Drainage system of automobile electric skylight

A drainage system, electric technology, applied in vehicle parts, transportation and packaging, etc., can solve the problems of low safety and low assembly efficiency, and achieve the effect of improving assembly efficiency, high assembly efficiency and fast assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0032] Example 1:

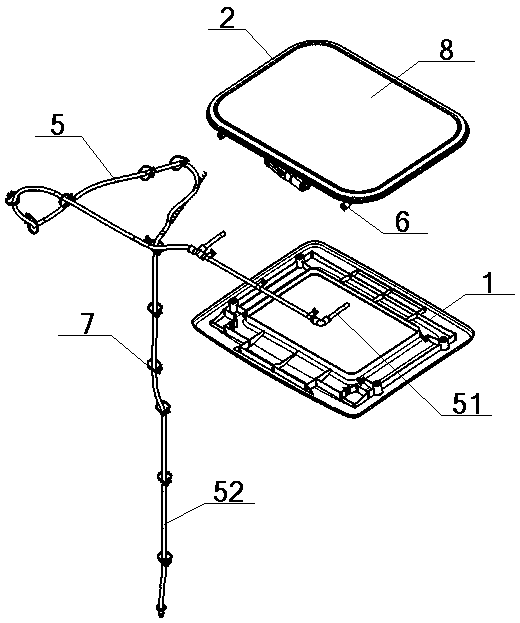

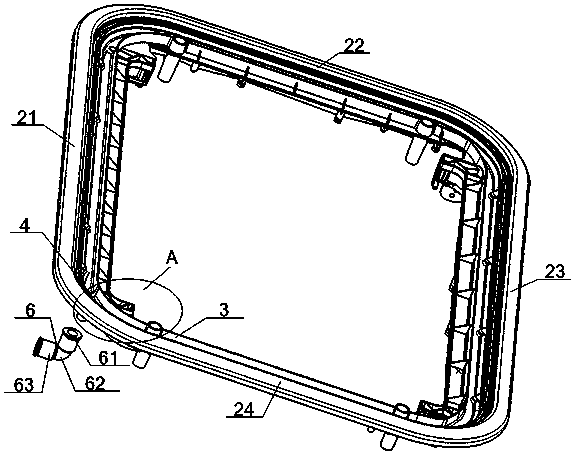

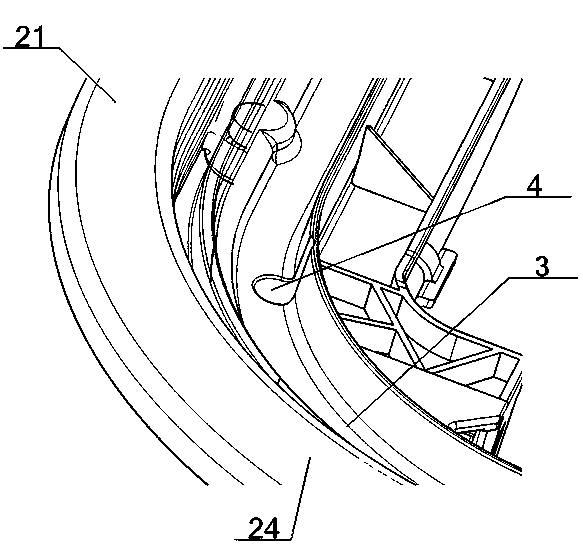

[0033] See figure 1 - Figure 4 , A drainage system for an automobile electric sunroof, comprising a sunroof frame 2 and a drainage groove 3 provided thereon; the sunroof frame 2 includes a first short beam 21, a first long beam 22, and a second short beam 23 that are connected in sequence. The second long beam 24, the first short beam 21 and the second short beam 23 are arranged in parallel, the first long beam 22 and the second long beam 24 are arranged in parallel, and the top of the skylight frame 2 is along the first short beam 21, The inner side of No. 1 long beam 22, No. 2 short beam 23, and No. 2 long beam 24 is provided with an annular drainage groove 3, and a drainage hole through the skylight frame 2 is provided on the drainage groove 3 near the junction of the short and long beams. 4. The number of drainage holes 4 is two, and the lower end of the drainage hole 4 is connected to the drainage pipe 5 located outside the skylight frame 2 through a quick

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap