Manufacturing method of civil defense door closing structure

A manufacturing method and technology for air defense doors, which are used in door/window fittings, building structures, switches with brakes, etc., can solve the problems of cumbersome operation, reduce work efficiency, spend a lot of time, etc., and increase assembly efficiency. , reduce the time spent, increase the effect of aesthetics and anti-rust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for manufacturing a closed door structure of a civil air defense door, comprising the following steps:

[0031] S1. After the steel is subjected to high-temperature treatment, it is directly upset into a billet of approximate shape and size with a cold heading machine. The temperature of the high-temperature treatment of the steel is 1100°C;

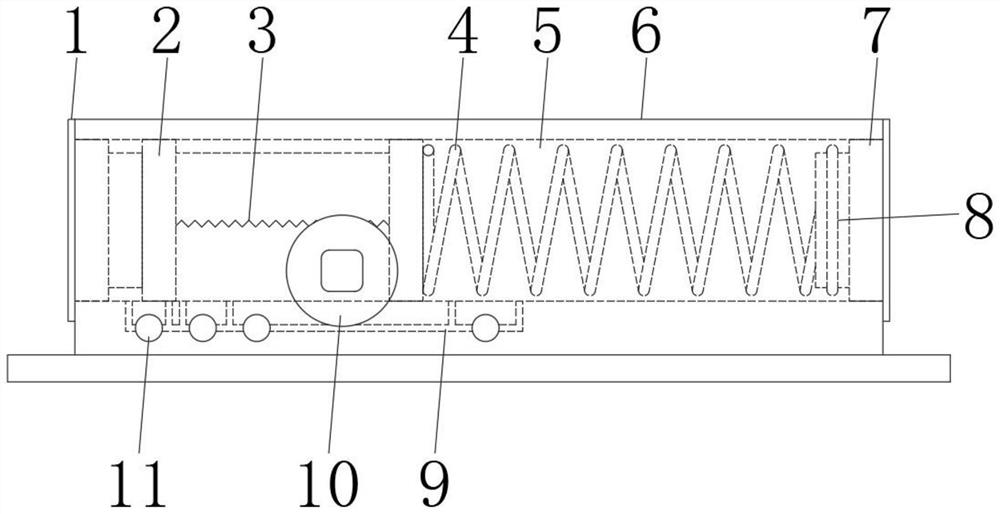

[0032] S2. Use a CNC lathe or a small lathe to carry out deep processing on the shaft cover blank, respectively process the first end cover 1, the baffle plate 2, the rack 3, the shell 6, the second end cover 7 and the gear 10, and use the electroplating process to process the baffle plate , racks, shells and gears are galvanized;

[0033] S3. Put the first end cap 1 and the second end cap 7 of qualified size on the thread rolling machine to process and form the threads, and use the lathe to carve out the clamping groove 8 on the second end cap 7, and use the electroplating process to the first end cap 7. The end cap and...

Embodiment 2

[0041] A method for manufacturing a closed door structure of a civil air defense door, comprising the following steps:

[0042] S1. After high-temperature treatment, the steel is directly upset into a blank of approximate shape and size with a cold heading machine;

[0043] S2. Carry out deep processing to the shaft cover blank with a CNC lathe or a small lathe, respectively process the first end cover 1, the baffle plate 2, the rack 3, the casing 6, the second end cover 7 and the gear 10, and the temperature of the high temperature treatment of the steel is 1000°C;

[0044] S3. Put the first end cap 1 and the second end cap 7 of qualified size on the thread rolling machine to process and form the threads, and use the lathe to carve out the clamping groove 8 on the second end cap 7, and use the electroplating process to the first end cap 7. Galvanized end caps, baffles, racks, housings, second end caps and gears;

[0045] S4, the baffle plate 2 is welded and fixed on the two...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap