Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about "Drill bits" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

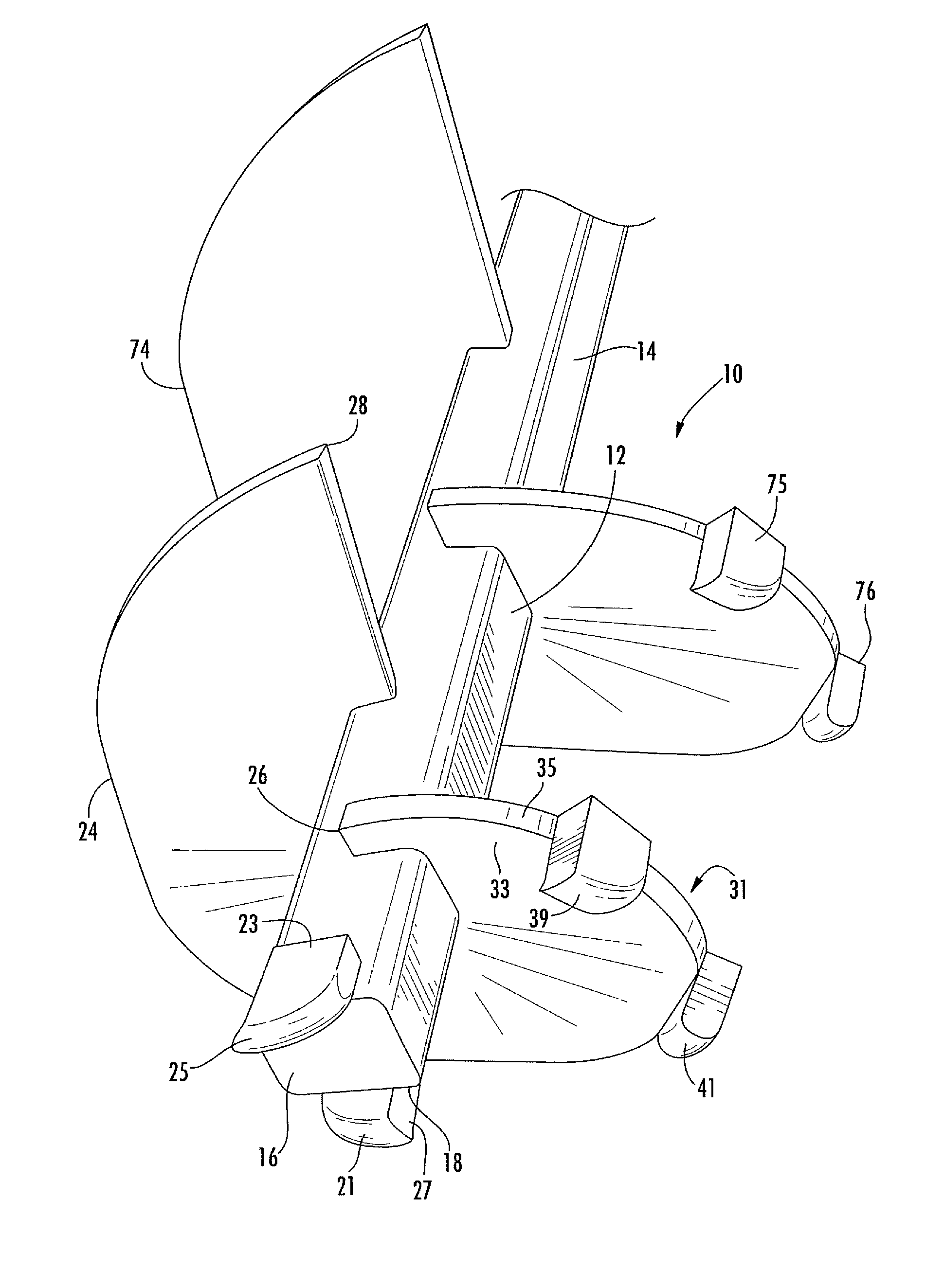

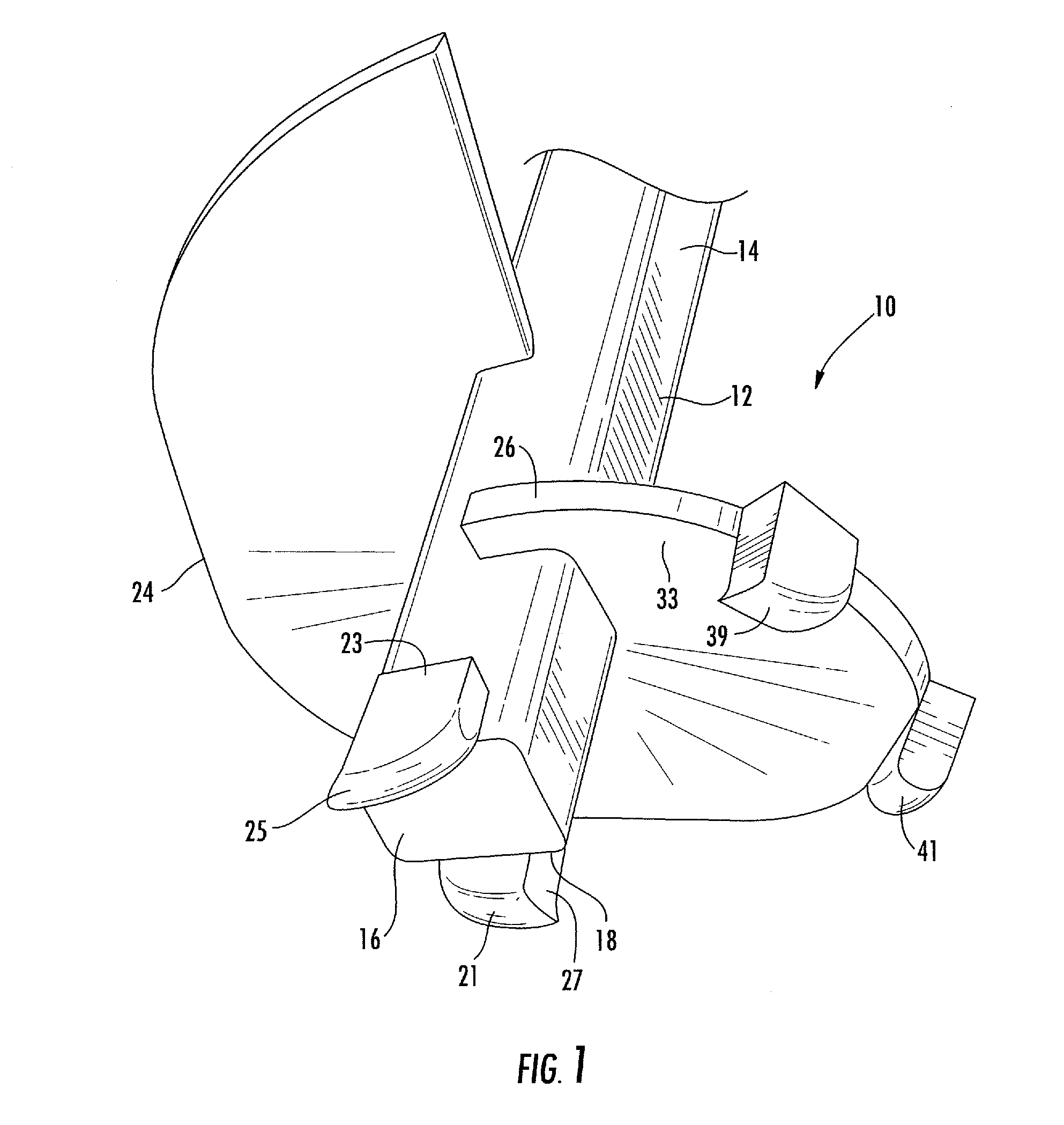

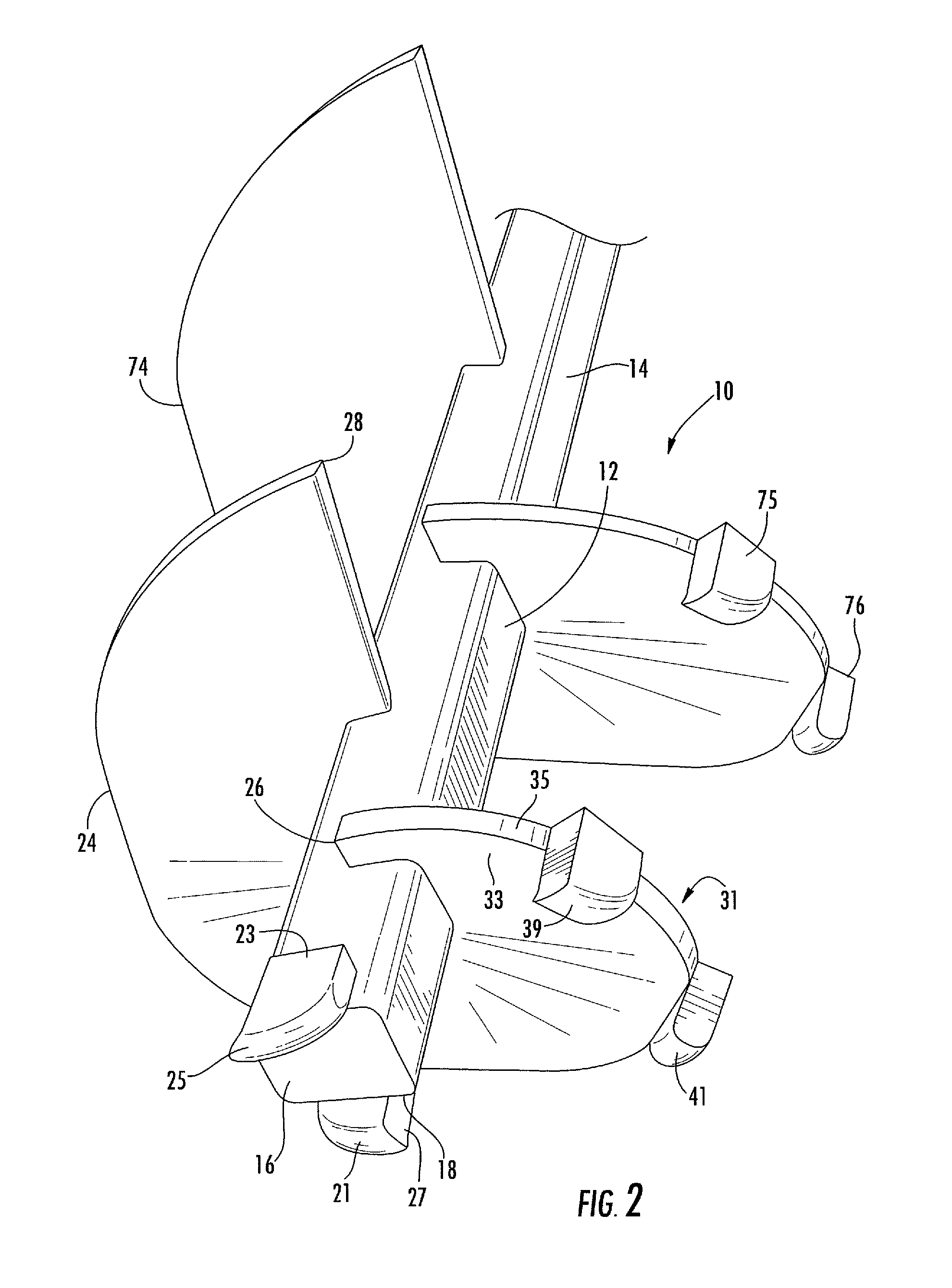

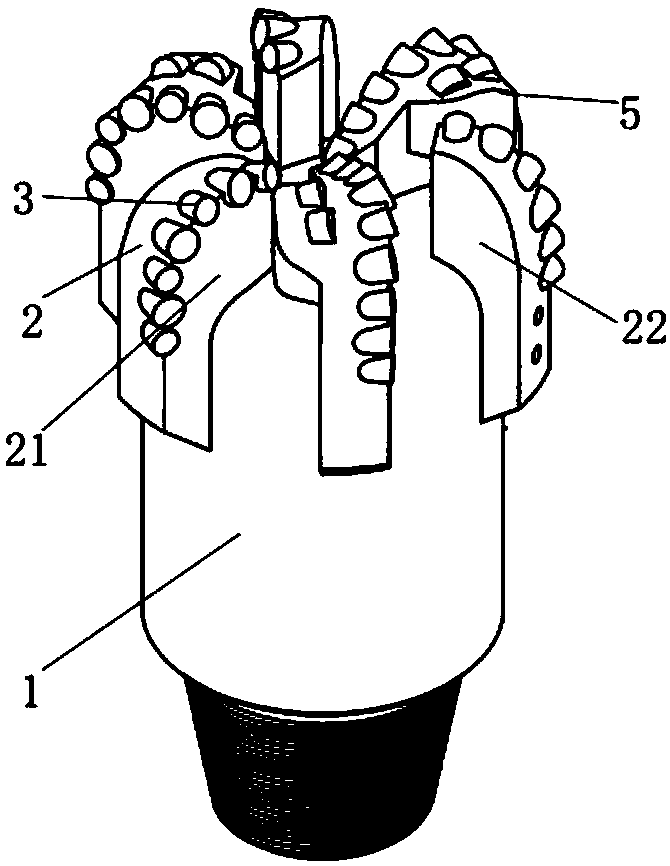

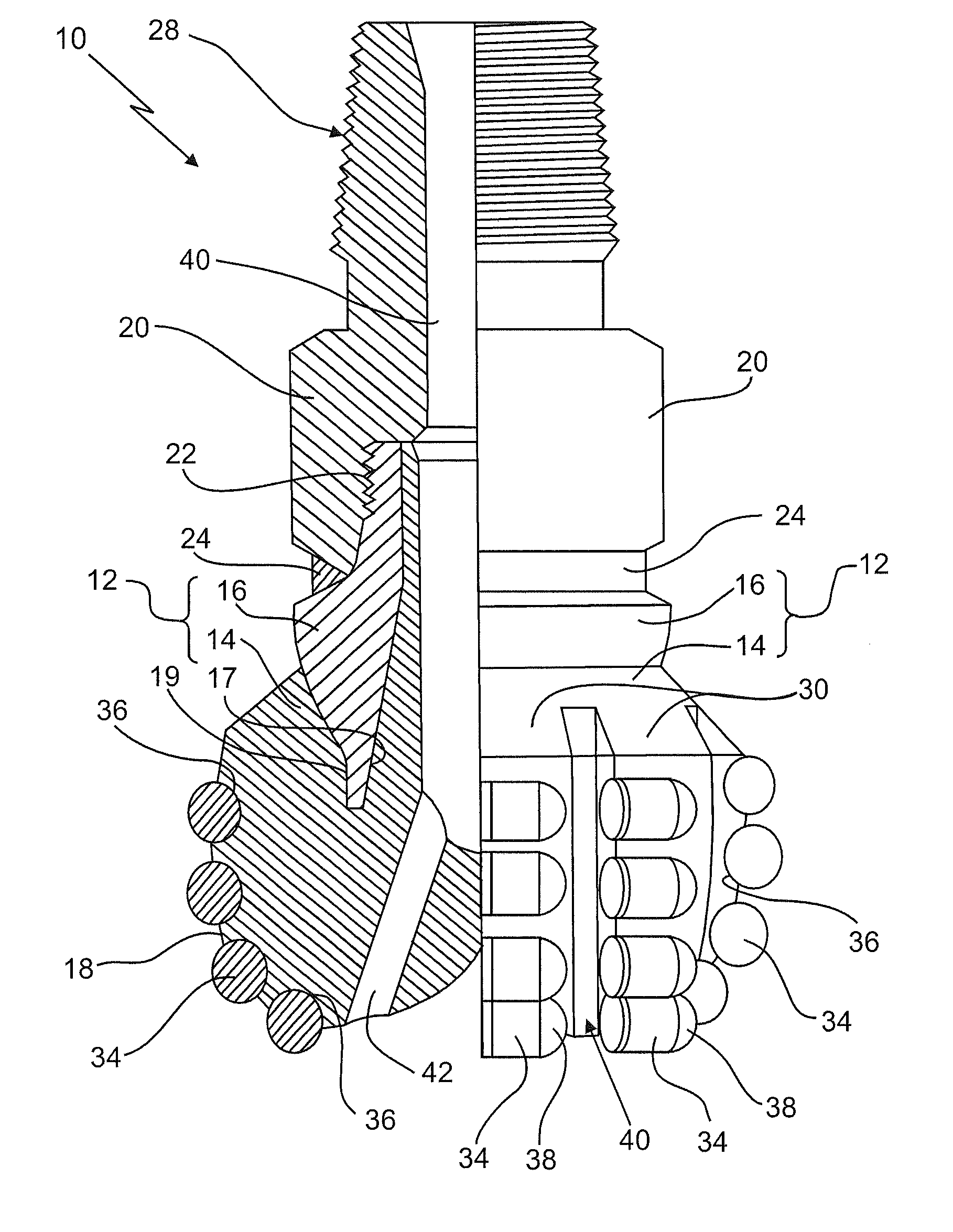

Pointed Diamond Working Ends on a Shear Bit

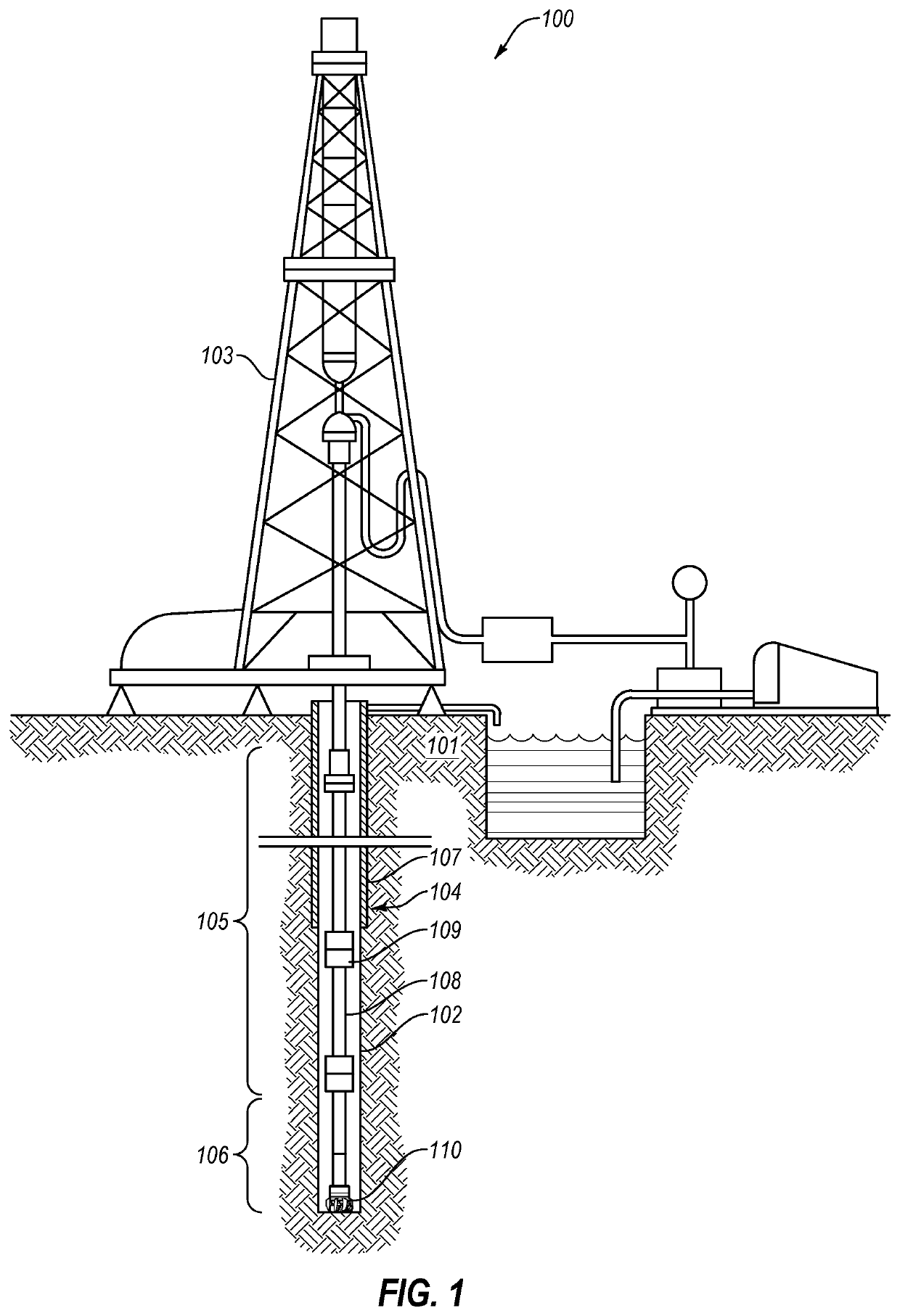

In one aspect of the present invention, a drill string has a drill bit with a body intermediate a shank and a working face. The working face has a plurality of blades converging at a center of the working surface and diverging towards a gauge of the working face. At least one blade has a cutting element with a carbide substrate bonded to a diamond working end with a pointed geometry. The diamond working end also has a central axis which intersects an apex of the pointed geometry. The axis is oriented between a 25 and 85 degree positive rake angle.

Owner:SCHLUMBERGER TECH CORP

Method and apparatus for rotary mining

Owner:FAMILY TRUST OF ALLEN J GOURLEY & FAITH KIMKO GOURLEY THE +1

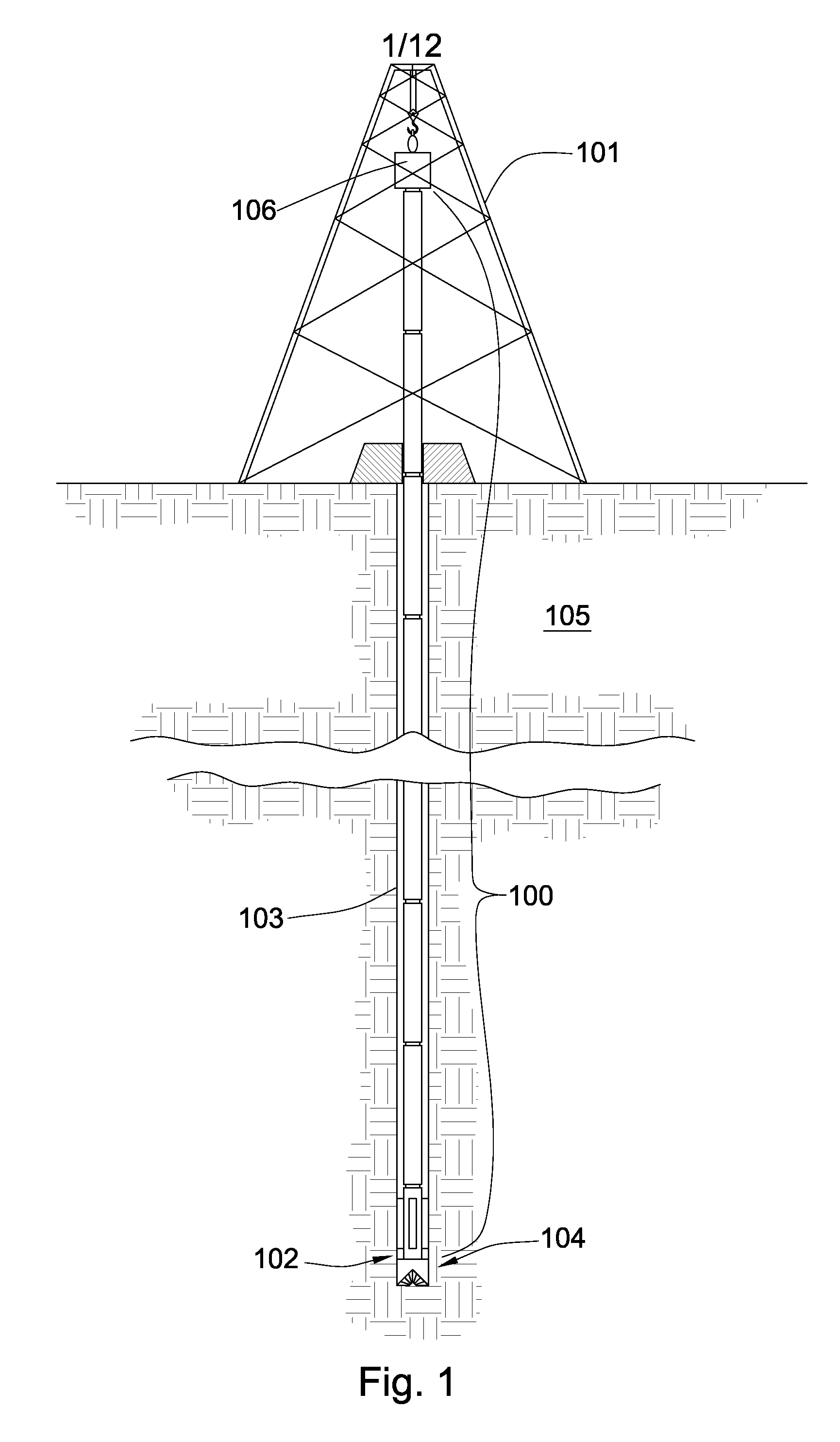

Method and system for accessing subterranean deposits from the surface and tools therefor

According to one embodiment, a system for accessing a subterranean zone from the surface includes a well bore extending from the surface to the subterranean zone, and a well bore pattern connected to the junction and operable to drain fluid from a region of the subterranean zone to the junction.

Owner:EFFECTIVE EXPLORATION

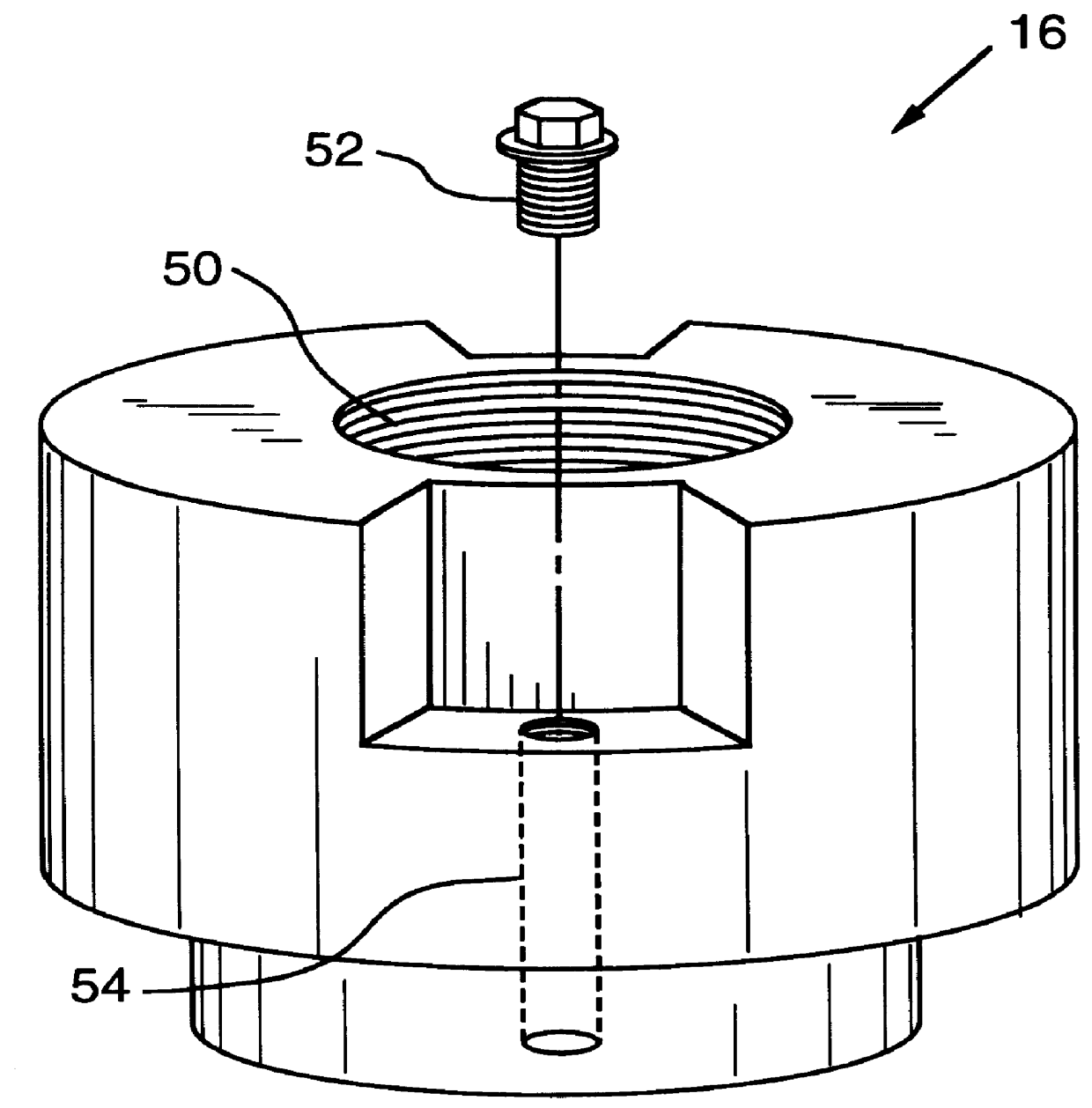

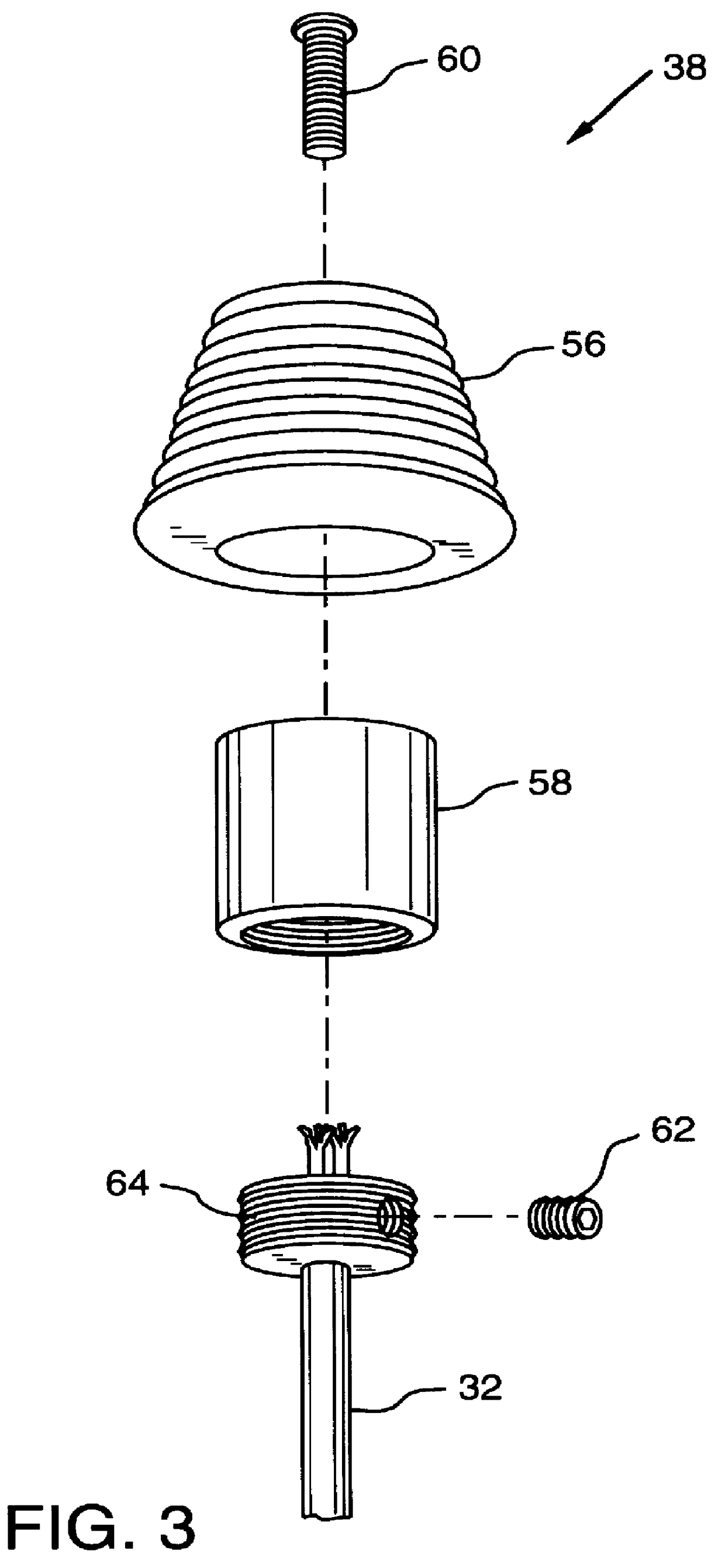

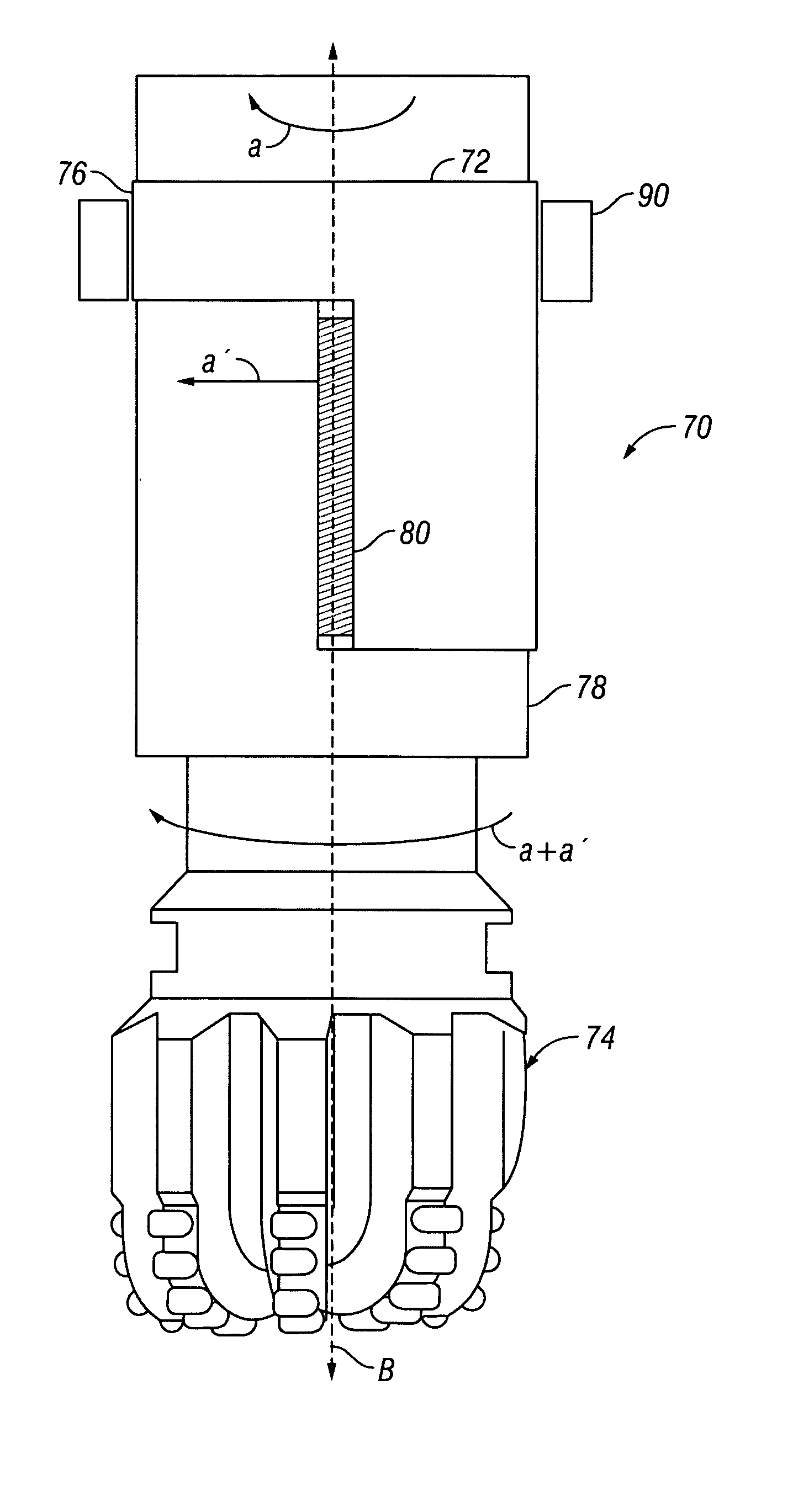

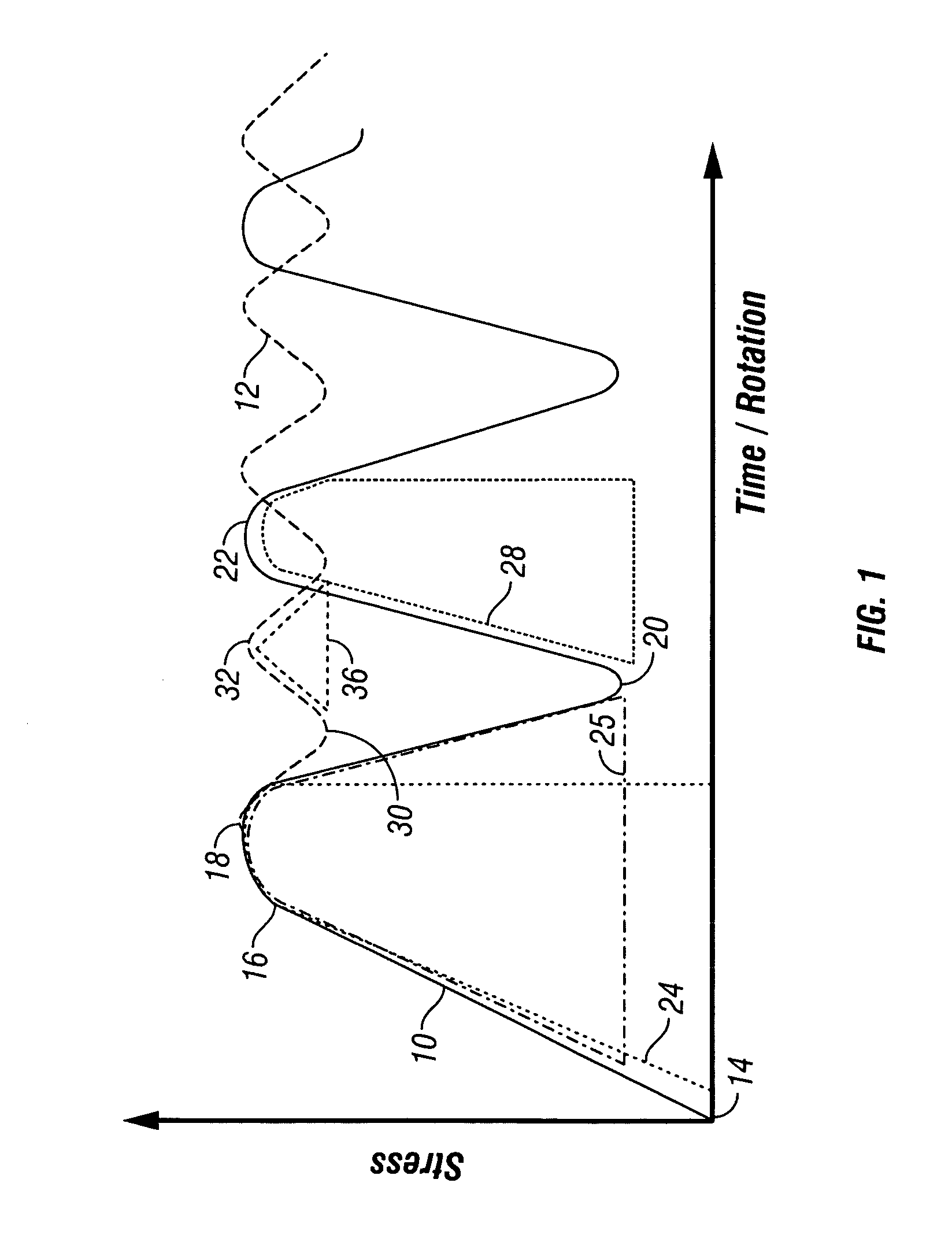

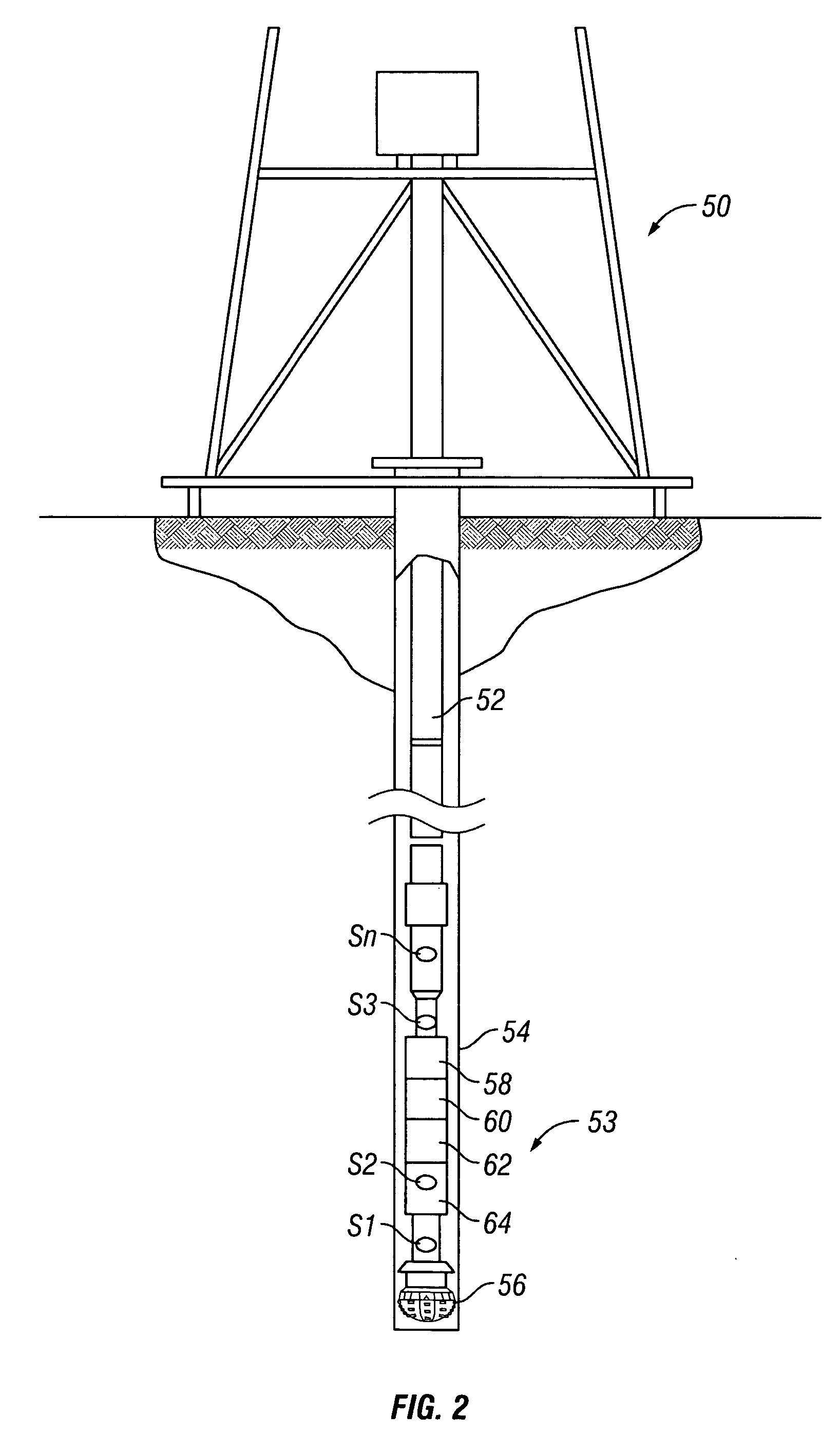

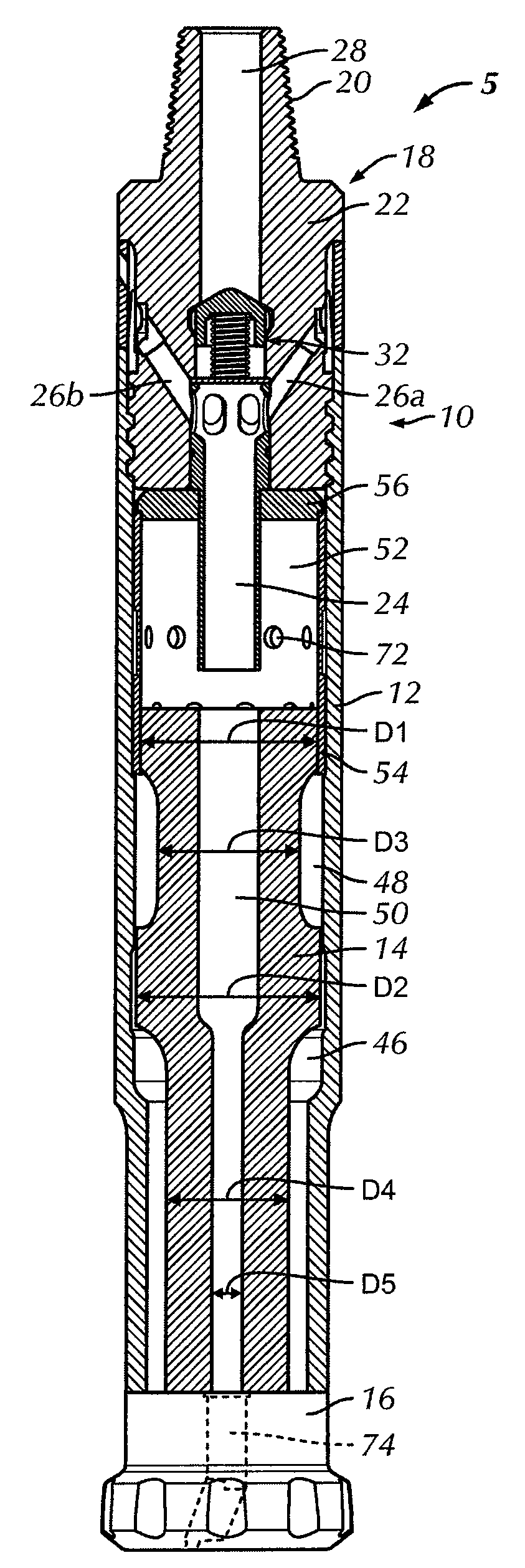

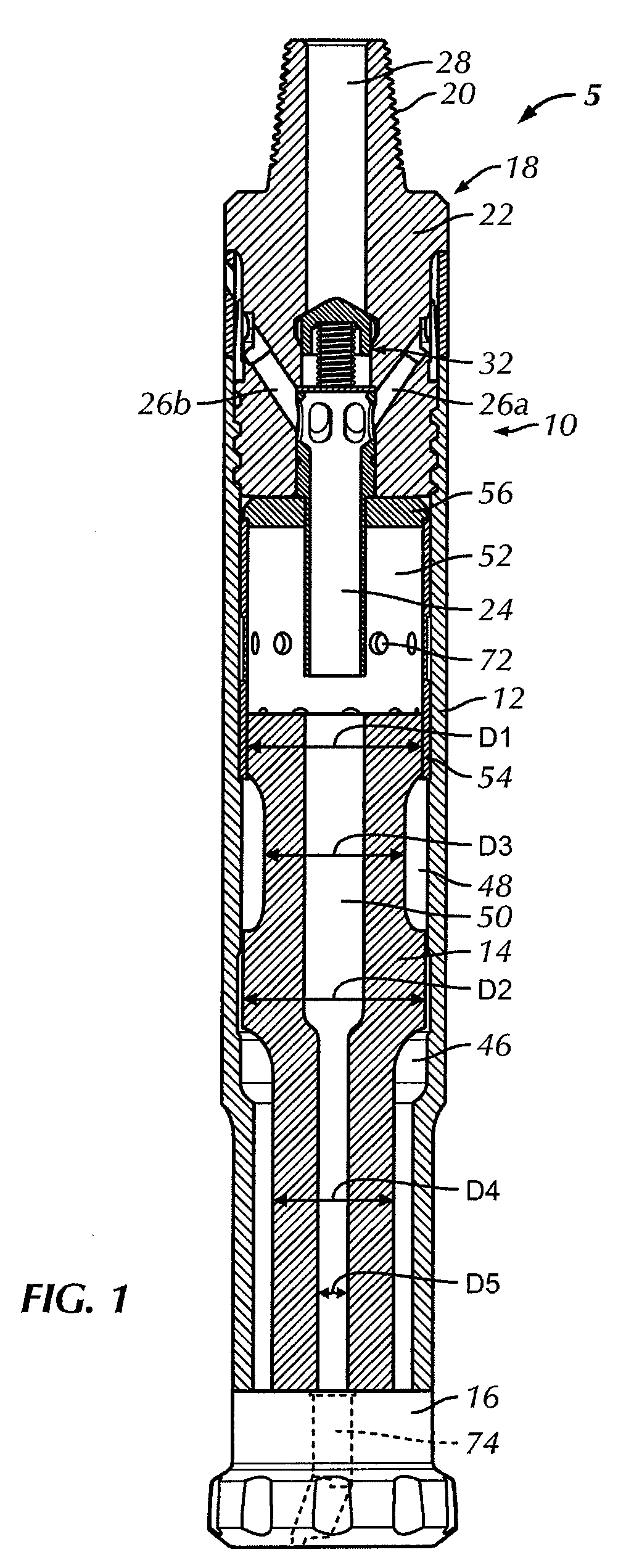

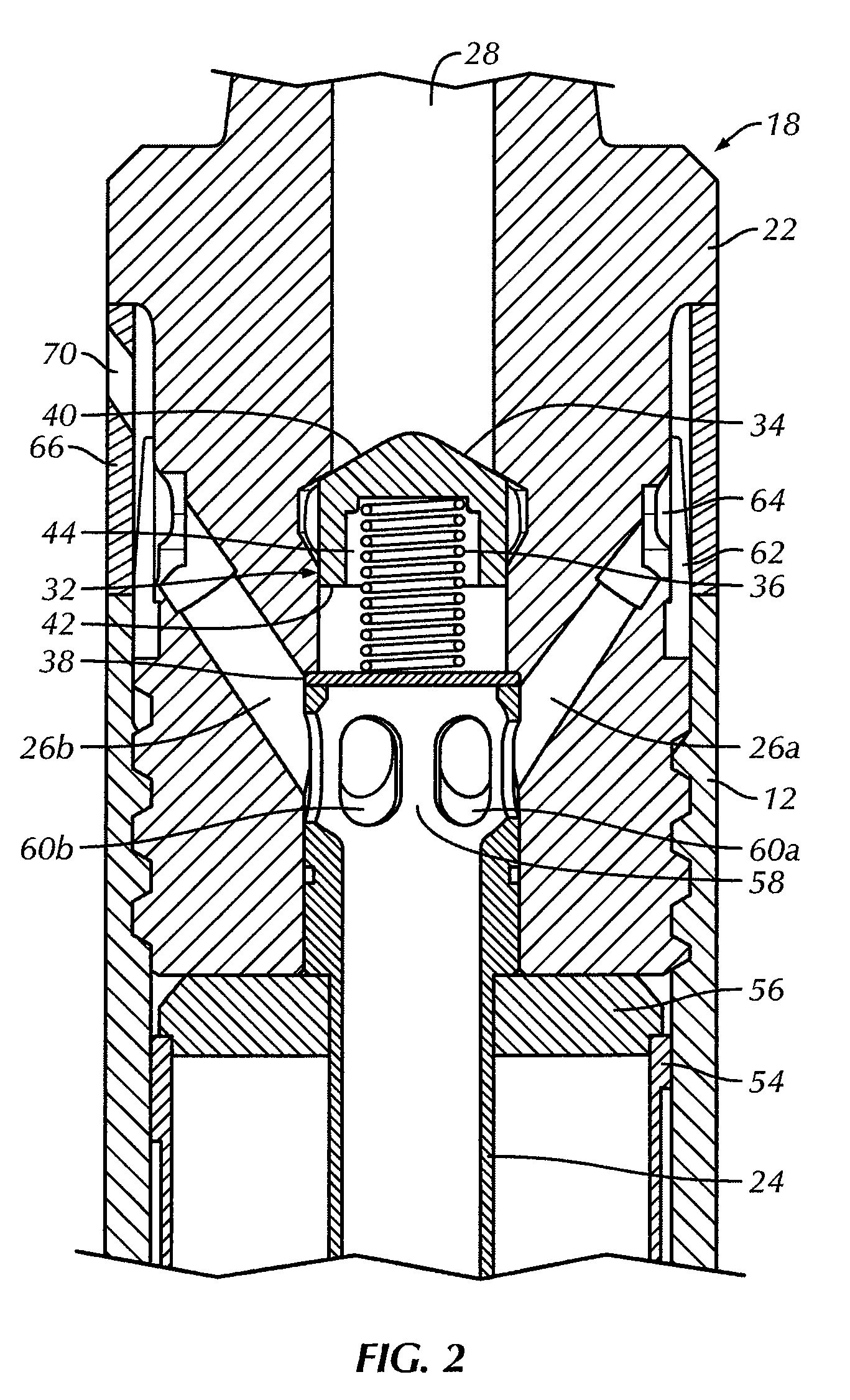

Drilling efficiency through beneficial management of rock stress levels via controlled oscillations of subterranean cutting elements

A device and system for improving efficiency of subterranean cutting elements uses a controlled oscillation super imposed on steady drill bit rotation to maintain a selected rock fracture level. In one aspect, a selected oscillation is applied to the cutting element so that at least some of the stress energy stored in an earthen formation is maintained after fracture of the rock is initiated. Thus, this maintained stress energy can thereafter be used for further crack propagation. In one embodiment, an oscillation device positioned adjacent to the drill bit provides the oscillation. A control unit can be used to operate the oscillation device at a selected oscillation. In one arrangement, the control unit performs a frequency sweep to determine an oscillation that optimizes the cutting action of the drill bit and configures the oscillation device accordingly. One or more sensors connected to the control unit measure parameters used in this determination.

Owner:BAKER HUGHES INC

Ground anchor

Owner:FIXDIRT

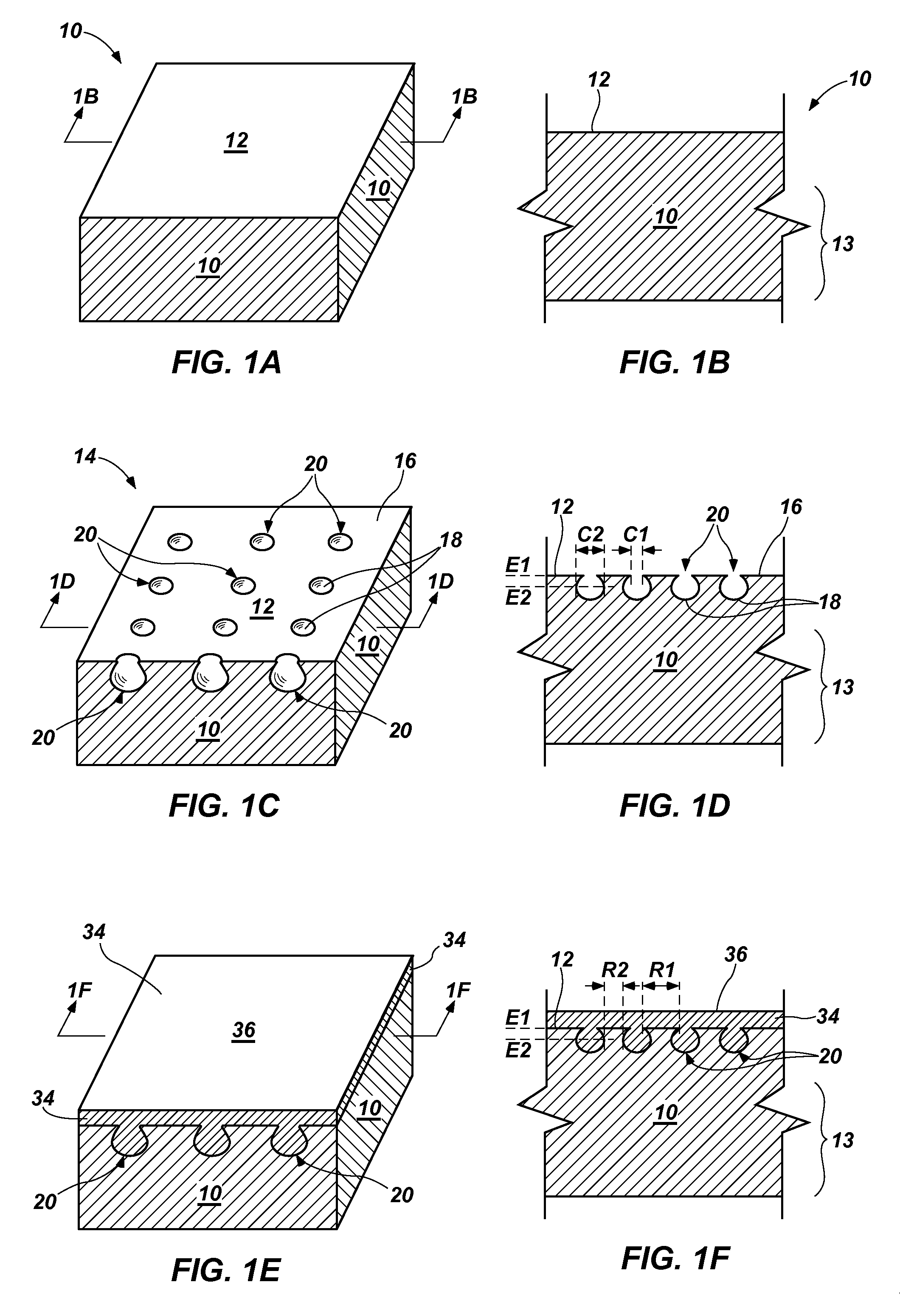

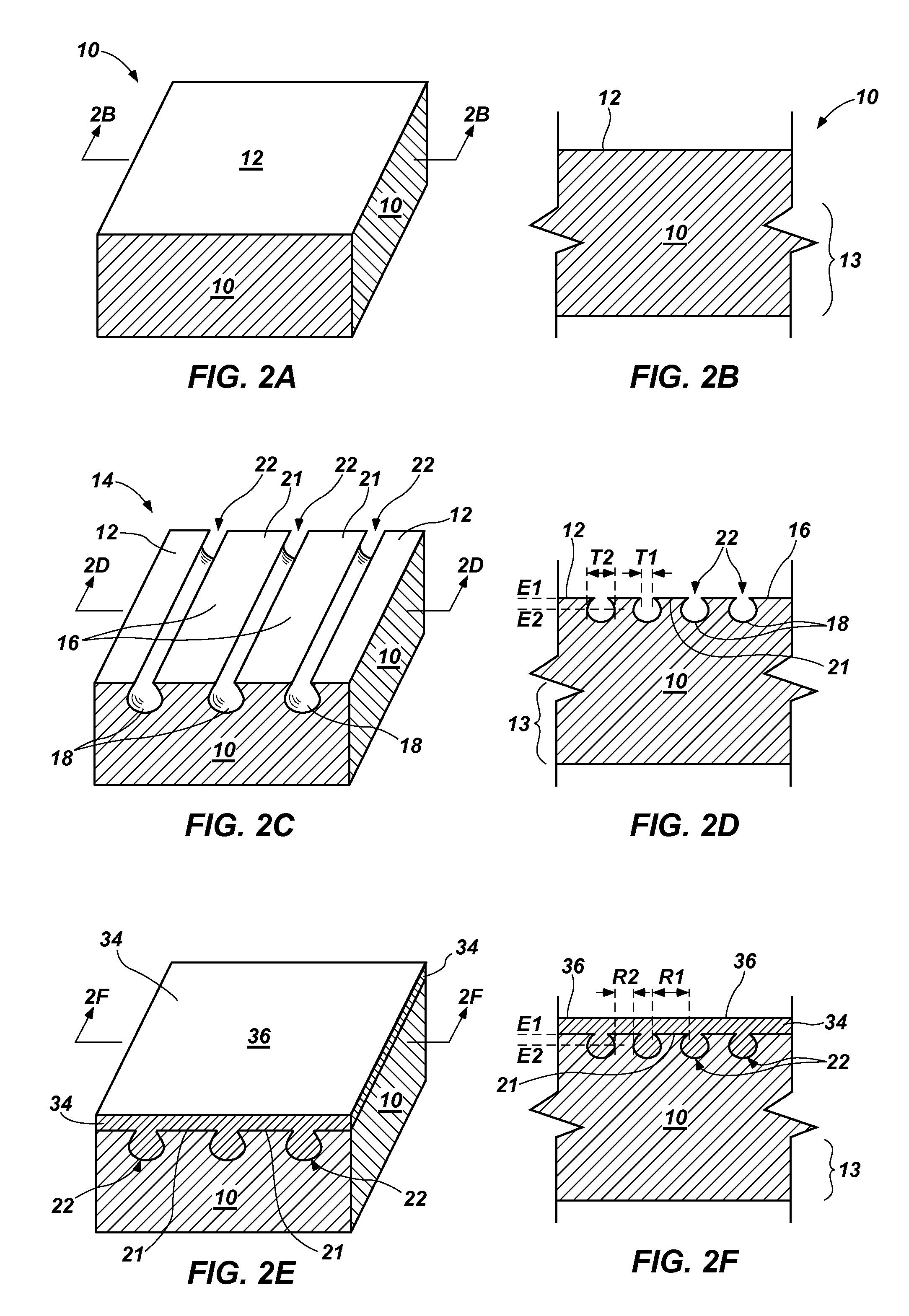

Cutting elements, methods for manufacturing such cutting elements, and tools incorporating such cutting elements

The present disclosure relates to cutting elements incorporating polycrystalline diamond bodies used for subterranean drilling applications, and more particularly, to polycrystalline diamond bodies having a high diamond content which are configured to provide improved properties of thermal stability and wear resistance, while maintaining a desired degree of impact resistance, when compared to prior polycrystalline diamond bodies, hi various embodiments disclosed herein, a cutting element with high diamond content includes a modified PCD structure and / or a modified interface (between the PCD body and a substrate), to provide superior performance.

Owner:SMITH INT INC

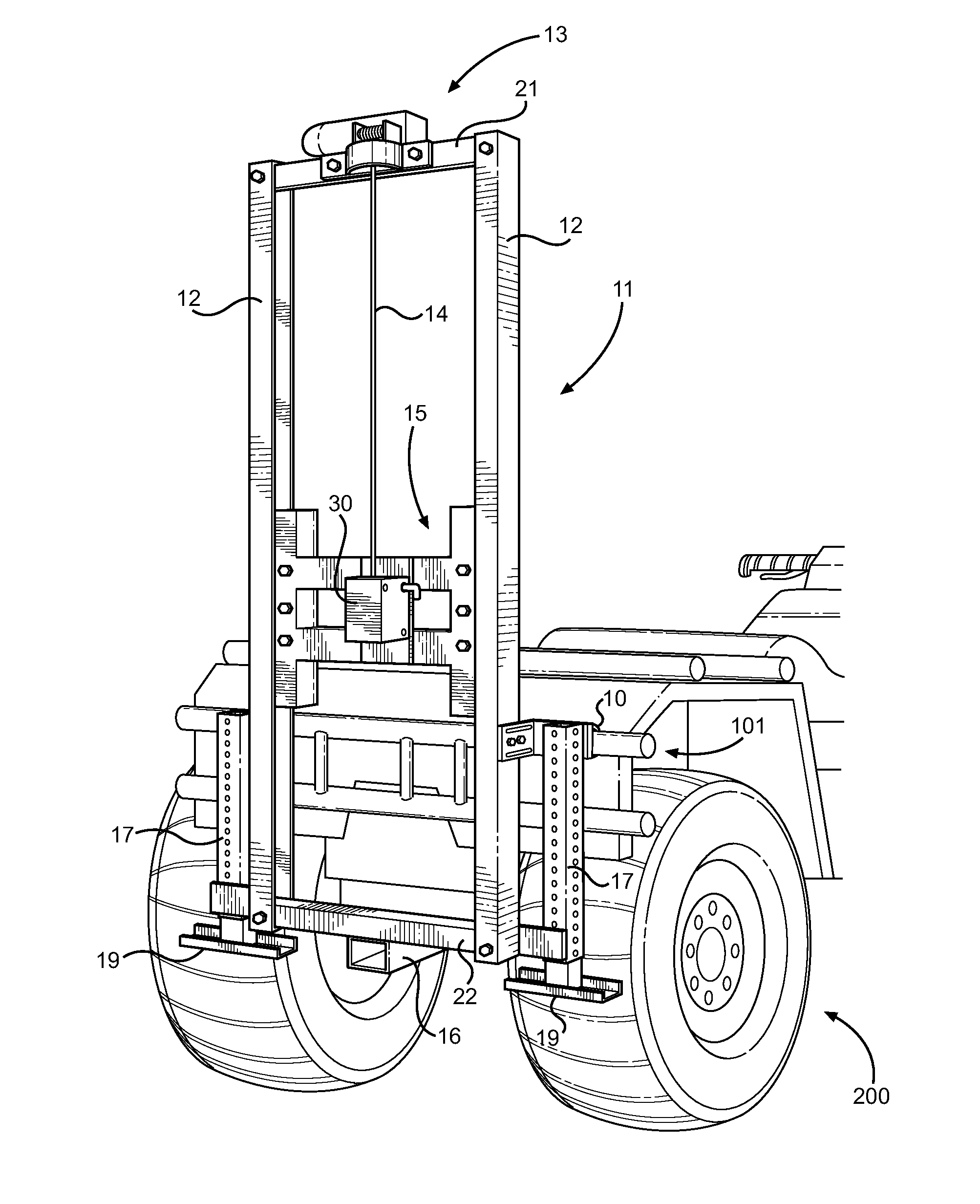

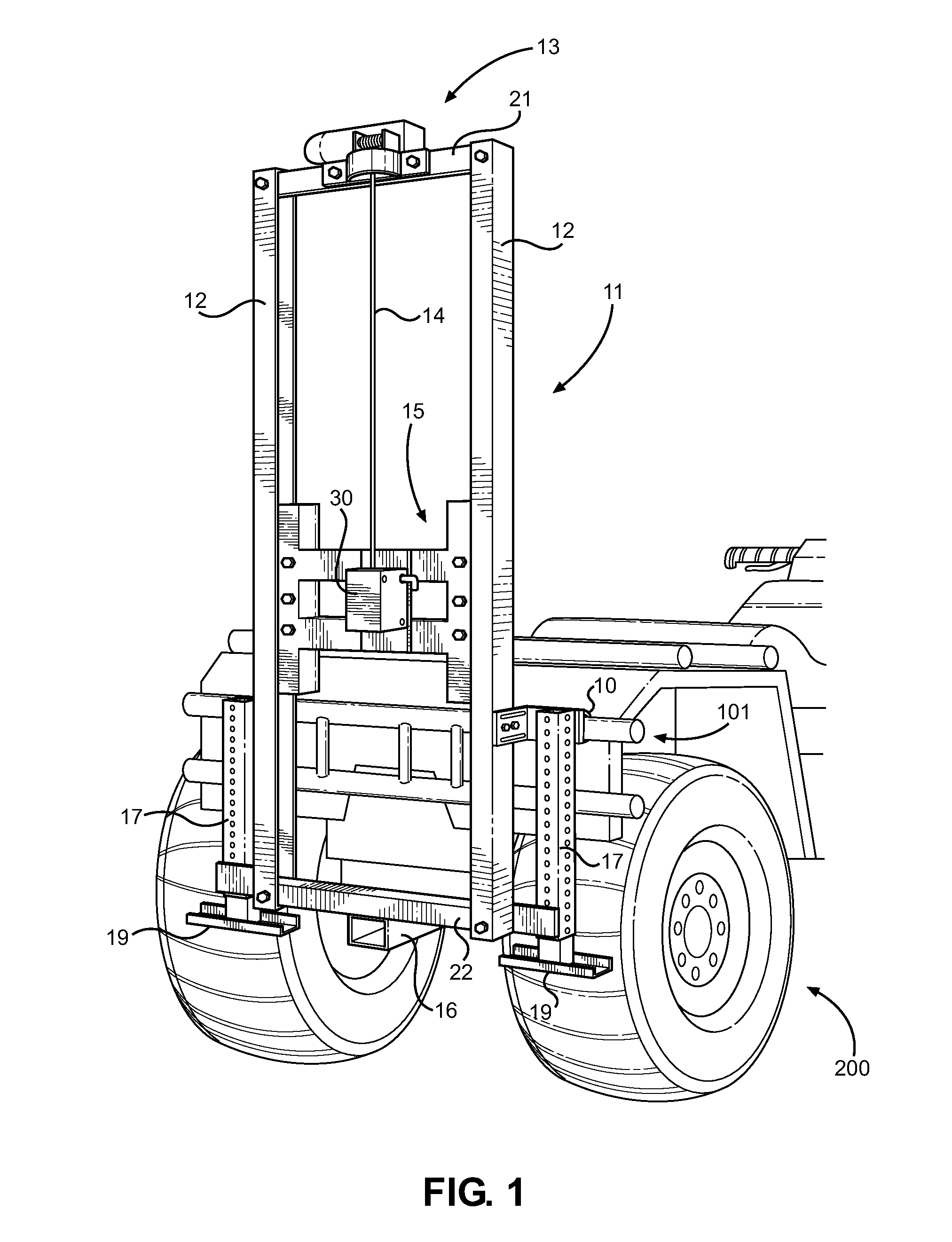

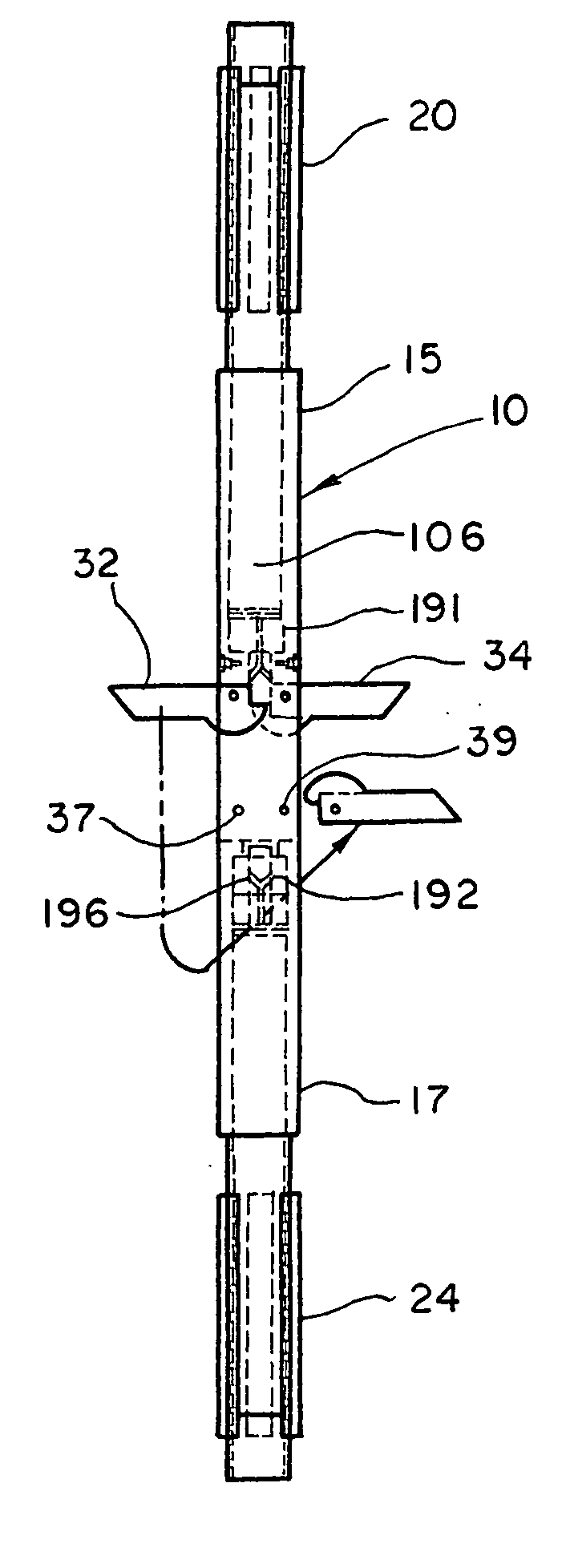

Vehicle-Attached Lifting and Tool Support Device

Owner:ROBINSON JAMES ALLEN +1

Reversible casing cutter

Owner:ABRADO

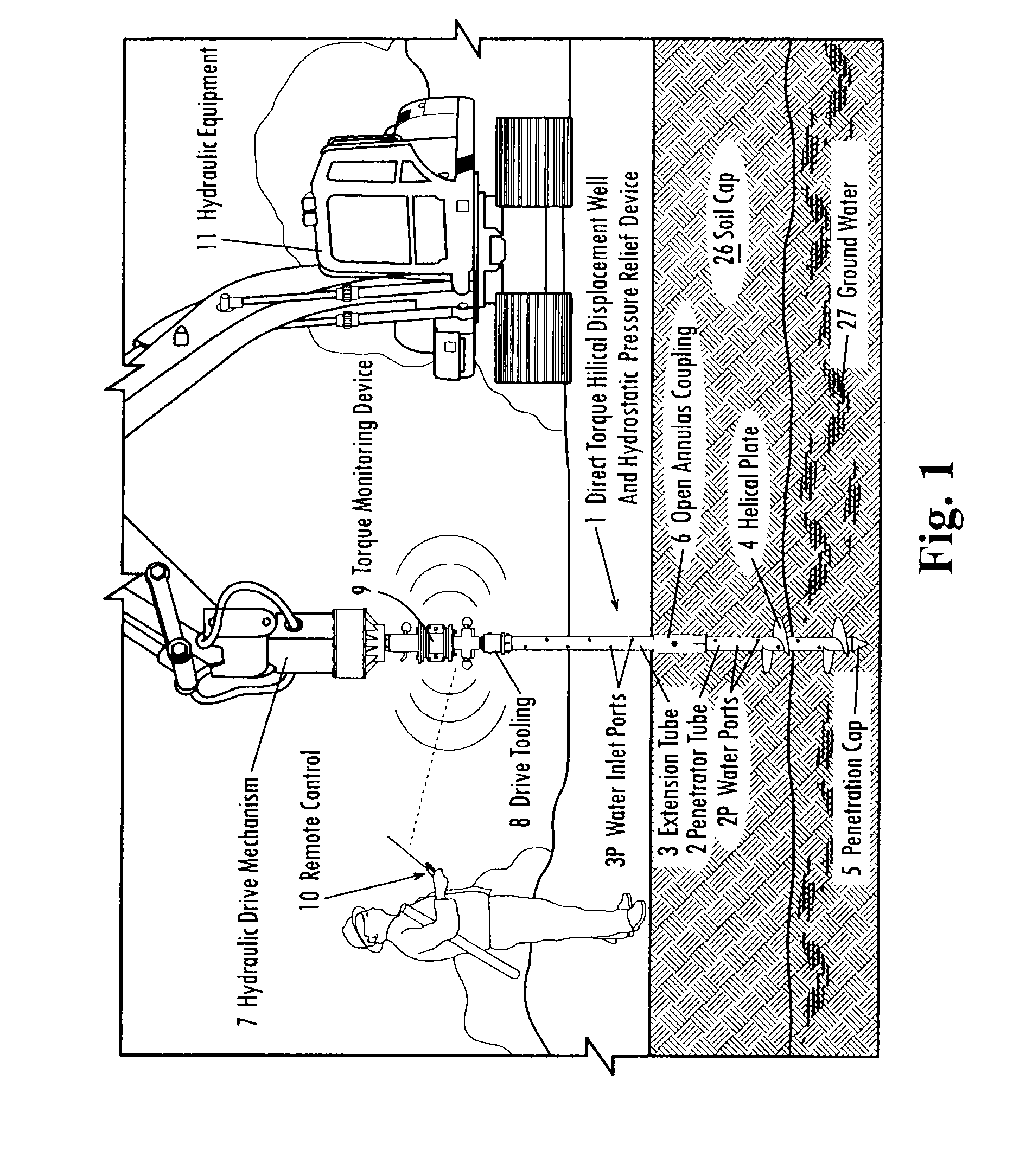

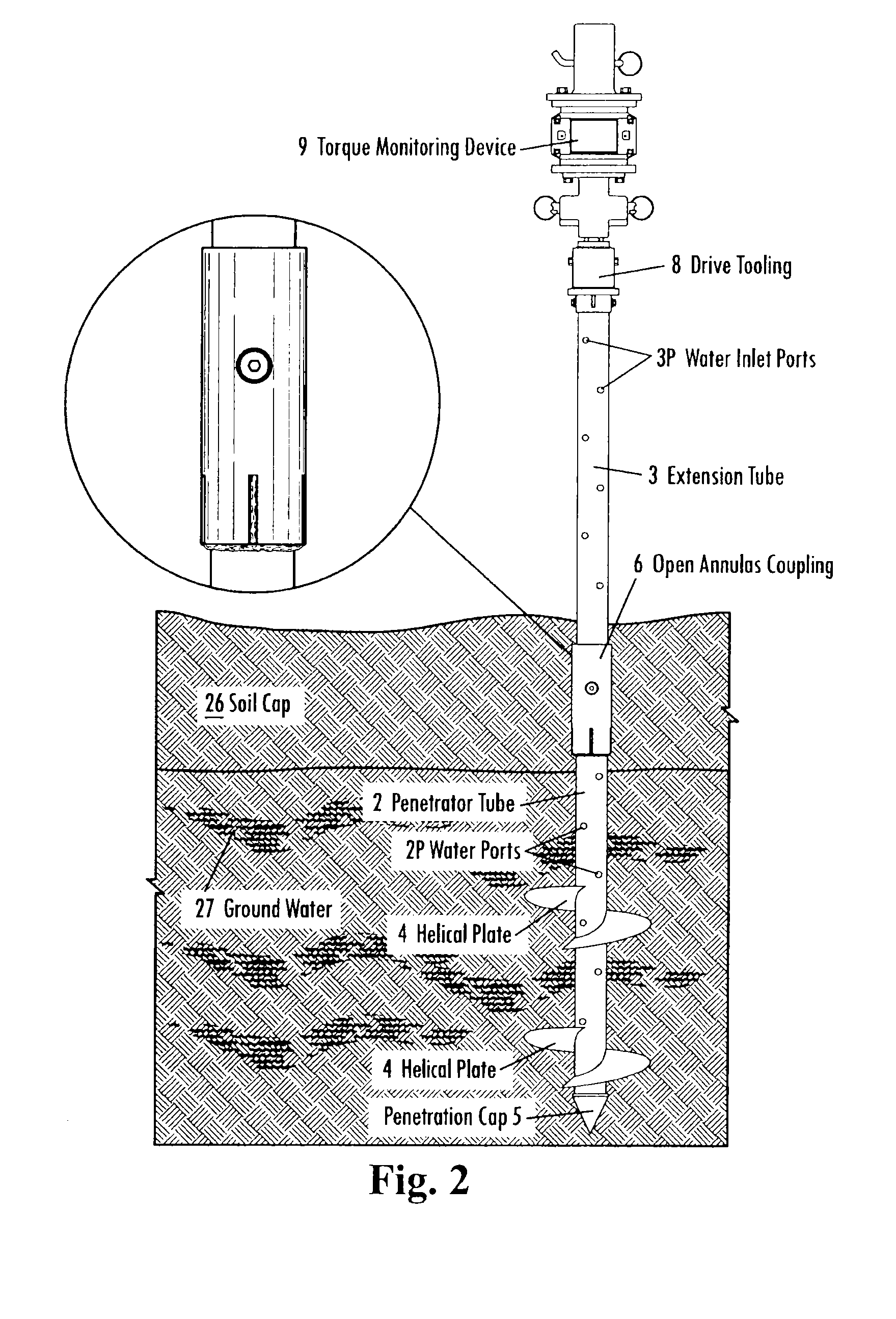

Direct Torque Helical Displacement Well and Hydrostatic Liquid Pressure Relief Device

Owner:QUEEN FRIE A R

Methods of coating wellbore tools and components having such coatings

Owner:BAKER HUGHES INC

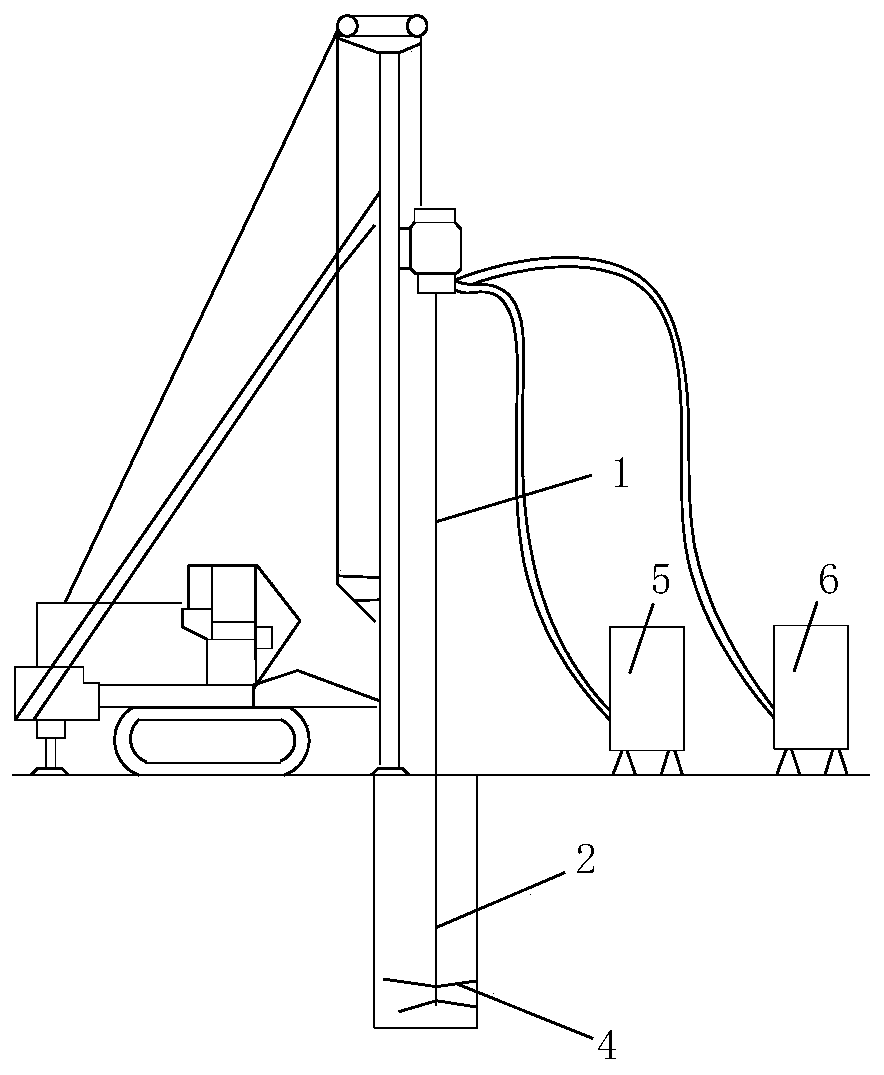

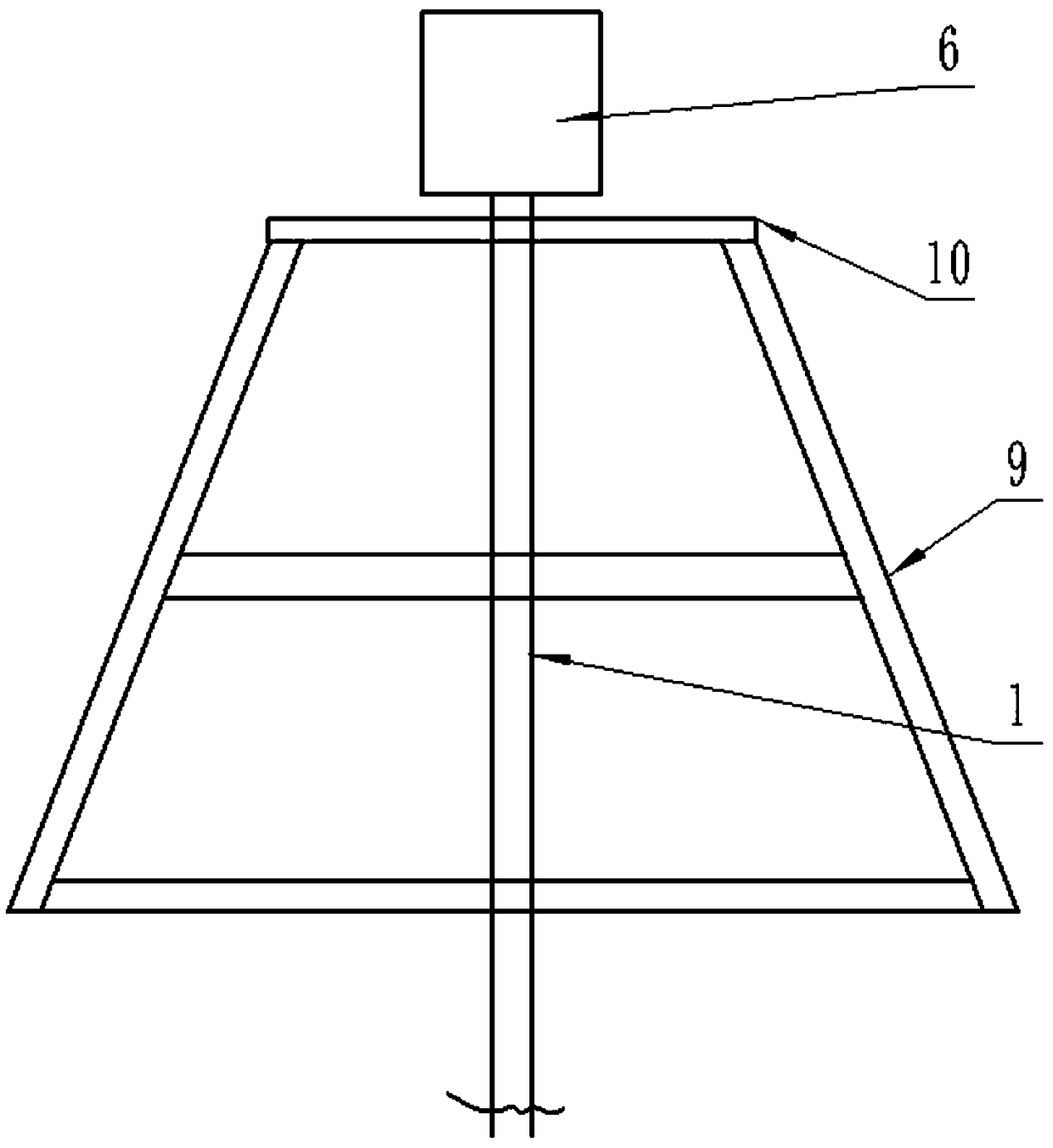

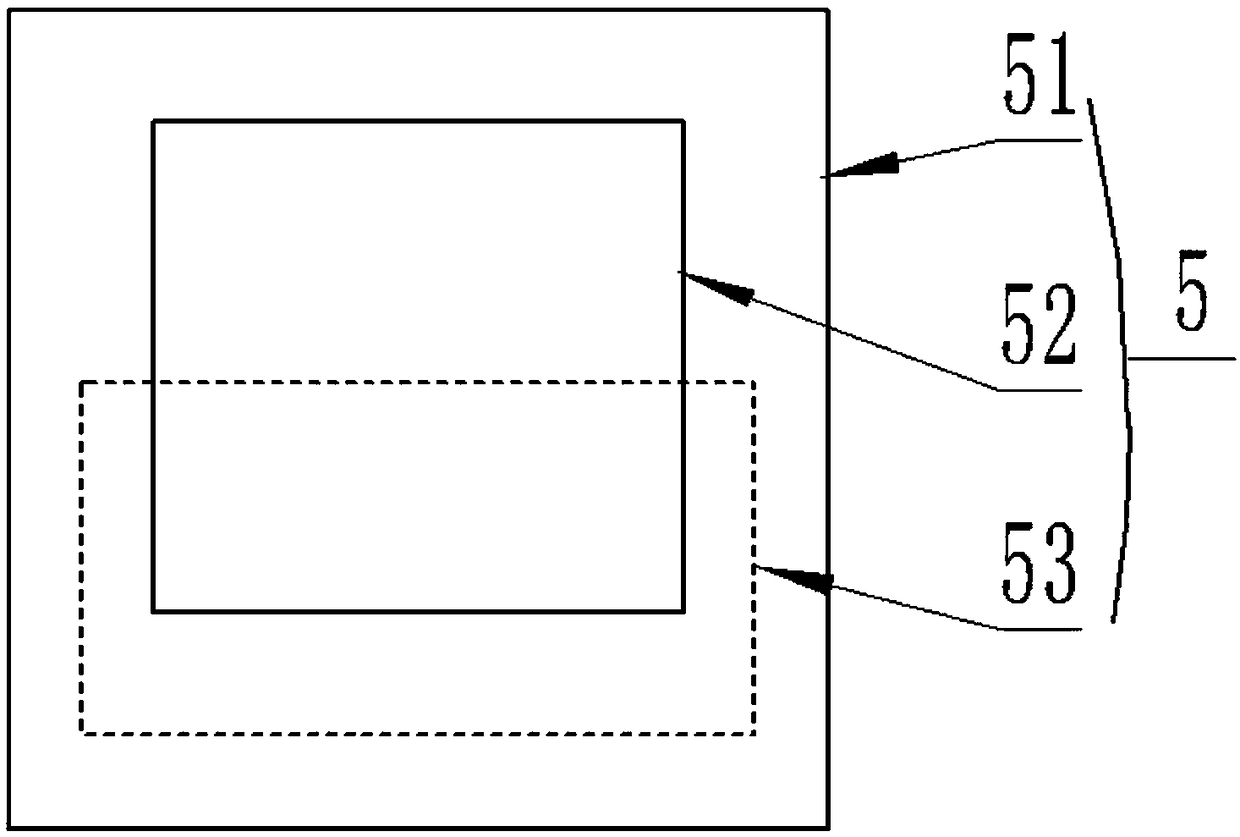

Diameter variable double high-pressure stir-spray pile and diameter variable method thereof

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +2

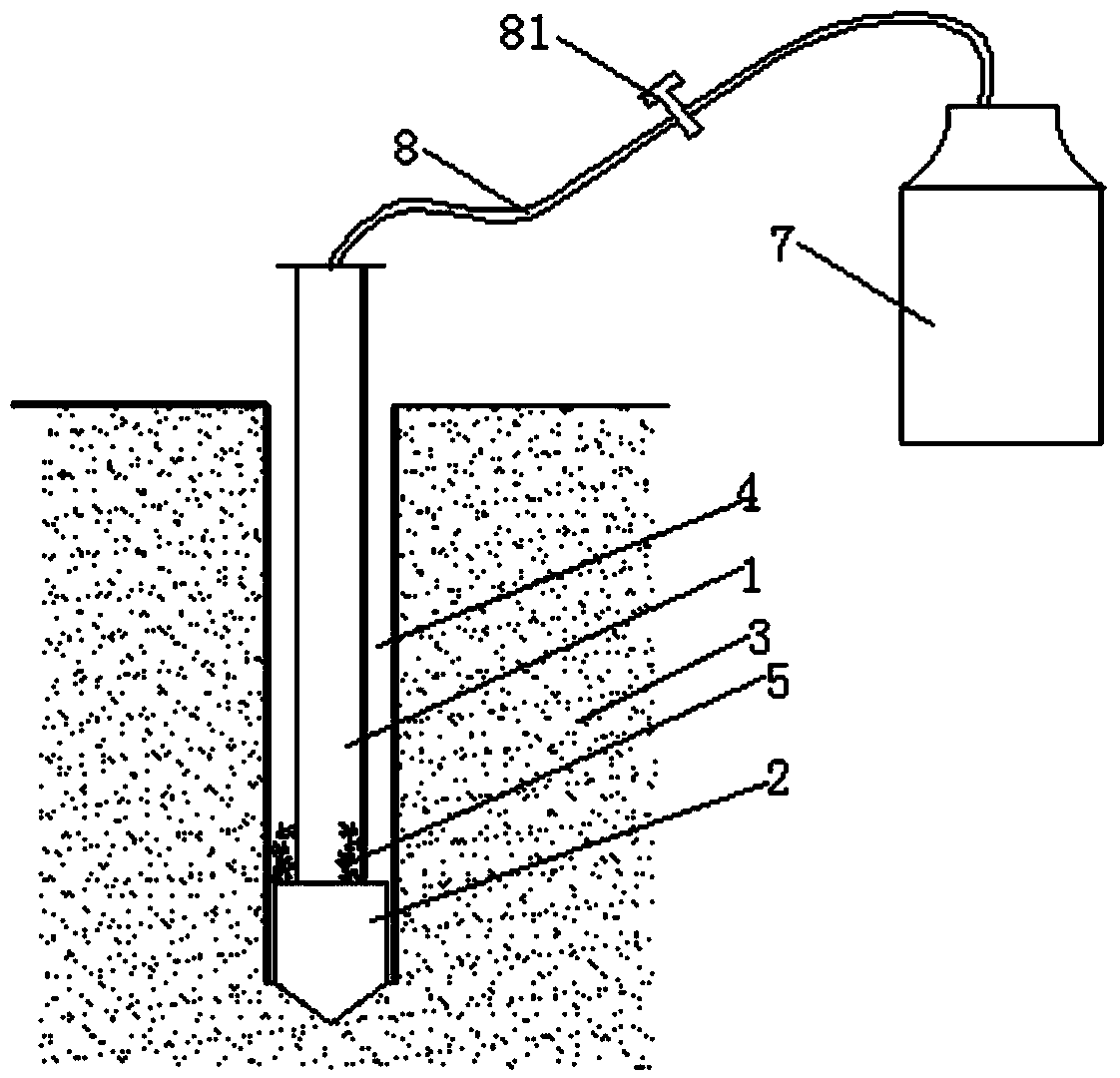

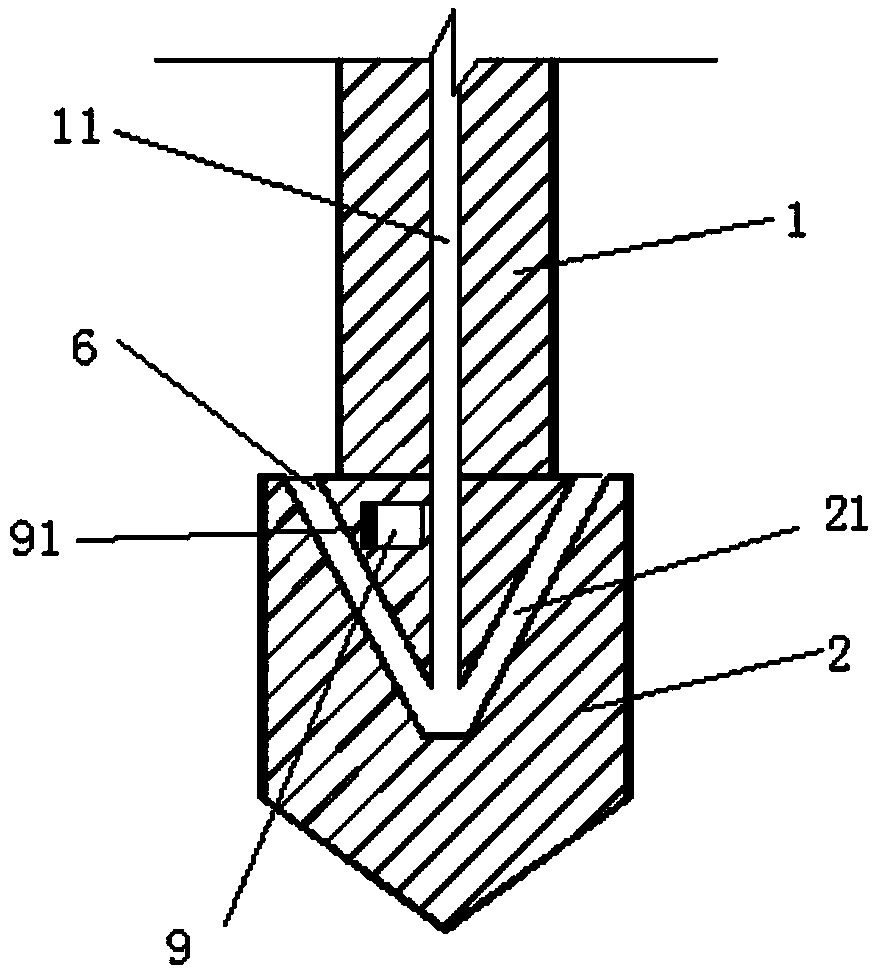

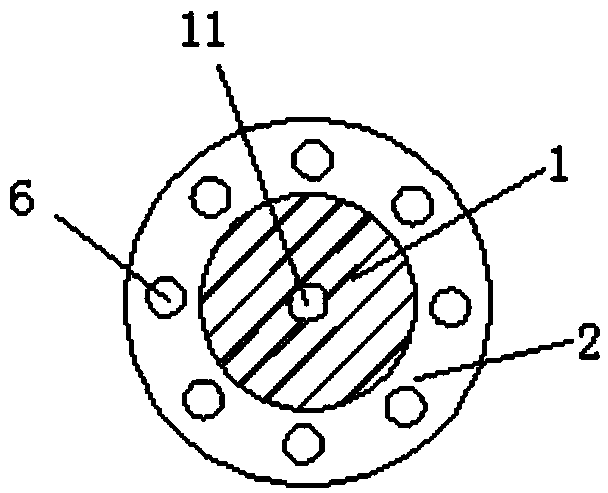

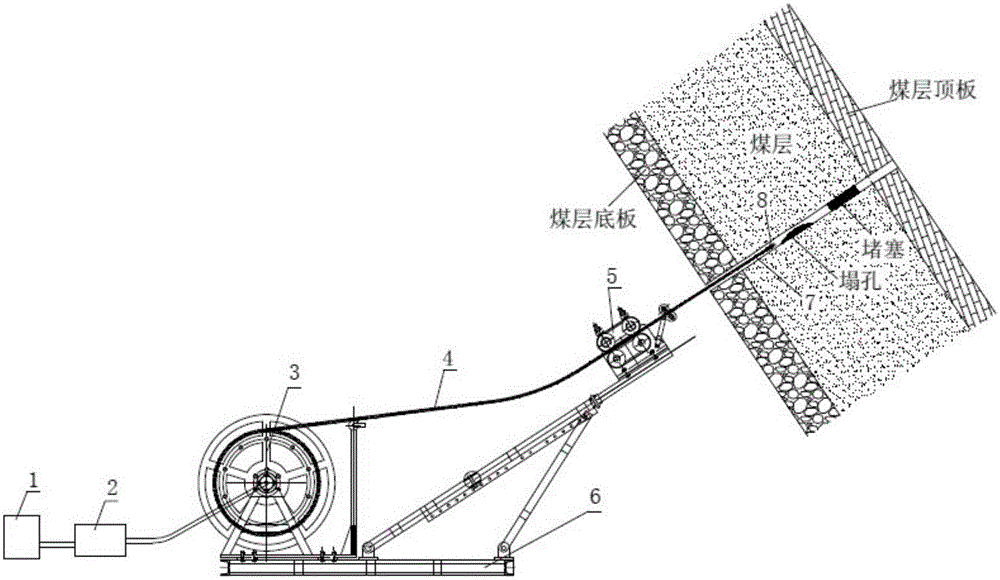

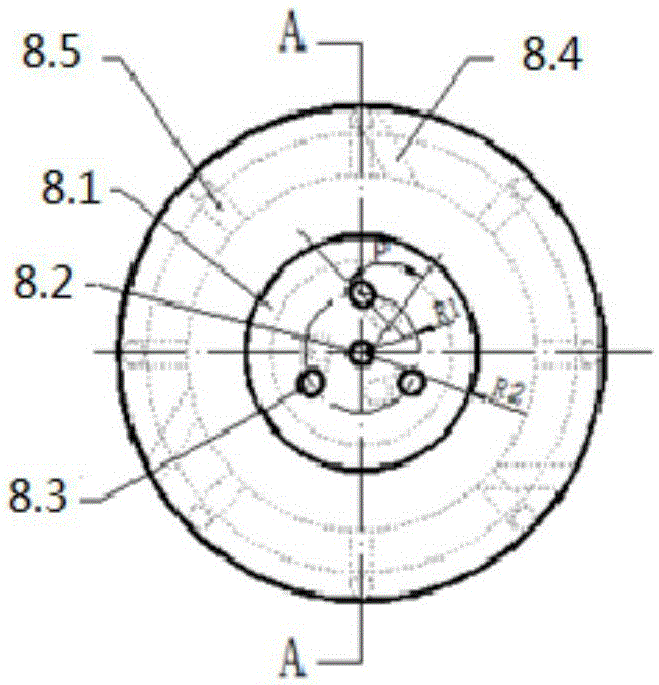

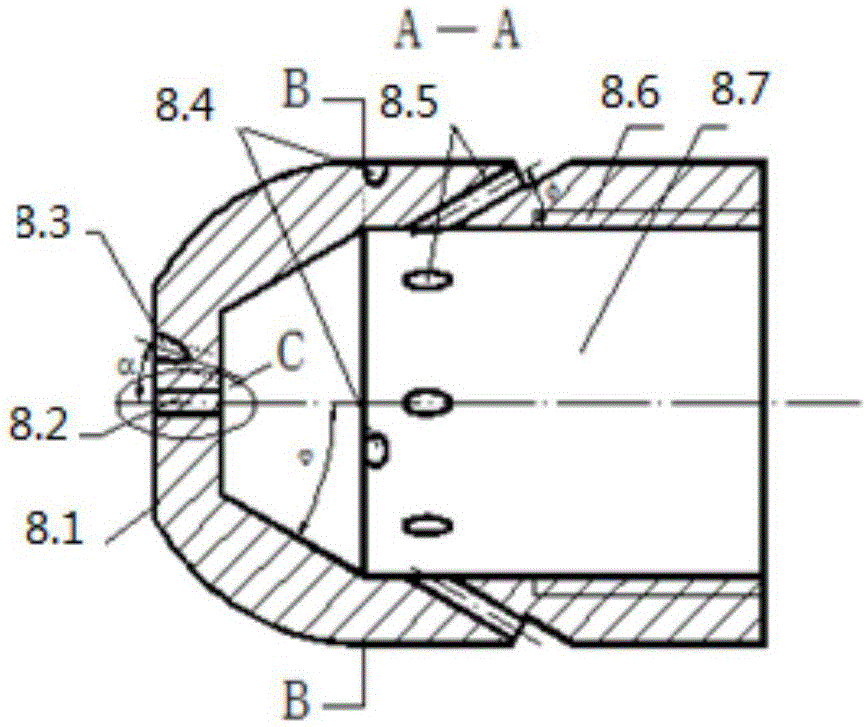

Drilling device for earthen archaeological site

ActiveCN104343383AOvercome time-consuming, labor-intensive and labor-intensive defectsGuaranteed to workDrill bitsConstructionsFlangeRotational joint

The invention discloses a drilling device for an earthen archaeological site. The drilling device is characterized in that a bottom plate is mounted on the upper surface of a slideway through two groups of bottom plate rollers; a pair of round guide rails is fixed on the bottom plate, and a motor mounting plate is mounted on the round guide rails through sliders; a gear motor is fixed on the motor mounting plate; a rotating connector is mounted on an output shaft of the gear motor in a sleeving manner; one end of a connecting sleeve is fixedly connected with the rotating connector through a flange, and the other end of the connecting sleeve is in sleeve joint with one end of a drill rod through threads; the other end of the drill rod is connected with a drill; and the drilling rod, the round guide rails and the slideway are parallel. According to the drilling device for the earthen archaeological site, when a drill tube penetrates into the earthen archaeological site continuously, a drill rod jacket arranged on the drill rod in a sleeving manner goes deep into earth mass with the drill rod and is supported on the earth mass through a drill rod support frame, further, the drill rod jacket can move forwards continuously with the drill rod, so that the drill rod is prevented from shaking in a drilling process, the drilling accuracy is guaranteed, safety and reliability are achieved, and the drilling device has the characteristics of convenience, fastness and high work efficiency.

Owner:SHAANXI NORMAL UNIV

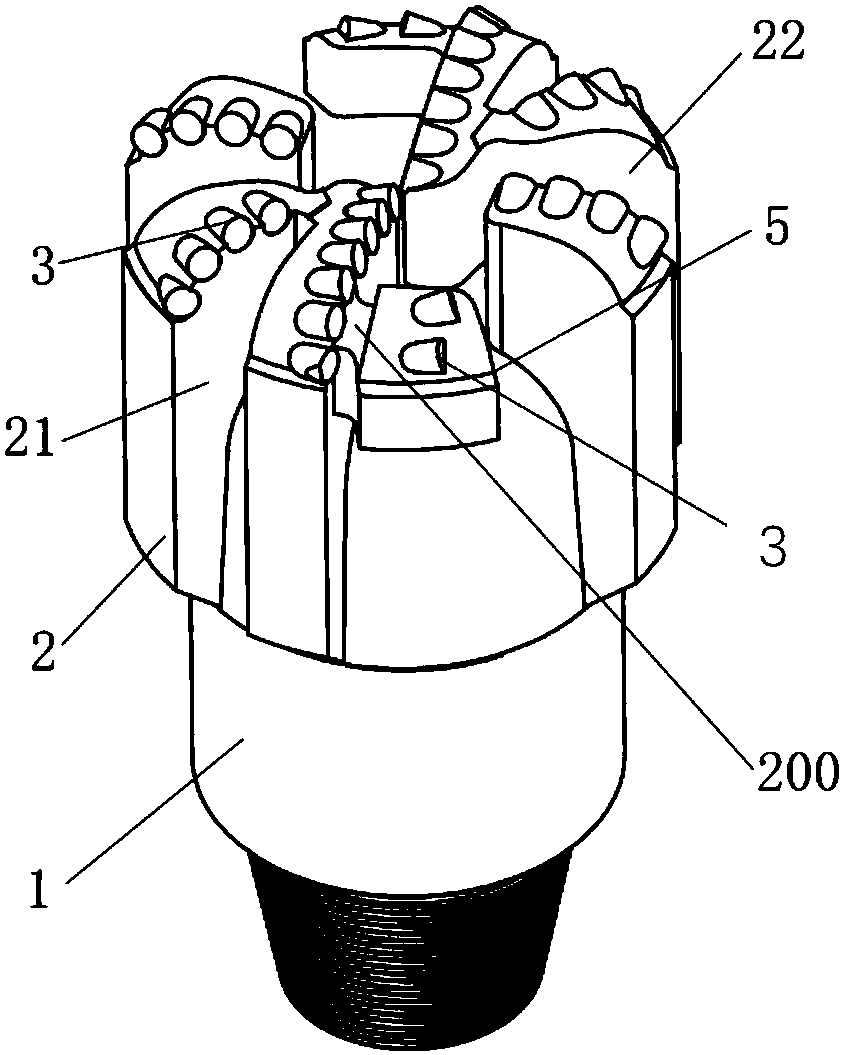

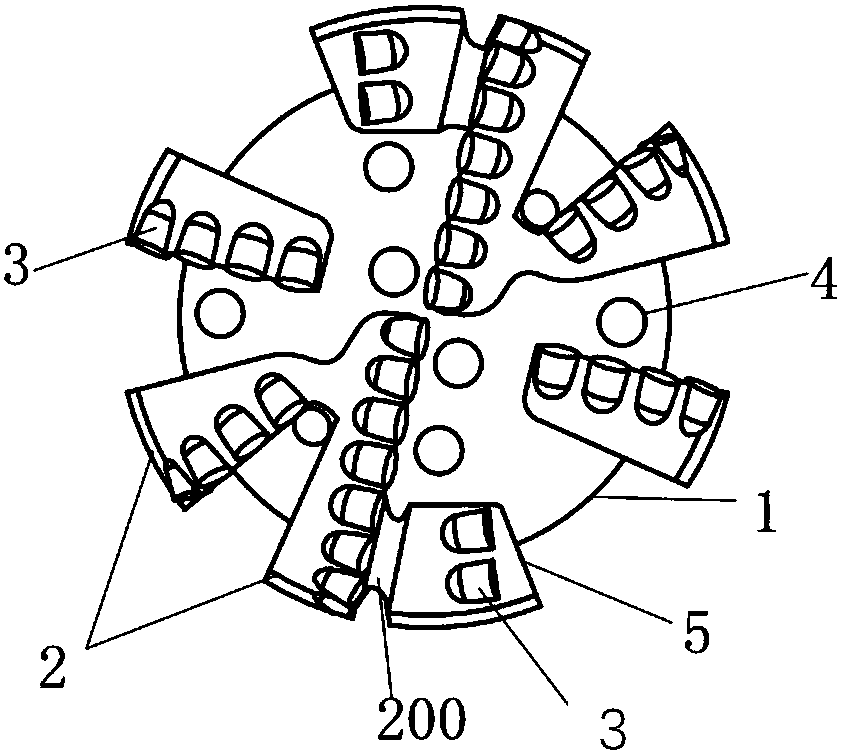

Diamond drill bit suitable for hard stratum drilling

Owner:SOUTHWEST PETROLEUM UNIV +1

Down-the-hole Drill Reverse Exhaust System

Owner:CENTER ROCK INC

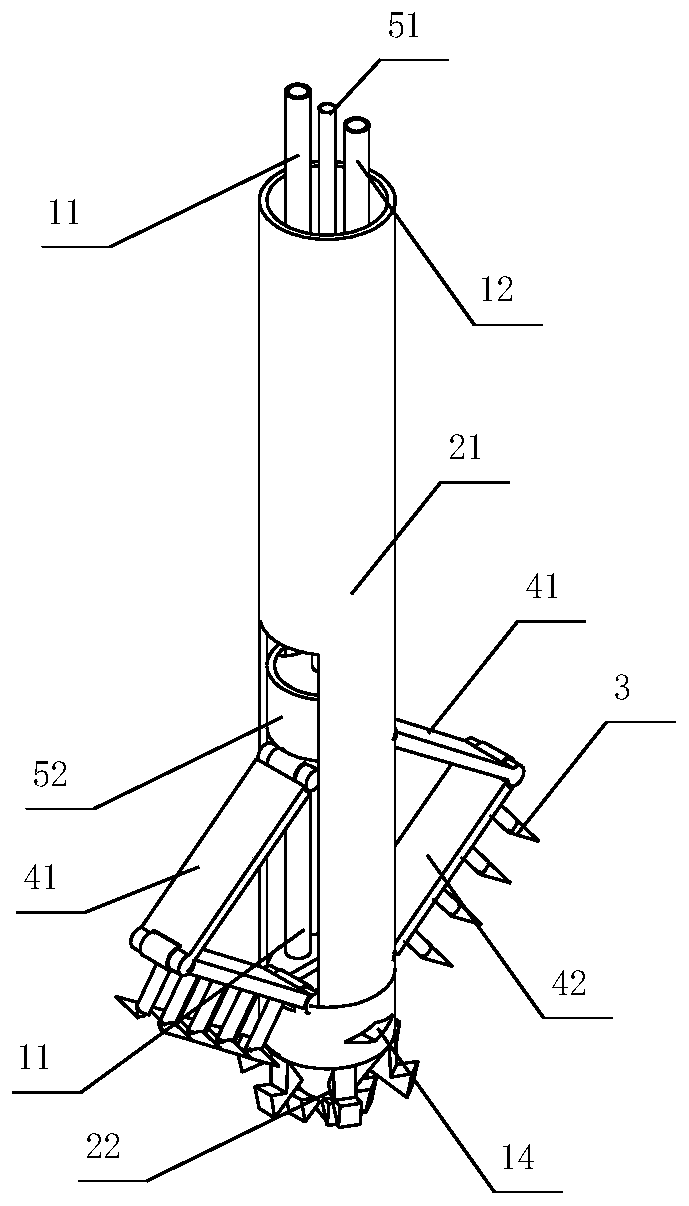

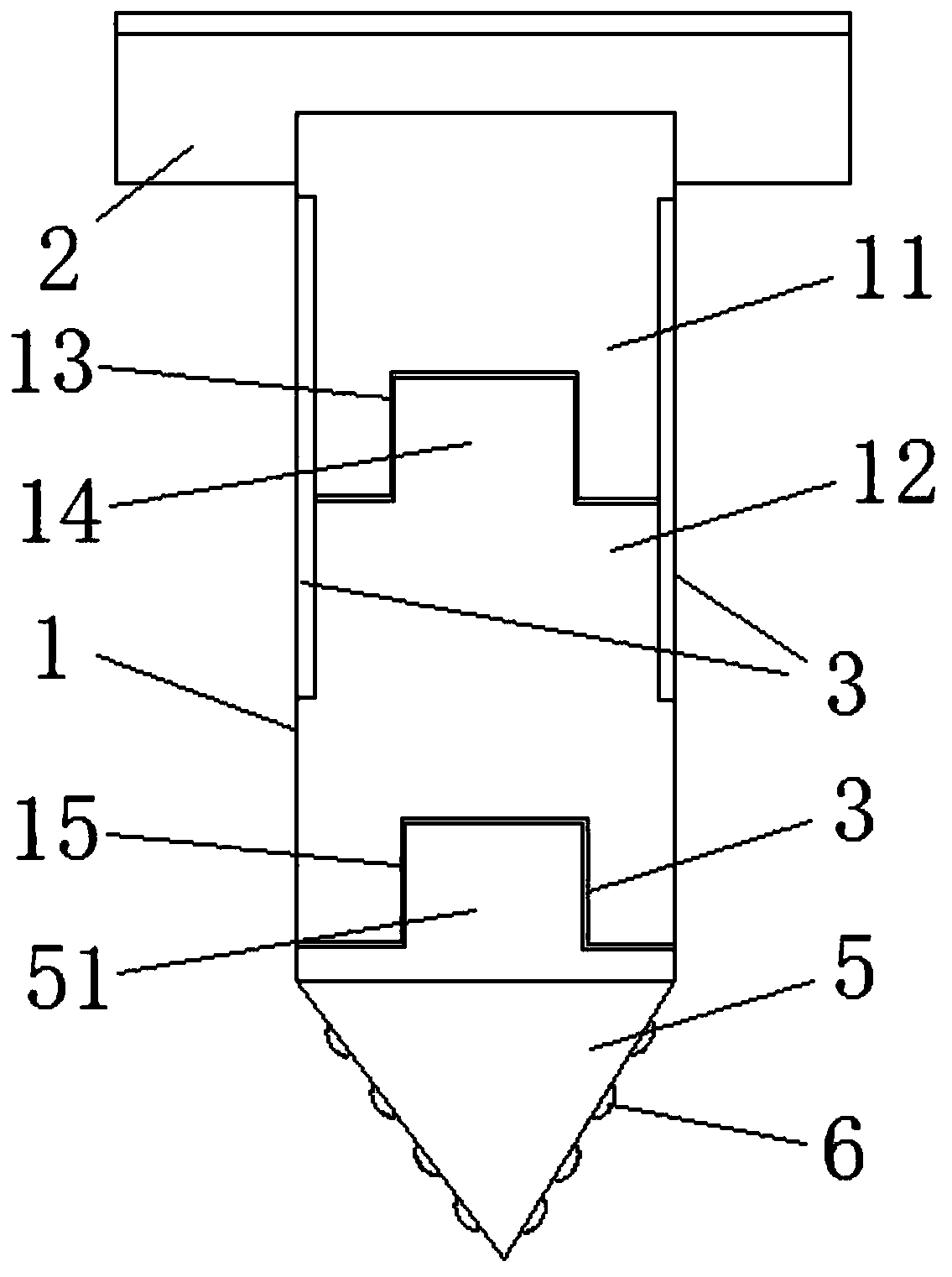

Device for quickly drilling in frozen earth and construction method thereof

ActiveCN104110221AHigh speedDecrease phenomenonEarth drilling toolsDrill bitsNitrogenLiquid nitrogen

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

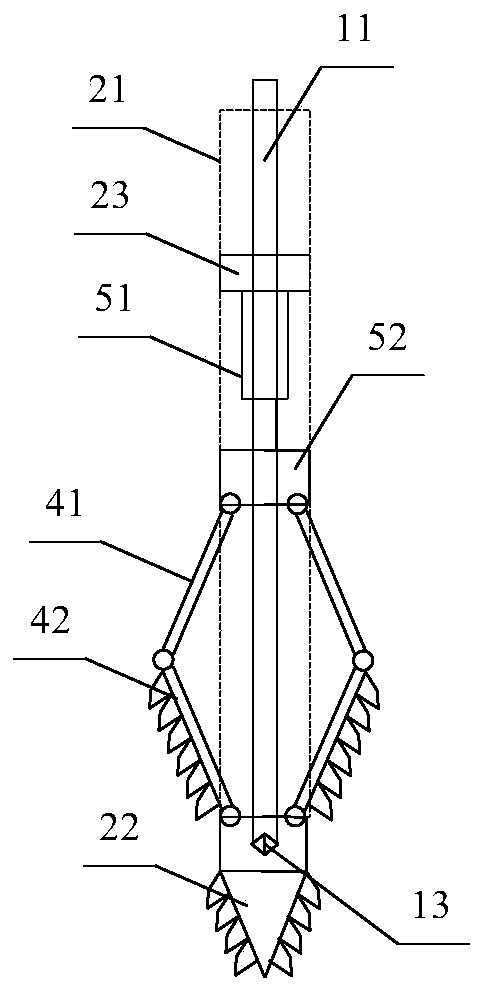

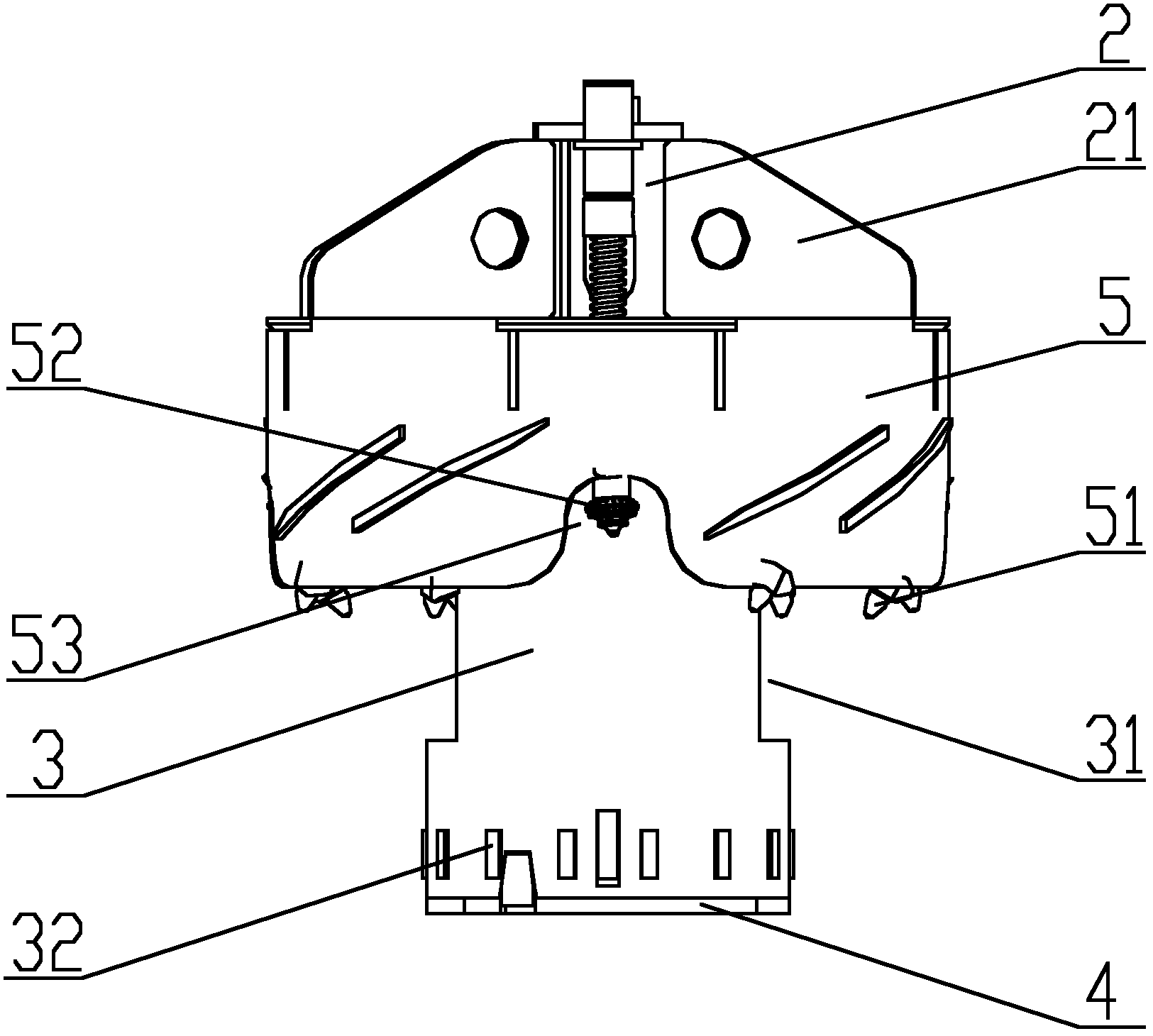

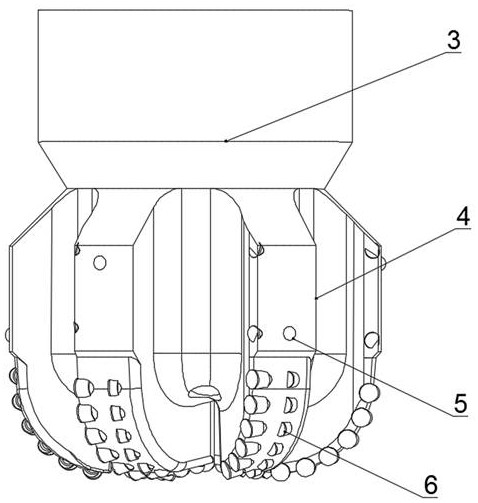

Drilling tool of rotary drilling rig and rotary drilling rig comprising same

InactiveCN102425376AGuaranteed drilling efficiencyImprove construction efficiencyDrill bitsDrilling rodsPetroleum engineeringAxial length

Owner:BEIJING SANY HEAVY MASCH CO LTD

Hole-flushing method for gas extraction drilled hole under coal mine

Owner:CHONGQING UNIV

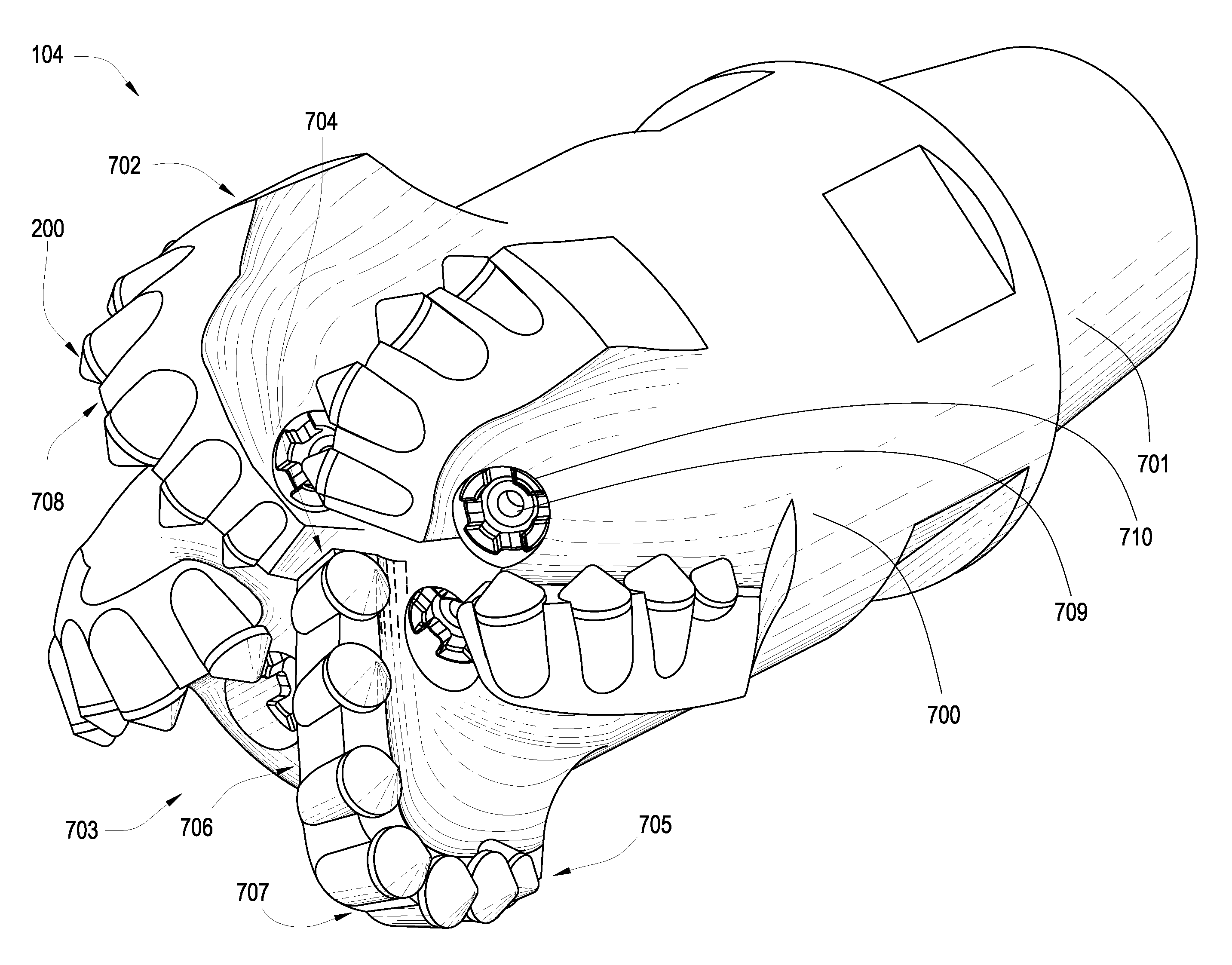

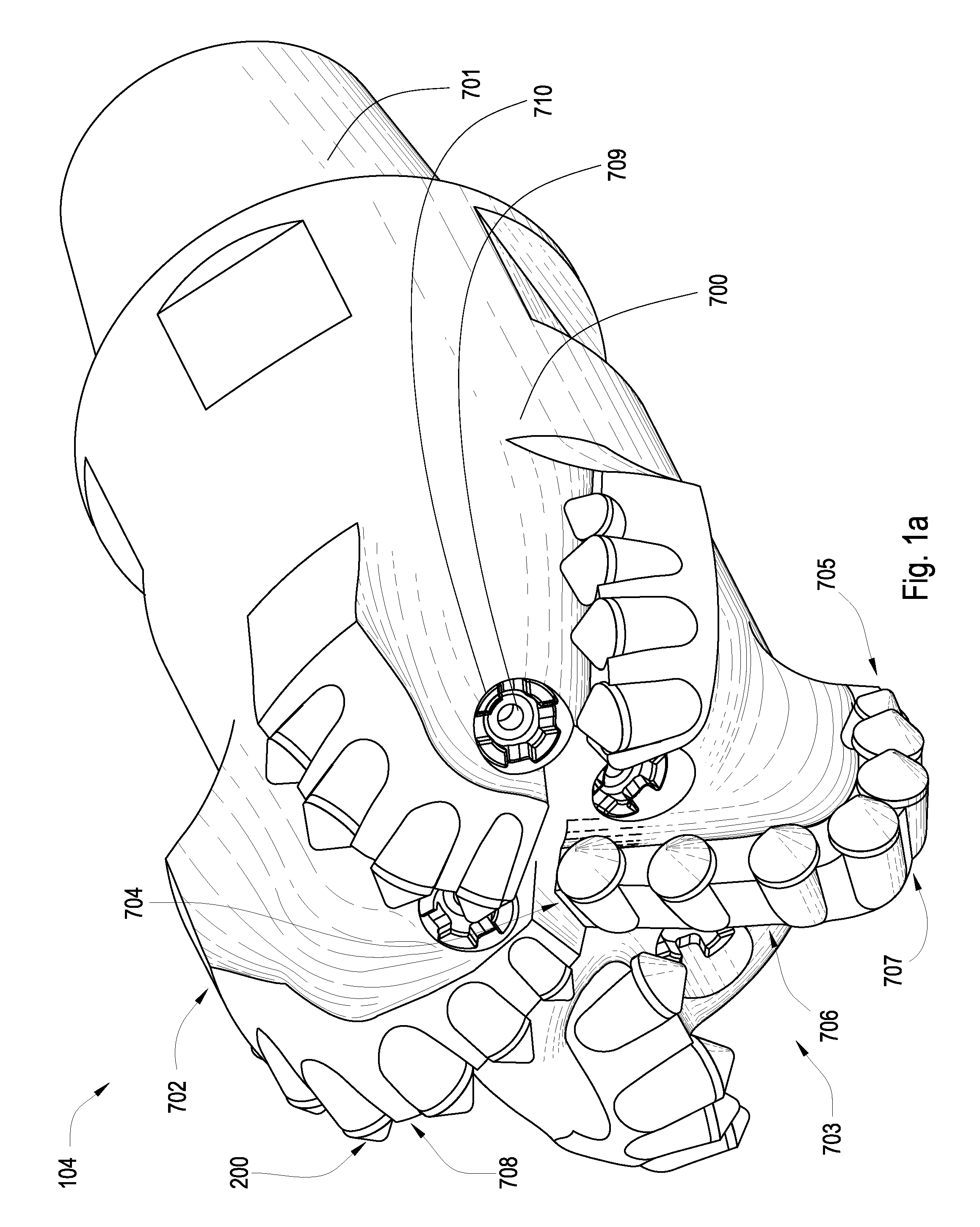

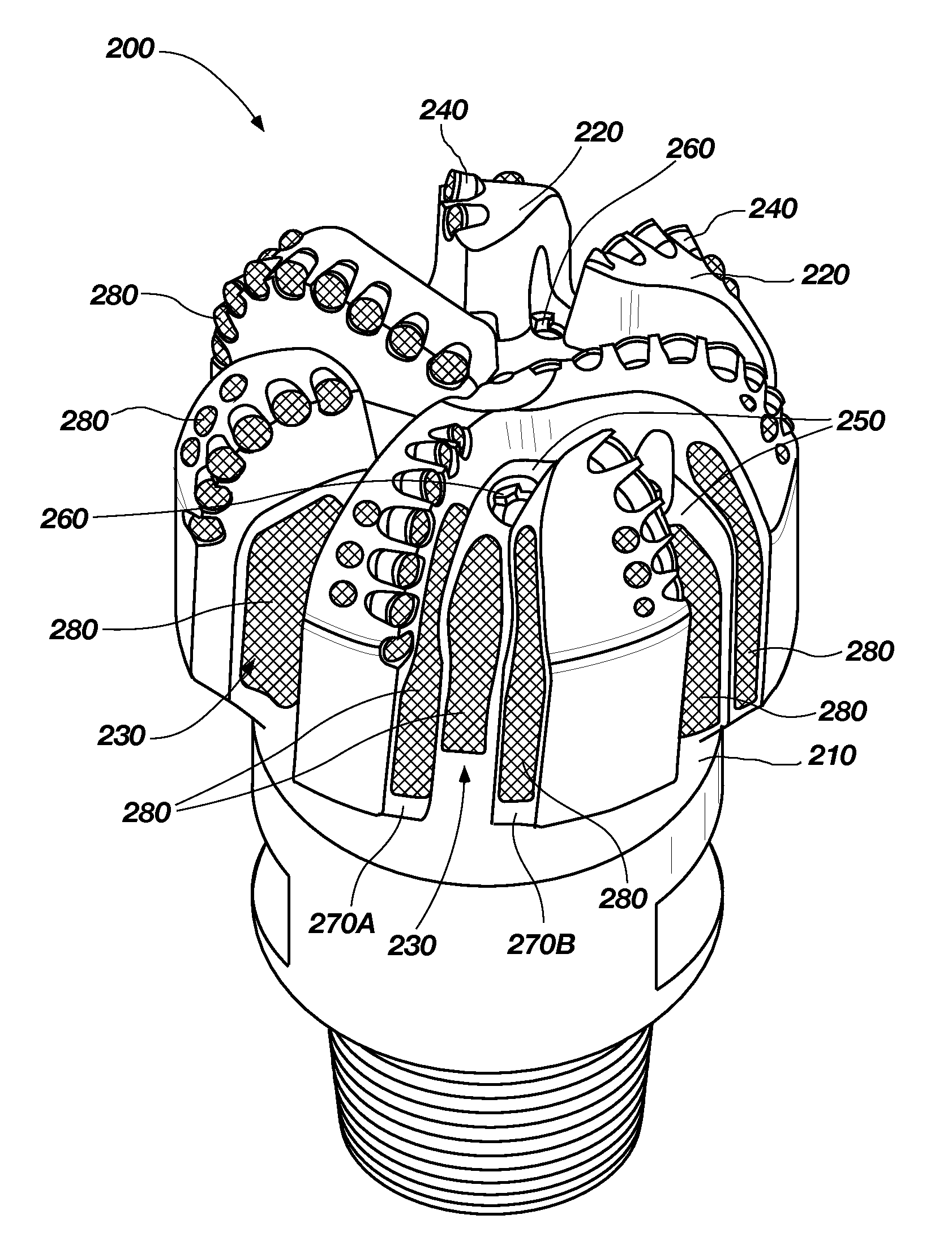

Drill bit with distributed force profile

Owner:BAKER HUGHES INC

Cross drill bit

InactiveCN102444384AReduce the temperatureExtended service lifeDrill bitsTool bitAgricultural engineering

Owner:TONGLING JIUTAI HEAVY IND MINE EQUIP

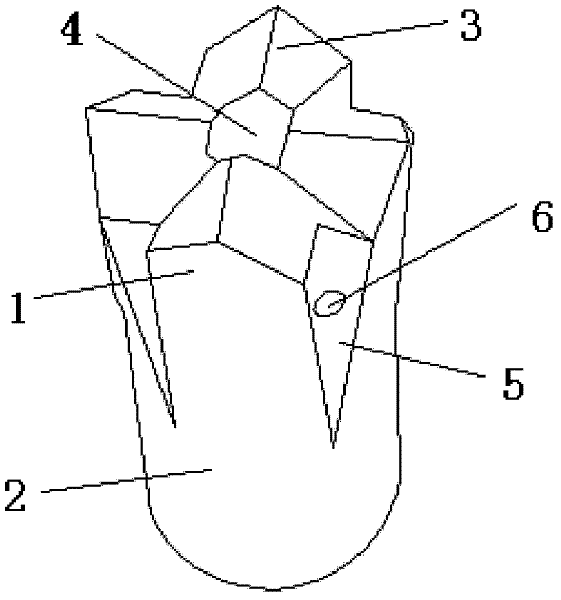

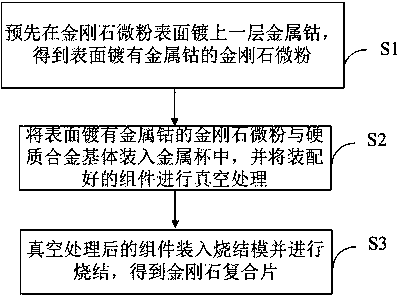

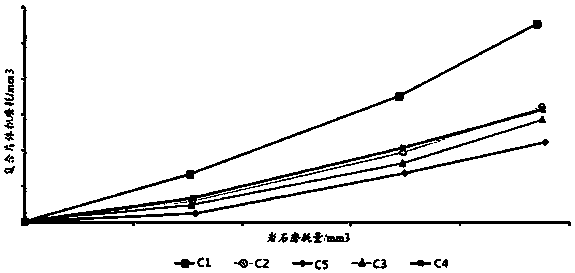

Diamond composite sheet and preparation method thereof

ActiveCN107790710AImprove wear resistanceAvoid abrasionDrill bitsTransportation and packagingAlloy substrateCemented carbide

Owner:SHENZHEN HAIMINGRUN SUPERHARD MATERIALS

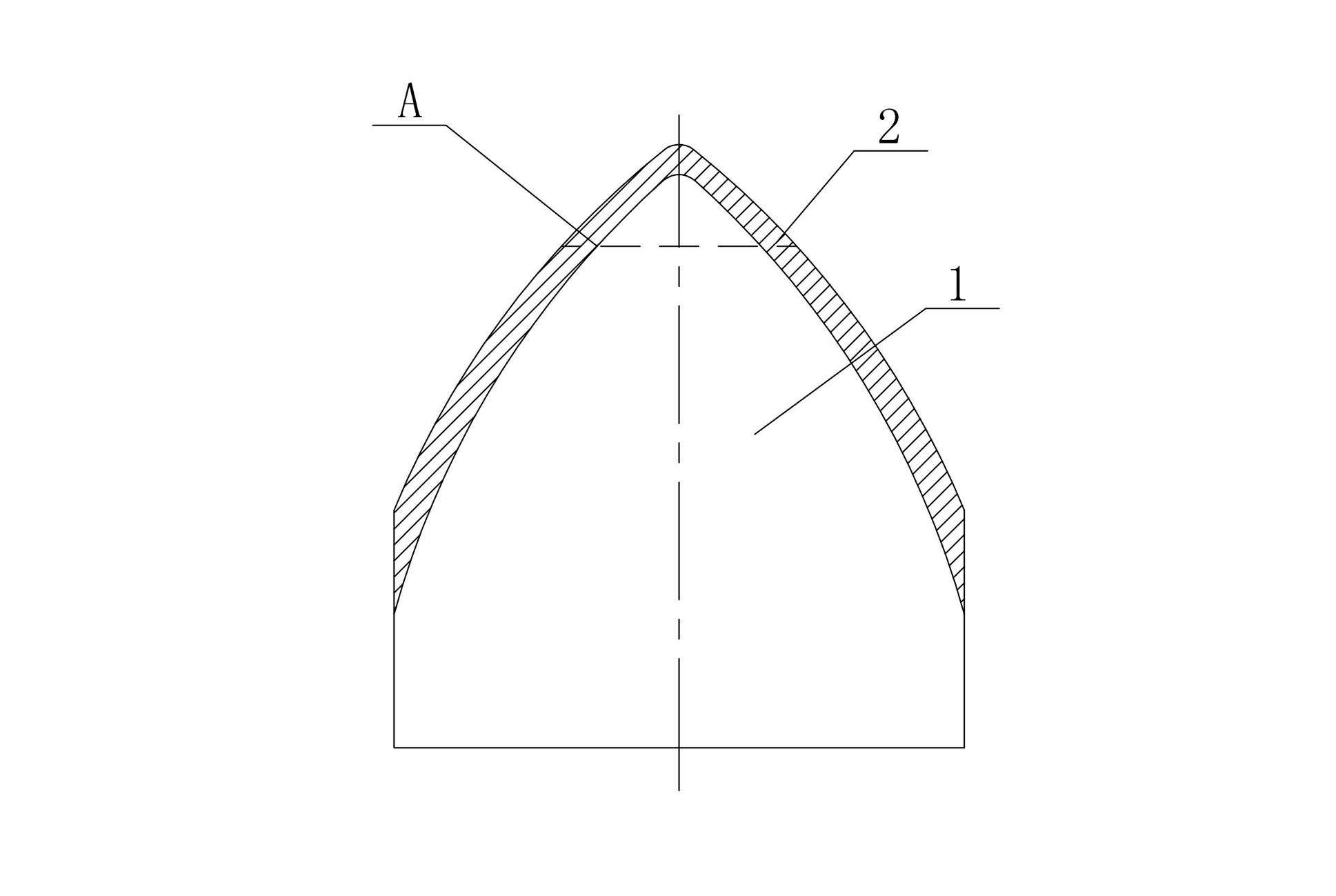

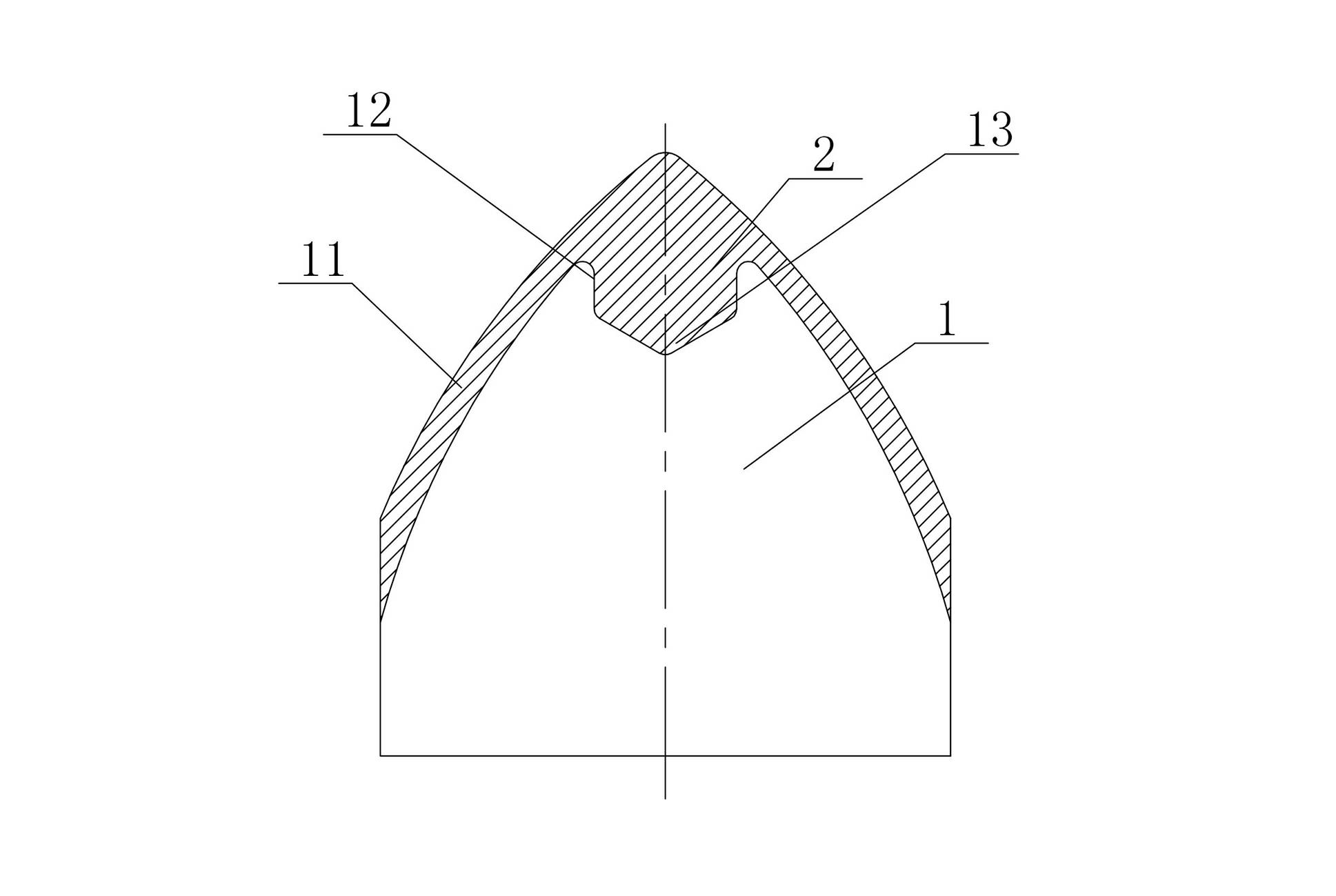

Diamond composite teeth

Owner:HUNAN FEIRAY COMPOSITE MATERIAL

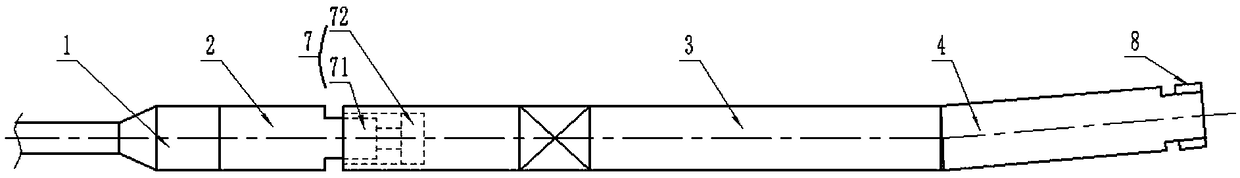

Fast explosive drilling device

InactiveCN111536844AImprove blasting effectImprove blasting efficiencyDrill bitsBlastingExplosive AgentsMining engineering

The invention provides a fast explosive drilling device which comprises a drill bit. The back end of the drill bit is connected to a flow guiding pipe body, an explosive injection hole is formed in the outer side wall of the back of the flow guiding pipe body in a rock drilling direction, an explosive injection channel is arranged in the flow guiding pipe body in a length direction, the explosiveinjection channel communicates to the explosive injection hole, a front sealing ring is arranged on the outer wall of the front part of the flow guiding pipe body in the rock drilling direction, a back sealing liquid ring is arranged on the outer wall of the back part of the flow guiding pipe body in the rock drilling direction, and the explosive injection hole is located in the front end of the back sealing liquid ring in the rock drilling direction. The fast explosive drilling device can be filled with a liquid explosive for explosion and is good in explosion effect. Explosion and rock drilling can be carried out simultaneously, and the explosive can be filled continuously without taking out a drill bit, so that the explosion efficiency is high.

Owner:李天北

Rotary steerable drilling tool

Owner:BEIJING LIUHE GREATNESS TECH

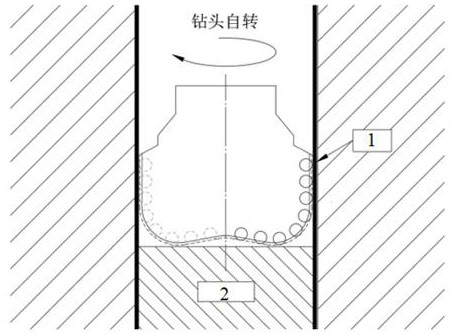

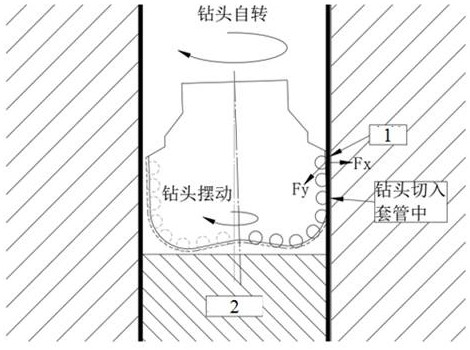

PDC drill bit capable of achieving casing drilling and design method thereof

ActiveCN113323592AEasy to wear offDrilling does not affectDrill bitsConstructionsStructural engineeringOil drilling

Owner:CCDC PETROLEUM CORING TECH

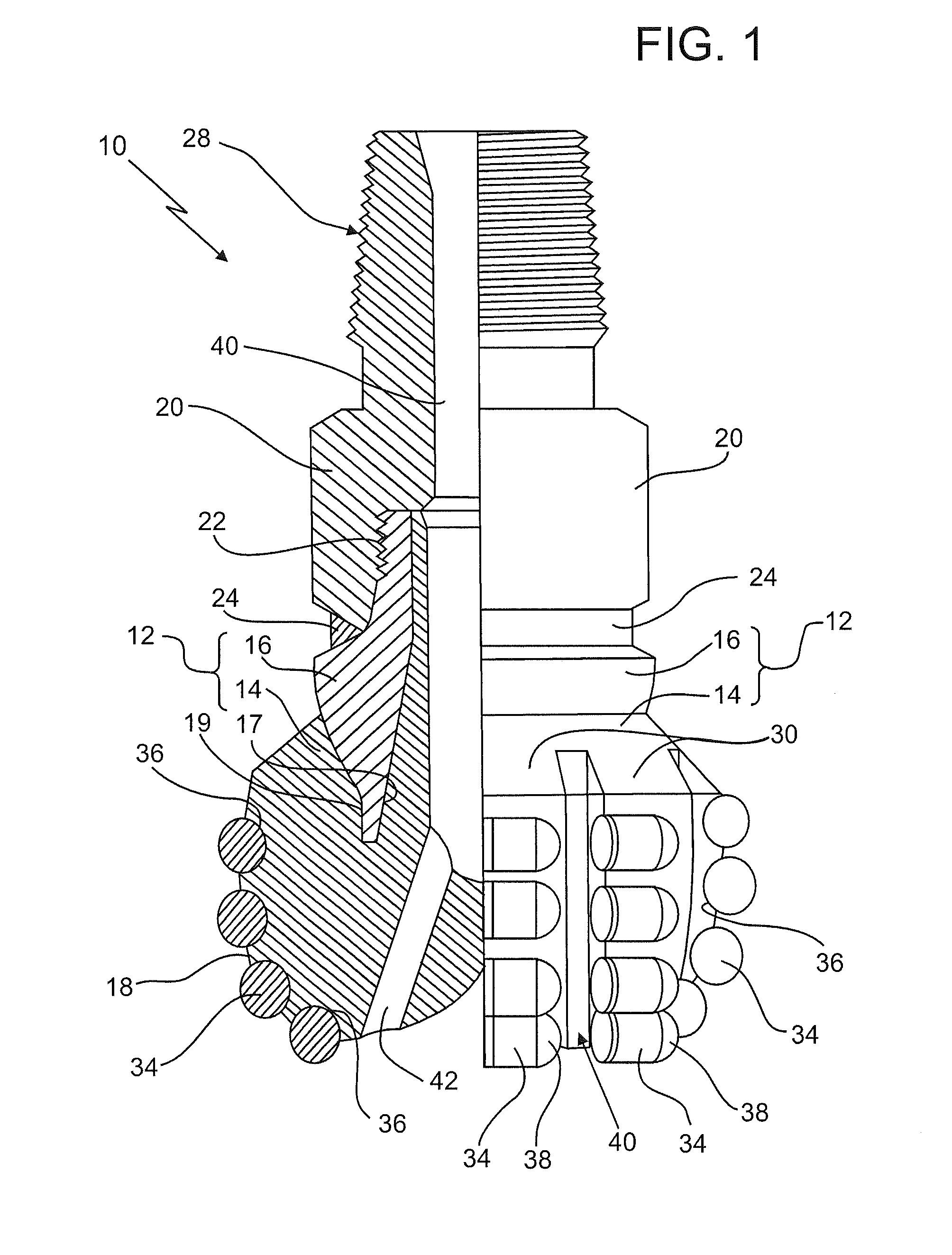

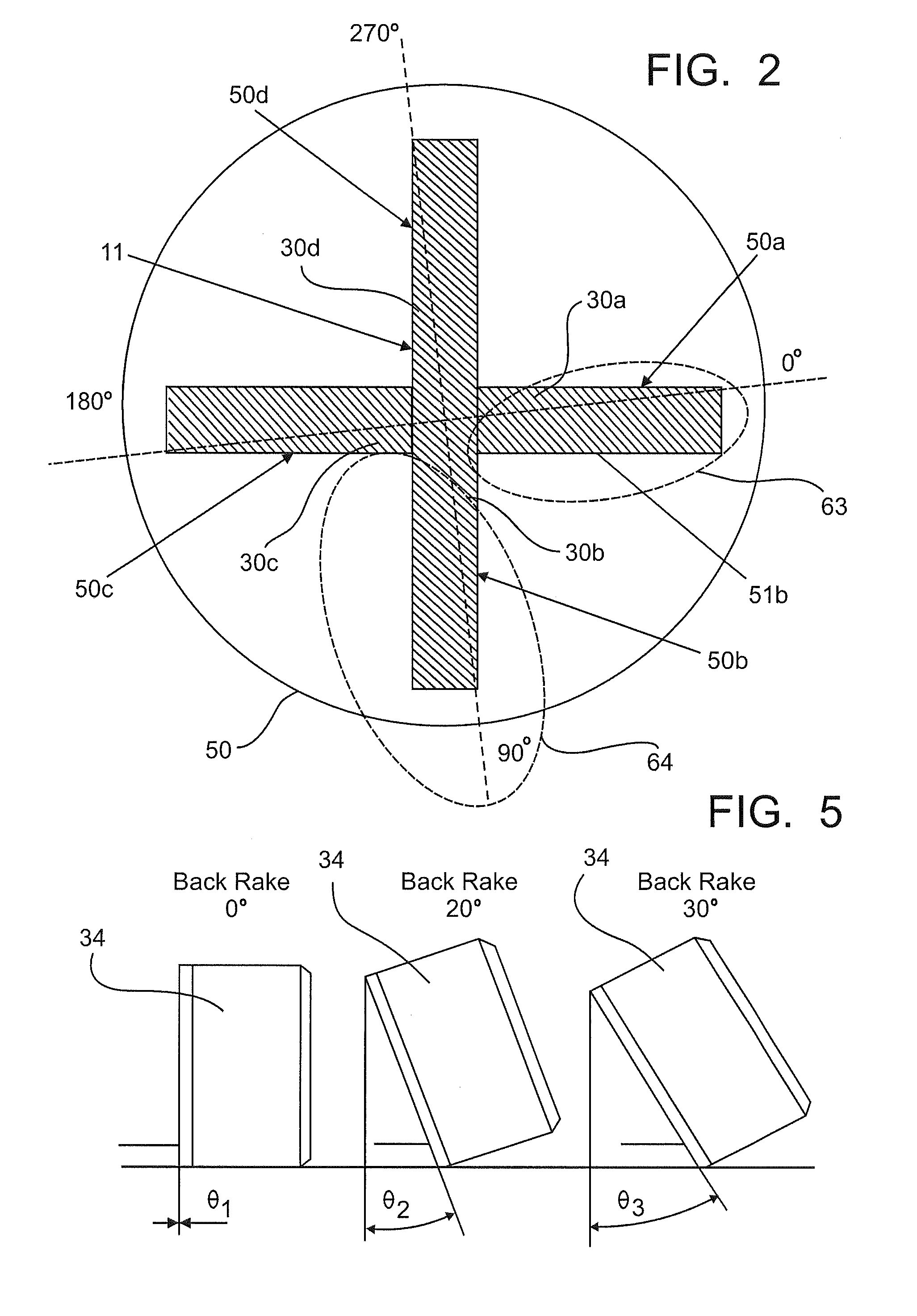

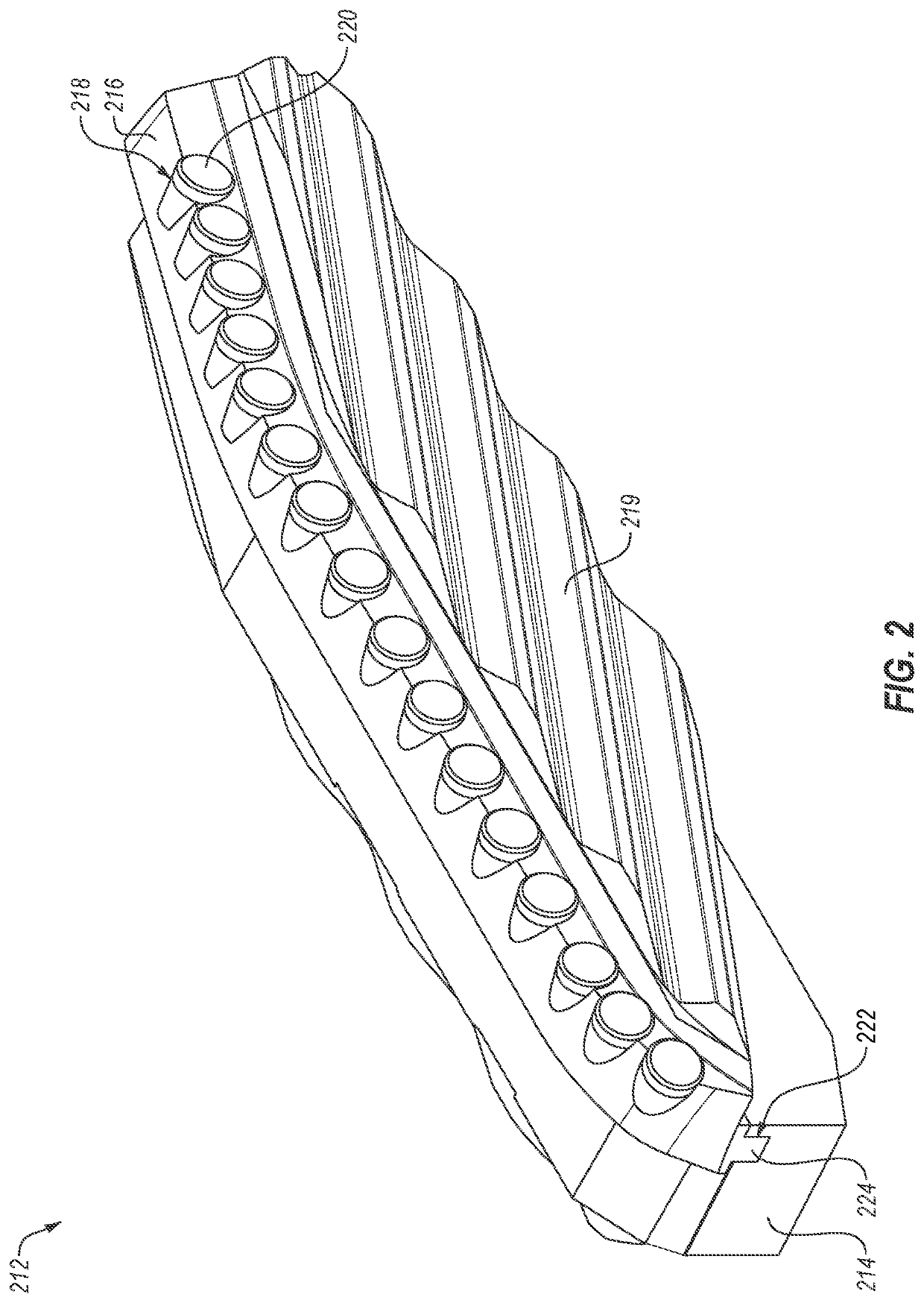

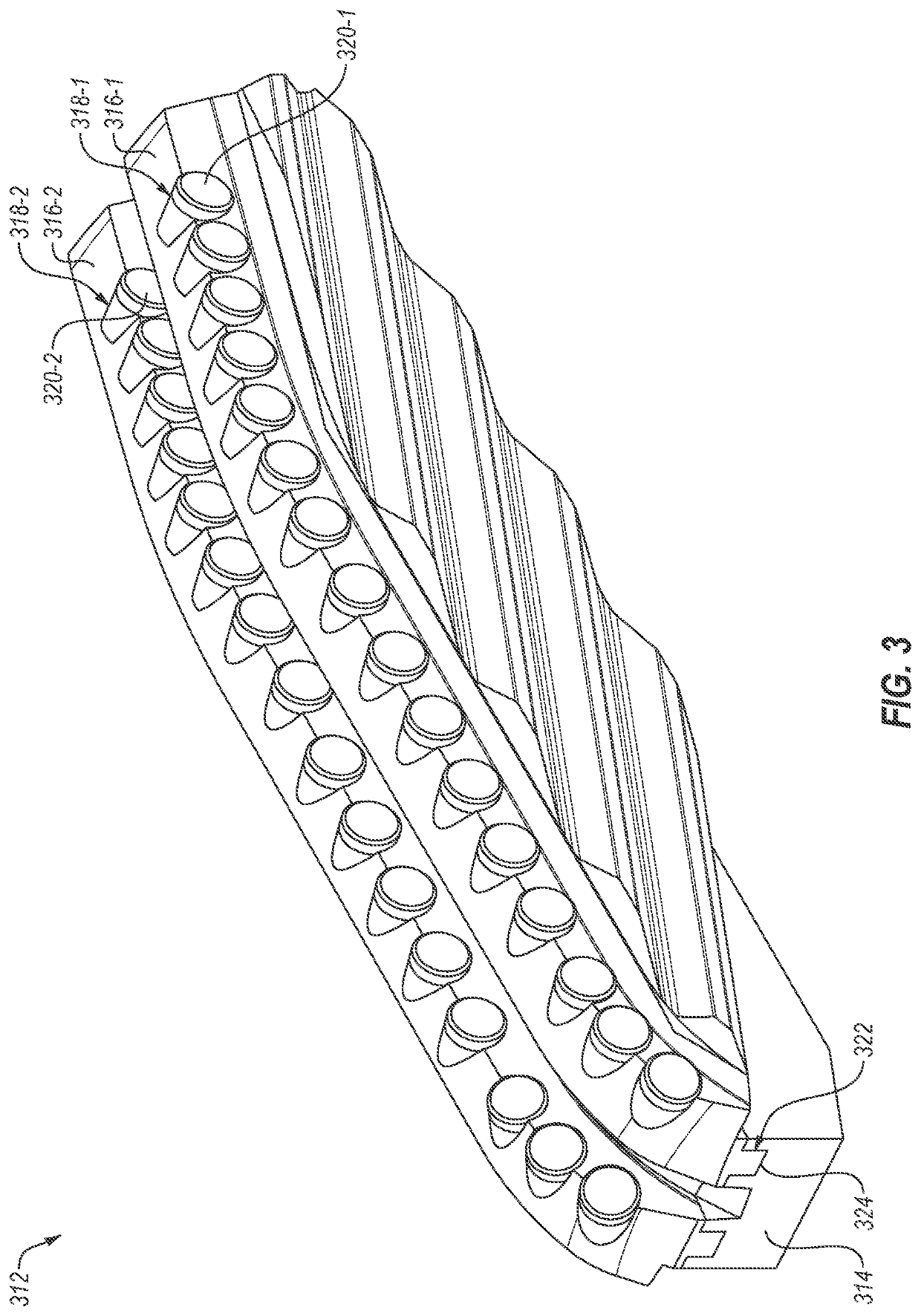

Reamer Wear Protection Assembly and Method

Embodiments of a reamer of the present invention generally include a front end containing components, such as pie wedge-shaped corebuster components, that are substantially axially disposed with respect to the axis of rotation of the reamer, wherein the pie wedges include abrasion-resistant inserts, which may be cylindrical in shape, oriented substantially longitudinally with respect to the axis of rotation of the reamer. Embodiments of a method of using an apparatus of the present invention are also provided.

Owner:INROCK DRILLING SYST INC

Drill bit for engineering geological drilling

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

Reamer block with cutter pocket holders

Owner:SMITH INT INC

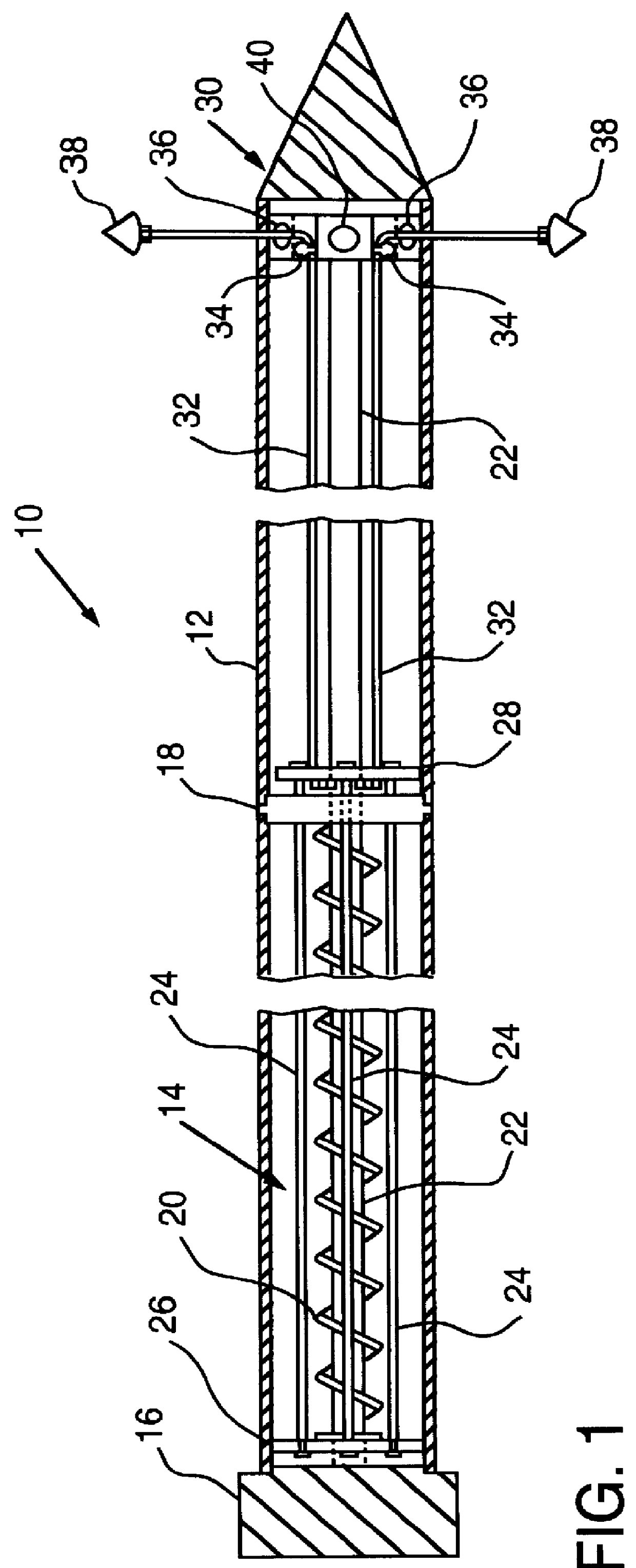

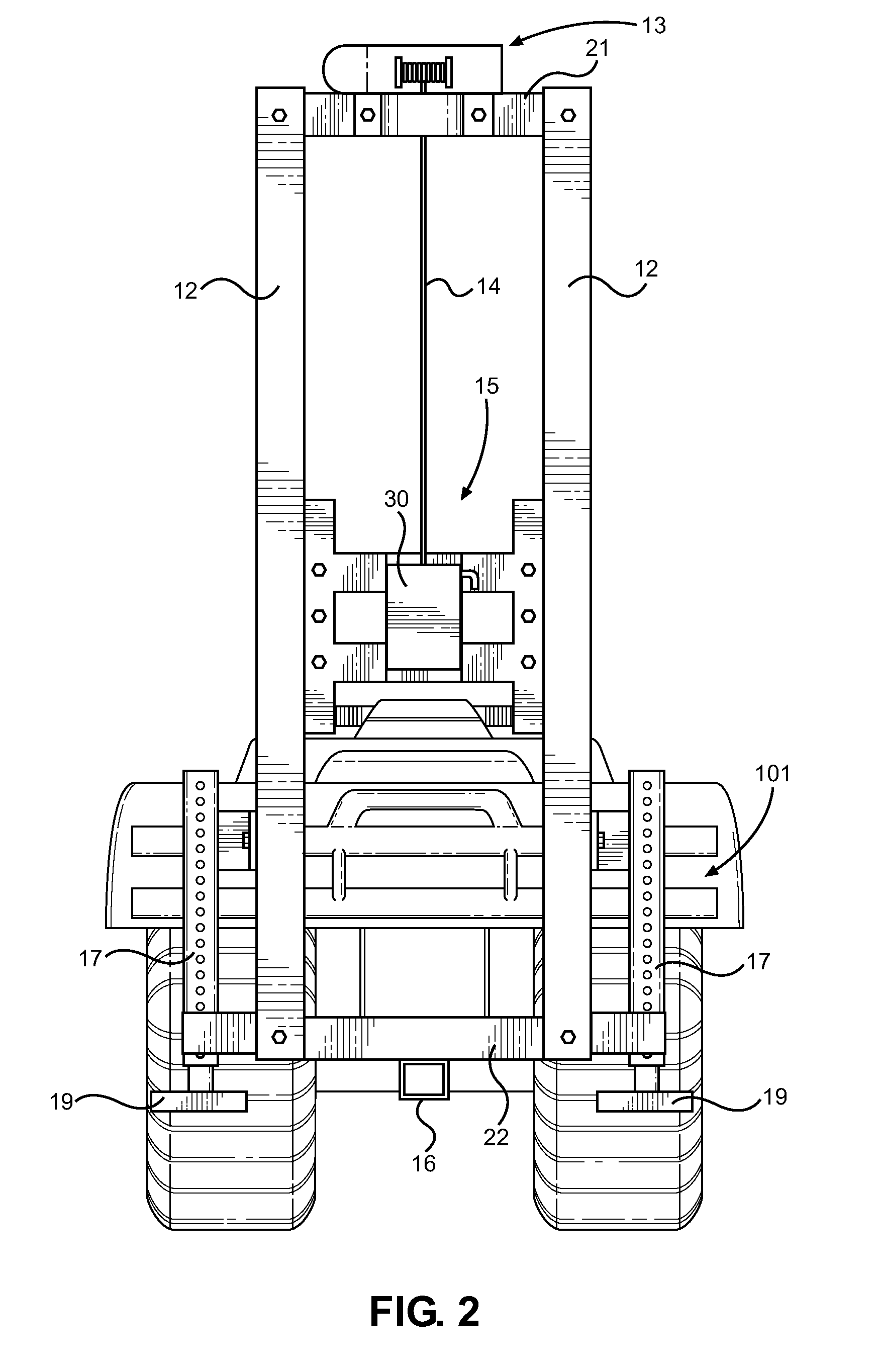

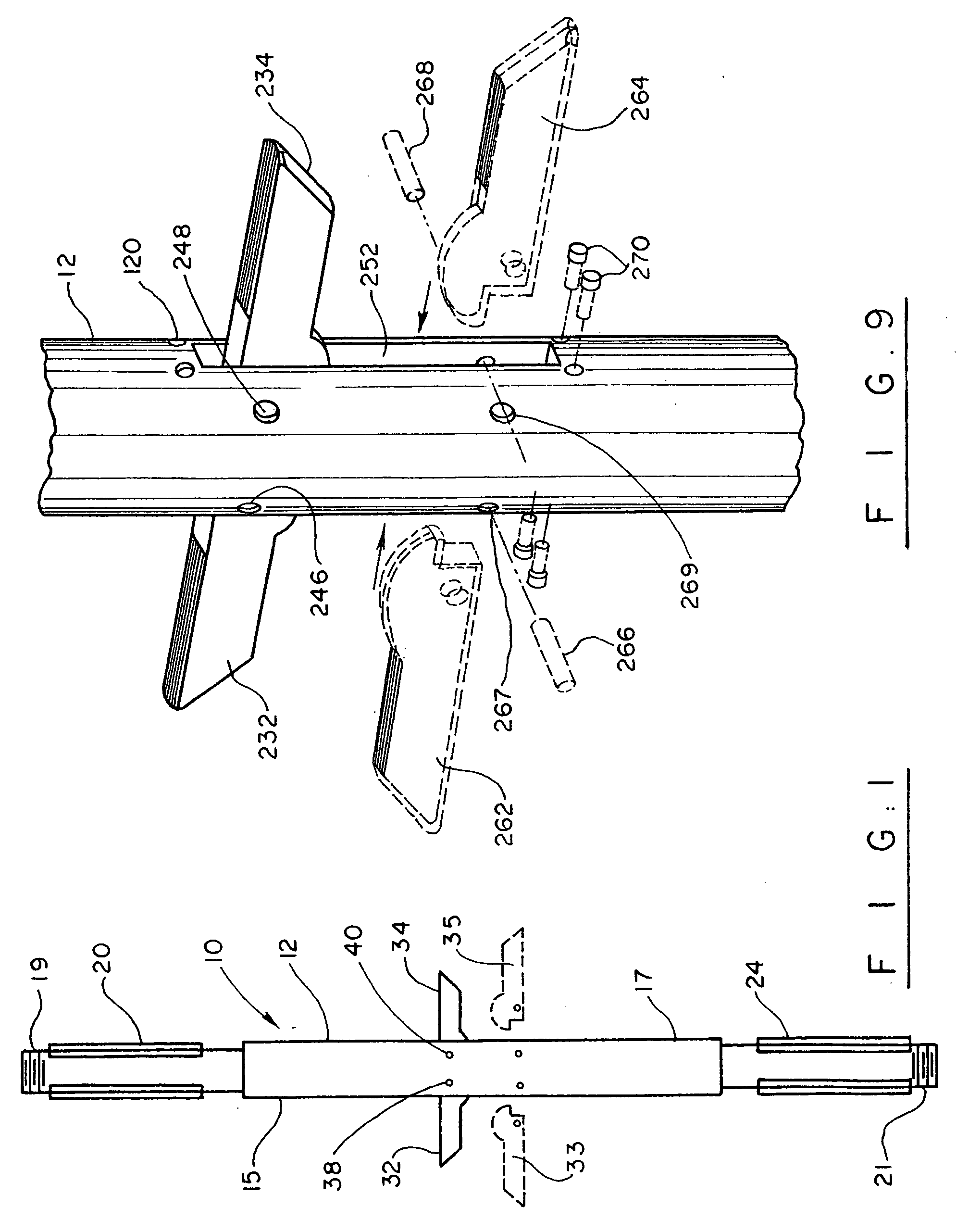

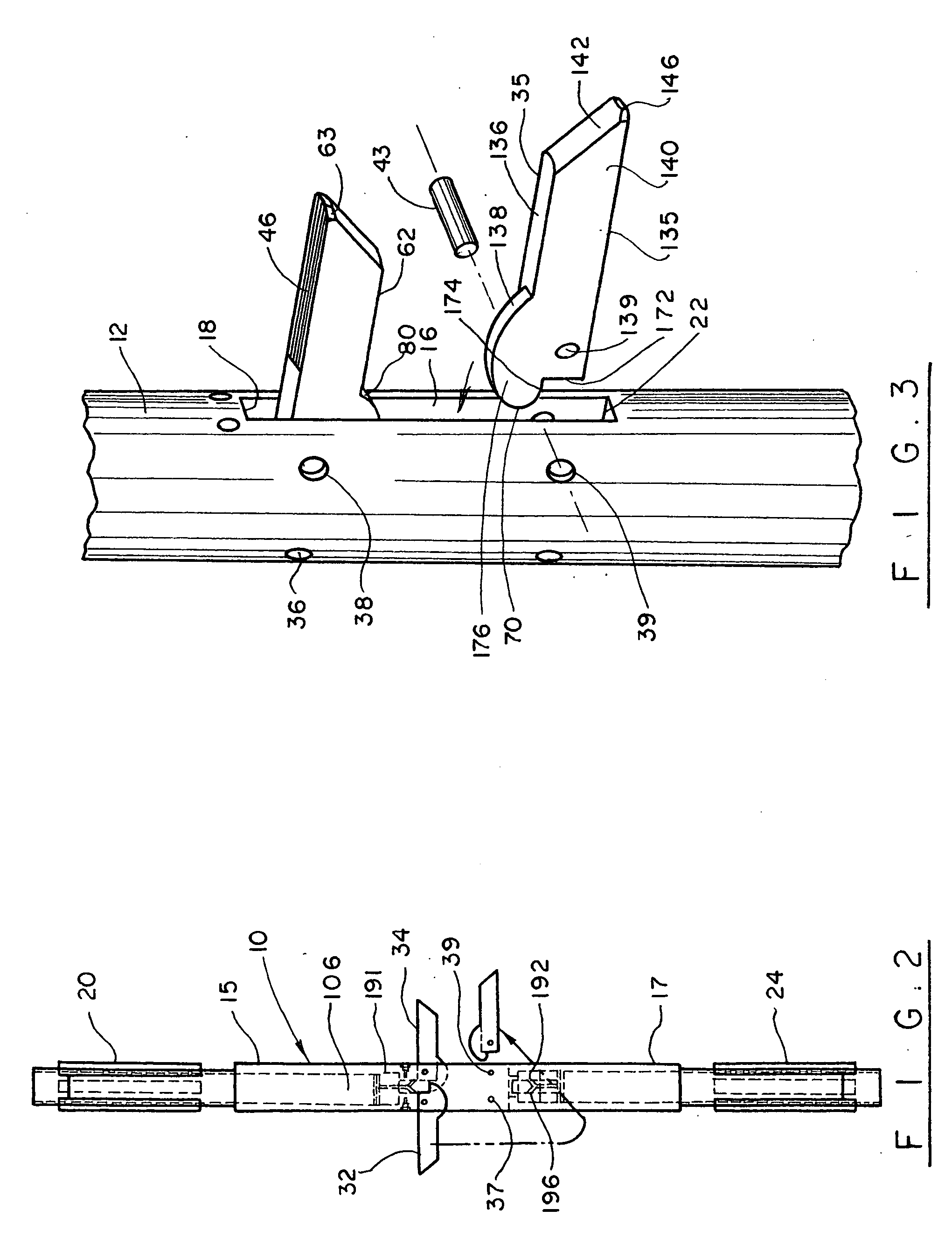

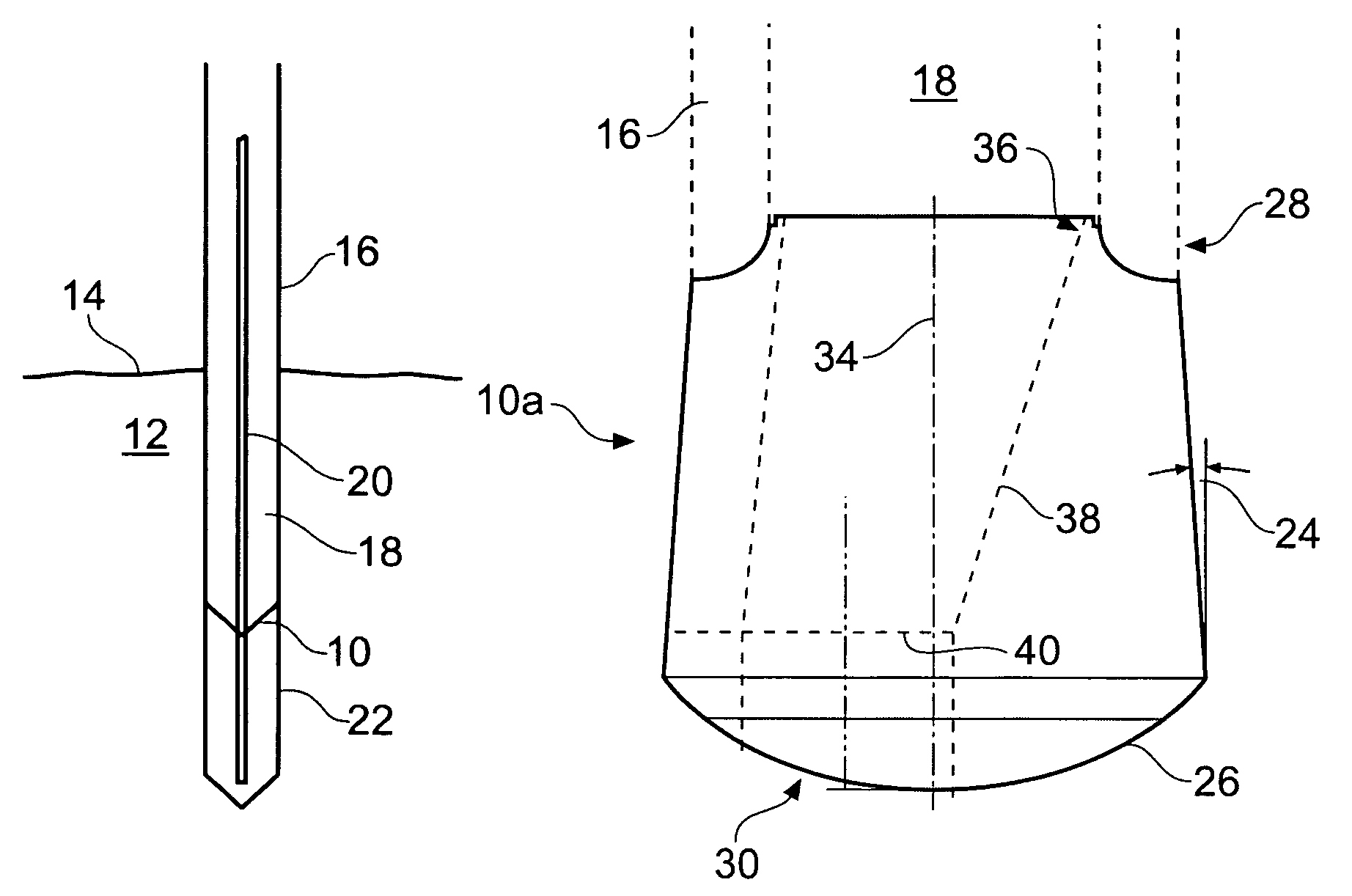

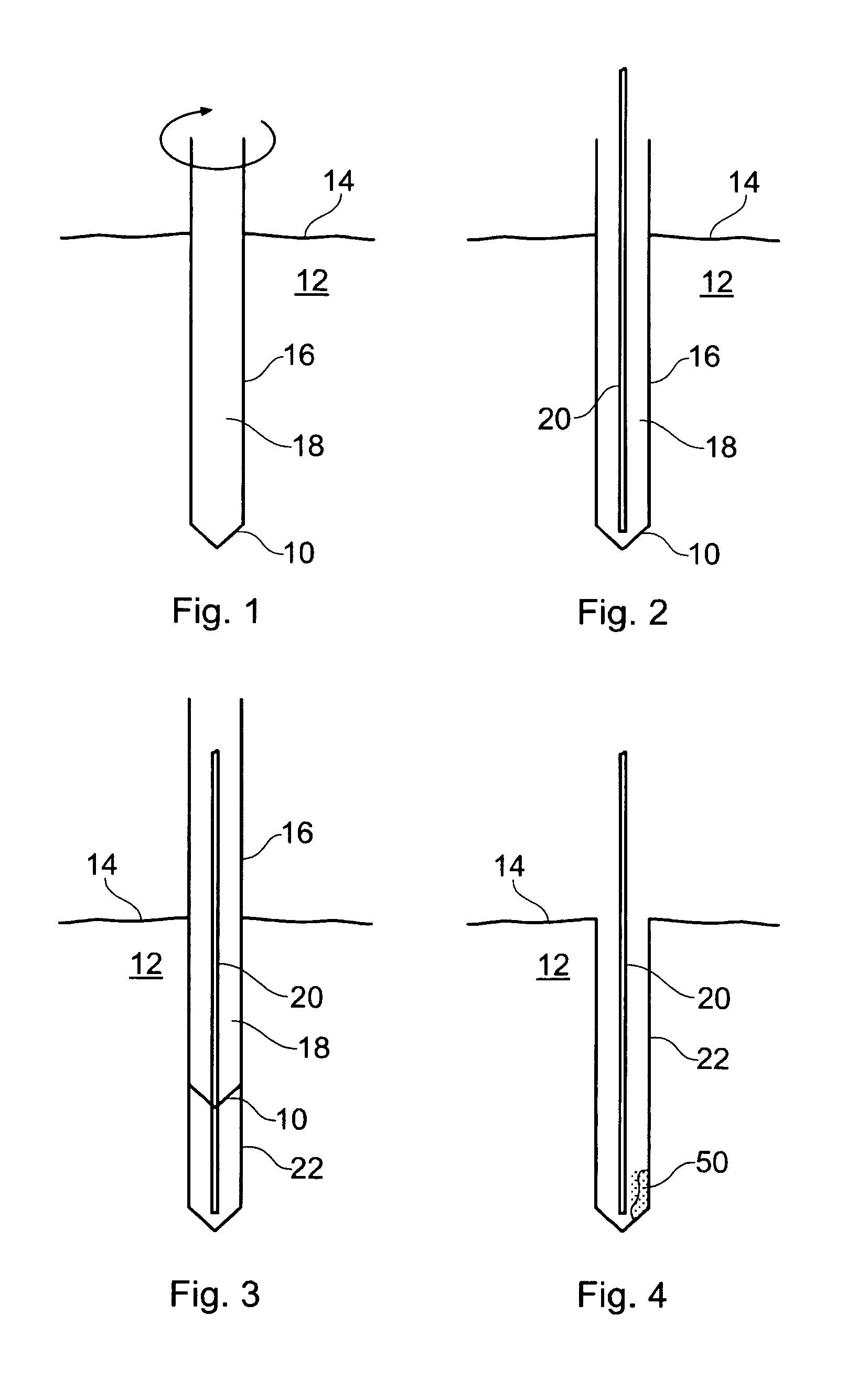

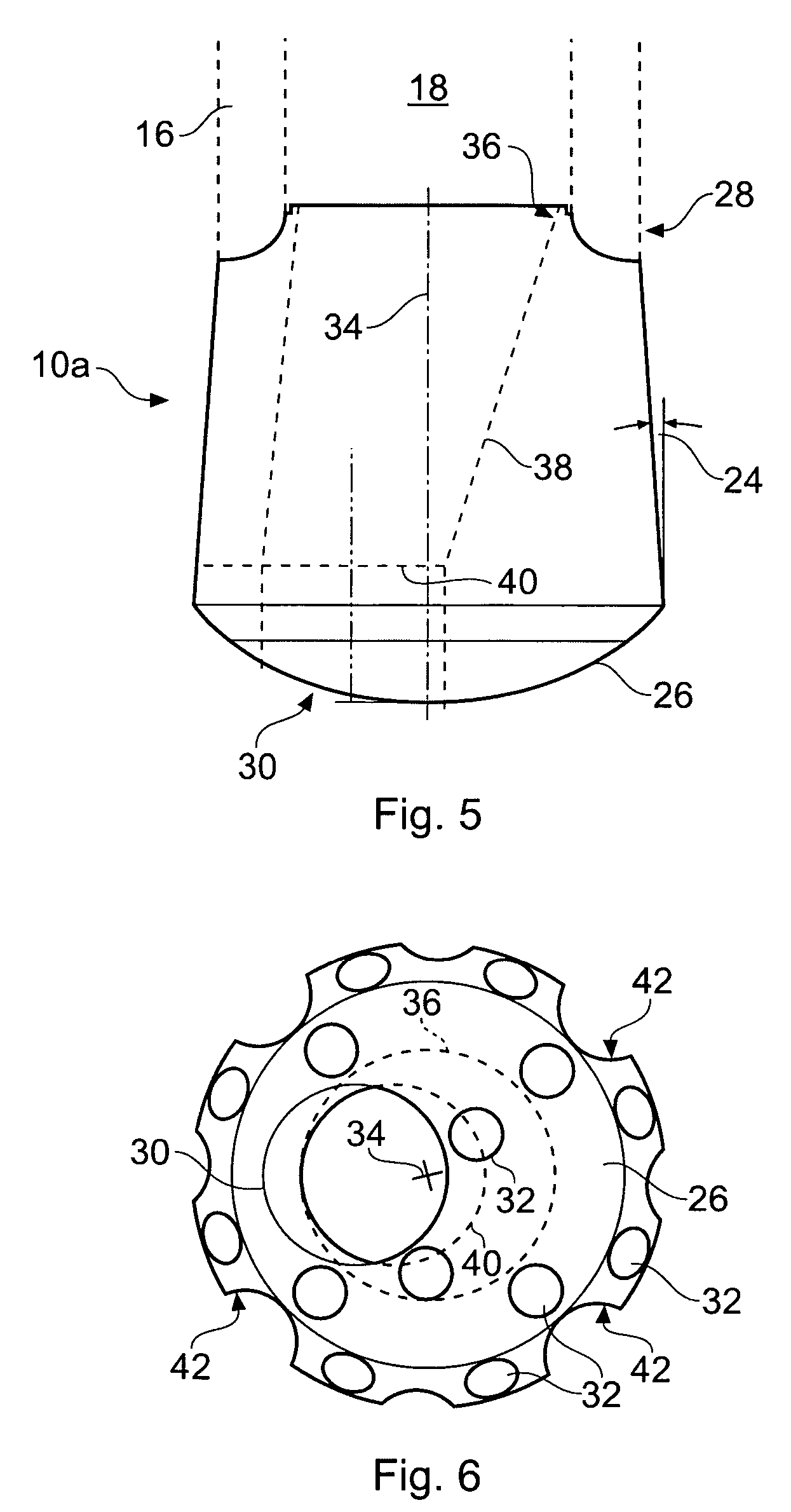

Method and apparatus for introducing elongate members into the ground

Owner:GLOBAL INNOVATIONS

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap