Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about "Drilling pipes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

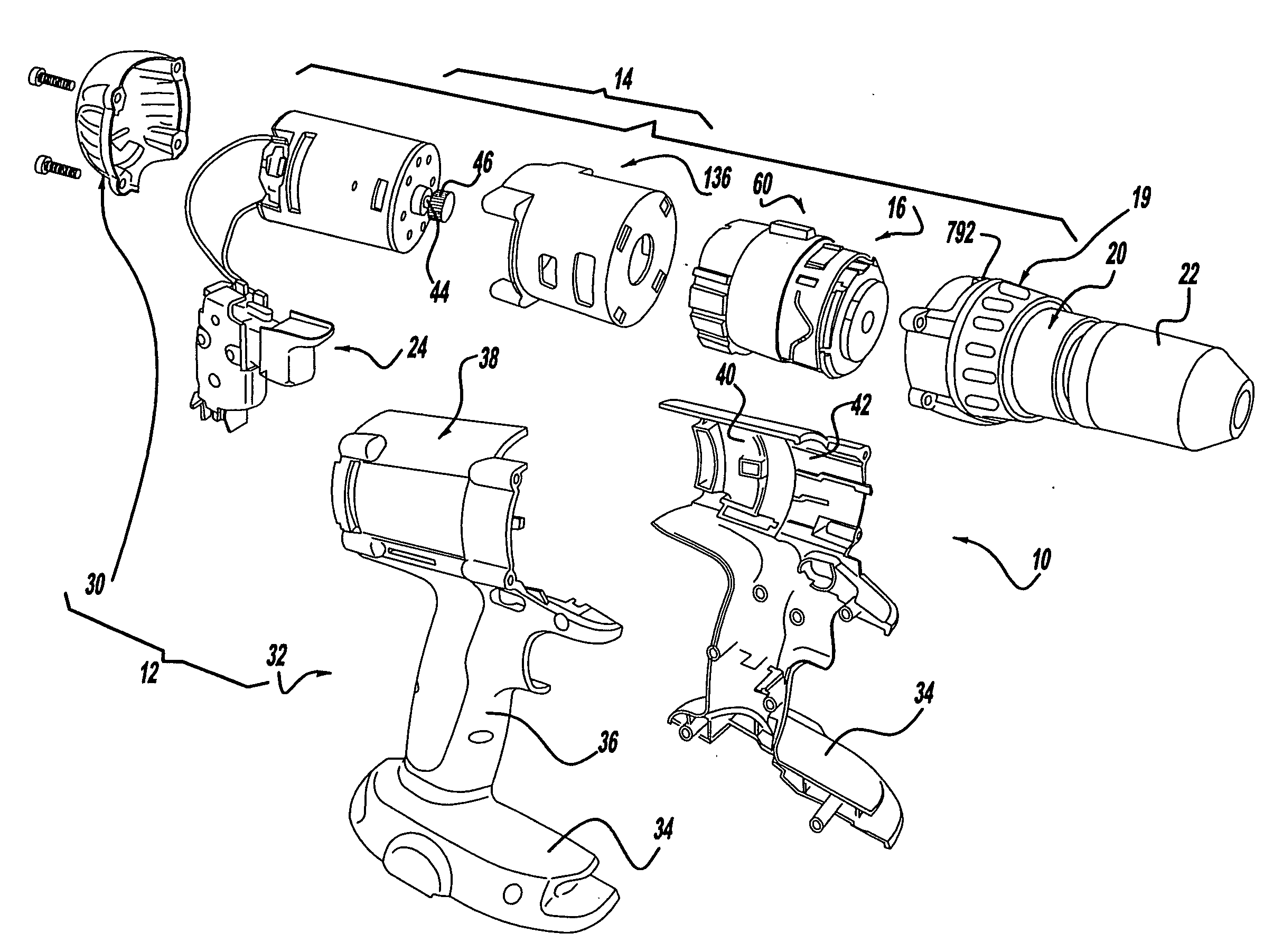

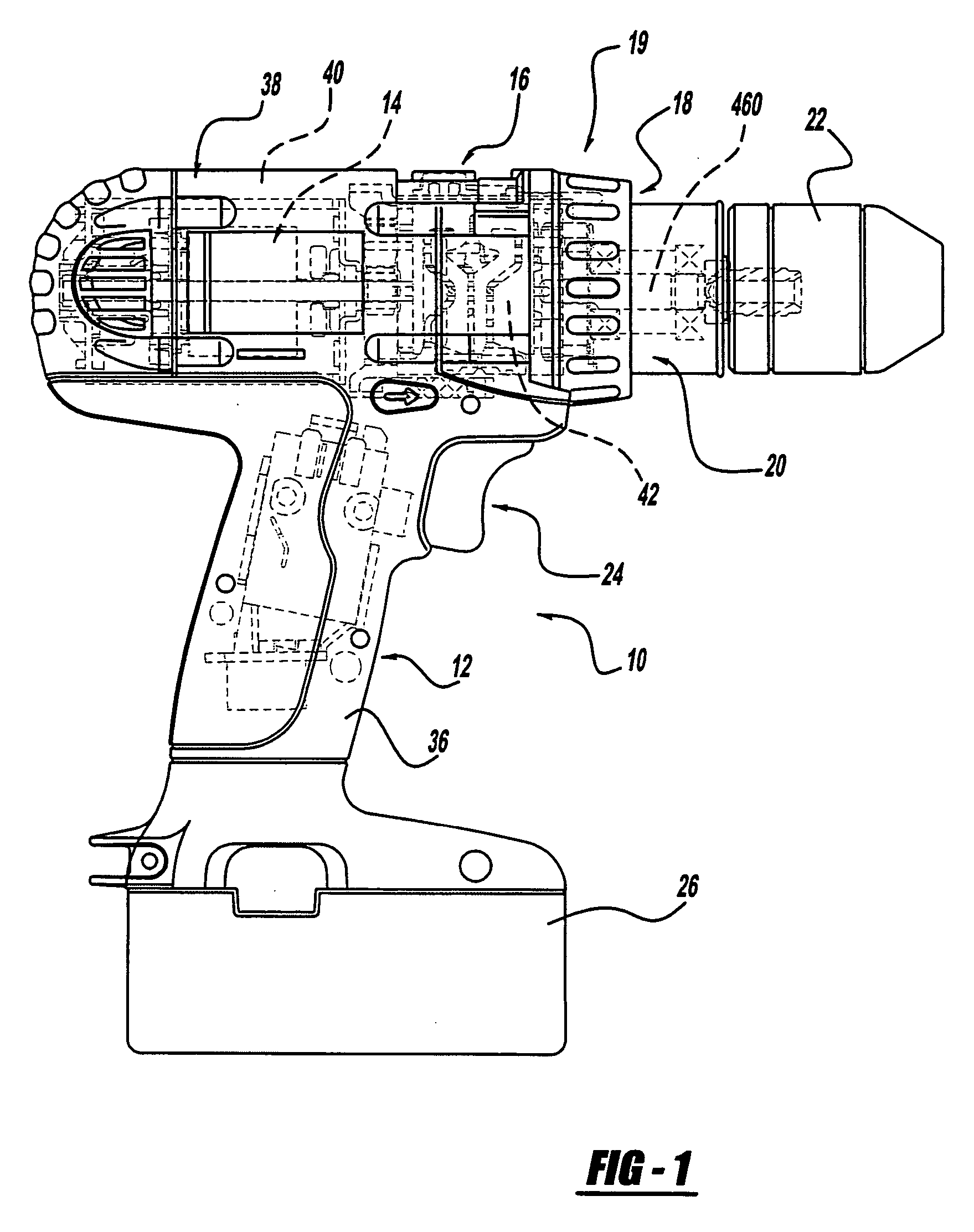

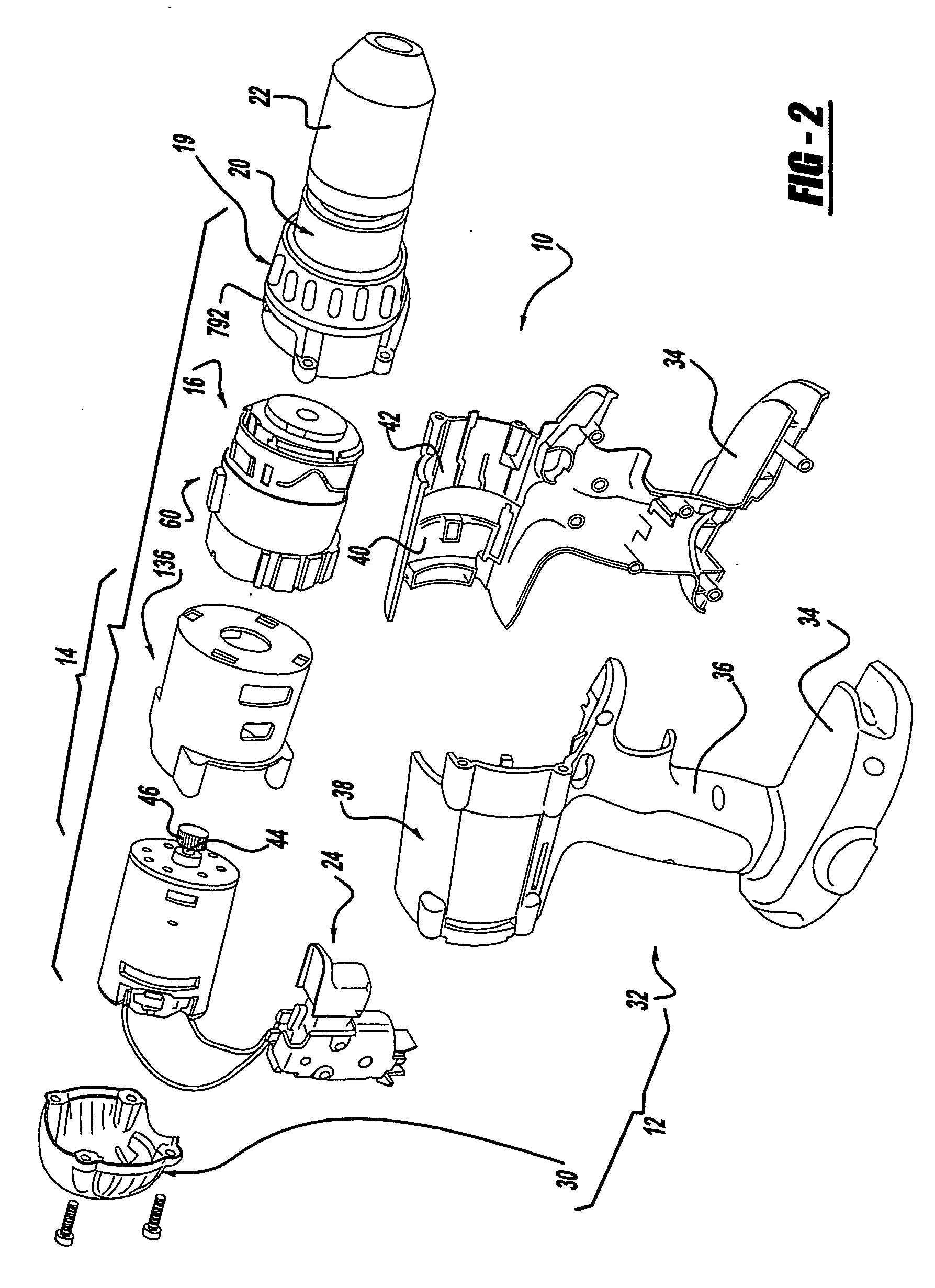

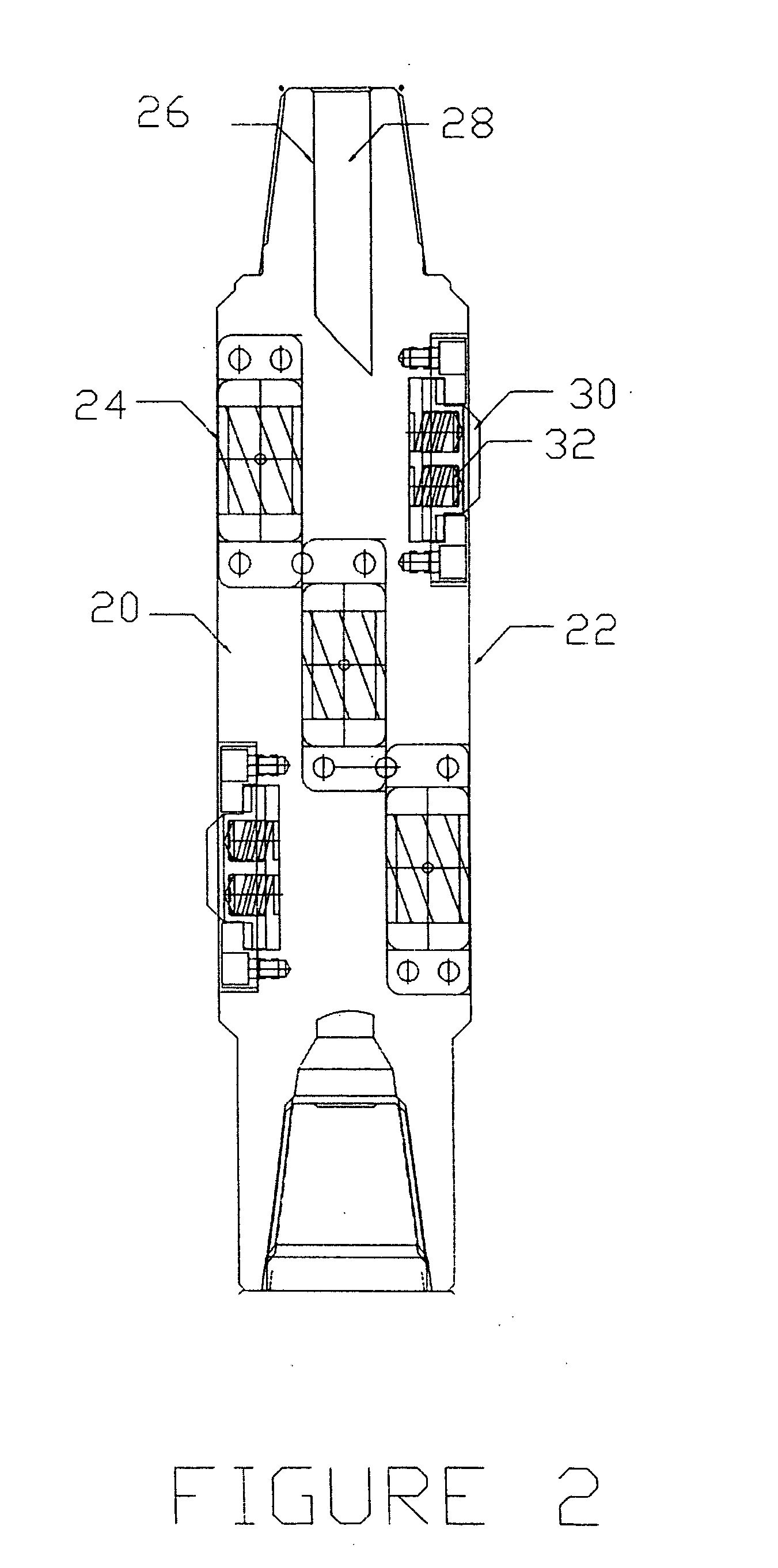

Hammer drill with a mode changeover mechanism

Owner:BLACK & DECKER INC

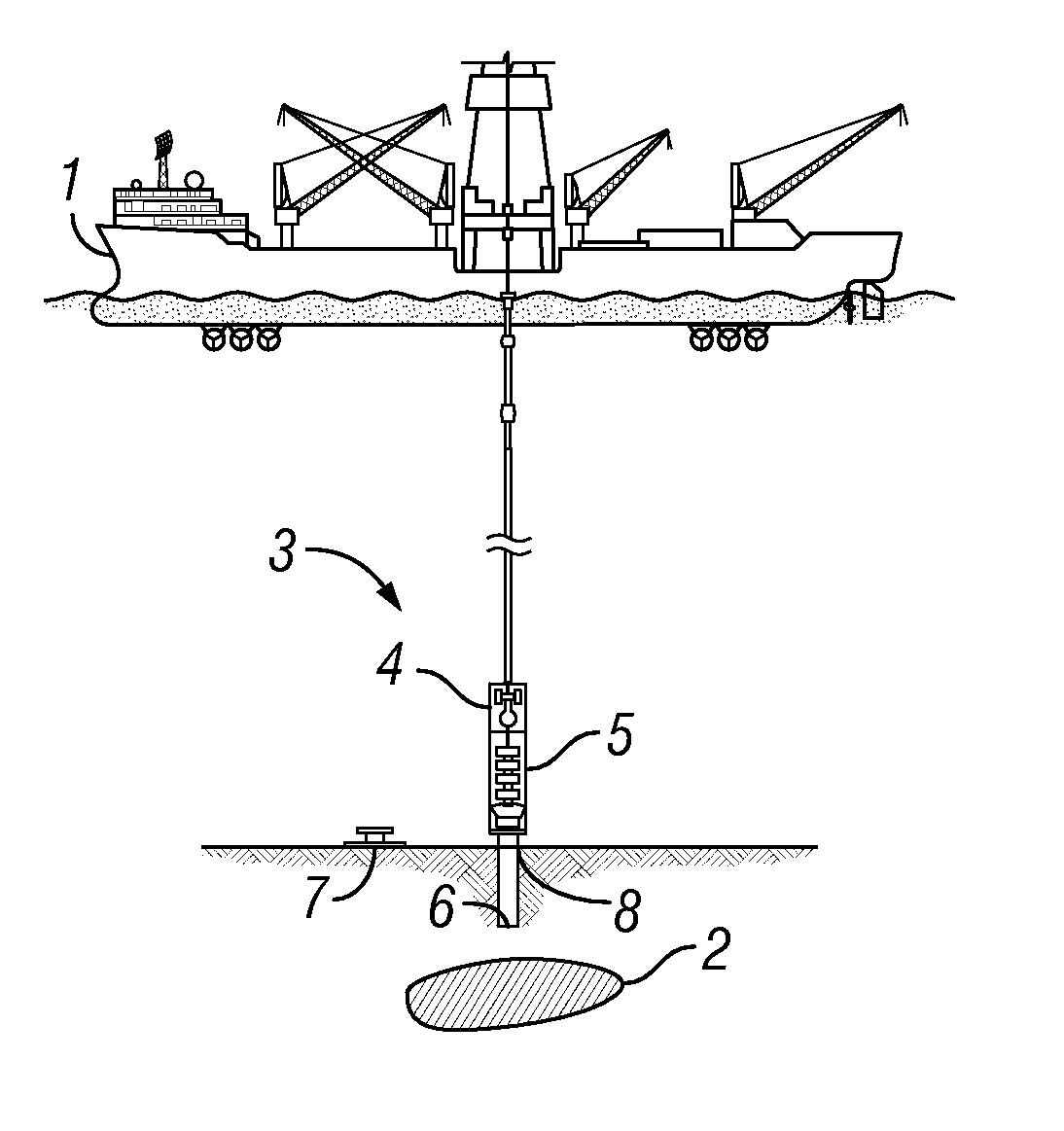

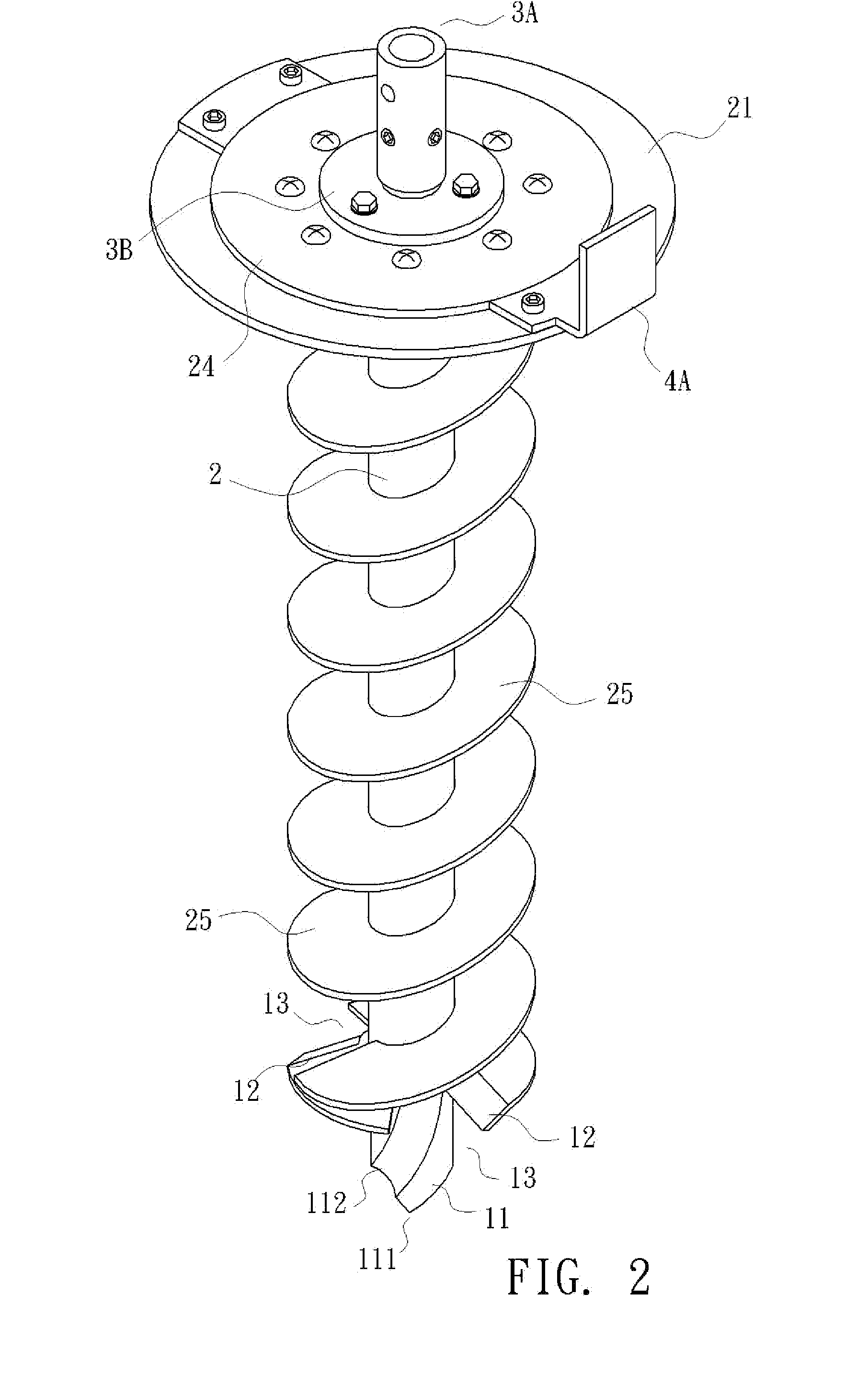

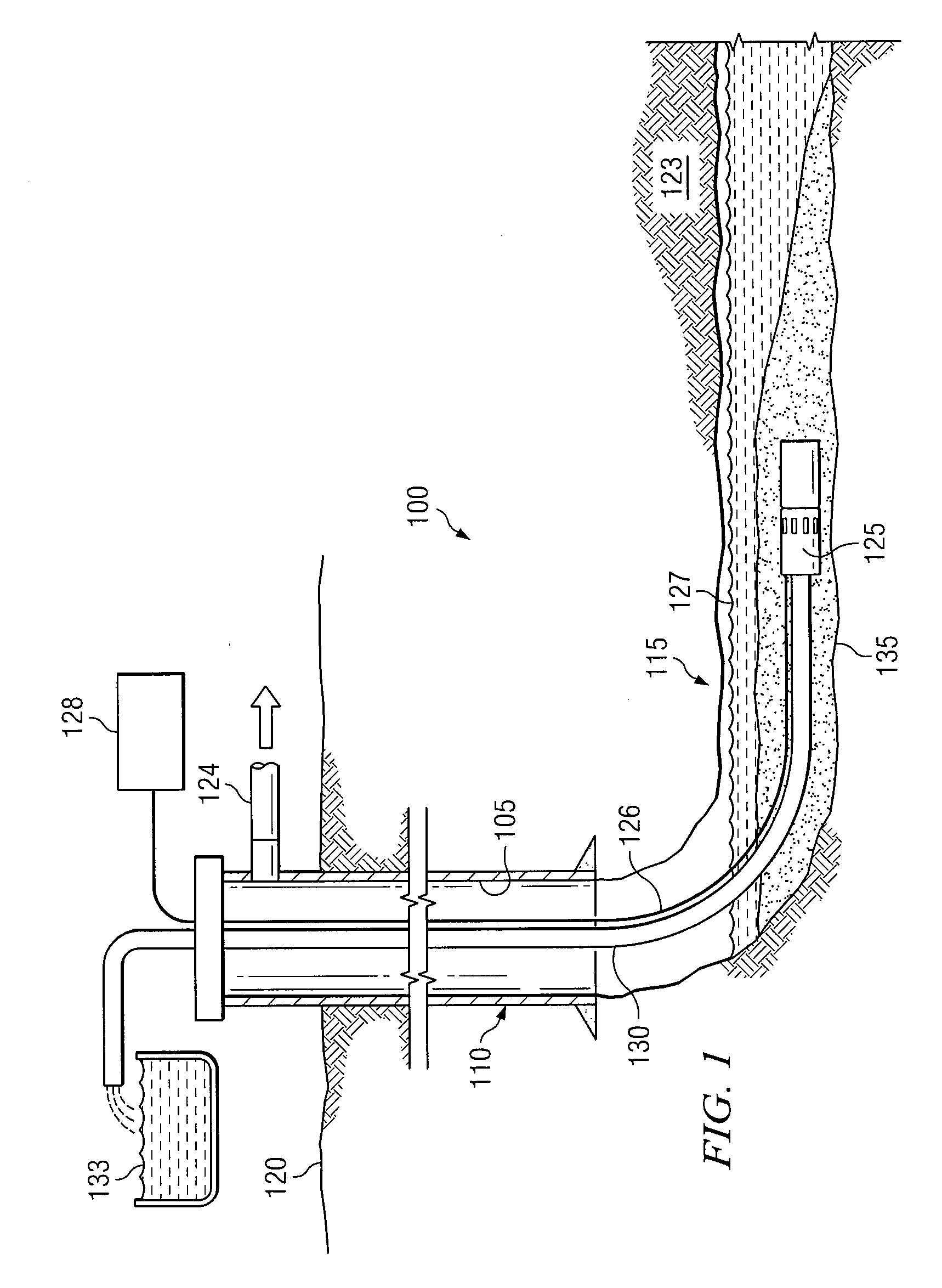

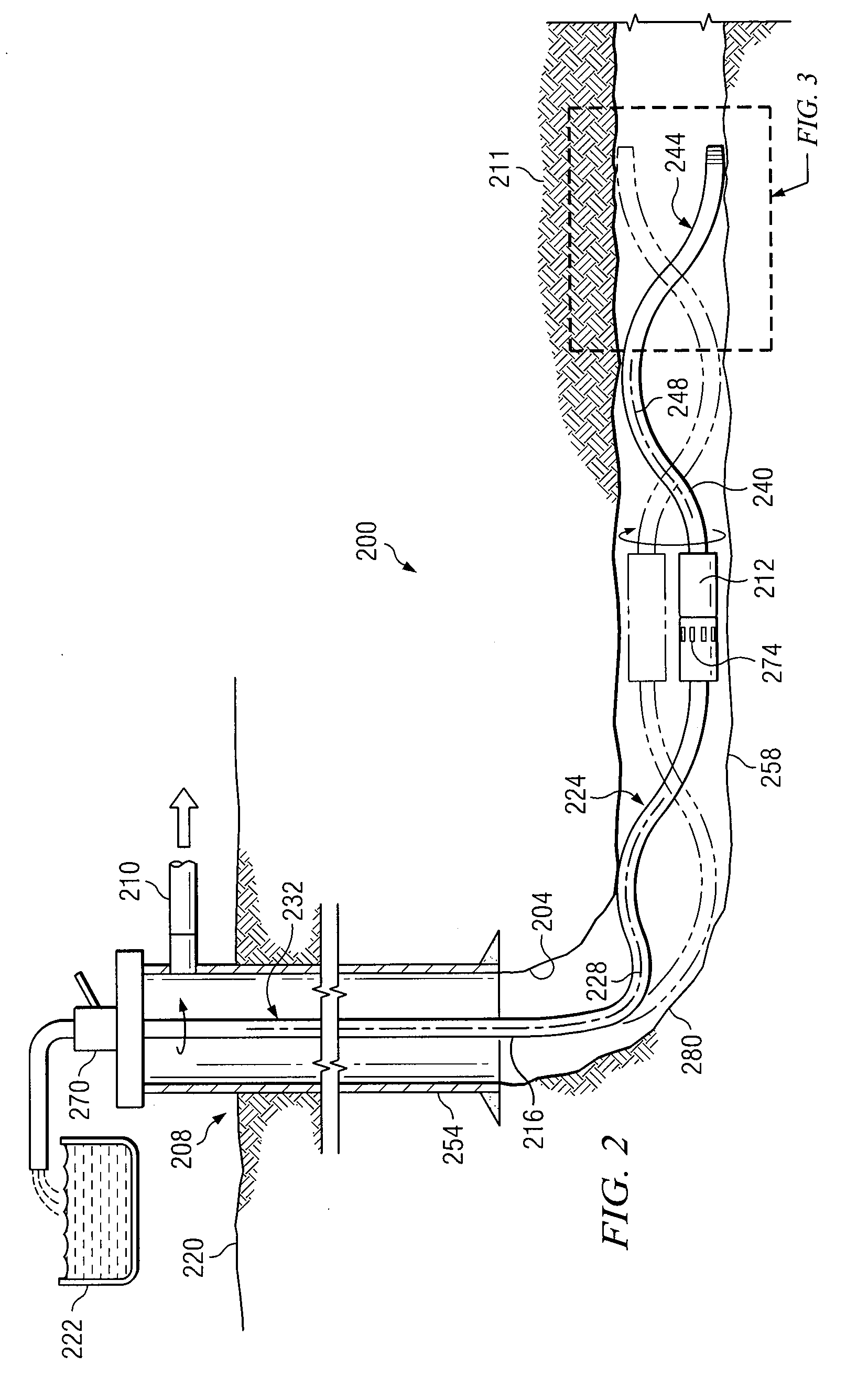

Method of producing hydrocarbons through a smart well

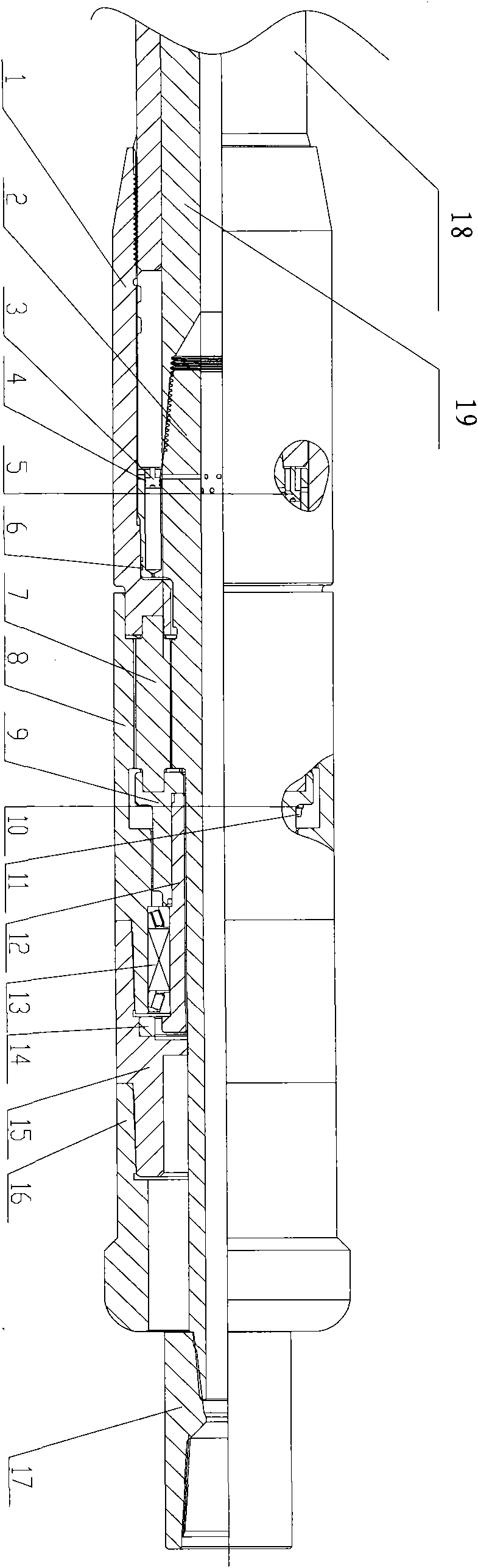

A method is disclosed for producing hydrocarbons through an instrumented smart well containing a well tubular (6,29-32) and an assembly of power, DTS and / or other sensing and / or signal transmission cables (13,40-44) comprising at least one power and / or signal transmission cable, which is bonded along at least part of its length to an outer surface of the well tubular (6,29-32) by an adhesive, which preferably is reusable and / or has a thermal conductive of at least 3 W / mK or at most 0.2 W / mK.

Owner:SHELL OIL CO

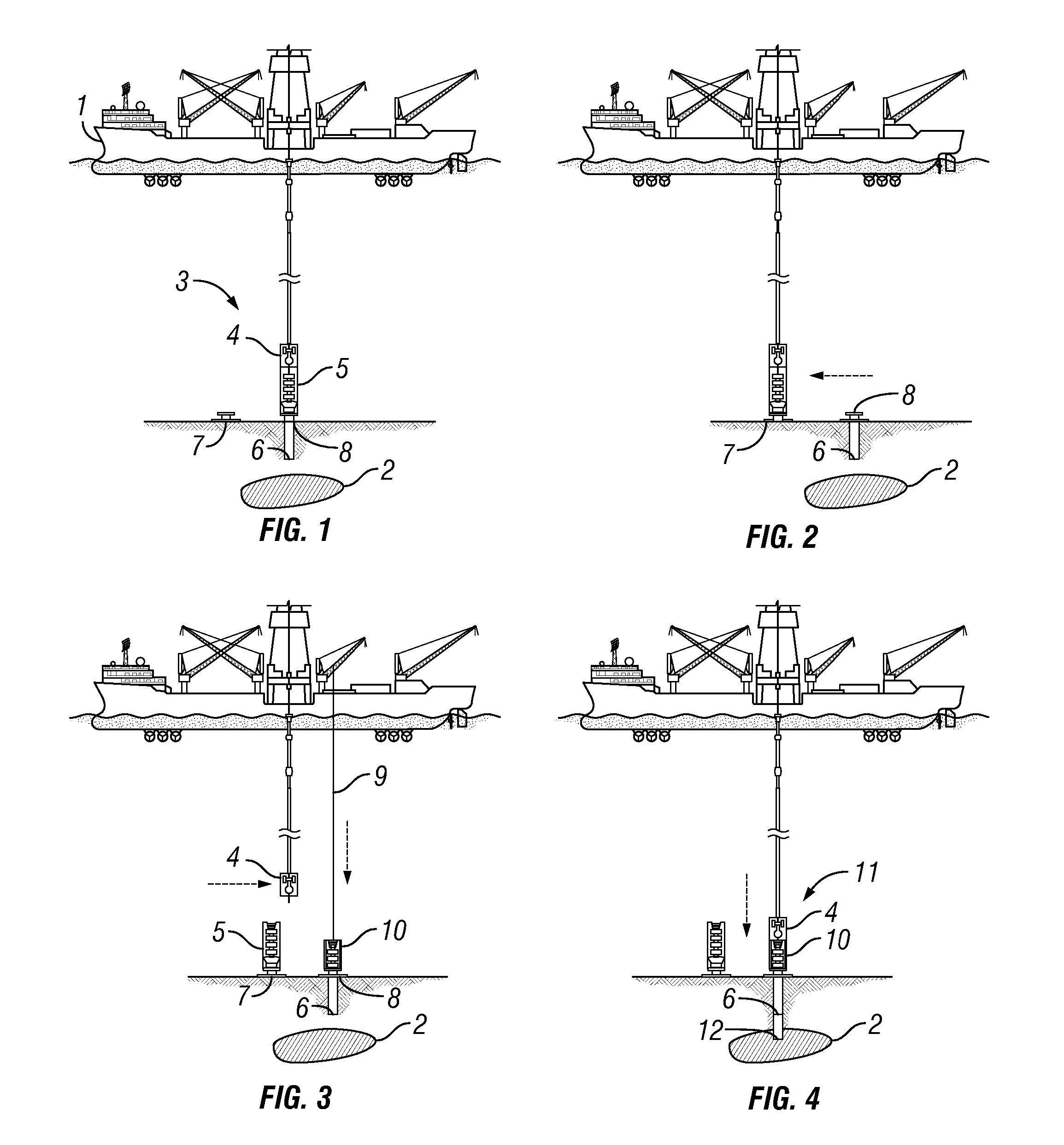

Dual-bop and common riser system

Owner:TRANSOCEAN OFFSHORE DEEPWATER DRILLING

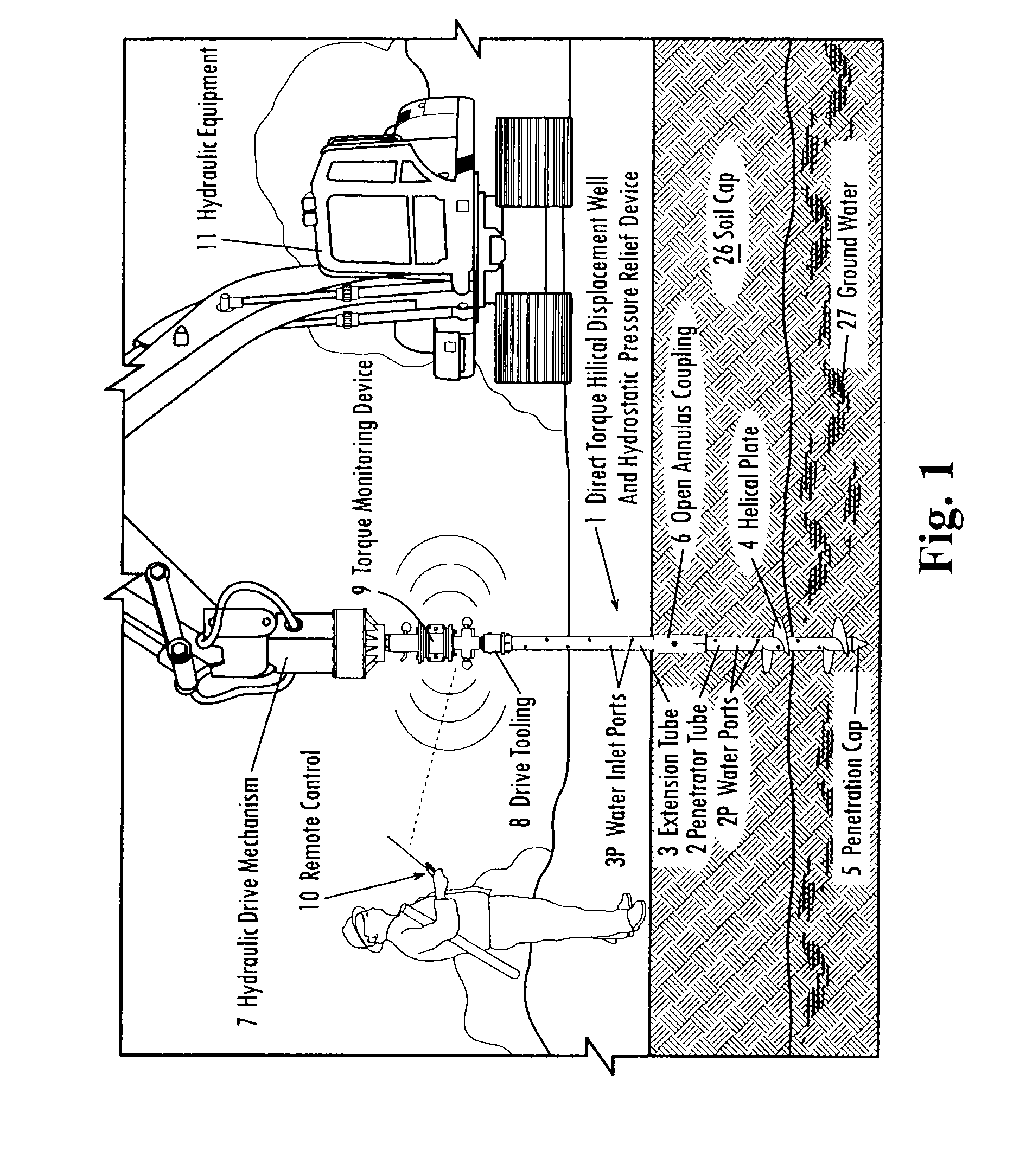

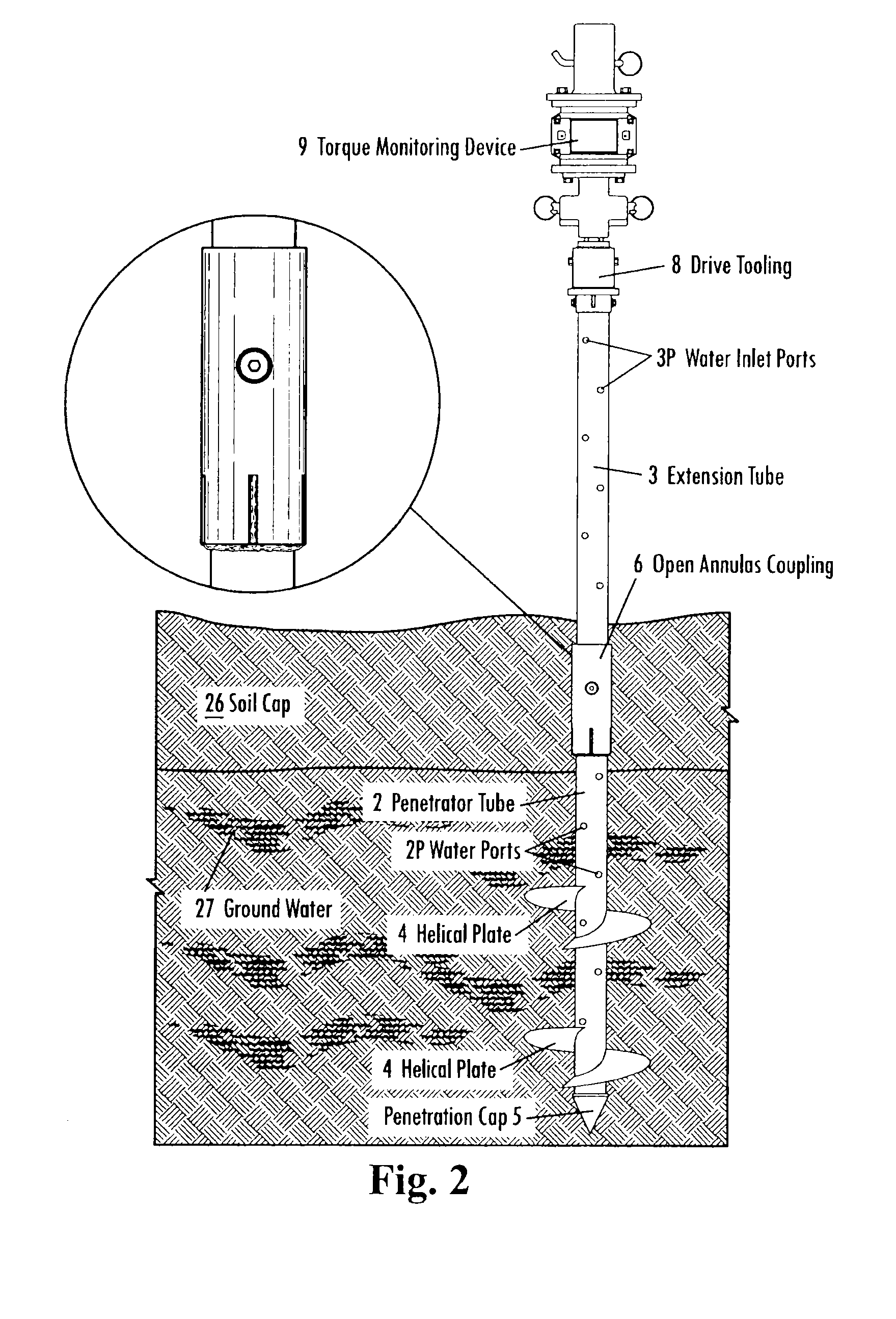

Direct Torque Helical Displacement Well and Hydrostatic Liquid Pressure Relief Device

Owner:QUEEN FRIE A R

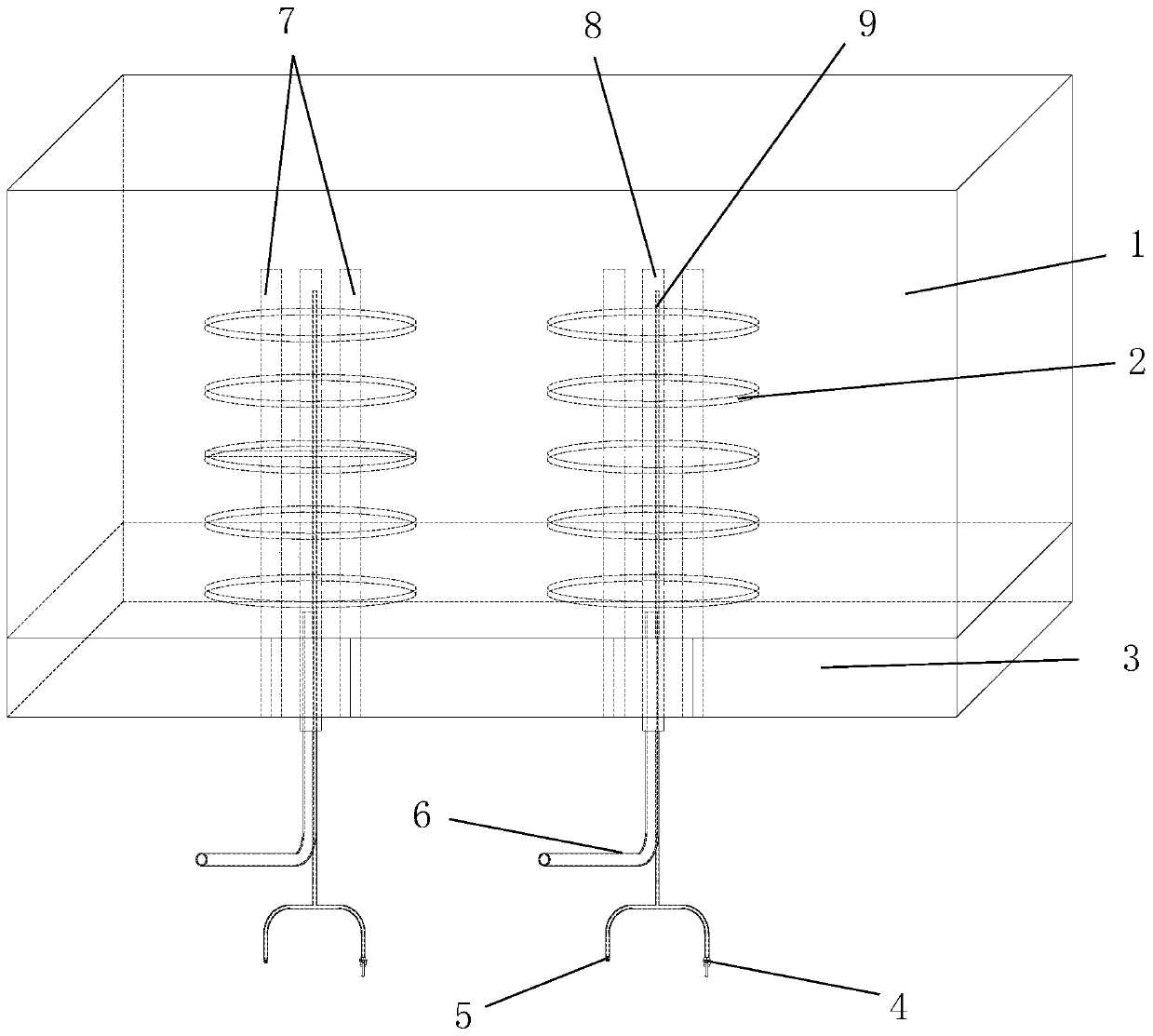

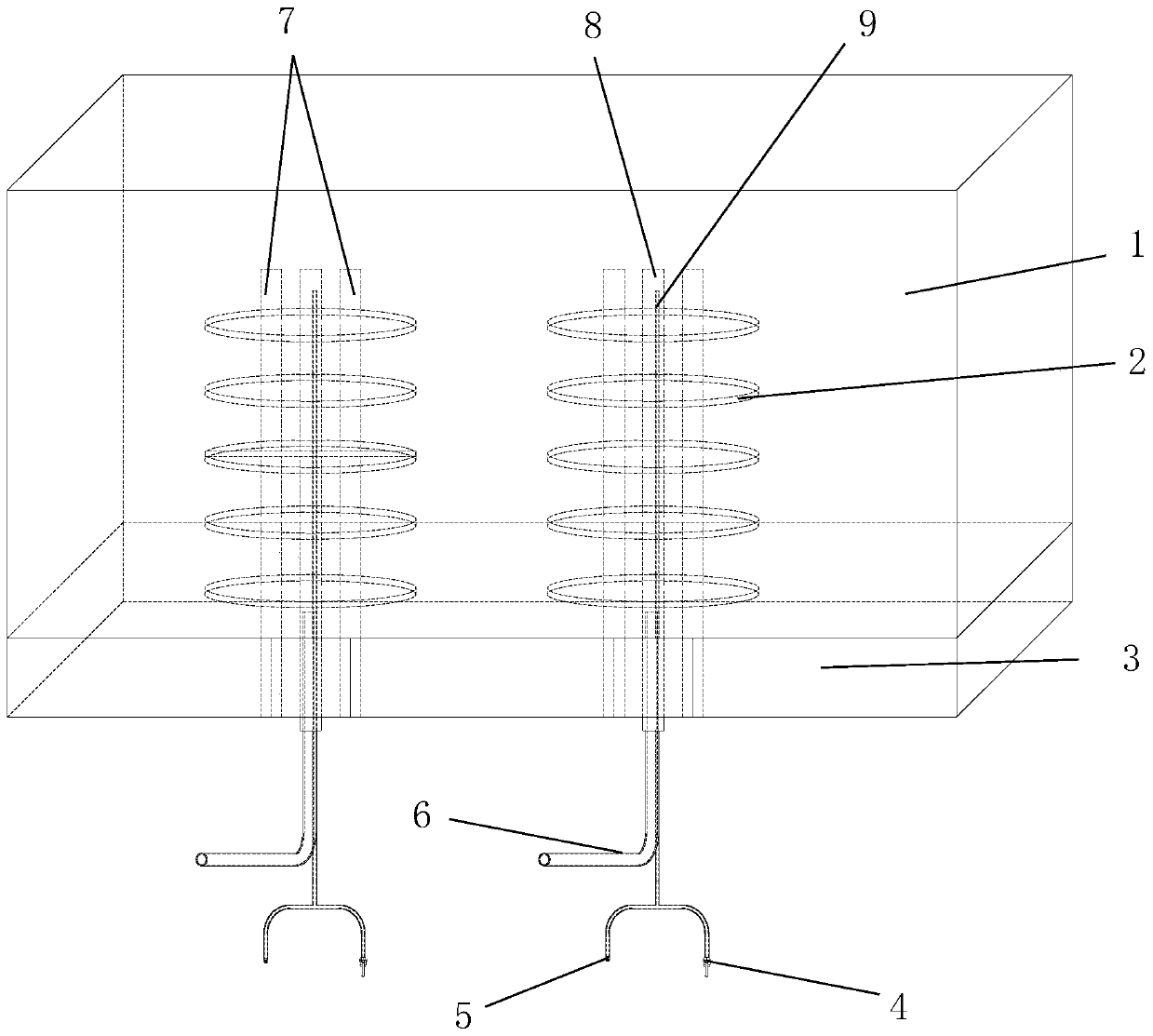

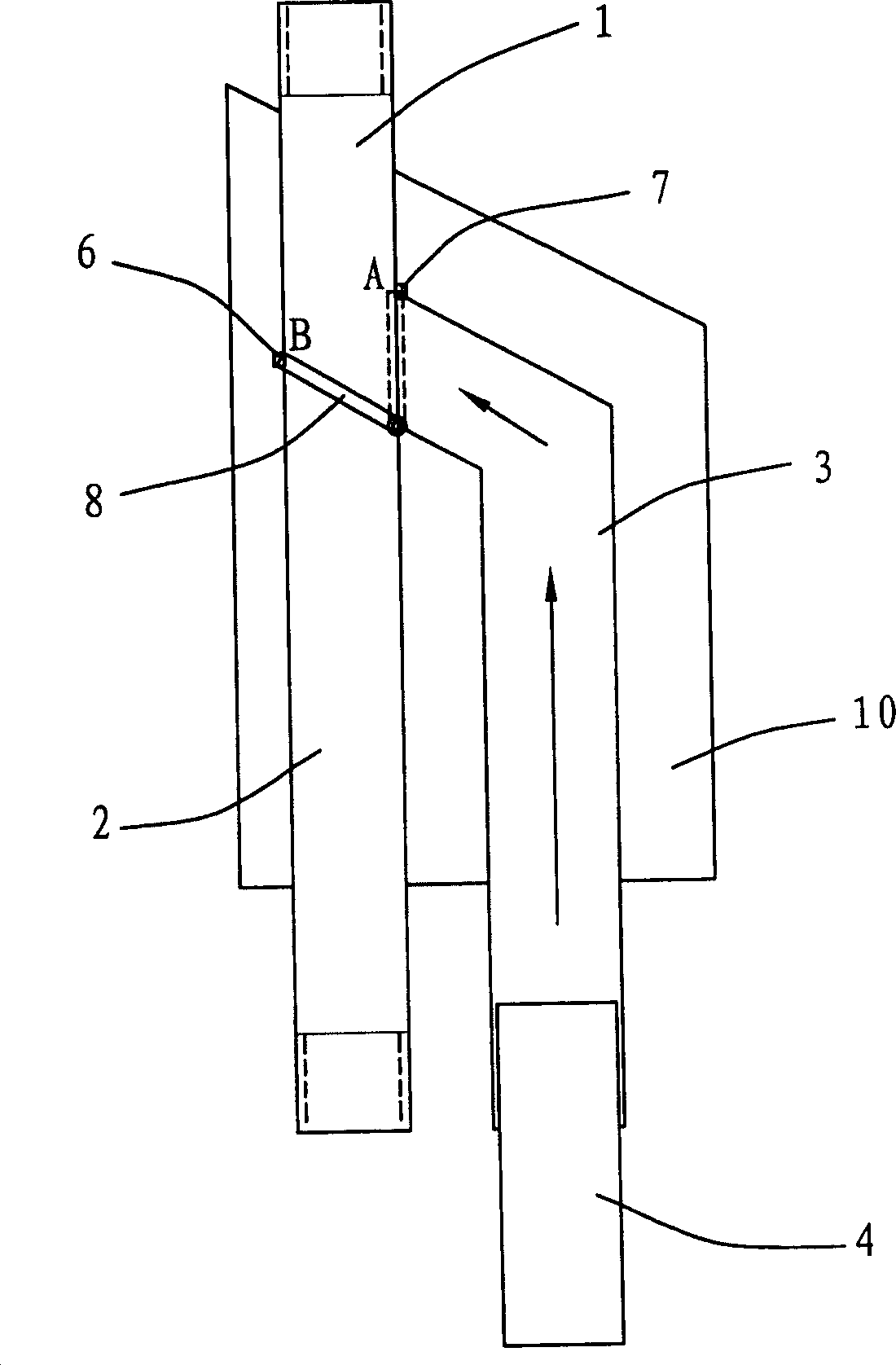

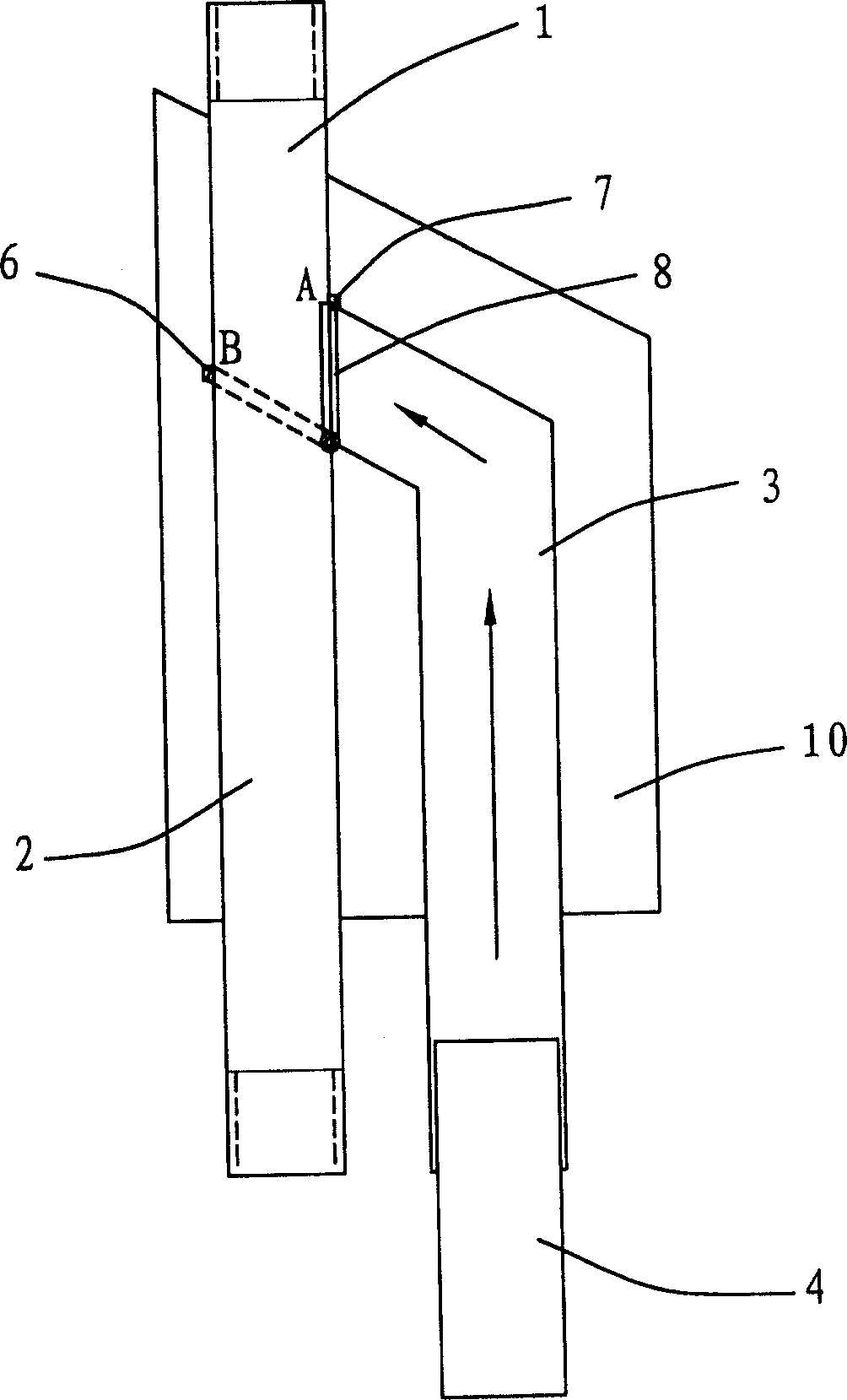

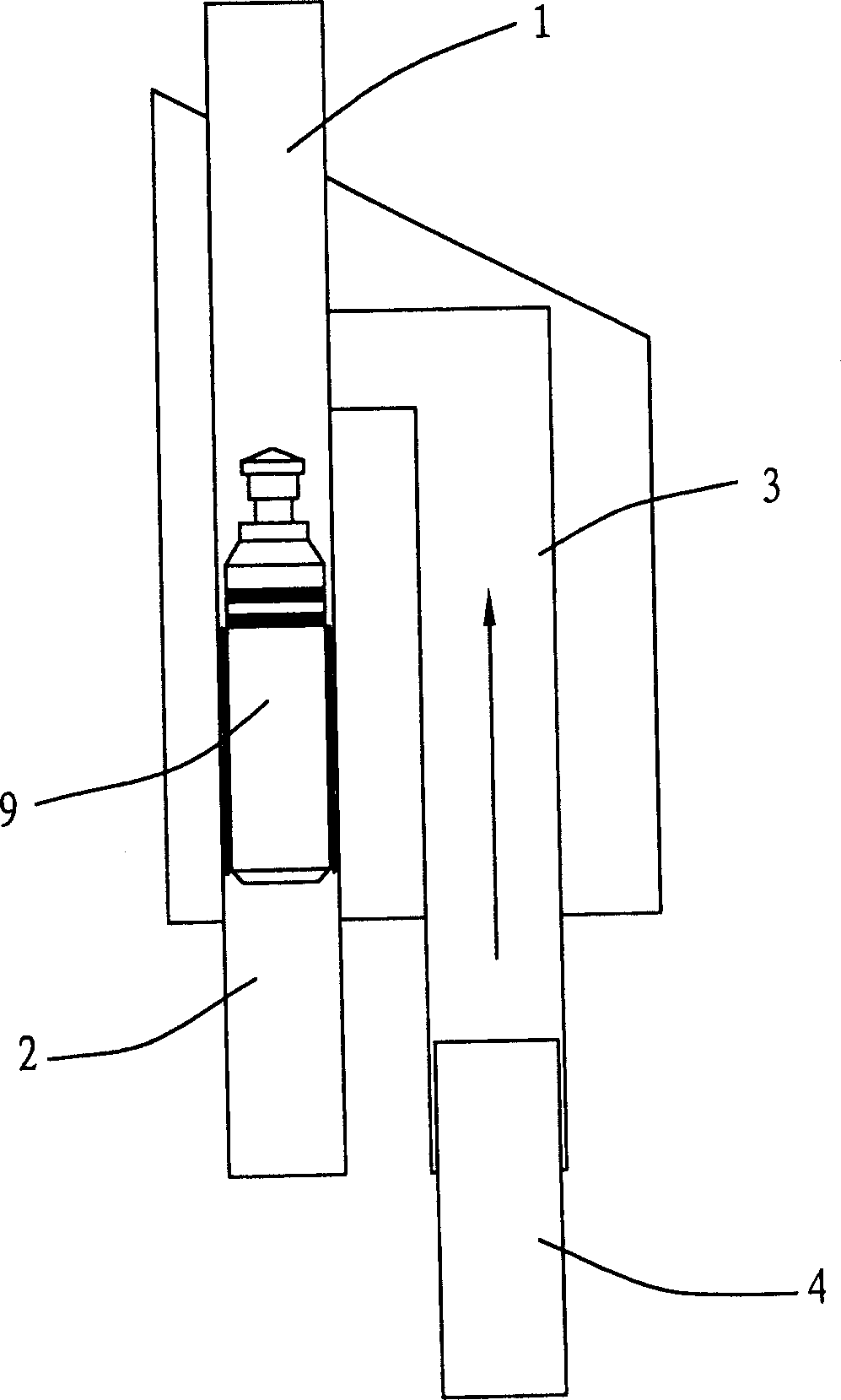

Planetary drill bit assembly for balancing reactive torque of drilling equipment in well drilling

ActiveCN101871328AImprove stabilityIncreased directional control capabilitiesDrilling rodsDirectional drillingWell drillingDrive shaft

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Tubing expansion tool

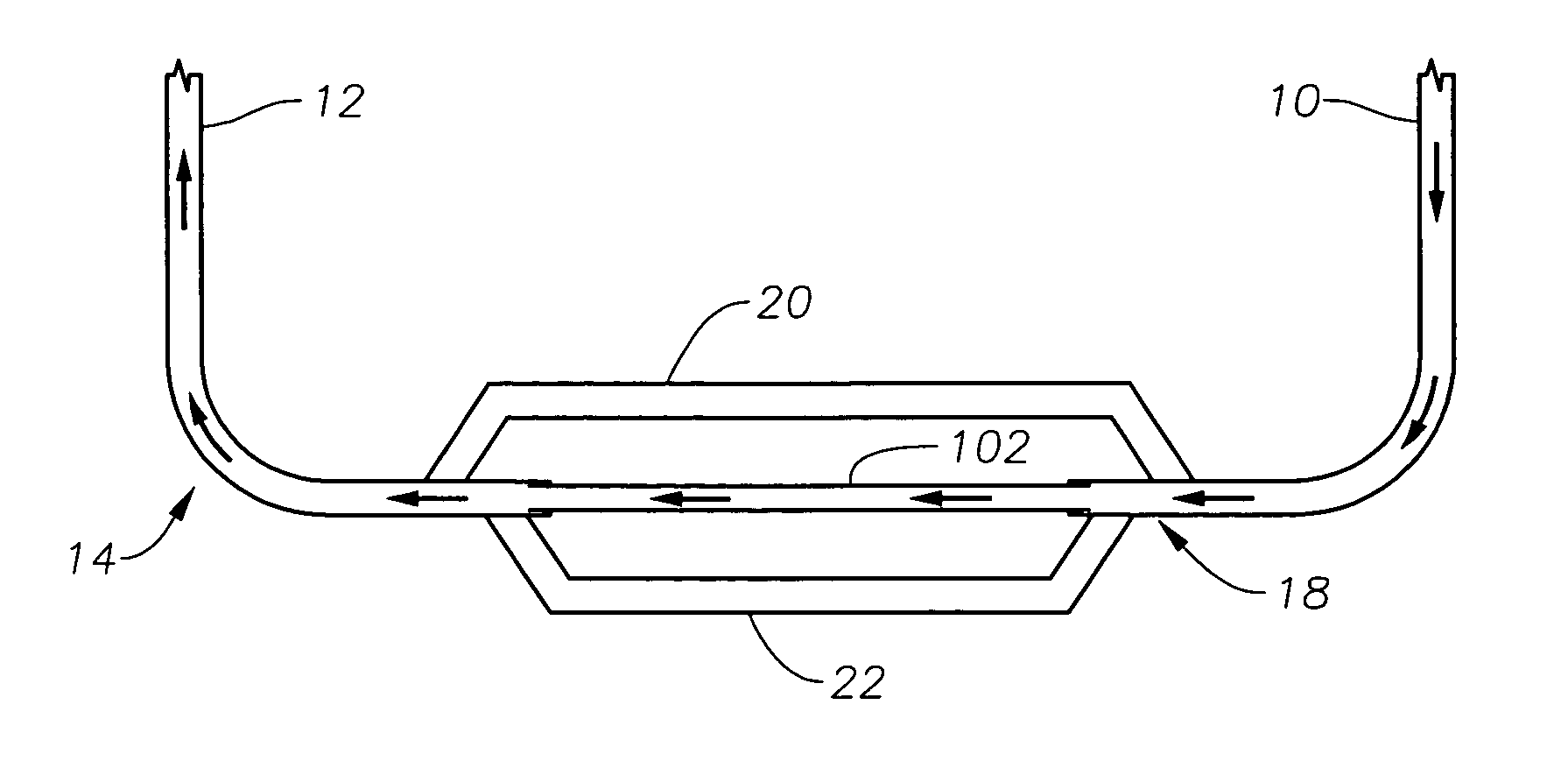

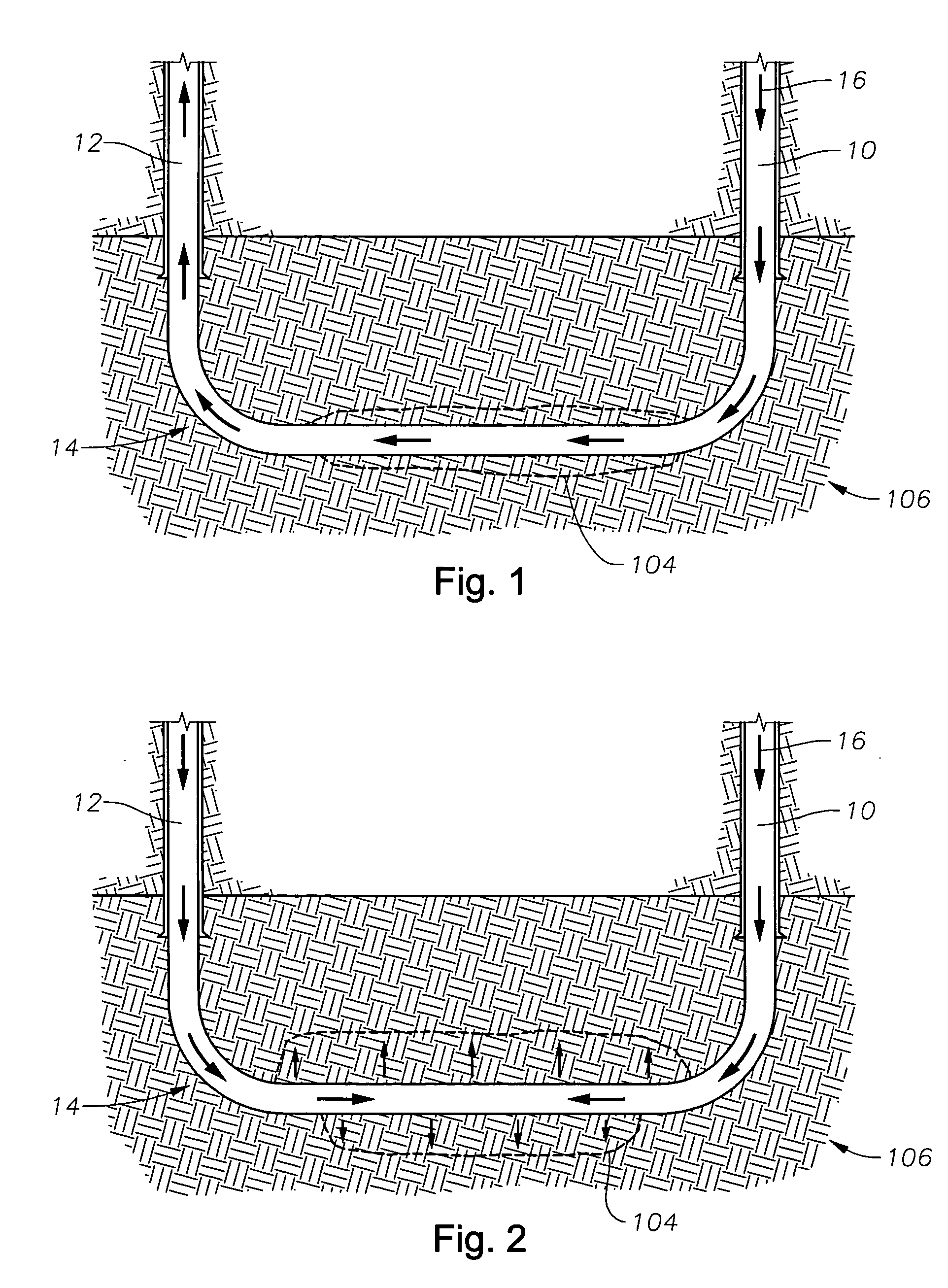

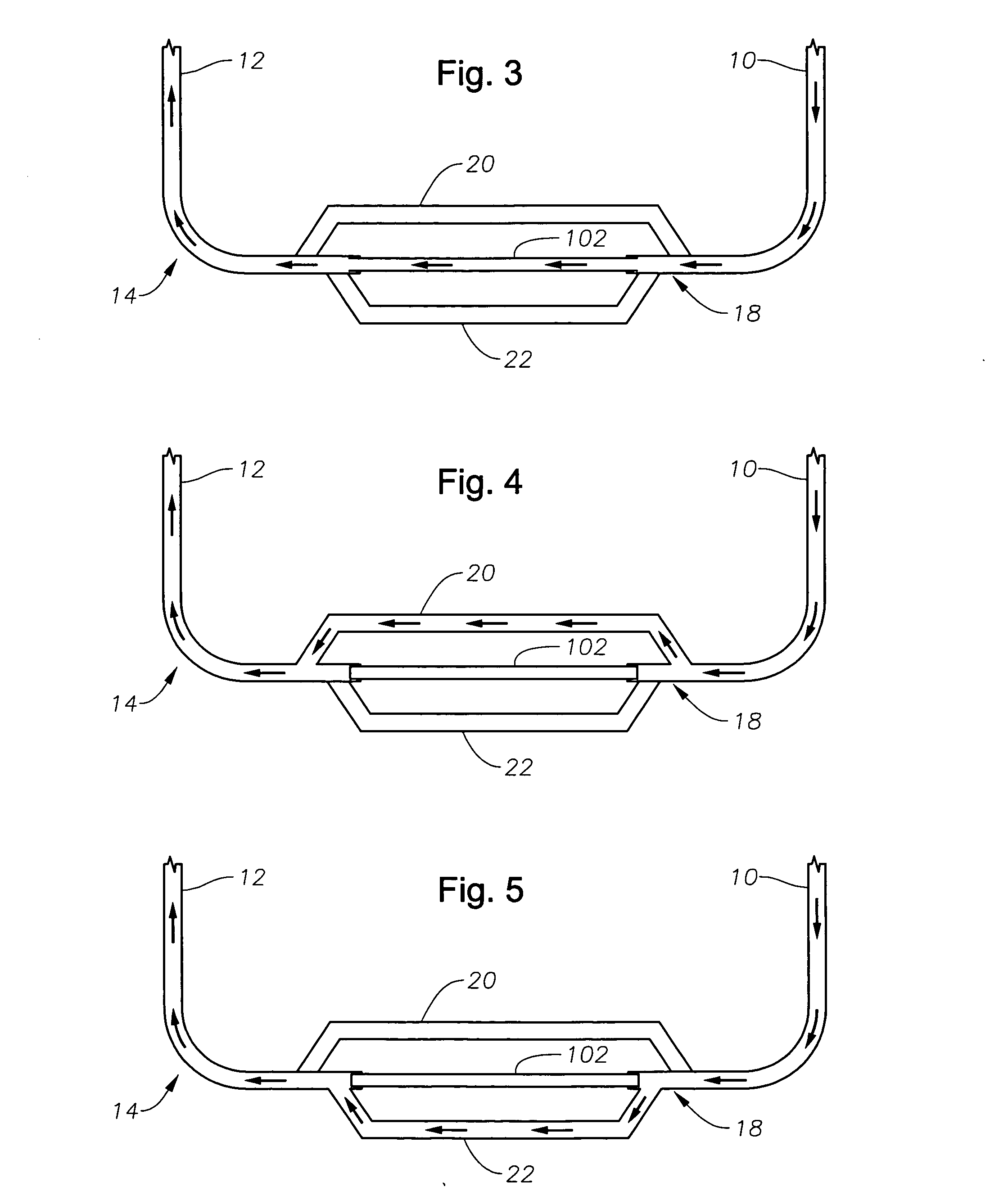

InactiveUS7086477B2Promote recoveryIncrease flexibilityDrilling rodsFluid removalBiomedical engineeringFluid pressure

The invention relates to a tubing expansion tool and to a method of expanding tubing. In one embodiment, a tubing expansion tool (10) is disclosed which comprises a body (14) and at least one expansion member (16) radially movably mounted on the body (14) for movement towards an extended configuration describing an expansion diameter for expanding tubing (12) to a predetermined diameter, the expansion member (16) being lockable in the extended configuration. In further embodiments, the expansion member (16) is biased radially inwardly; the expansion member (16) is moveable in response to both an applied mechanical force and an applied fluid pressure force; and the expansion member (16) is pivotably mounted with respect to the body (14).

Owner:WEATHERFORD TECH HLDG LLC

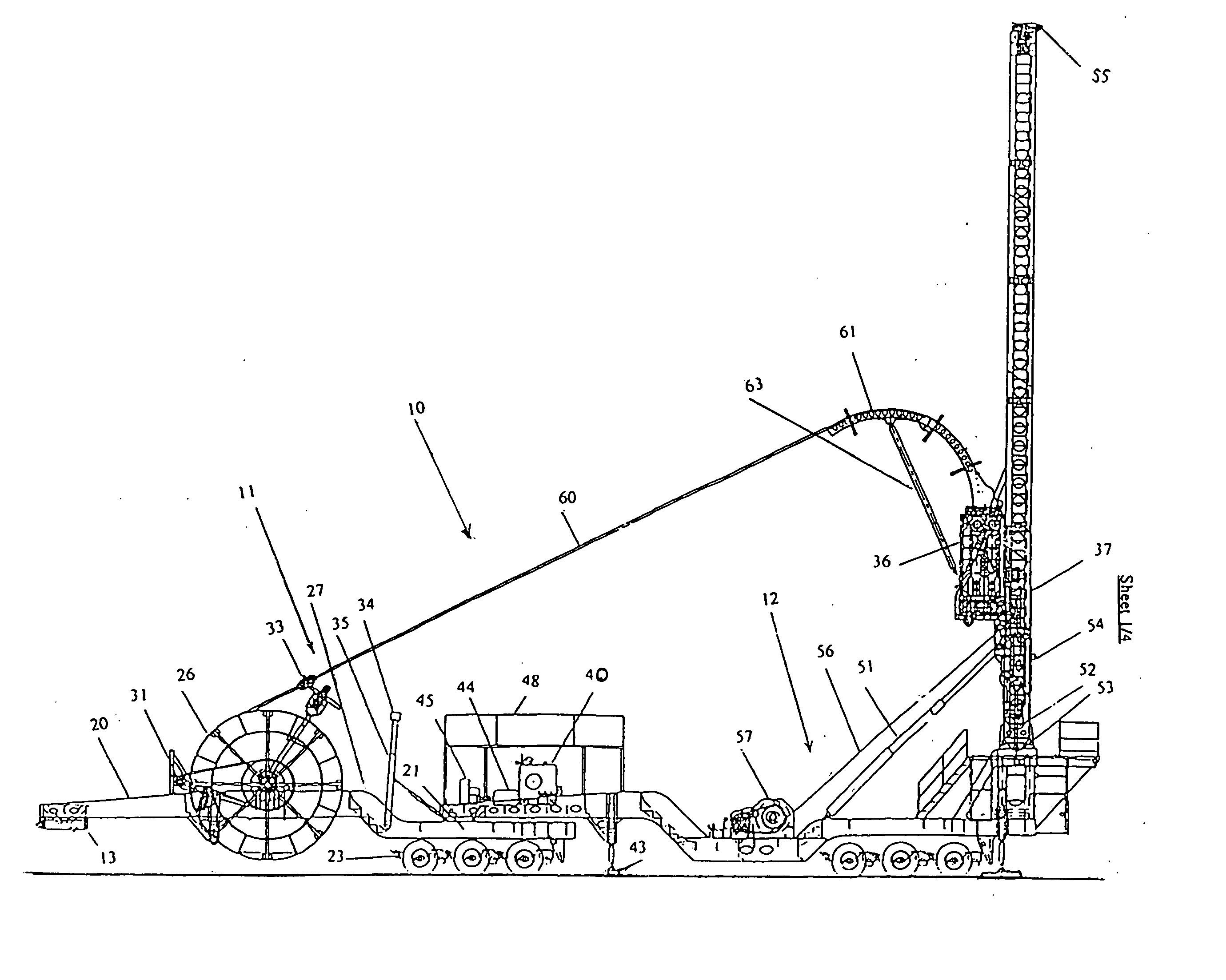

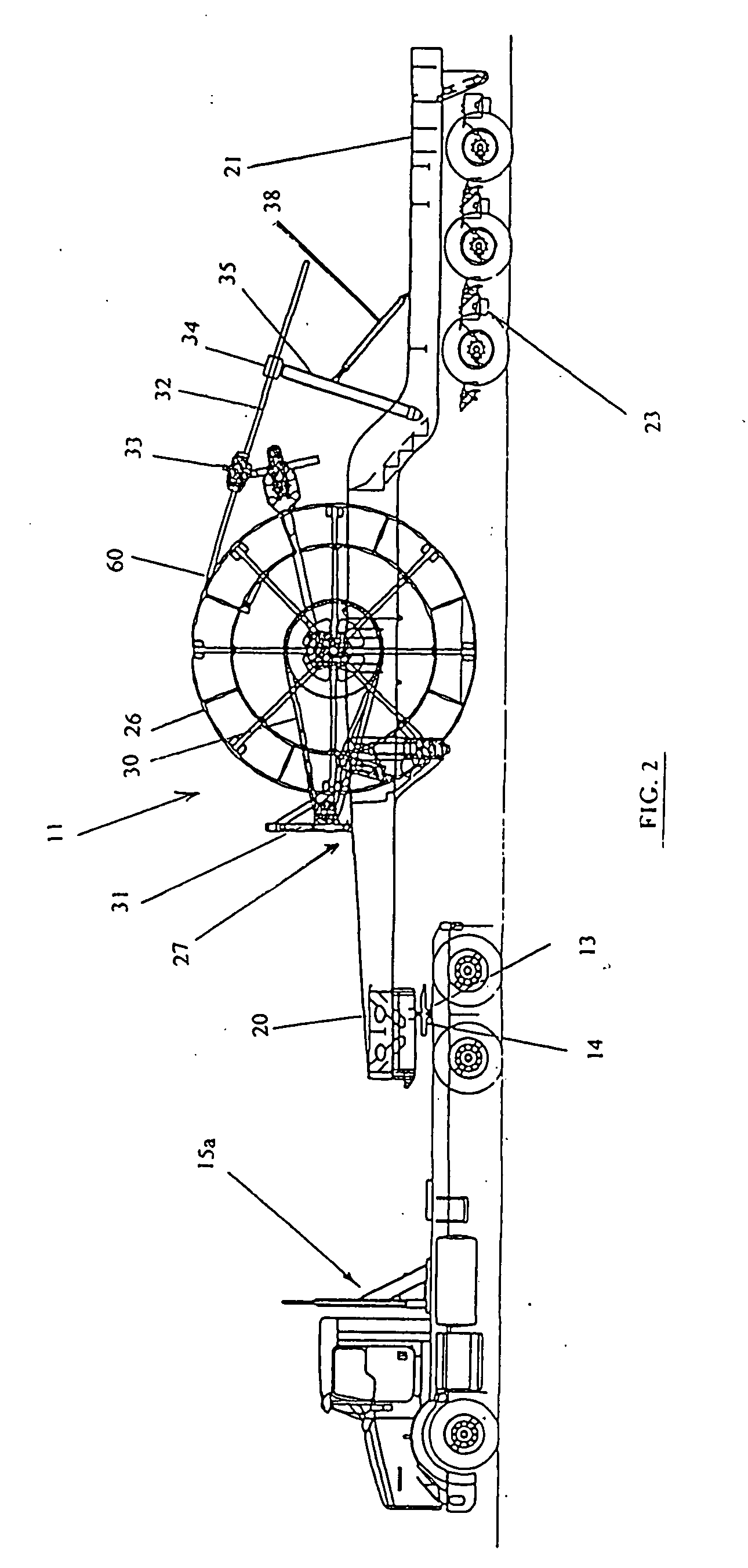

Coiled tubing injector system

Owner:FOREMOST INDS

Method of stimulating long horizontal wells to improve well productivity

Owner:SAUDI ARABIAN OIL CO

Coal seam anti-reflection method for circular damage by using cold shock of liquid nitrogen and phase change gas

ActiveCN111119829AGood cracking and anti-reflection effectFast injectionDrilling rodsFluid removalEngineeringNitrogen gas

Owner:CHINA UNIV OF MINING & TECH

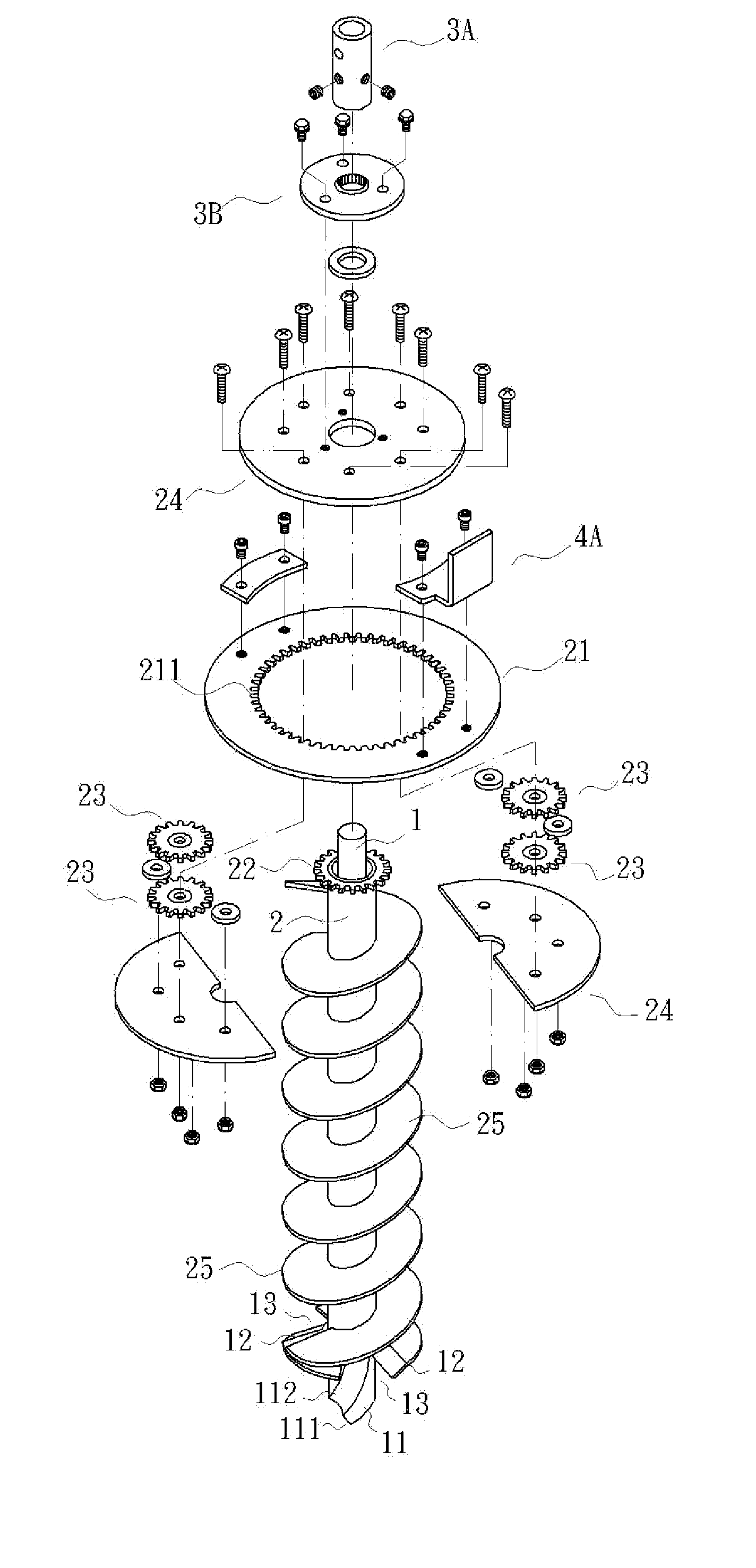

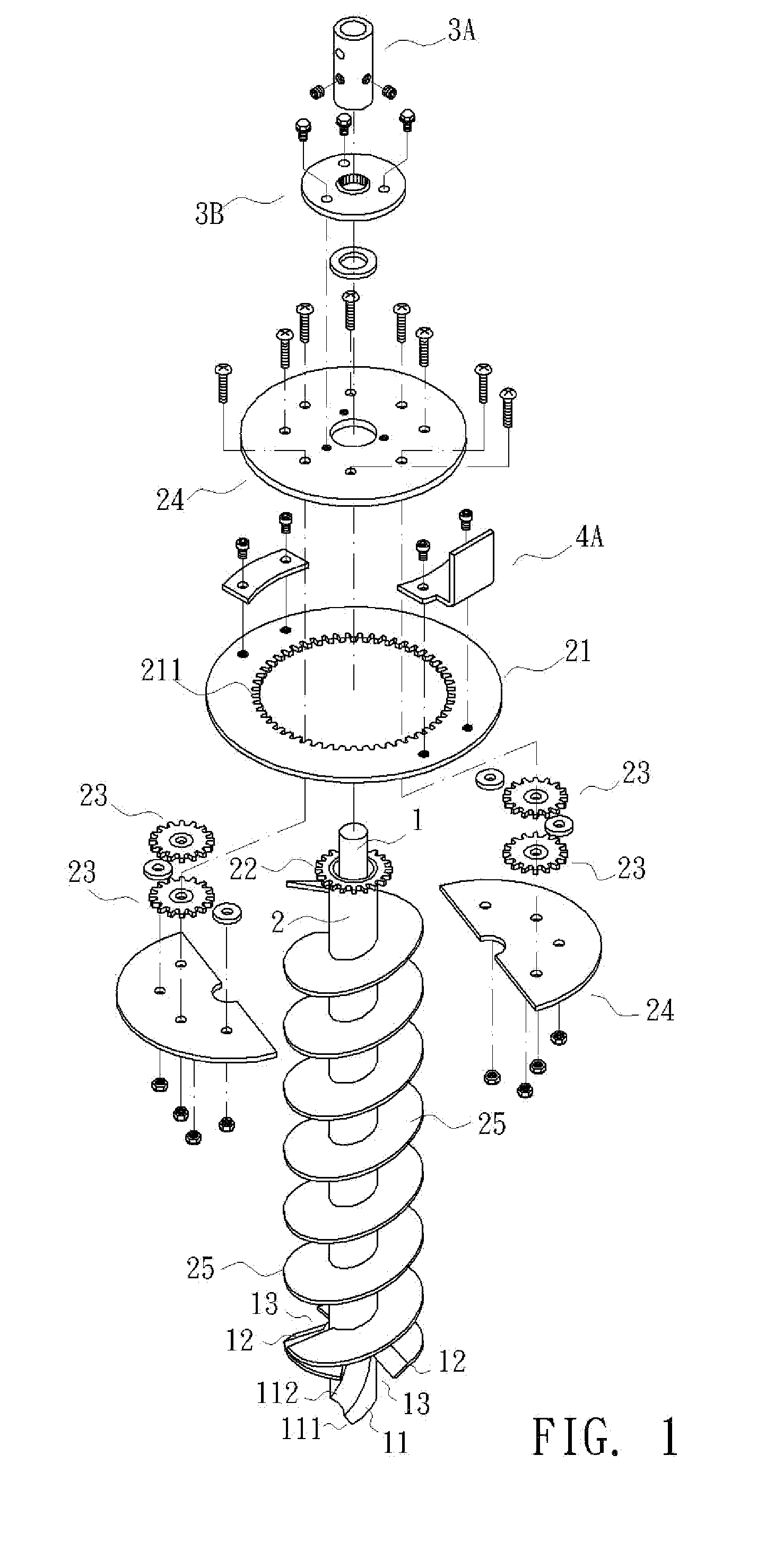

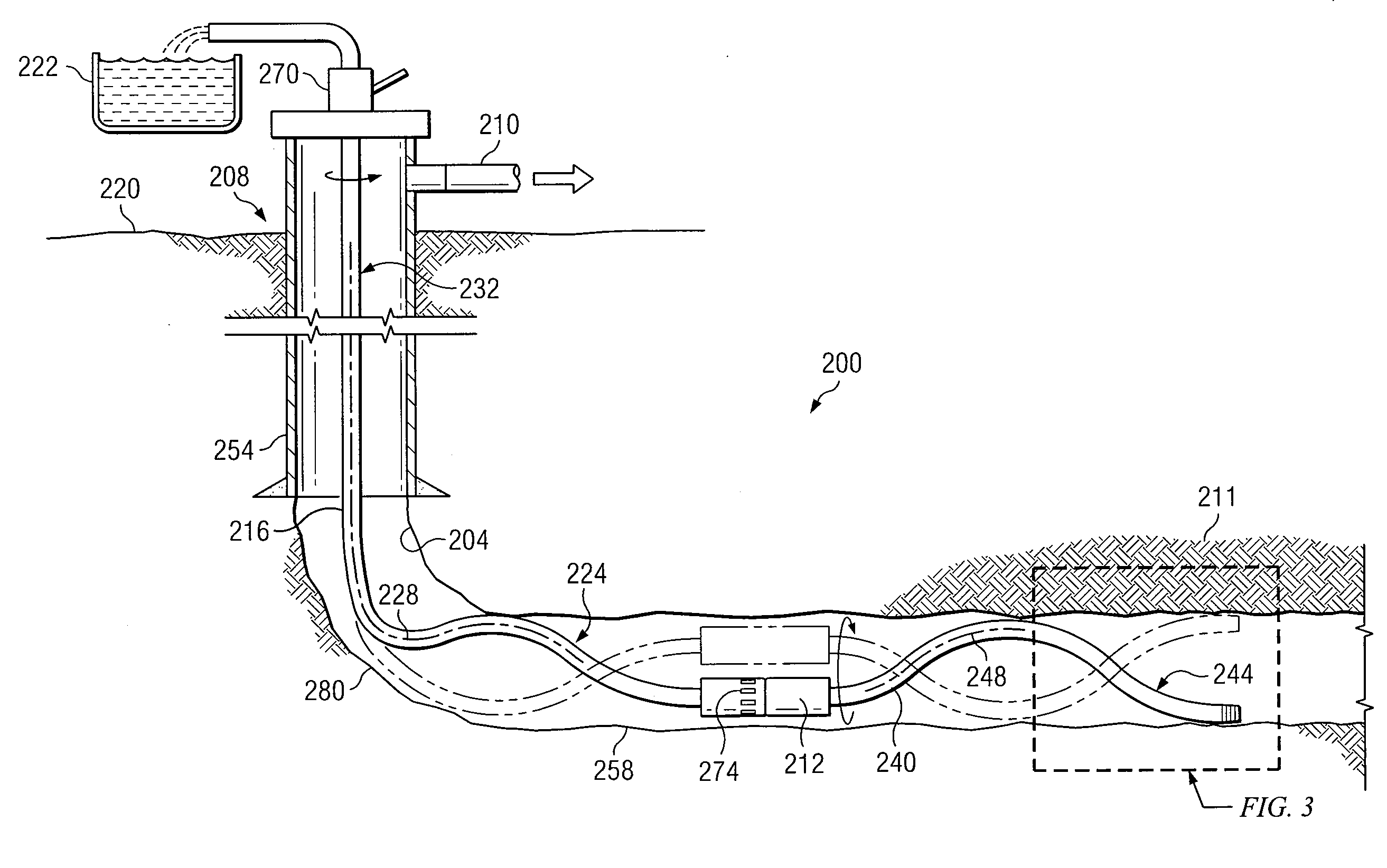

Drilling machine

InactiveUS20090107729A1Different turning speedEarth drilling toolsDrilling rodsEngineeringMechanical engineering

Owner:CHAN YAO PANG

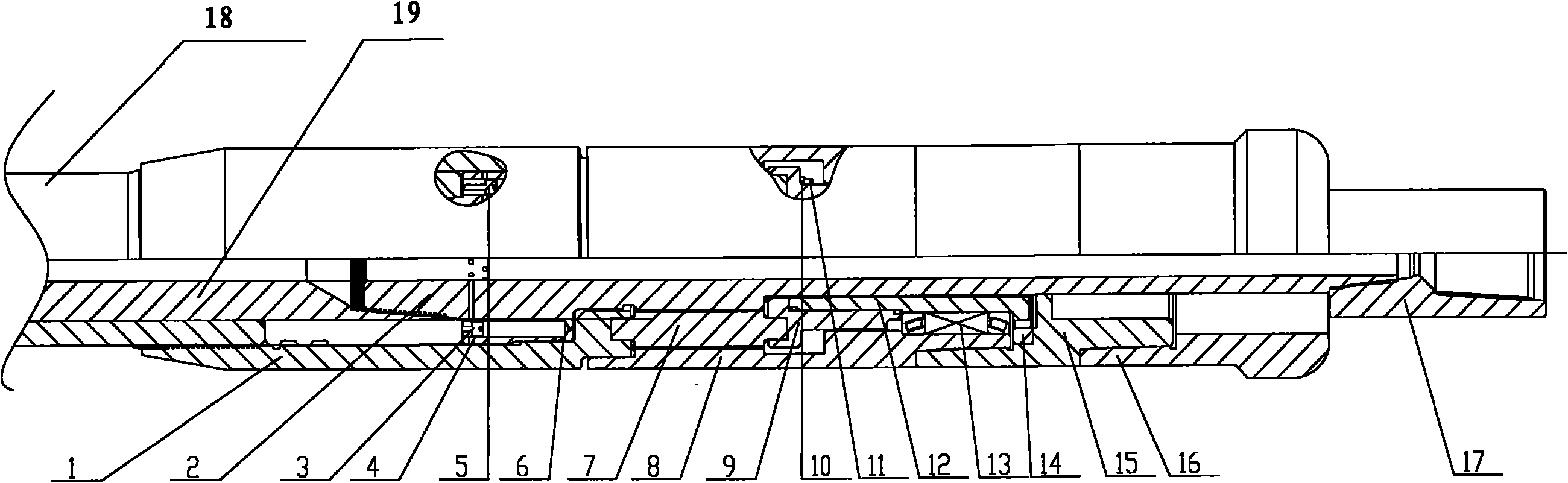

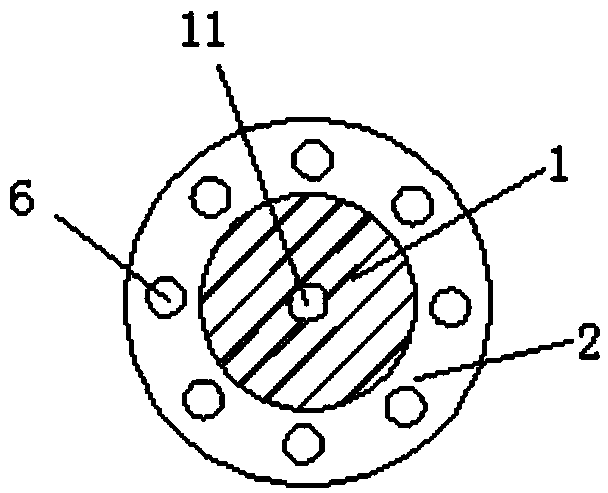

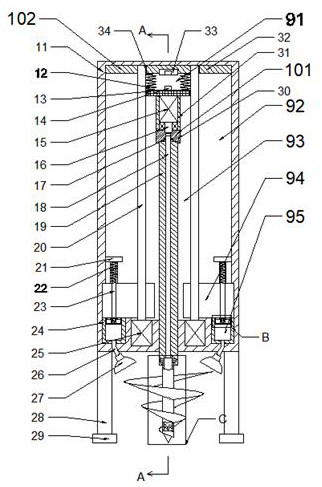

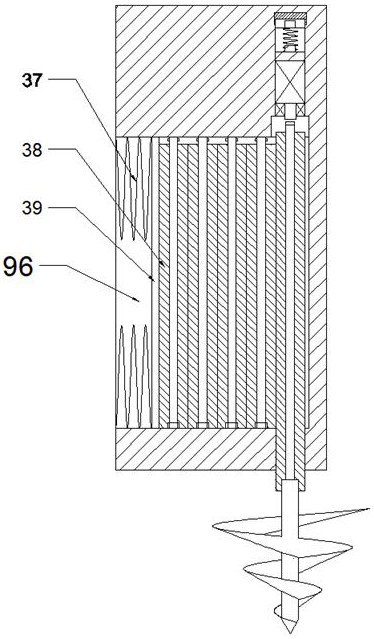

Material delivery pipe mechanism for bottom-mounted power drill rod

The invention belongs to the technical field of building, and relates to a material delivery pipe mechanism for a bottom-mounted power drill rod. The material delivery pipe mechanism comprises a drill rod and a length adjusting rod. A power mechanism is disposed between the drill rod and the length adjusting rod; the power mechanism is in driving connection with the drill rod, and is capable of driving the drill rod to rotate circumferentially. A delivery passage is formed within the drill rod, and a discharge hole is formed in the bottom of the drill rod and is communicated with the delivery passage. A slurry delivery pipe is disposed in the length adjusting rod, and extends into the power mechanism. A slurry delivery connecting pipe is disposed on the outer wall of the power mechanism, and one end of the slurry delivery connecting pipe is detachably connected to the slurry delivery pipe, while the other end of the slurry delivery connecting pipe is detachably connected to the delivery passage. The invention provides a delivery pipe mechanism capable of realizing bottom-mounted power of the drill rod, thereby guaranteeing that material can be delivered to the drill rod when power for the drill rod is mounted at bottom so as to obtain a high-strength cement soil mixing pile; no disturbance is produced for the power structure; and reliable and stable work is achieved.

Owner:ZHEJIANG ZHAODI TECH CO LTD

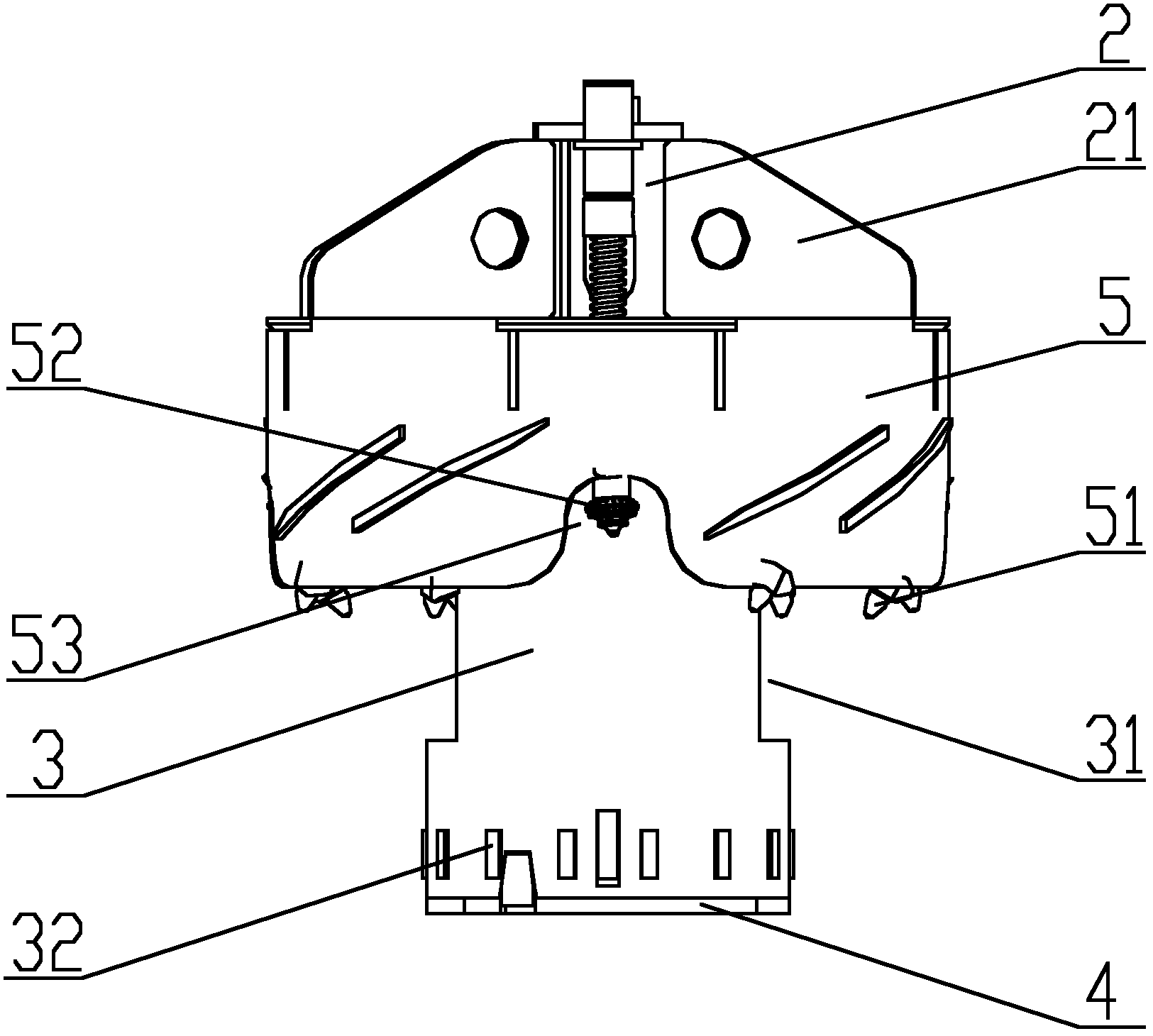

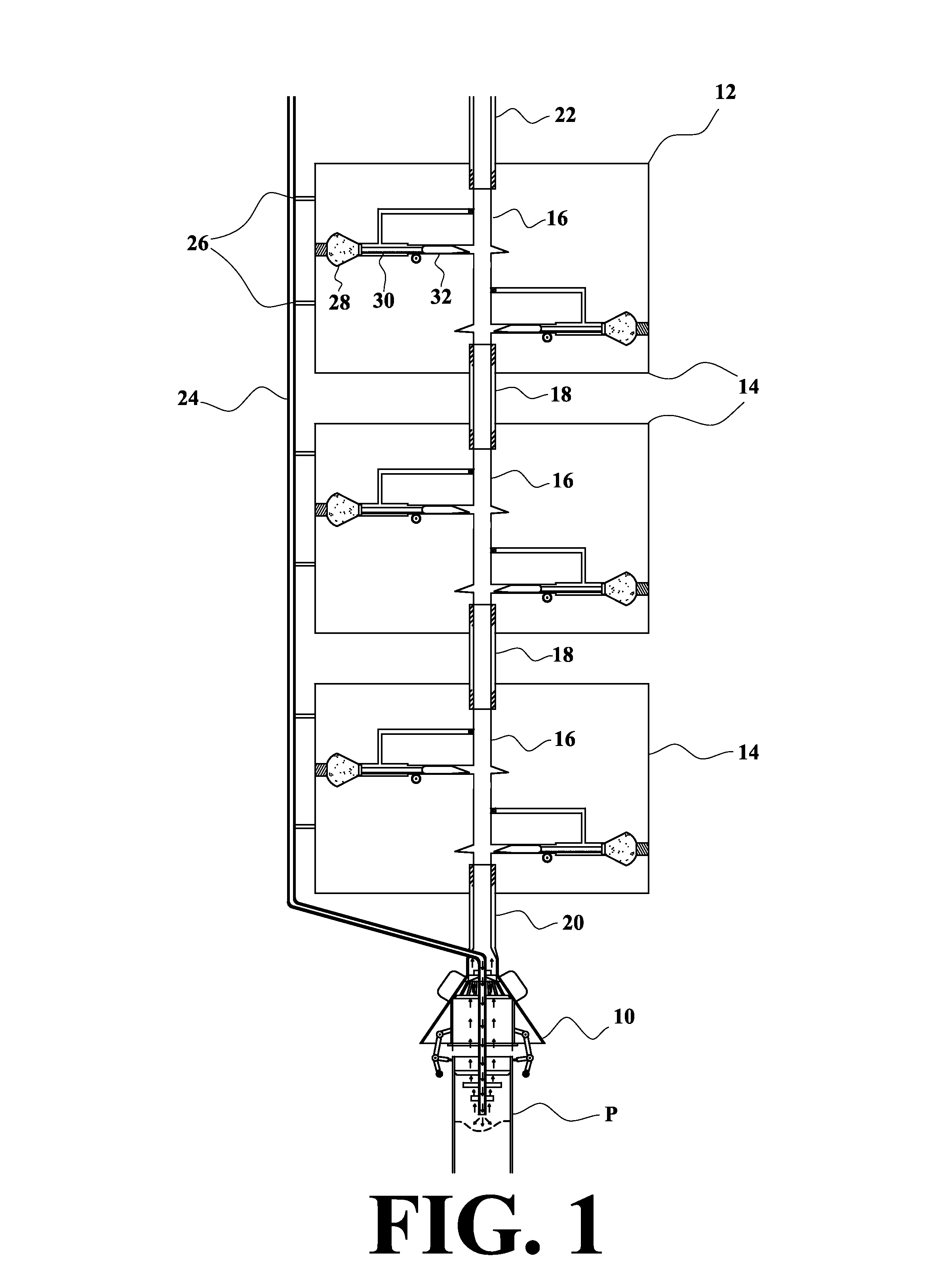

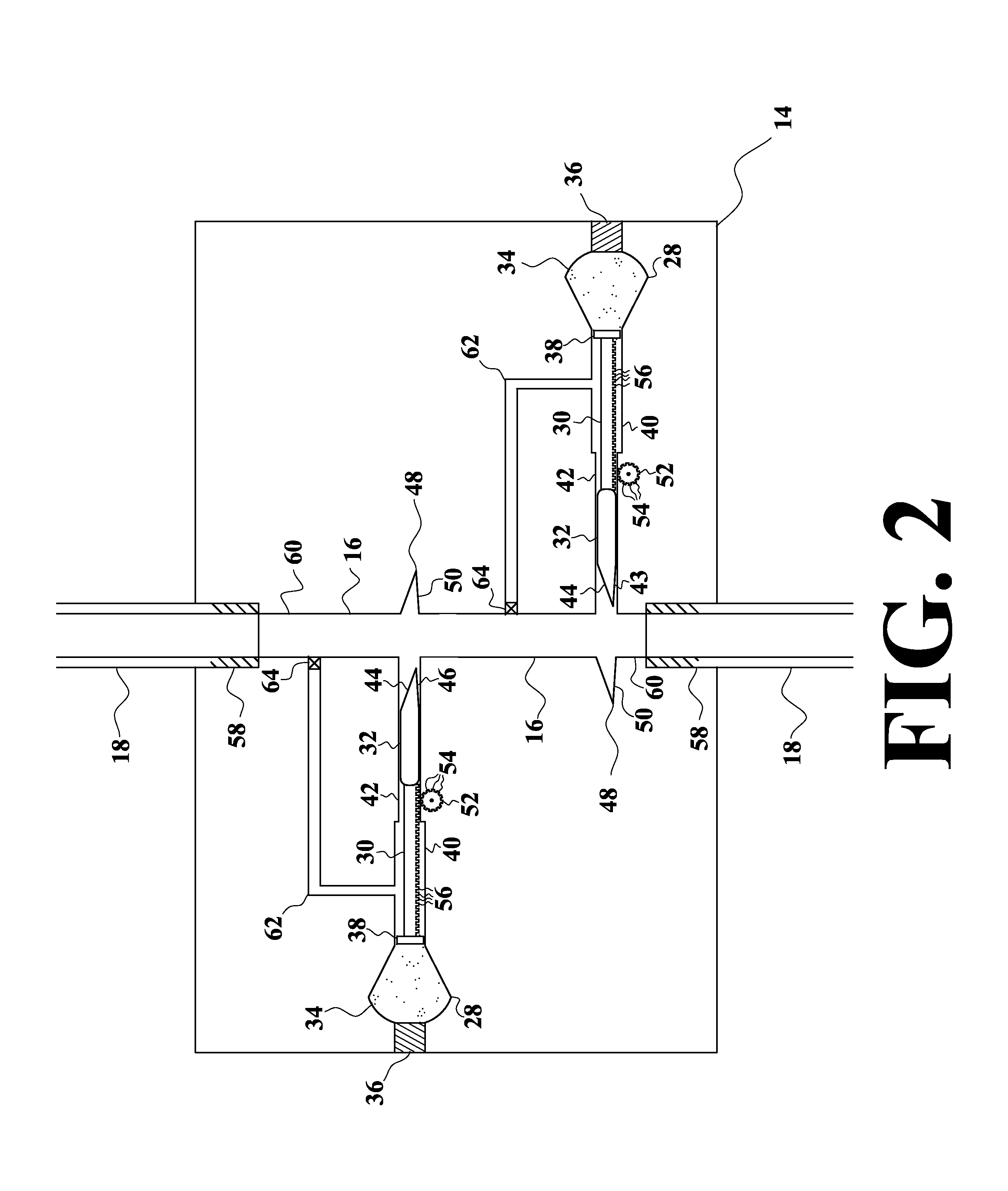

Sucker rod running and pulling device and sucker rod running and pulling system

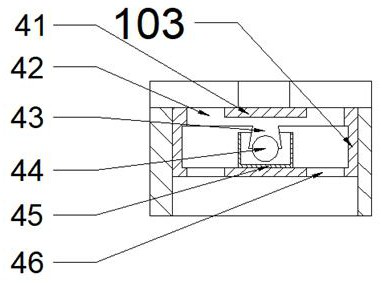

InactiveCN106703718AAvoid manual operationImprove efficiencyDrilling rodsDrilling casingsEngineeringOil drilling

The invention provides a sucker rod running and pulling device and a sucker running and pulling system, and relates to the technical field of oil drilling equipment to solve the problems of low efficiency and high labor intensity of manually operating a lift sub by operating personnel. The sucker rod running and pulling device comprises a lift sub and a slip, the lift sub and the slip both comprise a clamping mechanism and a driving mechanism, and the clamping mechanisms drive the corresponding driving mechanisms to be opened or closed to load or unload a sucker rod. The sucker rod running and pulling device is used for raising the sucker rod, the lift sub and the slip drive the clamping mechanisms through the respective driving mechanisms, and therefore the sucker rod is clamped or released. In the sucker rod raising operation, the sucker rod running and pulling device has the advantages that manual operation is avoided, efficiency is improved, and labor intensity is reduced.

Owner:HUNAN SANY PETROLEUM TECH

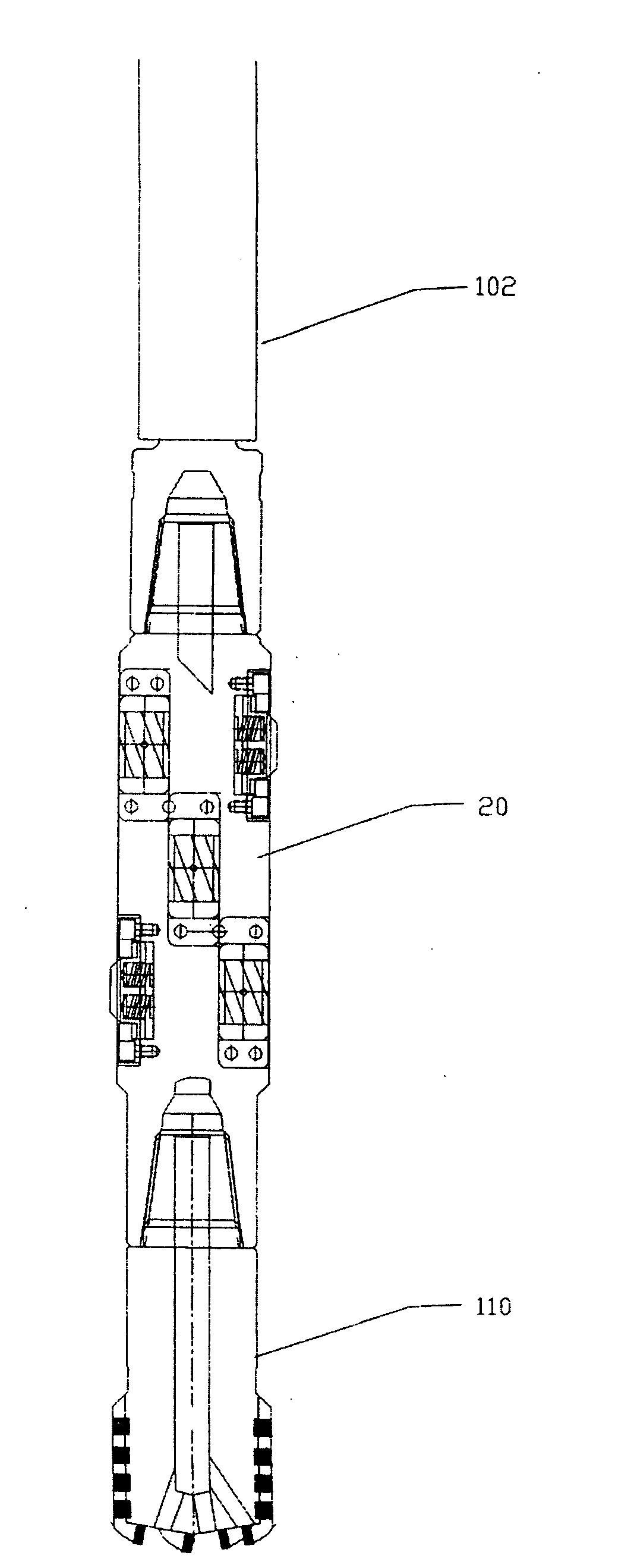

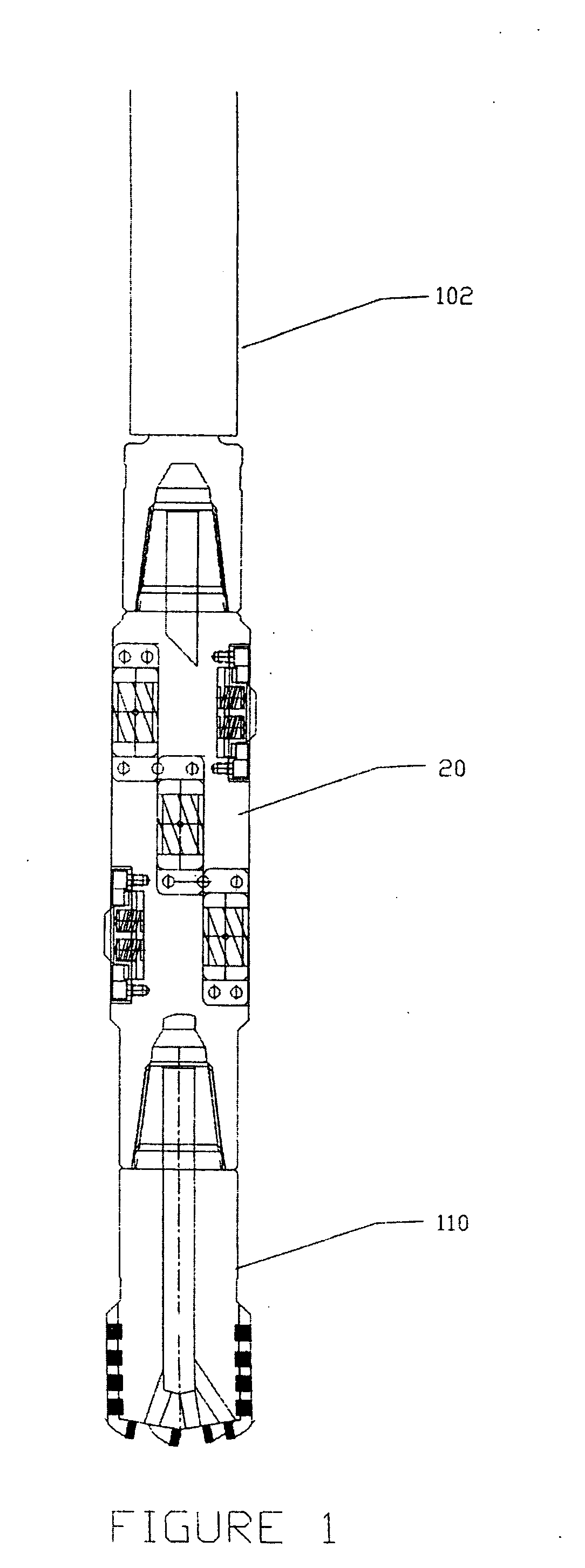

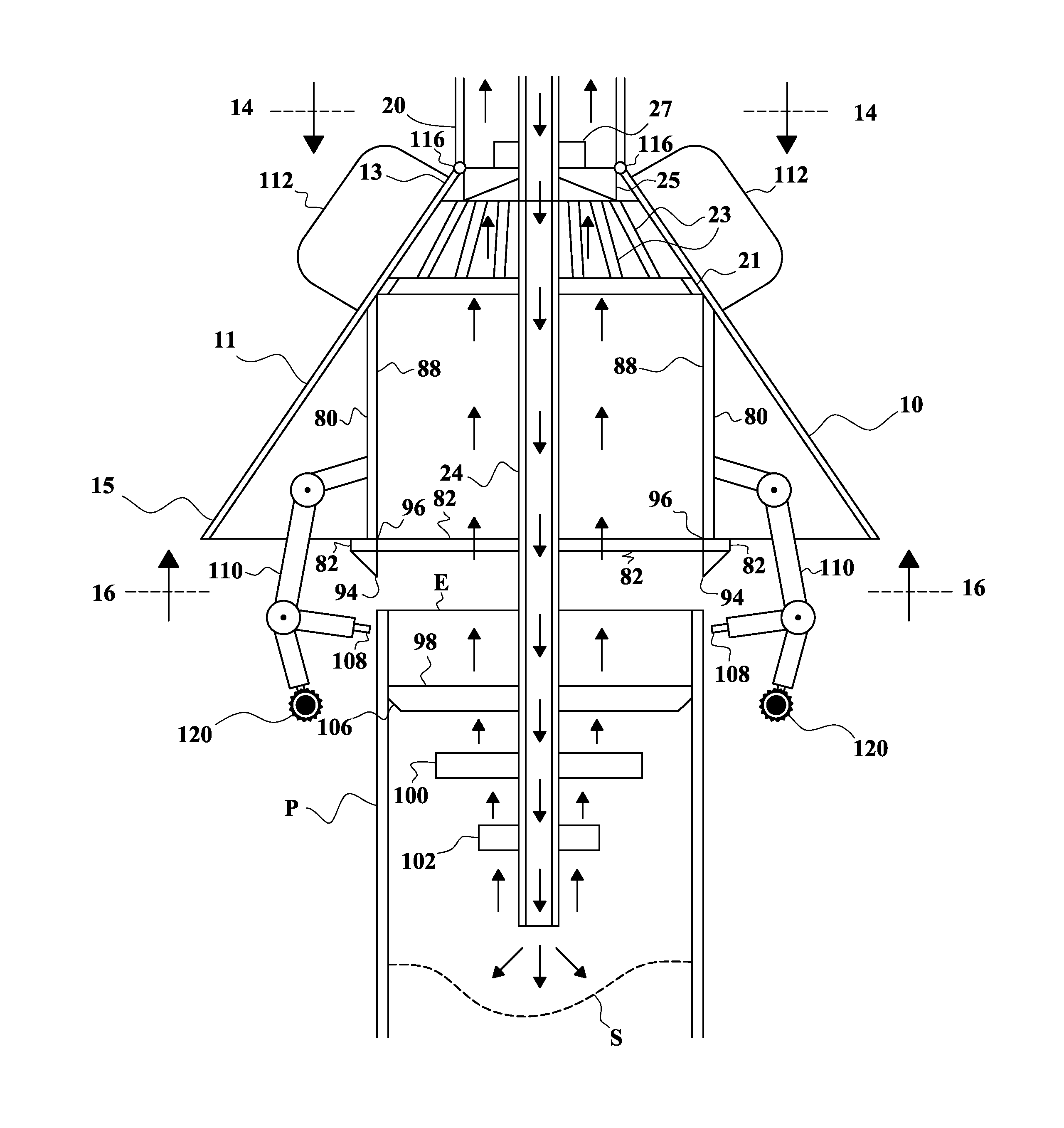

Adjustable Bent Drilling Tool Having in situ Drilling Direction Change Capability

An adjustable bent drilling tool capable of changing in situ drilling direction to facilitate horizontal drilling. The drilling tool may be controlled from the surface and eliminates the need to bring the tool to the surface for reconfiguration. In one embodiment, the drilling tool utilizes a communications module to communicate with upstream sections of the tool. The communications module is connected to a programmable electronic control module which controls an electric motor. A hydraulic valve assembly follows the control module, which receives input signals and controls a pilot piston between two fixed points of a mid-assembly typically located adjacent to and downstream of the hydraulic valve assembly on the drill tool. A lower assembly is attached to the drill tool immediately following the mid-assembly, and provides both a safety release sub-assembly as well as a bendable sub-assembly which directs the adjustable drill tool to change drilling angle and direction.

Owner:DAVID L ABNEY

System and method for controlling solids in a down-hole fluid pumping system

InactiveUS20090090511A1Reduce congestionEarth drilling toolsPositive displacement pump componentsEngineeringMechanical engineering

Owner:PINE TREE GAS

Construction method and system for hole cleaning and sediment thickness reducing of inclined steel pipe pile

ActiveCN107816324AEffectively and completely removesImprove flatnessDrilling rodsFlushingStructural conditionEngineering

The invention discloses a construction method and system for hole cleaning and sediment thickness reducing of an inclined steel pipe pile, and relate to the field of pile foundation construction. Themethod includes the following steps of S1, drilling holes through a reverse circulation drilling machine, and starting a gas lifting reverse circulation system to conduct sediment cleaning; S2, conducting sampling in a sediment discharge pipe after clean water flows out of the sediment discharge pipe, meanwhile the sand content of discharge, and stopping the gas lift reverse circulation system when the sand content is measured to be lower than 0.5%; S3, adding an alum or polyacrylamide solution into the inclined steel pipe pile, and starting the reverse circulation drilling machine to make theadded alum or polyacrylamide solution circulate and flow; S4, standing for 2-4 fours, and then starting the gas lift reverse circulation system for thoroughly removing sediments. By means of the method, the influences of hole drilling by means of turbid river water under silty-fine sand and intermediate-fine sand stratum structural conditions can be overcome, the good flatness of a soil insertingsurface is guaranteed, and the pile end bearing capacity is effectively improved.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

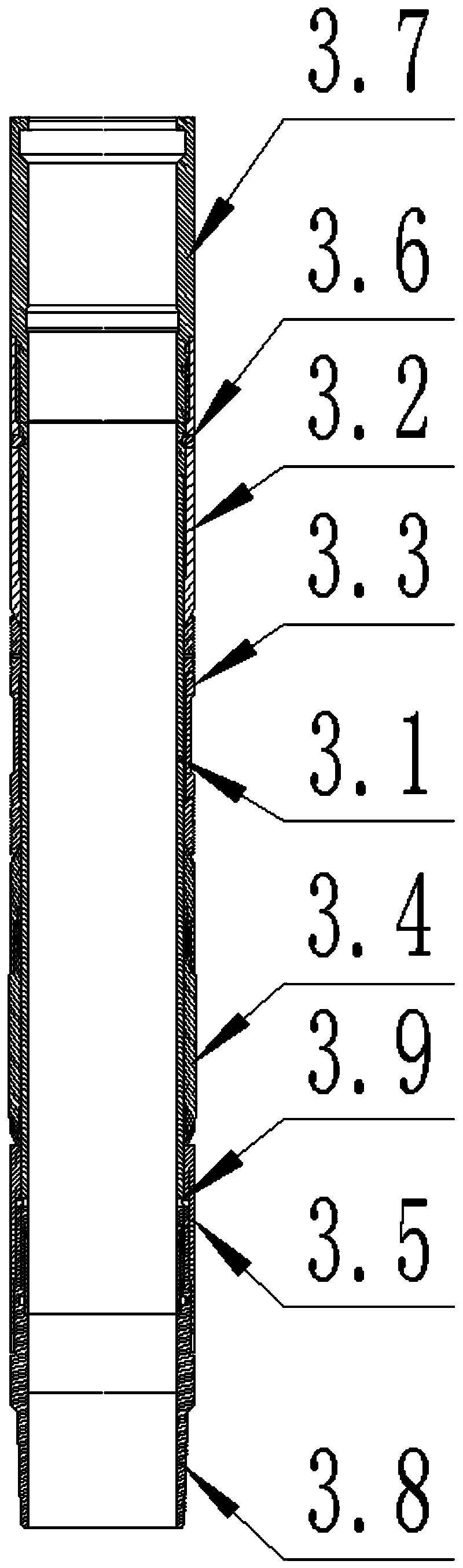

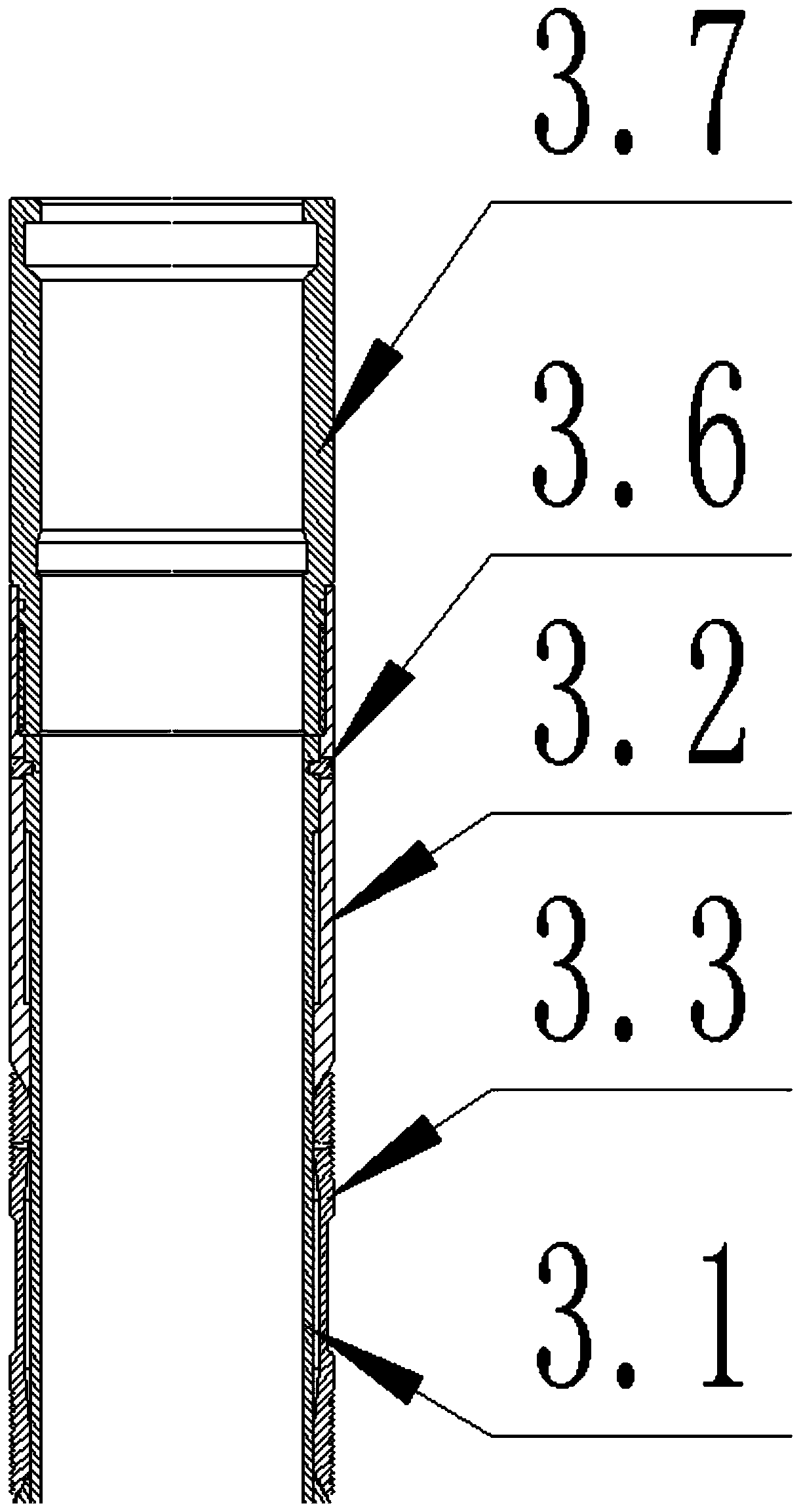

Core sectional rod and rotary drilling rig drilling rod including same

ActiveCN104612597AChange the force structureLow failure rateDrilling rodsDrilling casingsFailure ratePetroleum engineering

The invention provides a core section rod. The core section rod comprises a core section rod pipe body and a drilling tool connector arranged under the core section rod pipe body, wherein the drilling tool connector comprises a rectangular head portion, a connection portion and a boss portion located between the rectangular head portion and the connection portion; the boss portion is clamped between a bearing plate and a spring stop; the spring stop is connected with the core section rod pipe body and connected with the bearing plate through multiple driving keys. According to the core sectional rod, the connection mode of welding the drilling tool connector to the core section rod pipe body directly is changed, and the forced structure of the drilling tool connector is changed through the clamping of the boss portion of the drilling tool connector between the spring stop and the bearing plate. Accordingly, the forced pressure can reach the bearing plate position of the drilling tool connector without passing the wear area of the drilling tool connector and torque is also divided into two directions, so that the failure rate of a drilling rod is reduced and the service life of the drilling rod is prolonged. Moreover, a rotary drilling rig drilling rod with the core sectional rod is also provided.

Owner:SHANGHAI ZOOMLION HEAVY IND PILING MACHINERYCO +1

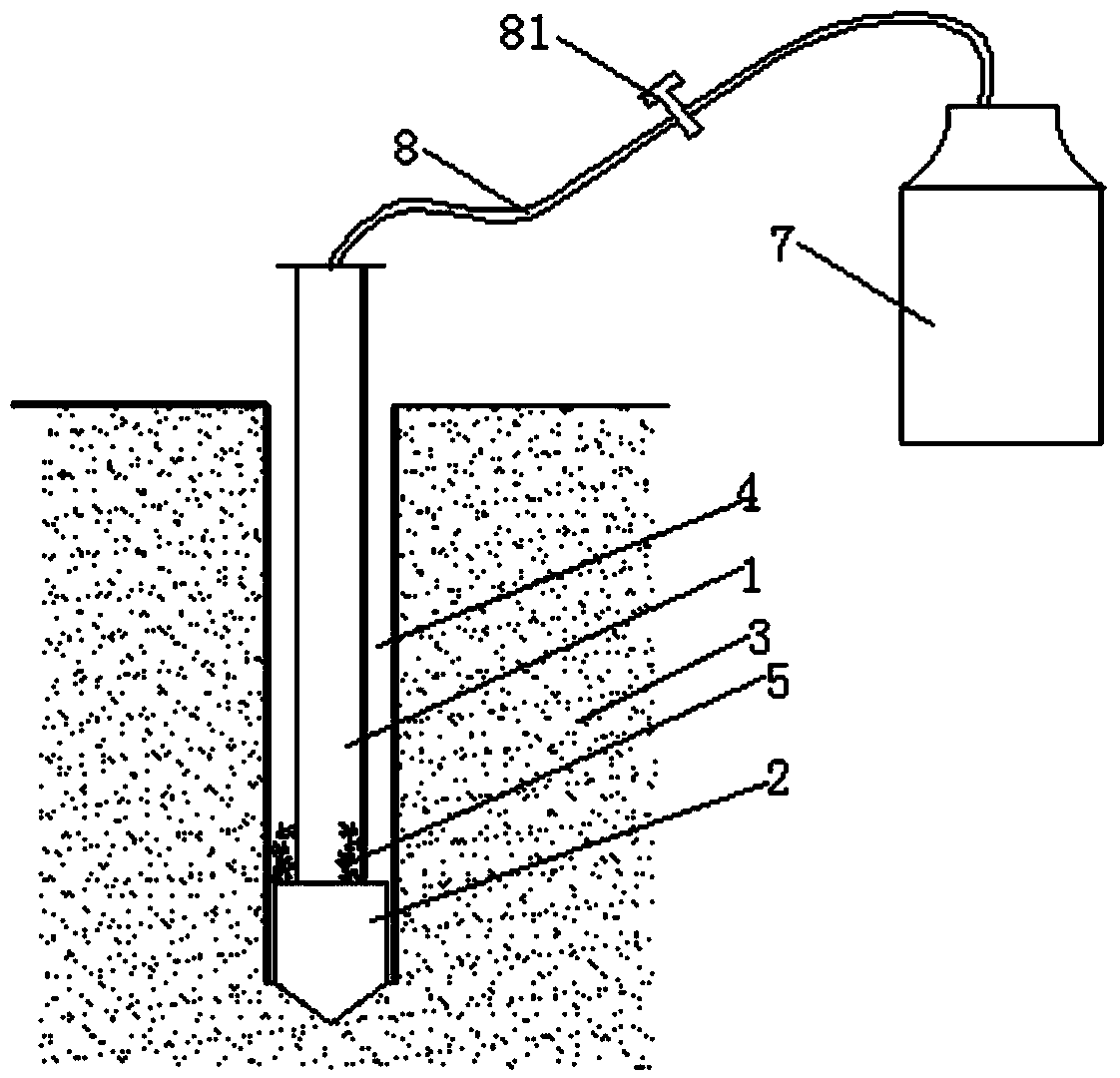

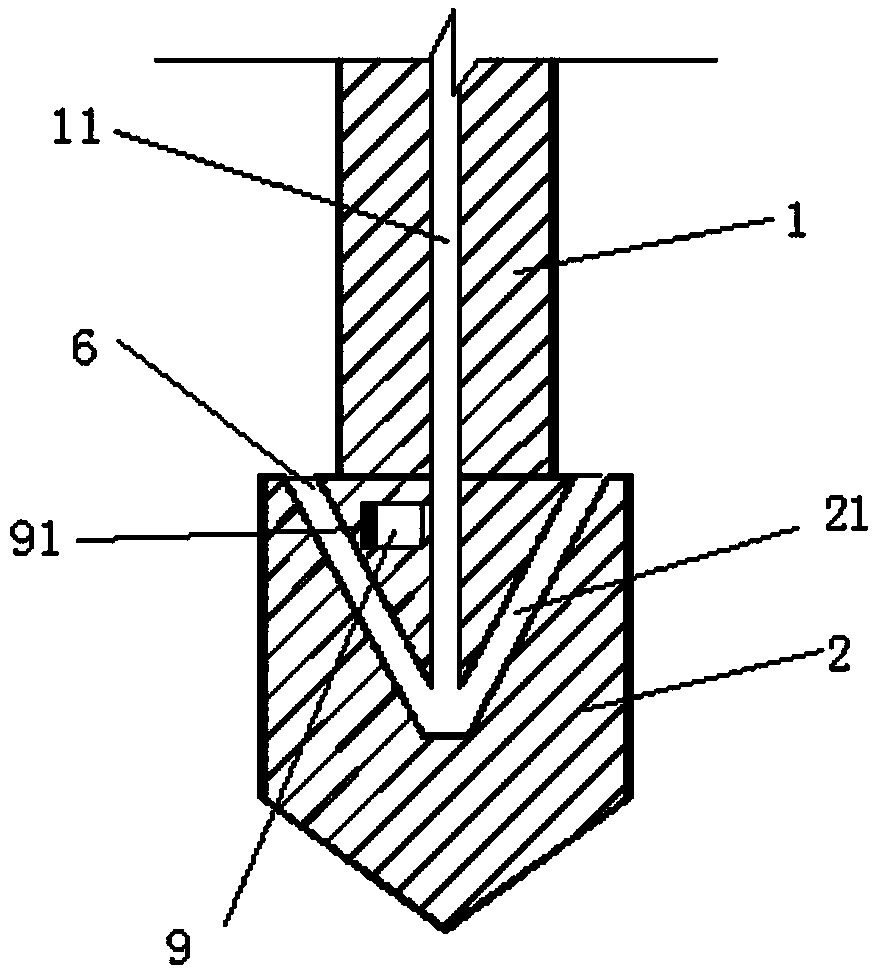

Device for quickly drilling in frozen earth and construction method thereof

ActiveCN104110221AHigh speedDecrease phenomenonEarth drilling toolsDrill bitsNitrogenLiquid nitrogen

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Drilling tool of rotary drilling rig and rotary drilling rig comprising same

InactiveCN102425376AGuaranteed drilling efficiencyImprove construction efficiencyDrill bitsDrilling rodsPetroleum engineeringAxial length

Owner:BEIJING SANY HEAVY MASCH CO LTD

Method of avoiding the need for a scraper run in drill out operations and a downhole drilling motor assembly

Owner:TARTAN ENERGY GRP INC +1

Spring type Y-shaped well joint

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Drill rod joint

InactiveCN102900379AUniform stress distributionImprove rigidityDrilling rodsDrilling casingsMating connectionEngineering

The invention discloses a drill rod joint which comprises a male joint and a female joint, wherein the male joint and the female joint are connected together through a male joint thread and a female joint thread in a mutual fit manner; a main male joint shoulder and a secondary male joint shoulder are respectively arranged at two sides of the male joint thread; a main female joint shoulder and a secondary female joint shoulder are respectively arranged at two sides of the female joint thread; when the male joint and the female joint are at the connected state, a main shoulder sealing cabin and a secondary shoulder sealing cabin are respectively arranged between the male and female joint threads and the main male and female joint shoulders and the secondary male and female joint shoulders; and the length ratio of the secondary and main shoulder sealing cabins is 1:1.9-2.2. With the adoption of the drill rod joint with the structure provided by the invention, the stress is distributed more uniformly; the load can be shared by the two ends of a thread buckle with stronger rigidity; and the anti-torque performance can be increased by more than 30% under the condition of identical wall thickness.

Owner:TIANJIN DEHUA GASOLINEEUM EQUIP MFG

Combination blowout preventer and recovery device

Owner:MILANOVICH INVESTMENTS L L C

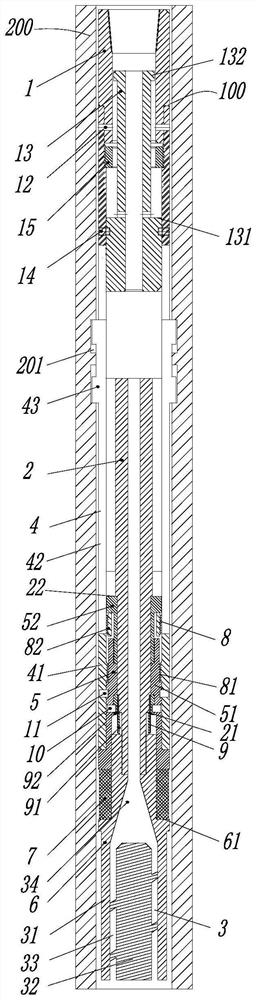

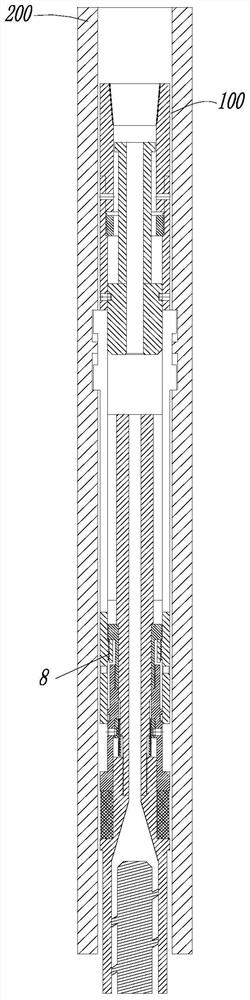

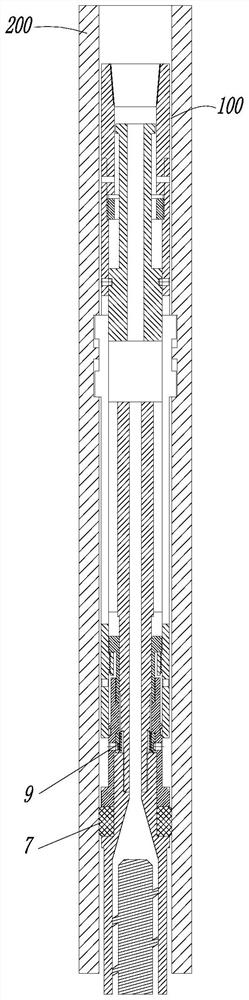

Separated layer water injection string for petroleum exploitation and water injection process thereof

PendingCN111396007AOvercoming the problem of short shelf lifeRealize layered water injectionDrilling rodsFluid removalTubing hangerPetroleum oil

Owner:天津克睿特维科技发展有限公司 +1

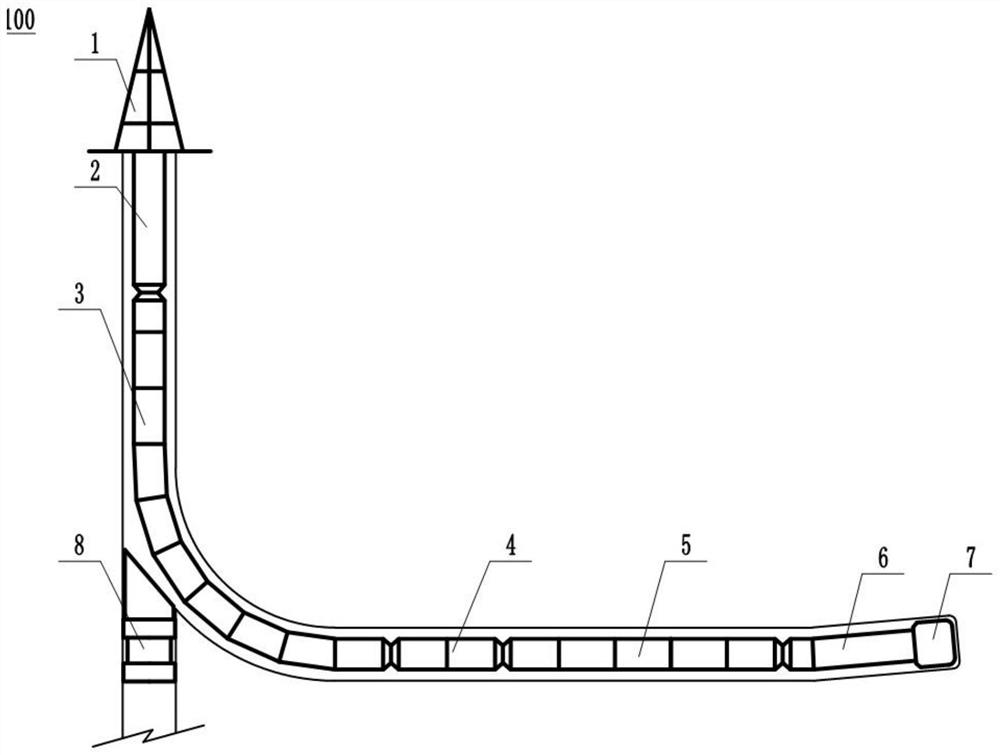

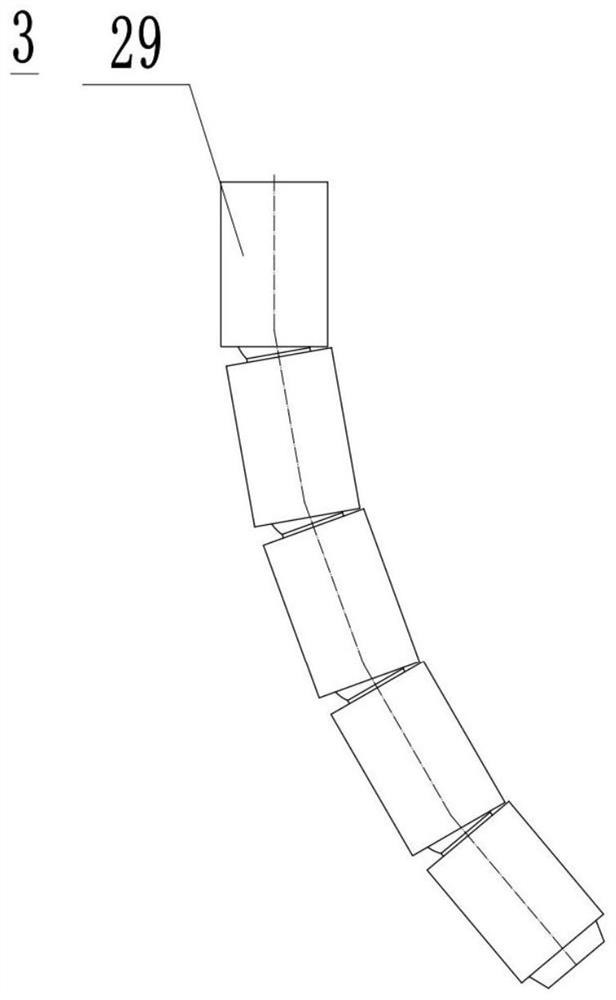

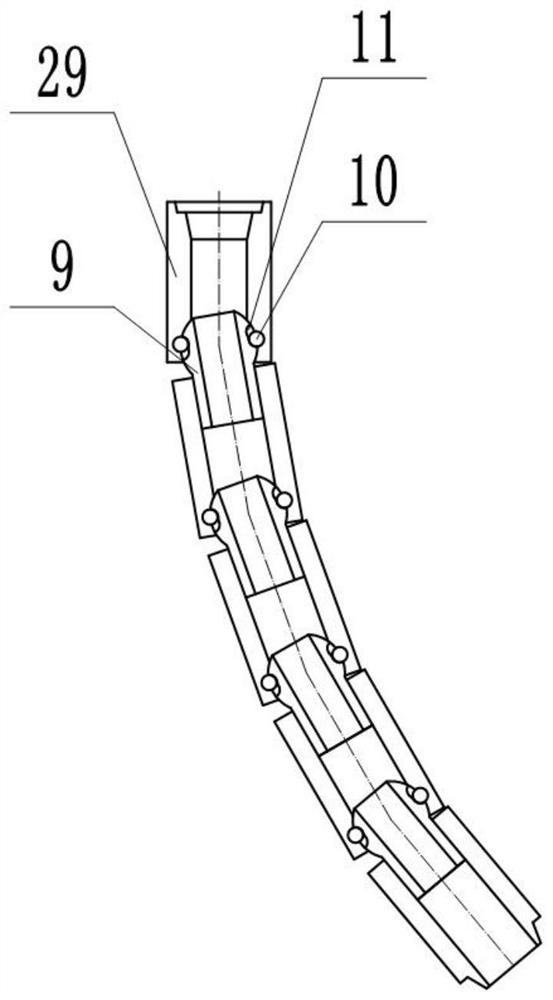

Controlled ultra-short radius guiding well drilling system and well drilling method

Owner:BEIJING INST OF EXPLORATION ENG

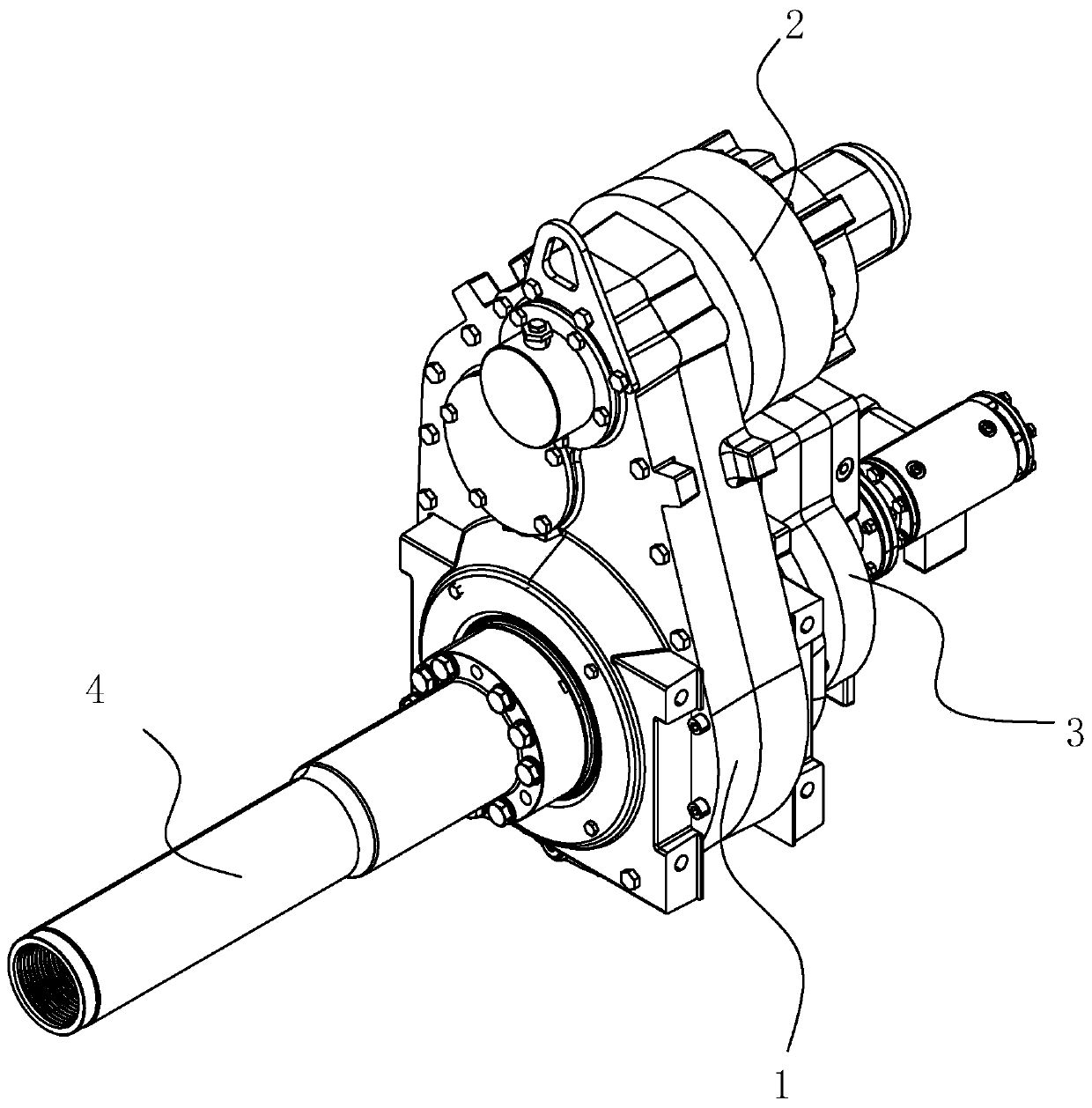

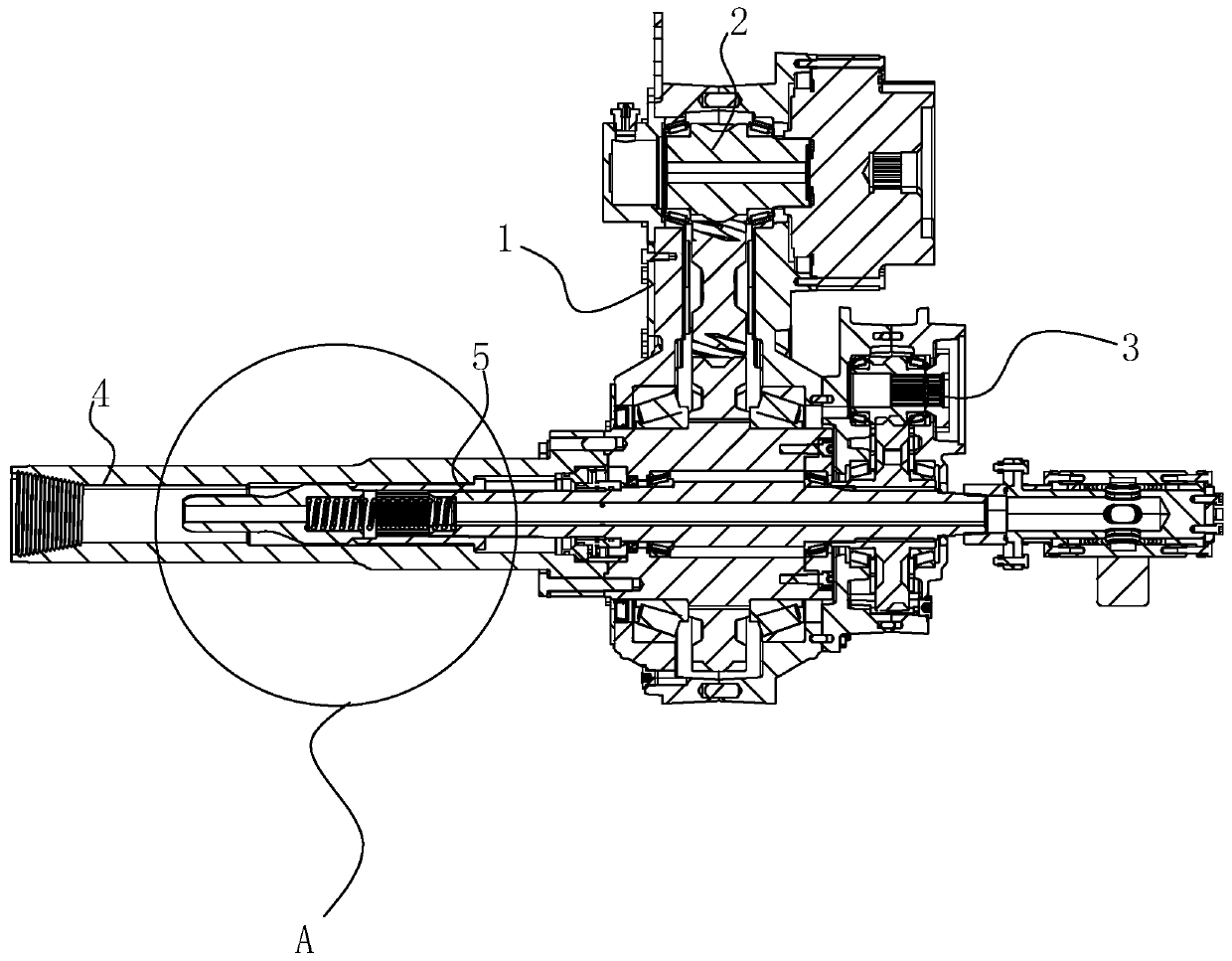

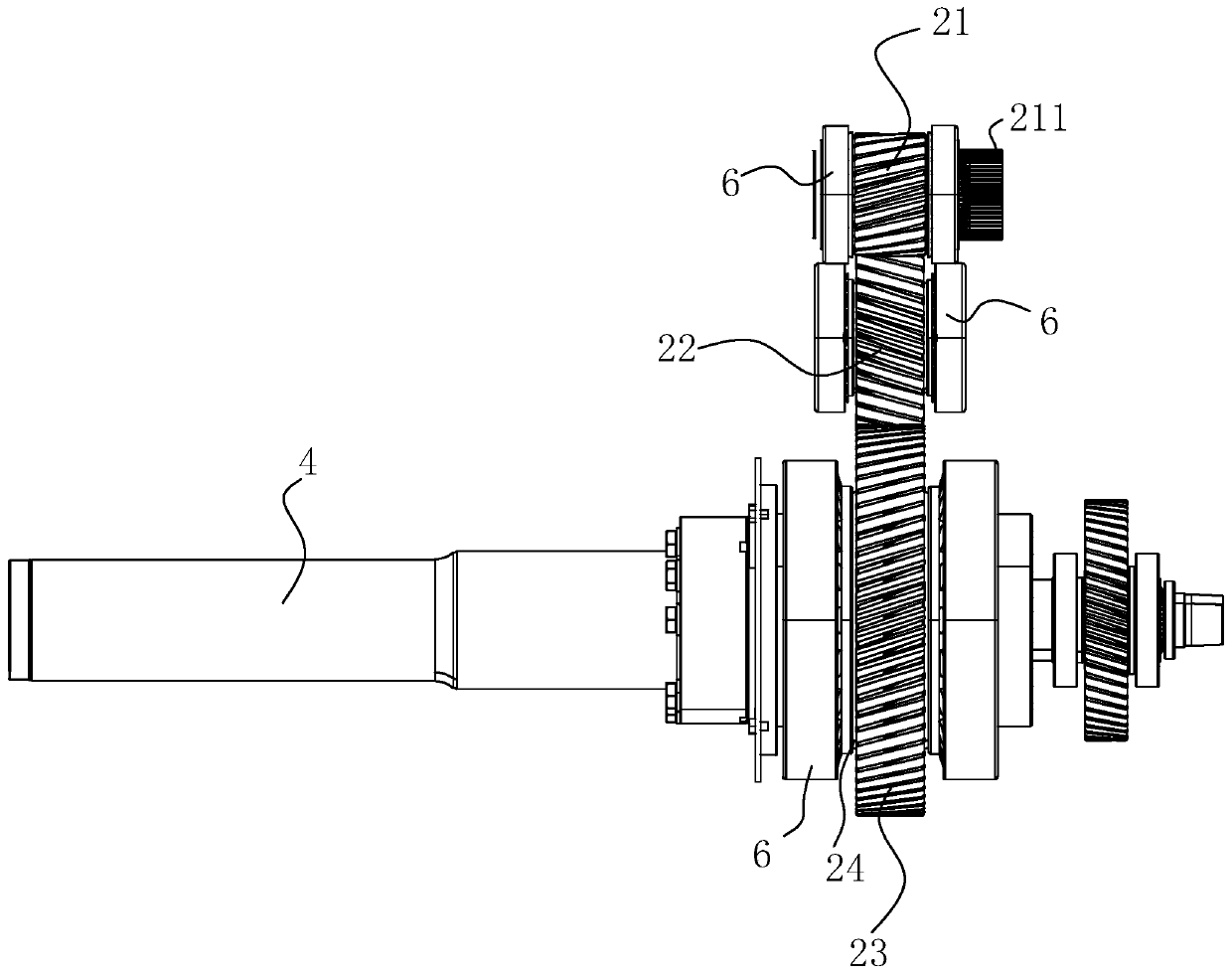

Double-output-shaft non-excavation directional drilling machine power device and drill rod matched with device

PendingCN110410009AEasy to move forwardDrilling rodsToothed gearingsDirectional drillingDrilling machines

Owner:DW TXS CONSTR EQUIP BEIJING

Drilling and perforating device for building construction piling

ActiveCN112627722AAvoid wastingSimple structureEarth drilling toolsDrilling rodsArchitectural engineeringMachine

Owner:青岛旭华建设集团有限公司

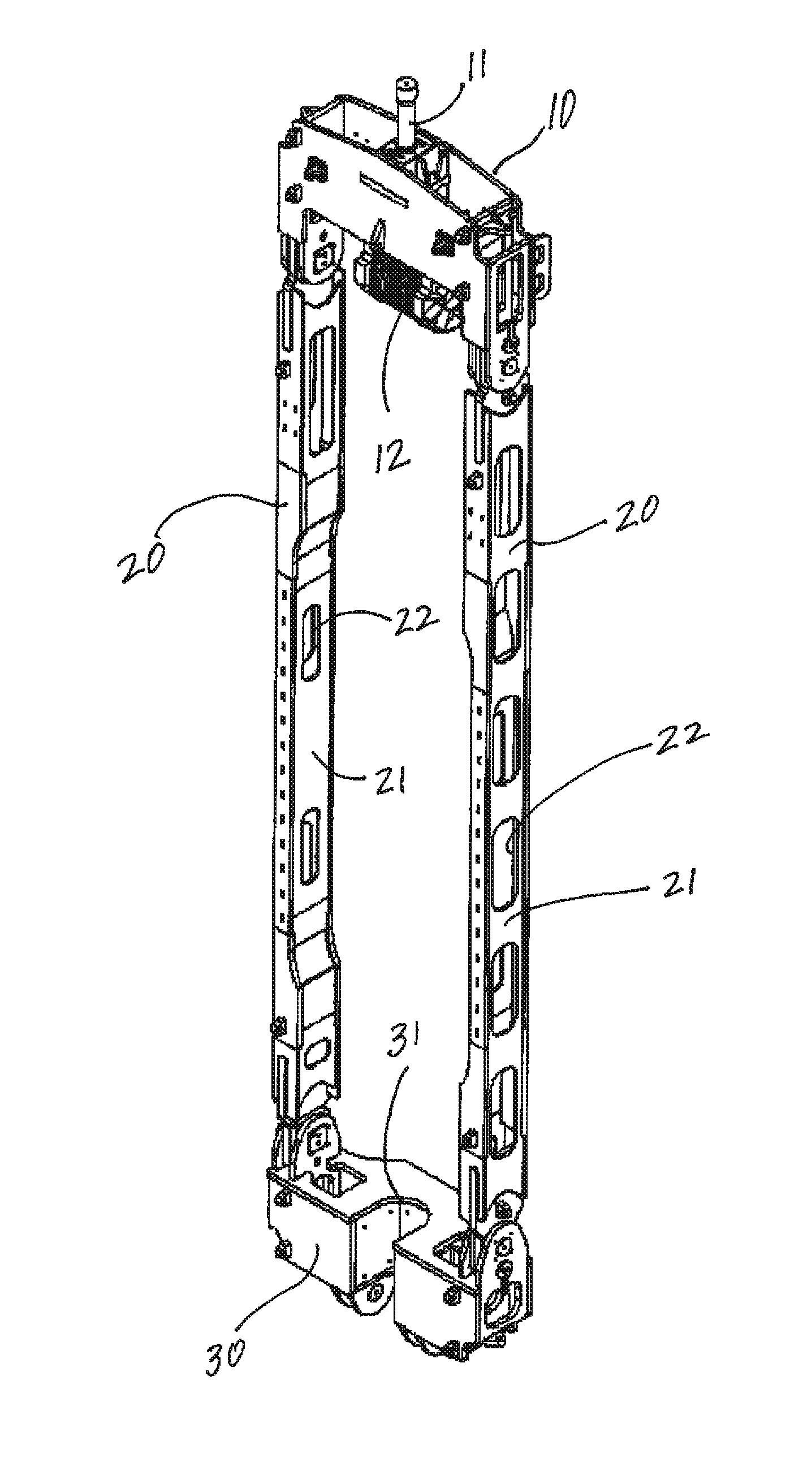

Support frame

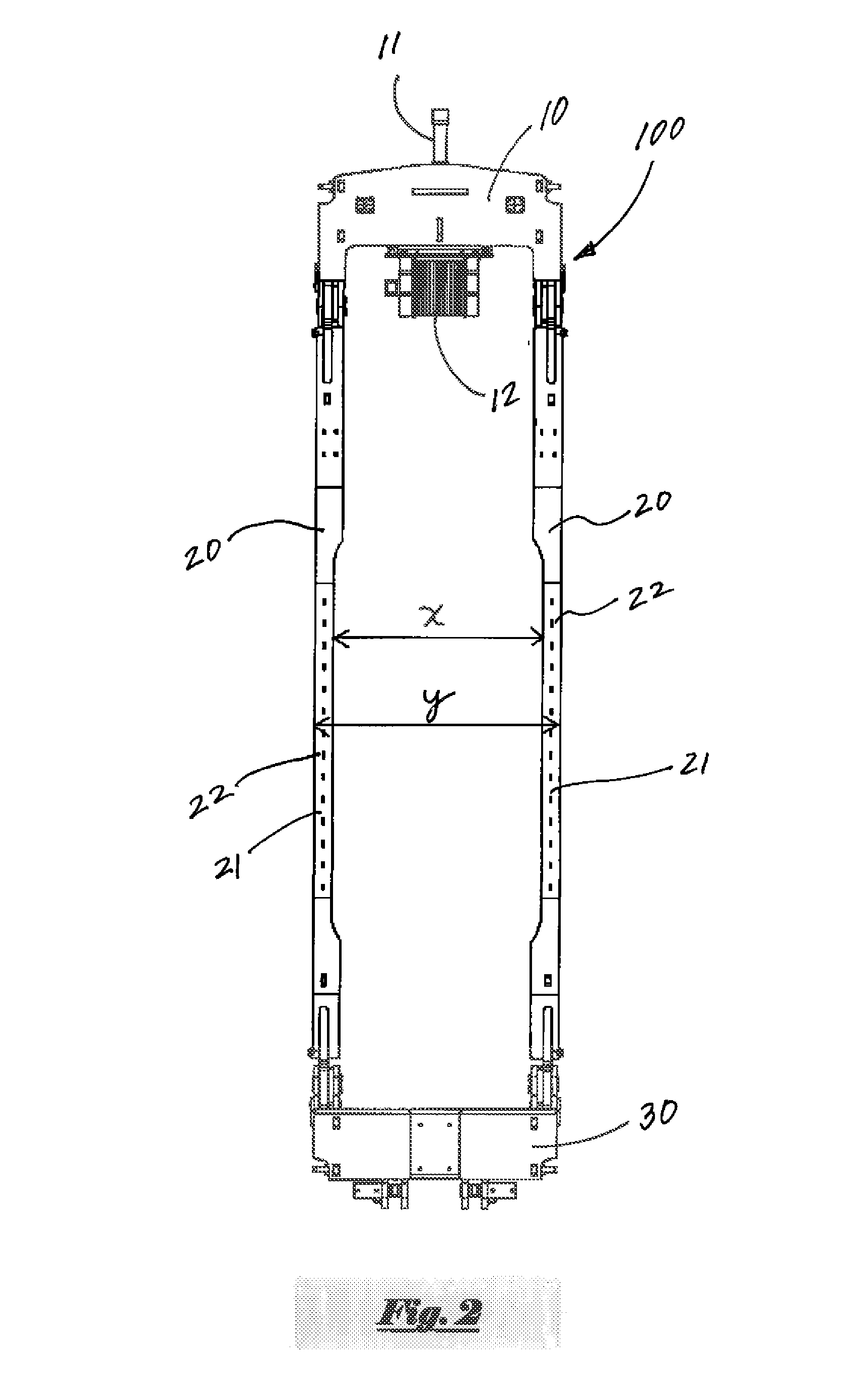

InactiveUS20140116676A1DistanceIncrease width dimensionDrilling rodsFluid removalTop driveEngineering

Owner:PROFESSIONAL RENTAL TOOLS

Underground drainage gas production device and pipe column

InactiveCN112302615ARelieve pressureReduce liquidityDrilling rodsFluid removalUpper jointStructural engineering

Owner:CHINA PETROLEUM & CHEM CORP +1

Heating processing technology for deep sea petroleum drill by adopting conduit joint

InactiveCN103215425AUniform heating effectUniform thermal deformationDrilling rodsFurnace typesFurnace temperatureWater cooling

The invention discloses a heating processing technology for a deep sea petroleum drill by adopting a conduit joint. The technology comprises the following steps: charging: vertically putting the conduit joint in a well type quenching furnace in the way that a welding neck end faces down, maintaining space between the periphery and upper and lower layers, keeping the furnace temperature at 871-910 DEG C for at least 80 minutes, hoisting out from a hearth and 15 seconds later, feeding into a quenching pool with water temperature of 40-48 DEG C for quenching; performing water cooling for at least 15 minutes; then feeding into the furnace for normalizing treatment at the normalizing temperature of 899-940 DEG C, performing tempering treatment within four hours from the beginning of quenching at the tempering temperature of 575-620 DEG C, wherein the tempering holding time at least lasts 160 minutes; and then hoisting the conduit joint blank out of the hearth and directly placing into a water tank, and cooling to normal temperature. The technology is reasonable in parameter and easy to implement; product quality is stable, and the pass percent is more than 96%.

Owner:JIANGSU SHUGUANG OIL DRILLING EQUIP CO LTD

Twist drill pipe

The invention discloses a twist drill rod which comprises a twist rod body. A connecting column is arranged at one end of the twist rod body, a connecting hole is formed in the other end of the twistrod body, the connecting column is provided with an external thread, the connecting hole is internally provided with an internal thread matched with the external thread on the connecting column, a torque transmission assembly is arranged in the connecting hole, the torque transmission assembly comprises an inner screw and a connecting sleeve pipe, and the connecting sleeve pipe sleeves the inner screw and is connected with the inner screw through the treads. A first plane clamping tooth is arranged at the end of the connecting sleeve pipe, a blind hole corresponding to the connecting sleeve pipe is arranged on the middle part of the connecting column, and a second plane clamping tooth corresponding to the first plane clamping tooth is arranged at the bottom of the blind hole. When the drill rod is driven, torque force between the connecting hole and the connecting column can be shared between the inner screw and the connecting sleeve pipe as well as between the first plane clamping tooth and the second plane clamping tooth, and the damage of the torque force to the threads between the connecting hole and the connecting column can be reduced.

Owner:ZOUCHENG YANKUANG TAIDE IND & TRADE CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap