Adaptive grinding machining platform and grinding machining device

A grinding, self-adaptive technology, applied in metal processing equipment, grinding/polishing equipment, grinding slides, etc., can solve the surface damage of hard and brittle workpieces, difficult grinding force, affecting the surface accuracy and forming quality of materials, etc. problem to avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

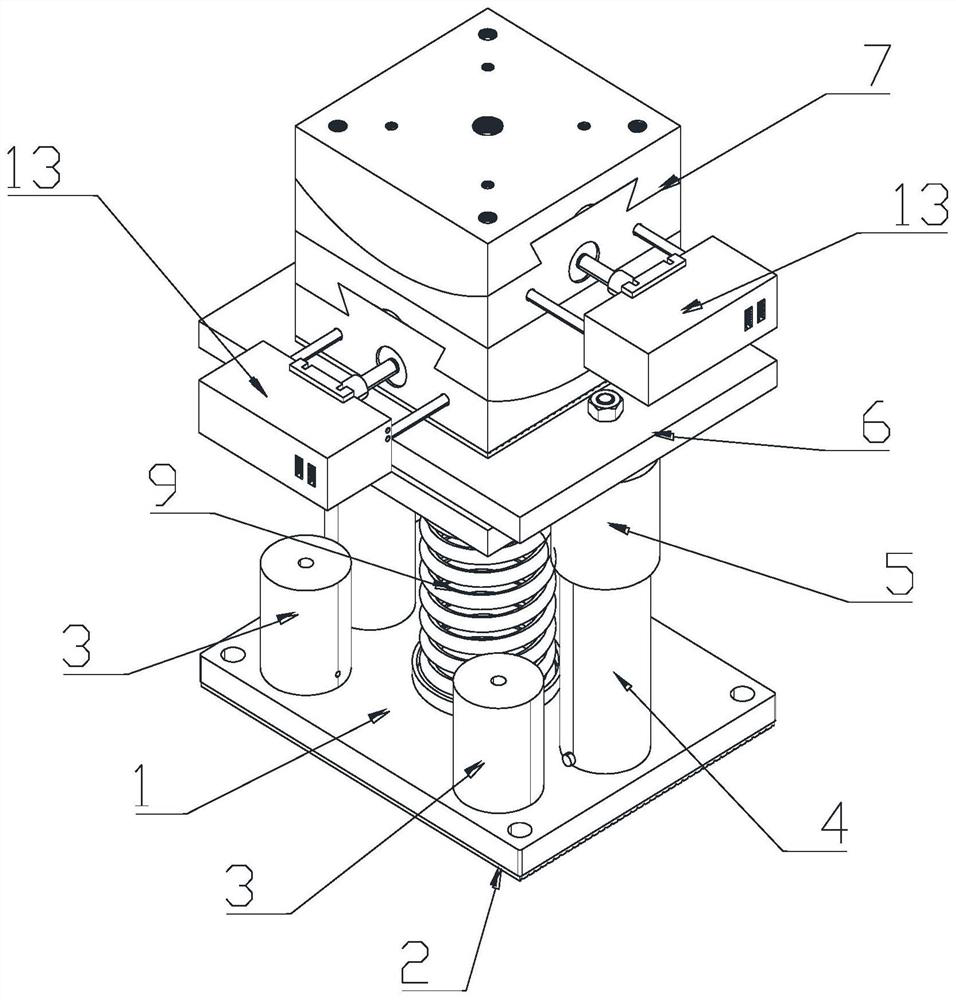

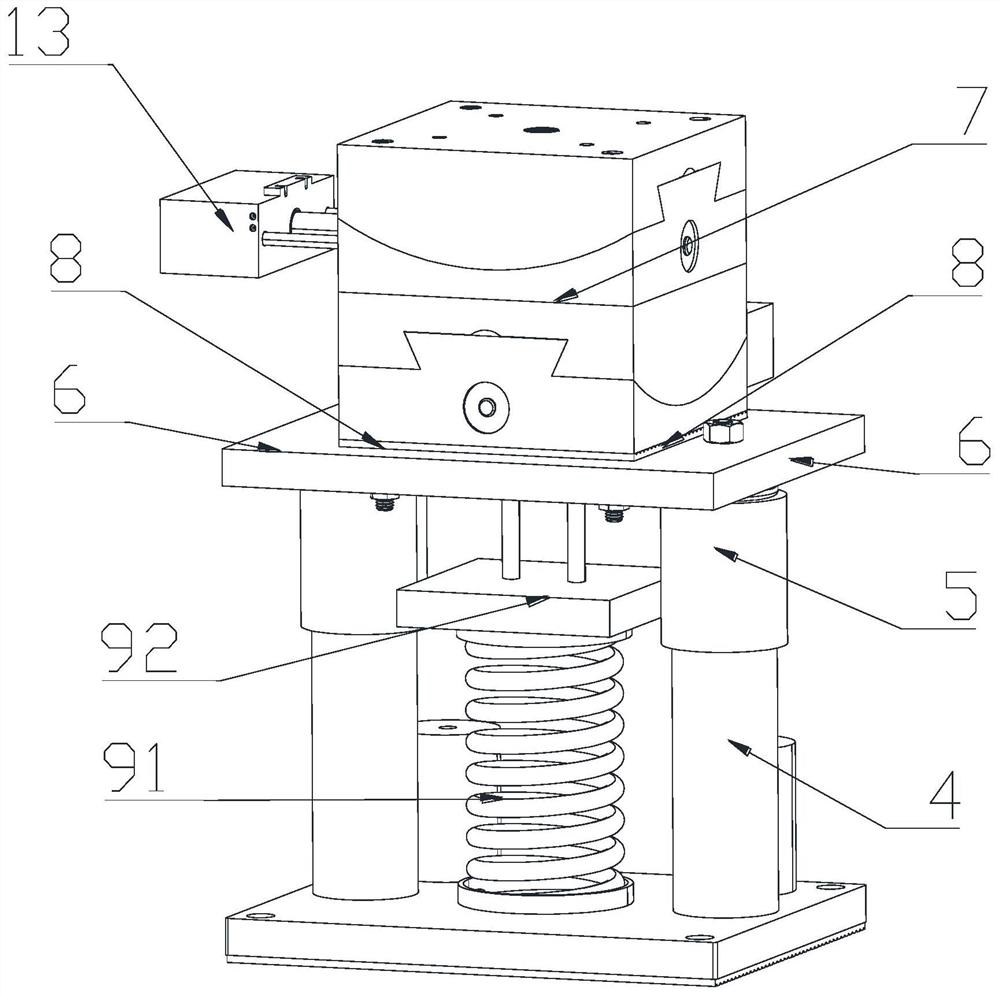

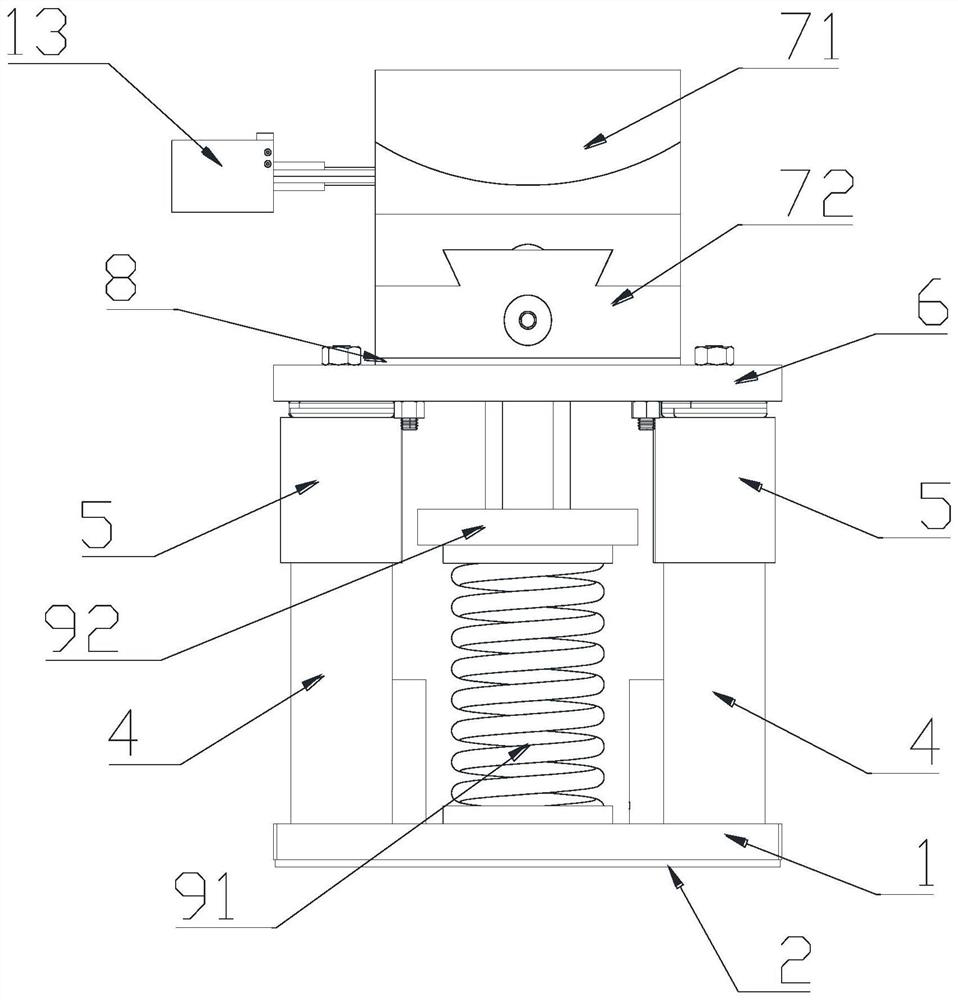

[0025] see Figure 1-Figure 5 , the self-adaptive grinding processing platform of the present invention includes a base 1, a working platform 6 arranged on the base 1, and an adaptive adjustment device arranged between the working platform 6 and the base 1, wherein the lower end of the base 1 is set There is a rubber damping layer 2; the self-adaptive adjustment device includes multiple groups of damping devices and elastic reset devices 9, wherein multiple groups of damping devices are symmetrically arranged on both sides of the base 1, and the upper end of each group of damping devices is connected to the The working platform 6 is connected, and the lower end is connected with the base 1; the elastic reset device 9 is arranged in the middle of the damping devices on both sides to promote the reset of the working platform 6. The elastic reset device 9 includes a The mounting seat 92 at the lower end and the spring 91 arranged on the mounting seat 92, wherein the mounting seat 92

Embodiment 2

[0037] The grinding processing equipment of the present invention includes the self-adaptive grinding processing platform, and other structures are implemented with reference to existing grinding machines.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap