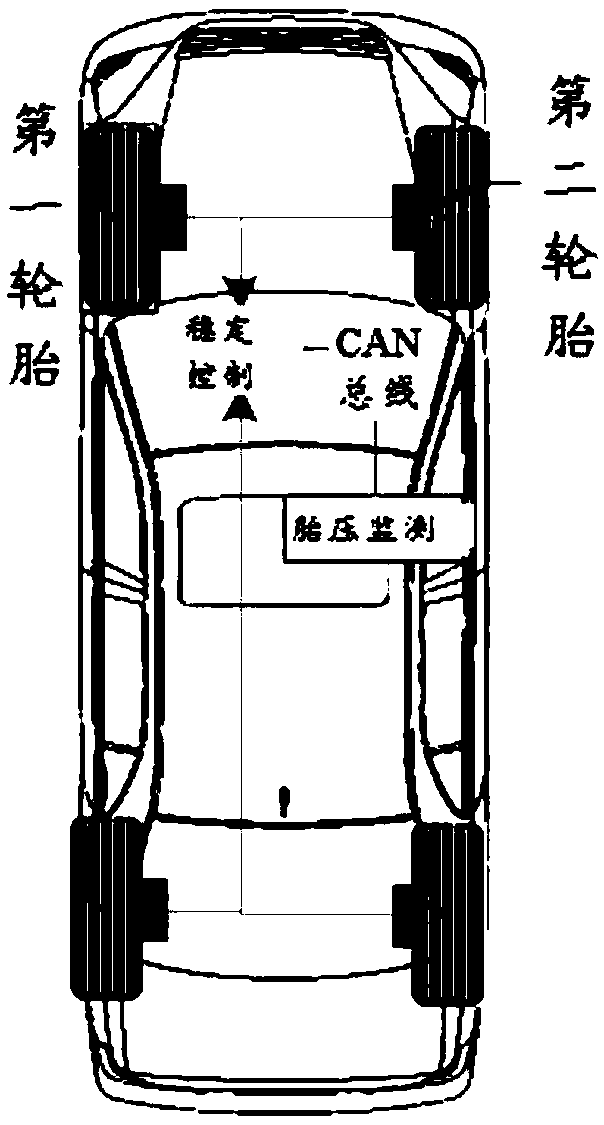

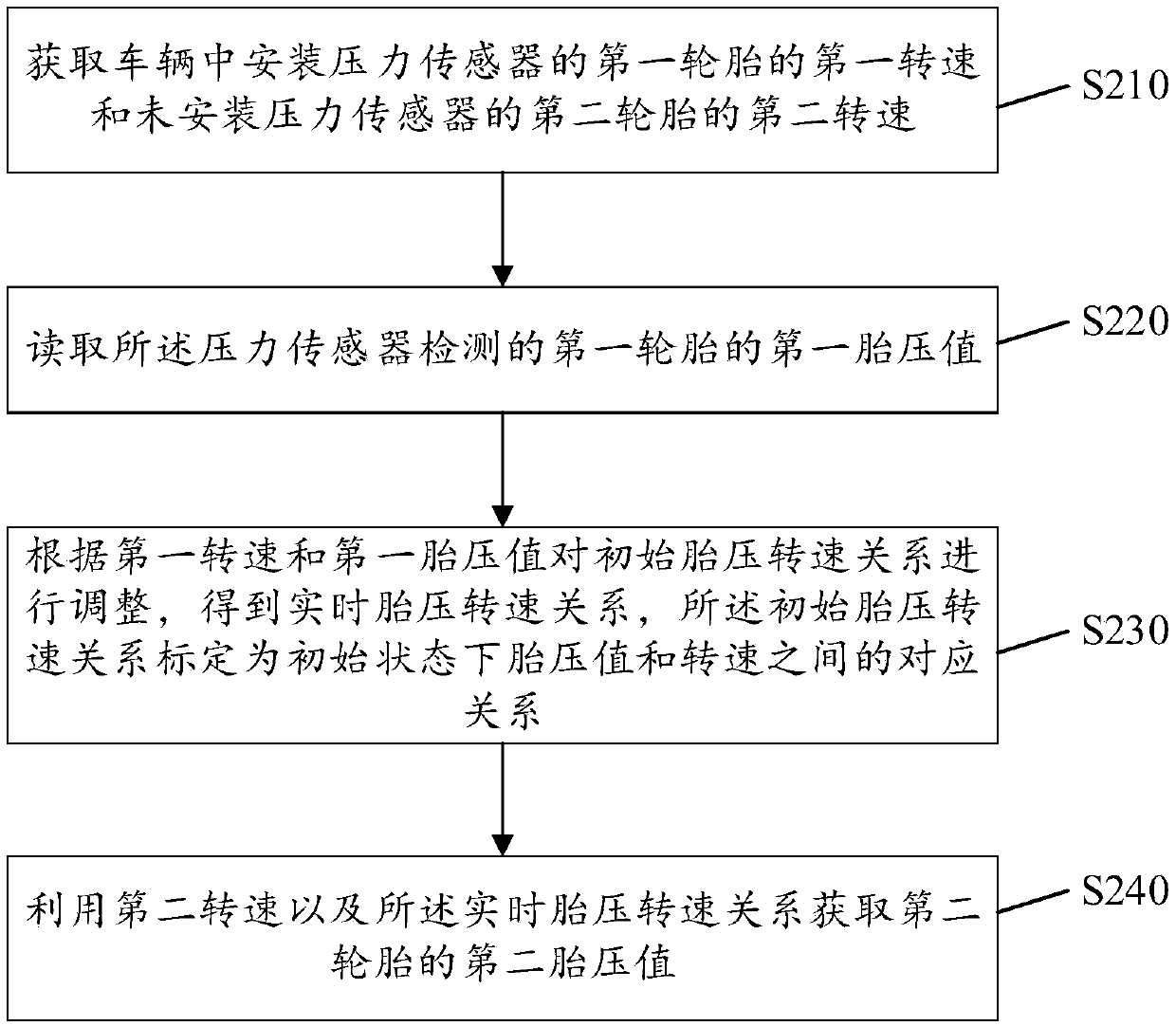

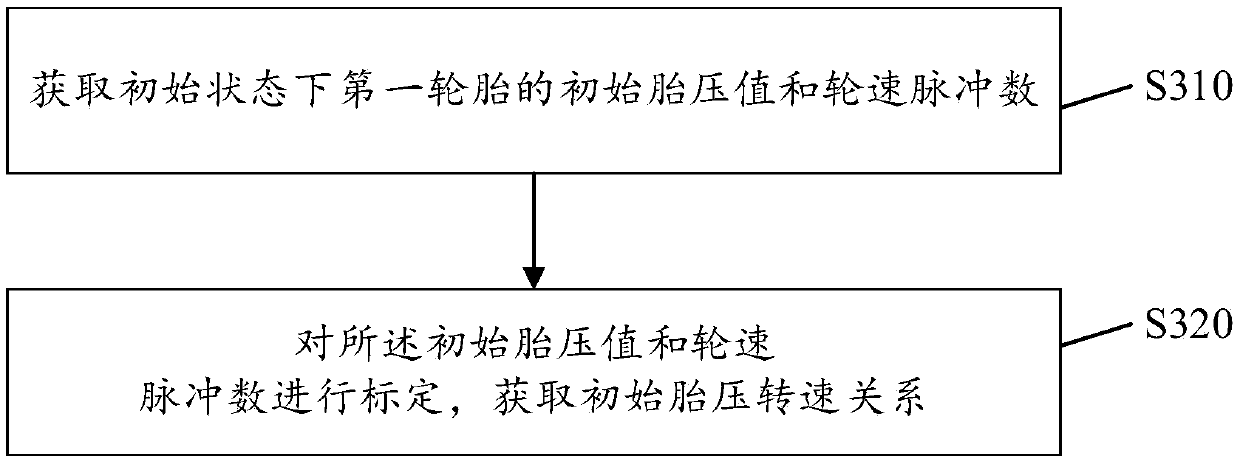

Composite tire pressure monitoring method and tire pressure monitoring device

Owner:STEELMATE CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap