Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Improve aesthetics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

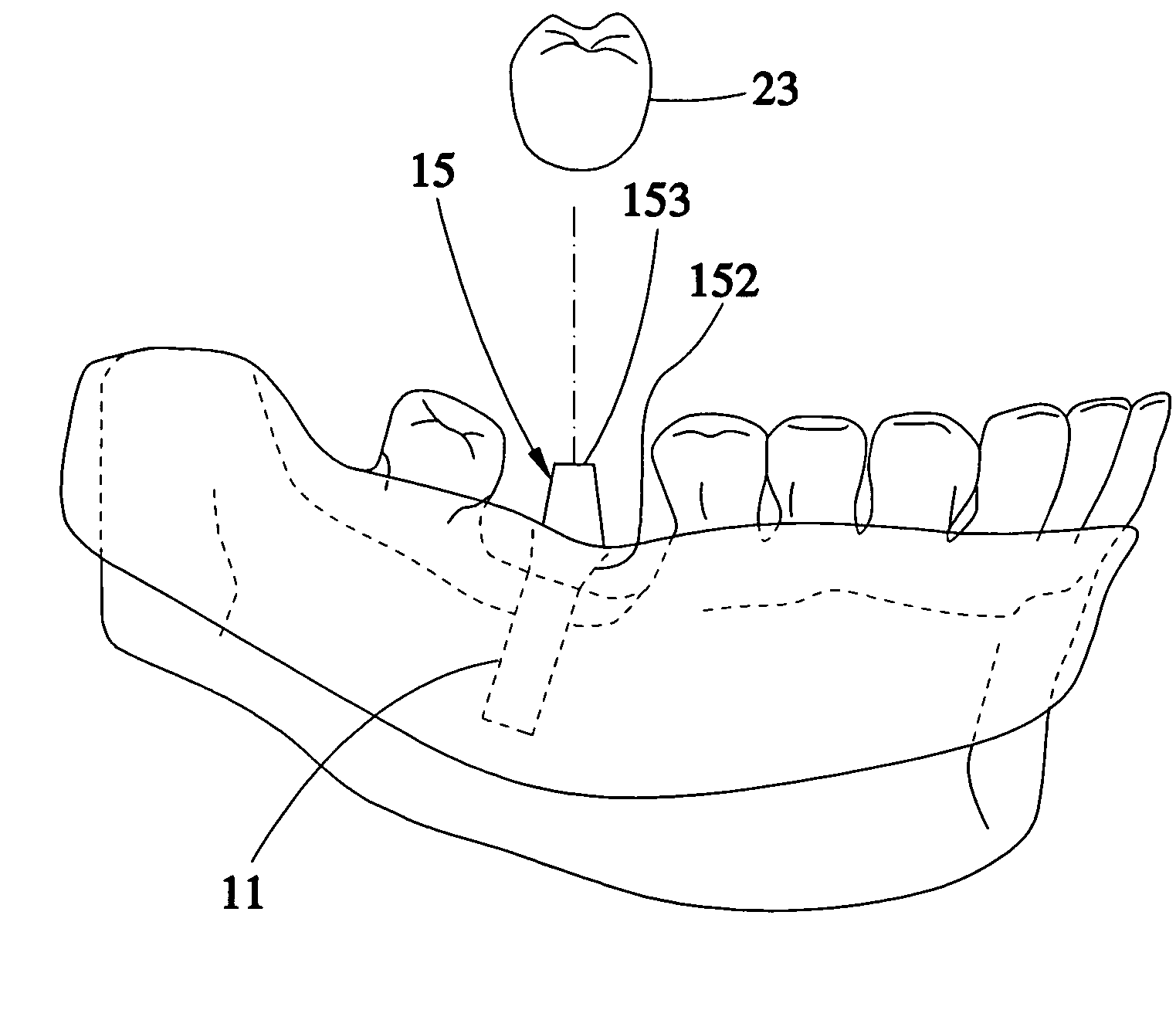

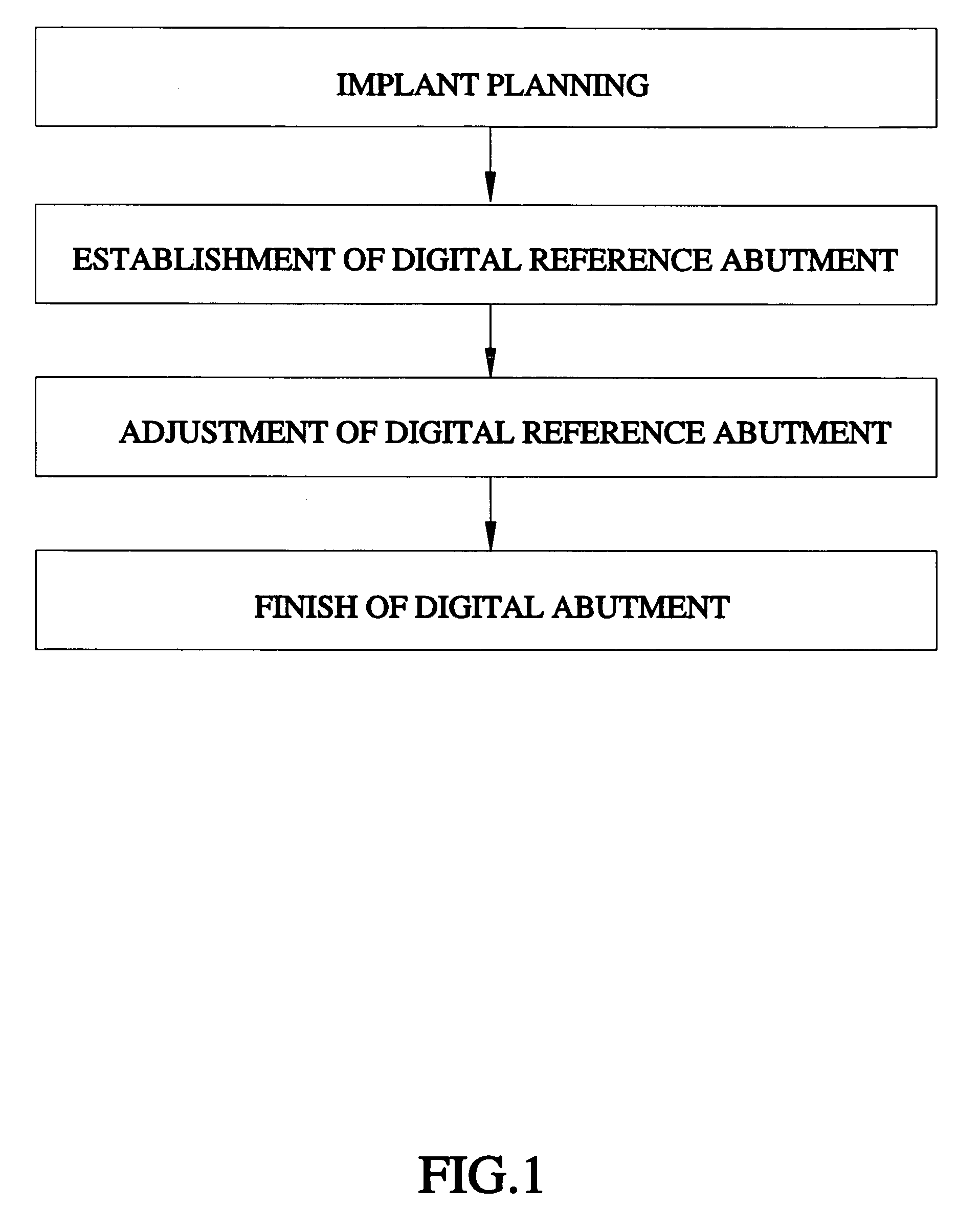

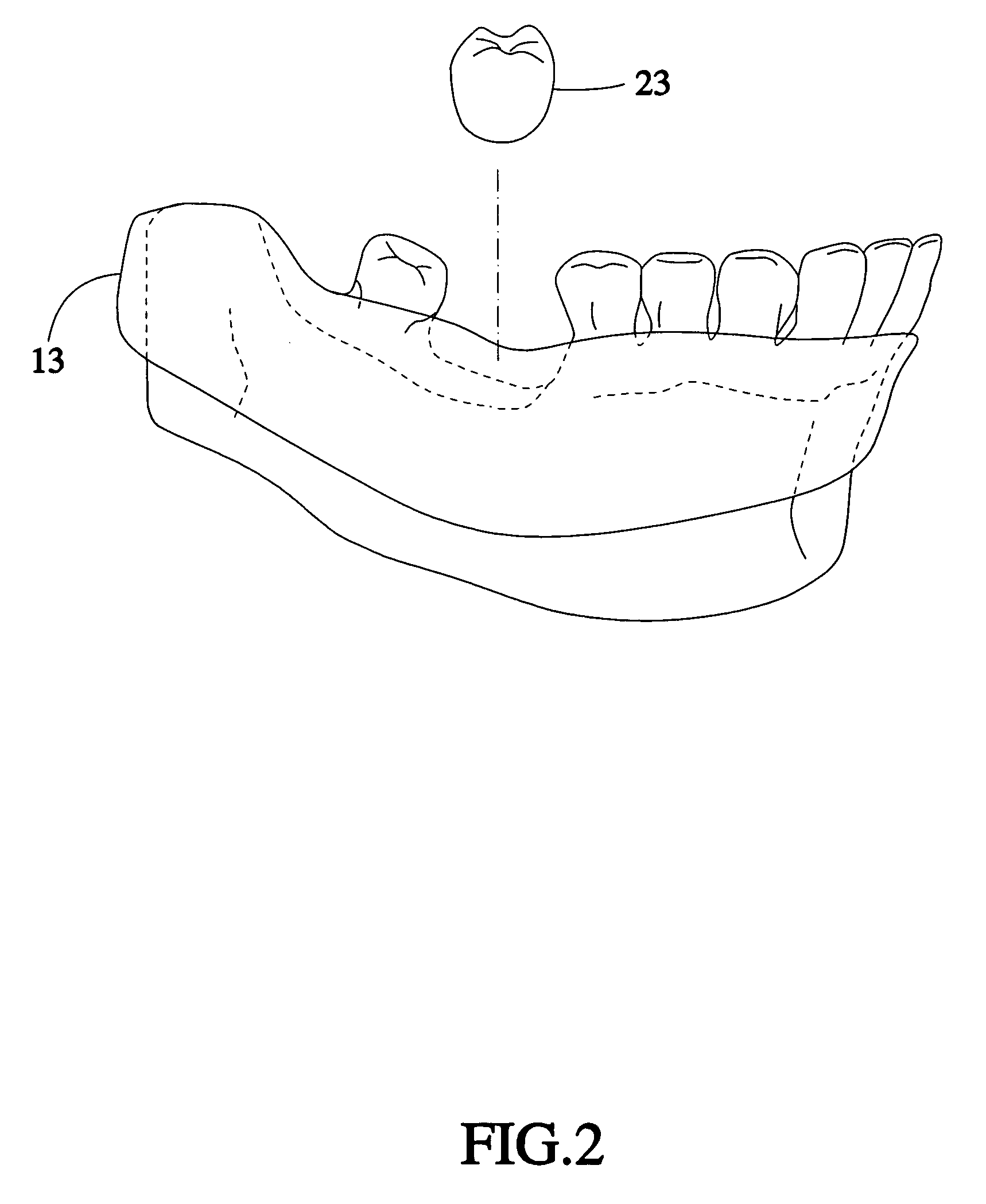

Method for designing a digital abutment for dental implant

InactiveUS20090111071A1Improve aestheticsDental implantsMechanical/radiation/invasive therapiesProsthesisDigital data

Owner:POU BIOTECH

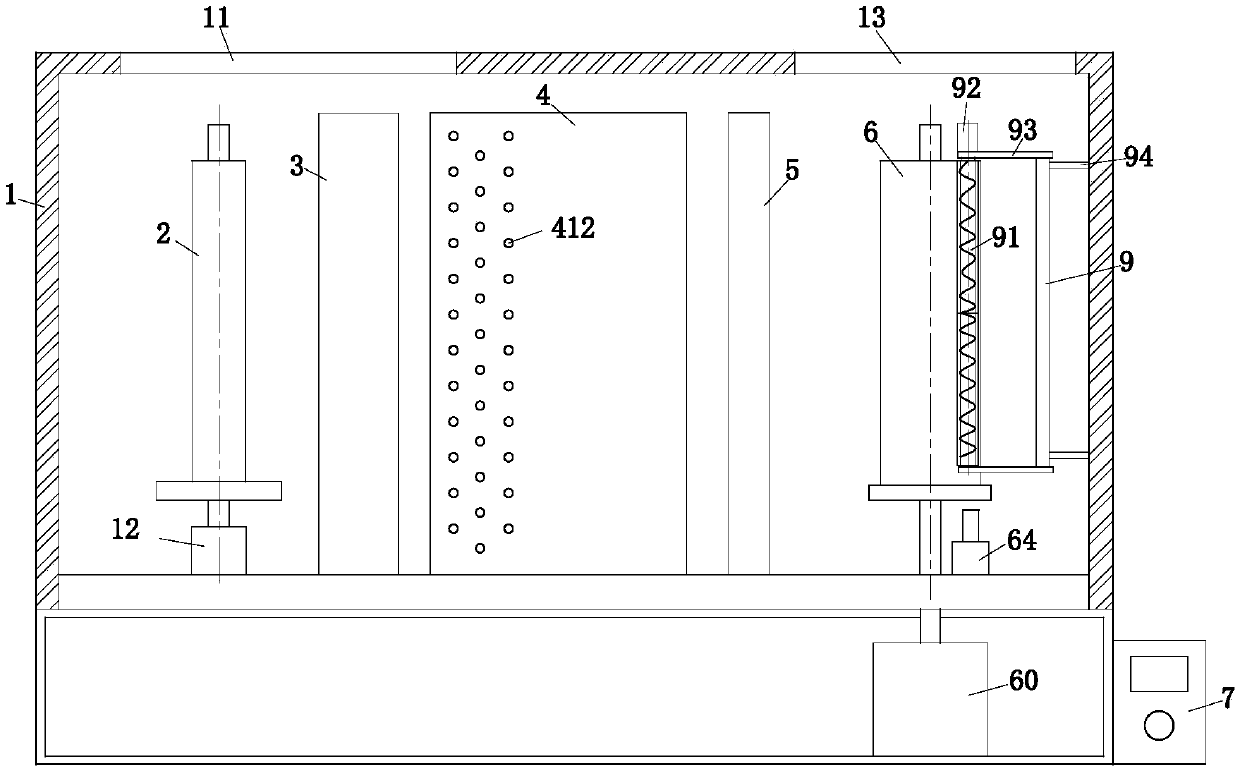

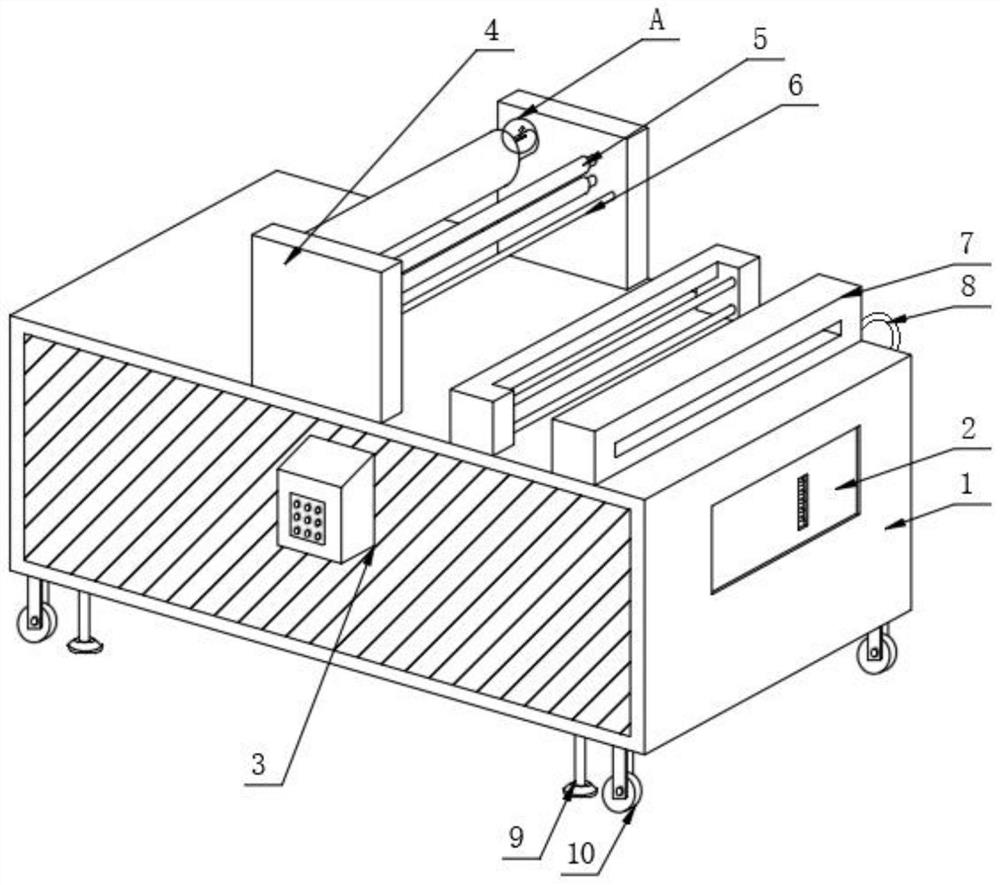

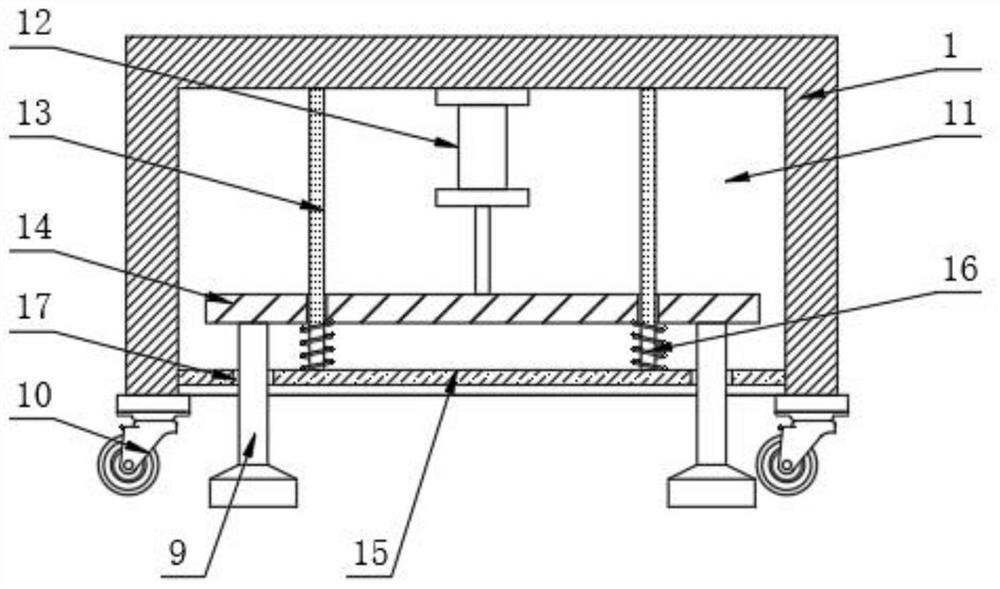

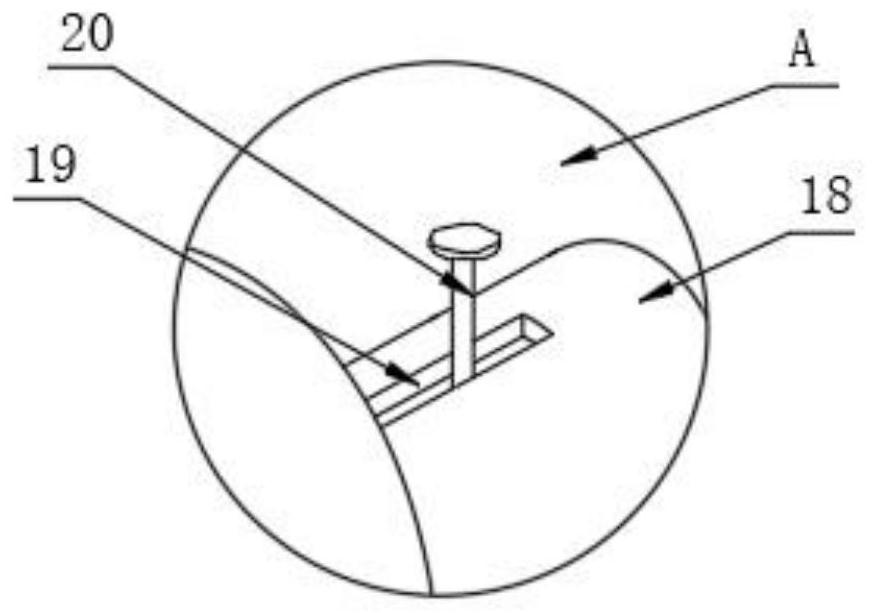

Multifunctional integrated cleaner unit machine

InactiveUS20100294004A1Small footprintReduce manufacturing costOther washing machinesTextiles and paperEngineeringSmall footprint

A multifunctional integrated cleaner unit machine includes a cabinet, washing basin and a full-automatic washing machine located in the cabinet. An enclosing frame is provided on an upper part of the cabinet. A cover corresponding with the full-automatic washing machine is hinged on the enclosing frame. A control panel and a main water inlet are provided at the enclosing frame. A dryer machine is located on one side of the full-automatic washing machine in the cabinet. The washing basin is located in the enclosing frame above the dryer machine. The washing machine, the washing basin and the dryer are combined into an integral machine with the security standard, thereby the multifunctional integrated cleaner unit machine has the advantages of small occupied area, low manufacturing cost, full functions, proper height, time saving in use, convenience, energy saving, convenient installation, little vibration and noise, low transporting cost and uniform integral style.

Owner:HU JIEBO

Clothing cloth drying equipment

ActiveCN107677084AEasy to acceptSmall footprintDrying gas arrangementsDrying machines with progressive movementsAir dryingEnergy consumption

The invention relates to the technical field of drying equipment, in particular to clothing cloth drying equipment. The clothing cloth drying equipment comprises a box body, a discharging shaft for discharging cloths, a drying module, an ironing module, an air-drying module, a rolling shaft for rolling the cloths and a controller. The top of the left side of the box body is provided with a storinghole for storing the cloths, a damping piece mounted at the bottom of the box body is arranged under the storing hole, and the discharging shaft is vertically mounted on the damping piece. The dryingmodule is used for drying the cloths, the ironing module is used for ironing the cloths, and the air-drying module is used for air-drying the ironed cloths. The rolling shaft is located on the rightside of the air-drying module, a material taking hole for taking out the cloths is formed in the top of the box body over the rolling shaft, the rolling shaft is driven through a rolling motor, and the rolling motor is electrically connected with the controller. The clothing cloth drying equipment is mainly suitable for being used in a clothing manufacturing shop and has the characteristics that the size is small, the weight is small, the price is low, and energy consumption is little.

Owner:安徽衣信纺织科技有限公司

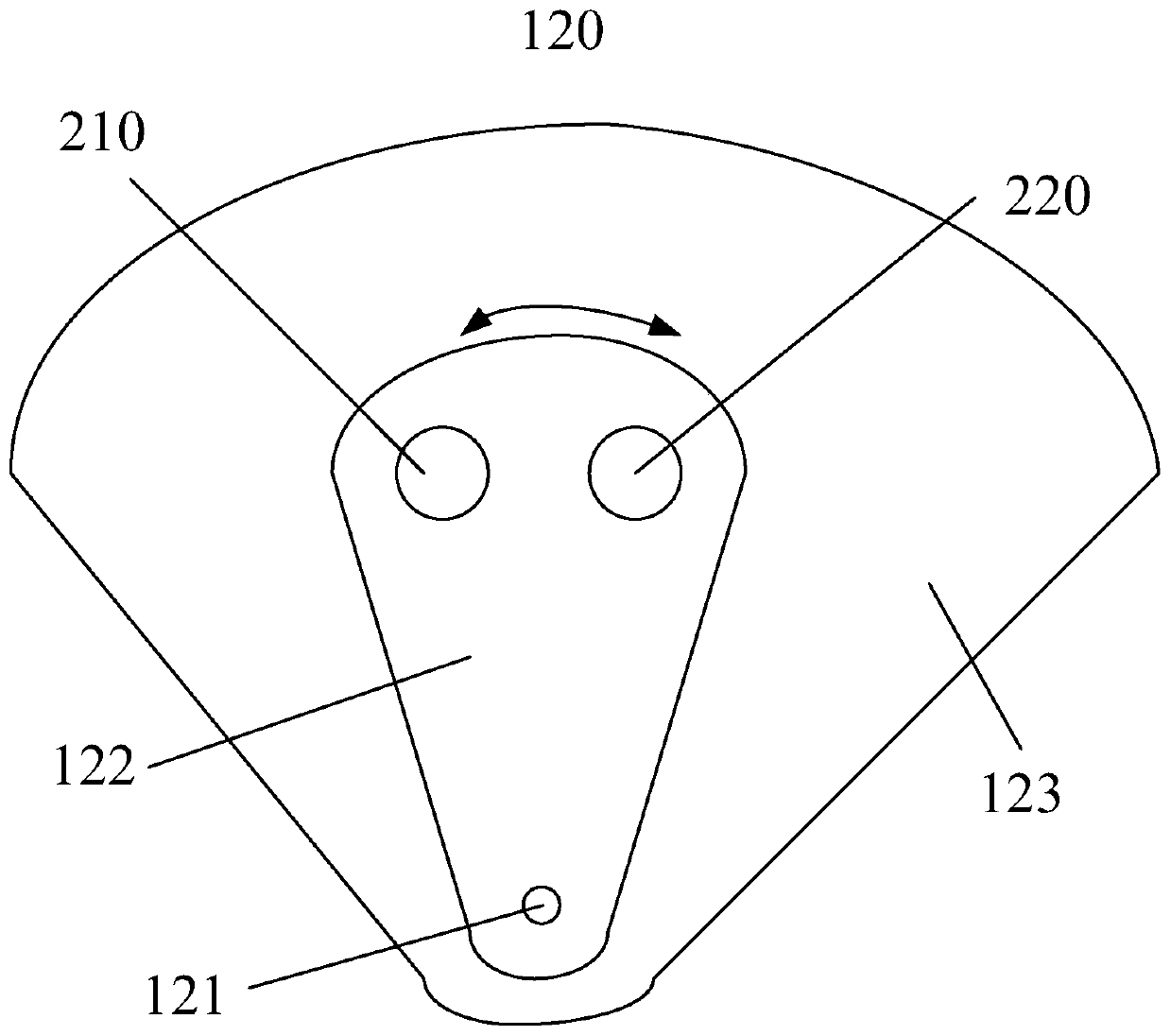

Range hood

ActiveCN111121116AImprove aestheticsImprove the smoke effectCooking fumes removalDomestic stoves or rangesAir volumeEngineering

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

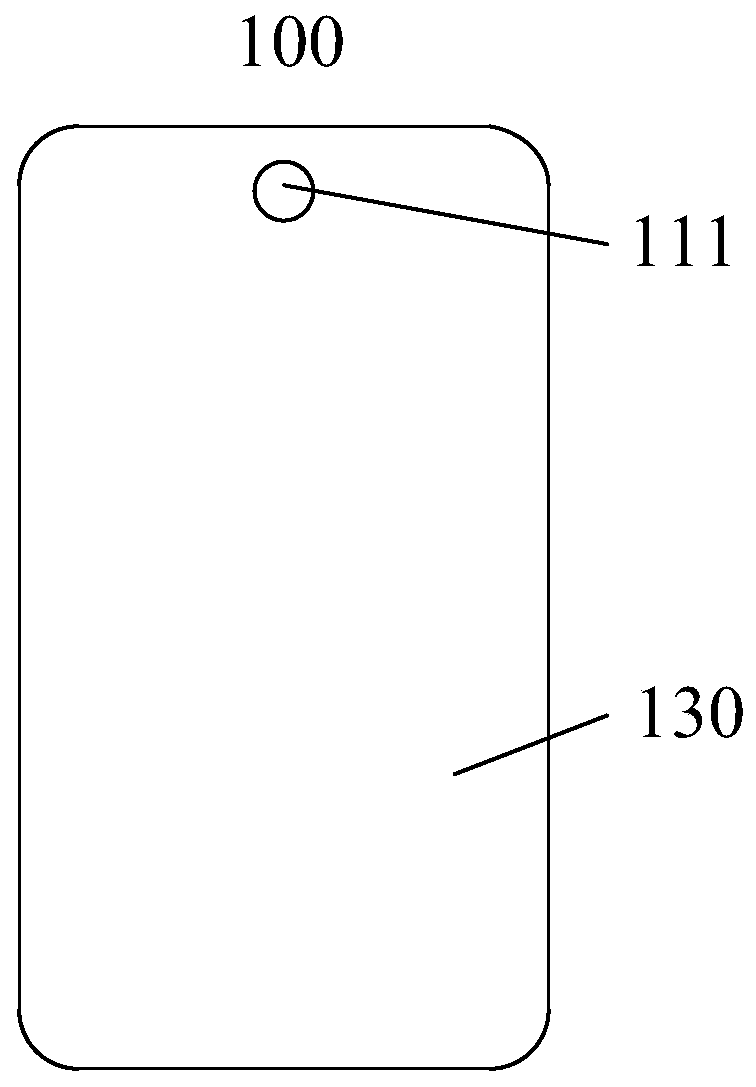

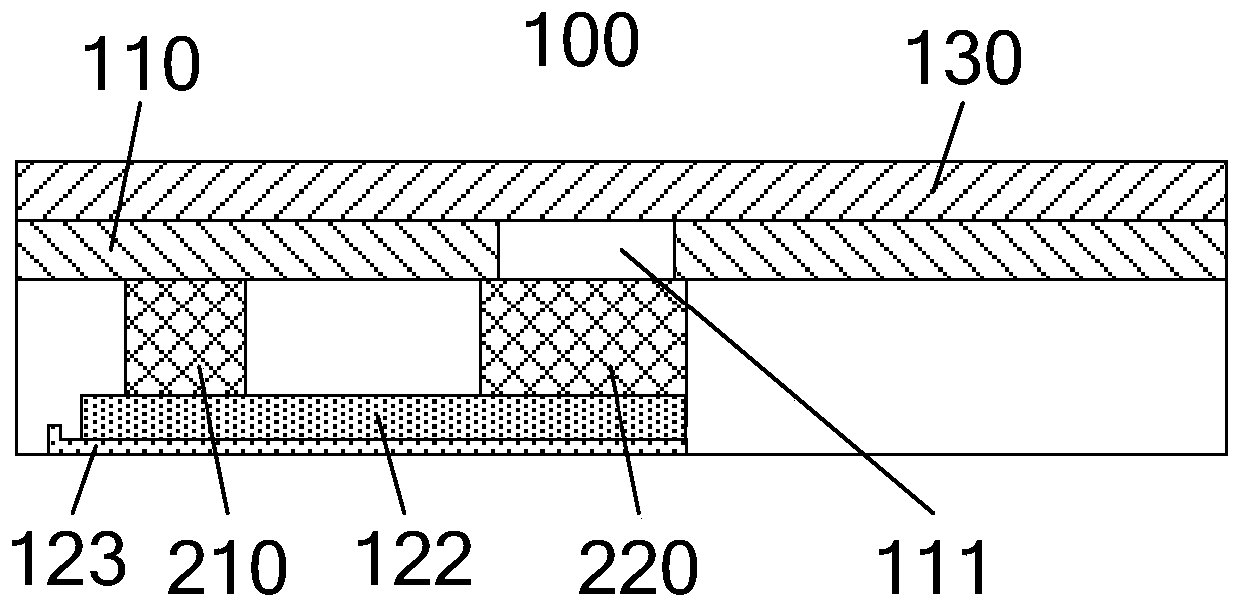

Mobile terminal

PendingCN110248003AImprove aestheticsTelephone set constructionsIdentification meansEmbedded systemFunctional module

Owner:BOE TECH GRP CO LTD +1

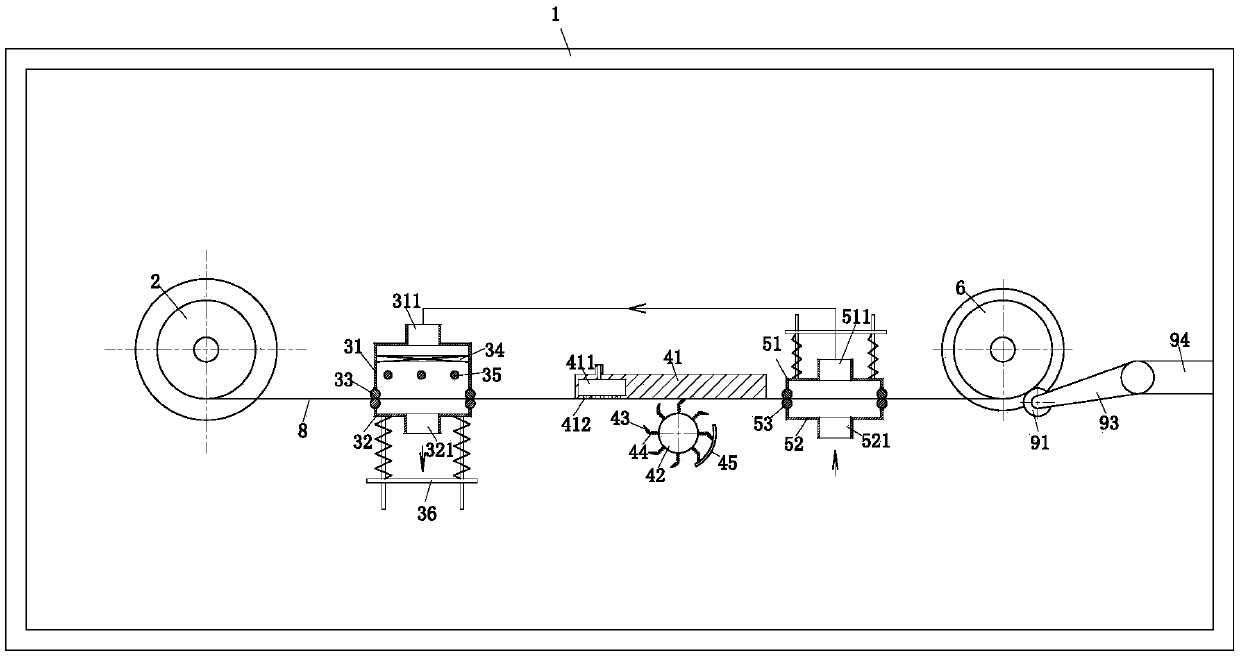

Automatic packaging device for woven bags

ActiveCN111114875AEasy to disassembleImprove aestheticsBundling machine detailsIndustrial engineeringMechanical engineering

Owner:浙江埃芮克环保科技有限公司

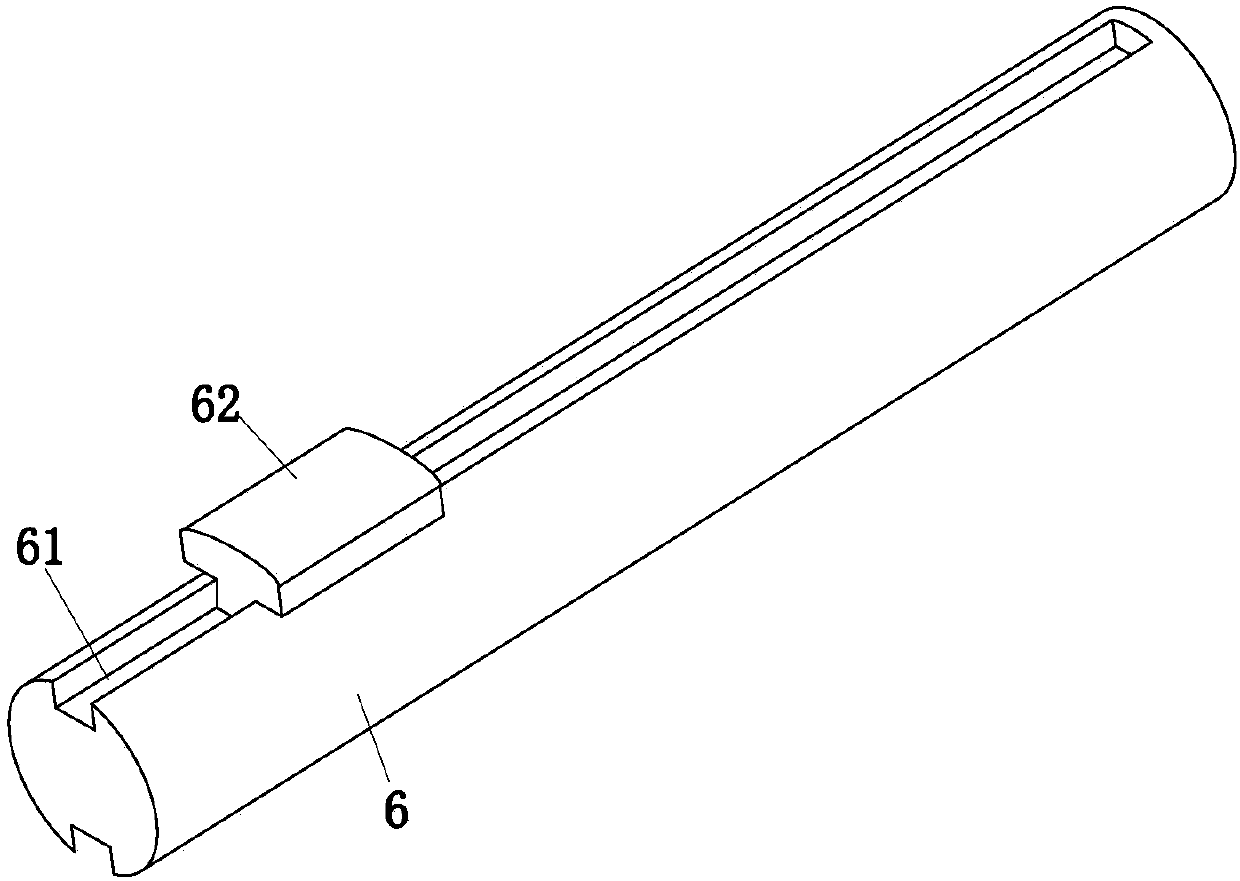

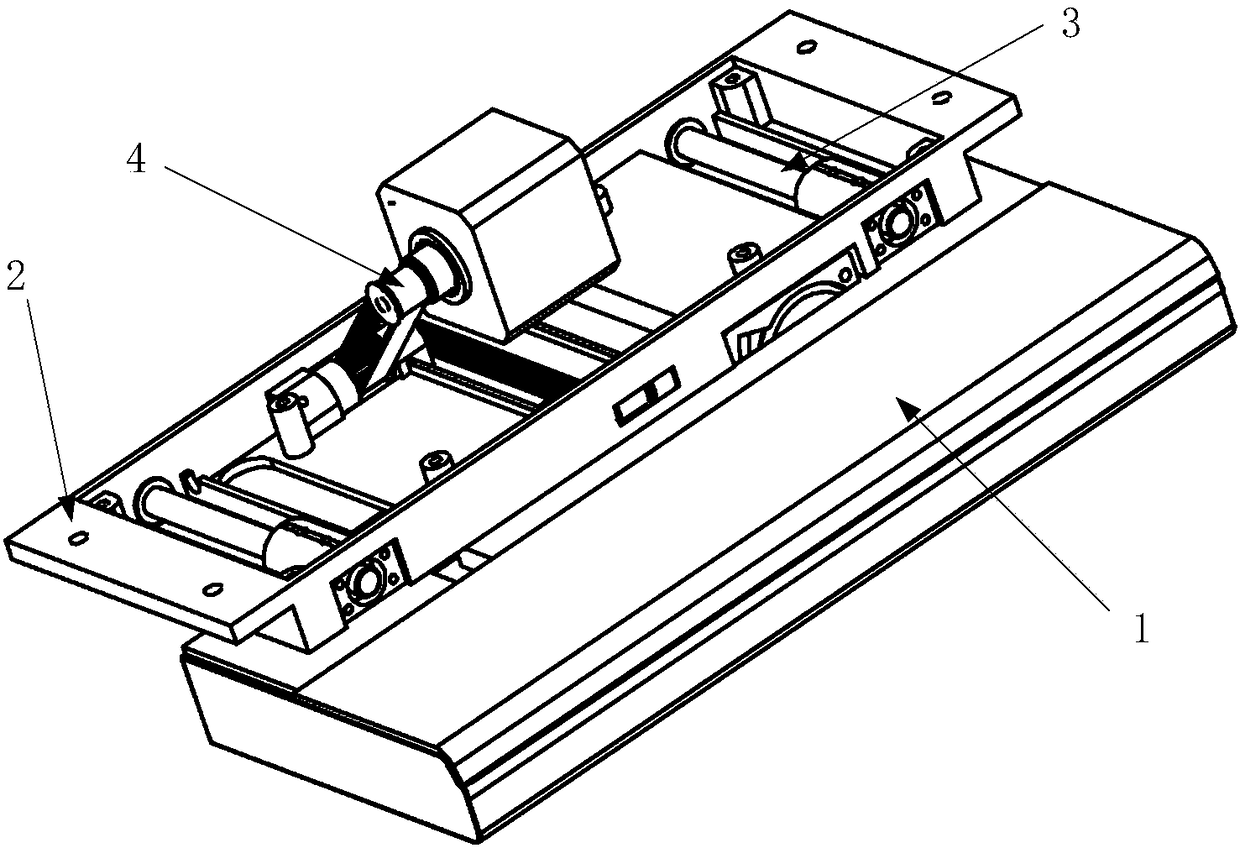

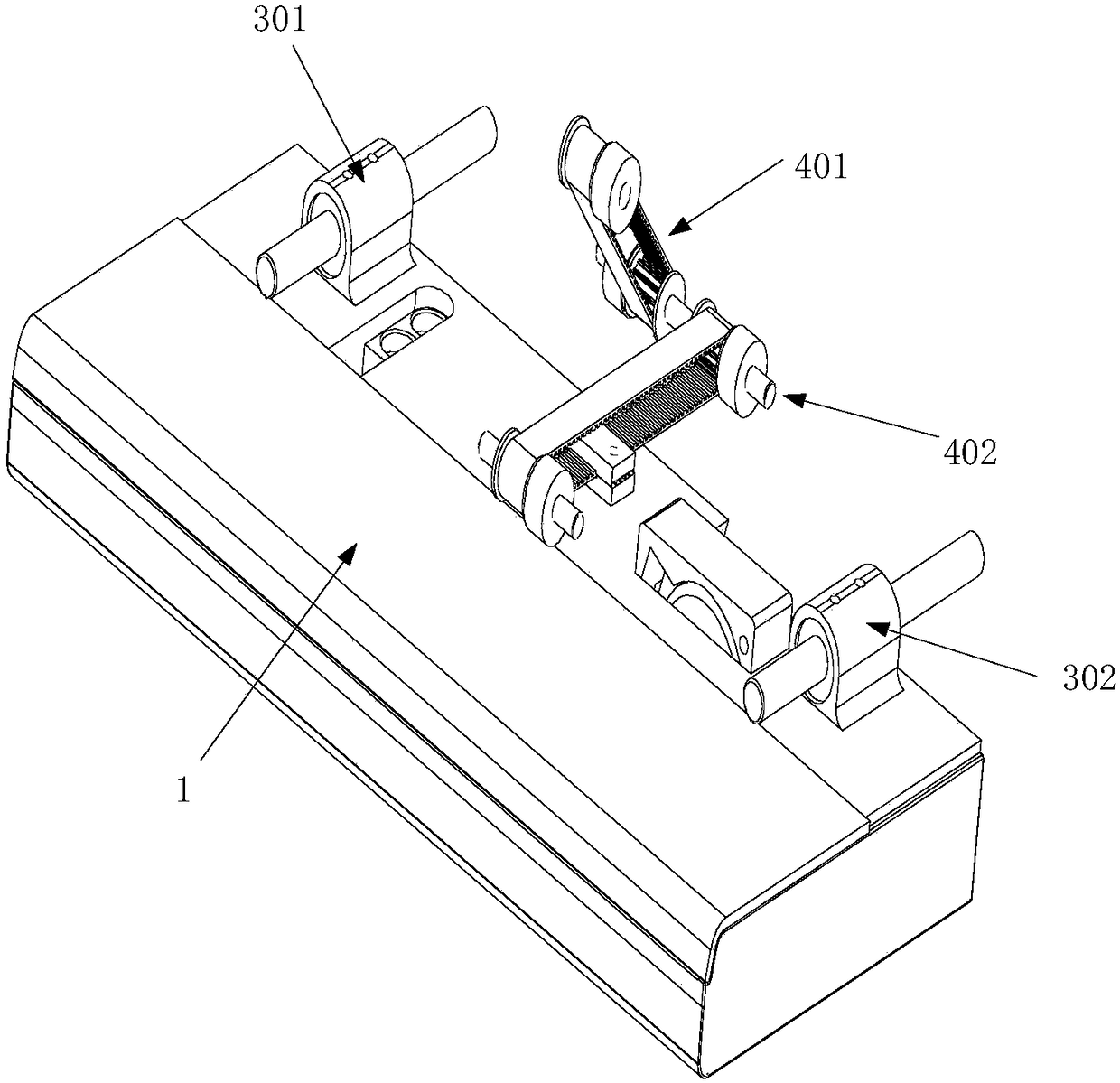

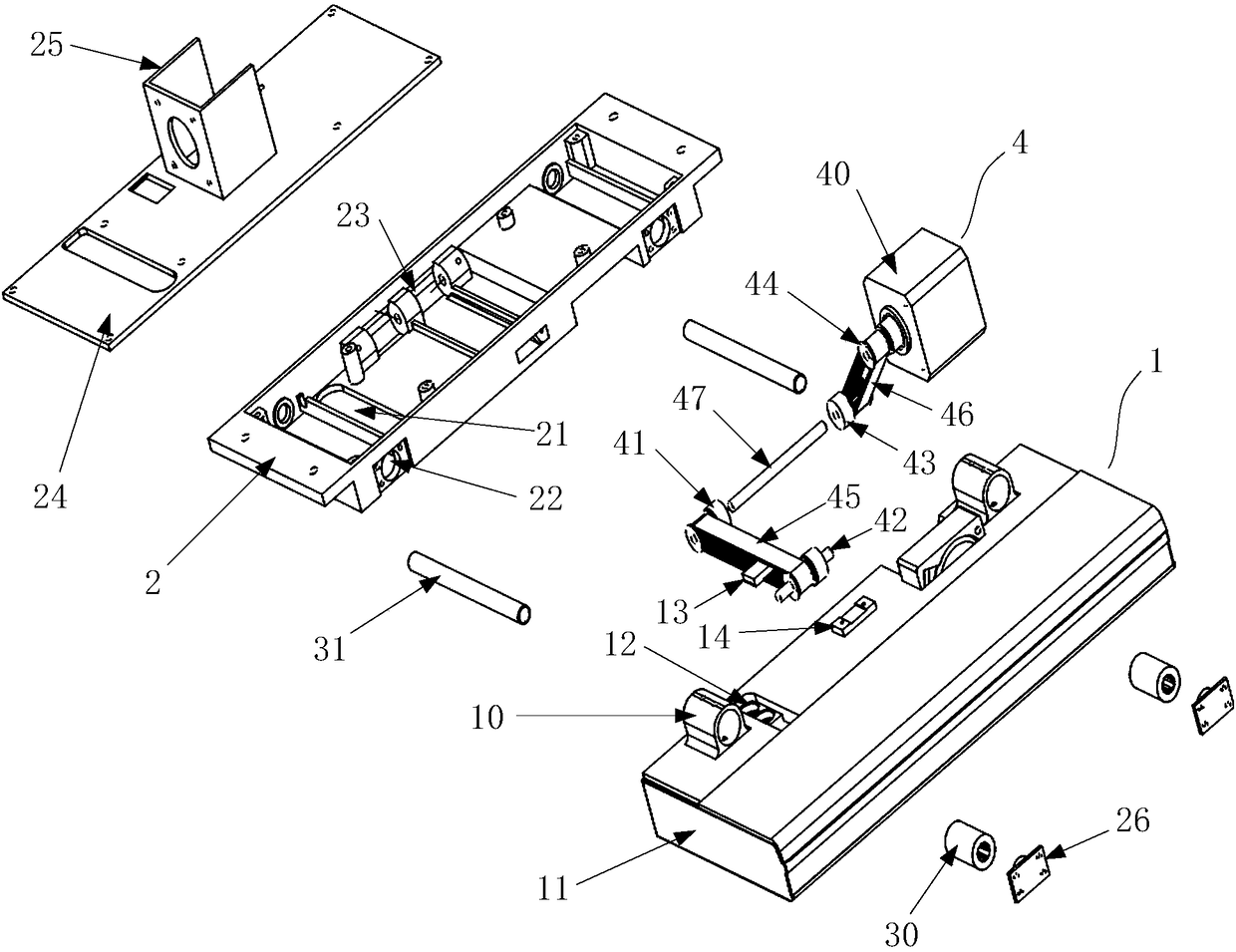

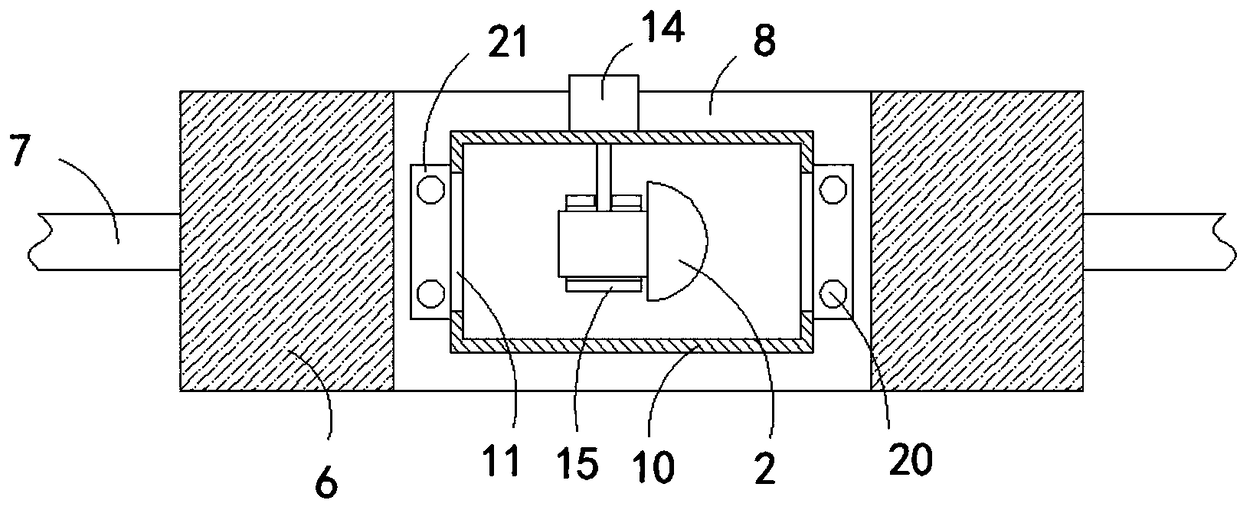

Cloth spreading machine for garment production

InactiveCN111762600AEasy to install and disassembleImprove aestheticsLiquid/gas/vapor textile treatmentWebs handlingEngineeringMechanical engineering

Owner:高邮萤火贸易有限公司

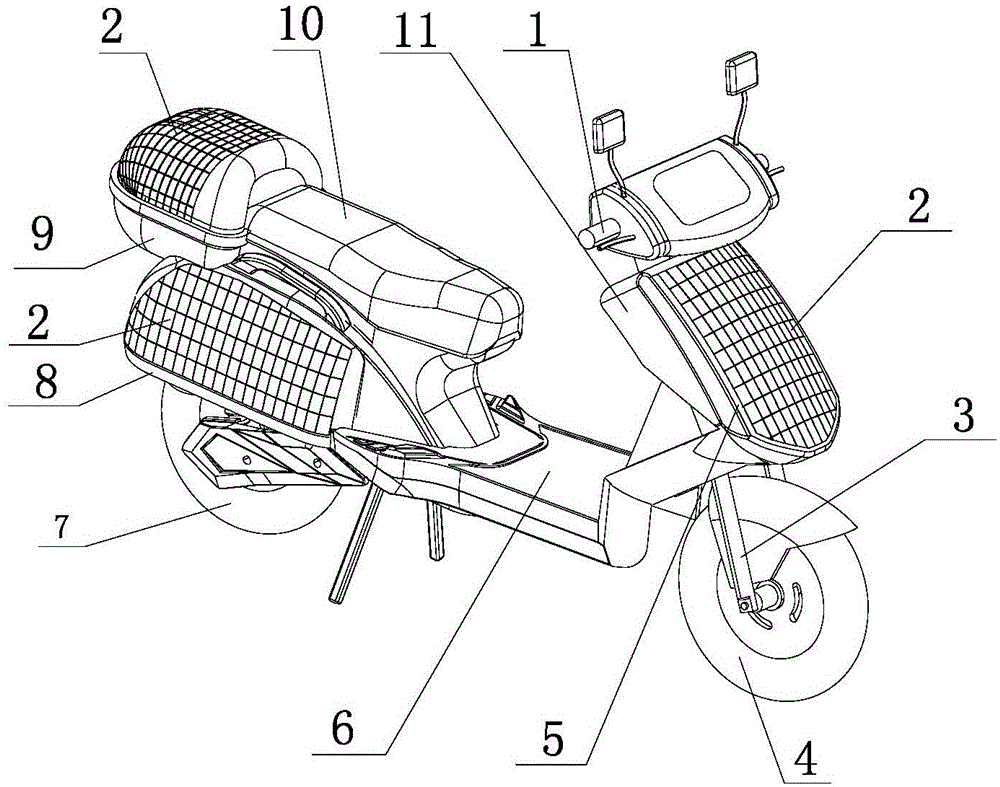

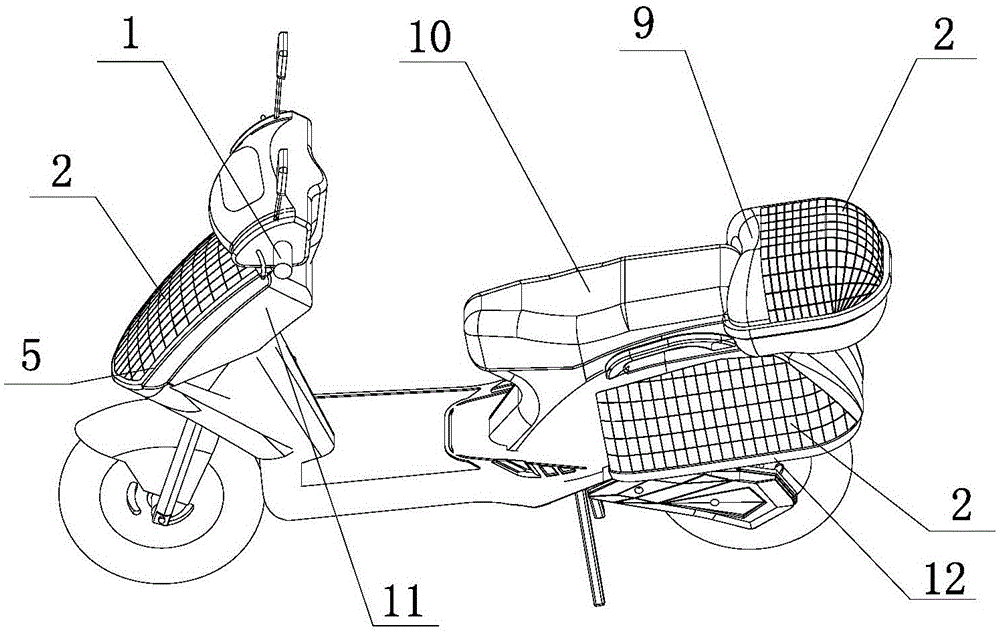

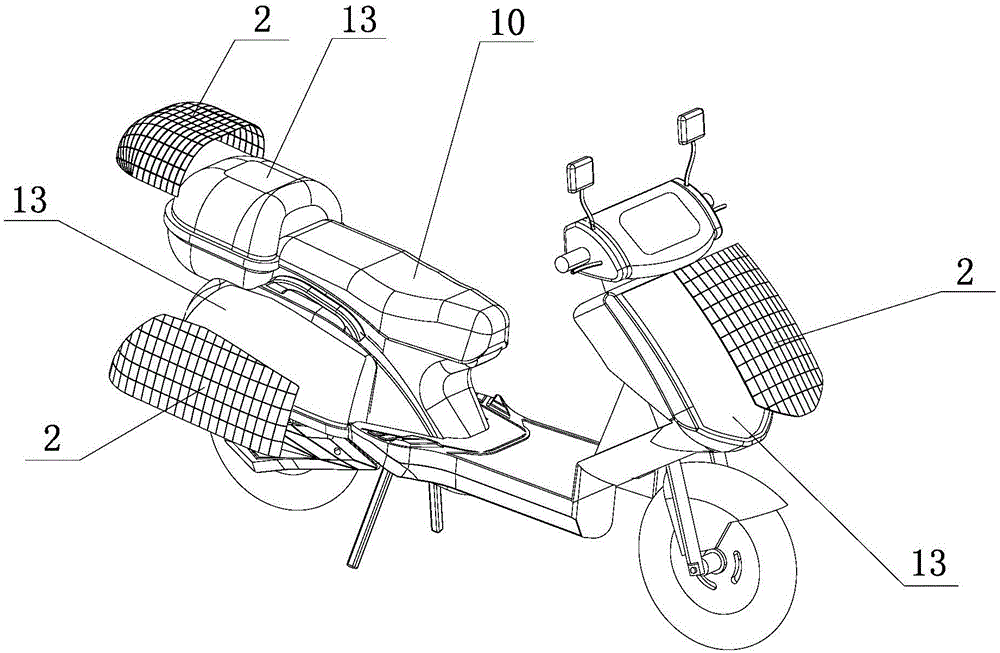

Novel photoelectric electric vehicle

InactiveCN105000105AExtend the light timeImprove aestheticsElectric propulsionMotorcyclesElectric carsElectric vehicle

Owner:XINCHANG CHAOYAN NEW ENERGY VEHICLE IND CO LTD

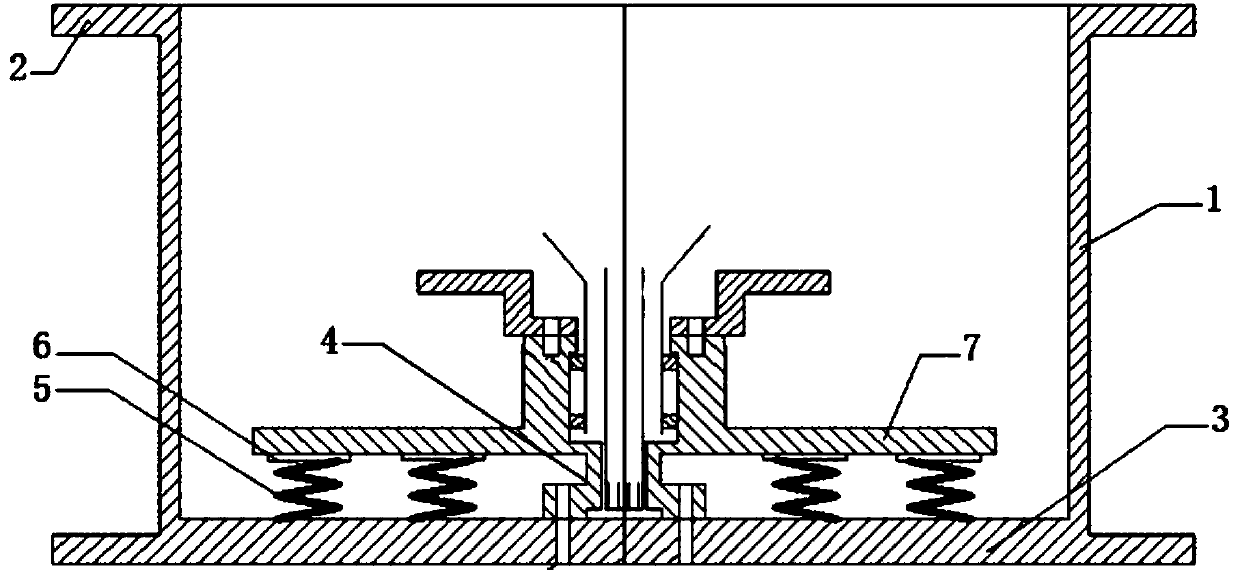

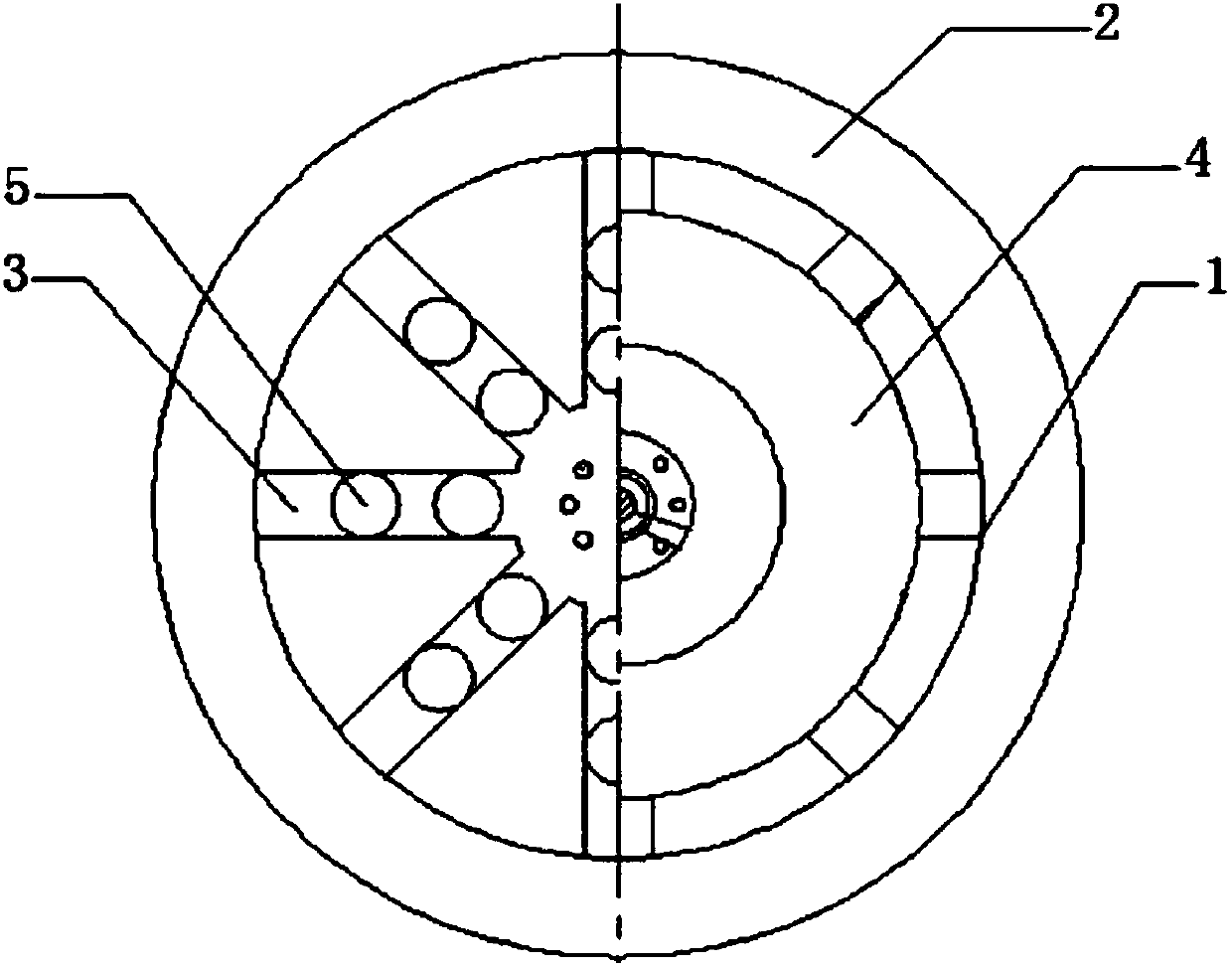

Anti-collision car wheel

ActiveCN107599736AImprove the ability of anti-collision deformationImprove aestheticsHigh resiliency wheelsSpokeEngineering

Owner:WUHAN UNIV OF TECH

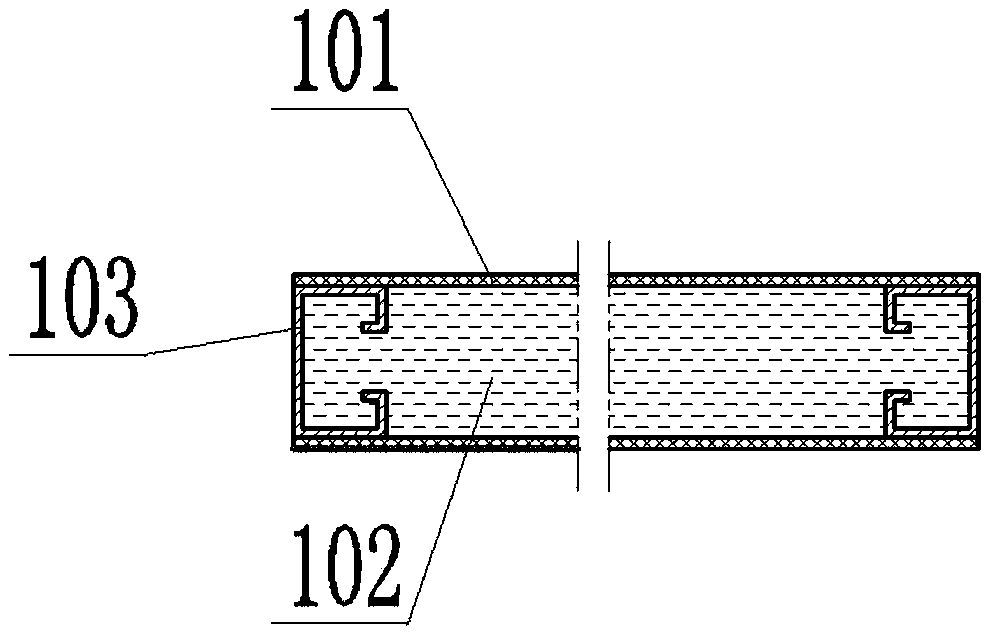

Prefabricated shear wall and construction technology thereof

ActiveCN109296110AGuaranteed structural strengthImprove aestheticsBuilding material handlingProtective buildings/sheltersBuilding constructionShear wall

Owner:南通龙哲混凝土制品有限公司

Shell machining mold and machining method and wearable device

InactiveCN108162313AImprove aestheticsImprove gripDetails for portable computersEngineeringMachining

Owner:ANHUI HUAMI INFORMATION TECH CO LTD

Lighting device for elevator car

Owner:HITACHI LTD

Bathroom cabinet and embedded tap

ActiveCN108086413AImprove aestheticsImprove convenienceDomestic plumbingWash-standsAutomatic controlMedicine cabinet

Owner:XIAMEN AXENT

Automobile signal lamp

ActiveCN105444084AGood warningImprove aestheticsFixed installationOptical signallingDistribution patternDriving safety

Owner:CHERY AUTOMOBILE CO LTD

LIFI transceiving device convenient for storage

ActiveCN108631869AImprove aestheticsReduce the impactClose-range type systemsVehicle componentsEngineeringChassis

Owner:FUYANG GUANGPU LIGHTING TECH

Production method for live porcelain earthenware

The invention discloses a production method for live porcelain earthenware. The live porcelain earthenware comprises a porcelain body fired into the earthenware and glazed porcelain sintered on an inner surface layer and an outer surface layer of the porcelain body. The earthenware is prepared from the following materials in percentage by weight: 12-20% of iron ore, 6-15% of silica, 15-17% of quartz stone, 3-4% of white feldspar, 15-22% of melilite, 7-10% of black stones, 6-10% of Maya stones, 3-4% of bovine bones, 2-5% of knar clay, 5-15% of kaolin and 5-10% of calcite. The production method comprises the steps of feeding calcined iron ore and silica into a ball mill; performing mixed ball-milling with the rest of the raw materials to prepare slurry; coating the inner and outer surfaces of the porcelain body with the slurry; and feeding the porcelain body into a furnace kiln for firing the porcelain body into the finished live porcelain earthenware. The finished earthenware has a magnetization function and a health effect.

Owner:HENAN TINGHUAIRU CERAMIC TECH CO LTD

Three-layer water-based cosmetic

ActiveCN102309418ABeautiful and novel appearanceImprove aestheticsCosmetic preparationsSkin careAlcoholAlkane

Owner:PROYA COSMETICS

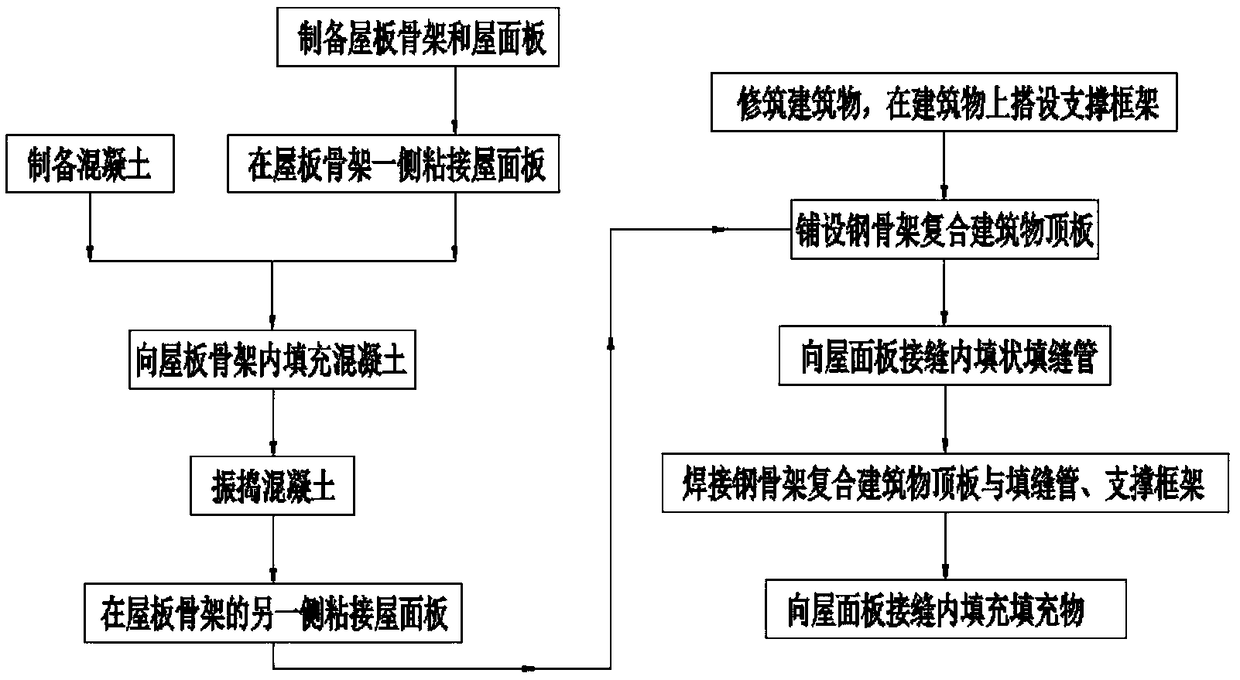

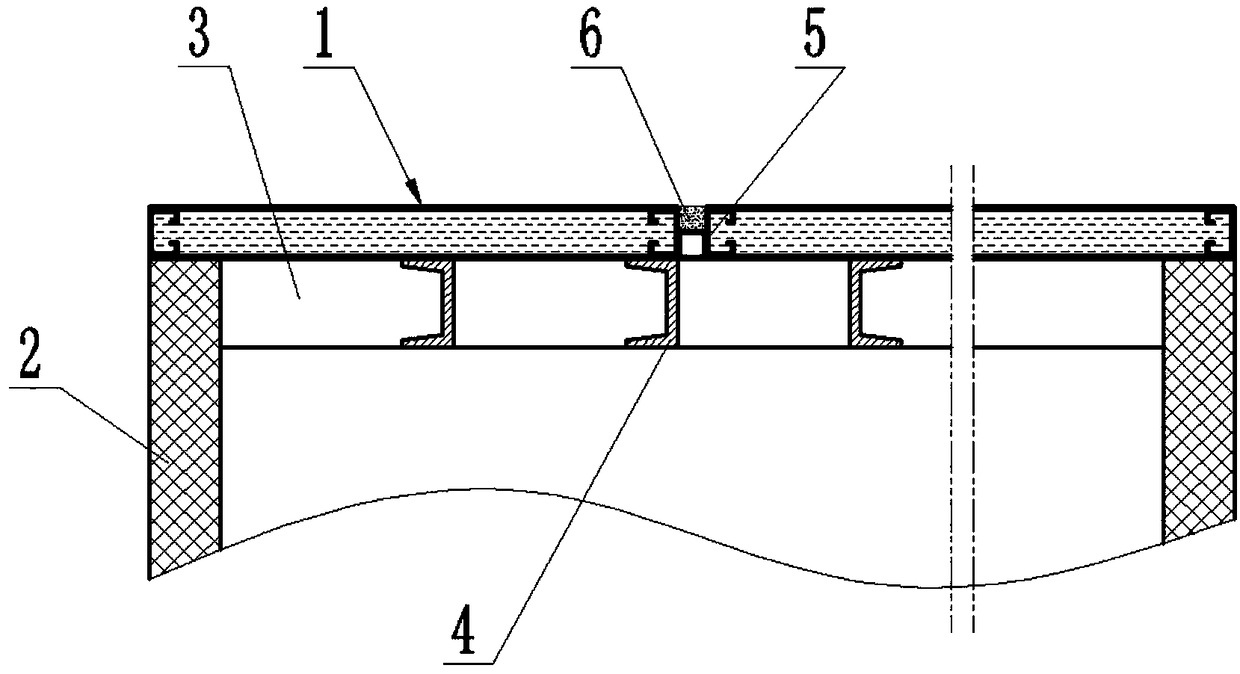

Paving construction process for roofs of steel framework composite building

ActiveCN108824810AUniform and consistent expansionSame expansion rateBuilding material handlingBraced frameArchitectural engineering

Owner:NO 1 CONSTR ENG CO LTD OF GUIZHOU CONSTR & ENG GRP

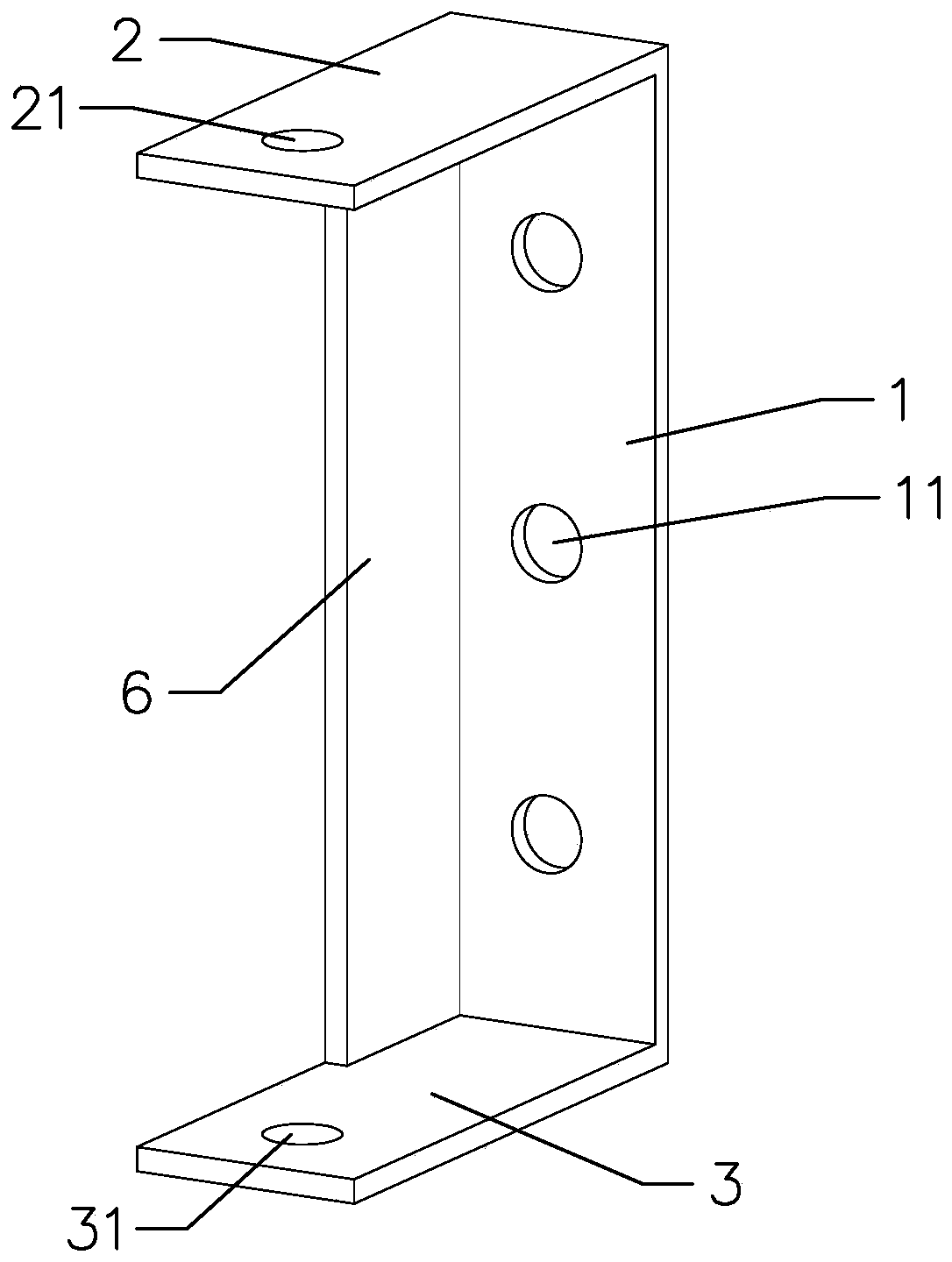

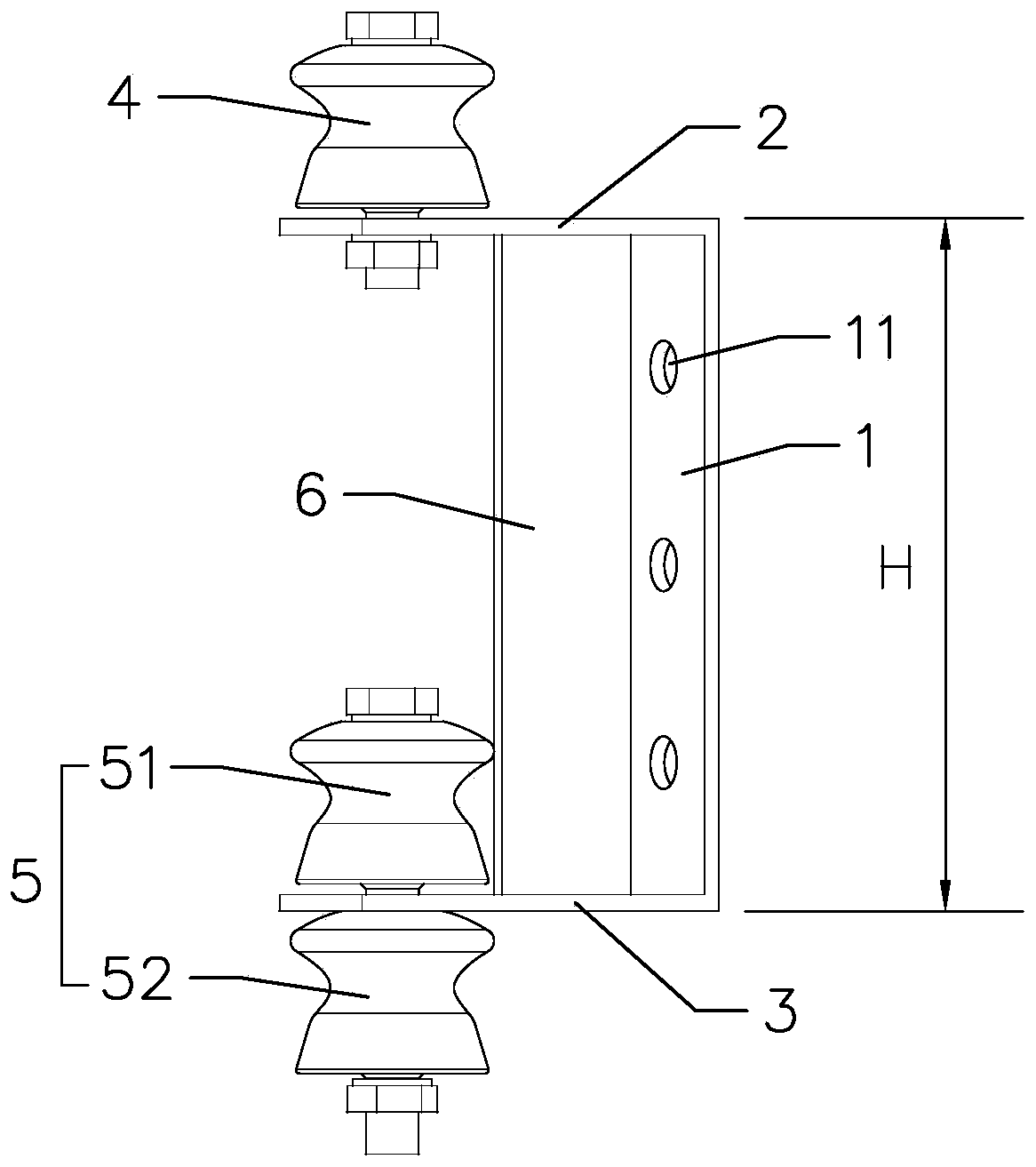

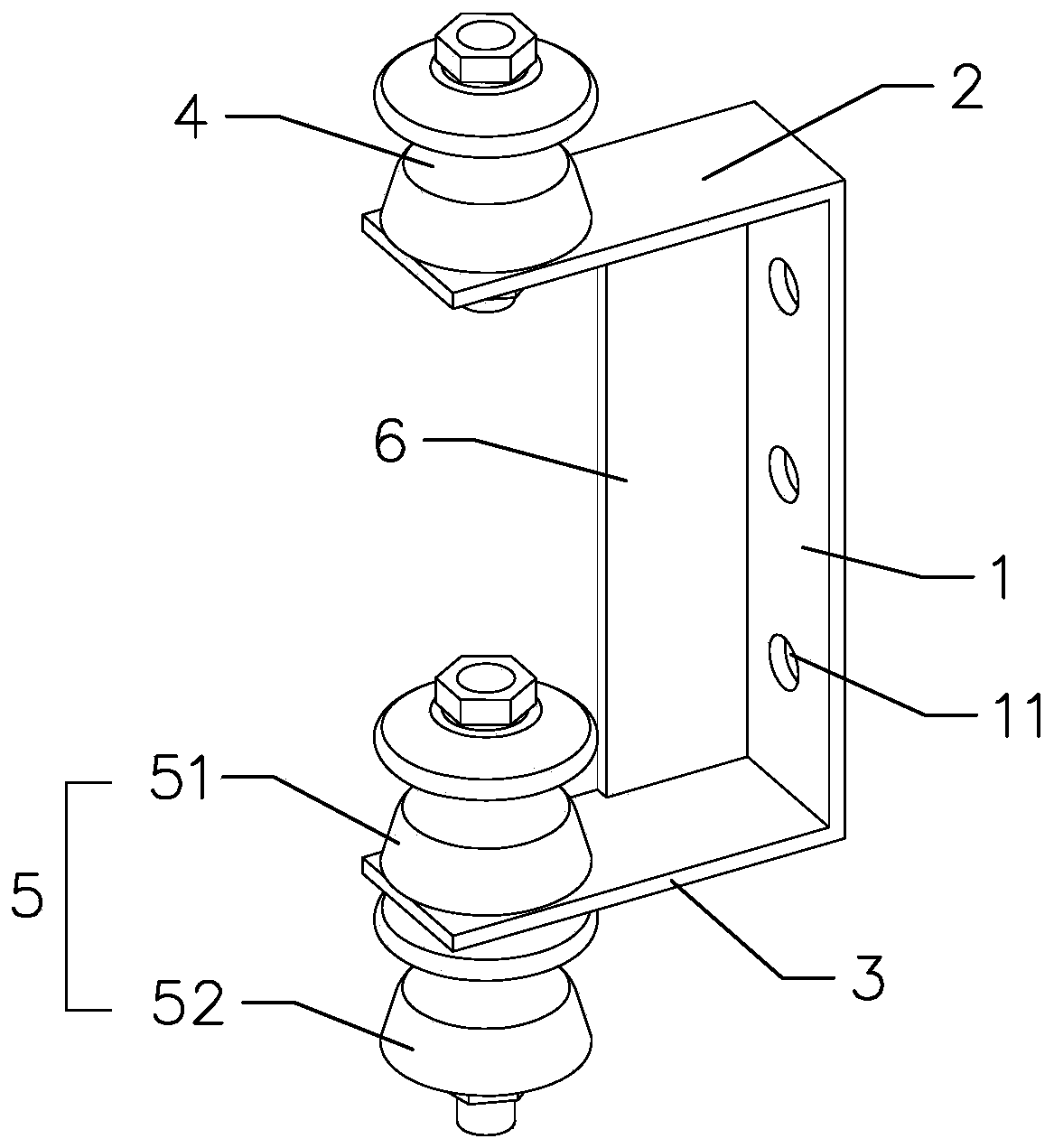

Interconnected bracket in compatible with weak electric line and wiring method

PendingCN109904810AImprove aestheticsReduce short circuitElectrical apparatusEngineeringElectric power

Owner:STATE GRID ZHEJIANG JIANDE POWER SUPPLY +1

L-shaped special-shaped column and beam fabricated connecting joint

InactiveCN112302169ASufficient lateral stiffnessImprove seismic performanceStrutsPillarsLateral stiffnessArchitectural engineering

The invention discloses an L-shaped special-shaped column and beam fabricated connecting joint, and belongs to the technical field of structural engineering. The L-shaped special-shaped column and beam fabricated connecting joint is composed of a special-shaped column, I-shaped beams, channel steel connecting pieces and high-strength bolt groups. Manufacturing and welding parts of steel componentsare completed in a factory, the welding quality is easy to control, only each prefabricated component needs to be hoisted, and is connected through a high-strength bolt on a construction site, and the construction efficiency is high; and the connecting joint has the advantages of mechanical property and practical property at the same time, and specifically, in the aspect of the mechanical property, the connecting joint makes full use of the bearing capacity and the lateral stiffness of the special-shaped column, and has the good anti-seismic property; and in the aspect of the practical property, the connecting joint emphatically achieves the rapid assembly concept, and solves the "protruding column" problem in a house.

Owner:BEIJING UNIV OF TECH

Preparation method of shell, shell and electronic equipment

ActiveCN110708926AGuaranteed connection strengthIncreasing the thicknessMetal casingsCooling/ventilation/heating modificationsMetallic enclosureMechanical engineering

The invention provides a preparation method of a shell, the shell and electronic equipment. The preparation method of the shell comprises the steps that a metal shell and a metal heat conduction pieceare provided; an accommodating space similar to the metal heat conduction piece in shape is formed in the metal shell; the metal heat conduction piece is placed in the accommodating space, and the metal heat conduction piece and the metal shell are welded together; and the material protruding out of the outer surface of the metal shell at the position of the accommodating space is removed so as to enable the outer surface of the metal shell to be smooth. The invention provides the preparation method of the shell, the shell and electronic equipment, which are suitable for ultrathin electronicproducts and have high reliability in high-temperature operation.

Owner:HUAWEI TECH CO LTD

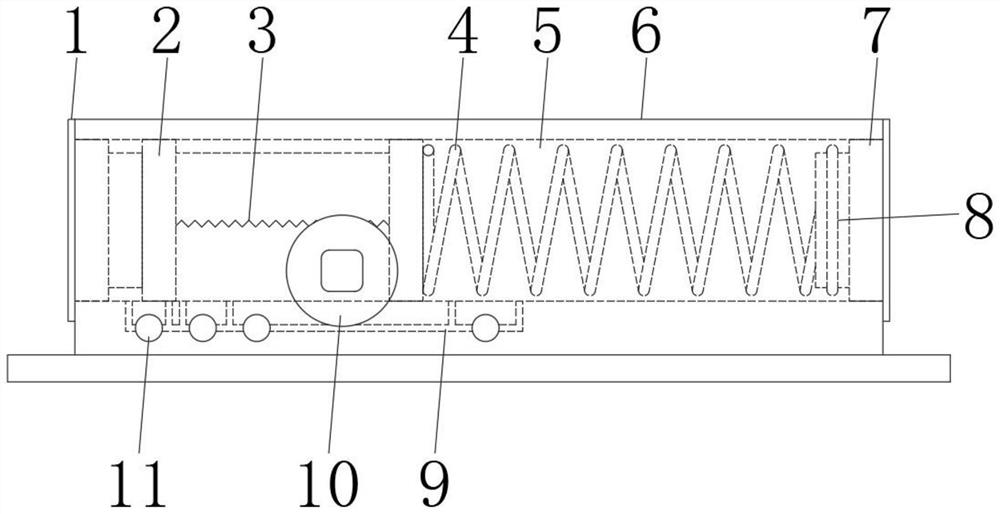

Ladder-type cable bridge with expansion structure

Owner:SICHUAN LIZHI JIUCHUANG INTPROP OPERATION CO LTD

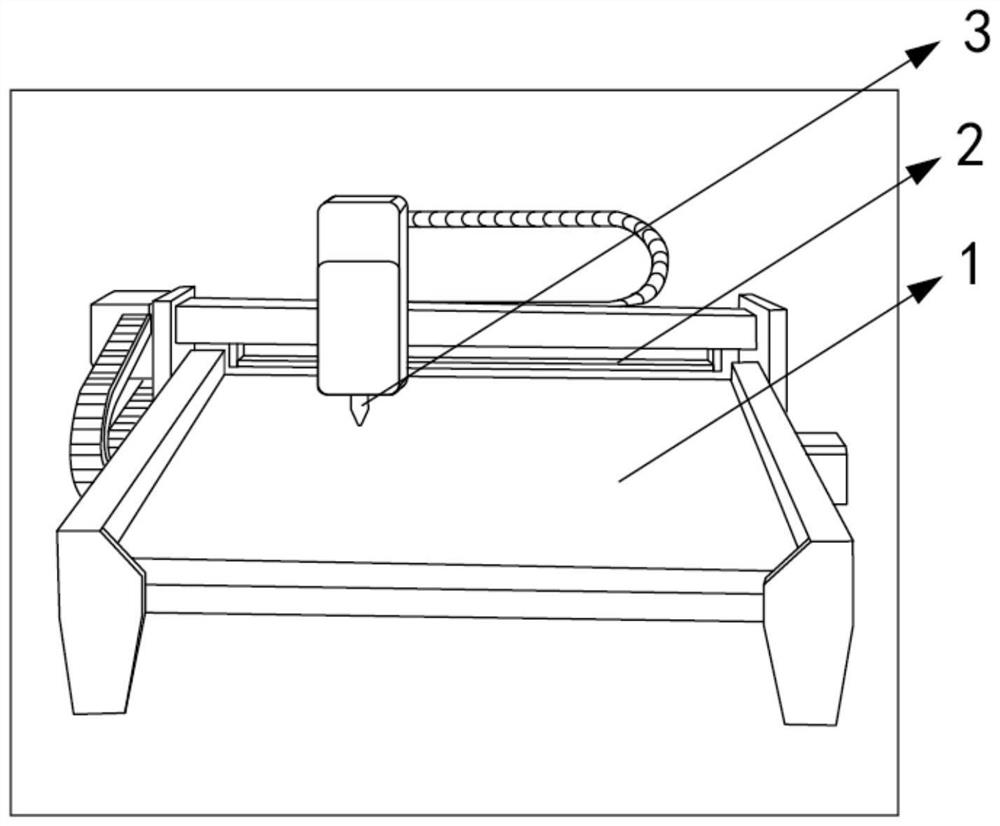

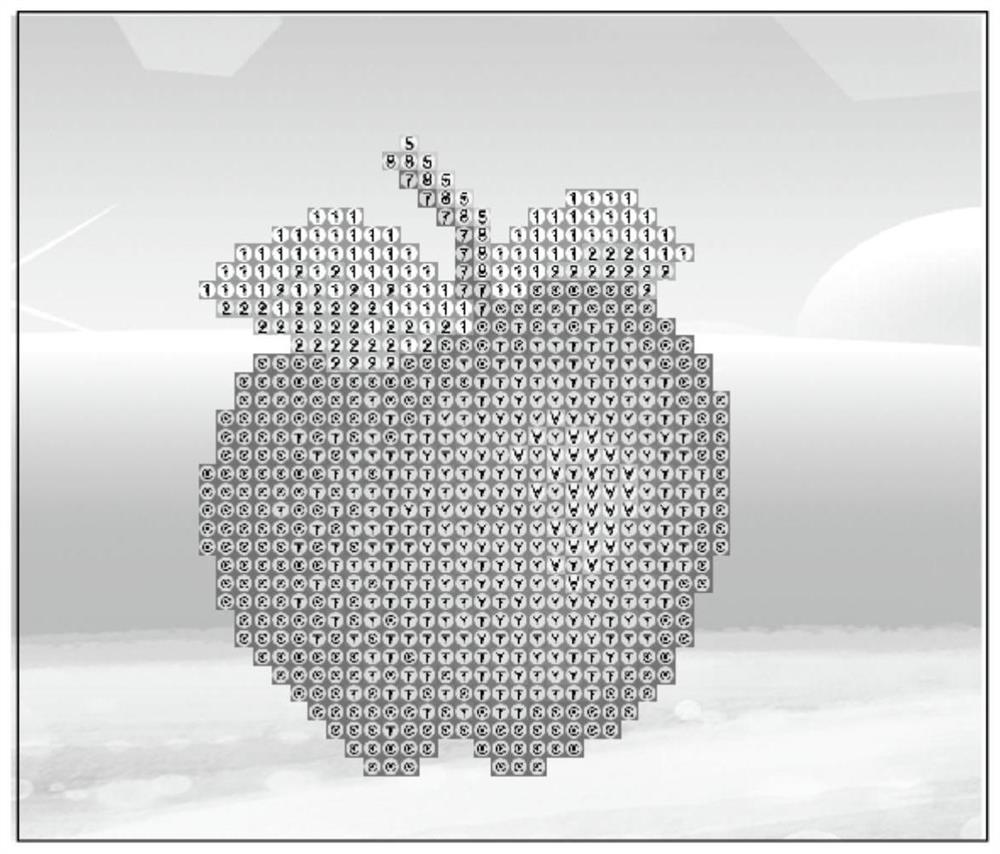

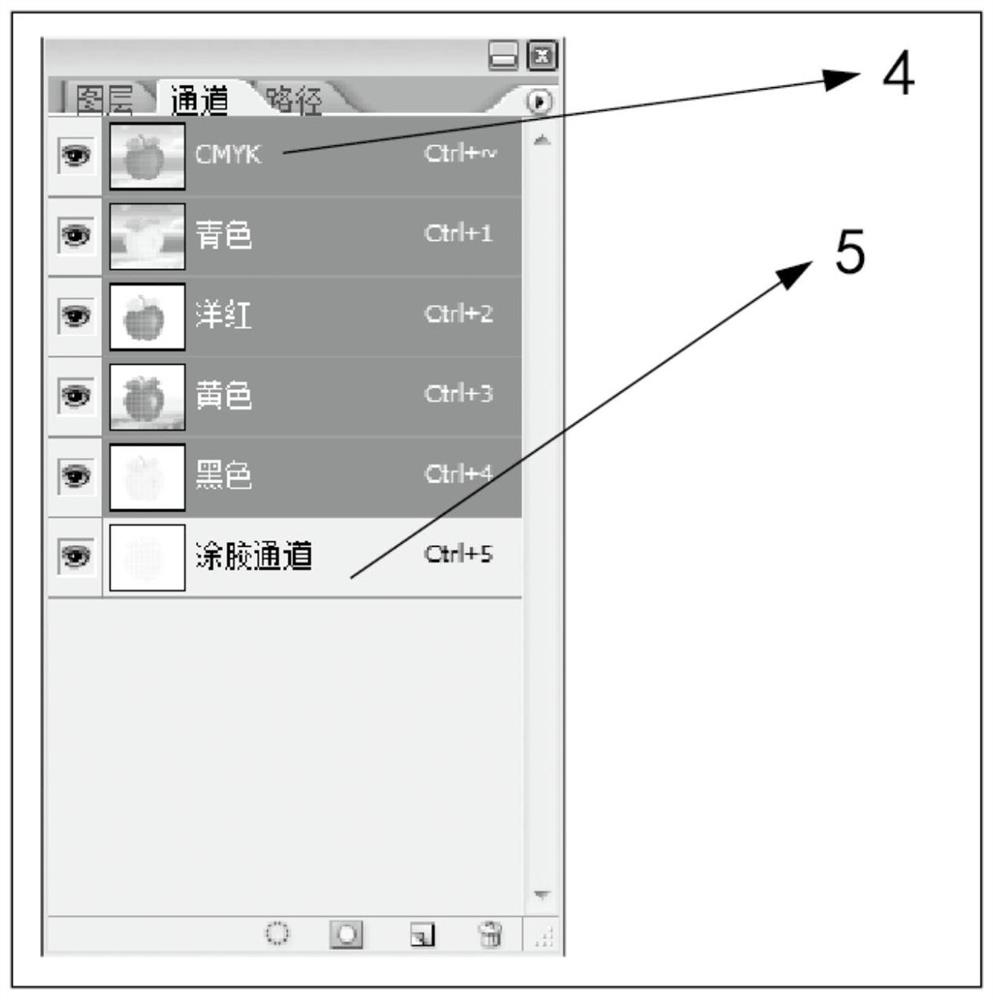

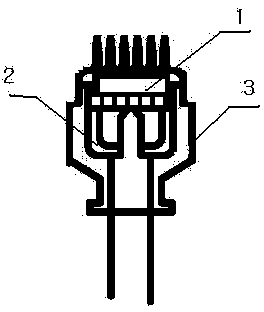

Diamond canvas gluing method

ActiveCN113276580AAchieve precisionImprove aestheticsLiquid surface applicatorsDuplicating/marking methodsDigital printingEngineering

The invention relates to the technical field of diamond canvas gluing, in particular to a diamond canvas gluing method. The diamond canvas gluing method comprises the following steps that 1, gluing positioning points are manufactured; 2, digital printing is carried out so that a diamond picture pattern and the gluing positioning points are jointly printed on a diamond canvas in a jet printing mode; 3, the diamond canvas is fixed and scanned, and gluing positioning point information on the diamond canvas is obtained; and 4, inputting into a gluing machine is performed, and gluing is performed on the diamond canvas according to the scanned and read positioning point information. According to the diamond canvas gluing method, gluing convenience is improved, and gluing is attractive.

Owner:杨振玉

Printed matter film covering and plastic packaging treatment method

InactiveCN113212022AAvoid secondary pollutionImprove aestheticsLaminationLamination ancillary operationsDust controlManufacturing engineering

Owner:武汉合一协同文化传媒有限公司

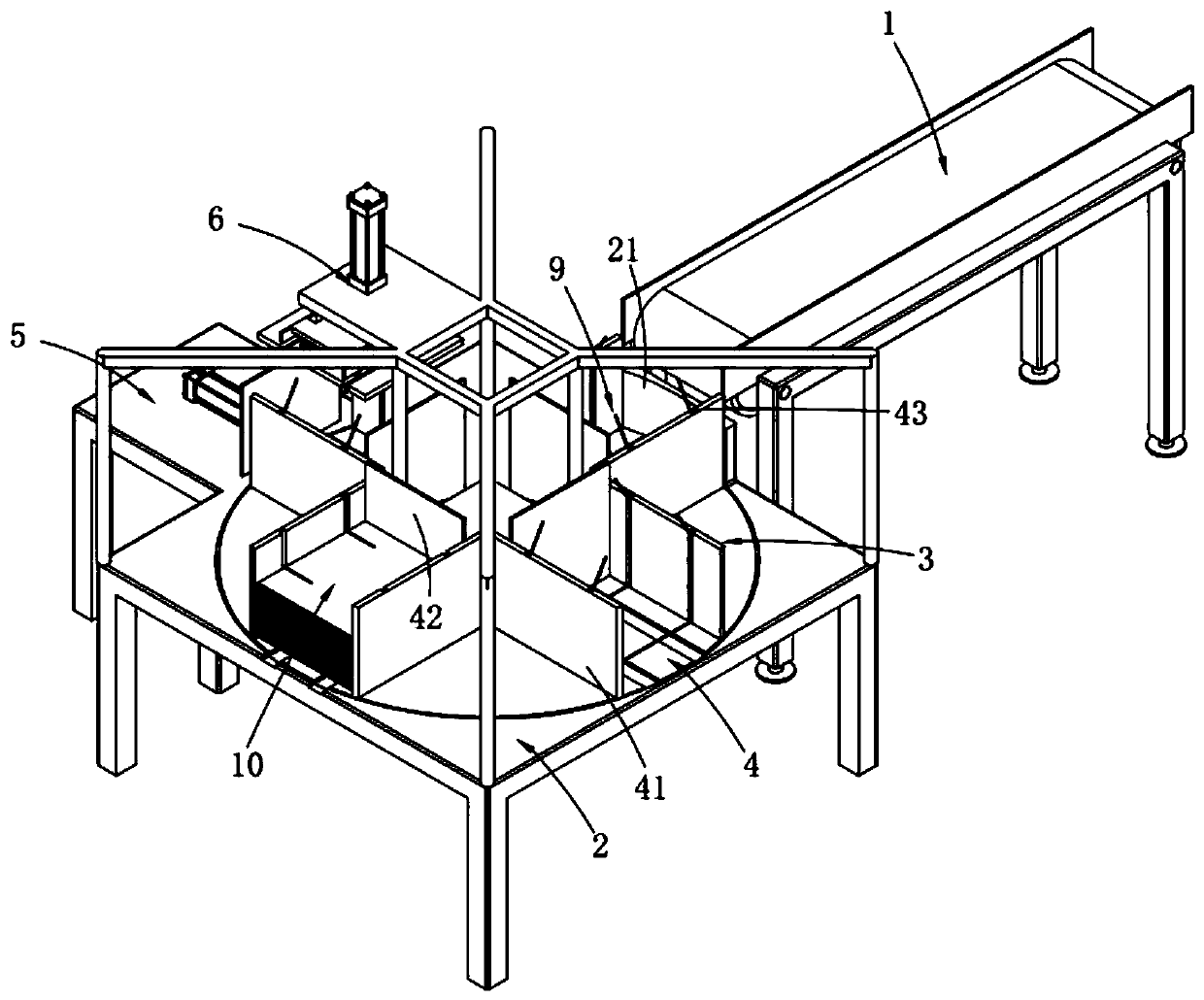

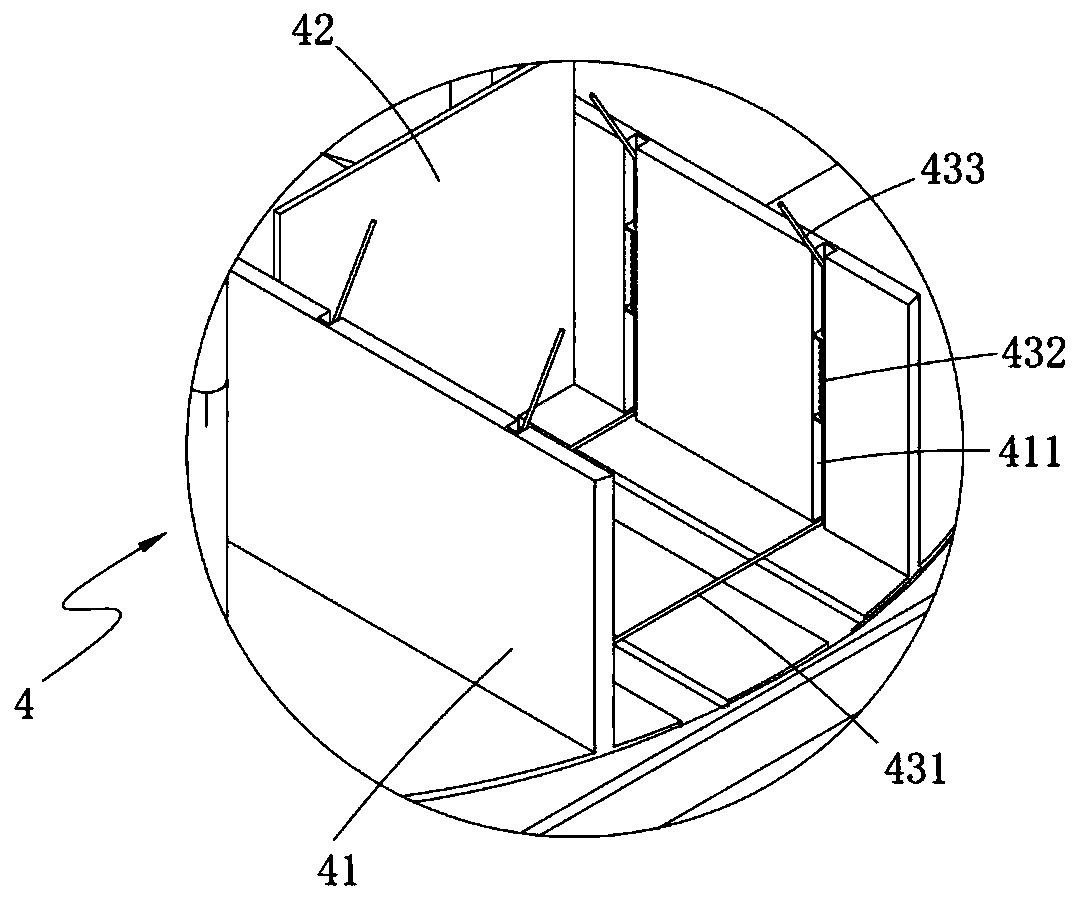

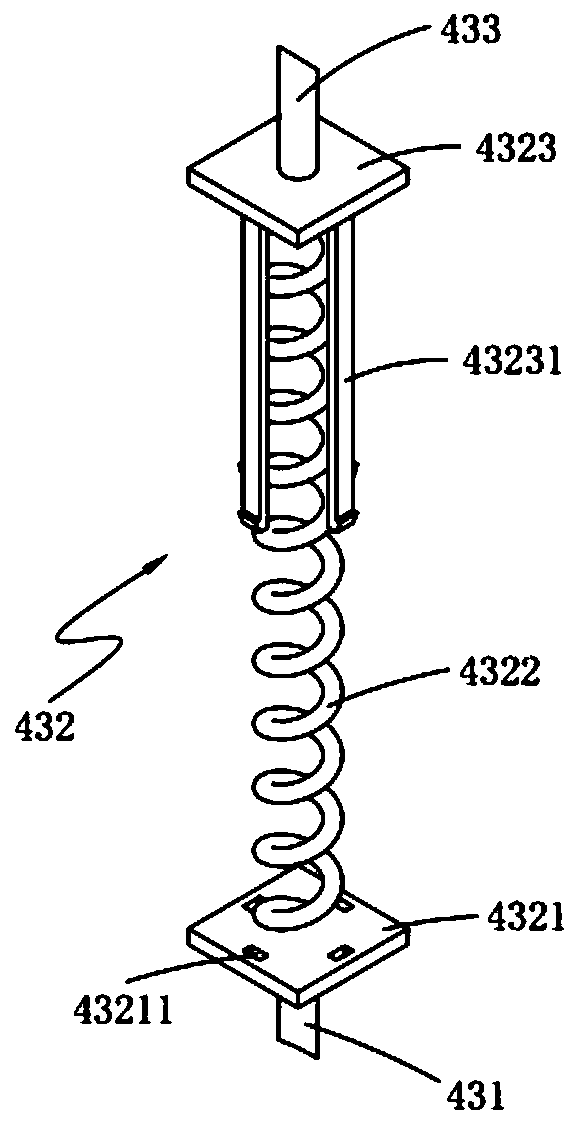

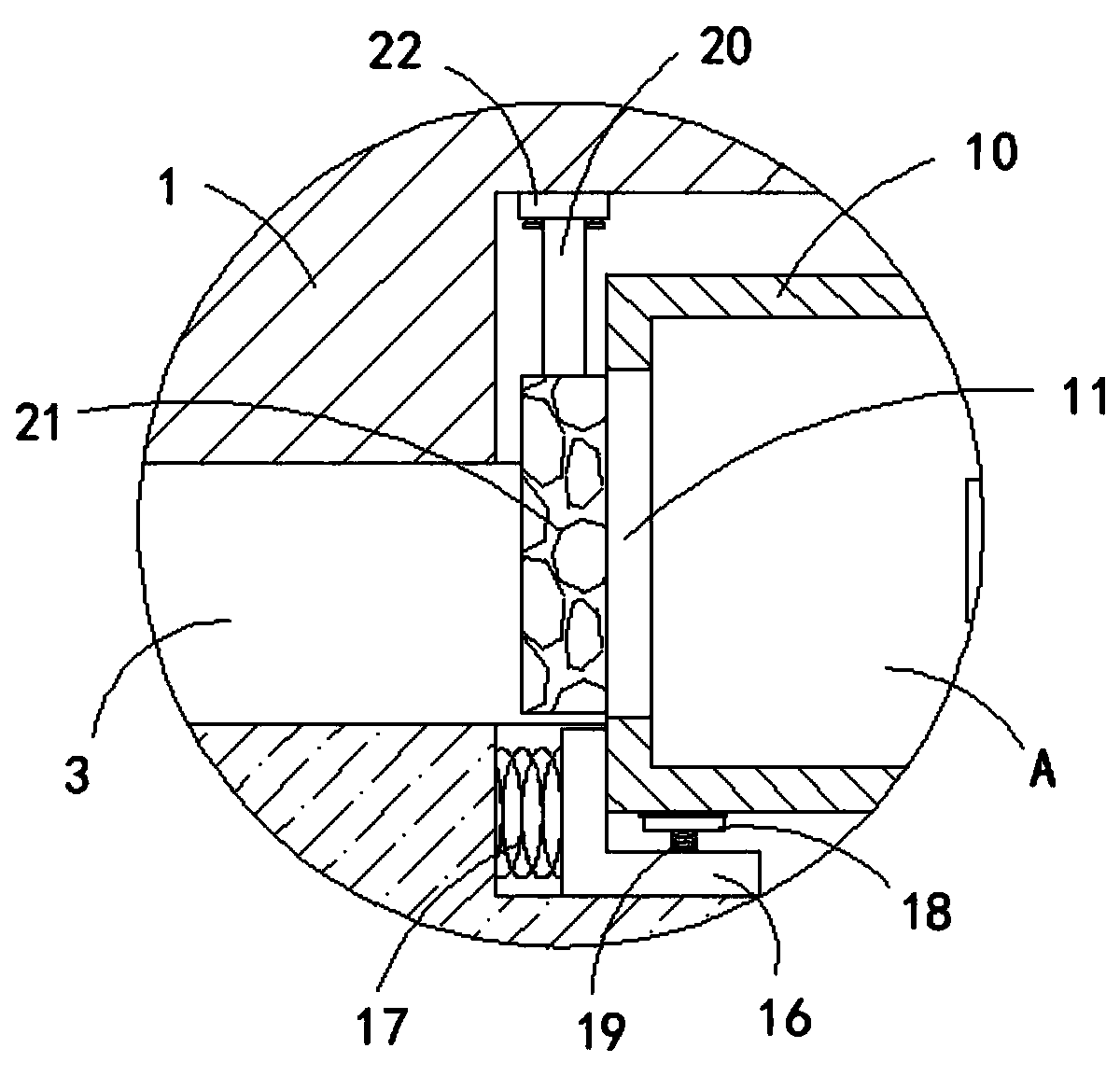

Sports ball storage, installation and use device and use method thereof

InactiveCN112978059AEasy to storeEasy accessBall sportsDischarging meansWater sourceStructural engineering

The invention discloses a sports ball storage, installation and use device and a use method thereof, and relates to the technical field of sports ball storage, installation and use. The storage problem of sports balls is solved. The sports ball storage, installation and use device specifically comprises a storage box, universal wheels are fixed to the four corners of the outer wall of the bottom of the storage box through screws, display mechanisms are arranged at the top ends of the inner walls of the two sides of the storage box, a marble mechanism is arranged on the inner wall of the bottom of the storage box, storage mechanisms are arranged in the middles of the inner walls of the two sides of the storage box, a flushing mechanism is fixed to the bottom end of the outer wall of one side of the storage box through screws, and a push handle is arranged at the top end of the outer wall of one side of the storage box. By arranging the flushing mechanism, the equipment is connected with a power supply, the sports balls are in a cleaning disc, a water inlet pipe is placed in a water source, a water pump is started, so that water is discharged through a water outlet pipe, the balls are cleaned, the sports balls are conveniently cleaned and stored, and the next use is facilitated while the attractiveness is improved.

Owner:金晓霞

Frozen beverage with chocolate coated particles and preparation process thereof

The invention discloses a frozen beverage with chocolate coated particles and a preparation process thereof. The preparation process comprises the steps that firstly, chocolate is coated on the surface of the frozen beverage to form chocolate crisps; and before chocolate crisps are dried, chocolate crisps are subjected to particle throwing and coating. The particle throwing speed of particle throwing and coating is controlled to be 2 to 8m / s, and the particle throwing direction of particle throwing and coating is obliquely above chocolate crisps, and sharp included angle between the particle throwing direction and chocolate crisps is 40 to 70 degrees. By controlling the particle throwing speed and the particle throwing direction, strong binding force between the particles and chocolate crisps can be ensured. The coverage rate of the particles coated in the frozen beverage with chocolate coated particles in chocolate crisps is improved. Tests show that the surface area of chocolate crisps covered by the particles in chocolate crisps exceeds more than 80% of the total surface area of chocolate crisps.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Square micro-needle massager manufacturing technical process

InactiveCN104225776AImprove aestheticsImprove practical effectMedical devicesMicroneedlesMicro-needle

Owner:QINGDAO KANGWEILONG COMMODITY COMPANY

Manufacturing method of civil defense door closing structure

PendingCN111877904ASpend less timeImprove assembly efficiencyBuilding braking devicesNumerical controlGear wheel

Owner:JINAN JINFENGYUAN PROTECTIVE EQUIP CO LTD

Novel insulation structure for building external wall

InactiveCN109811928AImprove aestheticsImprove firmnessHeat proofingWallsAnchor boltBuilding material

Owner:绍兴悦植科技有限公司

Aquaponic creative gift

InactiveCN108575865AEasy to removeEasy to useSelf-acting watering devicesPisciculture and aquariaAquaponicsEngineering

The invention discloses an aquaponic creative gift. The gift comprises a base and a clamping groove, wherein the clamping groove is formed in the inner left side of the base, a fish tank is clamped inside the clamping groove, a first groove is formed in the right side of the inner top end of the base, a second groove is formed in the left side of the inner top end of the base, a grid box is arranged on the left side of the inner top end of the fish tank, and flower mud is placed inside the grid box. According to the aquaponic creative gift, by matching of the base and the clamping groove, a user can conveniently remove the fish tank for cleaning and fix the fish tank in the clamping groove in the base, and use is facilitated for the user; through matching of the grid box and a first hook,the user can hang different numbers of grid boxes in any position on the edge of the fish tank according to own preference; the user can conveniently plant vegetables in the grid box to soak in waterby matching of the grid box and the flower mud, and attractiveness is greatly improved.

Owner:FOSHAN HENGNAN MICRO TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap