Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55results about "Grinding machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal plate forming mold and forming method thereof

Owner:浙江鑫正工贸有限公司

Die polishing device with dust collector

Owner:芜湖凝鑫机械有限公司

Dimension compensation quantity determining method for bearing machining

InactiveCN108262667AImprove machining accuracyImprove processing efficiencyGrinding feed controlAutomatic grinding controlEngineeringMachining

The invention belongs to the technical field of bearing machining, and particularly relates to a dimension compensation quantity determining method for bearing machining. The dimension compensation quantity determining method for bearing machining comprises the steps that the type of a to-be-machined workpiece is determined; the standard workpiece temperature T2 and the machined workpiece temperature T1 are detected; a pre-stored machining model and corresponding machining parameters are selected according to the type of the to-be-machined workpiece; and the bearing machining model is assignedaccording to the standard workpiece temperature T2, the machined workpiece temperature T1 and the corresponding machining parameter, so that the dimension compensation quantity of the to-be-machinedworkpiece is obtained through calculation. By adoption of the dimension compensation quantity determining method for bearing machining, machining dimension compensation quantity errors caused by experience-based judgment by operators are avoided, the machining precision and machining efficiency of bearings are improved, the machining repair rate of the bearings is greatly decreased, and the numberof rejected products is reduced; and operation is easy.

Owner:WAFANGDIAN BEARING GRP STATE BEARING ENG TECH RES CENT CO LTD

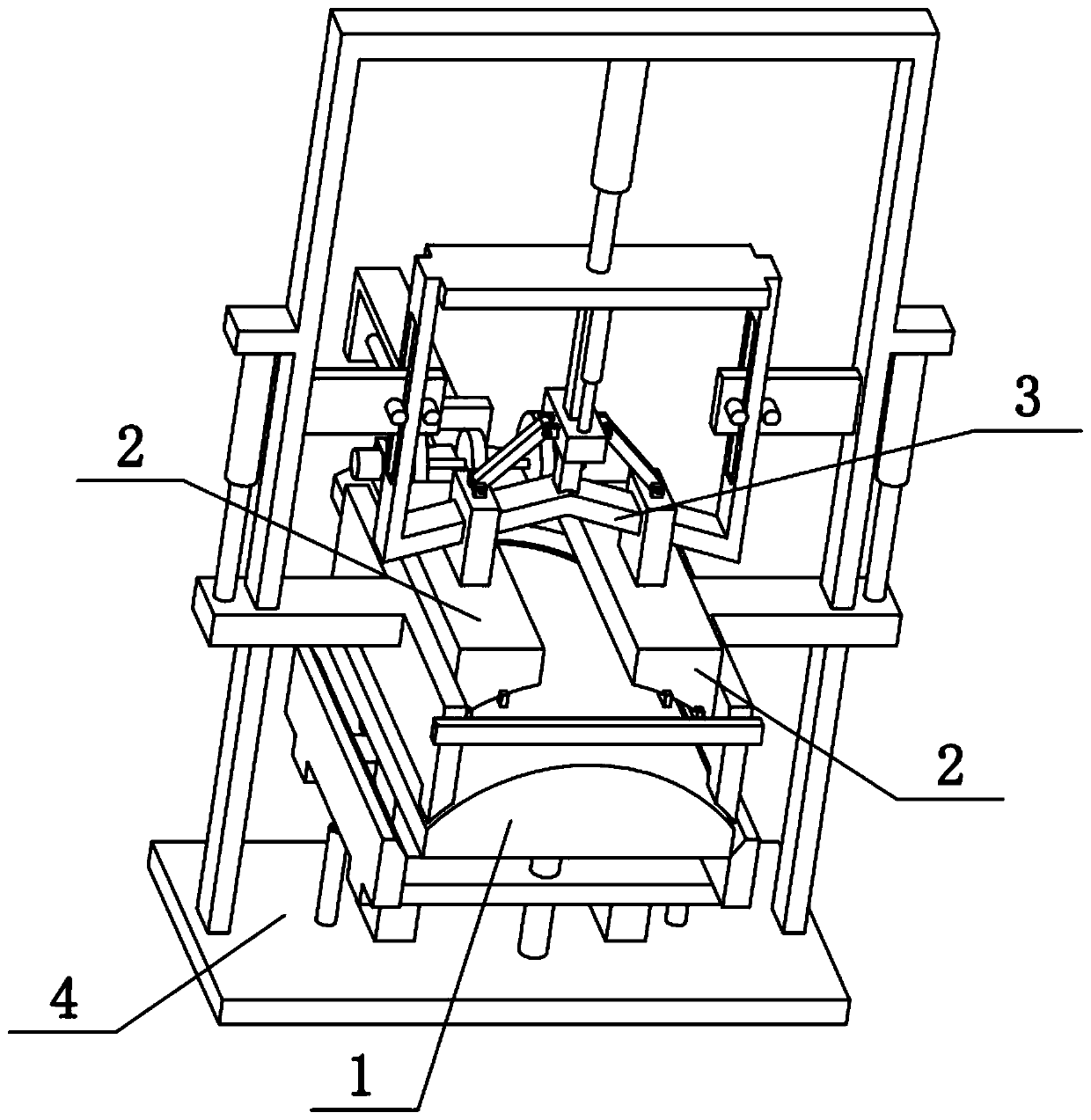

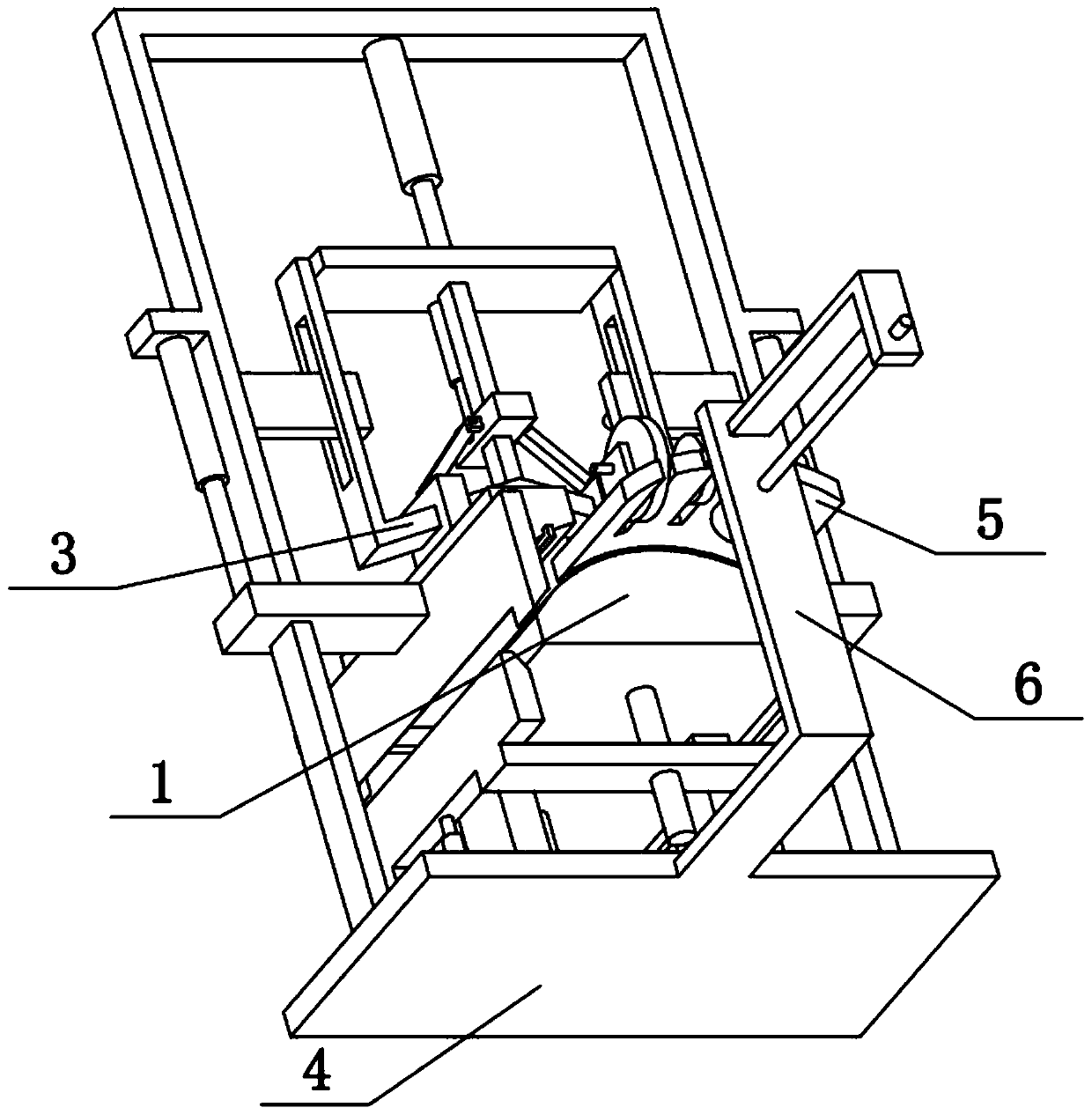

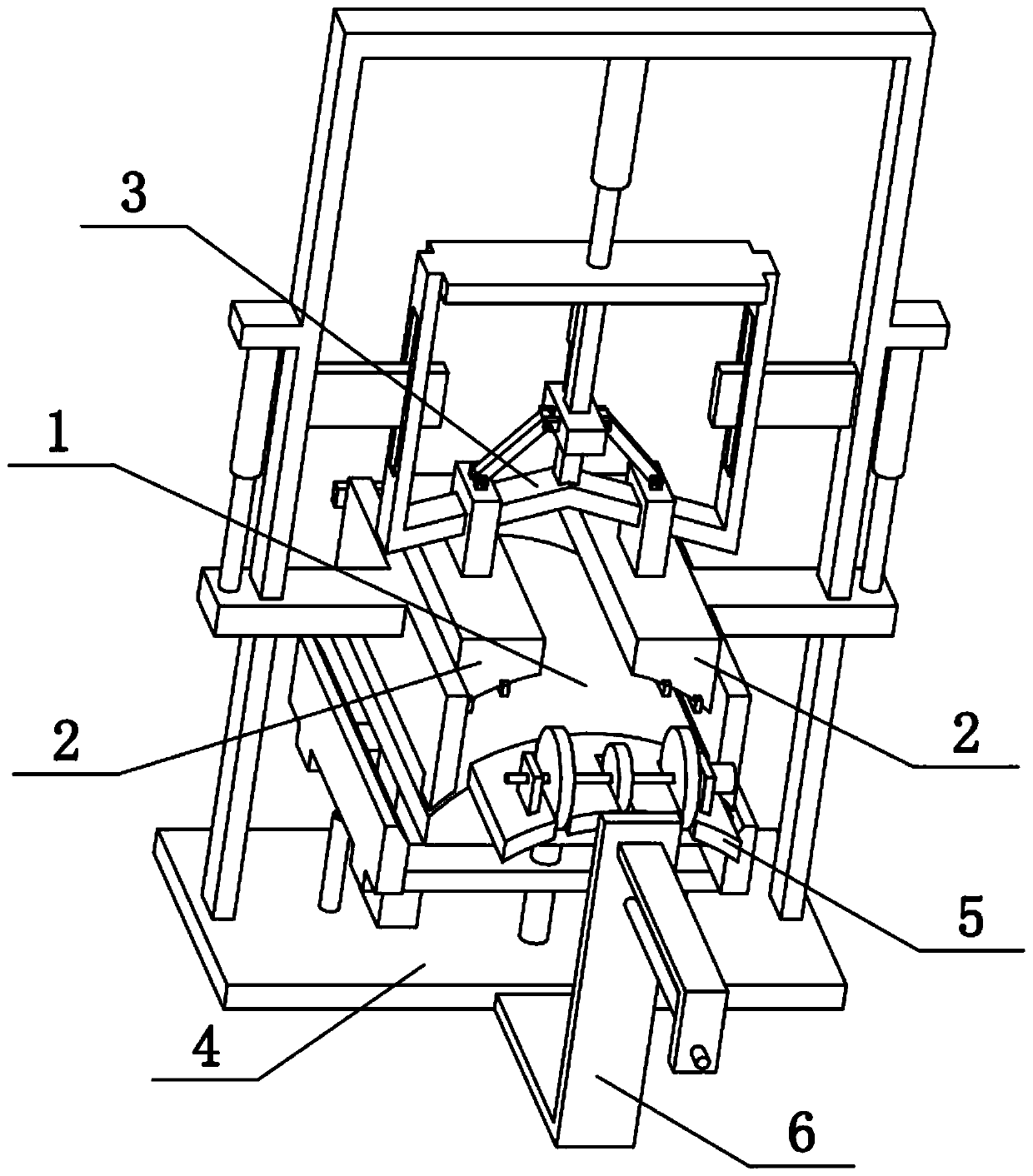

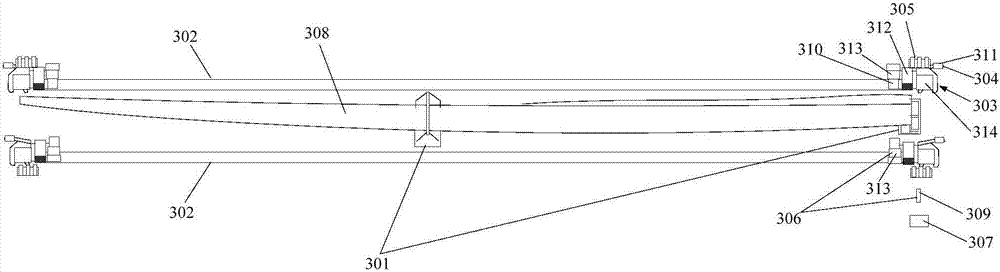

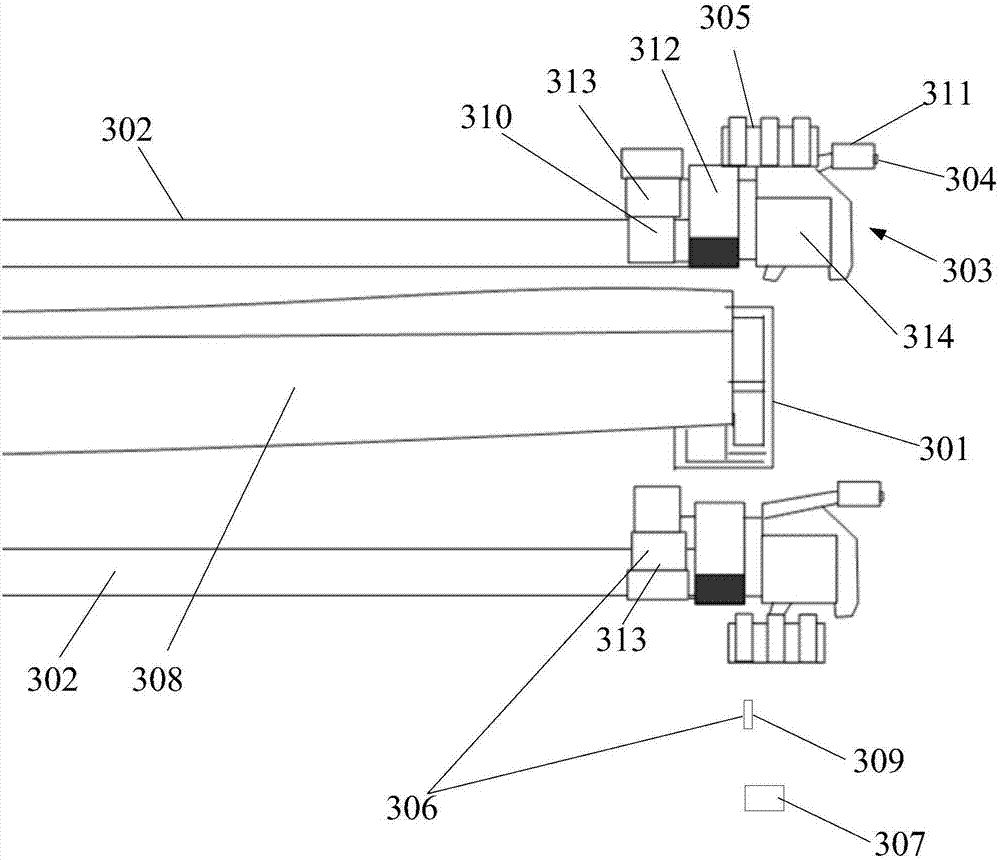

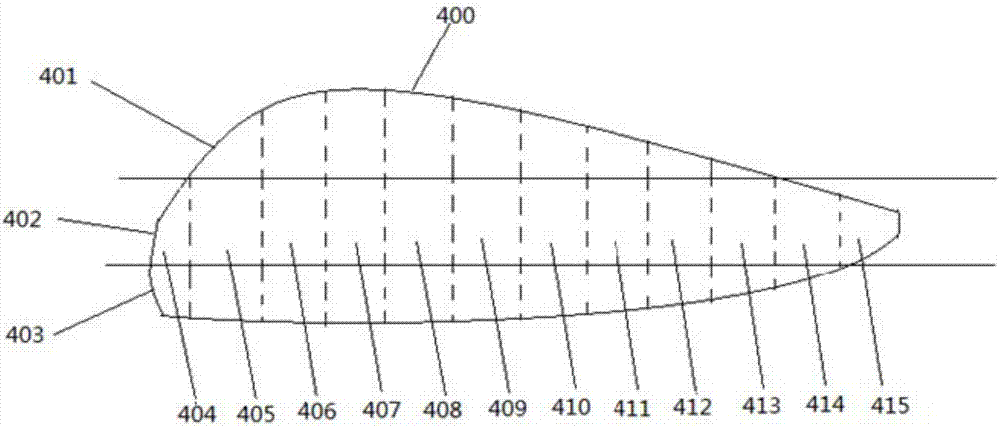

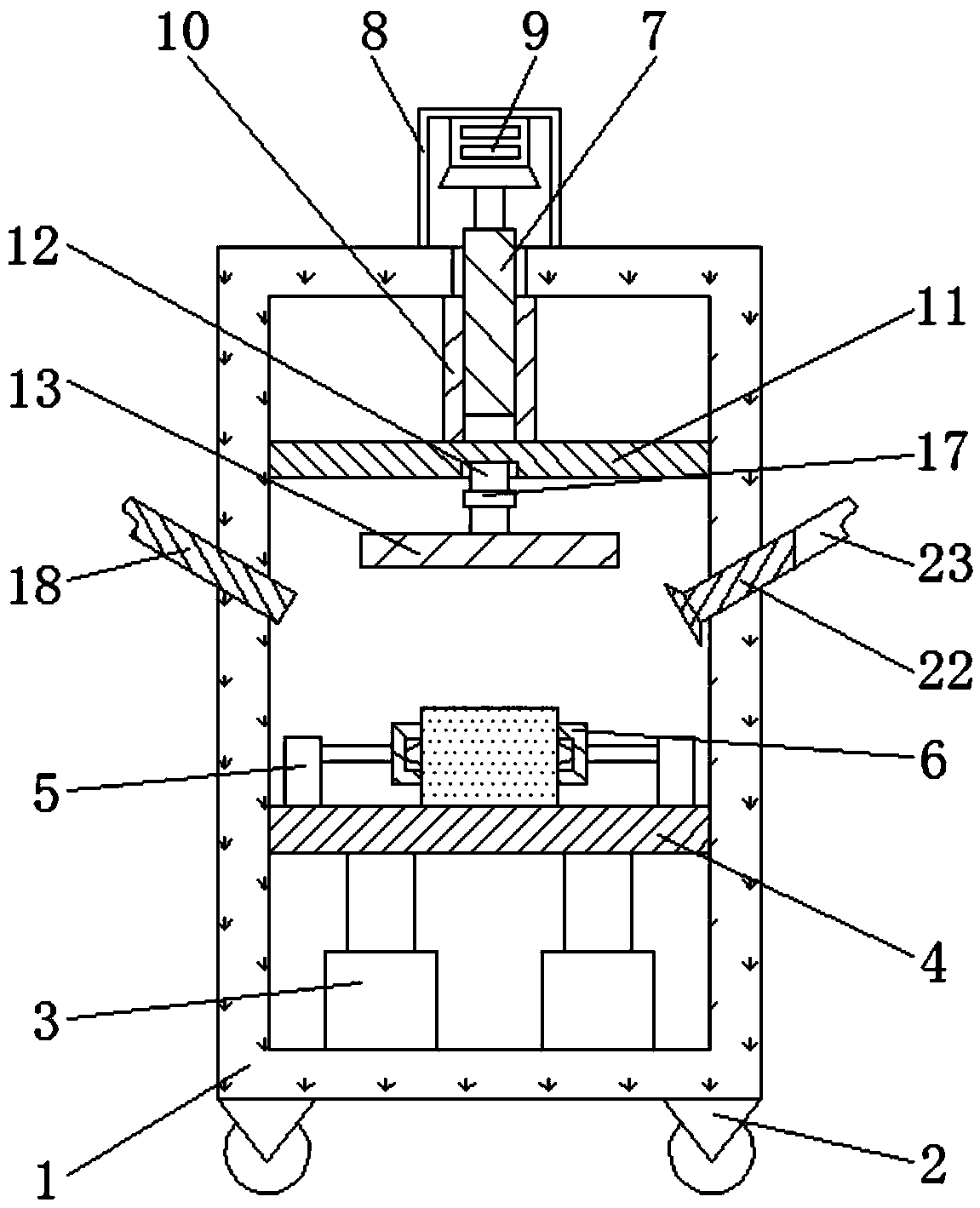

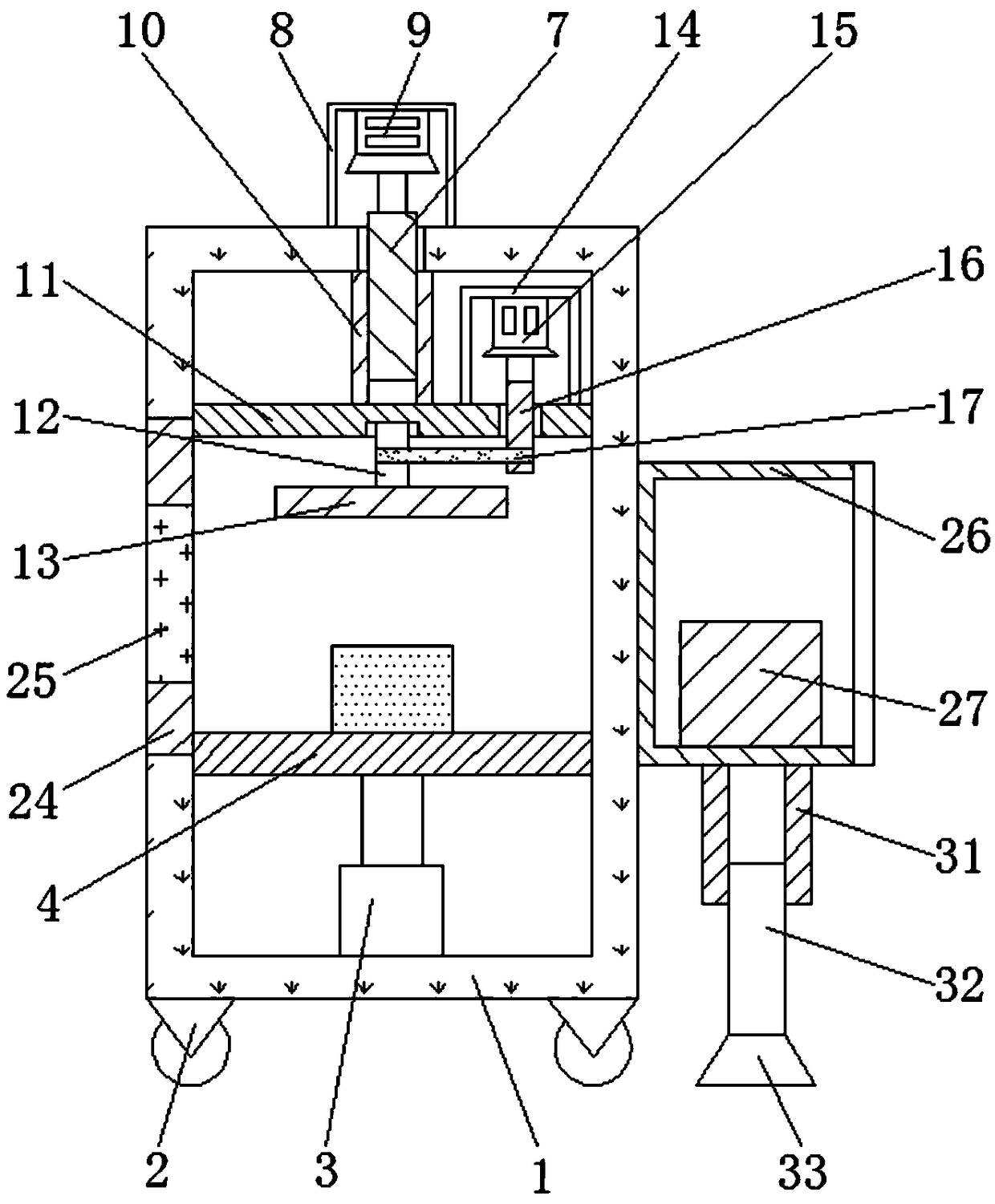

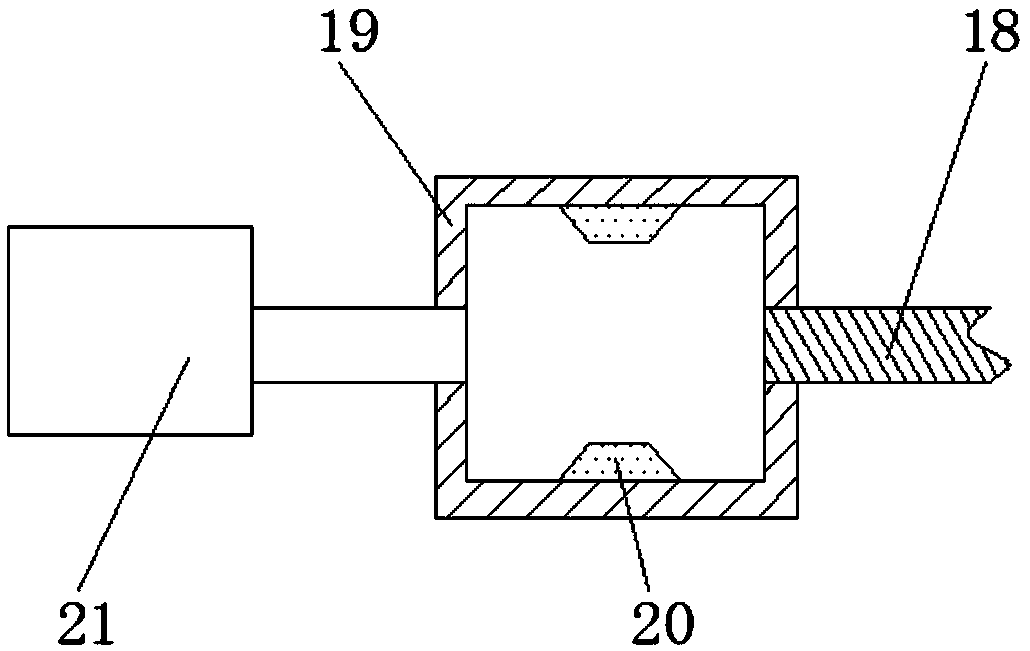

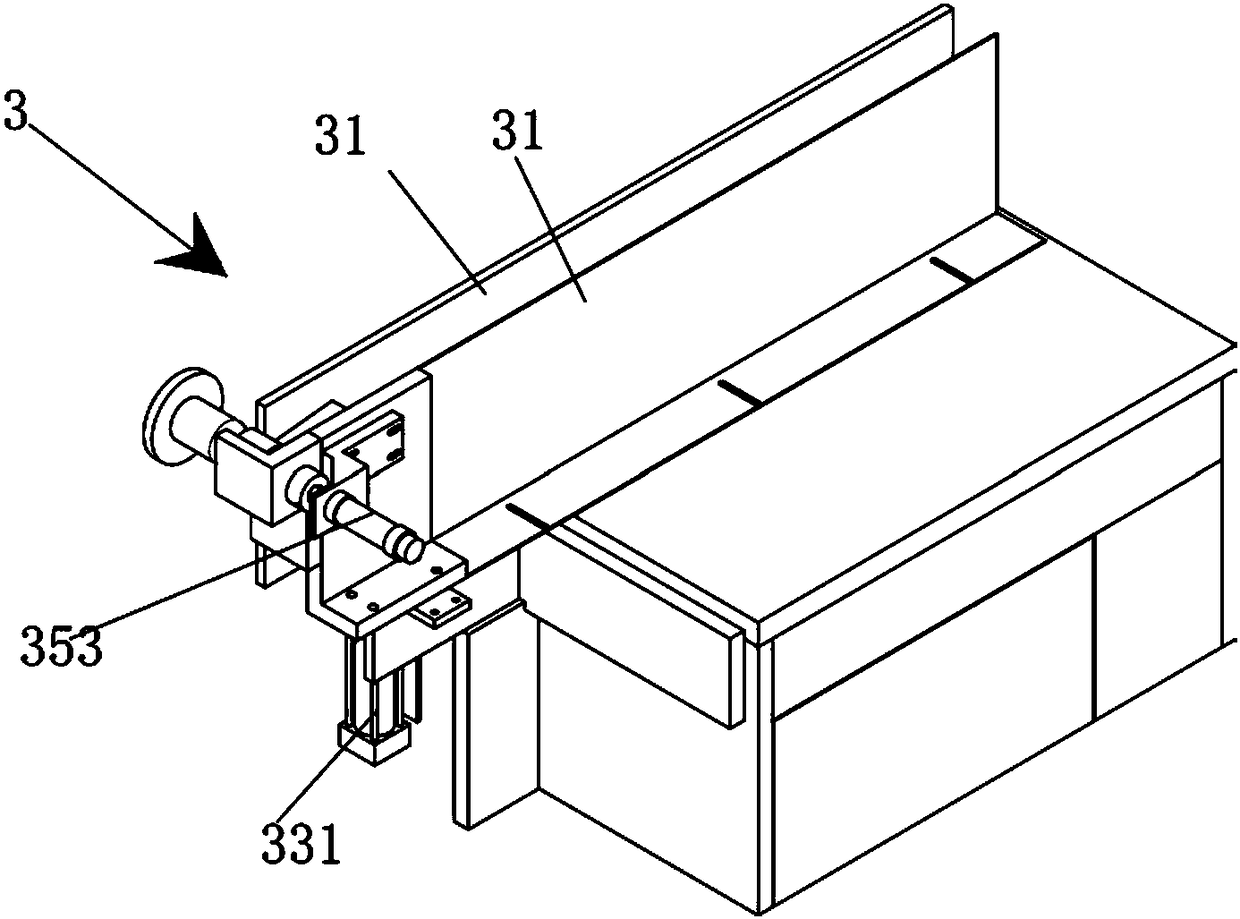

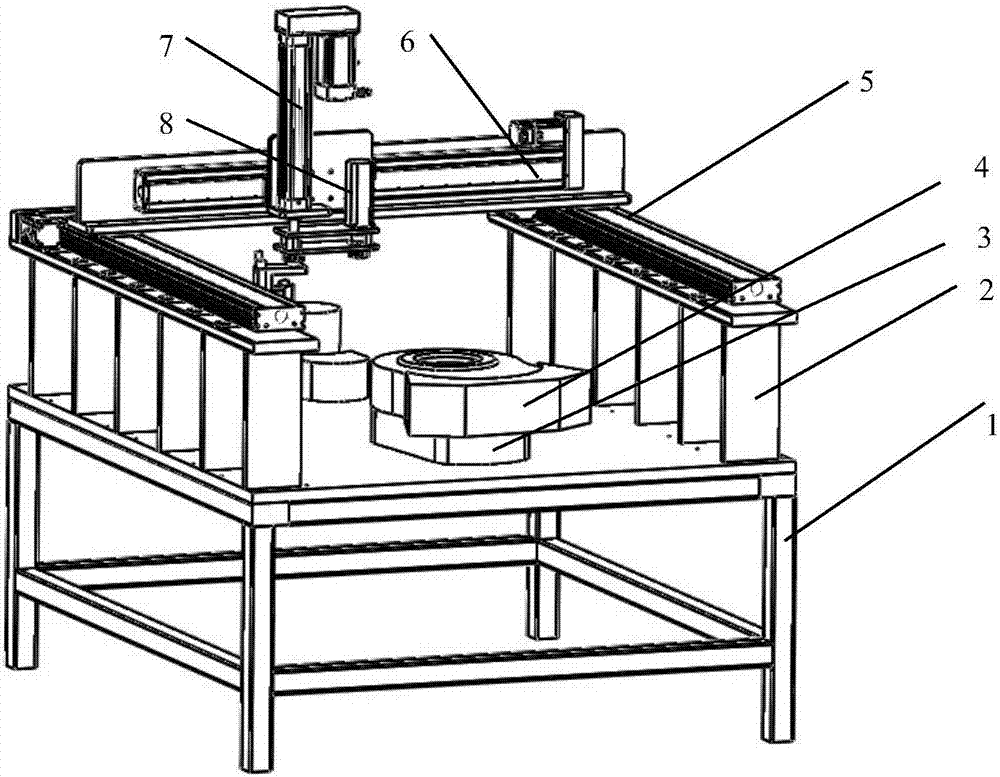

Large blade type workpiece robot collaborative grinding system and method

PendingCN107263255AGuarantee processing quality and consistencyHigh degree of automationGrinding feed controlGrinding machinesCorner angleControl theory

The invention provides a large blade type workpiece robot collaborative grinding system. The large blade type workpiece robot collaborative grinding system comprises a blade turnover clamping module, horizontal guide rails, N robot grinding units, N measuring modules corresponding to the robot grinding units, a control module and an upper computer module, wherein the control module comprises a tool control submodule and N robot grinding unit control submodules; the blade turnover clamping module is used for mounting and clamping blades to be ground; the two horizontal guide rails are arranged on the two sides of the blades in the long axis direction of the blades, and each horizontal guide rail is at least provided with one robot grinding unit; each robot grinding unit comprises a robot, a matched robot controller and a grinding device; each grinding device is mounted at the tail end of the robot corresponding to the grinding device, and each measuring module is mounted at the tail end of the corresponding robot; and the tool control submodules are connected with the blade turnover clamping module and control the turnover direction, turning angles and clamping operation of the blades. The large blade type workpiece robot collaborative grinding system can improve the grinding efficiency and quality of the blades.

Owner:无锡中车时代智能装备研究院有限公司

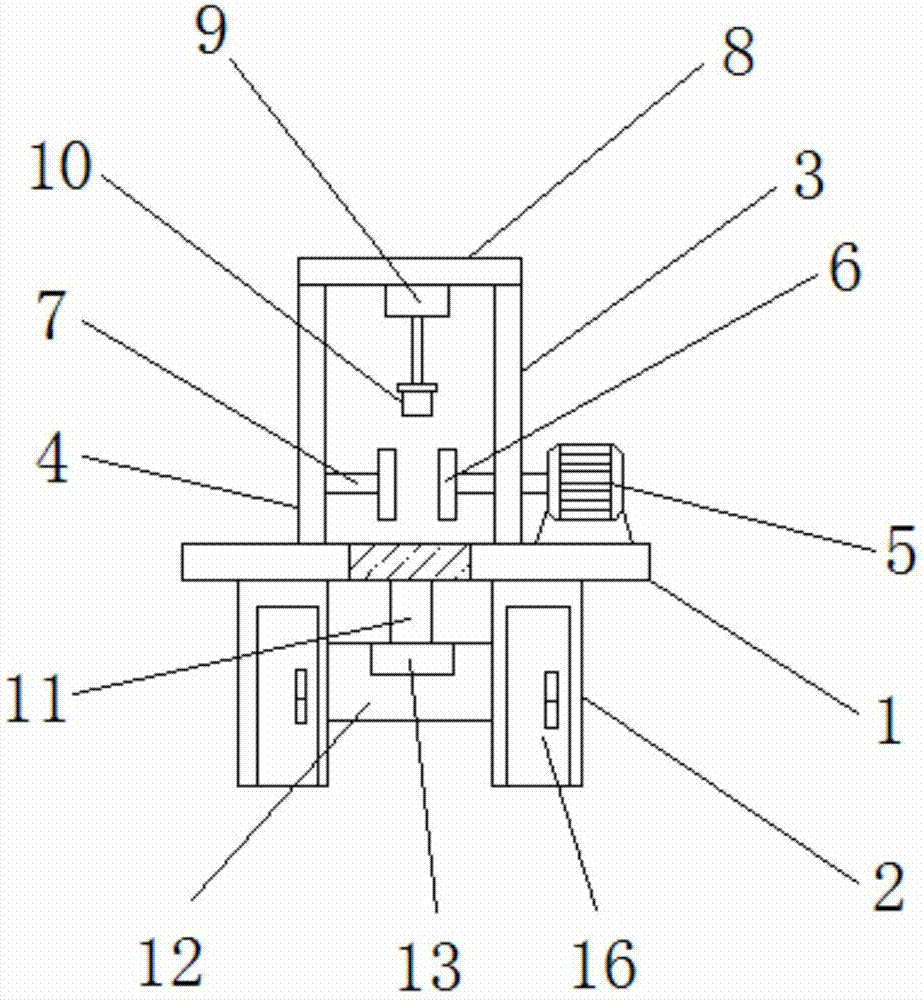

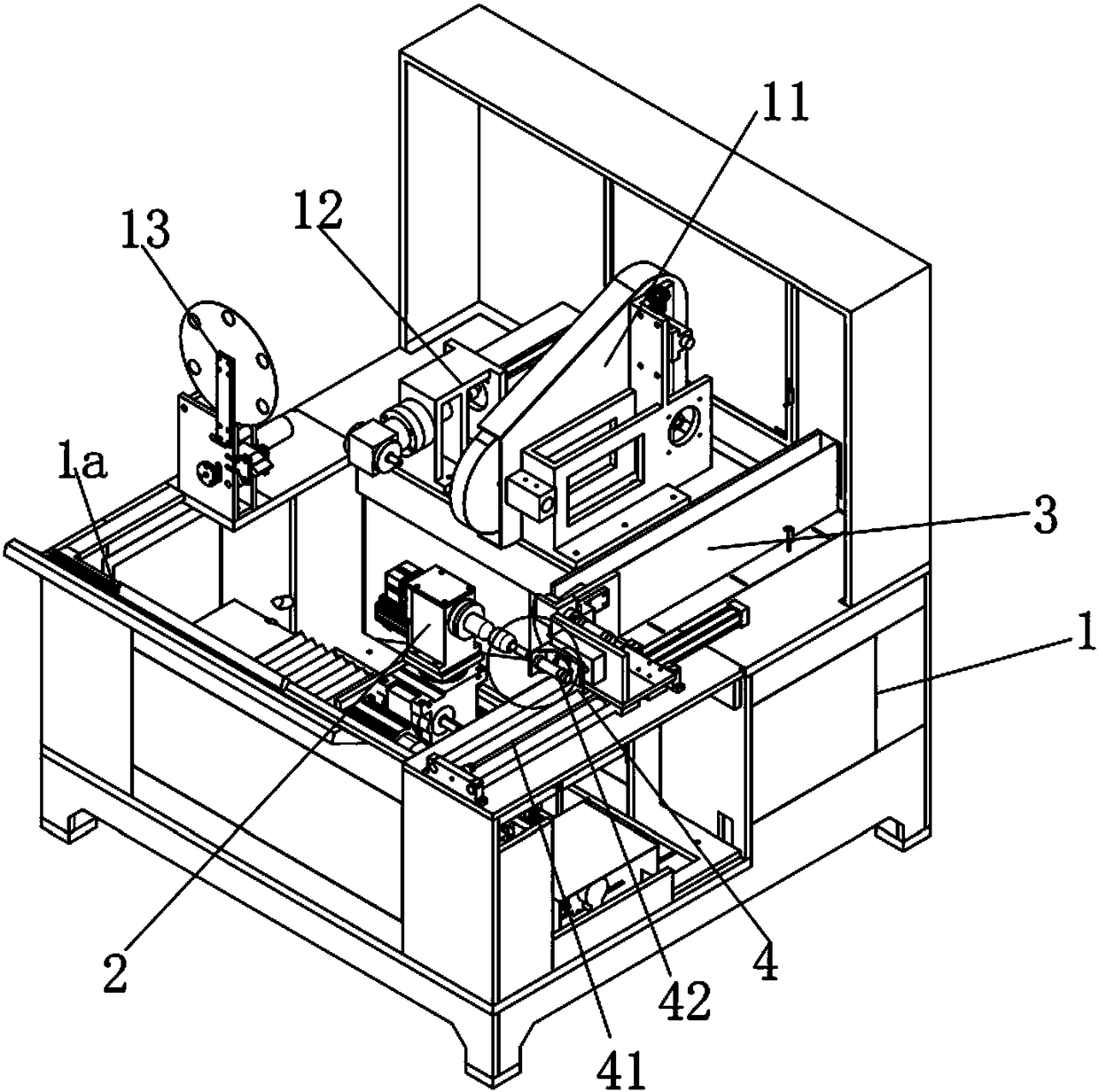

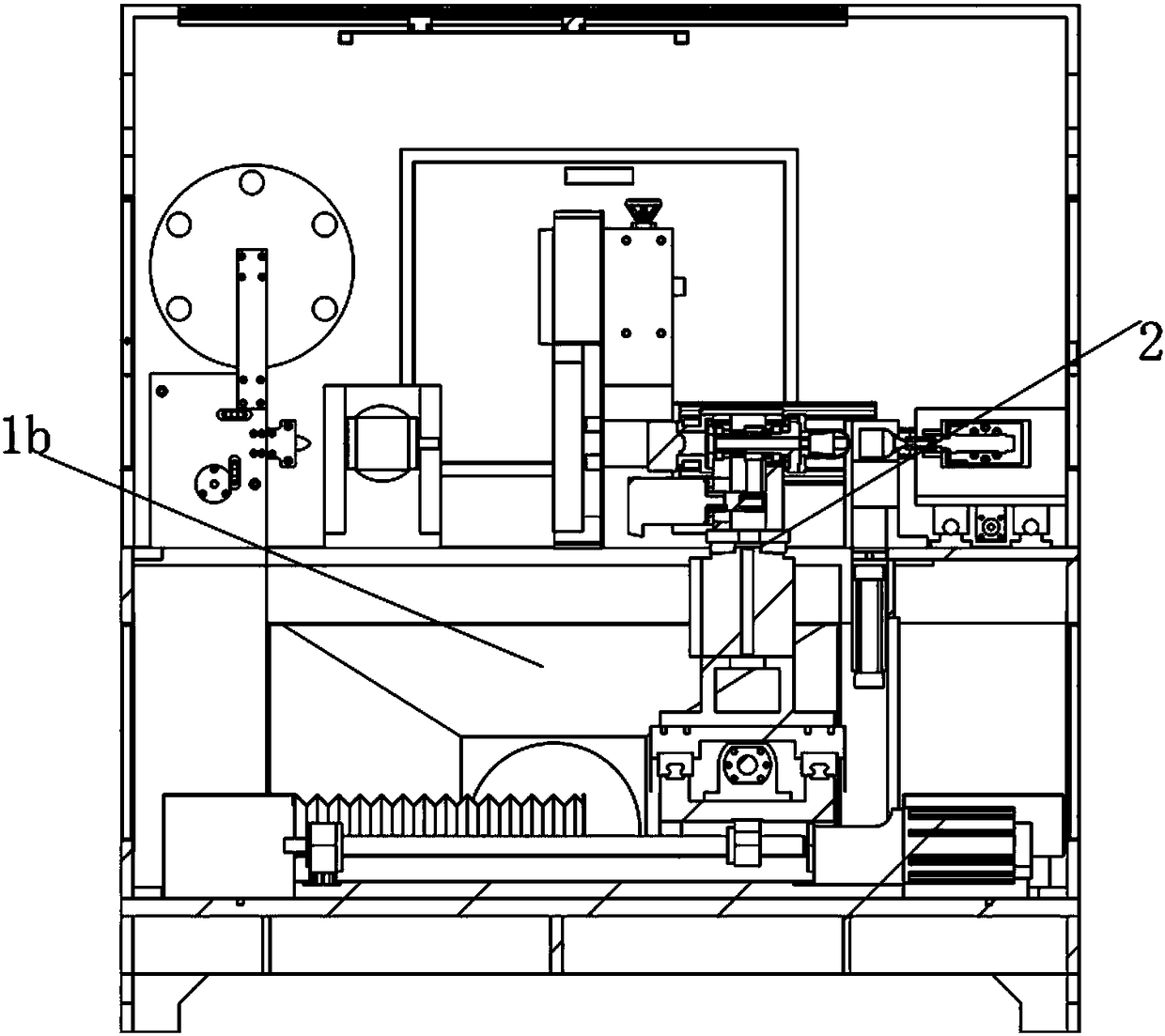

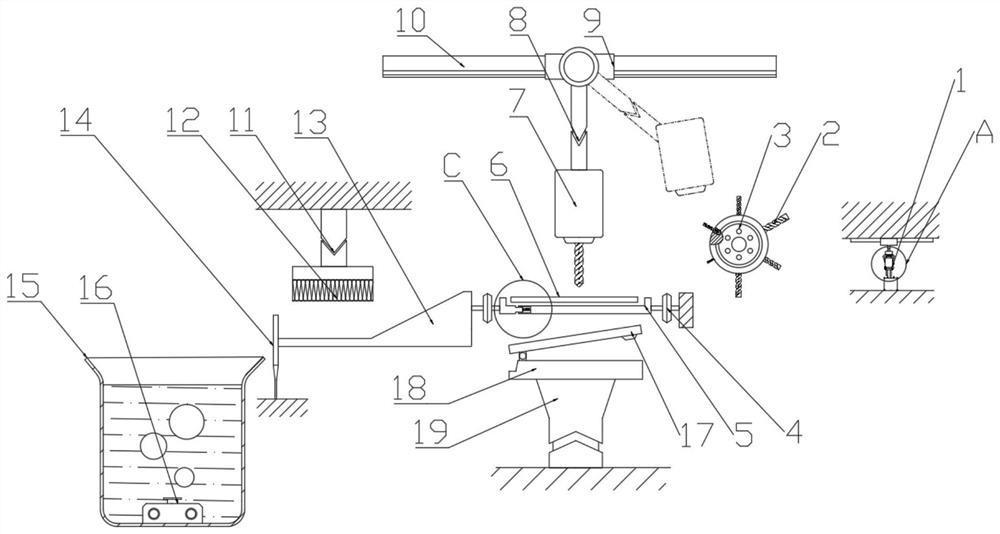

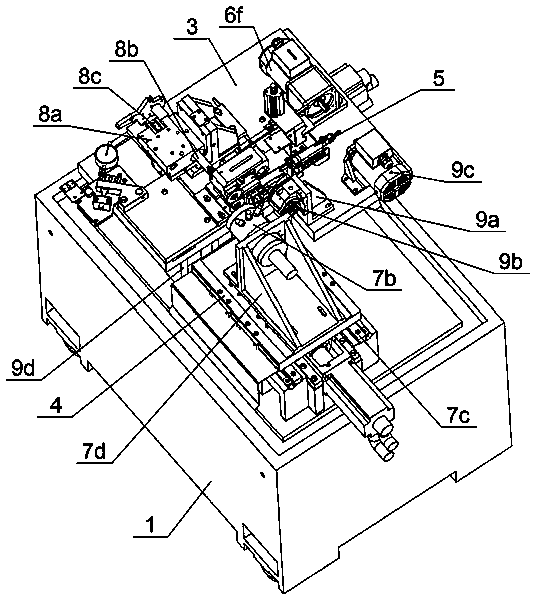

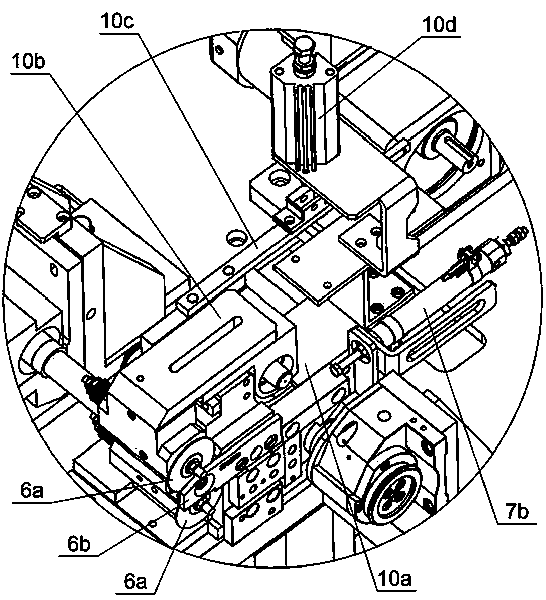

Automatic cutting, grinding and polishing machine for PCB

InactiveCN107378707AAccurate cutting positionImprove processing efficiencyGrinding feed controlGrinding machinesVertical planeWorkspace

The invention provides an automatic cutting, grinding and polishing machine for a PCB. The automatic cutting, grinding and polishing machine comprises a machine body, a working region, a clamping jaw, an action executing unit and a control panel, wherein the machine body is provided with a horizontal plane and a vertical plane which is perpendicular to the horizontal plane and is positioned at one side of the horizontal plane; the working region is arranged on the horizontal plane, and comprises a polishing disc, a grinding disc, a cutting disc and a laser aligning device; the action executing unit is arranged on the vertical plane, and the clamping jaw is connected with the action executing unit and is driven by the action executing unit to move in the vertical plane; and the control panel is arranged on the machine body and is positioned at one side of the working region. The automatic cutting, grinding and polishing machine for the PCB provided by the invention can realize advanced determining as well as automatic continuous cutting, grinding and polishing treatment of the PCB, is accurate in cutting position, is high in processing efficiency, is good in continuity, and sufficiently meets the needs, on product structure checking, of a laboratory of the PCB.

Owner:KUNSHAN HUANSHENG ELECTRONICS CO LTD

Computer hardware developing grinding device having dust removal function

InactiveCN108942516AReduce labor intensitySave time at workGrinding drivesGrinding machinesUltimate tensile strengthComputer engineering

Owner:上海宴阳智能科技有限公司

One-step form grinding method for double races

InactiveCN102463515AImprove production efficiencyAbrasive surface conditioning devicesGrinding machinesEngineeringGrinding wheel

The invention discloses a one-step form grinding method for double races, which includes the following steps: step 1: an emery wheel is mounted on a bracket, the emery wheel and the bracket are formed into a grinding wheel dresser, the bracket is fixed on a machine tool platform, and the central line of the emery wheel needs to be in parallel with the central line of the spindle of a grinding wheel; step 2: the emery wheel is rotated at high speed to dress the grinding wheel, so that the grinding wheel is formed into a shape required by grinding; and step 3: the dressed grinding wheel is used for grinding the inner and the outer races of a wind power bearing until the shapes of the inner and the outer races fully accord with the shape of the emery wheel and the requirement of a drawing. The one-step form grinding method for the double races increases the race-making precision.

Owner:SHANGHAI OUJIKETE SLEWING BEARING CO LTD

Steel plate machining rust removal device capable of collecting waste scraps conveniently

InactiveCN108687634AEasy to collectAvoid random flyingGrinding carriagesGrinding drivesFixed frameArchitectural engineering

Owner:芜湖良匠机械制造有限公司

Tubular steel frame dust-removal device

InactiveCN107745319AGuaranteed derusting effectNo shakingGrinding carriagesGrinding machinesEngineeringSteel frame

Owner:四川大黄河建设工程有限公司

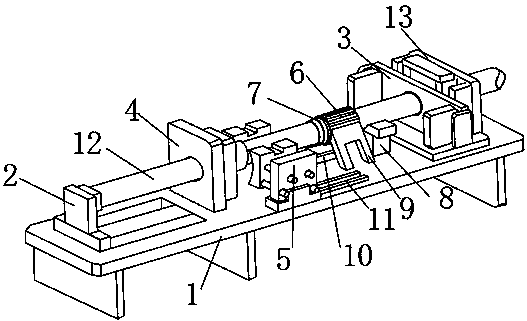

Automatic grinding device for short steel bars

InactiveCN109227288APrevent slidingPrevent rotationGrinding drivesGrinding feed controlArchitectural engineeringRebar

The invention discloses an automatic grinding device for short steel bars. The automatic grinding device comprises a base, wherein the left side of the upper portion of the base is provided with a positioning assembly, a sliding assembly is arranged under the positioning assembly, the positioning assembly is slidingly connected with the base through the sliding assembly, the right side of the upper portion of the base is provided with a grinding assembly, and the outer side of the base is provided with a central control module. The problem is solved that after steel bars are placed for a period of time, certain rust unavoidably exists on the surfaces, so steel bar grinding is needed, a worker needs to hole one end of each steel bar in the grinding process and then pull out the steel bar from the other end after the steel bar penetrates through the grinding device, the method needs manual control, unthorough surface grinding is possible if steel bar pulling is too quick, excessive grinding is also possible if the steel bar pulling is slower, the steel bar pulling is very strenuous, and large body burden is brought to the operator.

Owner:RUIXIONG METAL PROD (WUHU CO LTD

Steel structure painting device

ActiveCN111229521APaint efficiency is not highImprove work efficiencyPretreated surfacesGrinding machinesEngineeringRoller mill

The invention relates to the technical field of steel structure painting, and discloses a steel structure painting device which comprises a painting box with openings on two sides. Treatment groups are arranged on the two sides of the painting box; each treatment group comprises a roller grinding mechanism and a painting mechanism positioned on one side of the roller grinding mechanism, wherein heroller grinding mechanism comprises a plurality of grinding rollers driven by a driving piece, and the painting mechanism comprises a manhole formed in the painting box, a first supporting plate anda second supporting plate are arranged on the two sides of the manhole correspondingly, a painting assembly is mounted on the first supporting plate, the painting assembly faces the middle of the painting box, and a plurality of air injection assemblies are rotatably mounted on the second supporting plate. The steel structure painting device has the simple structure and can quickly grind and painta steel structure.

Owner:CHONGQING SHICHUANG STEEL STRUCTURE CO LTD

Intelligent processing equipment for traditional Chinese medicines

InactiveCN108247703ADoes not affect aestheticsGuaranteed economic valueFruit stoningGrinding machinesDiseaseLimb injury

The invention relates to intelligent processing equipment for traditional Chinese medicines. The intelligent processing equipment for traditional Chinese medicines comprises a bottom plate, wherein aworking frame is installed on the bottom plate; a partition is installed on the inner wall of the working frame; a part located at the front end of the partition, of the working frame, is a gourd seedcollection cavity; a gourd seed guide frame is arranged on the gourd seed collection cavity; a part located at the front end of the partition, of the working frame, is a powder collection cavity; a powder guide frame is arranged on the powder collection cavity; and a peeling device and a polishing device are installed at the upper end of the working frame from front to back. The intelligent processing equipment for traditional Chinese medicines is capable of solving the problems that division processing needs to be manually carried out on gourds by virtue of the existing cutting tool, gourd seeds need to be manually separated from the gourds by virtue of a tool, and the cutting sections of the gourds need to be manually polished in the existing process of manually carrying out dipper opening and separation on the traditional Chinese medicine gourds, serious human limb injury is caused due to the action of manual repeated separation for the gourd seeds, and the limb diseases of workingpersonnel are easily caused due to long-time working.

Owner:吴露露

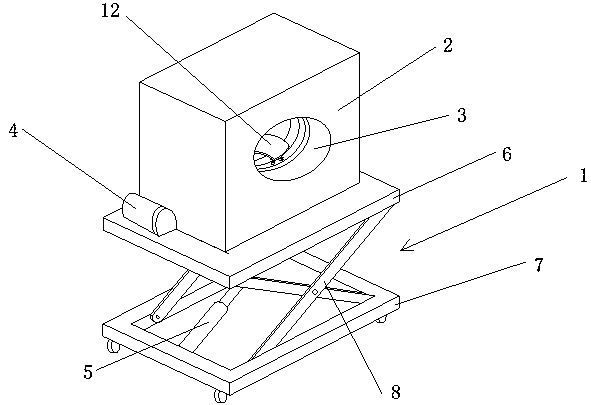

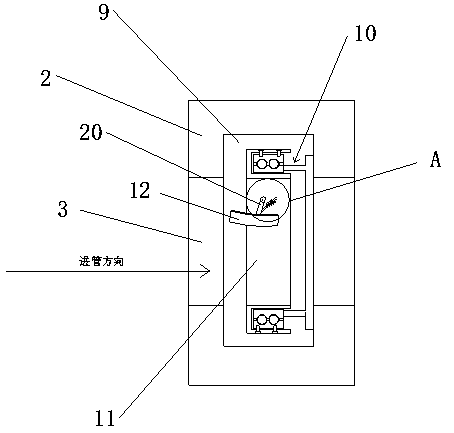

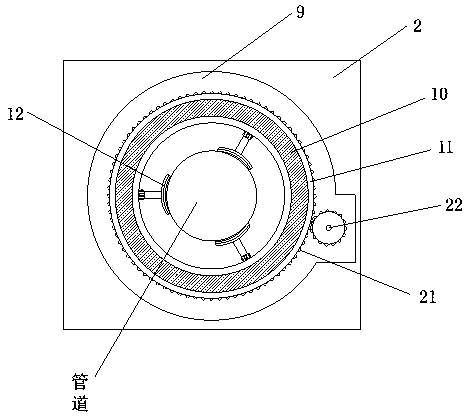

Steel pipe rust removal device

PendingCN108789101AAdjust effective lengthChange spacingGrinding carriagesGrinding drivesArchitectural engineeringDrive motor

Owner:HAIYAN HUITONG INTELLIGENT FURNITURE CO LTD

Machining tooling and machining method for ultra-large gas turbine blade

Owner:成都和鸿科技股份有限公司

Plastic part processing mechanism

ActiveCN112873392ARealize moving forwardImprove adaptabilityGrinding drivesPlastic recyclingStructural engineeringMechanical engineering

The invention discloses a plastic part processing mechanism, and belongs to the field of rubber part processing. The plastic part processing mechanism comprises a bending frame, wherein the bending frame is fixedly provided with four ground feet, the ground feet are uniformly arranged at the bottom end of the bending frame, the lower part of the side wall of the bending frame is provided with a passing opening and a pushing opening, the side wall of the bending frame is provided with an inclined plate pushing frame, the upper end and the lower end of the inclined plate pushing frame are fixedly connected with the side wall of the bending frame through compression springs correspondingly, and a plane shaft seat is fixedly installed at the top end of the bending frame. The plastic part processing mechanism can realize automatic blanking of plastic parts.

Owner:SHANGRAO MEIYUDA OPTICAL INSTR CO LTD

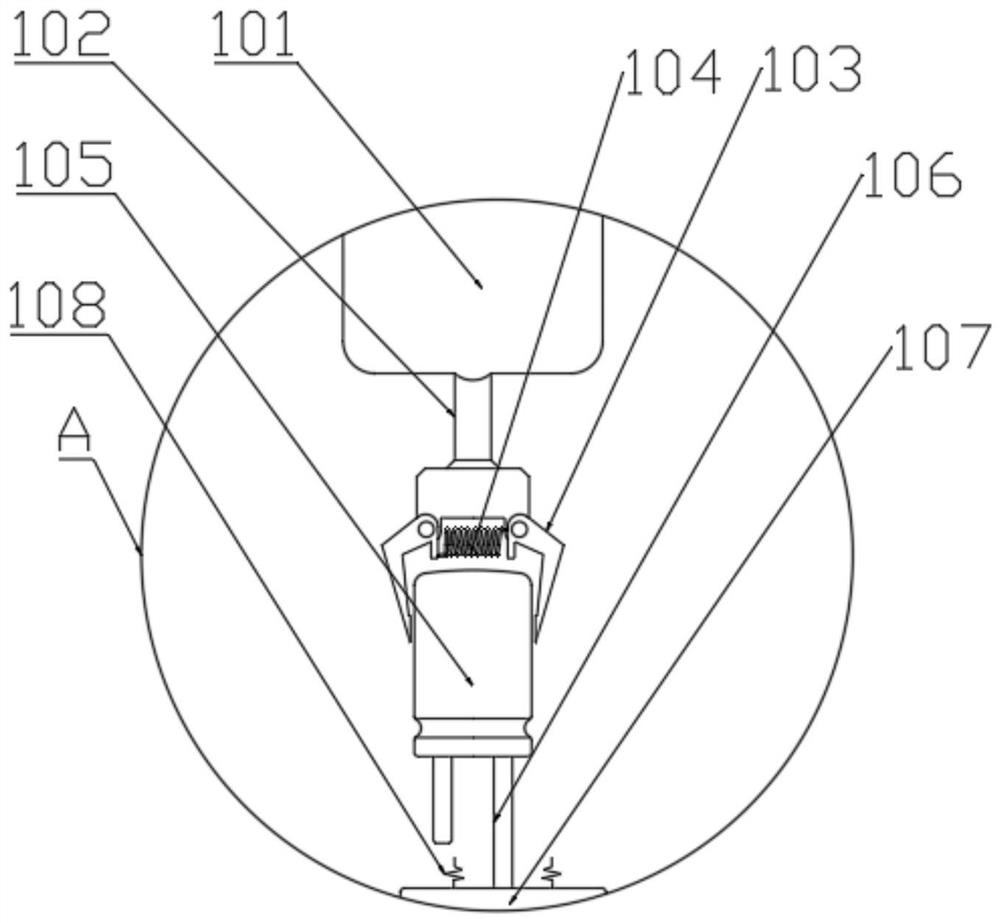

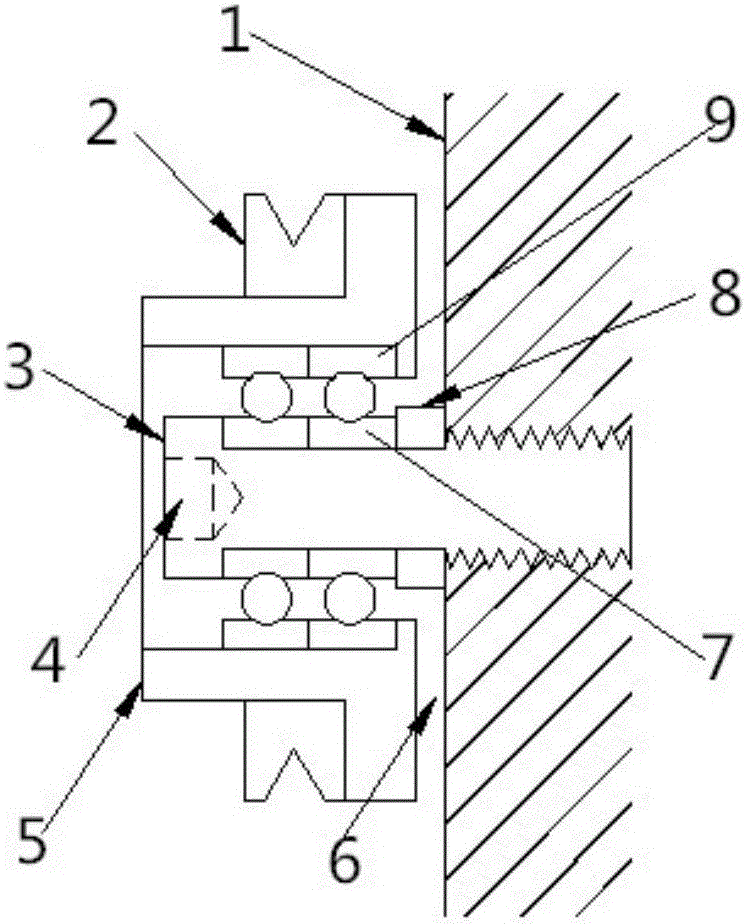

Workpiece holder and workpiece cutting method

ActiveCN107848092ACut offSemiconductor/solid-state device manufacturingWorking accessoriesAdhesiveIngot

The present invention provides a workpiece holder that is used when cutting a workpiece using a wire saw. The workpiece holder is provided with: a workpiece plate that is adhered and fixed to a workpiece with a back plate interposed therebetween; and a holder body that supports the workpiece plate. In a case where, among radial directions of the workpiece, the direction parallel to the workpiece adhesion surface of the workpiece plate is the x-axis direction and a direction perpendicular the workpiece adhesive surface is the y-axis direction, the workpiece plate corrects misalignment of a crystallographic orientation axis of the workpiece in the x-axis direction and is adhered and fixed to the workpiece. The workpiece holder adjusts a y-axis direction inclination of the workpiece held by the workpiece plate by inclining the workpiece plate in the y-axis direction and is able to fix the workpiece plate and the workpiece to the holder body at the adjusted inclination. Due to this configuration, there are provided a workpiece holder and a method of cutting a workpiece using the workpiece holder that can realize cutting of an ingot having strict directional standards for an external setup system.

Owner:SHIN-ETSU HANDOTAI CO LTD

Cup cover polishing machine

PendingCN108406541ANo manual operation requiredReasonable layoutGrinding machinesGrinding feedersGrinding wheelMechanical engineering

Owner:浙江司贝宁精工科技有限公司

Circuit board processing device for electrical components

Owner:SUZHOU GUIGUO ELECTRONICS

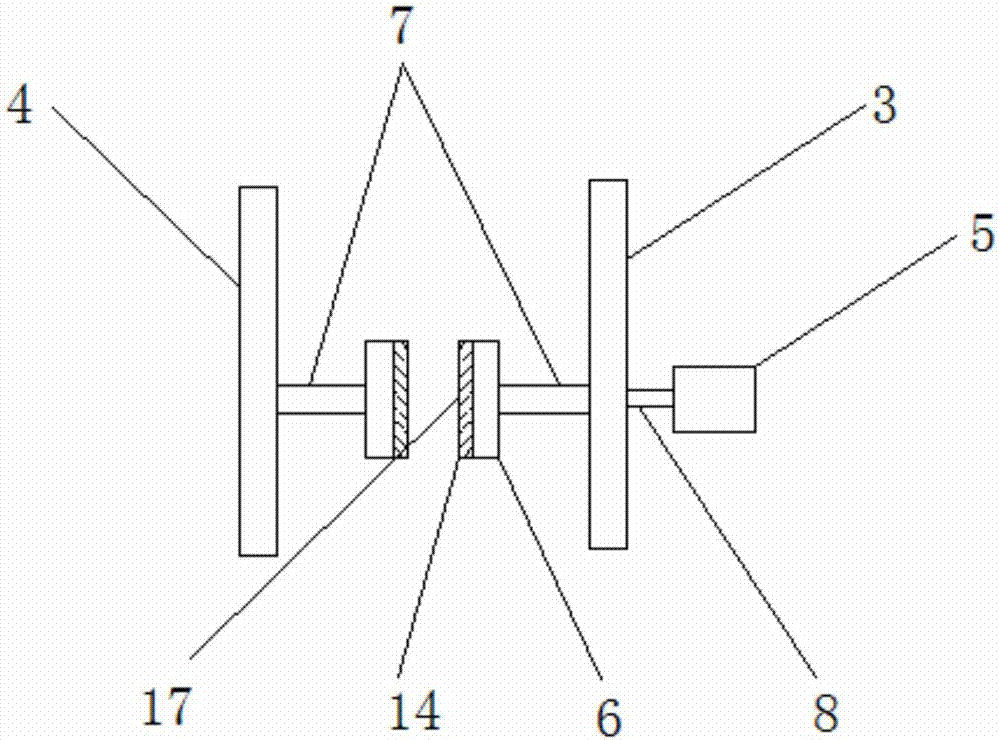

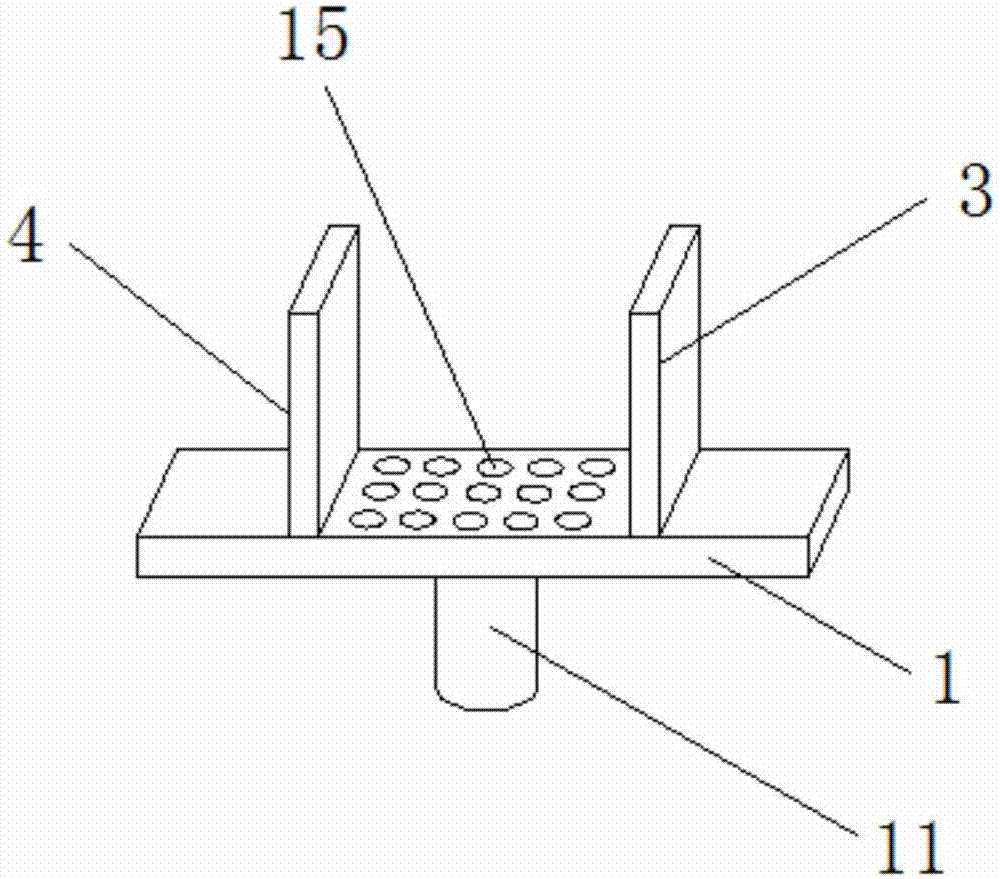

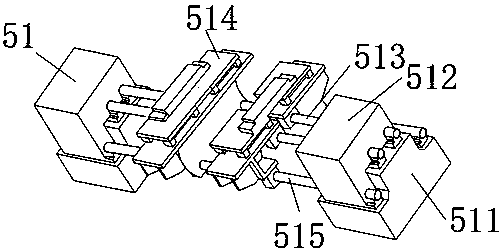

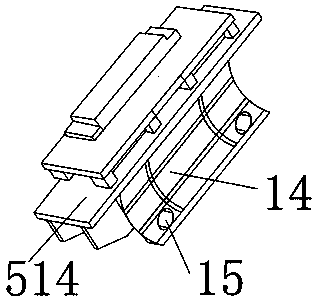

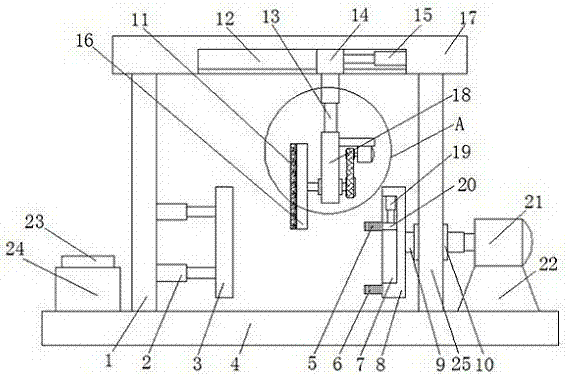

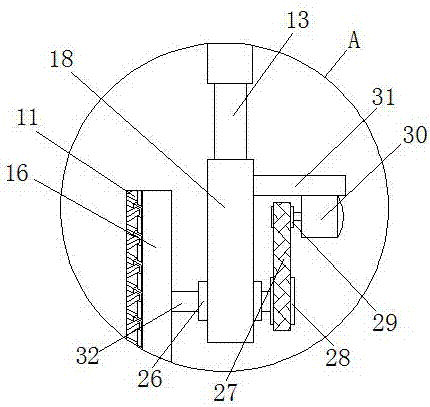

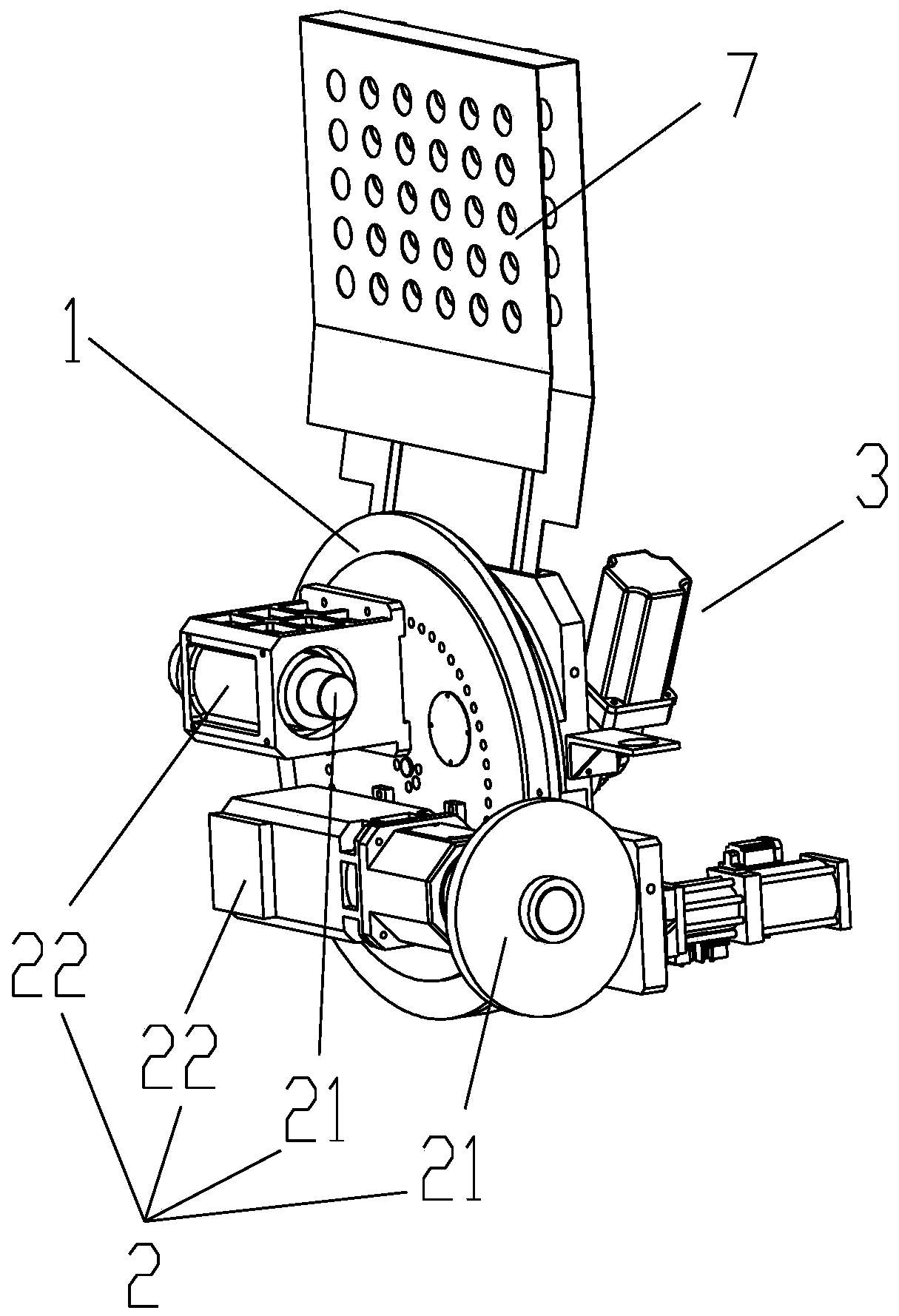

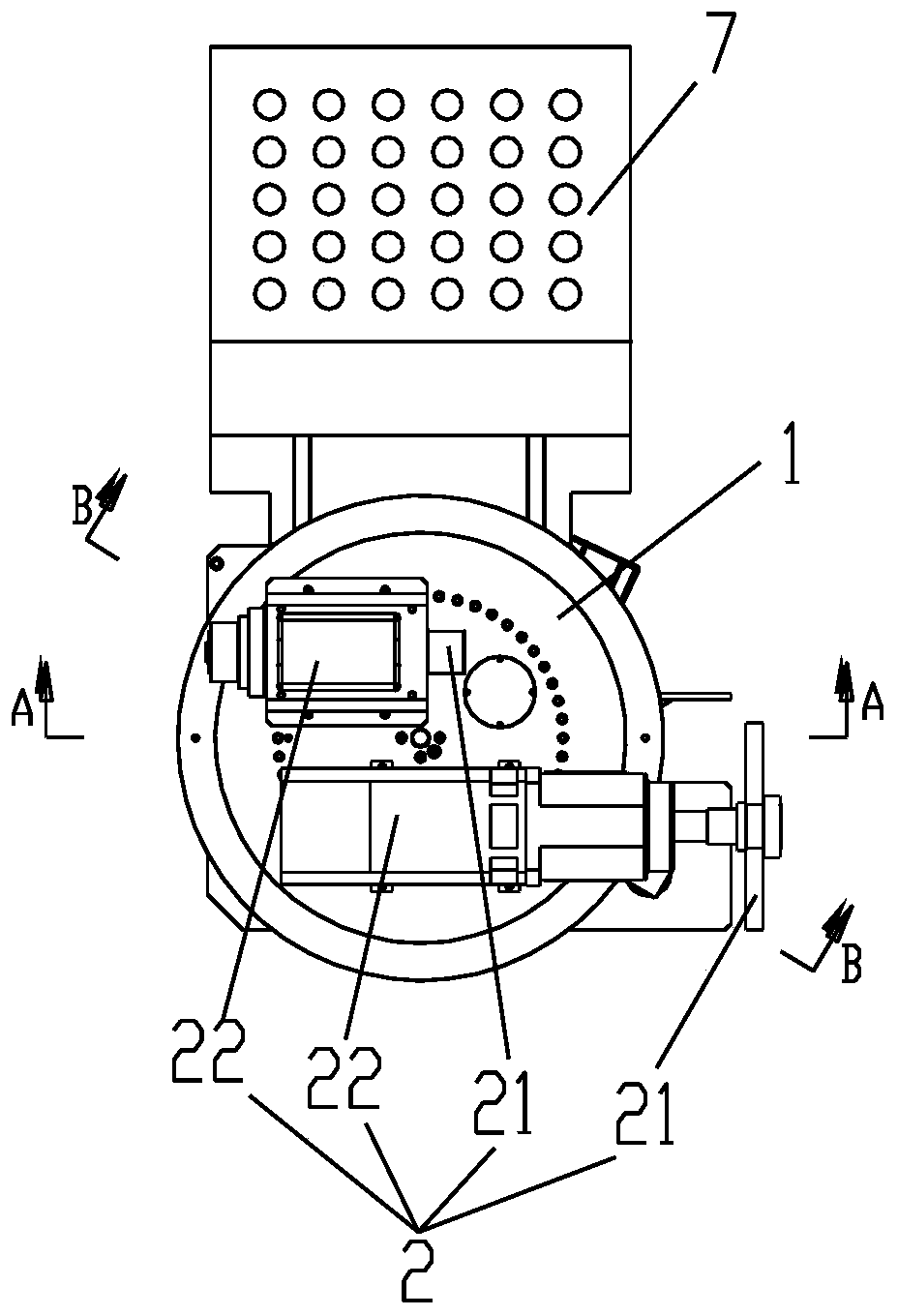

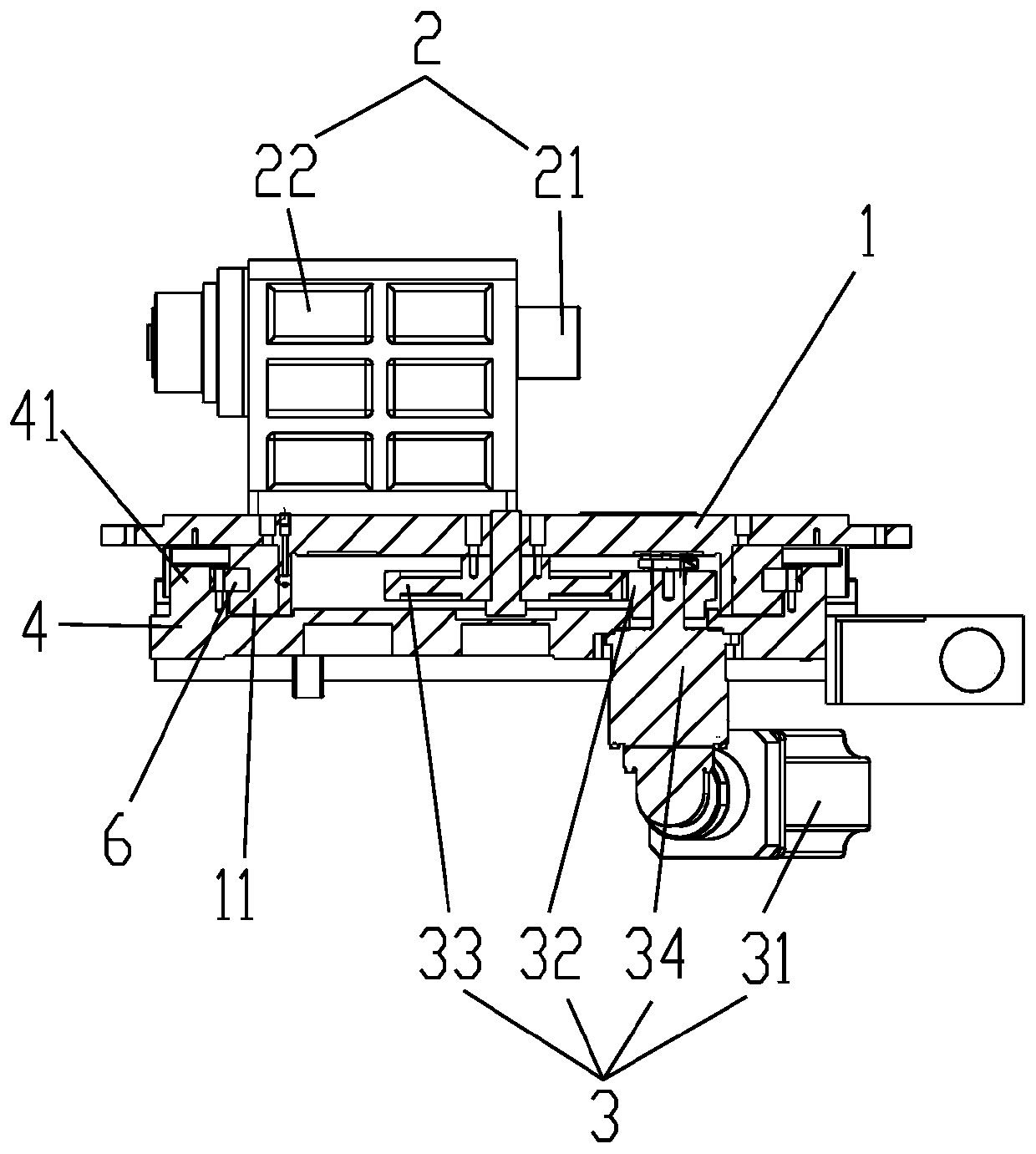

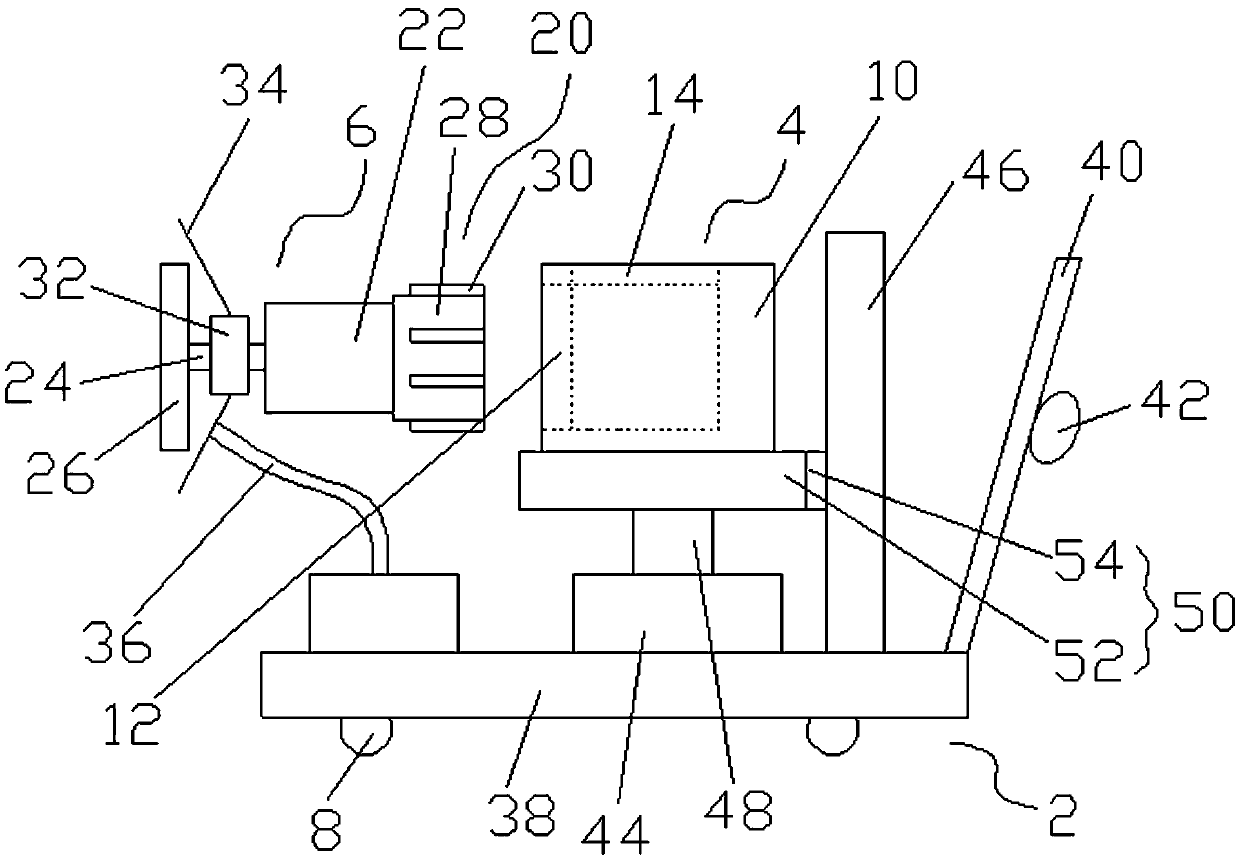

Workpiece machining mechanism, grinding device and grinding machine

PendingCN110103141AAvoid unsandable situationsImprove grinding efficiencyGrinding drivesGrinding machinesEngineeringMachining

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

Polishing mechanism

Owner:SUZHOU BOLAIXI ELECTRICAL APPLIANCE CO LTD

Dephosphorization wheel shaft

InactiveCN105965361AQuick releaseCompact structureGrinding machine componentsGrinding machinesScrew thread

Owner:ZHENJIANG NAISI ADVANCE MATERIALS

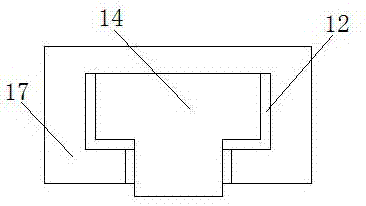

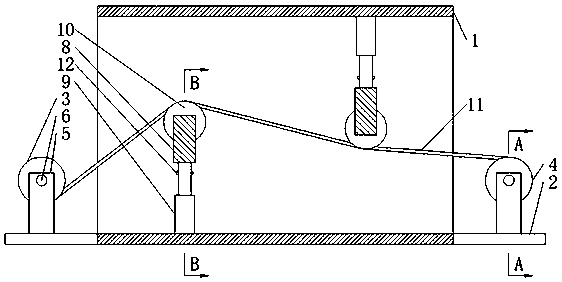

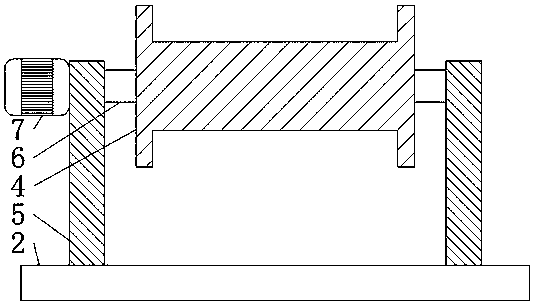

L-shaped grinding mechanism for forklift part

InactiveCN106625119ARealize automatic grinding functionSimple and fast operationGrinding carriagesGrinding drivesHydraulic cylinderEngineering

The invention relates to an L-shaped grinding mechanism for a forklift part. The L-shaped grinding mechanism comprises a bottom plate, wherein the upper end surface of the bottom plate is welded with a fixed plate; a hydraulic cylinder is mounted on the fixed plate; a middle part fixing frame of the hydraulic cylinder is erected on a supporting column; the supporting column is mounted on the bottom plate; the supporting column achieves an effect of fixedly supporting the hydraulic cylinder; a push plate is mounted at the front end of the hydraulic cylinder through a screw; the push plate is tightly attached to a workpiece; the workpiece is mounted on the bottom plate; the hydraulic cylinder drives the push plate to move, and the push plate drives the workpiece to move on the bottom plate; two auxiliary lifting lugs are arranged on the upper end surface of the bottom plate; an auxiliary shaft is mounted between the two auxiliary lifting lugs through bearings; a longitudinal grinding wheel is mounted at the middle part of the auxiliary shaft; a driven gear is mounted at the right end of the auxiliary shaft; and the longitudinal grinding wheel is used for longitudinally grinding and derusting the workpiece. The L-shaped grinding mechanism can realize an automatic grinding function of an L-shaped forklift part, and has the advantages of simplicity and convenience for operation, short grinding time, good grinding effect, high working efficiency and the like.

Owner:YUEXI COUNTY HONGSHENG CASTING

Core device and technology for preparation of electromagnetic shielding rubber

Owner:SHENZHEN COTRAN NEW MATERIAL CO LTD

Notebook enclosure production device

InactiveCN108214214AShorten the timeEasy to processGrinding drivesGrinding machinesGear wheelDrive shaft

Owner:英力电子科技(重庆)有限公司

Wire oxidation film grinding device

Owner:DEQING JIAWEI CABLE

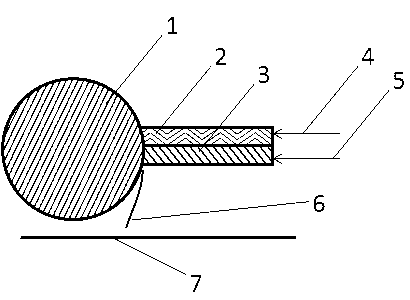

Propeller and abrasive belt grinding processing method of sharkskin surface thereof

The invention discloses an abrasive belt grinding processing method of a sharkskin surface of a propeller, which is used for solving the problem of the abrasive belt grinding processing method of thesharkskin surface of the propeller. The technical scheme is that the abrasive belt processing method of the sharkskin surface is provided, the smooth surface of the propeller is ground by an abrasivebelt grinding head, a cylinder controls a contact wheel driven by the high-speed moving abrasive belt to provide instantaneous micro-pressure while performing feed movement on the propeller surface togrind the required infinitesimal surface, and infinitesimals arranged in a regular pattern are sequentially ground along the propeller surface to achieve the state of the sharkskin surface. An abrasive belt grinding processing method of a sharkskin surface of a propeller is composed of a contact wheel, a contact wheel support, an abrasive belt, a cylinder rod sleeve and a cylinder. Processing ofthe sharkskin-like structure on the propeller surface is achieved, and the method of processing the sharkskin surface of the propeller is created, thereby facilitating actual production and promotion.

Owner:CHONGQING UNIV

Robot device for polishing casting parts

Owner:ANHUI HISEED ROBOT CO LTD

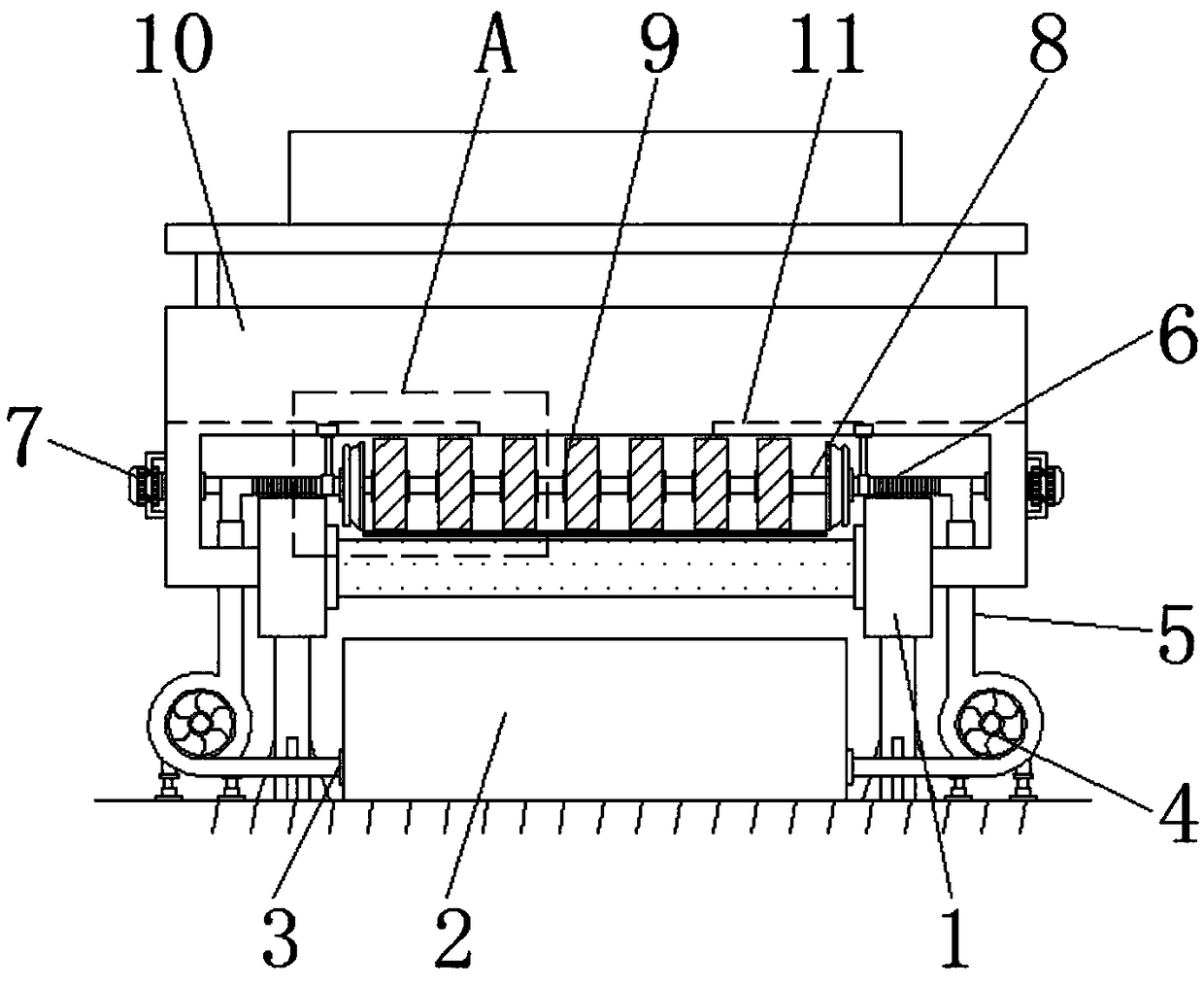

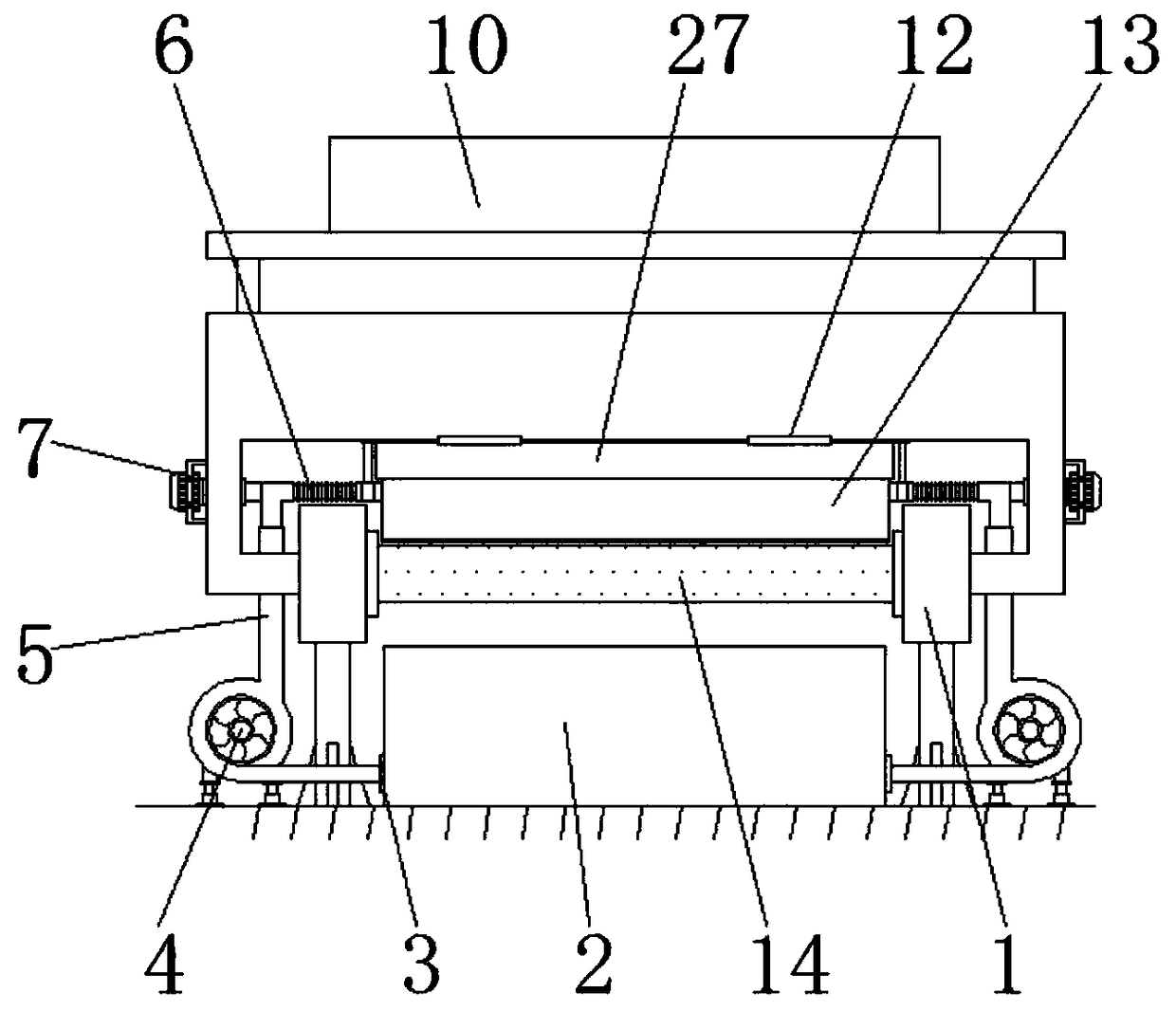

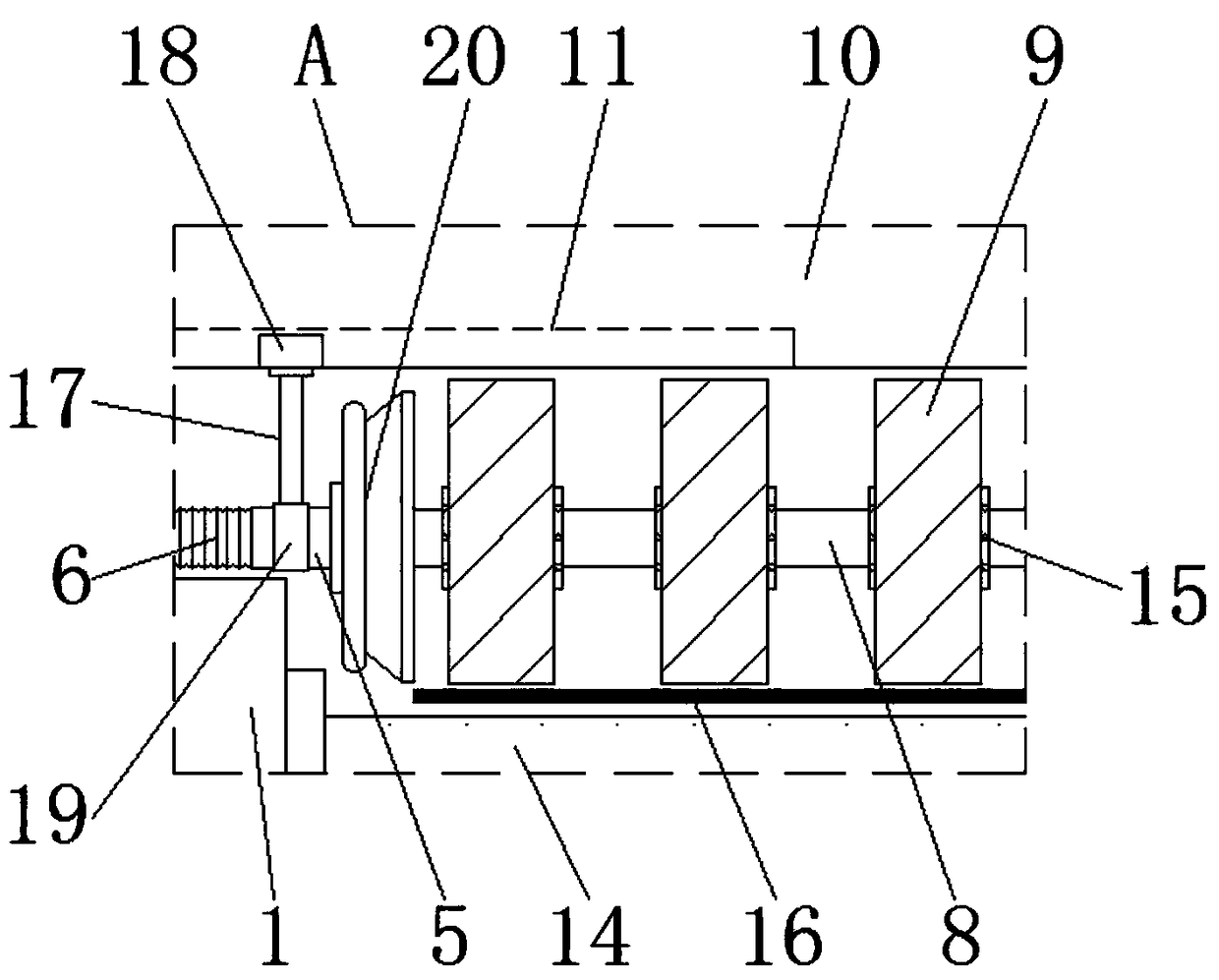

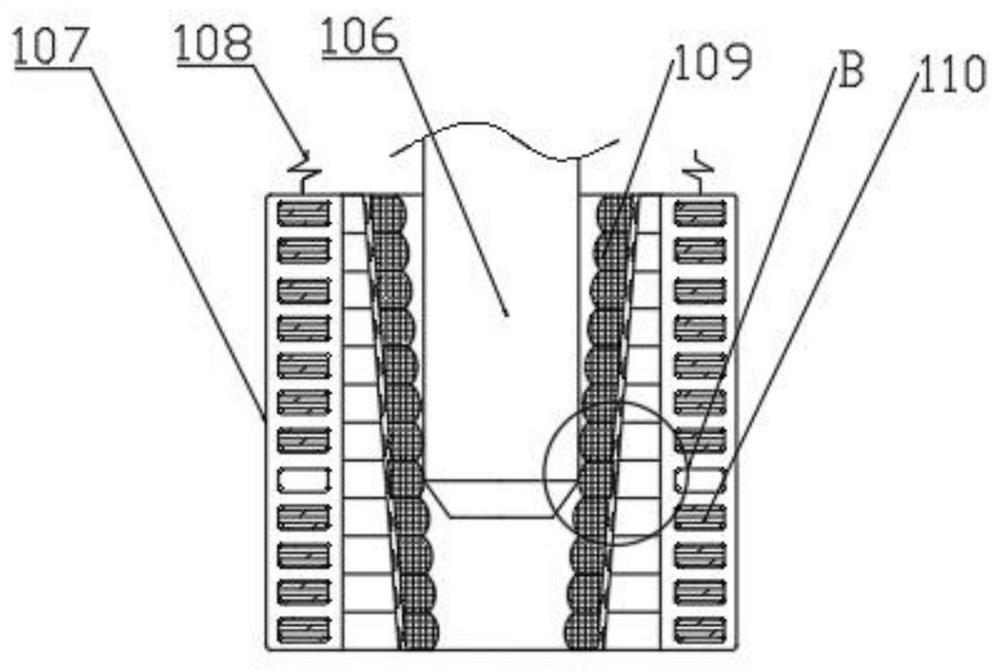

Bearing inner and outer ring roller bed and inner ring inner diameter grinding equipment

PendingCN110000661AReduce shakingConsistent contour shapeGrinding carriagesGrinding drivesEngineeringMechanical engineering

Owner:HUNAN MEIBEIDA TECH CO LTD

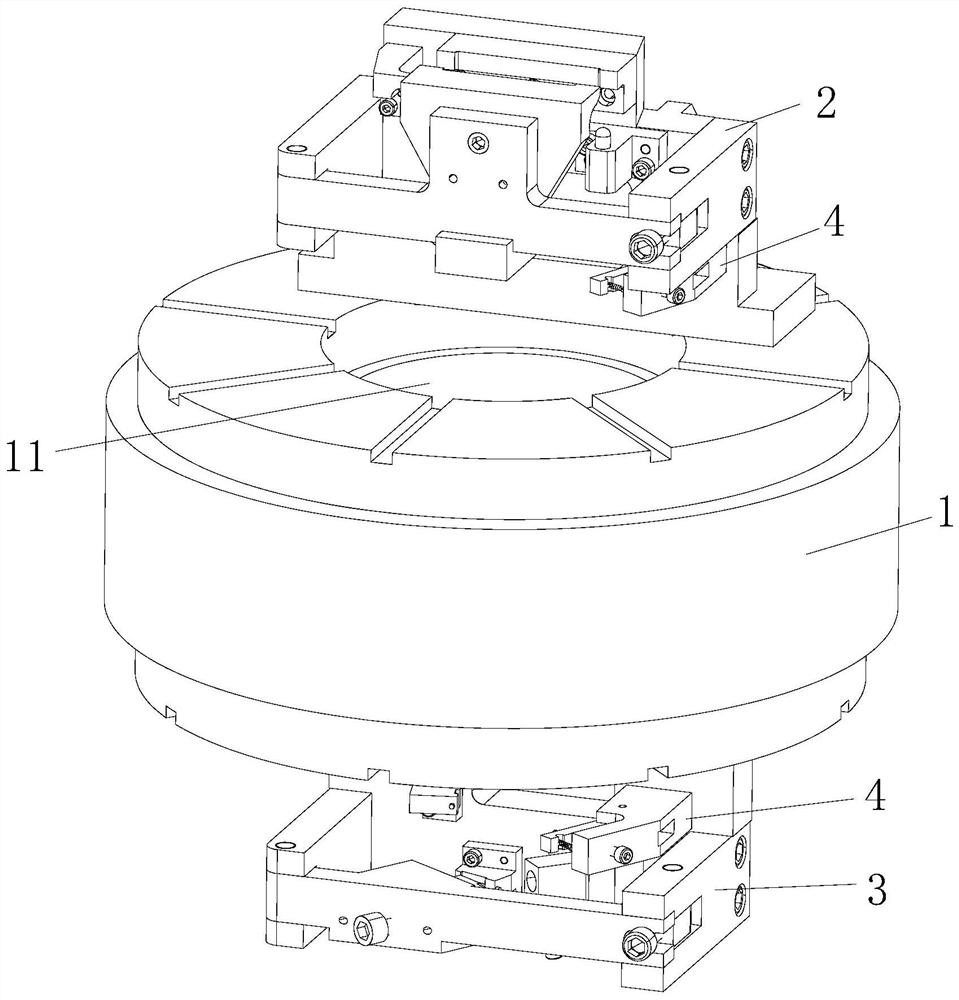

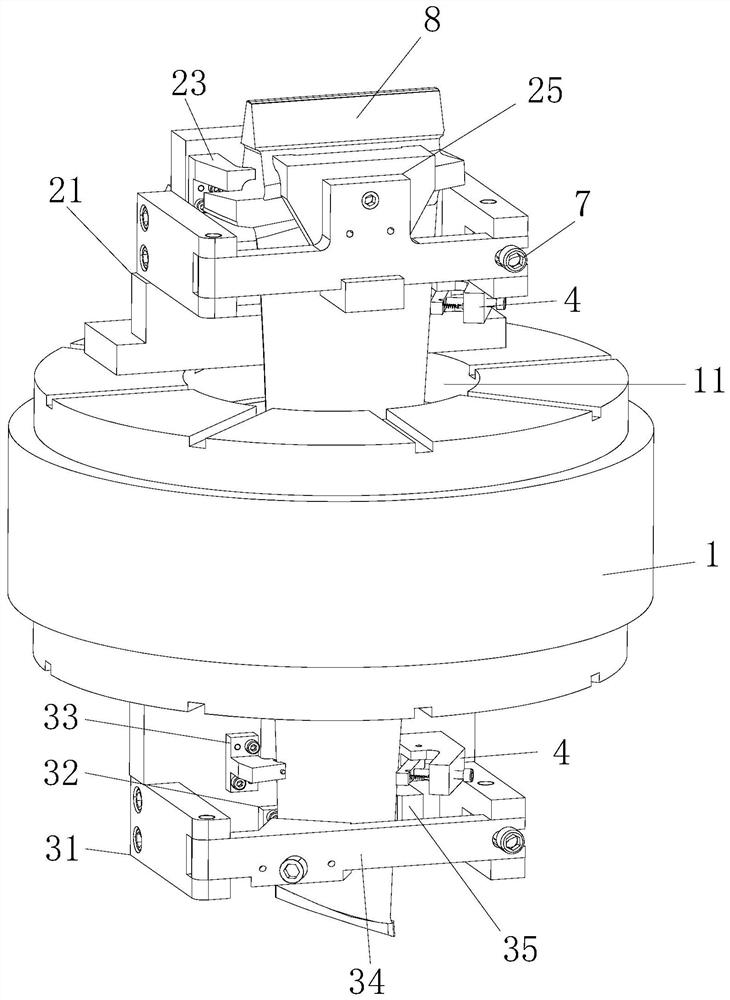

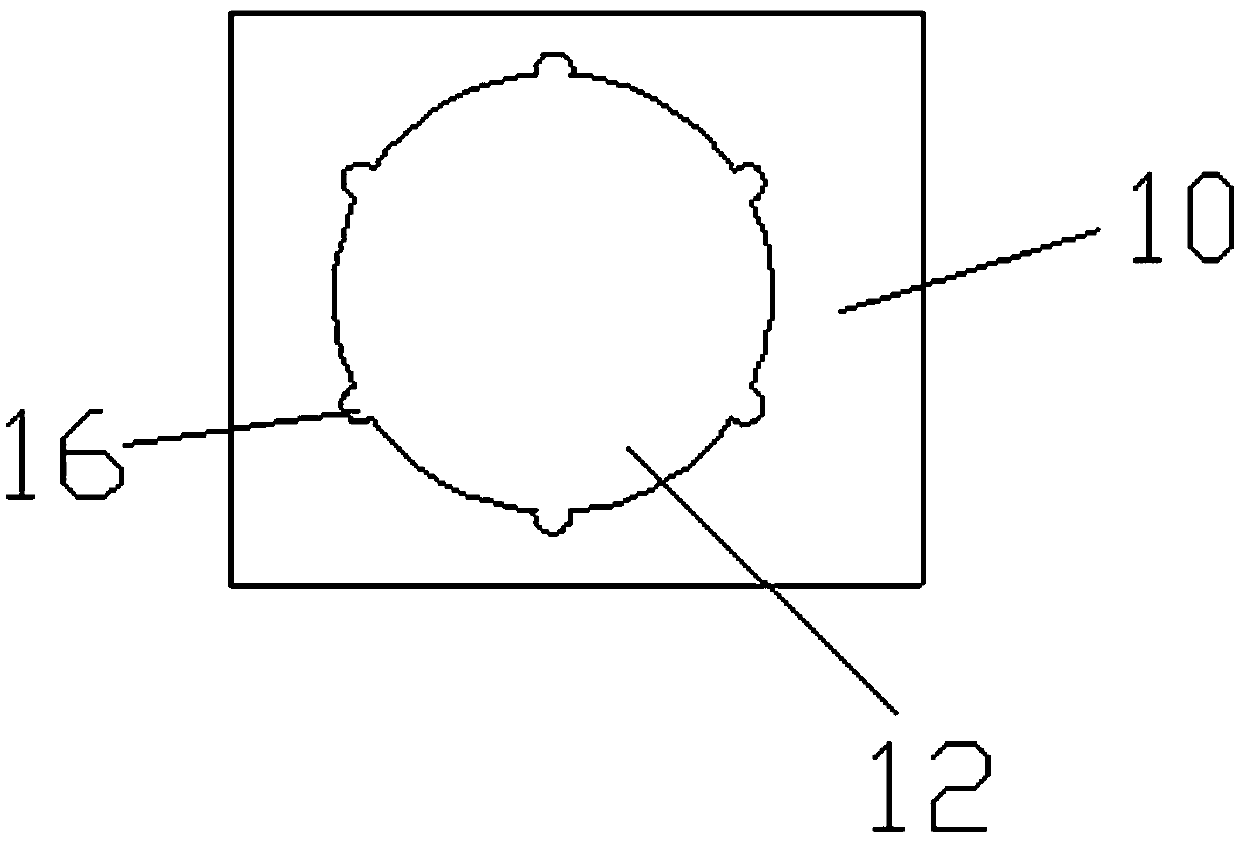

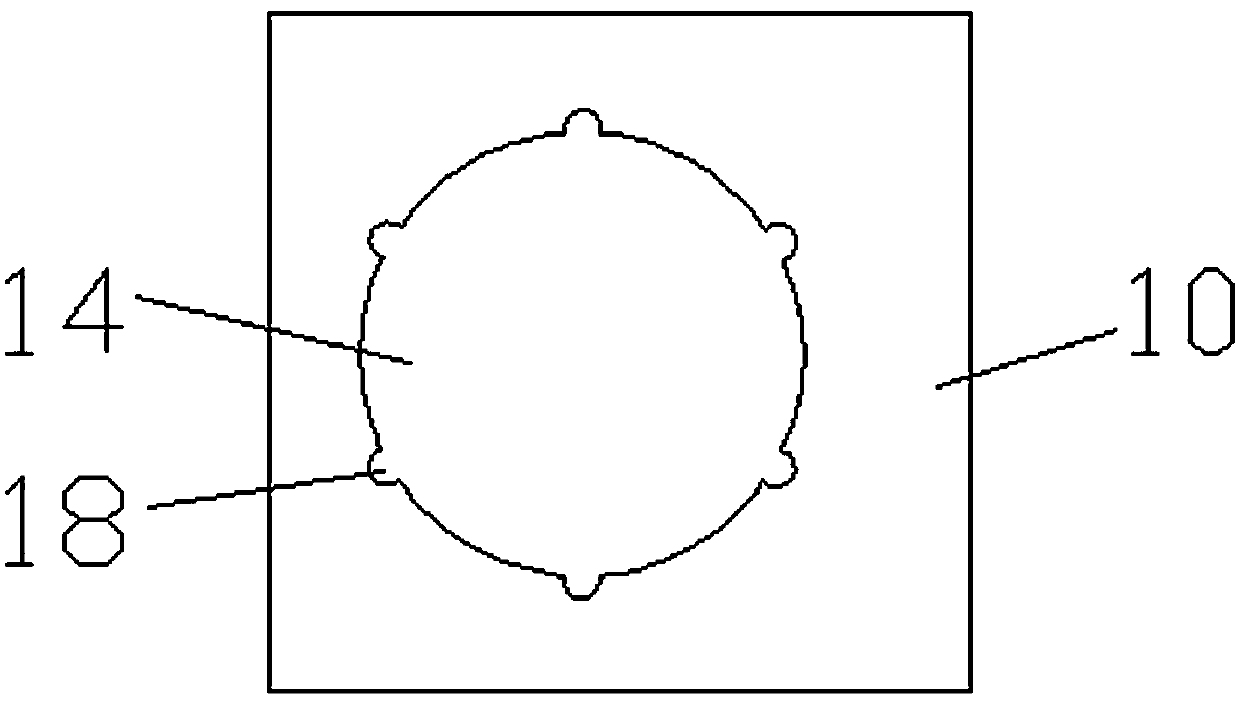

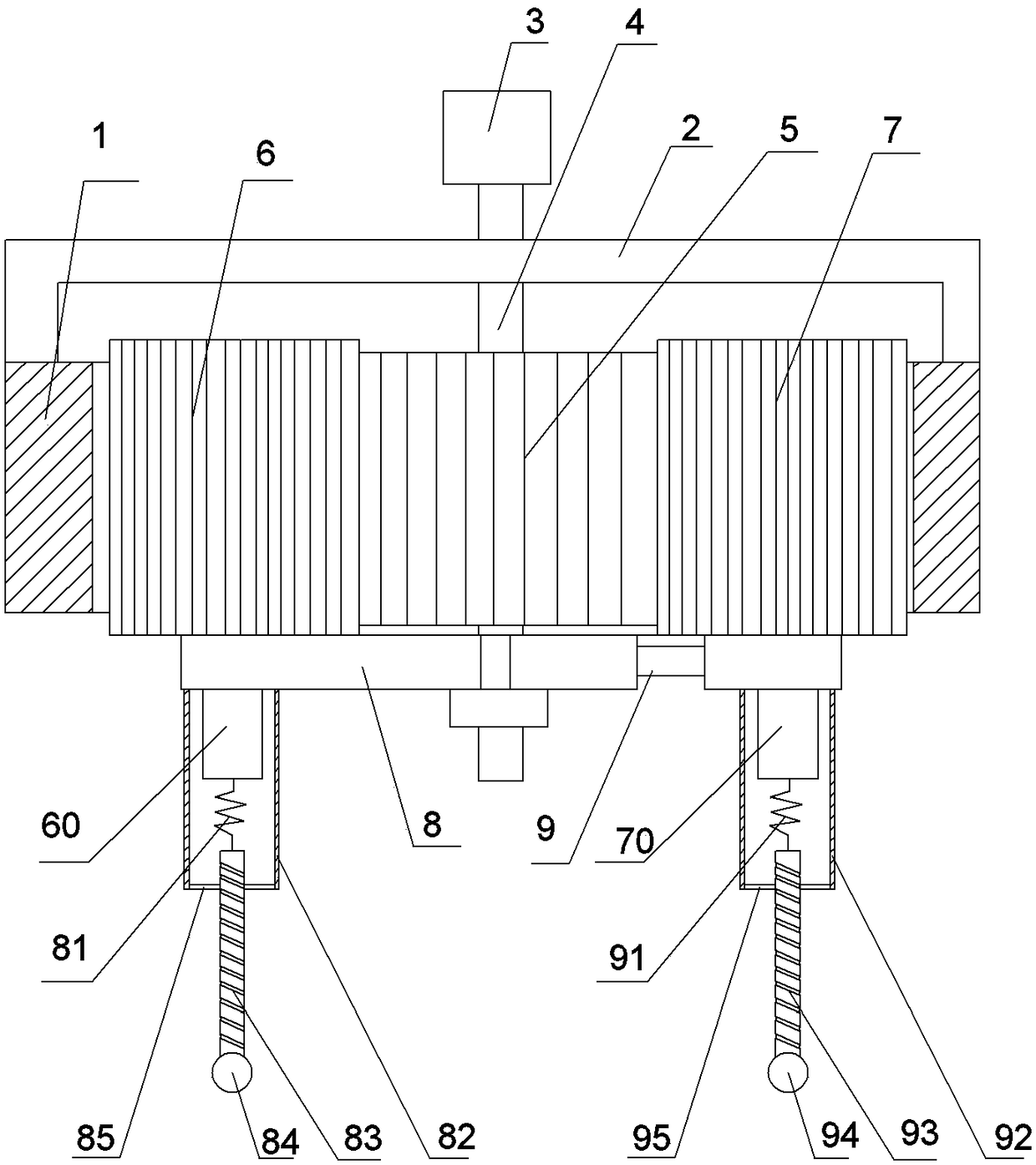

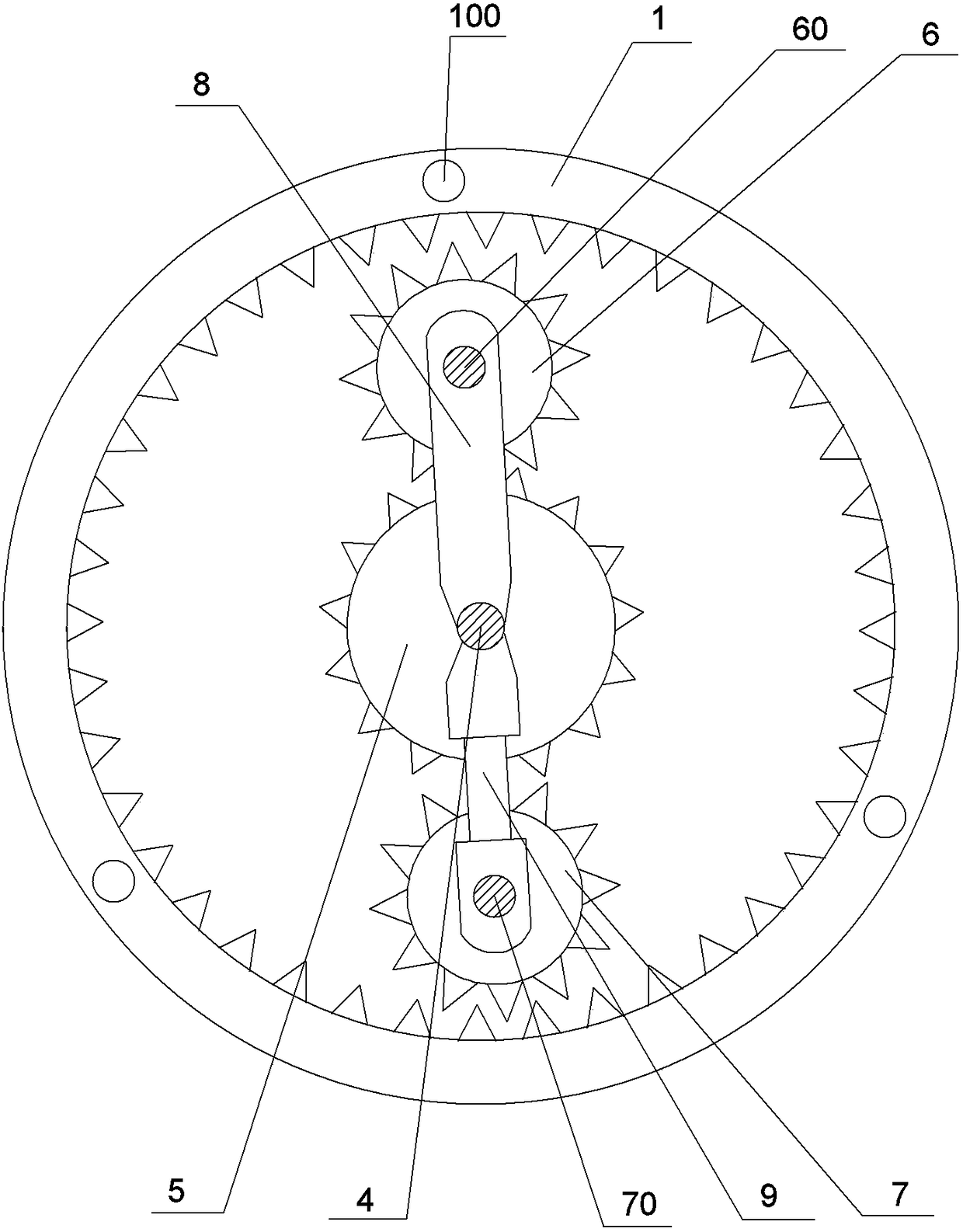

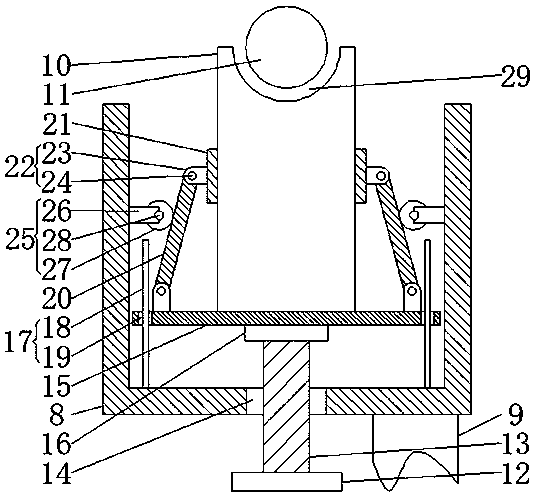

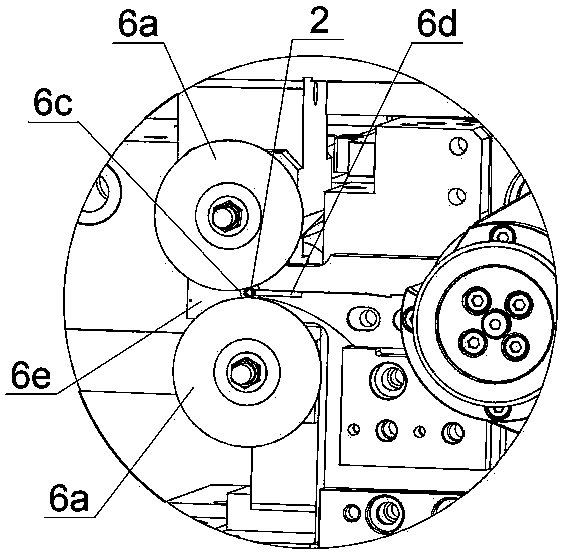

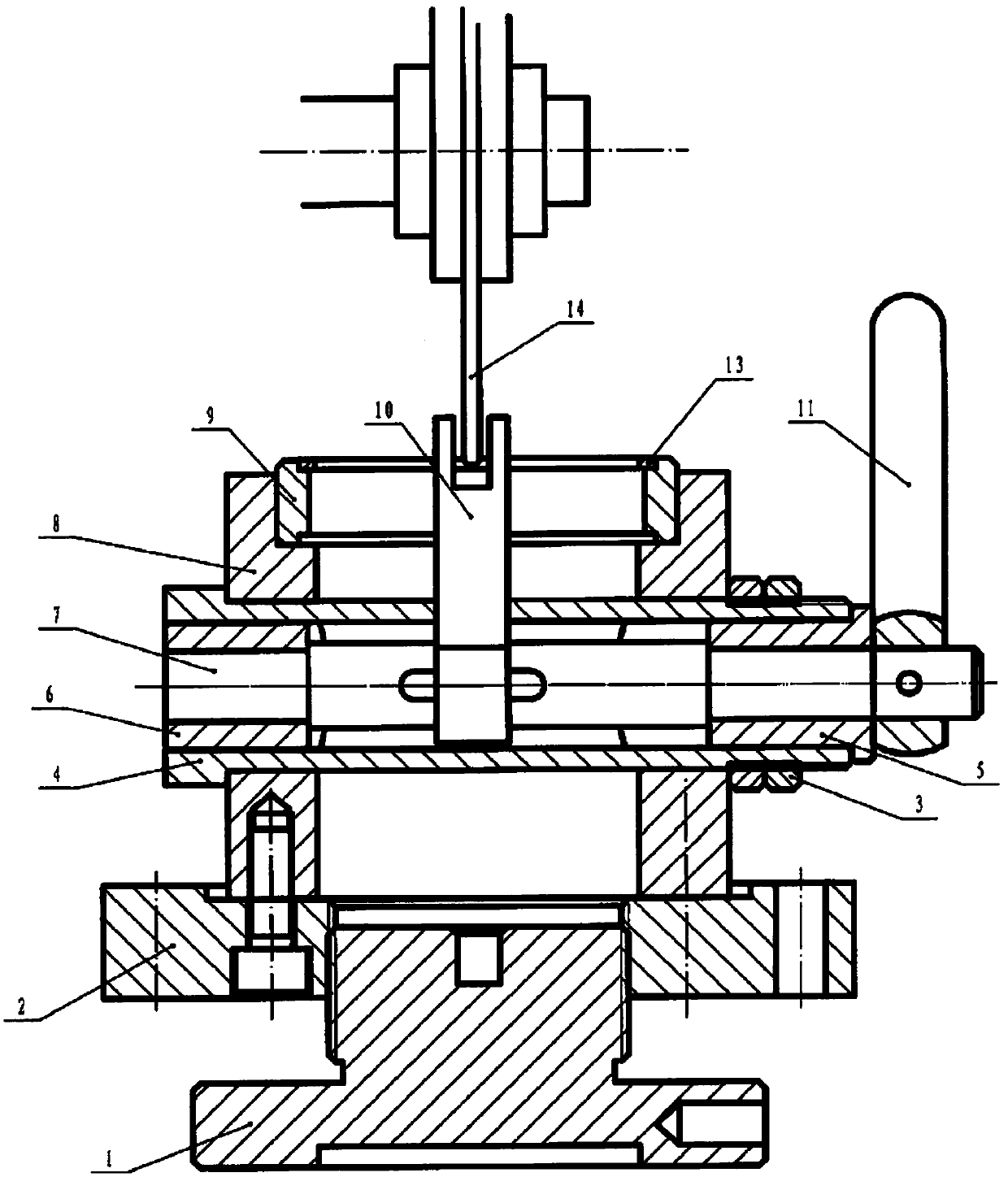

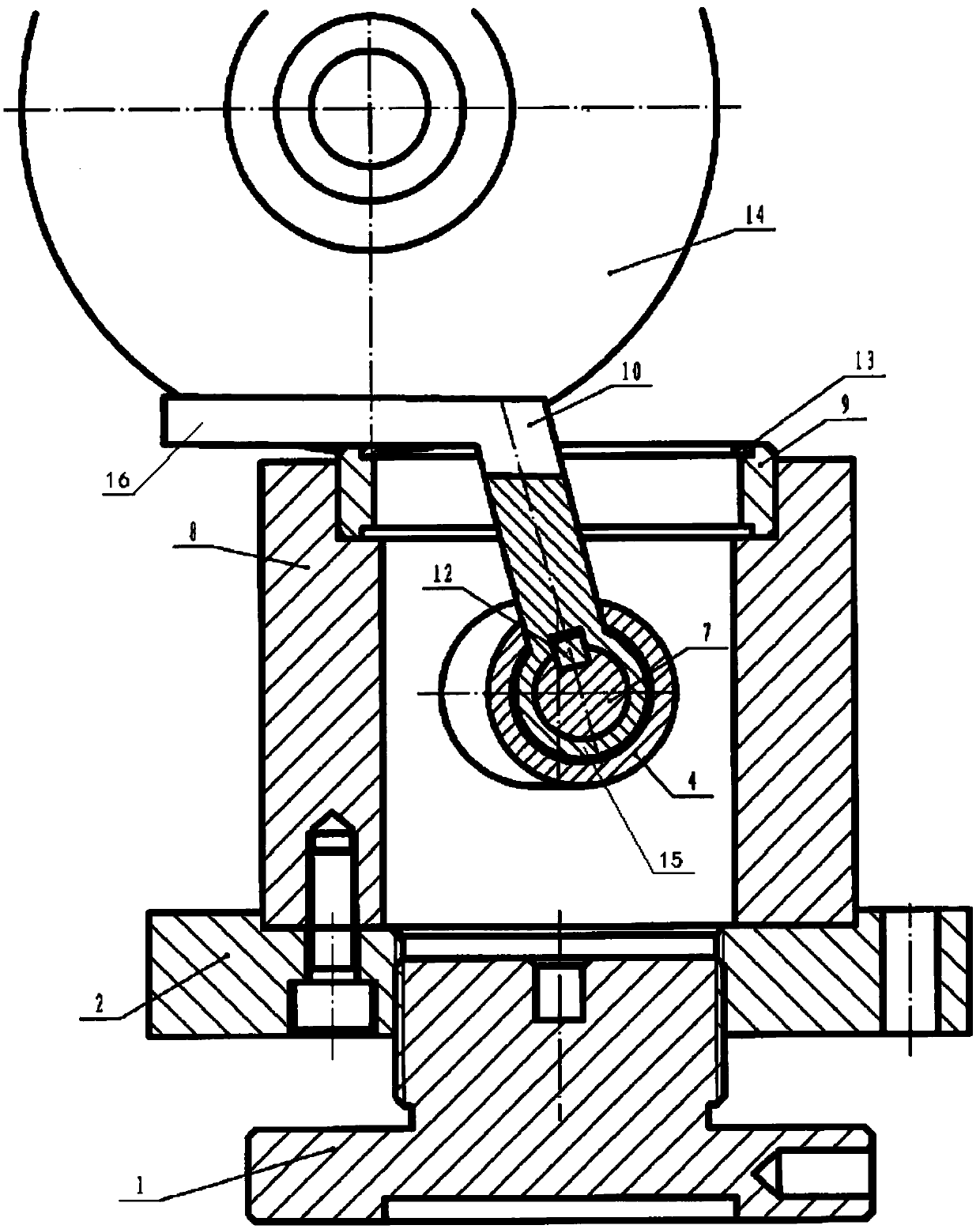

Quick clamping and grinding device for piston ring side positioning

PendingCN110814931AMeet processing needsPrecise positioningGrinding machinesGrinding work supportsPiston ringEngineering

Owner:无锡安尔达机械有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap