Clothing cloth drying equipment

A technology for drying equipment and fabrics, applied in progressive dryers, drying solid materials, drying gas layout, etc., can solve the problems that fabrics are easily contaminated with impurities and dust, affect the aesthetics of fabrics, and the fabrics cannot be recovered. Light, reduced heat loss, easy to accept effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

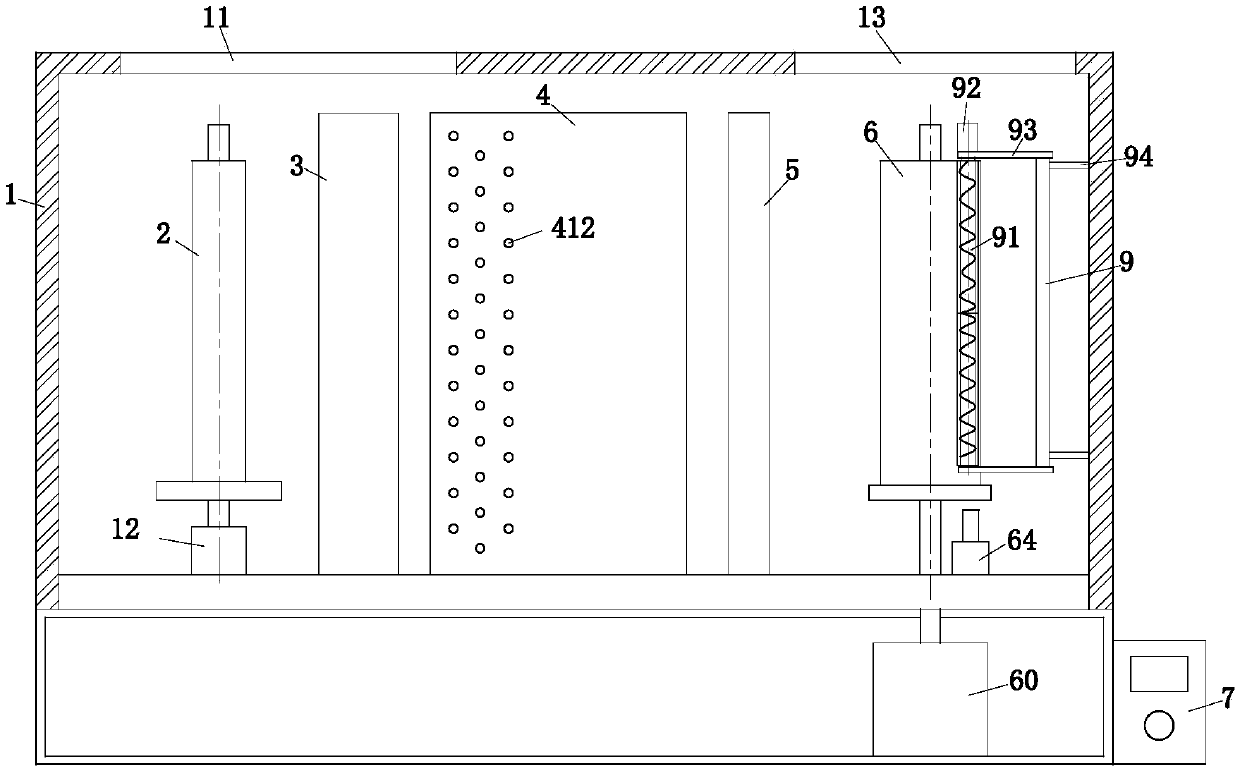

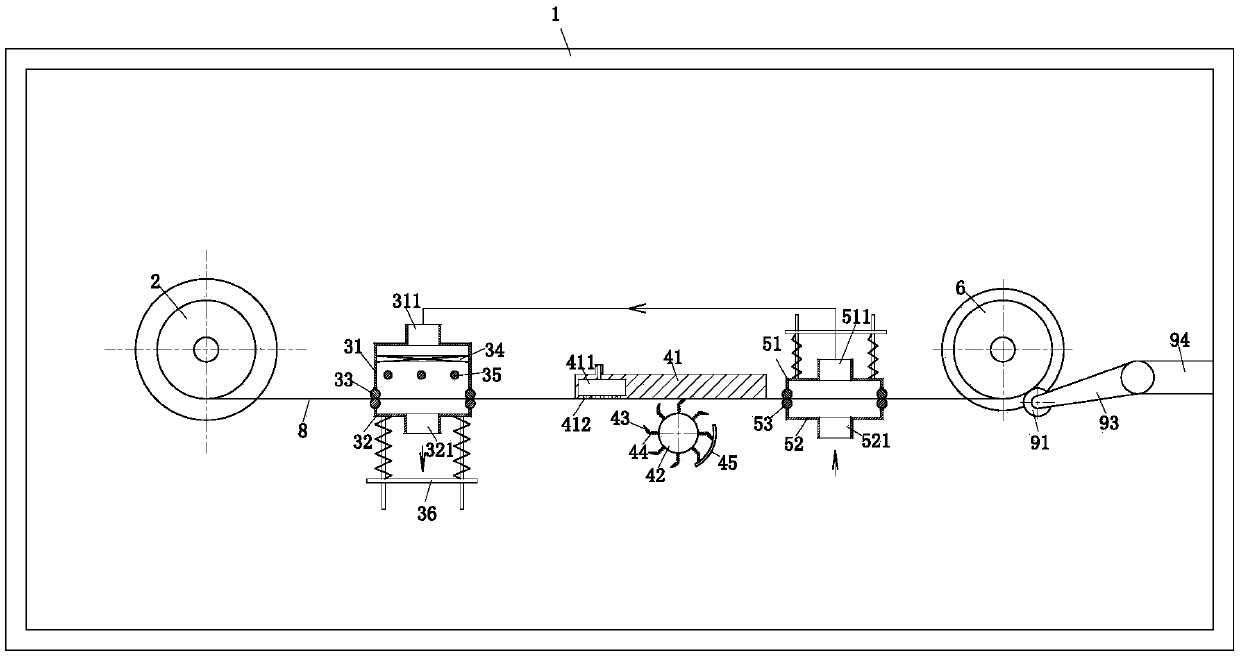

[0027] As an embodiment of the present invention, the drying module 3 includes an air inlet box 31, an air outlet box 32, a sealing roller 33, a fan 34, a heating rod 35 and a first elastic adjustment mechanism 36, and the air inlet box 31 is fixed on the box body 1, the air inlet box 31 is provided with a No. 1 air inlet 311; the air outlet box 32 is installed in the box body 1 through the first elastic adjustment mechanism 36, the air outlet box 32 is set opposite to the air inlet box 31, and the air outlet box 32 and the air inlet box 31 The cloth 8 can be sealed and dried, and the air outlet box 32 is provided with a moisture discharge port 321, which communicates with the outside world; there are four sealing rollers 33, and the four sealing rollers 33 are installed in the air outlet box 32 for rotation. and the left and right sides of the air inlet box 31, four sealing rollers 33 are all in contact with the cloth 8 to realize sealing and drying, and the movement of the cl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap