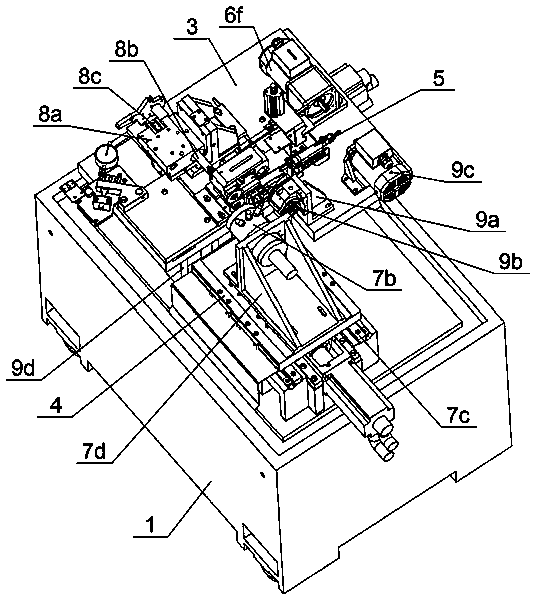

Bearing inner and outer ring roller bed and inner ring inner diameter grinding equipment

A technology of inner and outer rings and bearings, which is applied in the field of bearing processing, can solve the problems that cannot meet the technical requirements of verticality and concentricity, affect the stability of the bearing groove curvature, and difficult to guarantee the feeding accuracy, etc., and achieve low wear and long service life , the effect of uniform curvature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

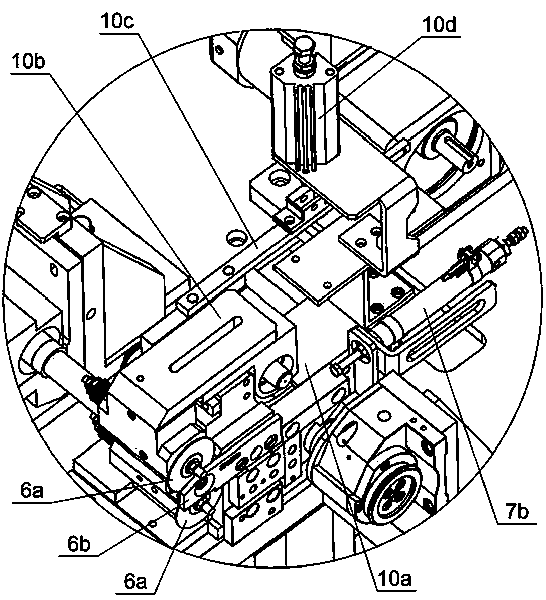

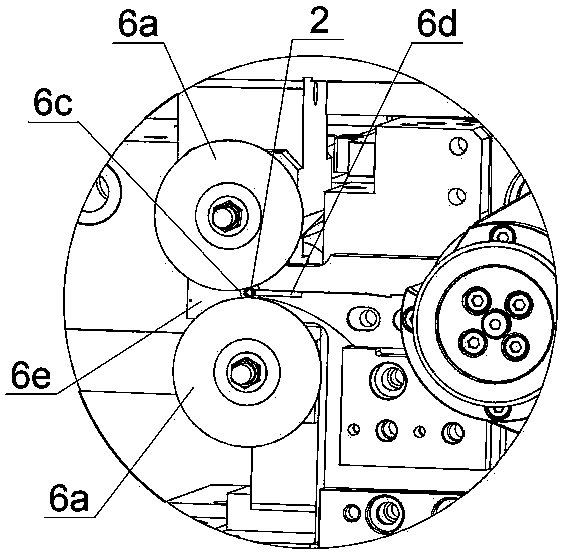

[0044] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and the drawings, and the content mentioned in the embodiments does not limit the present invention.

[0045] It should be noted in advance that, in the present invention, unless otherwise clearly specified and limited, the terms "installed", "connected", "connected", "fixed" and other terms should be understood in a broad sense. For example, it may be a fixed connection. It can also be detachably connected or integrally connected; it can be directly connected, or indirectly connected through an intermediate medium, and it can be the internal communication between two components. For those of ordinary skill in the art, the specific meanings of the above terms in the present invention can be understood according to specific circumstances.

[0046] In addition, in the present invention, unless otherwise clearly defined and

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap