Centrifugal fan with volute

A technology of centrifugal fan and volute, which is applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc., which can solve the problems of unsmooth air flow, improve fluency, smooth and smooth connection of molded lines, and reduce left and right dimensions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

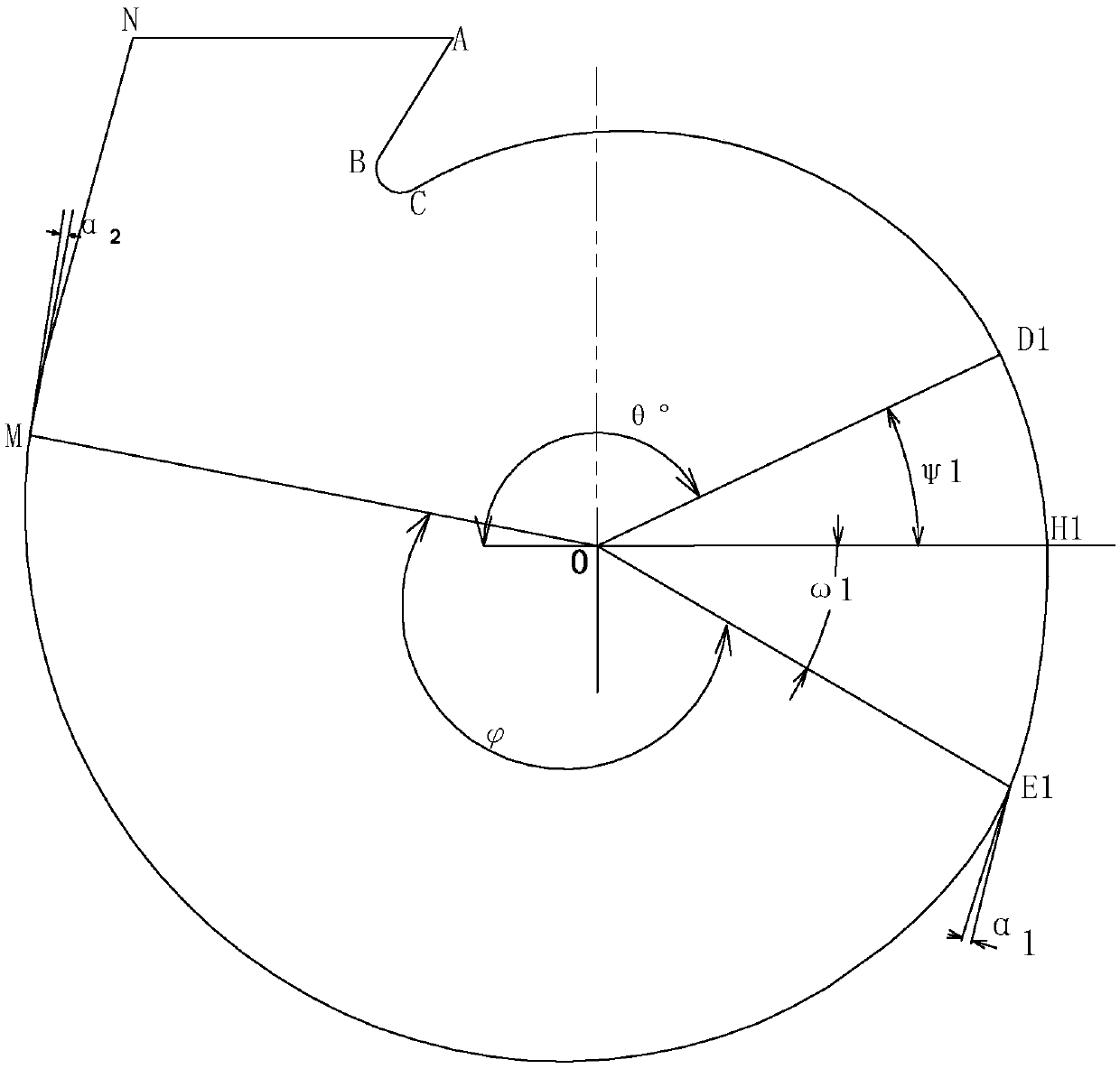

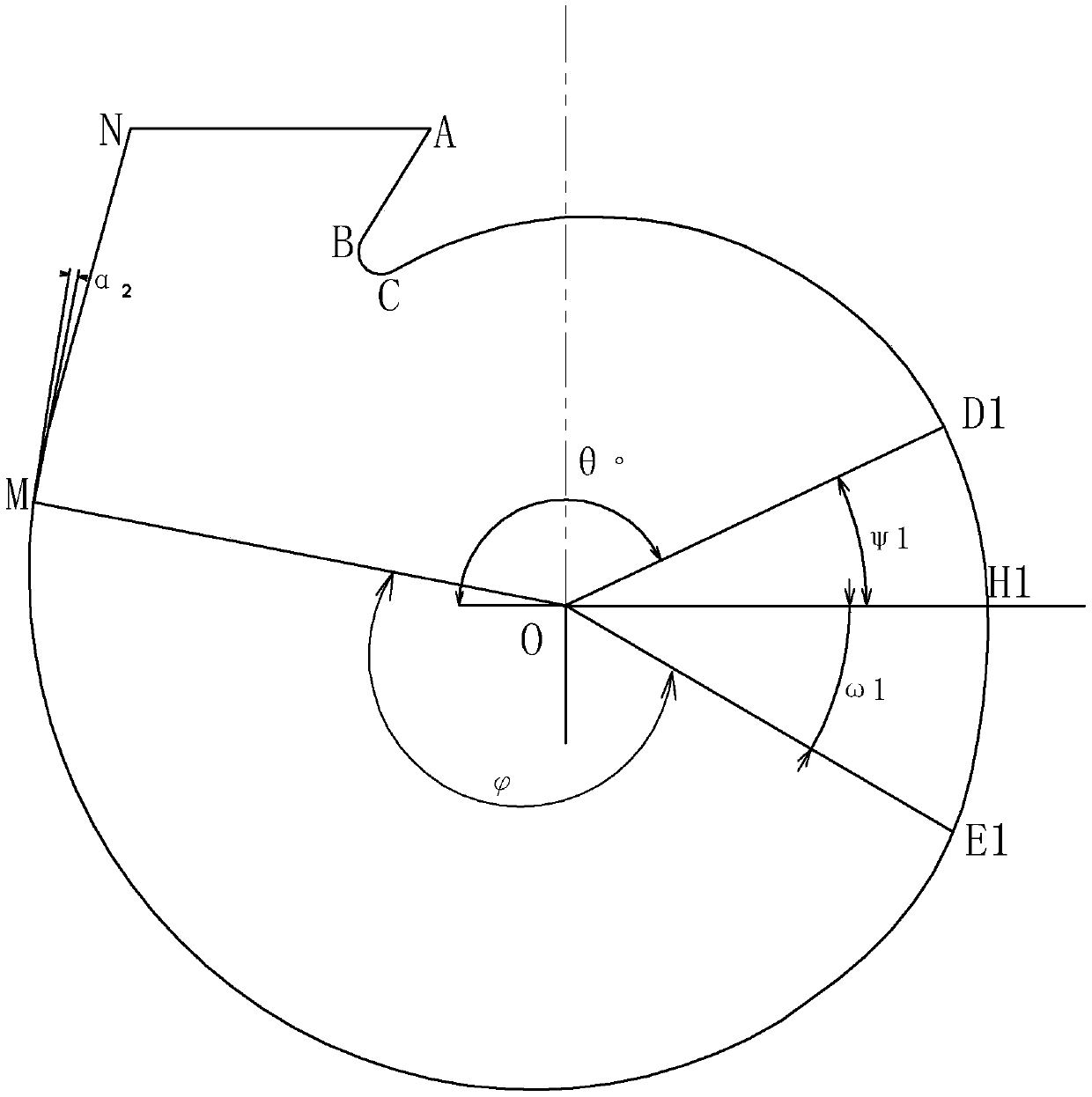

[0037] like image 3 Shown is the second preferred embodiment of the present invention. The difference between this embodiment and the above-mentioned embodiment is only: through the Bezier curve D 1 E.1 A section of logarithmic helix in the prior art is replaced, so as to reduce the left and right dimensions of the volute while increasing the fluency of the airflow.

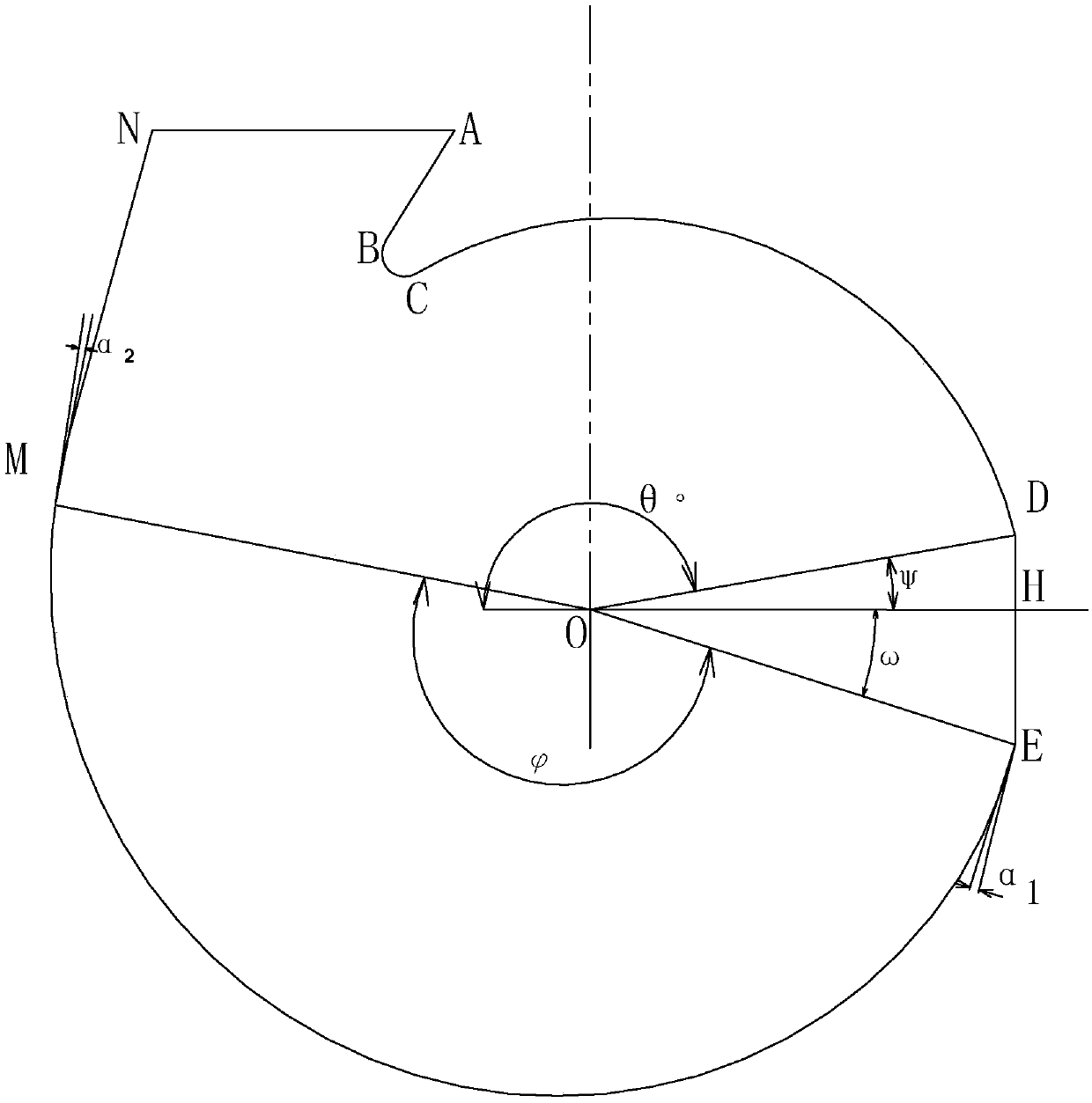

[0038] like Figure 4 As shown, it is the volute type wire of the prior art in this embodiment, and the first helix CD and the second helix DM are sequentially arranged between the start line AC and the end line MN of the volute type wire , the first helix CD is an equiangular helix with a constant expansion angle, the second helix DM is a variable-angle helix with a tapered expansion angle, and the intersection point between the second helix DM and the horizontal line passing through the center O of the volute is H ', the second helix DM is cut, the cut is DE, and the intersection point of the cut DE with the h

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap