Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Improve assembly efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

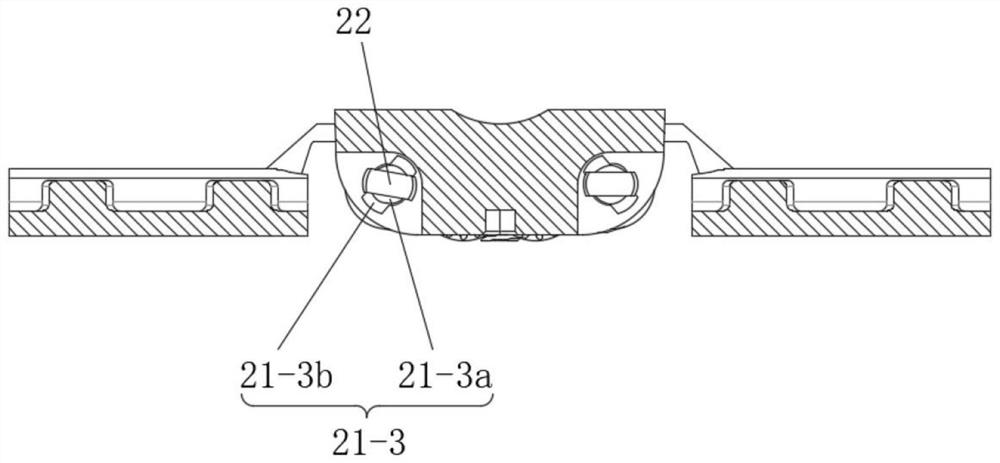

Press plate assembly, camera module and mobile terminal

PendingCN107493420AImprove assembly efficiencyTelevision system detailsColor television detailsFlexible circuitsEngineering

The invention provides a camera module. The camera module comprises a flashlight, a camera and a circuit board assembly. The circuit board assembly comprises a circuit board, a support and a flexible circuit board. The support is arranged on the circuit board. The support and the circuit board form an accommodation space. The flashlight is fixed on a bearing part of the support. The camera is arranged near the support. The flexible circuit board comprises a first branch flexible segment, a second branch flexible segment and a main flexible segment. The first branch flexible segment is electrically connected to the camera. The second branch flexible segment is electrically connected to the flashlight. The first branch flexible segment and the second branch flexible segment are gathered to form the main flexible segment. According to the invention, the flashlight and the camera share one flexible circuit board, and the flexible circuit board is electrically connected to the circuit board in the accommodation space of the support, so the flexible circuit board can be arranged under the support, and the use rate of the space is increased. The invention also provides a mobile terminal.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Component box

InactiveCN106211671AEasy to useImprove assembly efficiencyCasings/cabinets/drawers detailsSmall component housingsEngineeringExternal connection

Owner:HEFEI AGEDE INFORMATION TECH

Whole forming method for cylindrical netting support with horizontal sliding structure

InactiveCN1472408AImprove installation accuracyImprove construction qualityBuilding constructionsEngineeringMechanical engineering

A construction method for integrally formed cylindrical reticulated shell with horizontal slide structure is disclosed. A cylindrical reticulated shell is divided into two segments for individual assembly. Its one end is a fixing hinge and its another end is a slide hinge in slide way. The hinged points between two segments are borne on temporary supporter. Both slide hinges are horizontally moving until they reach designed positions and the slide hinges are fixed to base. When hinged point reached designed height, a horizontal rod is linked to fix the hinged points. Its advantages are short period, and low cost.

Owner:ZHEJIANG GUOSHENG STEEL STRUCTURE CO LTD

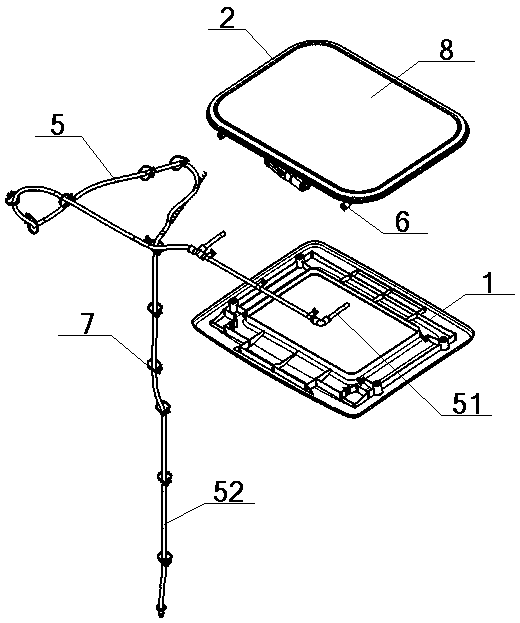

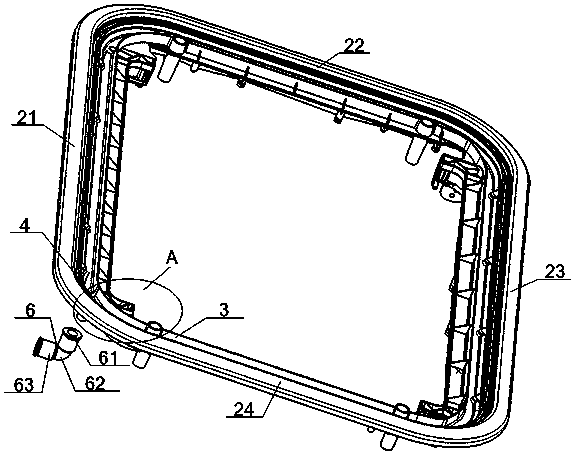

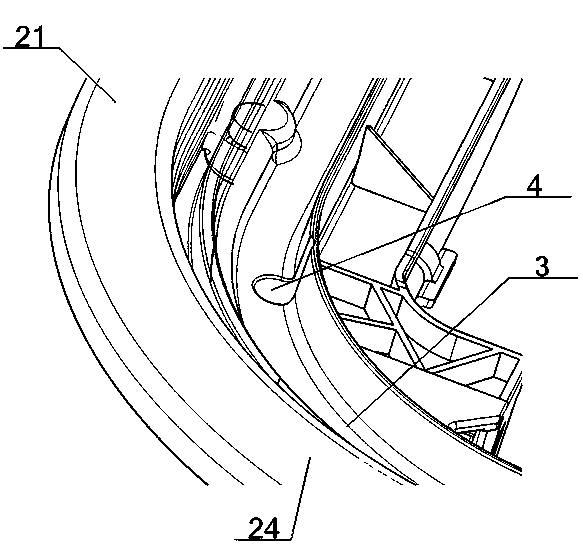

Drainage system of automobile electric skylight

Owner:DONGFENG COMML VEHICLE CO LTD

Finished refrigerator product assembling device

InactiveCN106553030AImprove assembly efficiencyReduce work proceduresMetal working apparatusAtmospheric pressureGrippers

Owner:明光市和诚电气有限公司

Method for determining thicknesses of gaskets for assembling roll to bearing pedestal

InactiveCN108547881AImprove assembly efficiencyImprove assembly qualityBearing unit rigid supportMeasurement devicesEngineeringMechanical engineering

Owner:BENGANG STEEL PLATES

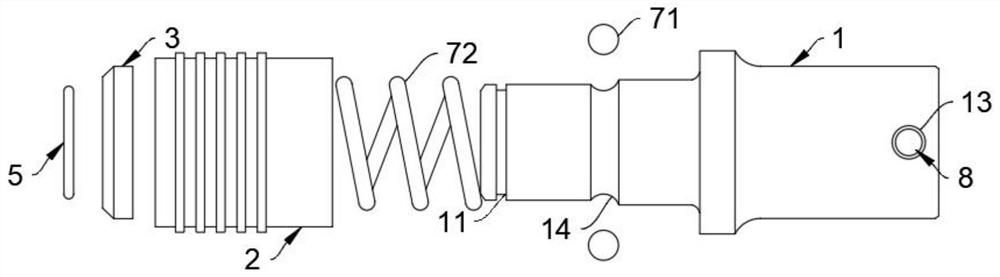

Automatic assembling device of fog lamp dimming ball component

ActiveCN103386609AGuaranteed assembly accuracyImprove assembly efficiencyAssembly machinesEngineeringLateral move

Owner:CHANGZHOU XINGYU AUTOMOTIVE LIGHTING SYST

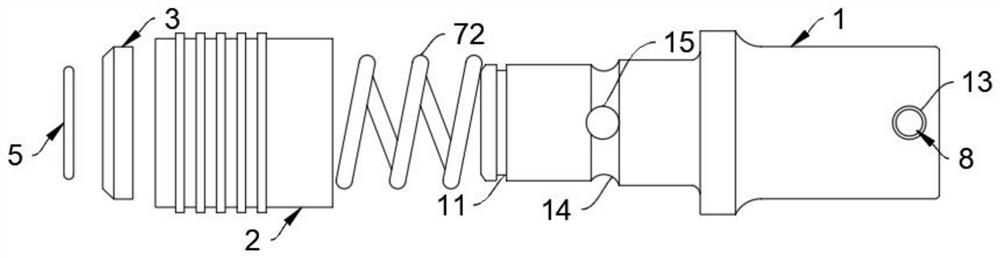

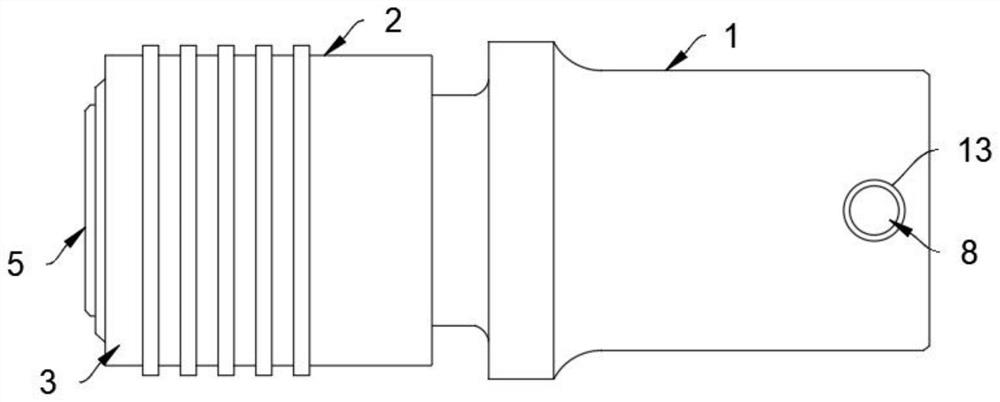

Multifunctional through sleeve

ActiveCN111958527AImprove assembly efficiencyMeet assembly needsScrewdriversSpannersEngineeringPhysics

Owner:重庆北方机械设备有限公司

Extensible collector ring

ActiveCN106025748AEasy to assemble and disassembleImprove assembly efficiencyRotary current collectorWear resistantStator

Owner:杭州摇头龙科技有限公司

Feature matching detection system for Creo model of fan device

PendingCN110659652AImprove assembly efficiencyReduce manufacturing cost3D modellingCharacter and pattern recognitionClosed cavityComputer science

Owner:DONGHUA UNIV

Automatic resistor production equipment

InactiveCN110480356AImprove assembly accuracyImprove assembly efficiencyOther manufacturing equipments/toolsElectrical resistance and conductanceElectronic component

Owner:楼显华

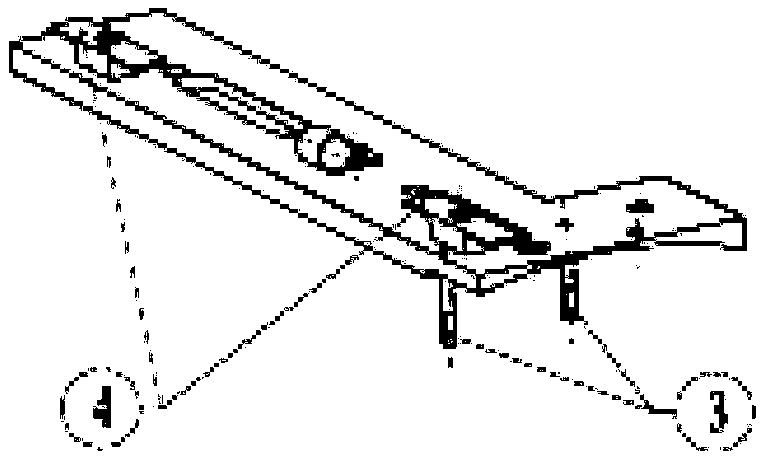

Assembling tool of steel wire rope inhaul cable in lorry-mounted crane boom

ActiveCN103331729AEasy to operateImprove assembly efficiencyMetal-working hand toolsArchitectural engineeringScrew thread

Owner:CHANGZHI QINGHUA MACHINERY FACTORY +1

Lamp core of LED light bar lamp and manufacturing method of lamp core

InactiveCN105953108AFacilitate automatic weldingImprove assembly efficiencyElectric lightingLight fasteningsEngineeringLED lamp

Owner:SHENZHEN CRYSTAL PORCELAIN PHOTOELECTRIC CO LTD

Sound box structure

InactiveCN110290436AEasy assemblyImprove assembly efficiencyTransducer casings/cabinets/supportsEngineeringMagnetic core

Owner:KONKA GROUP

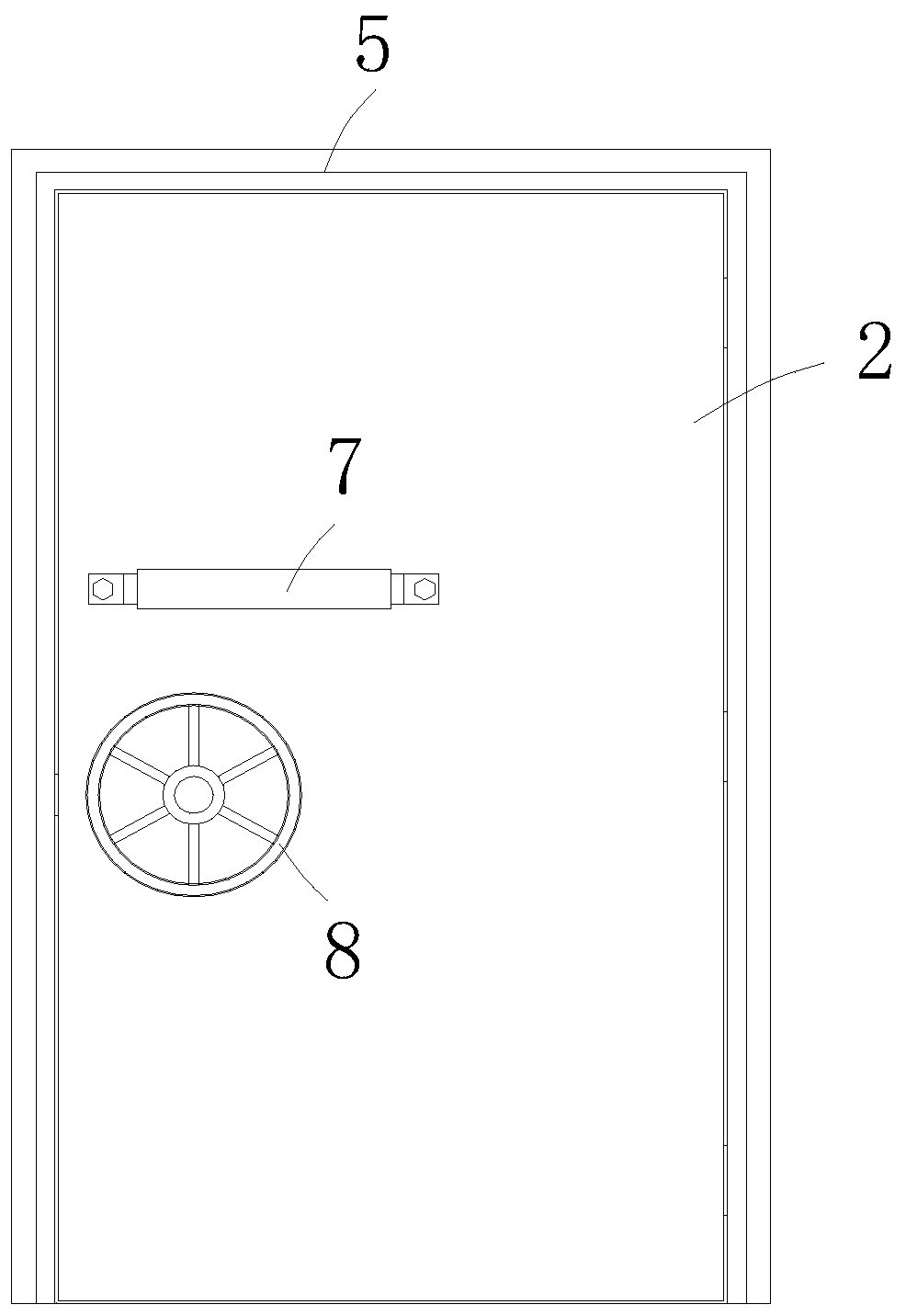

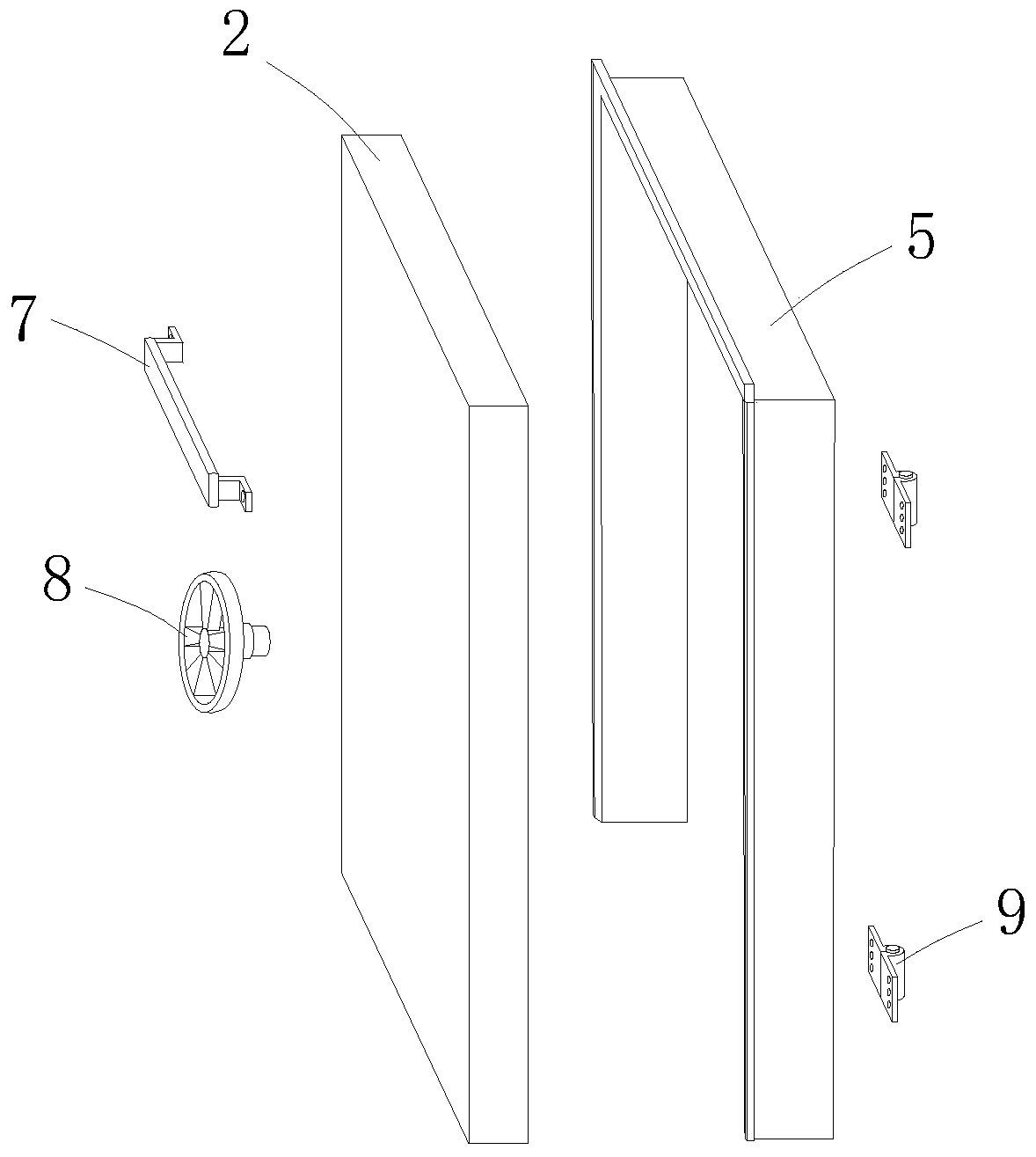

Assembly line for production of steel-structure protection doors

ActiveCN111438520AEasy and fast assemblyImprove assembly efficiencyAssembly machinesLoad-engaging elementsAssembly lineAssembly machine

Owner:ANHUI ZHONGNAN AIR DEFENCE WORKS PROTECTIVE EQUIP

Washing machine and control method thereof

PendingCN112111906AImprove assembly efficiencyImprove practical promotionControl devices for washing apparatusOther washing machinesElectromagnetic heatingLaundry washing machine

Owner:QINGDAO HAIER WASHING MASCH CO LTD +2

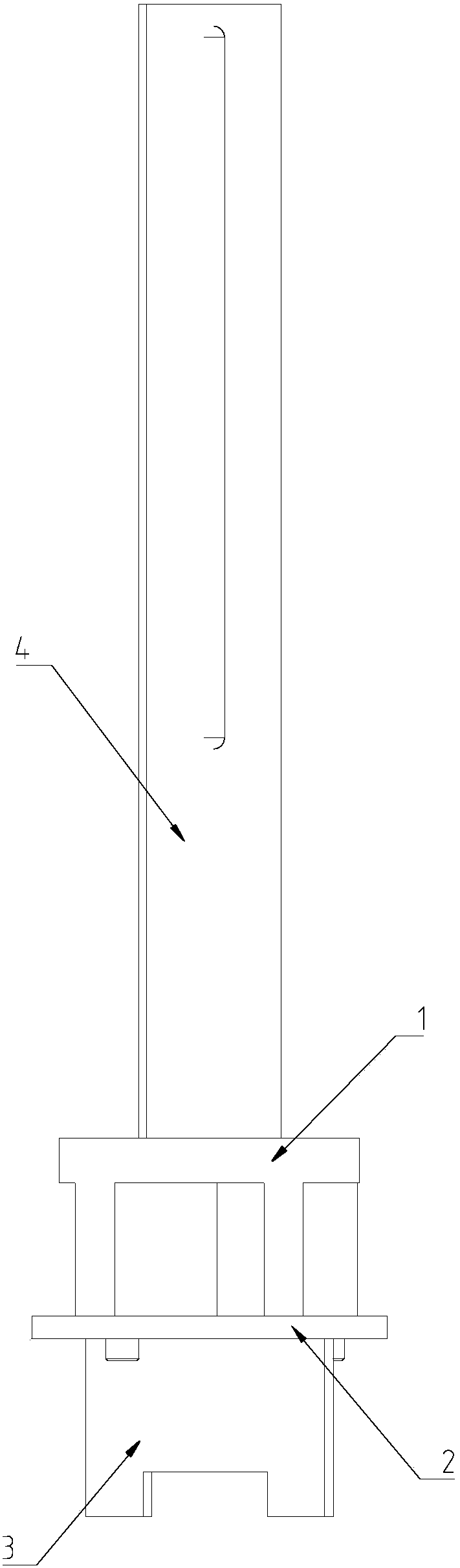

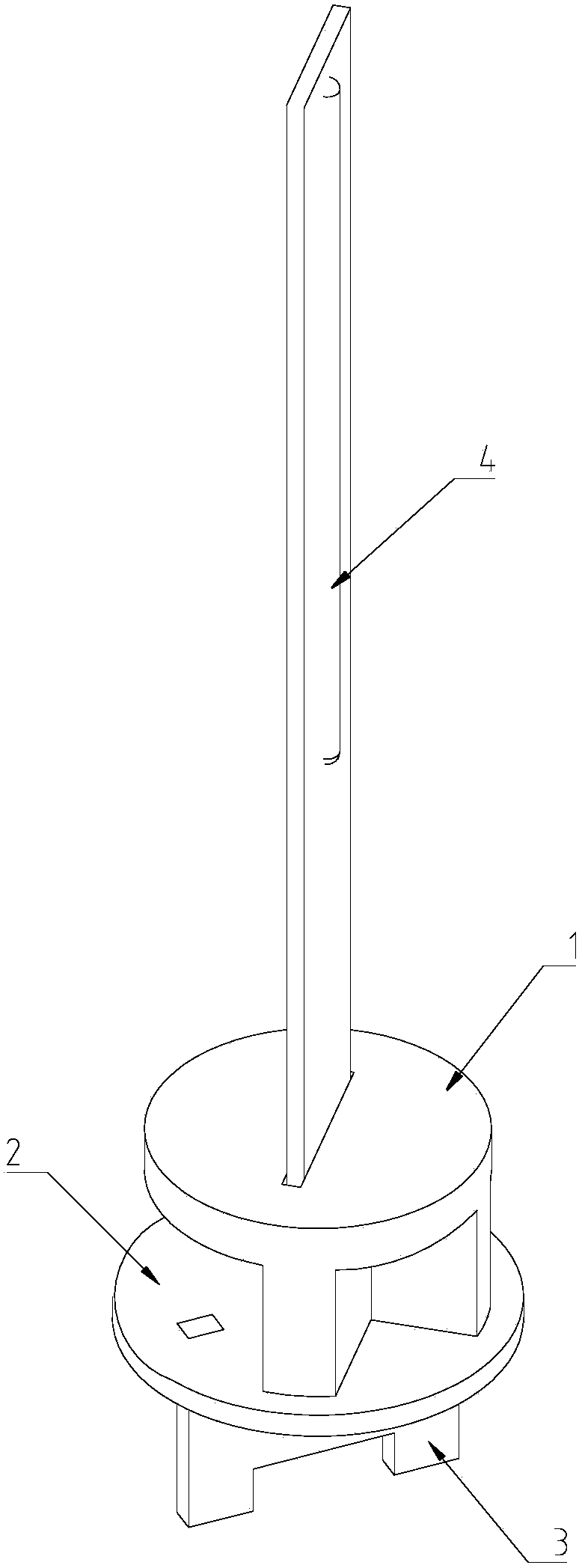

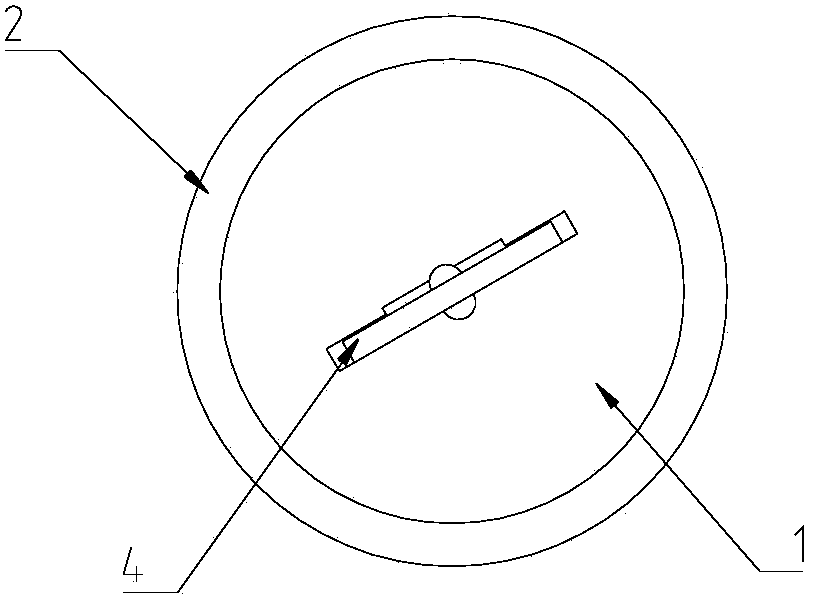

Magnet assembly tool and assembly process for application of matching magnet assembly tool with liquid nitrogen cold assembly technology

PendingCN112276475AImprove assembly efficiencyReasonable designMetal working apparatusEngineeringLever pressing

The invention relates to a magnet assembly tool and an assembly process for application of matching the magnet assembly tool with liquid nitrogen cold assembly technology. The magnet assembly tool comprises a bottom plate and a pressing rod located above the bottom plate, a first positioning pin is arranged in the middle of the bottom plate, and two second positioning pins are arranged on the sideportion of the bottom plate. The pressing rod comprises a rod part and a positioning disc on the rod part, a positioning block is arranged in the middle of the positioning disc, and two third positioning pins are arranged on the side portion of the positioning disc. A magnet is mounted at the upper end of the pressing rod. The assembly process that the magnet assembly tool and the liquid nitrogencold assembly technology are applied in a matched mode enables the manufacturing cost to be low and operation to be easy and convenient, and the application that the tool and the liquid nitrogen coldassembly technology are applied in a matched mode enables part assembly efficiency to be high and the size to be stable.

Owner:IMPRO AEROSPACE COMPONENTS (WUXI) CO LTD

Quickly-spliced sunlight room

PendingCN108952233AEasy to assembleImprove structural stabilityBuilding constructionsSmall buildingsEngineeringBeam column

The invention relates to a quickly-spliced sunlight room. The upper end of the corner of a rectangular frame is fixedly provided with a beam column assembly A, a beam column assembly B, a beam columnassembly C and a beam column assembly D separately; the left ends of a longitudinal beam column assembly A and a transverse beam column assembly E are fixed to the beam column assembly A, the right end of the transverse beam column assembly E is fixed to the beam column assembly D, the left end of a transverse beam column assembly D is fixed to the beam column assembly B, the right end of the transverse beam column assembly D is fixed to the beam column assembly C, the front end of a side beam assembly A is fixed to the left end of the transverse beam column assembly E, the rear end of the front end of the side beam assembly A is fixed to the left end of the transverse beam column assembly D, the front end of a side beam assembly B is fixed to the right end of the beam column assembly D, the rear end of the side beam assembly B is fixed to the right end of the beam column assembly C, the right side of the side beam assembly A is provided with a plurality of main beams A, the right endsof the main beams A are fixed to the left side wall of a beam ridge assembly, and the right side wall of the beam ridge assembly is fixedly provided with a plurality of main beams B. The quickly-spliced sunlight room has the advantages that the sun room is spliced by special-shaped pieces, splicing is easy, the stability is better, and the splicing efficiency is high.

Owner:SHANDONG HESHUN TENGDA HIGH-TECH MATERIALS CO LTD

Pipe clamp type temperature controller

InactiveCN101968662AImprove assembly efficiencyRapid productionTemperature control using electric meansEngineeringMechanical engineering

Owner:FOSHAN TIANPENG THERMOSTATS

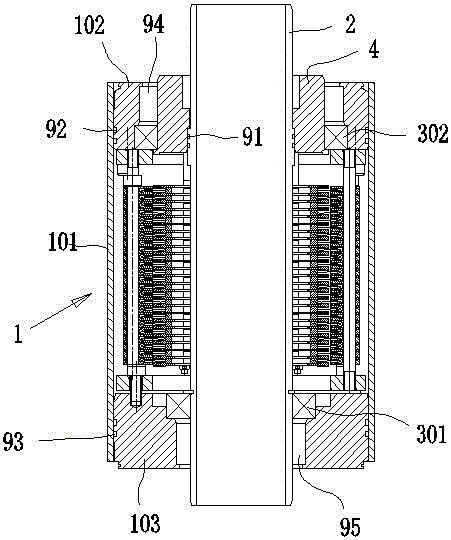

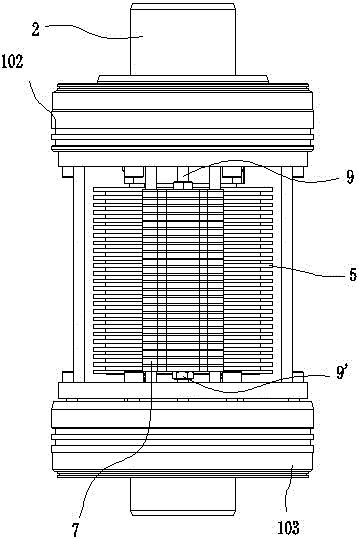

Automatic stator and rotor combining machine

ActiveCN105449957AImprove protectionGuaranteed accuracyCentering/balancing rotorsElectric machineComputer module

The invention belongs to the technical field of motor manufacturing, and discloses an automatic stator and rotor combining machine. The automatic stator and rotor combining machine comprises a combining platform, a stator axis adjusting module, a rotor support module and a running combining module, wherein the stator axis adjusting module, the rotor support module and the running combining module are located on the combining platform; the rotor support module supports a to-be-combined rotor; the stator axis adjusting module supports a to-be-combined stator and adjusts the angle of the stator axis, so that the stator axis overlaps with the axis of the to-be-combined rotor; the running combining module drives the to-be-combined stator and the to-be-combined rotor to move oppositely; and the to-be-combined rotor is embedded into the to-be-combined stator. According to the automatic stator and rotor combining machine provided by the invention, a manual combining operation is replaced with an automatic combining operation; the combining efficiency and quality are improved; and an accidental injury is reduced.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

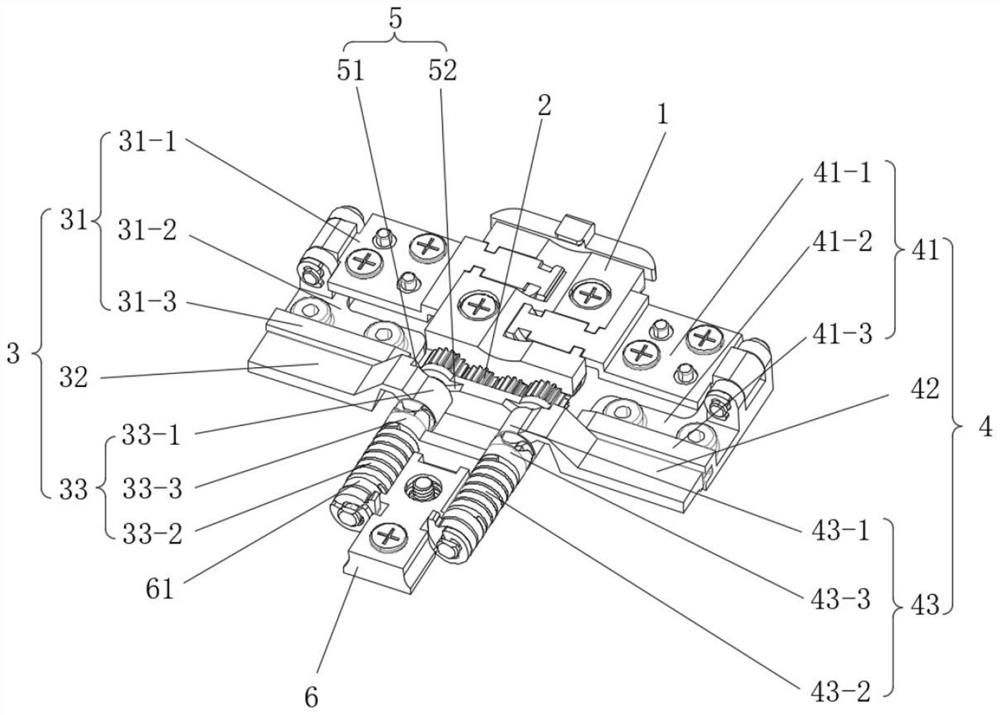

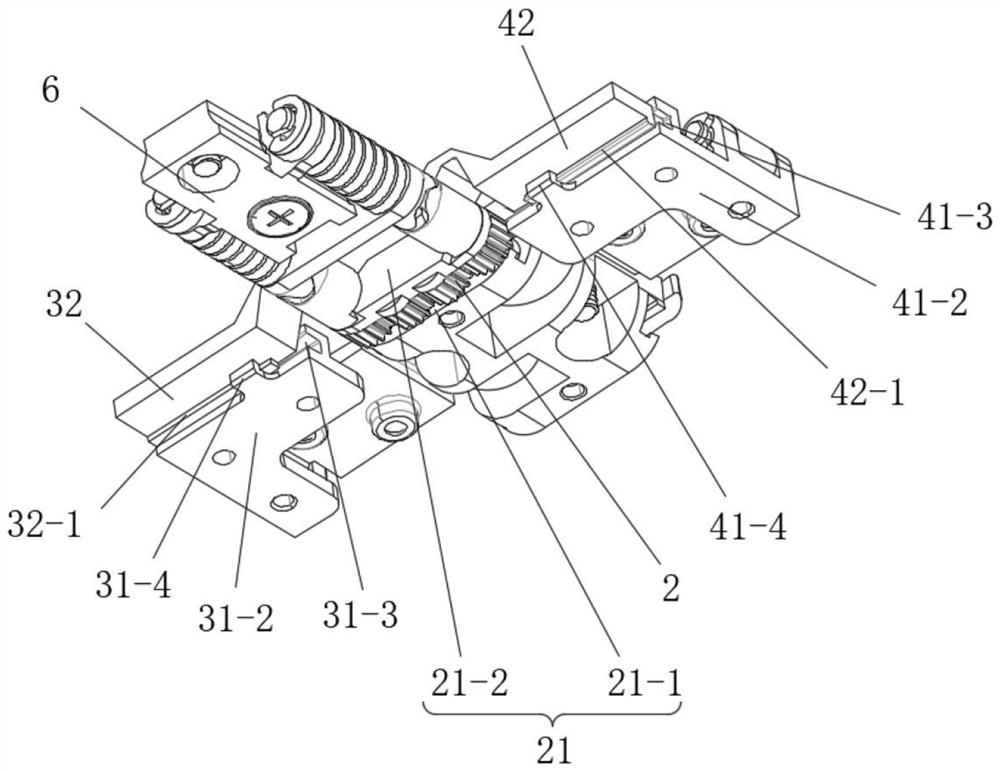

Hinge assembly for folding screen

PendingCN113411429ASimple structureHigh functional integrationDigital data processing detailsTelephone set constructionsEngineeringClassical mechanics

The invention relates to a hinge assembly for a folding screen. The hinge assembly comprises a mounting base for fixed mounting, and a left overturning assembly and a right overturning assembly which are rotationally arranged on the mounting base and form synchronous overturning through an even number of gear sets; and the left overturning assembly and the right overturning assembly are each provided with a sliding structure in an integrated mode, and damping pieces rotating along with the sliding structures to achieve the damping hand feeling are arranged on the sliding structures. The assembly is simple in structure and high in function integration, and the installation space can be effectively saved.

Owner:CHANGZHOU GIAN TECH

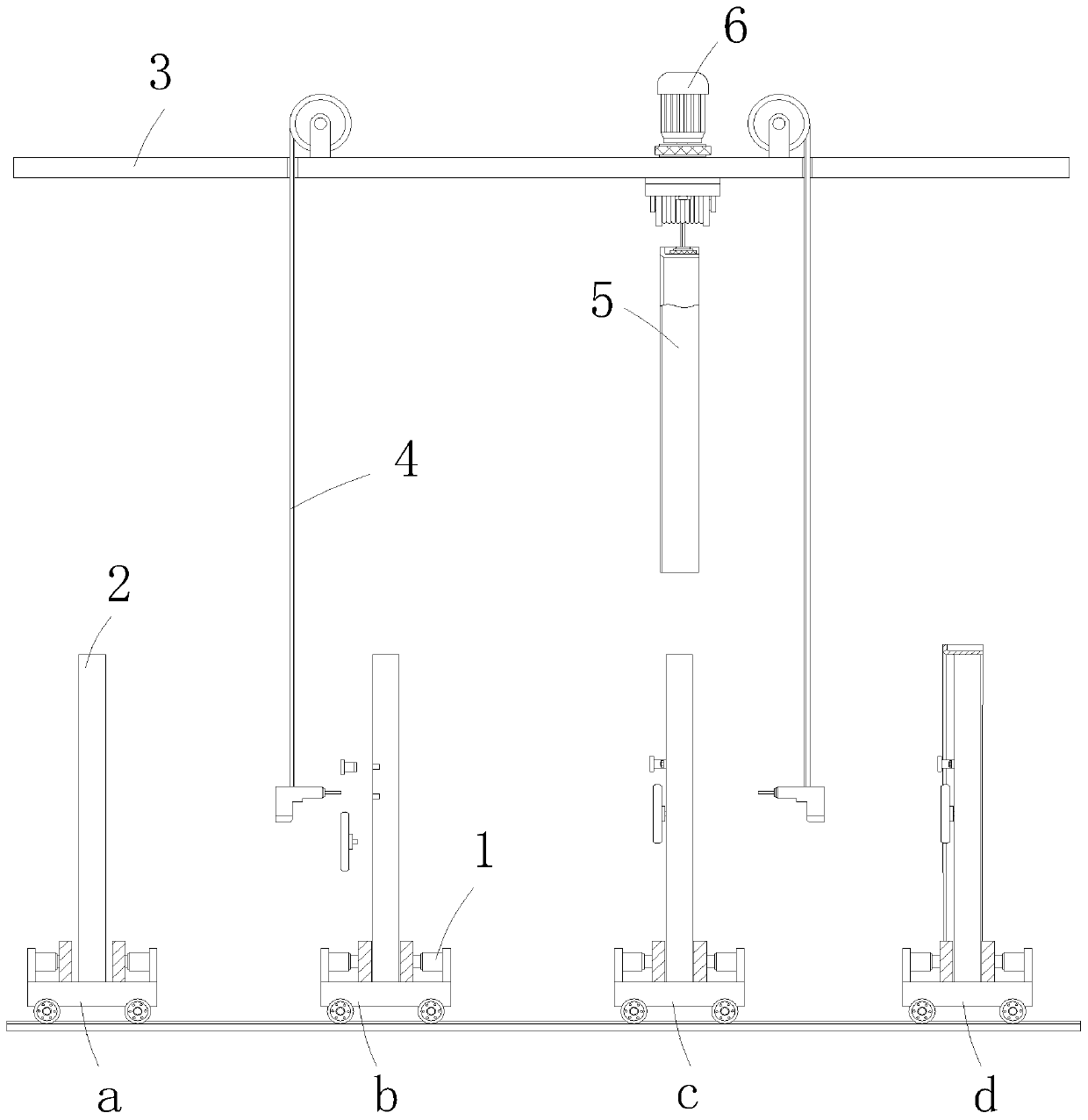

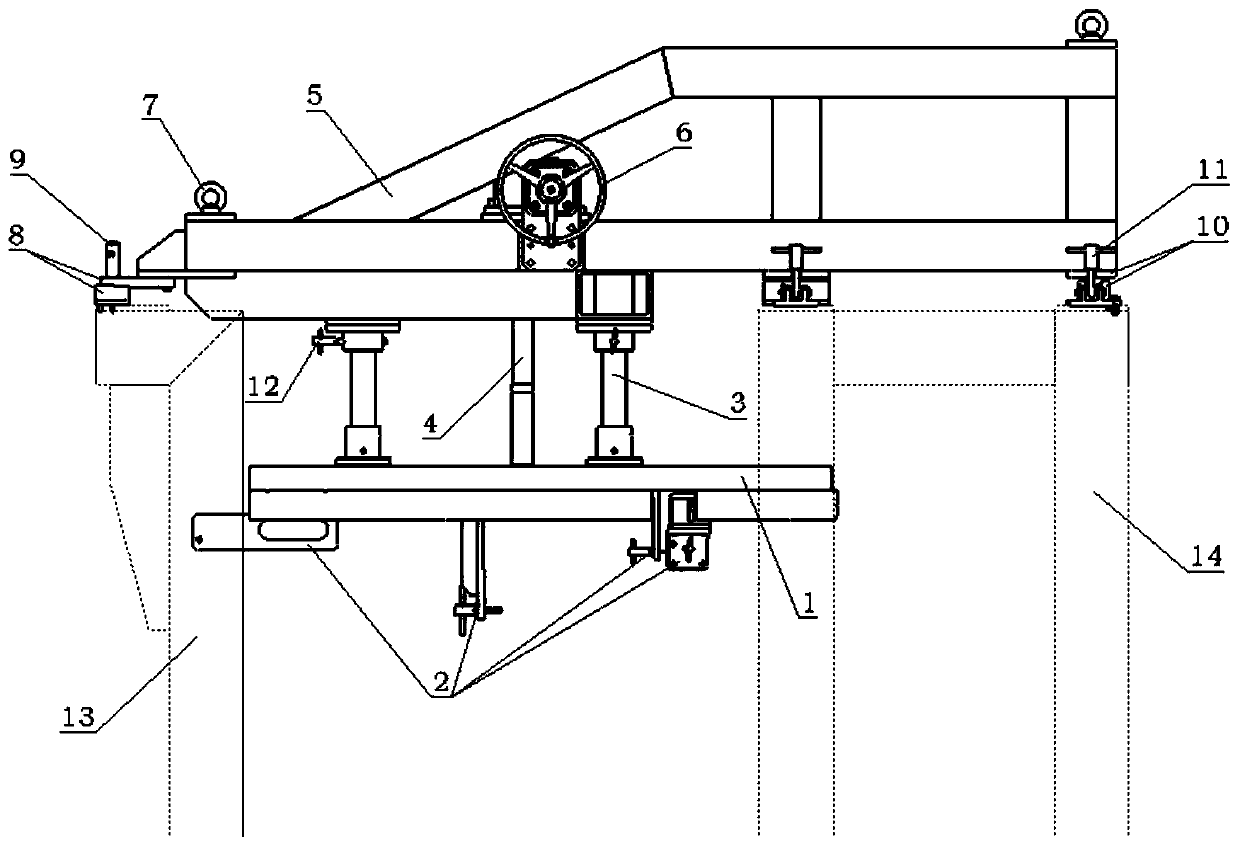

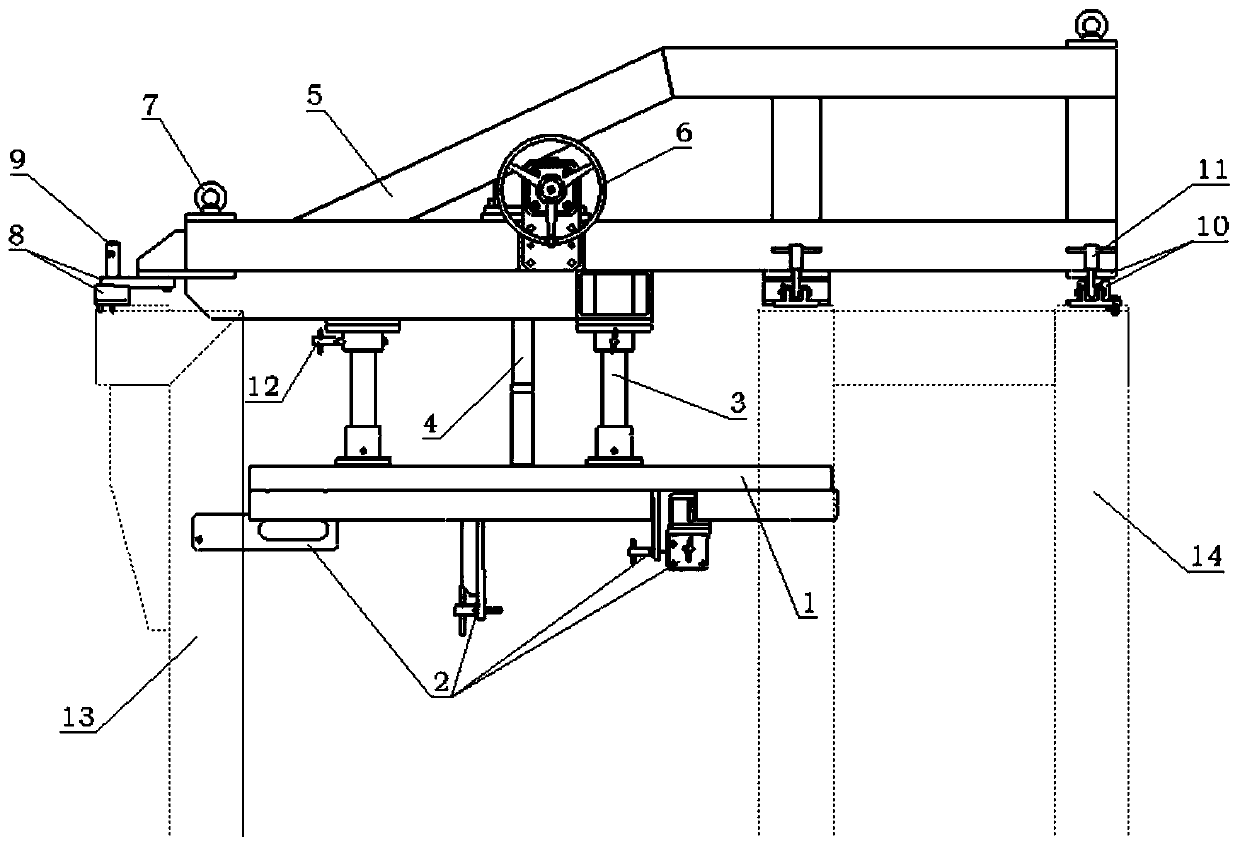

Lifting and transferring position-changing machine for lawn mower

PendingCN109158857AReduce labor intensityImprove assembly efficiencyMetal working apparatusEngineeringLawn mower

The invention discloses a lifting and transferring position-changing machine for a lawn mower, and belongs to the technical field of equipment manufacturing. The lifting and transferring position-changing machine comprises a base, horizontal travelling mechanisms, a vertical lifting mechanism and a rotary mechanism. The horizontal travelling mechanisms comprise the driving horizontal travelling mechanism and the driven horizontal travelling mechanism. The vertical lifting mechanism comprises a driving vertical lifting arm, a driven vertical lifting arm and a lifting power mechanism. The rotarymechanism comprises a driving rotary arm and a driven rotary arm. By utilizing the automatic lifting and transferring position-changing machine, manual carrying is not needed, manual turnover is notneeded, the labor intensity of carrying and turnover of the lawn mower is reduced; at least two operators are needed during manual carrying and turnover of the machine is avoided, but one worker is saved through the lifting and transferring position-changing machine; and the assembly efficiency is improved, equipment layout is reasonable, operation is easy and convenient, and digital management and control in the whole process are achieved.

Owner:INST OF INTELLIGENT MFG TECH JITRI

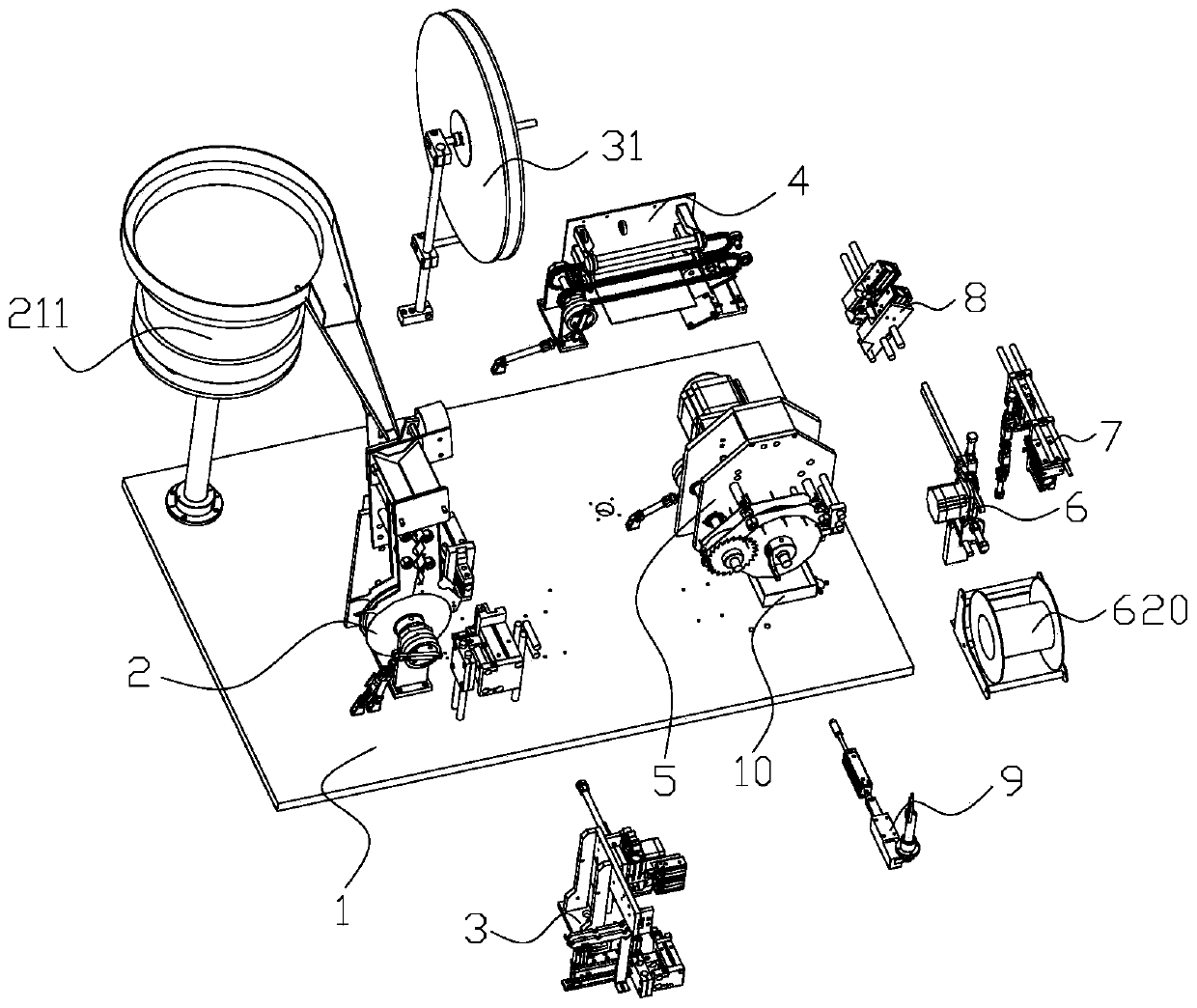

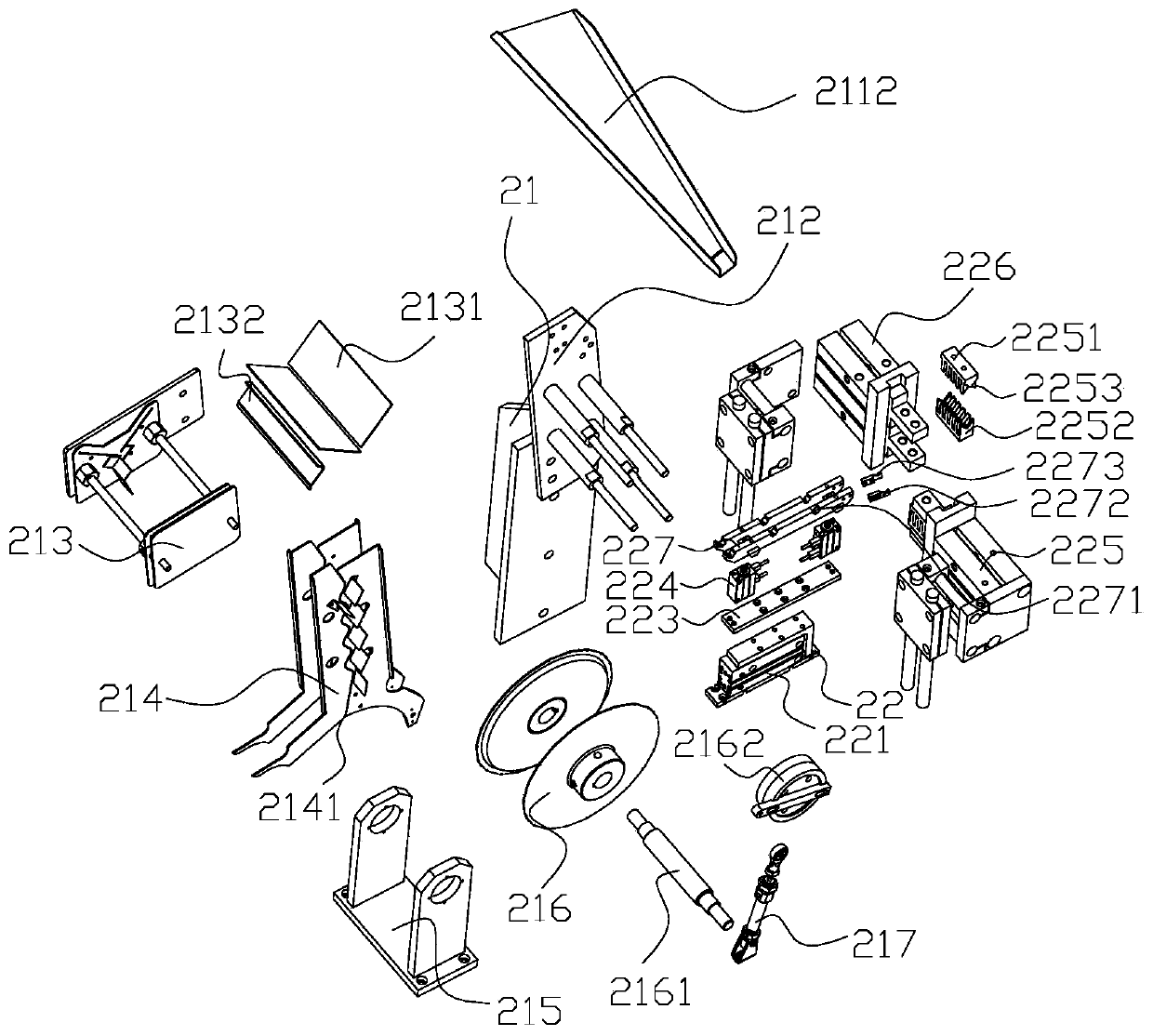

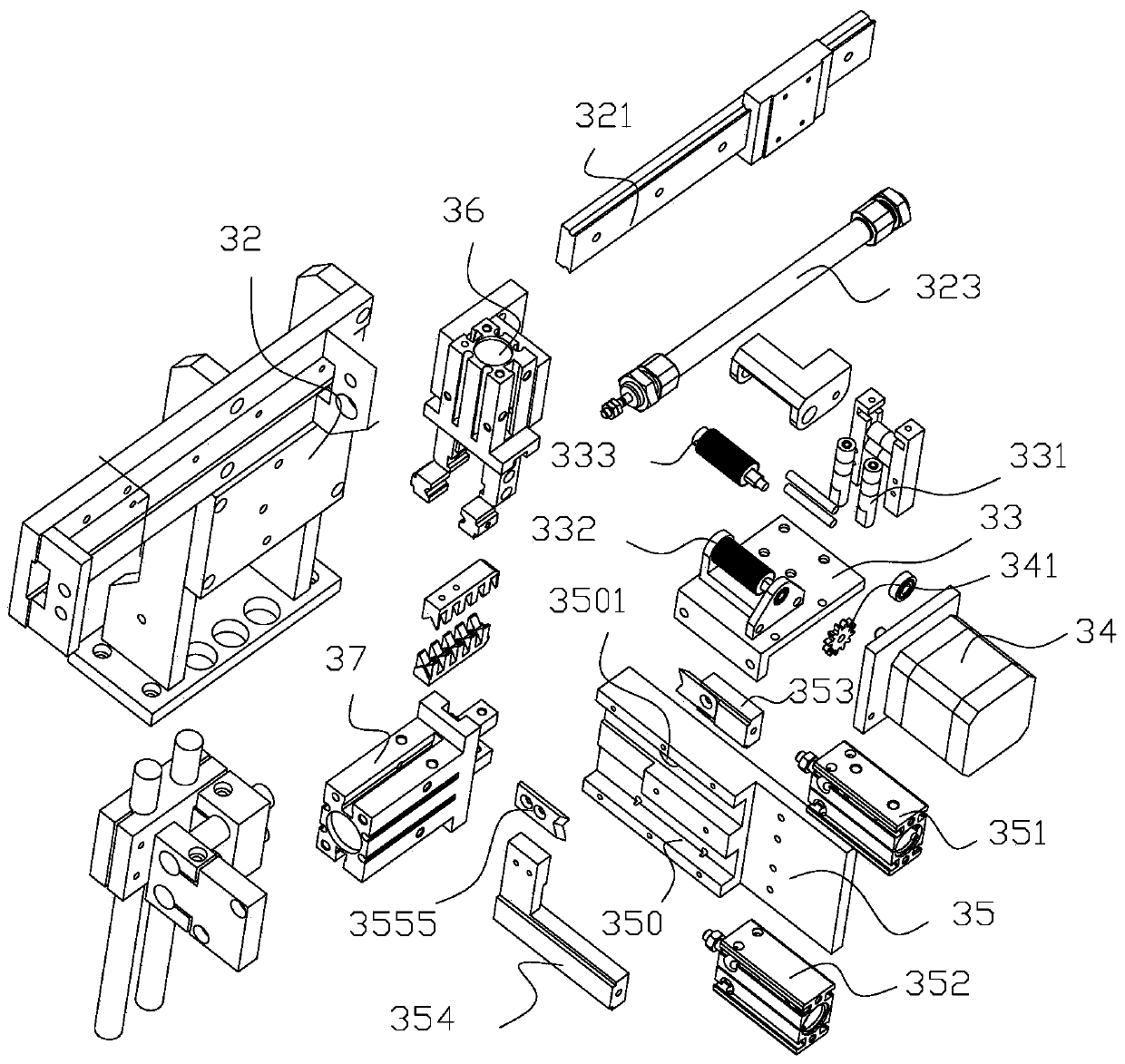

Automatic assembling equipment for electronic ignition element

PendingCN110961921AImprove assembly efficiencySpacing solutionOther manufacturing equipments/toolsMetal working apparatusEngineeringMaterial distribution

The invention provides automatic assembling equipment for an electronic ignition element. The automatic assembling equipment comprises a cutting mechanism, a crimping mechanism, a control mechanism and a material distribution mechanism, the material distribution mechanism comprises a plurality of clamping jaws, a first driving assembly and a second driving assembly, the multiple clamping jaws areconnected to the first driving assembly and driven by the first driving assembly to increase or decrease the distance, and the multiple clamping jaws and the first driving assembly are arranged on thesecond driving assembly and driven by the second driving assembly to move back and forth between the cutting station and the crimping station. Multiple electronic integrated ignition modules cut offby the cutting mechanism are conveyed to the crimping station through the material distribution mechanism, and the distance between the electronic integrated ignition modules is adjusted to be matchedwith the distance between multiple connectors on a transportation jig, so that the crimping mechanism can accurately crimp leg wires of a plurality of the connectors on a plurality of the electronicintegrated ignition modules at the same time, the whole process is controlled by the control mechanism, manual participation is not needed, and efficient assembly of the electronic ignition elements is achieved.

Owner:BEIJING JINYUAN HENGYE TECH DEV CO LTD

Tank body pressure intensity distribution test method and tank body internal pressure intensity test device of tank truck

InactiveCN111076857AImprove accuracyImprove securityFluid pressure measurementClassical mechanicsTank truck

The invention relates to the technical field of special vehicles and particularly provides a tank pressure distribution test method and a tank internal pressure test device for a tank truck. The testmethod comprises the following steps: (1) setting a sampling area in a tank body, fixing pressure sensing devices for acquiring pressure data in the sampling area, and setting a data acquisition device in signal connection with the pressure sensing devices to acquire the pressure data; and (2) injecting liquid into the tank body to enable each pressure sensing device to be immersed into the liquid, starting the tank truck to drive the tank body to move, and obtaining and processing test data. The pressure distribution at an end socket is obtained in a real test environment, the accuracy of test data can be improved, technicians are helped to master the pressure intensity distribution in the tank body when the vehicle runs, effective data support is provided for the structural design of thetank body in the future, and great help is provided for improving the safety of the whole vehicle.

Owner:ZHENGZHOU YUTONG HEAVY IND

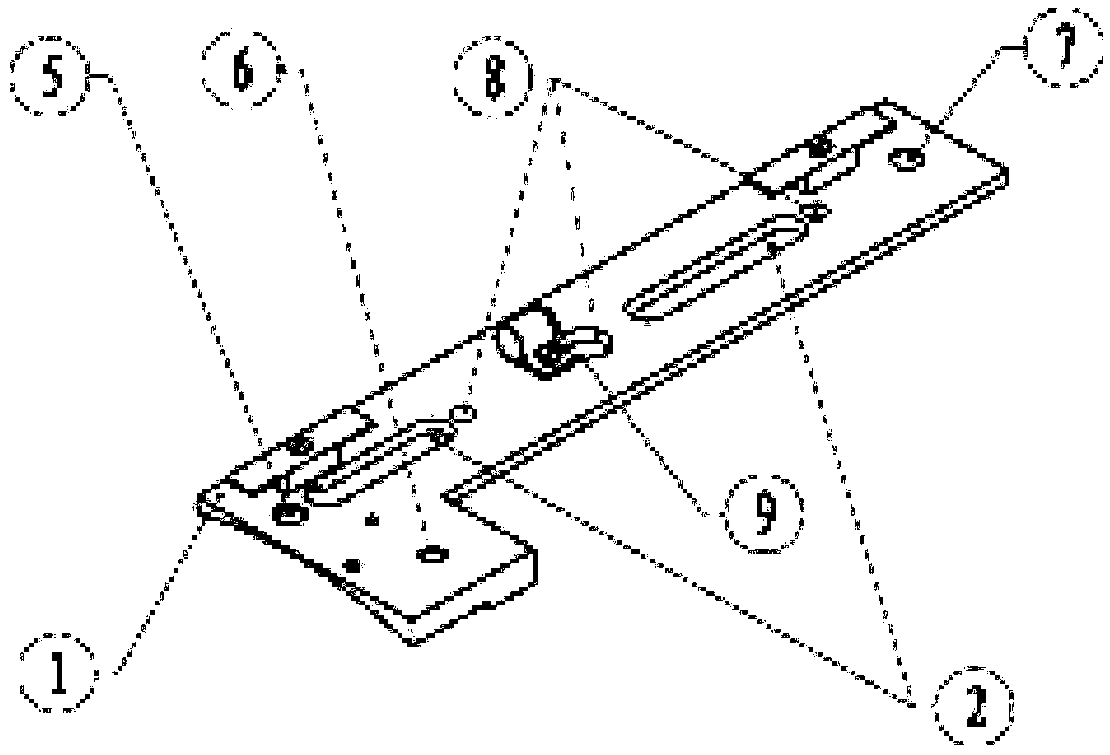

Moveable telescopic positioning device for tool upper product assembling

PendingCN110026926AEasy to operateImprove assembly efficiencyWork holdersAircraft assemblyProduct PartEngineering

The invention belongs to the field of aviation assembling, and relates to a moveable telescopic positioning device for tool upper product assembling. The moveable telescopic positioning device comprises a base plate, positioners, guide pillars, a telescoping mechanism, a framework, a hand wheel, flying rings, wedge-shaped positioning sets, auxiliary locating pins, V-shaped groove positioning sets,gland nuts, theoretical position locating pins, a front frame and a rear frame. The base plate is arranged above a product and further provided with the multiple positioners used for positioning product parts. The framework is arranged above the base plate and further connected with the telescoping mechanism through the guide pillars. The guide pillars are provided with the corresponding theoretical position locating pins used for determining the theoretical positions of the base plate and the positioners. The telescoping mechanism is connected with the hand wheel, and the base plate and thepositioners can move up and down by rotating the hand wheel. The wedge-shaped positioning sets and the auxiliary locating pins are used for being connected with the front frame. The V-shaped groove positioning sets and the gland nuts are used for being connected with the rear frame. By means of the moveable telescopic positioning device for tool upper product assembling, assembling efficiency andquality can be greatly improved, operation is made more convenient, and the production requirement can be met.

Owner:SHENYANG AIRCRAFT CORP

Automatic refrigerator door switch assembling machine and automatic button feeding mechanism thereof

PendingCN111113001AImprove assembly efficiencyImprove production and processing effectsMetal working apparatusEngineeringIndustrial engineering

The invention relates to an automatic refrigerator door switch assembling machine and an automatic button feeding mechanism thereof, and relates to the technical field of refrigerator door switch production and manufacturing. The automatic refrigerator door switch assembling machine comprises a workbench, the workbench is provided with a limiting piece used for placing a workpiece, the automatic refrigerator door switch assembling machine further comprises a feeding mechanism used for conveying a button, and a clamping mechanism arranged on the workbench; one end of the feeding mechanism gradually gets close to the clamping mechanism, an outlet of the feeding mechanism directly faces the lower end of the clamping mechanism; the clamping mechanism is used for conveying the button conveyed out of the feeding mechanism into the limiting piece; and the automatic refrigerator door switch assembling machine further comprises a spring pressing mechanism which is positioned between the clamping mechanism and the limiting piece and is used for downwards pressing and bending a torsional spring. The automatic refrigerator door switch assembling machine and the automatic button feeding mechanism thereof have the effects that automatic assembling of the button can be achieved, the assembling efficiency of the button is improved, and the overall production efficiency is further improved.

Owner:ZHEJIANG CHANGDECHENG ELECTRIC APPLIANCES CO LTD

L-shaped special-shaped column and beam fabricated connecting joint

InactiveCN112302169ASufficient lateral stiffnessImprove seismic performanceStrutsPillarsLateral stiffnessArchitectural engineering

The invention discloses an L-shaped special-shaped column and beam fabricated connecting joint, and belongs to the technical field of structural engineering. The L-shaped special-shaped column and beam fabricated connecting joint is composed of a special-shaped column, I-shaped beams, channel steel connecting pieces and high-strength bolt groups. Manufacturing and welding parts of steel componentsare completed in a factory, the welding quality is easy to control, only each prefabricated component needs to be hoisted, and is connected through a high-strength bolt on a construction site, and the construction efficiency is high; and the connecting joint has the advantages of mechanical property and practical property at the same time, and specifically, in the aspect of the mechanical property, the connecting joint makes full use of the bearing capacity and the lateral stiffness of the special-shaped column, and has the good anti-seismic property; and in the aspect of the practical property, the connecting joint emphatically achieves the rapid assembly concept, and solves the "protruding column" problem in a house.

Owner:BEIJING UNIV OF TECH

Electrically-driven three-stage planetary speed reduction driver

PendingCN114552871AImprove assembly efficiencyImprove pass rateMechanical energy handlingStructural associationDrive motorElectric machine

Owner:TIANJIN SNEIJDER PRECISION MACHINERY

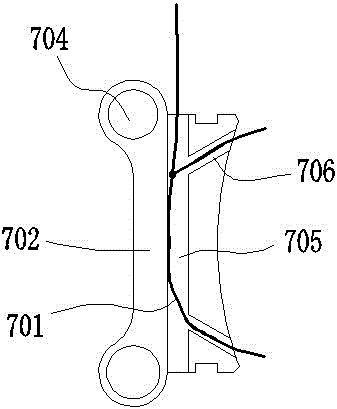

Valve rod sealing ring mounting mechanism

The invention discloses a valve rod sealing ring mounting mechanism. The valve rod sealing ring mounting mechanism comprises a rack, a support, a rotary table mechanism, a sealing ring vibration feeding machine, a sealing ring conveying track and a sealing ring assembling mechanism, the upper end of the sealing ring conveying track is connected with the discharging end of the sealing ring vibration feeding machine, and the lower end of the sealing ring conveying track is fixed to the support; multiple supporting stations are arranged on the rotary table mechanism in the circumferential direction, and each supporting station comprises a valve body supporting seat used for supporting a valve body; and the sealing ring vibration feeding machine is used for conveying sealing rings located in the sealing ring vibration feeding machine into the sealing ring conveying track. The sealing ring conveying track is used for conveying the sealing rings into the sealing ring assembling mechanism, and the sealing ring assembling mechanism is used for assembling the sealing rings from the sealing ring conveying track into valve rod mounting holes in the valve body; and the assembling efficiency of the sealing rings and the production efficiency of ball valves can be improved, and the labor cost of an enterprise can be reduced.

Owner:ZHEJIANG DADING INTELLIGENT TECH CO LTD

Tool for measuring assembly size of finished part

InactiveCN108645307AImprove labor efficiency and reliability of measurement resultsImprove assembly efficiencyMechanical measuring arrangementsMeasurement siteSelf checking

The invention provides a tool for measuring an assembly size of a finished part. The tool is used for measuring the size of a finished part of a circular cabin body,and comprises a measuring base,a self-checking plate and a detection sample column,wherein the bottom face of the measuring base is a cambered surface matched with the camber of the cabin body,the measuring base is used for fitting thesurface of the cabin body during measurement,the top face of the measuring base is located in a flat when the tool is located in a measuring position; a measuring hole cooperating with a to-be-measured portion is formed in the measuring base; the detection sample column can be located in the to-be-measured portion through the measuring hole; the self-checking plate at the side of the measuring hole is rotationally arranged on the measuring base,is an assembly produced according to a go-no go fixed gauge principle,and can quickly detect whether or not the size of the to-be-measured portion iswithin a tolerance range through the cooperation with the detection sample column. The tool for measuring assembly sizes of finished parts improves the measurement efficiency and measurement result reliability of the measurement,thereby improving the assembly efficiency of the finished part.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap