Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about "Grinding frames" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

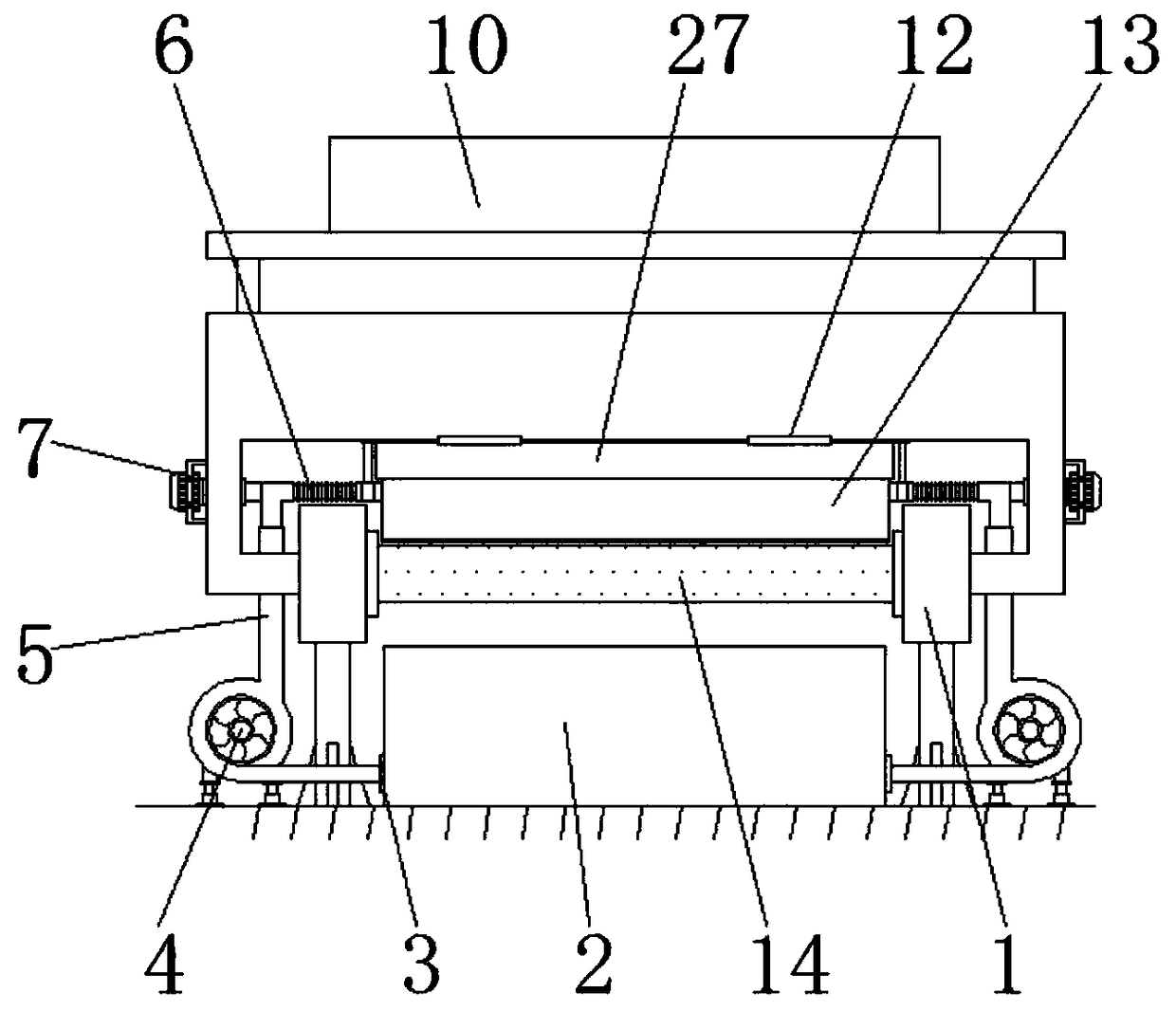

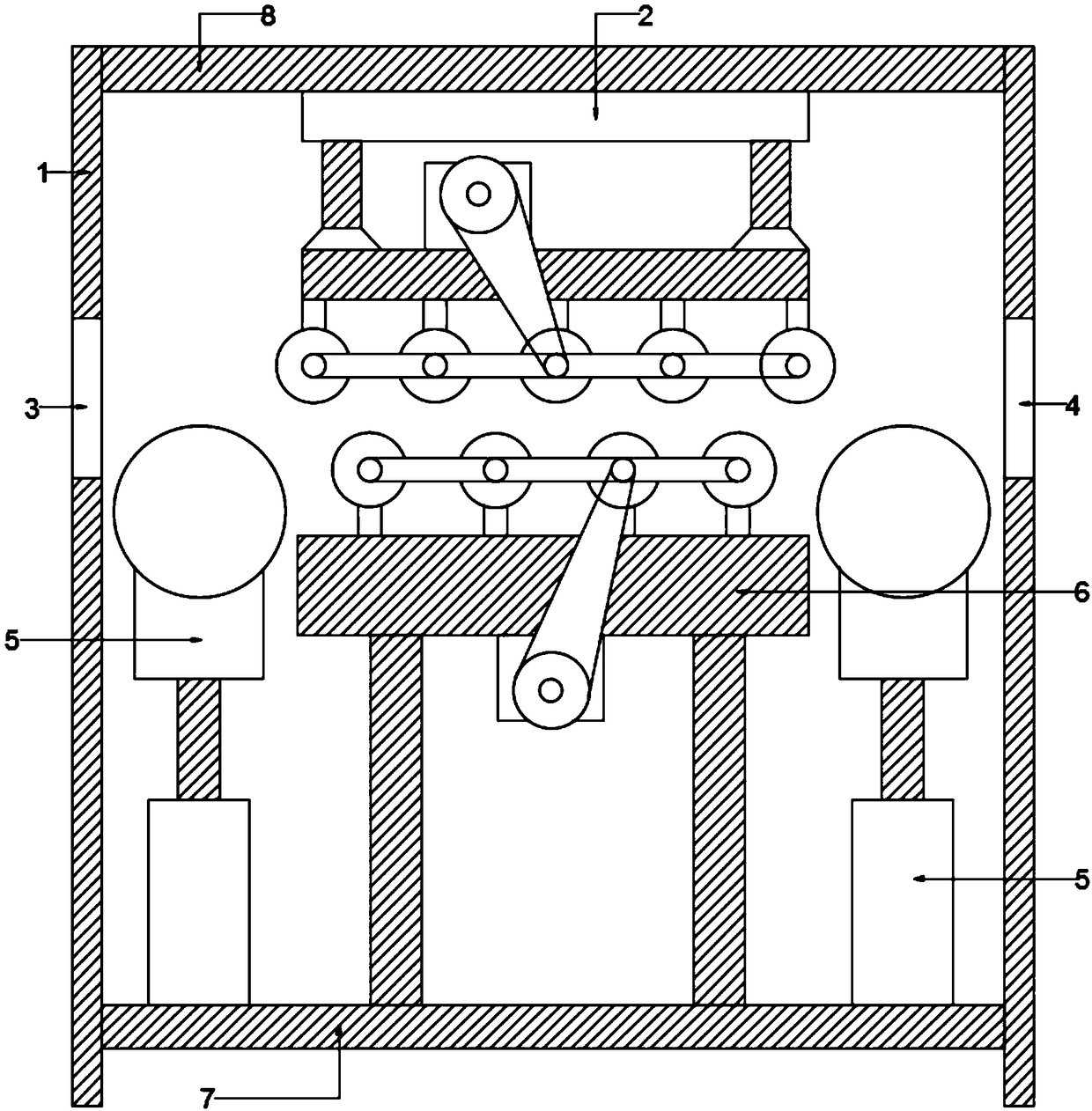

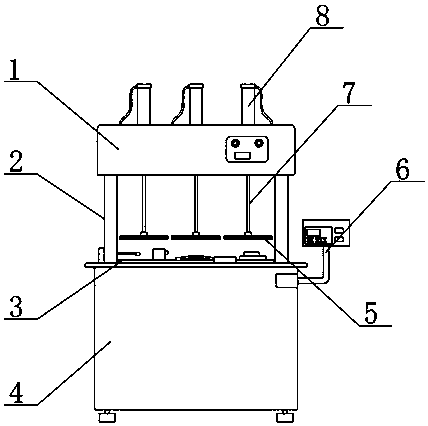

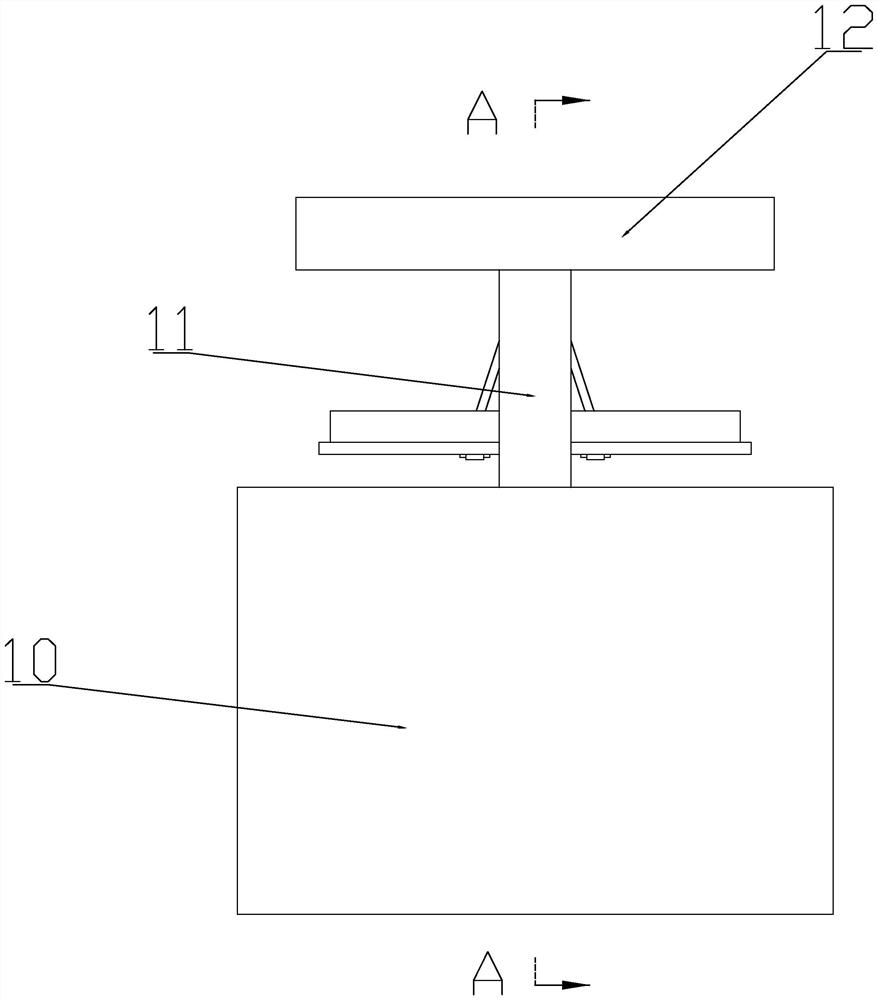

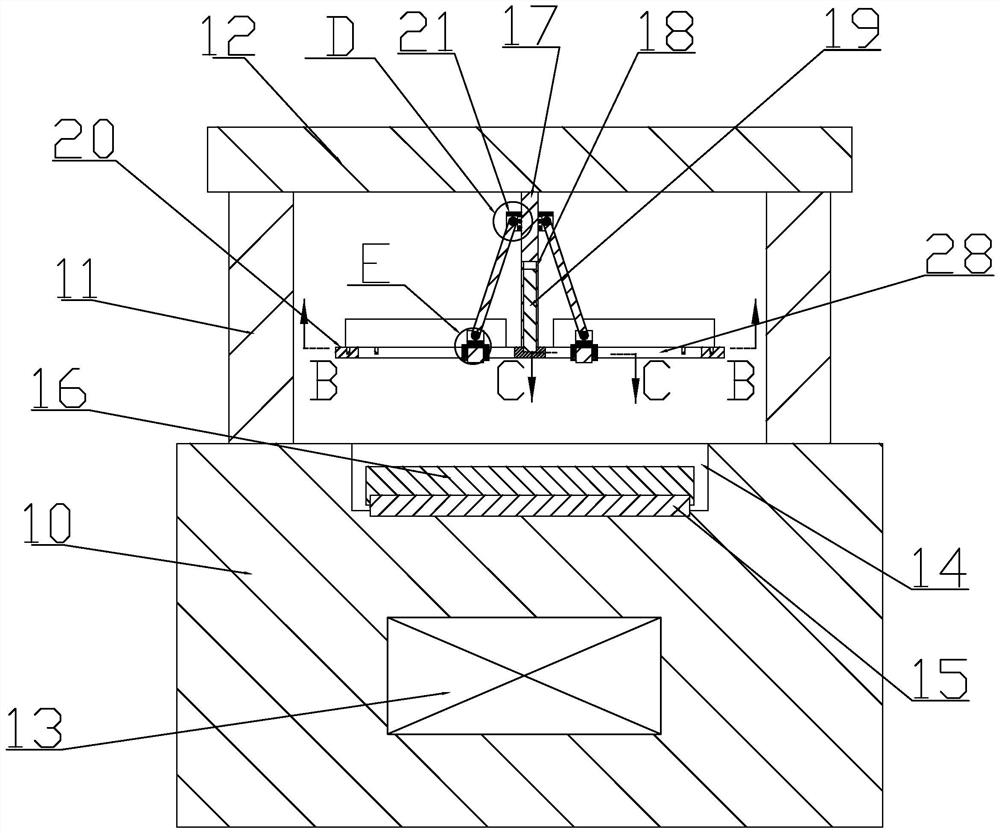

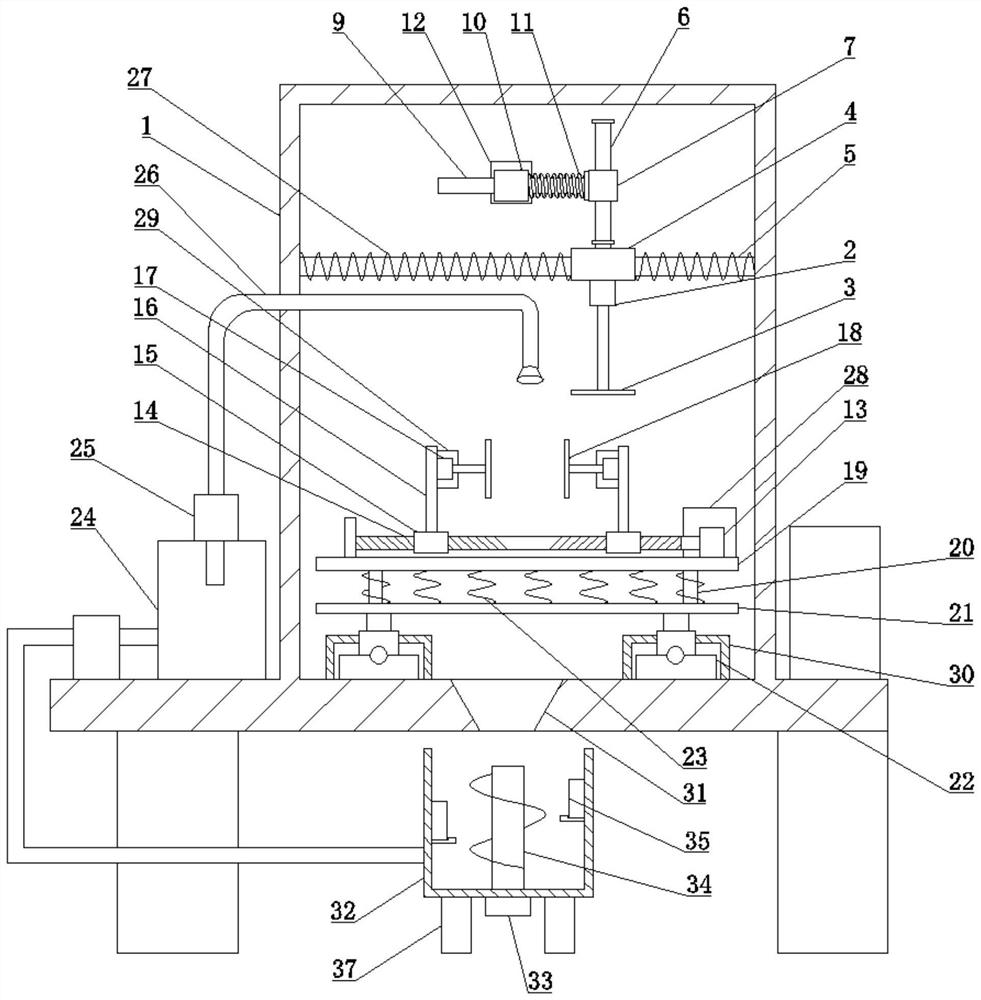

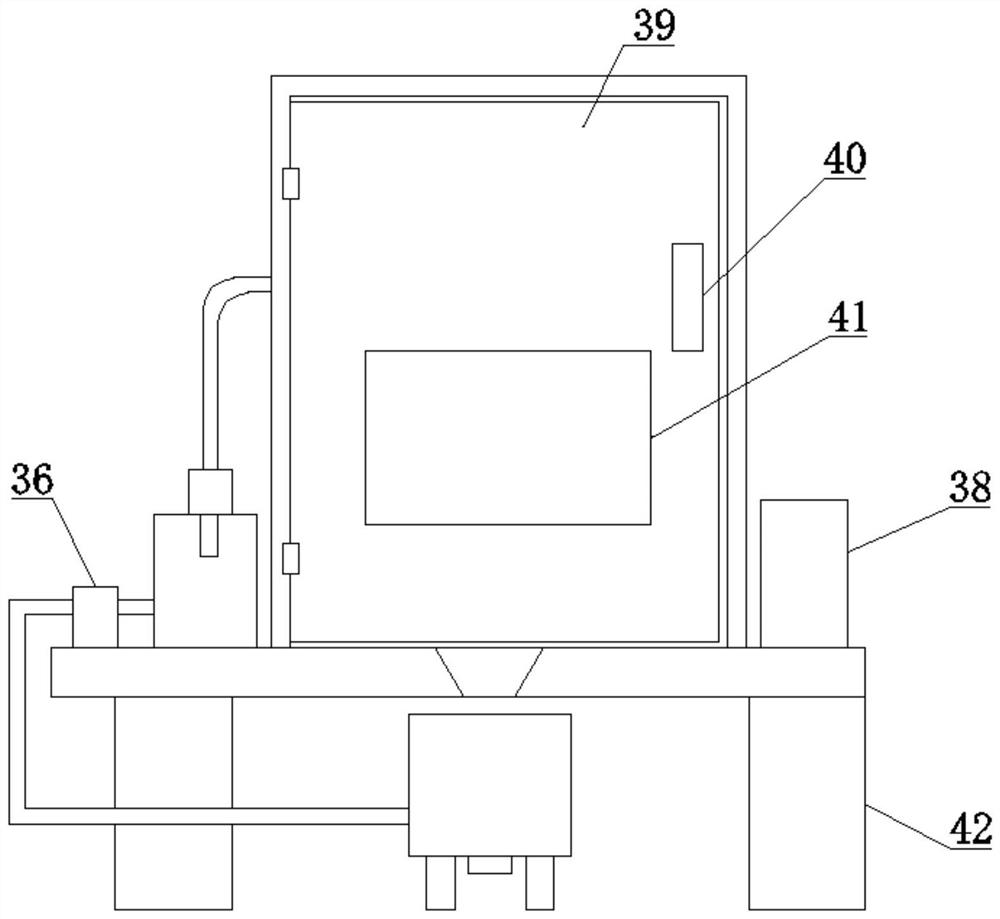

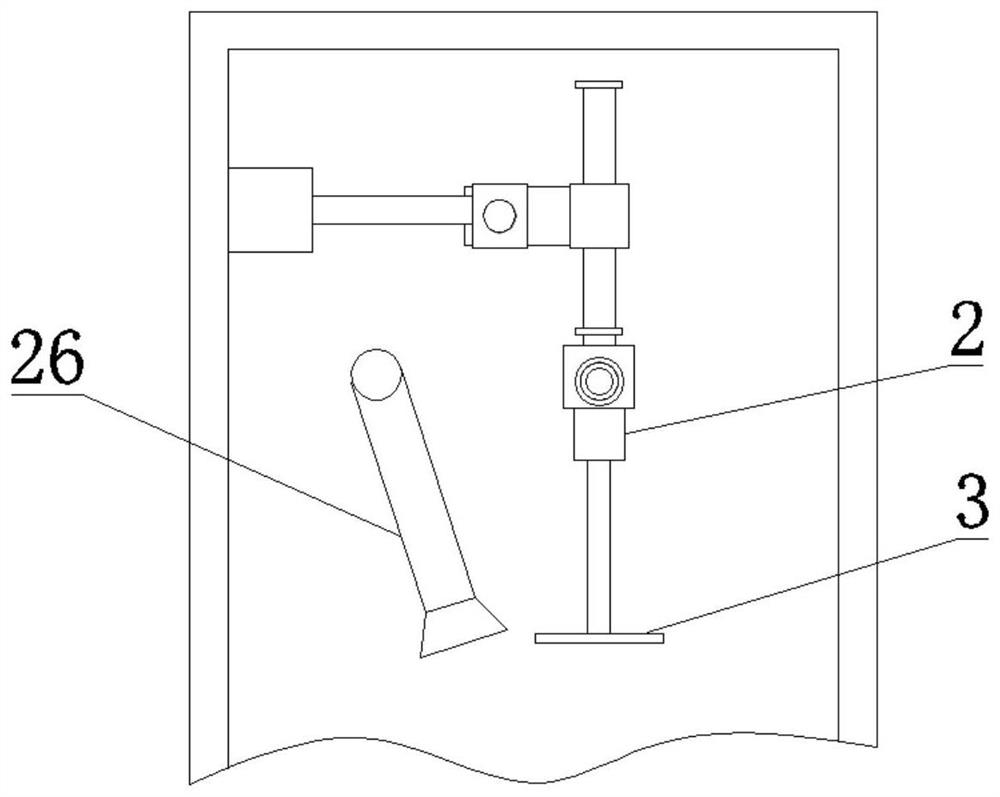

Glass edge grinding machine

InactiveCN106002530AImprove processing efficiencySmall footprintEdge grinding machinesGrinding carriagesMotor driveFeed drive

The invention provides a glass edge grinding machine. The glass edge grinding machine comprises a first double-edge grinding device and a second double-edge grinding device positioned below the first double-edge grinding device, wherein a transfer mechanism is arranged at an outlet end of the first double-edge grinding device; an inlet end of the second double-edge grinding device is positioned just below the outlet end of the first double-edge grinding device; the transfer mechanism comprises a rotating plate, a rotating motor, a transfer position-adjusting driving piece and a transfer feeding driving piece; the rotating plate receives glass from the outlet end of the first double-edge grinding device; the rotating motor drives the rotating plate to rotate at an angle of 180 degrees; the transfer position-adjusting driving piece drives the rotating plate to move at the outlet end of the first double-edge grinding device and the inlet end of the second double-edge grinding device; and the transfer feeding driving piece is used for pushing the glass on the rotating plate to enter the second double-edge grinding device when the rotating plate is positioned at the inlet end of the second double-edge grinding device. The machining efficiency is high.

Owner:HANGZHOU TUOCHUAN MASCH CO LTD

Ceramic tile surface polishing device

PendingCN112025523ATo achieve the function of high and low adjustmentTo achieve the effect of clampingGrinding wheel securing apparatusGrinding carriagesComposite materialCeramic tiles

Owner:凌亮

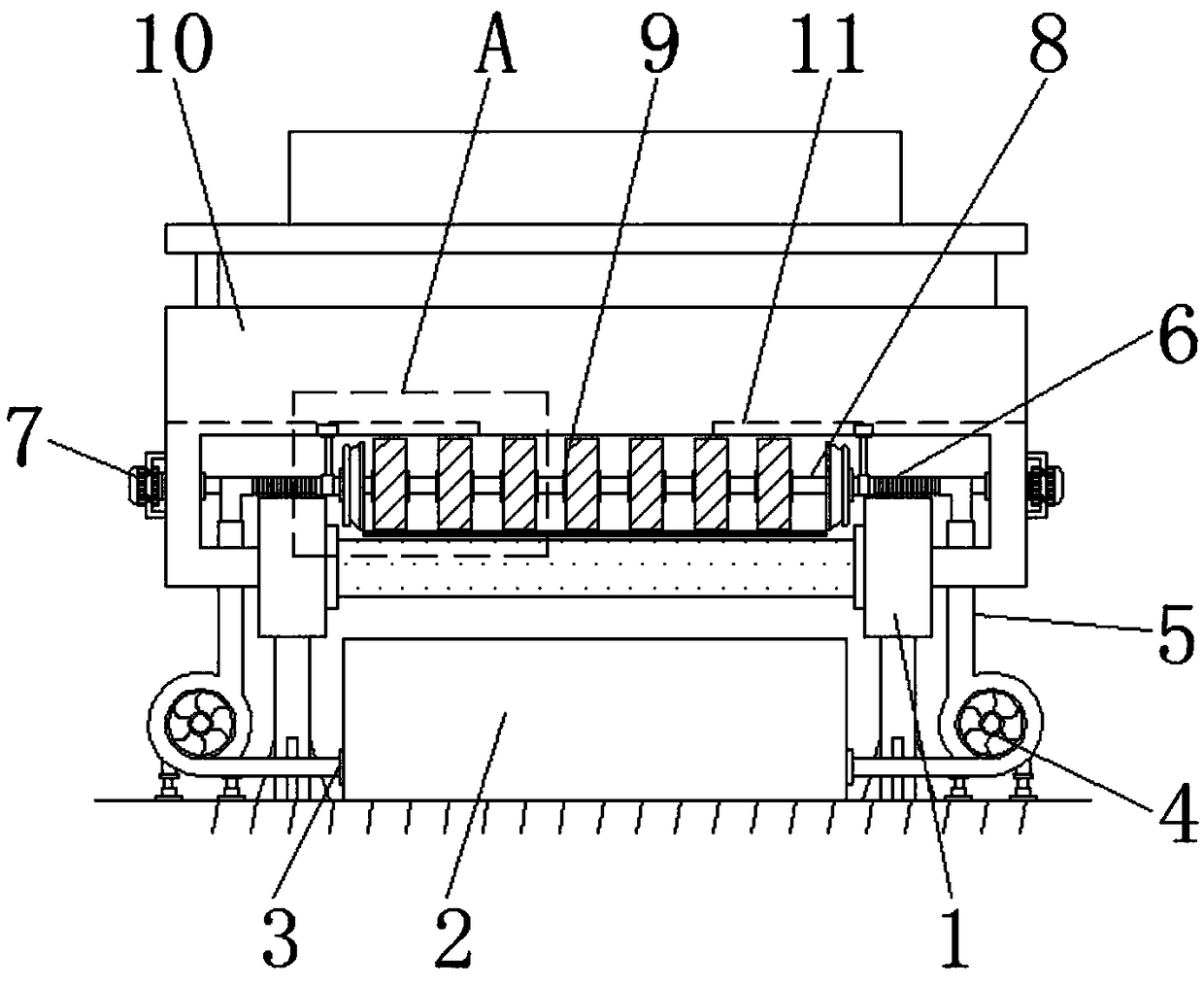

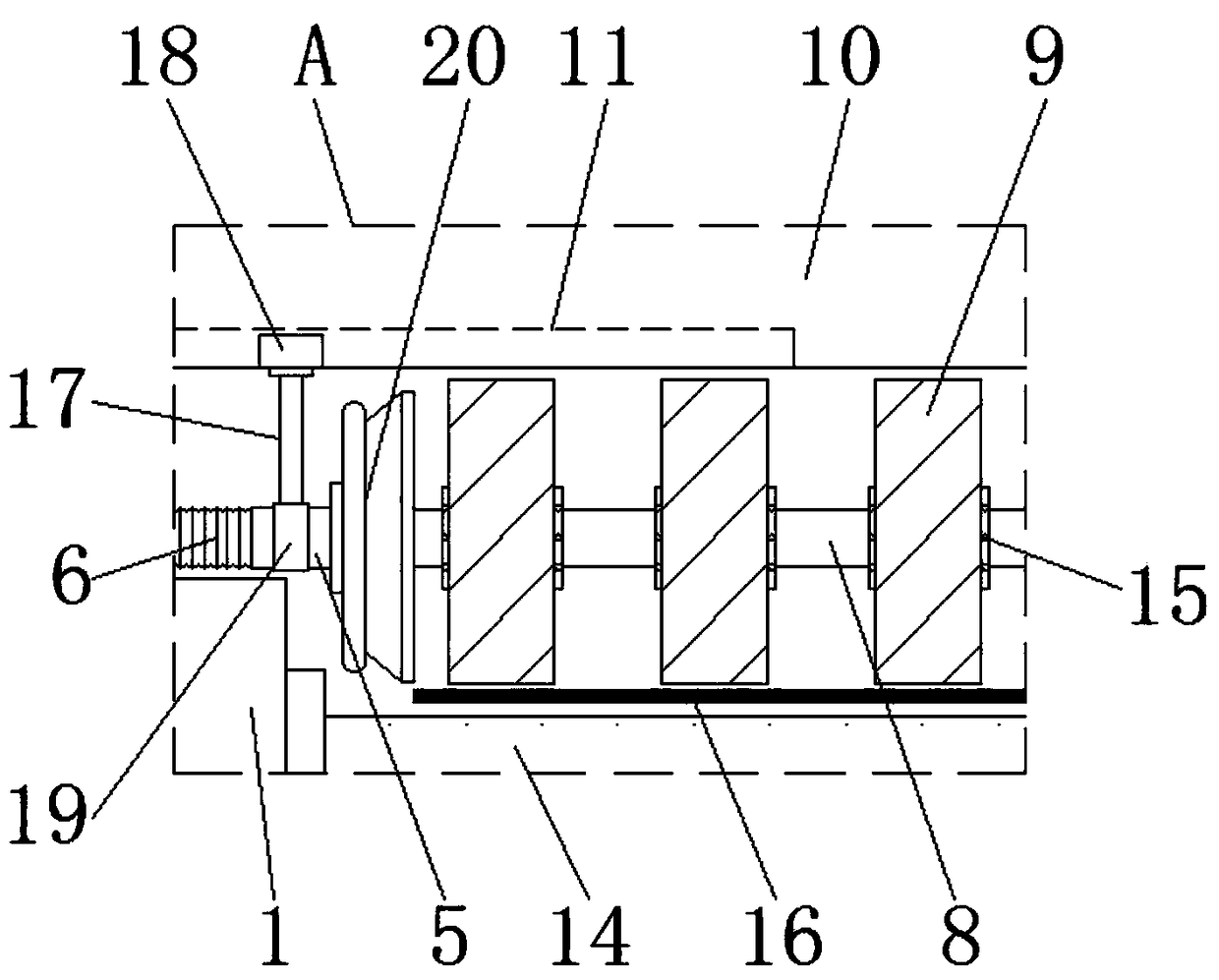

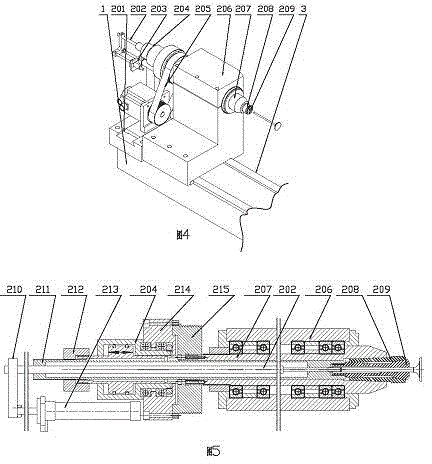

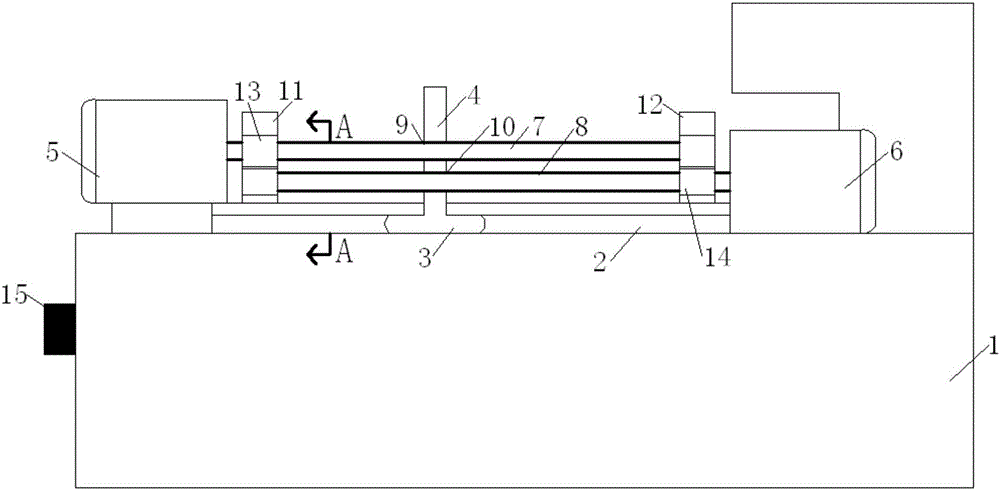

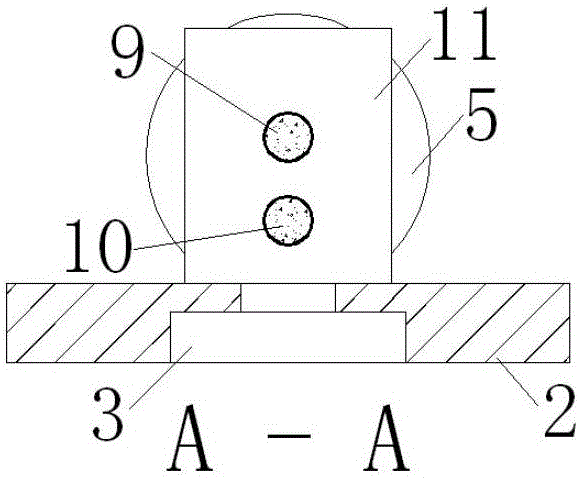

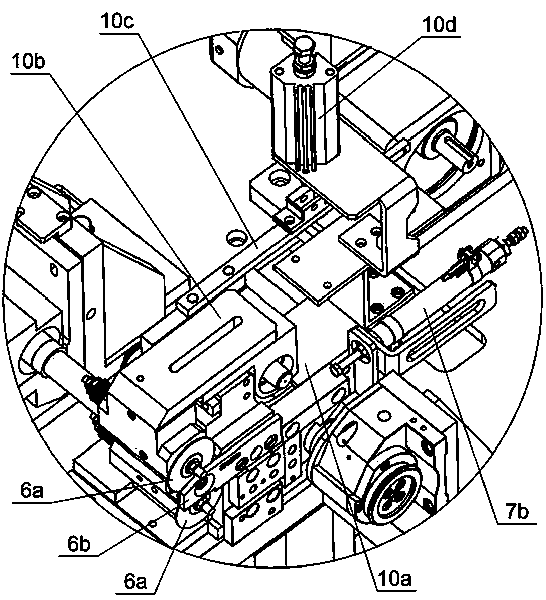

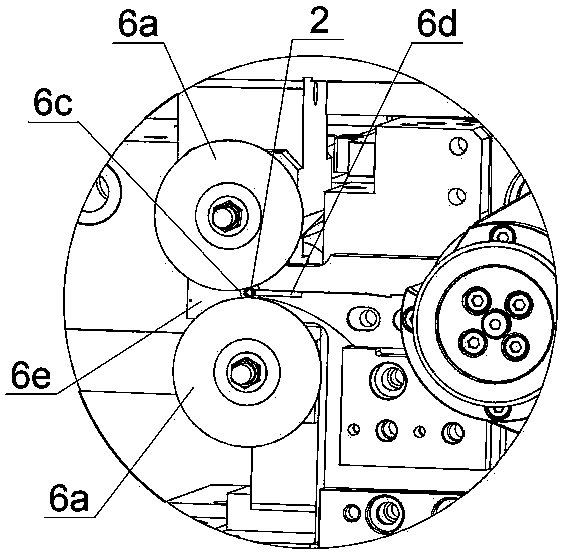

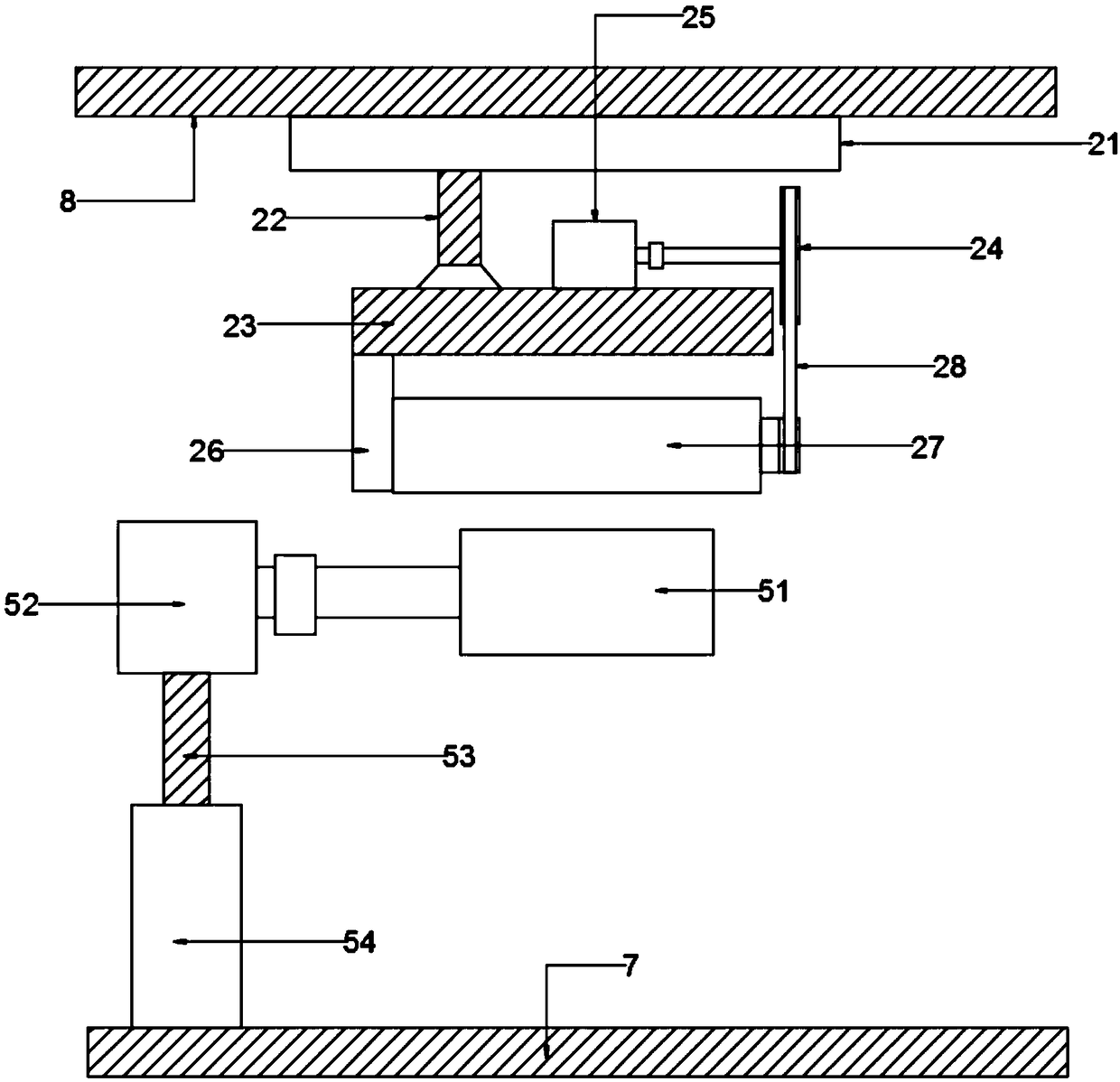

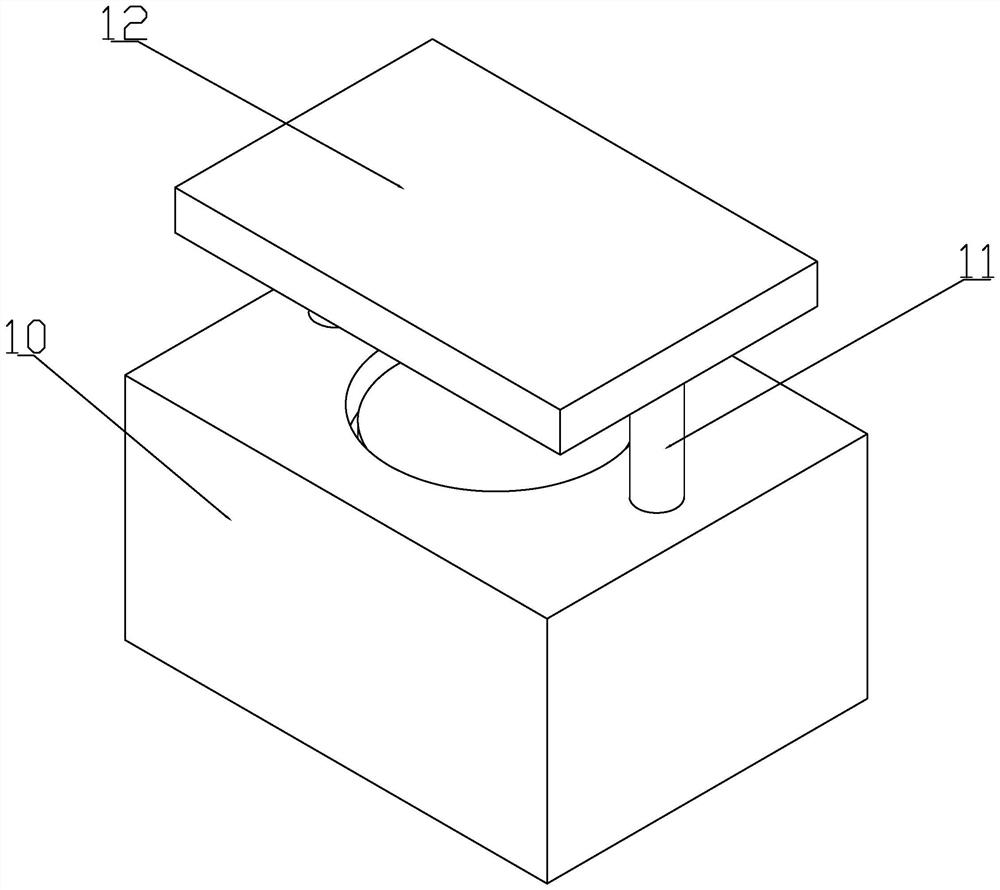

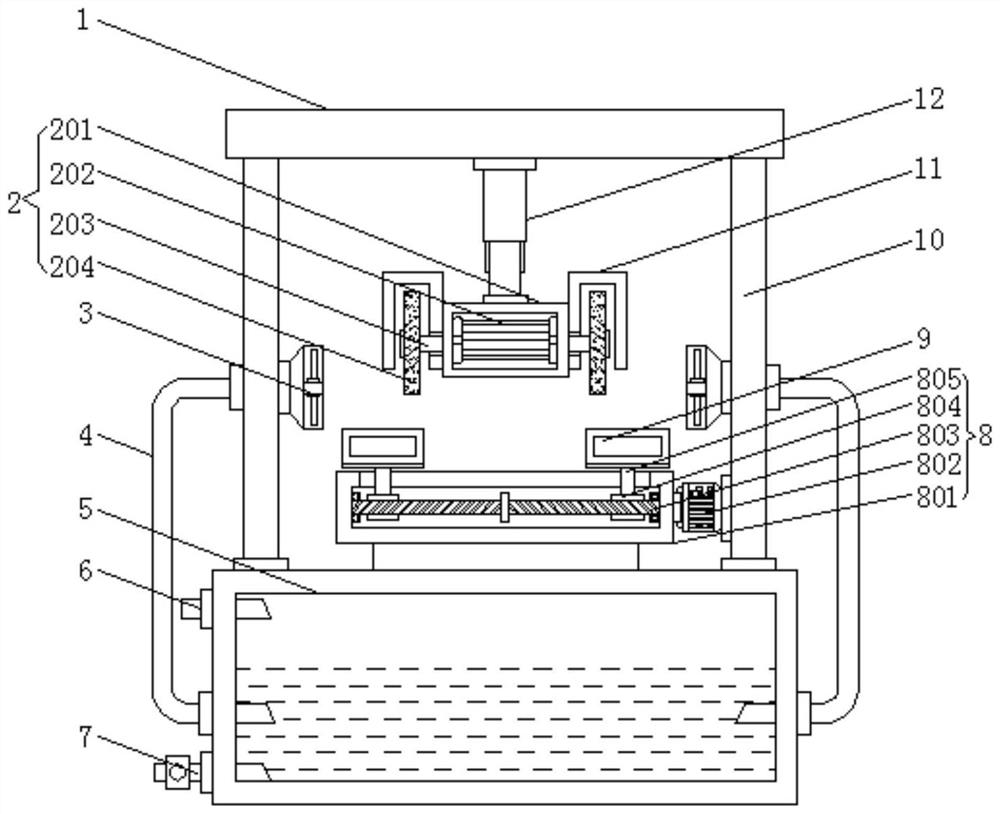

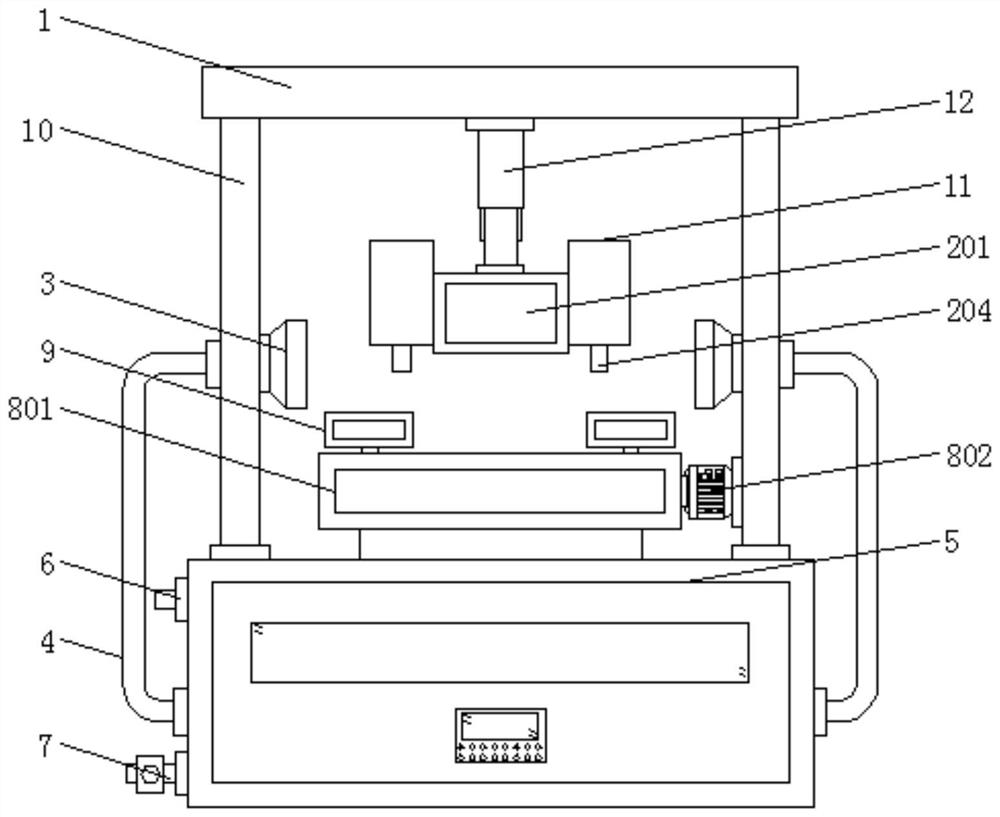

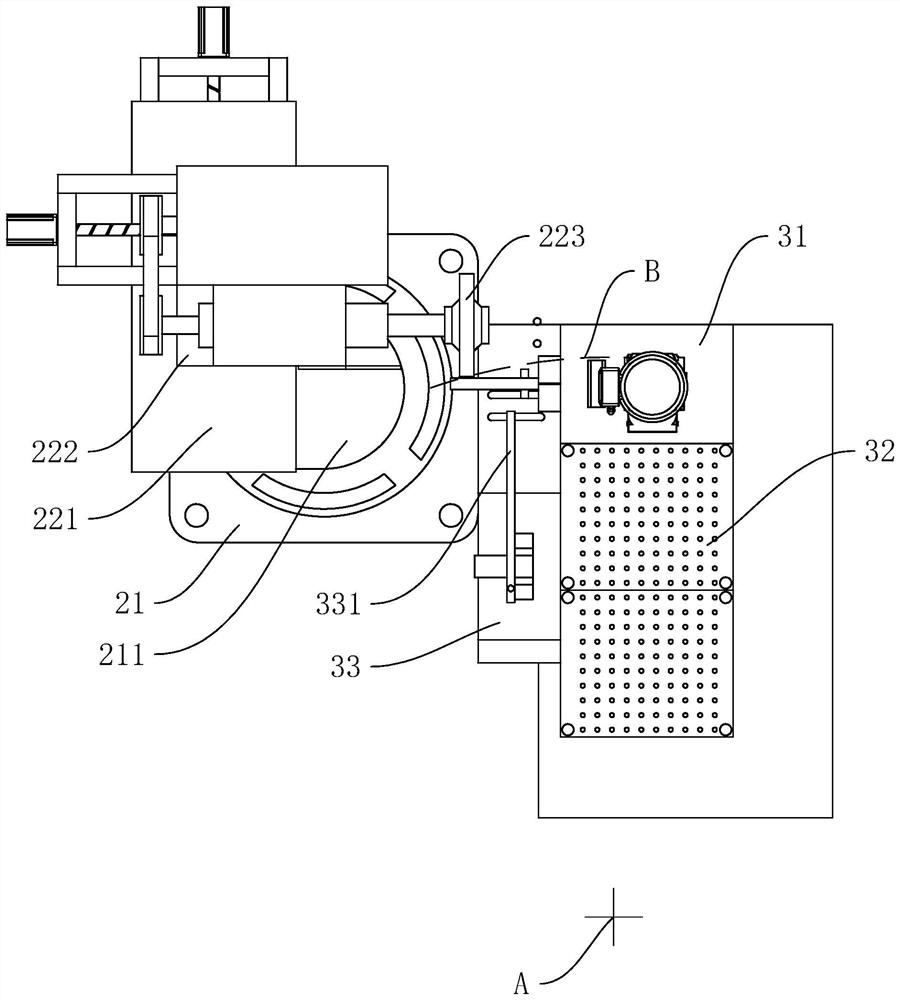

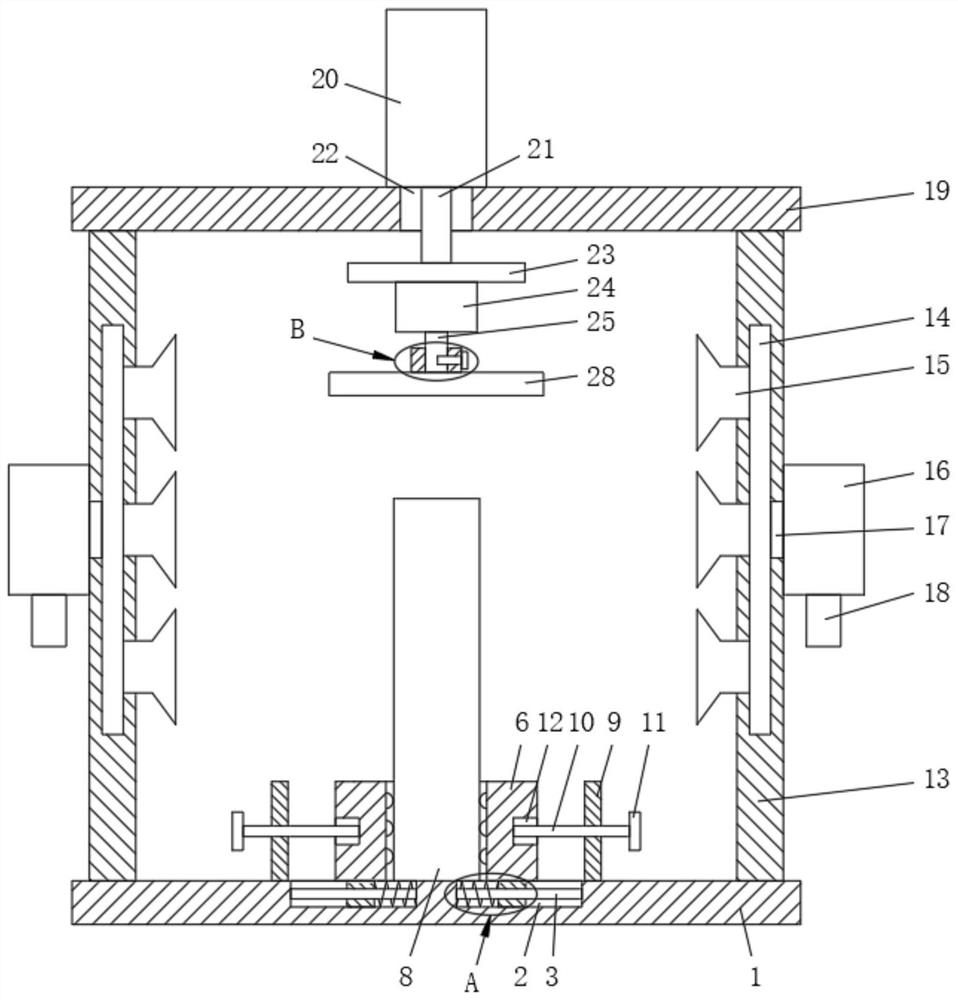

Efficient double-end-face grinding machine and control method thereof

ActiveCN106363475AHigh finish precisionHigh degree of automationGrinding carriagesGrinding drivesMotor driveControl system

The invention relates to an efficient double-end-face grinding machine and a control method thereof. The efficient double-end-face grinding machine comprises a machine body, tool feeding devices, a contact type measuring device and a feeder. Each tool feeding device comprises a spindle, a grinding wheel, a spindle motor and a tool feeding motor, wherein the spindle motor drives the spindle to drive the grinding wheel to rotate, and the tool feeding motor drives the spindle to move left and right. The contact type measuring device comprises a measuring head vertical-moving cylinder and a contact type measuring head, and the measuring head vertical-moving cylinder drives the contact type measuring head to move vertically. The feeder comprises a magnetic reciprocating workbench and a feeding motor. A five-axis control system is adopted by the efficient double-end-face grinding machine, automatic grinding, automatic compensation and automatic measuring of double end faces are achieved, coarse and fine machining and automatic measuring on the periphery of a mold core can be efficiently completed during one-time clamping of the ceramic mold core, production efficiency for the mold core is improved, and the precision and smoothness of the mold core are improved.

Owner:FOSHAN SHIWAN CERAMICS IND RES INST CO LTD

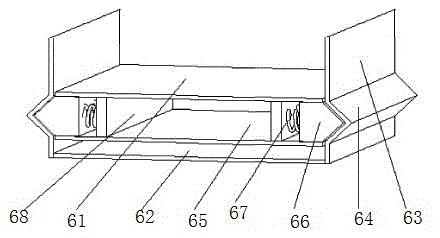

Steel plate machining rust removal device capable of collecting waste scraps conveniently

InactiveCN108687634AEasy to collectAvoid random flyingGrinding carriagesGrinding drivesFixed frameArchitectural engineering

Owner:芜湖良匠机械制造有限公司

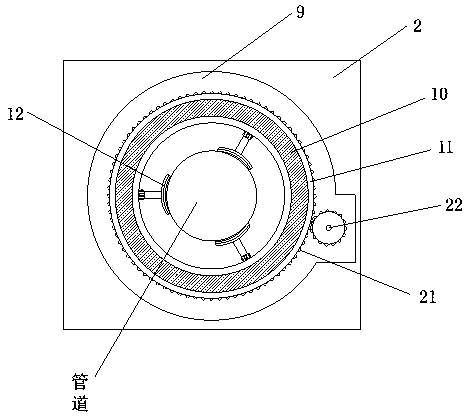

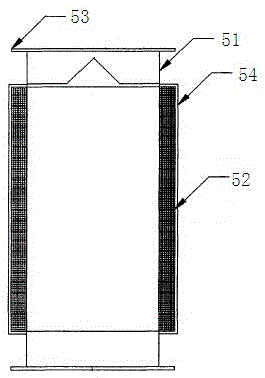

Tubular steel frame dust-removal device

InactiveCN107745319AGuaranteed derusting effectNo shakingGrinding carriagesGrinding machinesEngineeringSteel frame

Owner:四川大黄河建设工程有限公司

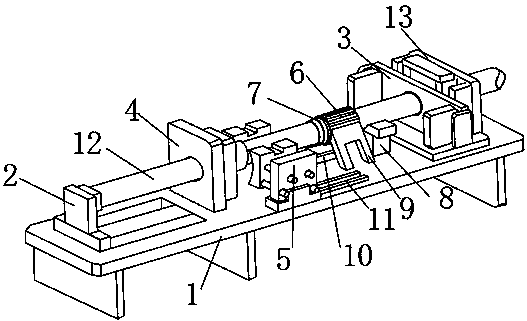

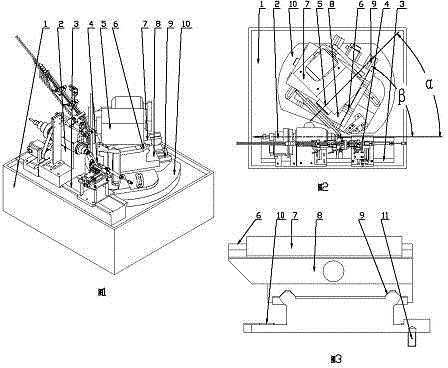

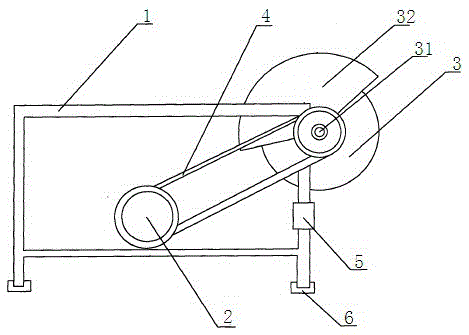

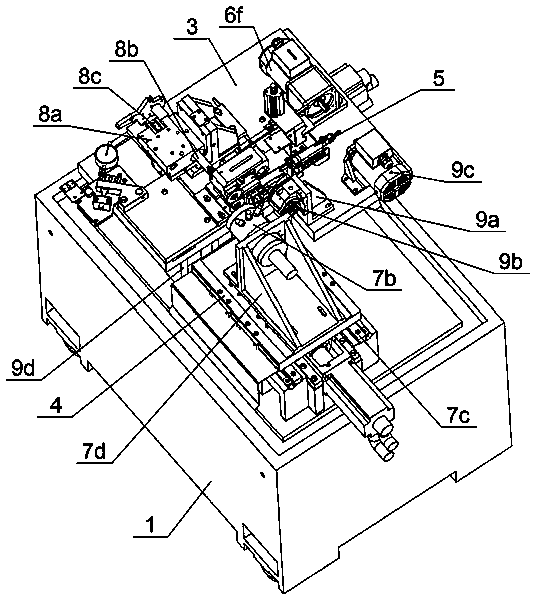

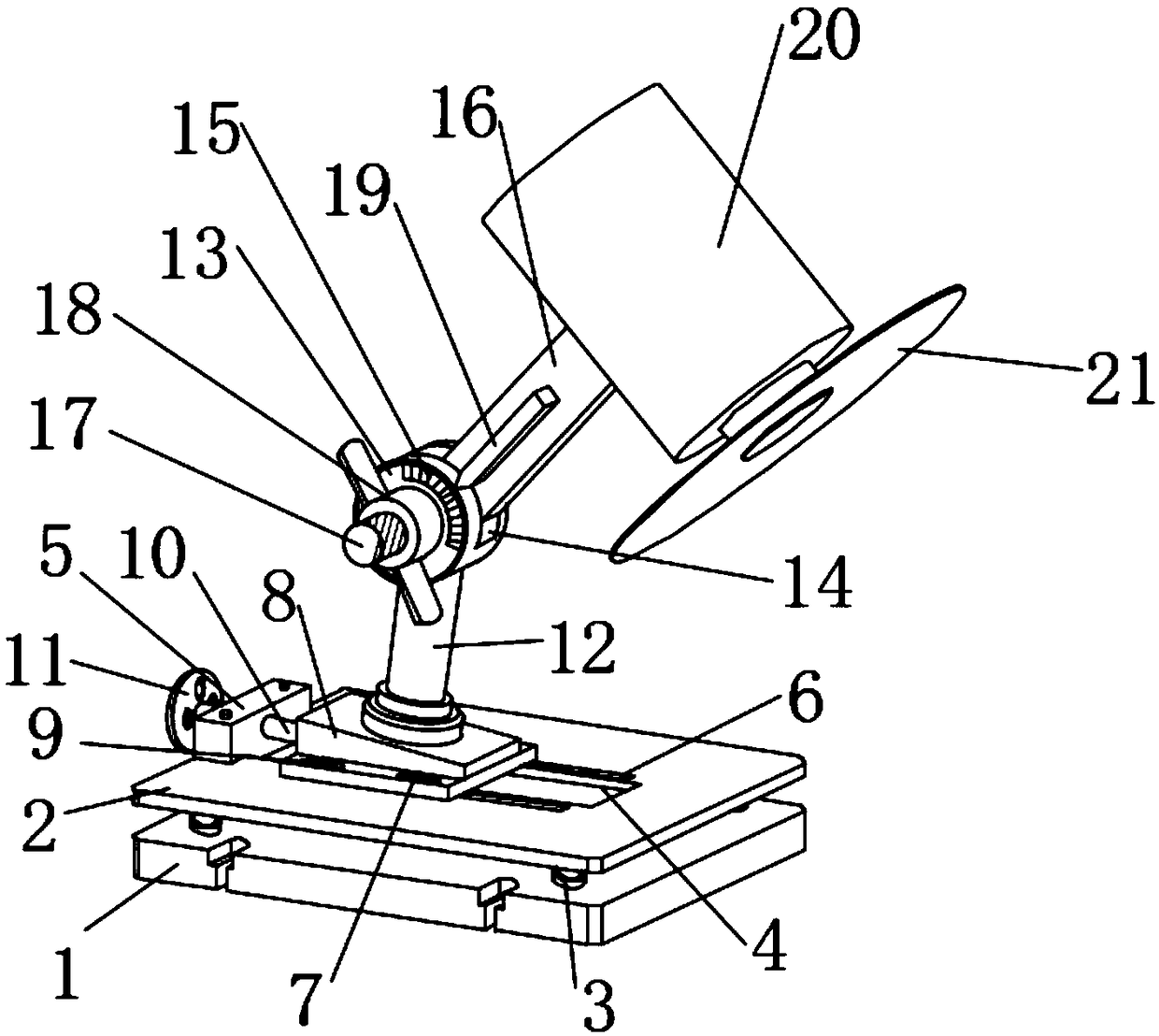

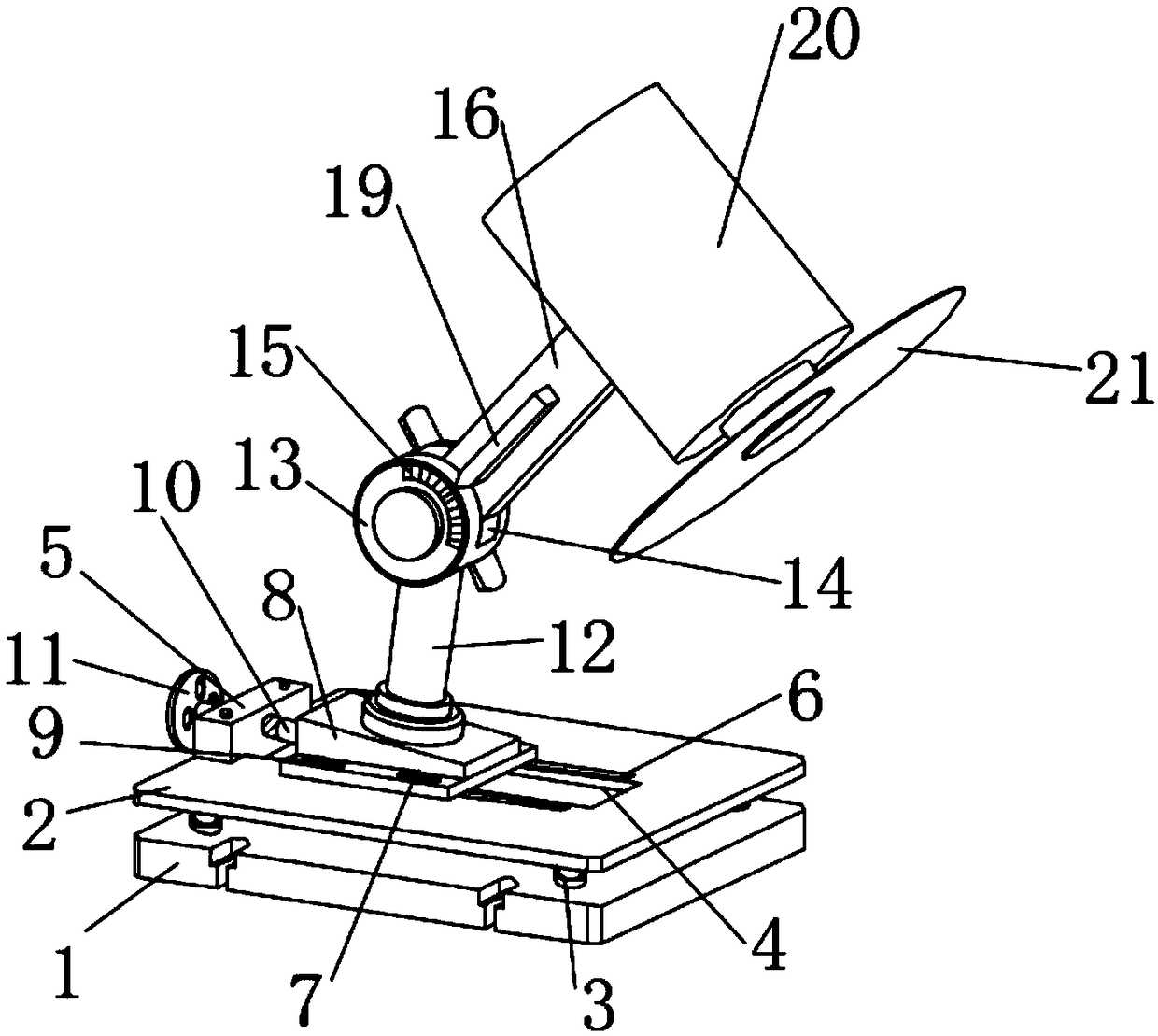

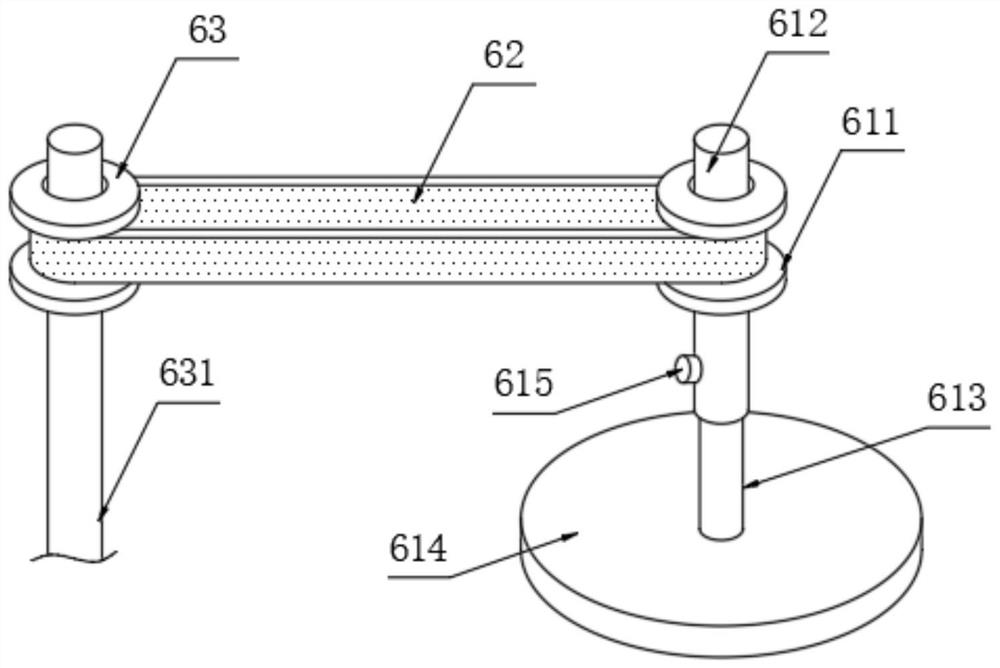

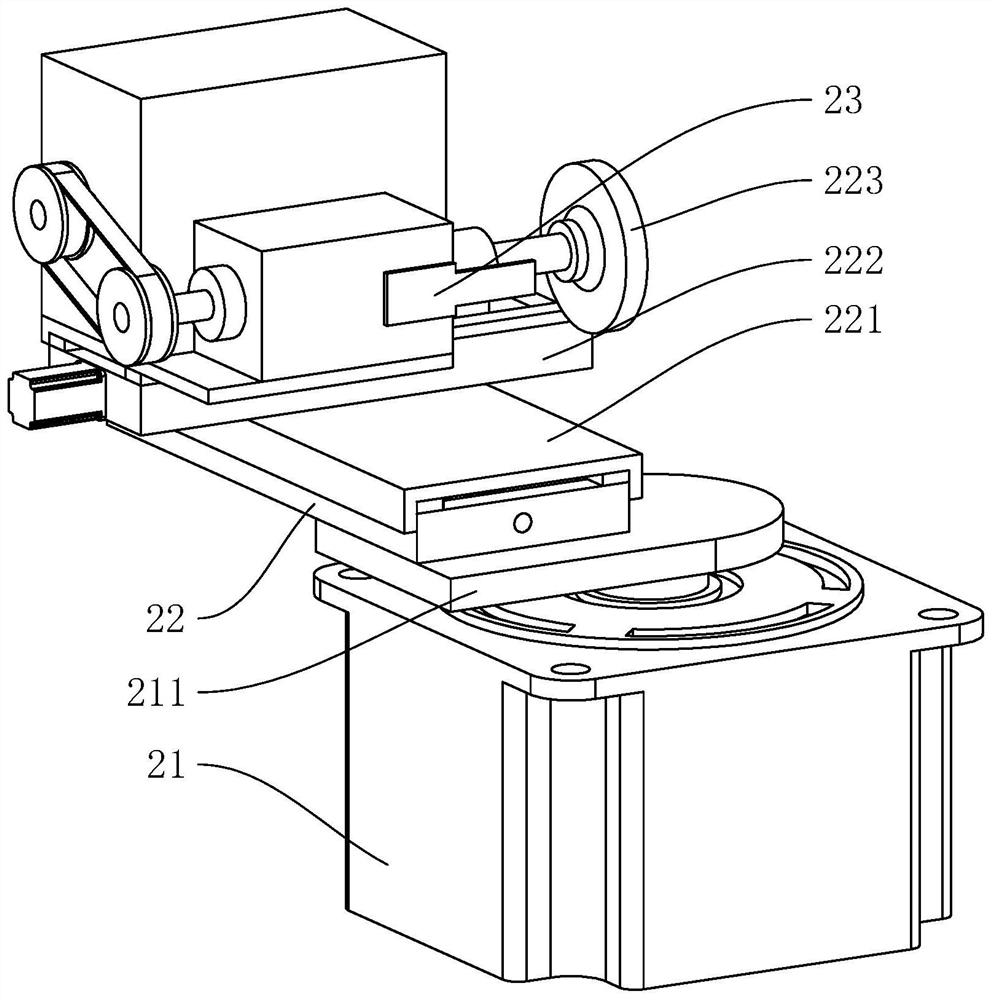

Adjustable swing angle grinding machine assembly

InactiveCN107139036AEasy to adjustSimple structureEdge grinding machinesGrinding carriagesEngineeringMechanical engineering

The present invention provides an adjustable swing angle grinding machine assembly, which includes a base, two cylinder supports are fixed on the left side of the upper end of the base, and two grinding supports are fixed on the right side of the upper end of the base. The adjustable swing angle grinding machine assembly has simple structure, convenient operation and good equipment stability; the adjustable swing angle grinder assembly has good grinding effect and high grinding efficiency, which greatly improves production efficiency and reduces The rate of defective products is reduced, which is conducive to saving production costs; the adjustable swing angle grinder assembly has multiple degrees of freedom, and the adjustability is greatly enhanced, which can adapt to the processing of different parts and improve production efficiency.

Owner:JIASHAN BAOHU CLOTHING

Steel ball grinding device

Owner:山东菏益科技有限公司

Steel pipe rust removal device

PendingCN108789101AAdjust effective lengthChange spacingGrinding carriagesGrinding drivesArchitectural engineeringDrive motor

Owner:HAIYAN HUITONG INTELLIGENT FURNITURE CO LTD

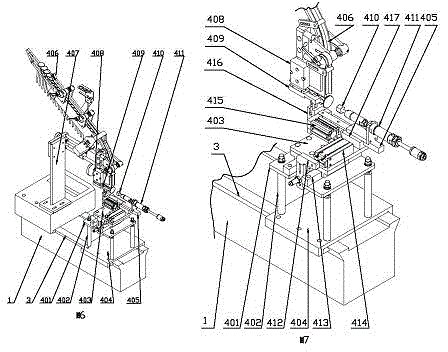

Grinding machine special for conical surface of valve

ActiveCN104128863AGuaranteed structural spaceGrind evenlyGrinding carriagesRevolution surface grinding machinesEngineeringGrinding wheel

Owner:江苏吉斯特科技有限公司

L-shaped grinding mechanism for forklift part

InactiveCN106625119ARealize automatic grinding functionSimple and fast operationGrinding carriagesGrinding drivesHydraulic cylinderEngineering

The invention relates to an L-shaped grinding mechanism for a forklift part. The L-shaped grinding mechanism comprises a bottom plate, wherein the upper end surface of the bottom plate is welded with a fixed plate; a hydraulic cylinder is mounted on the fixed plate; a middle part fixing frame of the hydraulic cylinder is erected on a supporting column; the supporting column is mounted on the bottom plate; the supporting column achieves an effect of fixedly supporting the hydraulic cylinder; a push plate is mounted at the front end of the hydraulic cylinder through a screw; the push plate is tightly attached to a workpiece; the workpiece is mounted on the bottom plate; the hydraulic cylinder drives the push plate to move, and the push plate drives the workpiece to move on the bottom plate; two auxiliary lifting lugs are arranged on the upper end surface of the bottom plate; an auxiliary shaft is mounted between the two auxiliary lifting lugs through bearings; a longitudinal grinding wheel is mounted at the middle part of the auxiliary shaft; a driven gear is mounted at the right end of the auxiliary shaft; and the longitudinal grinding wheel is used for longitudinally grinding and derusting the workpiece. The L-shaped grinding mechanism can realize an automatic grinding function of an L-shaped forklift part, and has the advantages of simplicity and convenience for operation, short grinding time, good grinding effect, high working efficiency and the like.

Owner:YUEXI COUNTY HONGSHENG CASTING

Casting polishing device capable of preventing vibration and noises

InactiveCN105598774AAvoid manual grinding and grinding of castingsHigh speedEdge grinding machinesGrinding carriagesEngineeringCasting

Owner:WUJIANG HYDRAULIC COMPONENTS FOUNDRY

Stamping part surface grinding device for refrigerator production

InactiveCN108453583AAchieve grindingEasy to polishEdge grinding machinesGrinding carriagesDrive motorPulp and paper industry

Owner:合肥光华机械有限公司

Numerically-controlled brake cam shaft grinding machine

Owner:QUANZHOU LICHENG FUHUI AUTOMOBILE PARTS CO LTD

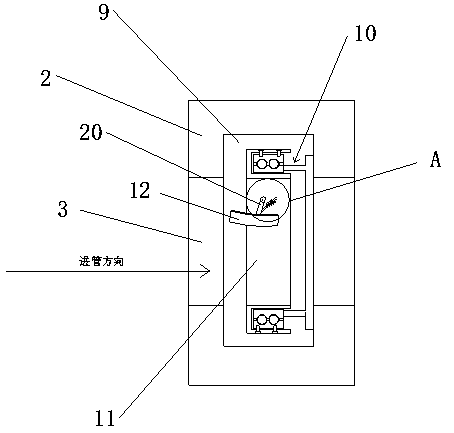

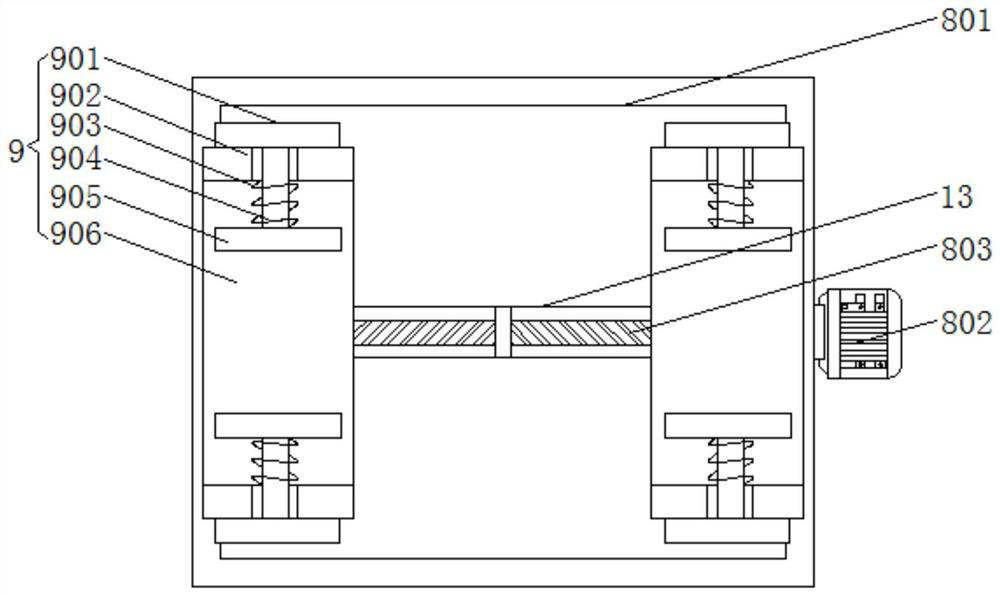

Bearing inner and outer ring roller bed and inner ring inner diameter grinding equipment

PendingCN110000661AReduce shakingConsistent contour shapeGrinding carriagesGrinding drivesEngineeringMechanical engineering

Owner:HUNAN MEIBEIDA TECH CO LTD

Corner polishing device for vehicle navigation displayer

PendingCN108747679AEasy to adjust the grinding angleEasy to useEdge grinding machinesGrinding carriagesTransverse grooveEngineering

Owner:上海光和光学制造大丰有限公司 +1

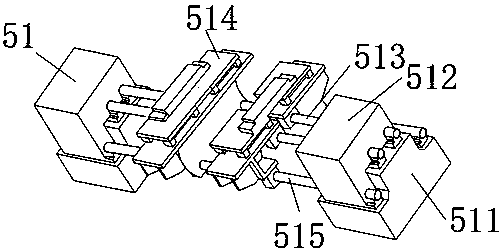

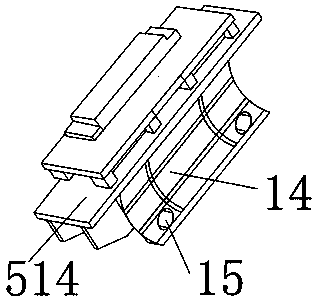

Press fit mechanism and splicing method of intelligent spliced screen

ActiveCN114038341AGuaranteed to screw inAvoid flyingGrinding carriagesGrinding machinesMechanical engineering

The invention relates to the technical field of spliced screens, in particular to a press fit mechanism of an intelligent spliced screen and a splicing method. When a frame of the spliced screen is placed on a feeding table, an inner layer of an adsorption part can be inserted into and grind a threaded hole; when a pushing part penetrates through the supporting frame to push the feeding table to extend out, the feeding table pushes the back plate of the spliced screen along a material blocking part; after the feeding table extends out and pushes the back plate of the spliced screen to abut against an upper top plate, the outer layer of the adsorption part is compressed, and the inner layer of the adsorption part penetrates out of the top of the back plate of the spliced screen, so that the top of the back plate of the spliced screen is coated with fastening glue; after a screw penetrates through the upper top plate to push the inner layer of the adsorption part to retract into the threaded hole, the screw is screwed, the inner layer of the adsorption part is turned over upwards and receives ground scraps, and meanwhile the threaded hole is coated with fastening glue; and when the pushing part drives the feeding table to retract, the inner layer of the adsorption part, the outer layer of the adsorption part and the frame of the spliced screen can be relatively sealed.

Owner:SUZHOU CHANGGE PRECISION MASCH CO LTD +1

Sheet material polishing device for metal 3D printing

InactiveCN109202678AAdjustable positionAdjustable heightGrinding carriagesPolishing machinesMetal sheetMetal

Owner:广西慧思通科技有限公司

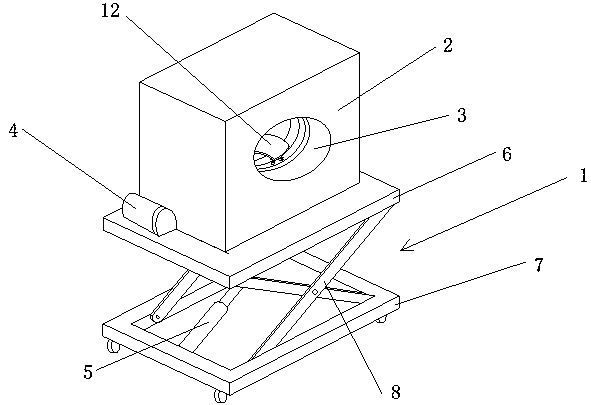

Grinding and polishing device and method based on glass machining

ActiveCN113696004AChange heightReduce the difficulty of manual cleaningGrinding carriagesRevolution surface grinding machinesPolishingEngineering

Owner:湖北浠玻实业有限公司

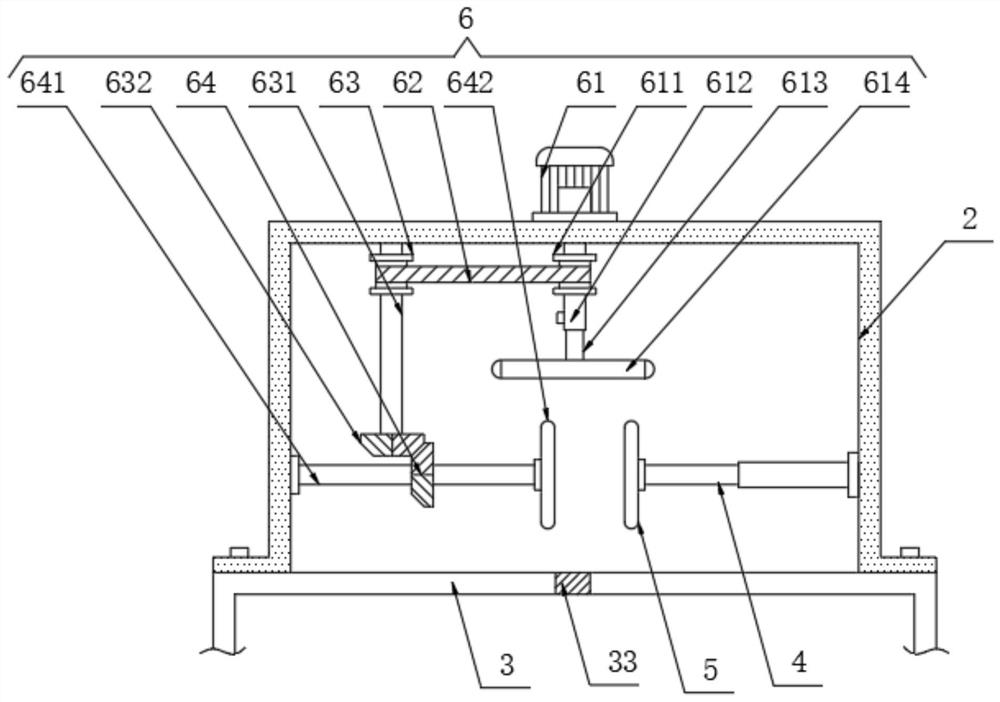

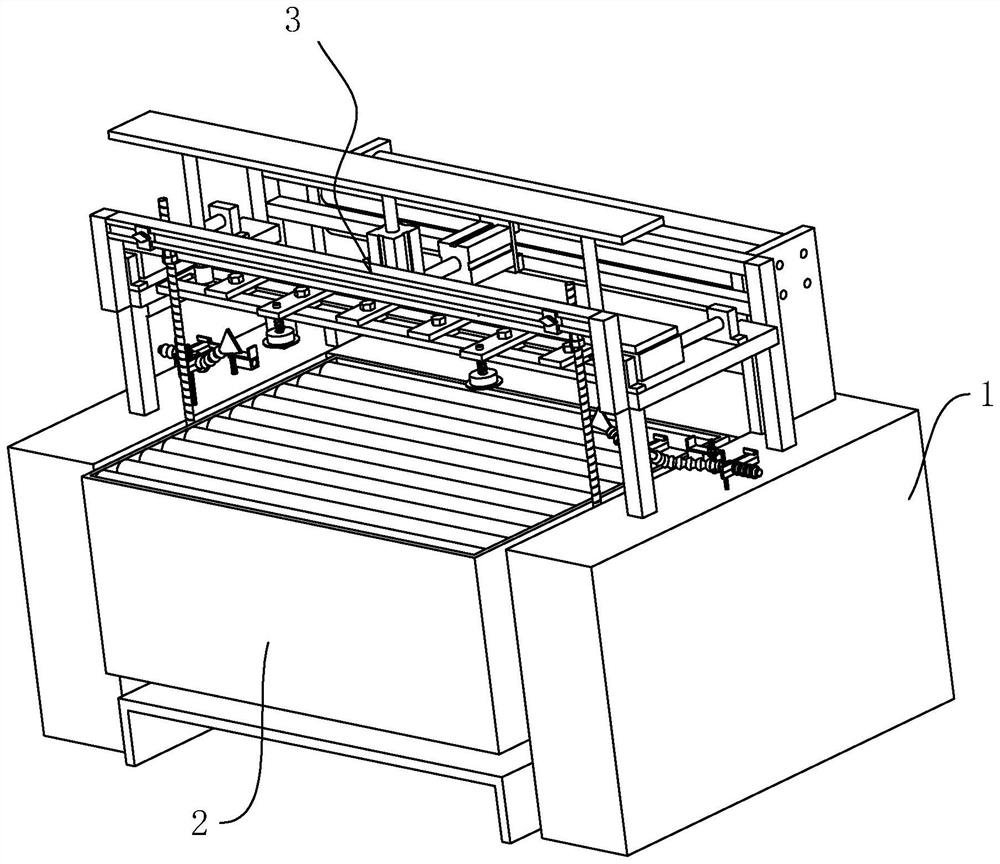

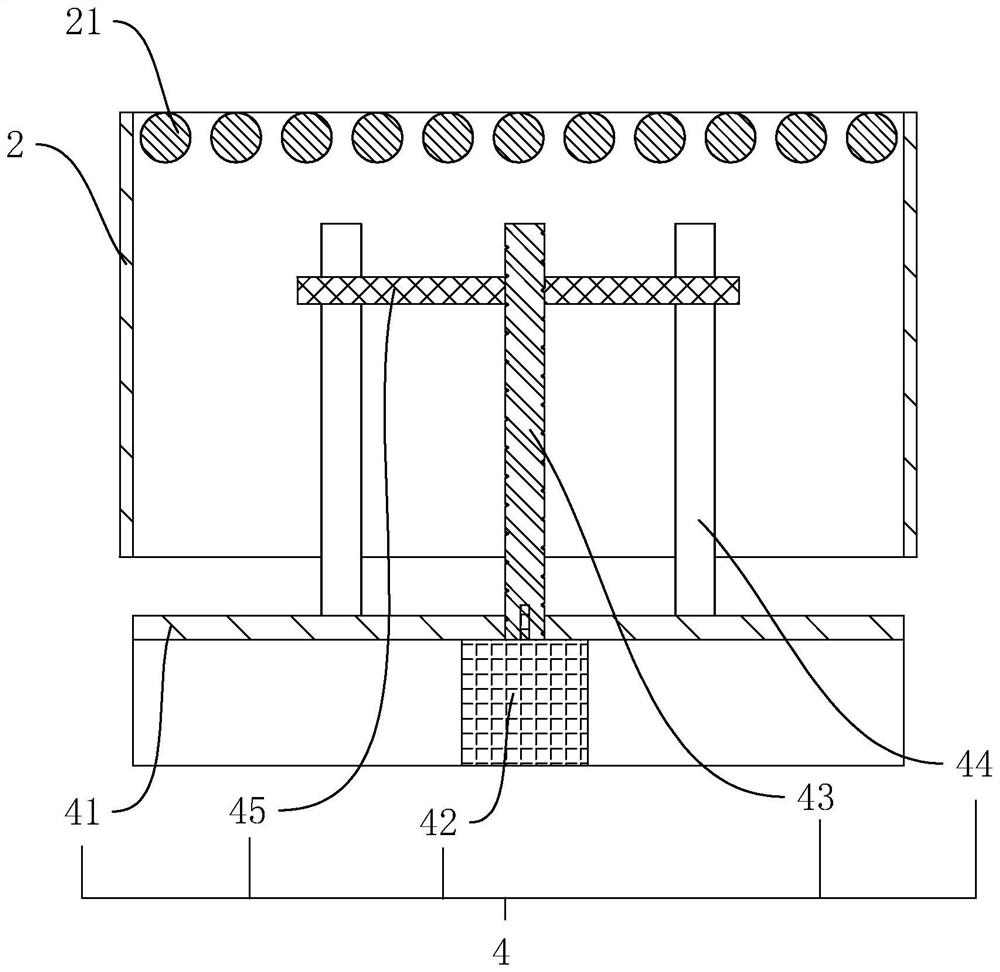

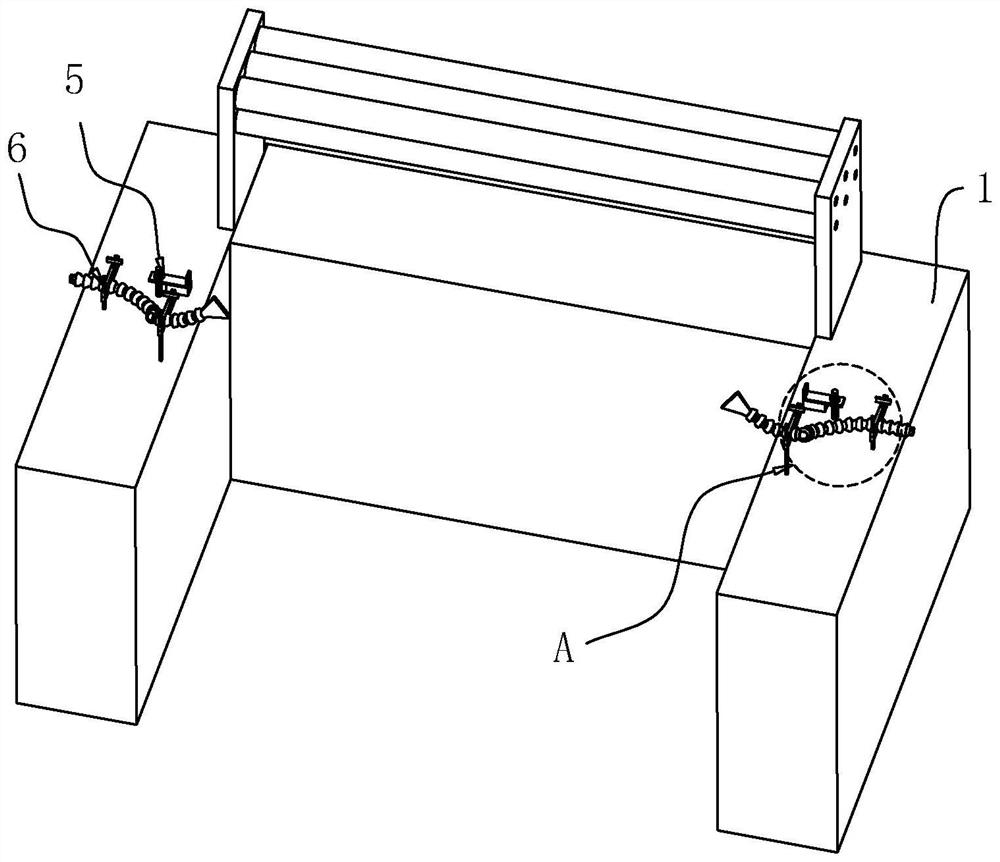

Full-automatic feeding device of plate grinding machine

PendingCN114523349AImprove work efficiencyGrinding carriagesGrinding drivesMechanical engineeringPrinted circuit board

Owner:佛山市普能达电子有限公司

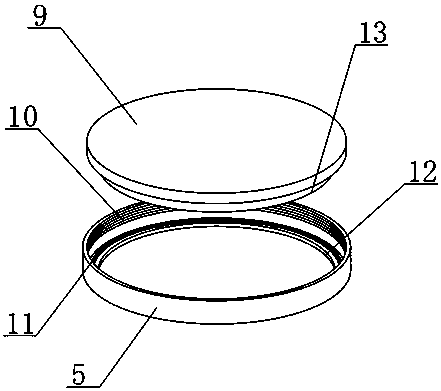

Equipment suitable for ceramic rear cover automatic polishing

InactiveCN111571392AEasy to disassembleEasy to replaceGrinding carriagesGrinding bedsPolishingMachine

Owner:陕西励峰德精密陶瓷科技有限公司

Polishing machine clamping system with automatic reversing and cooling functions

PendingCN114473809AAvoid it happening againAvoid influenceGrinding carriagesPolishing machinesElectric machineEngineering

Owner:诸暨市理磊机械制造有限公司

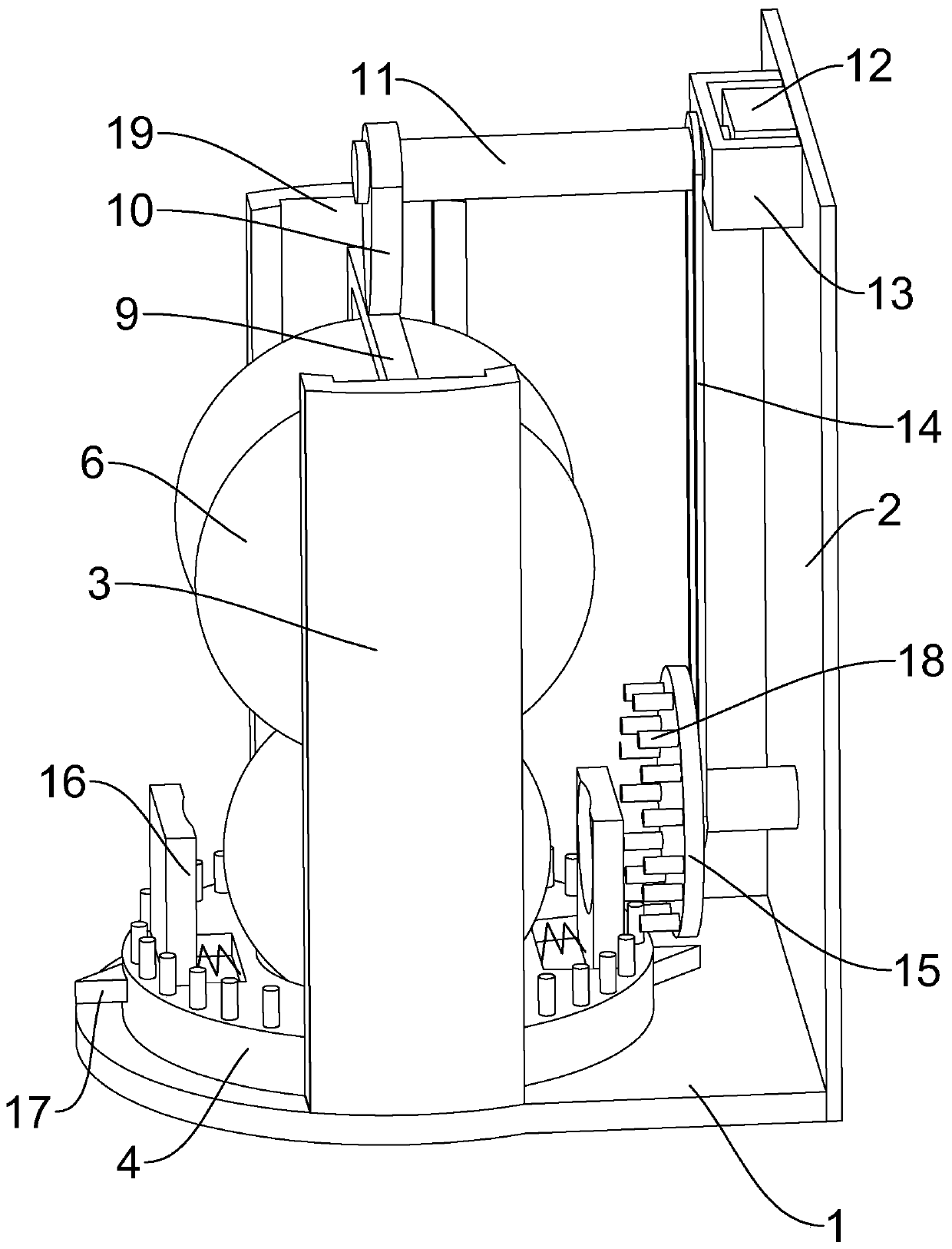

Polishing equipment for flywheel shell machining

InactiveCN114178925AAchieve grindingChange sanding areaEdge grinding machinesGrinding carriagesStructural engineeringFlywheel

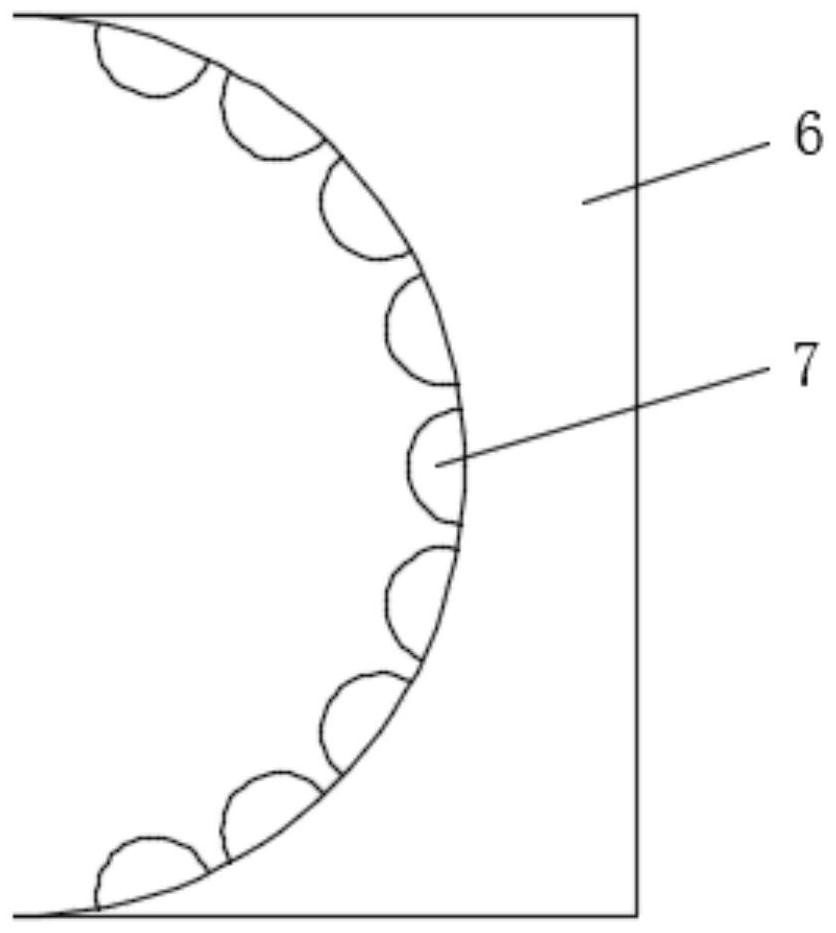

The grinding equipment for flywheel shell machining comprises a shell, a sliding rail is arranged and connected in the shell, a movable plate is connected to one side of the sliding rail, a fixed plate is arranged in the movable plate, a clamping plate is arranged on one side of the fixed plate, a clamping rod is connected to one side of the clamping plate, and a clamping lead screw is connected to the interior of the clamping plate. A movable lead screw is arranged in the shell, a movable rod is connected to the periphery of the movable lead screw, a movable rail is arranged in the movable rod, and a movable block is connected into the movable rail. According to the grinding equipment for flywheel shell machining, the arranged pressing wheel structure is utilized, grinding is conducted through the grinding strips, so that the distance between the pressing wheels is changed through stretching and retracting of the telescopic rods, the grinding area is changed, grinding of the whole flywheel shell is achieved, grinding can be conducted on the surface structure of the flywheel shell, automatic grinding is achieved, manpower is not needed, and the grinding efficiency is improved. And the grinding efficiency is further ensured.

Owner:WEIFANG HONGYANG MASCH TECH CO LTD

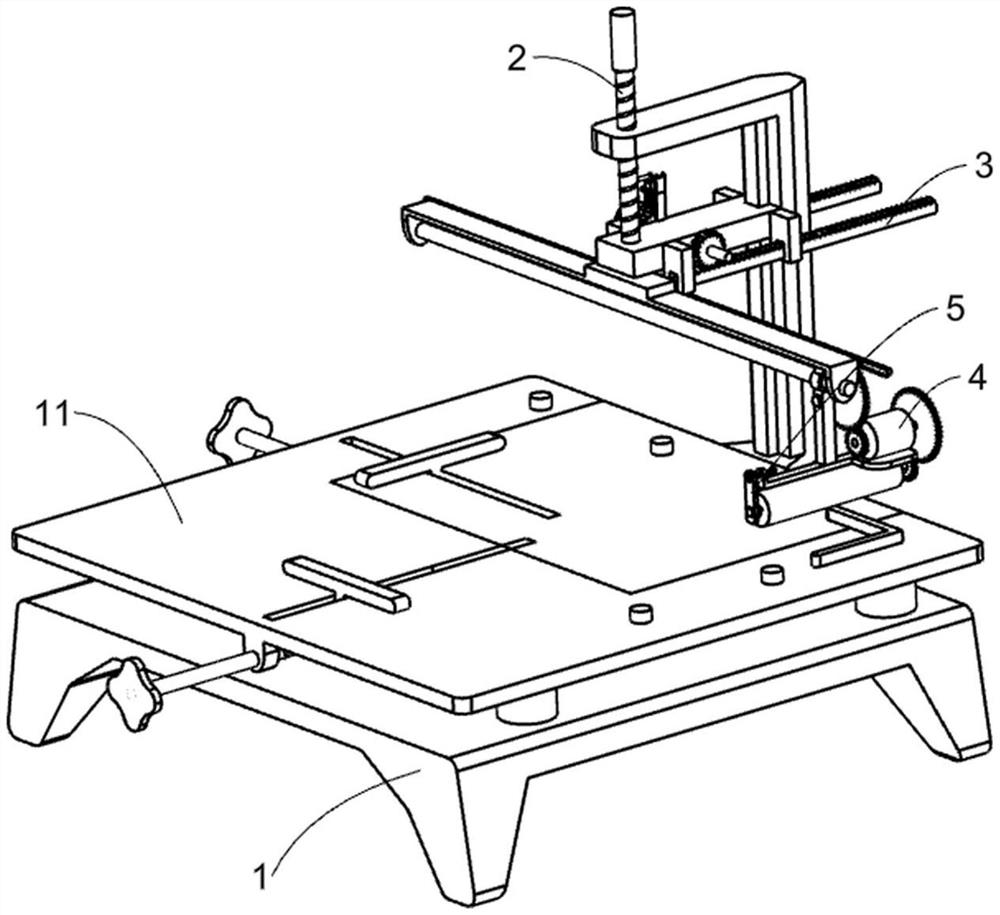

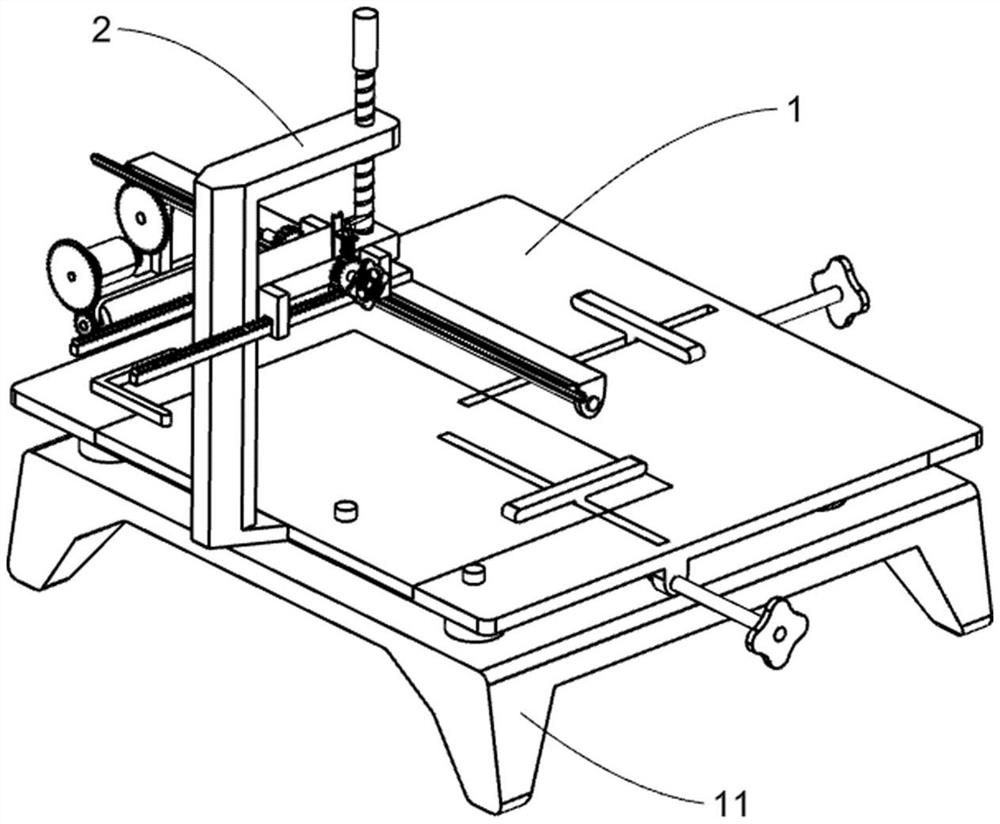

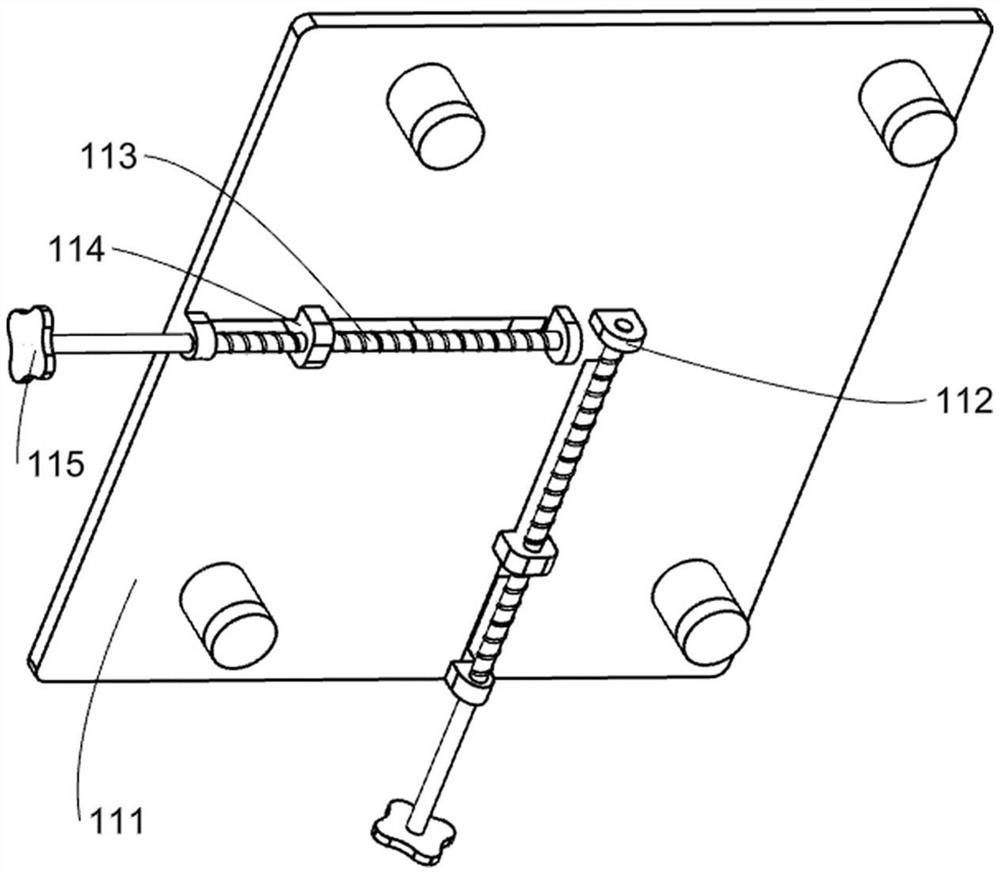

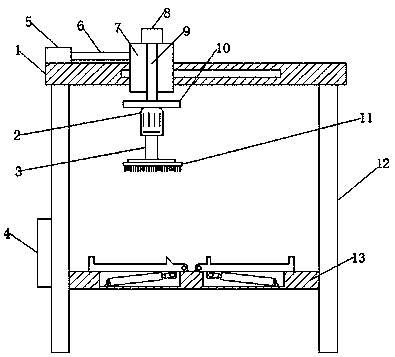

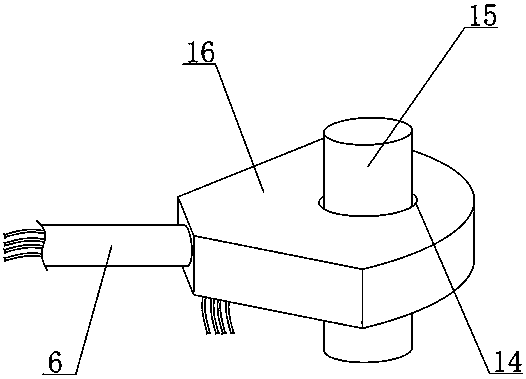

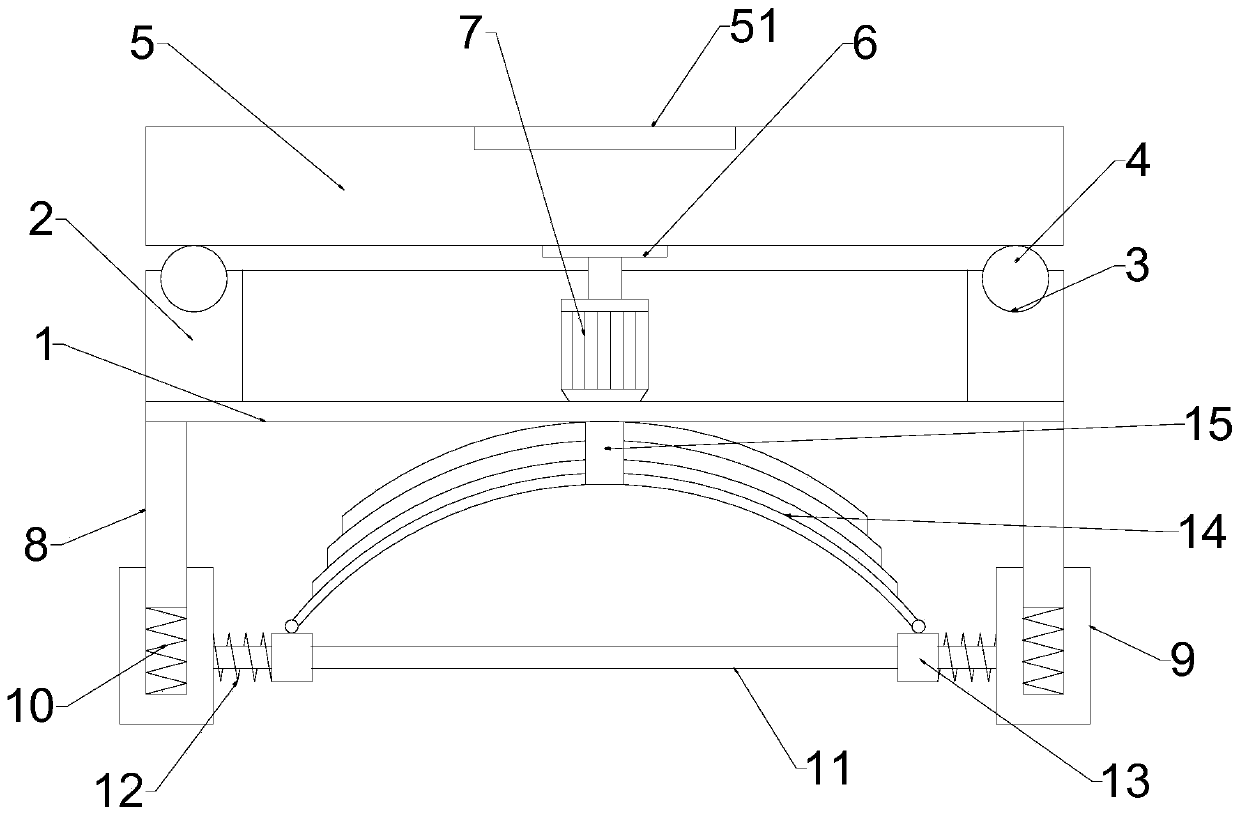

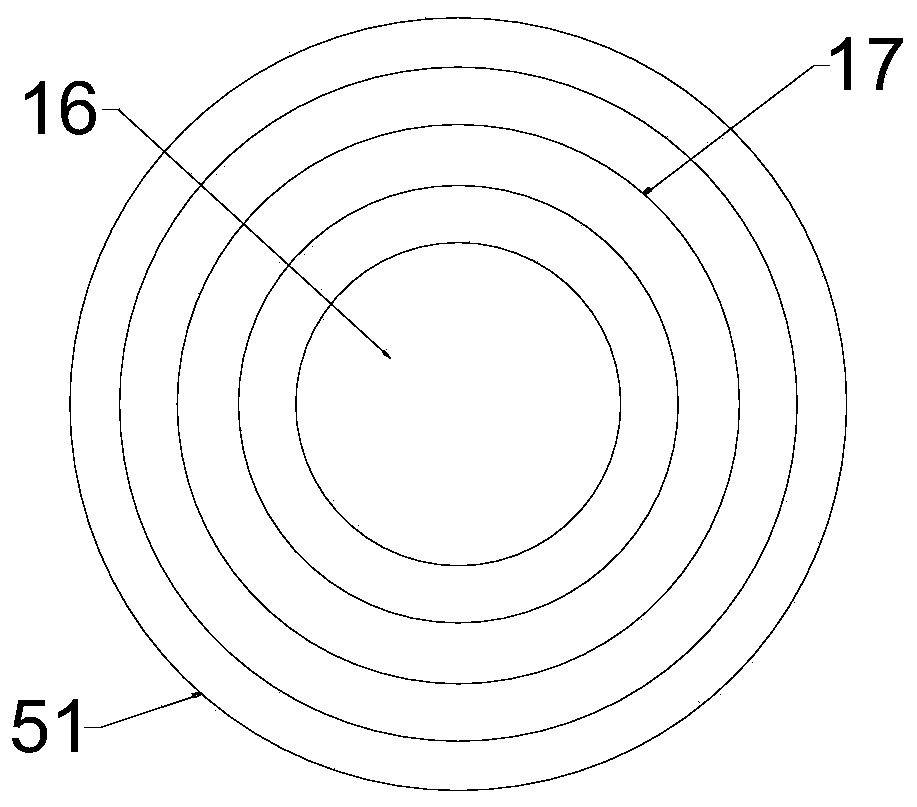

Workpiece end face grinding and polishing platform adopting multi-mode grinding

ActiveCN109702607ARich end face grinding formsEasy to useGrinding carriagesRevolution surface grinding machinesEngineeringMachining process

Owner:苏州跃尔瀚机械科技有限公司

Grinding equipment for direct current (DC) plug plating layer

PendingCN110076671AClean up in timeAvoid pollutionGrinding carriagesGrinding feed controlEngineeringDirect current

Owner:深圳市优机智能技术有限公司

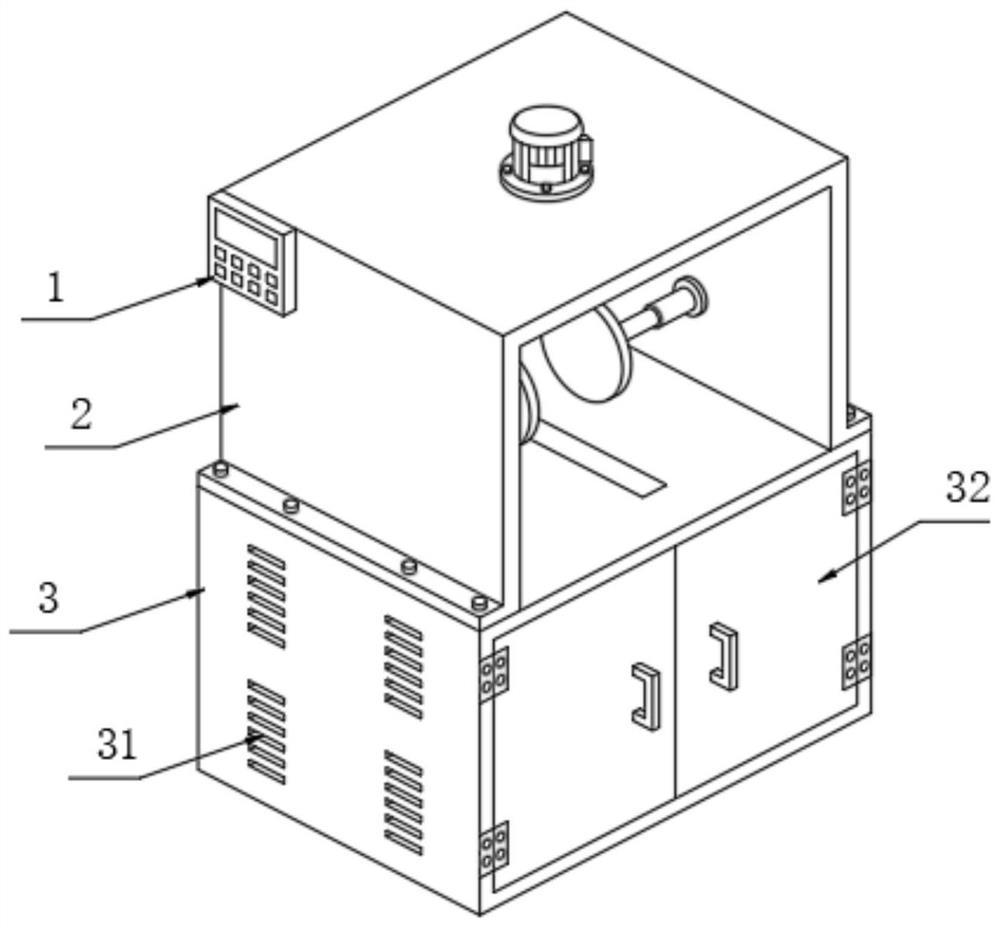

Environment-friendly grinding machine

PendingCN114290181AAvoid outreachFully contactedGrinding carriagesGrinding drivesThermodynamicsDust control

Owner:YANCHENG JIANFENG ELECTRIC MOTOR INSTR

Cutter head molding machine

PendingCN114770235AGood for one-shot moldingImprove processing efficiencyGrinding carriagesOther manufacturing equipments/toolsTool bitMolding machine

Owner:SHANGHAI WELL SUN PRECISION TOOLS

Grinding device used for removing burrs at cut openings of steel pipes

InactiveCN113400127APlay the effect of clamping and positioningPrevent movementEdge grinding machinesGrinding wheel securing apparatusEngineeringPipe

Owner:中诚惠容实业集团有限公司

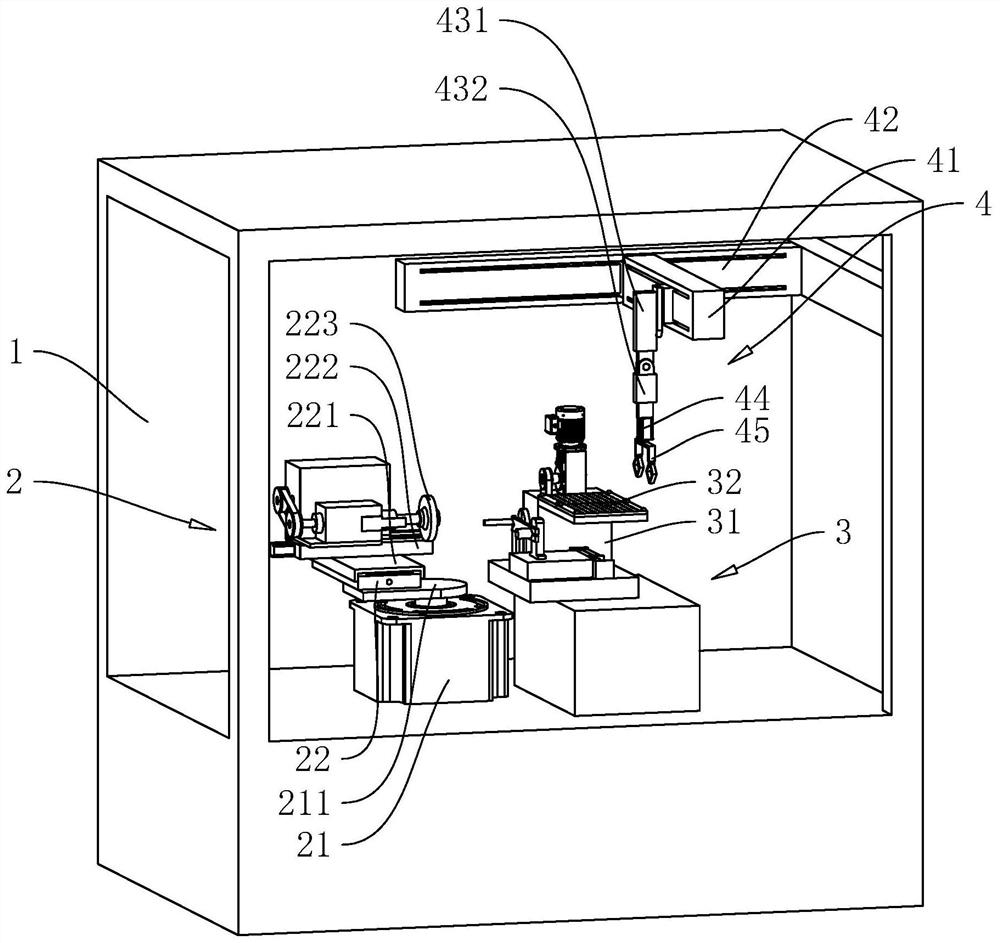

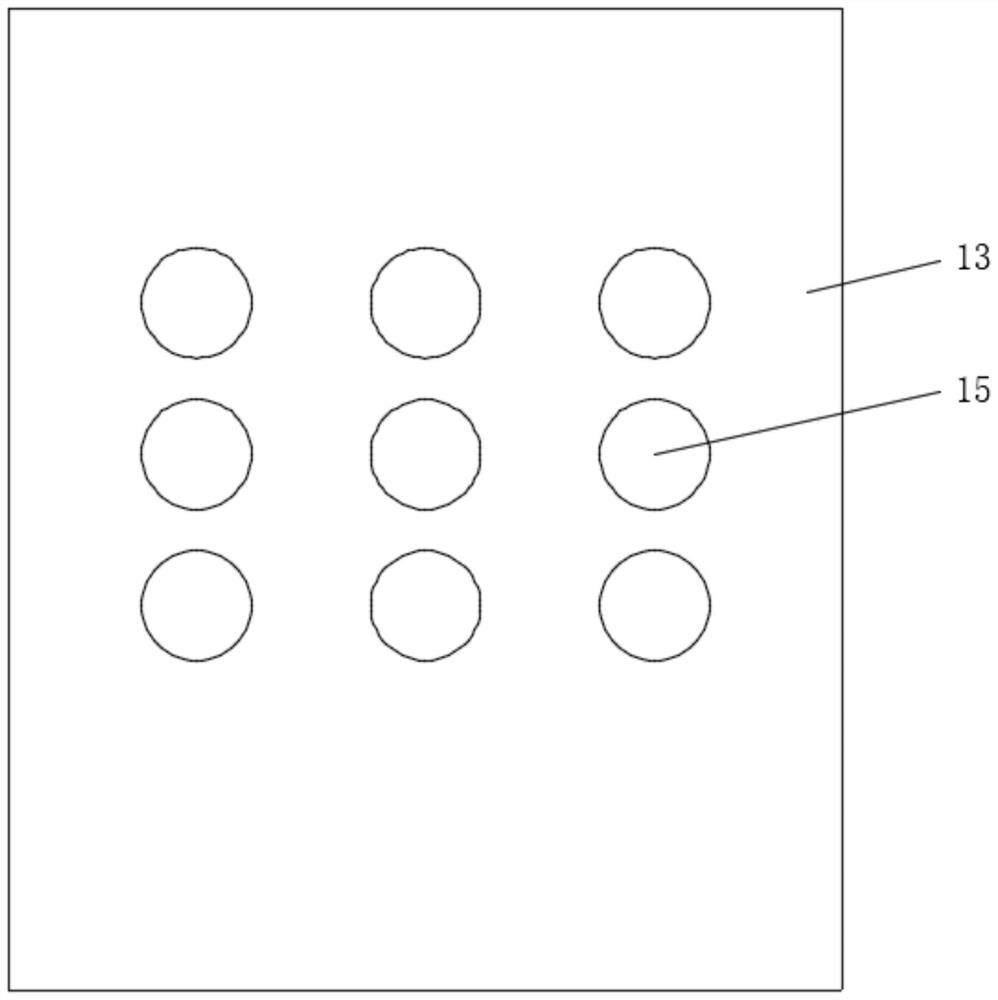

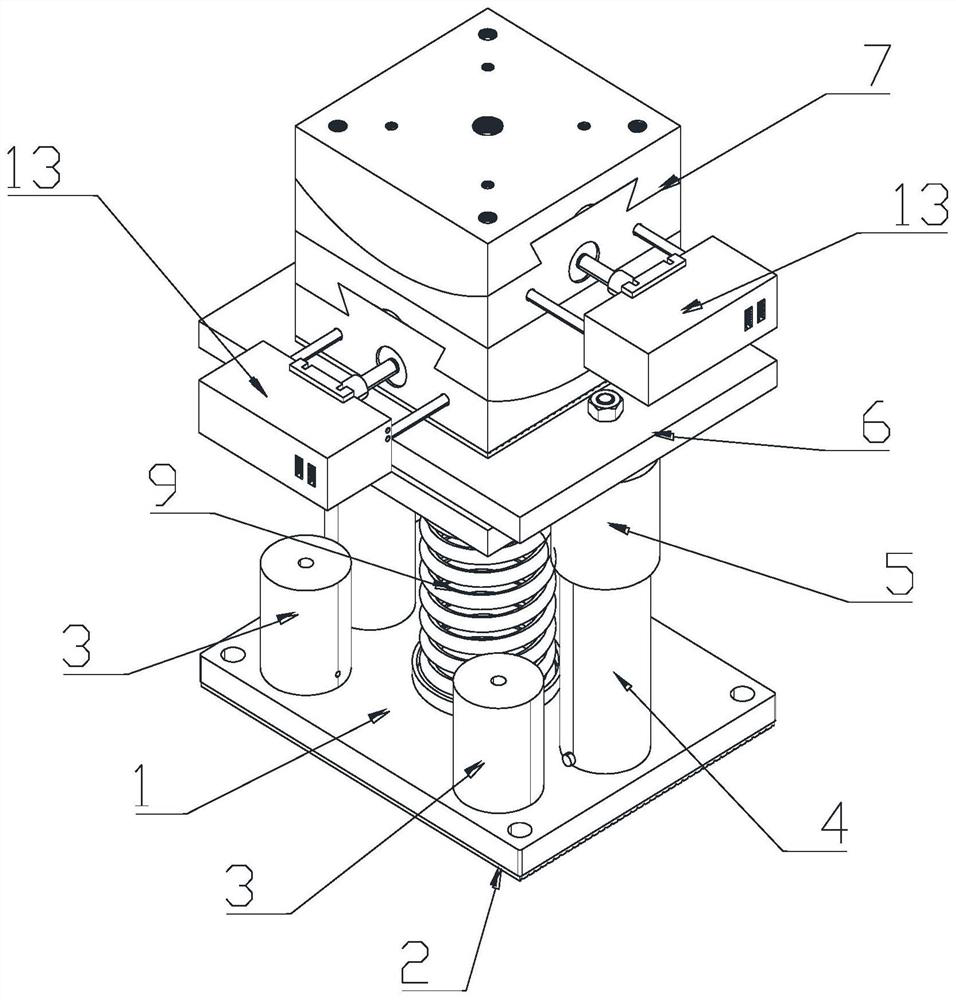

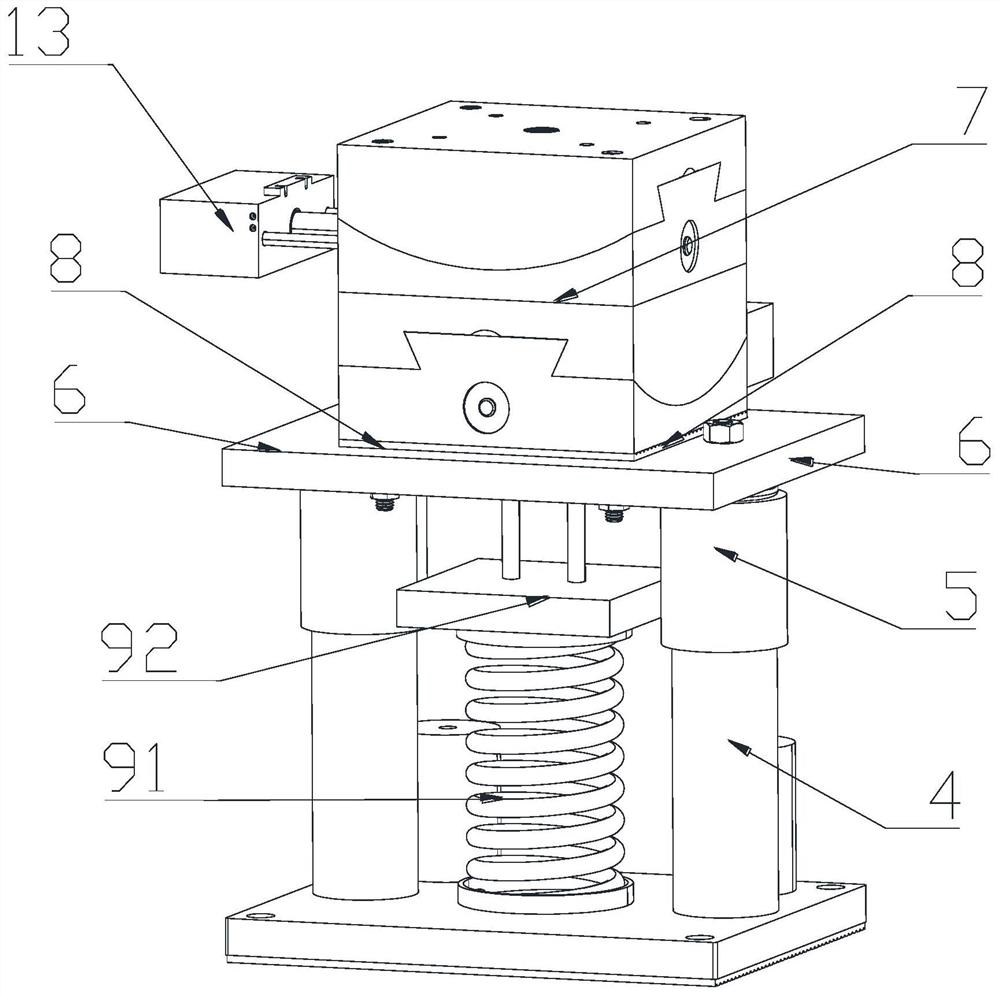

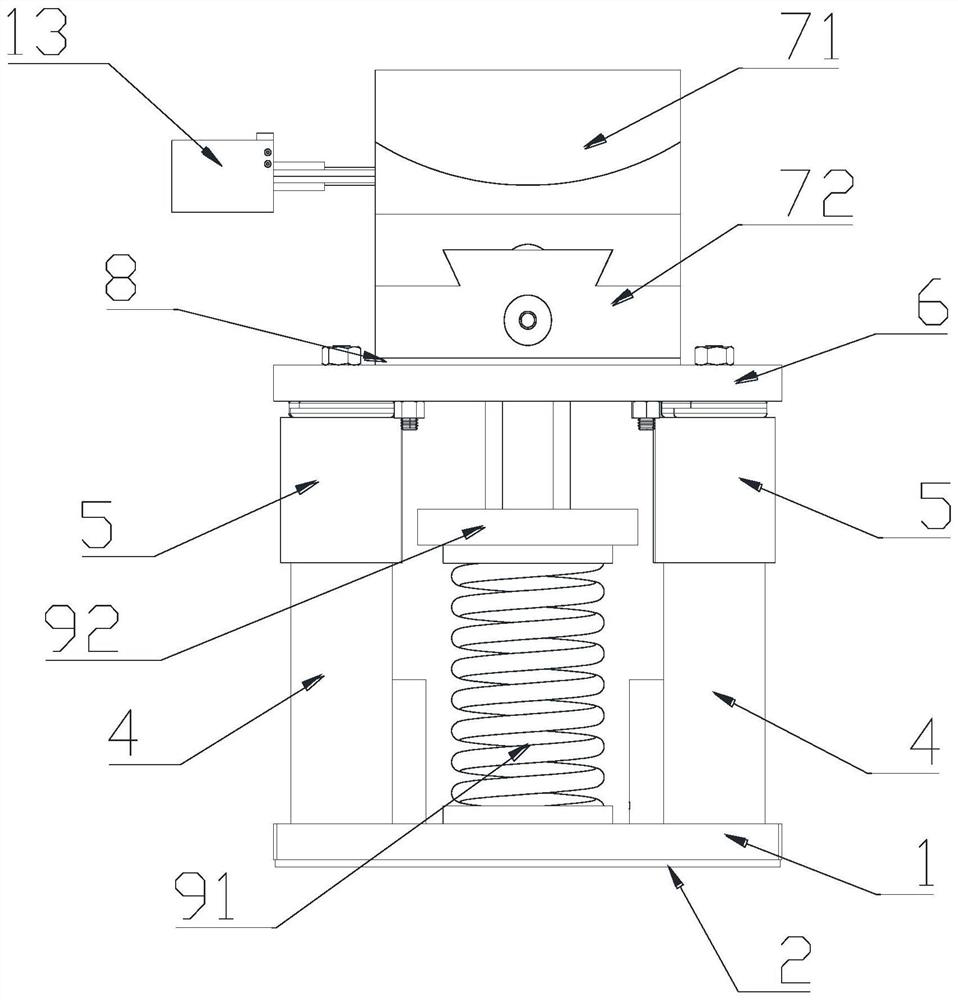

Adaptive grinding machining platform and grinding machining device

InactiveCN113500518ASmall grinding forceAvoid damageGrinding carriagesGrinding bedsMachined surfaceEngineering

Owner:GUANGZHOU UNIVERSITY

Electric power fitting grinding device for smart power grid

InactiveCN112123108ARealize automatic grinding processReduce generationGrinding carriagesGrinding drivesPower gridSmart grid

Owner:武秀侠

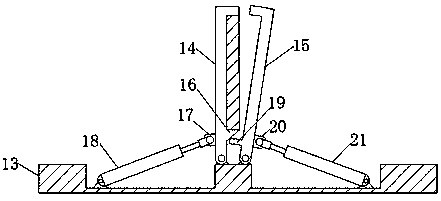

Repair device for highway bridge lane isolation building

InactiveCN113931106AReduce the number of peopleLow costGrinding carriagesGrinding drivesArchitectural engineeringStructural engineering

The invention discloses a repair device for a highway bridge lane isolation building, and relates to the field of building repairing, the repair device comprises a shell repair mechanism, the bottom end of the repair mechanism is fixedly connected with a fixing mechanism, the top end of the repairing mechanism is provided with a rust removal mechanism, and the front end of the repair mechanism is provided with a polishing control mechanism, a grinding executing mechanism is arranged on the inner side of the front end of the repair mechanism, the repair mechanism comprises a connecting bottom plate, a connecting sliding rail is arranged at the bottom end of the inner side of the connecting bottom plate, a lifting controller is movably connected to the outer side of the connecting sliding rail, lifting connecting supports are movably connected to the outer side of the lifting controller, and a movable connecting support is connected between the lifting connecting supports at the two ends. The outer side of the movable connecting support is movably connected with a movable sealing plate, and the top end of the connecting bottom plate is fixedly connected with a lifting containing groove. Meanwhile, during use, by arranging the inflatable sealing mechanism, a cavity can be automatically formed in the use process, and rust removal liquid is contained to conduct rust removal work on the guardrail single bodies.

Owner:毛风善

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap