Down-the-hole Drill Reverse Exhaust System

a reverse exhaust system and drill bit technology, which is applied in the direction of portable drilling machines, manufacturing tools, and borehole/well accessories, etc., can solve the problems of reducing affecting the overall power and performance of the tool, and consuming a lot of air than is needed to clean the bit-end of the hammer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

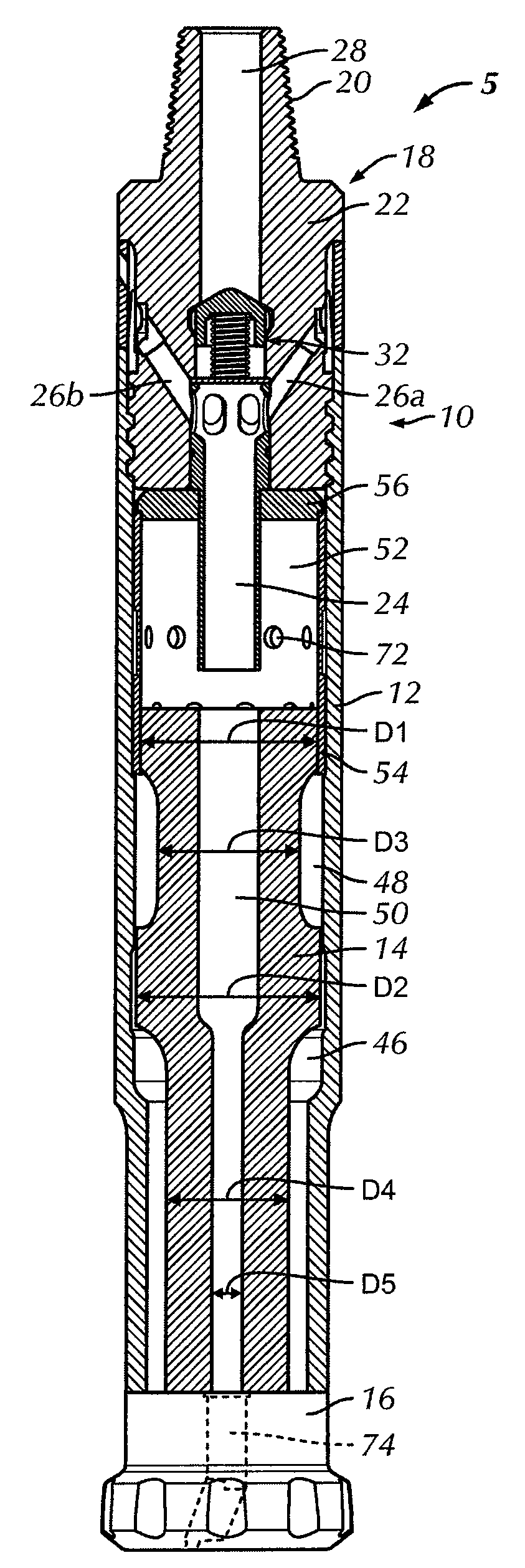

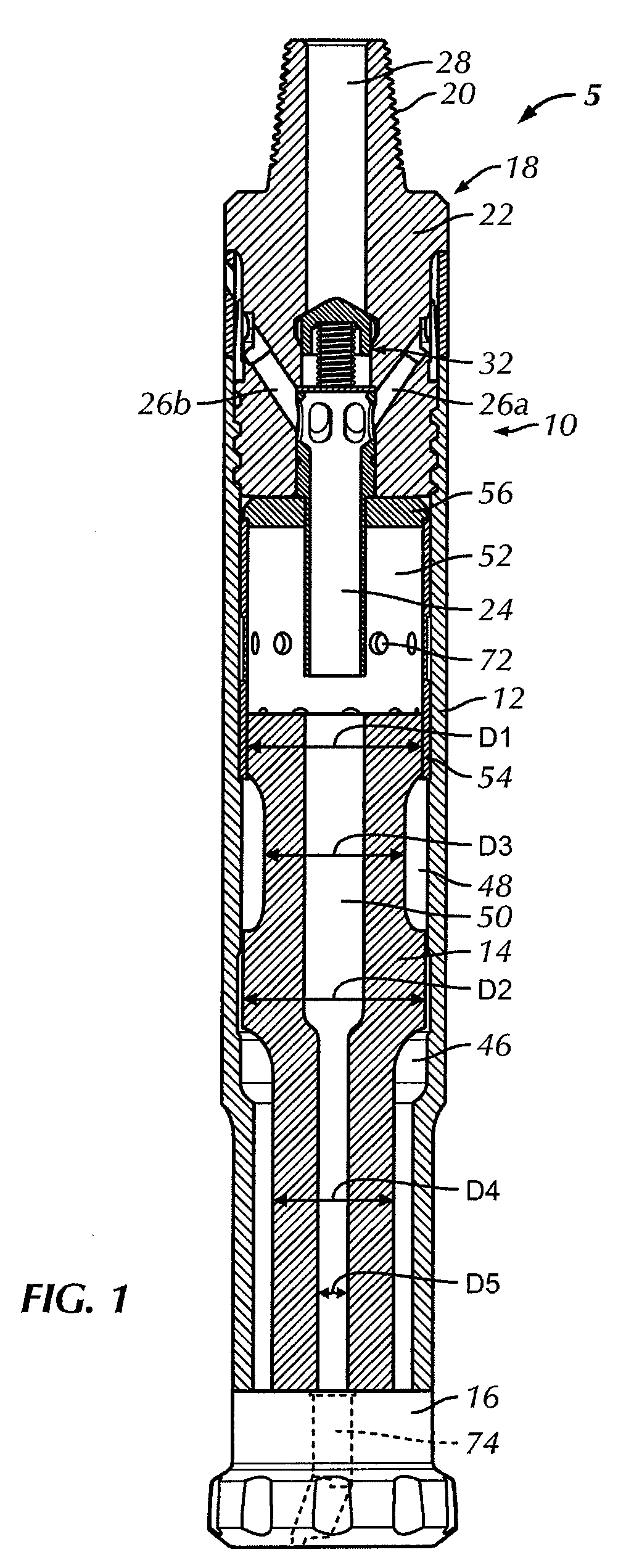

[0018]Certain terminology is used in the following description for convenience only and is not limiting. The words “right,”“left,”“upper,” and “lower” designate directions in the drawings to which reference is made. For purposes of convenience, “distal” is generally referred to as toward the drill bit end of the DHD hammer, and “proximal” is generally referred to as toward the backhead end of the DHD hammer as illustrated in FIG. 1. The terminology includes the words above specifically mentioned, derivatives thereof, and words of similar import.

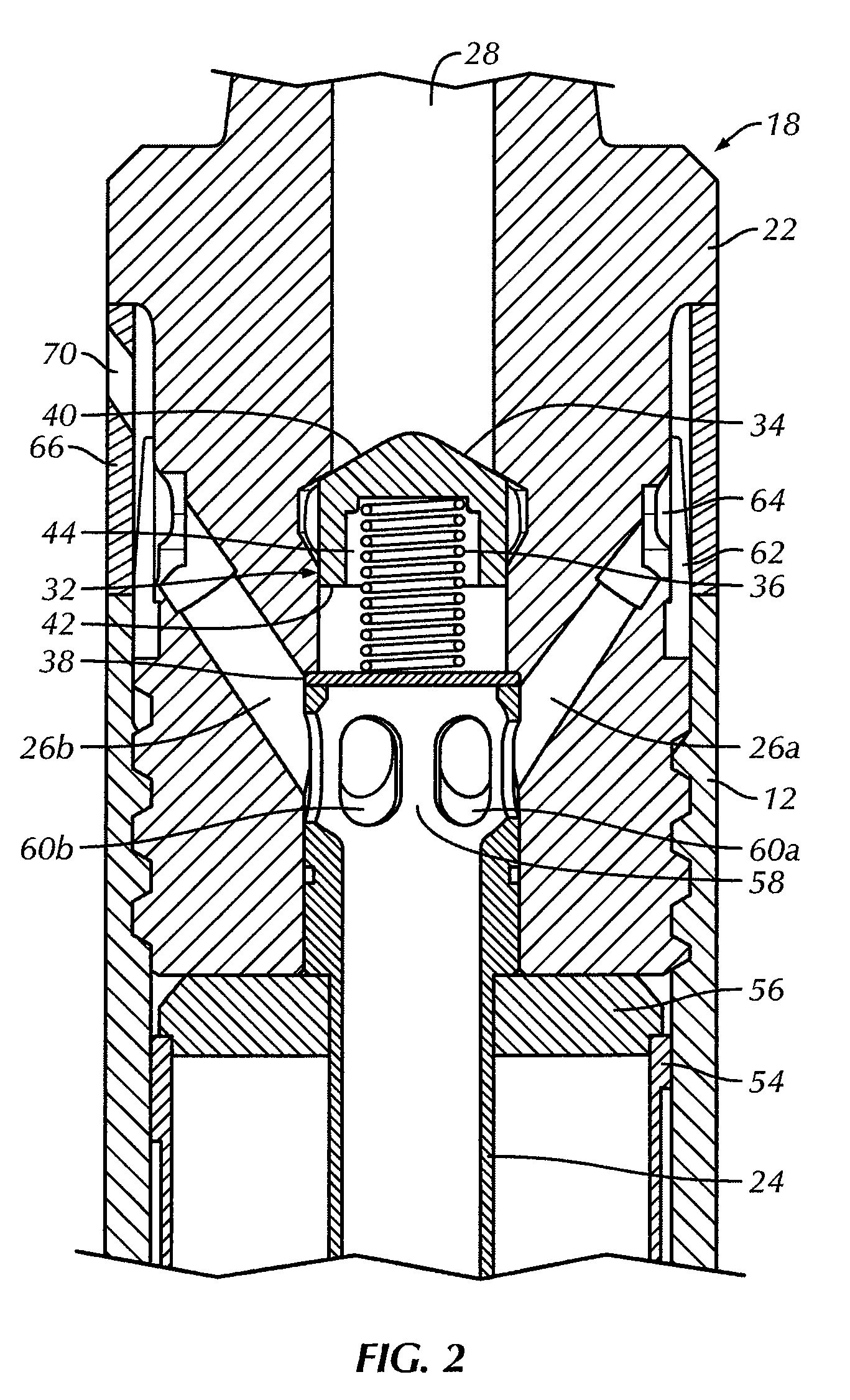

[0019]In a preferred embodiment, the present invention provides for a DHD hammer 5 having a percussive actuator assembly 10 as shown in FIGS. 1 and 2, for use with a conventional down-the-hole drill pipe (not shown). Referring to FIG. 1, the DHD hammer 5 includes an actuator assembly 10, a casing 12, such as an elongated housing 12, and a drill bit 16. The actuator assembly 10 includes a piston 14, a backhead 18, a cylinder 54, and a cylinder ca

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap